Contactor for realizing electric connection between moving and stationary contact poles in transformer

A technology of dynamic and static contacts and electrical connection, which is applied in the field of electricity, can solve the problems of unreliable electrical connection, etc., and achieve the effect of increasing the electrical contact area and tight and firm fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

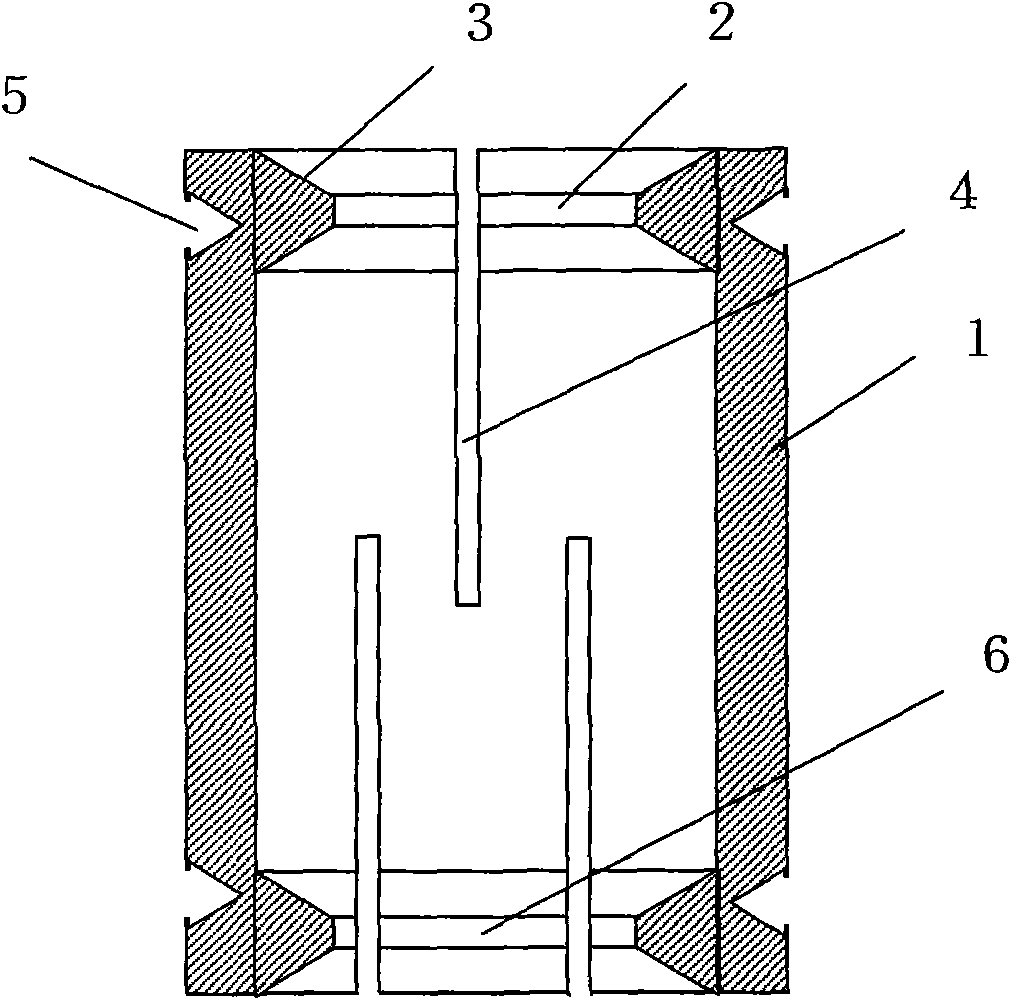

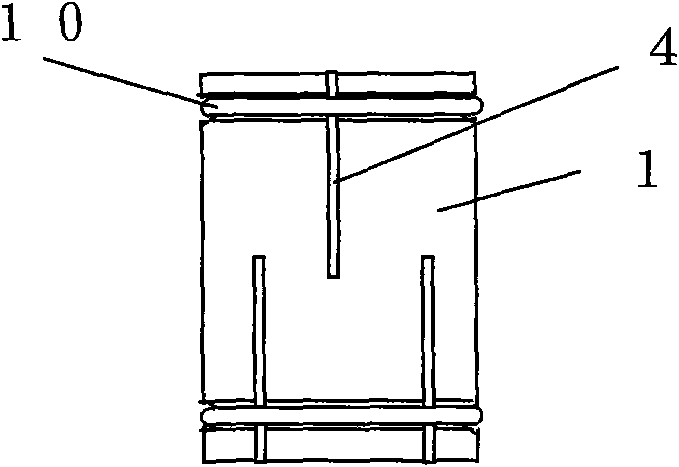

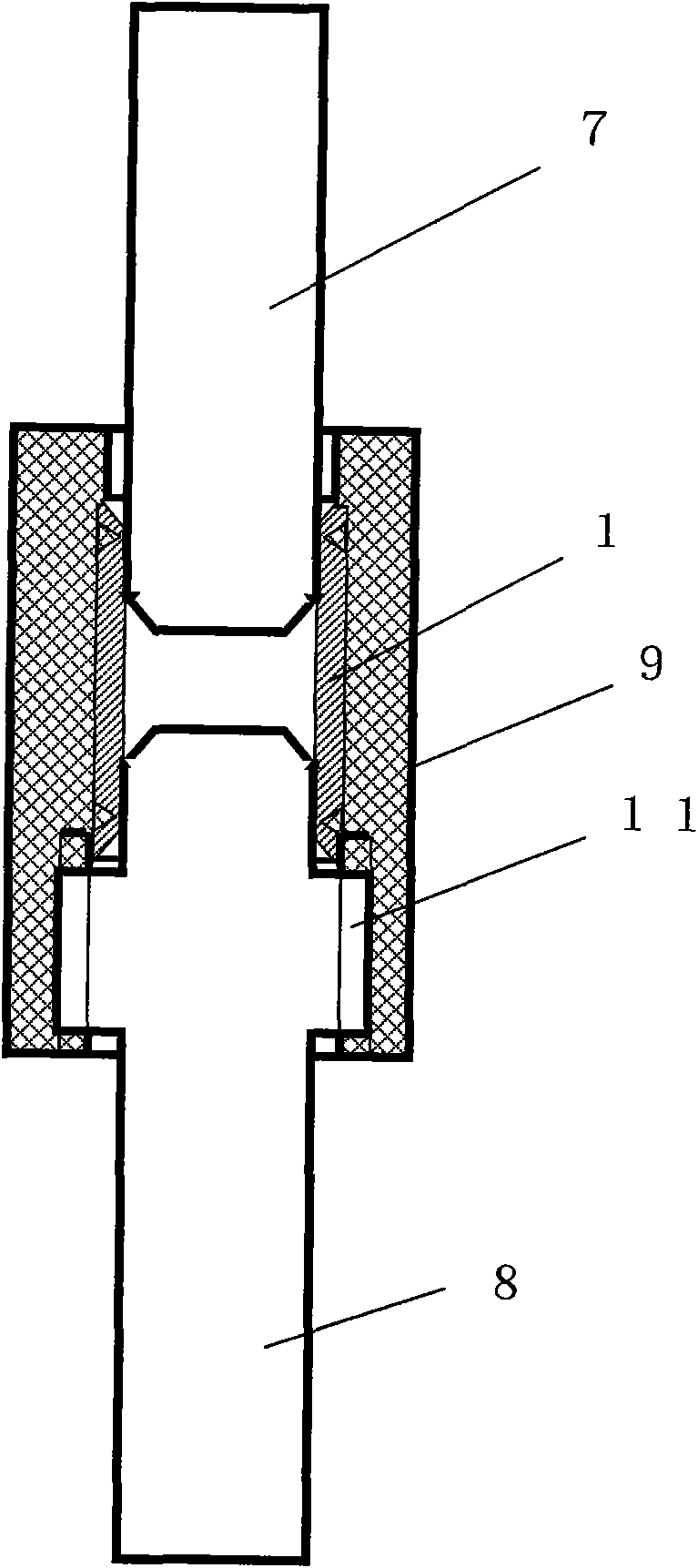

[0015] Such as figure 1 and figure 2 As shown, the contactor of the present invention for realizing the electrical connection of the moving and static contact rods in the transformer is composed of a cylindrical metal tube 1, wherein an annular ring is arranged on the inner peripheral wall of one end of the cylindrical metal tube 1 toward the axial direction. Flange 2, the connecting surface 3 between the annular flange 2 and the end surface of the cylindrical metal pipe 1 is a conical surface, the inner diameter of the annular flange 2 is smaller than the inner diameter of the middle part of the cylindrical metal pipe 1, and the inner diameter of the cylindrical metal pipe 1 There are more than two cracks 4 arranged in the tube wall, the extension direction of any one of the cracks 4 is parallel to the axial direction of the cylindrical metal tube 1, and the cracks 4 start from the cylindrical metal tube 1 where the annular flange 2 is located. One end begins to extend towa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com