Quenching basket

A hanger and hook technology, applied in the field of heat treatment equipment, can solve the problems of limited processing quantity, hidden dangers, low production efficiency, etc., and achieve the effect of improving firmness, high safety, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

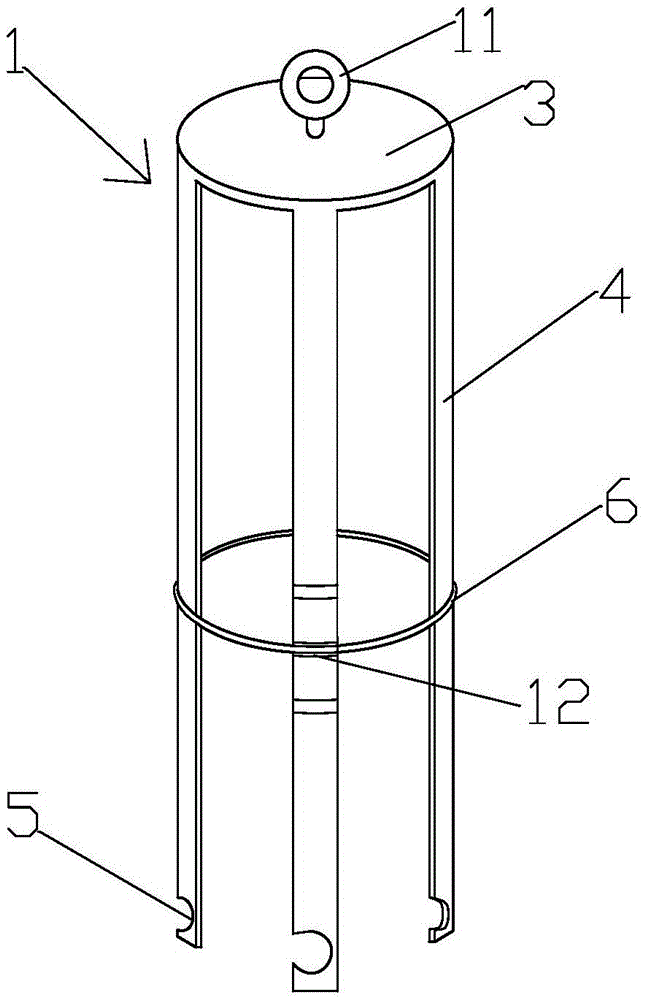

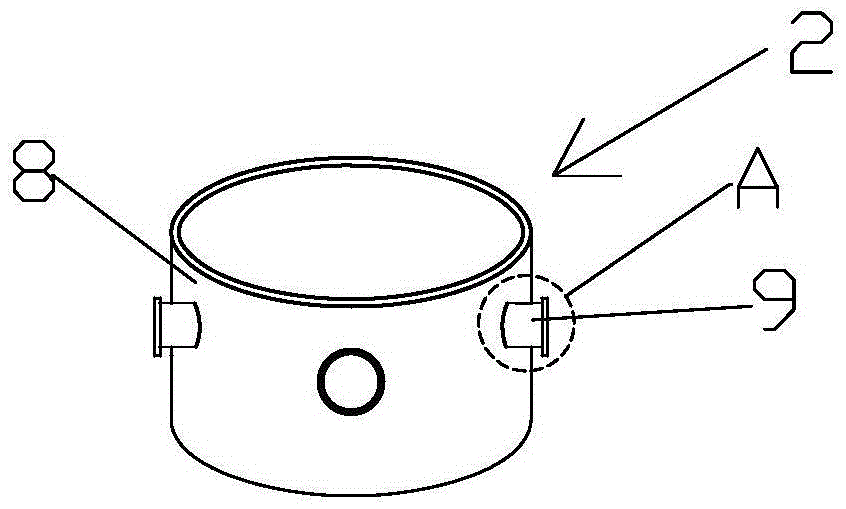

[0024] Embodiment: Quenching is used hanging basket, as Figure 1~5 As shown, including: spreader 1 and basket 2, such as figure 1 As shown, the spreader 1 includes a circular suspension pan 3, a suspension ring 11 is welded at the center of the suspension pan 3, and at least three vertically downwardly extending steel bars 4 are evenly arranged on the edge of the suspension pan 3 along the circumferential direction. In terms of the stability of the hanger 1 during specific use, four steel bars 4 are welded in this embodiment, and the bottom end of each steel bar 4 is provided with a hook 5, and the opening direction of each hook 5 is kept clockwise. Consistent, the opening direction of each hook 5 can also be consistent along the counterclockwise direction.

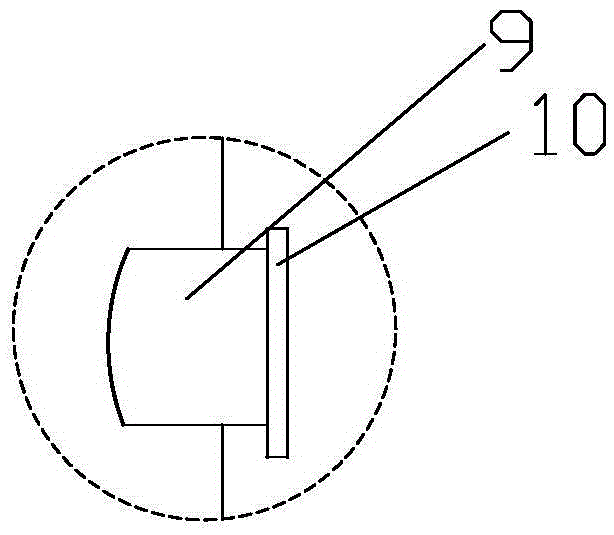

[0025] There is at least one steel ring 6 surrounding all the steel bars 4 on the spreader 1, the steel ring 6 is arranged in the middle of the steel bar 4, the inner diameter of the steel ring 6 is equal to the diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com