Patents

Literature

68results about How to "Fit tightly and firmly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

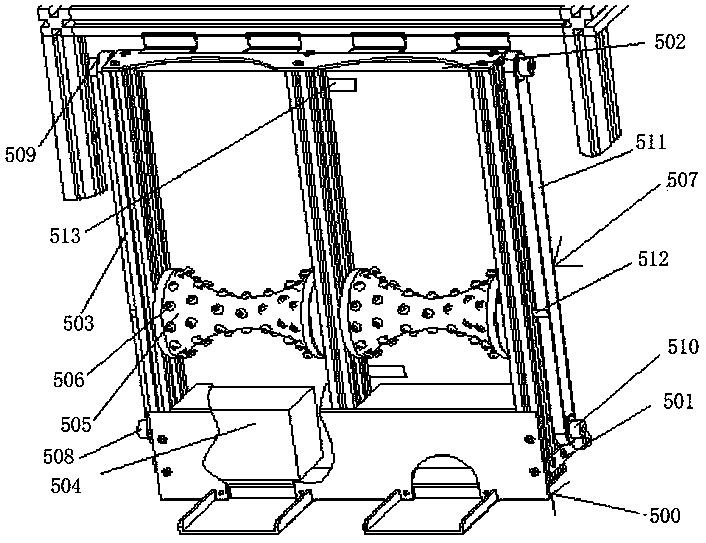

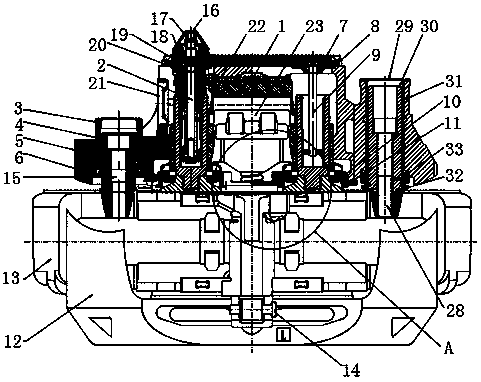

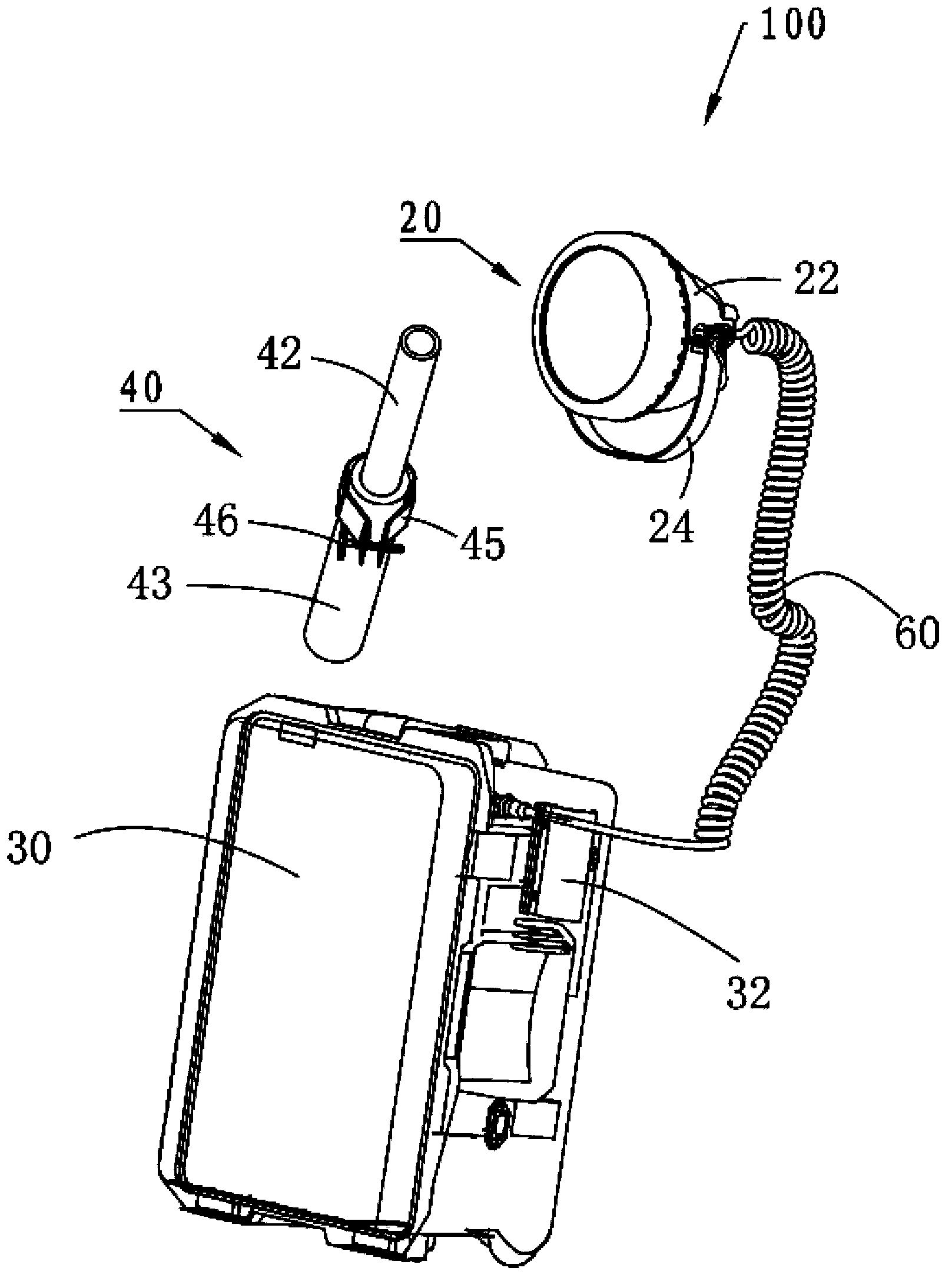

Rehabilitation physiotherapy complex device

InactiveCN108926466AGuaranteed positioningPrecise positioningVibration massageRoller massageThighPhysical medicine and rehabilitation

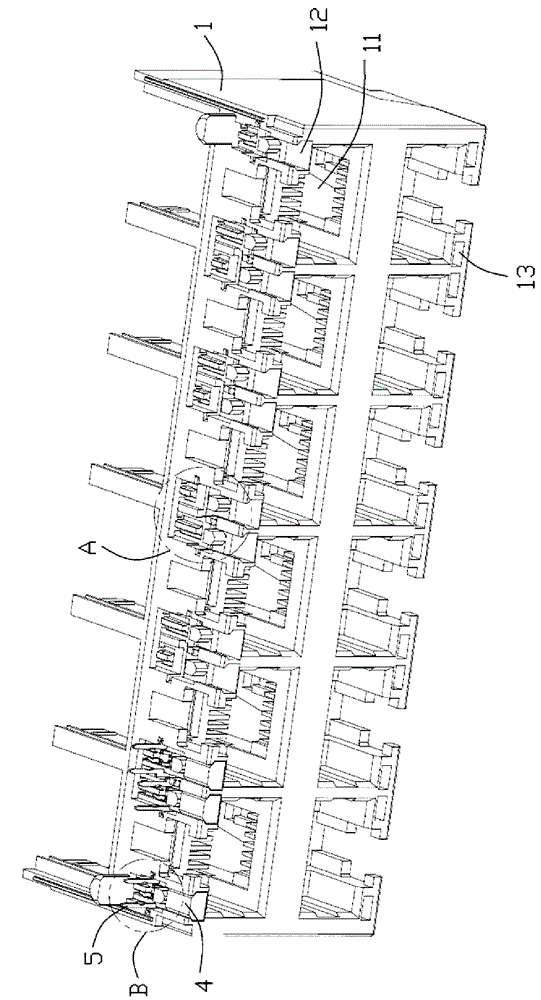

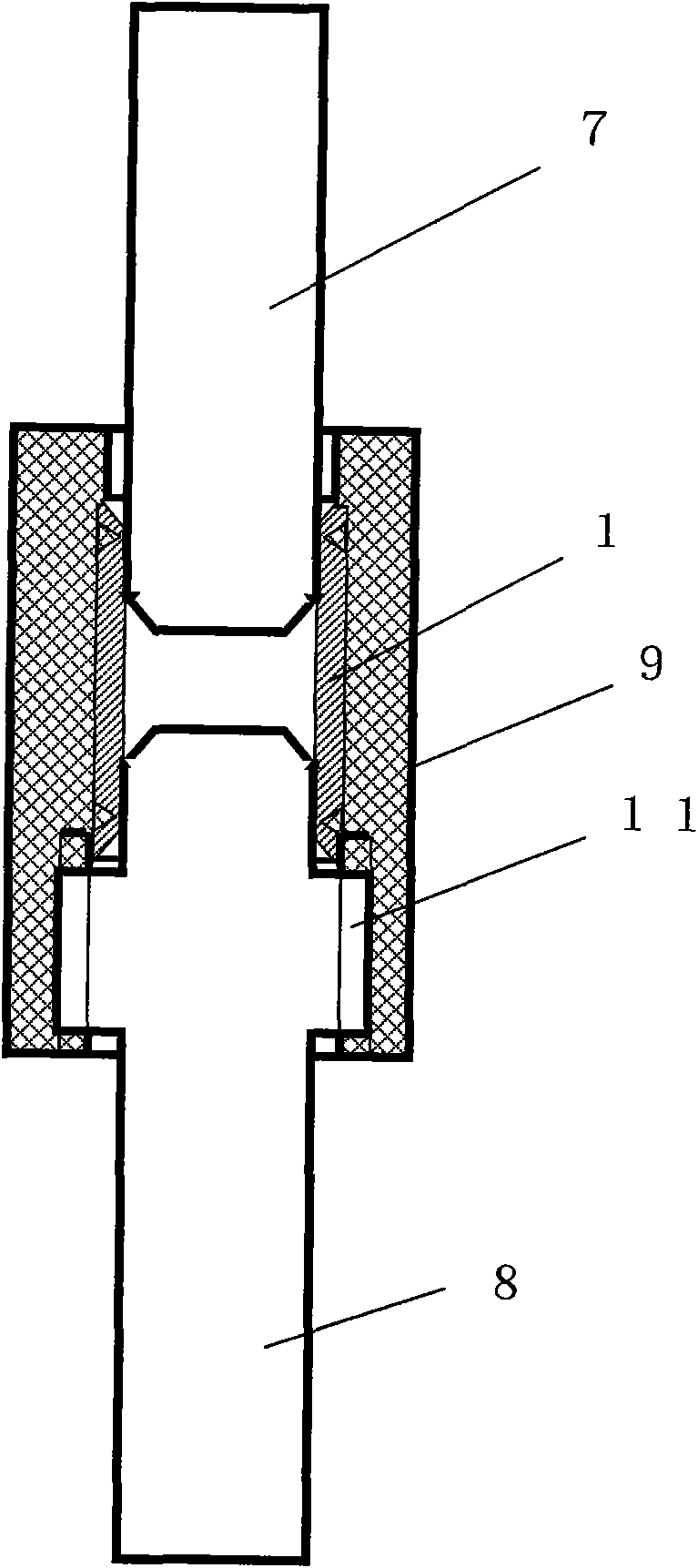

The invention discloses a rehabilitation physiotherapy complex device. According to the technical scheme, the rehabilitation physiotherapy complex device is characterized by being composed of a leg massaging mechanism, a connecting rod transmission device, a movable joint mechanism, a bionic manipulator, a back knocking mechanism and a neck kneading mechanism. With the application of the rehabilitation physiotherapy complex device provided by the invention, physiotherapy massaging can be conducted on calves, thighs, backs and necks; and in addition, the complex device, which simulates actionsin physiotherapy massaging of traditional Chinese medicine, fits more to the reality.

Owner:哈尔滨身心健康高新技术有限公司

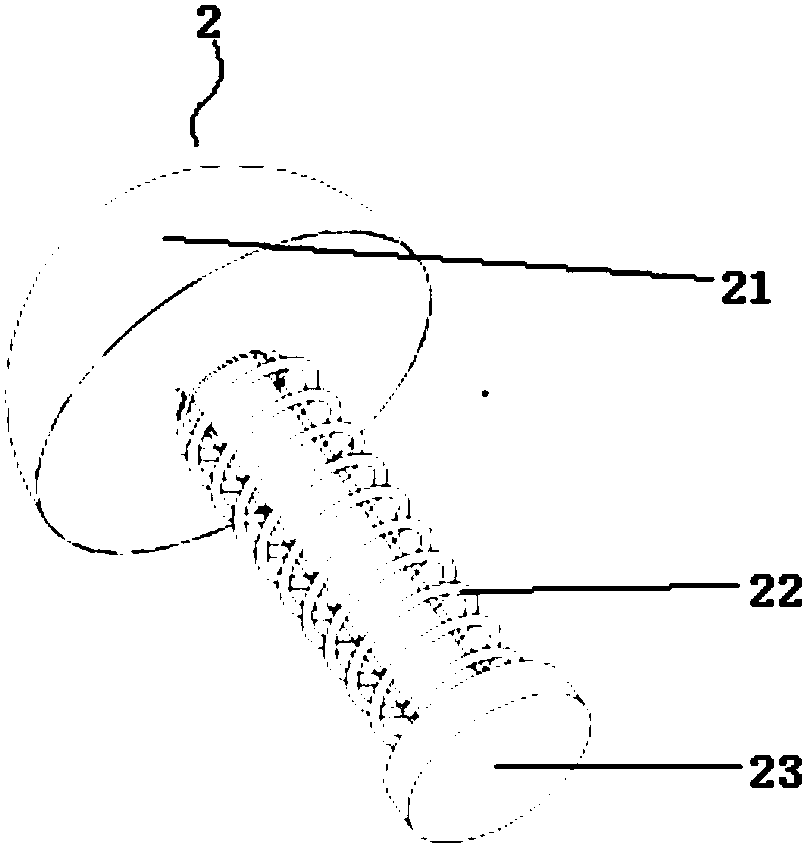

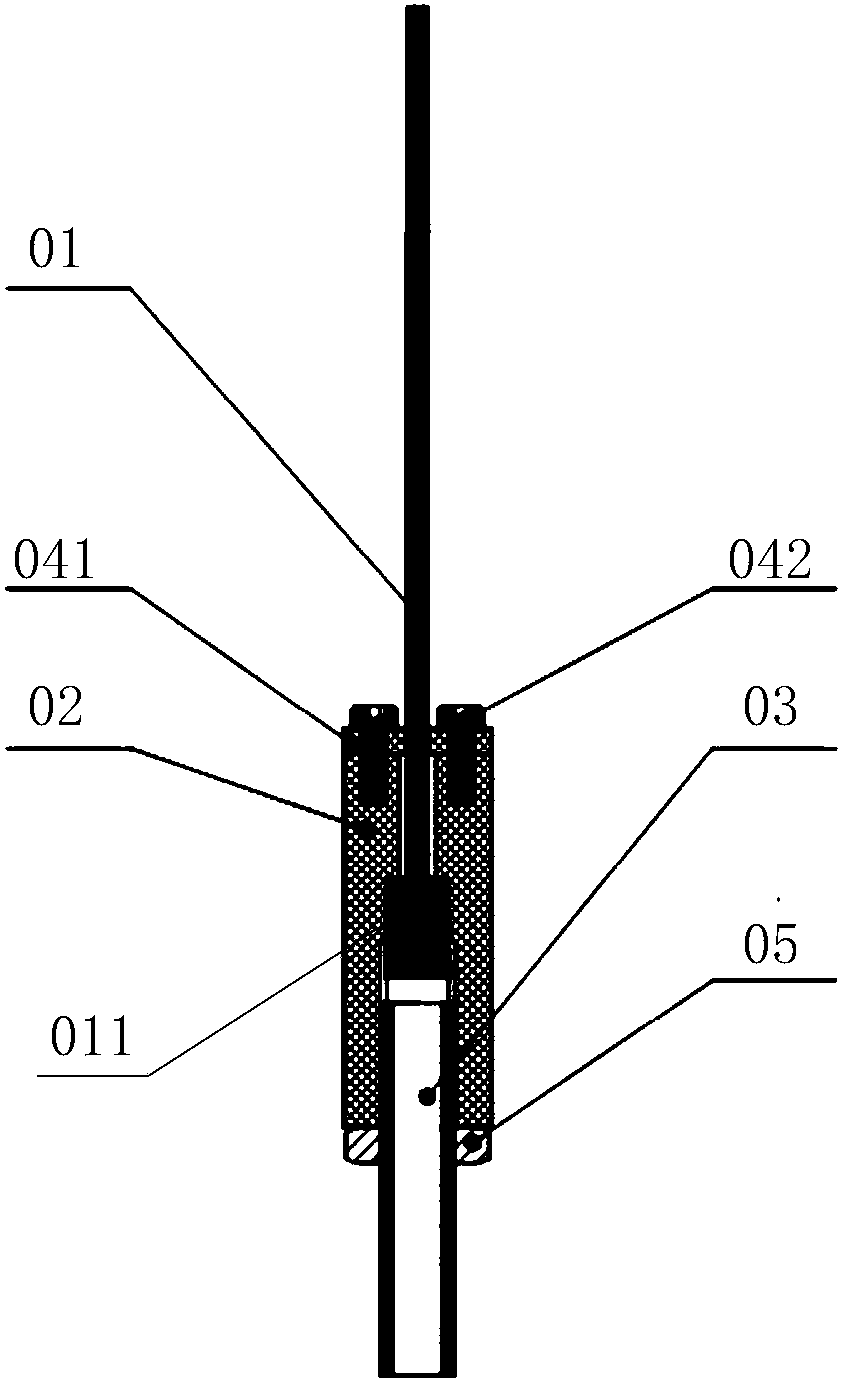

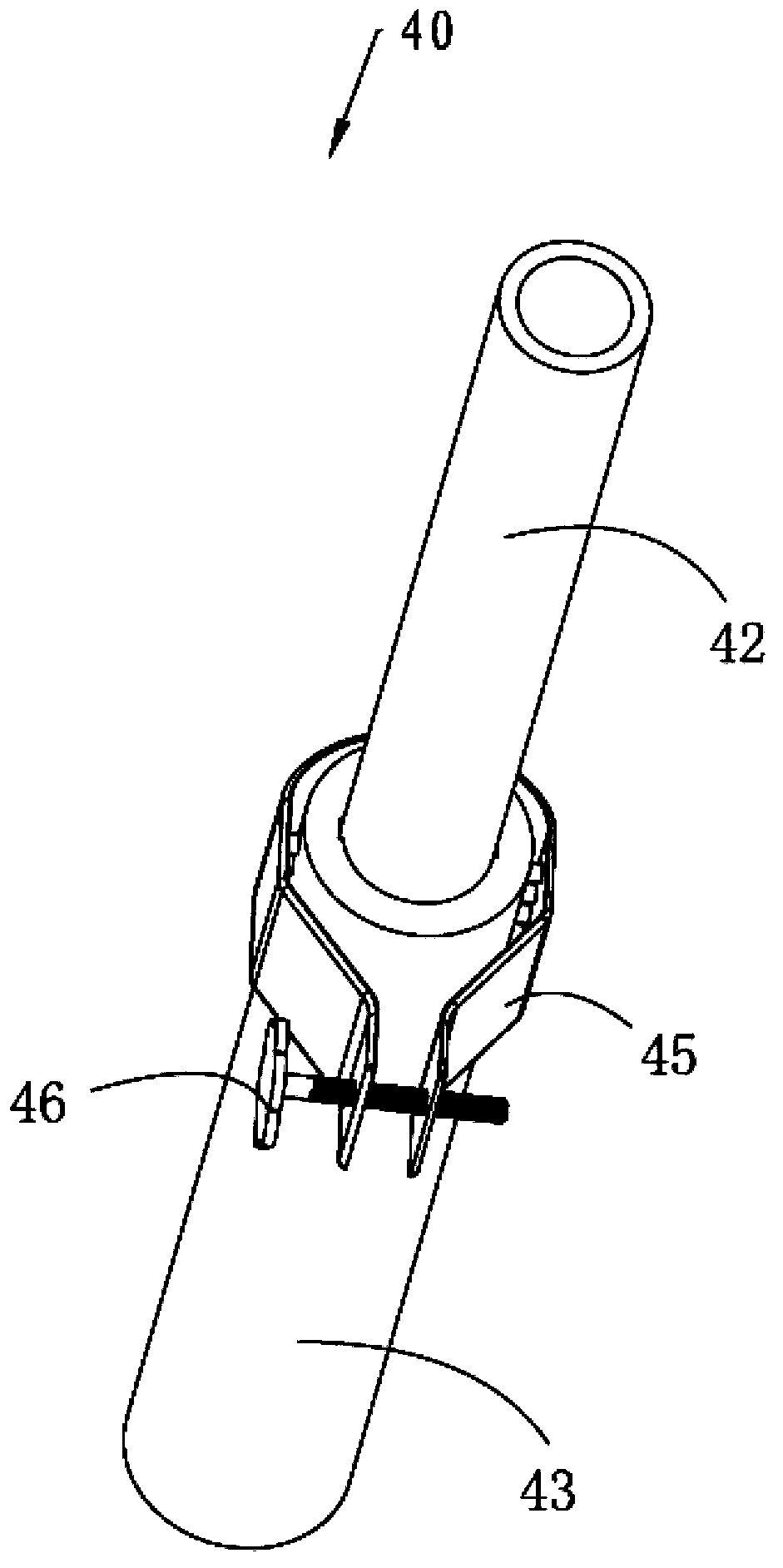

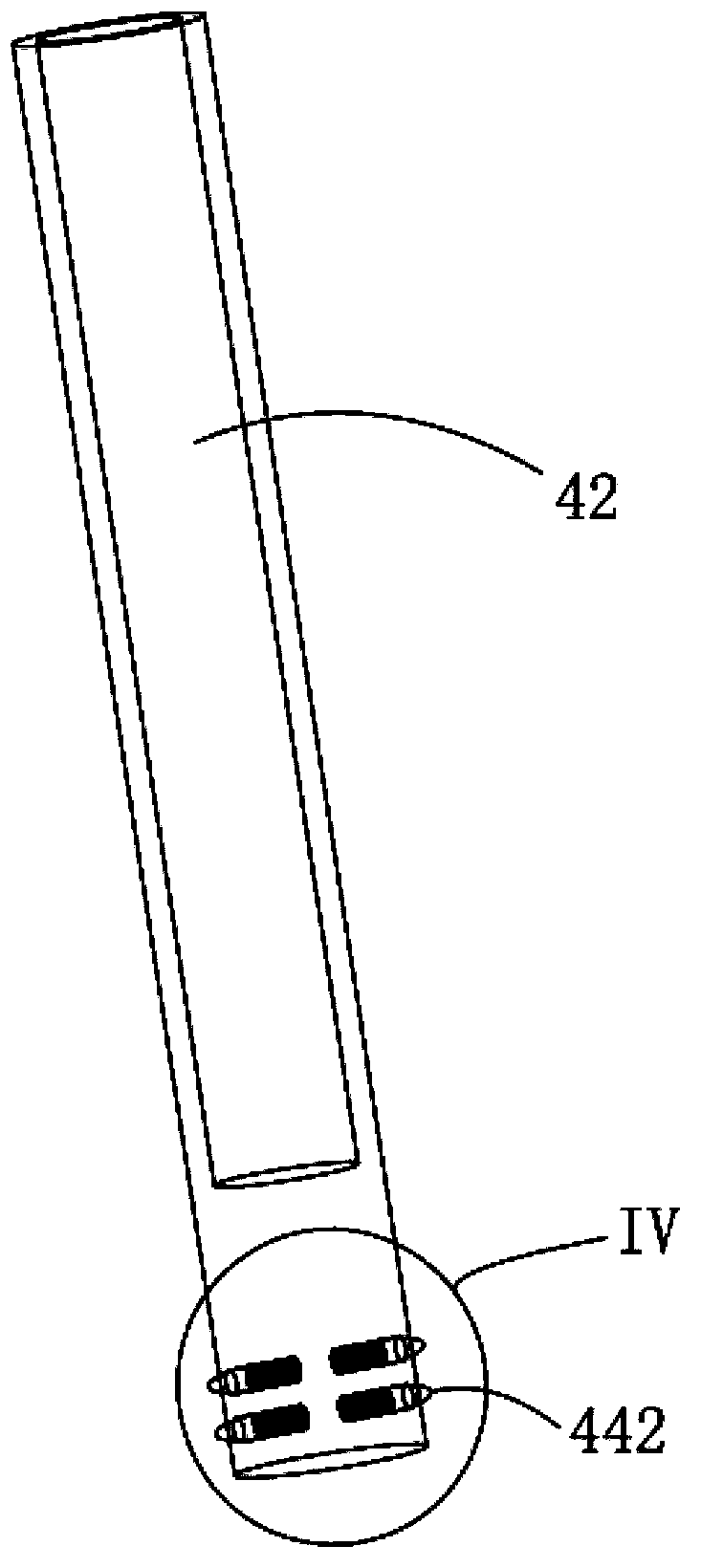

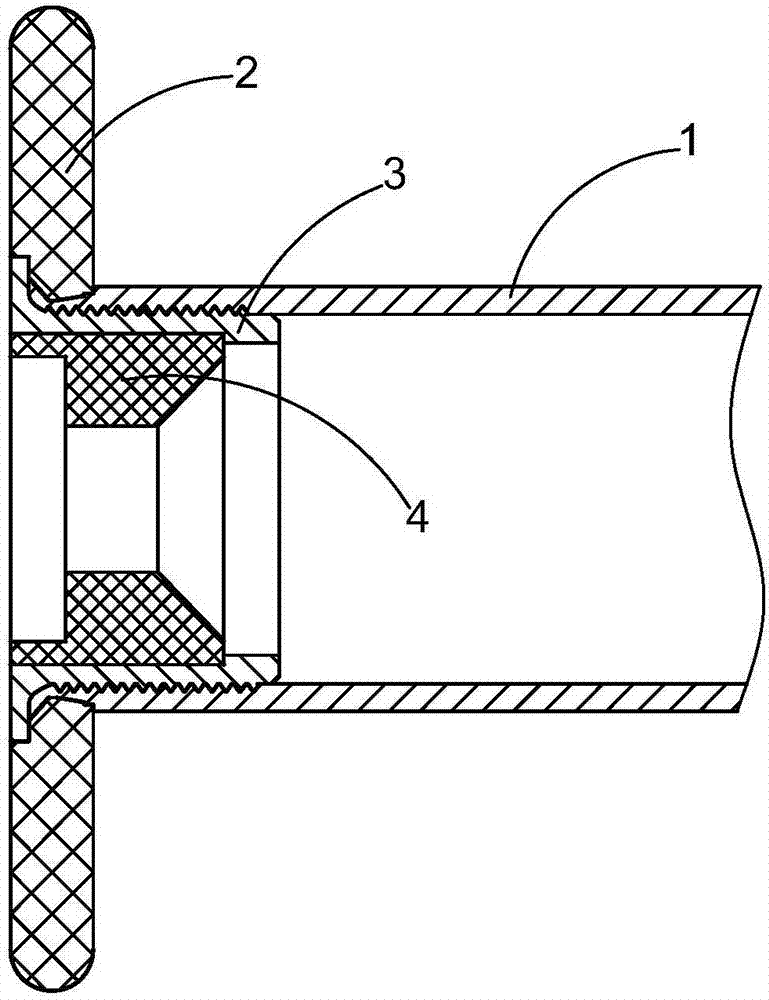

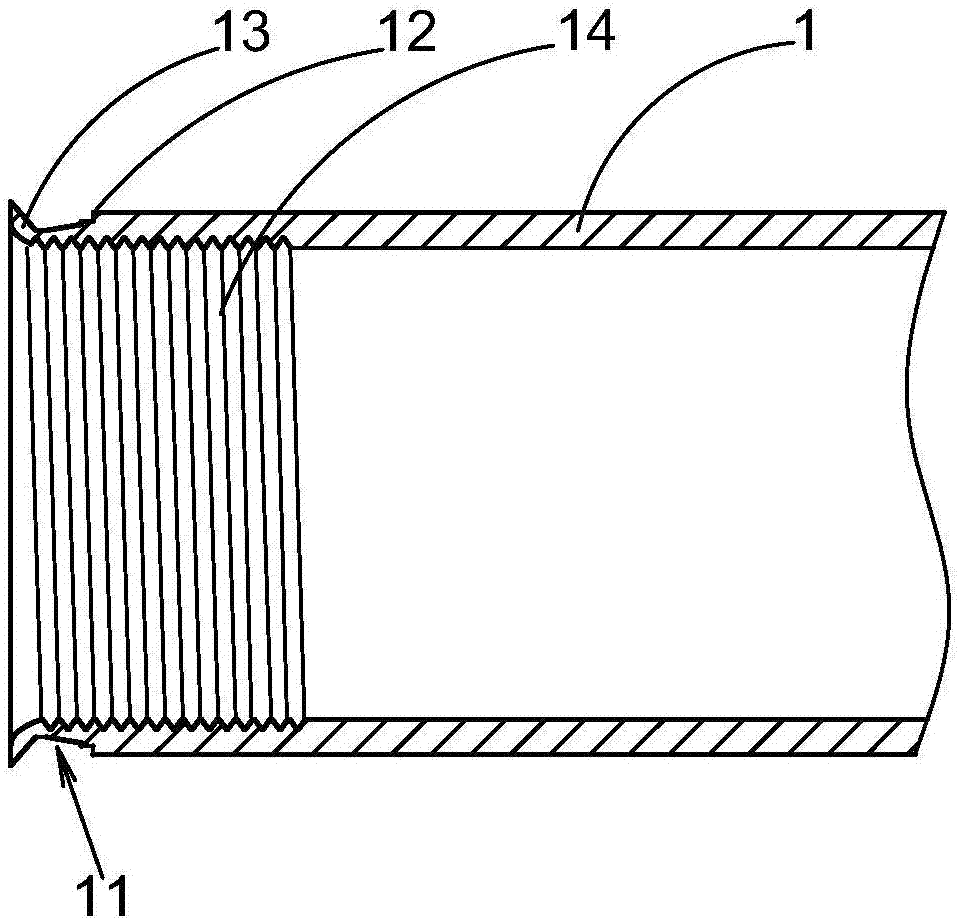

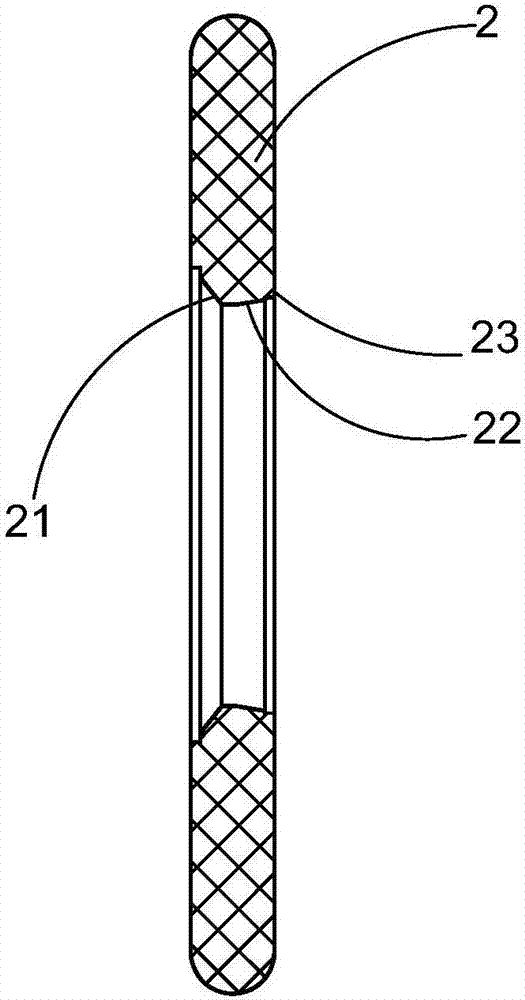

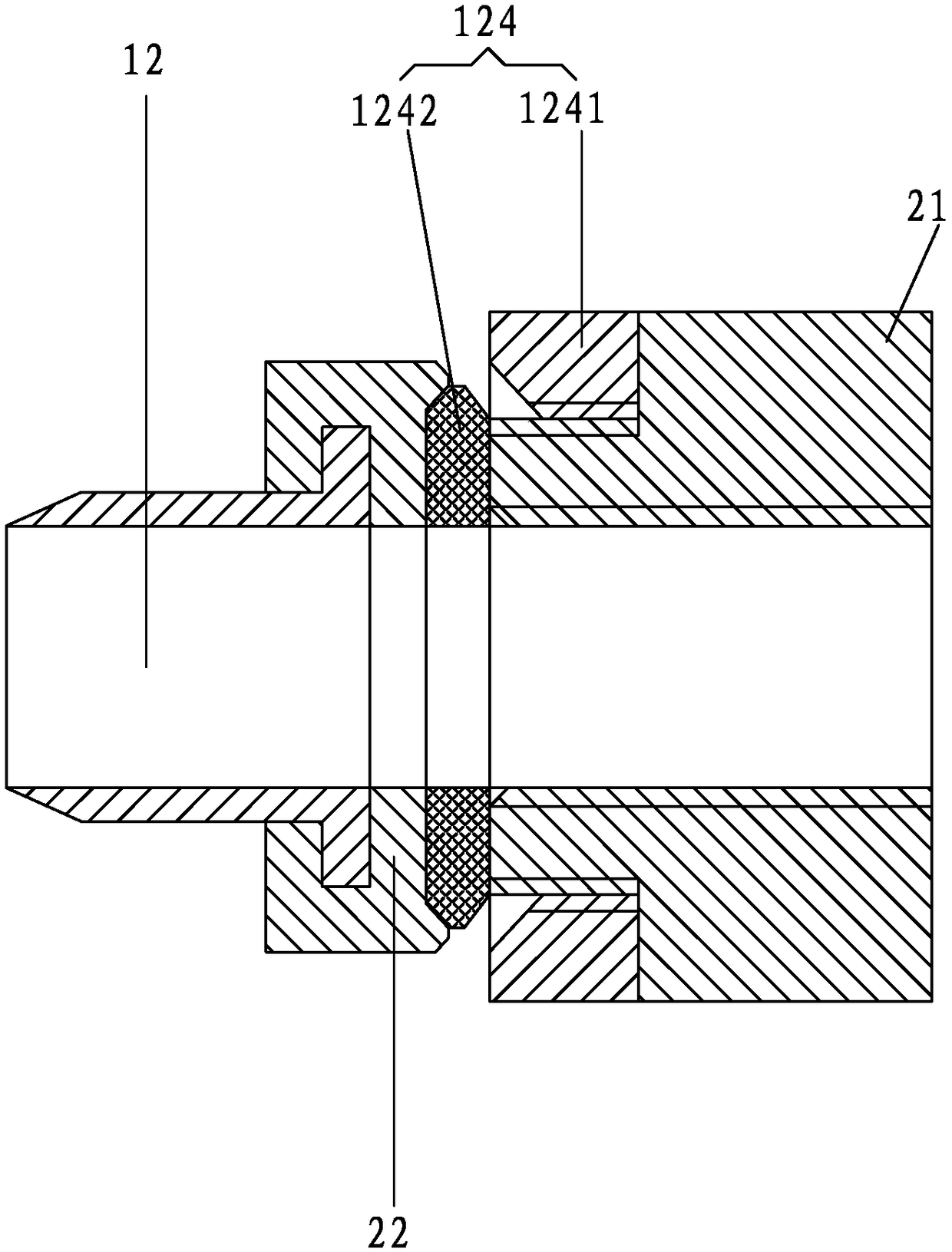

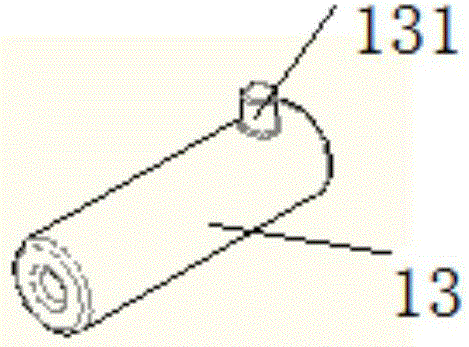

Cylindrical Langmuir probe, probe assembly and plasma plume flow field detection system

ActiveCN108601189AFit tightly and firmlyReduce distractionsPlasma techniqueLangmuir probeBiomedical engineering

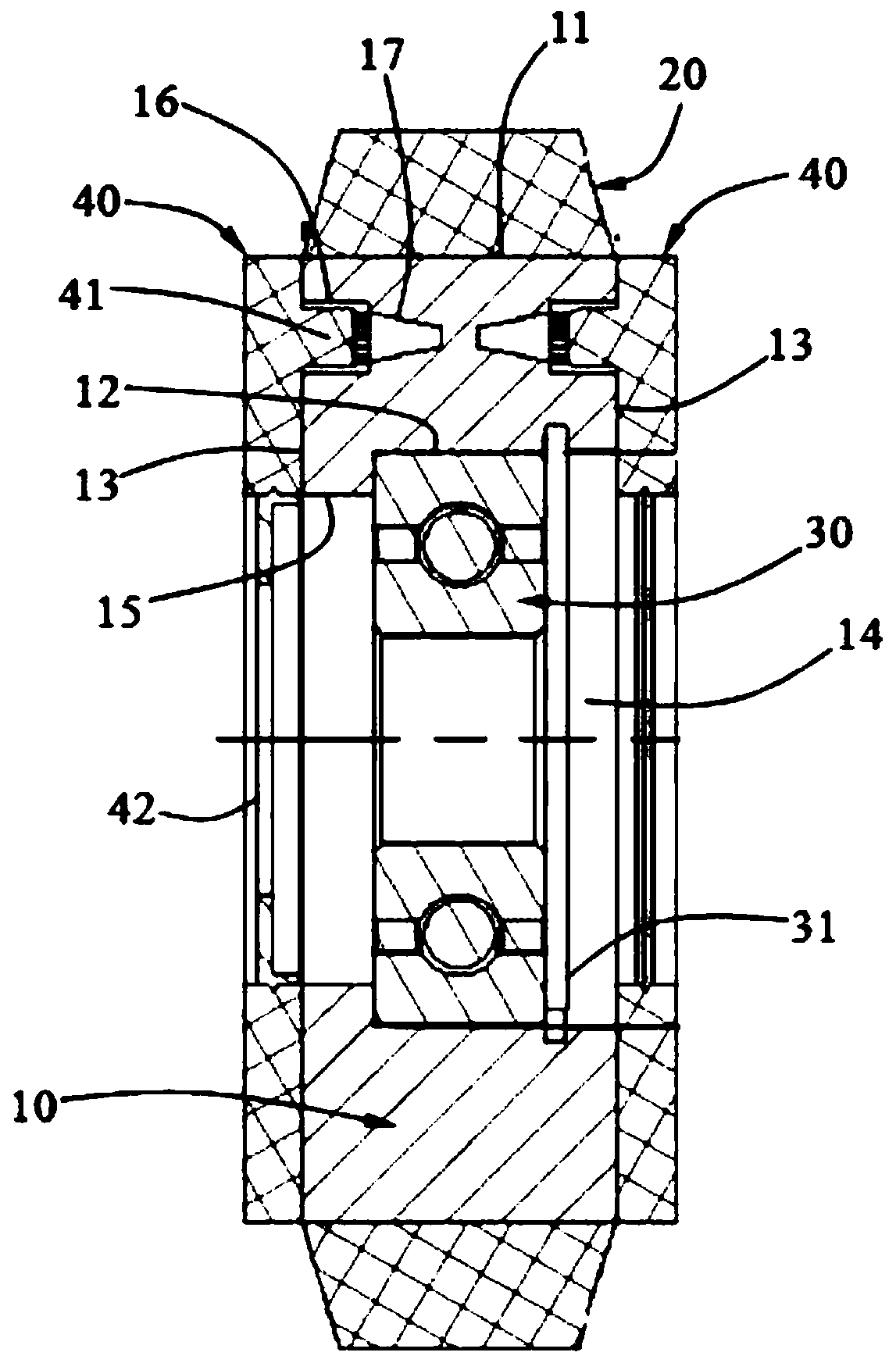

The invention provides a cylindrical Langmuir probe, a probe assembly and a plume flow field detection system, and relates to the technical field of plasma detection. The cylindrical Langmuir probe comprises a tungsten rod needle body, a sheath cylinder and a hollow locking rod; the sheath cylinder and the hollow locking rod are both made from insulated materials; a needle body connecting column is arranged at one end of the tungsten rod needle body; the tungsten rod needle body penetrates out of a first end of the sheath cylinder, and the sheath cylinder is internally provided with a needle body locating cavity which cooperates with the needle body connecting column; a cable through hole for a cable to penetrate through is formed in the hollow locking rod; the hollow locking rod is inserted into a second end of the sheath cylinder, and can push the needle body connecting column to abut against the end face of the needle body locating cavity; the hollow locking rod is locked with the sheath cylinder. By means of the cylindrical Langmuir probe, the technical problems in the prior art that a measuring result of a Langmuir probe is easily interfered with, and the measuring precision is low are solved.

Owner:BEIHANG UNIV

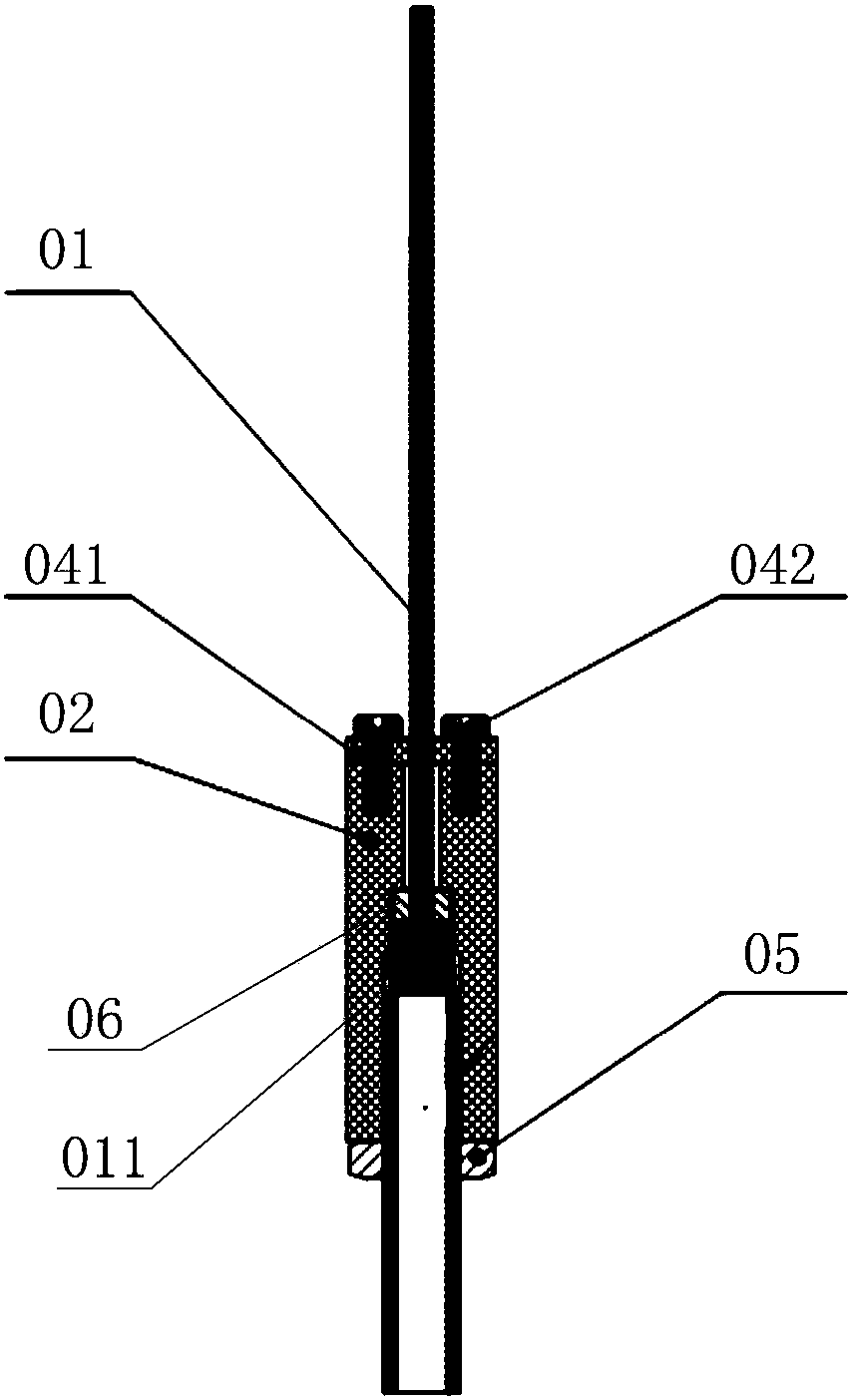

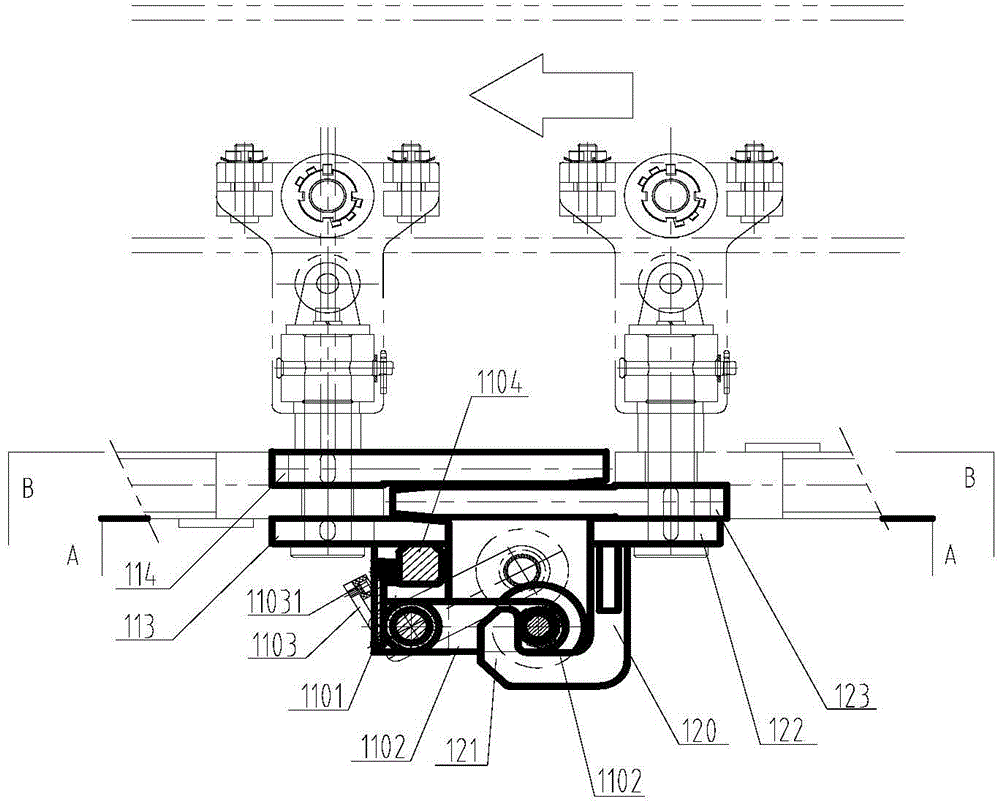

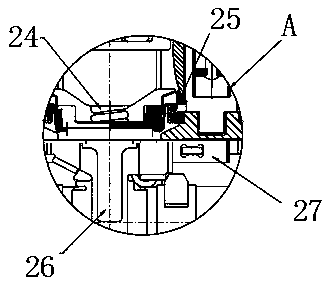

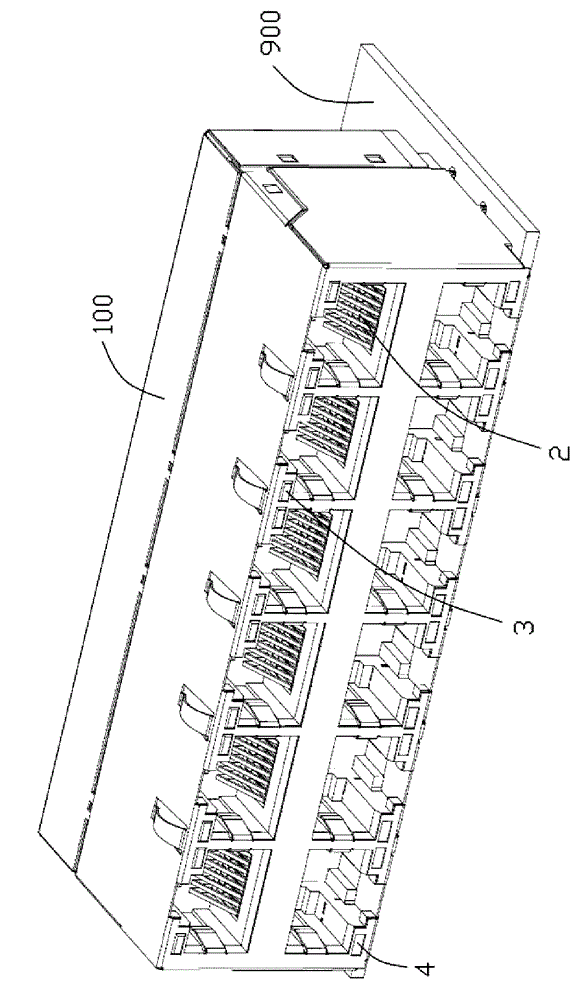

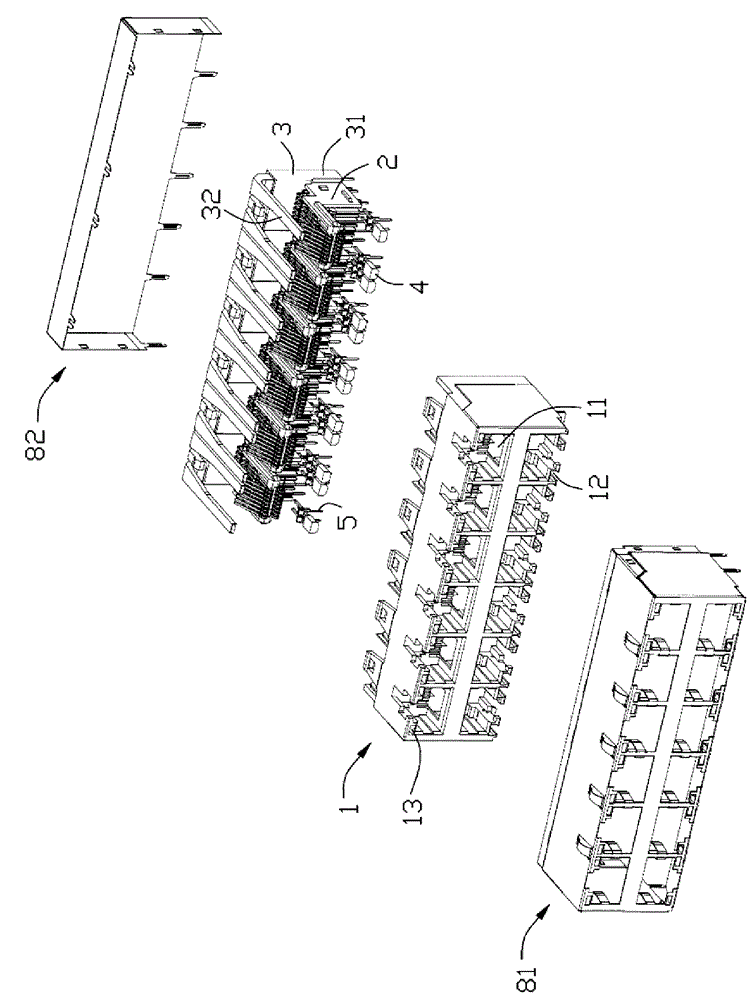

Conveying trolley group, accompanying connecting device and air friction conveying system

ActiveCN104692061AImprove reliabilityImprove stabilityMechanical conveyorsEngineeringMechanical engineering

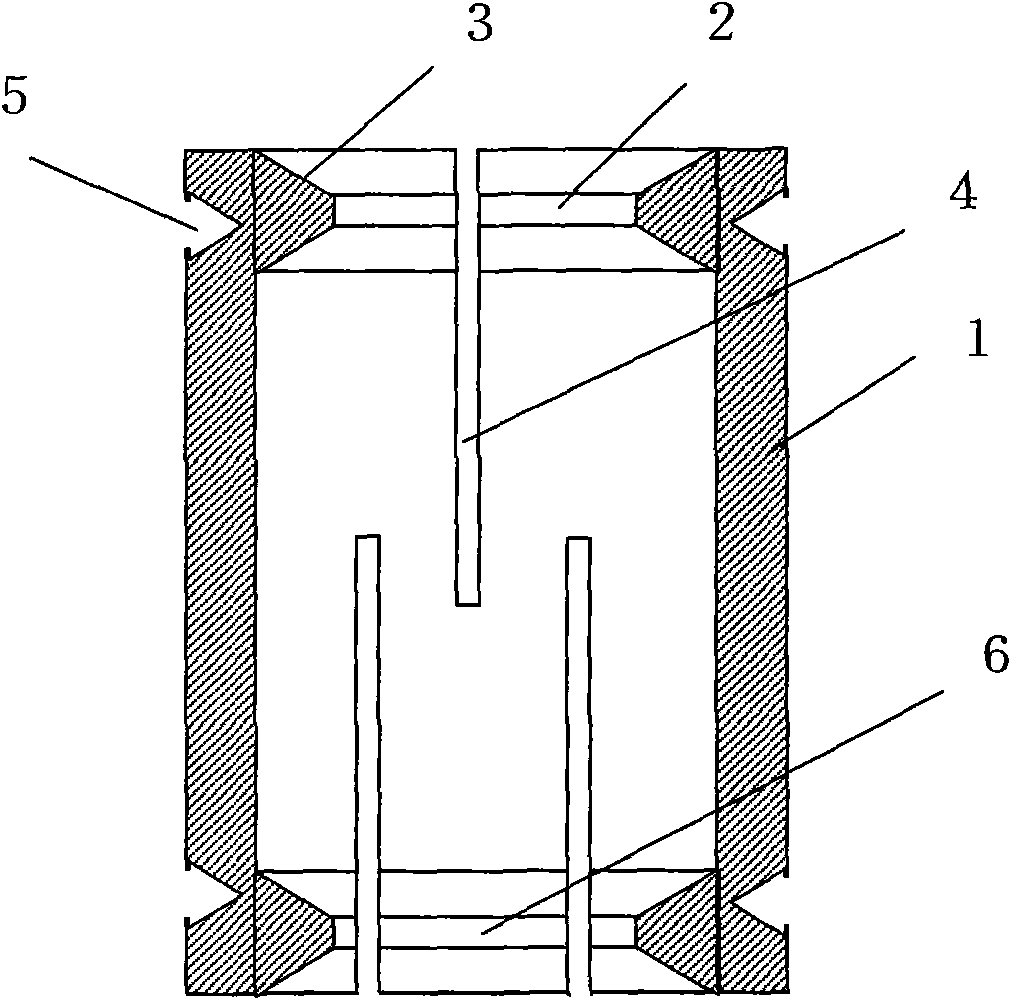

The invention discloses a conveying trolley group, an accompanying connecting device and an air friction conveying system. The conveying trolley group comprises at least two trolleys arranged in the running direction in sequence; the accompanying connecting device is arranged between the opposite ends of the adjacent two trolleys and comprises a pothook and a hanging buckle matched with the pothook; the pothook comprises a pothook handle and a pothook bending part fixedly arranged at one end of the pothook handle; the hanging buckle comprises a hanging arm and a hanging shaft; during connection, the hanging shaft falls into the pothook bending part of the pothook under the rotation of the hanging arm around the connecting shaft, so that the front trolley and the rear trolley which are adjacent are connected with each other; during disengagement, the hanging buckle rotates in the opposite direction during falling, so that the hanging shaft is separated from the pothook bending part, and the accompanying reliability and stability of the conveying trolley are improved.

Owner:HUBEI HUACHANGDA INTELLIGENT EQUIP

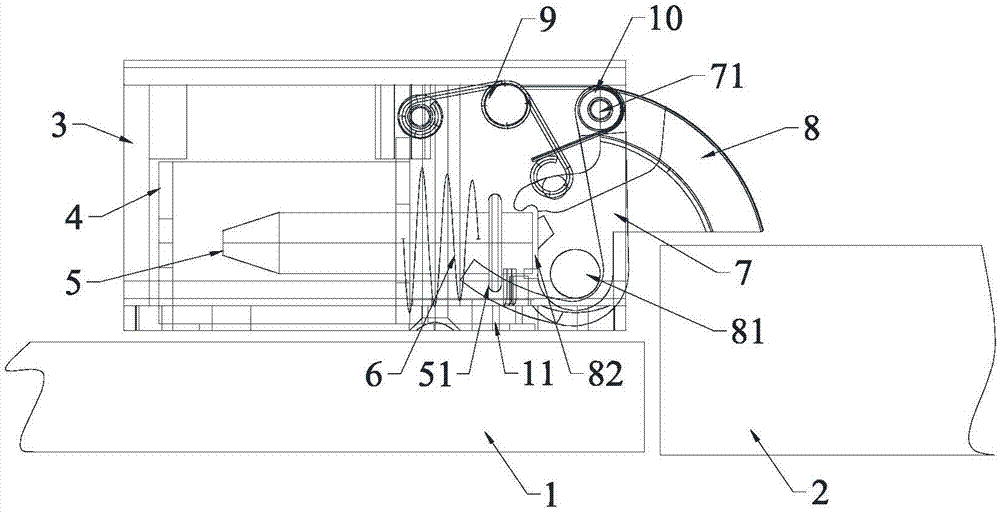

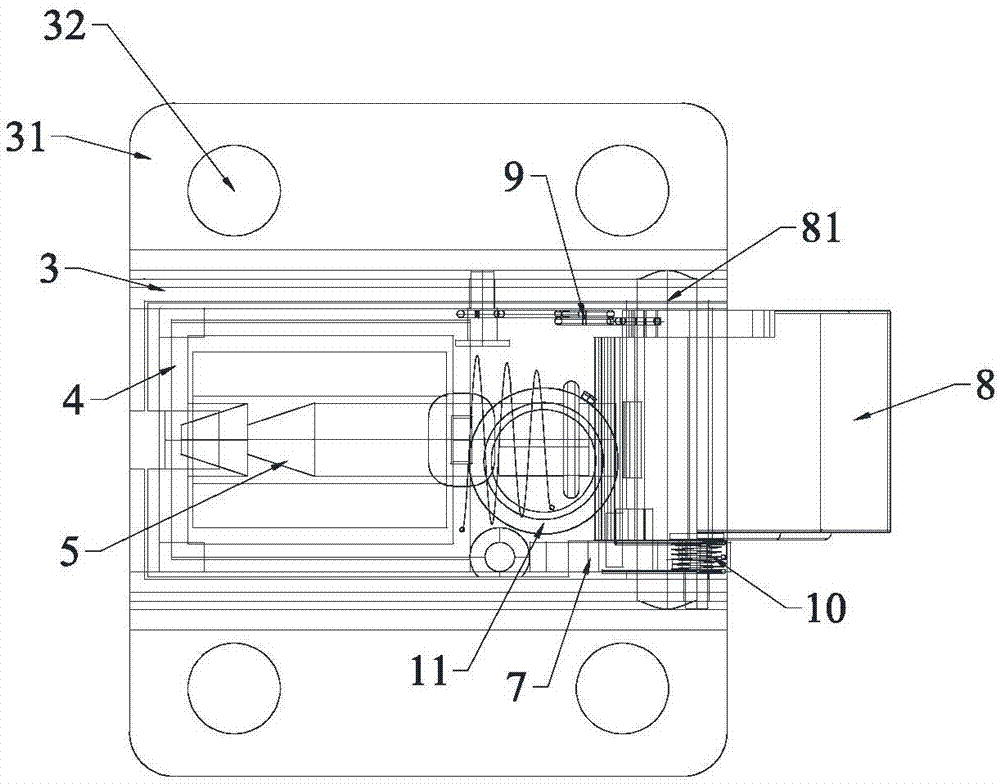

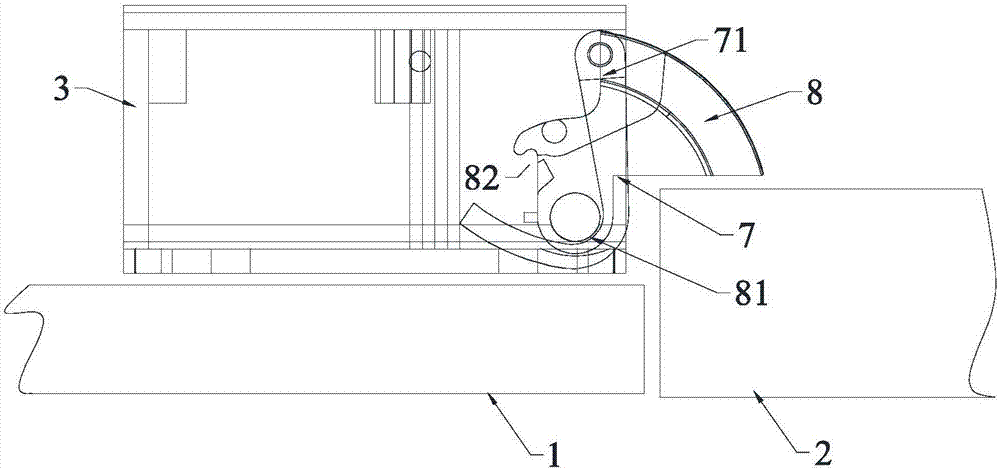

Electronic lock and application of access control system of electronic lock

PendingCN107355139AGuaranteed StrengthEnsure safetyNon-mechanical controlsControl theoryMechanical engineering

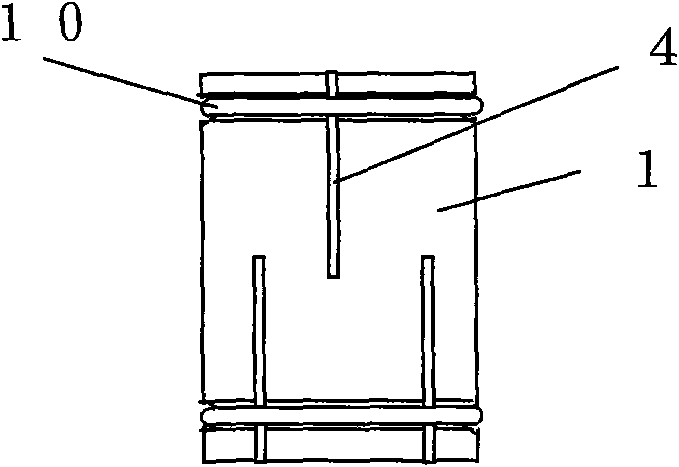

The invention discloses an electronic lock and application of access control system of electronic lock and is mounted on the edge of the door body by a lock box. An electromagnet, a self-locking mechanism and a locking tab are provided in the lock box. The electromagnet is arranged on the one side of the locking tab. The other side of the locking tab is correspondingly provided with a door frame. One end of the self-locking mechanism is connected to one end of the locking tab. The other end of the self-locking mechanism is located in the lock box. The electromagnet can do back and forth movement relative to the locking tab. When the door opens, the electromagnet is controlled by electric power to move a certain distance away from the direction of the locking tab and is free from the restriction of the locking tab. When the door body is pulled, the door frame forces the locking tab to rotate at a certain angle in the forward direction of a first rotating shaft, and the door can be opened. Meanwhile, the self-locking mechanism rotates the lock box out with the opening angle of the door. When the door closes, the door frame first touches the self-locking mechanism. The self-locking mechanism rotates the front end of the self-locking mechanism and meets the tail of the locking tab. The locking tab is rotated through the first rotating shaft to complete the closing action. The electronic lock and the application of access control system of electronic lock have the advantages of simple structure, strong generality, safety and convenience.

Owner:佛山市奇点安防科技有限公司

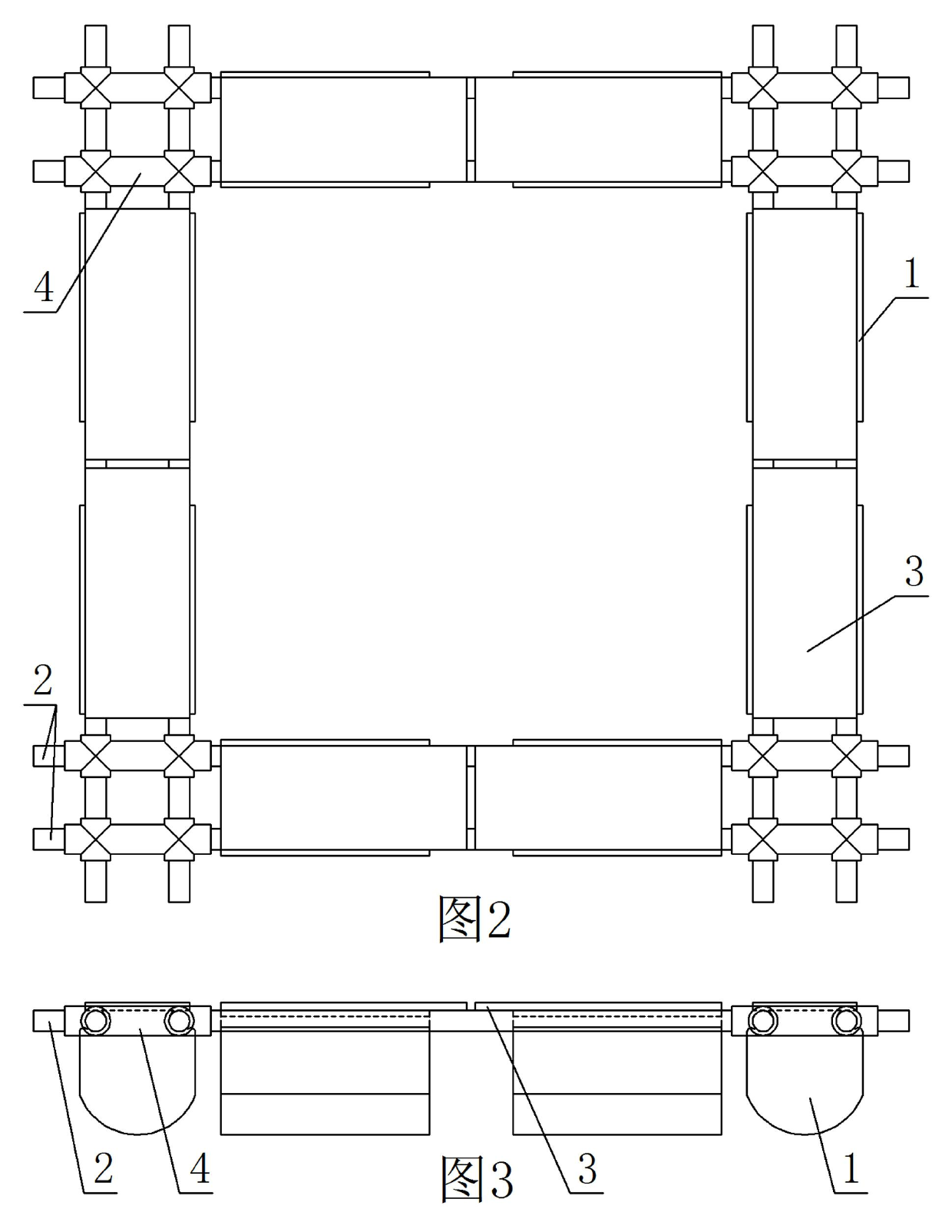

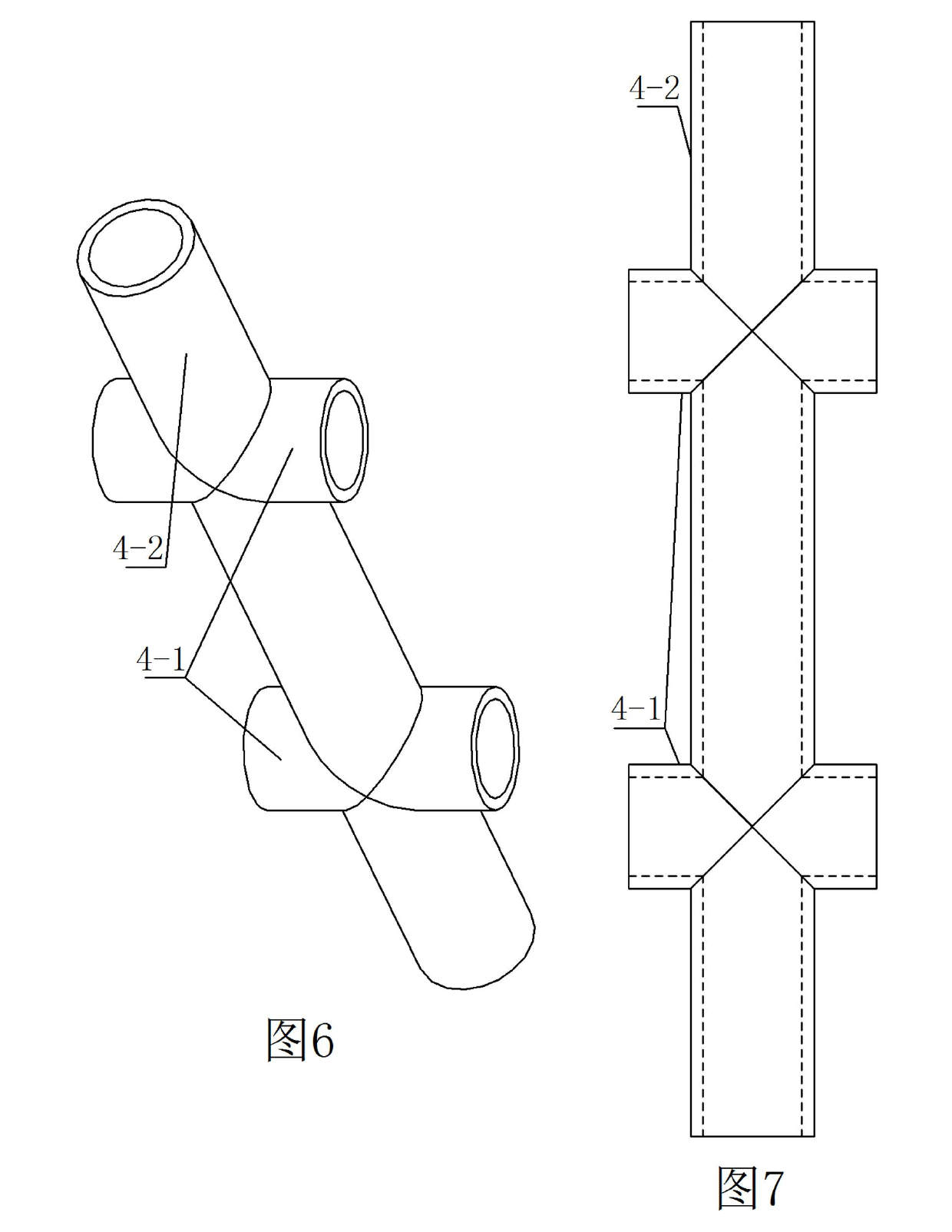

Environment-friendly anti-wave plastic aquiculture fish raft

InactiveCN102124976AFit tightly and firmlyImprove stabilityClimate change adaptationPisciculture and aquariaEngineeringBuoyancy

The invention relates to an environment-friendly anti-wave plastic aquiculture fish raft. The environment-friendly anti-wave plastic aquiculture fish raft is characterized by comprising more than two groups of buoyancy units, wherein each group of buoyancy unit comprises a pair of supporting rods which are parallel to each other, more than one plastic floating body which is erected and fixedly connected with the lower part of the two supporting rods, and a plastic walking road platen which is erected and fixedly connected with the upper part of the supporting rods and / or floating bodies; and the adjacent buoyancy units are connected and fixed through a supporting, fixing and connecting device. The invention aims to provide the environment-friendly anti-wave plastic aquiculture fish raft which not only has a steady structure, but also has a good anti-wave effect.

Owner:宁德市金鼎海洋科技有限公司

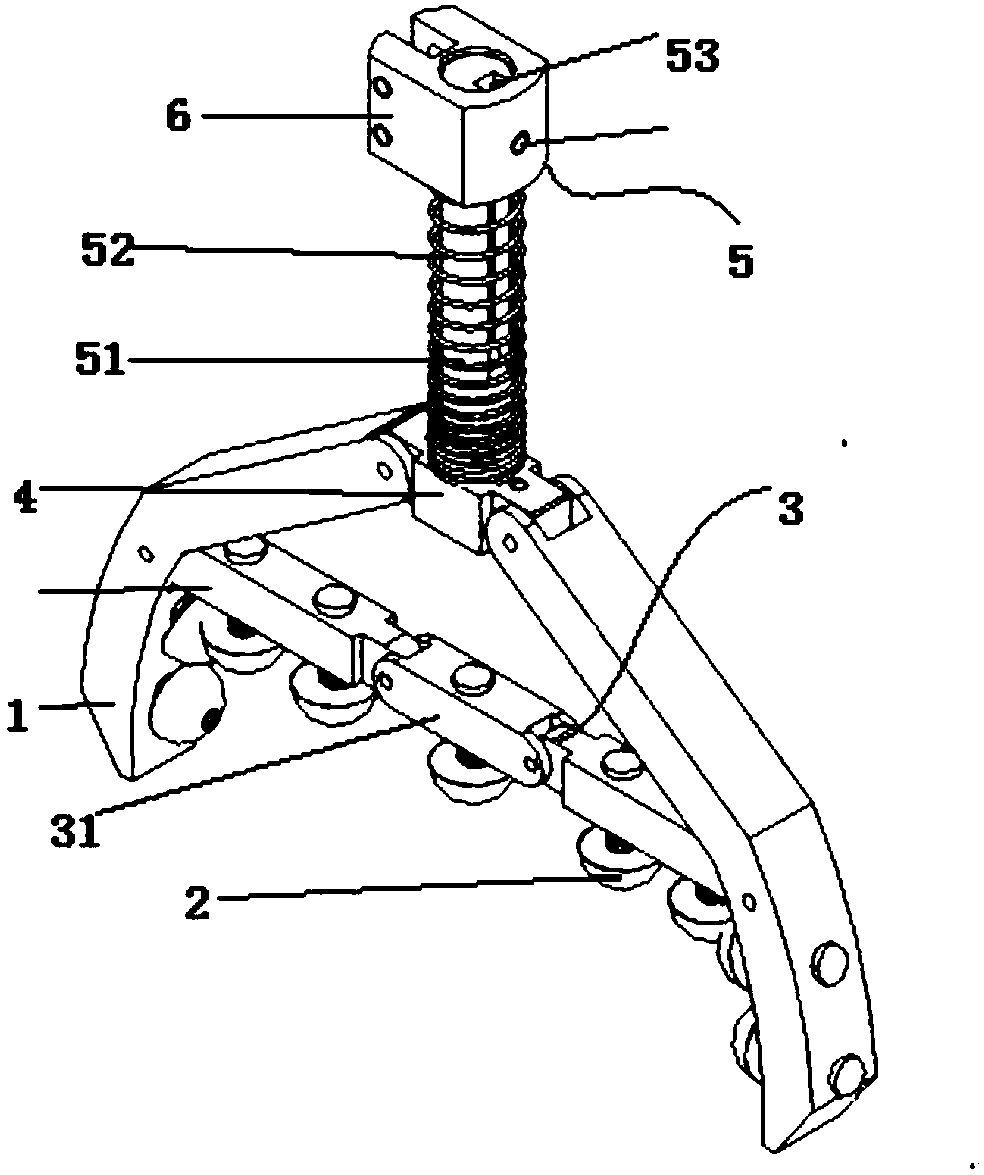

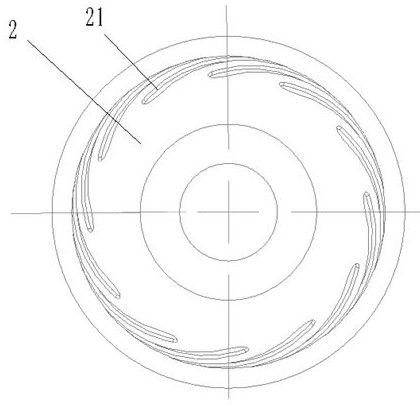

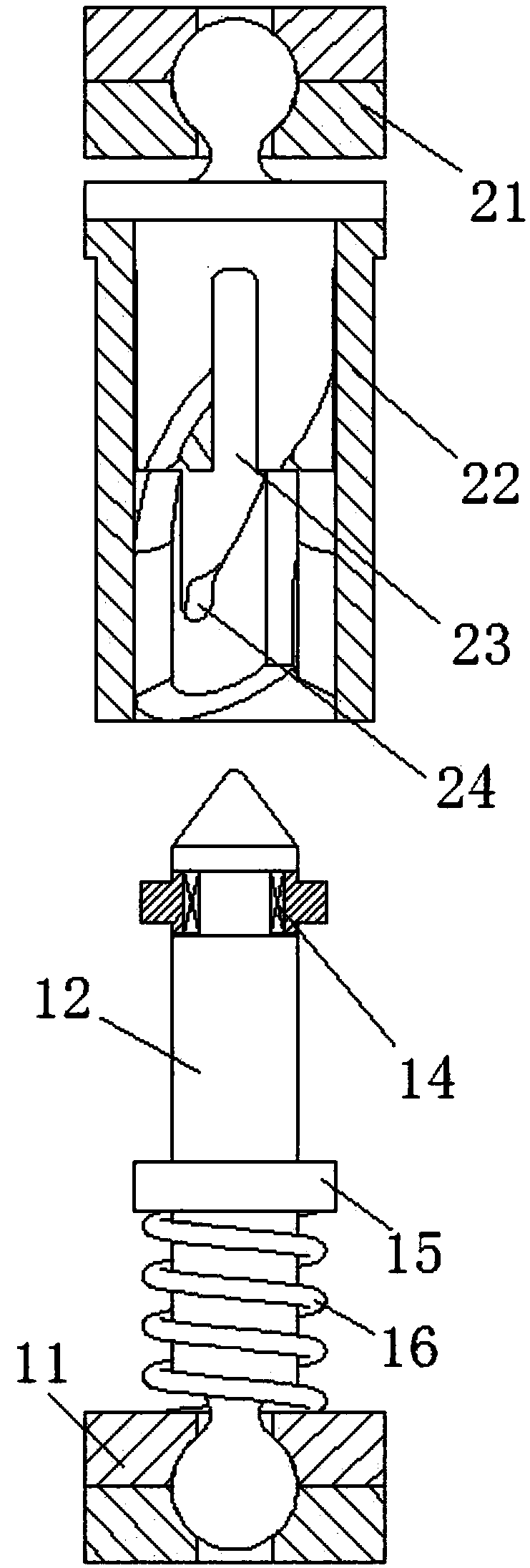

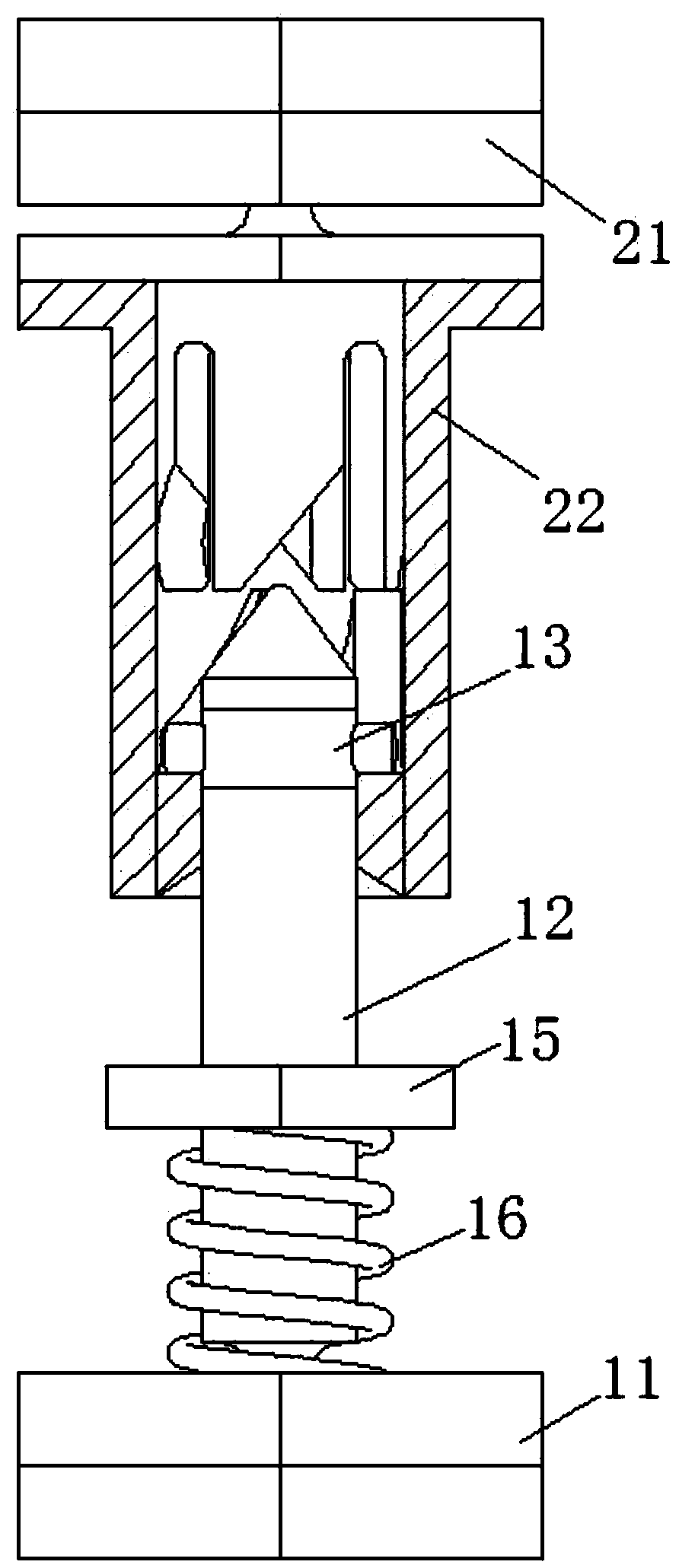

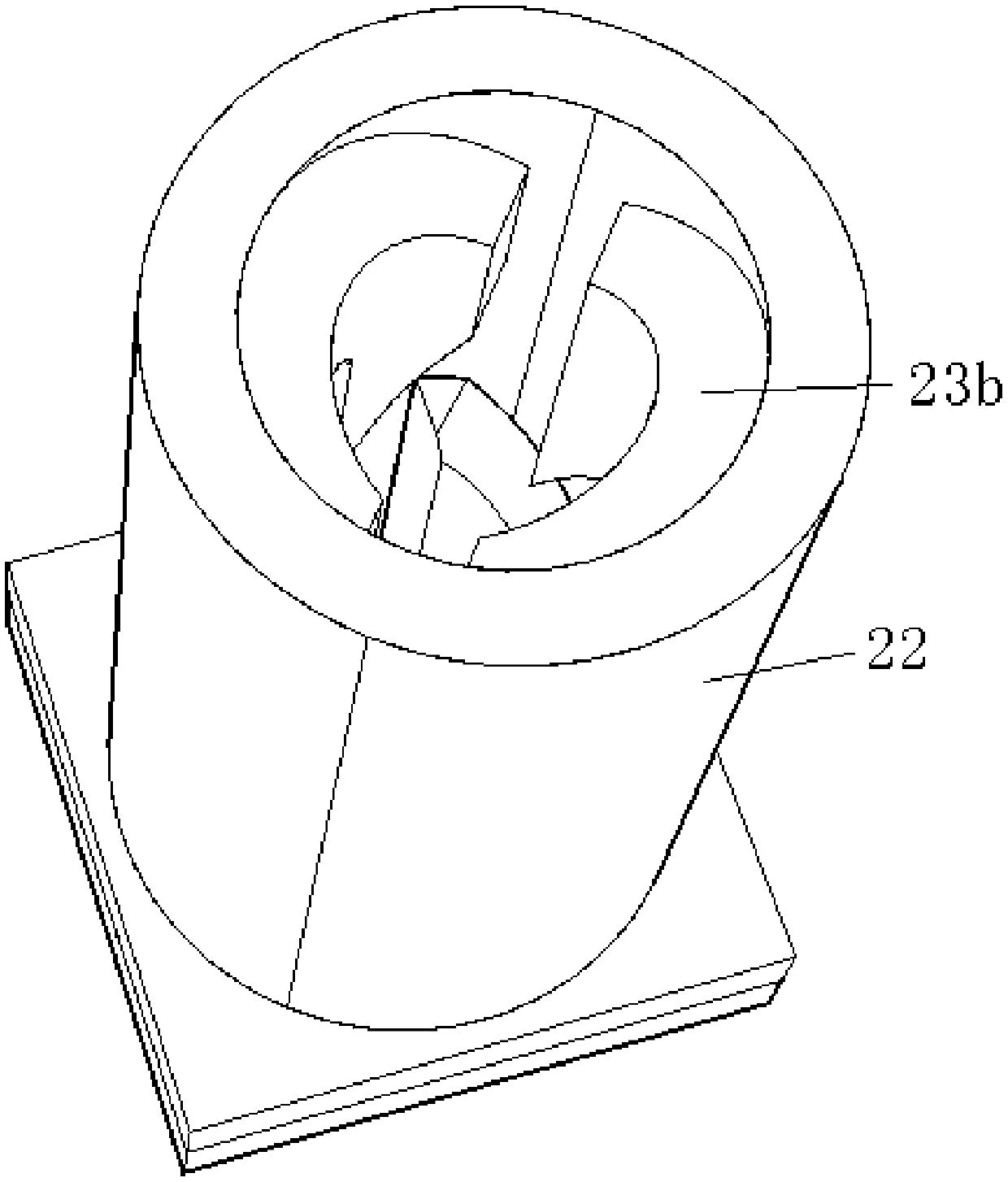

Detachable spring coil

The invention provides a detachable spring coil which includes a guide-in sheath, a pushing system and a spring coil assembly. The pushing system is located in the guide-in sheath and includes clamps.By optimizing the shape and number of the clamps and arranging a protrusion part at the proximal end of a spring coil body, the spring coil body is more tightly and firmly through the clamp fixing cooperation in normal times, so that the detachable spring coil can stably deliver the spring coil body to the position, needing thrombus occlusion, in a human body, then the spring coil body can be easily detached, instant detaching can be achieved during detaching, the operating method is simple and convenient, and damage to blood vessels is avoided; a mechanical detaching system is high in controllability and good in development on an embolization spring coil before detaching, and instant detaching can be achieved; and compared with a lock-catch-type detaching method, the detachable spring coil can enable the spring coil body to be easier to be pushed, damage to the spring coil body is avoided, and when the spring coil body is pushed out of a catheter, the catheter is not damaged when a push rod is retracted.

Owner:SHANGHAI SHENQI MEDICAL TECH CO LTD

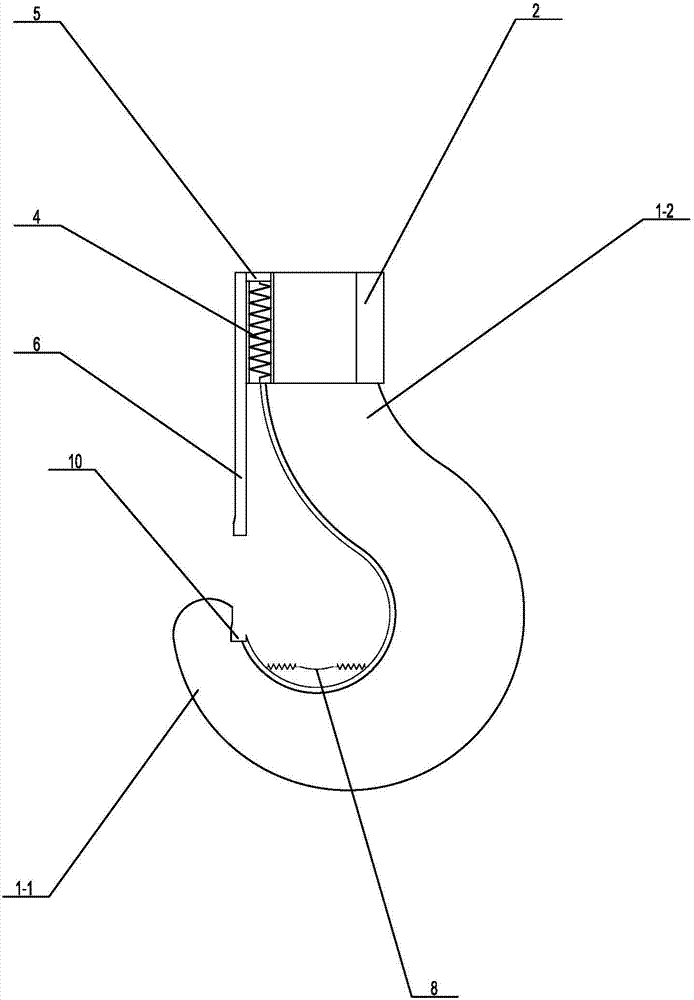

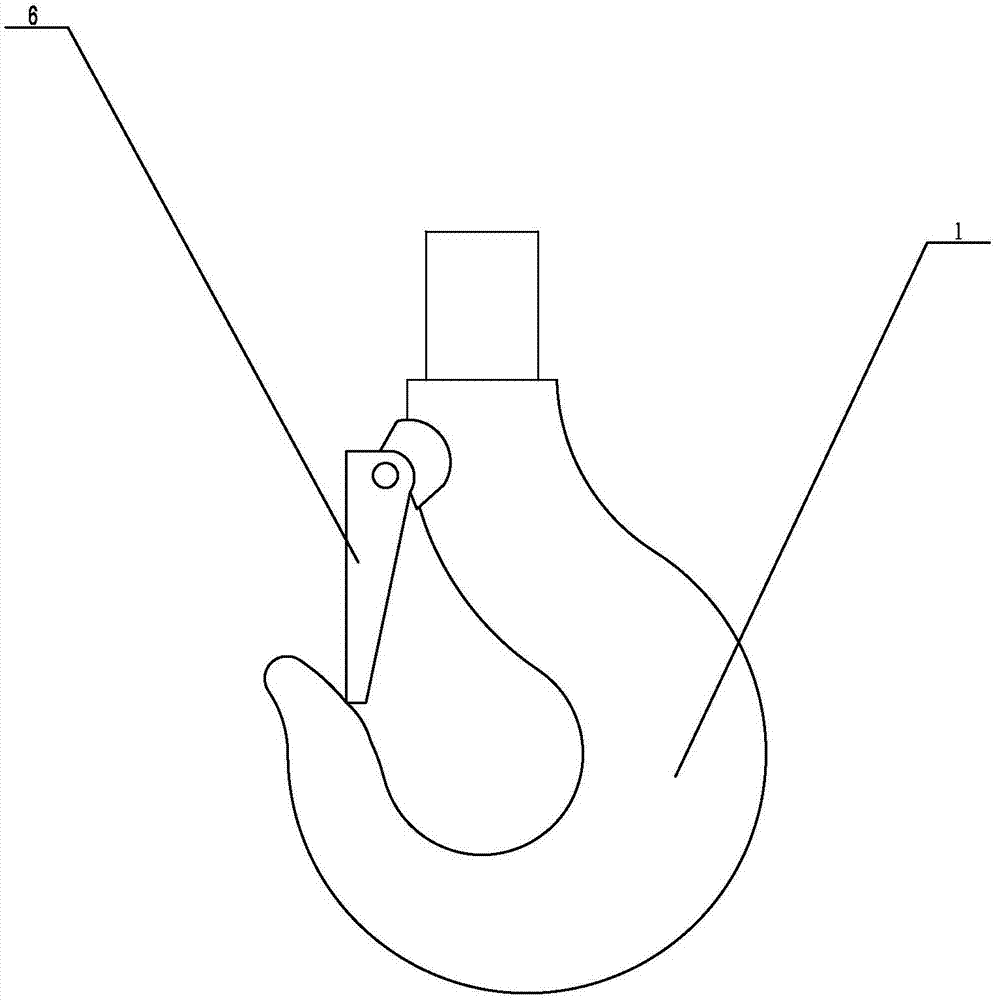

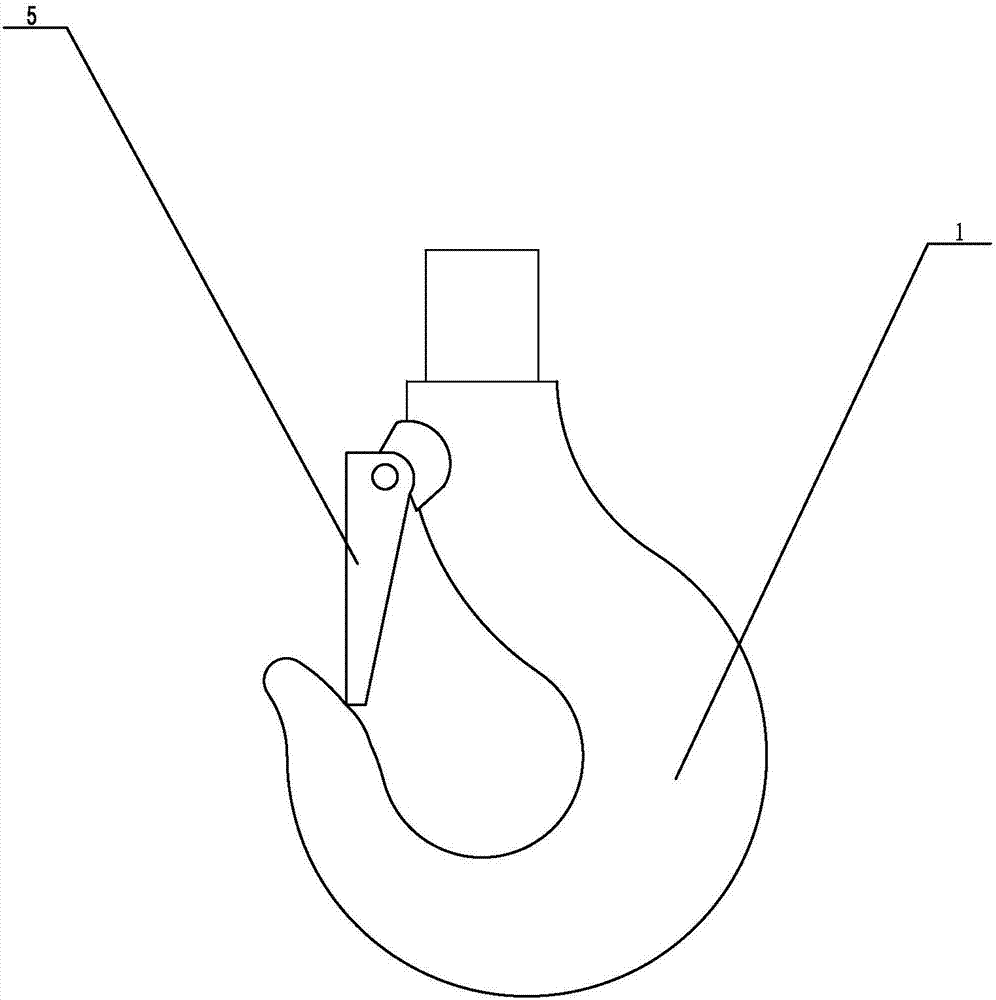

Crane lifting hook capable of being automatically opened and closed

InactiveCN106892348ARealize automatic up and down movementRealize automatic openingLoad-engaging elementsEngineering

Owner:QINZHOU UNIV

Commercial vehicle disc brake caliper assembly with ventilation and self-adjusting structure

InactiveCN107869536AIncrease sliding strokeImprove wear resistanceEngine sealsBrake actuating mechanismsEngineeringSelf locking

The invention discloses a commercial vehicle disc brake caliper assembly with a ventilation and self-adjusting structure. The commercial vehicle disc brake caliper assembly comprises a supporting sleeve, a short bushing, a short pin, a skeleton oil seal and a plastic dust cover; a brake support is mounted on the outer side of a brake caliper body; and a pin shaft is mounted on the middle side inside the brake caliper body. Increasing of the sliding stroke of the short pin is facilitated, the abrasion resistance and better guidance performance of the short bushing can be improved easily, mounting is easy, and the waterproof and dustproof functions are promoted; the bottom of a sealing cushion and the brake caliper body are matched more tightly and more reliably, the sealing effect is promoted, and the water leakage and water seepage problems are solved thoroughly; and the working performance of an adjusting mechanism is promoted, matching and working stability of internal parts are strengthened, the multiple problems such as nonuniform braking force, failure in clearance adjustment, deformation of the adjusting mechanism and braking failure in the braking process are solved, and thefunction of self-locking of a thread adjusting sleeve can be well achieved.

Owner:张健

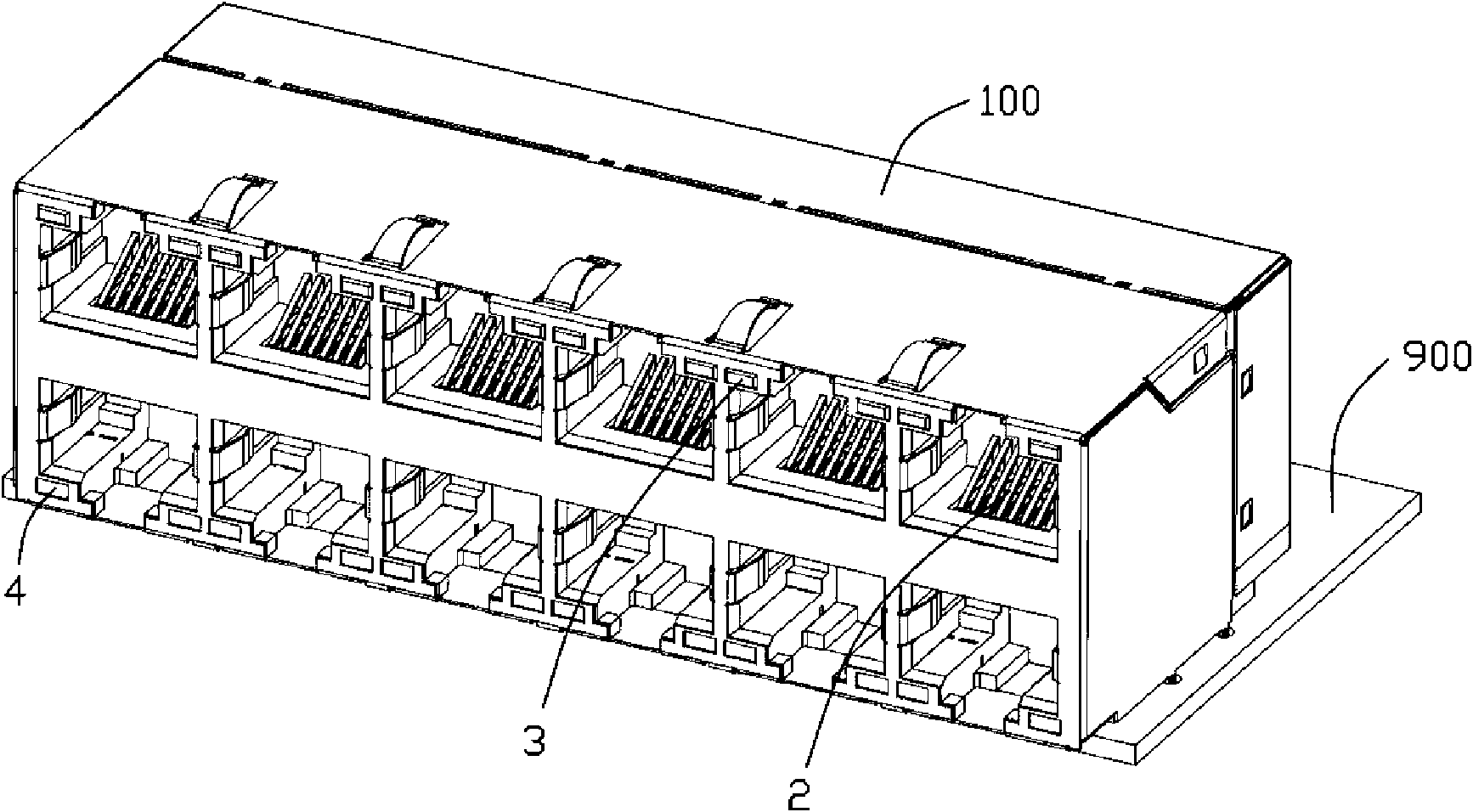

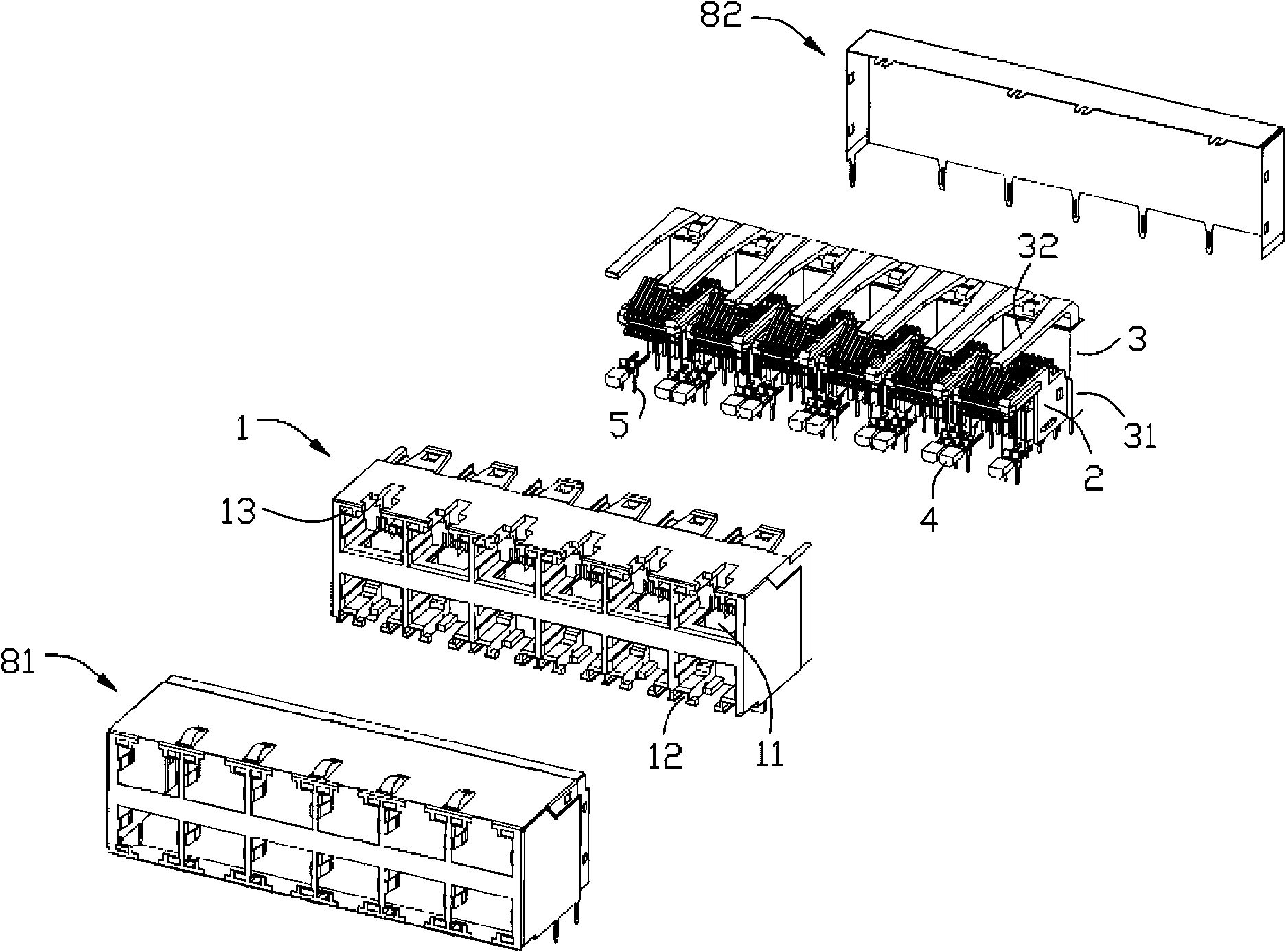

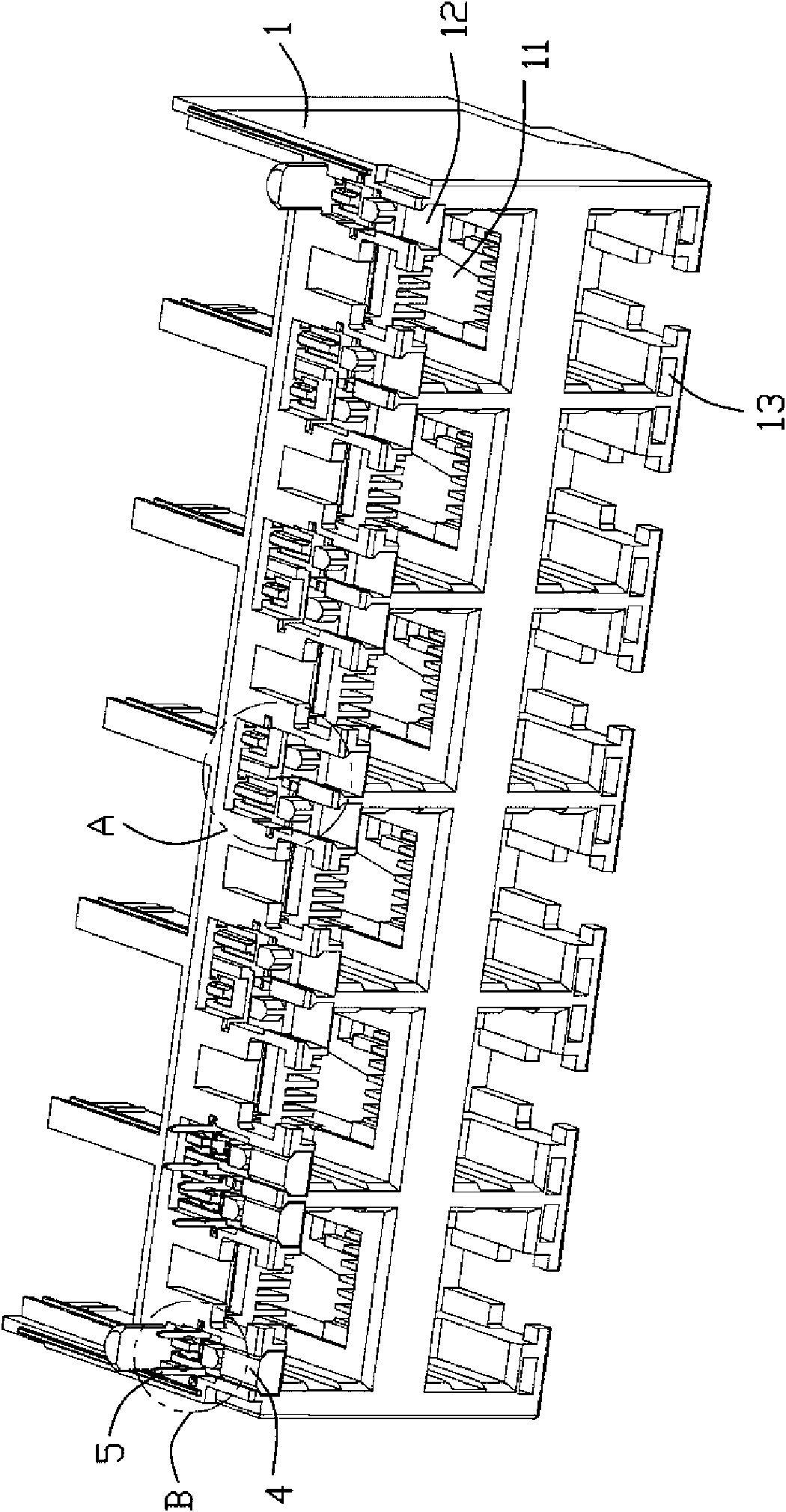

Module connector and assembling method thereof

InactiveCN102055121ANot easy to damageFit tightly and reliablyContact member manufacturingContact member assembly/disassemblyEngineeringLight-emitting diode

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

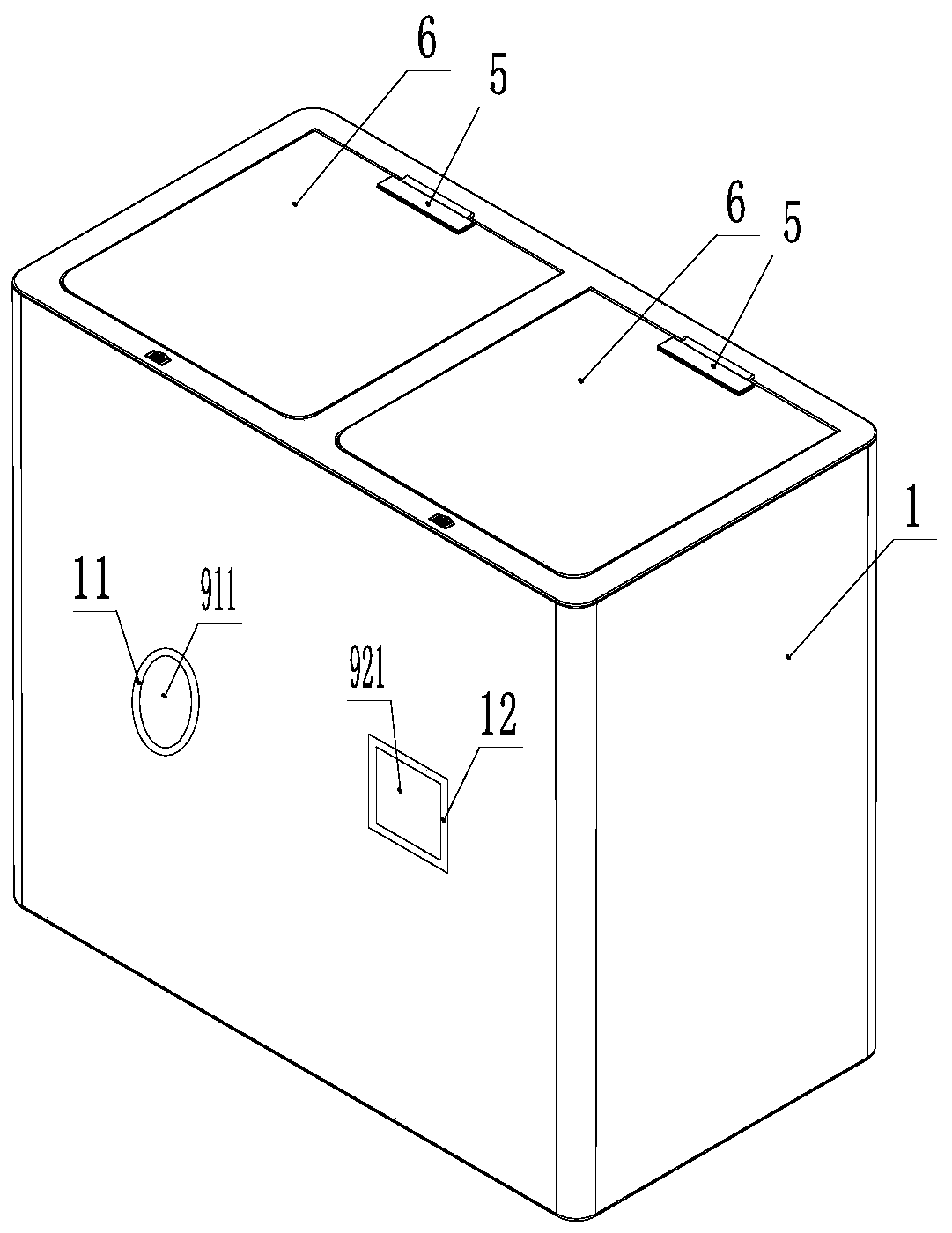

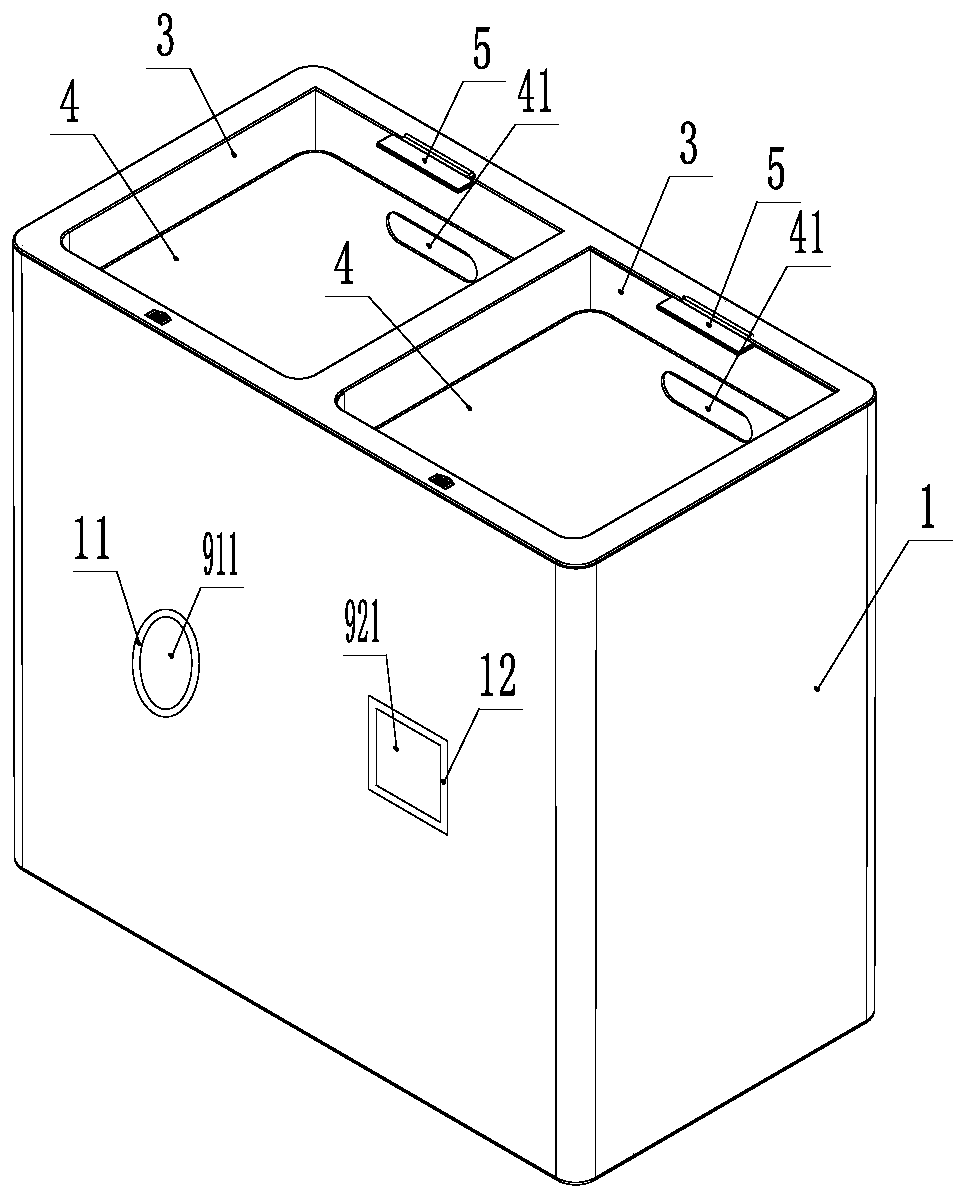

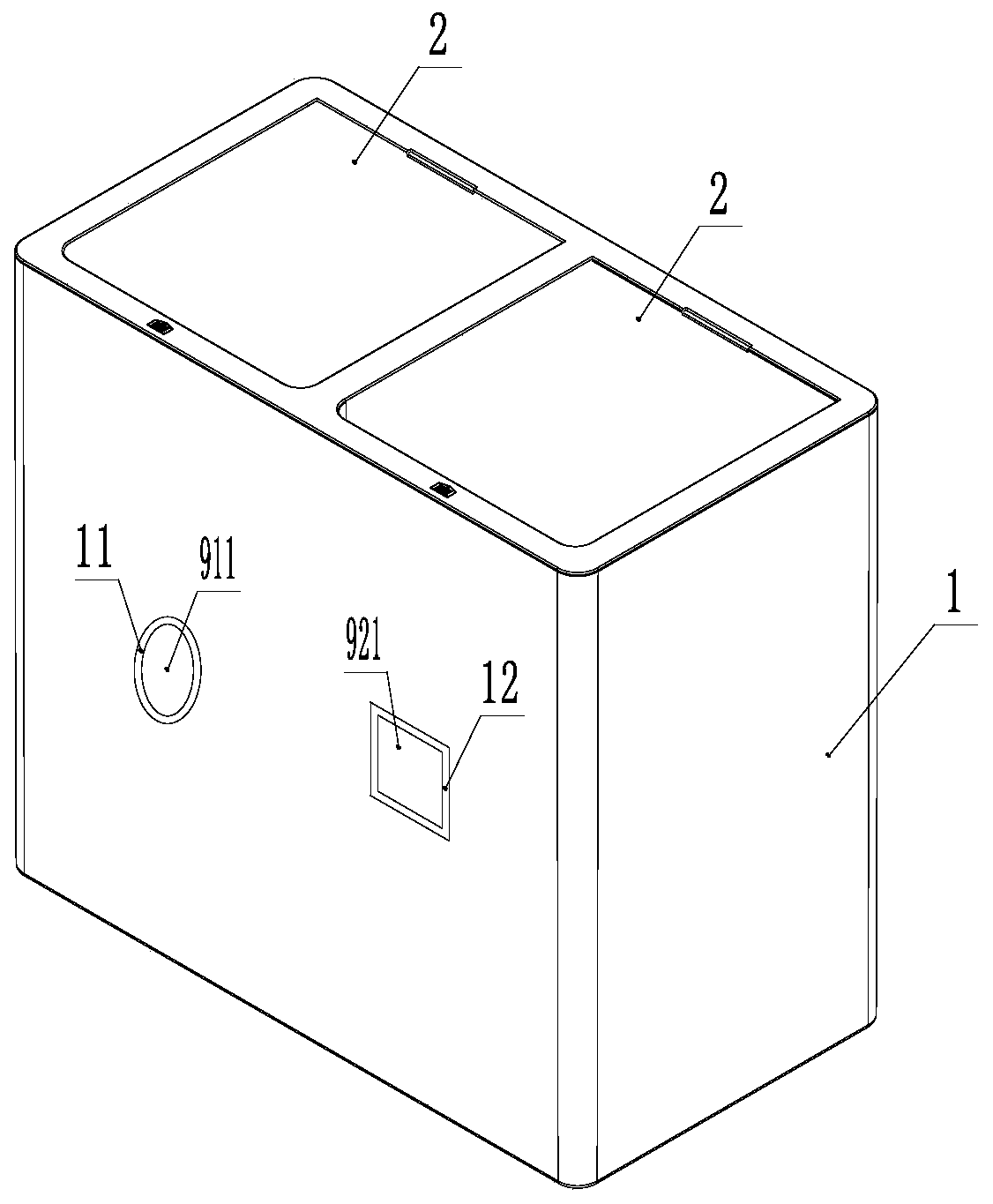

Household intelligent classification garbage bin

PendingCN111071649ACultivate classification awarenessEnvironmental AwarenessRefuse receptaclesImaging processingElectric machinery

The invention provides a household intelligent classification garbage bin. The household intelligent classification garbage bin comprises an outer shell. A top plate of the outer shell is at least provided with two inner bin holes. The upper portions of the inner bin holes and the top plate of the outer shell are perpendicularly and fixedly connected with intermediate covers. An inner bin is mounted on the lower portion of the interior of each intermediate cover. Upper covers are movably connected to the top plate of the outer shell through opening and closing devices and openings of the intermediate covers correspondingly. The opening and closing devices are connected with motors. The motors are connected with a control module. The control module is connected with a garbage classificationrecognition and judgment module. The control module is arranged on the inner side of a rear side plate of the outer shell. The garbage classification recognition and judgment module is arranged on the inner side of a front side plate of the outer shell. The front side plate of the outer shell is provided with a microphone hole and an infrared camera hole. The garbage classification recognition and judgment module comprises a speech recognition judgment module and an image processing judgment module. The household intelligent classification garbage bin is compact in structure, has two garbageclassification and recognition modes, improves the garbage identifiability, can prevent interference of other speeches in the ambient environment on speech recognition through arrangement of a garbageclassification interlocking module, thereby improving the garbage classification accuracy.

Owner:金月梅

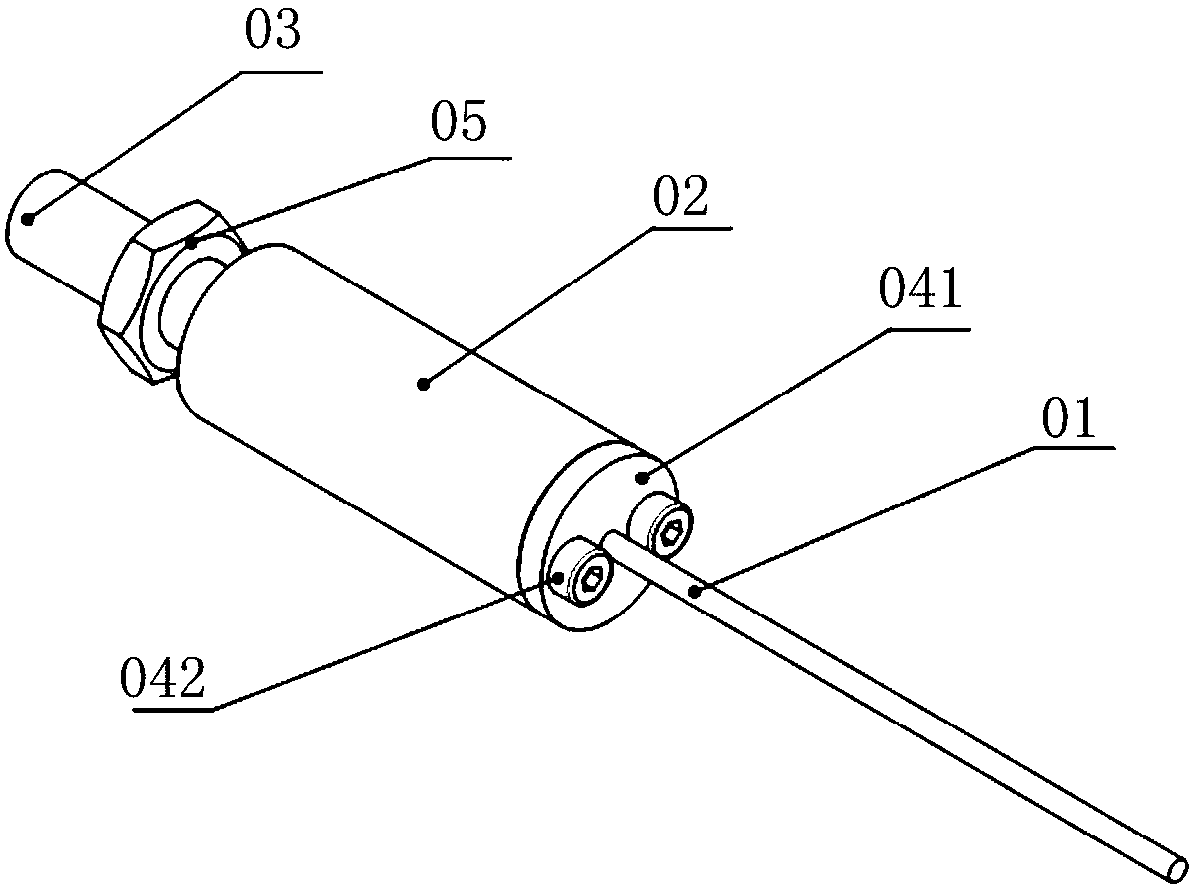

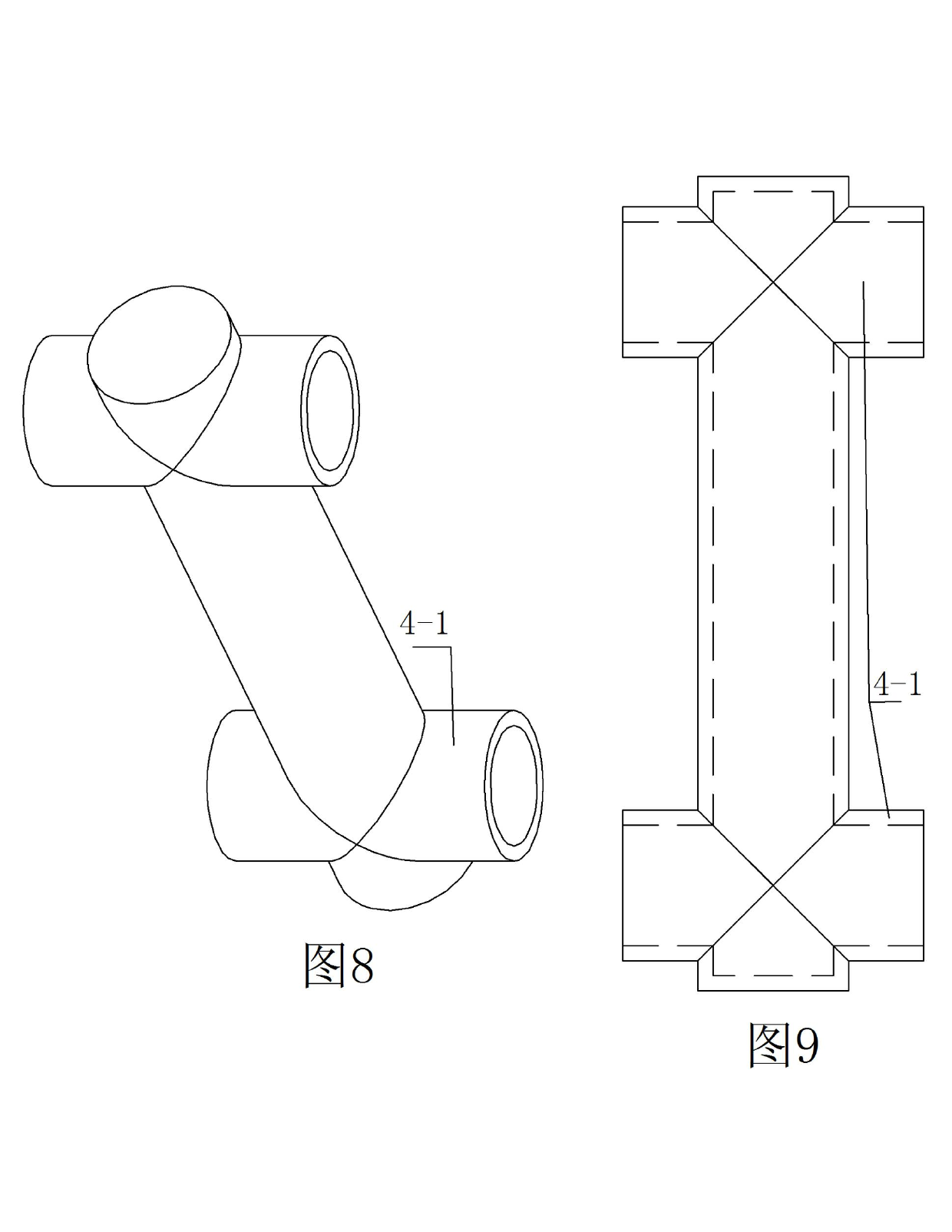

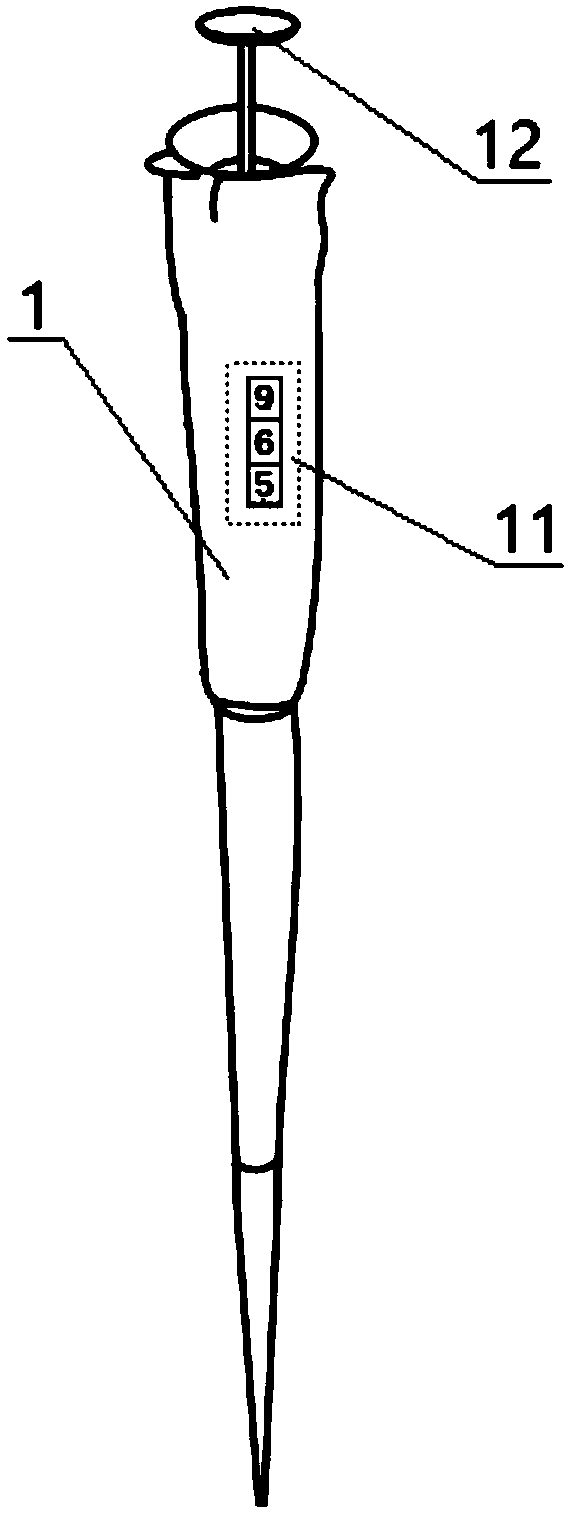

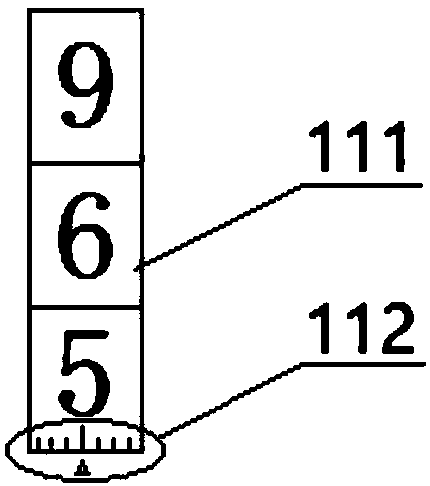

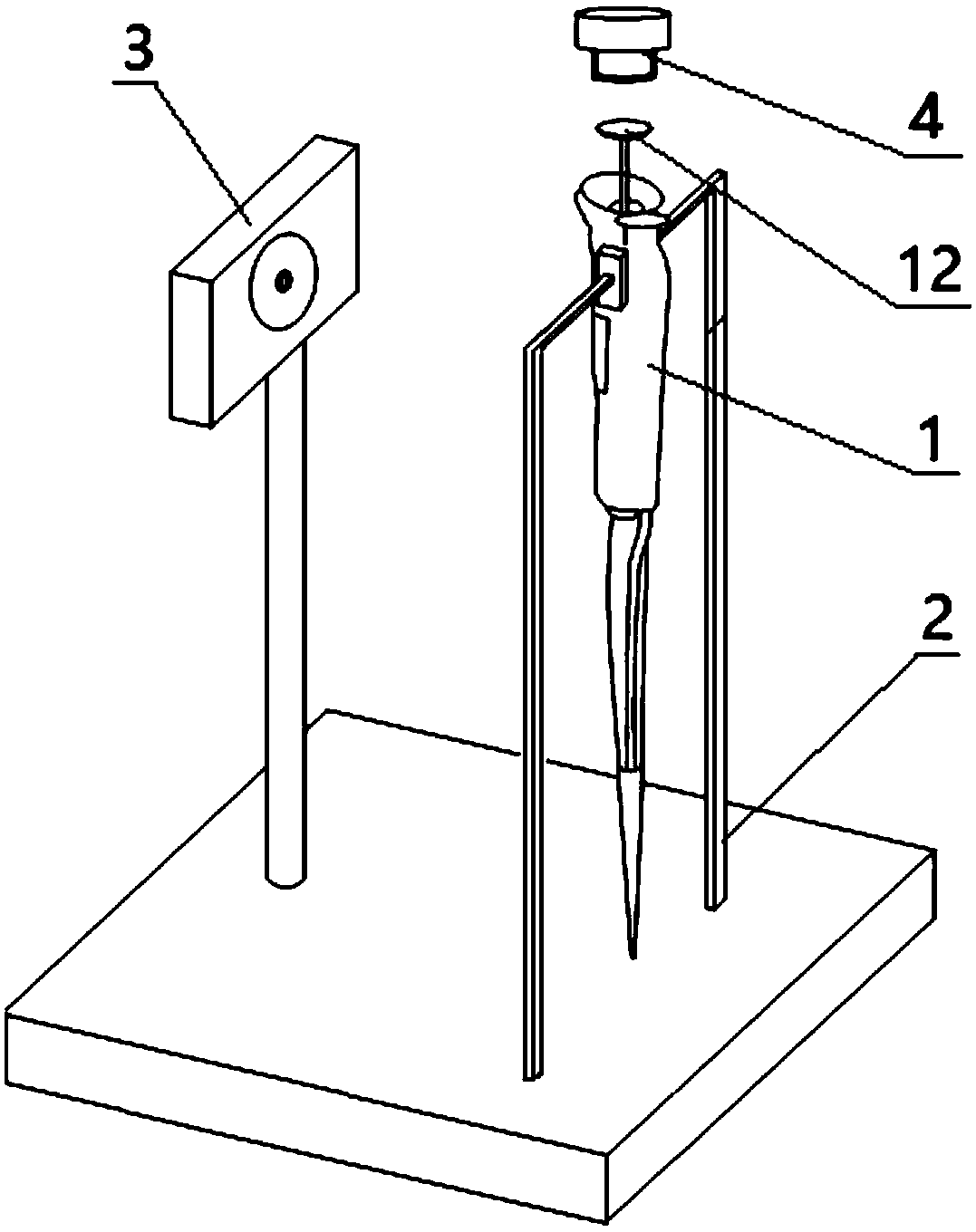

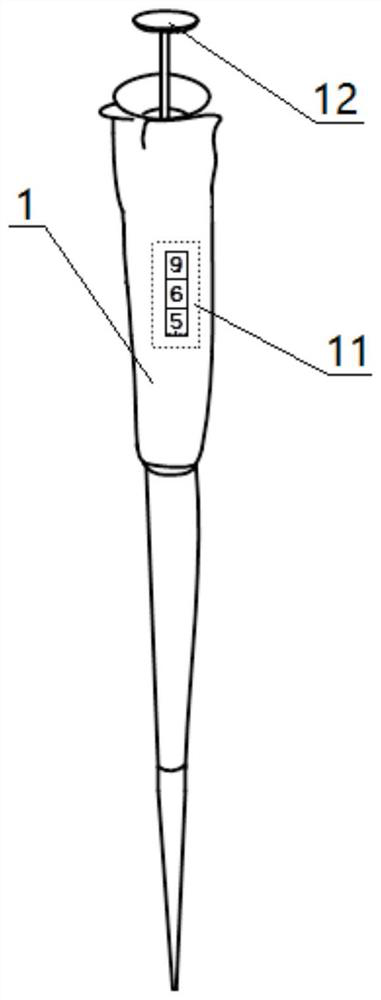

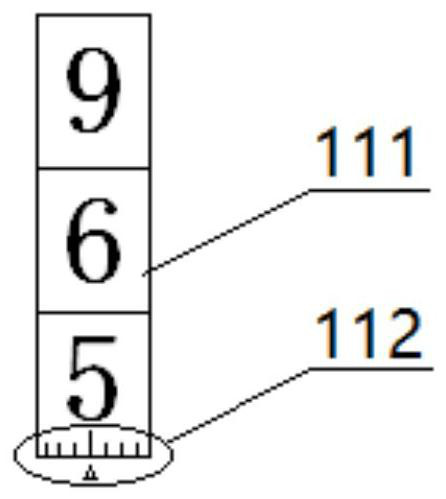

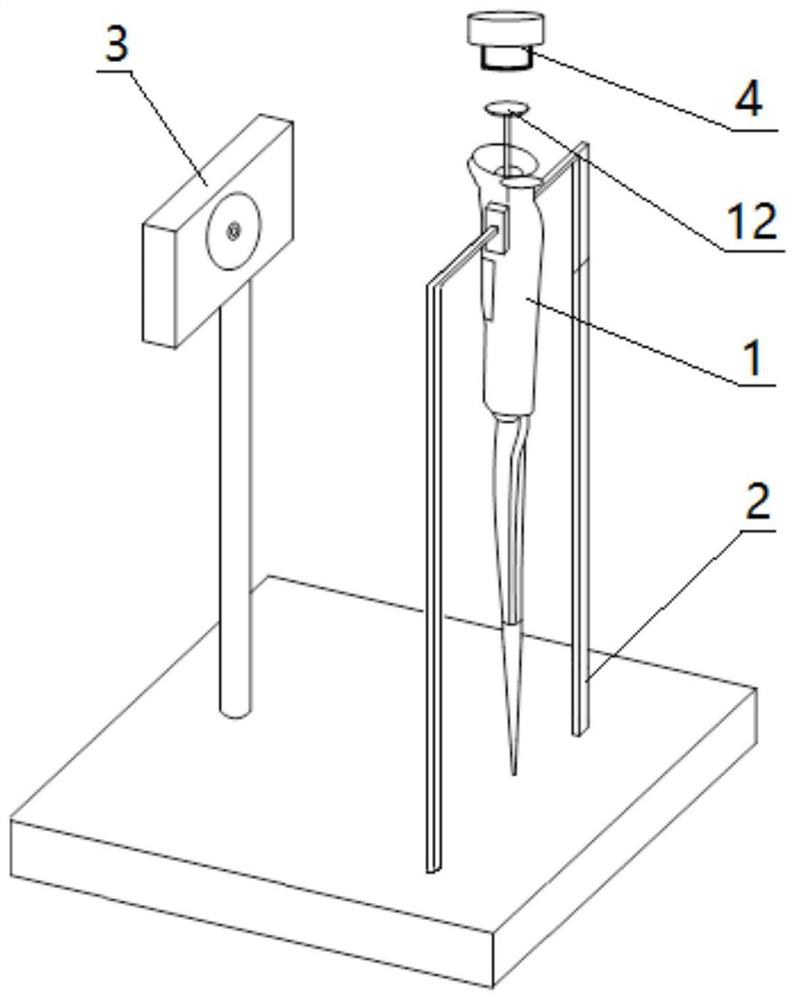

Adjusting method of range of pipette and adjusting device

ActiveCN109225368AAchieve regulationMeet the needs of pipetting and samplingBurettes/pipettesPipetteCurrent range

The invention discloses an adjusting method of the range of a pipette. The adjusting method comprises the following steps: setting a preset range value; acquiring an image of the current range value of the pipette; recognizing the range value in the image; and rotating a range rotary disc according to the current range value and the preset range value. The range of the pipette is adjusted to the preset range value by acquiring the image of a scale observation window of the pipette, recognizing the range value of the current pipette and then rotating the range rotary disc by a specified angle,so that convenience is brought for following direct operation and use. The application also provides an adjusting device of the range of the pipette applicable to the above adjusting method of the range of the pipette.

Owner:SCI EQUIP COMPANY OF SICHUAN PROVINCE

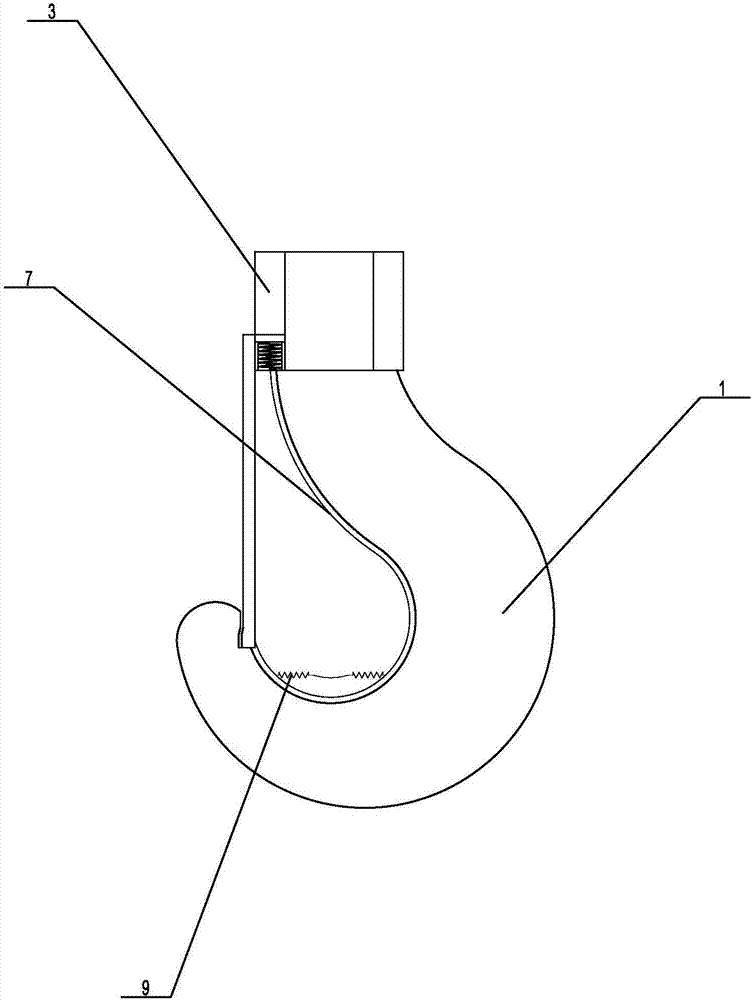

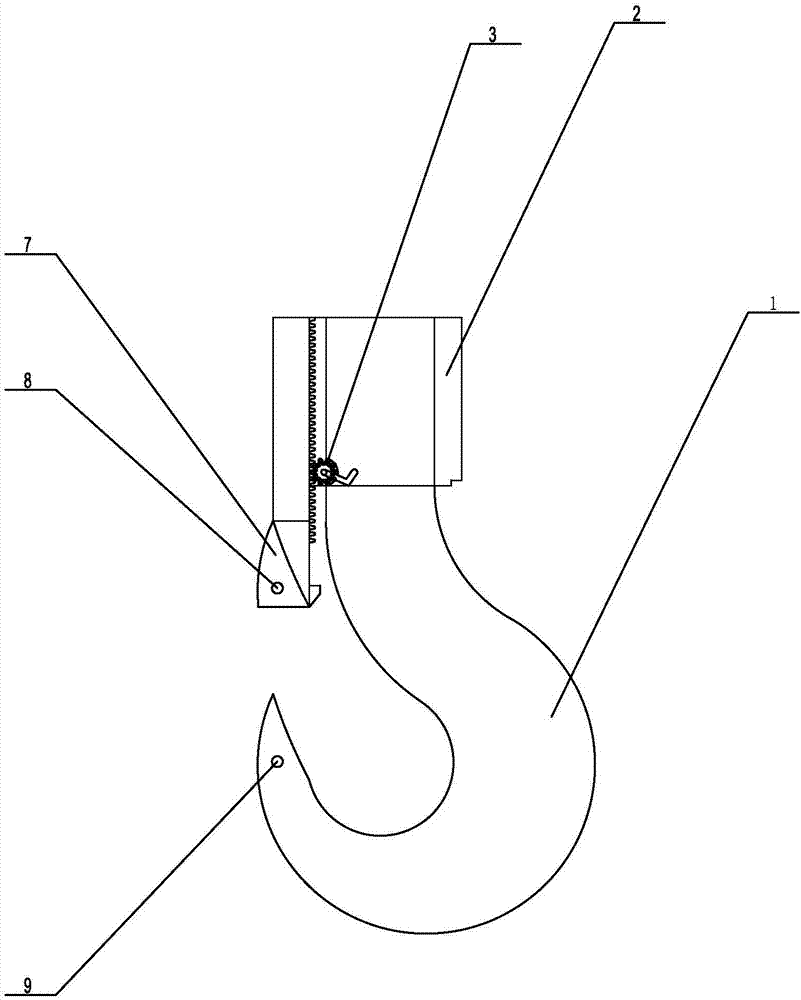

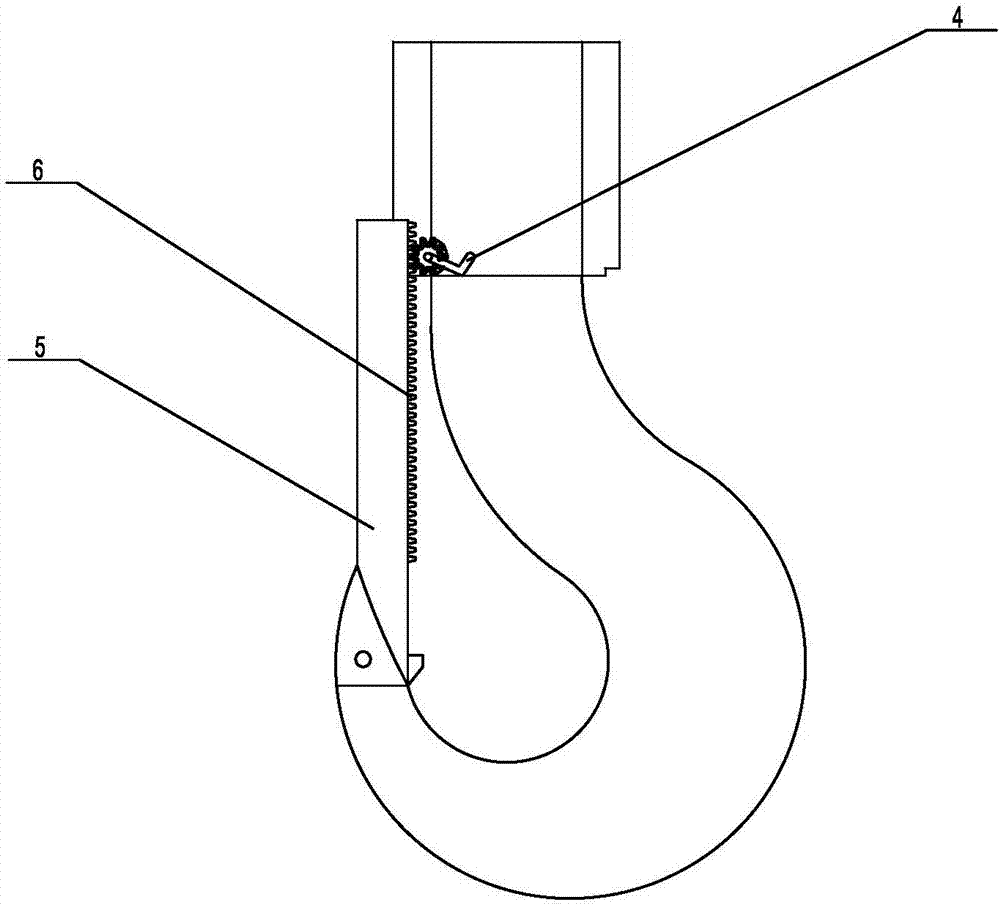

Non-slip lifting hook based on gear and rack

InactiveCN106966288ASimple and fast operationSave human effortLoad-engaging elementsIndustrial engineering

The invention discloses a non-slip lifting hook based on a gear and a rack. The non-slip lifting hook comprises a lifting hook body, a non-slip installation block is arranged at the upper end of the lifting hook body, the gear is fixedly arranged on the non-slip installation block, and a crank handle is coaxially installed on the gear; the lifting hook body is movably connected with a vertically-arranged non-slip rod, and the rack capable of being meshed with the gear is arranged on one side of the non-slip rod; a hook tip cover is arranged at the bottom end of the non-slip rod, a hook tip can be sleeved with the hook tip cover, a first locking hole is formed in the hook tip cover, a second locking hole matched with the first locking hole is formed in the hook tip, and the first locking hole and the second locking hole can be locked through a locking piece. The non-slip rod of the non-slip lifting hook is driven to move up and down through the gear and the rack, opening and closing of the lifting hook body are achieved conveniently and rapidly, operation is easy and convenient, manpower is saved, working efficiency is high, unhooking resistance is good, safety performance is high, and the non-slip lifting hook is light, high in strength, long in service life, good in practicability and worthy of being widely popularized.

Owner:QINZHOU UNIV

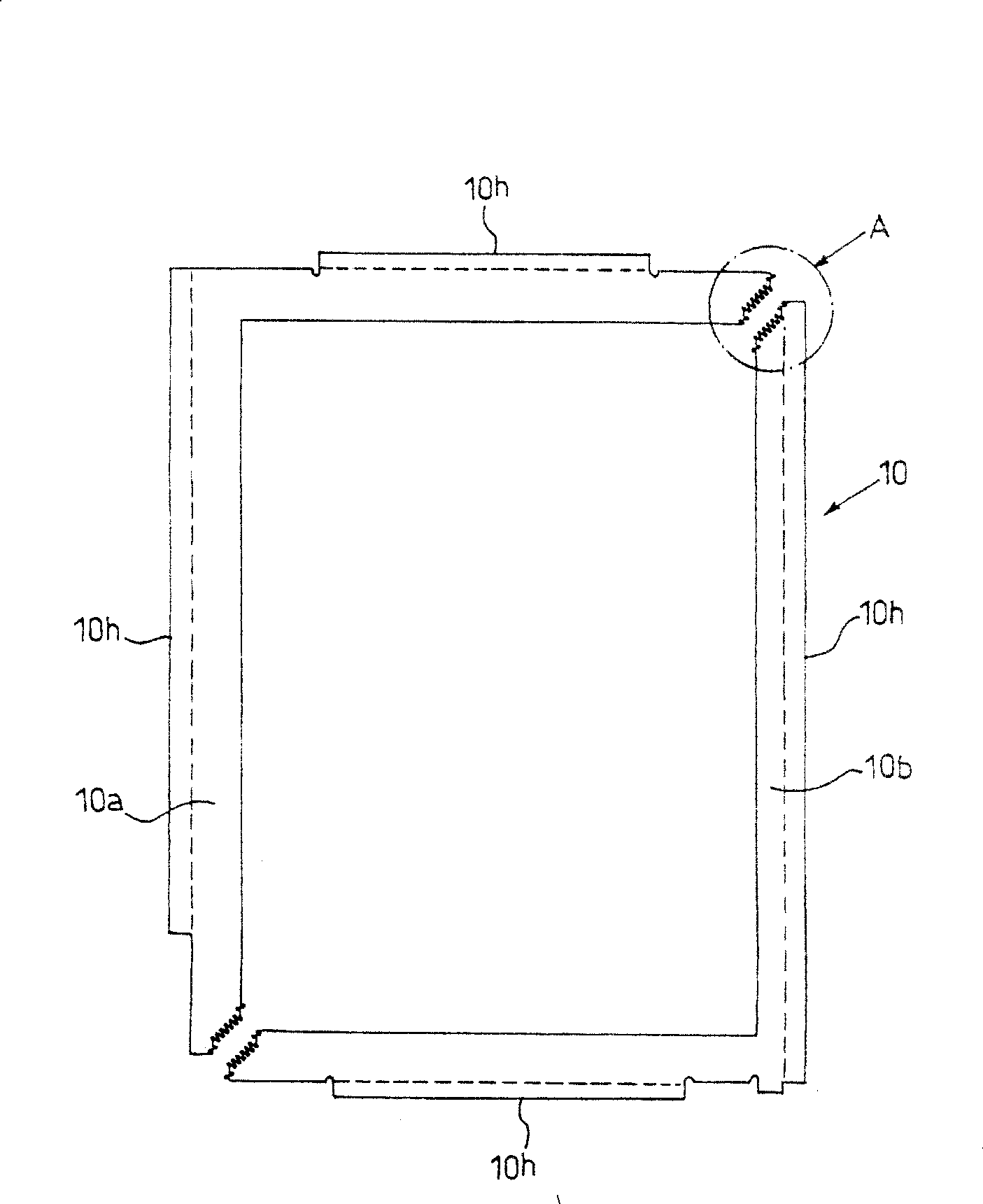

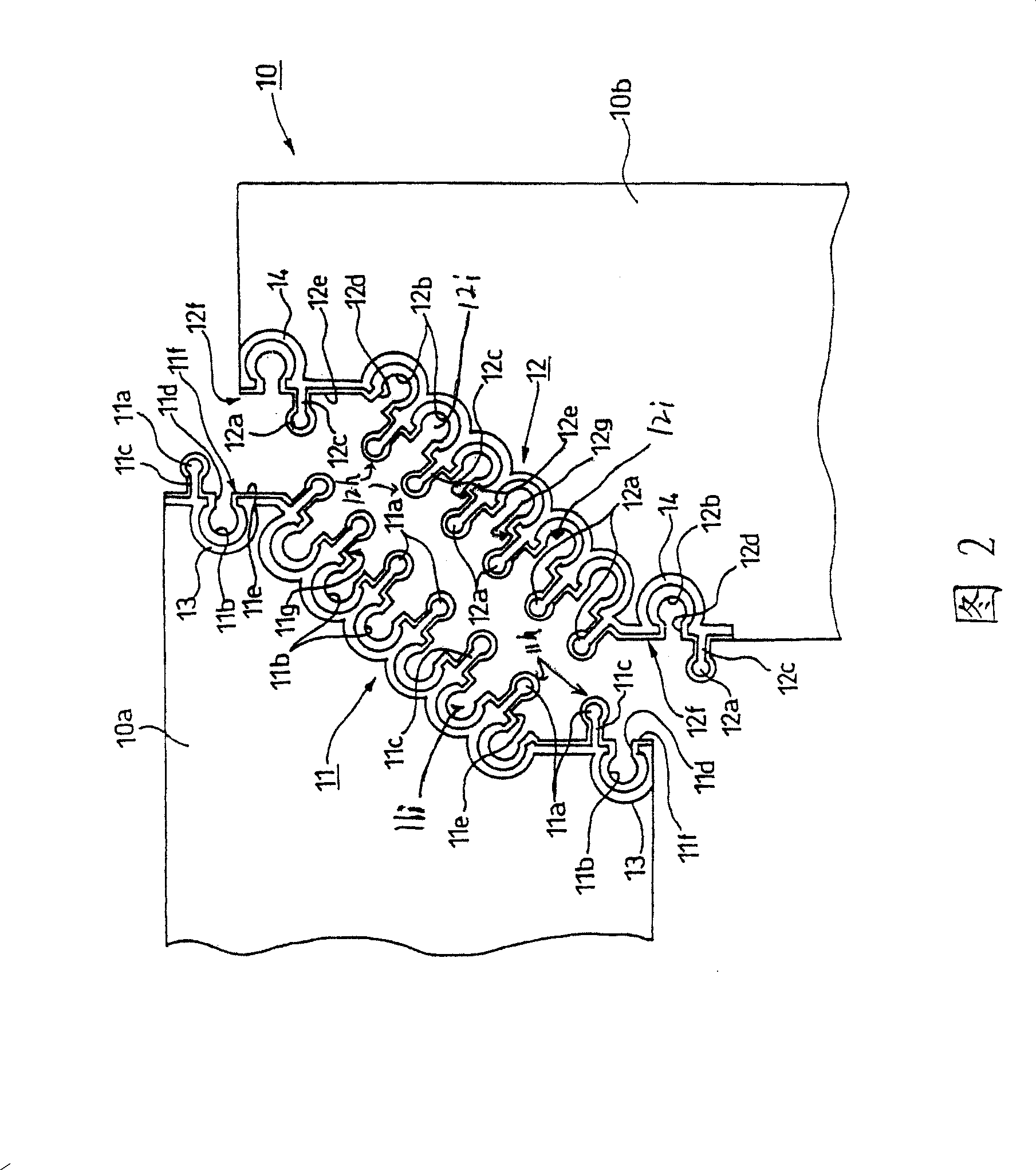

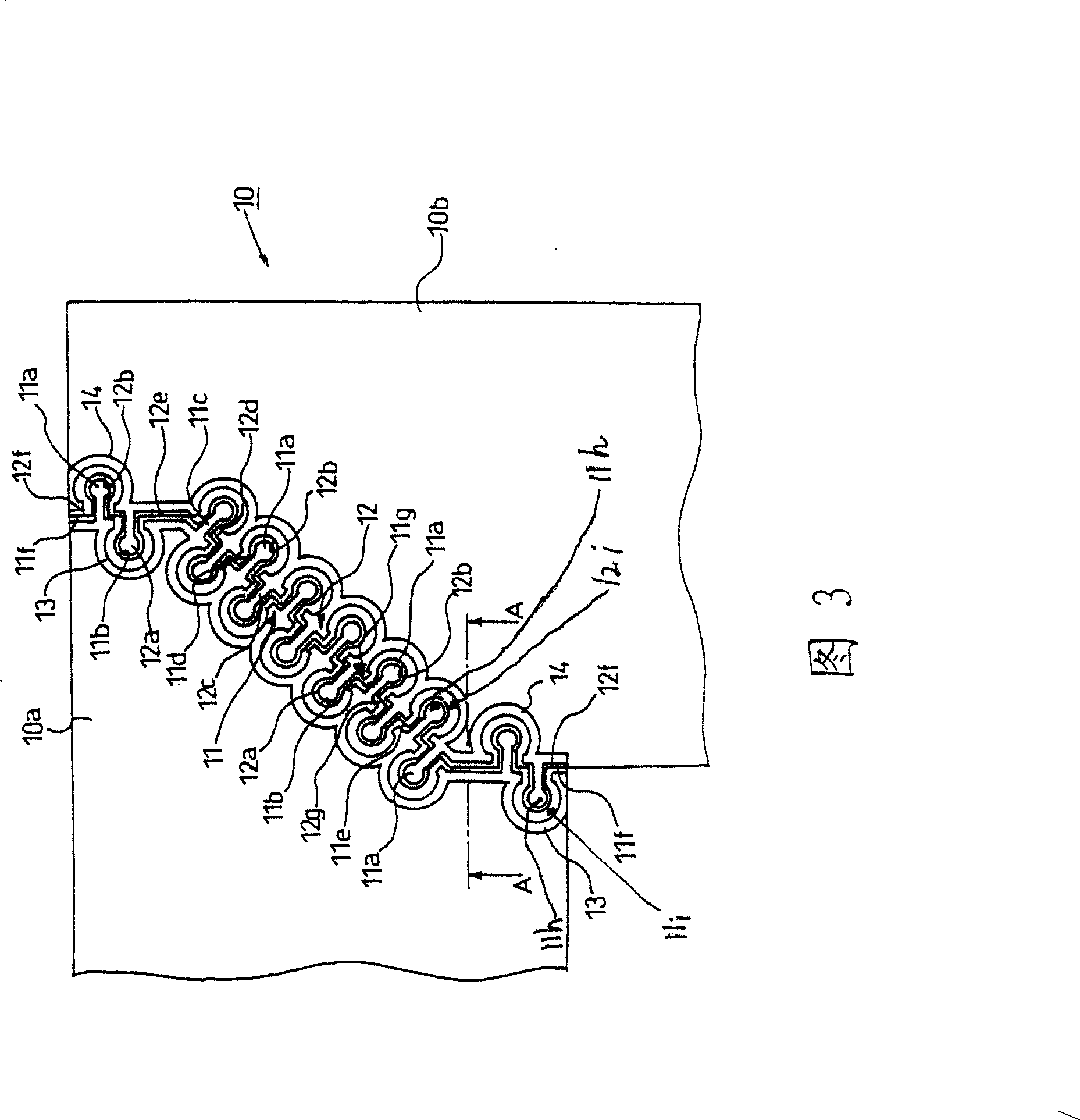

Connecting method for metal plate, liquid crystal display protective cover and producing method thereof

InactiveCN100460941CThe connection is tight and firmFit tightly and firmlyNon-linear opticsIdentification meansLiquid-crystal displayUltimate tensile strength

The present invention relates to an engaging and locking means by which a manufacturing cost of a shielding frame can be reduced to provide a joining method of plate materials made of metal preventing that light is leaked and insufficient strength is generated as much as possible, and to provide the shielding frame of a liquid crystal display using the joining method and to provide a manufacturing method of the shielding frame. Engaging and locking parts each having a plurality of projecting parts and recessed parts having leader parts and constricted parts and alternately provided are provided at respective joining end parts of the plate material made of metal and the shielding frame of the liquid crystal display which are to be joined along respective contours while upheaval parts are continuously or discontinuously formed. The projecting parts and the recessed parts of these engaging and locking parts are engaged with and connected to each other from a vertical direction and then the upheaval parts are crashed by caulking the engaged and connected parts from the vertical direction to integrally join the engaged and connected parts.

Owner:SHIN EI SANGYO

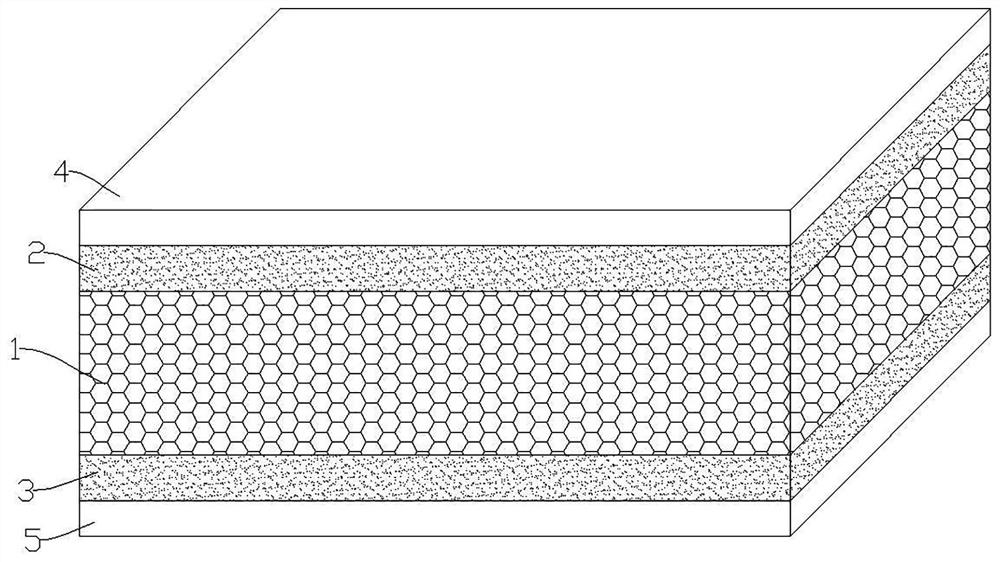

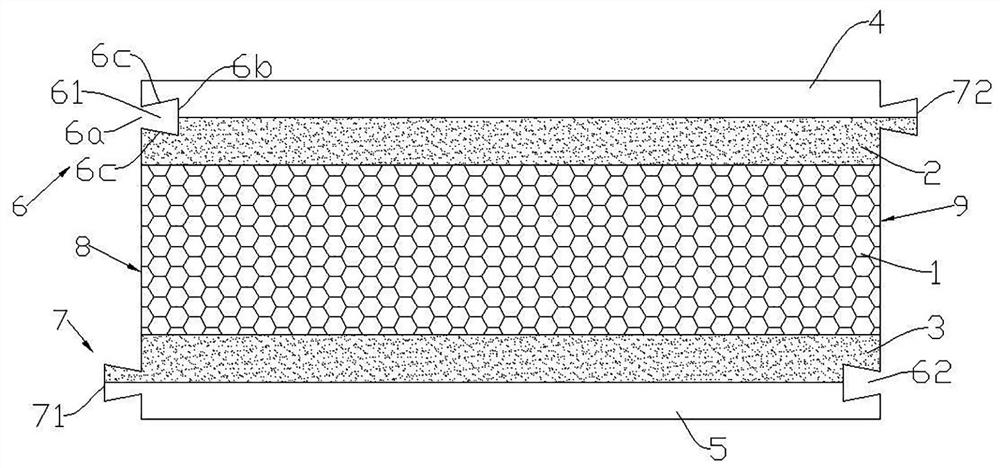

Building energy-saving wall enclosure OSB cladding structure insulation board

InactiveCN112095819APlay a protective effectAvoid situations where thermal insulation capacity is reducedHeat proofingCalcium silicatePolyurethane adhesive

The invention belongs to the technical field of energy-saving building materials, and particularly discloses a building energy-saving wall enclosure OSB cladding structure insulation board. The cladding structure insulation board comprises an XPS core board, an upper surface board arranged on one side of the XPS core board and a lower surface board arranged on the other side of the XPS core board,wherein an upper cladding board is arranged between the XPS core board and the upper surface board, a lower cladding board is arranged between the XPS core board and the lower surface board, the upper cladding board and the lower cladding board are OSB boards, he upper surface board and the lower surface board are light calcium silicate boards, and the boards are bonded through a single-componentreactive polyurethane adhesive. The cladding structure insulation board has the characteristics of high efficiency, energy conservation, moisture resistance, water resistance, fire prevention, good sound insulation, simple structure, convenience in production, manufacturing, use and installation and long service life, and has a very good market application prospect.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

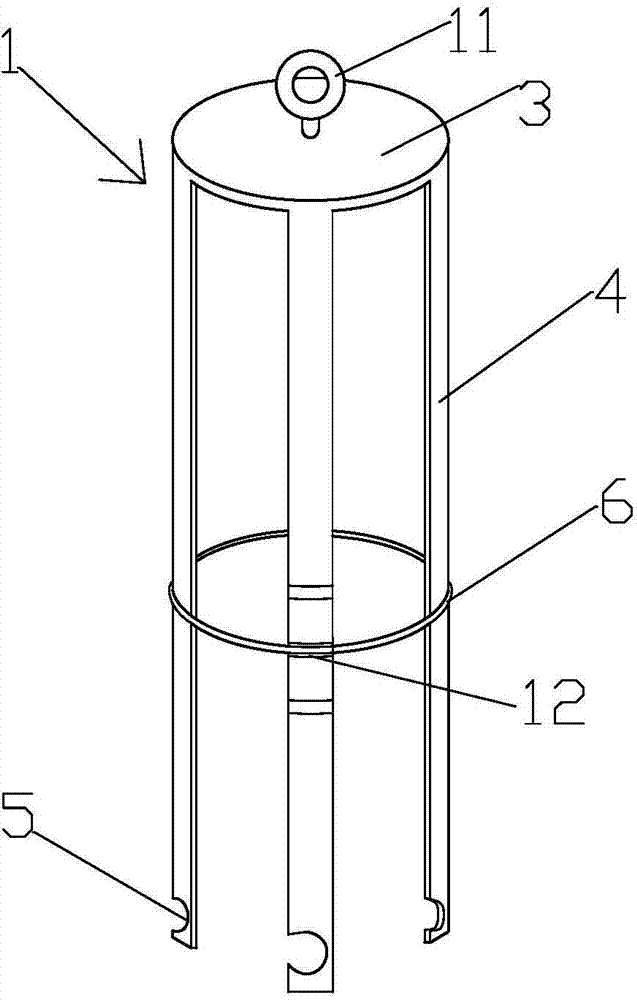

Hanging basket for quenching

InactiveCN103539001AImprove securityIncrease productivityLoad-engaging elementsHanging basketEngineering

The invention discloses a hanging basket for quenching. The hanging basket comprises a hanger and a basket, wherein the hanger comprises a hanging scaffold welded with a hanging ring, at least three steel rods extending downwards vertically are uniformly arranged along the circumferential direction at the edge of the hanging scaffold, the bottom end of each steel rod is provided with a hook, and the opening direction of each hook keeps consistent along the clockwise direction; the basket comprises a basket bottom and a basket wall extending upwards from the periphery of the basket bottom, at least three lugs matched with the hooks are uniformly welded along the circumferential direction on the basket wall, and the hooks are hung on the lugs. Compared with the prior art, the hanging basket has the advantages that people do not need to close fire sources during the quenching process of steel products or moulds, thus the safety is improved; a great deal of steel products or moulds are placed in the basket for disposable quenching, so that the production efficiency is improved, and the human and material resources are saved.

Owner:PERFECT WORLD CO LTD

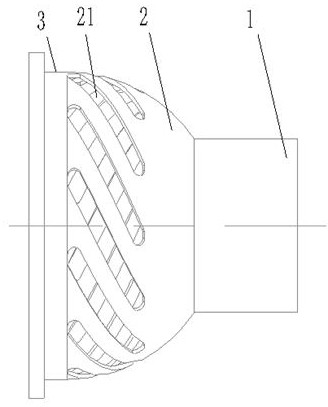

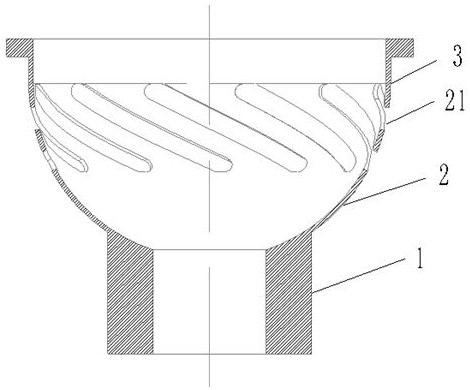

Mask for processing convex hemisphere of gyro motor and processing method thereof

The invention provides a mask for machining a convex hemisphere of a gyro motor and a machining method of the mask, and solves the problem that the performance of the gyro motor is influenced due to the fact that the machining precision of the convex hemisphere cannot be guaranteed by an existing machining tool of the convex hemisphere. The mask for processing the convex hemisphere of the gyro motor comprises a mounting sleeve, a hemisphere shell and an extension sleeve, the mounting sleeve, the hemispherical shell and the extension sleeve are sequentially and coaxially arranged, and a plurality of logarithmic curve spiral holes matched with the logarithmic curve spiral grooves of the convex hemisphere in shape are formed in the hemispherical shell in the circumferential direction; the invention provides a processing method of a mask for processing a convex hemisphere of a gyro motor. The processing method comprises the following steps: step 1, primary processing; secondly, a positioning mandrel and a positioning clamp are machined; step 3, processing an outer spherical surface; fourthly, the logarithmic curve spiral hole is machined through numerical control milling; fifthly, burrs on the outer spherical surface are removed; step 6, separating the mask workpiece from the positioning mandrel; and seventhly, burrs on the inner spherical surface are removed.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Lifting rod structure and lamp thereof

InactiveCN104048274AGuaranteed stabilityFit tightly and firmlyLighting support devicesMechanical engineeringEngineering

The invention relates to a lifting rod structure, which comprises an upper rod, a lower rod, at least one positioning assembly, a locking assembly and an adjusting piece, wherein the positioning assembly is arranged in the upper rod, the positioning assembly and the upper rod move in the lower rod, one part of the positioning assembly is contained in the lower rod to position the upper rod, the locking assembly is arranged on the lower rod, the adjusting piece is arranged on the locking assembly and is used for adjusting the locking assembly, the positioning assembly can be moved out of the lower rod through the locking assembly, and the upper rod is engaged from the blockage of the positioning assembly. The invention also provides a lamp using the lifting rod structure. The lifting rod structure has the advantages that the structure is simple, the operation is convenient, the upper rod and the lower rod are stably and tightly matched, the sliding is avoided between the upper rod and the lower rod, and the stability of the lamp during use is ensured.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

Module connector and assembling method thereof

InactiveCN102055121BNot easy to damageFit tightly and firmlyContact member manufacturingContact member assembly/disassemblyEngineeringLight-emitting diode

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

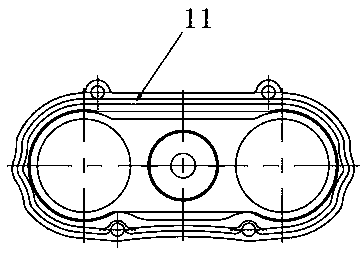

Noise-free elevator idler wheel assembly

The invention discloses a noise-free elevator idler wheel assembly. The noise-free elevator idler wheel assembly comprises a hub made of a nylon material of 49.0-70.0 parts by weight, a polyurethane elastic tire bead formed on the surface of the hub, and polyformaldehyde friction plates located on the two sides of the hub. The hub is provided with an annular outer wall face, an annular inner wallface and two side faces for connecting the annular inner wall face and the annular outer wall face; the two side faces of the hub are provided with grooves matched with the polyformaldehyde friction plates correspondingly; the grooves are formed in the mode of being sunken from the side faces; and each groove comprises an open groove and a clamping groove located in the inner side of the open groove. The hub is made of the nylon material of 49.0-70.0 parts by weight, the polyformaldehyde friction plates are adopted in a matched mode, a matched structure of the friction plates and the hub is improved, thus the friction plates and the hub are bonded more tightly and firmly, noise is reduced, and the polyformaldehyde friction plates are better in performance, more environmentally friendly andlower in cost.

Owner:天津市三志电梯有限公司

Contactor for realizing electric connection between moving and stationary contact poles in transformer

InactiveCN102110916AFit tightly and firmlyIncrease electrical contact areaTransformers/inductances coils/windings/connectionsClamped/spring connectionsElectricityTransformer

The invention discloses a contactor for realizing electric connection between moving and stationary contact poles in a transformer, which consists of a cylindrical metal tube, wherein an annular flange is arranged on an inner circumferential wall at one end of the cylindrical metal tube toward the direction of an axial centre; a connection surface between the annular flange and an end face of the cylindrical metal tube is a conical surface; more than two cracks are arranged in a tube wall of the cylindrical metal tube; the extending direction of any one of the cracks is parallel to the axial direction of the cylindrical metal tube; the cracks extend to the cylindrical metal tube from one end of the cylindrical metal tube where the annular flange is located; an annular groove is arranged on an outer circumferential wall of the end of the cylindrical metal tube where the annular flange is located; and a reinforcing clamping spring is sleeved in the annular groove. In the use of the contactor for realizing the electric connection between the moving and stationary contact poles in the transformer, the electric connection between an inner circumferential surface of the cylindrical metal tube and outer circumferential surfaces of the stationary and moving contact poles is realized, so that electric contact area is increased greatly and tight and firm connection between the annular flange and the conical surface thereof and between the stationary contact pole and an internal thread sleeve is realized.

Owner:SHANGHAI RITCHEY ELECTRICAL EQUIP

A pair of locking device

Owner:CHENGDU SIYUAN BROTHER SCI & TECH CO LTD

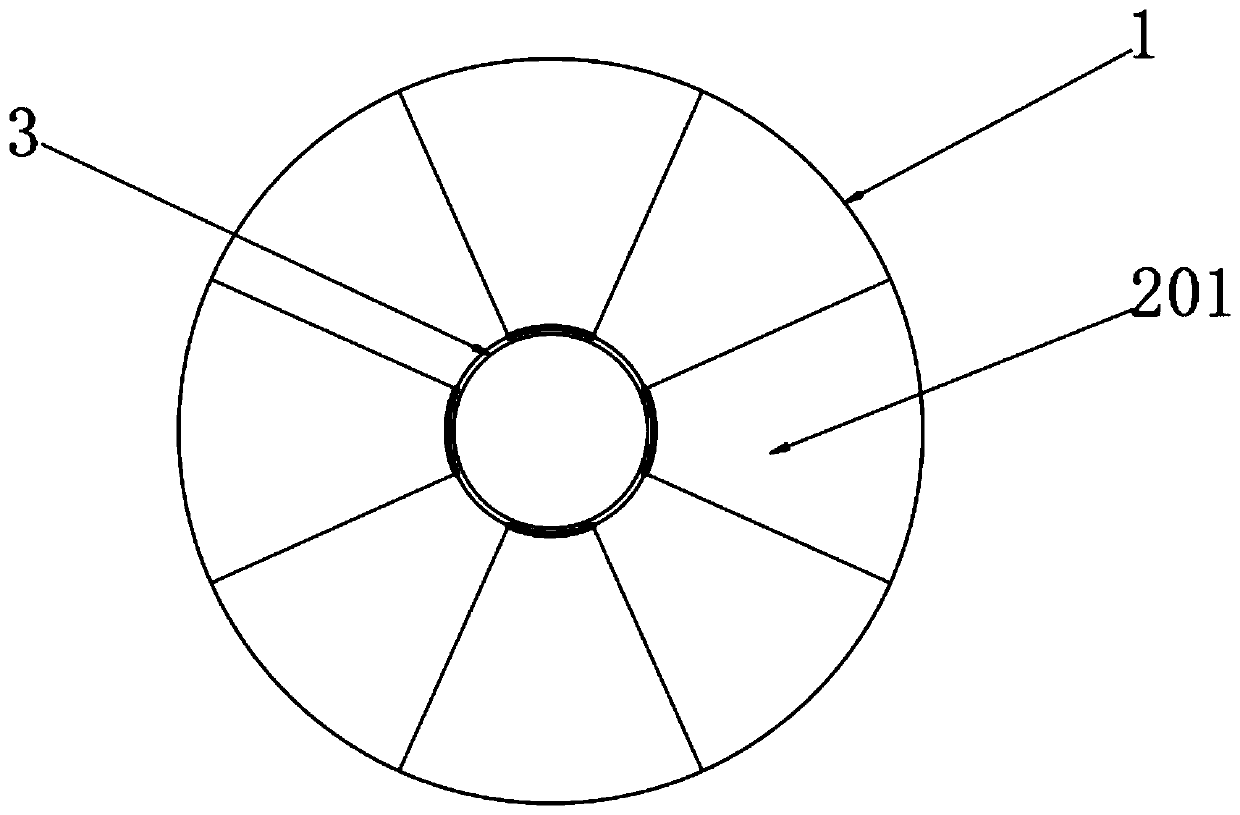

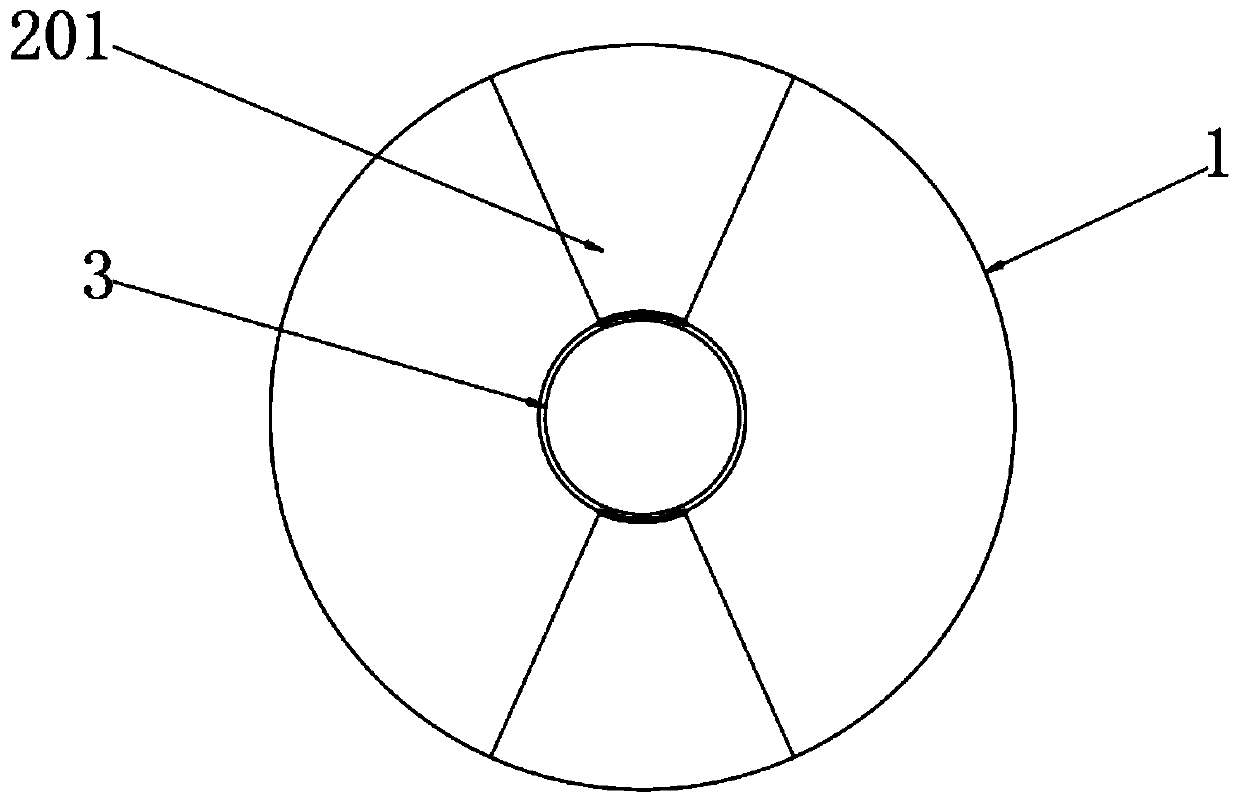

Bobbin for textile

Provided is a bobbin for textile. The bobbin is simple in structure, solid in combination of parts, and long in service life; the bobbin is provided with a center tube and a side plate; the two ends of the center tube are provided with a neck with a contractive outer diameter and a shoulder at the tail end of the neck; the neck of the center tube is sleeved with a side plate; the edge of an innermouth of a center hole of the side plate is buckled and pressed on the shoulder of the center tube; a bellmouth-shaped cone is arranged in the direction of an outer mouth of the center hole of the side plate; an outwards-turned buckle is formed by the outwards-turning of the edge portion of the neck of the center tube, and the outwards-turned buckle is buckled and pressed on the bellmouth-shaped cone of the center hole of the side plate; both ends of the central tube are provided with internal thread sections, the internal thread sections are fitted with screw sleeves, and the outer end partsof the screw sleeves are provided with outwards-turned edges; the inner walls of the inner end parts of the screw sleeves are provided with screw sleeve shoulders; the outwards-turned edges of the outer end parts of the screw sleeves are embedded and buckled on a combined shoulder of the center hole of the side plate; the interior of the screw sleeves are combined with inner plugs and each plug isprovided with a center hole, the outer edge portion of the inner end surface of the inner plug presses against the screw sleeve shoulders. The bobbin for textile is equipped with a textile machine for a textile process.

Owner:王正华

Method and device for adjusting the range of a pipette gun

ActiveCN109225368BAchieve regulationMeet the needs of pipetting and samplingBurettes/pipettesPipetteCurrent range

The invention discloses an adjusting method of the range of a pipette. The adjusting method comprises the following steps: setting a preset range value; acquiring an image of the current range value of the pipette; recognizing the range value in the image; and rotating a range rotary disc according to the current range value and the preset range value. The range of the pipette is adjusted to the preset range value by acquiring the image of a scale observation window of the pipette, recognizing the range value of the current pipette and then rotating the range rotary disc by a specified angle,so that convenience is brought for following direct operation and use. The application also provides an adjusting device of the range of the pipette applicable to the above adjusting method of the range of the pipette.

Owner:SCI EQUIP COMPANY OF SICHUAN PROVINCE

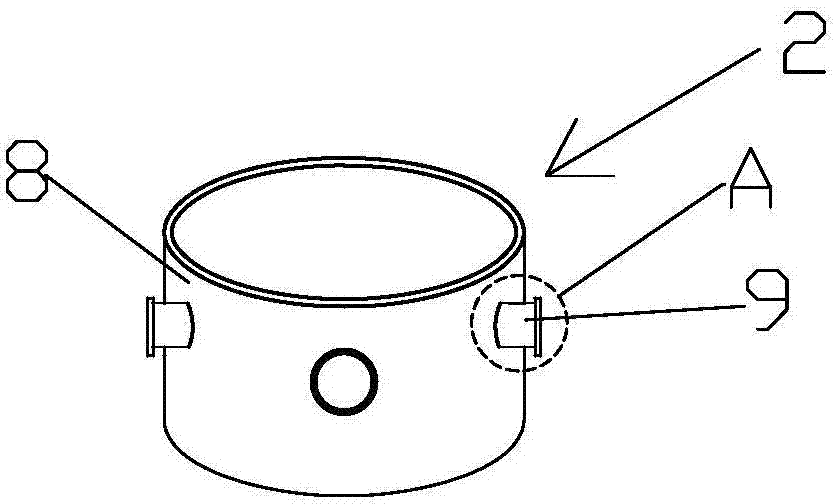

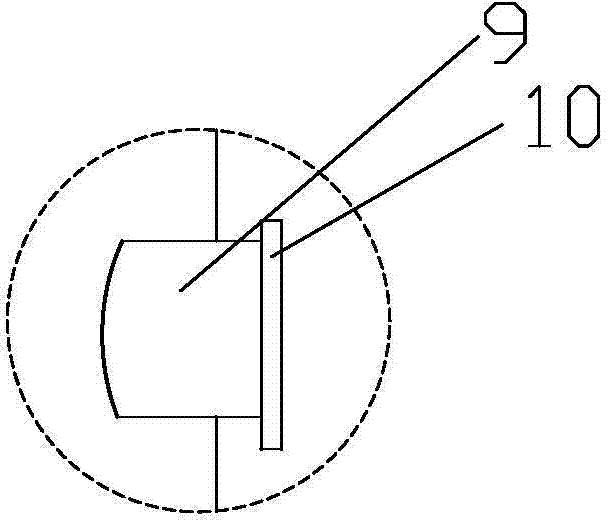

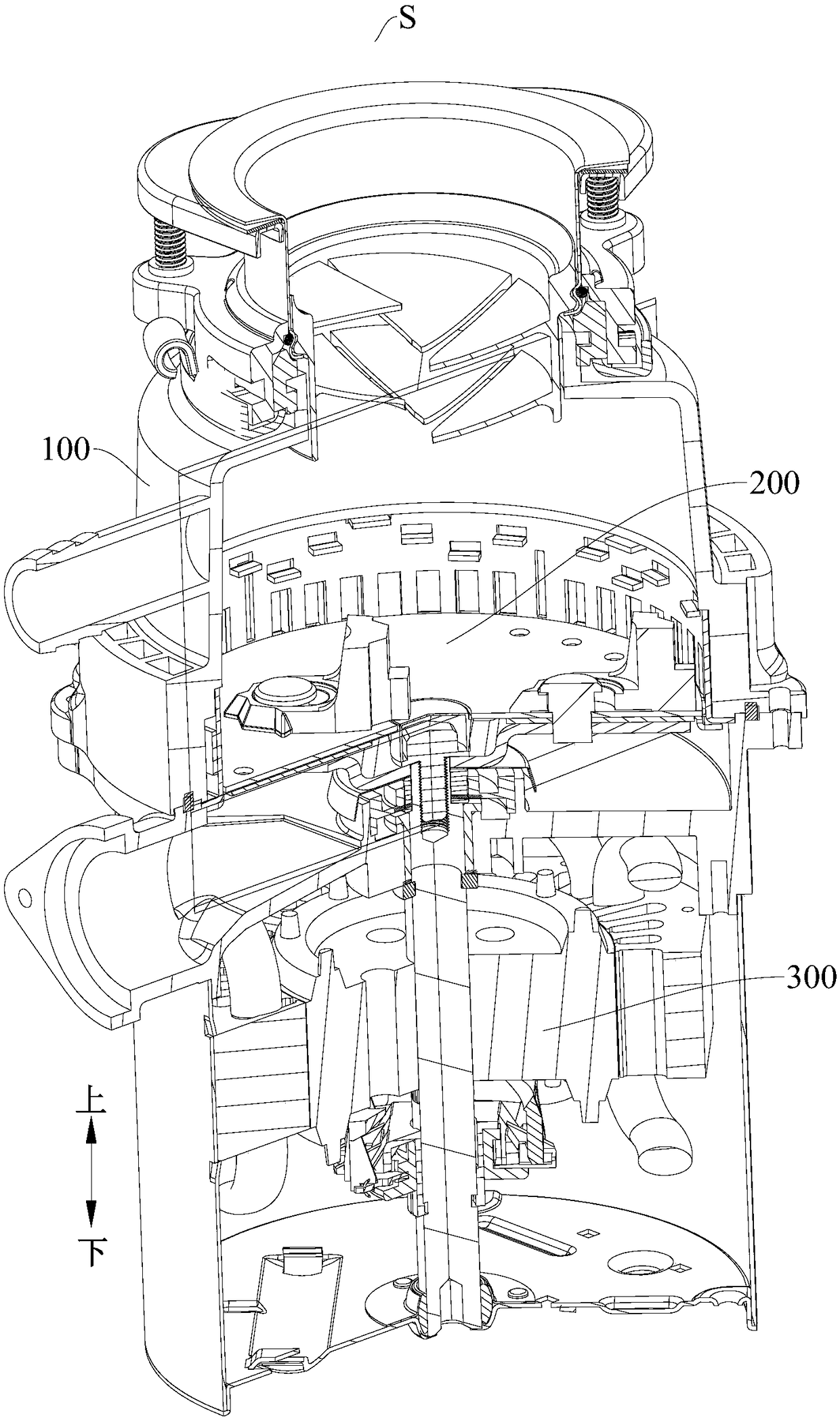

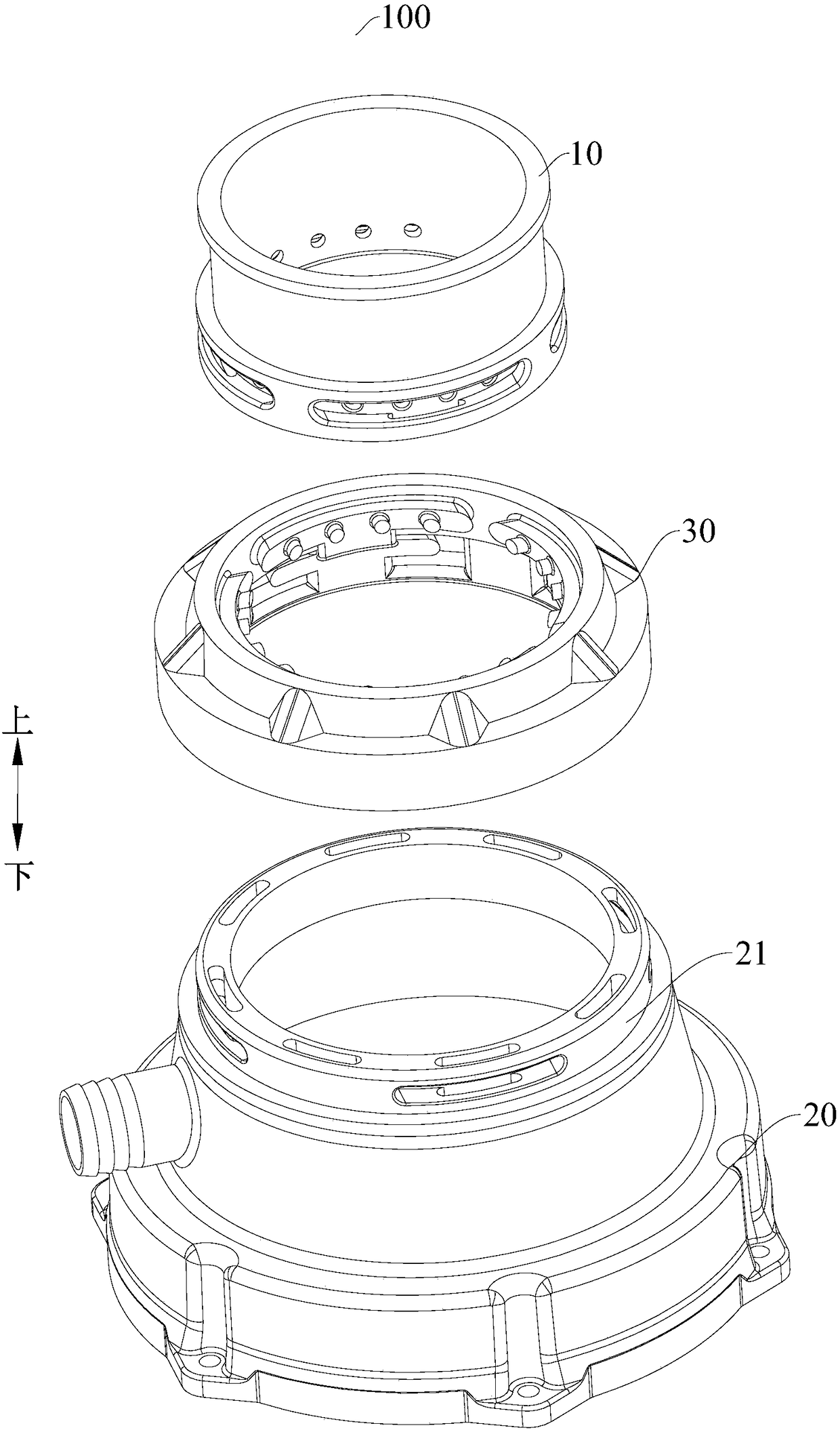

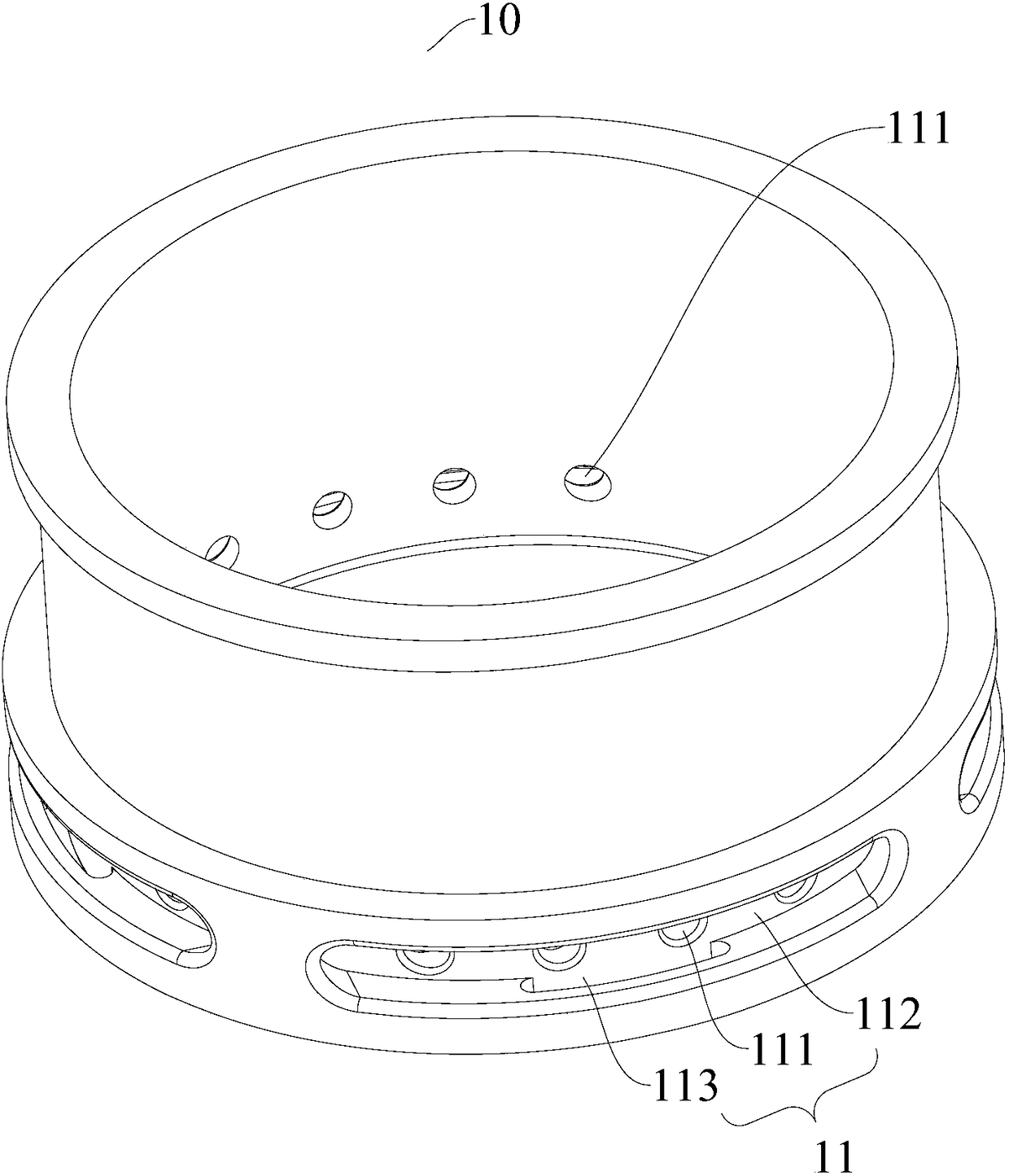

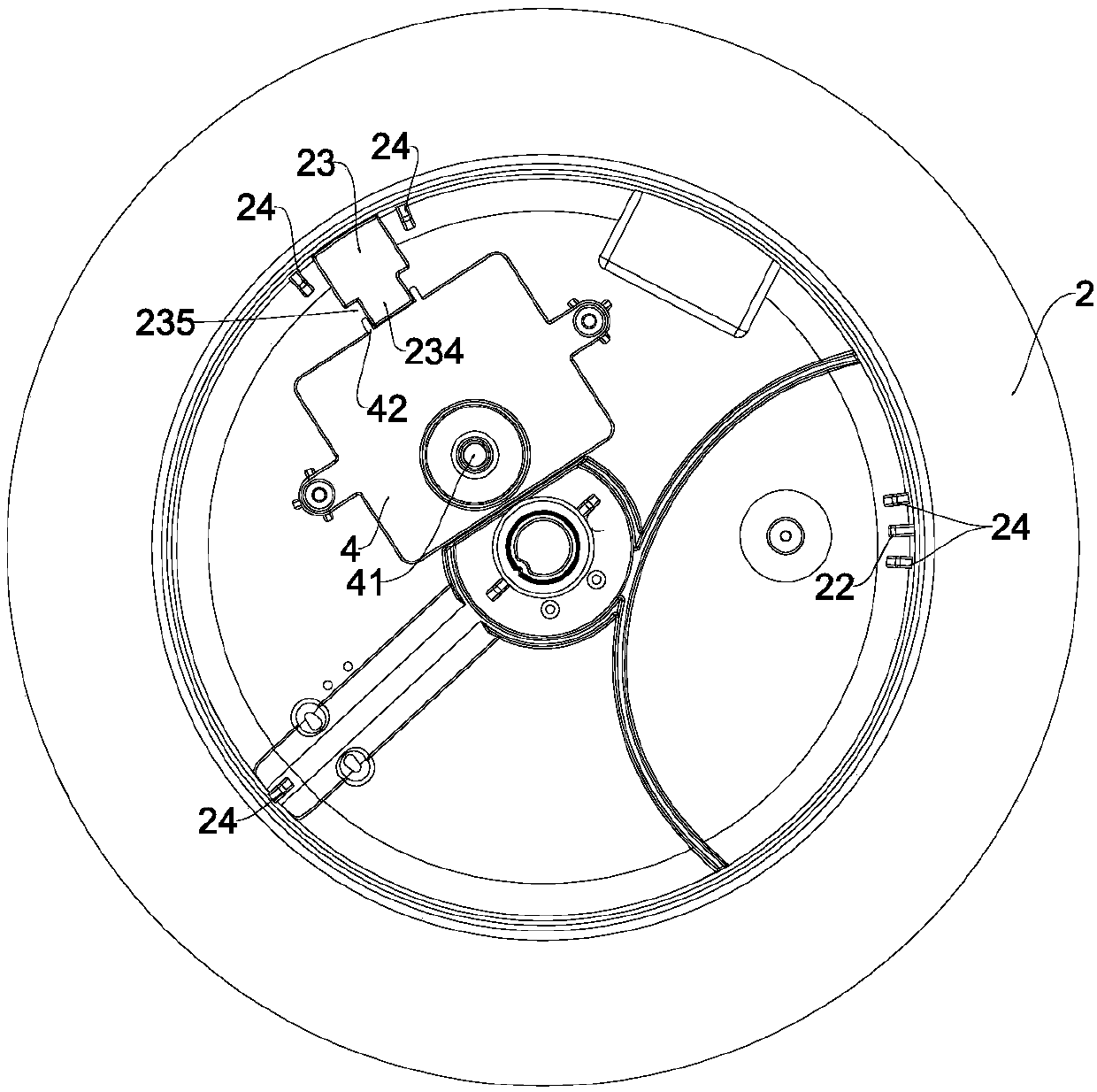

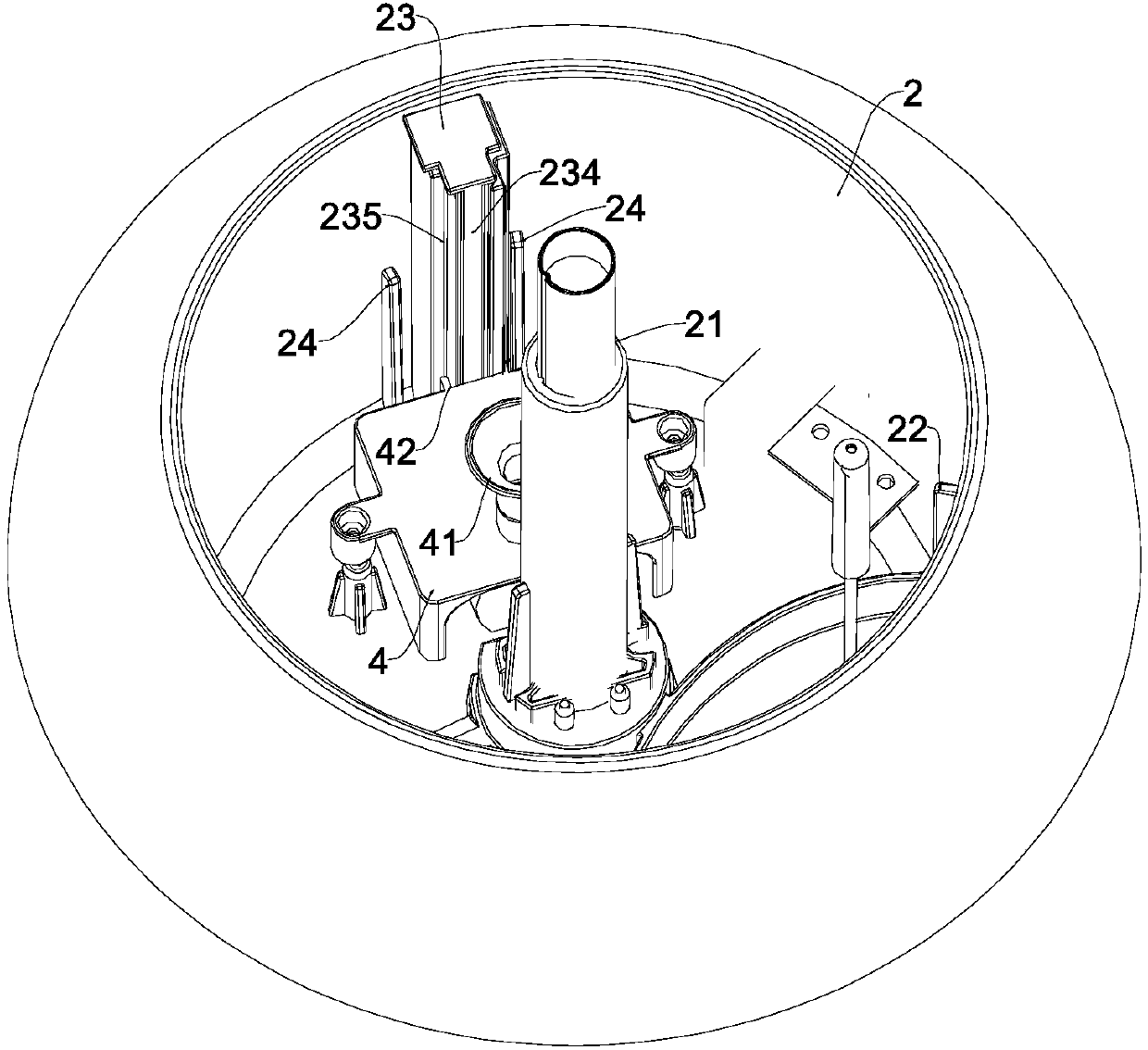

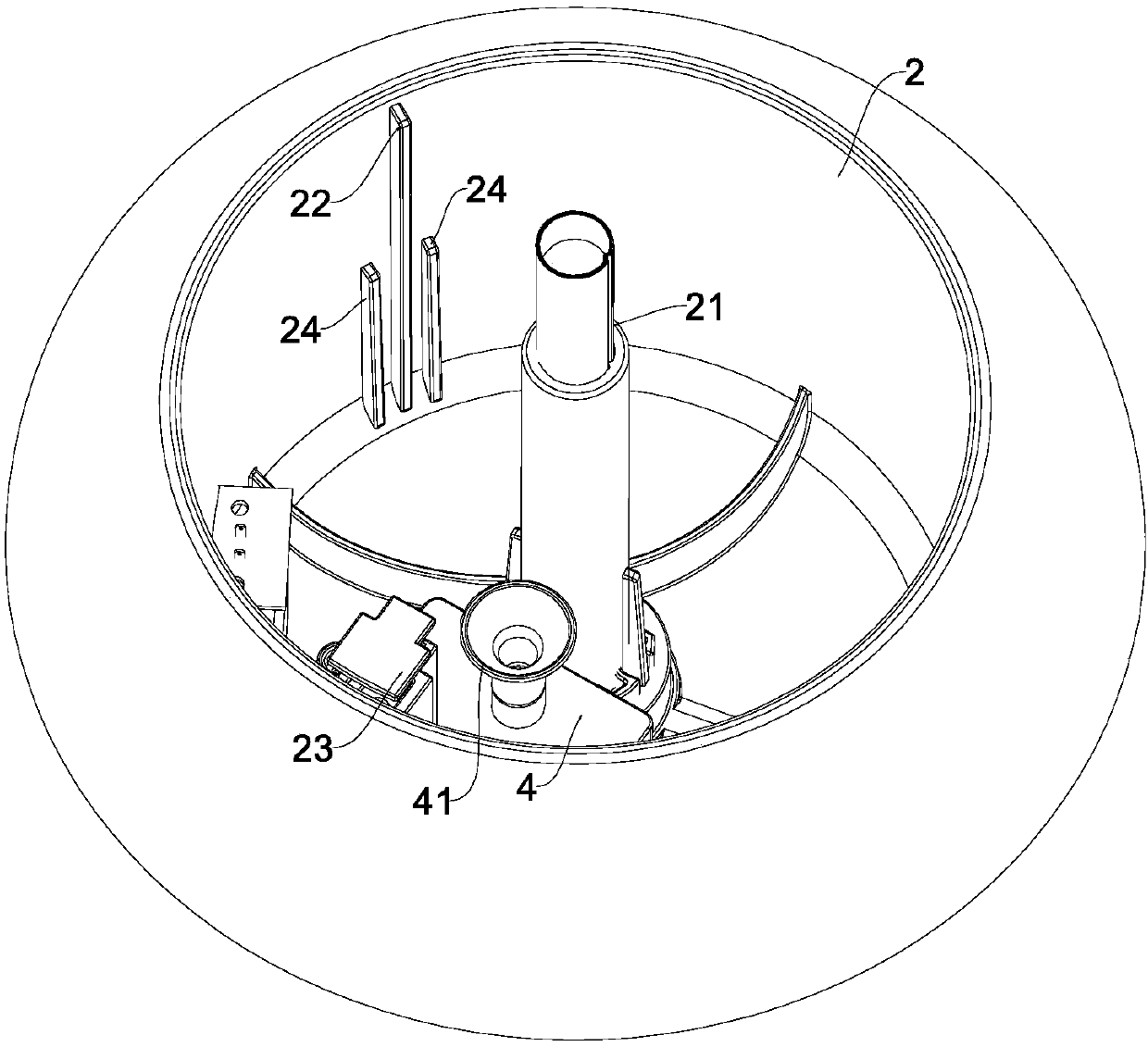

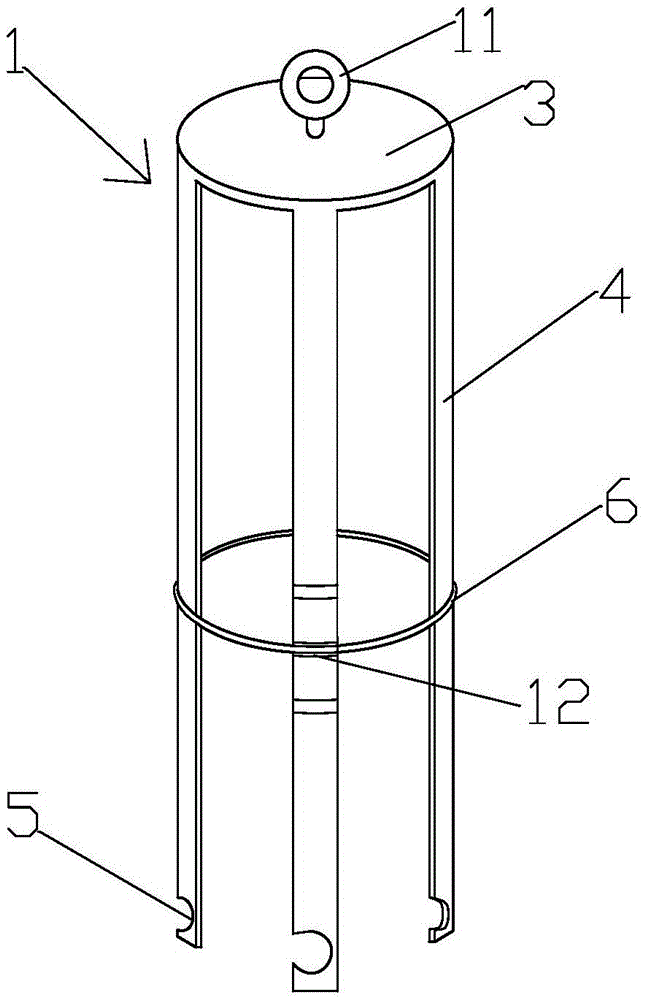

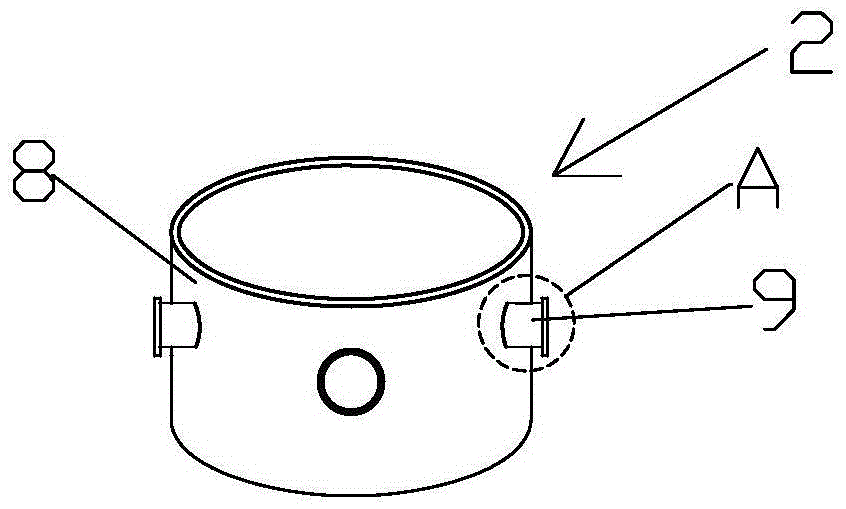

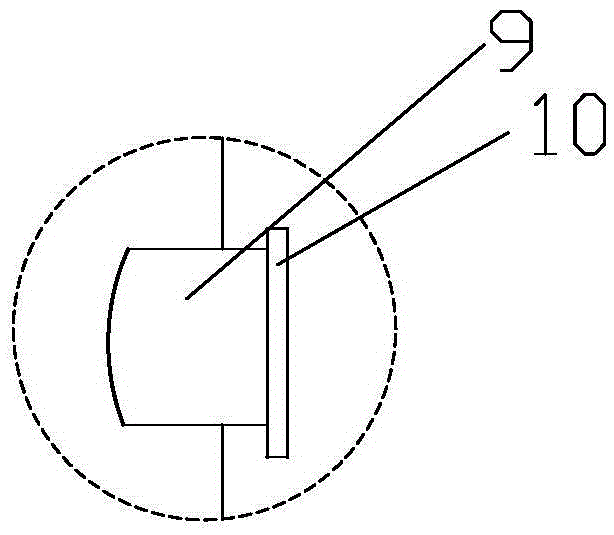

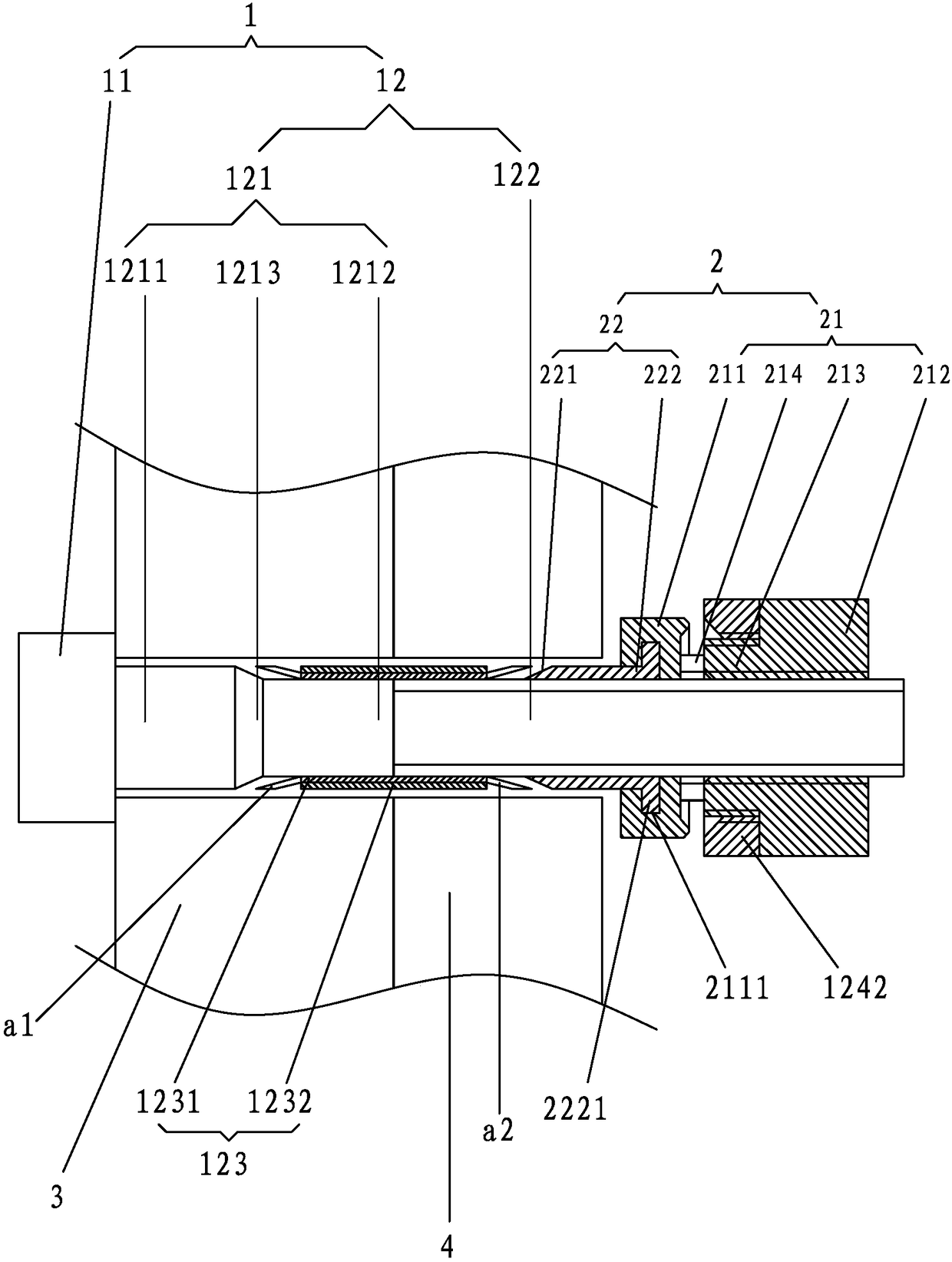

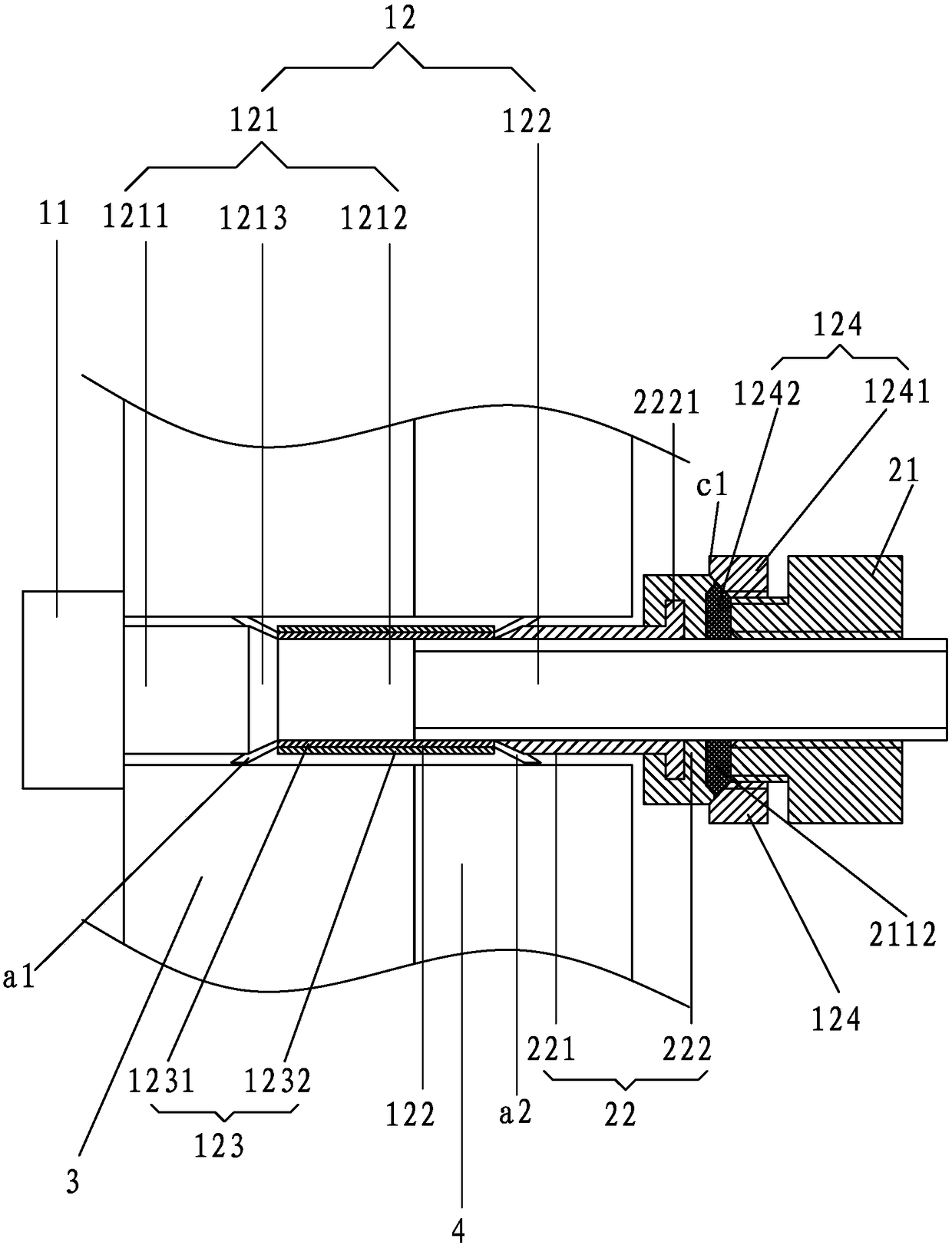

Housing assembly of food waste disposer and food waste disposer

PendingCN108380374AStructural integrationReduce vibrationGrain treatmentsWaste collection and transferInjection molding machineFood waste

The invention discloses a housing assembly of a food waste disposer and the food waste disposer. The housing assembly comprises an annular retaining ring, a connecting tube and an elastic connecting ring. First injection holes are formed in the peripheral wall of the annular retaining ring; the connecting tube is arranged opposite to the annular retaining ring, and second injection holes are formed in the peripheral wall of the connecting tube; the elastic connecting ring is elastically connected between the annular retaining ring and the connecting tube through secondary injection molding, the annular retaining ring and the connecting tube are spaced apart and in sealed connection through the elastic connecting ring, first injection parts and second injection parts are integrally formed on the elastic connecting ring, the first injection parts are injection molding pieces which formed by injecting fluids into the first injection holes and then solidifying the fluids, and the second injection parts are injection molding pieces which formed by injecting fluids into the second injection holes and then solidifying the fluids. According to the housing assembly of the food waste disposer, there is no actual direct contact between the annular retaining ring and the connecting tube, the vibration and noise can be effectively reduced, the structure is integrated, fitting is reliable, the contact is close, and the sealing performance is good.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG +1

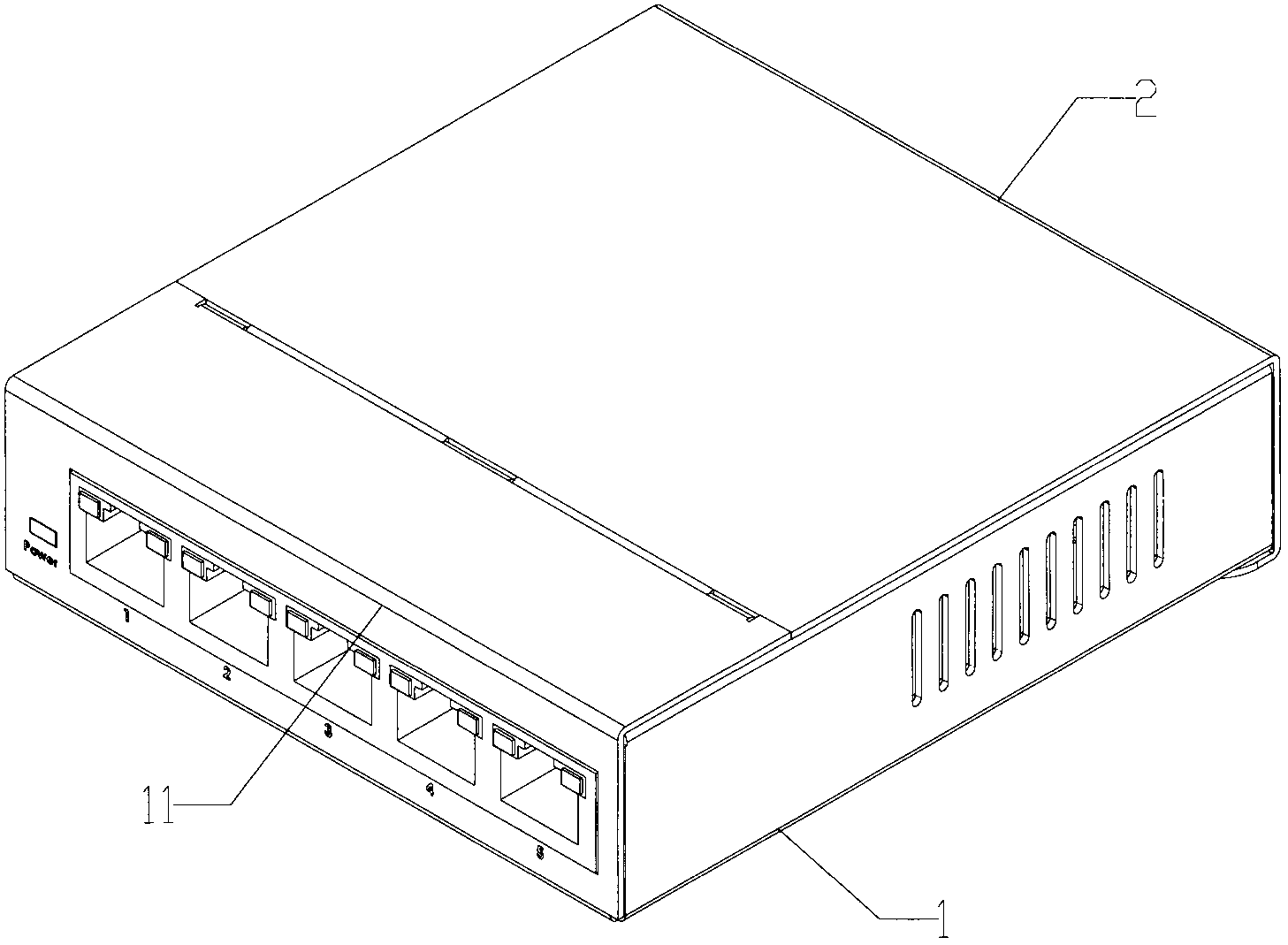

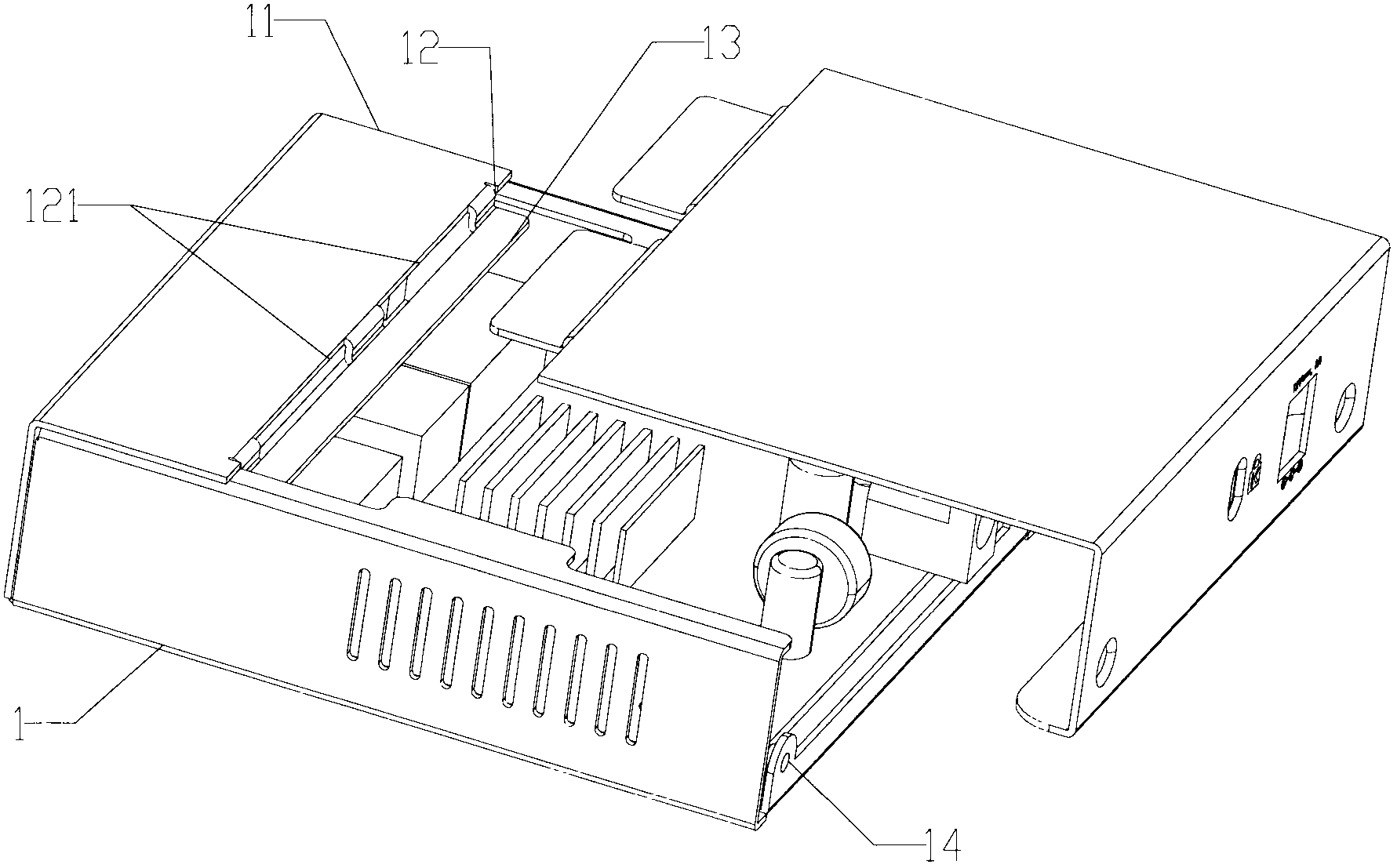

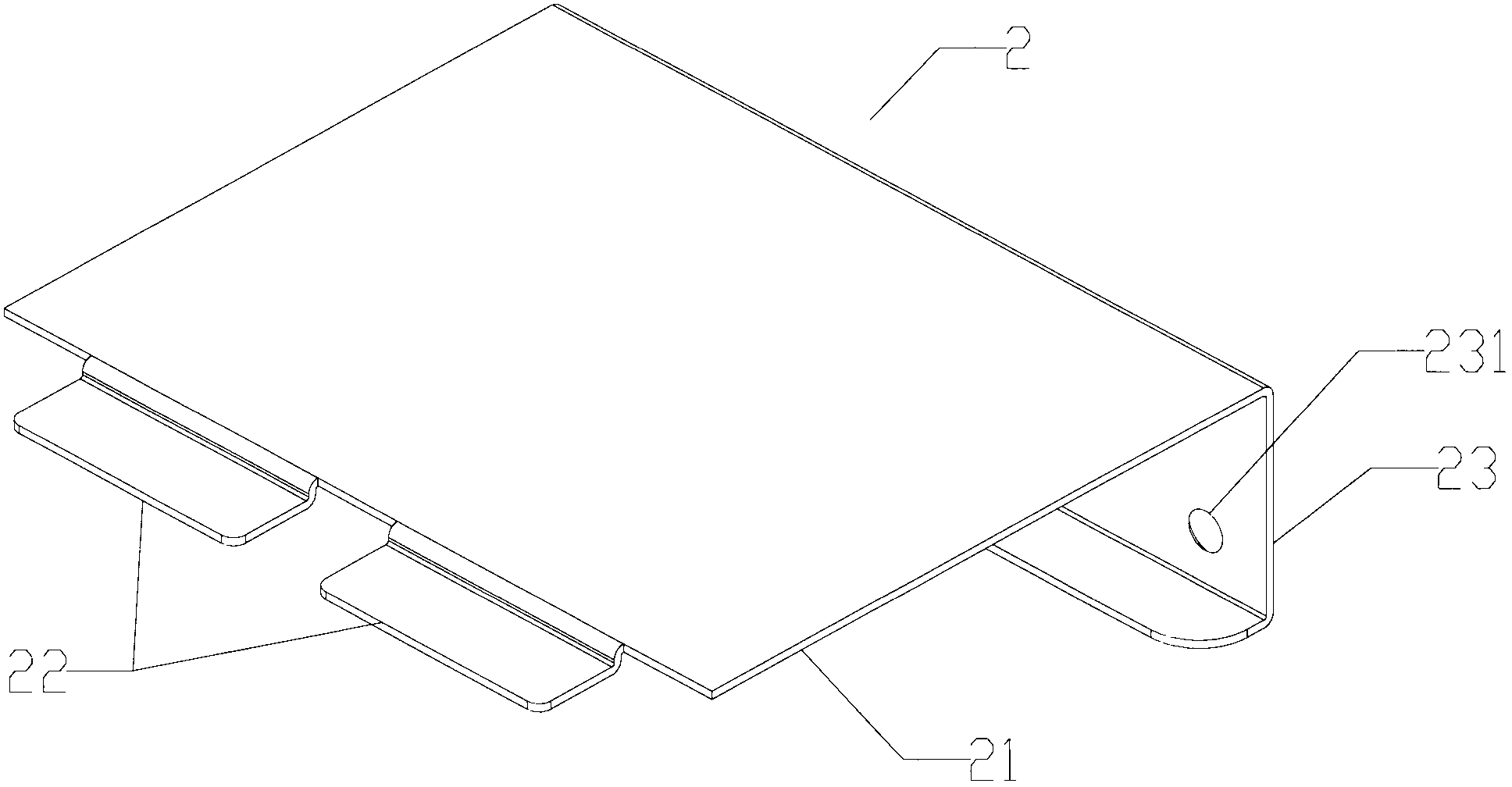

Switchboard with detachable cover plate

InactiveCN102684890AFit tightly and firmlyEasy to disassembleData switching switchboardsAgricultural engineering

Owner:SUZHOU XINRUILA PHOTOELECTRIC TECH

Spliced water tank with displacement resisting structure

PendingCN108029536AEasy to manageTightly bondedSelf-acting watering devicesDirect liquid fertiliser deliveryWater storage tankEngineering

The invention discloses a spliced water tank with a displacement resisting structure. The spliced water tank comprises a water storage tank and a water supply tank. The water storage tank is used forstoring water and can supply the water to the water supply tank. A positioning flange is arranged on the water storage tank. The water supply tank is arranged in the water storage tank. The water supply tank is formed by splicing of at least two bodies. The bodies are recessed inwardly at the splicing joints to form positioning grooves matched with the positioning flange. The spliced water tank has the advantages that the water supply tank is fastened into the water storage tank conveniently through the positioning grooves and the positioning flange, and the water supply tank and the water storage tank are combined tightly and firmly, so that mutual displacement caused by non-firm combination between the water supply tank and the water storage tank during moving and transporting of a plantplanting device is avoided, the water can be prevented from overflowing from the water storage tank or the water supply tank effectively, and service life of the whole device is prolonged; the watertank is designed as a spliced type, and the water supply tank is mounted or taken down conveniently, so that the water supply tank or the water storage tank is convenient to clean, maintain or repair.

Owner:杭州智控网络有限公司

Quenching basket

InactiveCN103539001BImprove securityIncrease productivityLoad-engaging elementsEngineeringHanging basket

The invention discloses a hanging basket for quenching. The hanging basket comprises a hanger and a basket, wherein the hanger comprises a hanging scaffold welded with a hanging ring, at least three steel rods extending downwards vertically are uniformly arranged along the circumferential direction at the edge of the hanging scaffold, the bottom end of each steel rod is provided with a hook, and the opening direction of each hook keeps consistent along the clockwise direction; the basket comprises a basket bottom and a basket wall extending upwards from the periphery of the basket bottom, at least three lugs matched with the hooks are uniformly welded along the circumferential direction on the basket wall, and the hooks are hung on the lugs. Compared with the prior art, the hanging basket has the advantages that people do not need to close fire sources during the quenching process of steel products or moulds, thus the safety is improved; a great deal of steel products or moulds are placed in the basket for disposable quenching, so that the production efficiency is improved, and the human and material resources are saved.

Owner:PERFECT WORLD CO LTD

Firm tire bolt

The invention provides a firm tire bolt. In actual use, a screw of a bolt first passes through corresponding wheel holes of a wheel shaft connecting part and a hub connecting part of a tire, a supporting sleeve sleeves the screw, the screw is locked by tightening a nut; when the nut is tightened, the abutting end of an abutting sleeve abuts against and is connected with a second protruding portionof an inner sleeve, a cone column section abuts against a first protruding portion of the inner sleeve, an initial state of the supporting sleeve is that the first protruding portion and the second protruding portion of the inner sleeve are cocked up; after the nut is tightened, the first protruding portion and the second protruding portion are cocked up more significantly and abut against holesin the wheel shaft connecting part and the hub connecting part respectively, so that balance supporting is performed on the wheel shaft connecting part and the hub connecting part, and the breakage cause by the generation of shear stress due to the shaking of the screw in the hole in the tire rotating process is avoided.

Owner:MING YANG AUTO PARTS MFG CO LTD

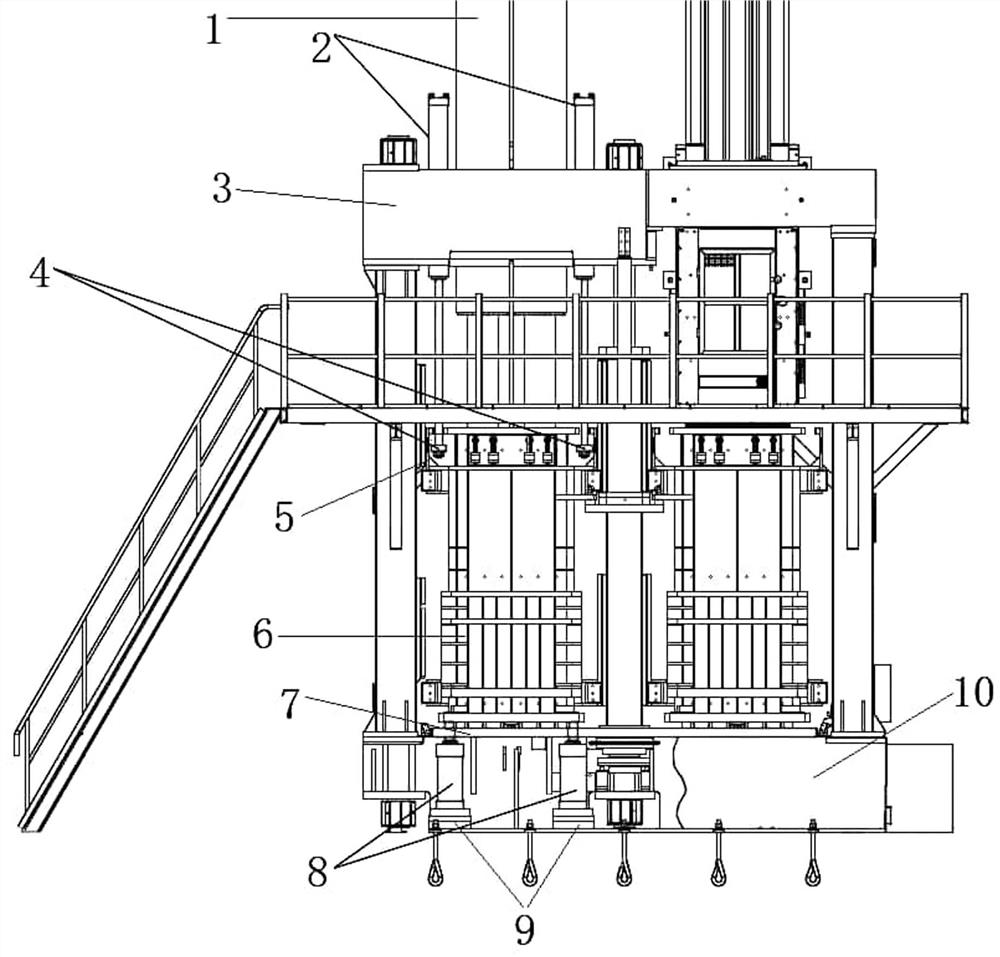

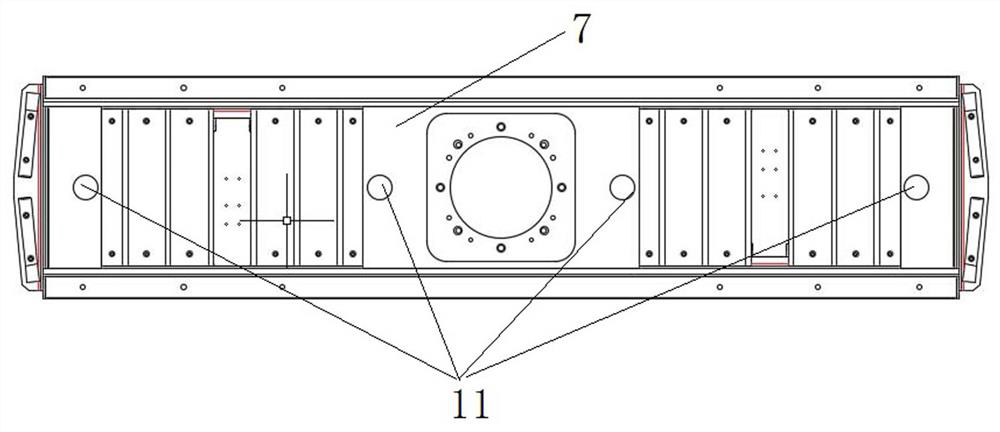

Cotton packing machine with box removing pressurizing function and box removing method

The invention provides a cotton packing machine with a box removing pressurizing function and a box removing method. The machine comprises a main pressure oil cylinder assembly, box removing cylinders, a main pressure cross beam, box removing discs, cotton box lifting lugs, a cotton box, a rotating disc and a lower cross beam assembly, wherein two driving devices are arranged in the lower cross beam assembly, and the left and right ends of the rotating disc are provided with two locking holes by taking a rotating shaft as an axis. In the box removing process, the cotton box is moved upwards through oil cylinders, and then cotton and the cotton box are preliminarily separated; and after the oil cylinders finish the stroke, the box removing cylinders continue to move upwards, the cotton andthe cotton box are thoroughly separated, and the box removing process is completed. According to the machine and the method, box removing of the cotton packing machine is simple, the stress of the cotton box lifting lugs is reduced, and the problem that the cotton box lifting lugs are damaged due to overlarge impact force is avoided.

Owner:SHANDONG SWAN COTTON INDAL MACHINERY STOCK

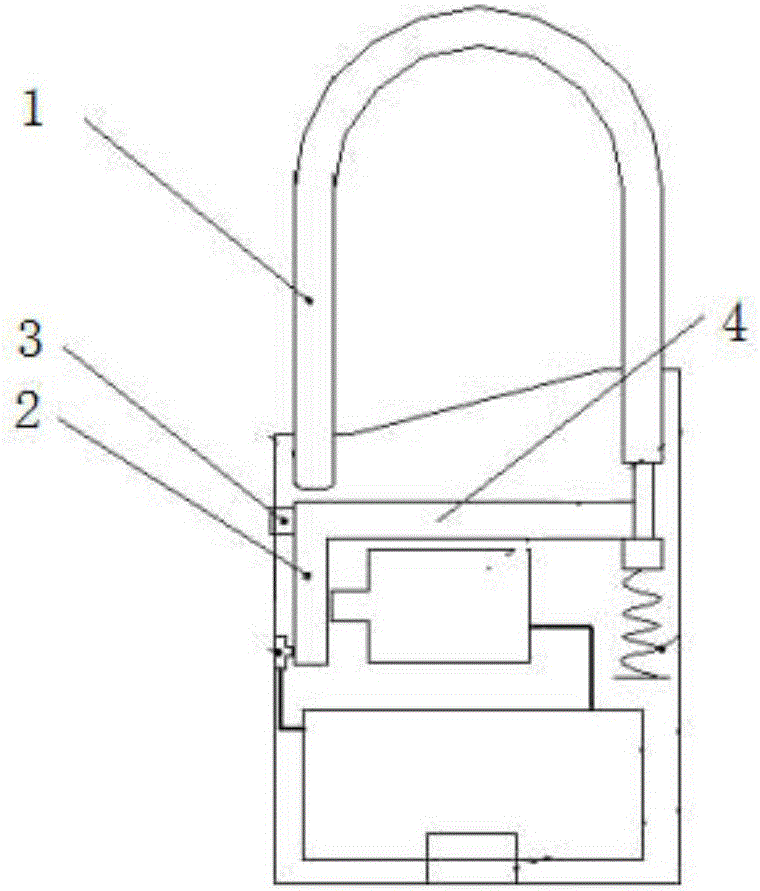

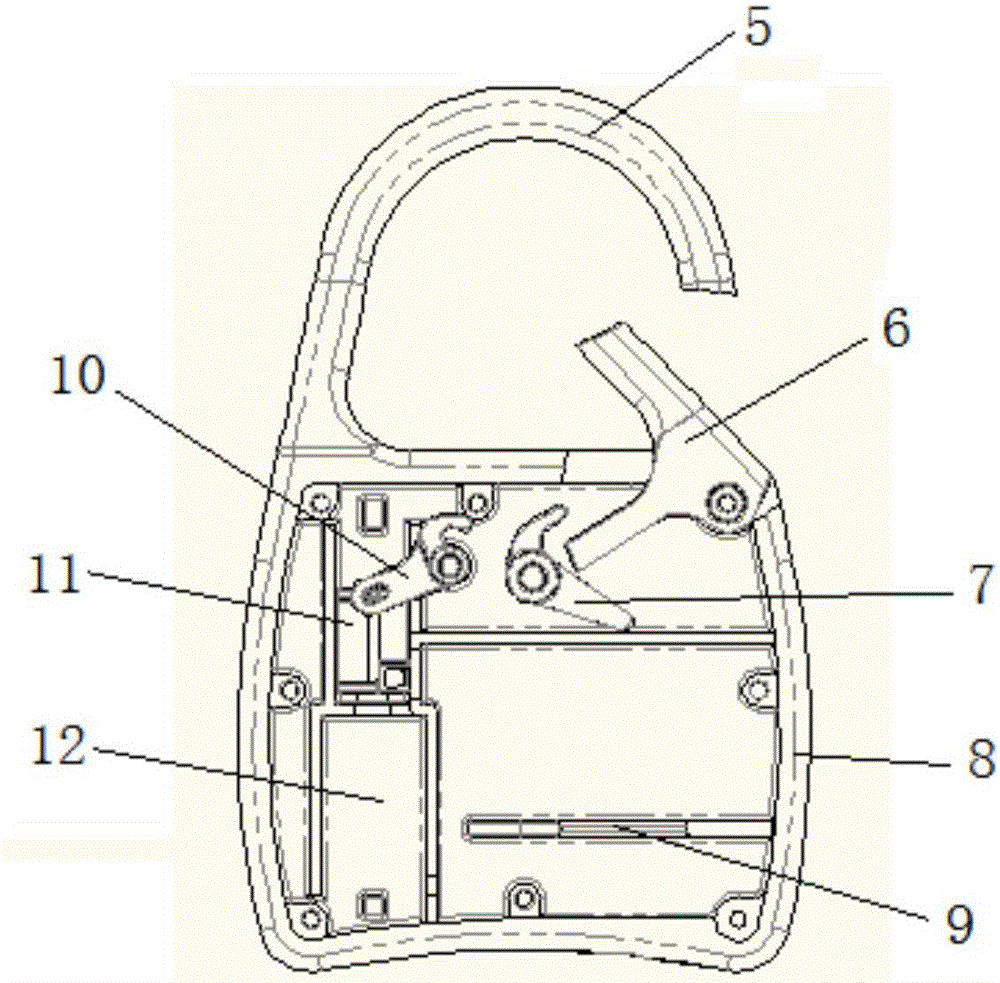

Ring latch device for electrical five preventions

ActiveCN106320848ARealize latchingFit tightly and firmlyNon-mechanical controlsPadlocksMechanical engineeringHigh voltage

The invention relates to the field of high-voltage switch cabinets, in particular to a ring latch device for electrical five preventions. The ring latch device for the electrical five preventions comprises a clamping piece, a lock body, and a lock fork, a lever section, a driving assembly and a control unit which are arranged in the lock body; the control unit controls the driving assembly to work; the driving assembly drives the connection end of the lever section to move up and down; when the connection end of the lever section moves upwards, the device can be locked reliably and firmly due to mutually close cooperation of the lever section, the locking fork and the clamping piece; when the connection end of the lever section moves downwards, the buckling end moves upwards and releases the buckling fork end of the locking fork, the bearing end of the clamping piece is not fixed and limited by the driving fork end of the locking fork, and a clamping part can be separated from the free end of a hook section to realize unlocking; and the whole process of locking and unlocking is convenient and reliable, and the ring latch device is high in safety.

Owner:华电北瑞电气(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com