Bobbin for textile

A bobbin and center tube technology, which is applied in the field of textile machine accessories, can solve the problems of complex structure, loose parts or even falling off, and many parts and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

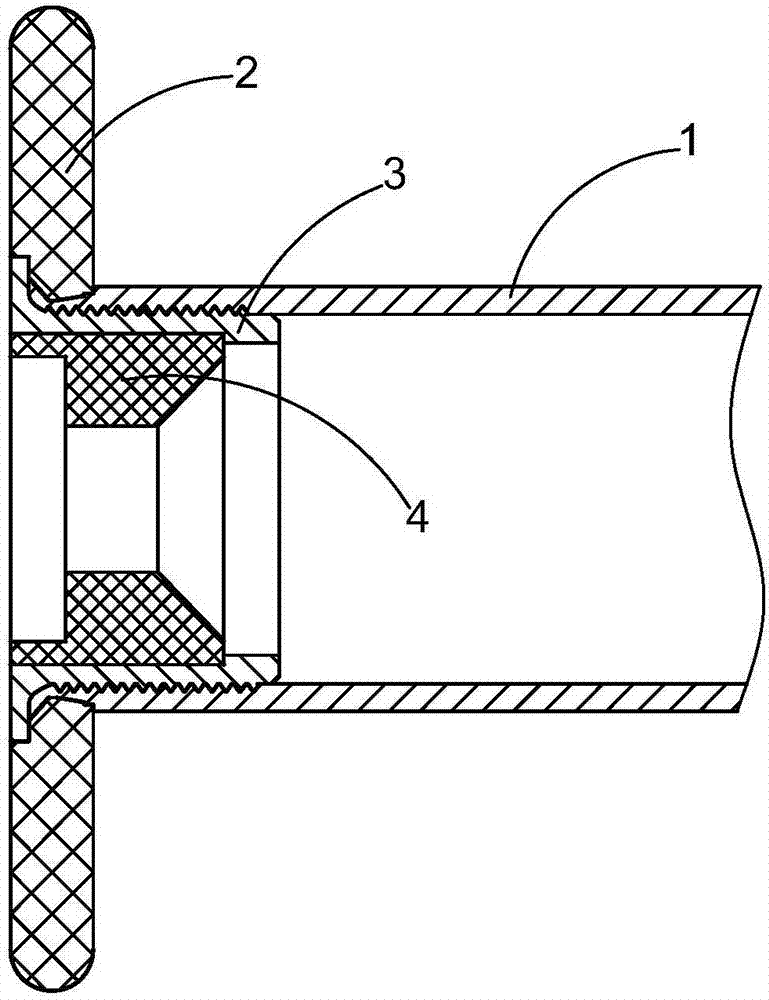

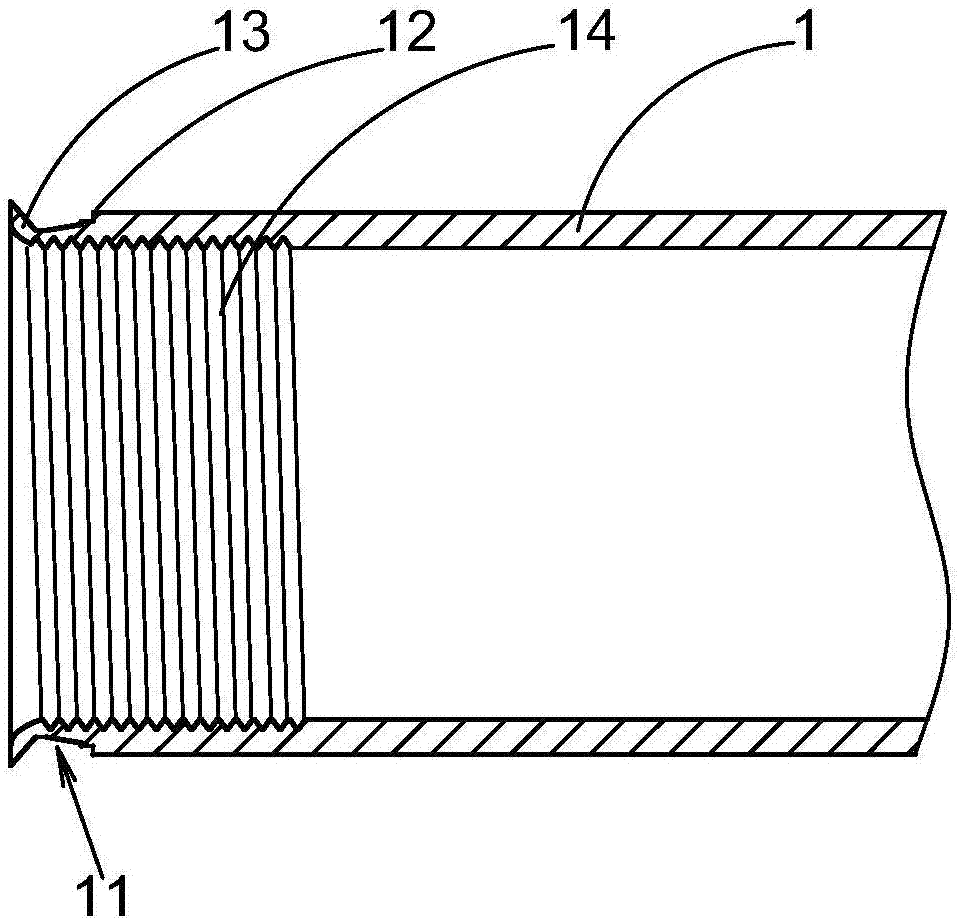

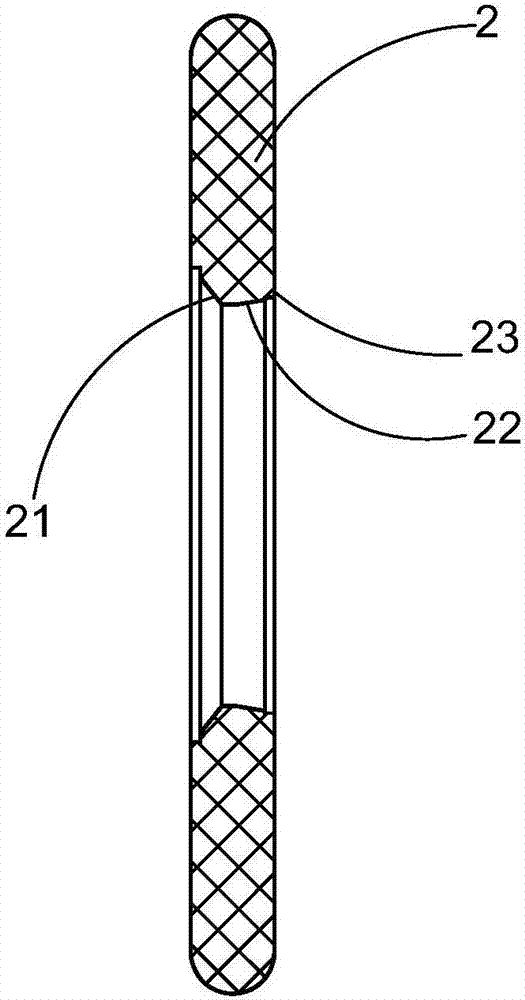

[0019] The textile bobbin has a central tube 1 and a side disc 2 with a central hole, the central tube is made of aluminum alloy, the side disc is made of phenolic laminated cloth board, and the two ends of the central tube 1 have outer diameter shrinkage formed by turning the neck and the shoulder 12 at the end of the neck, Image 6 Indicates the central tube semi-finished product in the processing process of the present invention, its two ends have necks 11 with shrinking outer diameters formed by turning, the outer end direction of the neck is the equal outer diameter part 111, and the opposite outer end direction is the outer diameter from inside to outside Tapered cone portion 112 . The side plate 2 is sleeved on the neck of the central tube 1 through the central hole, and the inner edge 23 of the central hole of the side plate is buckled on the shoulder 12 of the central tube. The direction of the outer opening of the central hole of the side plate has a horn Mouth-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com