A pair of locking device

A mortise lock and mounting seat technology, applied in the direction of mechanical equipment, connecting components, etc., can solve the problems of rigid impact, cannot be locked at the same time, complex structure, etc., to prevent the rise of the stroke from exceeding the limit, the bearing load range is large, and the quality of personnel is achieved. less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

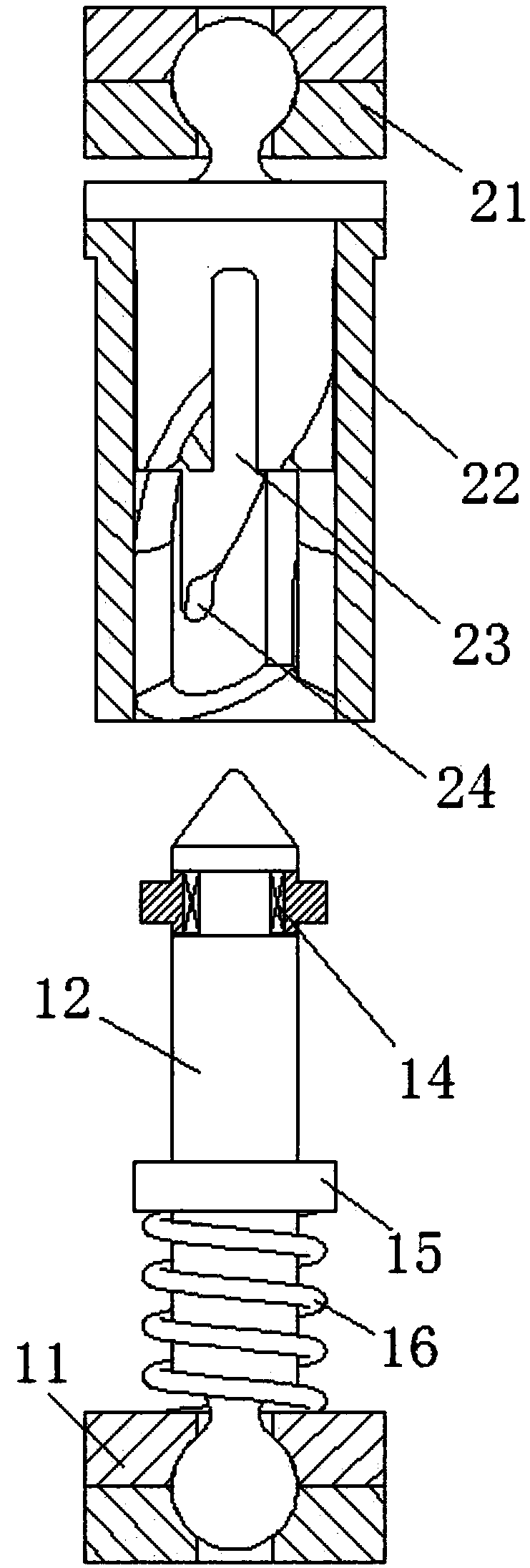

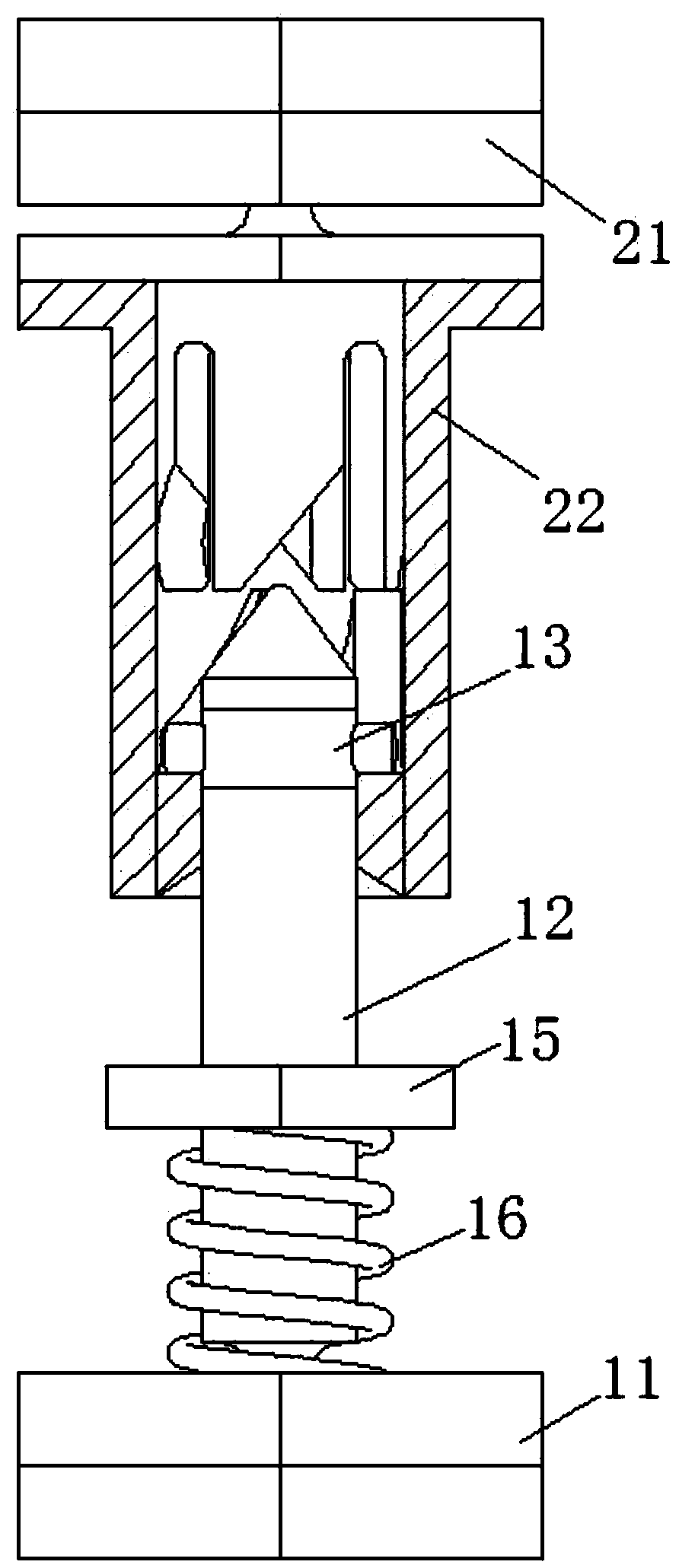

[0023] Example: see Figure 1 to Figure 7 , an anti-mortise locking device, comprising a first mounting seat 11 on which a male head 12 is arranged, and the bottom of the male head 12 is assembled with the first mounting seat 11 to form a spherical pair, the The lower part of the male head 12 is provided with a support structure for keeping the male head in an upright state, the upper part of the male head 12 is provided with a rotating sleeve 13 , the rotating sleeve 13 is connected with the male head 12 through a one-way bearing 14 , and the outside of the rotating sleeve 13 is Set the pin.

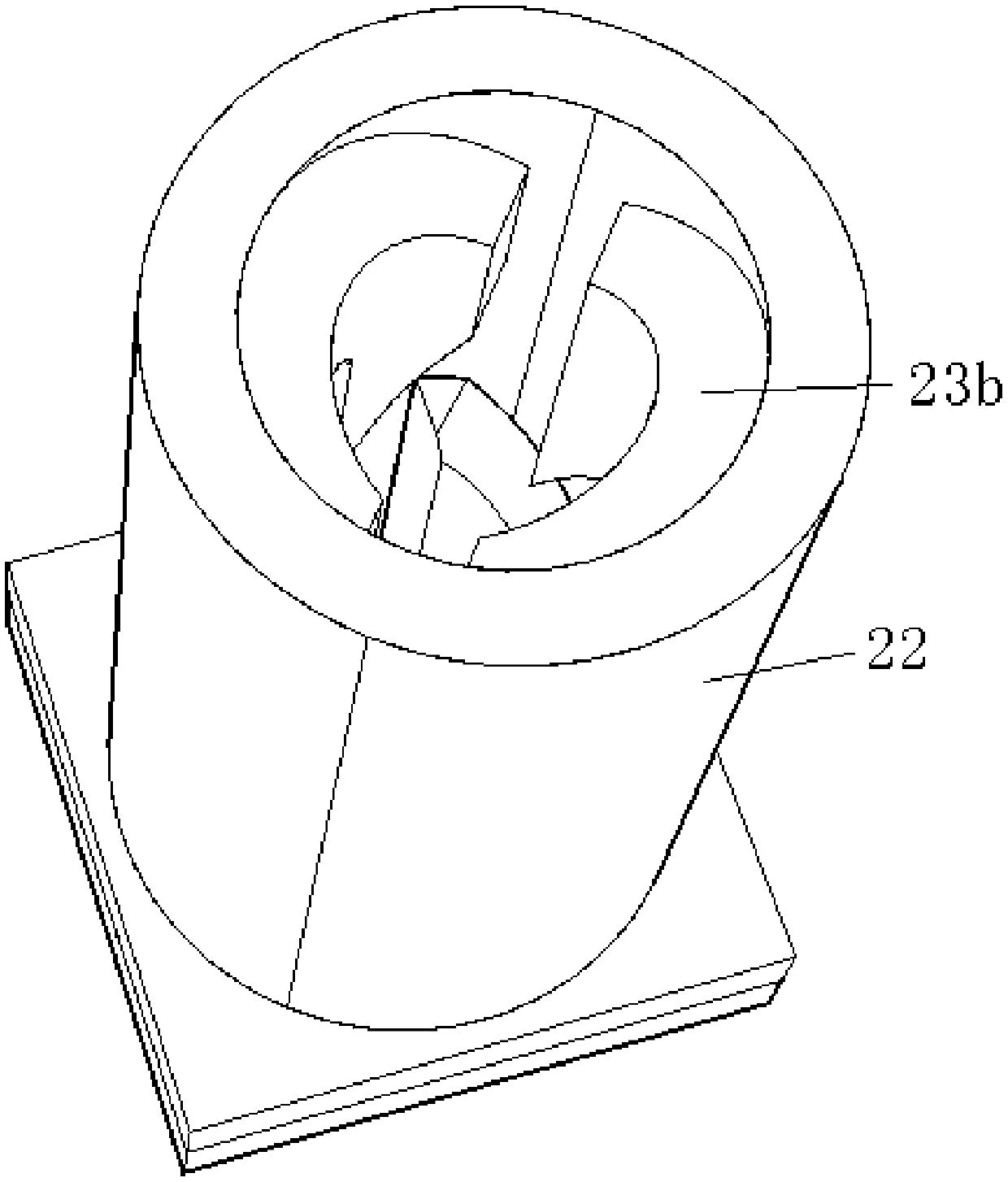

[0024] A female header 22 is arranged under the second mounting seat 21 , the top of the female header 22 is assembled with the second mounting seat 21 to form a spherical pair, a guide groove structure 23 is arranged in the female header 22 , and a lock is arranged at the guide groove structure 23 The notch 24 is tightened, and the locking notch cooperates with the pin to lock the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com