Non-slip lifting hook based on gear and rack

A hook and gear technology, applied in the field of anti-slip hooks, can solve the problems of increasing difficulty in replacing or taking out the sling, reducing work efficiency, wasting manpower, etc., and achieves the effects of saving manpower, improving work efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

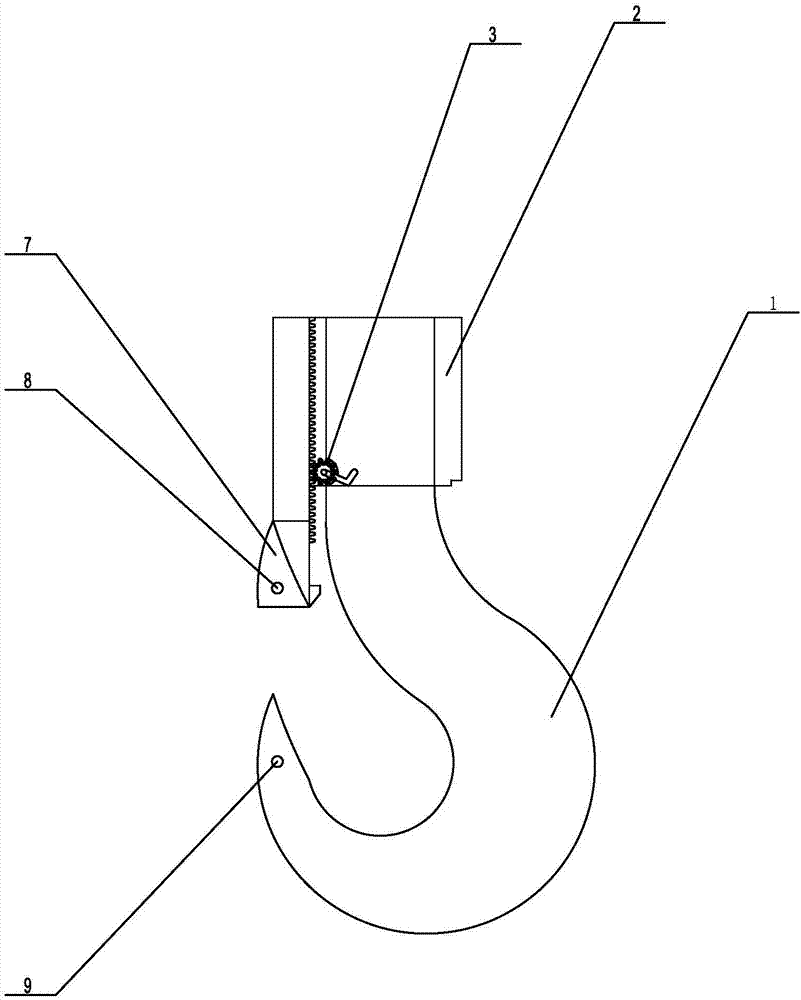

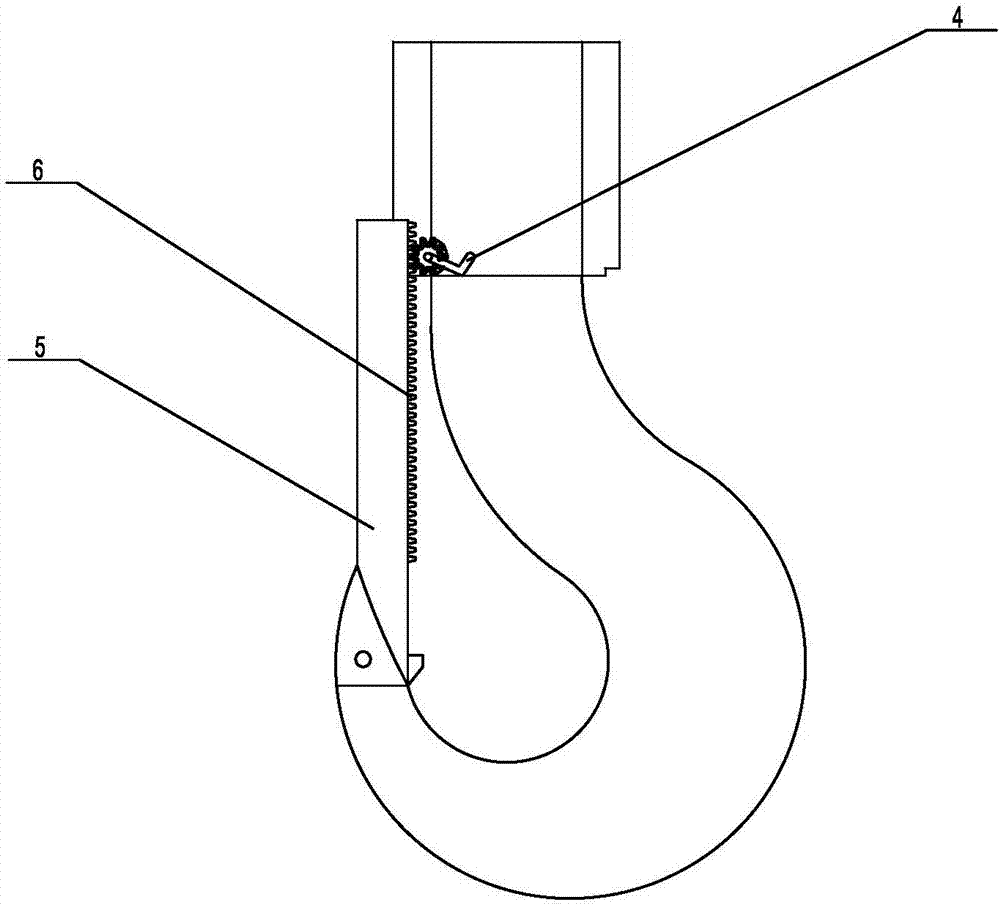

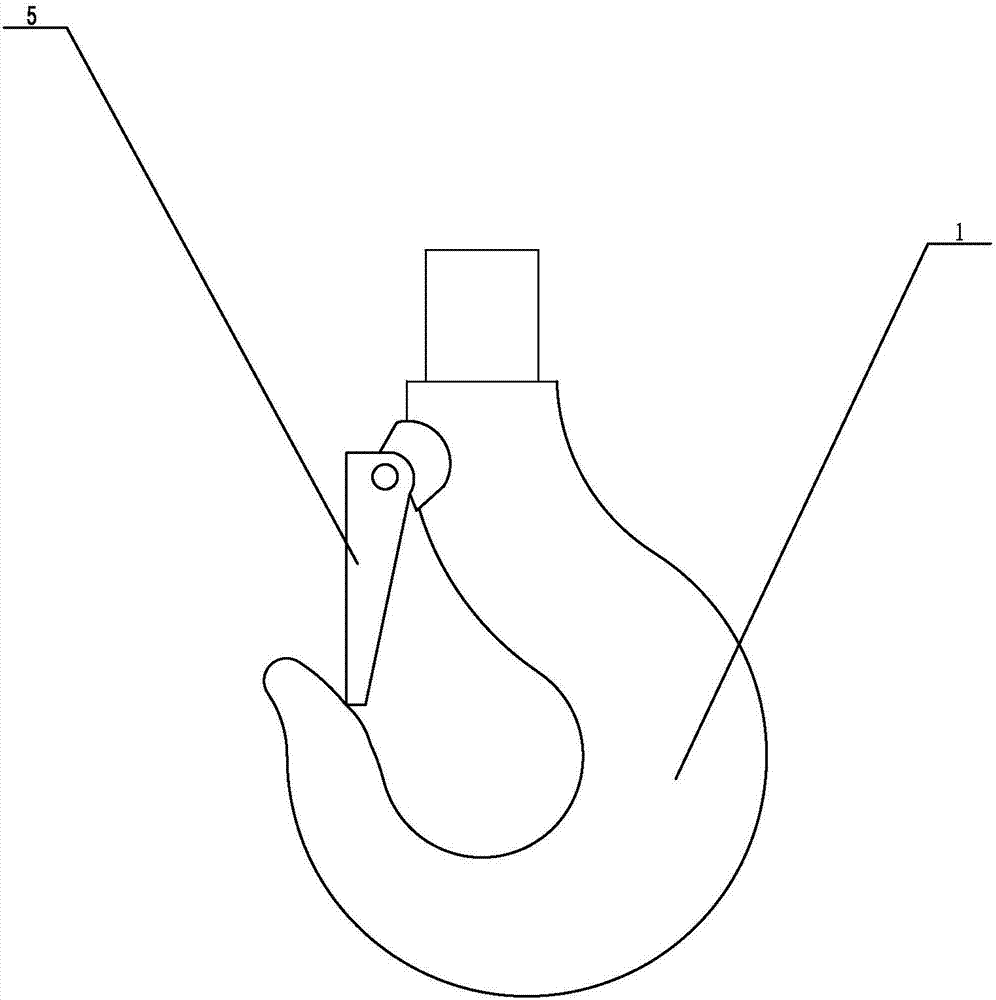

[0018] Such as figure 1 A specific embodiment of the present invention is proposed as shown, the anti-slip hook based on the gear-rack, including the hook body 1, the upper end of the hook body 1 is provided with an anti-slip mounting block 2, and the anti-slip mounting block 2 is fixed A gear 3 is provided. In this embodiment, the gear 3 is located at the bottom of one side of the anti-slip mounting block 2. A hand crank 4 is coaxially installed on the gear 3. Then shaking the hand crank 4 can make the gear 3 rotate. The hook body 1 is movably connected with a vertical anti-slip bar 5 through a connector, and the anti-slip bar 5 can be movably connected to the hook body 1 by buckles or ropes. Moving up and down, the side of the anti-skid bar 5 opposite to the gear 3 is provided with a rack 6 that can mesh with the gear 3, and the bottom end of the anti-skid bar 5 is provided with a hook that can be sleeved on the hook body 1. The hook point cover 7 on the outer surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com