Noise-free elevator idler wheel assembly

A noise-free, elevator technology, applied in elevators, transportation and packaging, etc., can solve the problems of unreliable combination of friction plates and rollers, health hazards of employees, easy dispersion and uneven distribution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] To enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

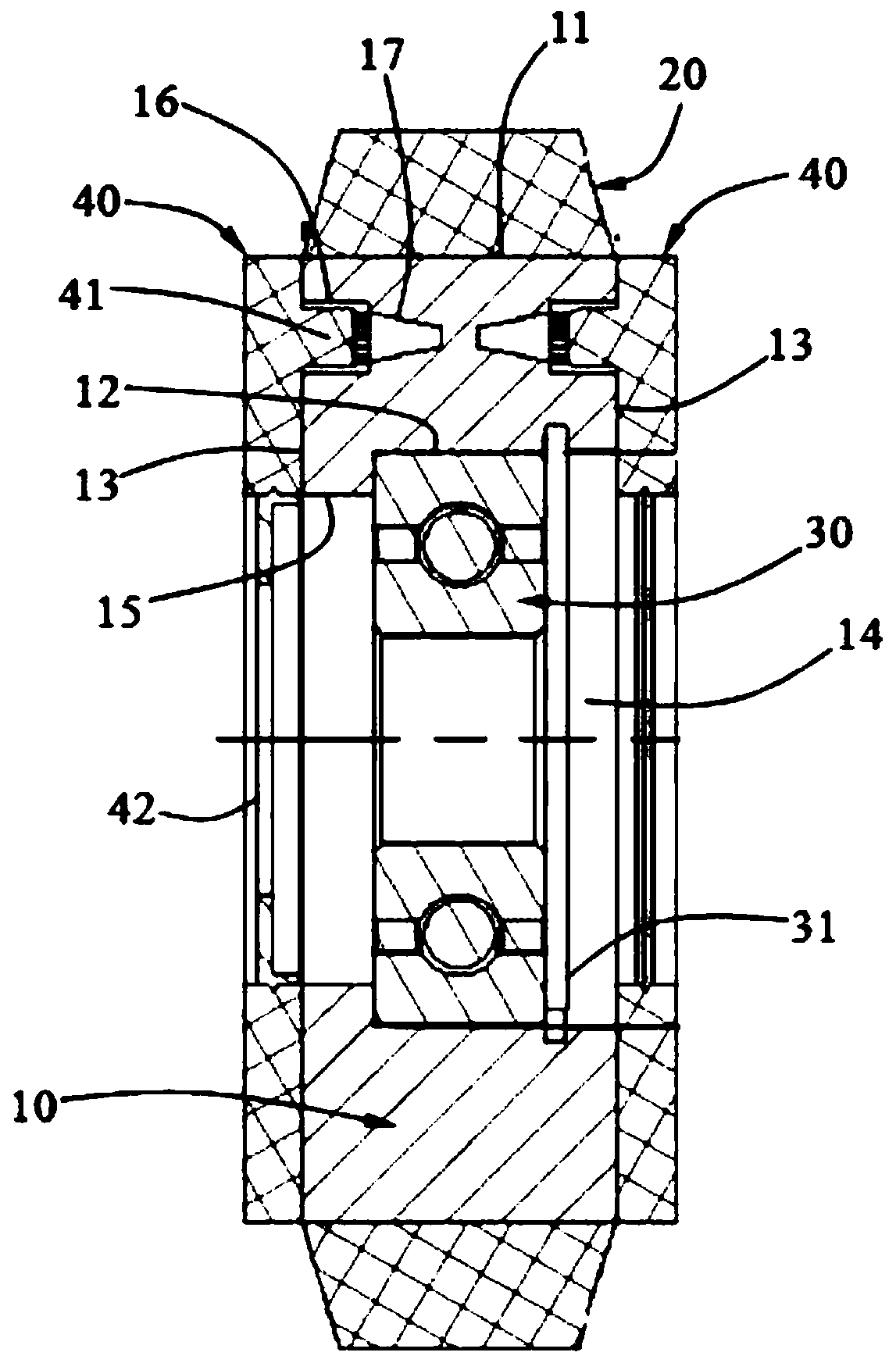

[0014] Such as figure 1 As shown, the embodiment of the present invention discloses a noiseless elevator roller assembly, comprising a wheel hub 10 made of nylon material with a weight of 49.0-70.0, a polyurethane elastic bead 20 formed on the surface of the wheel hub 10, mounted on the wheel hub The bearing 30 inside the hub 10, and the friction plates 40 located on both sides of the hub 10. Wherein, the hub 10 is provided with an annular outer wall surface 11 , an annular inner wall surface 12 , two side surfaces 13 connecting the annular inner and outer wall surfaces 11 , and a receiving hole 14 formed inside the annular inner wall surface 12 . The annular outer wall surface 11 is bonded to the polyurethane elastic bead 20 , and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com