Module connector and assembling method thereof

An assembly method and a connector technology, which are applied in the parts, connection, and contact assembly/disassembly of connection devices, can solve the problem of unreliable contact between pins and conduction terminals of light-emitting diodes, inconvenient operation, and problems with light-emitting diodes. Damage and other problems, to achieve the effect of not easy to damage, tight and reliable, easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

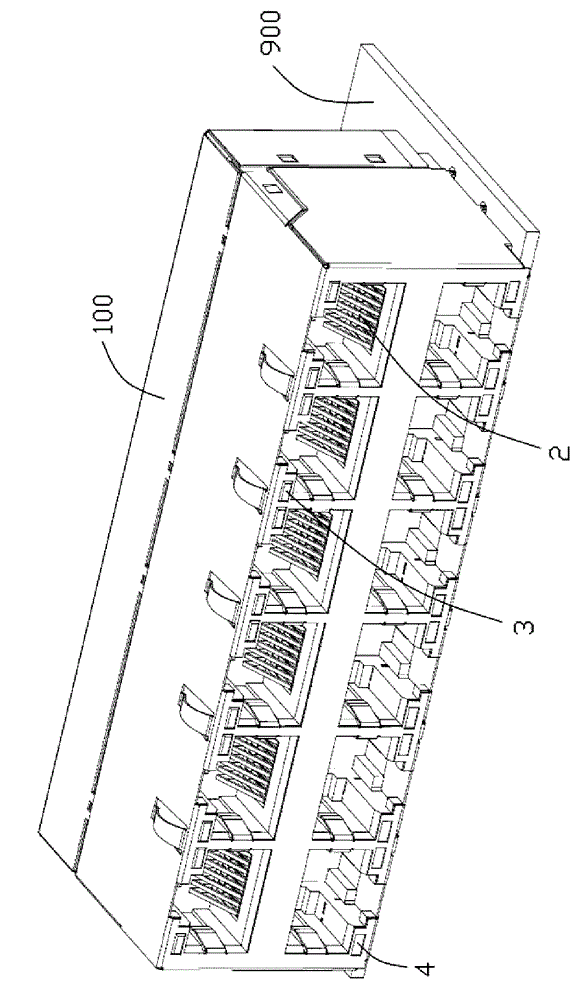

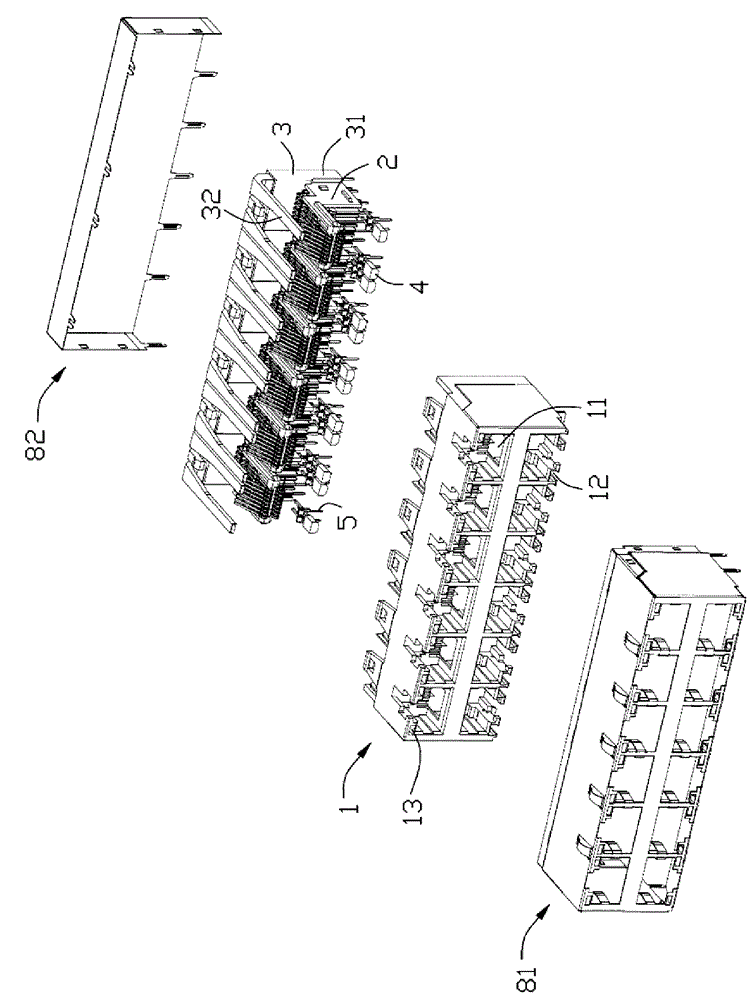

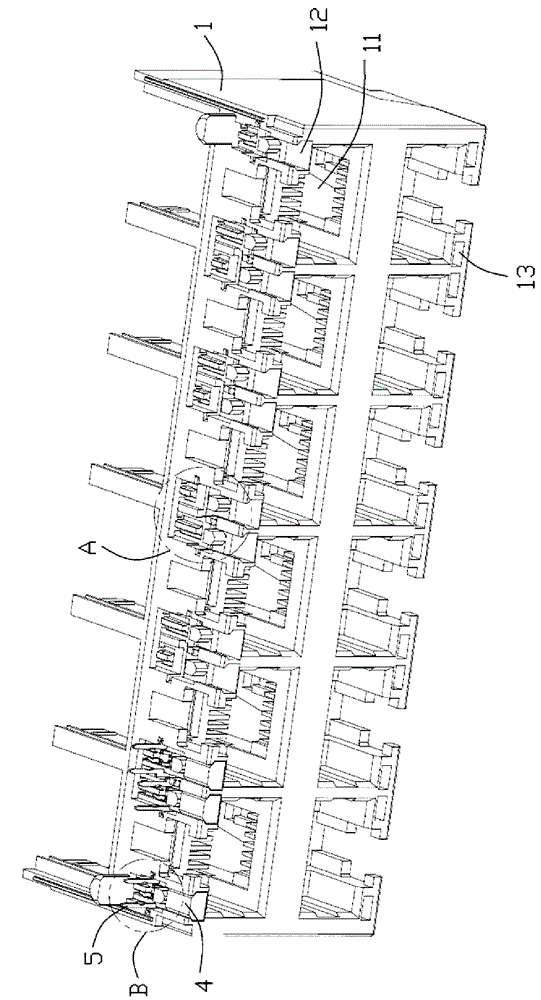

[0018] see figure 1 and figure 2 , the present invention discloses a module connector 100 electrically connected to a mother circuit board 900, which includes: an insulating body 1 provided with a plurality of receiving cavities 11, and a terminal module 2 accommodated in the receiving cavities 11 of the insulating body 1 , the light guide module 3 installed on the insulating body 1, a number of light-emitting diodes 4 assembled on the insulating body 1, the conducting terminals 5 embedded in the insulating body 1, and the first and second covering on the insulating body 1 Two shielding covers 81,82.

[0019] refer to Figure 1 to Figure 3 , the several housing cavities 11 of the insulating body 1 are stacked up and down. A plurality of light guide grooves 13 cooperating with the light guide module 3 are arranged above the upper row of receiving cavities 11 . A plurality of mounting slots 12 for matching with the light emitting diodes 4 are provided below the lower row of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com