Commercial vehicle disc brake caliper assembly with ventilation and self-adjusting structure

A technology of disc brakes and commercial vehicles, which is applied in the direction of brake types, brake actuators, brake components, etc., and can solve the dust-proof effect of the dust cover. The spring structure is complex and the one-way bearing structure is mainly used Problems such as short service life and spring fatigue service life can solve the problem of water leakage and water seepage, improve the waterproof and dustproof function, and reduce the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

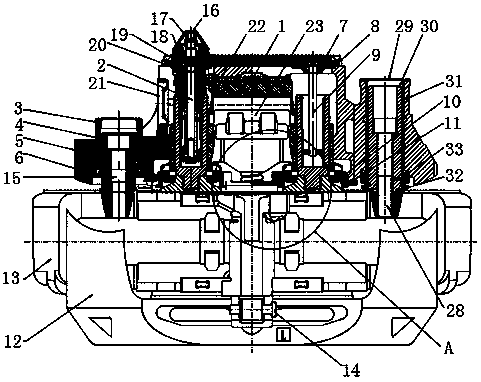

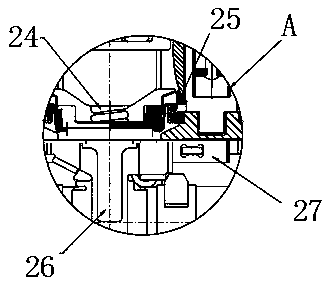

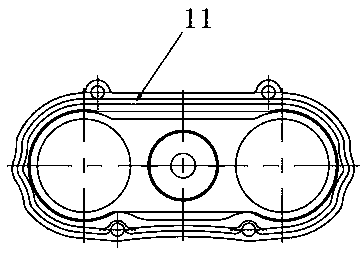

[0025] Example: such as Figure 1-8 As shown, the present invention provides a commercial vehicle disc brake caliper body assembly with a ventilation self-adjusting structure, including a booster arm assembly 1, a main adjuster assembly 2, a support sleeve 3, a short bushing 4, and a short column Pin 5, skeleton oil seal 6, plastic dust cover 7, gasket 8, driven adjuster assembly 9, support seat dust cover 10, bottom cover 11, brake caliper body 12, brake bracket 13, pin shaft 14. Hexagonal cylinder head screw 15, rubber cover 16, torque protector 17, driving sprocket 18, chain 19, rubber strip 20, blockage 21, needle roller assembly 22, bearing seat assembly 23, return spring 24 , shaft seal 25, first hexagon socket head screw 26, brake lining pressure spring 27, second hexagon socket head screw 28, long lug cap 29, long guide sleeve 30, lock ring 31, guide sleeve dustproof Cover 32, long bushing 33 and ventilation hole 33, the outer side of brake caliper body 12 is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com