Clamping tool for rectangular block workpieces

A technology for clamping tooling and rectangular blocks, applied in the field of tooling and fixtures, can solve the problems of low workpiece clamping efficiency and can not effectively meet the production needs of enterprises, and achieve the effect of ensuring processing quality, avoiding shaking, and avoiding potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the present invention, the components without specific structures and connection methods are usually conventional components or connection methods.

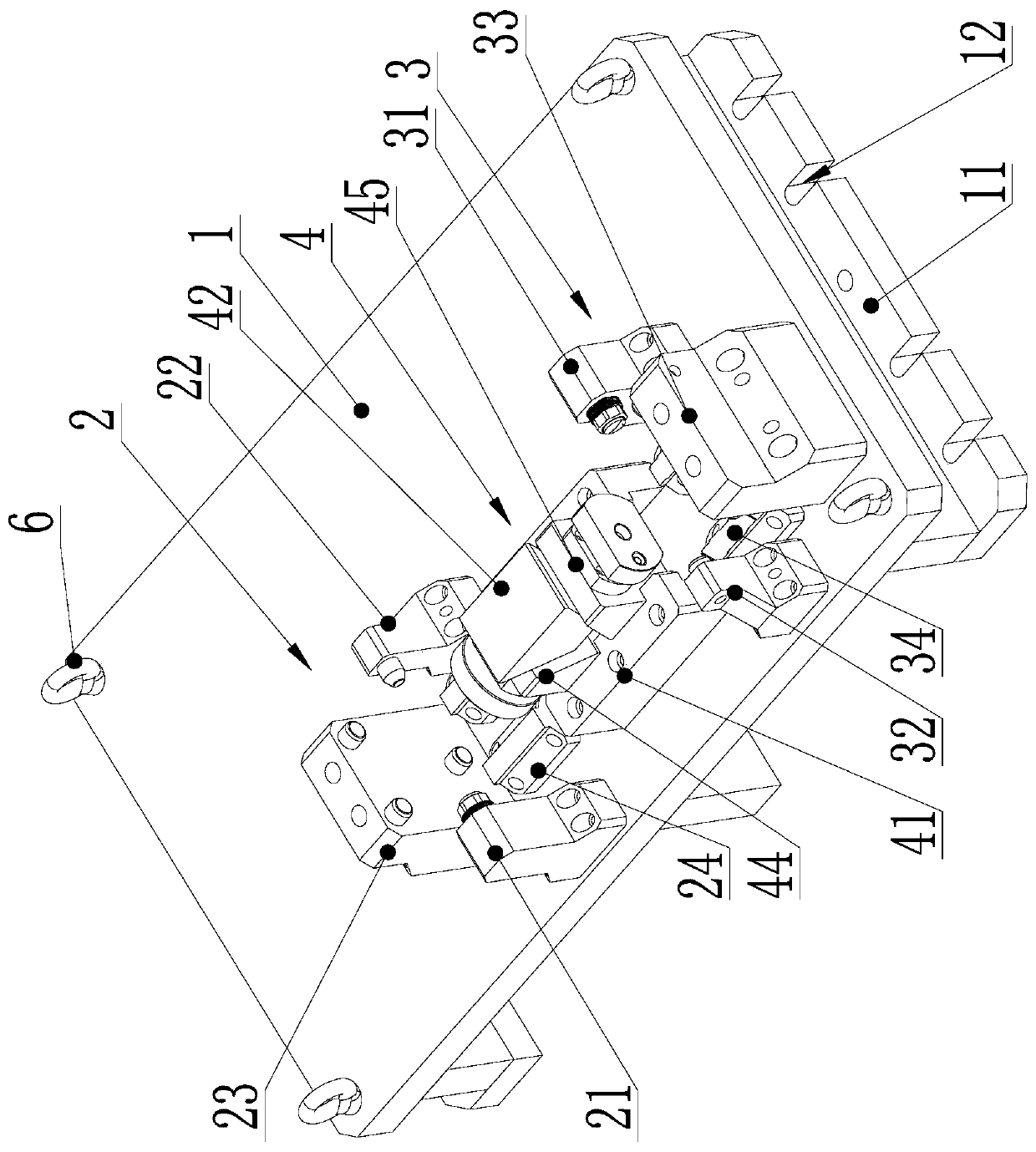

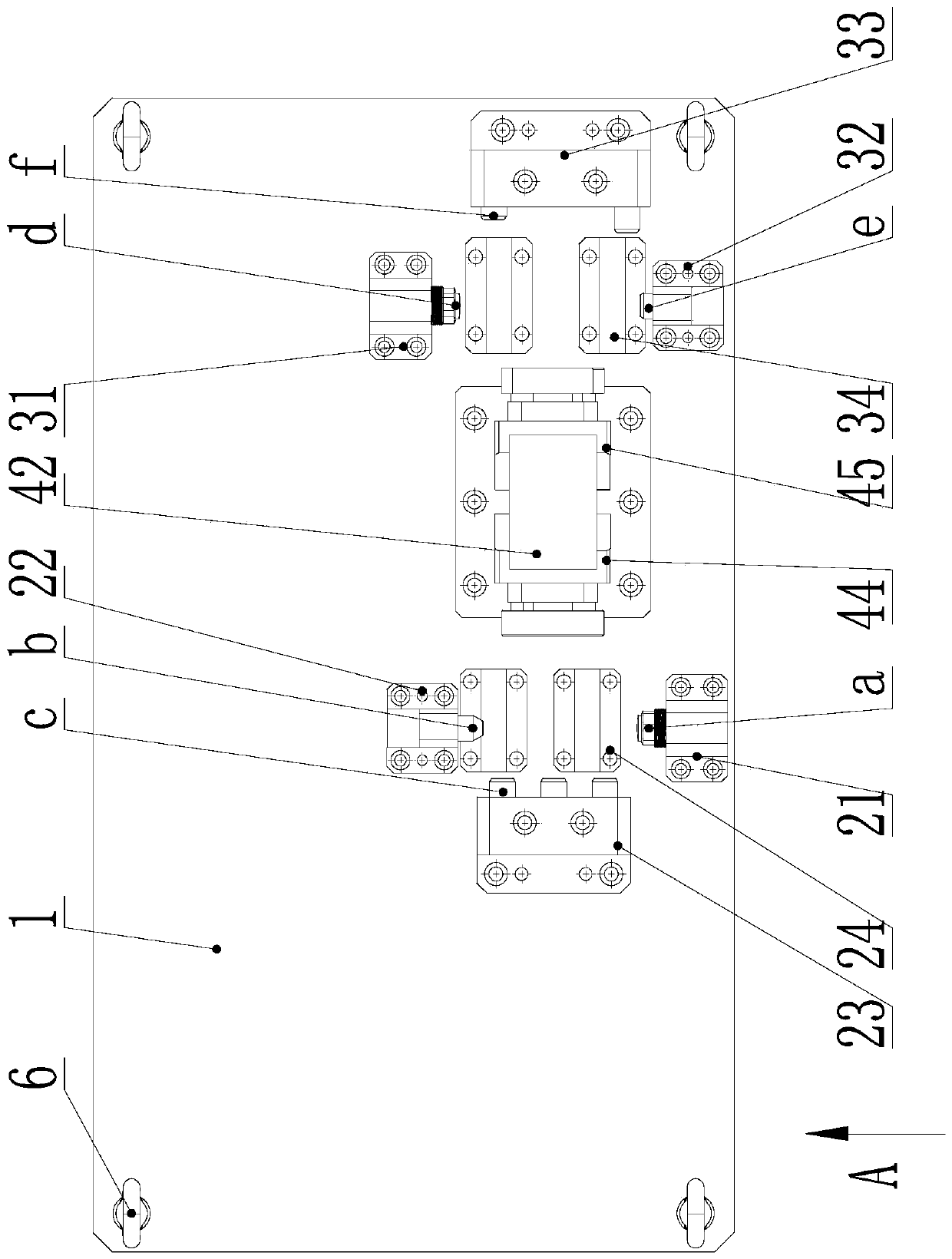

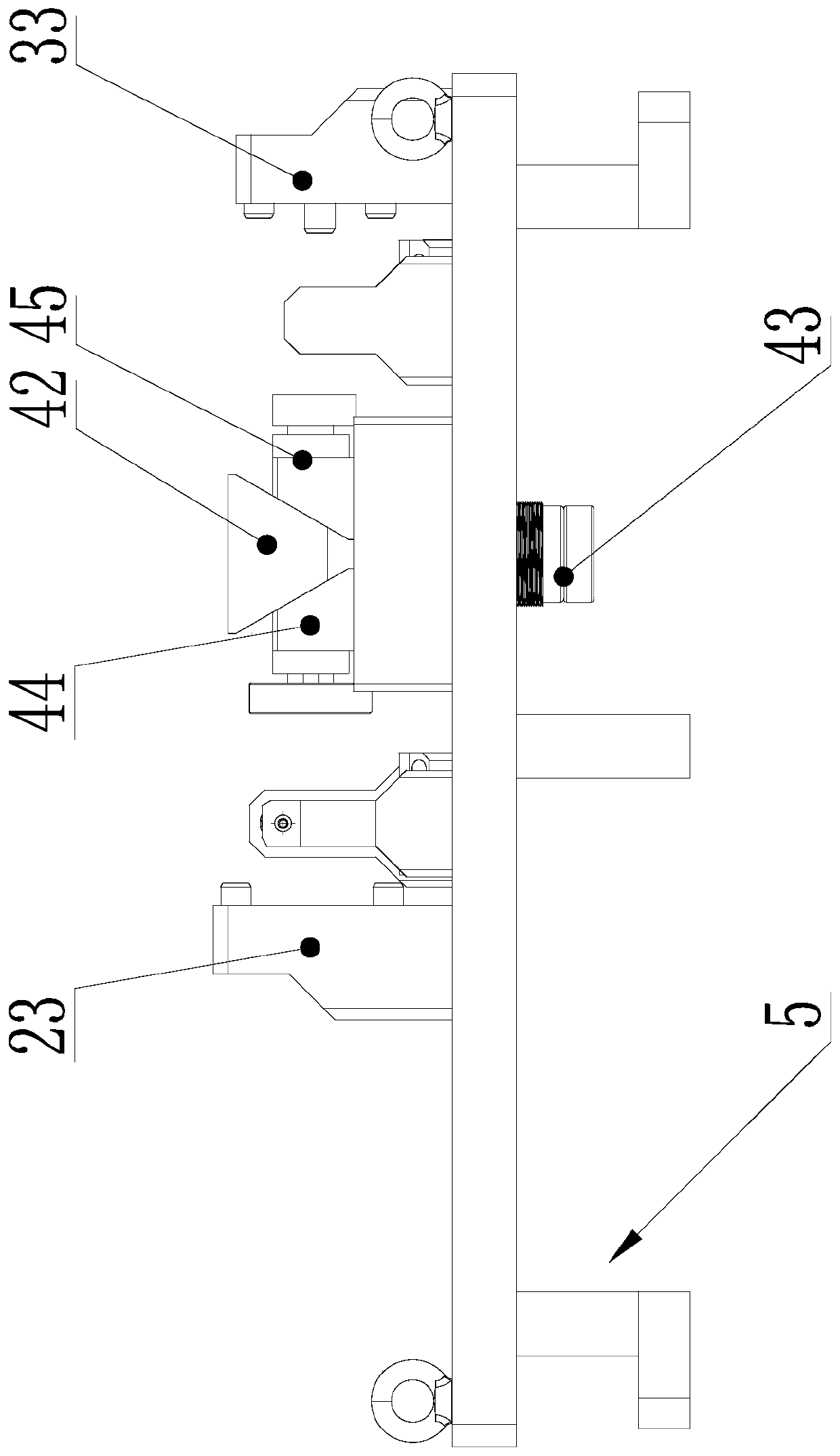

[0029] see Figure 1 to Figure 6, is a specific embodiment of a clamping tool for a rectangular block workpiece. The clamping tool of the rectangular block workpiece includes a base 1, a left positioning mechanism 2, a right positioning mechanism 3 arranged on the base 1, and a clamping mechanism 4. The bottom surface of the base 1 is provided with a bracket 5, so that the base is suspended , in the present embodiment, the base has a rectangular structure, and the four corners of the base 1 are screwed with hanging rings 6 respectively. The bracket 5 includes an L-shaped bracket 11 arranged on the left and right sides of the base 1, and the level The side extends outwards and is provided with a positioning opening slot 12 for bolts to pass through. In order to improve the support strength, a bar-shaped bracket is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com