lifting column

A sliding element and sliding structure technology, applied in the field of lifting columns, can solve the problems of large gaps and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following description of the figures, identical or functionally identical components are provided with the same reference symbols. In addition, generalized reference numbers can be used for components and objects which appear several times in the exemplary embodiments or figures, but which are described jointly with respect to one or more features. Parts or objects described with the same or general reference signs can be implemented identically with regard to individual, multiple or all features (eg in terms of dimensions), but can also differ if necessary, unless otherwise explained or illustrated by the description. implemented.

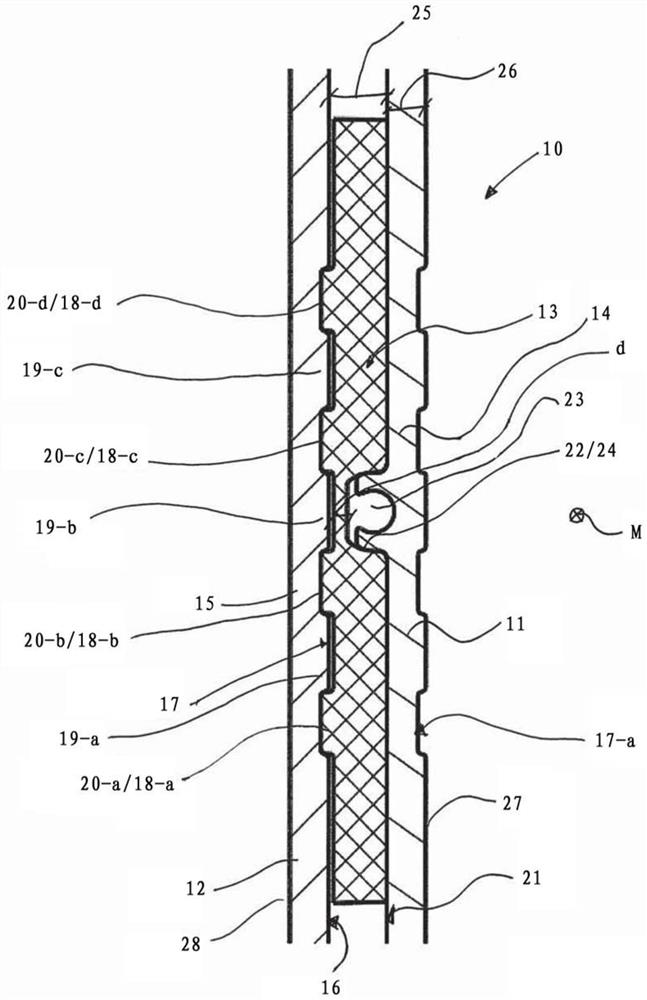

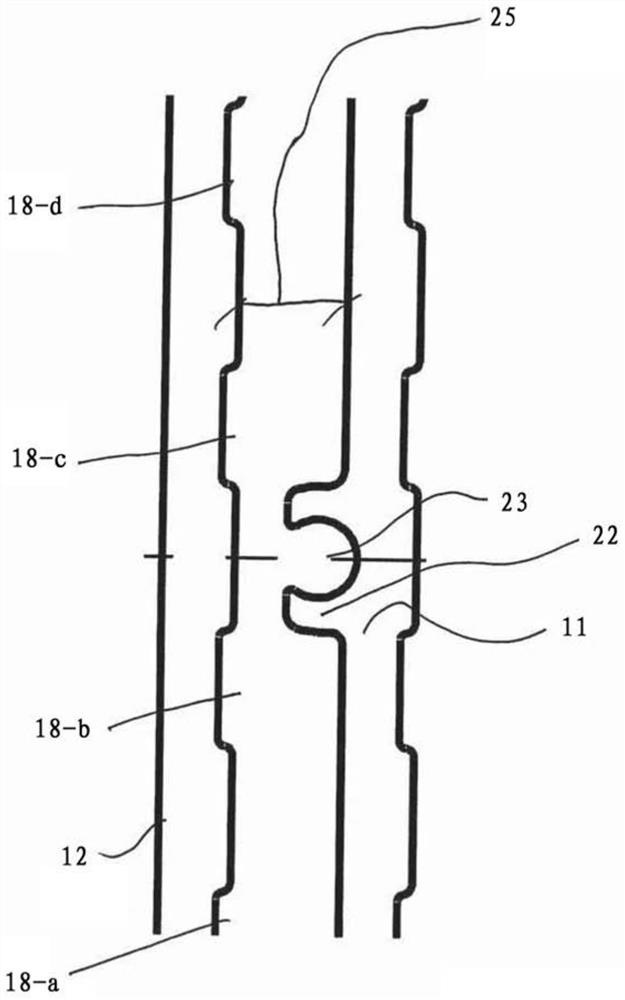

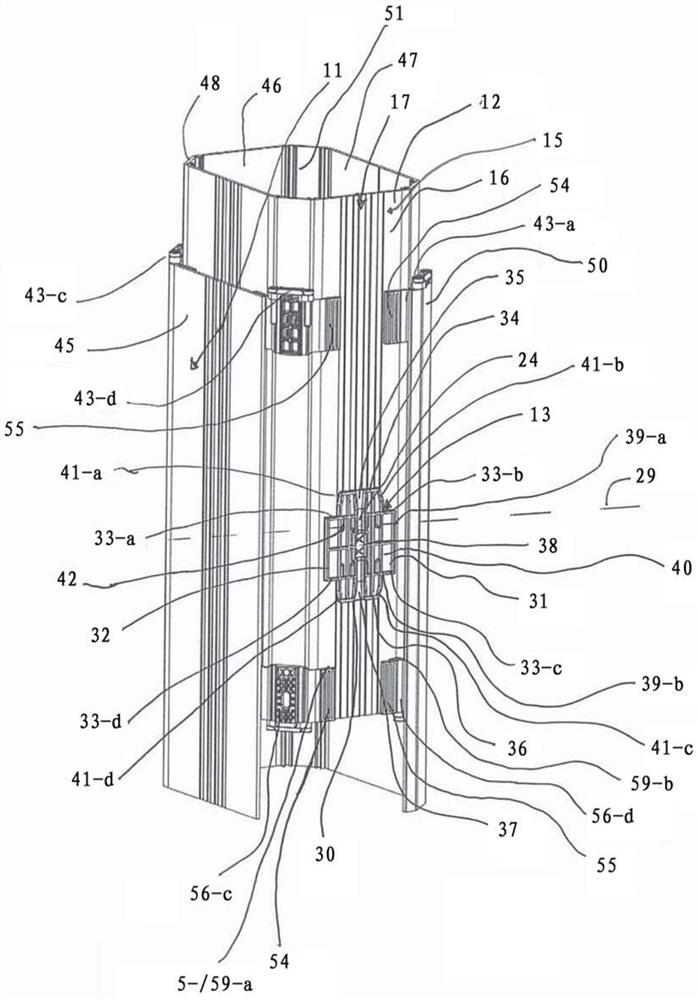

[0025] figure 1 and 2 A schematic cross-section of the lifting column 10 is shown in different cut planes, wherein figure 1 cut through the sliding element 13 of the lifting column and figure 2 The tangent plane of extends beyond the sliding element 13. exist image 3 A section 29 can be seen in , which represents figure 1 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com