Ladle hydraulic slide runner glidingly stroke converting method

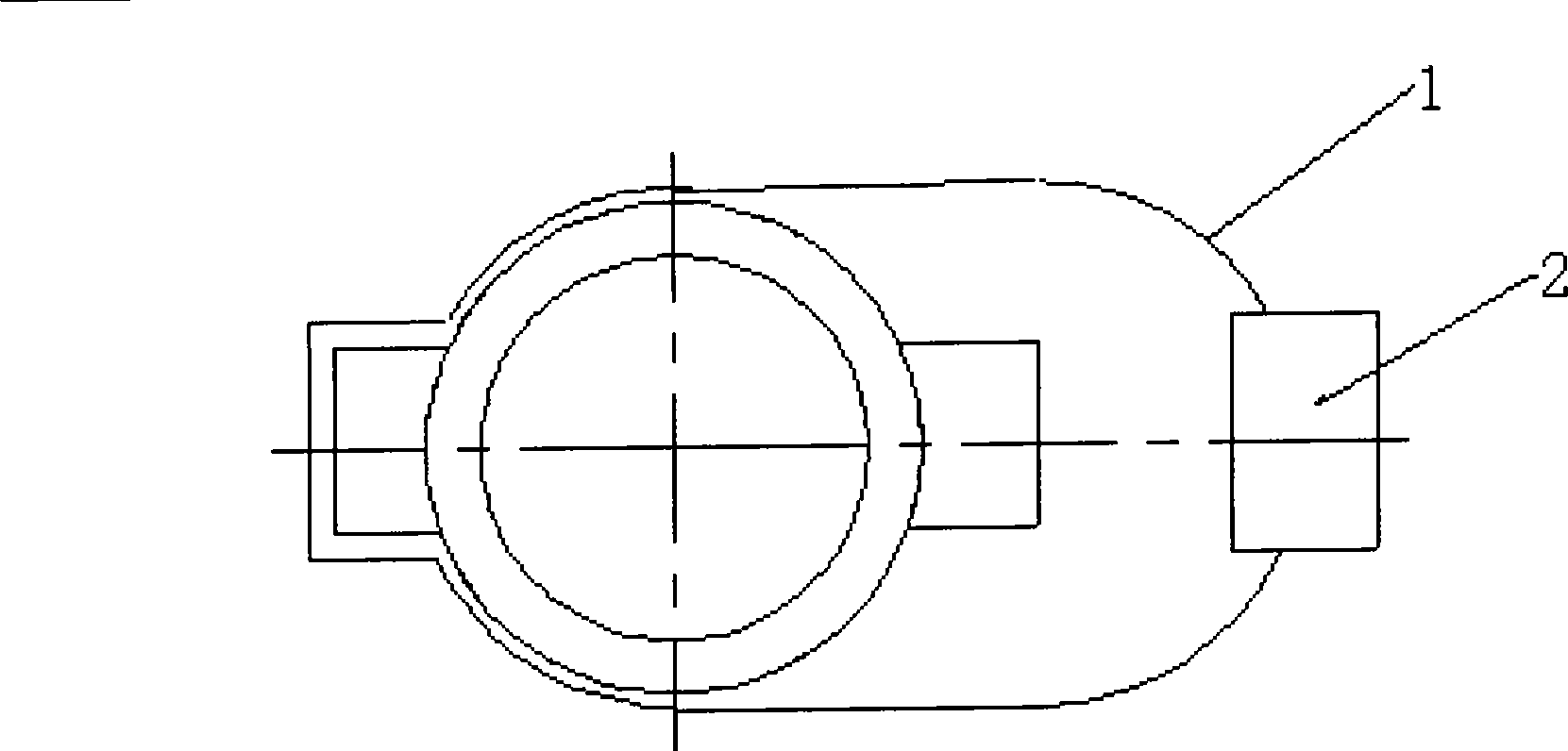

A sliding nozzle and conversion method technology, which is applied in the direction of casting molten material container, metal processing equipment, casting equipment, etc., can solve the problems of sliding nozzle flow control failure, production accidents, reduce the safety factor of sliding nozzle, etc., and achieve the purpose of increasing the continuous use of sliding plates Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

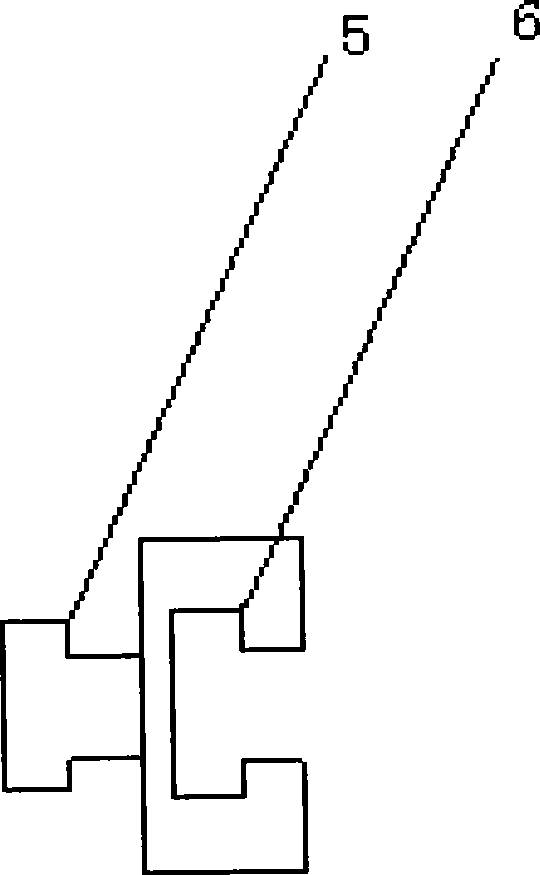

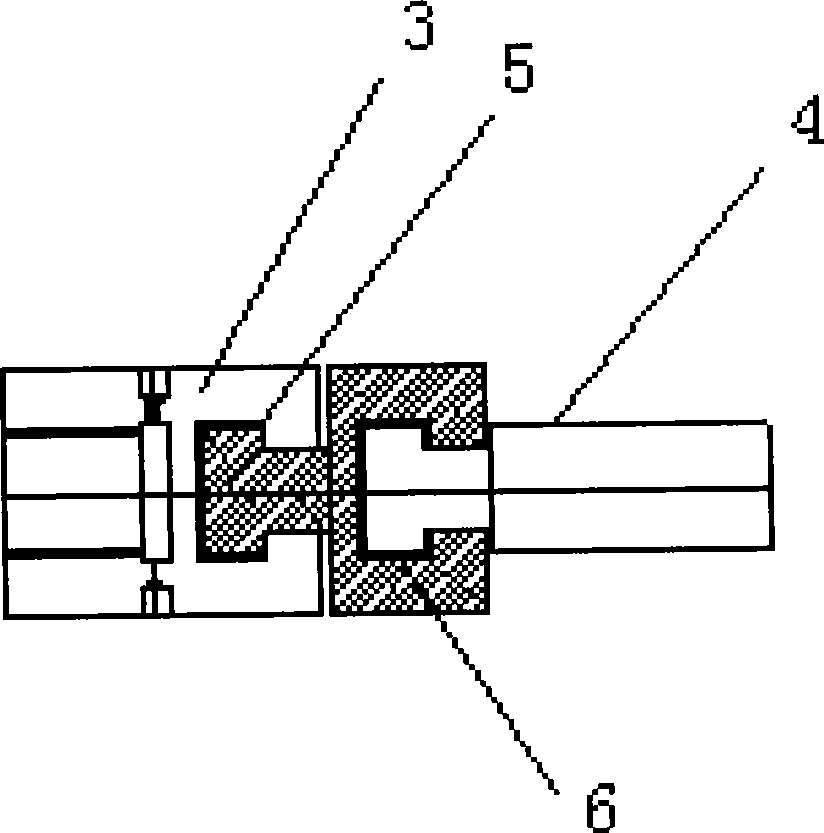

[0018] 1) Temporarily weld a stroke control module on the limit control part of the switch mold frame of the sliding nozzle mechanism, so that the sliding stroke is temporarily adjusted from the designed stroke to the old stroke before the transformation;

[0019] The sliding stroke is increased from 165mm to 200mm, and a stroke control module with a width of 35mm is temporarily welded to the limit control part of the switch mold frame of the sliding nozzle mechanism, so that the sliding stroke of the slide plate is temporarily adjusted from the designed 200mm to 165mm.

[0020] 2) After the transformation of the sliding stroke of all ladle sliding nozzle mechanisms is completed, cut off the stroke control module for the ladle that is not used for online turnover, so that the sliding stroke can be restored to the designed stroke, and replace the cylinder stroke of the ladle nozzle preparation area from the old stroke cylinder to Design stroke cylinder, cylinder stroke changed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com