Patents

Literature

799results about How to "Warranty requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

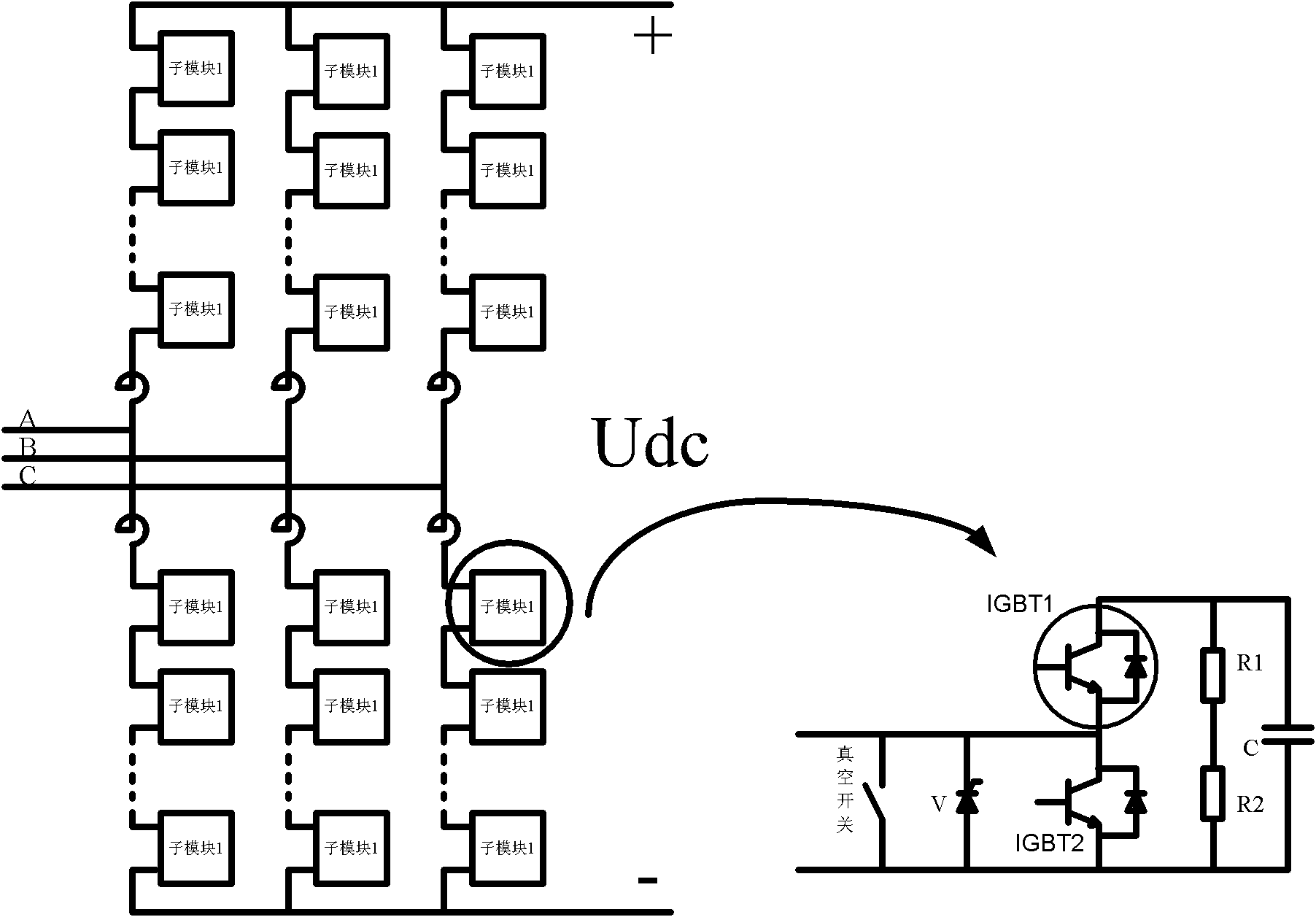

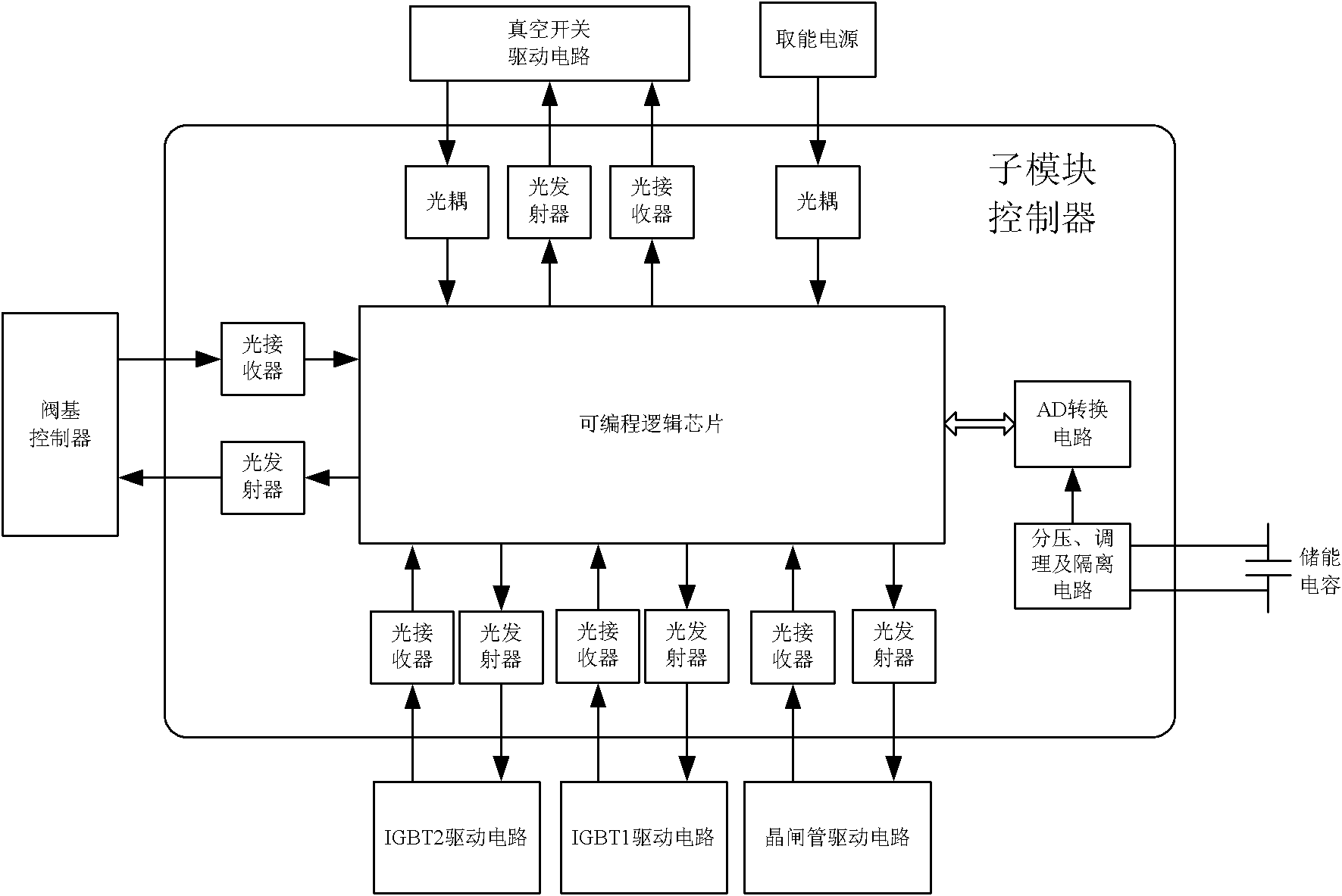

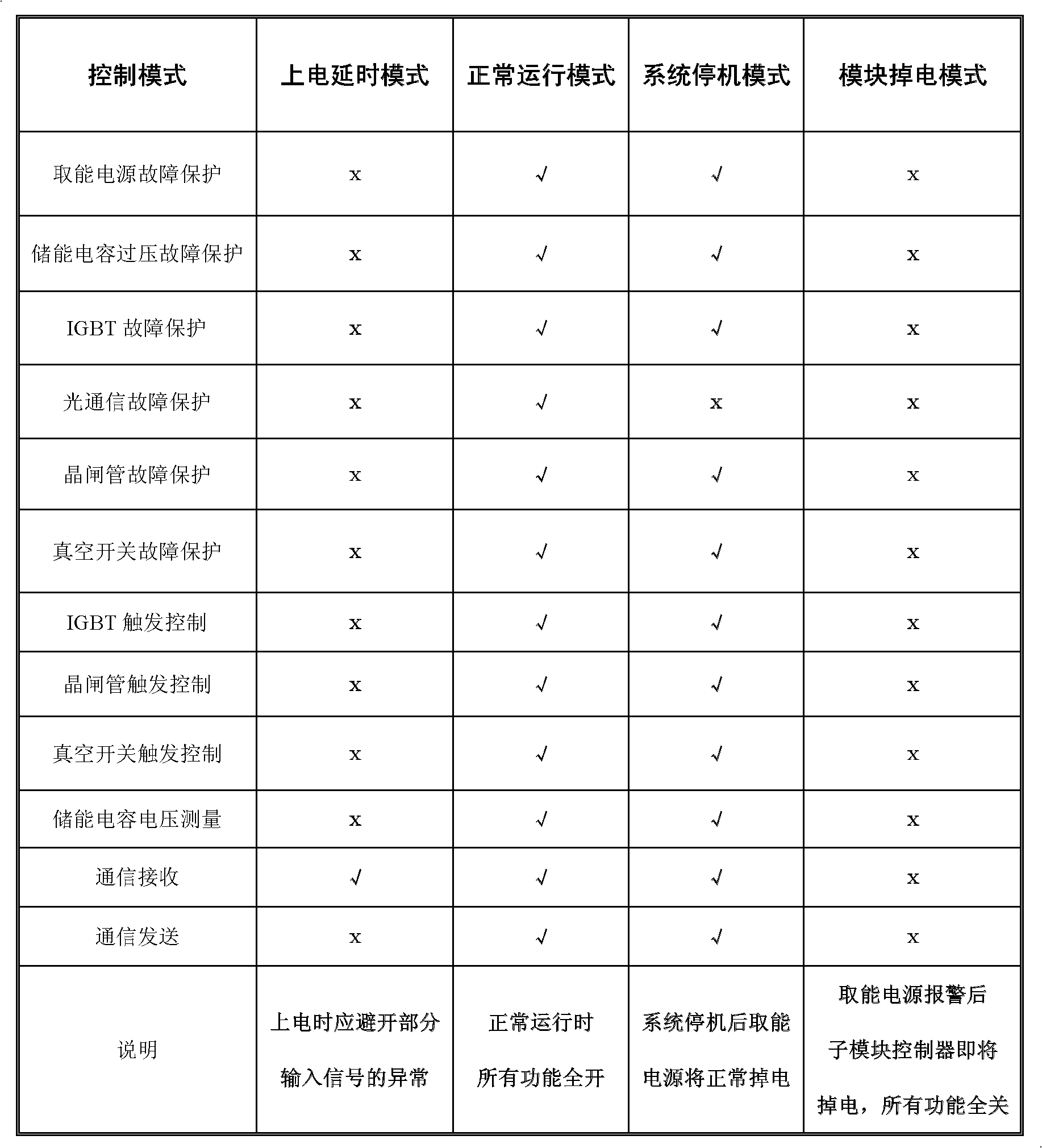

Modularized multi-level converter sub-module control and protection method

ActiveCN102118019AAchieve relatively independent controlGuaranteed reliabilityEmergency protective circuit arrangementsAc-dc conversionAsynchronous serial communicationComputer module

The invention relates to a modularized multi-level converter sub-module control and protection method. The control and protection method comprises the following processing modes: in four control models of a sub-module, executing different control and protection logics by using a sub-module controller; generating a sub-module internal interface output signal, detecting an input signal and diagnosing a plurality of faults; executing control and protection actions by using the sub-module controller according to an action priority level; detecting the voltage of an energy storage capacitor C by using the sub-module controller; and performing asynchronous serial communication between the sub-module controller and a valve-based controller. In the method, a complete and intelligent control and protection scheme is designed aiming at the structure of the modularized multi-level converter sub-module, the coordinated control and protection of the overall sub-module can be realized, so that the stable and reliable operation of the sub-module in a converter and the coordinated matching with an overall control and protection system of the converter are ensured.

Owner:CHINA ELECTRIC POWER RES INST +1

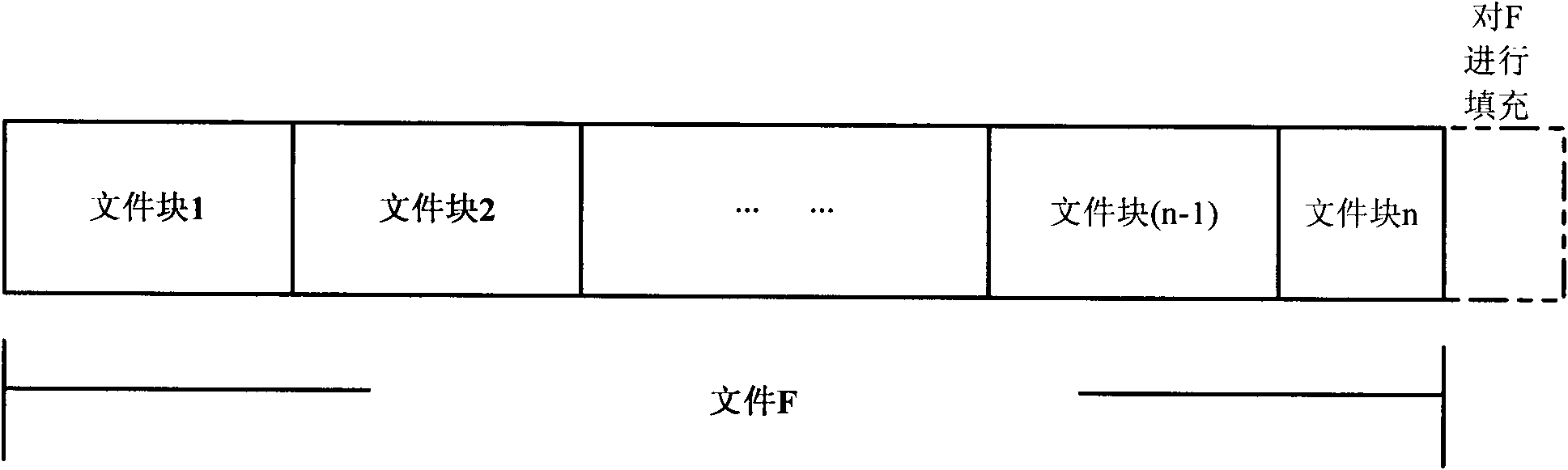

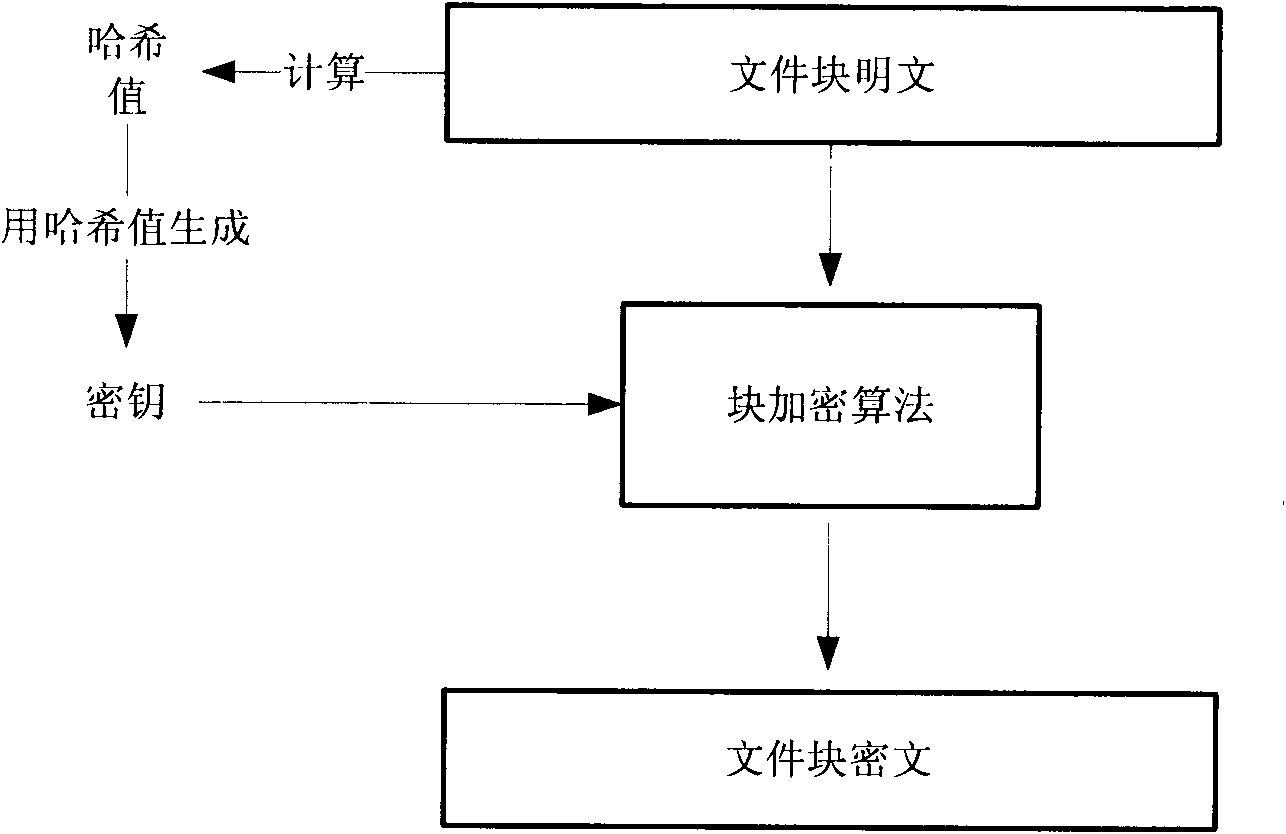

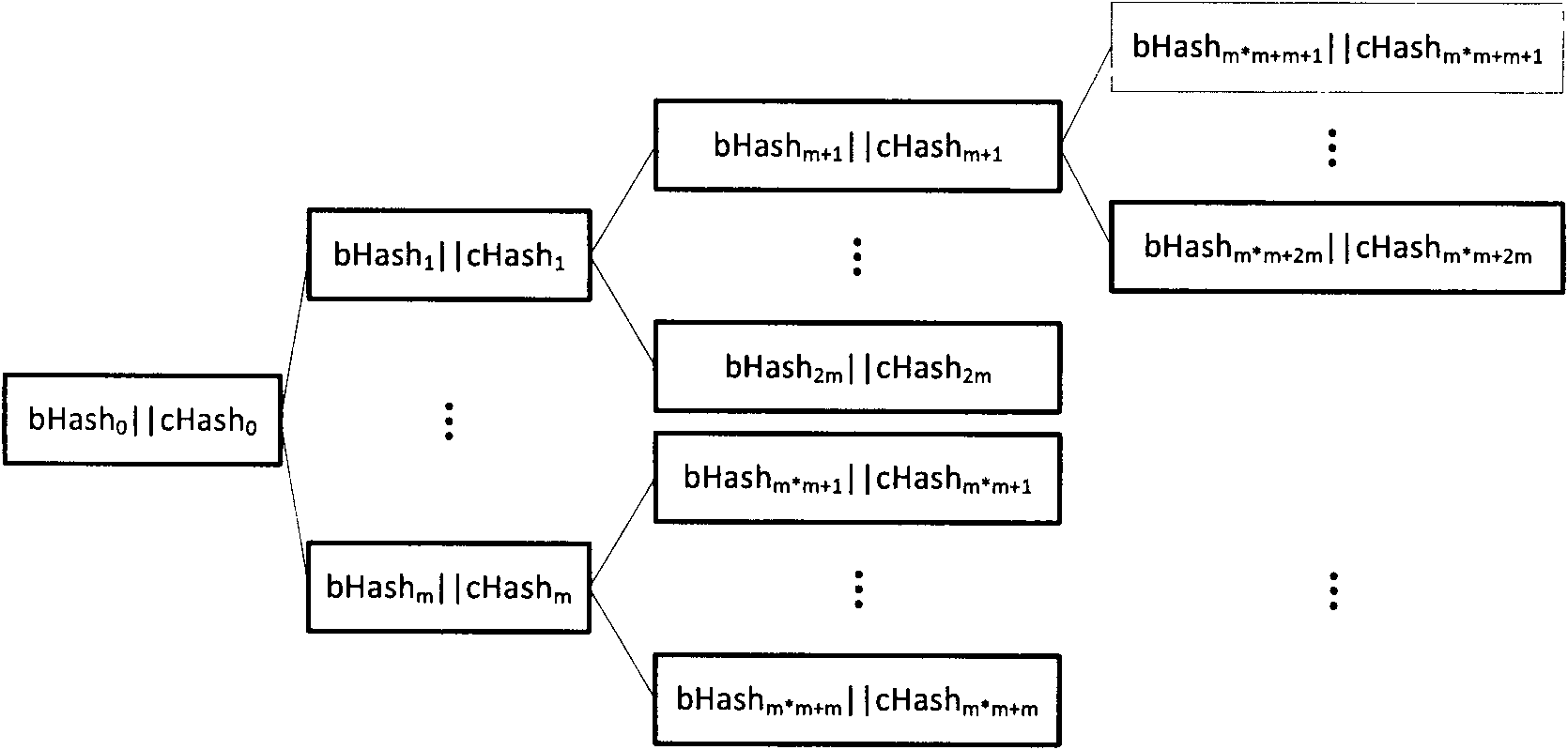

Safety metadata management method based on integrality checking

InactiveCN101976322AGuaranteed confidentialityWarranty requirementsDigital data protectionSpecial data processing applicationsMetadata managementData management

The invention relates to a safety metadata management method based on integrality checking, belonging to the field of storage safety. The method is characterized in that a self encryption technology for file data is used at a client to encrypt the file data, thereby improving the storage efficiency; a 64-heap hash tree is used at a safety metadata management server end to maintain the hash value of a file block, thereby providing integrality protection on the hash value of the file data block and realizing the high-efficiency verification on the user's access to file and the high-efficiency data updating; and simultaneously a root hash virtual linked list technology is used, thereby ensuring the integrality of root hash values of multiple 64-heap hash trees belonging to one file and supporting the user's concurrent access to the file to a certain extent.

Owner:TSINGHUA UNIV

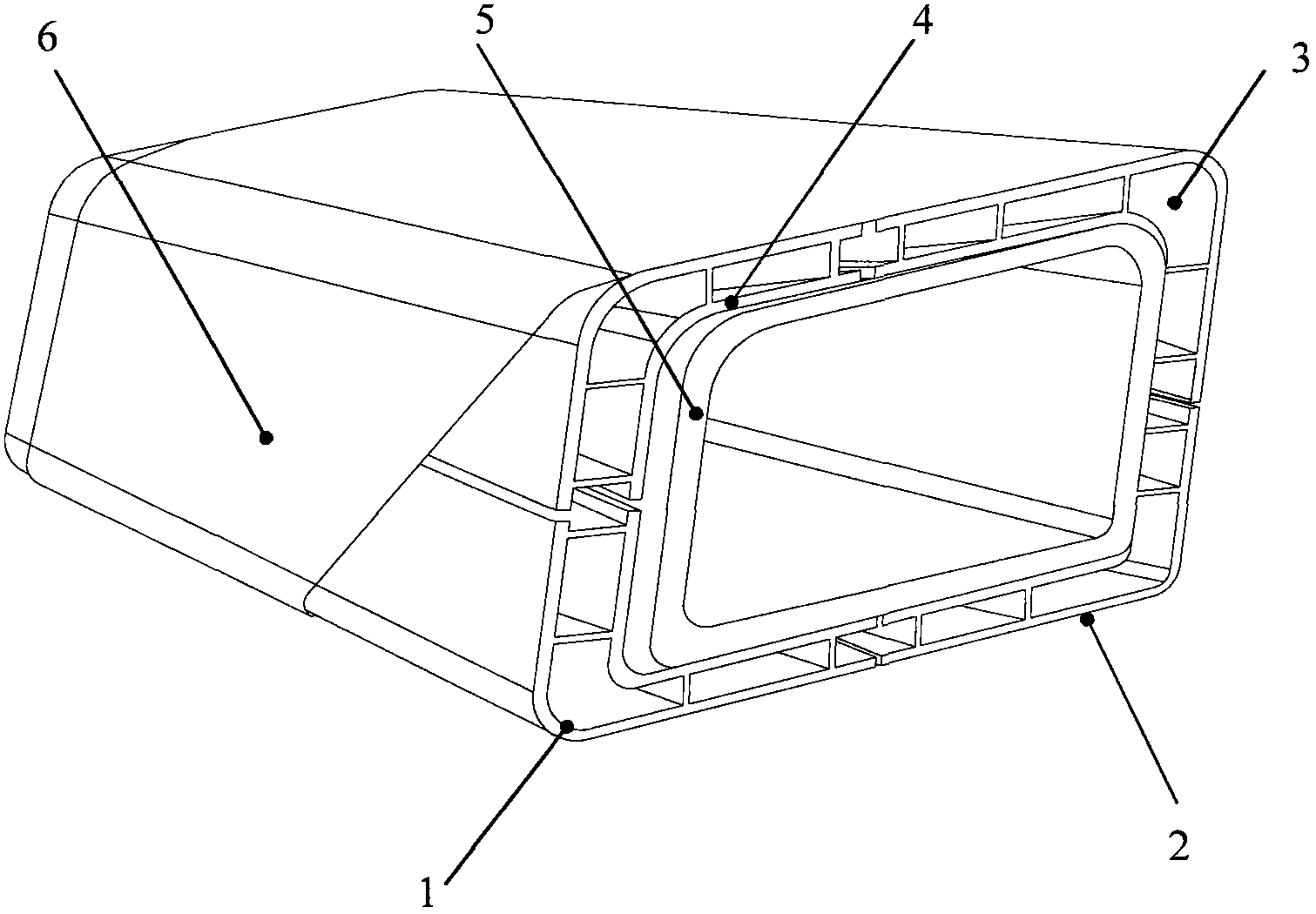

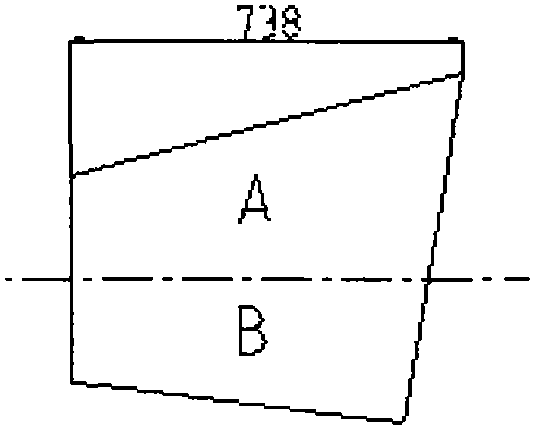

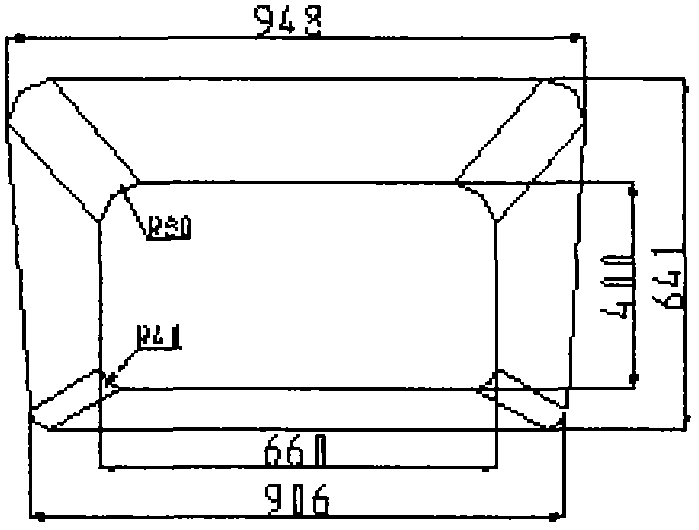

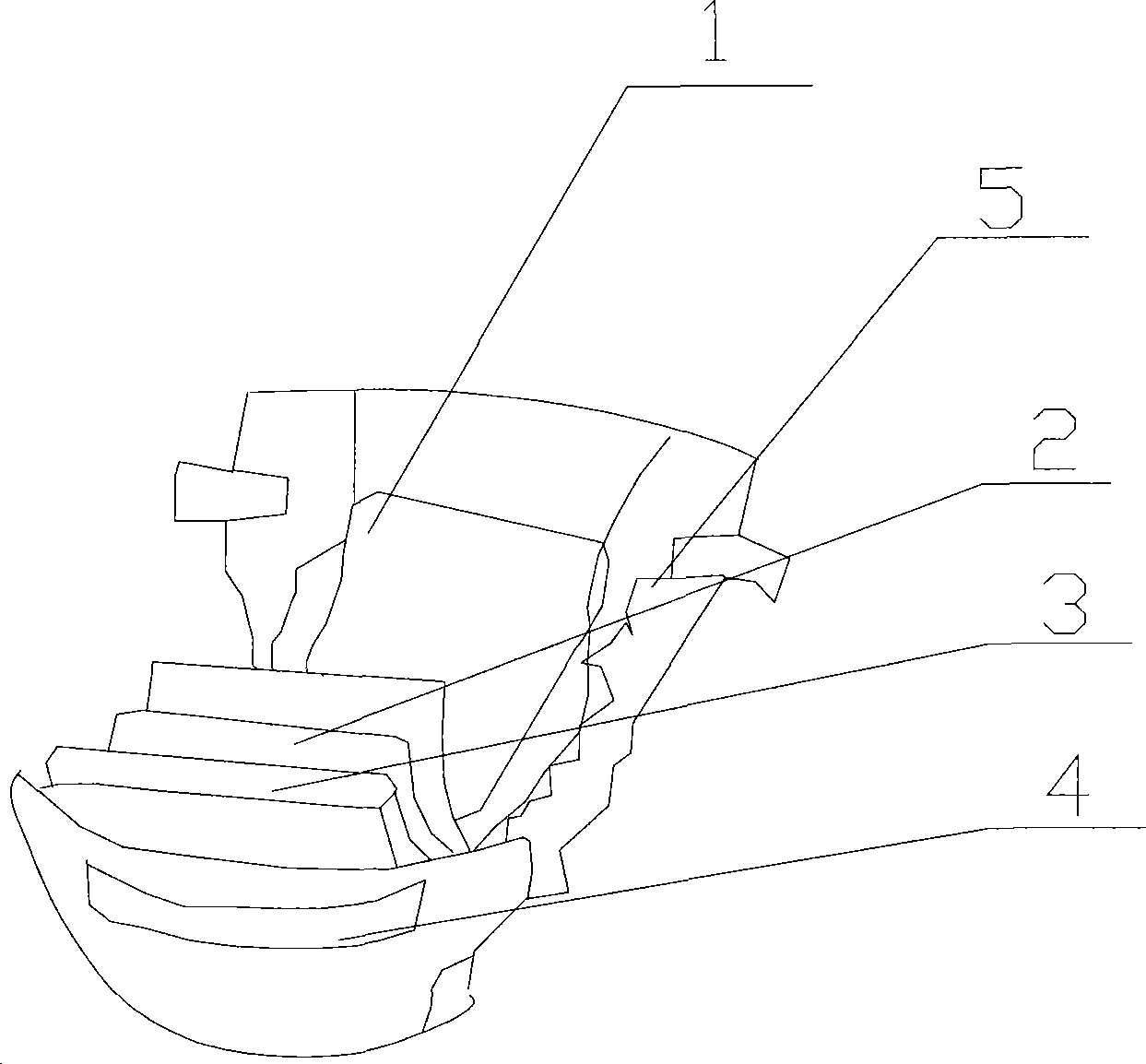

Integral forming method for thin-walled titanium alloy part with irregularly-shaped curved surface and die

InactiveCN102672435AOvercoming shape constraintsOvercome the processShaping toolsLaser beam welding apparatusTitanium alloyMetal

The invention belongs to the field of sheet metal and welding processing, and relates to an integral forming method for a thin-walled titanium alloy part with an irregularly-shaped curved surface. The integral forming method aims at overcoming the defects that the shape of parts processed through the prior art is limited or the procedure and the cost are higher, and effectively ensuring the precision forming of a thin-walled component with an irregular shape. The integral forming method comprises the steps as follows: a parting surface is determined; blanking is carried out; in the preforming step, a plate is bent from a flat into a circular arc through a bending die or a bending machine; welding is carried out; in the hot shaping step, a hot shaping die is put in the inner part of a part that is processed through the assembly welding under the ordinary temperature, and the part is supported tightly due to the dead weight of the die and is heated in a hot shaping machine; and in addition, a pressing machine applies pressure to the hot shaping die when the part is heated until material is softened, so as to enable the part to reach the needed size. The integral forming method comprehensively utilizes the advantages of various processes, can obtain the large-sized thin-walled titanium alloy part with the irregularly-shaped curved surface through only two weld joints, and achieves higher surface quality of the part.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

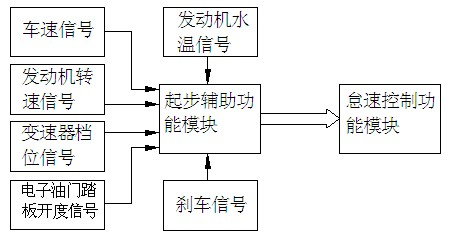

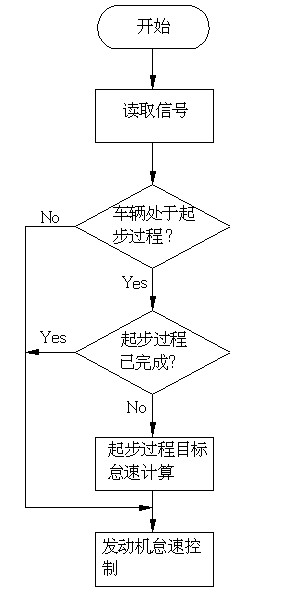

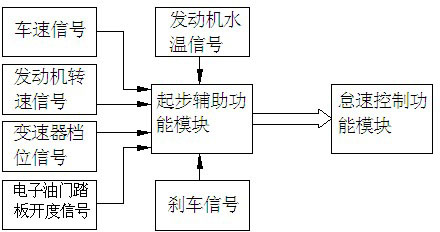

Logic control method for improving starting performance of vehicle

InactiveCN102536479AImprove starting performanceGuaranteed NVH performanceProgramme-controlMachines/enginesIdle speed controlWater temperature

The invention relates to a logic control method for improving the starting performance of a vehicle, which comprises the following steps of: judging whether the vehicle is in a starting process at present or not by a starting-assisting function module according to a vehicle-speed signal, an engine rotating-speed signal, a speed-changer gear signal, an electronic accelerator-pedal opening signal and a braking signal; if so, calculating and outputting a starting-target idling-speed increment to an idle-speed control function module according to a current engine water-temperature signal, and controlling an engine by the idle-speed control function module to increase the starting-target idling-speed increment part to be used as a target idle speed in the starting process by the engine on the basis of an original target idle speed; and after the starting process of the vehicle is judged to be finished by the starting-assisting function module according to the vehicle-speed signal, the speed-changer gear signal, the electronic accelerator-pedal opening signal or the braking signal, quitting a starting-assisting function to enable the engine to be restored at the original target idle speed to normally operate. Through the control method, the engine can have a lower idling speed in an idle-speed state, and the vehicle has a higher idling speed in the starting process.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

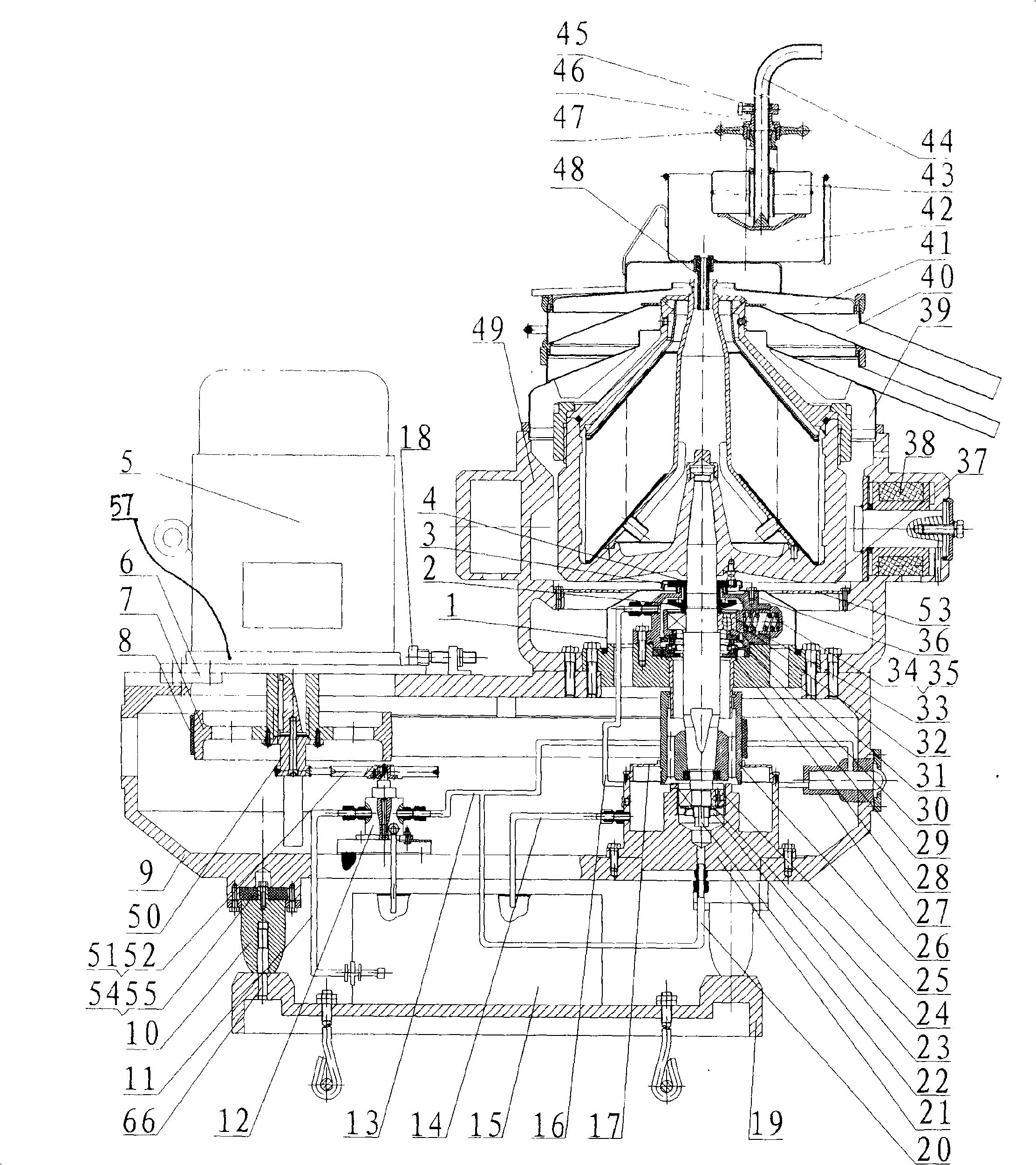

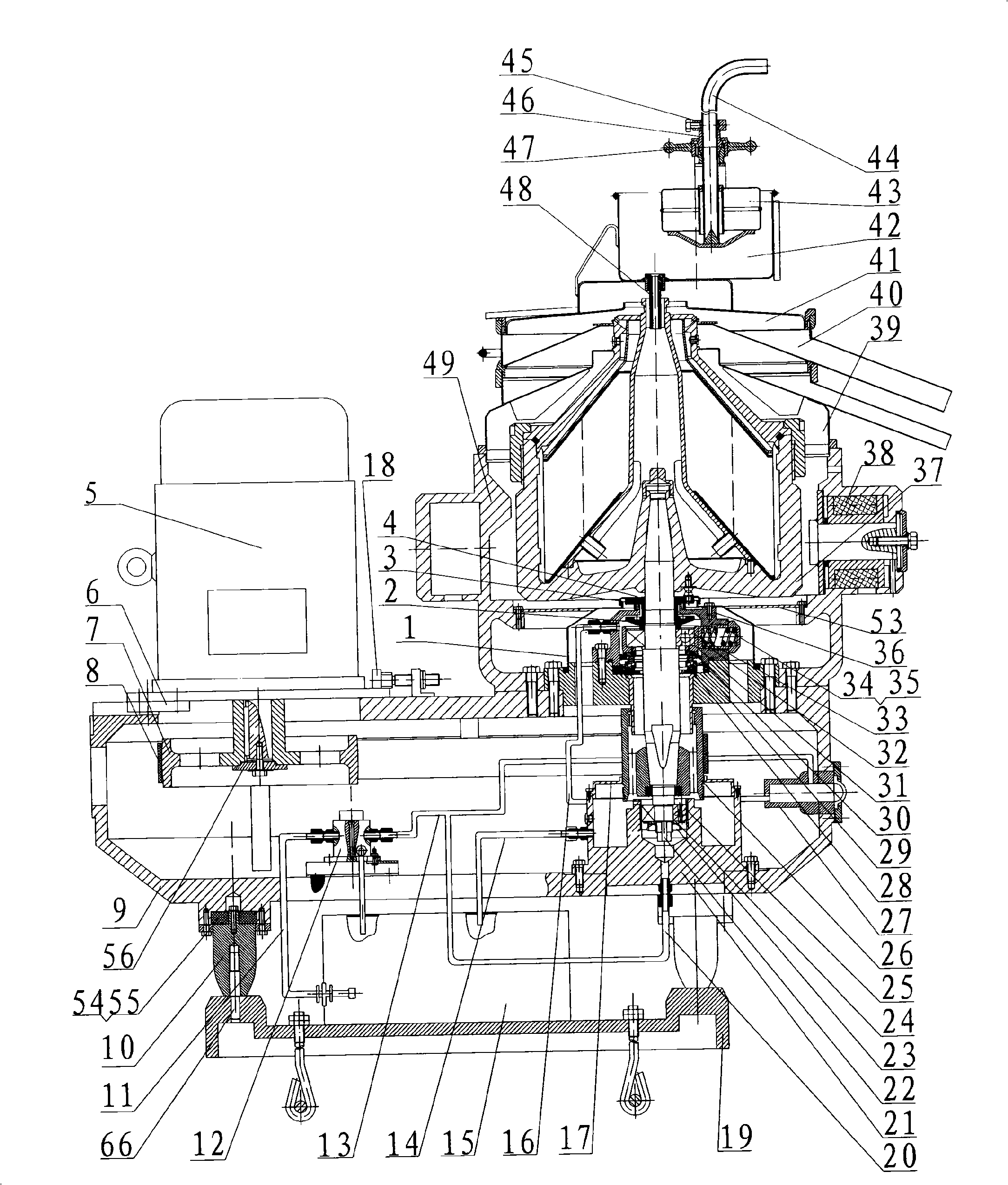

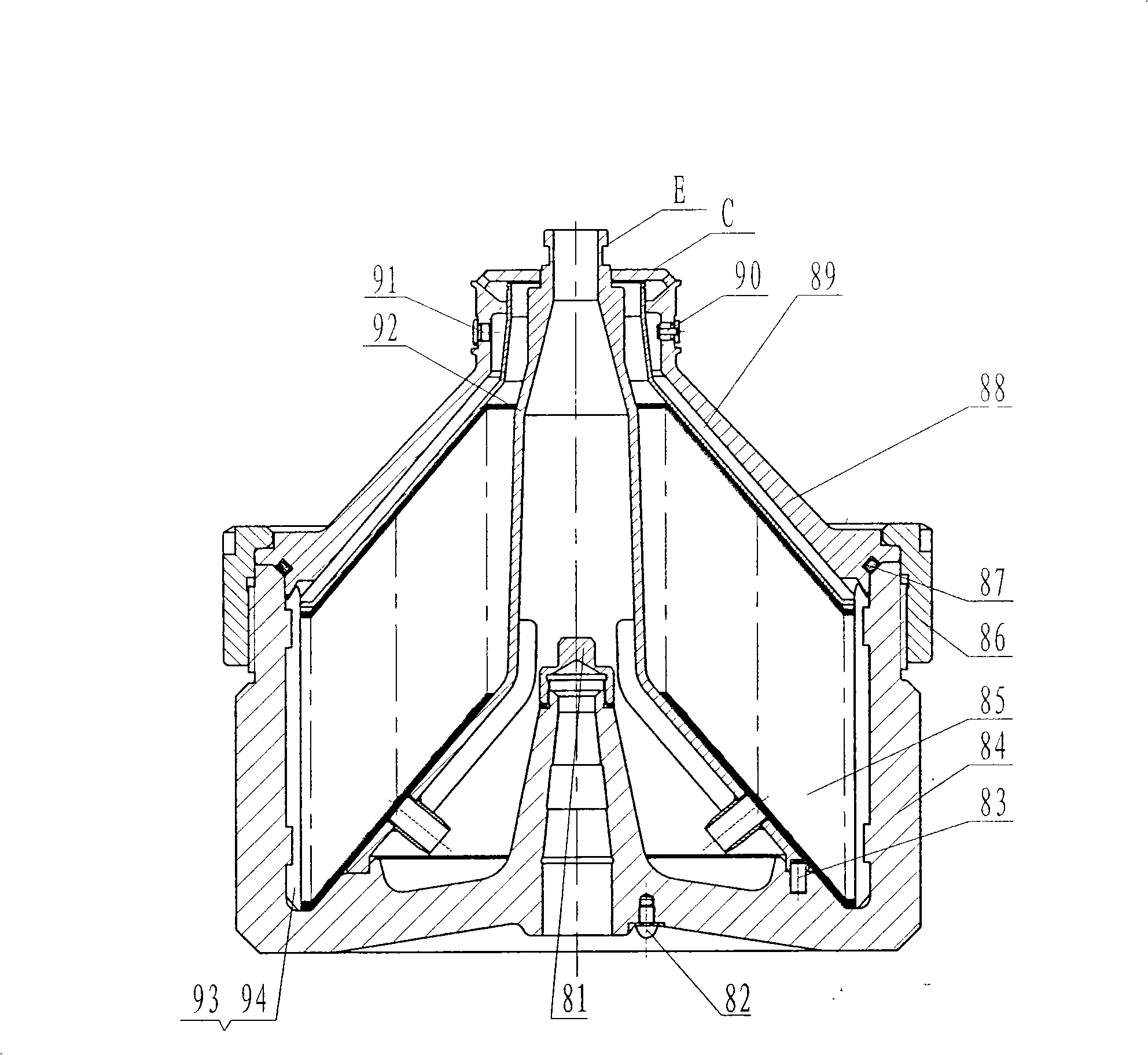

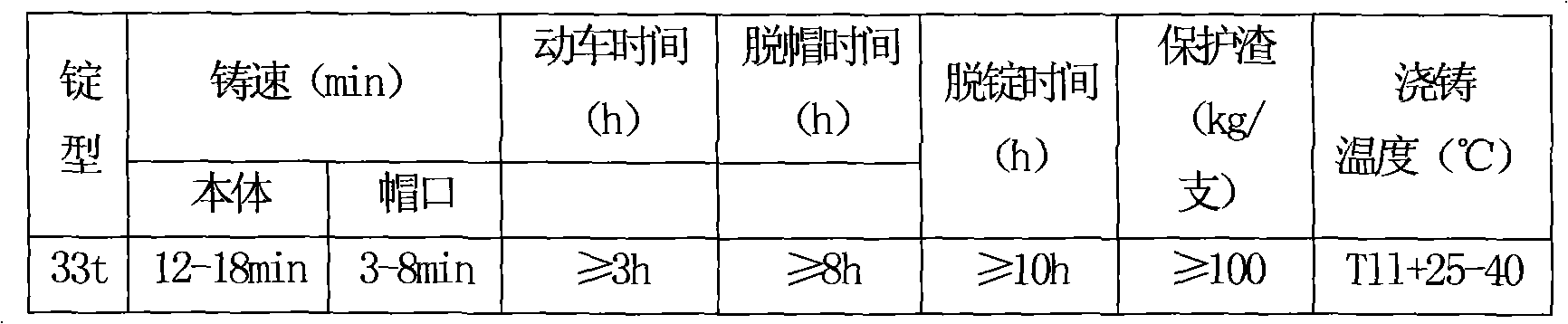

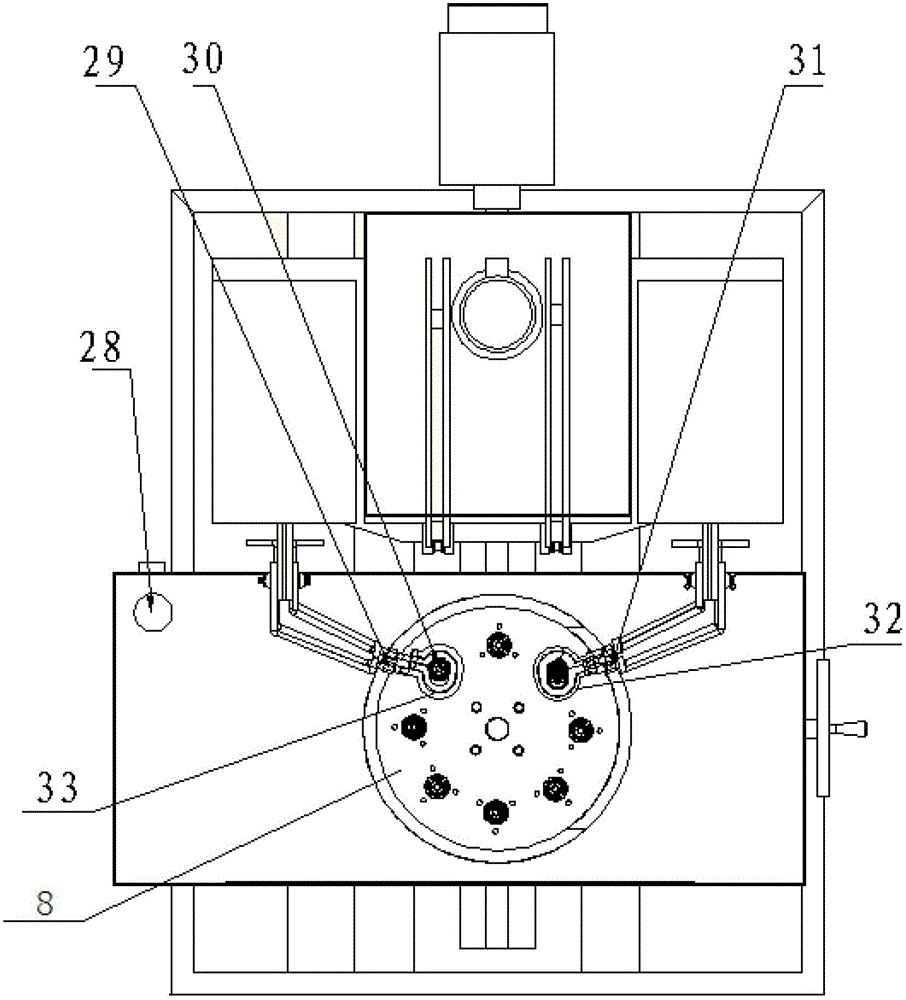

Flat belt driven dish type splitter

The present invention discloses a flat-belt driven disc separator, comprising a power part, a driving part, a lubrication system, a working part, a machine part and a control and assisting part. In addition to that the requirements of the function and performance of the separator is satisfied, the driving system is largely simplified, the driving path is brief, the quantity of driving components is largely reduced and the technical requirement of processing is lowered; regular replacement of expensive copper gear wheel, friction drum and other wearing parts is avoided, and as a result, the structure of the complete machine is simplified, the cost of production and use is reduced, the failure rate of the machine is lowered, and the technical performance of the complete machine is improved. The invention can be directly applied to condensing separation of natural rubber, and the invention can also be applied to separating other emulsions; the rotary-drum structure of the invention can overcome the disadvantages of the prior art; the continuous operation time is prolonged and the rotary-drum heating is alleviated; the strength, safety, reliability and maintenance technique are improved. The driving part and the lower machine body can form the driving of a manual slag-discharge separator, a gushing slag-discharge separator and a ring-valve slag-discharge separator and the lower machine body.

Owner:薛晓宁

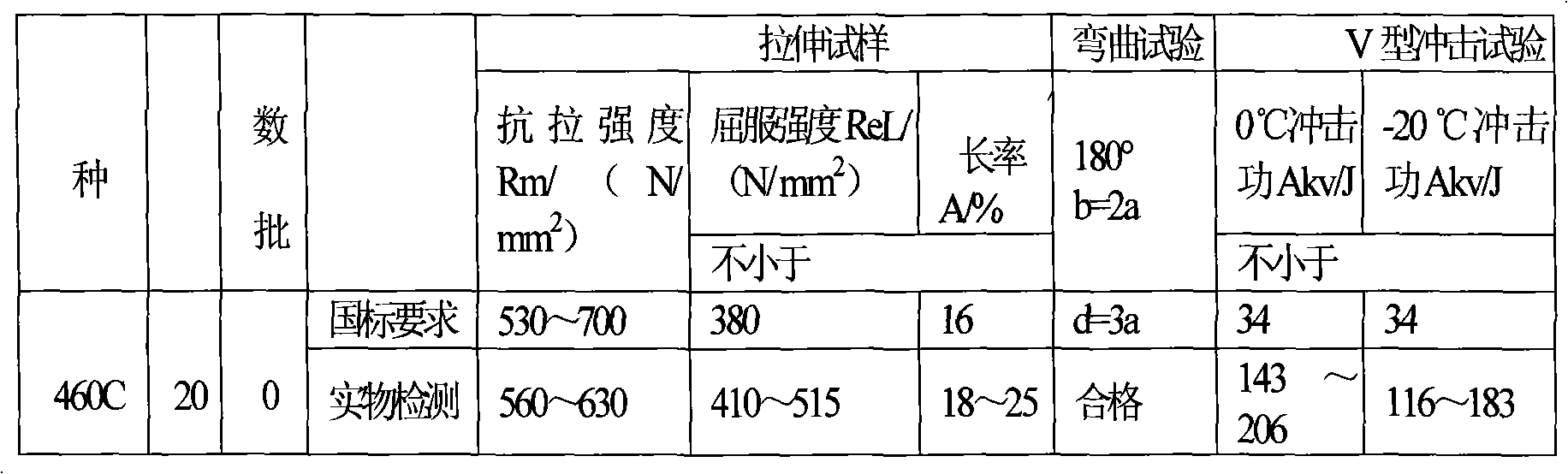

Low-alloy high-strength structural-steel extra-thick board Q460C and production method thereof

ActiveCN102041438AGuaranteed mechanical propertiesWarranty requirementsProcess efficiency improvementNational standardAlloy

The invention discloses a low-alloy high-strength structural-steel extra-thick board Q460C and a production method thereof, the extra-thick board comprises the following chemical constituents in percentage by weight (with wt% as a unit): C: not more than 0.20, Si: not more than 0.60, Mn: 1.40-1.60, P: not more than 0.020, S: not more than 0.005, microalloying elements (V+Nb+Ti+Ni): not more than 0.25, Als: not less than 0.015, and the balance of Fe and residual elements. The microalloying elements are selected reasonably, the elements V, Nb, Ti, and Ni are added in best match, and therefore, the double effects of precipitation strengthening and fine-grain strengthening are fully exerted to ensure that each performance index of a pressure vessel board can meet the requirement of national standard on 120mm under the premise of not reducing plasticity and toughness.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

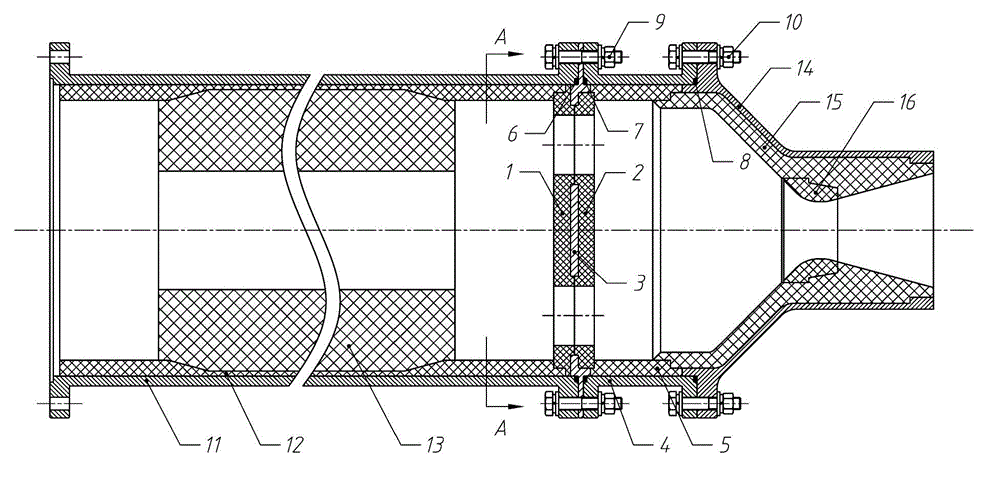

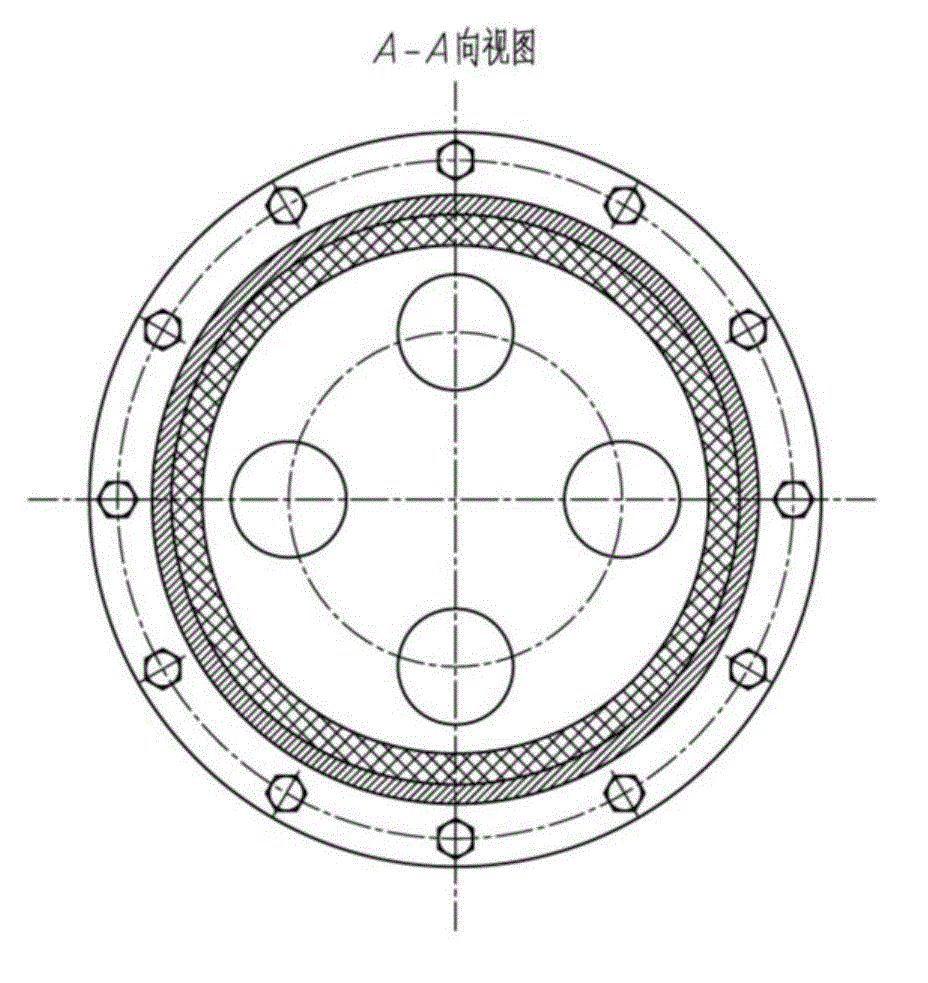

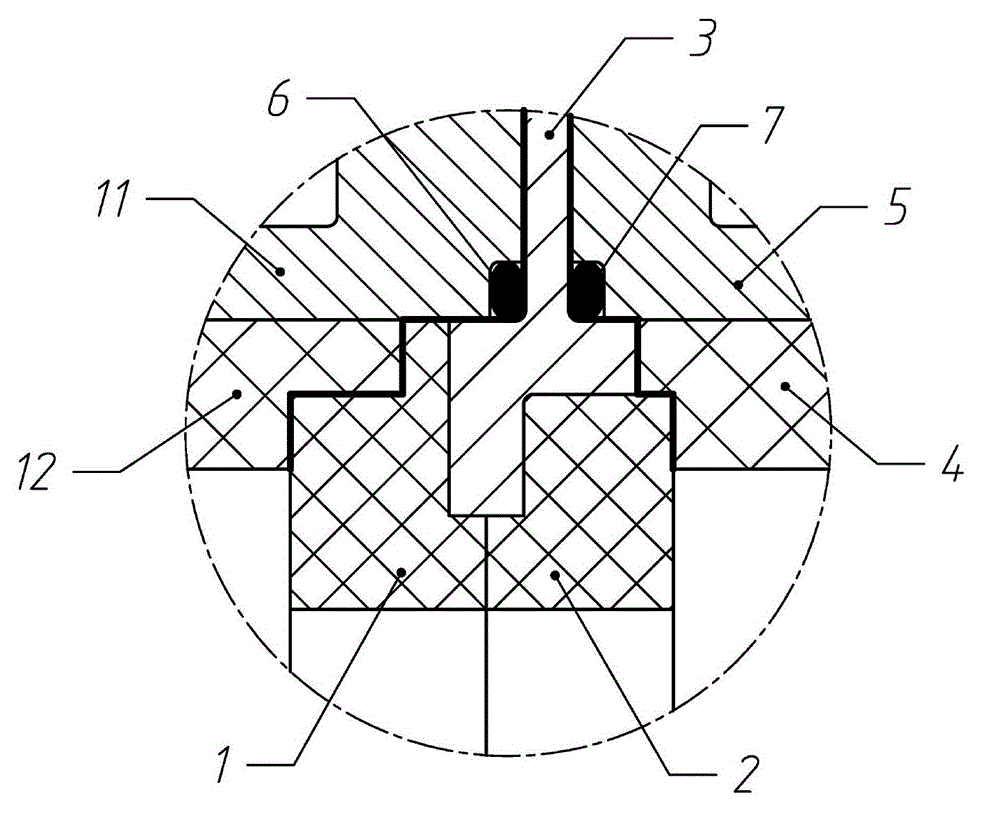

Turbulence device for postcombustion chamber of hybrid rocket engine

ActiveCN102943719ANo need to change charge designPlay structural strengthRocket engine plantsCombustion chamberAir tightness

The invention discloses a turbulence device for a postcombustion chamber of a hybrid rocket engine, which is suitable for ground heat run test of the hybrid rocket engine, is applied to a central single-channel hybrid rocket engine, but is not limited by specific propellant forms. The turbulence device comprises a combustion chamber component, a spoiler component, a spoiler postcombustion chamber component, a sealing and connecting component and a spray pipe component. The spoiler component and the spoiler postcombustion chamber component are combined into a whole so as to be connected with the spray pipe component through the sealing and connecting component and the spoiler postcombustion chamber component. The spoiler component consists of an internal metal spoiler and an external heat insulating structure, and spoiling holes are uniformly distributed in a circle taking the axis of the engine as the center. The spoiler component is used for realizing the turbulence function in gas in the central area, requirements on structural strength and thermal protection of the turbulence device can be satisfied during the working process of the engine, all the components are connected through a stepped fold line mode and O-shaped sealing ring connection, so that the requirements on airtightness and thermal protection are ensured during the working of the engine.

Owner:BEIHANG UNIV

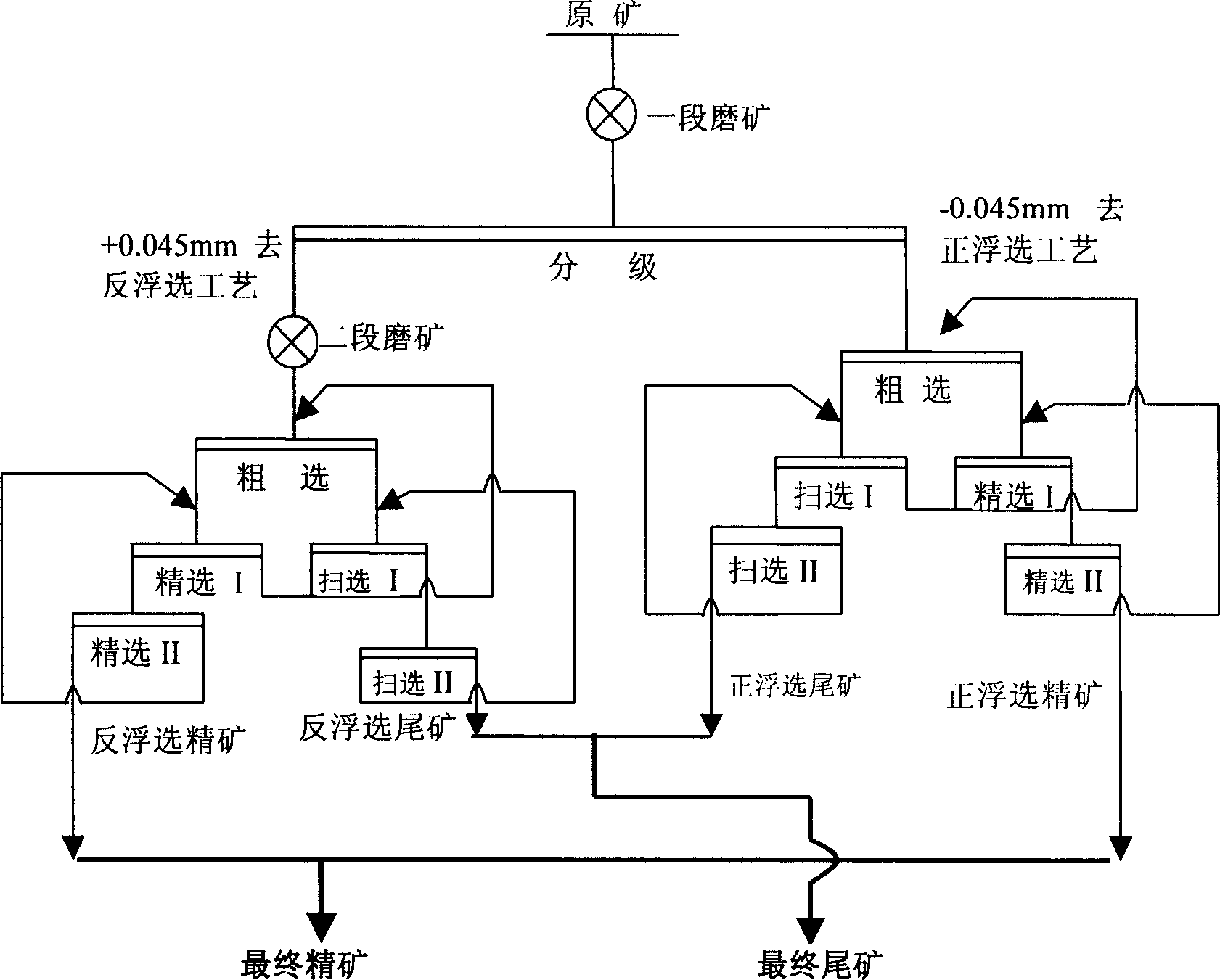

Parallel floatation process of desilionization for bauxite

InactiveCN1869258AEfficient separationIncrease production capacityFlotationProcess efficiency improvementEngineeringMaceral

The invention relates to a parallel floatation selecting method for bauxite desilication that adopts one section or two sections grinding technology to take classification to the bauxite pulp to gain raw and fine class product. The fine class product adopts positive floatation technology, and the raw class product adopts reverse floatation technology after taking or not taking second grinding. The positive floatation mine and the reverse floatation mine could be mixed to form final fine mine, and the positive floatation tail mine and the reverse floatation tail mine would be mixed to form final tail mine. The invention has great advantages and has wide application prospect.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

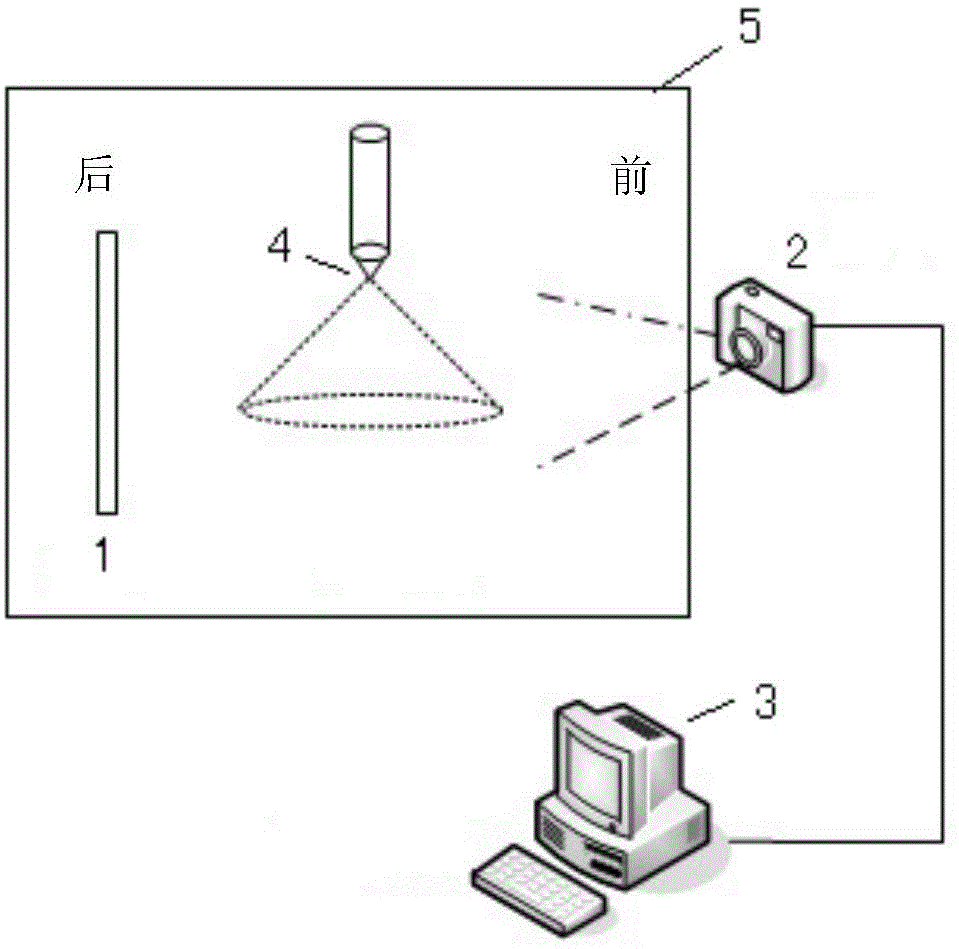

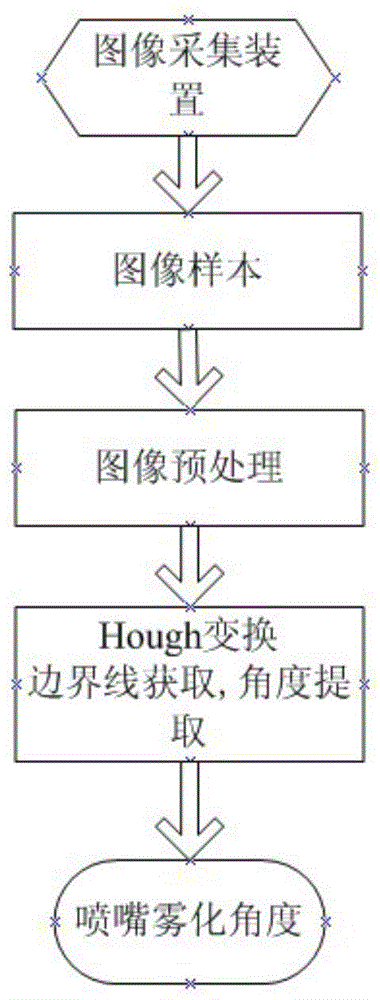

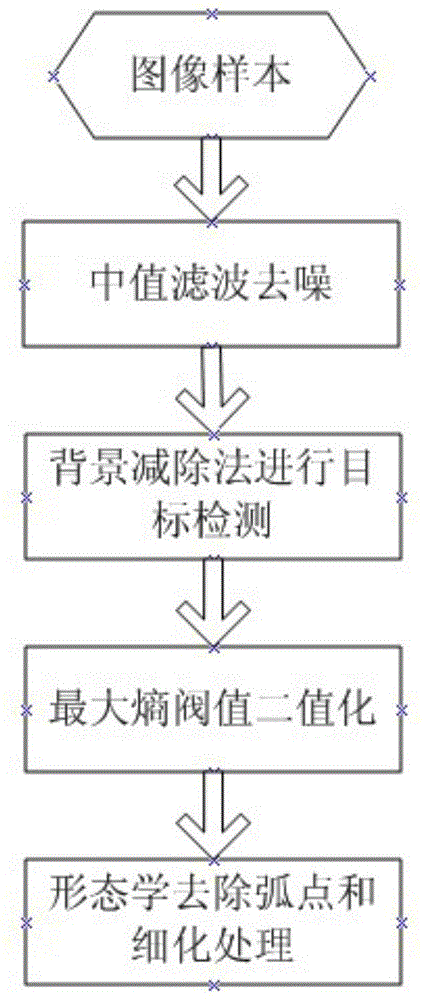

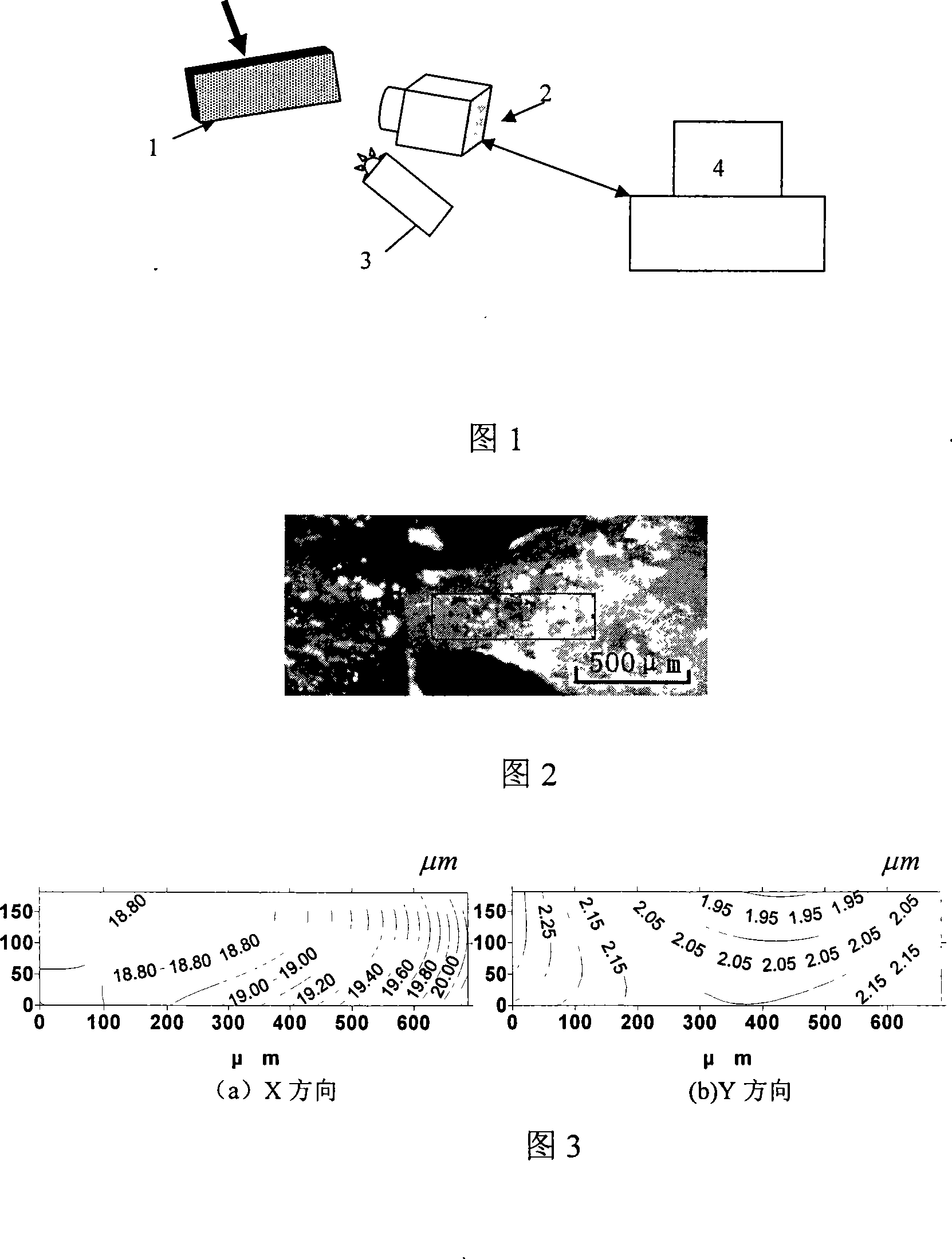

Vision-based automatic aviation oil mist nozzle atomization angle detection device and method

InactiveCN104634279AOpen up new fields of applicationAvoid randomnessUsing optical meansHough transformAviation

The invention relates to a vision-based automatic aviation oil mist nozzle atomization angle detection device. A light source is arranged inside a tank, and an industrial camera is arranged on the outer side of the tank, connected with an explosion-proof computer through an internal digital I / O (input / output) trigger interface card and used for shooting spray of the oil mist nozzle fixed in the tank. A detection method includes the following steps that the industrial camera shoots a digital image of a spray cone angle by receiving an external trigger signal and sends the digital image to the explosion-proof computer; the explosion-proof computer preprocesses the digital image to obtain a binary image; the binary image is subjected to Hough transform to obtain a boundary of degrees of the cone angle and the degrees of the cone angle. By the device and method, the problem about randomness of manual measurement of the aviation nozzle is solved, accuracy is improved, reliability in measurement is guaranteed, and automation level is heightened.

Owner:中国科学院沈阳计算技术研究所有限公司

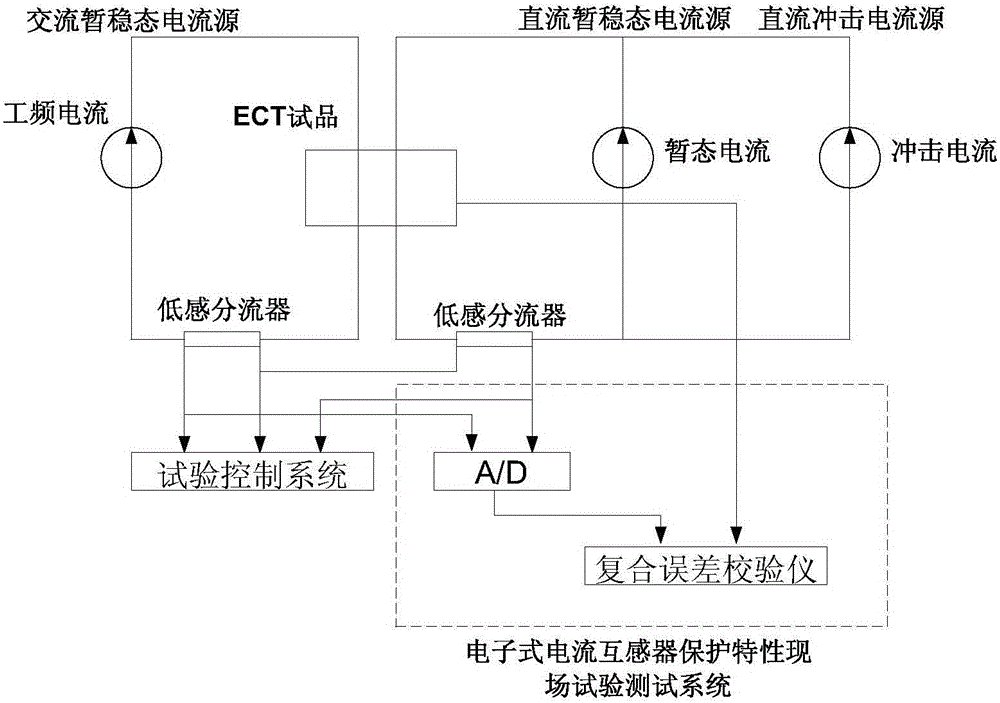

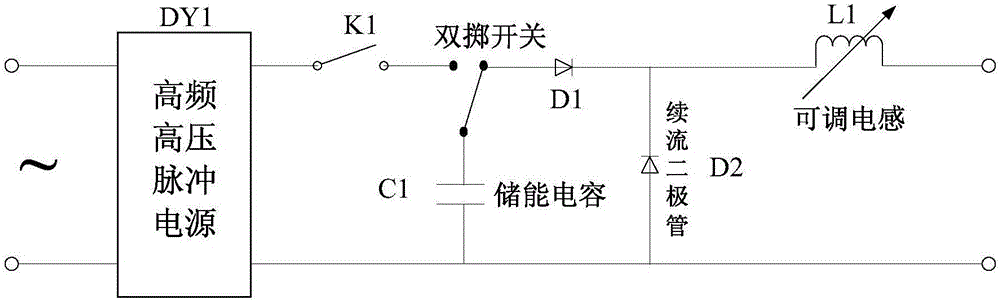

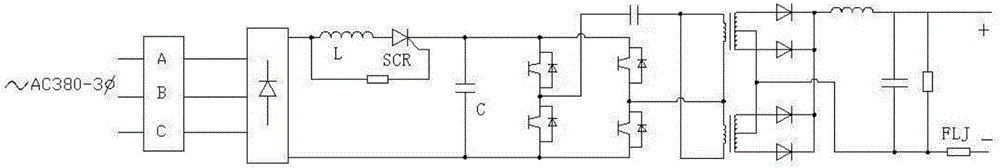

Alternating current/direct current transient steady state integrated detection device

ActiveCN105676161AEasy to controlAccurate adjustment effectElectrical measurementsTest powerCapacitance

The invention discloses an alternating current / direct current transient steady state integrated detection device. The alternating current / direct current transient steady state integrated detection device includes an alternating current / direct current transient steady state integrated test power source and an electronic type current transformer field test detection system; the alternating current / direct current transient steady state integrated test power source includes a direct-current impact power source, a direct-current transient steady state power source, an alternating current power frequency transient steady state power source and a combined loop control system; and the electronic type current transformer field test detection system includes a standard transformer, a standard conversion device and a transformer composite error tester. With the detection device adopted, transient steady state integrated tests of a direct current transformer and an alternating current transformer can be realized separately. With a method according to which a combined test loop composed of the direct-current impact power source, the transient steady state test power source and the alternating current transient steady state test power source is adopted, the capacity of an energy-storage capacitor in a direct-current impact / transient steady state test can be obviously decreased, and important parameters such as a transient current peak value, a decay time constant and step current response can be adjusted and configured more flexibly and accurately.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +1

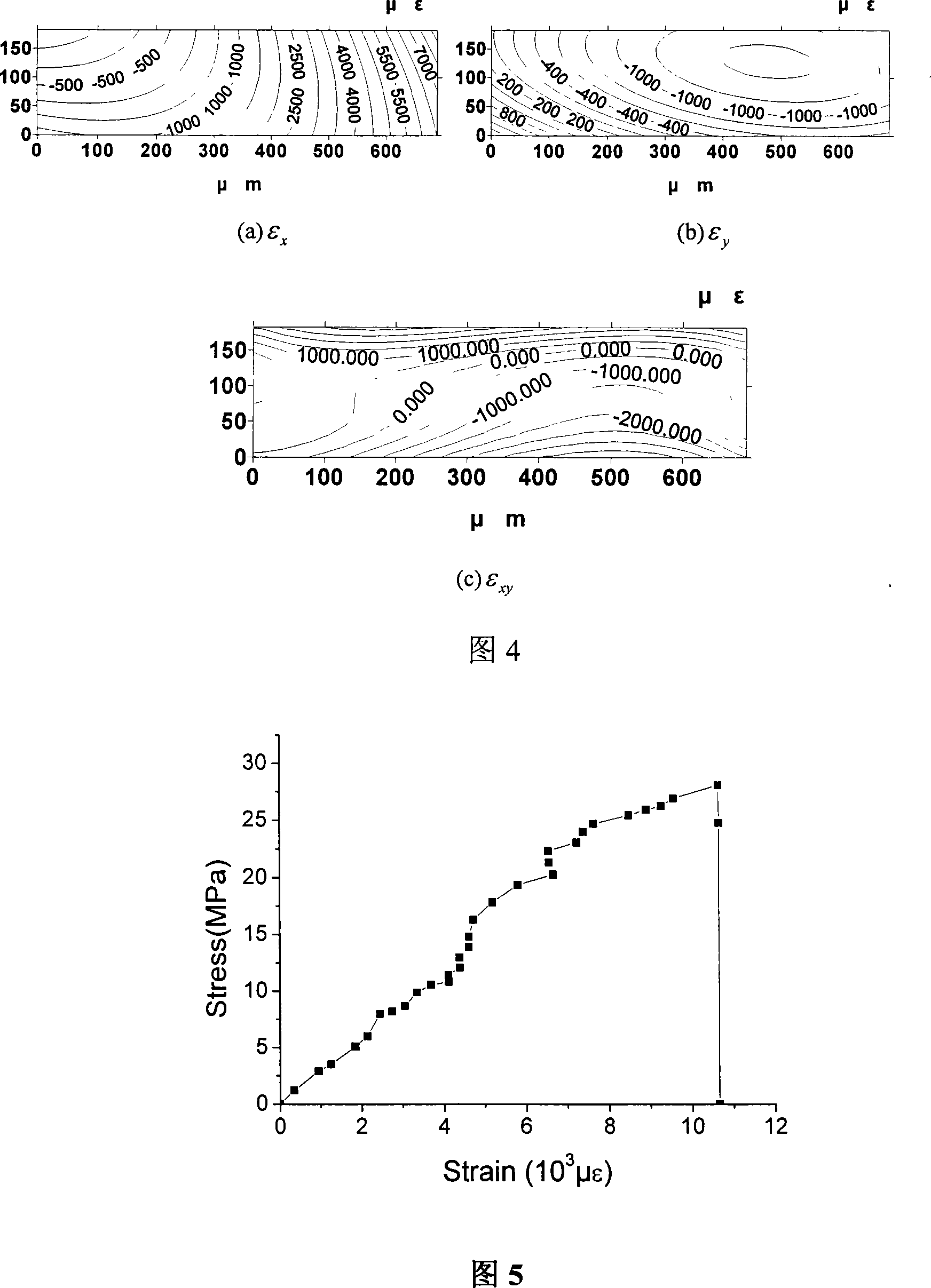

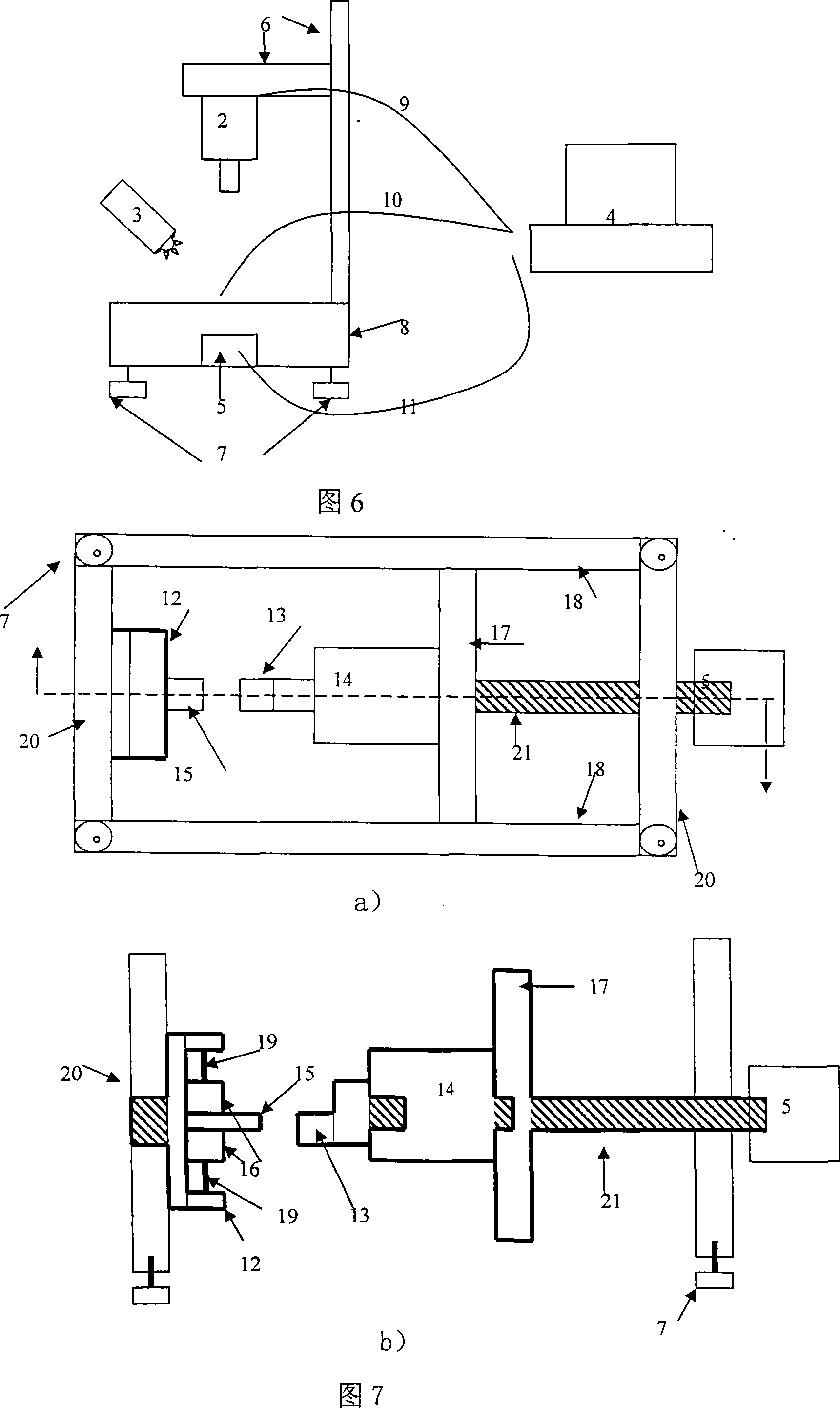

Extract and mechanical properties measurement method of bone trabecula and measurement mechanism

InactiveCN101158679AAvoid damageSubsequent measurement results are authentic and reliableUsing mechanical meansMaterial analysisMeasurement deviceBiomechanics

The invention relates to an extracting of a bone trabecula and a test method and a device of mechanical property, which belongs to the biological mechanics experiment technical field. The method comprises: 1. the bone is cut into a plurality of small blocks at the length of the bone trabecula; 2. the marrow in the middle of each small spongy bone block is rejected clearly and the spongy bone structure is only left; 3. a small spongy bone block which has an intact bone trabecula is chosen and the bone trabecula around the intact bone trabecula is cut away; 4. the bone trabecula is stretched and compressed at the direction paralleled with a loading force, and the two ends of the bone trabecula are fixed; 5. the CCD camera is aimed to the bone trabecula so as to lead the picture of the bone trabecula in the CCD to be clear; 6. the displacement of the stretching or compressing of the bone trabecula is controlled; 7. the picture and the load of the bone trabecula in each time quantum are recorded synchronously; 8. the displacement field and the strain field of each load is worked out according to DSCM; namely the poisson ratio of the material and the strain curve of the strain of the bone trabecula can be obtained. The invention can minimize the damage greatly, and lead a plurality of mechanical property parameters to be more correct.

Owner:TSINGHUA UNIV

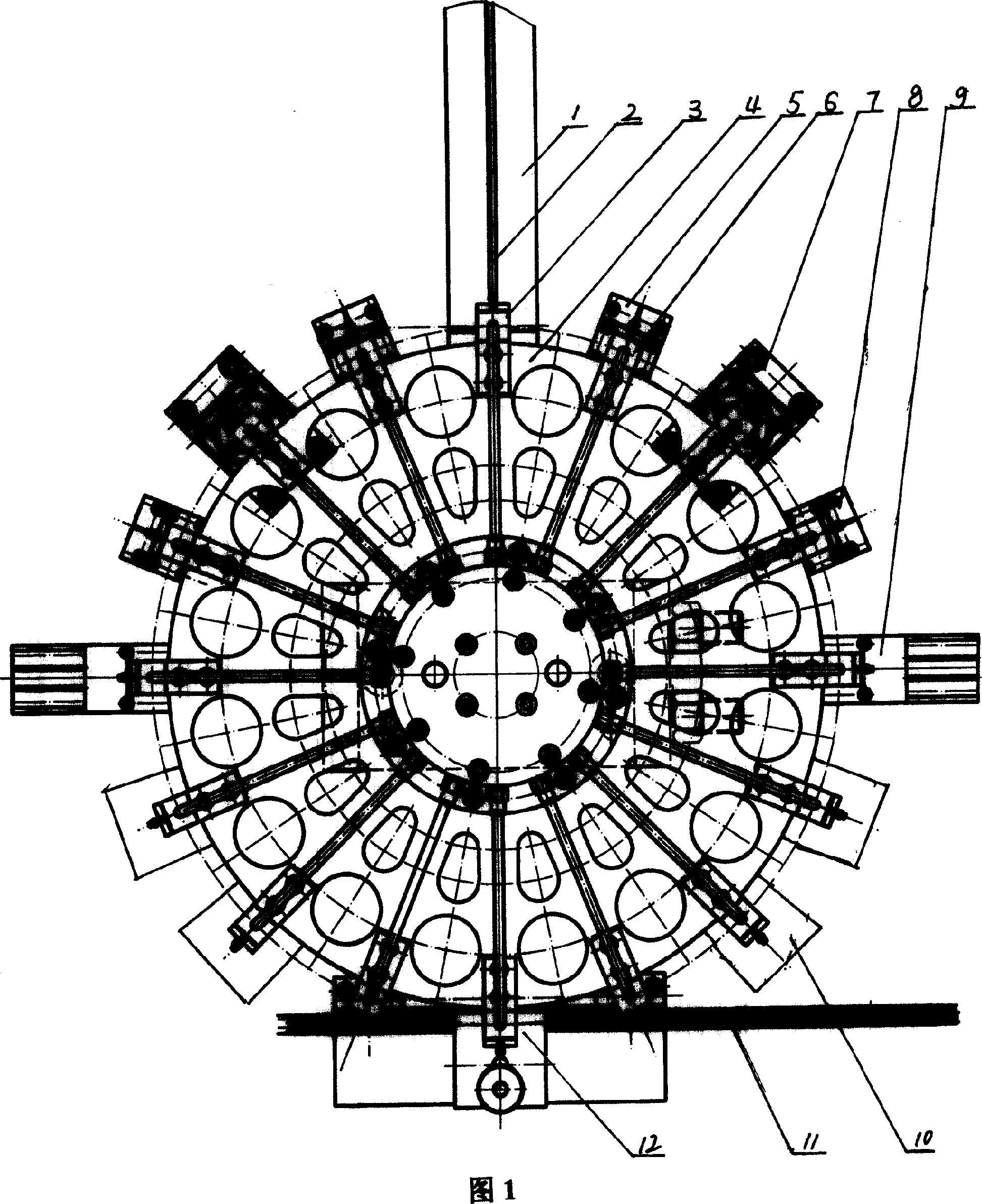

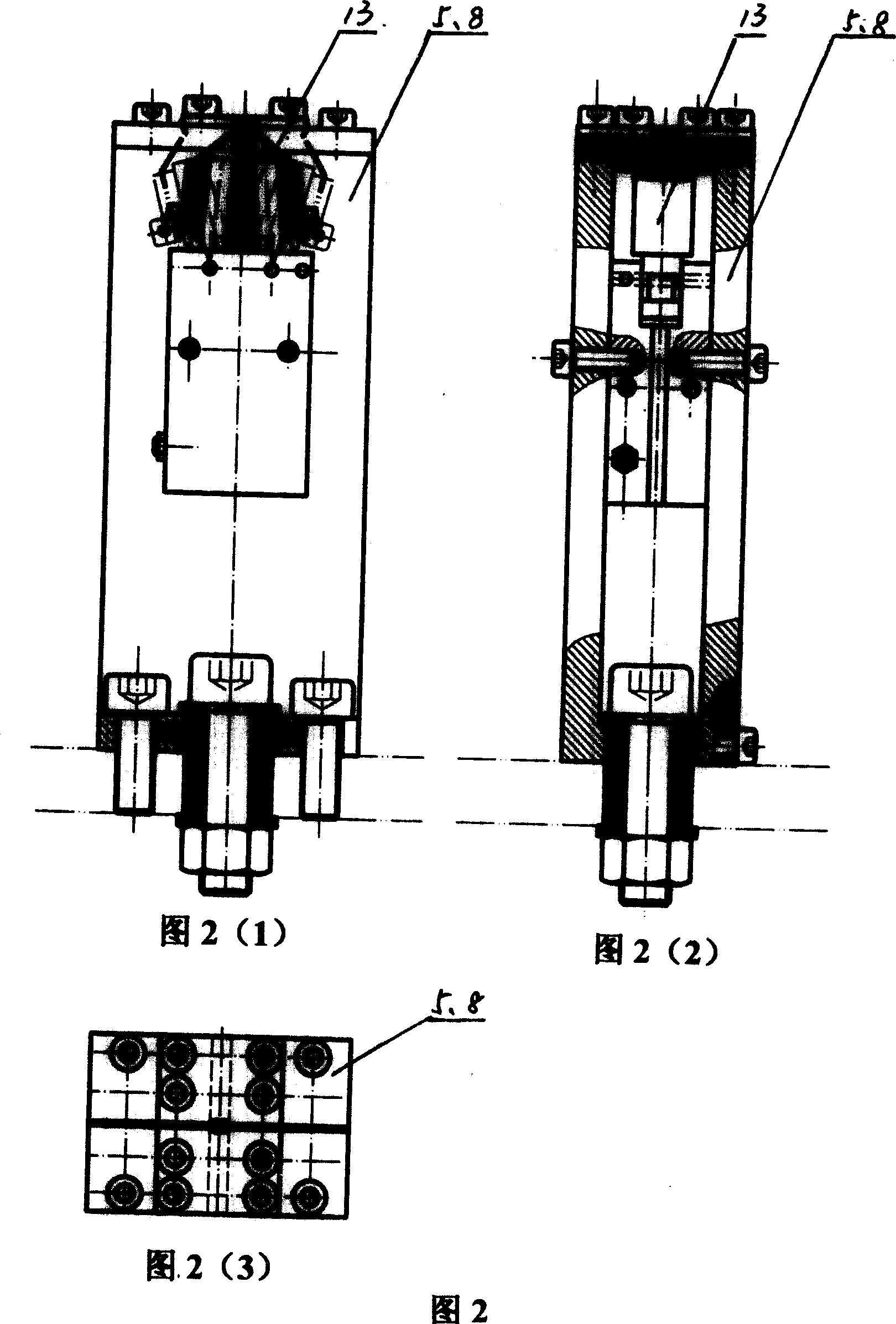

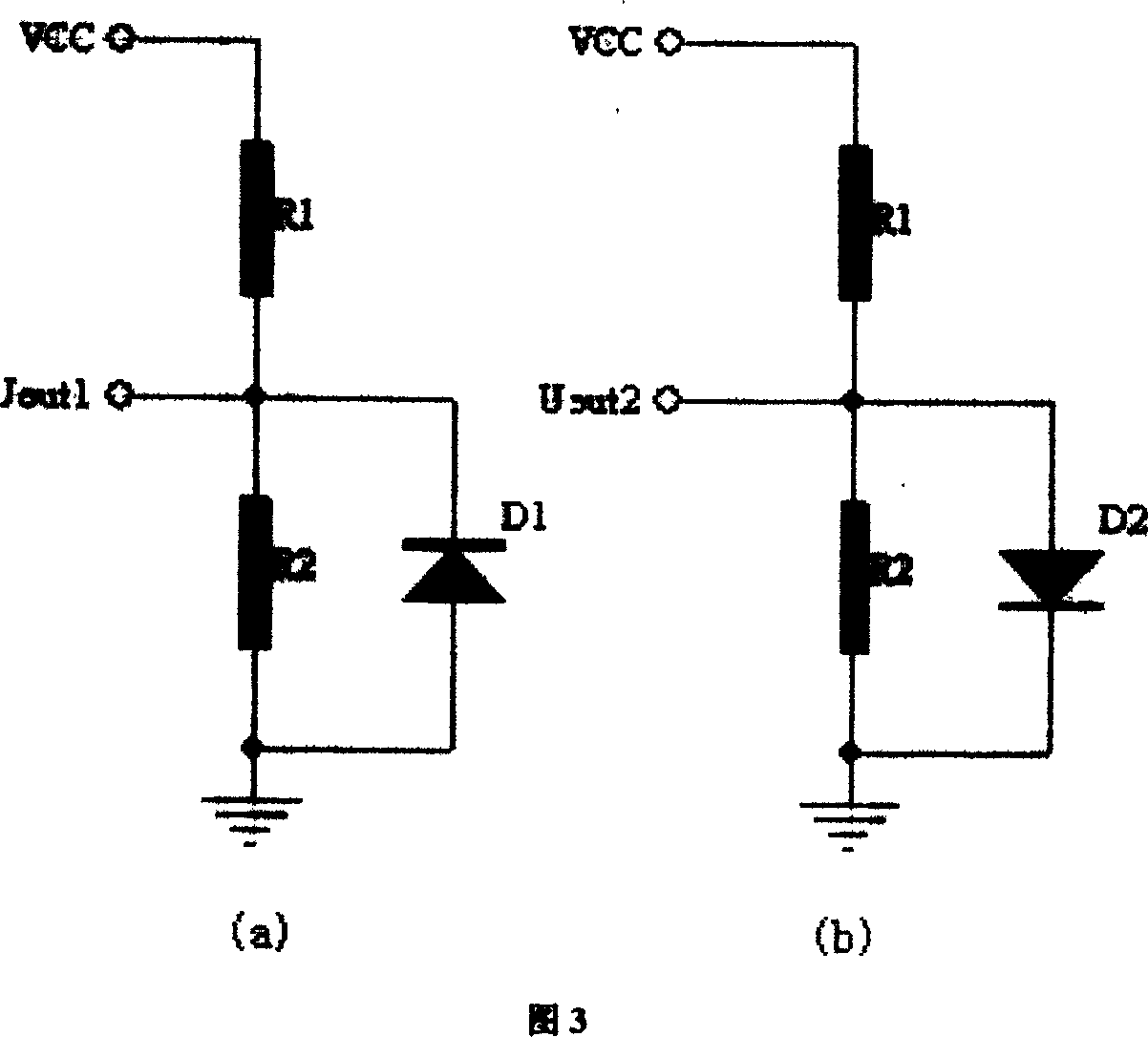

Polarity finder of electronic device of automatic braiding machine and testing method thereof

InactiveCN1952672AAchieve discardQuality assuranceElectrical testingPackagingElectrical polarityEngineering

The invention belongs to an electronic device polarity supervisory instrument and testing method of automatic braider. It characterized in that several vacuum suction nozzles are equispaced in circumference of swash plate, and divided into two groups to realize the shifting that a component is transferred from one station to the next station. The detecting station, component rotating station, quadratic detecting station of the component and component abandoning station are set symmetrically under the vacuum suction nozzles to realize the polarity detecting, polarity adjusting, quadratic polarity detecting and the abandoning of components in course of shifting that a component is transferred from one station to the next station. The whole apparatus is simple and compact, can realize synchronously the detecting in course of shifting of components, the efficiency of work is improved and the cost is decreased. The apparatus has the function of self-centering.

Owner:TIANJIN UNIV OF SCI & TECH

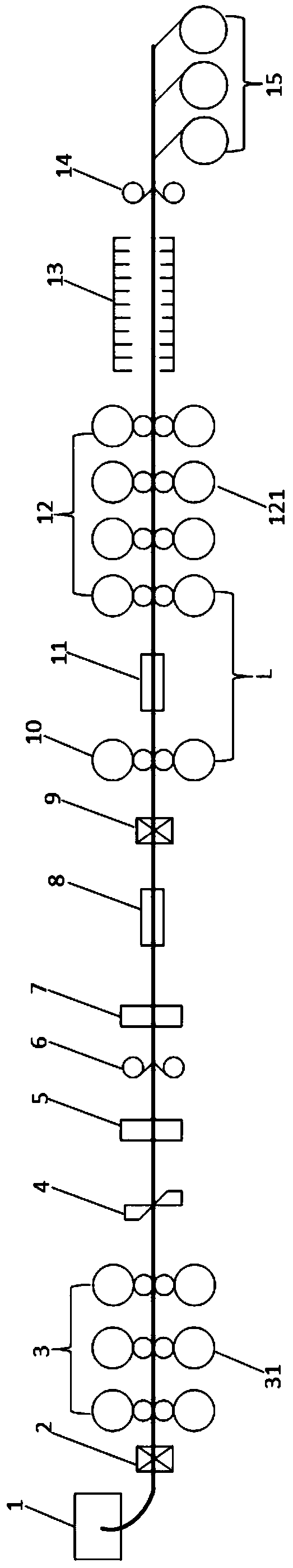

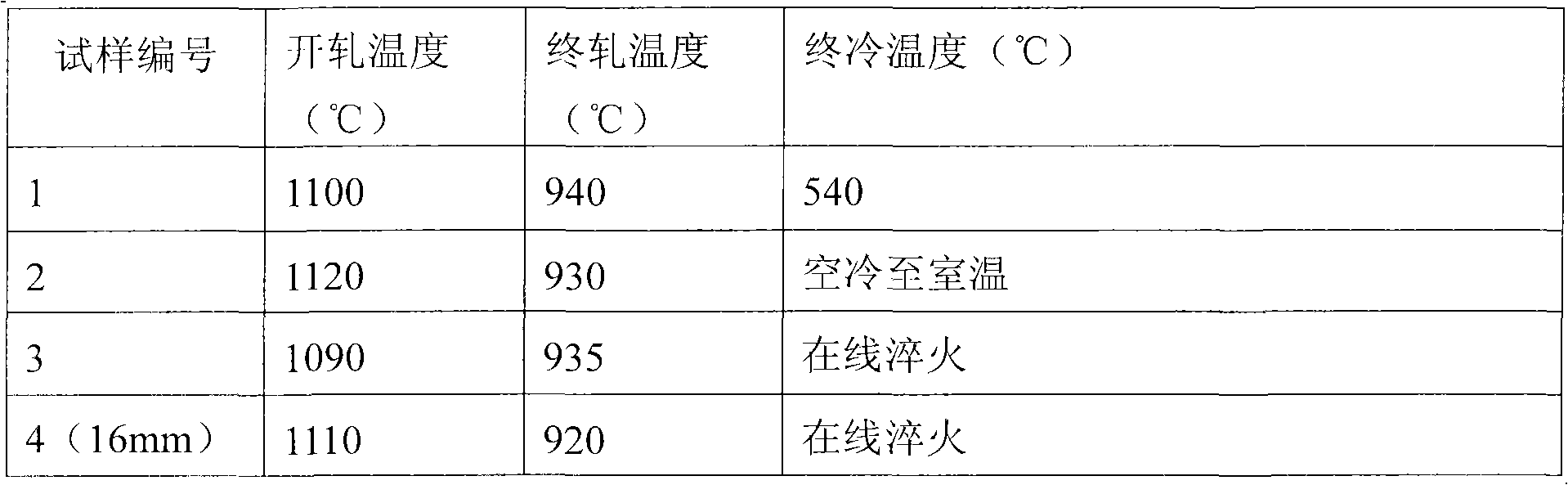

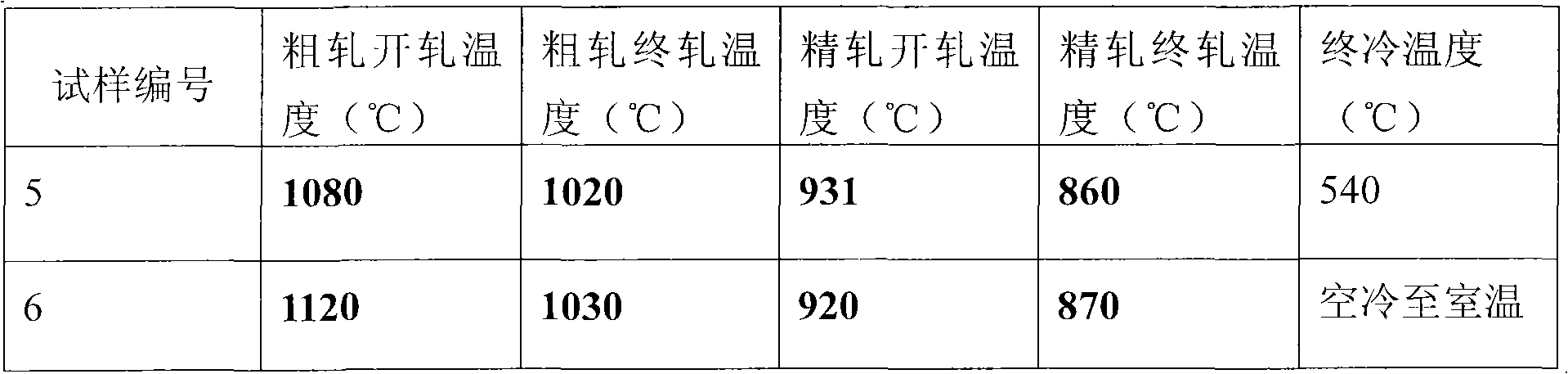

Low-carbon steel continuous casting and rolling production line and production technology thereof

PendingCN108526221AMeet the temperatureFulfil requirementsMetal rolling arrangementsSlab casterHigh pressure water

The invention discloses a low-carbon steel continuous casting and rolling production line and a production technology thereof. The low-carbon steel continuous casting and rolling production line and the production technology thereof are applied to the technical field of steel rolling. The production line comprises a slab continuous casting machine, a high-pressure water rough descaling device, a roughing rolling unit, a swing shear, a pushing-out and sheet stacking device, a rotating drum flying shear, a waste material removal device, an induction heating furnace, a high-pressure water fine descaling device, a middle rolling rack, a middle water cooling device, a finishing rolling unit, a laminar flow cooling device, a high-speed flying shear and a recoiling machine. The finishing rollingunit comprises four finishing rolling racks. The distance L between the middle rolling rack and the centre line of the first finishing rolling rack ranges from 10 m to 20 m. According to the low-carbon steel continuous casting and rolling production line and the production technology thereof, by means of reasonable production line arrangement and the proper production technology, the low-temperature rolling and high-temperature recoiling requirements for ferrite rolling are guaranteed; the sufficient finishing rolling total reduction rate is guaranteed; complete transforming, from austenite toferrite, of strip steel before being subjected to finishing rolling is completed; the finishing rolling is conducted in a ferrite zone, and thus real-sense ferrite rolling conducted through the continuous casting and rolling production line is achieved.

Owner:CISDI RES & DEV CO LTD

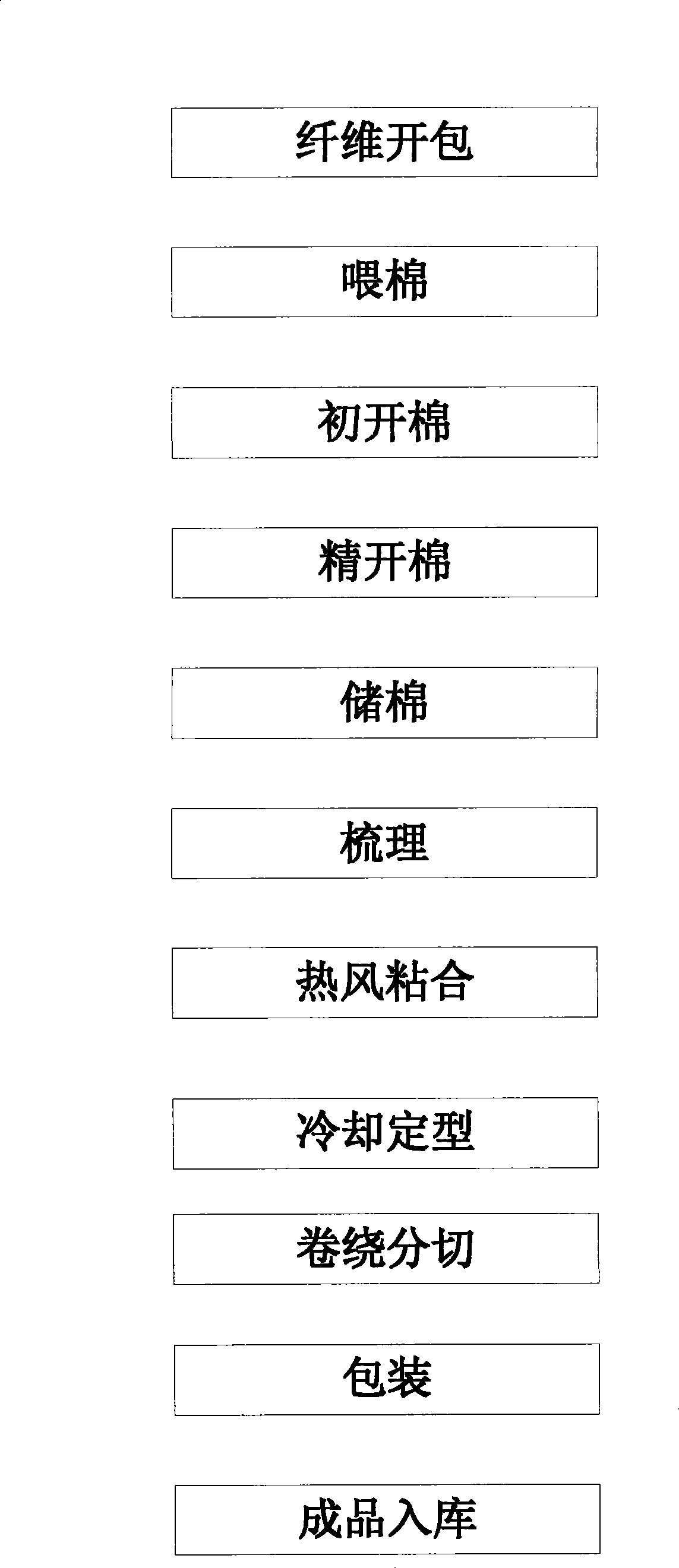

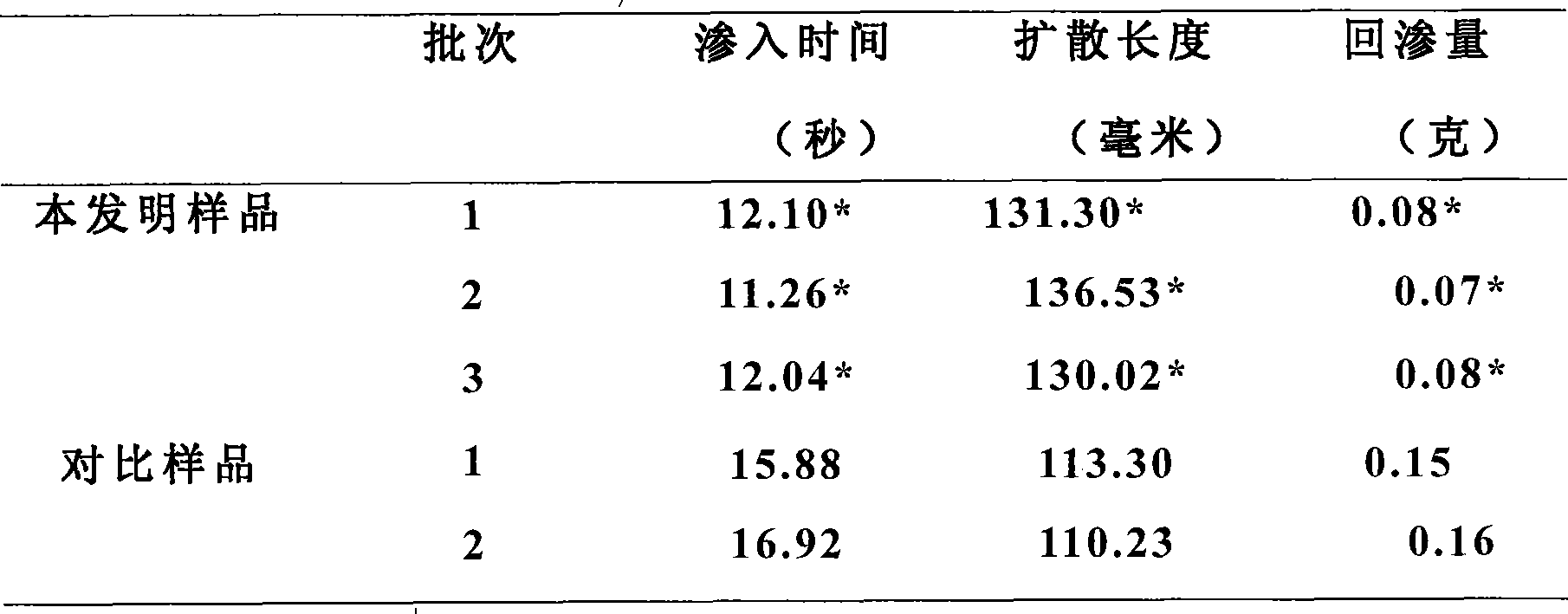

Nonwoven fabric containing polyester complex fiber, preparation thereof and use as hydroscopic substance flow guiding layer

InactiveCN101481852AGood flexibilityLow melting pointFilament/thread formingAbsorbent padsPolyesterPolymer science

The invention discloses a nonwoven fabric. The nonwoven fabric is characterized by comprising a polyethylene / polyester complex fiber material and a polyethylene / polypropylene complex fiber material, wherein, the polyethylene / polyester complex fiber material is 1-100% of the nonwoven fabric of a diversion layer, and the polyethylene / polypropylene complex fiber material is 0-99% of the nonwoven fabric of the diversion layer. The nonwoven fabric has the advantages of good diversion effect, excellent reverse osmosis effect, as well as good bulkiness and softness.

Owner:SUZHOU KIMBONDLY NONWOVENS FABRIC

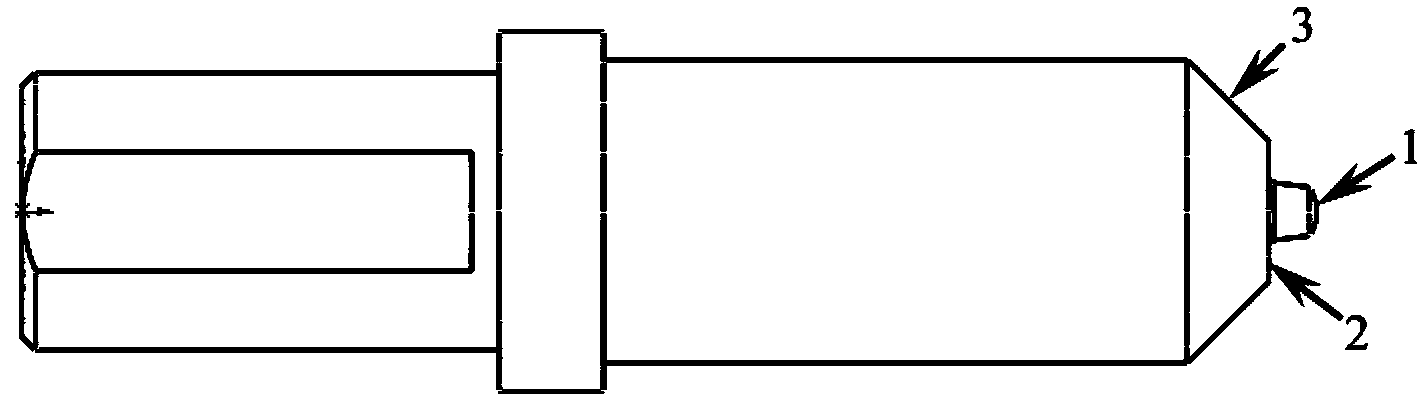

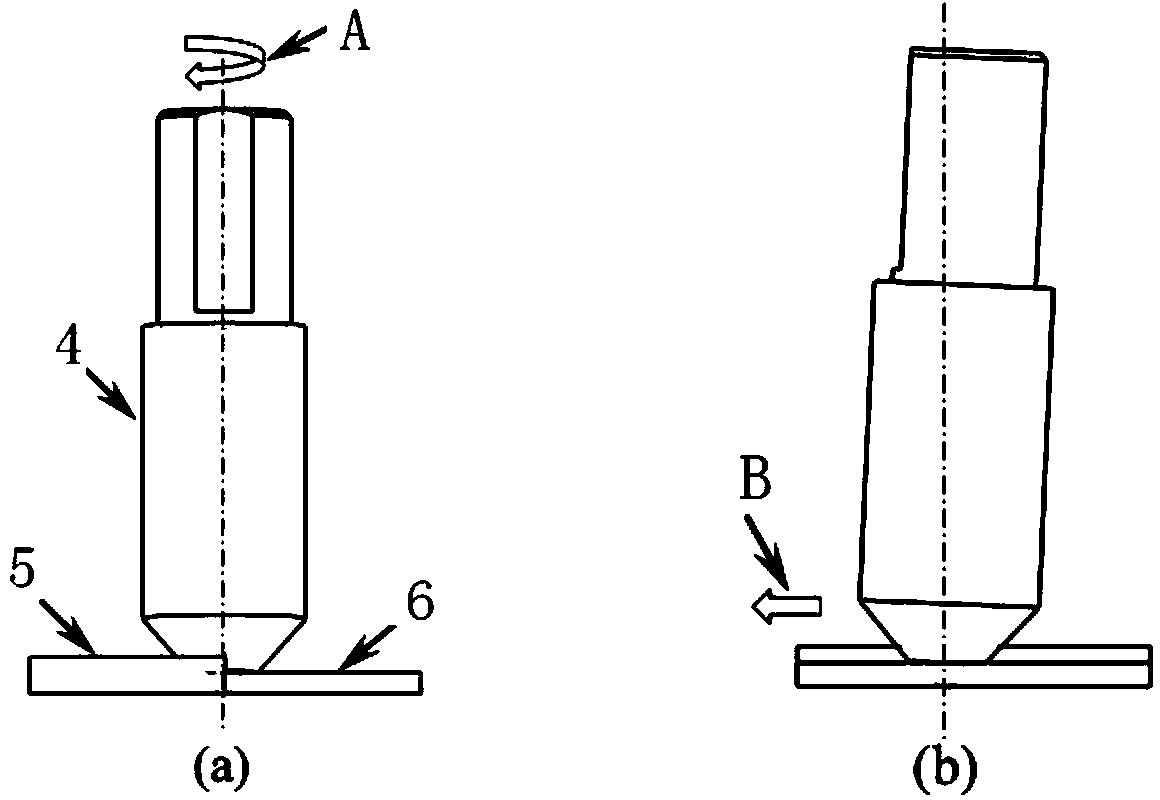

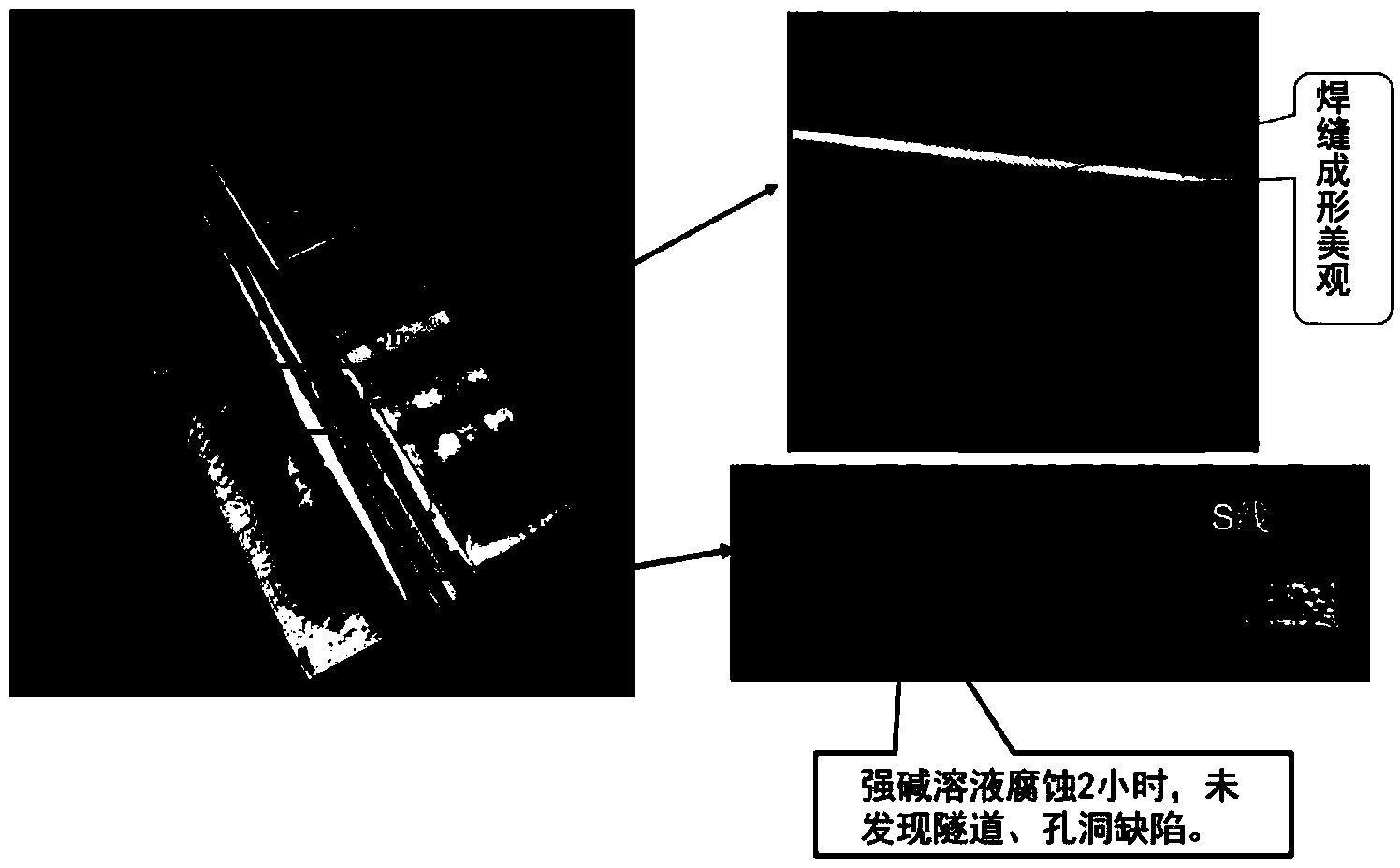

Stirring head for friction stir welding used for welding parts with different thicknesses and welding method

InactiveCN103949769AIntegrity guaranteedGuaranteed reliabilityWelding/soldering/cutting articlesMetal working apparatusEngineeringFriction stud welding

The invention relates to a stirring head for friction stir welding used for welding parts with different thicknesses and a welding method. A cutting accessory shaft shoulder is added on the basis of the existing stirring head, and the accessory shaft shoulder plays a role in cutting and removing the redundant material on the thicker side of connectors having different thicknesses to acquire a flat friction stir welding joint. The method is carried out on common friction stir welding equipment, a nose or tool of the equipment is not transformed at all, then the requirements on the equipment and the welding method are greatly simplified; in addition, in the welding process, a shaft shoulder of the stirring head and the two side surfaces of the part are parallel, so that the phenomena that metal of the connector is insufficiently extruded or damaged by shearing are not caused, the integrity and the reliability of the part are guaranteed; moreover, the accessory cutting shaft shoulder of the stirring head also plays an important role as for the part whose thickness suddenly changes, and the smooth welding process of the part is guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for manufacturing low-cost super-high intensity steel plate with yield strength of over 960 MPa for wide process operation window

ActiveCN101935810ALow costGuaranteed to dissolveTemperature control deviceHeat treatment process controlMetallurgyHigh intensity

The invention relates to a super-high intensity steel plate with yield strength of over 960 MPa. The steel plate comprises the following chemical constituents in percentage by weight: 0.12 to 0.14 percent of C, 0.3 to 0.4 percent of Si, 1.45 to 1.6 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.002 percent of S, 0.02 to 0.04 percent of Al, 0.38 to 0.42 percent of Cr, 0.28 to 0.32 percent of Ni, 0.35 to 0.41 percent of Cu, 0.35 to 0.45 percent of Mo, 0.015 to 0.025 percent of Ti, 0.02 to 0.03 percent of Nb, 0.0012 to 0.002 percent of B, less than or equal to 0.004 percent of N, less than or equal to 0.002 percent of O and the balance of iron and inevitable impurities. Production methods include conventional rolling and thermo-mechanical control process (TMCP) rolling.

Owner:SHANDONG IRON & STEEL CO LTD +1

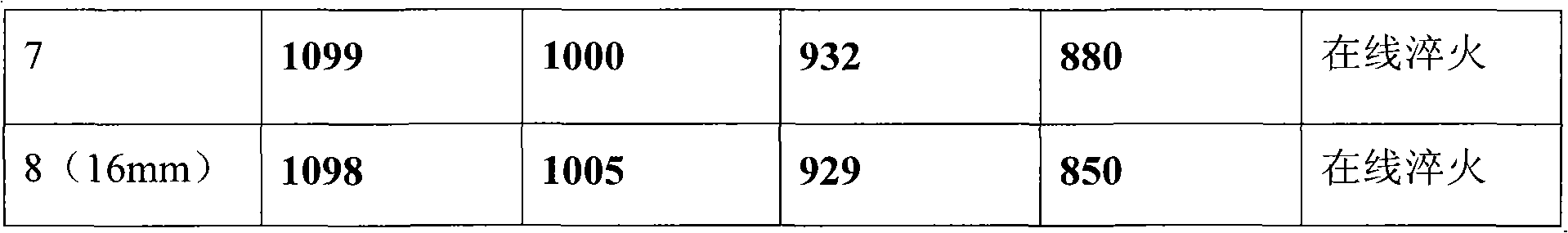

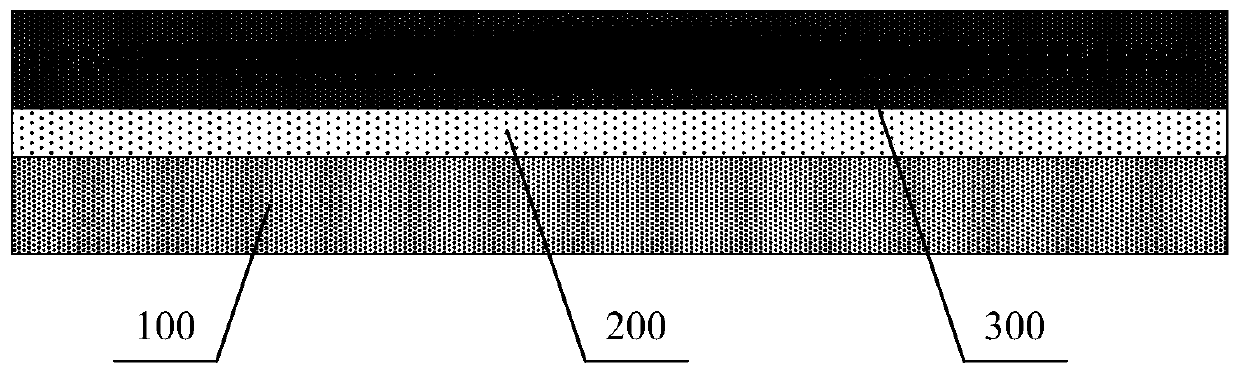

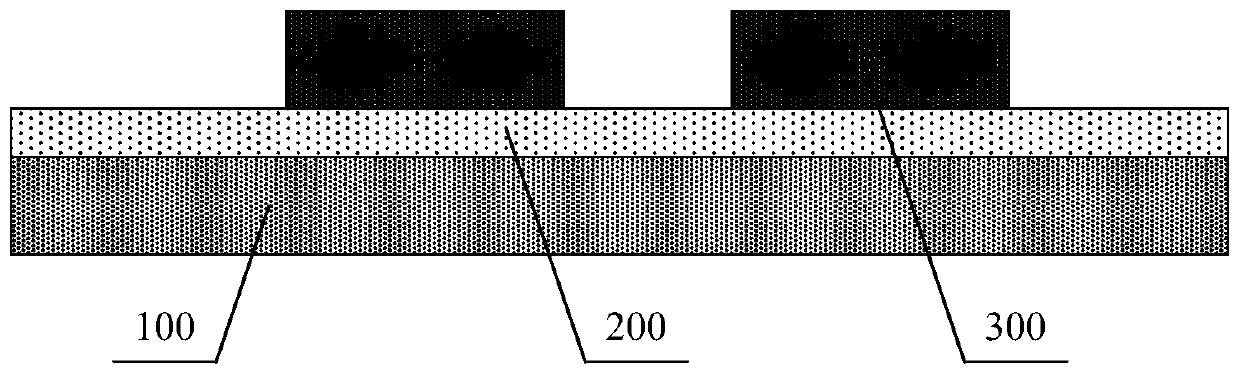

Display substrate and preparation method thereof and display device

ActiveCN110610975AControl gapGuaranteed flatnessSolid-state devicesSemiconductor devicesDisplay deviceEvaporation

The invention provides a display substrate and a preparation method thereof and a display device. The display substrate comprises a micro-cavity structure layer and a light-emitting structure layer which are arranged in a stacked mode. A reflection electrode is arranged in the micro-cavity structure layer. A groove is formed in the surface of the micro-cavity structure layer. The light-emitting structure layer comprises a first electrode arranged in the groove, and the first electrode is connected with the reflection electrode. According to the invention, because the groove is formed in the micro-cavity structure layer and the first electrode of the light-emitting structure layer is arranged in the groove, the offset between the first electrode and the micro-cavity structure layer is controlled, the problem that a cathode and an anode are short-circuited in the preparation process of an existing silicon-based OLED micro-display is solved, and the surface flatness and uniformity requirements of subsequent evaporation are met.

Owner:BOE TECH GRP CO LTD

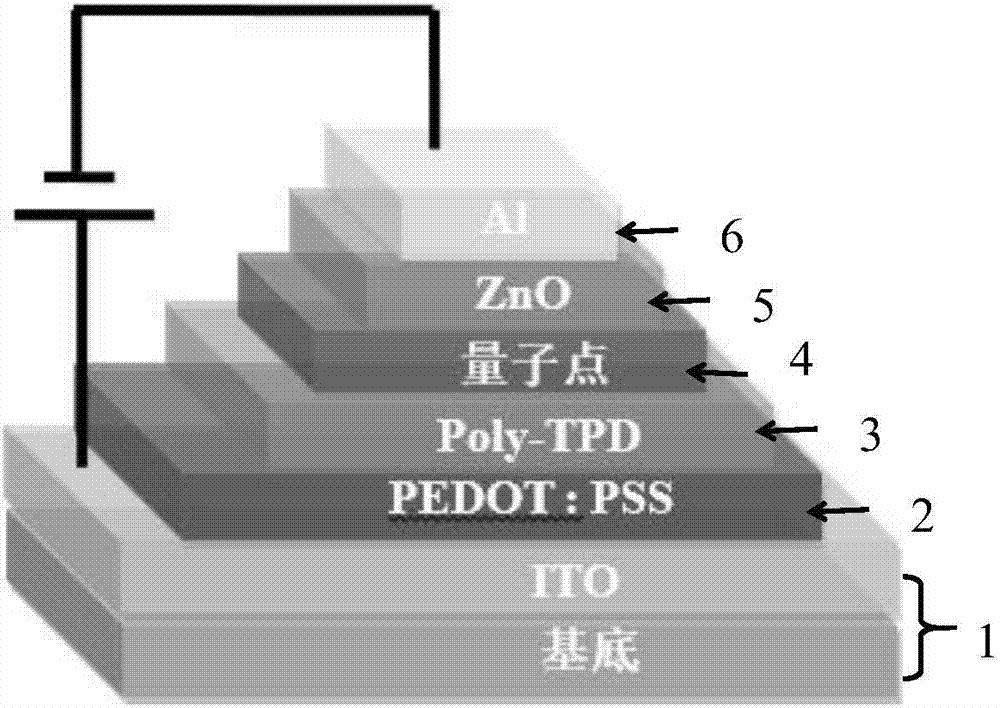

Quantum dot light-emitting diode and preparation method thereof

InactiveCN107275499AConducive to conductive lightConductive Luminescence GuaranteeSolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotZinc

The invention provides a quantum dot light-emitting diode and preparation method thereof. The preparation method includes printing a mixed organic solution including poly(3,4-ethylenedioxythiophene) and polystyrolsulfon acid salt, an organic solution including a triphenyl diamine polymer, an organic solution including quantum dots and an organic solution including zinc oxide on a conductive substrate surface in sequence through an ink-jet printing method to obtain a primary quantum dot light-emitting diode; and depositing an electrode on the non-conductive substrate side of the obtained primary quantum dot light-emitting diode to obtain the quantum dot light-emitting diode. The preparation method realizes large-area simple preparation of quantum dot light-emitting diode by adoption of an ink-jet printing technology combined with a defined proportion of ink, and the operation is simple; and the ink used by the preparation method contributes to improvement of printing resolution, ensures uniformity of printing, and facilitates electric conduction light emission of the diode.

Owner:广州琉芯光电科技有限公司

Transparent protective coat for concrete

The invention belongs to the technical field of anticorrosive materials and discloses a transparent protective coat for concrete. According to a three-layer matched scheme of a combined action principle of physical shielding and chemical sealing, the transparent protective coat for concrete comprises a base coat, a floating coat and a topcoat, wherein the base coat is alkyl alkoxy silane, the floating coat is a cationic acrylic polymer emulsion film-forming system; the topcoat is a water-based fluorocarbon resin and polyurethane associative thickener system with pH value of 8-9; the content of the water-based fluorocarbon resin is not less than 20%; the minimum film-forming temperature is not less than 27 DEG C. The transparent protective coat for the concrete has high permeability and excellent sealing property for the concrete, is simple and convenient to construct, transparent in coating and excellent in stain resistance, avoids water dampness and discoloration of the concrete, inhibits nonuniform absorption of the concrete, effectively prevents the concrete surface from blackening, keeps the natural surface effect of the concrete, and is suitable for the protection and application field of various reinforced concrete structures.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

Production method of 350 MPa grade cold rolled magnetic pole steel

InactiveCN1904114ACooperate wellExcellent overall performanceRoll mill control devicesHeat treatment process controlChemical compositionUltimate tensile strength

This invention relates to a process of producing 350MPa cold rolled steel magnet. It includes steps as follows: (1)to heat plate body to 1160-1230DEG C;(2)hot

Owner:WUHAN IRON & STEEL (GROUP) CORP

Production method of 250 MPa grade cold rolled magnetic pole steel

InactiveCN1904113ACooperate wellExcellent overall performanceRoll mill control devicesHeat treatment process controlChemical compositionMetallurgy

This invention relates to a process of producing 250MPa cold rolled steel magnet. It includes steps as follows: (1)to heat plate body to 1160-1230DEG C;(2)hot rolling steps: the start rolling temperature 1050-1100DEG C,end rolling temperature 840-880DEG C,cooling to 640-700DEG C for coiling. (3)cooling to 70DEG C below for acid picking. (4)cold rolling steps; (5) bell furnace anneal; controlling temperature 660-680DEG C (6) temper rolling, then the products. Account to weight the main chemical composition is: C 0.03-0.09%,Si 0.10-0.30%,Mn 0.30-0.70%,Nb 0.015-0.025 %,Als 0.01-0.07%,P <=0.025%,S <=0.010%, Fe the rest.

Owner:WUHAN IRON & STEEL (GROUP) CORP

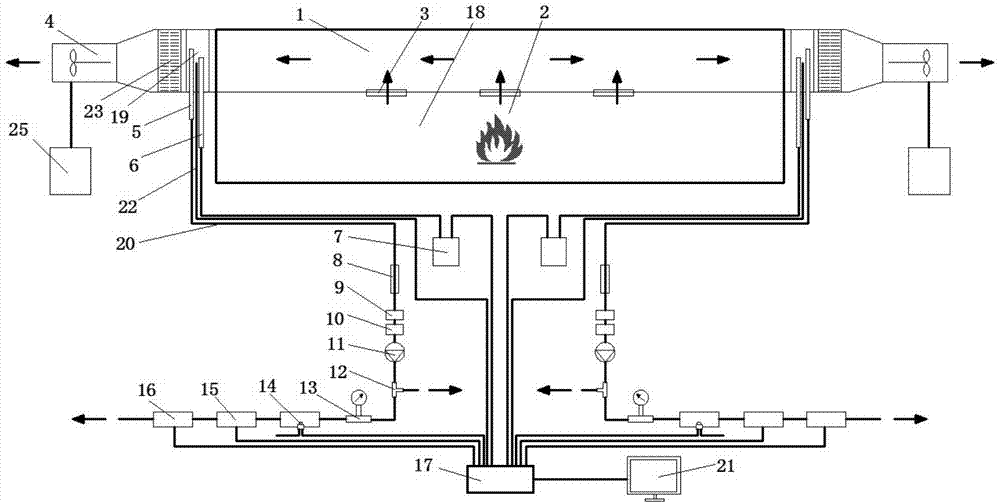

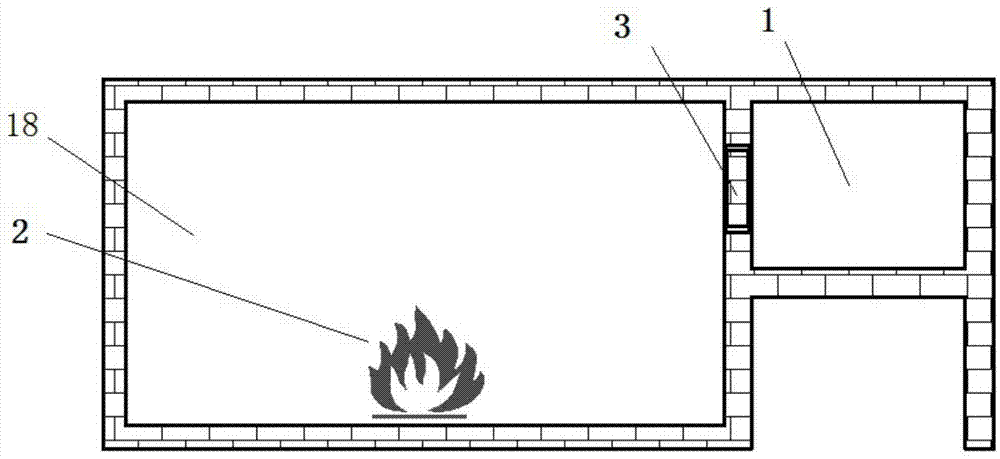

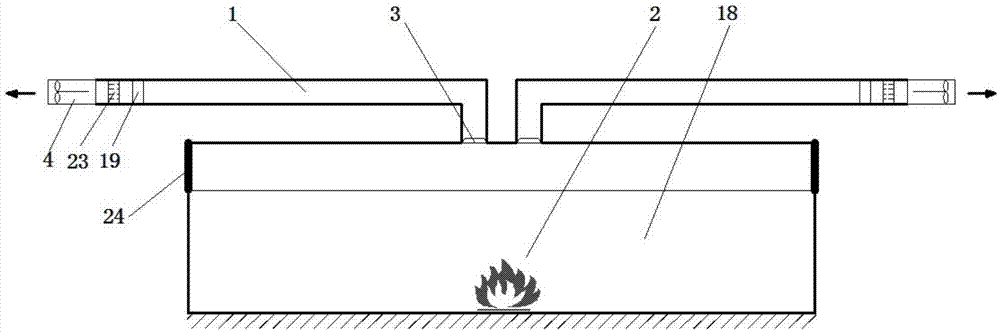

Multichannel parallel heat release rate test system and test method

InactiveCN104764769AHigh trafficReduce loadMaterial heat developmentCombustion chamberCollection system

The invention discloses a multichannel parallel heat release rate test system and test method, and aims at providing a system and a test method for accurate calorimetric measurement of a fire disaster with large burning area and high heat release rate through a multichannel parallel mode. The test system comprises a combustor, a data acquisition unit, a data processor and a plurality of test units; each test unit comprises a smoke collection system, a smoke flow measuring system and a smoke sampling system, and the smoke collection system comprises a smoke discharge pipeline, a damping screen, a sampling section and a smoke discharge blower; the smoke flow measuring system comprises a bidirectional pitot tube, a differential pressure transducer and a thermocouple; the smoke sampling system comprises a smoke sampling pipe, a condenser, a smoke filter, a drying device, a sampling pump, a rotor flow meter, an oxygen sensor, a CO2 sensor and a CO sensor; and the smoke discharge pipelines in the test units are connected in parallel. The multichannel parallel heat release rate test system and the test method, provided by the invention, can be used for testing the heat release rate of a tunnel fire disaster, and also can be used for testing the heat release rates of fire disasters of automobiles and trains.

Owner:TIANJIN UNIV OF COMMERCE

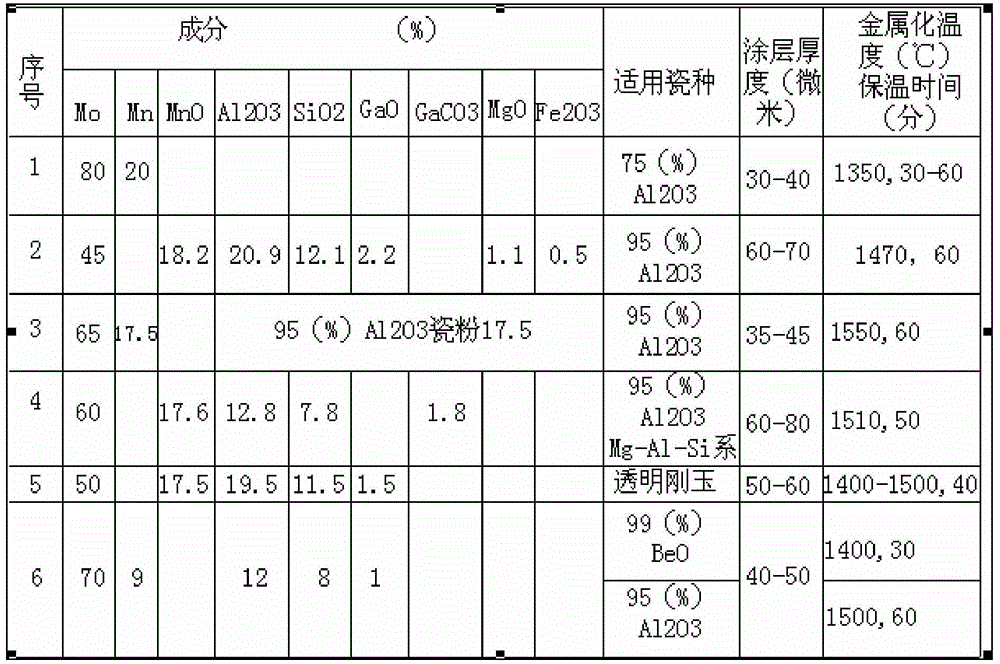

Metallization sintering powder for 95 alumina ceramic middle temperate metallization paste and preparation method thereof

The invention discloses metallization sintering powder for 95 alumina ceramic middle temperate metallization paste and a preparation method thereof, and the metallization sintering powder comprises the following components by weight: 60-80 parts of molybdenum powder; a glass phase component comprising 10-20 parts of MnO, 0.5-4 parts of Al2O3, 7-12 parts of SiO2, 0.5-1 part of CaO and 1-5 parts of Mg; and a sintering additive component comprising at least one substance of 0-1.2 parts of TiO2, 0-1.2 parts of BaO, 0-1.2 parts of Y2O3, 0-1.2 parts of La2O3 and 0-1.2 parts of P2O5. The sintering additive is added into the metallization paste, so that the metallization sintering temperature is reduced, Al2O3 ceramic surface metallization can be realized at 1370-1420 DEG C by the metallization paste using the sintering additive, and a ceramic metallization layer with high sintered density, good air tightness and high sealing tensile strength can be obtained. The tensile strength of a sample sealed with the metallization paste is over 120MPa, and at the same temperature, the metallization paste is much better than metallization paste without adding of a sintering additive in performance, and the preparation method has the advantages of simple process and convenient operation, and can ensure the stability of the paste and the requirements for mass production.

Owner:XIAN YUANXING VACUUM ELECTRONICS TECH

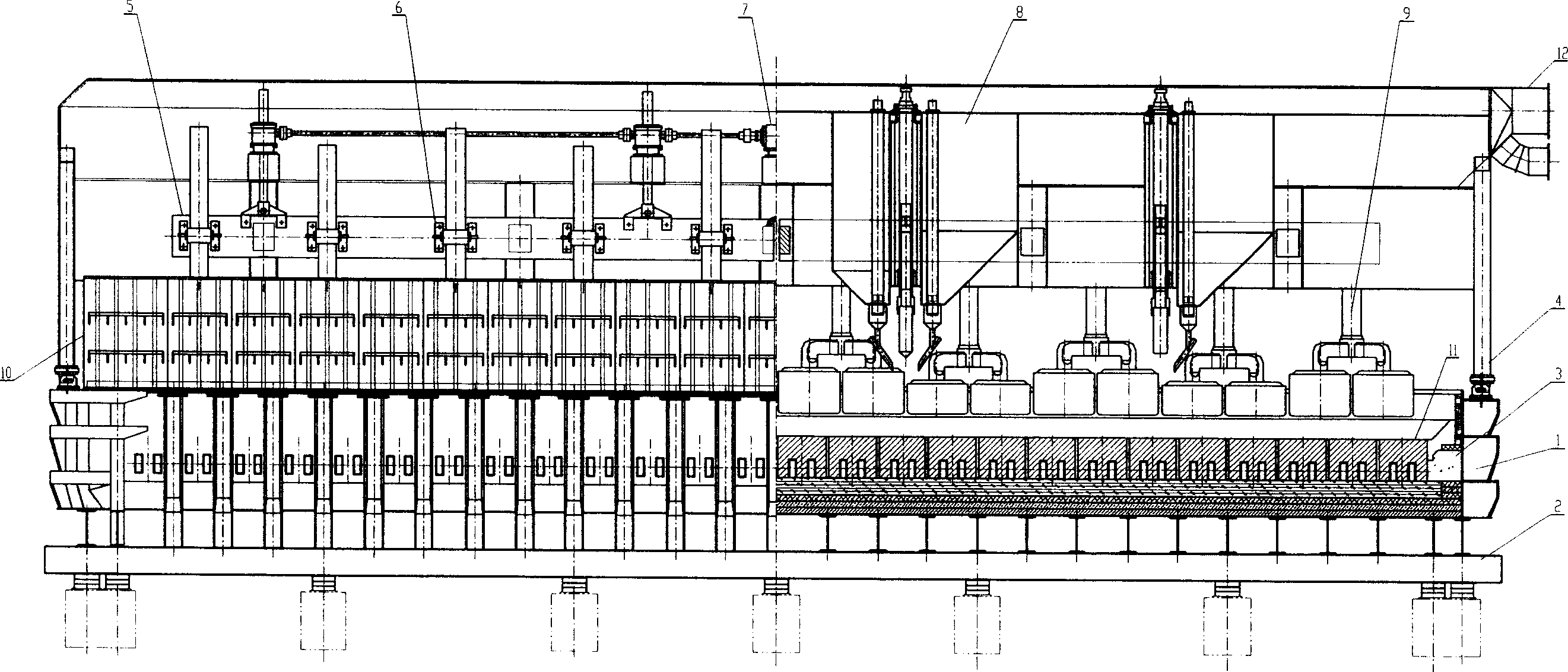

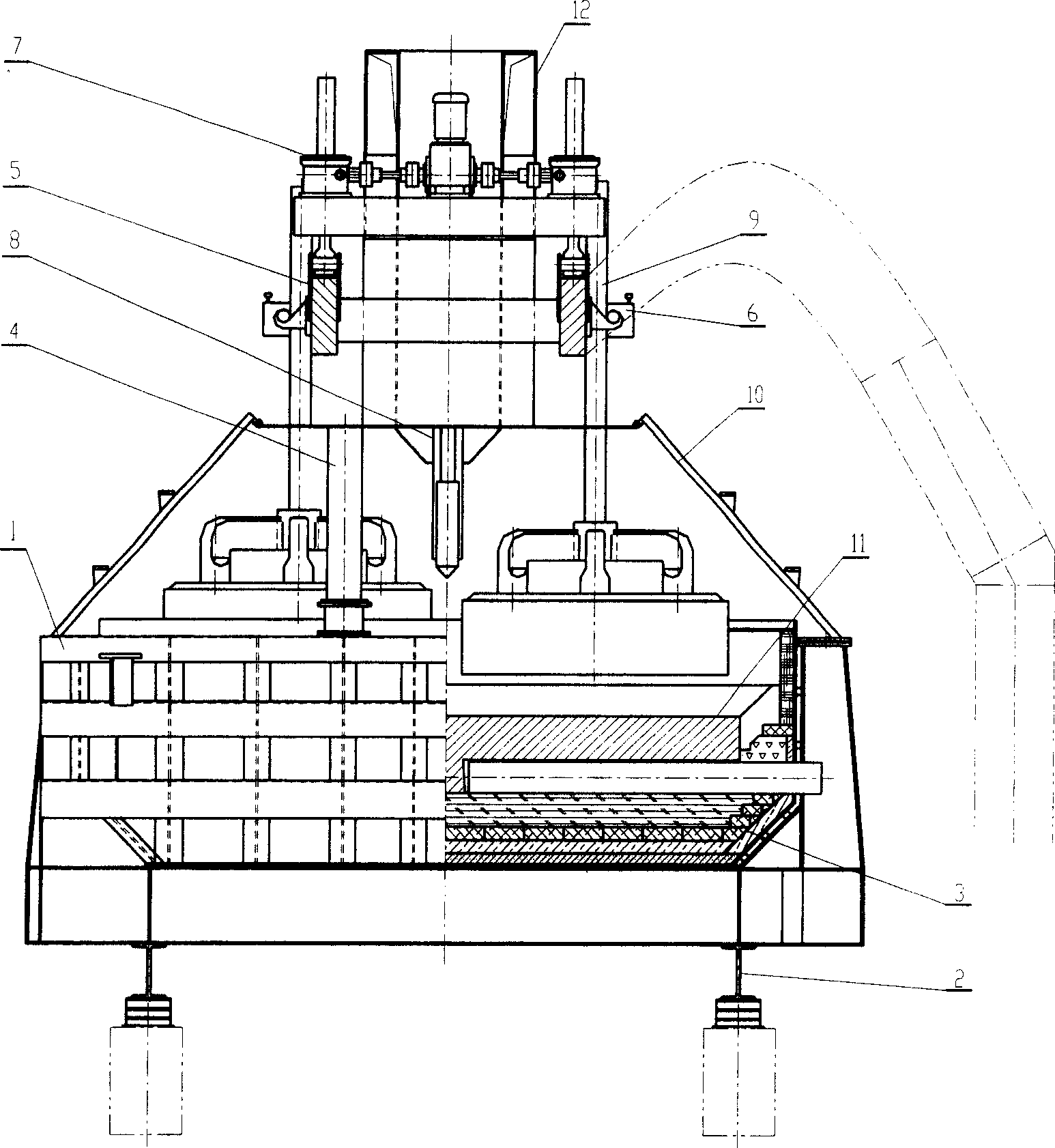

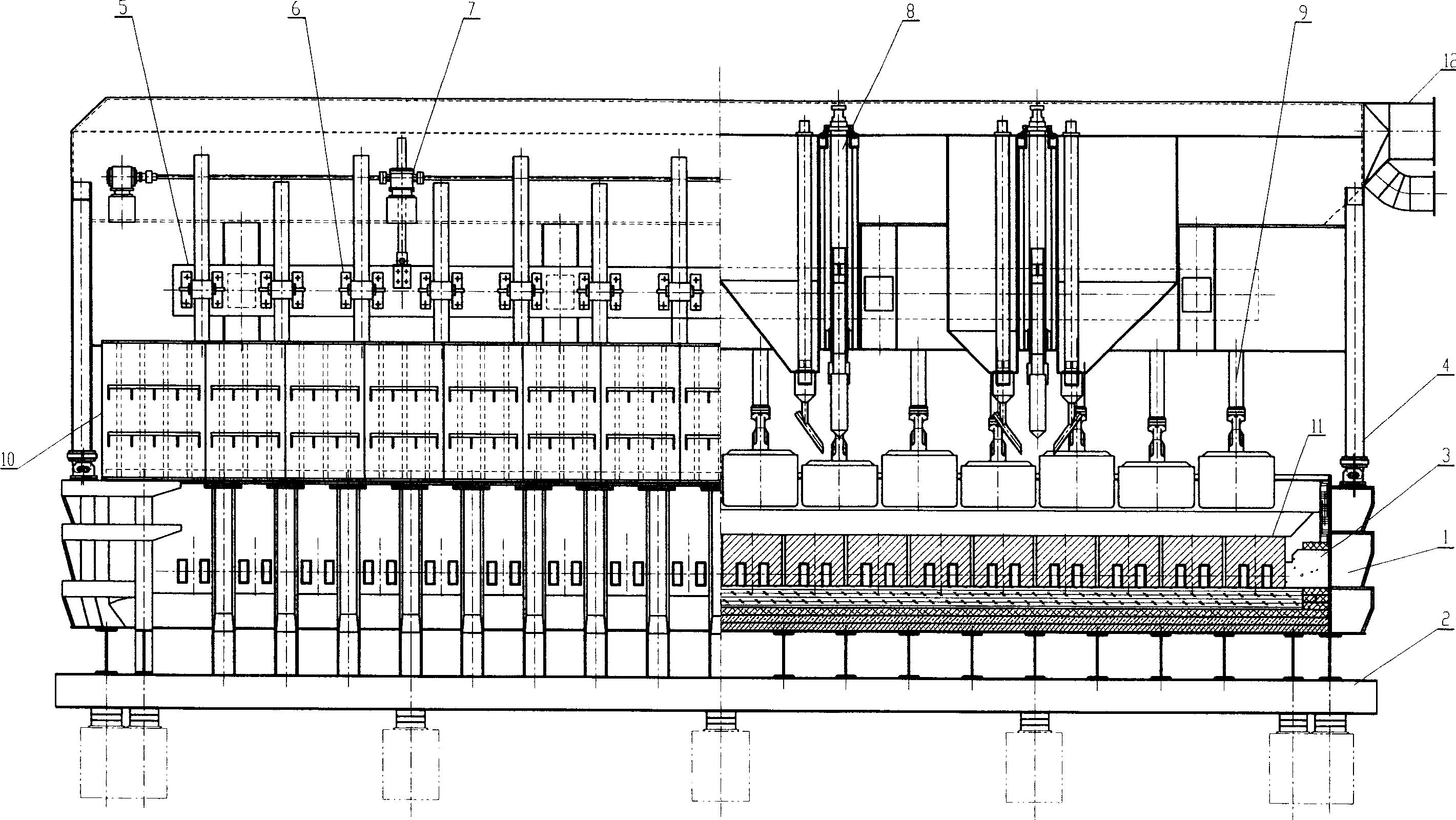

Large-scale aluminium electrolysis pre-baking tank

The large aluminum electrolyzing pre-roasting tank includes anode carbon block combination, anode bus, breaking and feeding unit, anode elevating mechanism, crossbeam and portal upright, tank sealing air exhaust system, tank casing, cathode structure and bottom heat insulating structure. It features the double anode structure comprising two anode carbon blocks assembled through aluminum rod and steel pawl; the elevator installed below the top surface of the crossbeam; the tank sealing air exhaust system set inside the crossbeam; and the cathode with surround casing, carbon block with bottom composite heat insulating layer, side silicon nitride to combine silicon carbide blocks and surrounding cast material. The present invention has improved structure resulting in raised fume collecting efficiency, reasonable gas flow distribution and smooth aluminum electrolyzing process.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

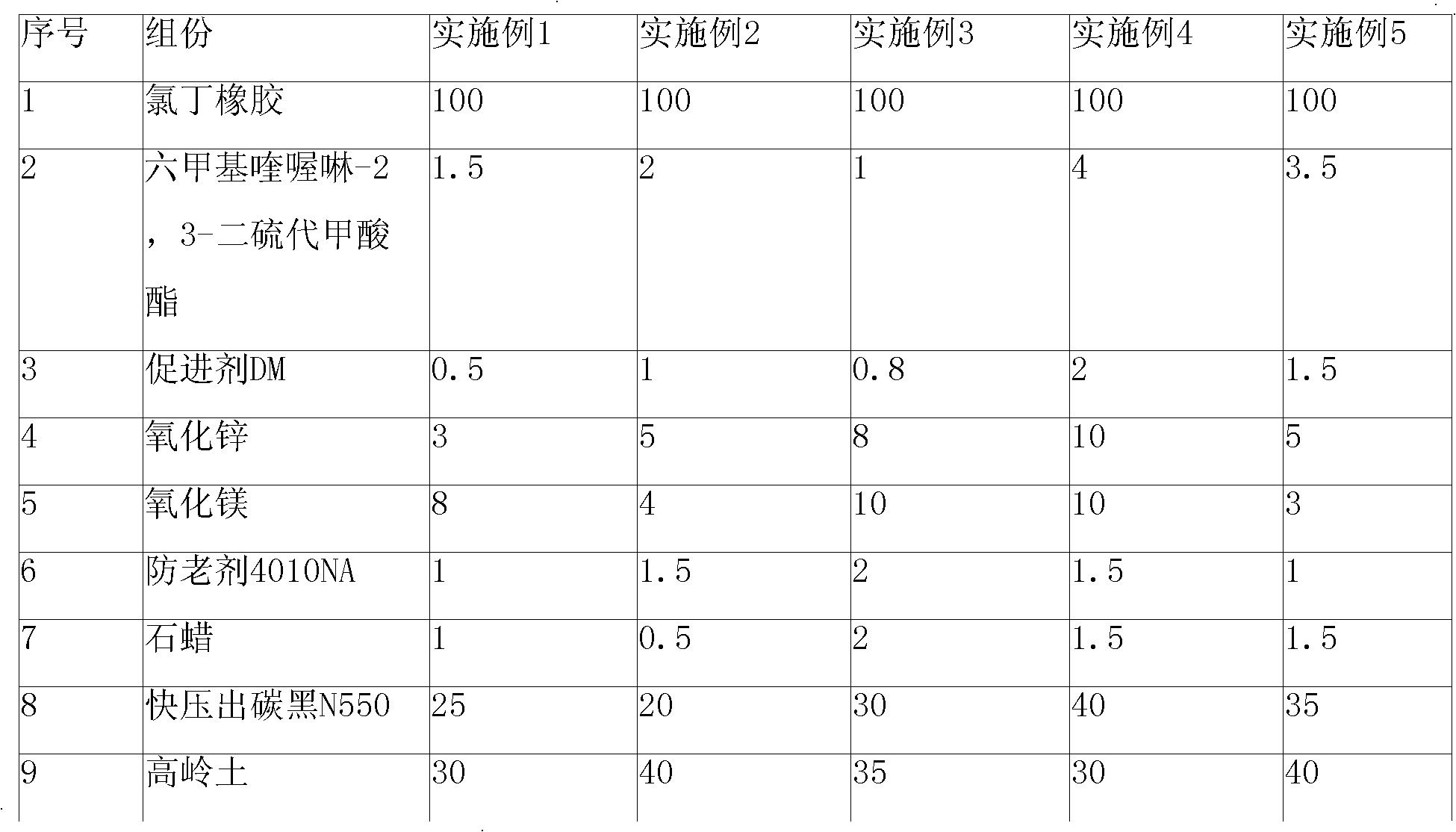

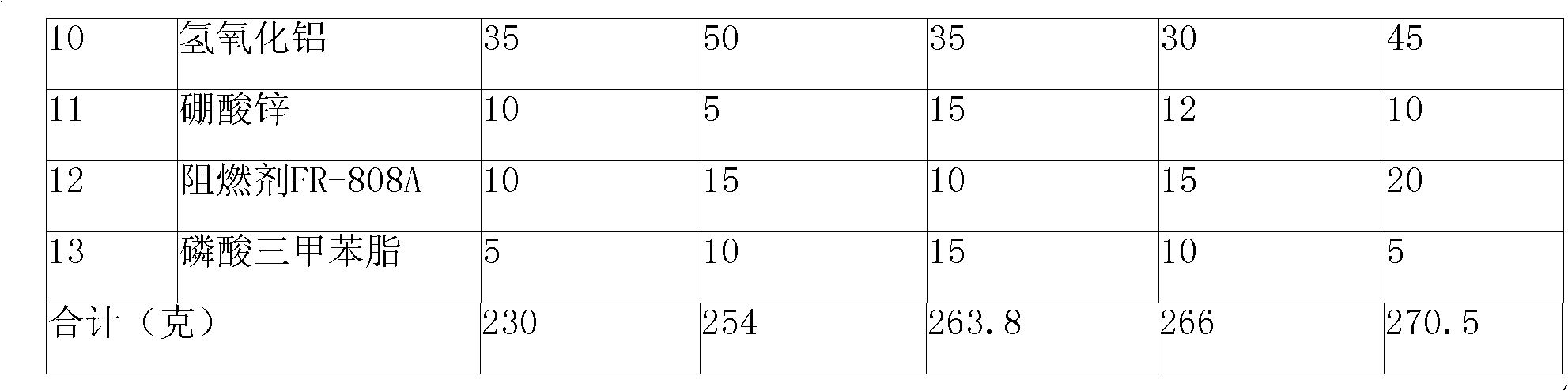

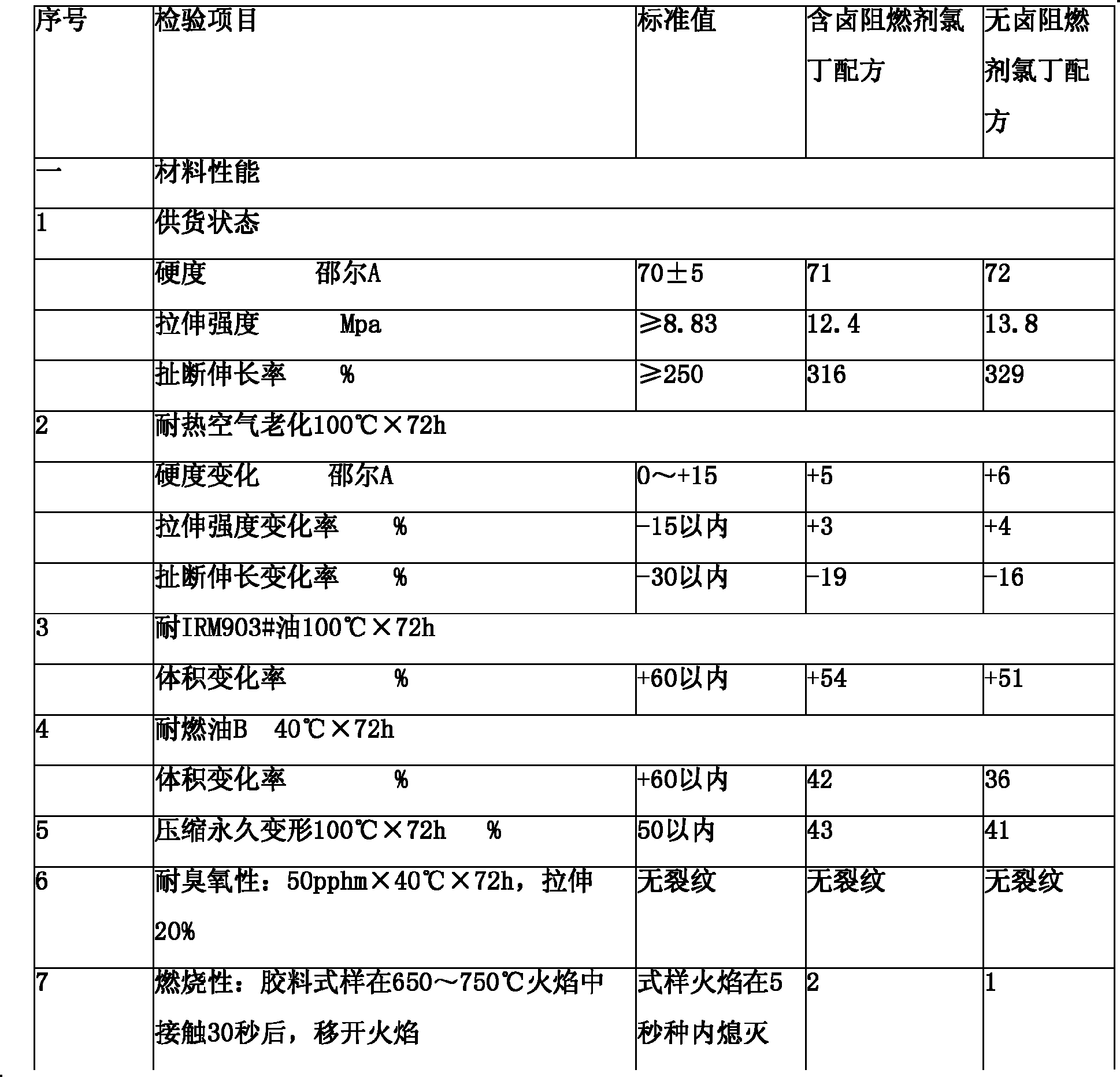

Formula of environment-friendly flame-retardant chloroprene rubber

The invention relates to the formula of environment-friendly flame-retardant chloroprene rubber. The flame-retardant chloroprene rubber, according to the formula thereof, comprises the following components by weight part: 100 parts of chloroprene rubber, 1 to 4 parts of hexamethyl-quinoxaline-2,3-dithioformate, 1 to 2 parts of DM as accelerator, 3 to 10 parts of zinc oxide, 3 to 10 parts of magnesium oxide, 1 to 2 parts of 4010NA as anti-ager, 0.5 to 2 parts of paraffin, 20 to 40 parts of FEF (fast-extruding furnace) carbon black (N550), 30 to 40 parts of kaolin, 30 to 50 parts of aluminum hydroxide, 5 to 15 parts of zinc borate, 10 to 20 parts of FR-808A and 5 to 15 parts of tricresyl phosphate. According to the comparative analysis on the performance of the chloroprene formula using halogen-containing flame retardant and the chloroprene rubber formula using halogen-free flame retardant, the performance of the formula using the halogen-free flame retardant in the invention can fully satisfy the requirements of standards, thus substituting for the chloroprene formula using the halogen-containing flame retardant; and based on the chloroprene rubber formula, the invention can meet the requirements of the flame-retardant application, and the materials of the formula are environment friendly and safe for human bodies.

Owner:TIANJIN PENGYI GRP CO LTD

Method for recycling mica, feldspar and quartz sand from kaolin tailings

The invention provides a method for recycling mica, feldspar and quartz sand from kaolin tailings. The method includes the following steps that the kaolin tailings are subjected to selective milling; then screening is conducted, oversize coarse products are almost flaky pure mica, and undersize products are subjected to hydraulic classification so that fine sand containing mud can be removed; classification settled sand is reselected repeatedly so that heavy minerals can be removed; reselected fine sand is subjected to medium magnet and strong magnet operations and then magnetic separation fine sand can be obtained; the magnetic separation fine sand is subjected to the first segment of flotation, the mica can be separated at first, and a fragmental mica product is obtained; the feldspar is separated from quartz in the second segment of flotation; and finally the mica, feldspar and quartz product can be obtained, and the fine sand and milltailings produced in the beneficiation process can be used for unfiring of new building materials like aerated bricks. By adoption of the method, kaolin tailing resources can be utilized comprehensively and effectively; and moreover, the technological process is simple, energy consumption is low, 'zero' release of solid waste is realized, the policy requirements of environmental protection act can be met, and the economic, social and environmental protection benefits are good.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

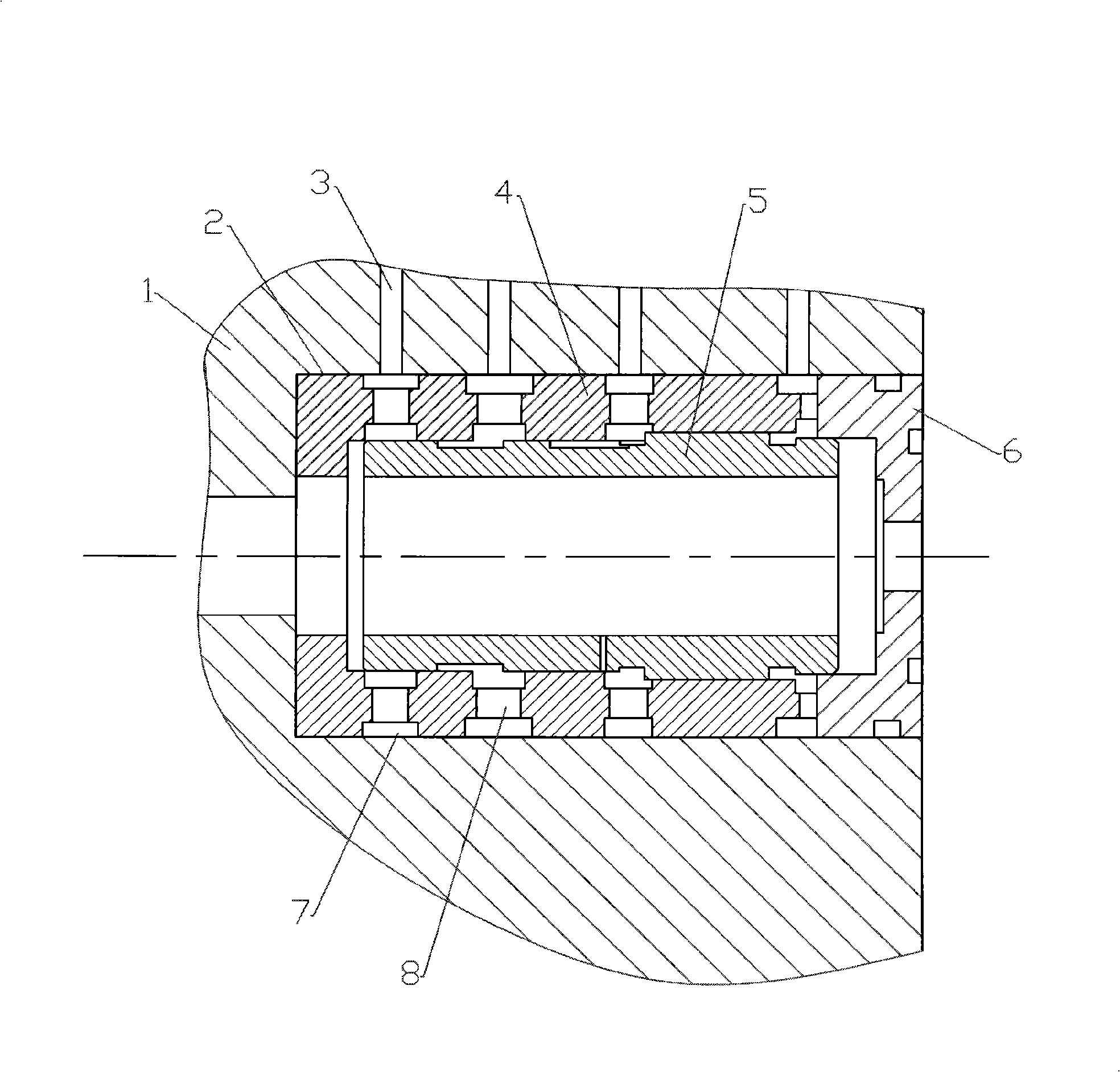

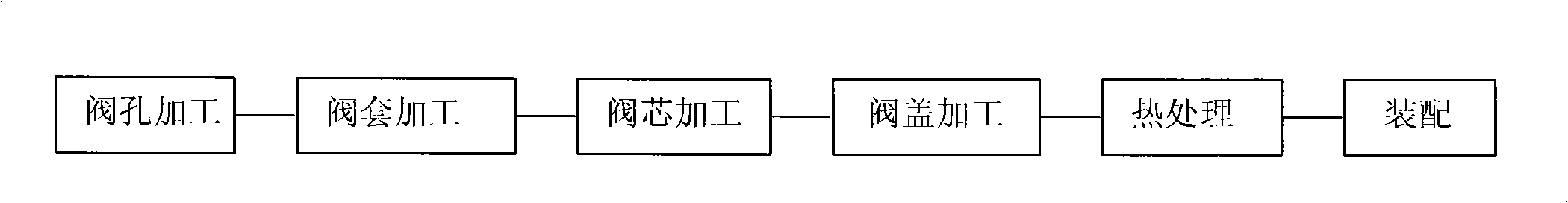

Hydraulic breaking hammer change-over valve and manufacturing method thereof

InactiveCN101324278AReasonable structureLow costServomotor componentsMultiple way valvesCylinder blockProcessing cost

The invention discloses a hydraulic pressure breaking hammer selector valve and a manufacturing method thereof in the technical field of hydraulic components. The hydraulic breaking hammer selector valve takes a middle cylinder body as a valve body; a valve opening is formed on the valve body; an oil duct is communicated with the inner wall of the valve hole and led to a cylinder of the middle cylinder body; a valve jacket is arranged in the valve hole and matched with the valve hole; a valve plug is arranged in the valve jacket; and a valve cover is arranged on the end part of the valve hole. The selector valve is characterized in that the valve hole is an unthreaded hole; an annular groove is formed on the outer wall of the valve jacket corresponding to the position of an opening of the oil duct; and an oil hole communicates the annular groove with a centre hole of the valve jacket. The manufacturing method comprises the steps of processing the valve hole, the valve jacket, the valve plug and the valve cover; conducting heat treatment; and assembling finished products. The method of the hydraulic pressure breaking hammer selector valve has the advantages of processing conveniently, reducing processing difficulty and effectively ensuring precision. The selector valve has the advantages of high functional reliability, lower processing cost and suitability for batch production.

Owner:NANYANG KAITIAN ENG MACHINERY +1

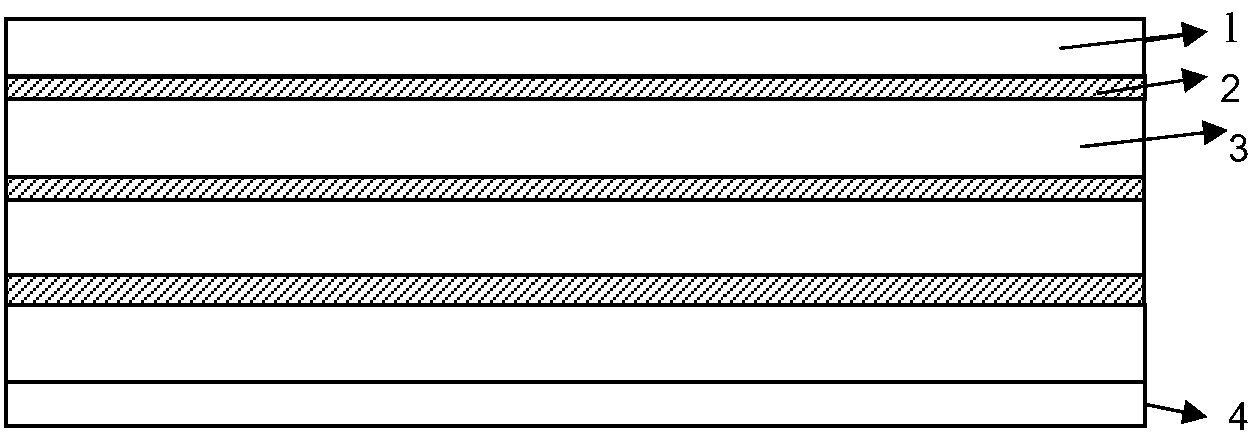

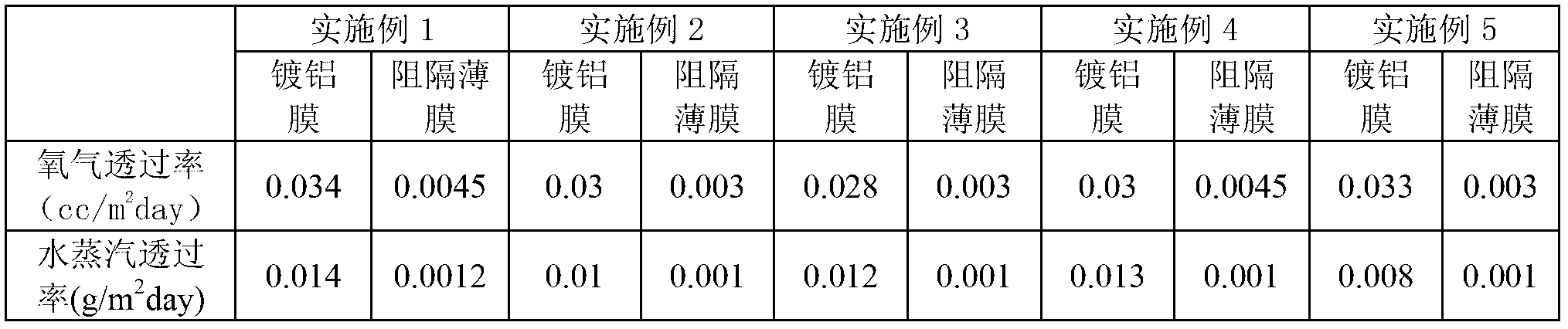

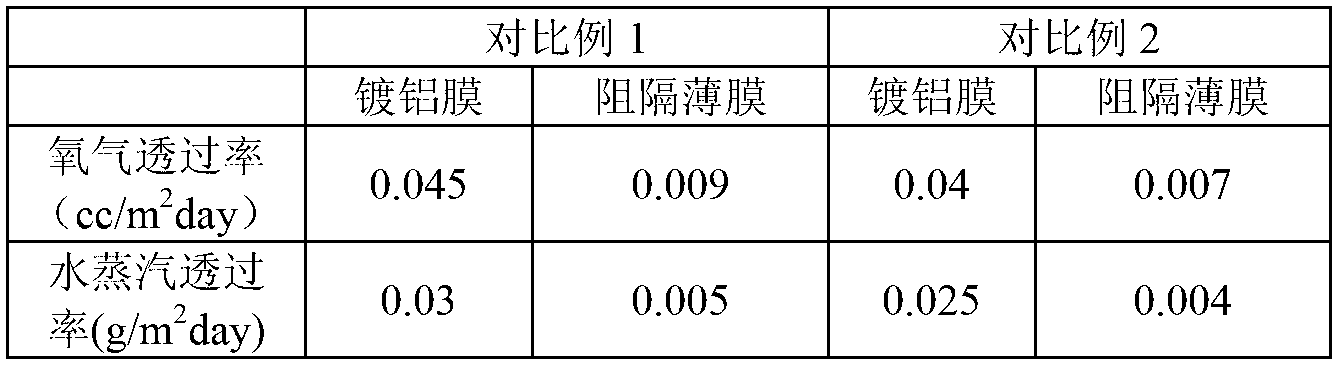

Barrier film and vacuum insulating board adopting same

ActiveCN103057212AHigh gas barrierHigh barrierVacuum evaporation coatingSputtering coatingPolyethylene terephthalateSurface layer

The invention provides a barrier film and a vacuum insulating board compounded by utilizing the barrier film. The barrier film is formed by adhering a surface layer, a gas barrier layer and a heat seal layer, wherein the gas barrier layer consists of at least one aluminum-plated polyethylene terephthalate (PET) film layer. The preparation process of the aluminum-plated PET film comprises the following of: (1) arranging a PET substrate film in an aluminum-plating chamber for performing vacuum aluminum plating, and forming an aluminum-plating layer on the surface of the PET substrate film; and (2) introducing nitrogen into the aluminum-plating chamber in stages after aluminum plating is ended, introducing the nitrogen until the nitrogen pressure is 800-1200pa at the first time, maintaining for 8-12 hours, introducing the nitrogen until the nitrogen pressure is 1300-1500pa, maintaining for at least 12 hours, and obtaining the aluminum-plated PET film. Compared with the conventional aluminum-plated film prepared by the prior art, the aluminum-plated film has the advantages that the overall barrier performance of the barrier film can be effectively improved, so that the requirements can be met in occasions with strict barrier performance requirement.

Owner:中亨新型材料科技有限公司

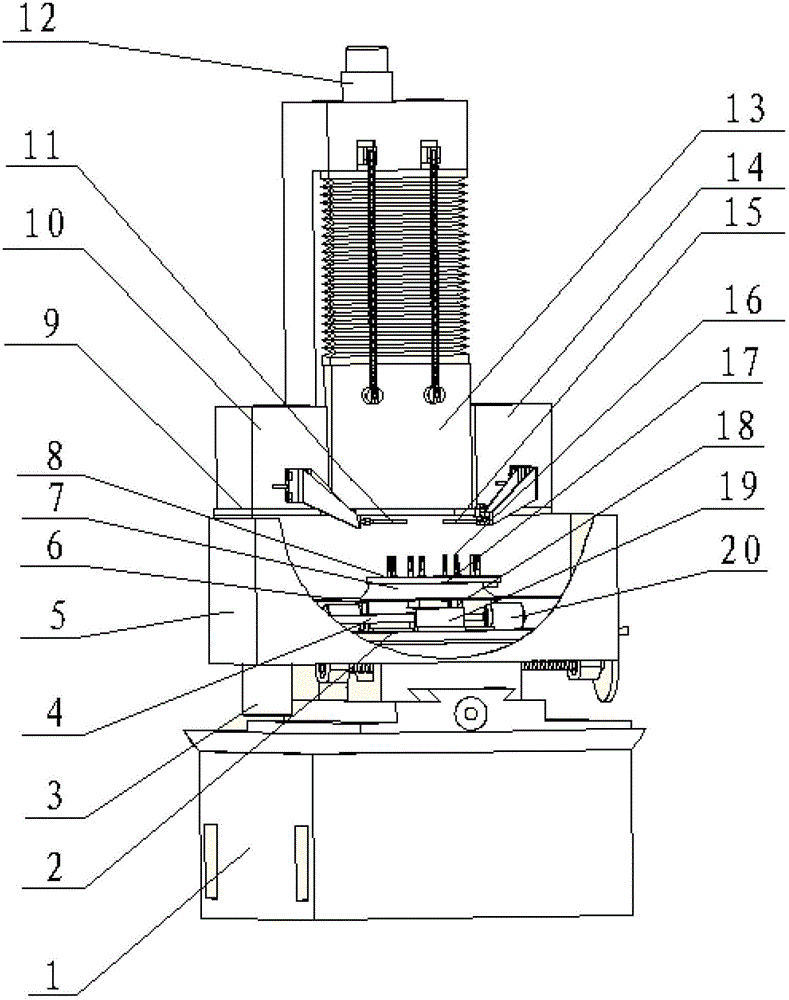

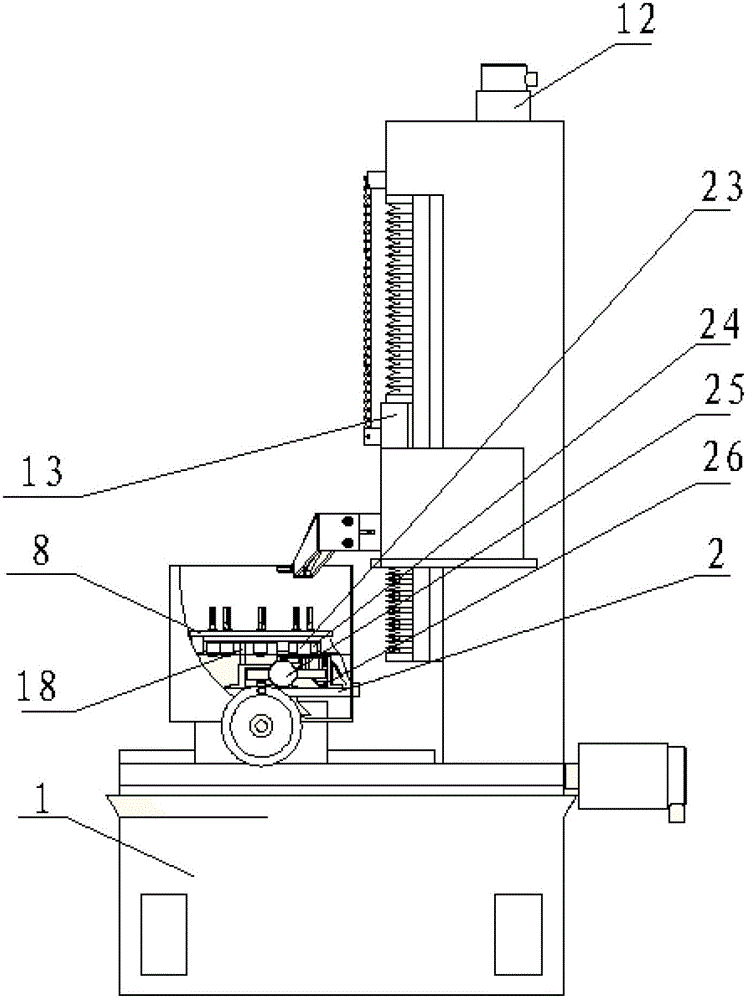

Numerical control machine tool capable of quenching and tempering simultaneously at high frequency

InactiveCN102719631AMeet batch quenching treatmentGuaranteed depthIncreasing energy efficiencyQuenching devicesNumerical controlUltimate tensile strength

The invention relates to a numerical control machine tool capable of quenching and tempering simultaneously at a high frequency, which belongs to the technical field of local inductive heat treatment on surfaces of metal parts, and mainly aims to solve the problems to realize that quenching and tempering are simultaneously carried out when workpieces are clamped in one step, multi-stage power andspeed variation can be realized on complex parts, and batch quenching of various small parts can be met through programming. The numerical control machine tool mainly comprises an 8-shaped double-turn double-position quenching induction coil and a tempering induction coil on a vertically moving Z-axis sliding table of the numerical control machine tool, and an eight-station rotary workpiece holder plate indexing rotating mechanism, eight workpieces are clamped in one step, heat treatment is carried out continuously, two processes are completed automatically on one machine tool, the repeated workpiece assembly and disassembly processes are omitted, the labor intensity is reduced, the production of continuous quenching and tempering treatment of workpieces in batches can be realized, and the production efficiency is improved.

Owner:HUAIHAI IND GRP

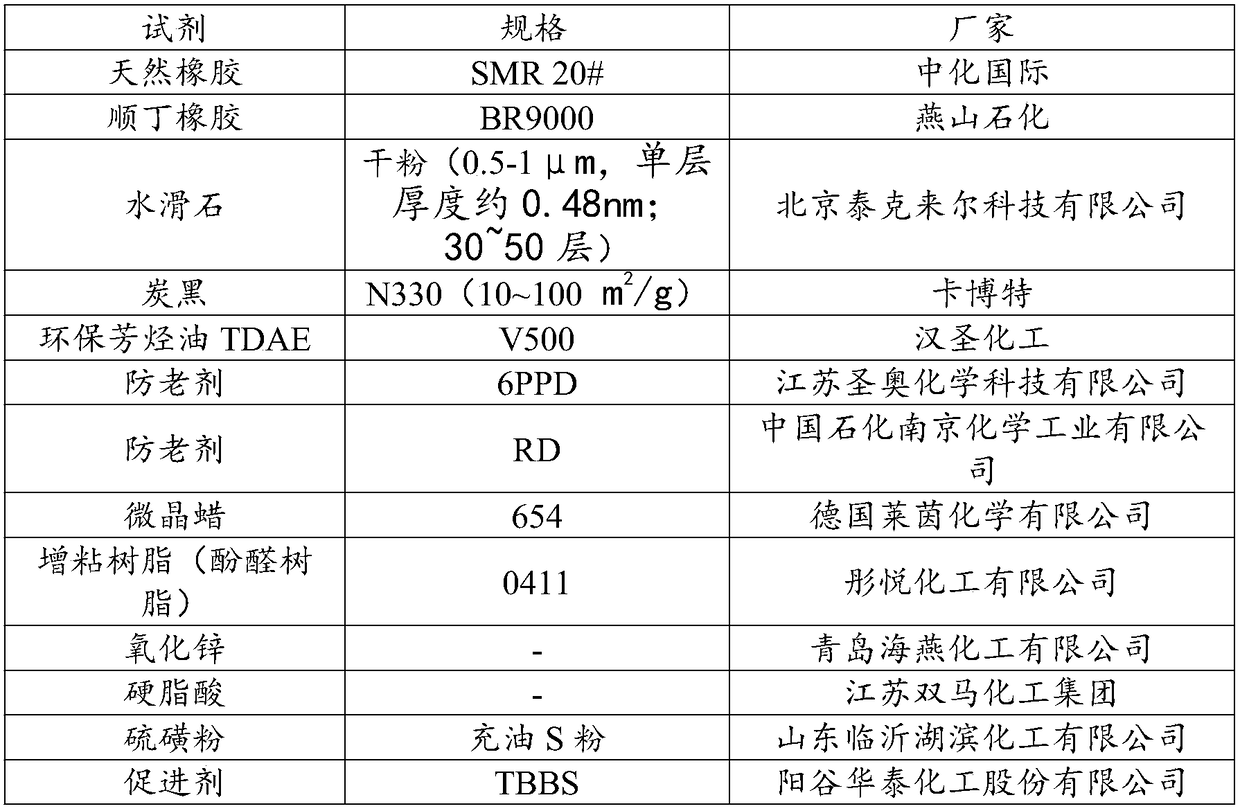

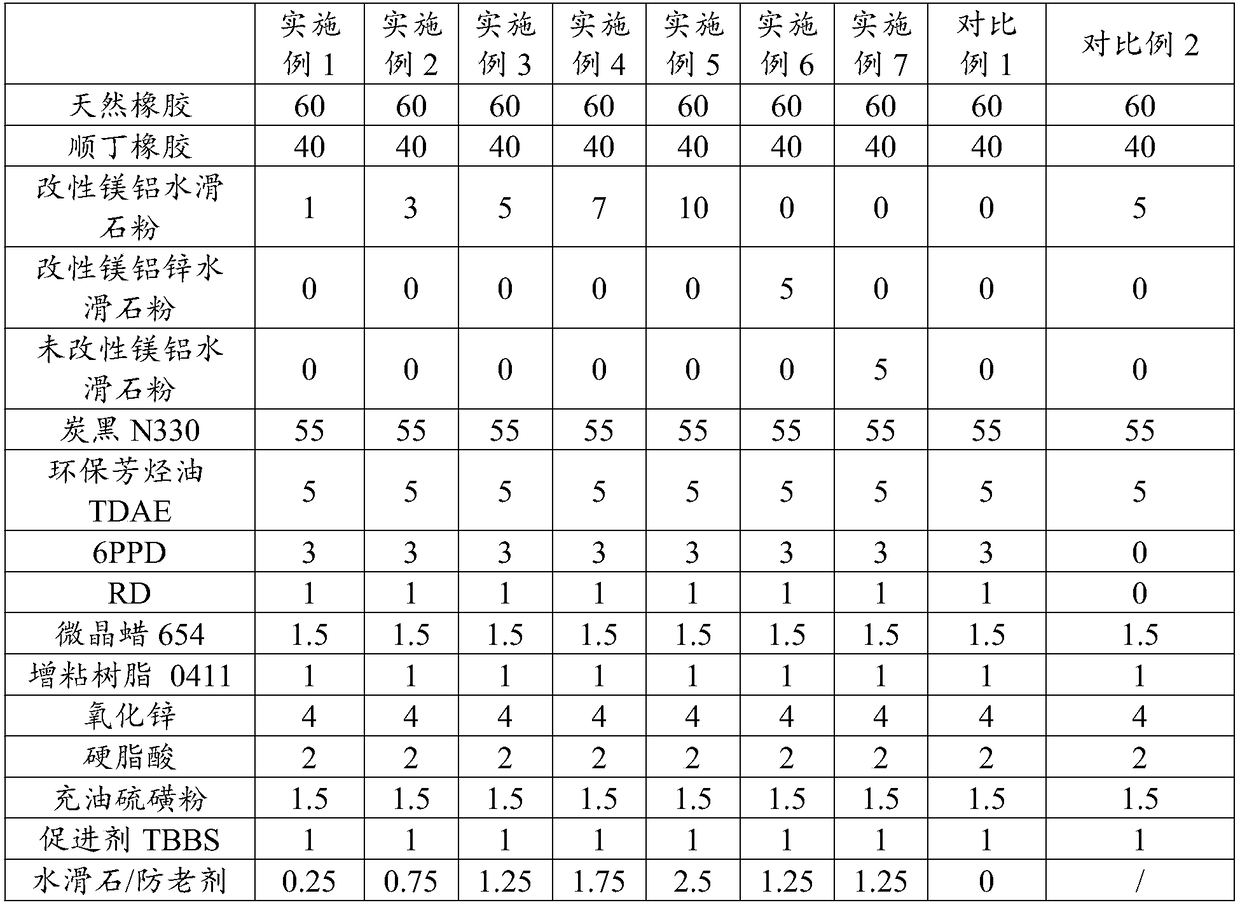

Tire sidewall rubber composite material and preparation method thereof

ActiveCN108239306AWarranty requirementsExcellent heat and oxygen aging resistanceSpecial tyresStearic acidOxygen

The invention relates to a composite material for tires, and in particular relates to a tire sidewall rubber composite material. The material comprises 100 parts by weight of rubber, by weight of rubber, 1-10 parts by weight of hydrotalcite, 40-70 parts by weight of carbon black, 4.0-8.0 parts by weight of environment-friendly aromatic hydrocarbon oil, 3.0-9.0 parts by weight of an anti-aging agent, 1.0-4.0 parts by weight of wax, 0.5-3.0 parts by weight of tackifying resin, 1.5-5.0 parts by weight of zinc oxide, 1.0-3.5 parts by weight of stearic acid, 1.0-3.0 parts by weight of sulfur powderand 0.5-2.0 parts by weight of an accelerant. A preparation method of the composite material comprises the following steps: plasticating rubber in an internal mixer, adding other components except the sulfur powder and the accelerator for mixing, lifting a top bolt at the temperature of 120-125 DEG C, performing dumping at 150-160 DEG C to obtain the mixed rubber, mixing the mixed rubber, the sulfur powder and the accelerator in an open mill, rolling for 4-5 times, and conducting thin-pass for 5-8 times to obtain a product. The composite material disclosed by the invention not only meets thebasic mechanical property requirements of the sidewall rubber, but also obviously improves the heat oxygen aging resistance and the ultraviolet aging resistance of the sidewall rubber and the servicelife of the tire can be effectively prolonged.

Owner:SHANDONG LINGLONG TIRE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com