Patents

Literature

132 results about "Furnace anneal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Furnace annealing is a process used in semiconductor device fabrication which consist of heating multiple semiconductor wafers in order to affect their electrical properties. Heat treatments are designed for different effects. Wafers can be heated in order to activate dopants, change film to film or film to wafer substrate interfaces, densify deposited films, change states of grown films, repair damage from implants, move dopants or drive dopants from one film into another or from a film into the wafer substrate. During ion implantation process, the crystal substrate is damaged due to bombardment with high energy ions. The damage caused can be repaired by subjecting the crystal to high temperature. This process is called annealing. Furnace anneals may be integrated into other furnace processing steps, such as oxidations, or may be processed on their own.

Method to control mechanical stress of copper interconnect line using post-plating copper anneal

A method is provided, the method comprising forming a first dielectric layer above a first structure layer, forming a first opening in the first dielectric layer, and forming a first copper structure above the first dielectric layer and in the first opening. The method also comprises annealing the first copper structure using one of a furnace anneal process performed at a temperature ranging from approximately 100-400° C. for a time ranging from approximately 10-90 minutes and a rapid thermal anneal (RTA) process performed at a temperature ranging from approximately 100-400° C. for a time ranging from approximately 10-180 seconds.

Owner:GLOBALFOUNDRIES INC

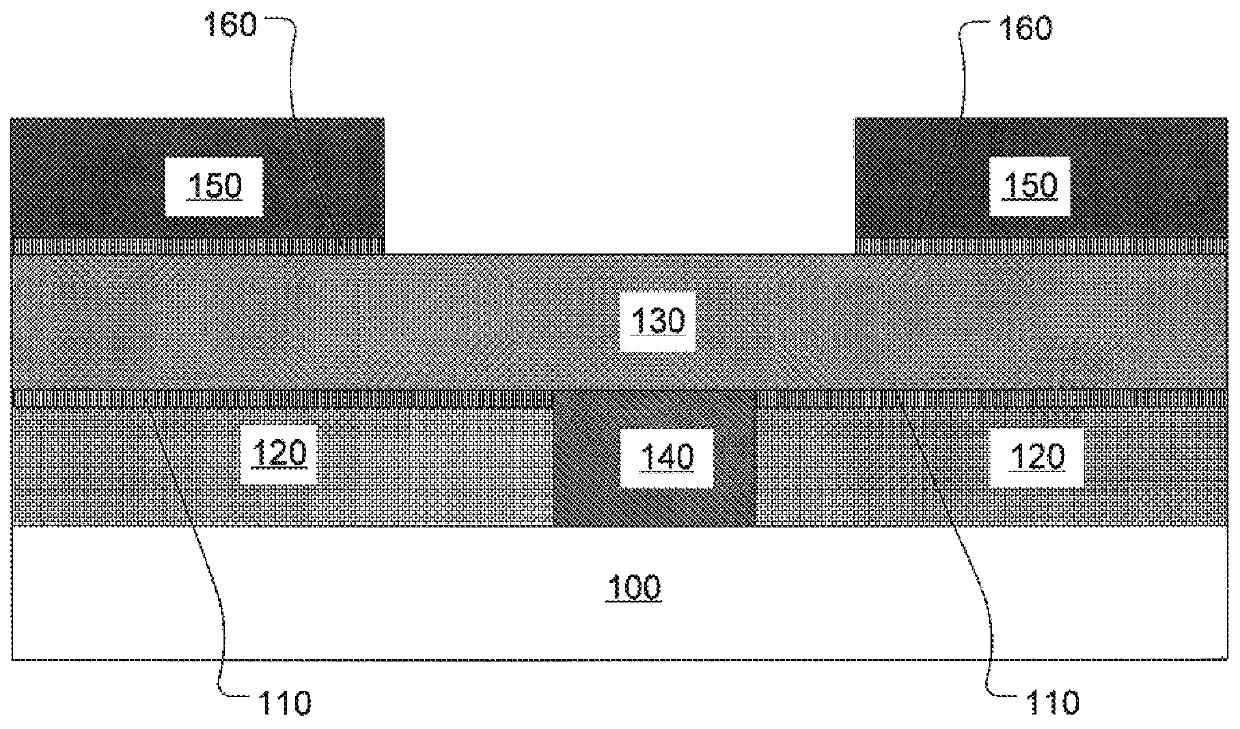

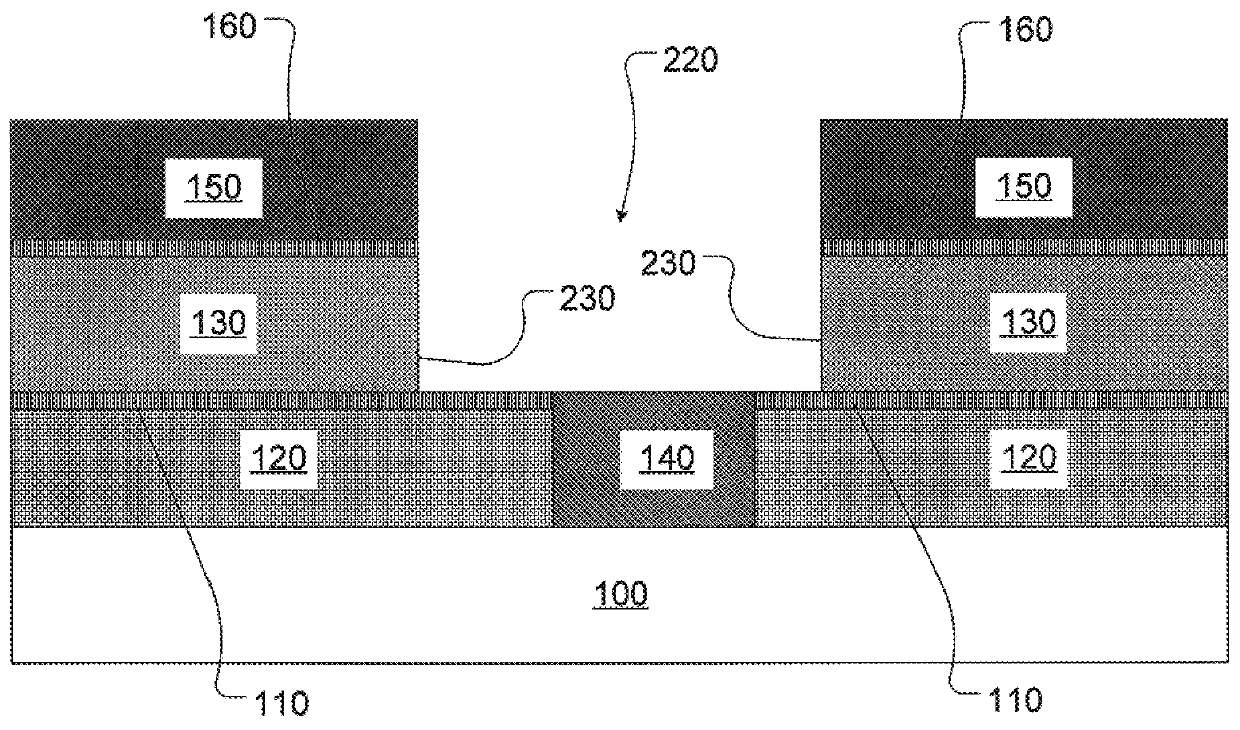

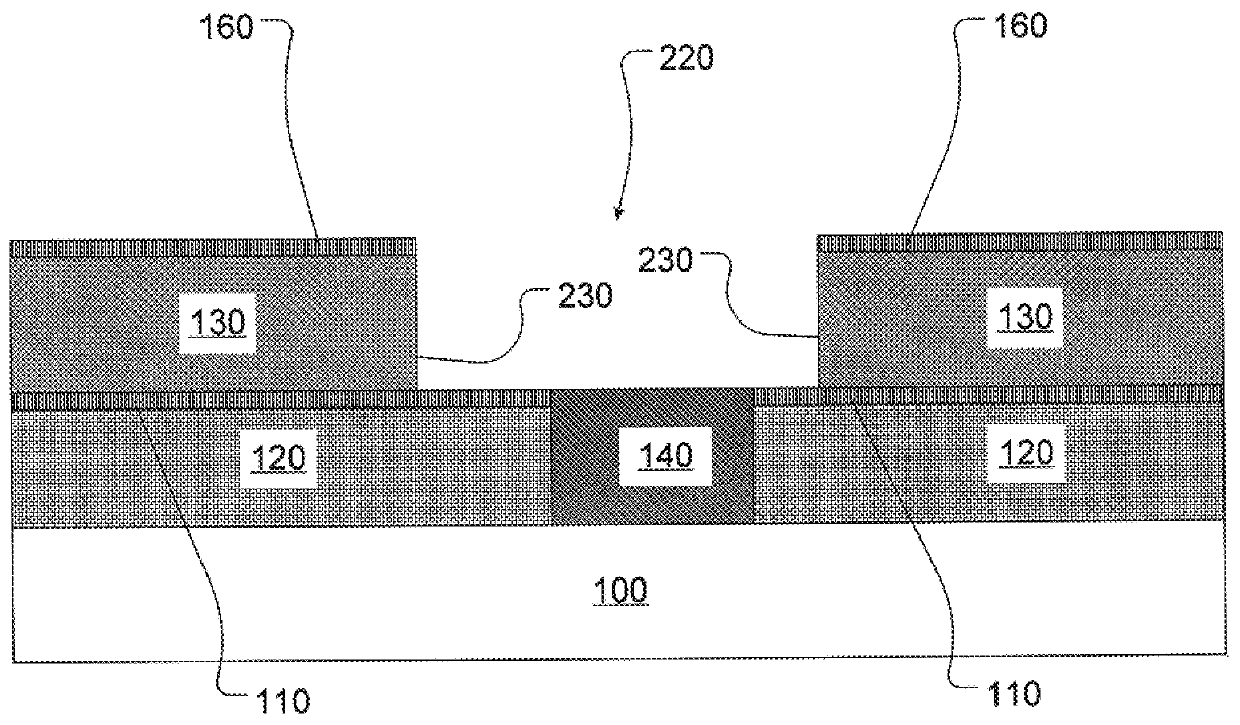

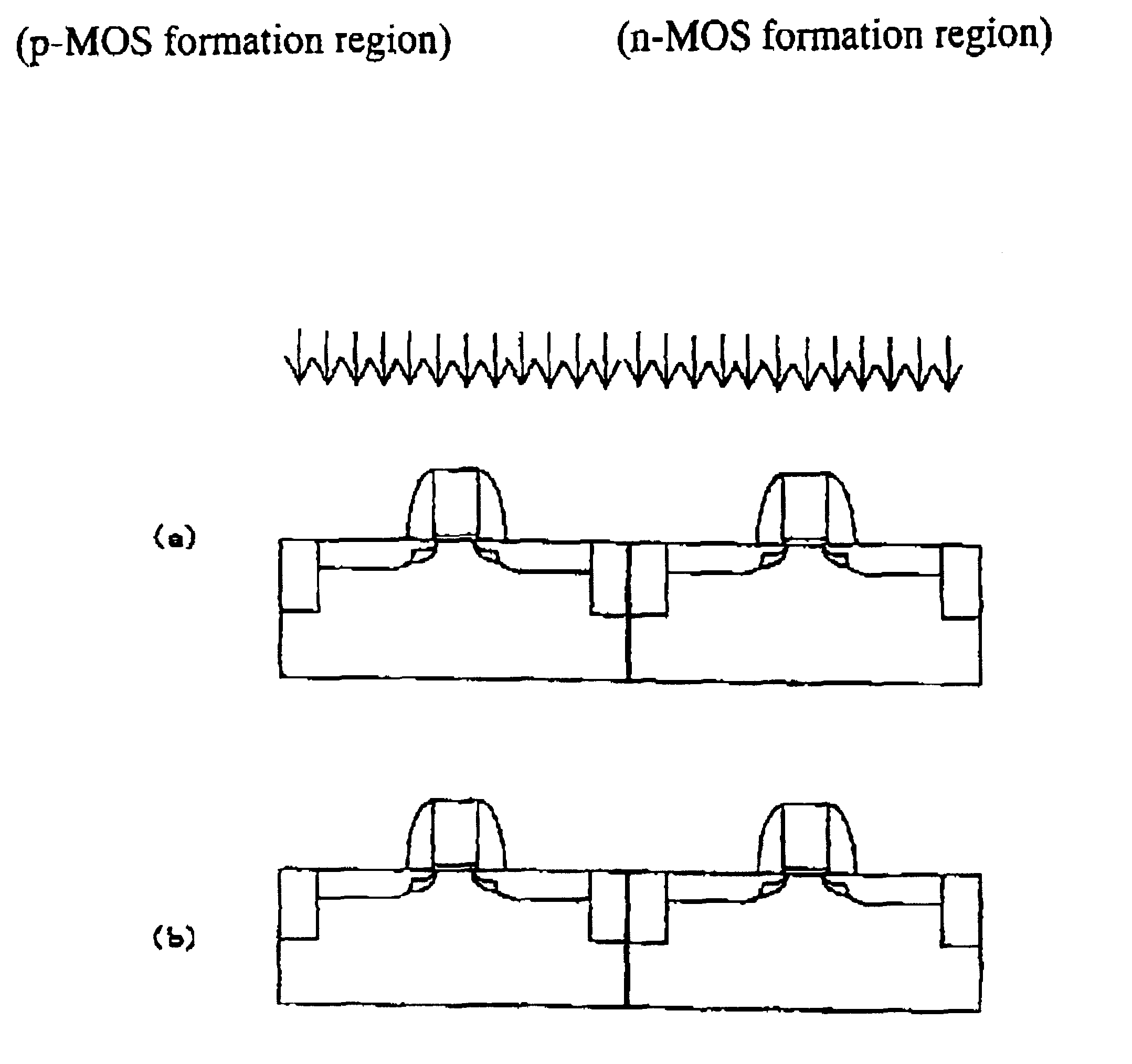

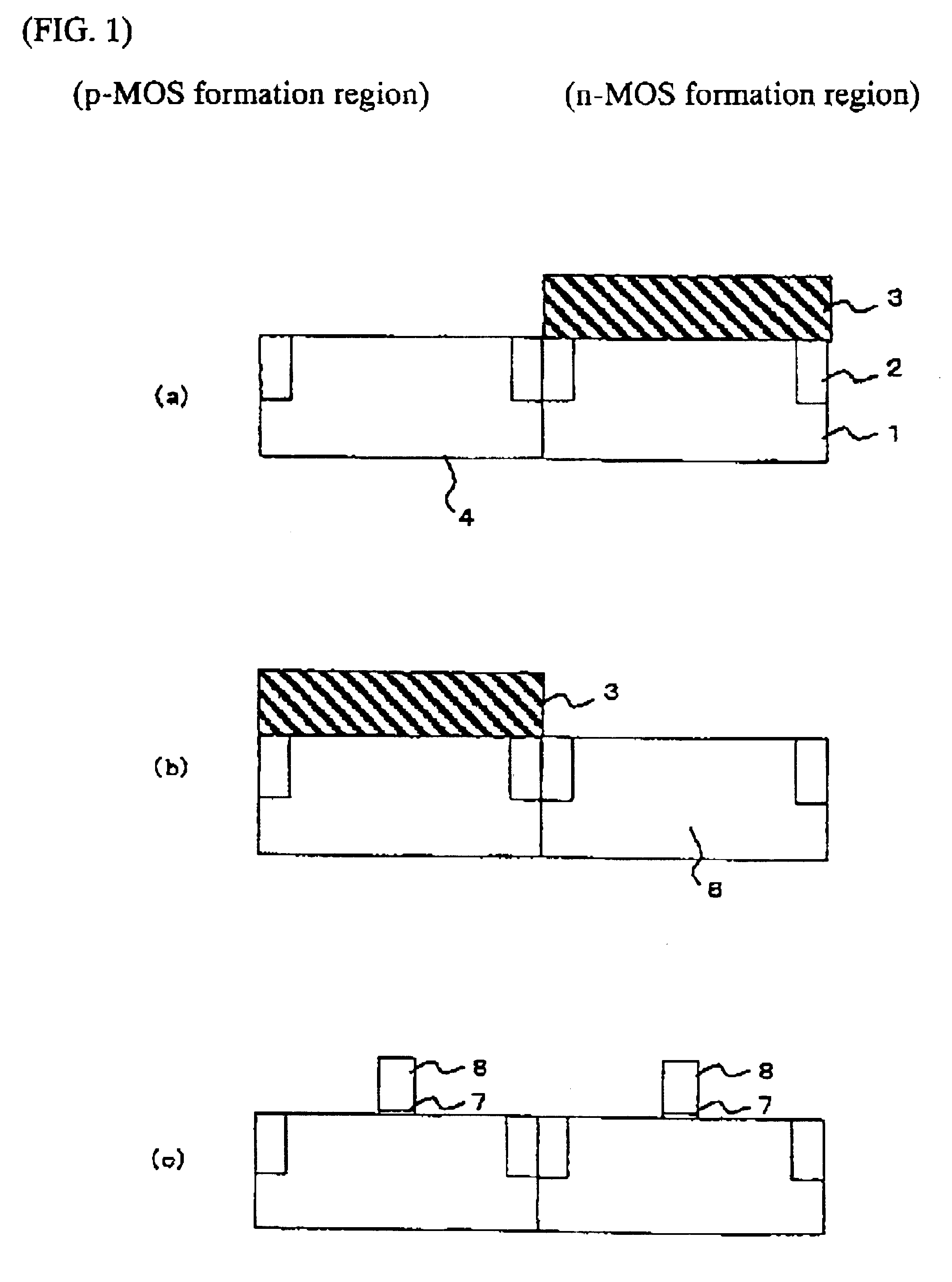

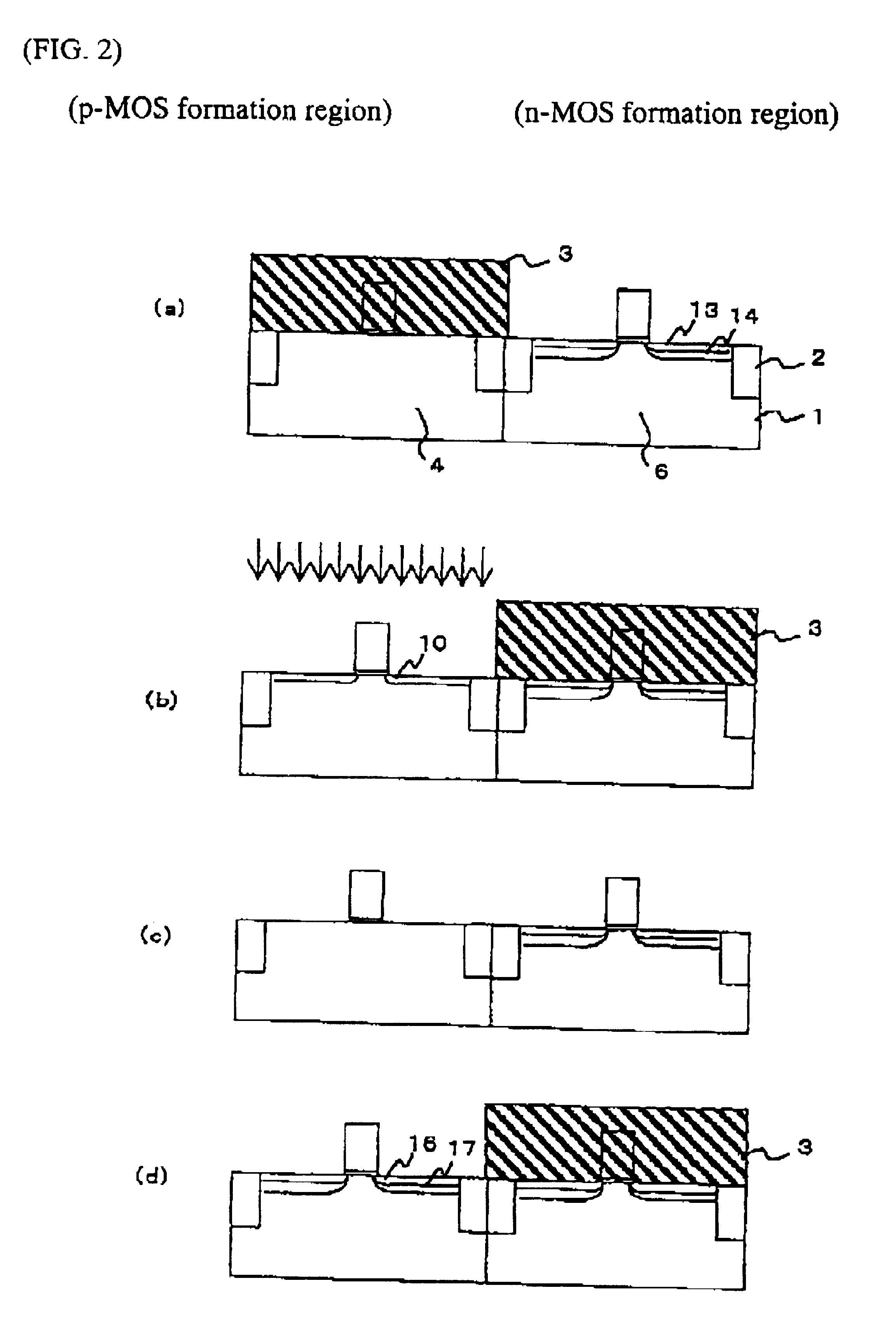

Method of forming MOS transistor

InactiveUS6436783B1Remarkable effectTransistorSemiconductor/solid-state device manufacturingEngineeringThreshold voltage

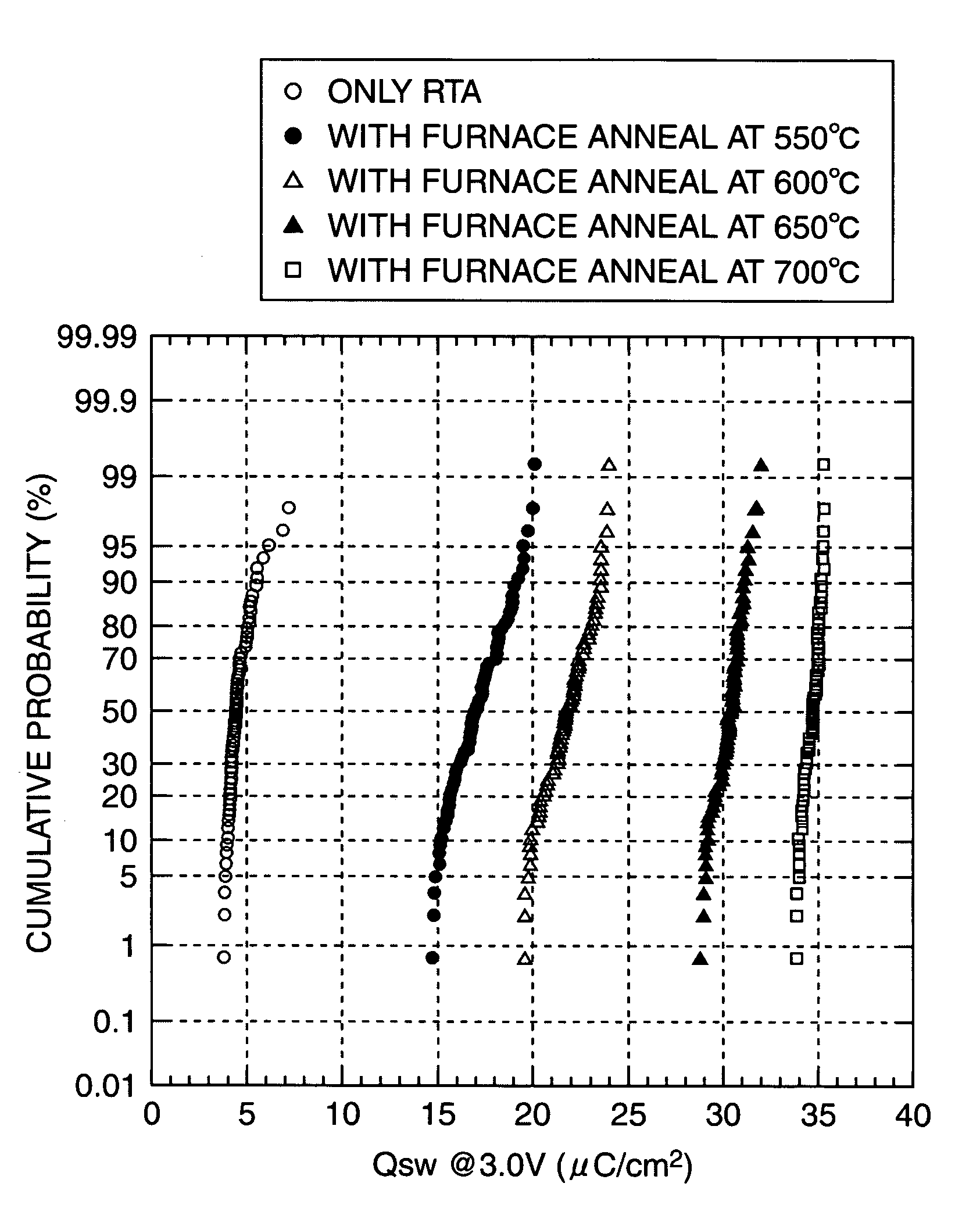

(issue) It is an issue to suppress variation in threshold voltage due to deterioration in shot channel characteristics and improve the slow trap characteristics of the MOS transistor for suppressing variation in threshold voltage of the transistor for a long-term use.(means for solving the issue) fluorine ions are implanted into a surface of a silicon substrate 1 but a peripheral region of a gate electrode on a p-MOS formation region. A first heat treatment is carried out for removing inter-lattice silicon atoms generated upon ion-implantation. Thereafter, a second heat treatment is carried out for diffusing fluorine ions into a region directly under the gate electrode. The first heat treatment is a lamp anneal such as RTA, and the second heat treatment is a furnace anneal.

Owner:RENESAS ELECTRONICS CORP

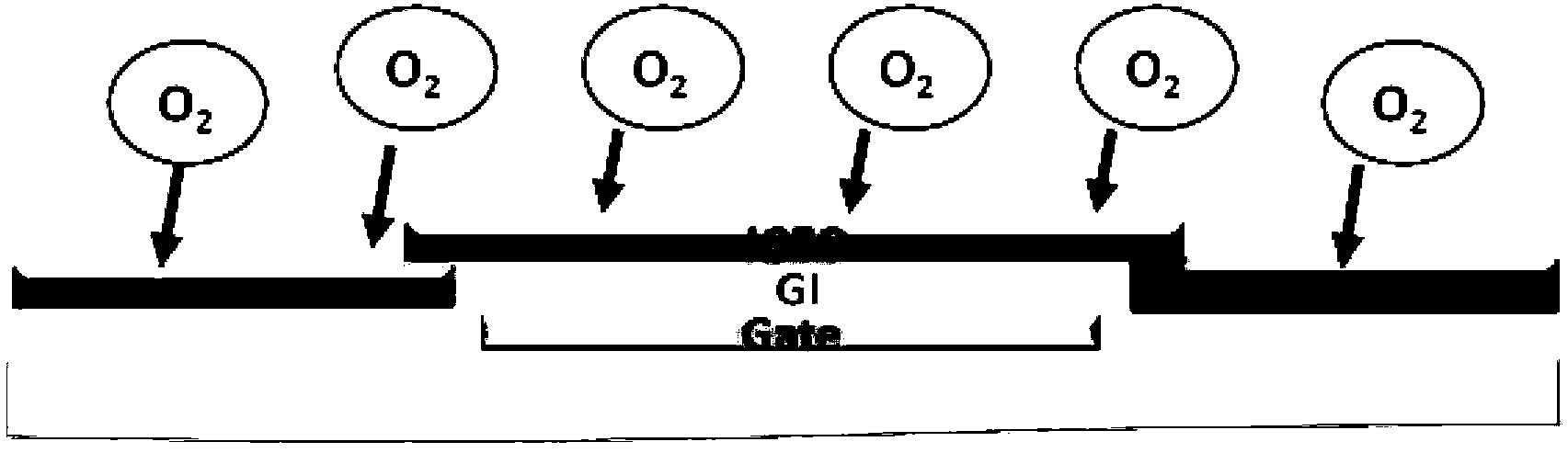

Manufacturing method of semiconductor device

InactiveUS20050136556A1Avoid small quantitiesExcellent fatigue propertiesTransistorSolid-state devicesMetallurgyAtmospheric pressure

An IrOx film is formed as a first conductive oxide film on a PLZT film by a reactive sputtering method. Thereafter, thermal treatment by, for example, RTA is performed in an atmosphere containing oxygen having partial pressure of less than 5% of atmospheric pressure. As a result, crystallization of the PLZT film is promoted, and annealing treatment is performed for the IrOx film. Thereafter, furnace annealing at 600° C. or higher, for example, 650° C. is performed for 60 minutes in, for example, an O2 atmosphere as recovering annealing to recover oxygen deficiency in the PLZT film. Subsequently, an IrO2 film is formed as a second conductive oxide film on the IrOx film by a sputtering method.

Owner:FUJITSU SEMICON LTD

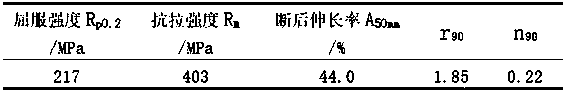

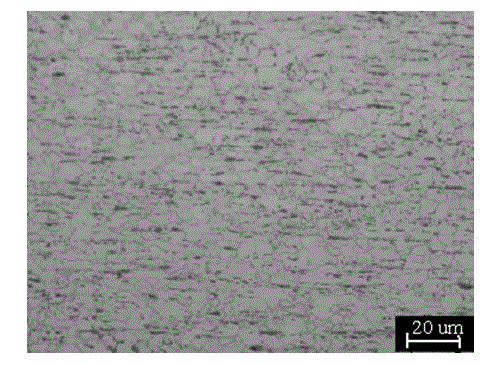

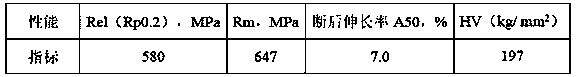

Production method of 450MPa grade cold rolled magnetic pole steel

InactiveCN1904115AGuaranteed StrengthWarranty requirementsRoll mill control devicesHeat treatment process controlChemical compositionMagnetic poles

This invention relates to a process of producing 450MPa cold rolled steel magnet. It includes steps as follows: (1)to heat plate body to 1160-1230DEG C;(2)hot rolling steps: the start rolling temperature 1070-1130DEG C,end rolling temperature 870-930DEG C,cooling to 620-680DEG C for coiling. (3)cooling to 70DEG C below for acid picking. (4)cold rolling steps; (5) bell furnace anneal; controlling temperature 620-680DEG C (6) temper rolling, then the products. Account to weight the main chemical composition is: C 0.06-0.1%,Si 0.10-0.30%,Mn 0.80-1.20%,Nb 0.025-0.045 %,Ti:0.025-0.045%,Als 0.02-0.07%,P <=0.025%,S <=0.010%, Fe the rest.

Owner:WUHAN IRON & STEEL (GROUP) CORP

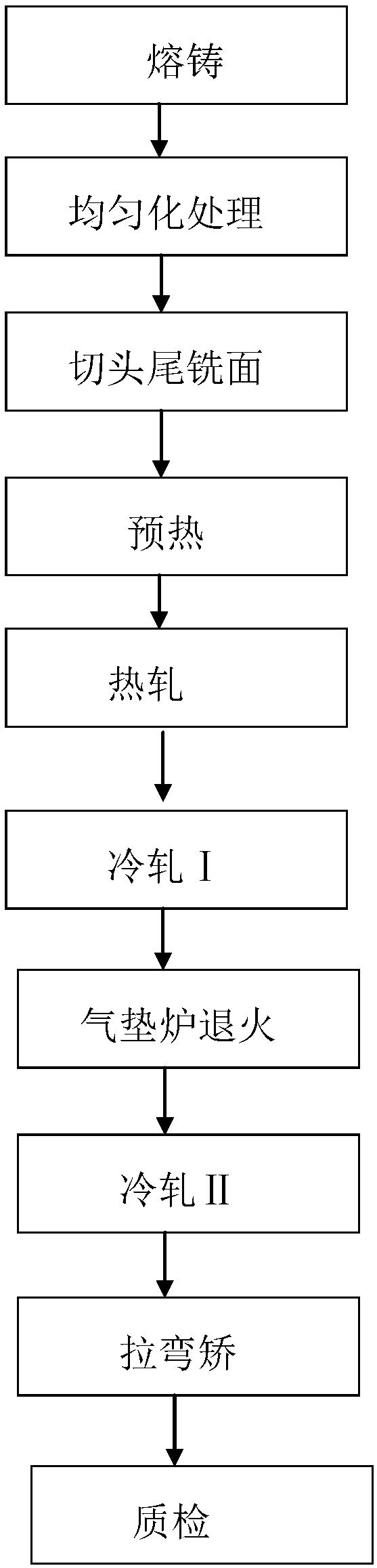

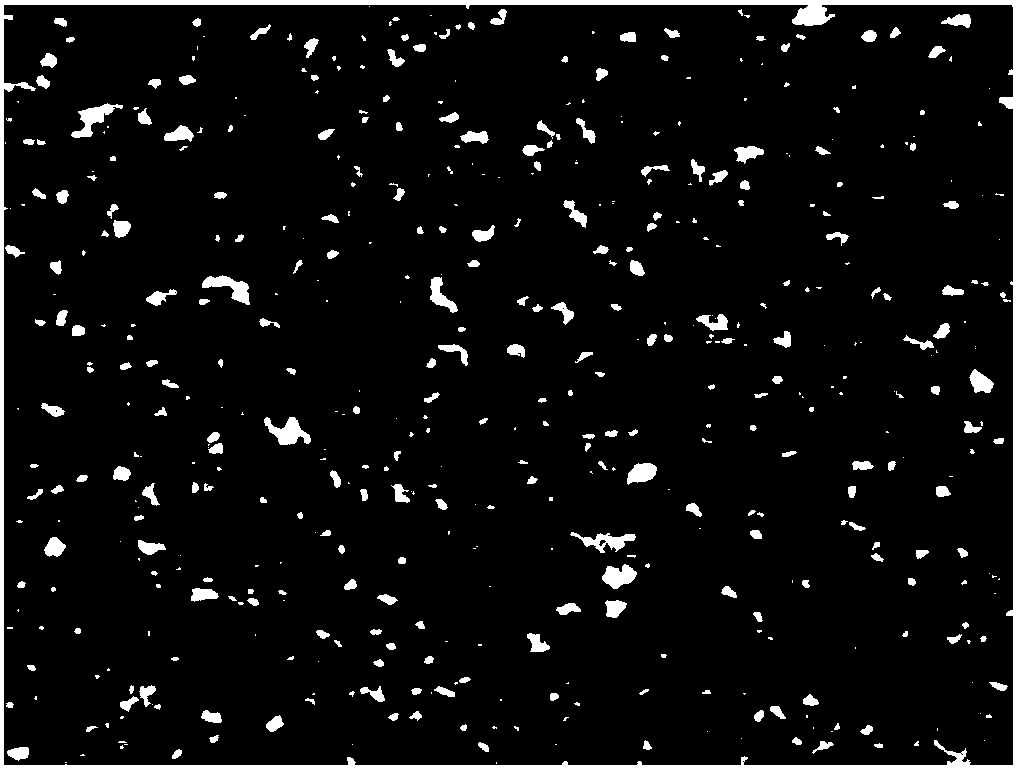

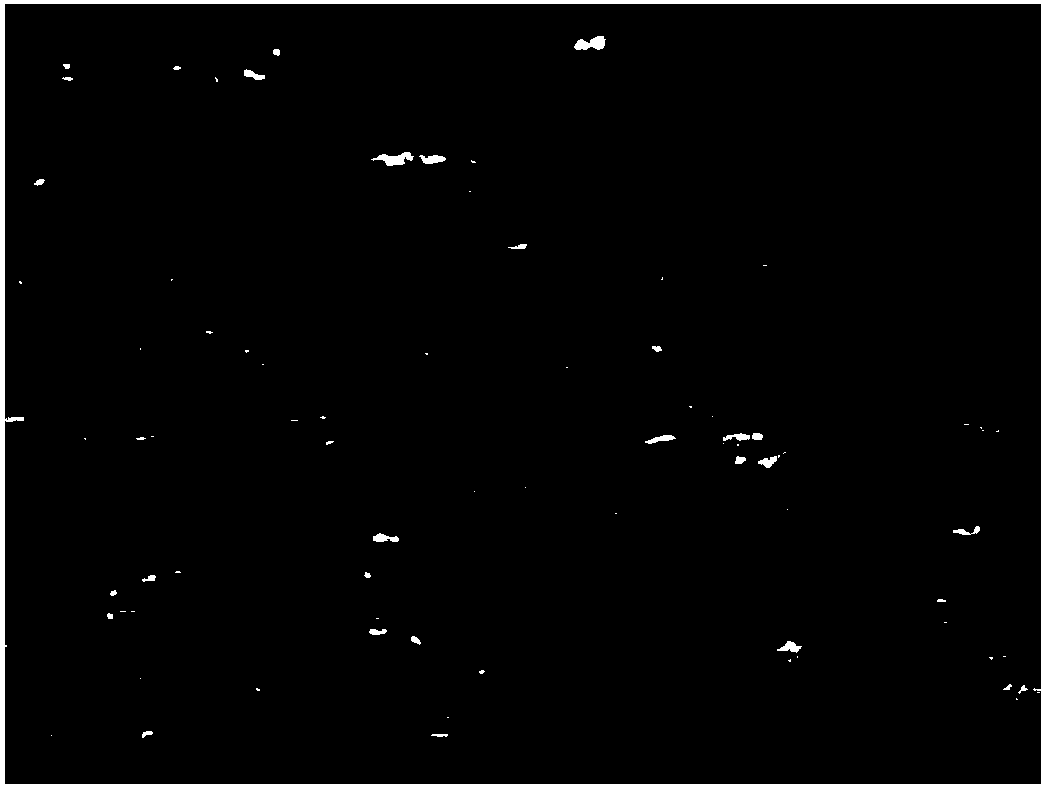

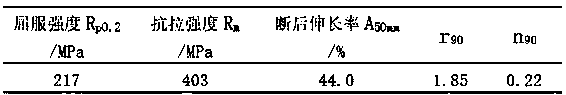

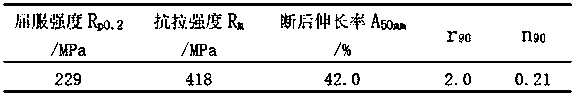

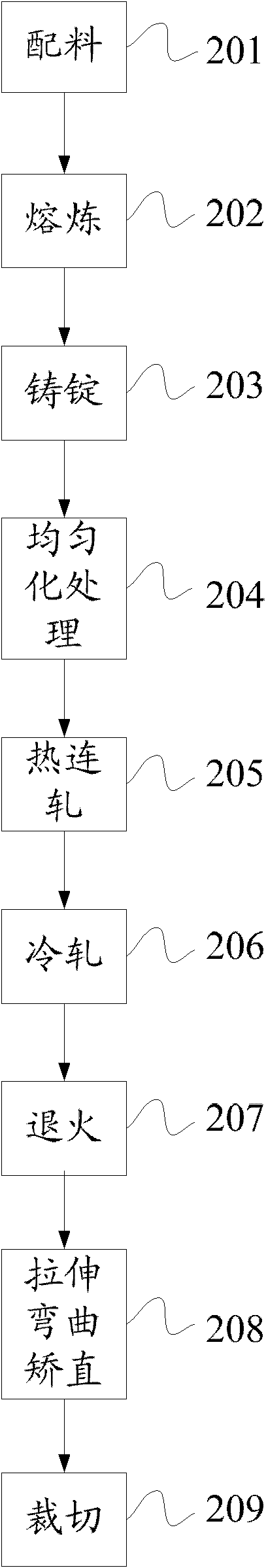

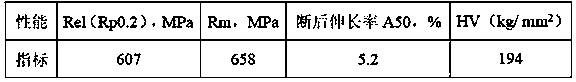

5182 aluminum alloy and technology method for preparing tank cover material strip through aluminum alloy

ActiveCN106834825AHigh strengthImprove performance uniformityTemperature control deviceRolling mill drivesUltimate tensile strengthImpurity

The invention discloses a 5182 aluminum alloy. The aluminum alloy is composed of Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti, and remaining Al and some inevitable impurities. A preparing technology of a tank cover material strip through the 5182 aluminum alloy comprises the steps of firstly, taking of the 5182 aluminum alloy; secondly, hot rolling, cooling and obtaining a blank for cold rolling; thirdly, primary cold rolling, and obtaining a cold-rolled intermediate product, wherein the total deformation amount ranges from 66% to 78%; fourthly, air cushion furnace annealing; fifthly, secondary cold rolling, wherein the total deformation amount ranges from 71% to 76%; sixthly, stretch bending and correcting. According to the 5182 aluminum alloy and the preparing technology of the tank cover material strip through the 5182 aluminum alloy, through high alloying, the alloy strength is improved, meanwhile, the content of Fe and Si is reasonably controlled, and bank mark generation is restrained; continuous air cushion furnace annealing is adopted, through high-temperature short-time annealing, the grains are adjusted and controlled, uniformity of the strip performance is improved, and meanwhile the strip surface quality is ensured.

Owner:广西南南铝加工有限公司

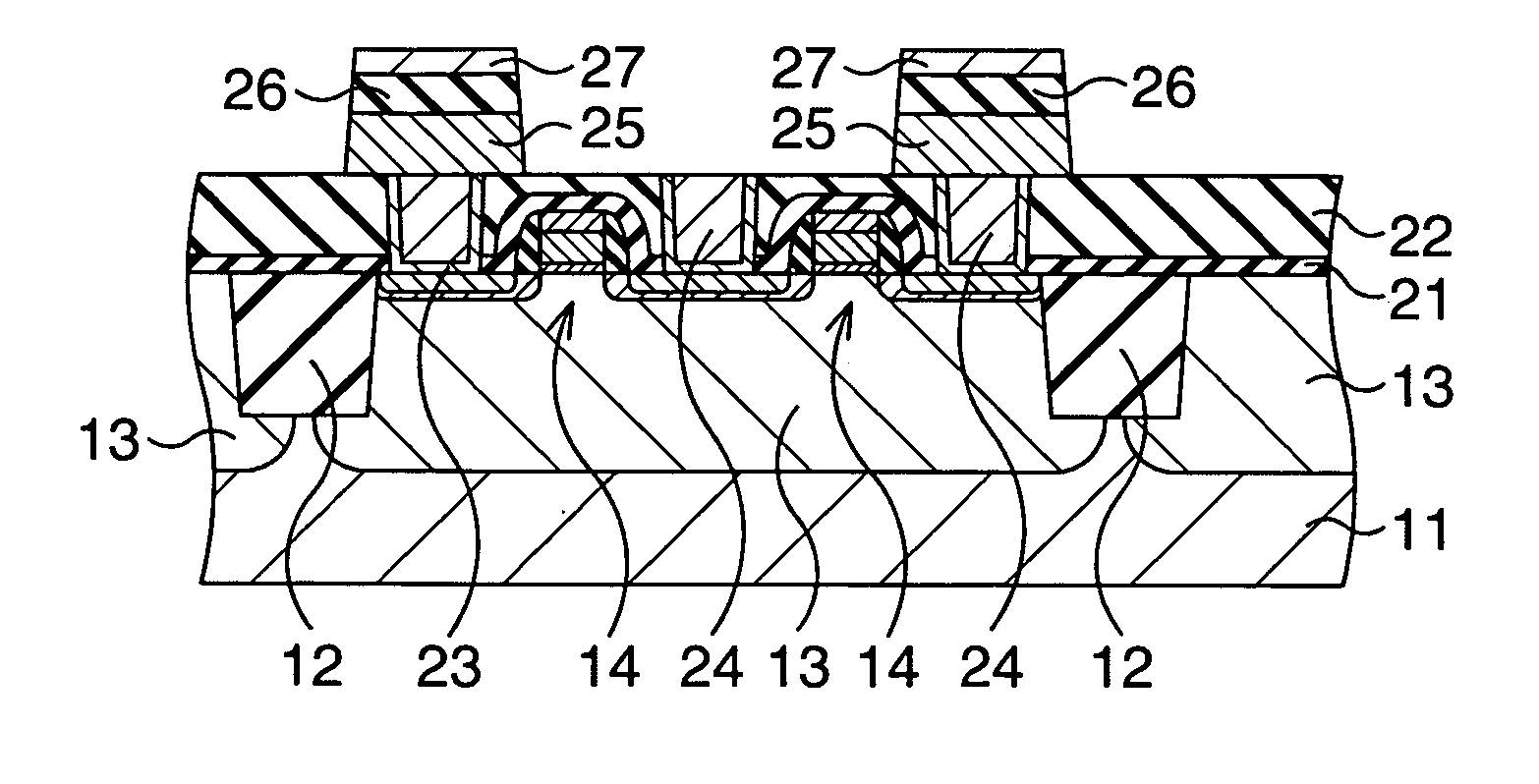

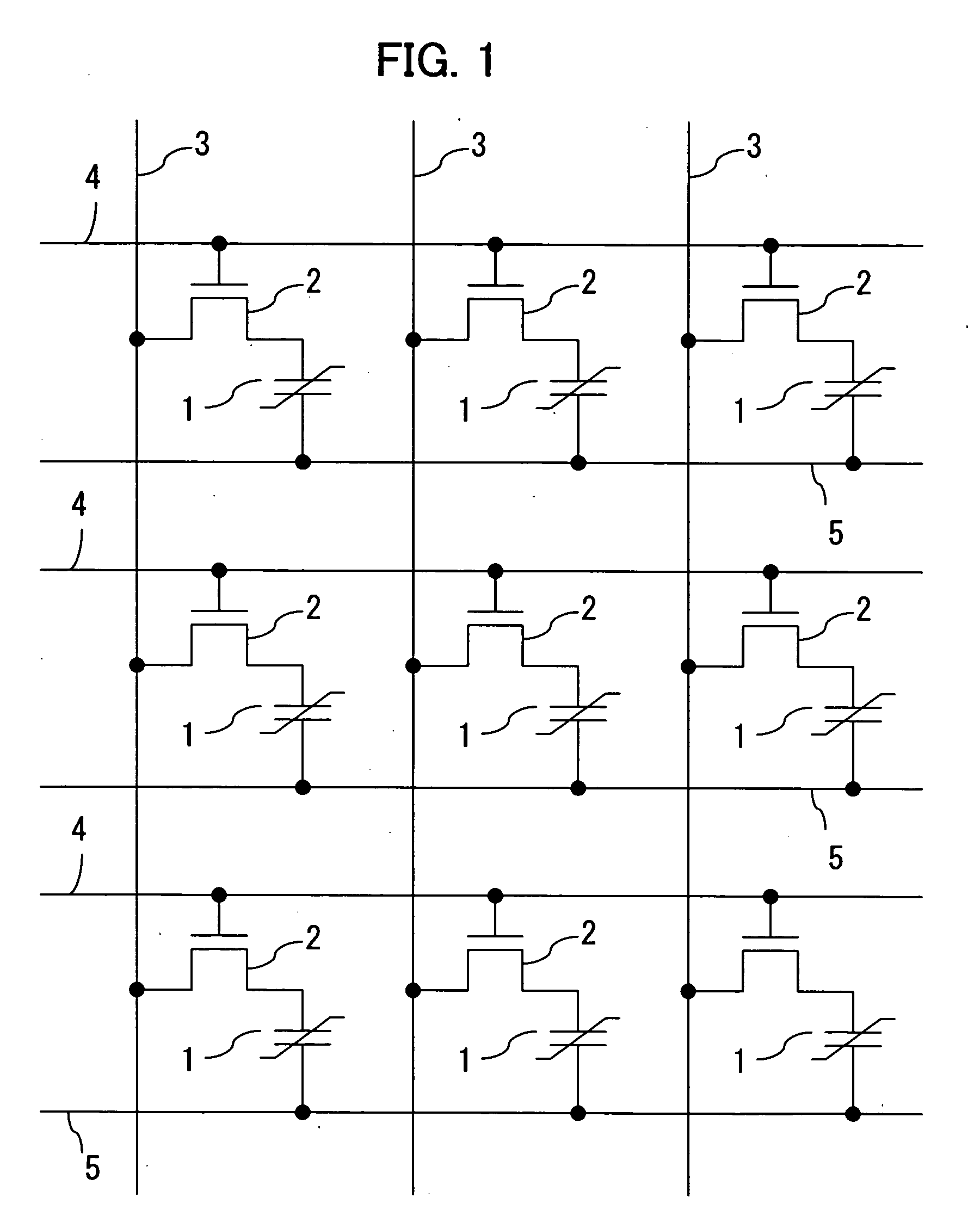

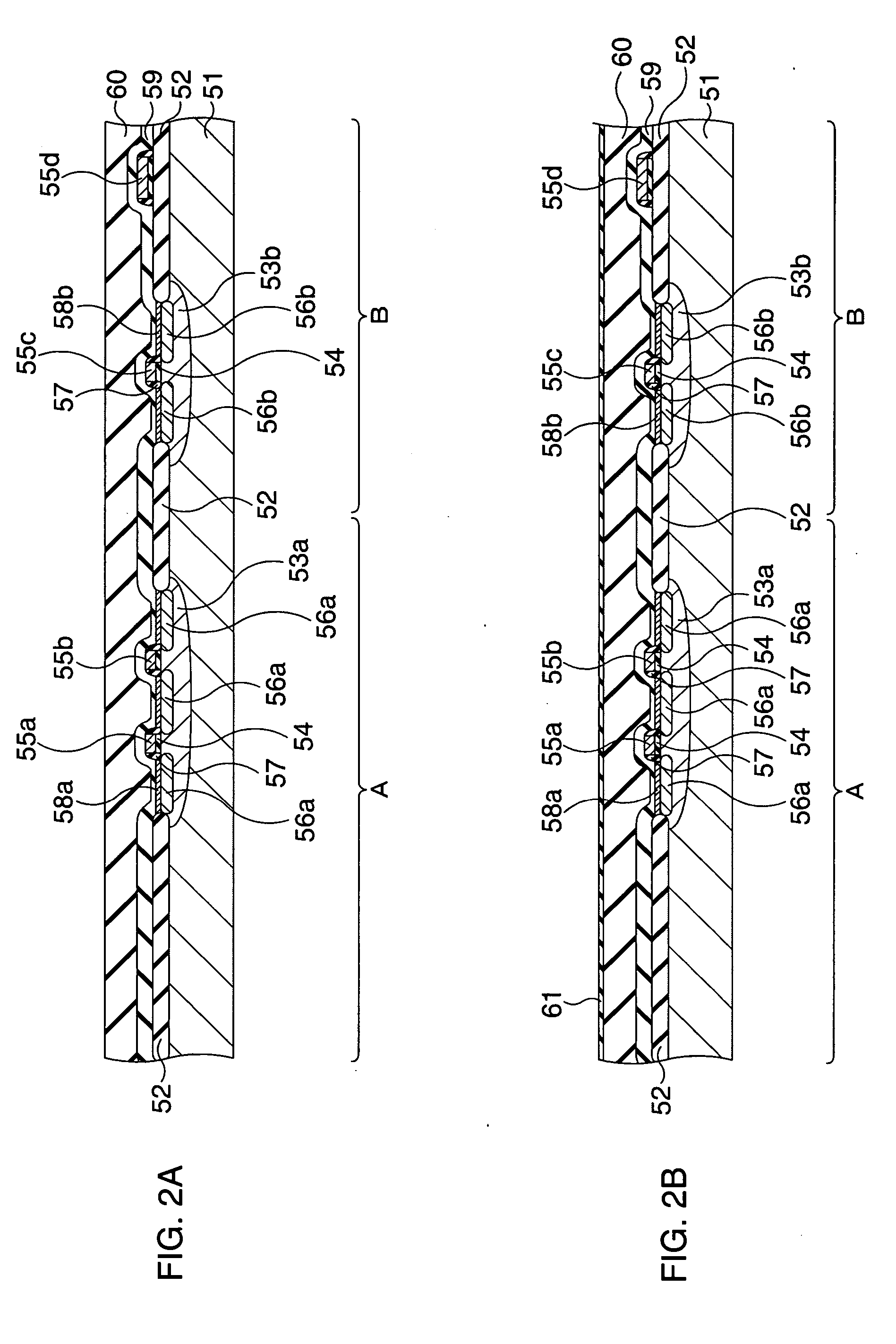

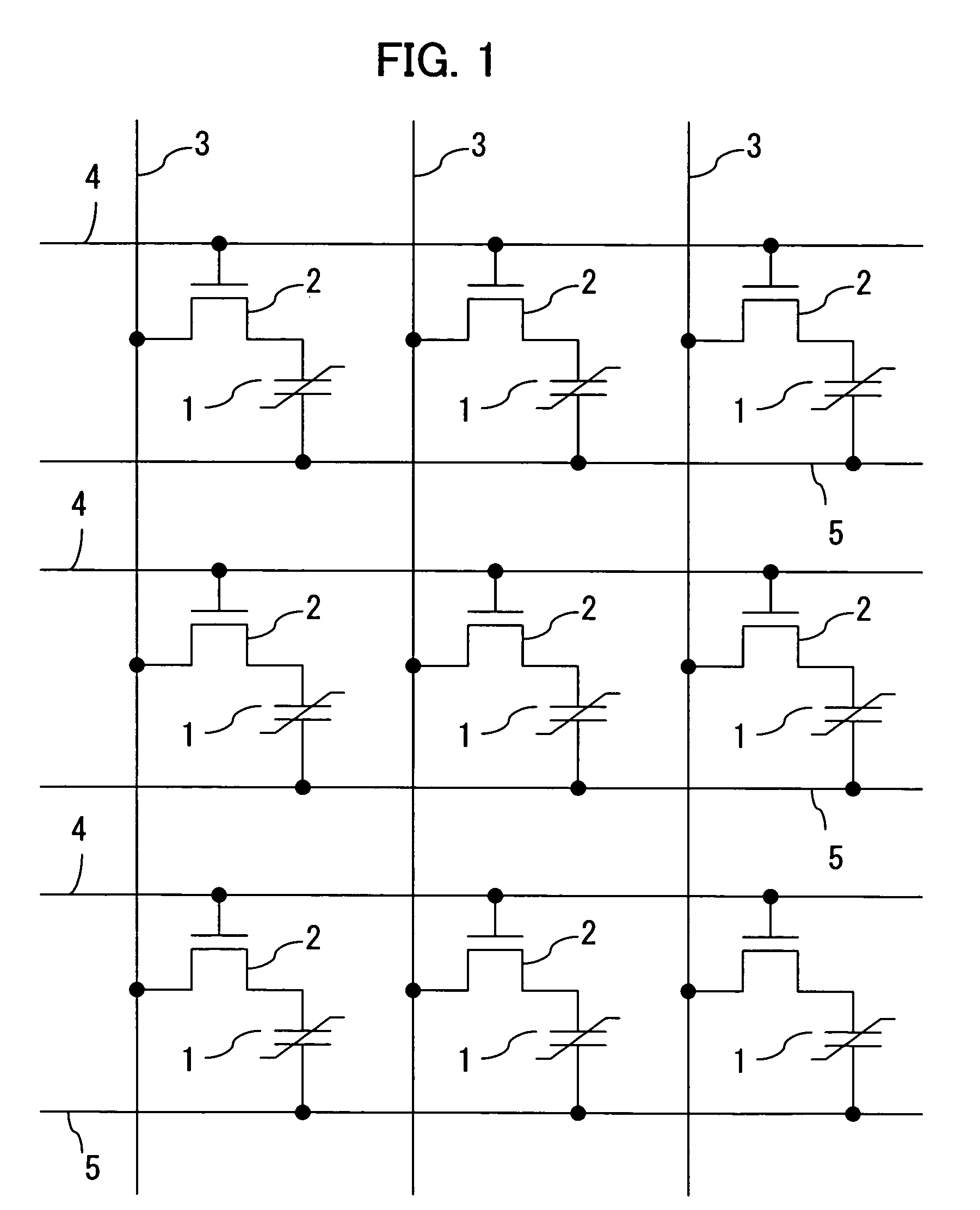

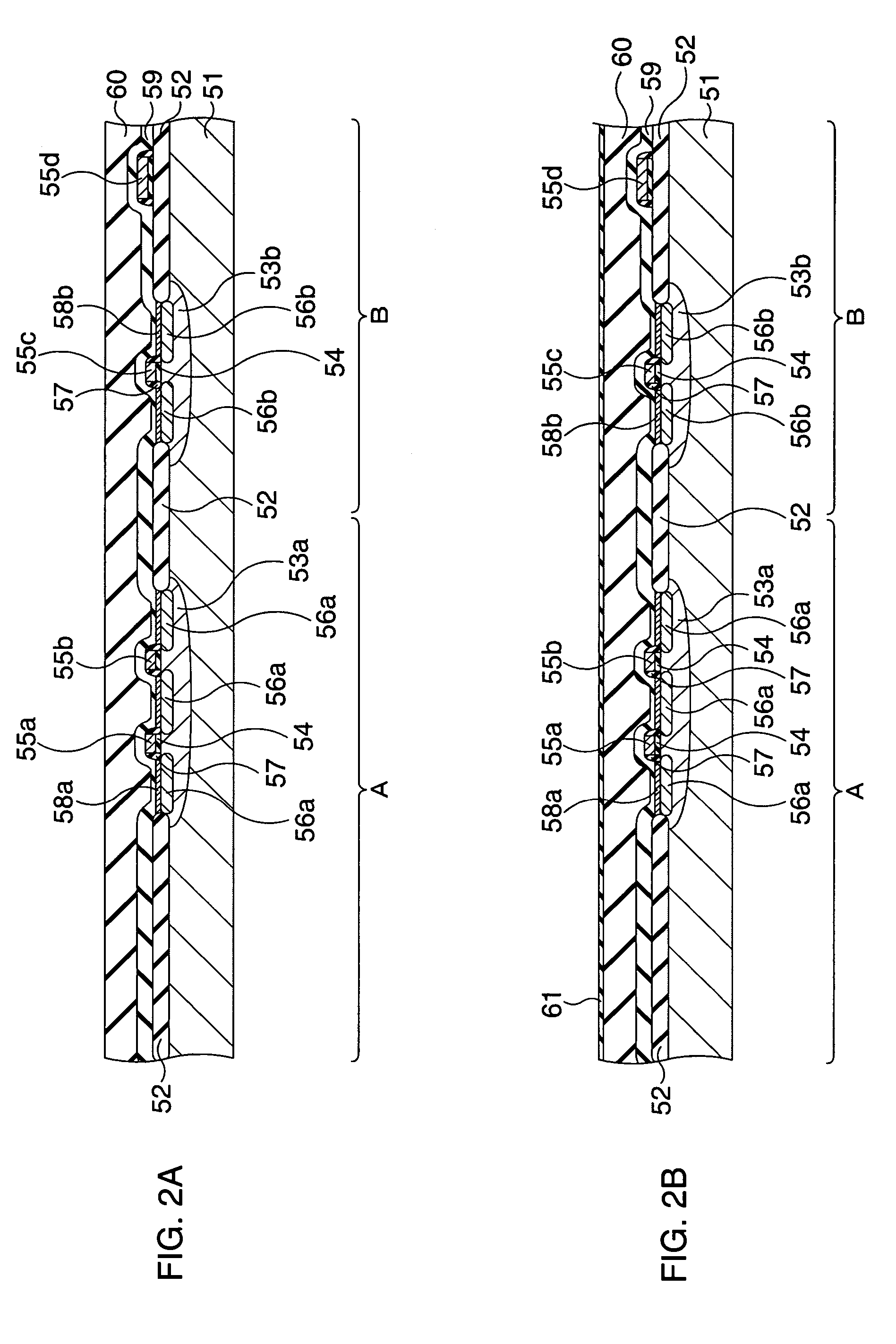

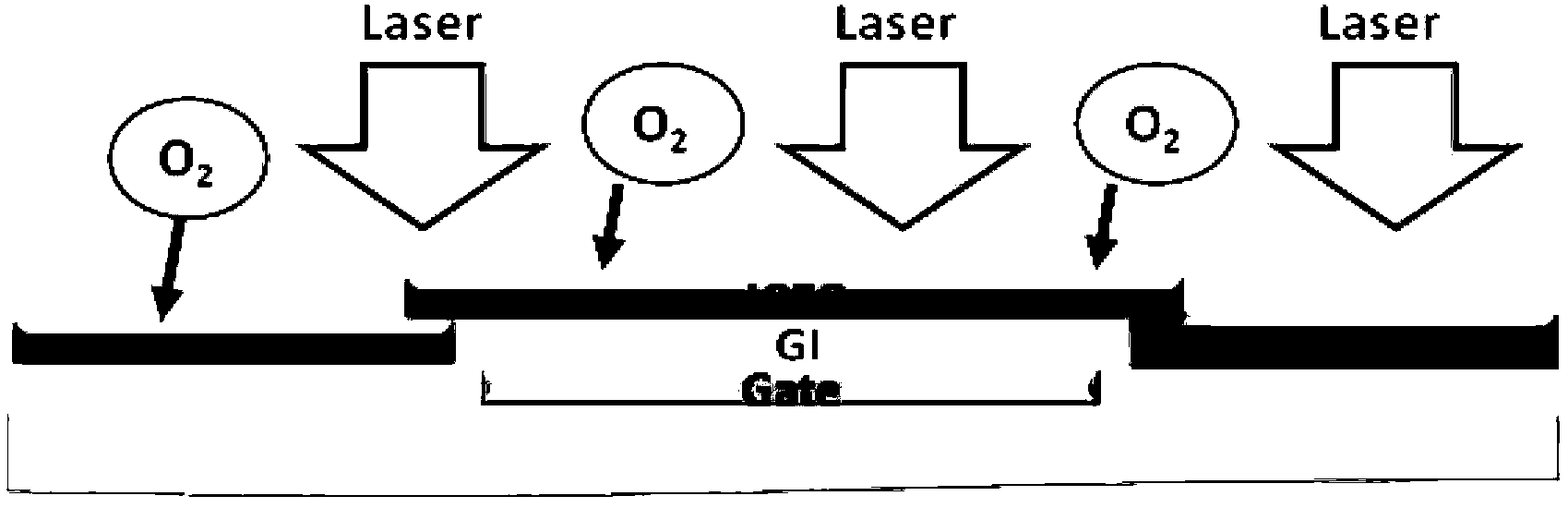

Semiconductor device and method of manufacturing the same

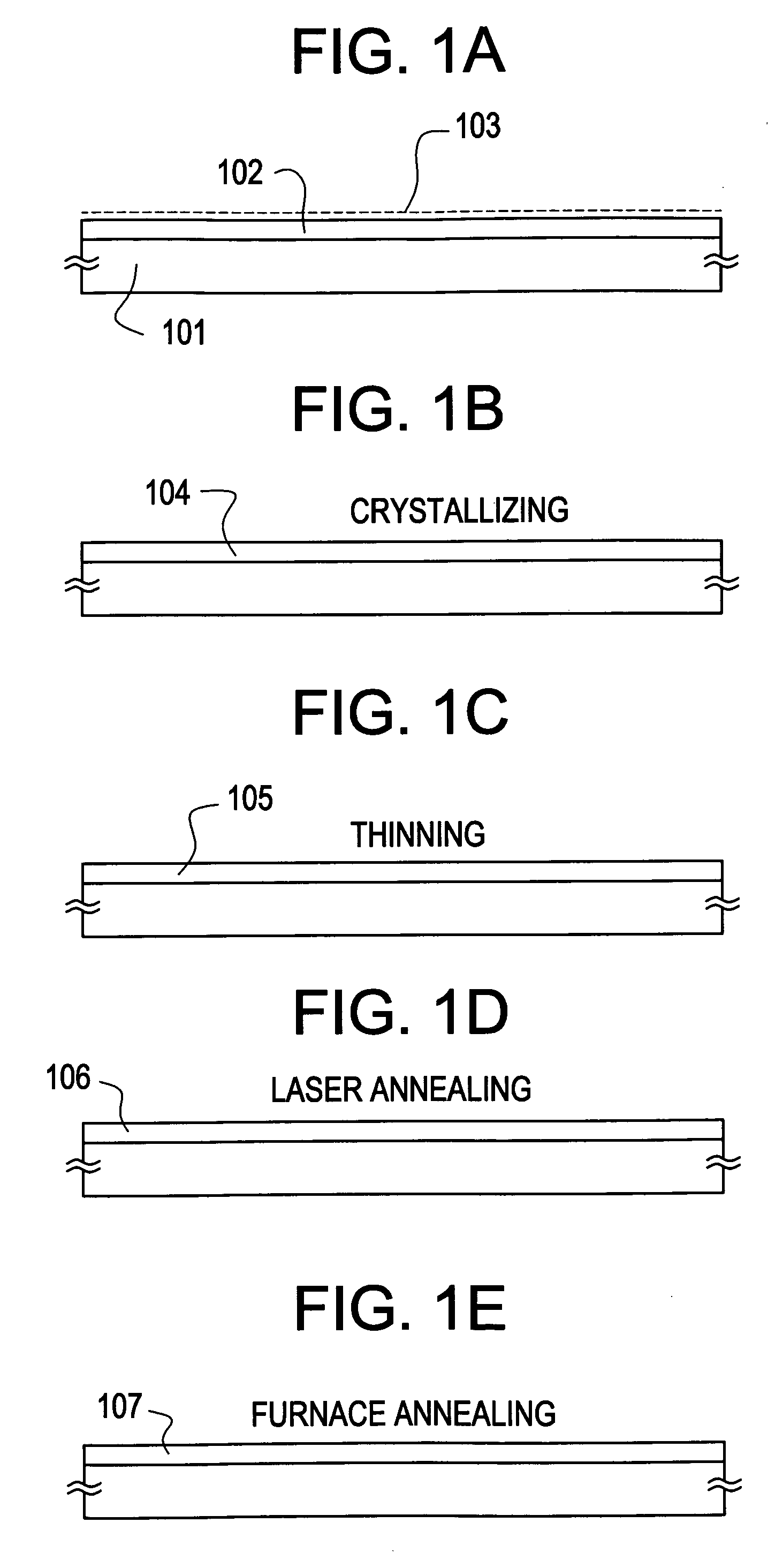

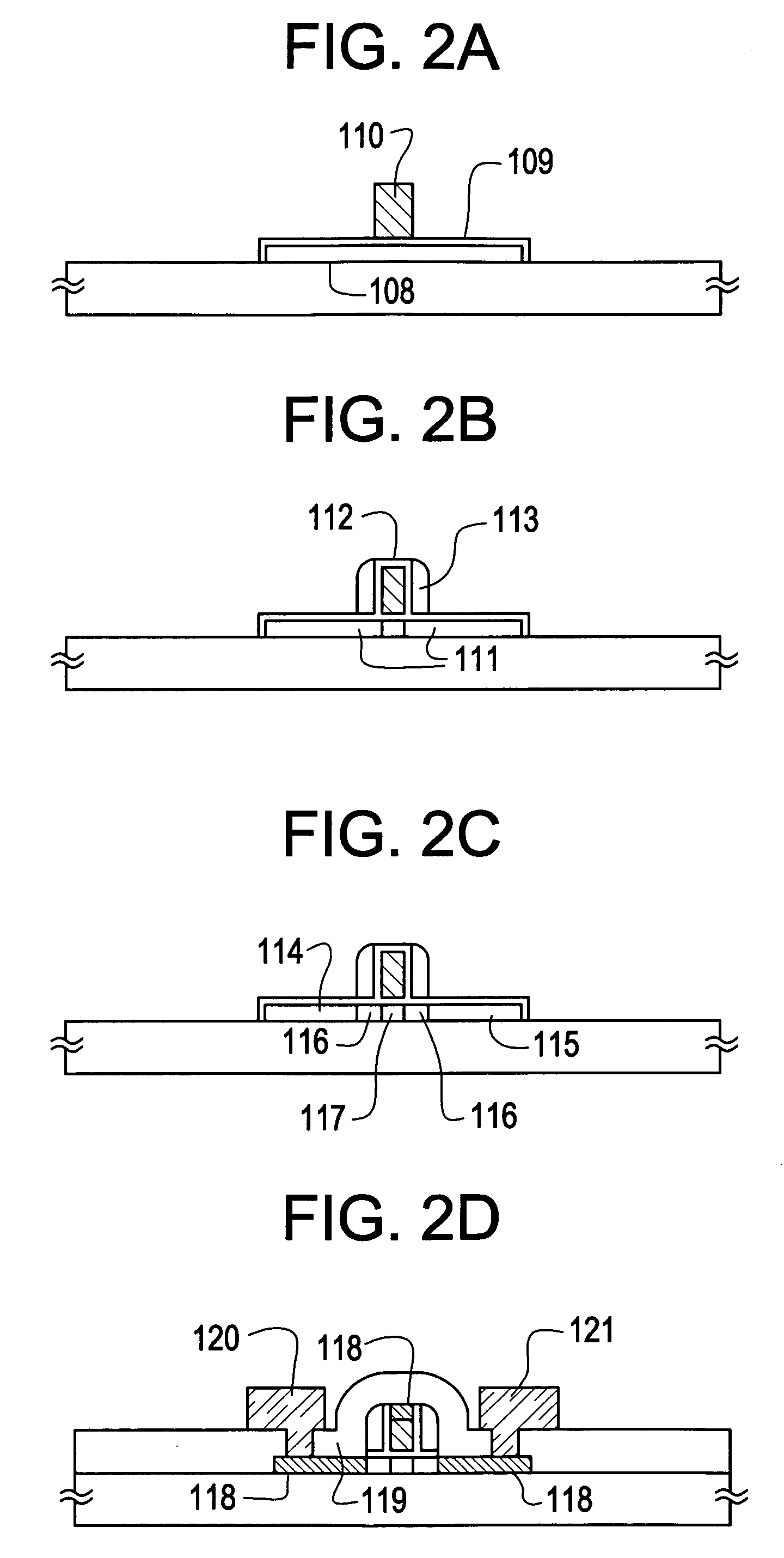

InactiveUS7186600B2Improve performanceImprove featuresTransistorSolid-state devicesOptoelectronicsSemiconductor

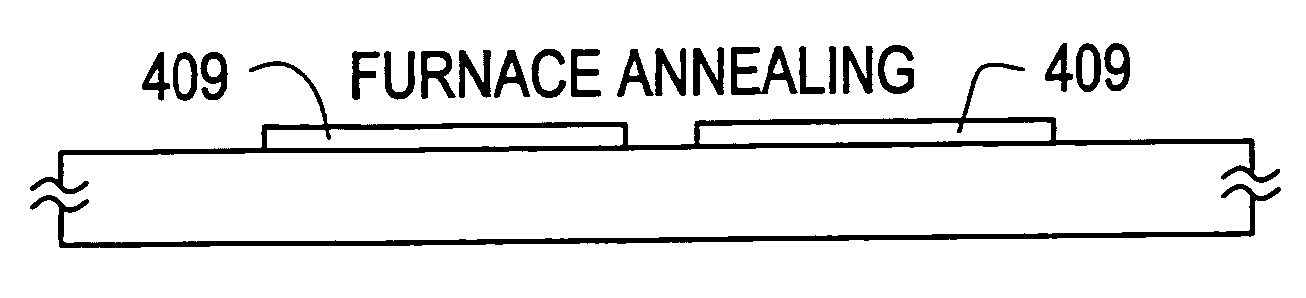

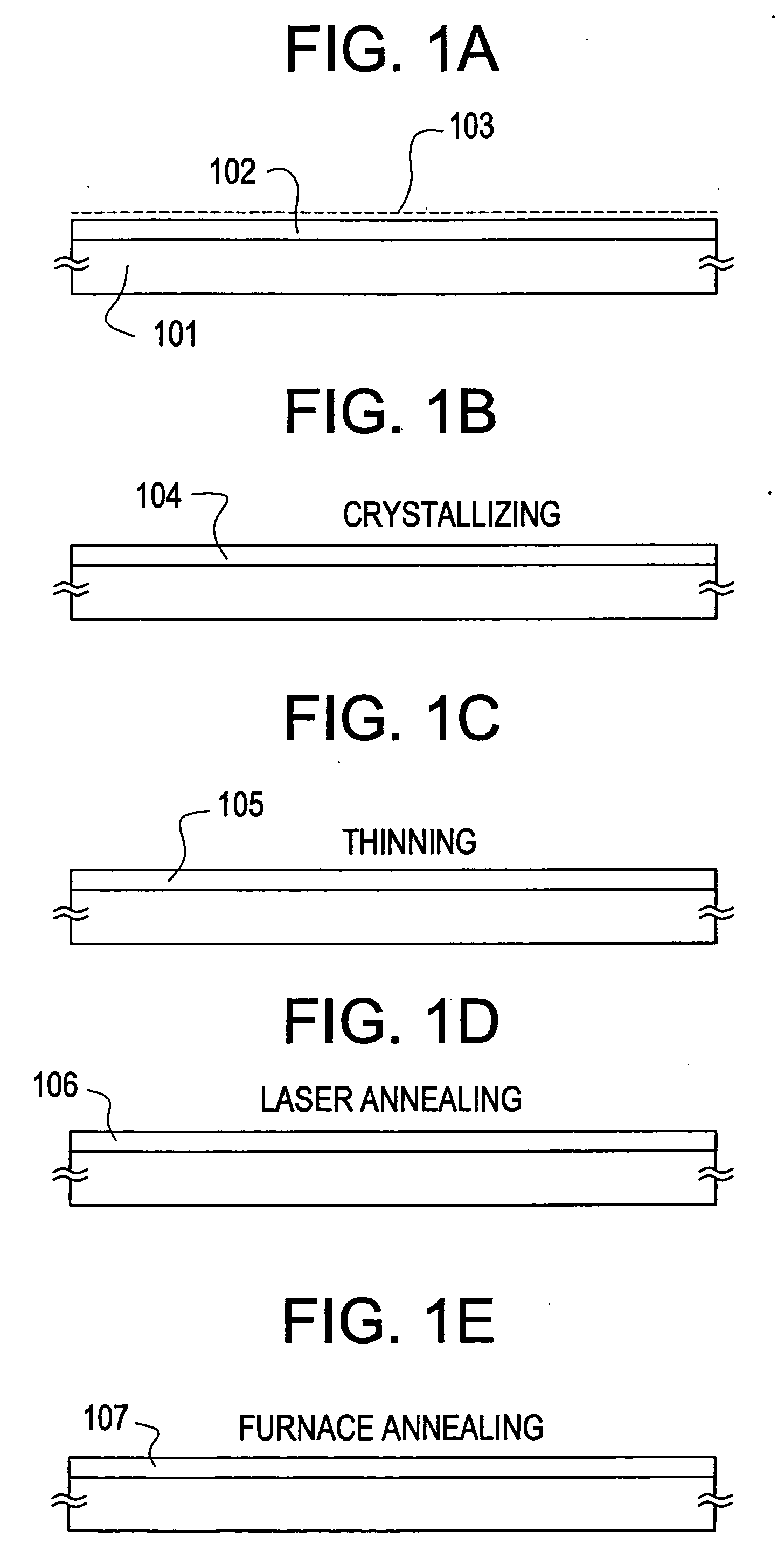

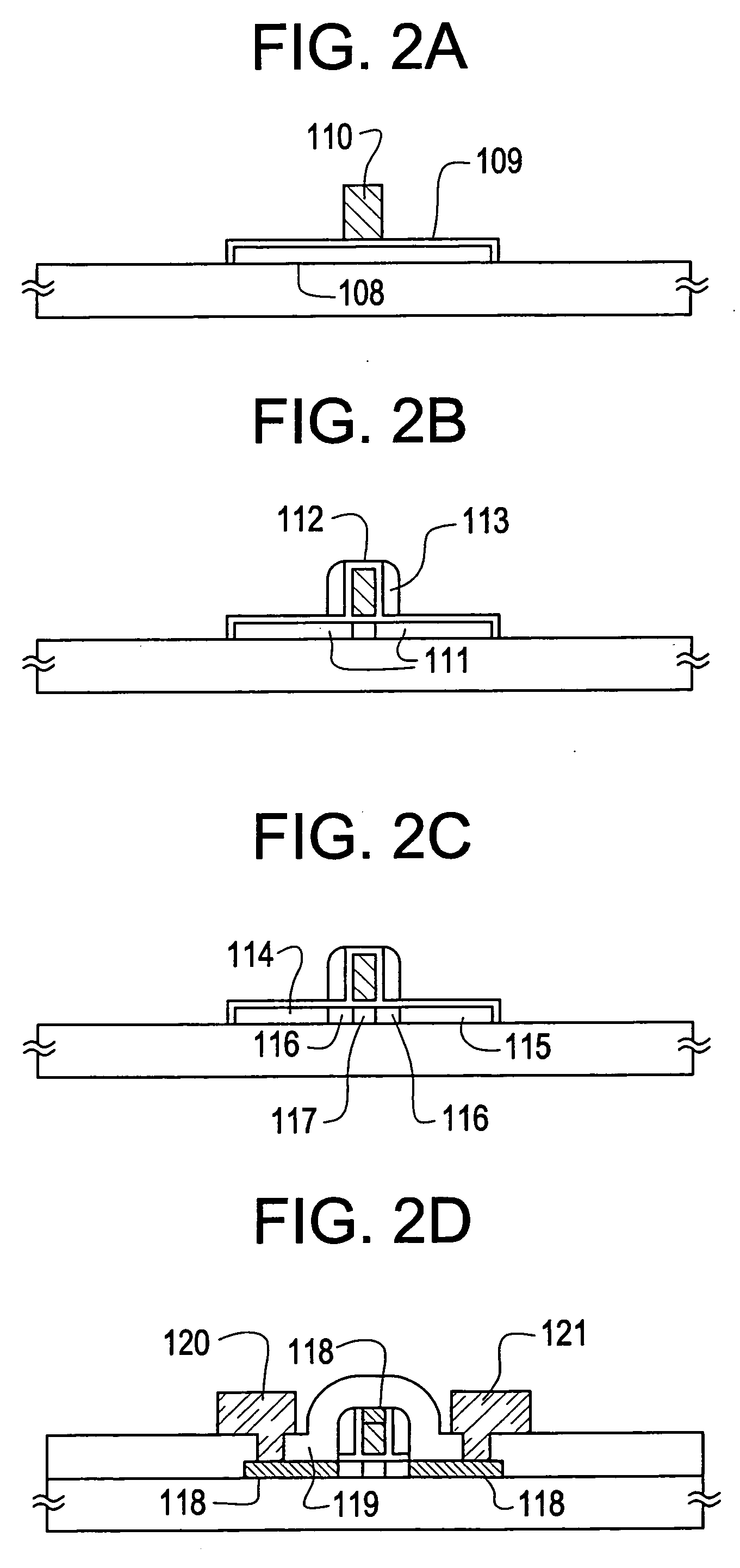

There is provided a method in which a TFT with superior electrical characteristics is manufactured and a high performance semiconductor device is realized by assembling a circuit with the TFT. The method of manufacturing the semiconductor device includes: a step of forming a crystal-containing semiconductor film by carrying out a thermal annealing to a semiconductor film; a step of carrying out an oxidizing treatment to the crystal-containing semiconductor film; a step of carrying out a laser annealing treatment to the crystal-containing semiconductor film after the oxidizing treatment has been carried out; and a step of carrying out a furnace annealing treatment to the crystal-containing semiconductor film after the laser annealing. The laser annealing treatment is carried out with an energy density of 250 to 5000 mJ / cm2.

Owner:SEMICON ENERGY LAB CO LTD

Manufacturing method of semiconducter device

An IrOx film is formed as a first conductive oxide film on a PLZT film by a reactive sputtering method. Thereafter, thermal treatment by, for example, RTA is performed in an atmosphere containing oxygen having partial pressure of less than 5% of atmospheric pressure. As a result, crystallization of the PLZT film is promoted, and annealing treatment is performed for the IrOx film. Thereafter, furnace annealing at 600° C. or higher, for example, 650° C. is performed for 60 minutes in, for example, an O2 atmosphere as recovering annealing to recover oxygen deficiency in the PLZT film. Subsequently, an IrO2 film is formed as a second conductive oxide film on the IrOx film by a sputtering method.

Owner:FUJITSU SEMICON LTD

Production method of anti-aging tinning black plate

InactiveCN101643828AUniform mechanical propertiesImprove corrosion resistanceManufacturing convertersSlip lineChemical composition

The invention relates to a production method of an anti-aging tinning black plate with hardness HR30Tm of 55+ / -4 and discloses a production method of an anti-aging tinning black plate. The method comprises the following steps: smelting: adopting KR desulfurization, smelting in a converter, RH vacuum treatment and continuous casting; hot rolling: carrying out the hot rolling of a continuous castingblank comprising the following chemical components in percentage by weight: C: 0.02-0.06, Si: smaller than or equal to 0.025, Mn: smaller than or equal to 0.50, P: smaller than or equal to 0.020, S:smaller than or equal to 0.030, Als: 0.005-0.040, Ti: 0.005-0.020, N: smaller than or equal to 0.005, the balance of Fe and inevitable impurities; and carrying out pickling, cold rolling, electrolyticdegreasing, full-hydrogen bell furnace annealing and leveling of a tinning black plate with hardness HR30Tm of 51-59. The invention has the advantages of small production control difficulty and low cost and hardness value, is beneficial for users to use the anti-aging tinning black plate to manufacture deep drawing cans and can lids with complicated deformation, lessens the canning defects of cracks, crazing slip lines or corded bent surfaces, and the like and improves the canning yield rate and the canning qualified rate.

Owner:WUHAN IRON & STEEL (GROUP) CORP

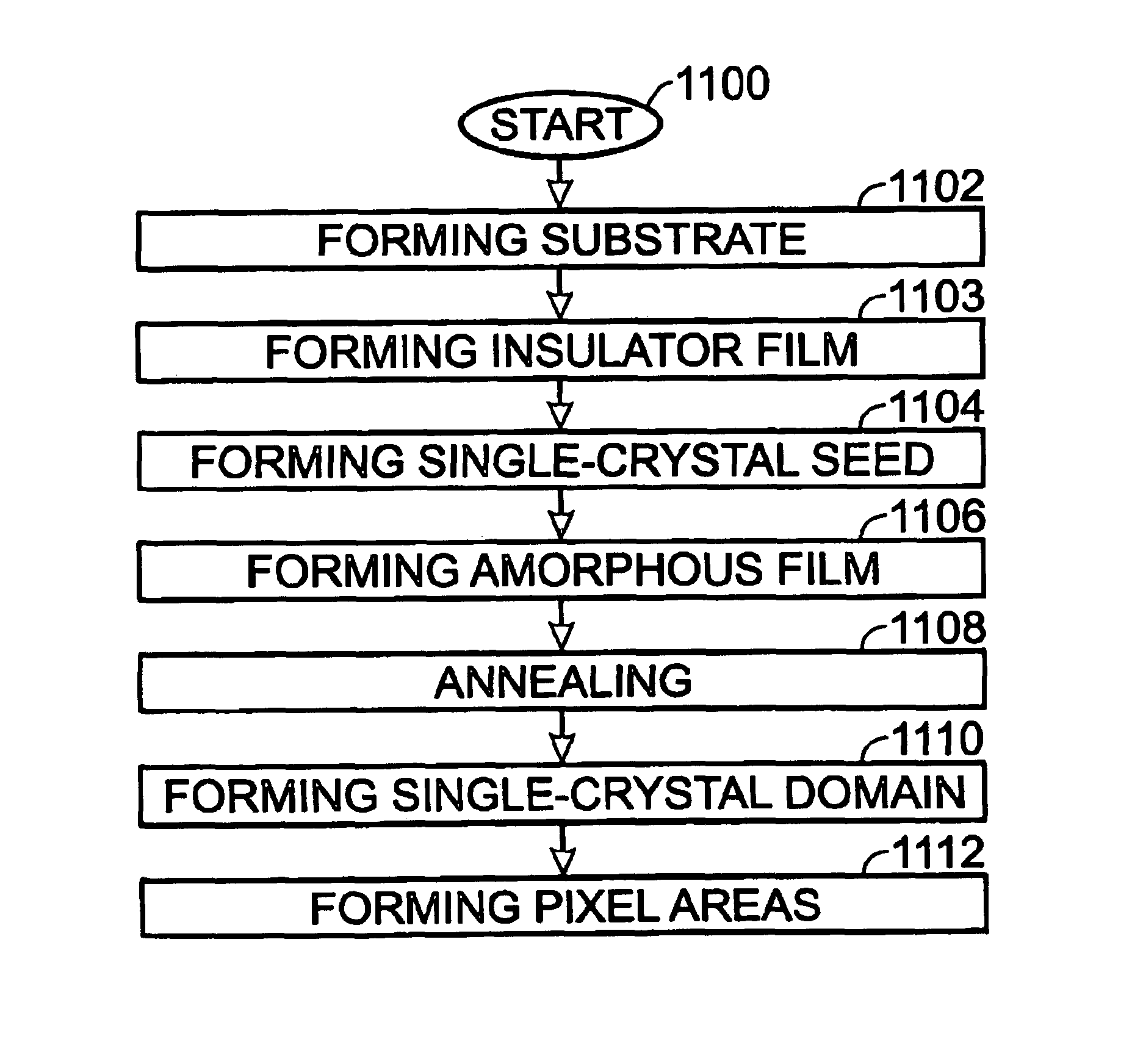

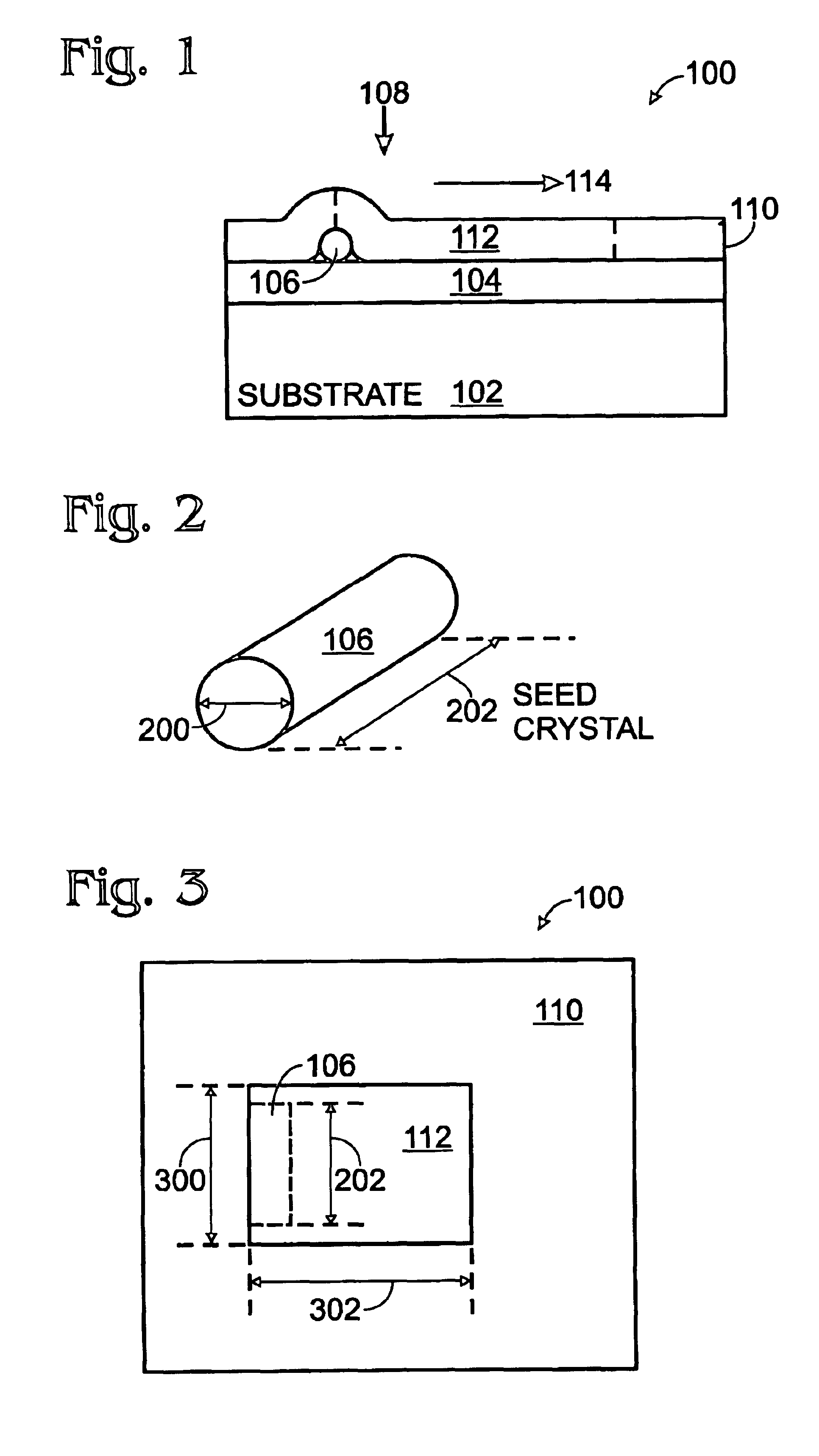

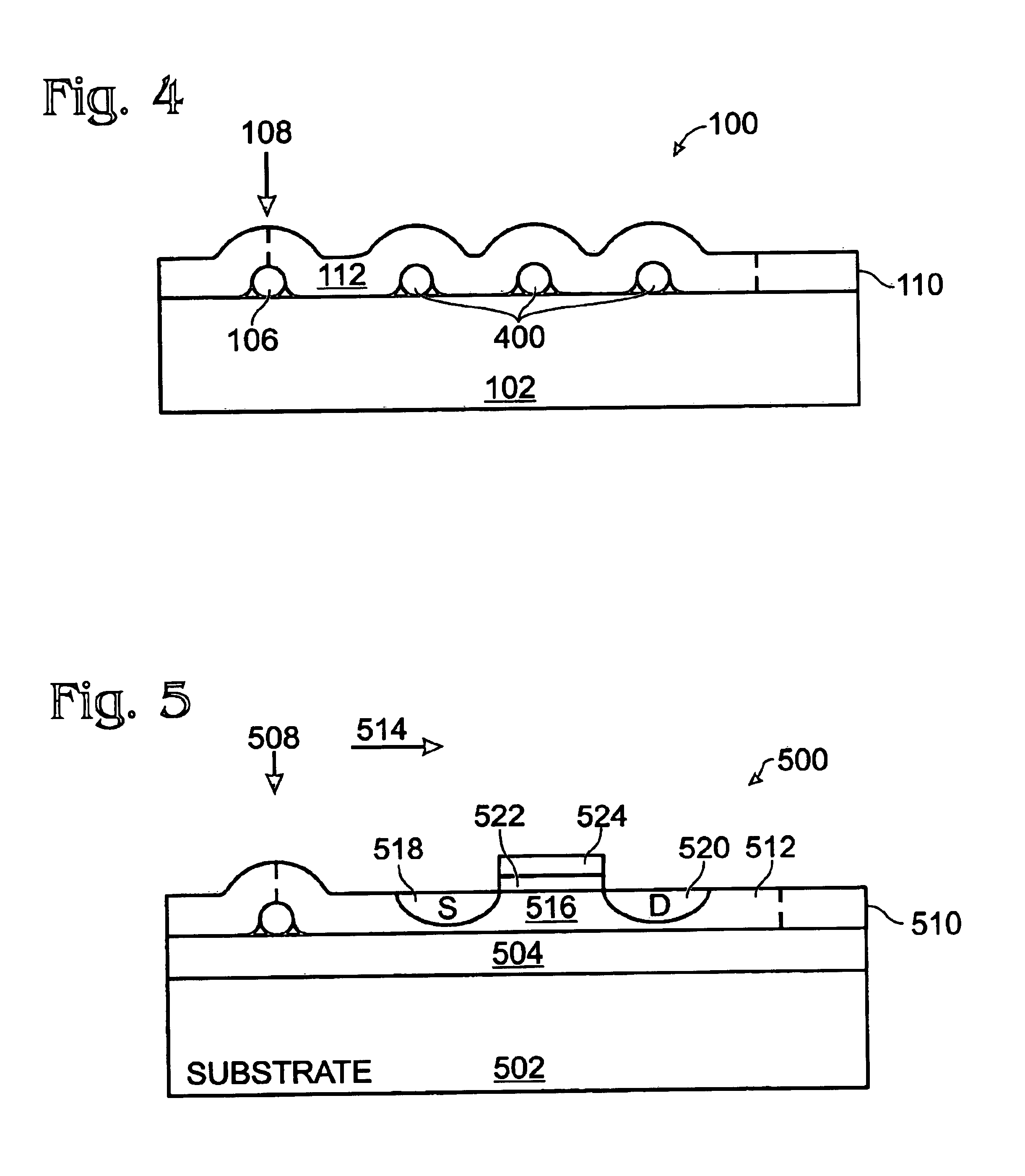

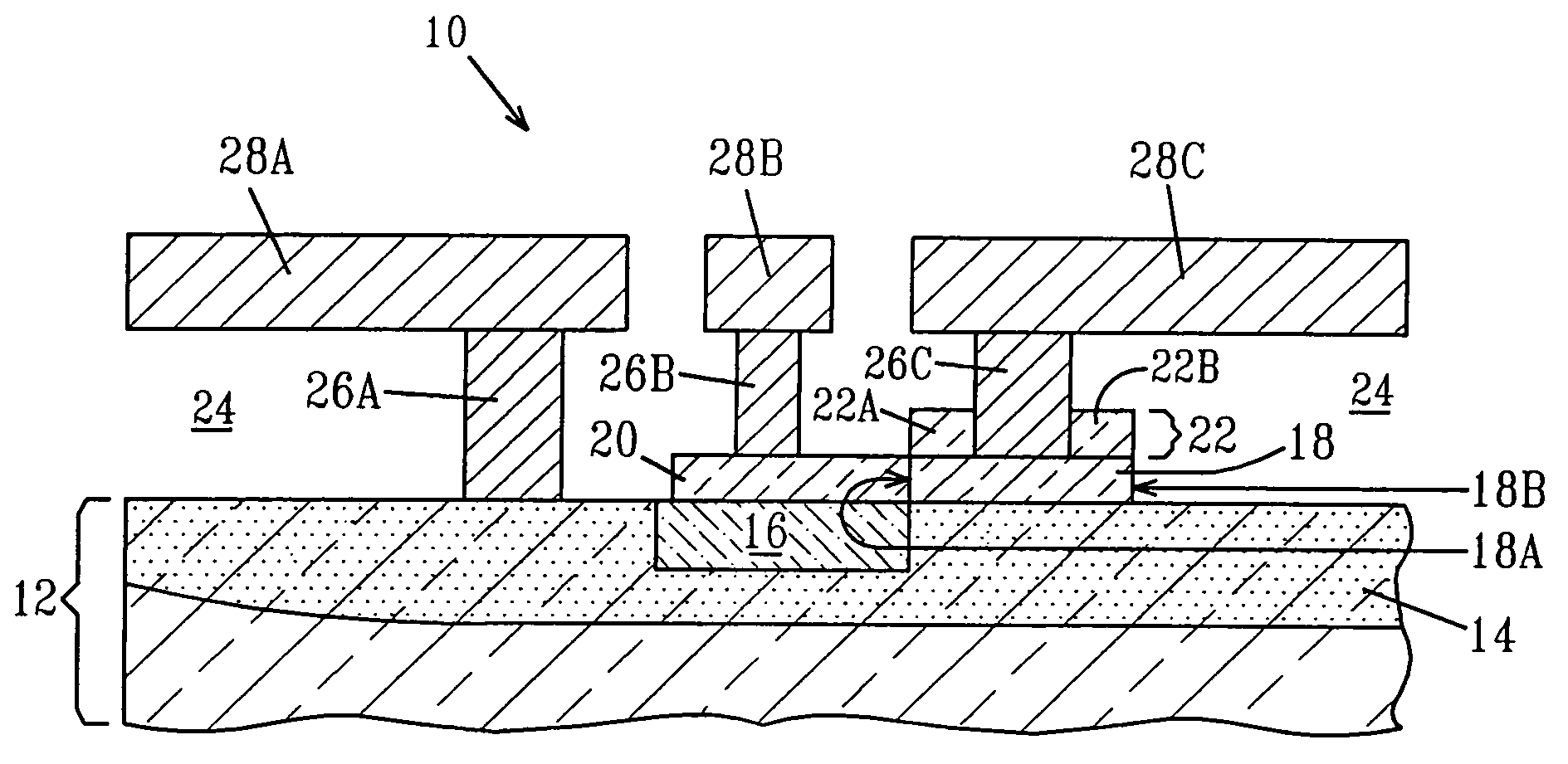

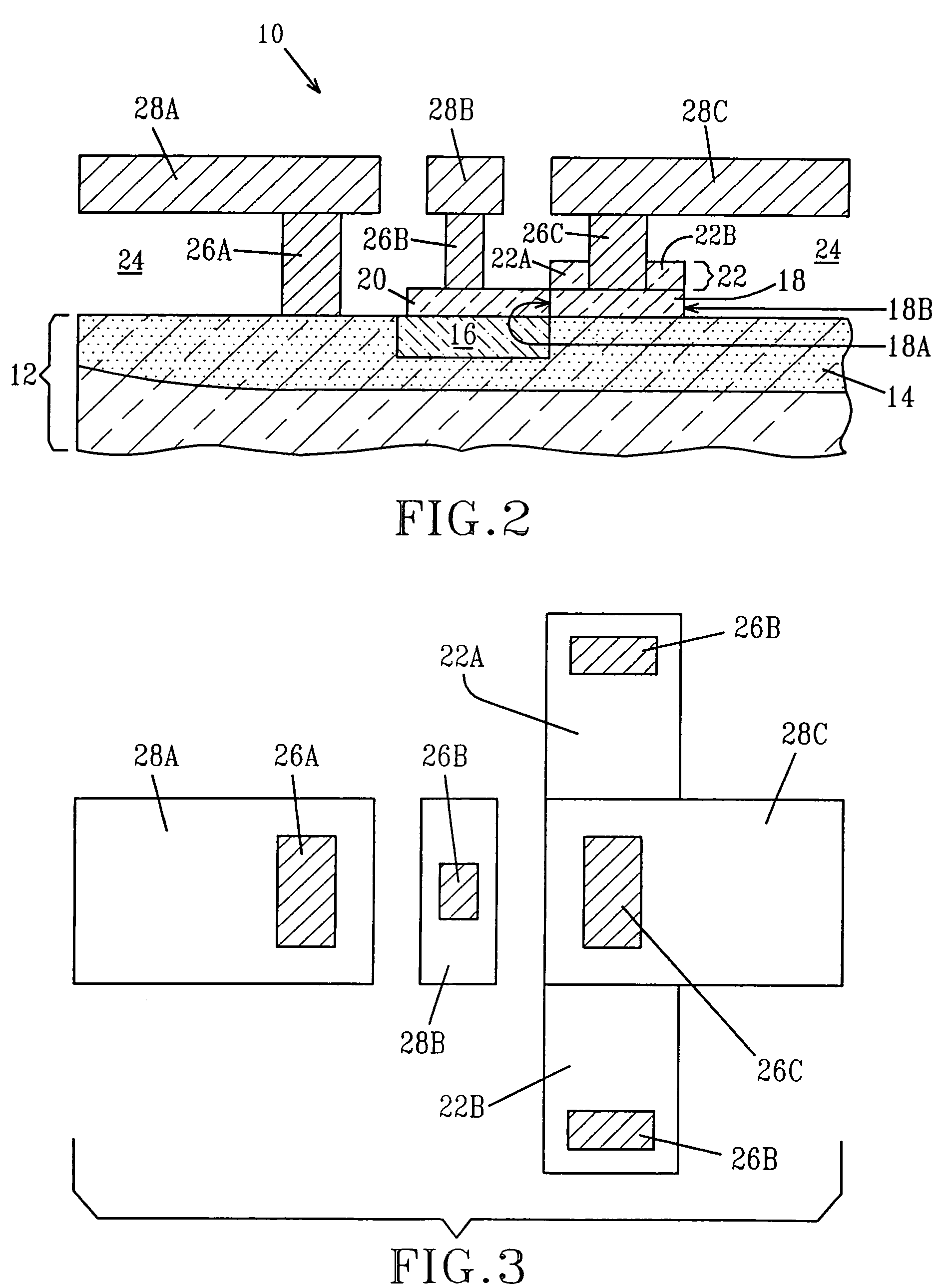

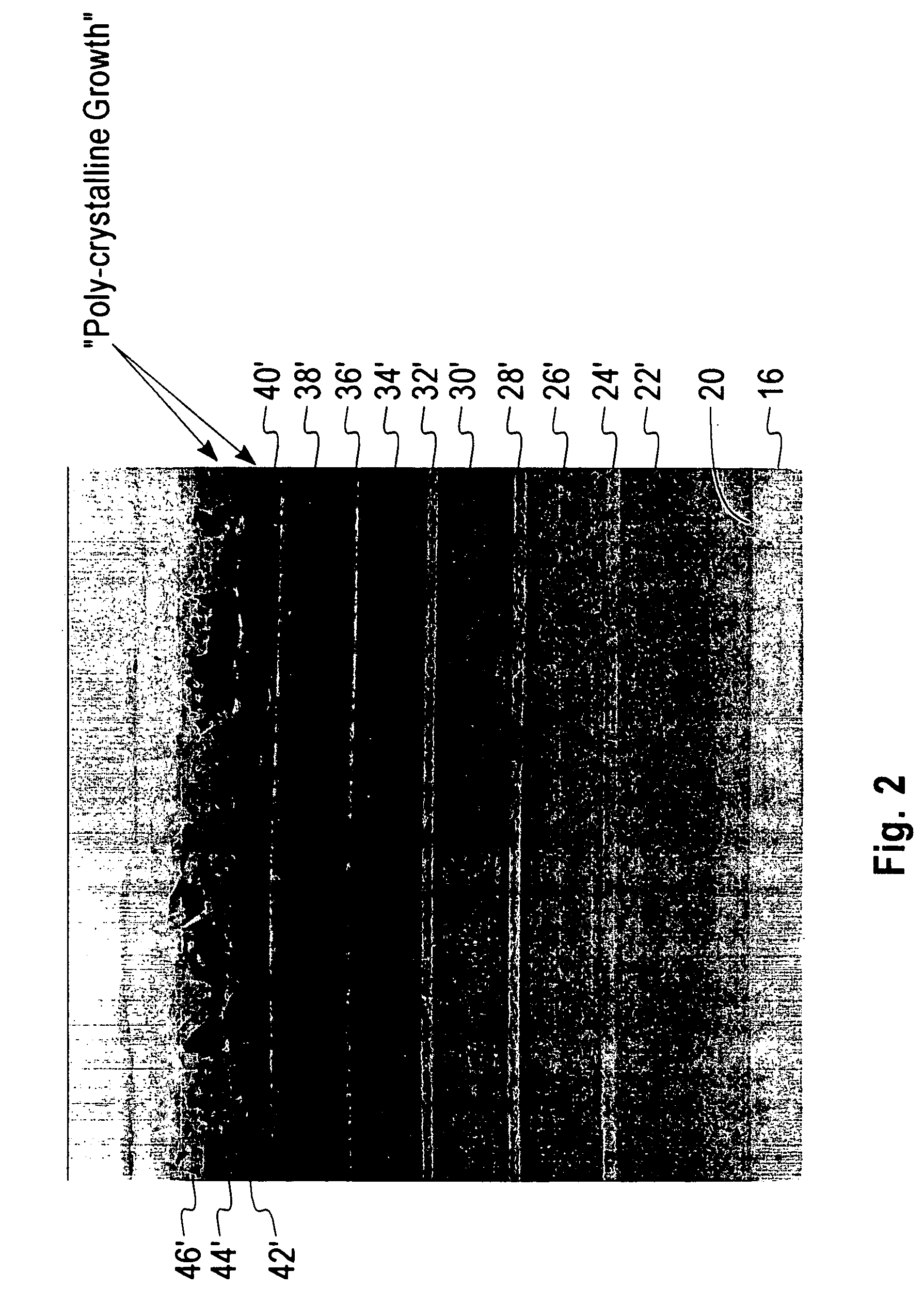

System and method for forming single-crystal domains using crystal seeds

InactiveUS6913649B2Material nanotechnologyPolycrystalline material growthNanowireSelf-assembled monolayer

Single-crystal devices and a method for forming semiconductor film single-crystal domains are provided. The method comprises: forming a substrate, such as glass or Si; forming an insulator film overlying the substrate; forming a single-crystal seed overlying the substrate and insulator; forming an amorphous film overlying the seed; annealing the amorphous film; and, forming a single-crystal domain in the film responsive to the single-crystal seed. The annealing technique can be (conventional) laser annealing, a laser induced lateral growth (LiLAC) process, or conventional furnace annealing. In some aspects forming a single-crystal seed includes forming a nanowire or a self assembled monolayer (SAM). For example, a Si nanowire can be formed having a crystallographic orientation of <110> or <100>. When, the seed has a <100> crystallographic orientation, then an n-type TFT can be formed. Likewise, when a single-crystal seed has a <110> crystallographic orientation, a p-type TFT can be formed.

Owner:SHARP LAB OF AMERICA INC

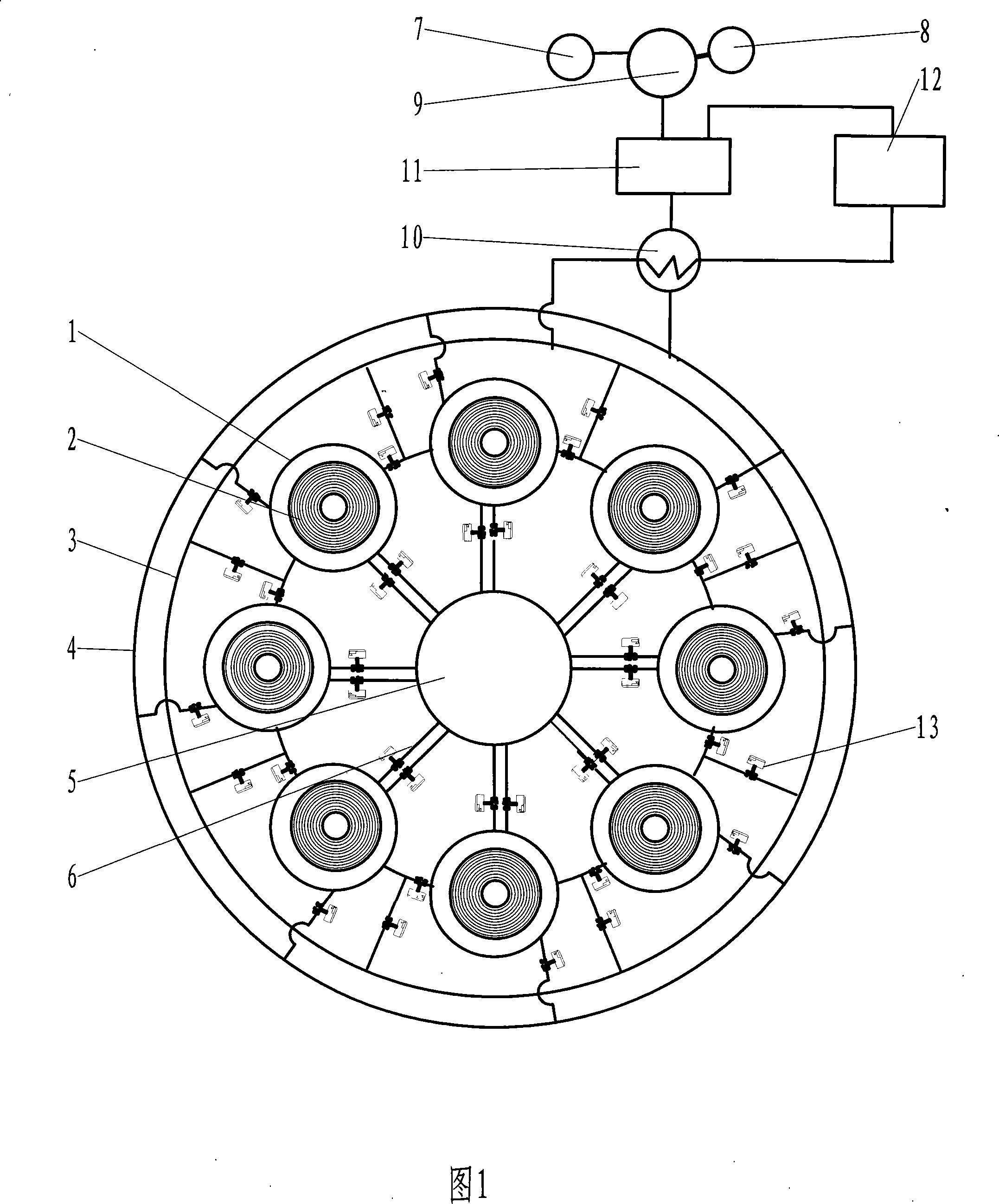

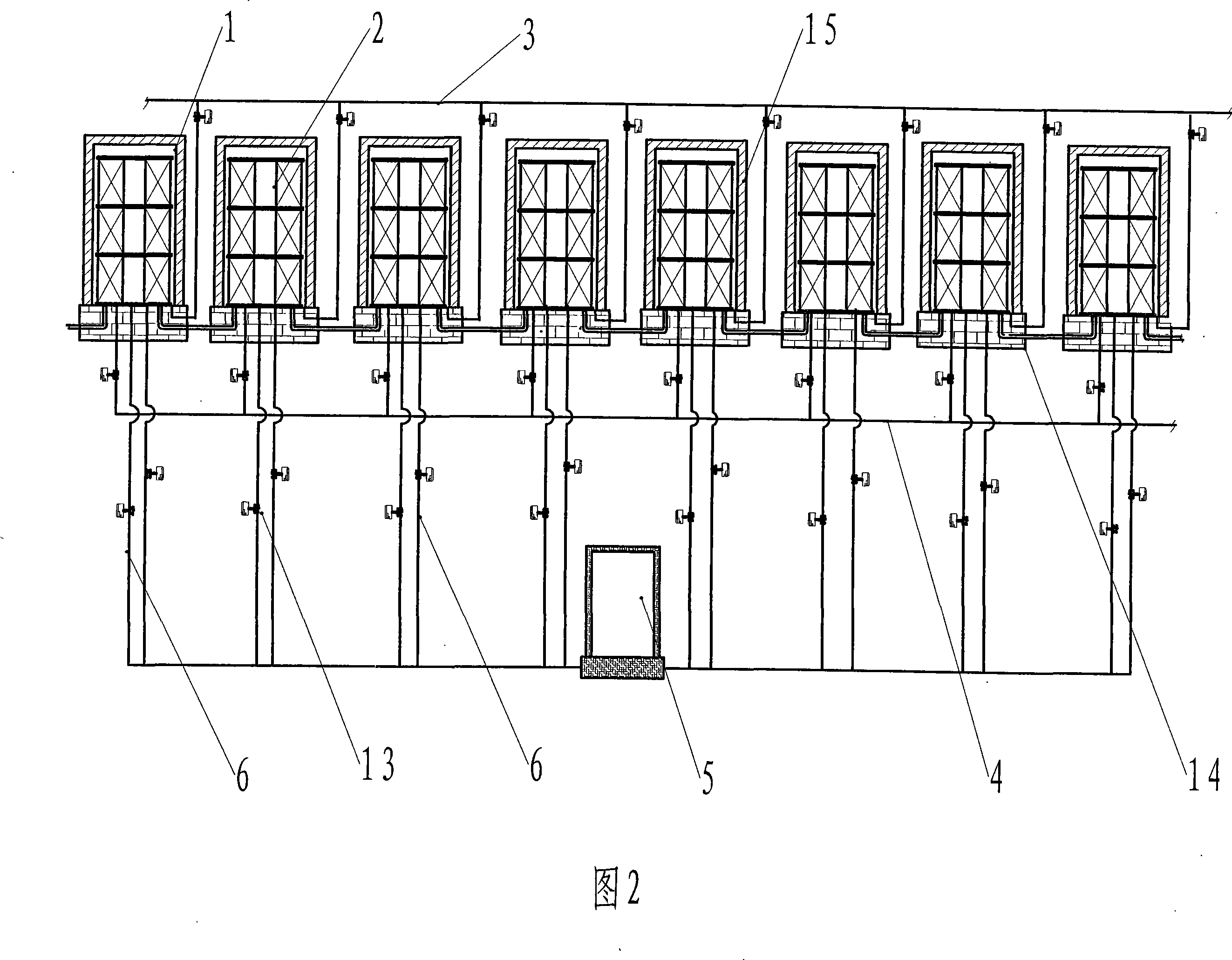

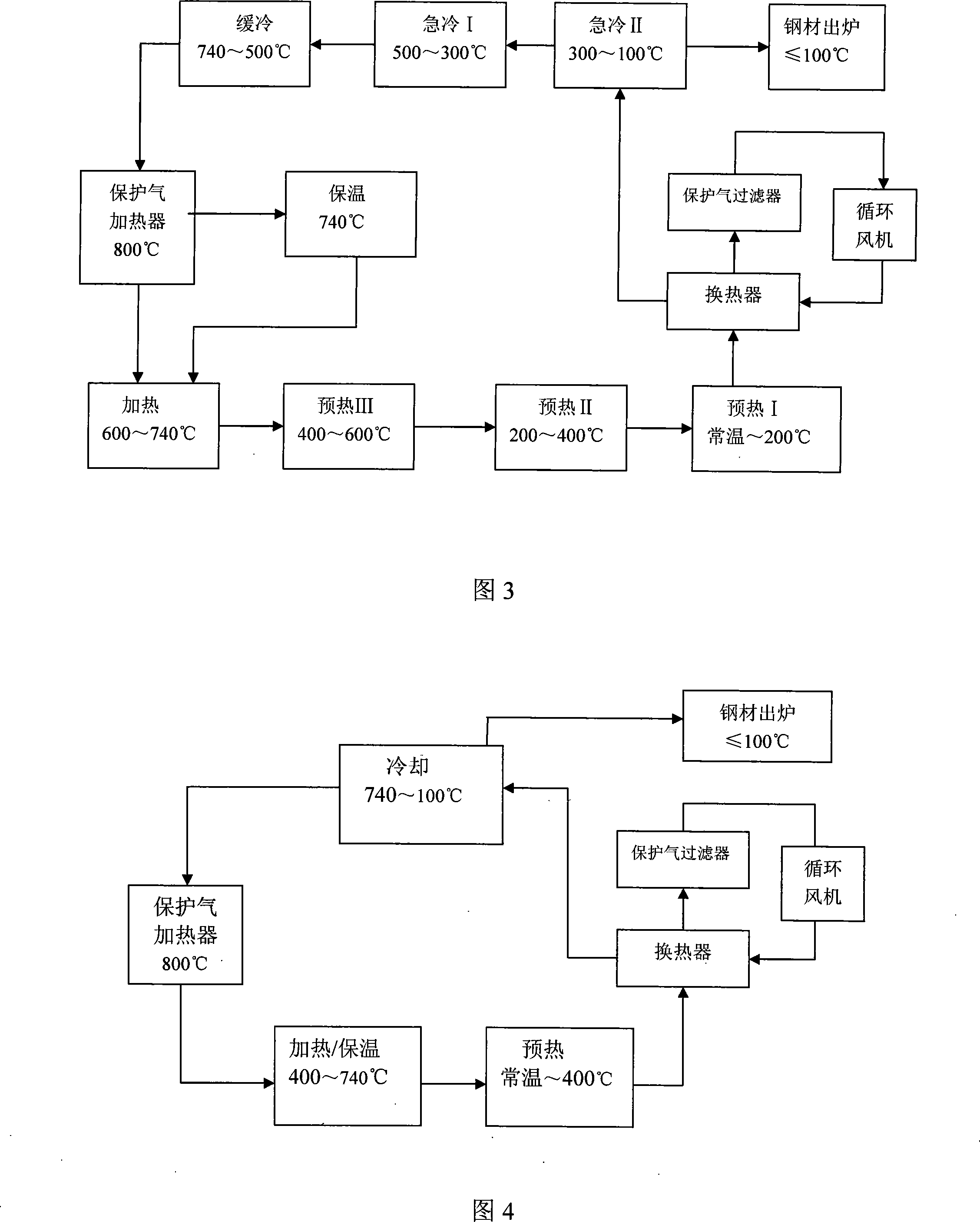

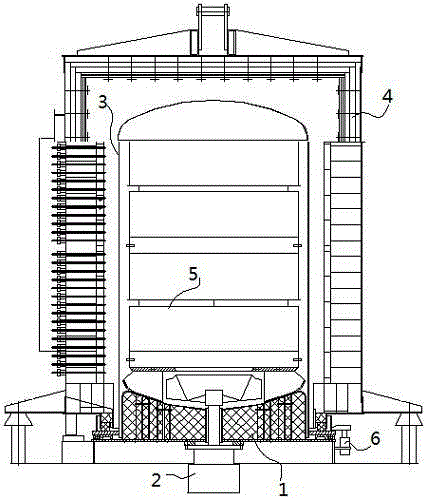

Combined hood-type furnace annealing method and annealing furnace device thereof

The invention relates to a combined cover annealing method and annealing furnace device thereof. At least two cover furnaces are installed in series, protecting gas central heater and matched feeding device are provided, using the heated protecting gas, preheat, heat, heat-insulate and cool the annealing material inside of the protective cover, the protecting gas circularly flows in the cover furnace during the annealing process, the excessive heat at high temperature stage is transferred to the next low temperature stage, the low temperature protecting gas returns to the protecting gas heater after the cooling stage, the turbid gas returns to the protecting gas system for used after filtering. Compared with current technology, the advantages of the invention reside in: the heat during the annealing process is recycling, which saves 30% to 40% of energy; no heating cover or cooling cover is used during the annealing process, heat or cool material inside the protective cover by protecting gas, which simplifies the operation process, saves equipment cost and operation expense, and the annealed material has good quality.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

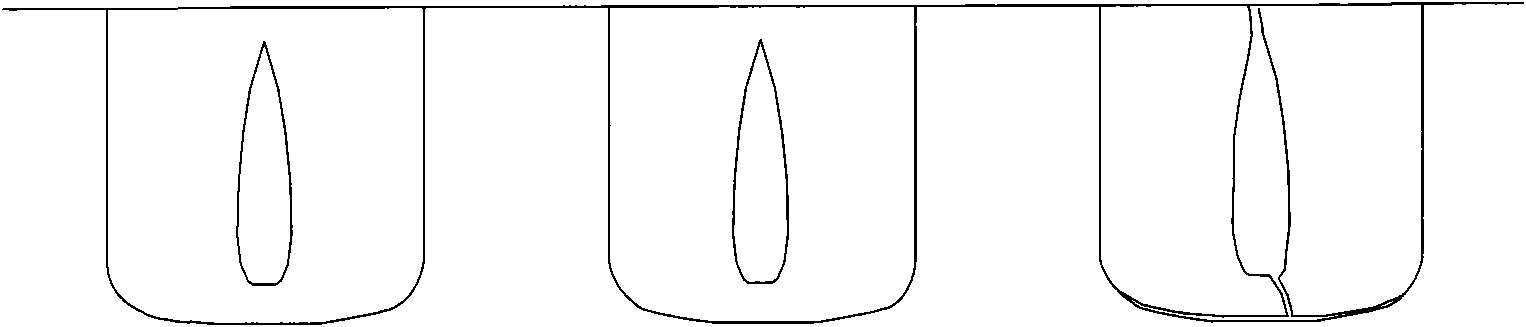

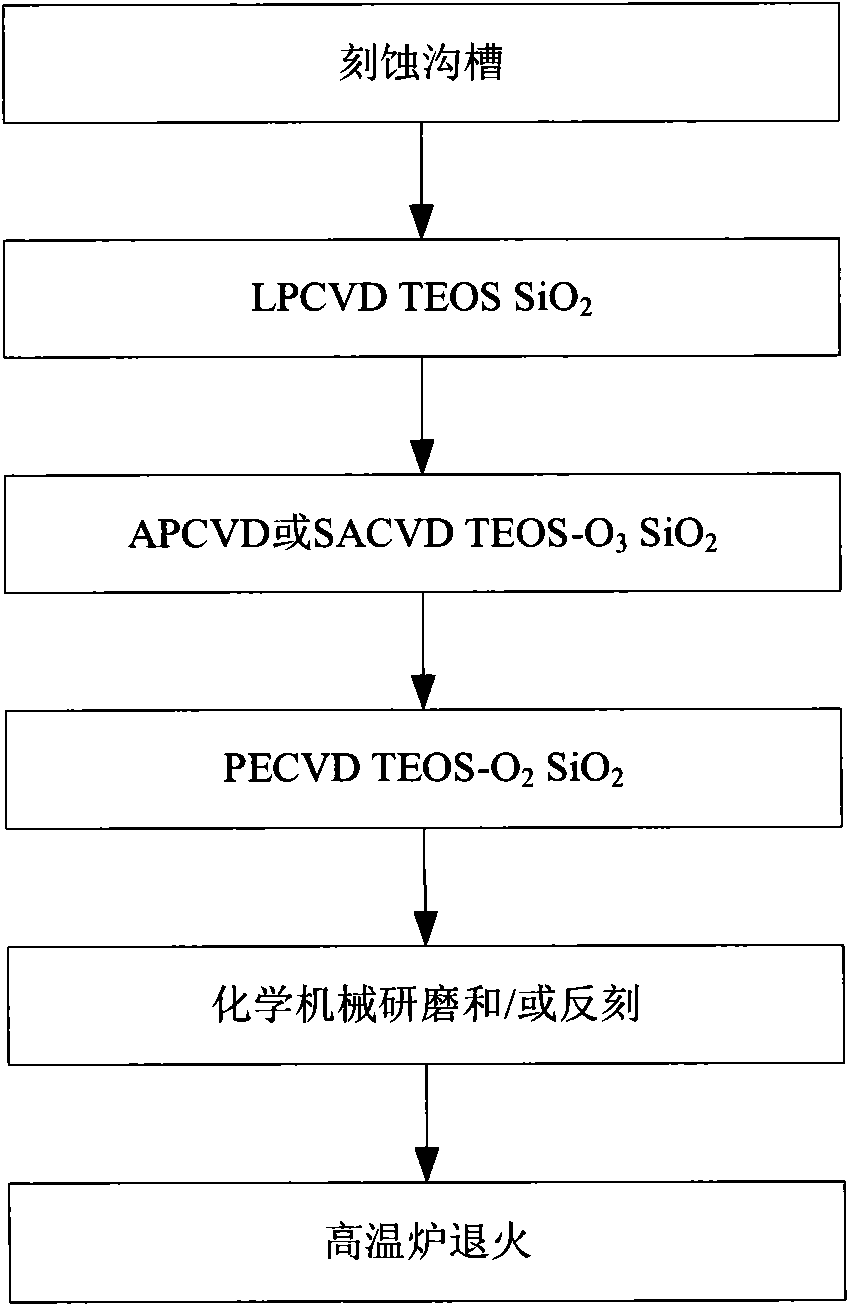

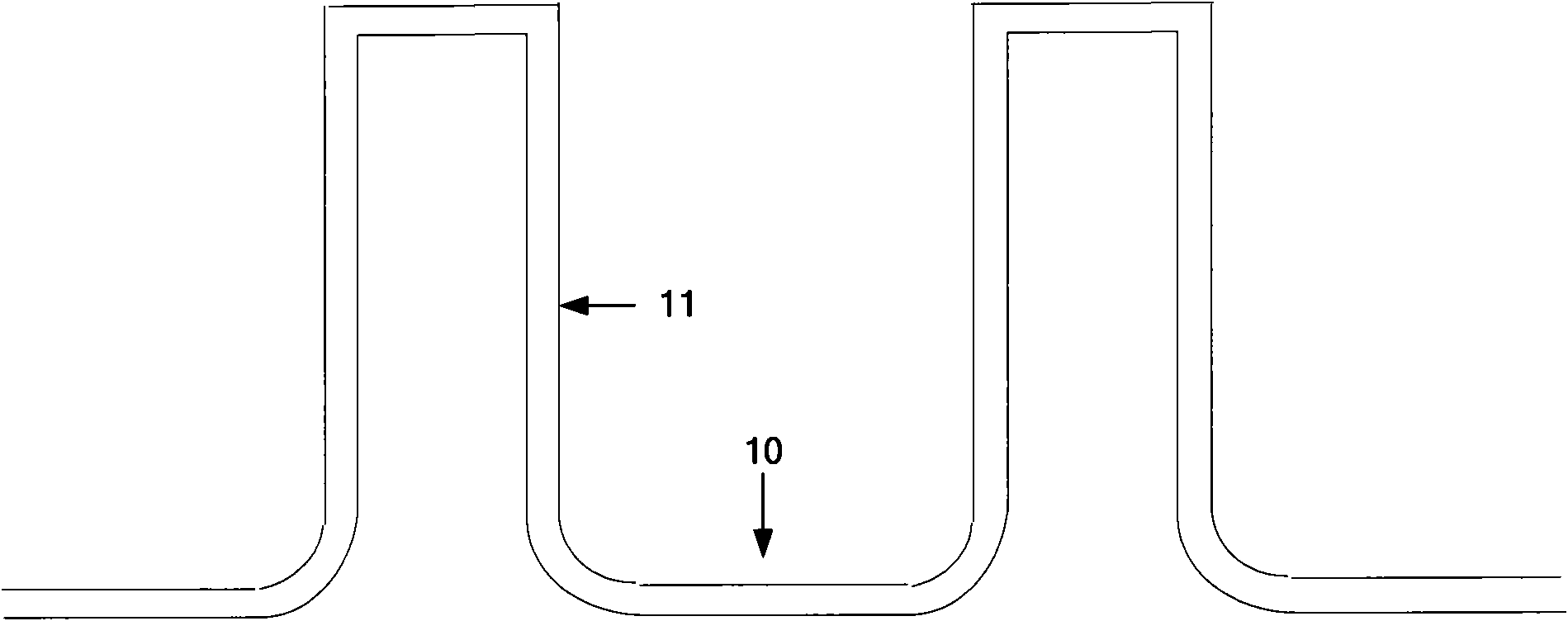

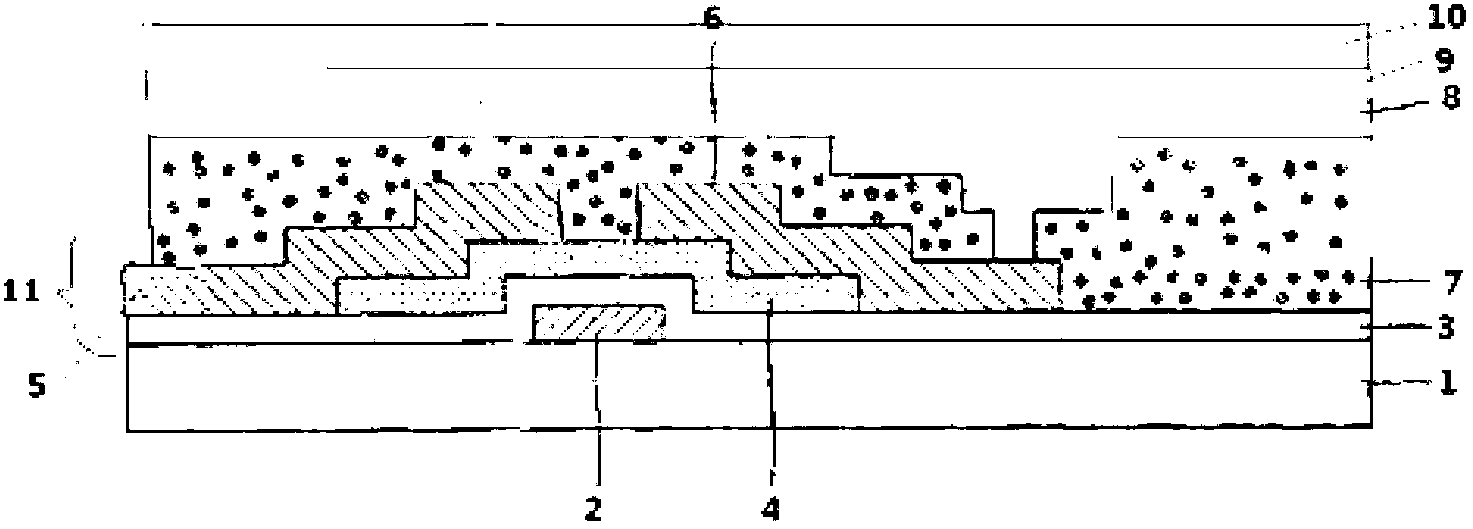

Groove filling method

ActiveCN101872739AWon't breakSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSiliconFilm structure

The invention discloses a groove filling method. The width of a groove is above 1 mu m and the depth of the groove is above 3 mu m. The method comprises the following steps: step 1, using TEOS as a raw material to deposit a layer of SiO2 on the surface of a silicon slice with a groove by an LPCVD process; step 2, using TEOS and O3 as raw materials to deposit a layer of SiO2 again on the surface of the silicon slice by an APCVD or SACVD process; and step 3, using TEOS and O2 as raw materials to deposit a layer of SiO2 again on the surface of the silicon slice by the PECVD process. After the groove is filled according to the method of the invention, fillers in the groove are of a multilayer film structure; and the multilayer film structure is not cracked in a subsequent high-temperature furnace annealing process.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

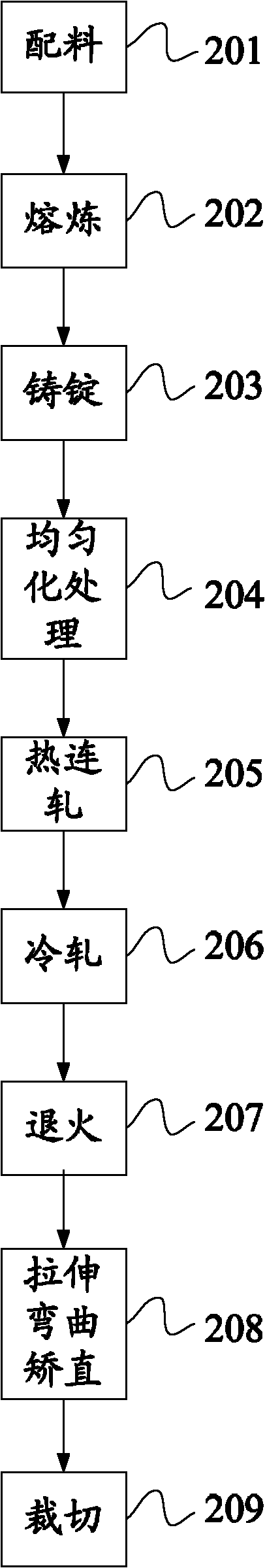

390MPa grade cold-rolled phosphorus-containing IF high-strength steel strip and LF-RH duplex production process thereof

InactiveCN108842024AChemically stableStable mechanical propertiesManufacturing convertersBell type furnacesMechanical propertyContinuous rolling

The invention discloses a 390MPa grade cold-rolled phosphorus-containing IF high-strength steel strip and an LF-RH duplex production process thereof, and belongs to the technical field of production of interstitial-free steel. The steel strip comprises, by weight, less than or equal to 0.0050% of C, 0.030-0.055% of Si, 0.55-0.60% of Mn, 0.055-0.070% of P, less than or equal to 0.008% of S, 0.020-0.040% of Als, 0.035-0.050% of Nb, 0.015-0.035% of Ti, 0.0005-0.0010% of B and the balance Fe, Ca, Cr and inevitable trace elements. The production process flow comprises the steps of blast furnace hotmetal smelting, converter molten steel smelting, LF molten steel refining, RH molten steel refining, CSP sheet billet continuous casting and rolling, pickling cold continuous rolling, cover furnace annealing, leveling and inspection, packaging and storage. The composition design thoughts of micro-carbon smelting, [Nb, Ti] microalloying and solid solution strengthening of P and Mn are adopted, the390MPa grade cold-rolled phosphorus-containing IF high-strength steel strip with stable chemical compositions and stable mechanical properties is obtained through an LF-RH duplex refining process, hot rolling, cold rolling and an annealing process, the production cycle is short, the production cost is low, the steel strip is stable in quality, and the requirements of the automobile industry on the high-strength steel strip can be met.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Production method for ultra-thin cold-rolled enamelled steel strips

ActiveCN105689392AMeet quality requirementsImprove deep drawing performanceWork cleaning devicesMetal rolling arrangementsBlack spotHydrogen

The invention discloses a production method for ultra-thin cold-rolled enamelled steel strips. The production method is characterized in that the ultra-thin cold-rolled enamelled steel strips have thicknesses of 0.18-0.20mm, and are obtained through the steps of carrying out hot-rolling production for cold-rolled materials, chlorohydric acid pickling, primary cold-rolling, primary intermediate annealing, and secondary cold-rolling to prepare ultra-thin cold and hard steel strips, and then carrying out smoothing and texturing, rewinding and tension losing, secondary intermediate annealing, and strip shape straightening. According to the method, the products have excellent deep drawing properties, and have no fish-scaling phenomenon, and moreover, with the adoption of a 950mm single-stand six-roll reversible cold-rolling mill, single-stand smoothing and texturing, severe-convection full-hydrogen bright bell-type annealing furnace annealing, the equipment is simplified, and the products achieve high-accuracy and ultra-thin requirements; the surfaces are smooth, and free from bonding, chromatic aberration, black spots, dots, oil stain and other defects; and the production method achieves the quality requirements of ultra-thin deep-drawn cold-rolled enamelled steel strips, is suitable for the fields of kitchen sanitary ware and ovens, water heater liners, decoration panels and the like, and has a broad market prospect.

Owner:山东泰山轧钢有限公司

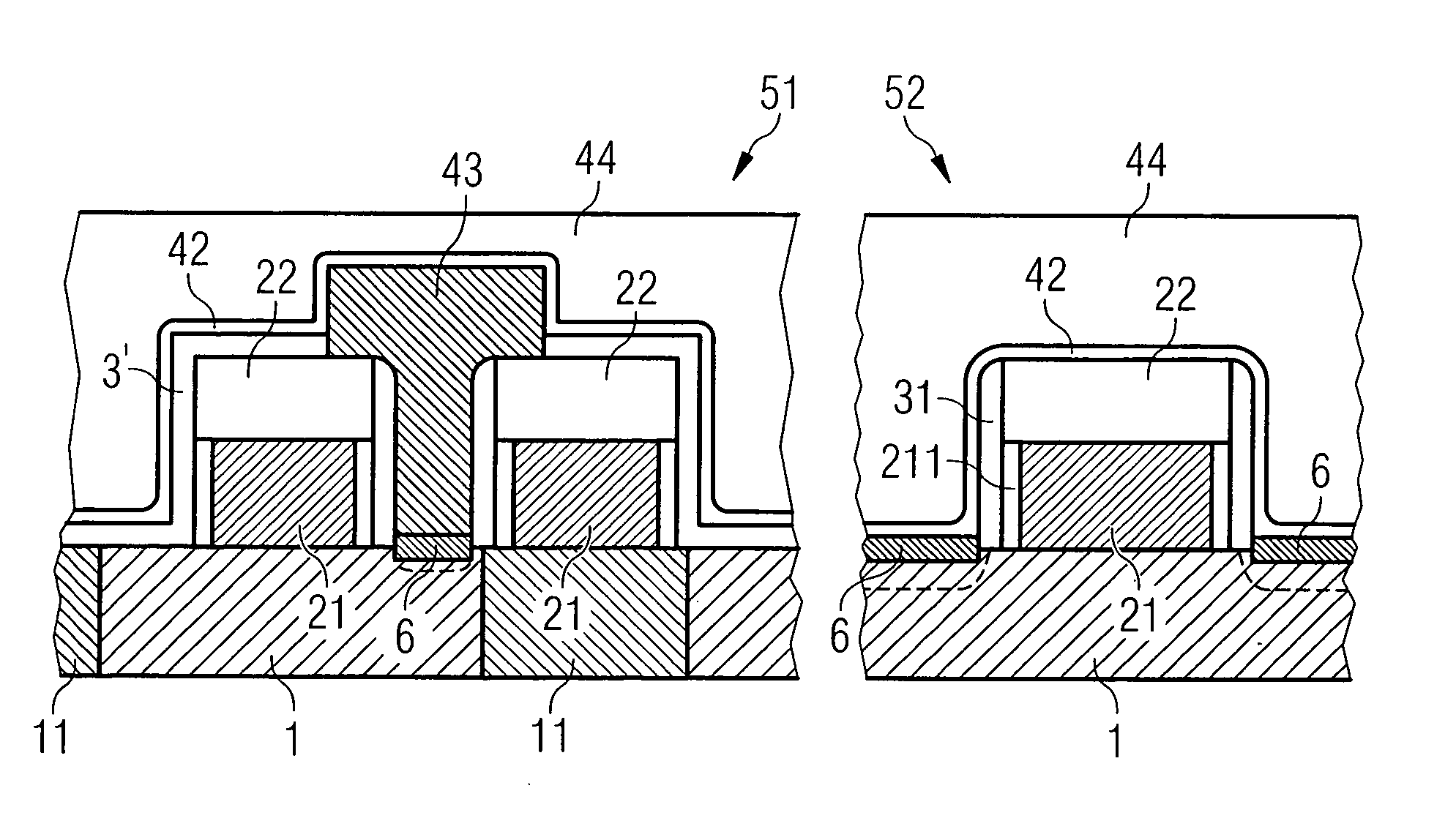

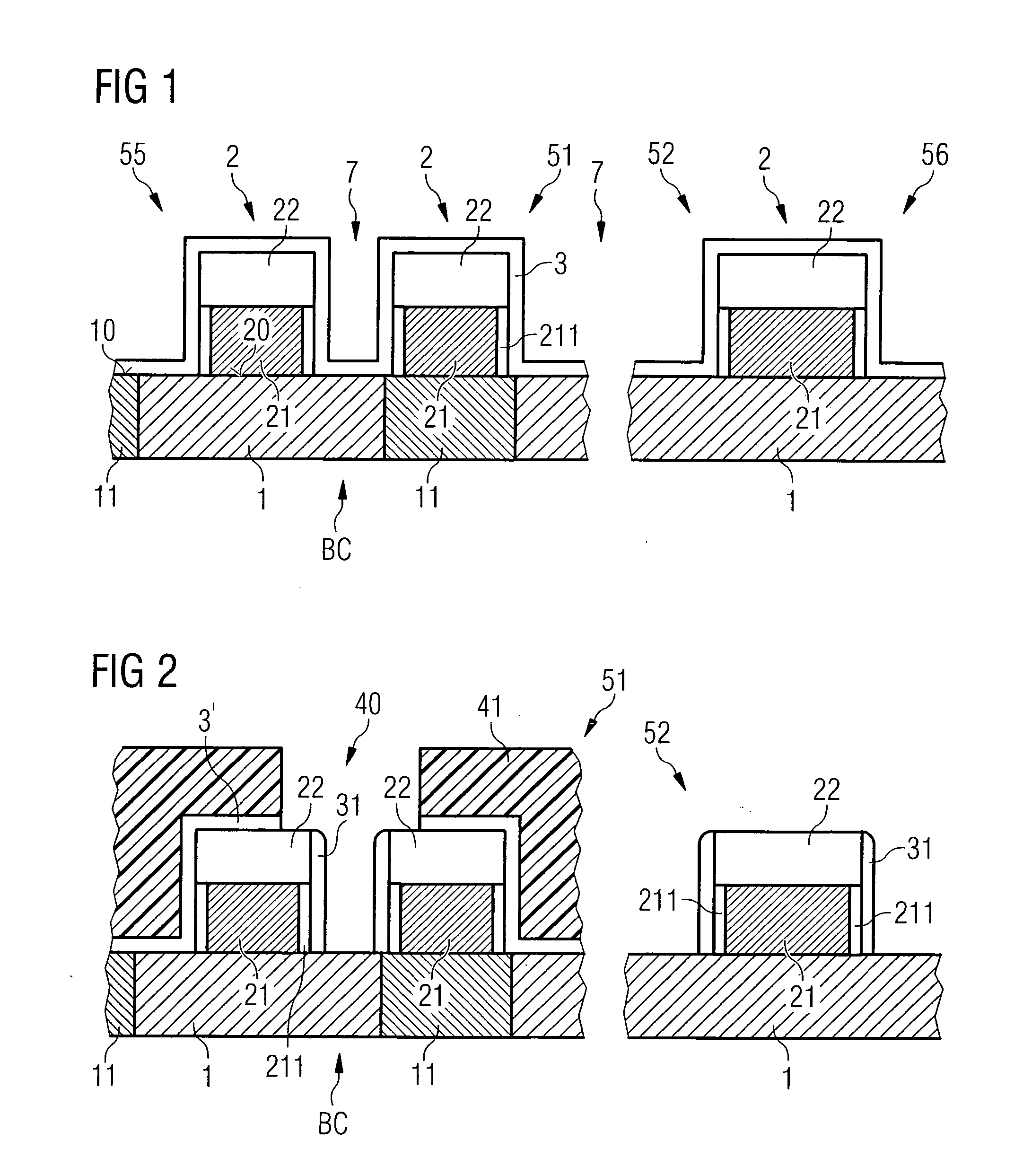

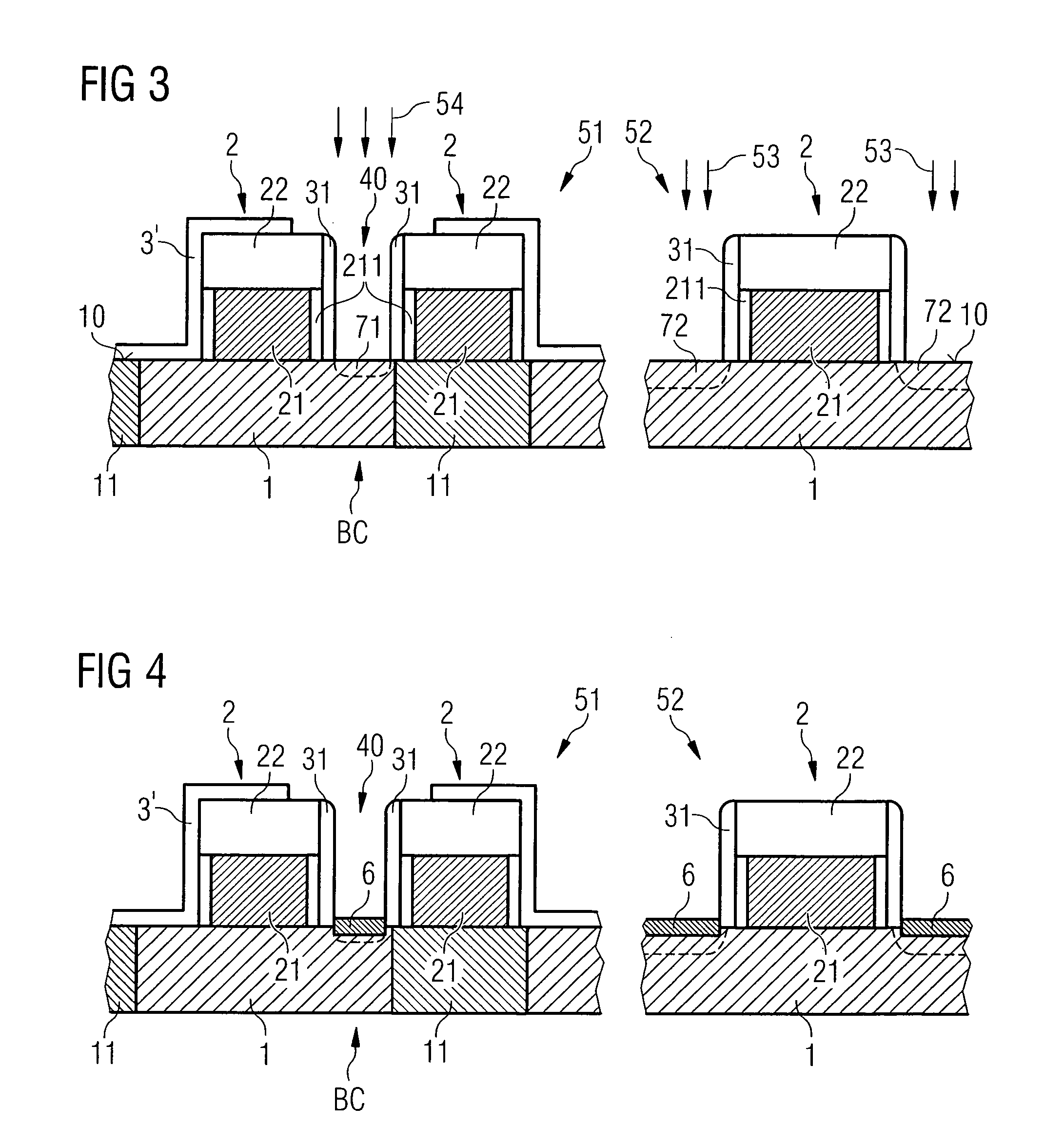

Fabricating transistor structures for DRAM semiconductor components

InactiveUS20060068545A1Reduce contact resistanceFacilitate a final furnace annealSolid-state devicesSemiconductor/solid-state device manufacturingLattice defectsElectrical conductor

A method for fabricating transistor structures for DRAM semiconductor components includes forming gate conductor structures in a cell array of a DRAM semiconductor component and covering the structures with a spacer liner. The gate conductor structures lie on a silicon semiconductor substrate. A masked spacer etch produces a spacer mask with horizontal sections and vertical spacer structures from the spacer liner for aligning implantation steps and for self-aligned formation of silicide structures at the surface of the semiconductor substrate. A CB contact implantation step is provided prior to the filling of trenches between the gate conductor structures with dielectric silicate glass fillings, and this obviates the need for an isolated high-temperature activation anneal for the CB contact implantation as well as reducing the thermal stresses on regions of the semiconductor substrate which have already been doped. A reflow heating step for partially melting the silicate glass is controlled as a final furnace anneal for annealing lattice defects in the semiconductor substrate. The contact resistance of a bit contact structure is lowered, while at the same time the thermal stresses are reduced.

Owner:INFINEON TECH AG

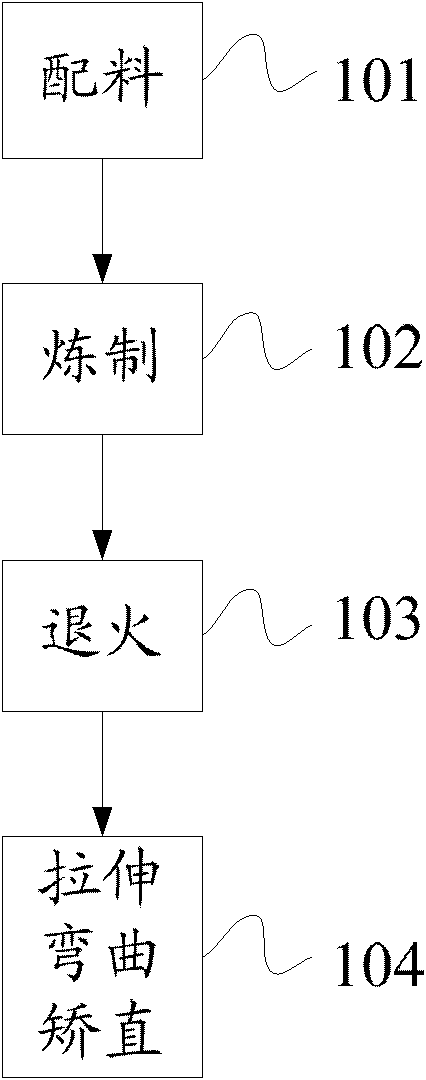

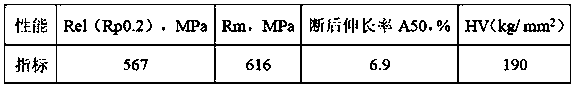

Production method of aluminum alloy base material used for LED television sets

The invention discloses a production method of an aluminum alloy base material used for LED (light emitting diode) television sets. During batching, on the basis of existing manufacturing components of 3104 aluminum alloy, the method readjusts the mass fractions of each chemical component in aluminum alloy raw materials, and adopts a box-type furnace annealing process during annealing treatment, as well as adjusts an annealing system so as to make the prepared aluminum alloy base material have stable mechanical properties and a surface with a uniform color. Meanwhile, the strength and elongation percentage of the aluminum alloy base material are improved. The method of the invention employs a unique stretching, bending and straightening technology while straightening an aluminum alloy finished product so as to guarantee the flatness of the aluminum alloy base material and stabilize its yield tensile ratio, thus guaranteeing that the aluminum alloy base material is difficult to crack during punching.

Owner:SOUTHWEST ALUMINUM GRP

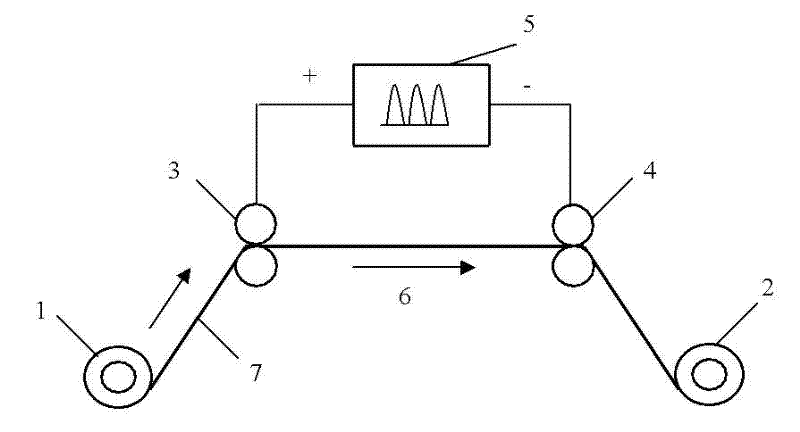

Method for promoting growth of GOSS textures of silicon steel strips by using pulse current

InactiveCN102212671AReduce the degree of oxidationShort initial recrystallization timeFurnace typesHeat treatment furnacesAir atmosphereElectricity

The invention discloses a method for promoting growth of GOSS textures of silicon steel strips by using pulse current. The method comprises the following steps of: conveying the silicon steel strips at the speed of 2 to 10 meters per minute under the drive of a conveying device; and guiding the pulse current of a pulse power supply to a moving silicon steel strip electrifying zone through a pair of electric contact devices, and performing electric stimulation treatment on the silicon steel strip electrifying zone in air atmosphere to promote the generation of a large amount of GOSS textures in the primary re-crystallization process, wherein the silicon steel strips are in a high magnetic induction cold-rolled state, the thickness of the silicon steel strips is 0.1 to 0.5 millimeter, the width of the silicon steel strips is 10 to 150 millimeters and the silicon content of the silicon steel strips is 0.5 to 6.5 percent. Compared with the traditional thermal treatment furnace annealing treatment process, the method has the advantages of low energy consumption, high production efficiency and low production cost, and the GOSS textures in the primary re-crystallization process have manycomponents. By electron back-scattered diffraction (EBSD) detection, the GOSS texture content of the silicon steel strips treated by adopting electric stimulation of the pulse current reaches 15 to 25 percent.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Copper strip cover-type furnace annealing technology

InactiveCN105349766AImprove sealingConsistent locking forceFurnace typesHeat treatment furnacesHeating timeMetallic materials

The invention discloses a copper strip cover-type furnace annealing technology and belongs to the field of heat treatment of metal materials. The technology comprises the following steps: 1, sealing and locking a cover-type furnace; 2, filling the cover-type furnace with safe gas; 3, carrying out a heating stage of the cover-type furnace, wherein the heating time is 4-5 h so that the temperature in an inner cover reaches 420-450 DEG C, and protective gas is introduced continuously in the heating process; 4 carrying out a heat preservation stage of the cover-type furnace; 5, carrying out a cooling stage of the cover-type furnace, wherein air cooling is carried out before water cooling, and protective gas is introduced continuously in the air cooling and water cooling stages; 6, filling the cover-type furnace with safe gas; and 7, unlocking the cover-type furnace and taking out a product. Through the adoption of the technical scheme of the invention, an annealed copper strip with better surface quality and more stable properties can be obtained, and the consumption of the protective gas resource in the annealing process can be reduced so as to reduce the production cost and improve the productivity effect.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

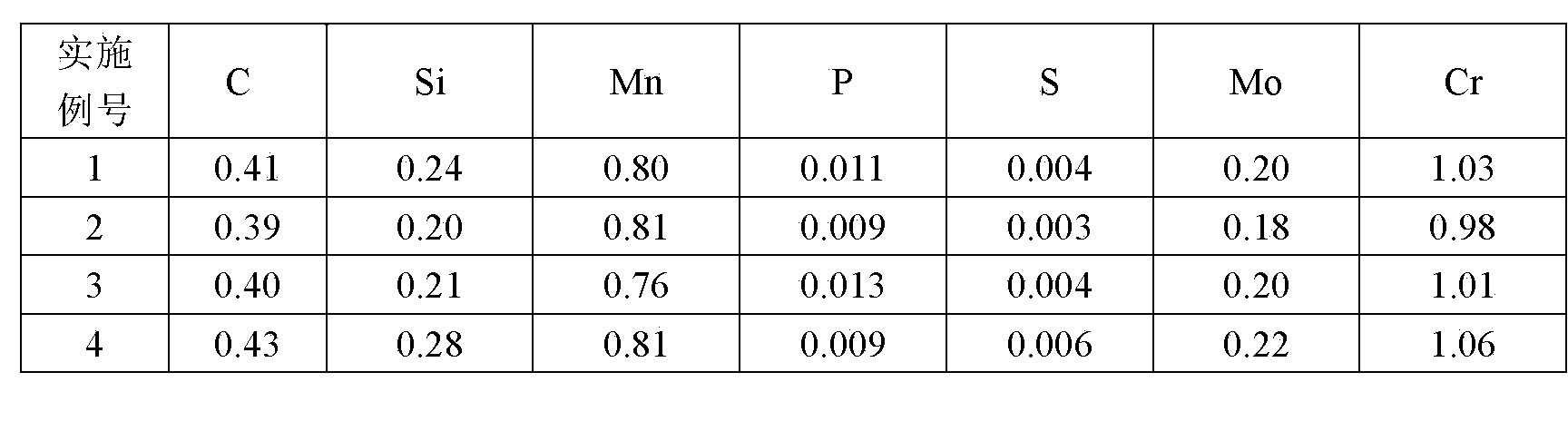

42 CrMo steel cold-rolled sheet and its production method

The invention discloses a 42CrMo steel cold-rolled plate and its production method, and the 42CrMo steel cold-rolled plate comprises the following chemical components by mass: 0.38-0.45% of C, 0.17-0.37% of Si, 0.50-0.90% of Mn, less than 0.035% of P, less than 0.035% of S, 1.02-1.14% of Cr, 0.15-0.25% of Mo, and balance of Fe. The production method comprises molten steel smelting, continuous casting, hot rolling, cold rolling, bell-type furnace annealing, finishing and other processes, and is characterized in that, the hot rolled steel billet heating temperature is 1170-1270 DEG C, the finish rolling temperature is 850-950 DEG C, the coiling temperature is 700-750 DEG C, the cold rolling ratio down press rate is 25%-55%, the annealing temperature is Ac1-(10-30) DEG C, the heat insulation time is 8-14h, air cooling is performed when the billet is heat insulated to 400 DEG with a bell, and the flat elongation is 0.5%-1.2%. The 42CrMo steel cold-rolled plate is good in plasticity, toughness and cutting performances, and helps a user to perform cutting, stamping process and subsequent heat treatment.

Owner:ANGANG STEEL CO LTD

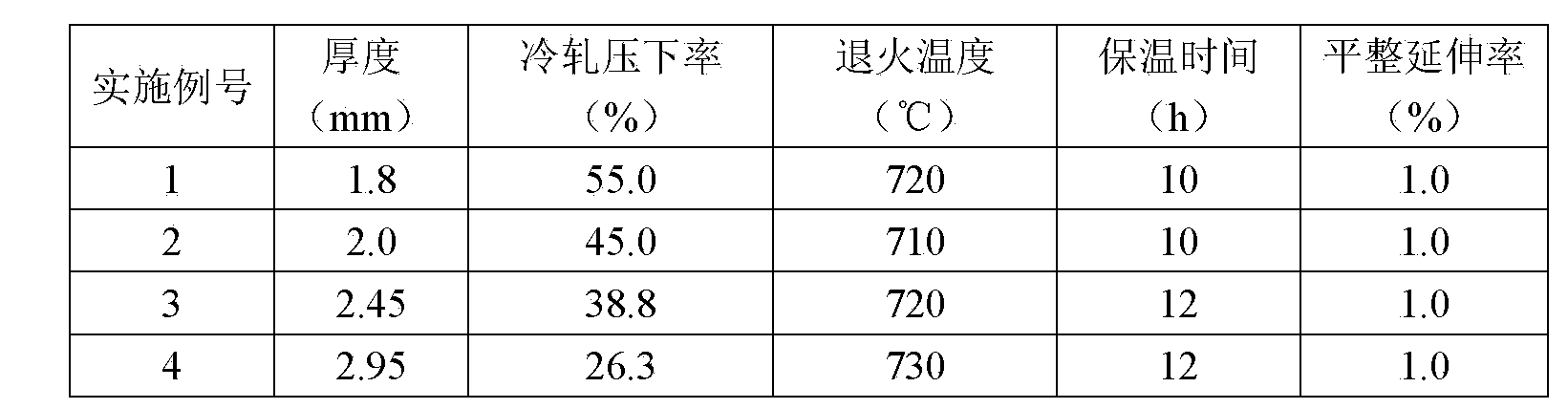

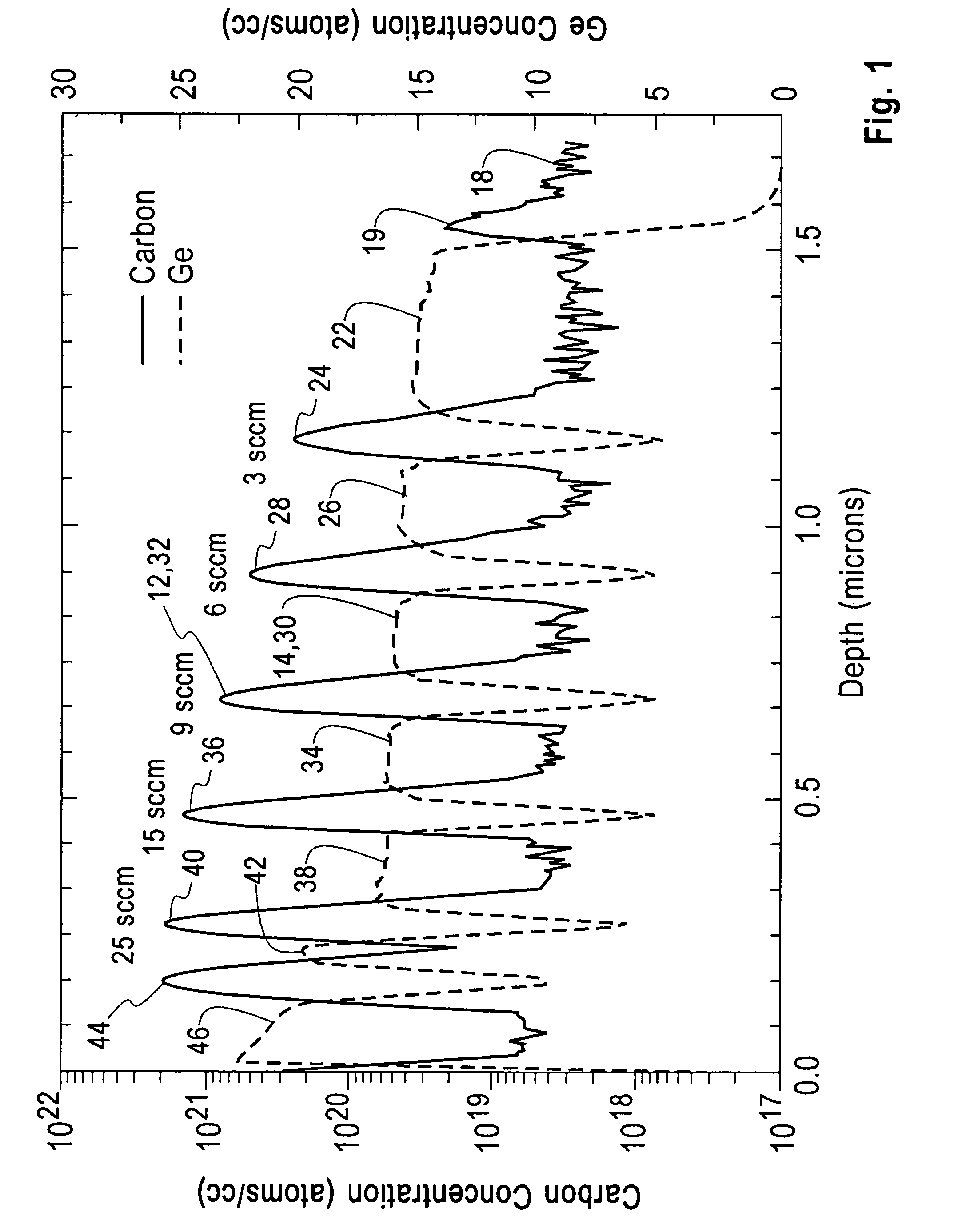

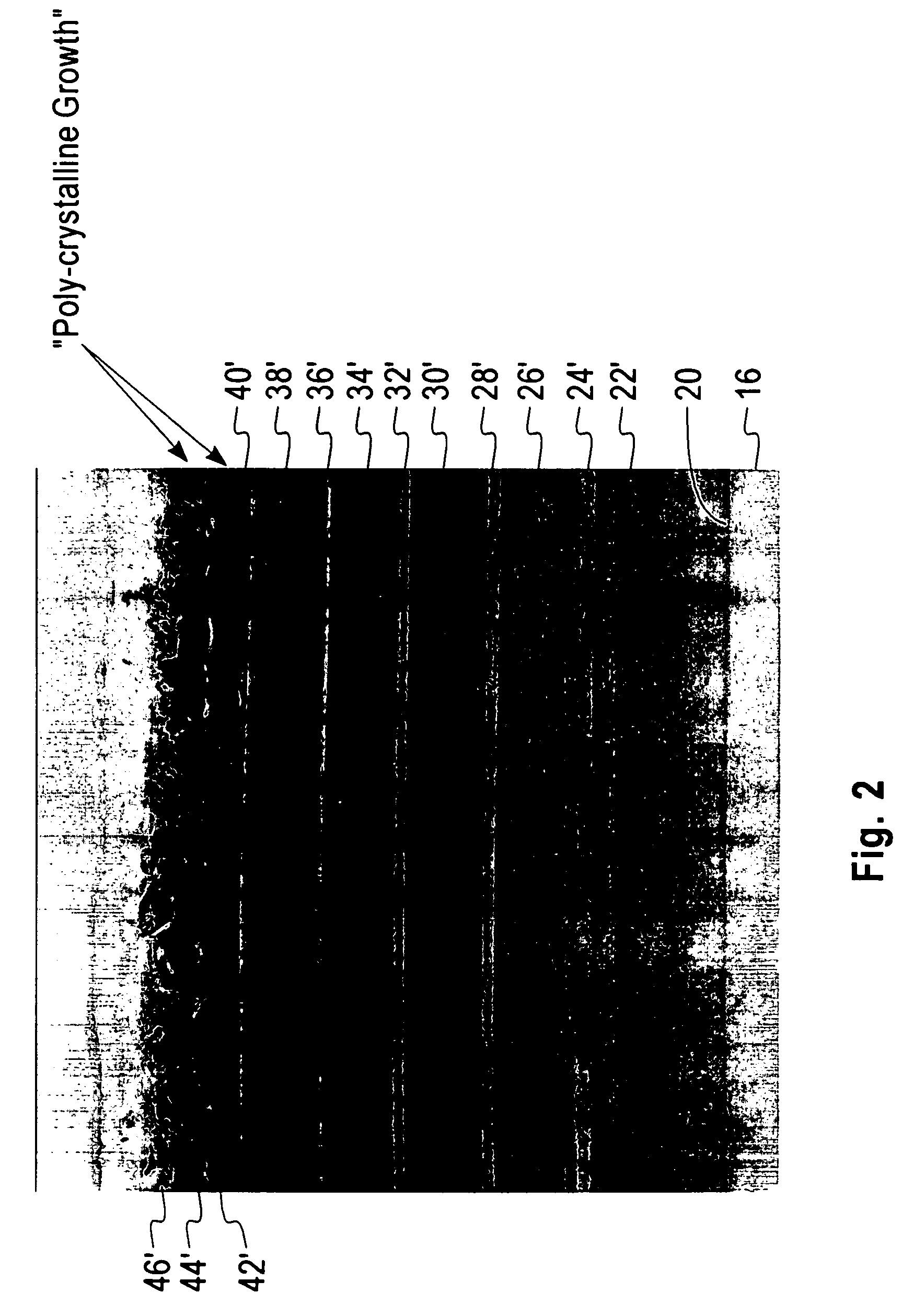

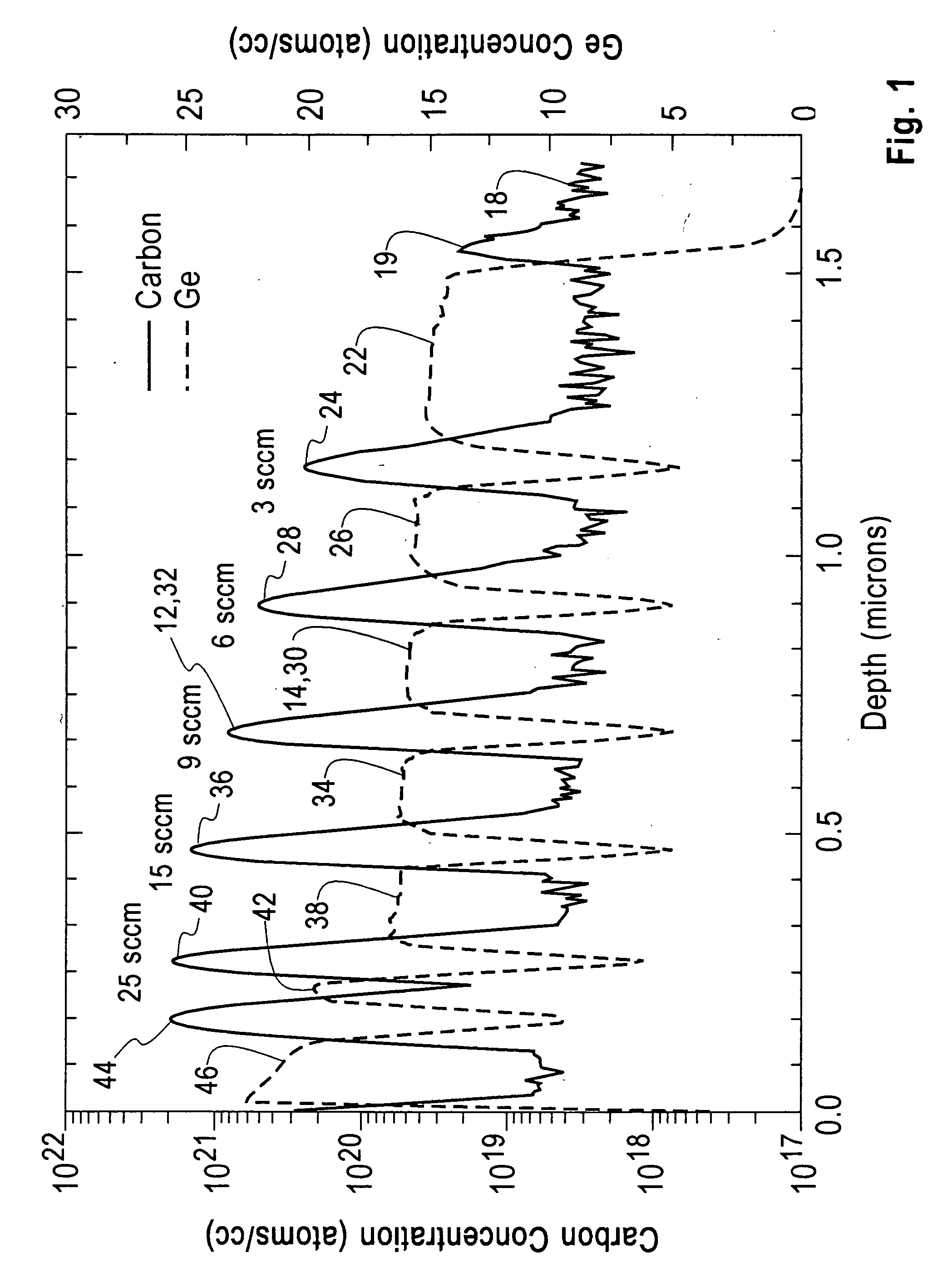

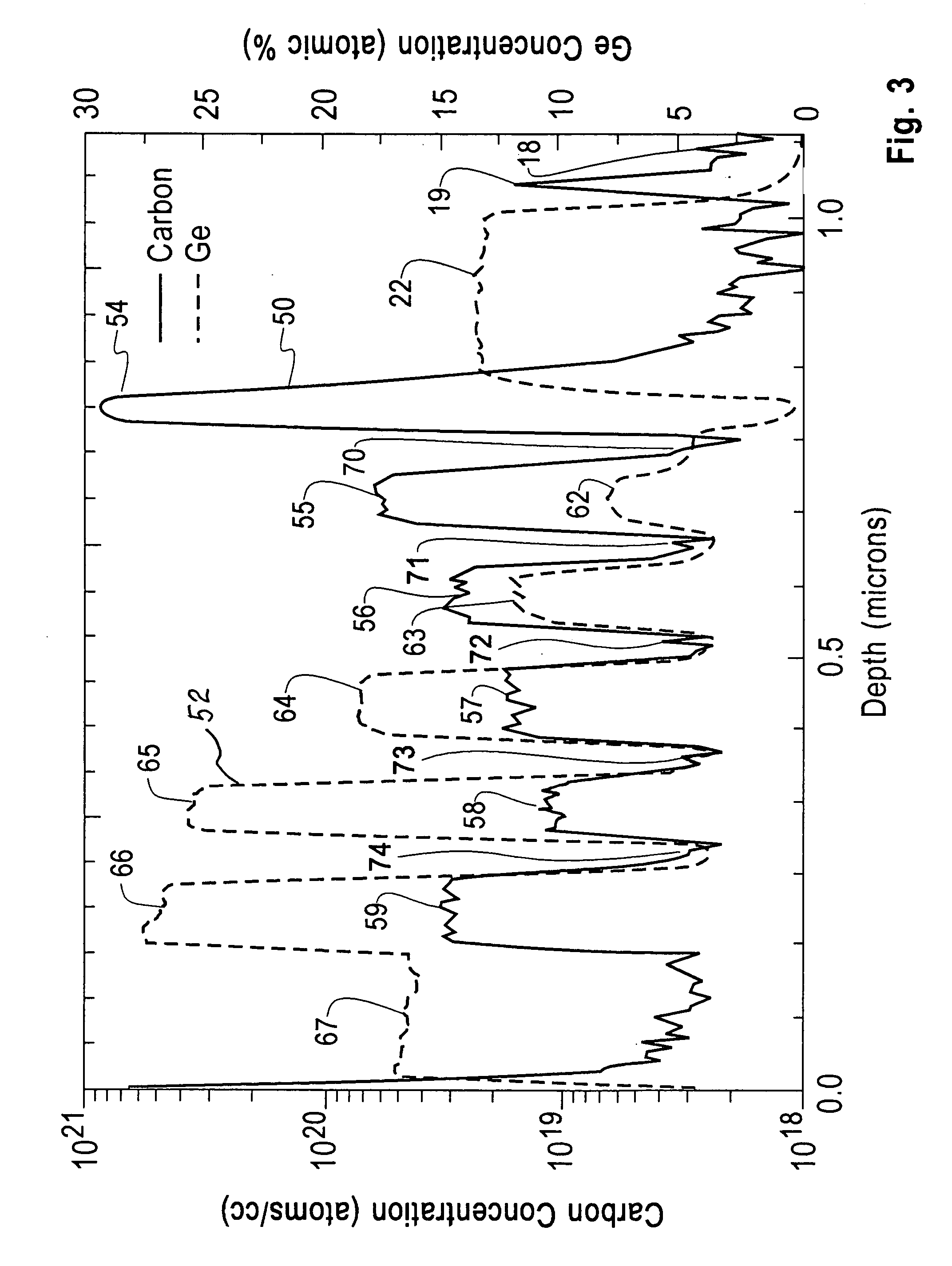

Epitaxial and polycrystalline growth of Si1-x-yGexCy and Si1-yCy alloy layers on Si by UHV-CVD

InactiveUS7183576B2Reduce oxygen concentrationPolycrystalline material growthSemiconductor/solid-state device manufacturingIn situ dopingSingle crystal

A method and apparatus for depositing single crystal, epitaxial films of silicon carbon and silicon germanium carbon on a plurality of substrates in a hot wall, isothermal UHV-CVD system is described. In particular, a multiple wafer low temperature growth technique in the range from 350° C. to 750° C. is described for incorporating carbon epitaxially in Si and SiGe films with very abrupt and well defined junctions, but without any associated oxygen background contamination. Preferably, these epitakial SiC and SiGeC films are in-situ doped p- or n-type and with the presence of low concentration of carbon <1020 cm−3, the as-grown p- or n-type dopant profile can withstand furnace anneals to temperatures of 850° C. and rapid thermal anneal temperatures to 1000° C.

Owner:GLOBALFOUNDRIES INC

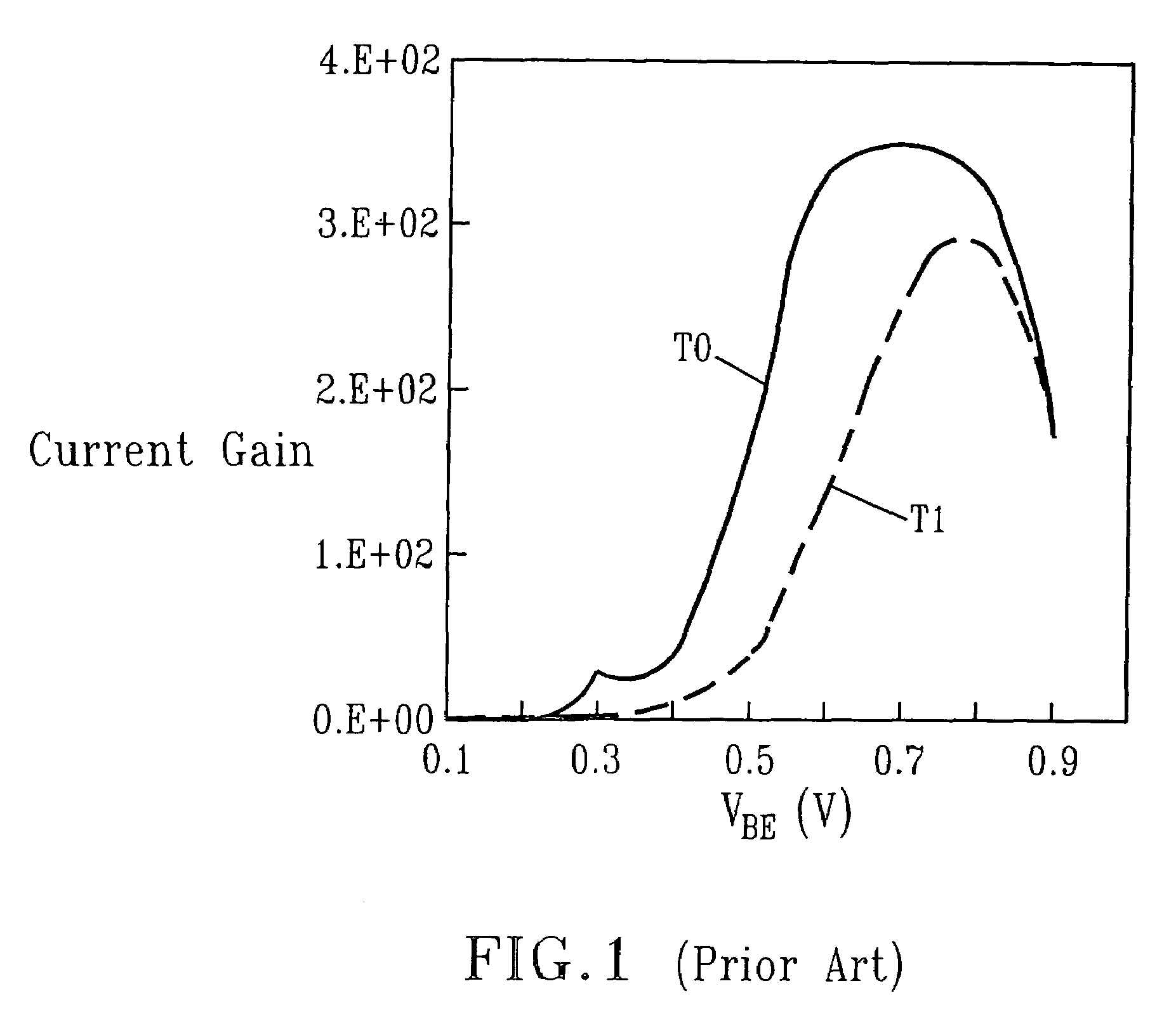

Methodology for recovery of hot carrier induced degradation in bipolar devices

InactiveUS7238565B2Increase temperatureSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringPeak value

A method for recovery of degradation caused by avalanche hot carriers is provided that includes subjecting an idle bipolar transistor exhibiting avalanche degradation to a thermal anneal step which increases temperature of the transistor thereby recovering the avalanche degradation of the bipolar transistor. In one embodiment, the annealing source is a self-heating structure that is a Si-containing resistor that is located side by side with an emitter of the bipolar transistor. During the recovering step, the bipolar transistor including the self-heating structure is placed in the idle mode (i.e., without bias) and a current from a separate circuit is flown through the self-heating structure. In another embodiment of the present, the annealing step is a result of providing a high forward current (around the peak fT current or greater) to the bipolar transistor while operating below the avalanche condition (V″CB of less than 1 V). Under the above conditions, about 40% or greater of the degradation can be recovered. In yet another embodiment of the present invention, the thermal annealing step may include a rapid thermal anneal (RTA), a furnace anneal, a laser anneal or a spike anneal.

Owner:ULTRATECH INT INC

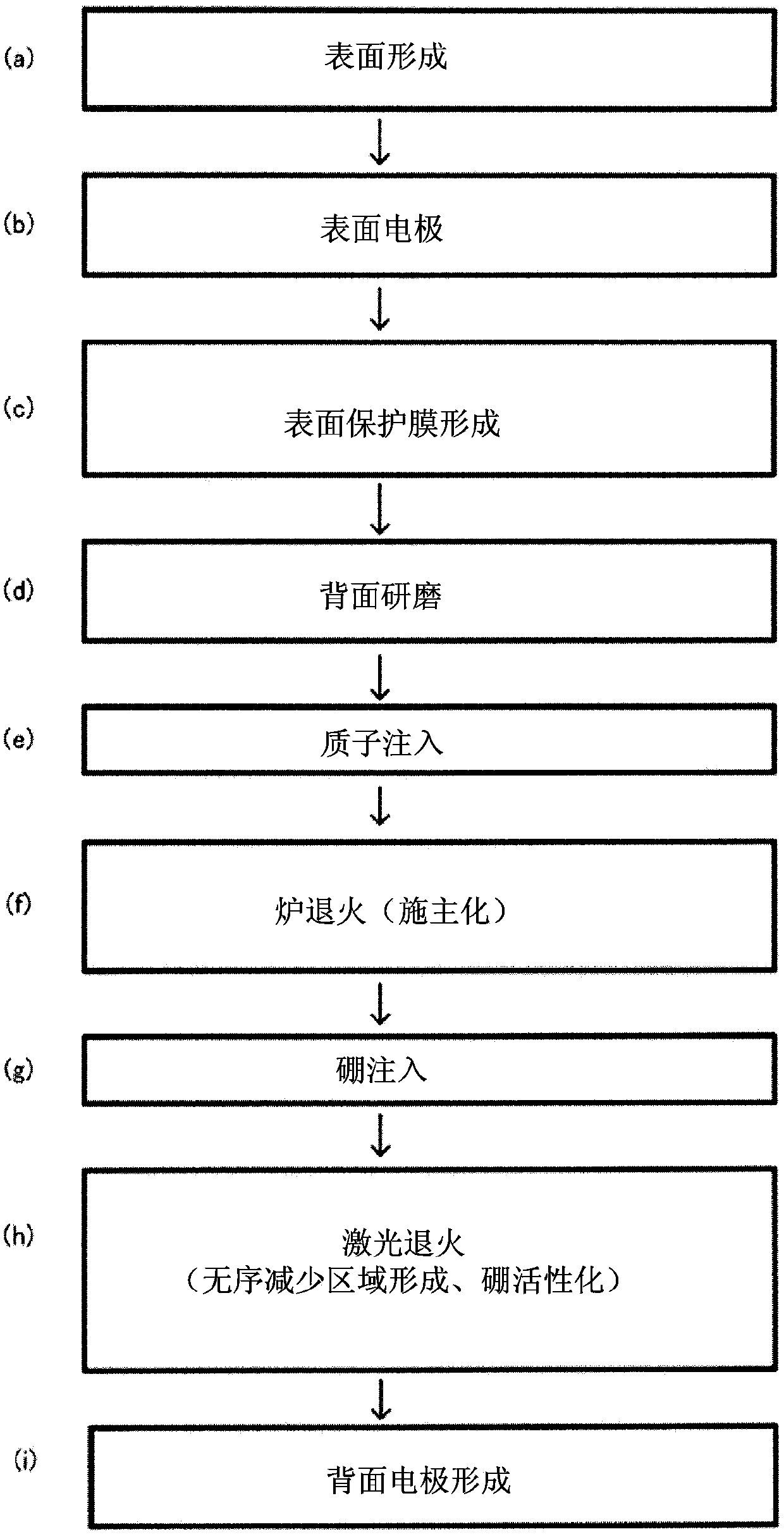

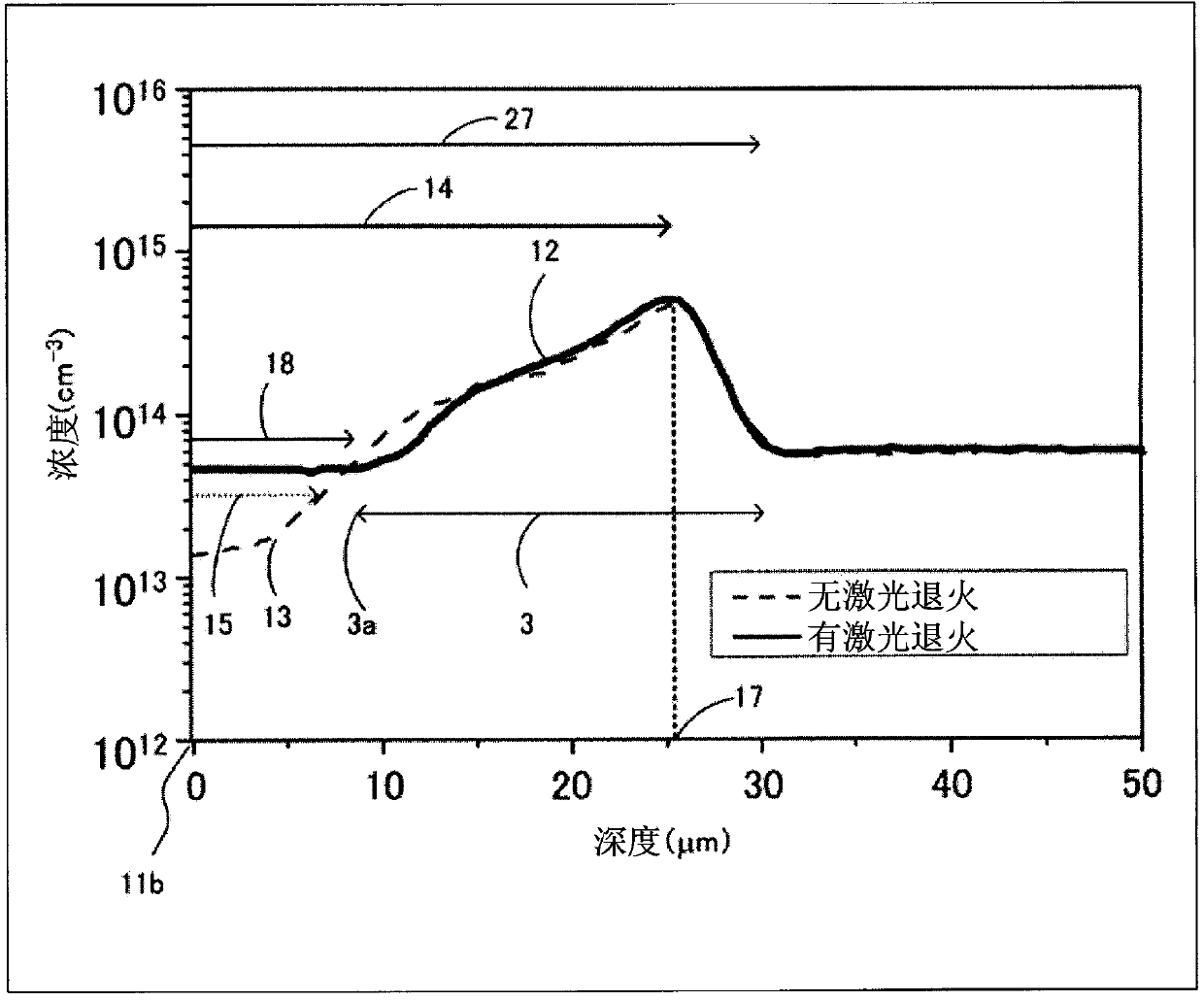

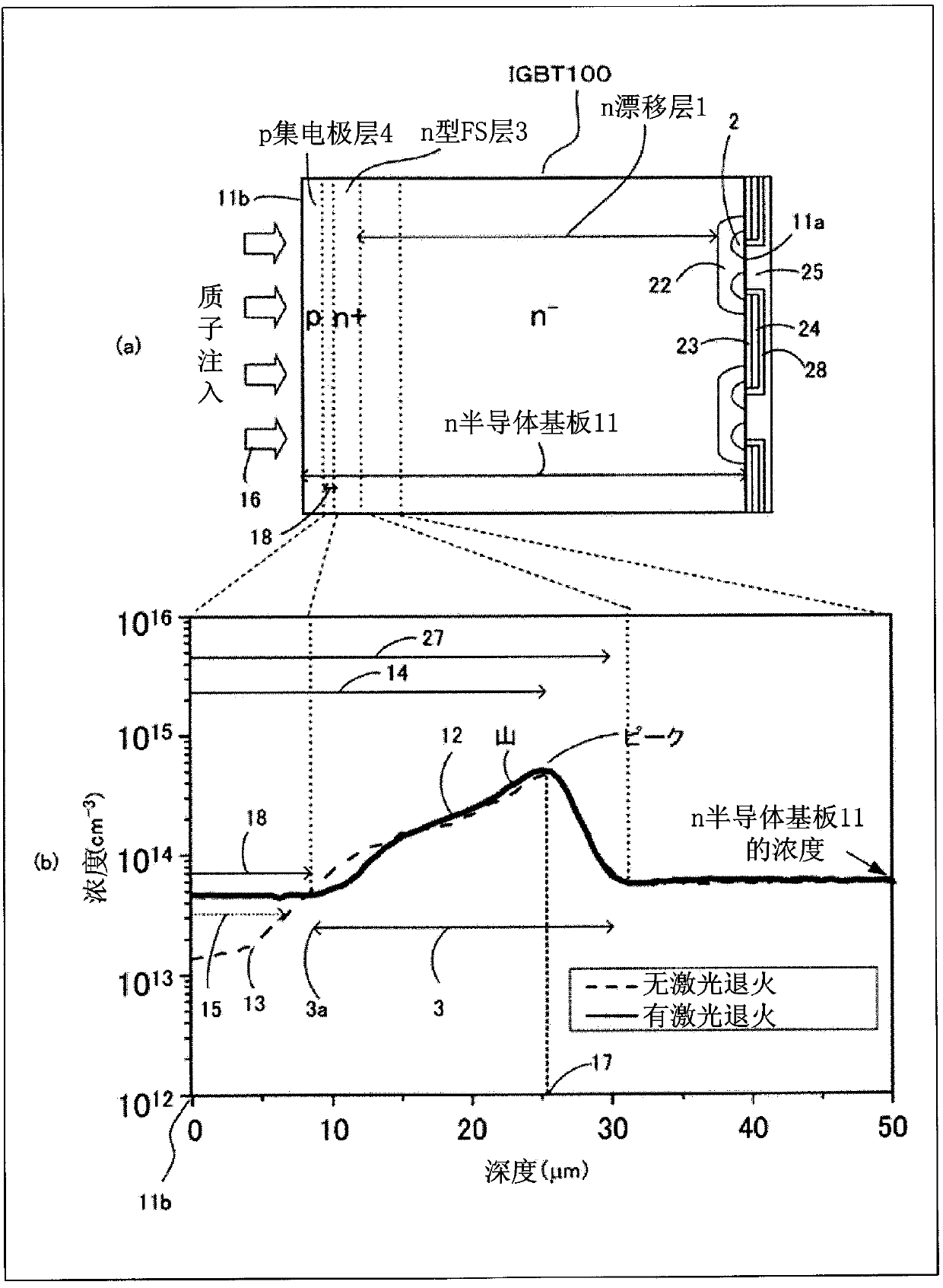

Semiconductor device and method for producing same

ActiveCN103999225AIncrease the on-resistanceImprove leakage currentTransistorSemiconductor/solid-state device manufacturingElectrical resistance and conductanceProton implantation

A method of producing a seminconductor device is disclosed in which, after proton implantation is performed, a hydrogen-induced donor is formed by a furnace annealing process to form an n-type field stop layer. A disorder generated in a proton passage region is reduced by a laser annealing process to form an n-type disorder reduction region. As such, the n-type field stop layer and the n-type disorder reduction region are formed by the proton implantation. Therefore, it is possible to provide a stable and inexpensive semiconductor device which has low conduction resistance and can improve electrical characteristics, such as a leakage current, and a method for producing the semiconductor device.

Owner:FUJI ELECTRIC CO LTD

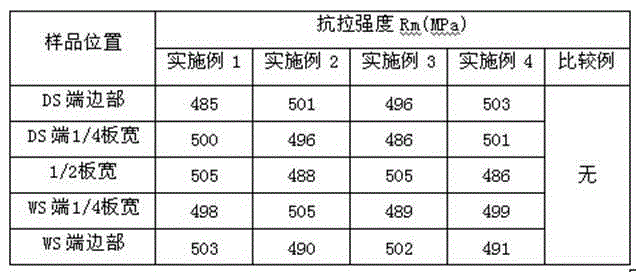

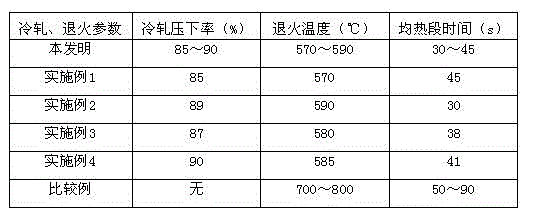

Cold-rolled tin plate for easy-to-open lid and production method of cold-rolled tin plate

ActiveCN104419865AGuaranteed Yield StrengthMeeting stamping and forming manufacturing needsReduction ratioStrip steel

The invention relates to a cold-rolled tin plate for an easy-to-open lid and a production method of the cold-rolled tin plate, and mainly aims at solving the technical problems that an existing cold-rolled tin plate for the easy-to-open lid cracks in the stamping and forming processes of manufacturing the easy-to-open lid, and is low in yield strength. The production method sequentially comprises the following steps: smelting according to the ingredients; carrying out molten iron desulfuration and converter top-bottom composite blowing, blowing argon from the ladle bottom or refining by an LF furnace; blowing Ar to protect pouring in the whole course; heating by virtue of a slab heating furnace; descaling, roughly rolling, carrying out finish rolling, and rolling to obtain hot-rolled steel coils; decoiling again; and carrying out acid pickling, cold rolling, vertical continuous annealing furnace annealing, electrotinning and rolling to obtain the finished product, wherein the precision rolling and finish rolling temperature is 820-850 DEG C, the hot rolling and coiling temperature is 630-660 DEG C, the cold rolling reduction ratio is 85%-90%, the temperature range of cold-rolled strip steel in a hard state in a soaking zone of a vertical continuous annealing furnace is 570-590 DEG C, and the soaking time of the strip steel in the vertical continuous annealing furnace is 30-45s. The cold-rolled tin plate is mainly used for fabricating the easy-to-open lid.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Epitaxial and polycrystalline growth of Si1-x-yGexCy and Si1-yCy alloy layers on Si by UHV-CVD

InactiveUS20040161911A1Reduce the temperatureReduce oxygen concentrationPolycrystalline material growthFrom solid stateDopantIn situ doping

A method and apparatus for depositing single crystal, epitaxial films of silicon carbon and silicon germanium carbon on a plurality of substrates in a hot wall, isothermal UHV-CVD system is described. In particular, a multiple wafer low temperature growth technique in the range from 350.degree. C. to 750.degree. C. is described for incorporating carbon epitaxially in Si and SiGe films with very abrupt and well defined junctions, but without any associated oxygen background contamination. Preferably, these epitaxial SiC and SiGeC films are in-situ doped p- or n-type and with the presence of low concentration of carbon <10.sup.20 cm.sup.-3, the as-grown p- or n-type dopant profile can withstand furnace anneals to temperatures of 850.degree. C. and rapid thermal anneal temperatures to 1000.degree. C.

Owner:GLOBALFOUNDRIES INC

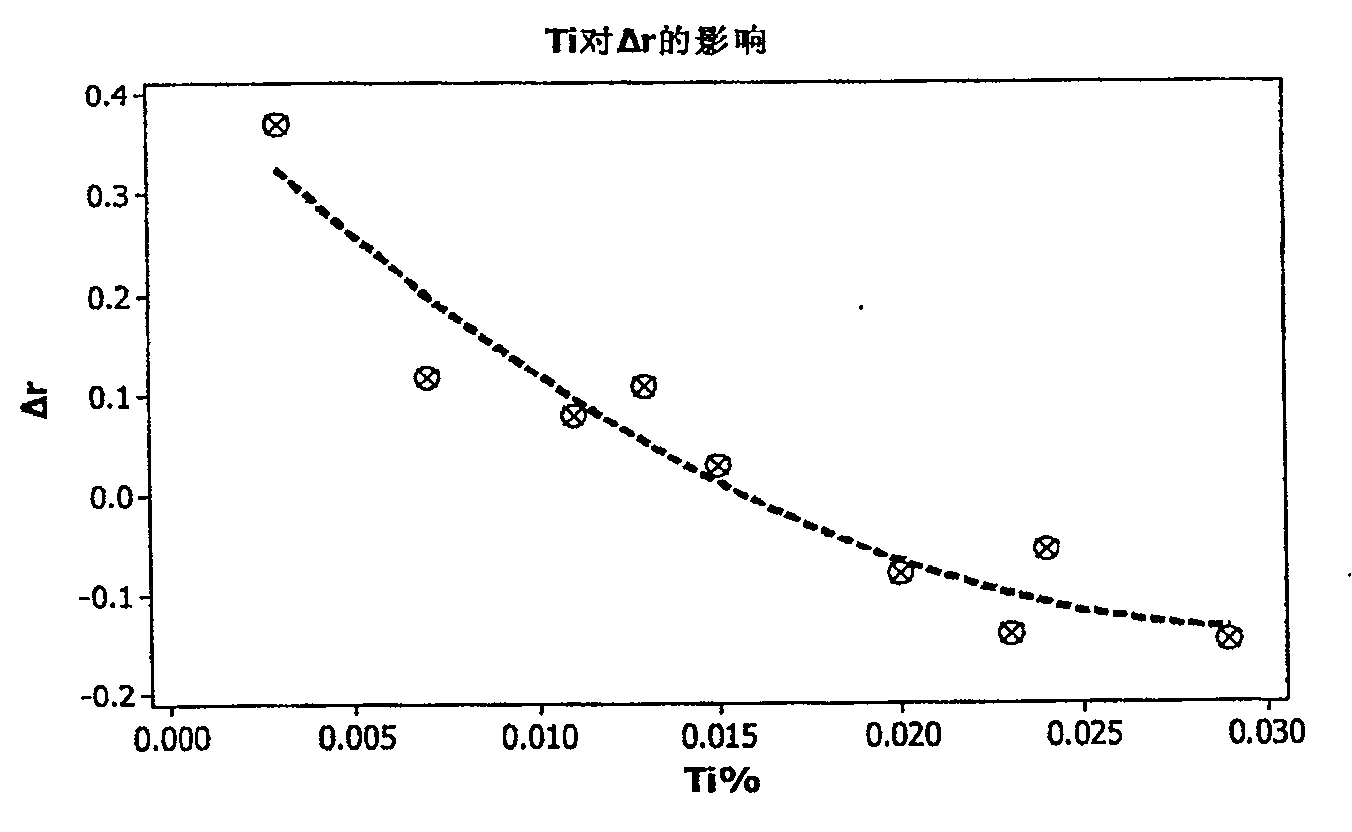

Steel for battery shell with excellent planar isotropism and its production

ActiveCN100560770CIsotropicImprove deep drawing performanceHeat treatment process controlPre treatmentHeating temperature

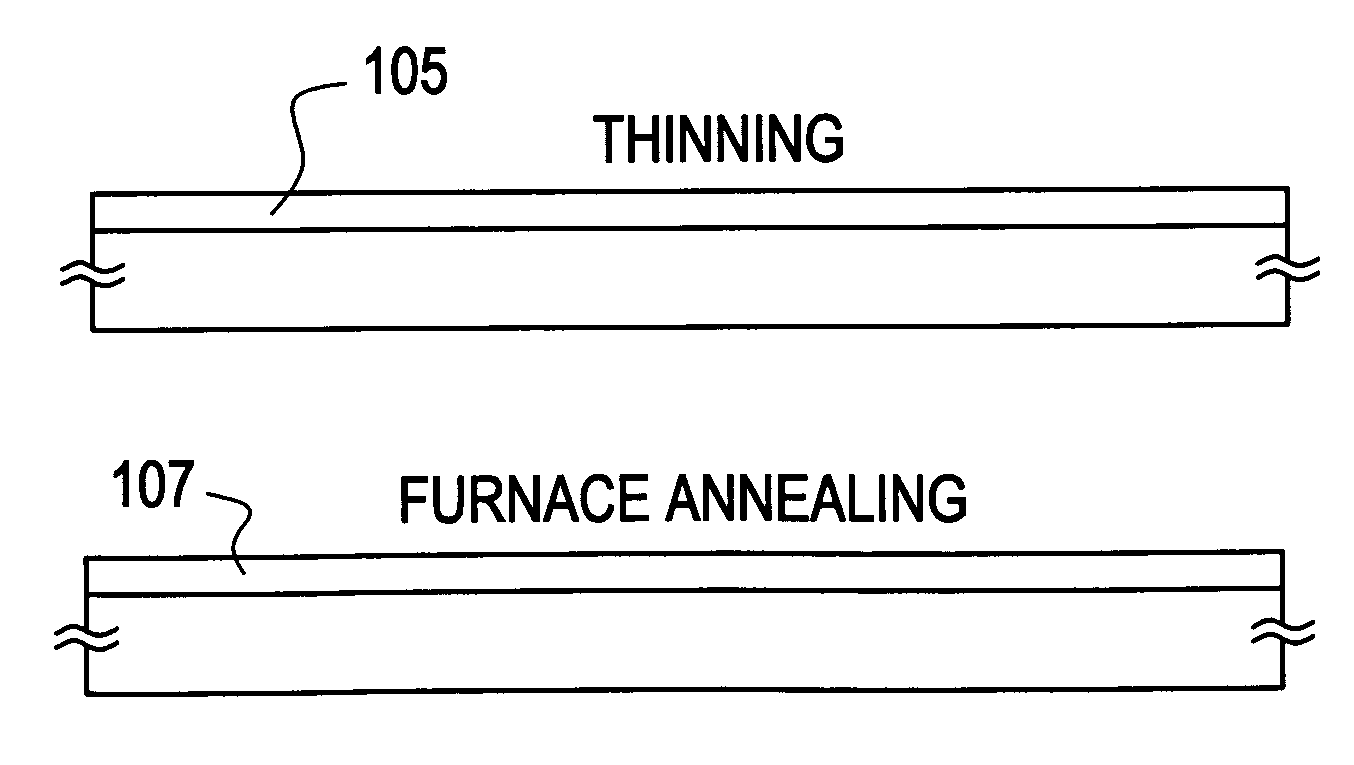

The invention relates to steel for battery steel shells and a manufacturing method thereof. The invention mainly solves the defects of large plane anisotropy, poor secondary processing embrittlement resistance, high production cost and the like existing in the existing steel for battery shells. The steel for battery case with excellent planar isotropy of the present invention has the following chemical element components by weight percentage: C: ≤0.01-0.05%, Si: ≤0.03%, Mn: 0.10-0.50%, P: ≤0.02%, S: ≤0.015%, Al: 0.01-0.10%, N: 0.002-0.007%, Ti: 0.005-0.02%, and the rest are iron and inevitable inclusions. The manufacturing method includes the following steps: molten iron pretreatment, converter smelting, post-furnace refining, hot rolling, pickling, cold rolling, bell annealing, leveling, finishing into finished coils, and is characterized by: heating temperature: ≤1270°C , Finish rolling temperature: 860~930℃, coiling temperature: ≤640℃; cold rolling deformation is controlled at 75%~90%, bell furnace annealing temperature: 650~800℃; others are carried out according to conventional processes. The product is used for stamping after electroplating nickel or directly stamping into battery case.

Owner:BAOSHAN IRON & STEEL CO LTD

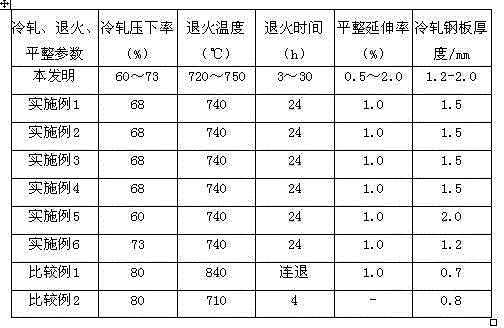

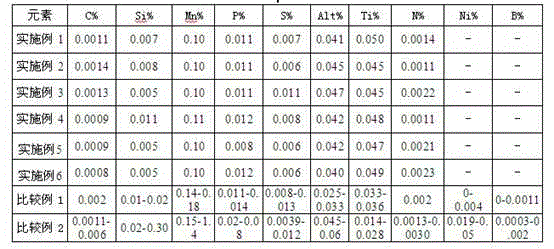

Thick-gauge ultra-deep drawing cold rolled steel plate and manufacturing method thereof

The present invention relates to a thick-gauge ultra-deep drawing cold rolled steel plate and a manufacturing method thereof. In the prior art, when the cold rolling reduction rate is insufficient, the stamping performance of the ultra-deep drawing cold rolled steel plate with the thickness of 1.2-2.0 mm and produced by using the bell furnace annealing process does not meet the standard. A purpose of the present invention is to solve the technical problem in the prior art. The chemical components of the thick-gauge ultra-deep drawing cold rolled steel plate comprise, by weight, less than or equal to 0.003% of C, less than or equal to 0.03% of Si, 0.1-1.0% of Mn, less than or equal to 0.02% of P, less than or equal to 0.02% of S, less than or equal to 0.005% of N, less than or equal to 0.05% of Alt, and the balance of Fe and unavoidable impurities, wherein the content of Ti% satisfies the equation that (Ti%)-3.4*(N%)-1.5*(S%)-4*(C%) is (0.004-0.03). According to the present invention, the thick-gauge ultra-deep drawing cold rolled steel plate is mainly used for outer covers, shells and other members of mechanical and electrical products.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

590 MPa semi-cold hardened steel strip and cover furnace production process thereof

InactiveCN108823508ARaise the recrystallization temperatureHigh strengthMetal rolling arrangementsAcid washingContinuous rolling

The invention discloses a 590 MPa semi-cold hardened steel strip and a cover furnace production process thereof, and belongs to the technical field of cold hardened steel production. The steel strip comprises the following chemical components in percentage by weight: C not more than 0.0050%, Si not more than 0.05%, Mn not more than 0.30%, P not more than 0.010%, S not more than 0.020%, 0.030-0.050% of Als, and the balance iron, Ca and inevitable microelements. The production process comprises the flow of blast furnace molten iron smelting, converter molten steel smelting, LF molten steel refining, RH molten steel refining, CSP sheet blank continuous casting and continuous rolling, acid washing and cold continuous rolling, cover furnace annealing, leveling and inspection, packing and warehousing. The smelting, rolling, annealing and finishing process with ultralow carbons, CSP sheet blank continuous casting and continuous rolling production lines and cover furnace annealing as a core isadopted to obtain the semi-hard steel strip with stable chemical components and mechanical performance, high strength and hardness and a certain of plasticity to meet the requirements of 590 MPa coldhardened steel strip DC03-C590 for vehicle sealing strip substrates.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Metallic oxide semiconductor film and preparation method and application thereof

ActiveCN103065972AImprove stabilityImprove efficiencyTransistorSolid-state devicesOxide semiconductorVoltage

The invention belongs to the field of electron devices and particularly relates to a metallic oxide semiconductor film which is obtained by adopting of laser annealing craft, and application of the metallic oxide semiconductor film in a thin film transistor (TFT) device and an organic light emitting diode (OLED) device. The method of preparing of the metallic oxide semiconductor film includes of (1) preparing the metallic oxide semiconductor film which is based on zinc oxide and formed by adding of other metallic elements; (2), under oxygen atmosphere, the metallic oxide semiconductor film which is obtained in the step (1) conducting laser annealing for 3-6min, and the needed metallic oxide semiconductor film forming. Performance of the metallic oxide semiconductor film, such as migration rate and stability of threshold voltage, is greatly improved, compared with a traditional manner which uses a high-temperature annealing furnace for annealing, efficiency is higher, and stability is better.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

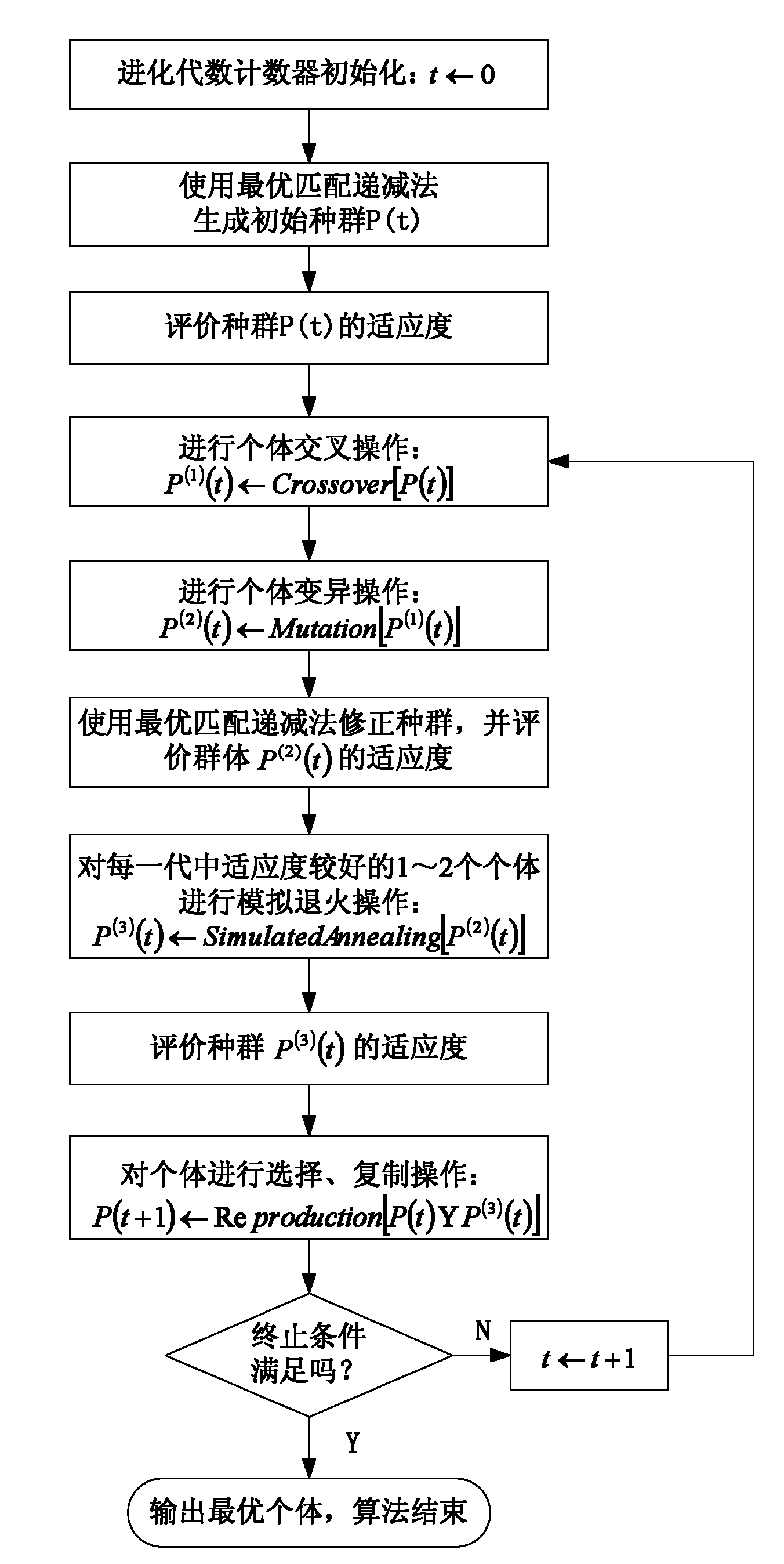

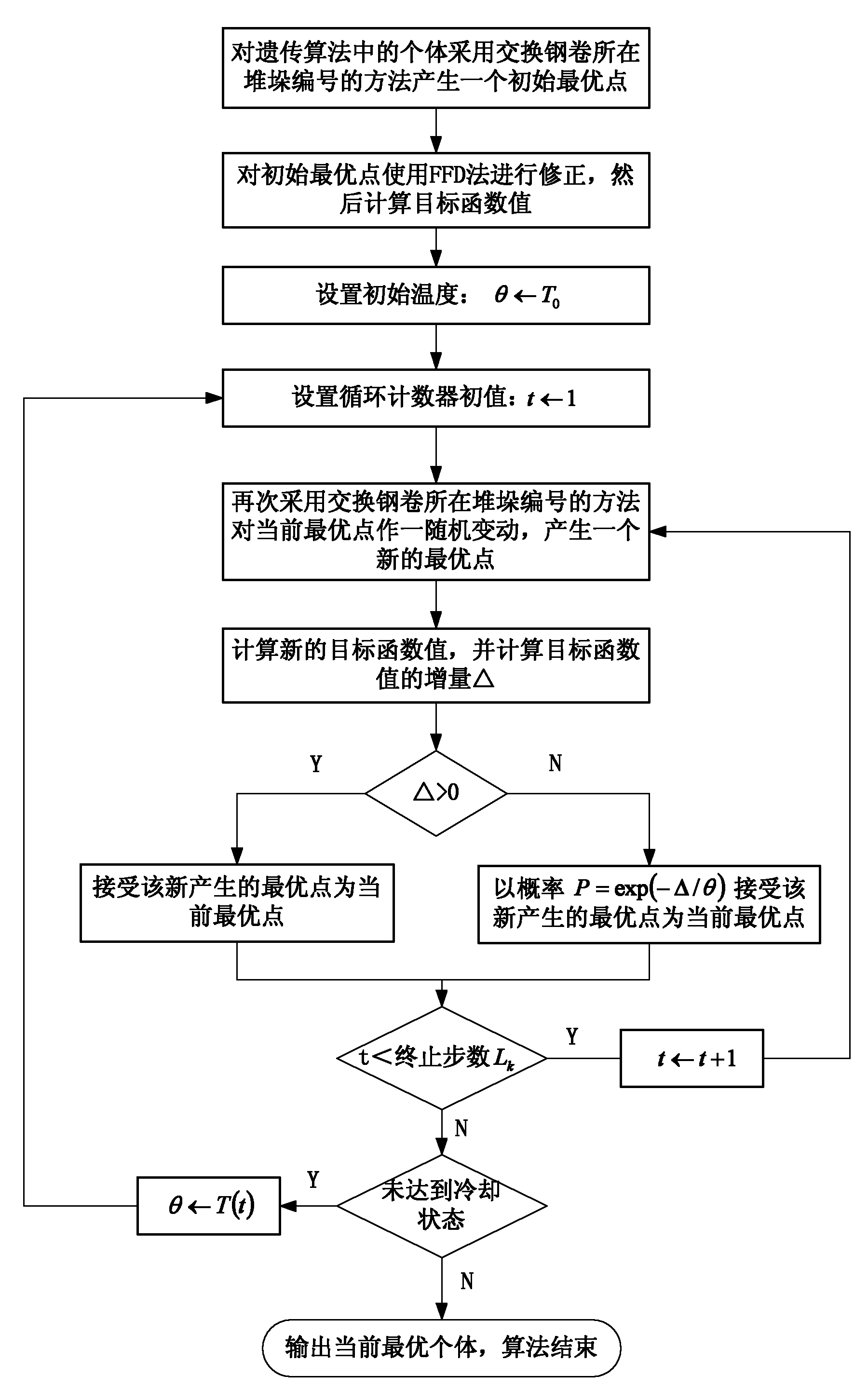

Combinatorial optimization method of steel coil stacking of hood-type annealing furnace

ActiveCN102206741AHigh precisionRealize automatic stackingBell type furnacesHeat treatment furnacesInformatizationMathematical model

The invention relates to the technical field of ferrous metallurgy information technology, and particularly relates to a combinatorial optimization method of steel coil stacking of a hood-type annealing furnace. According to the characteristics of an annealing process of a hood-type annealing furnace, based on the analysis of the effect of steel coil overall dimensions (external diameter, width, thickness, etc.) and steel grades on annealing time and the restriction of various constraint conditions, and aiming at the optimization objects of minimizing stacking number and maximizing furnace stage production efficiency, the invention establishes a mathematical model for the optimization of hood-type furnace stacking, and provides a hybrid genetic algorithm (FGSA) combining algorithms of a first fit decreasing algorithm (FFD), a genetic algorithm (GA), and a simulated annealing algorithm (SA) for the solution of the model. The method can realize the informatization and the automation of hood-type furnace annealing production, reduce the labor intensity of scheduling personnel, increase the production efficiency of production factories, and has the effect of energy saving and consumption reduction.

Owner:WISDRI WUHAN WIS IND FURNACE

Semiconductor device and method of manufacturing the same

InactiveUS20070117293A1Facilitated DiffusionReduce defectsTransistorSolid-state devicesCrystalline semiconductorLaser annealing

There is provided a method in which a TFT with superior electrical characteristics is manufactured and a high performance semiconductor device is realized by assembling a circuit with the TFT. The method of manufacturing the semiconductor device includes: a step of forming a crystal-containing semiconductor film by carrying out a thermal annealing to a semiconductor film; a step of carrying out an oxidizing treatment to the crystal-containing semiconductor film; a step of carrying out a laser annealing treatment to the crystal-containing semiconductor film after the oxidizing treatment has been carried out; and a step of carrying out a furnace annealing treatment to the crystal-containing semiconductor film after the laser annealing. The laser annealing treatment is carried out with an energy density of 250 to 5000 mJ / cm2.

Owner:SEMICON ENERGY LAB CO LTD

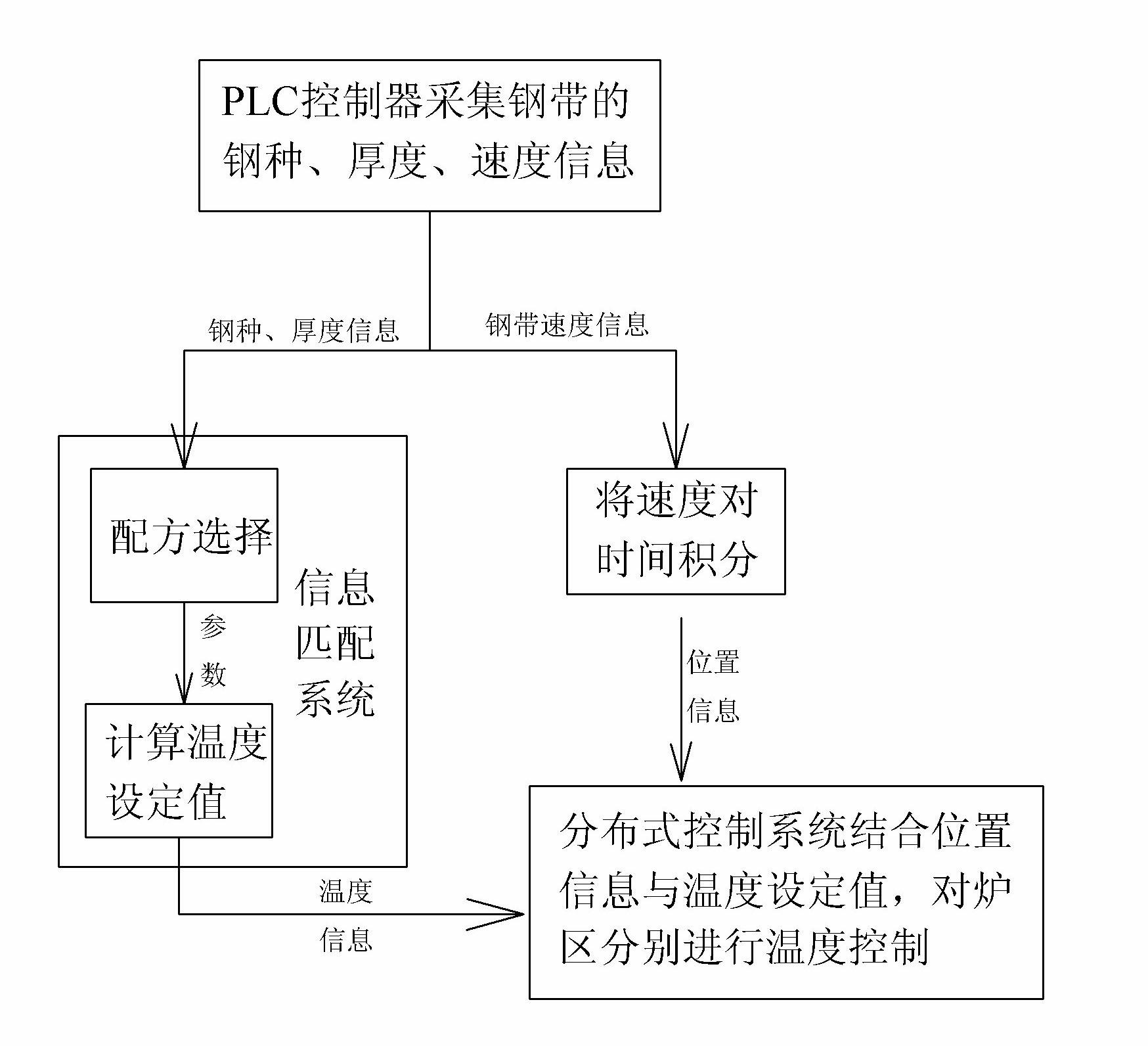

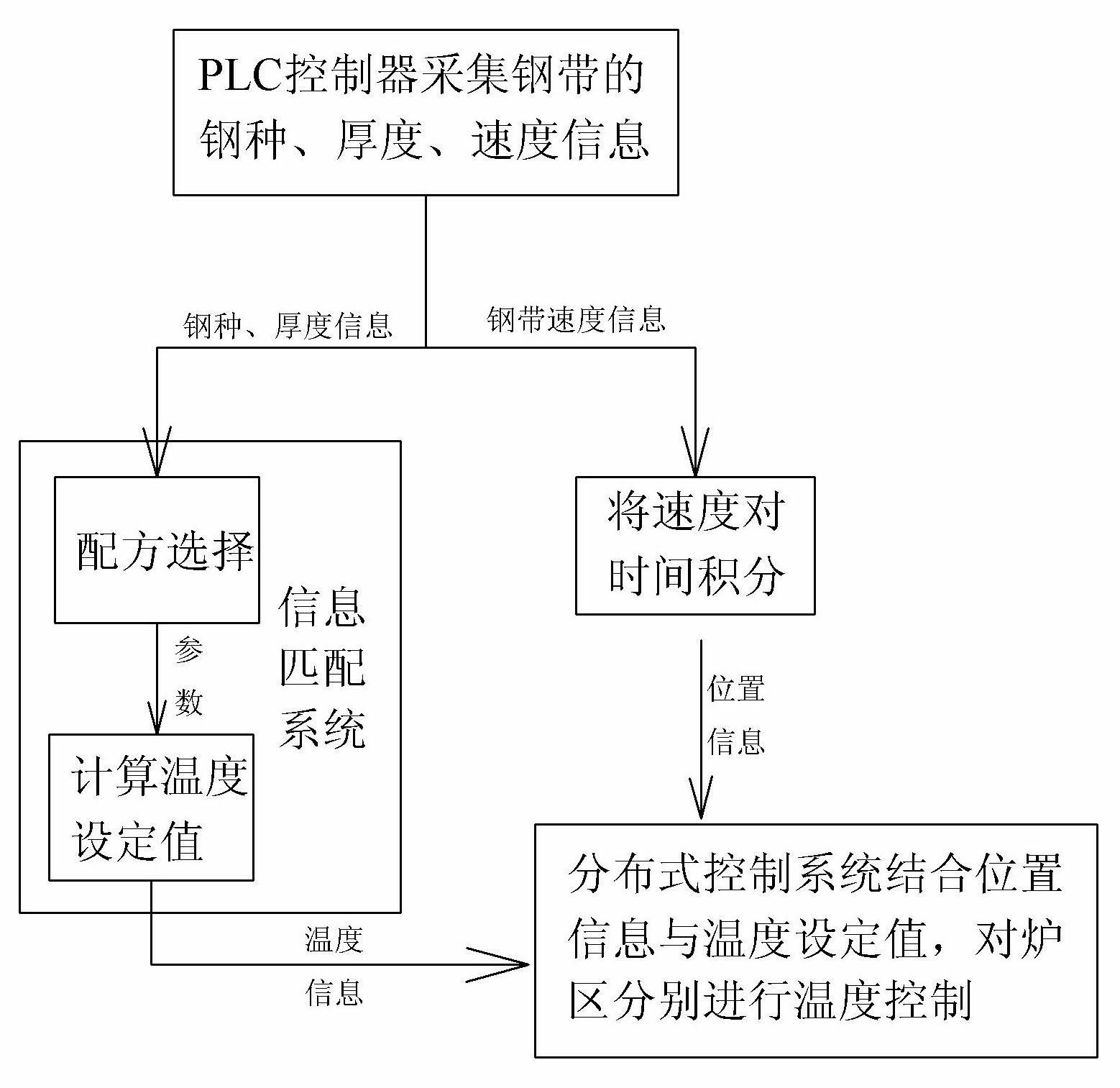

A temperature control method for an annealing furnace zone

InactiveCN102279607AProtect annealing qualityAvoid lagAuxillary controllers with auxillary heating devicesFurnace typesTemperature controlHysteresis

The invention discloses a method for controlling the temperature of an annealing furnace area, which includes the steps of information collection, data processing, and temperature setting. The speed information of the steel strip is collected at the PLC controller, and the time is integrated according to the speed value to obtain The location information of the specific furnace area where the steel strip is located; the information matching system calculates the required annealing temperature value of the steel strip according to the steel type and thickness information, and when the steel strip arrives at the furnace area, the temperature of the furnace area is adjusted accordingly The adjustment and change of the steel strip can avoid the phenomenon of hysteresis or advance in the temperature control and the position of the steel strip, and ensure that the steel strip is annealed at the correct set temperature, thereby protecting the annealing quality of the steel strip and improving the qualified rate of the product. In addition, when the steel strip is broken, the distributed control system can quickly search and calculate the location information of the steel strip, quickly perform positioning, shorten the processing time of the broken strip, and improve work efficiency.

Owner:鞍钢联众(广州)不锈钢有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com