Combinatorial optimization method of steel coil stacking of hood-type annealing furnace

A bell-type annealing furnace and combination optimization technology, which is applied in the field of iron and steel metallurgy information, can solve the problems of poor adaptability of expert systems, unsuitable production environment, and influence of algorithm efficiency, so as to save programming time, improve production efficiency, and save energy and reduce consumption. level, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

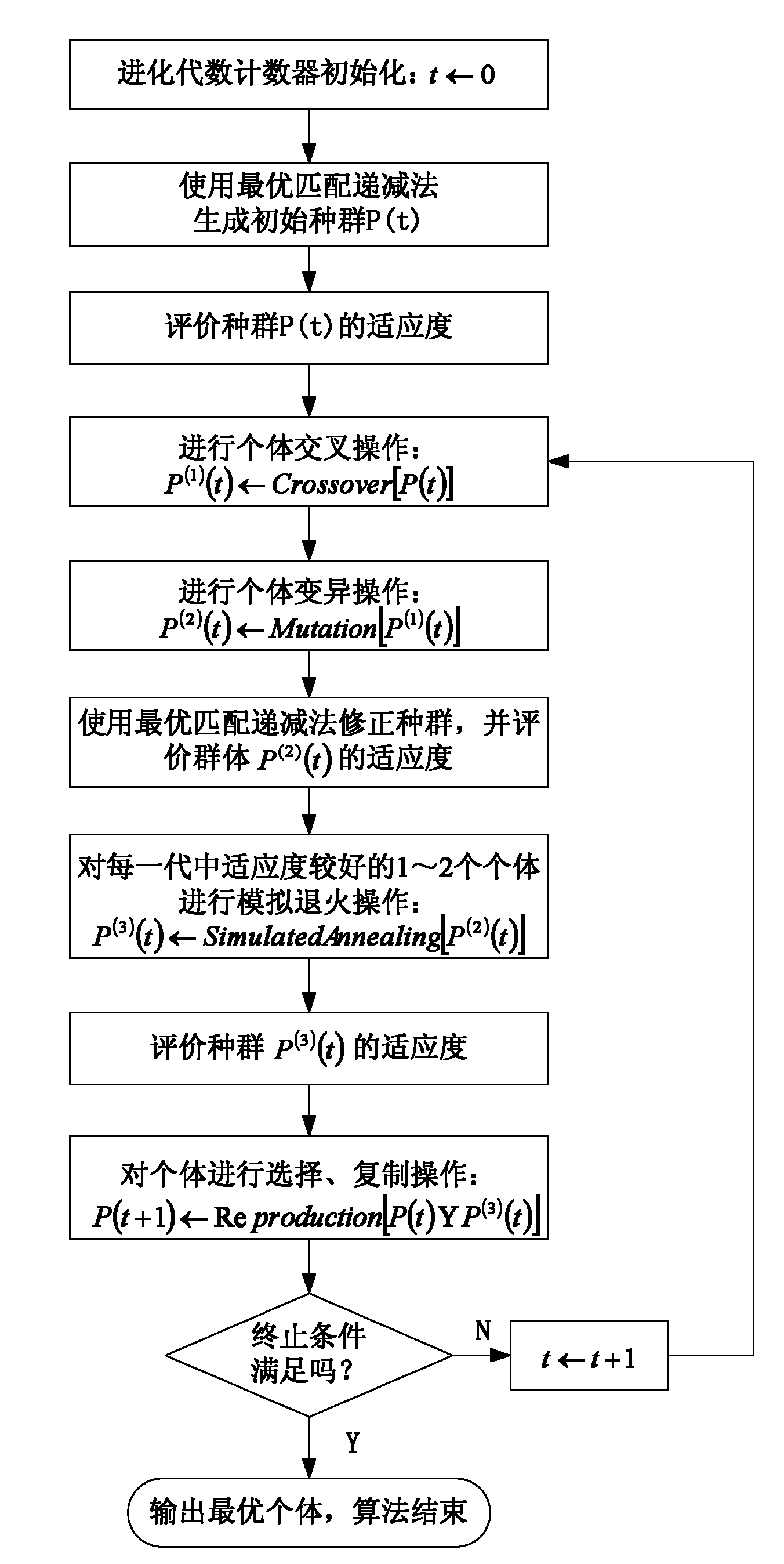

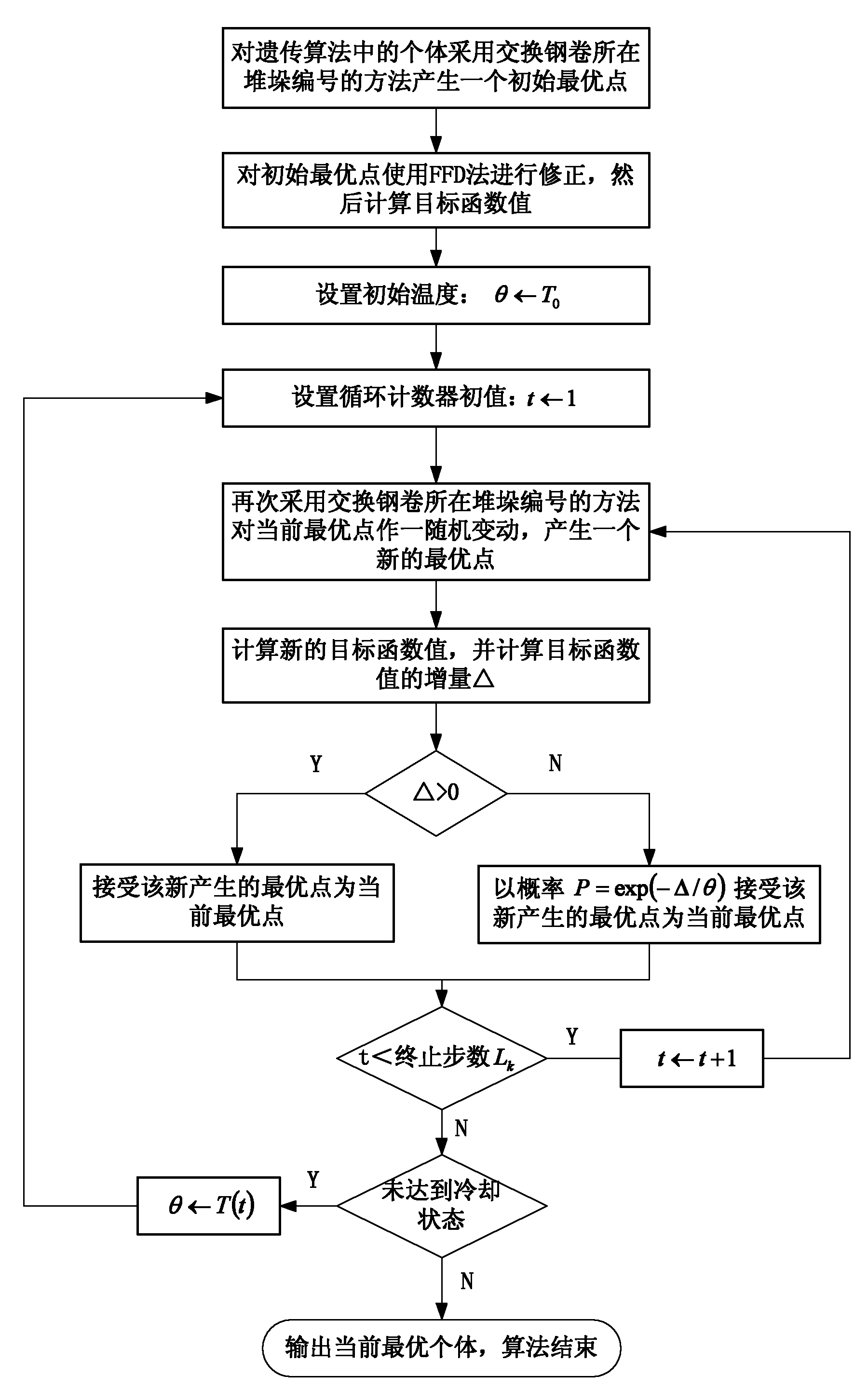

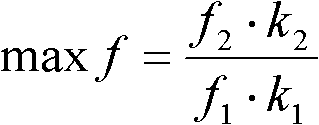

[0071] The present invention aims at the characteristics of bell furnace annealing process, on the basis of analyzing the external dimensions (outer diameter, width, thickness, etc.) of different steel coils and the influence of factors such as steel types on annealing time and various constraints With the optimization goals of minimizing the number of stacks and maximizing the production efficiency of the hearth, a mathematical model for the stacking optimization of bell-type furnaces was established, and a combination of optimal matching decrement method (FFD), genetic algorithm (GA) and simulated annealing algorithm ( SA) and other methods of hybrid genetic algorithm (FGSA) to solve the model.

[0072] The optimization problem of steel coil stacking combination in bell annealing furnace can be described as the following model:

[0073] max f = f 2 · k ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com