Patents

Literature

151results about How to "Realize automatic stacking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

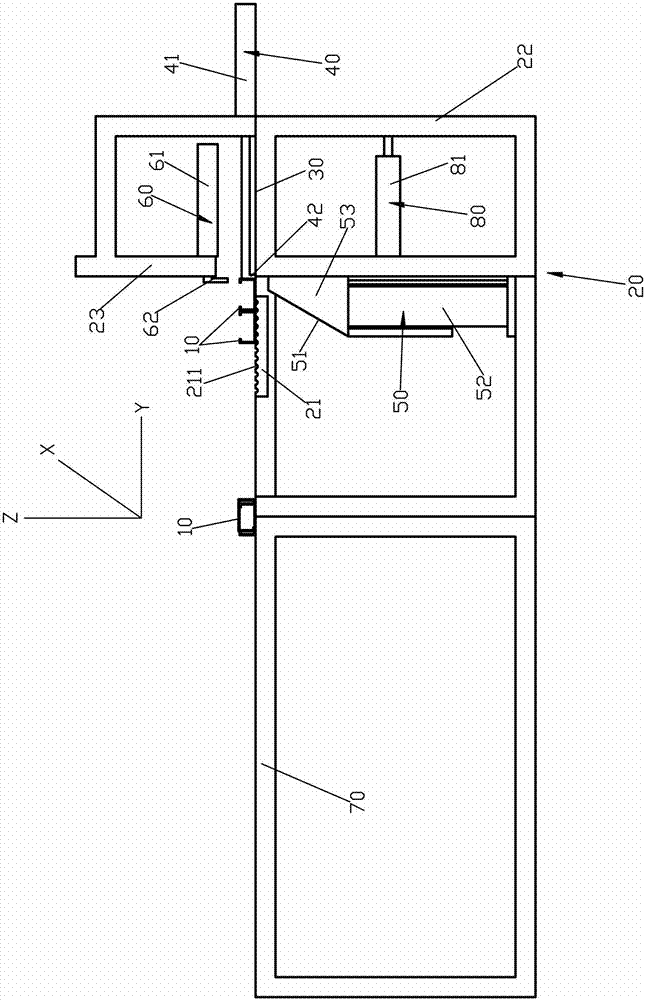

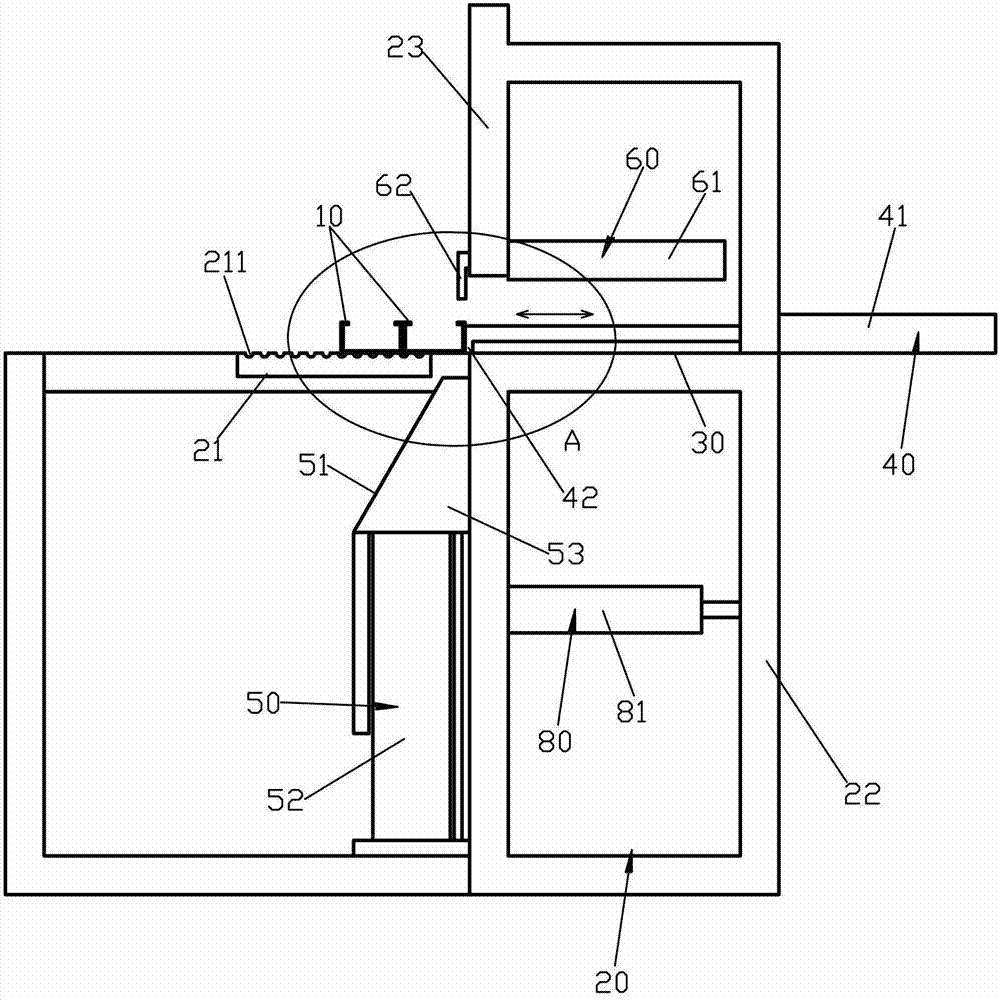

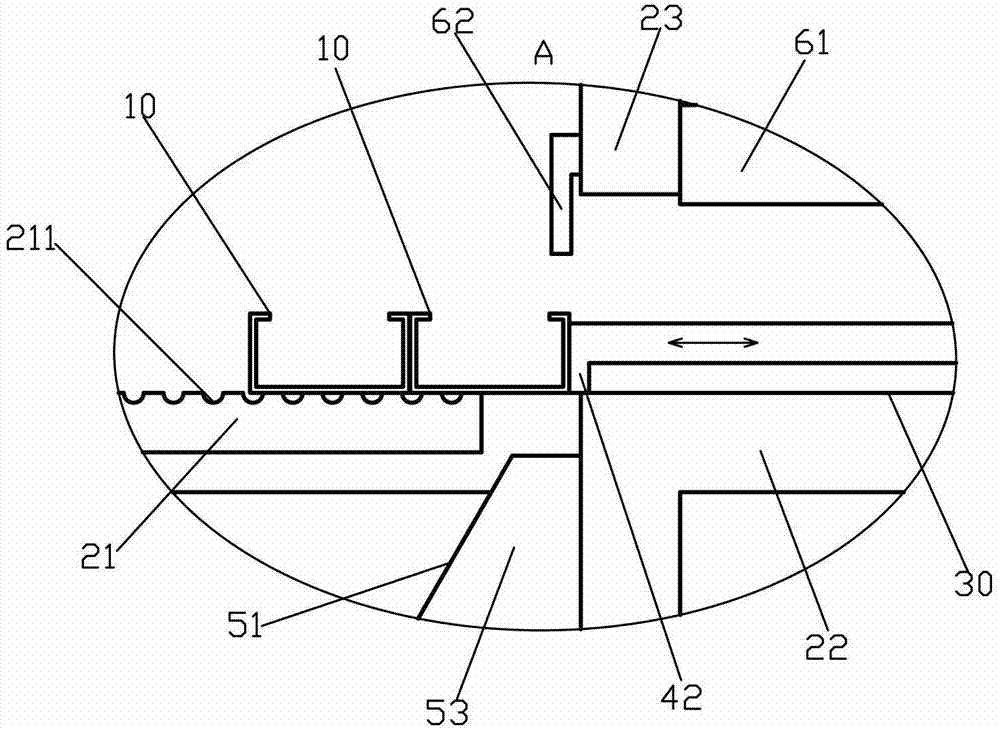

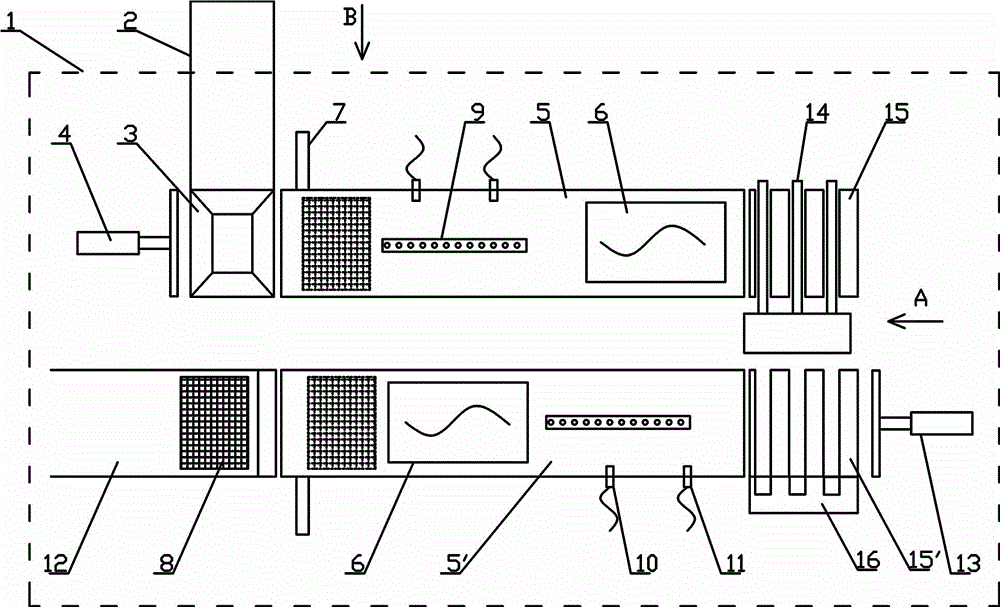

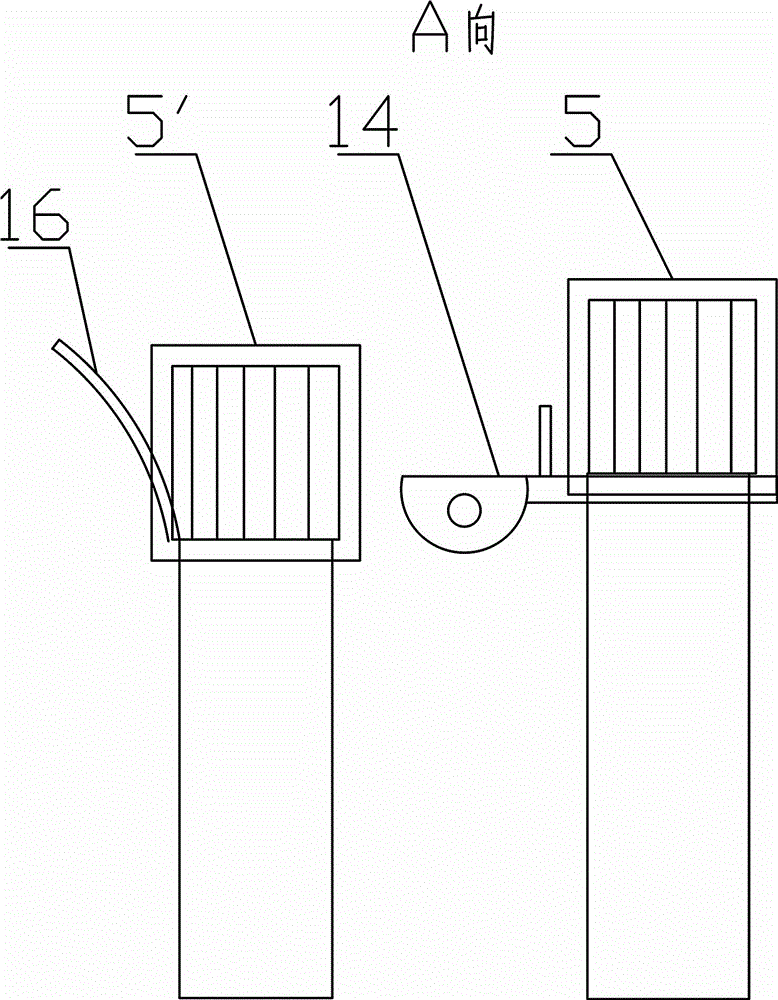

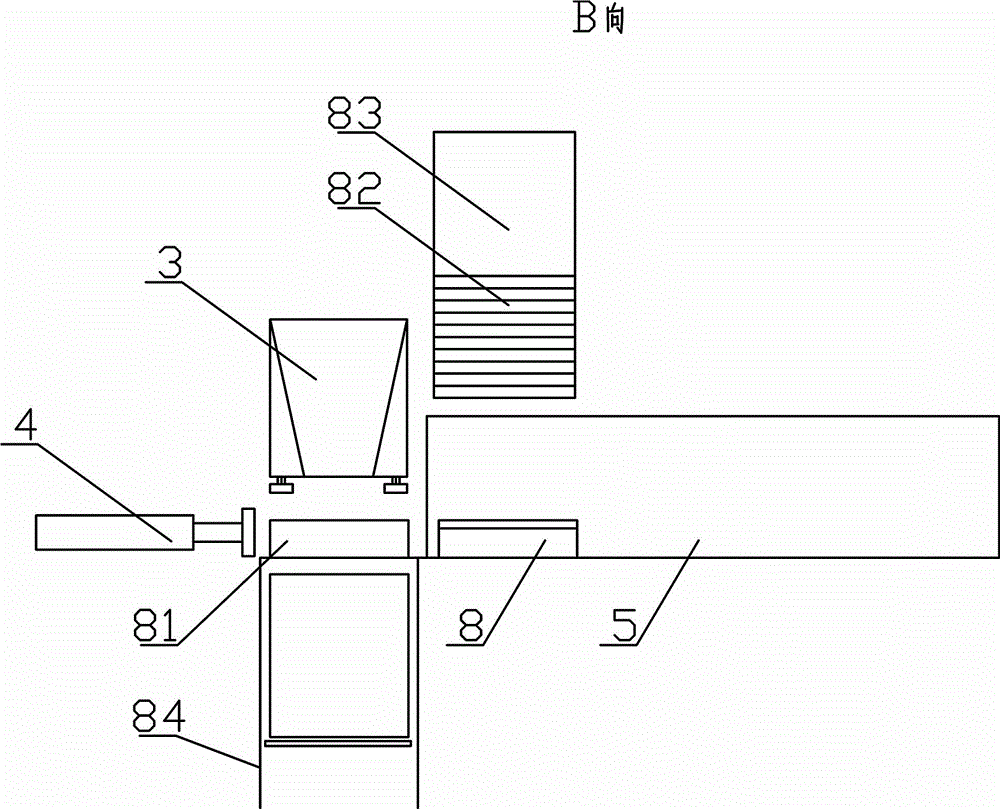

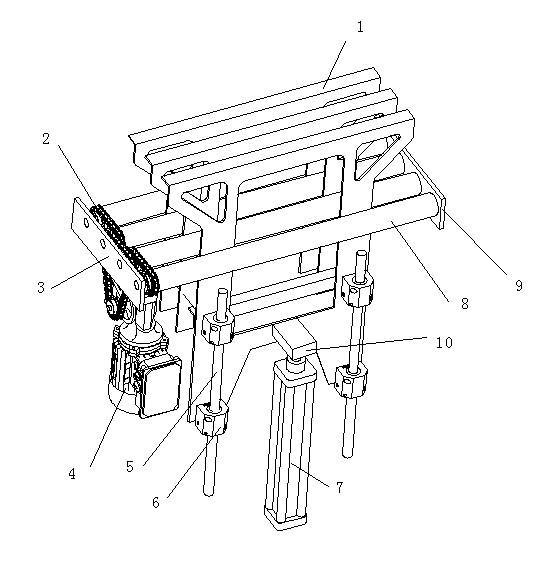

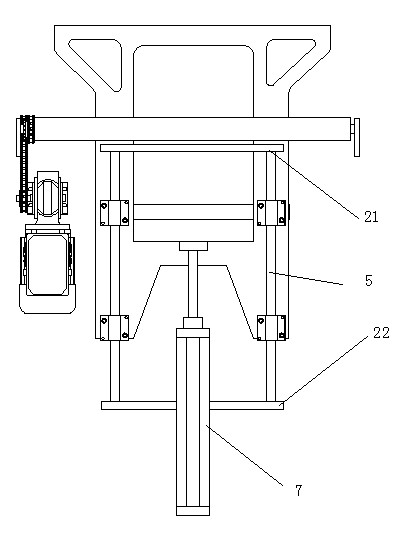

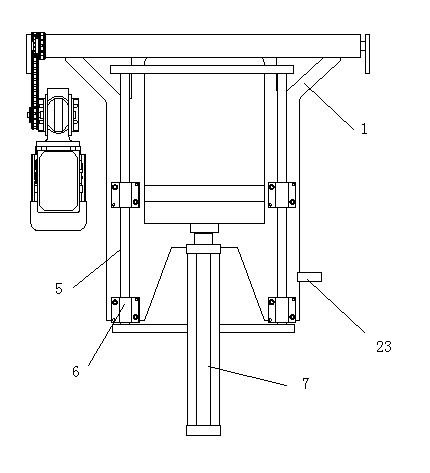

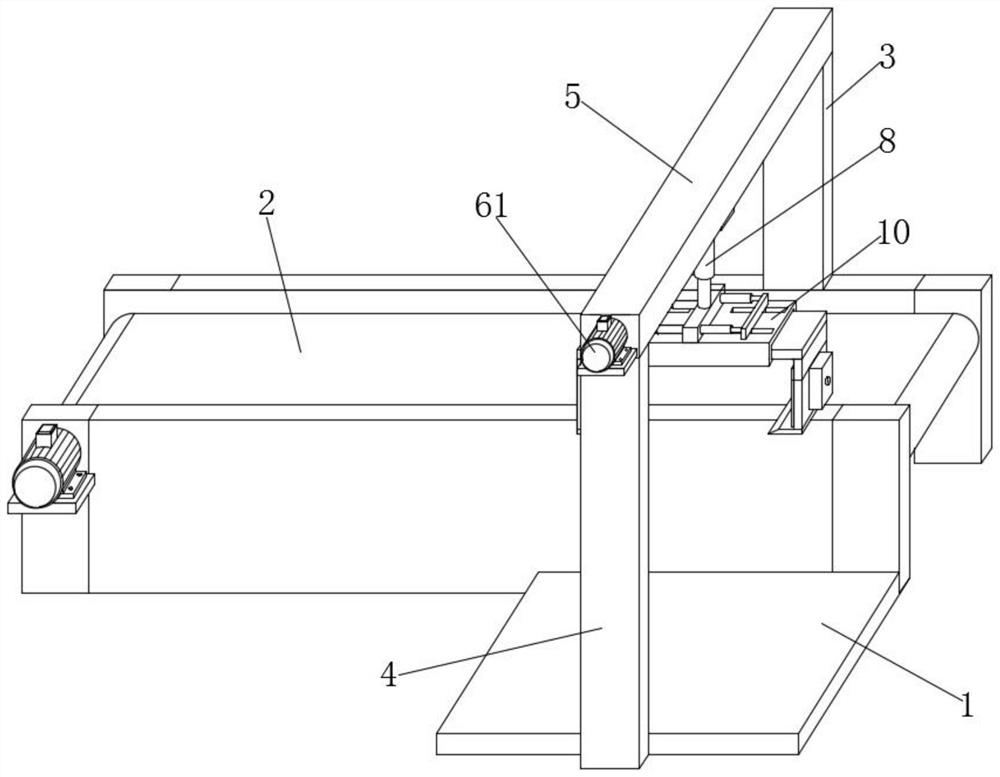

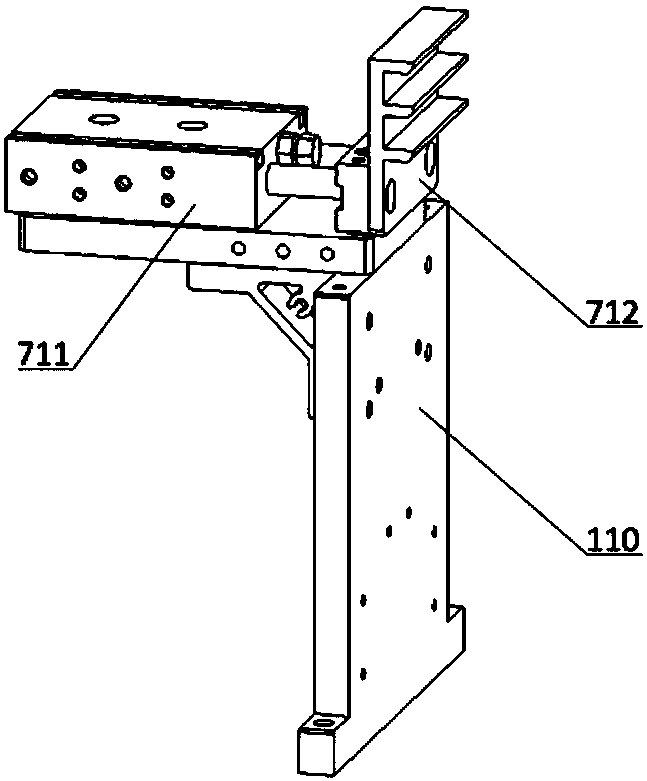

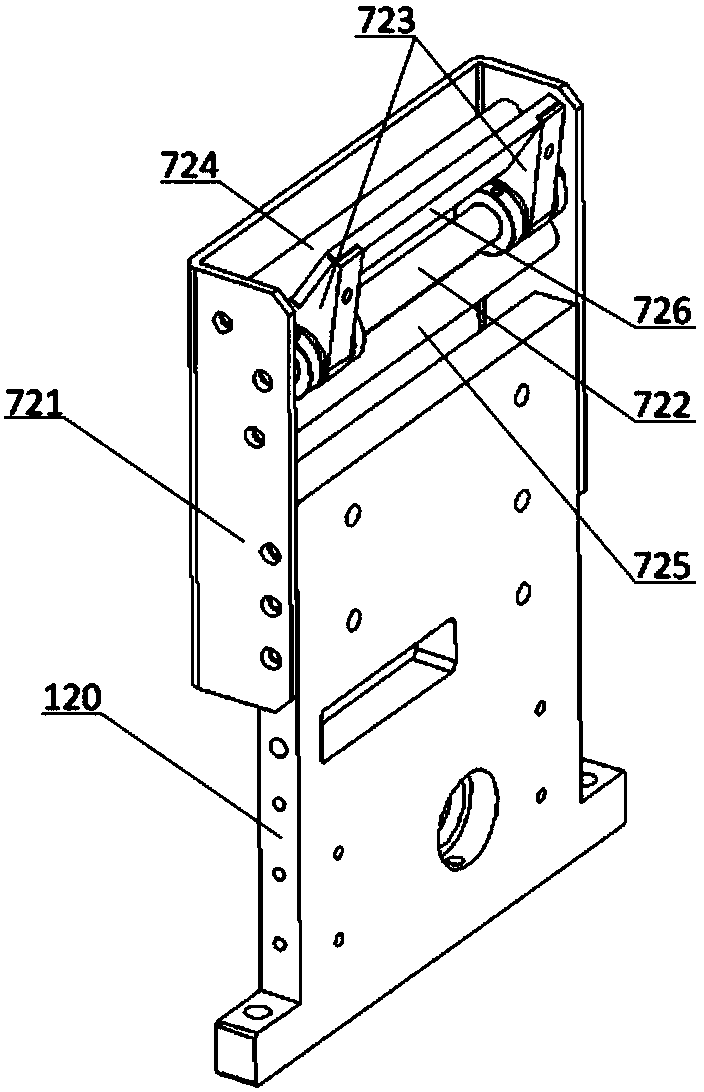

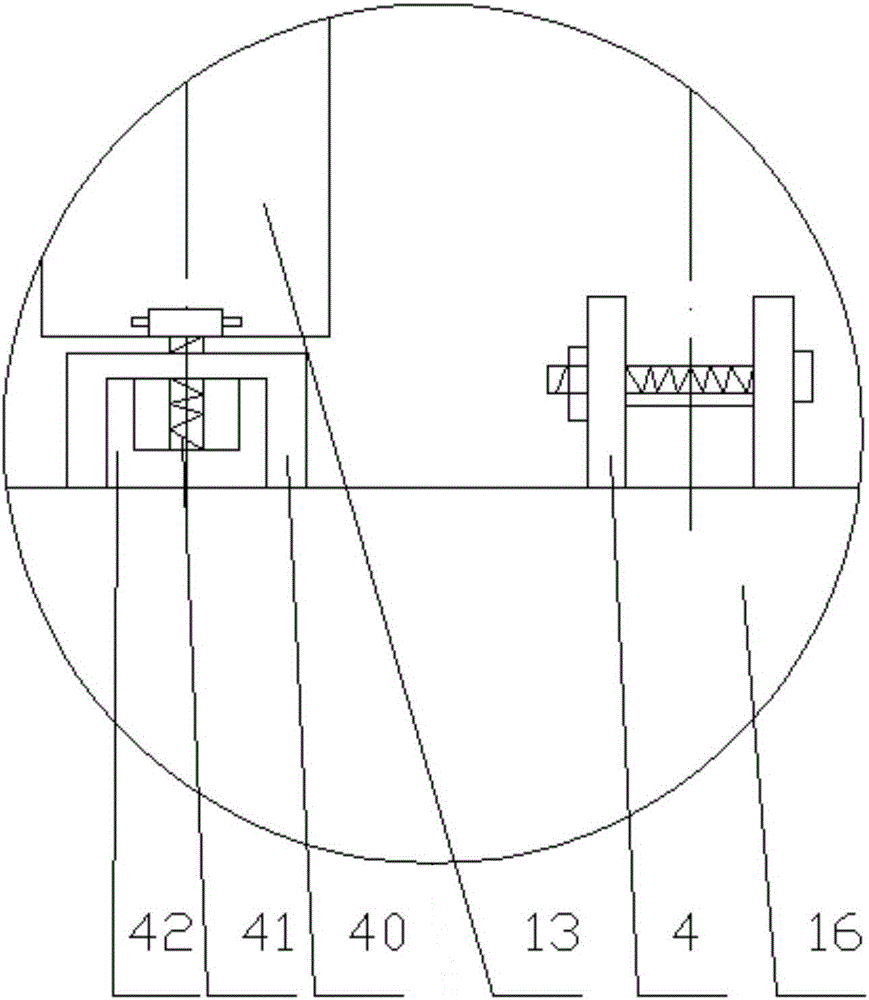

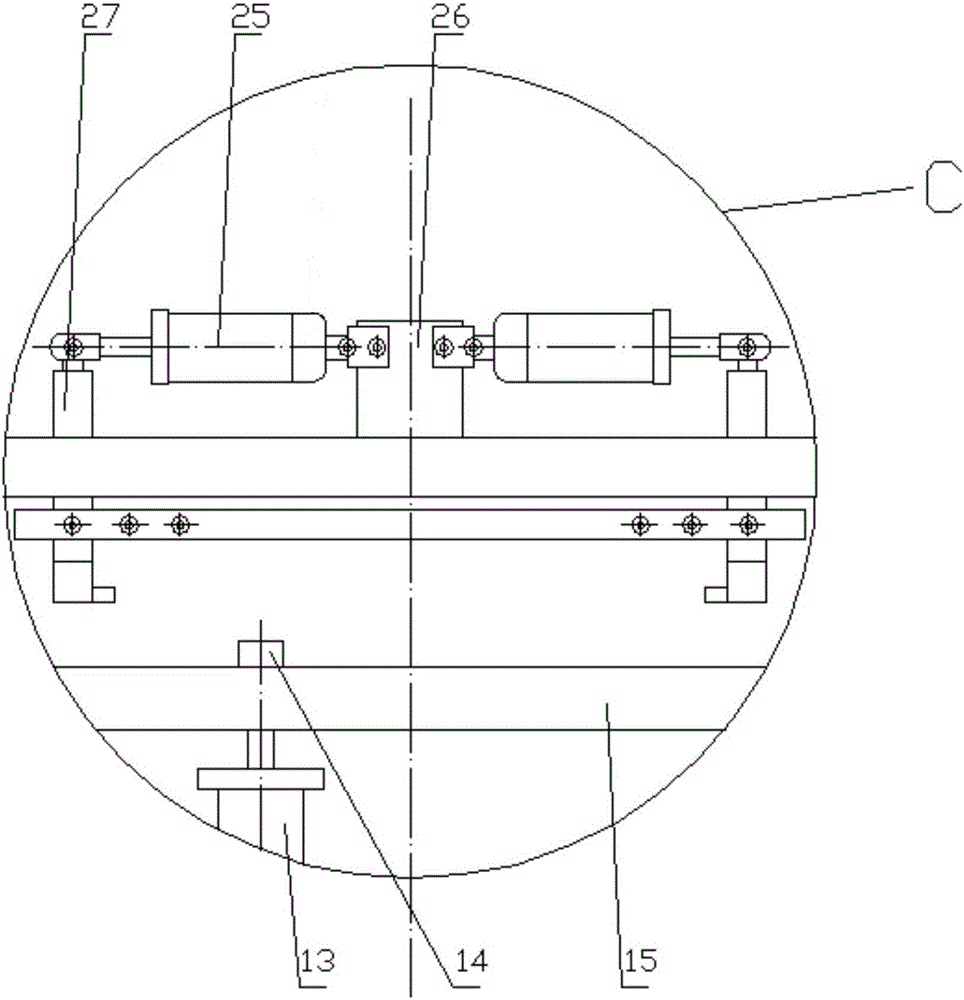

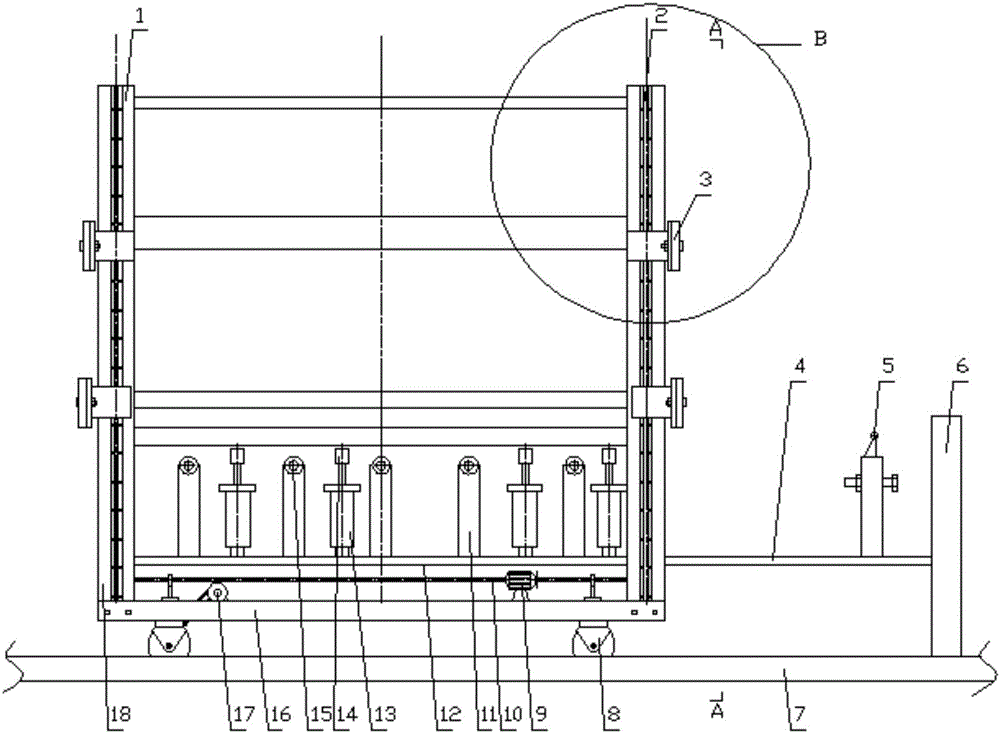

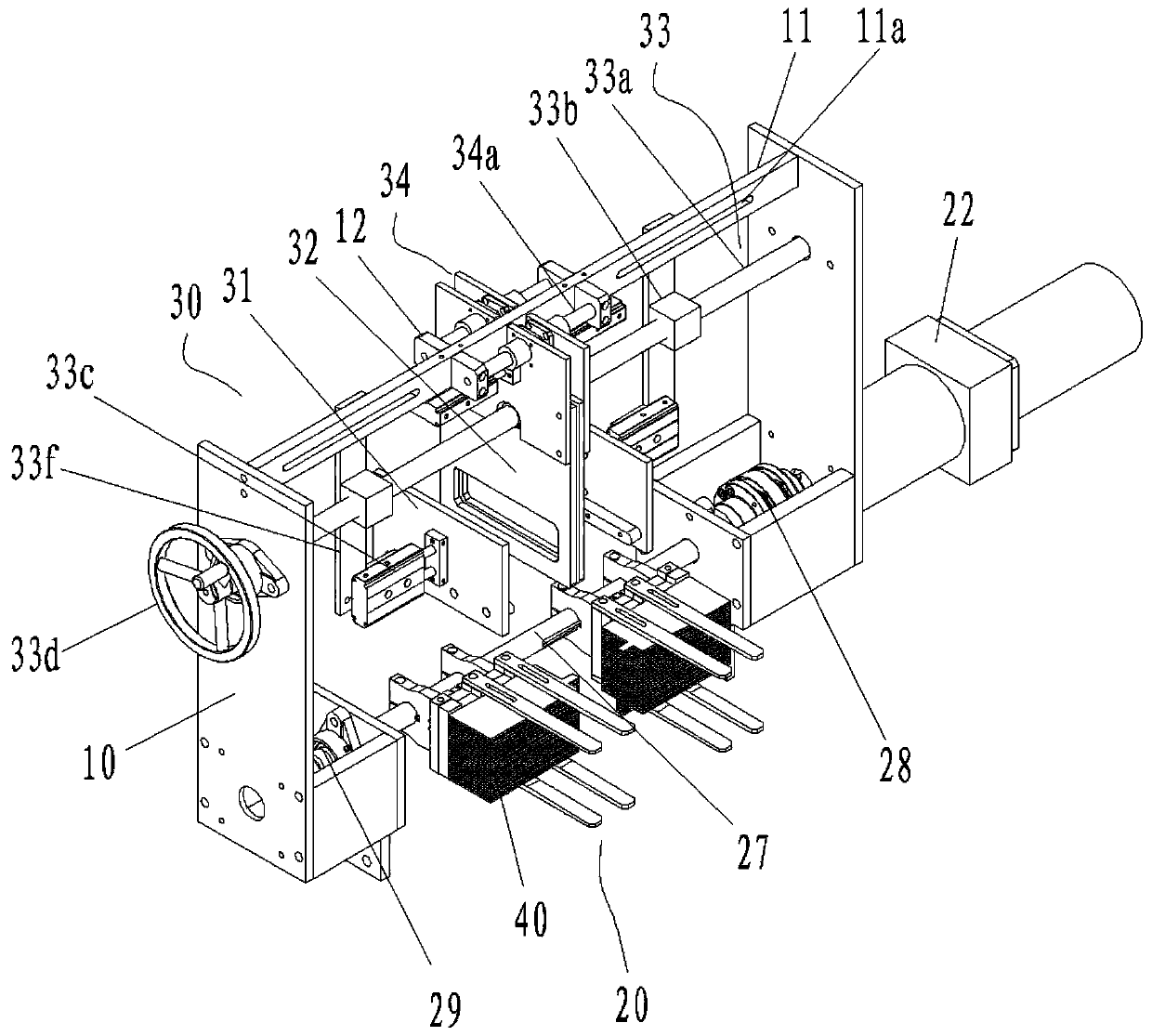

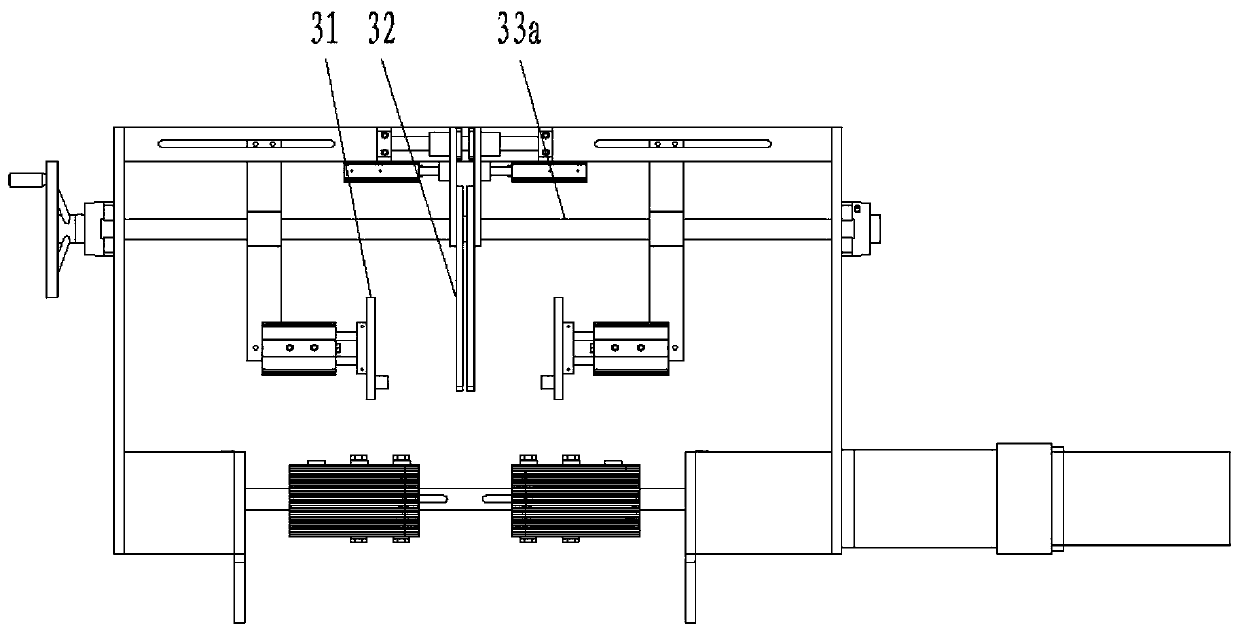

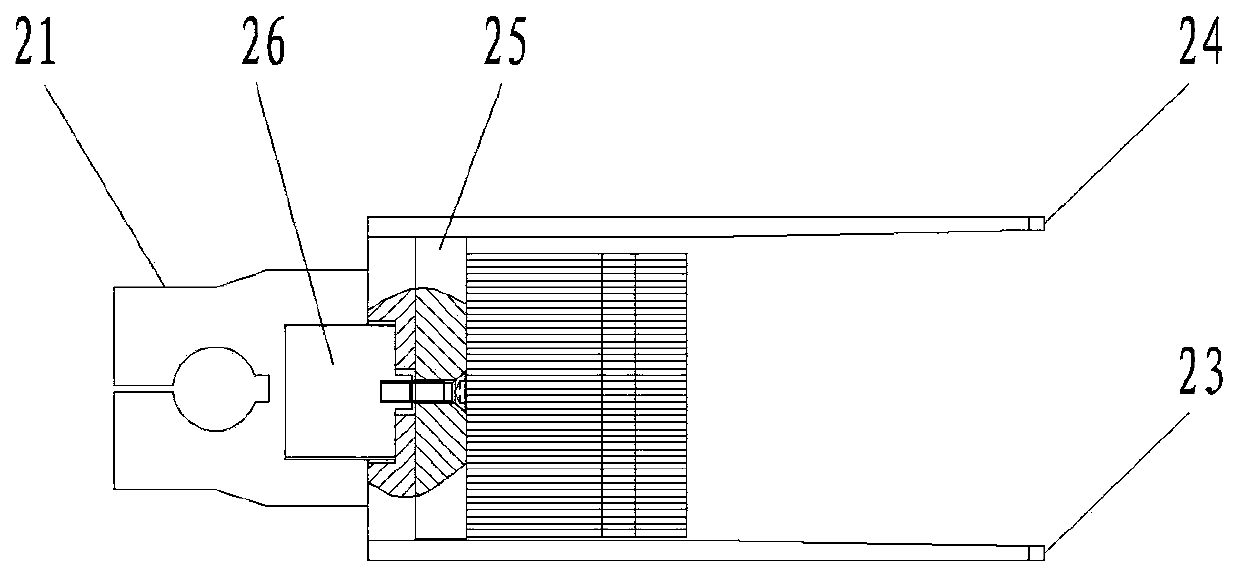

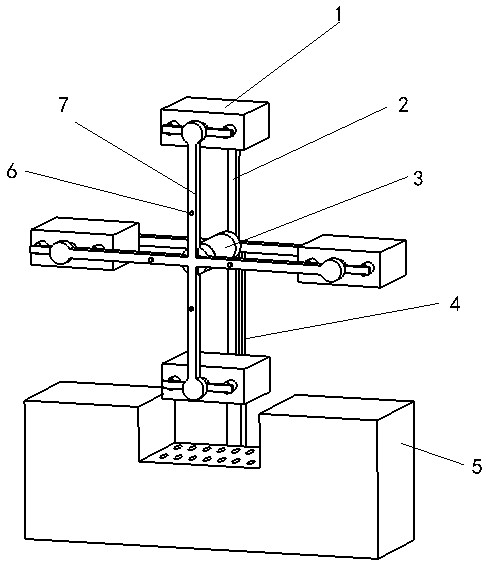

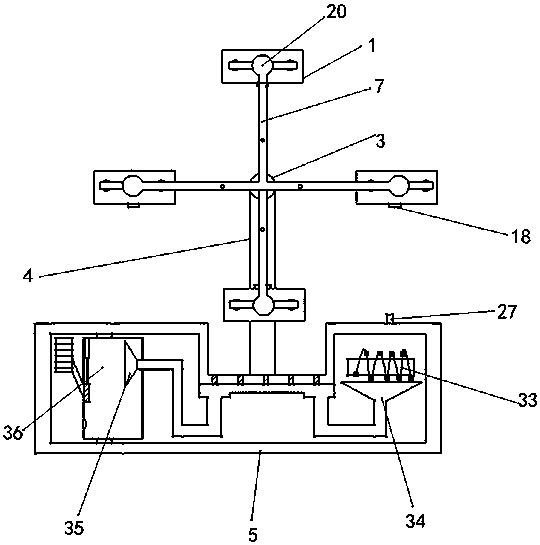

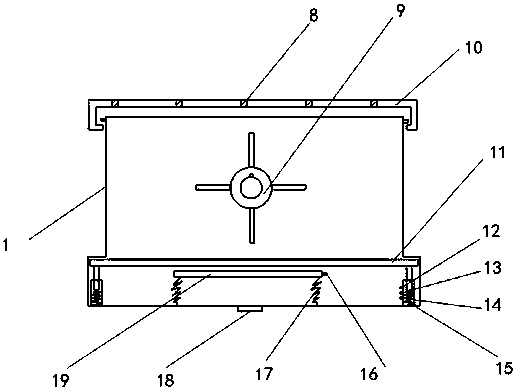

Automatic stacking device of C type steel and stacking device

ActiveCN102887369ARealize automatic stackingTurning arm lengthStacking articlesMechanical engineeringEngineering

Owner:XIAMEN ZHENGLIMING METALLURGICAL MACHINERY

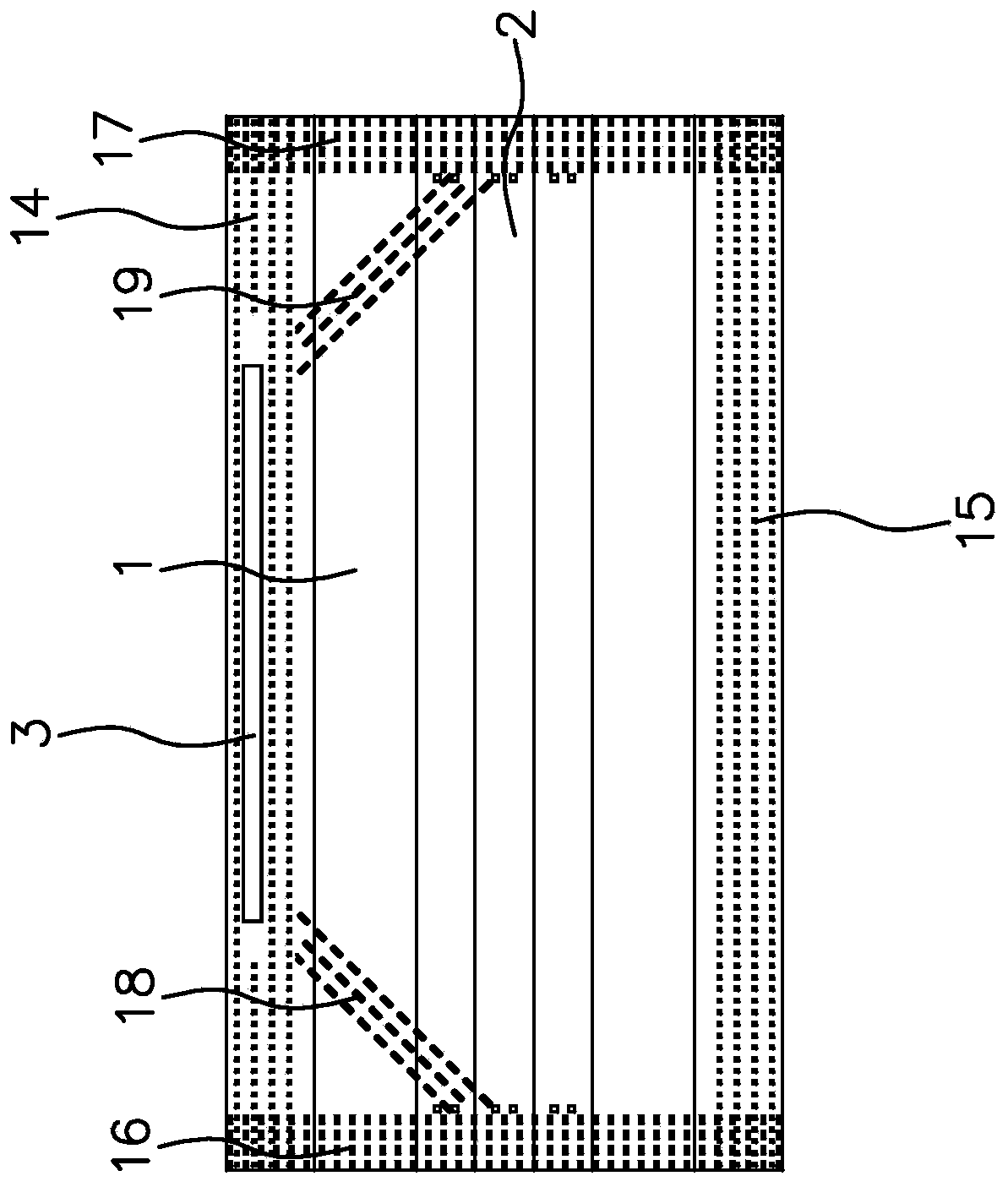

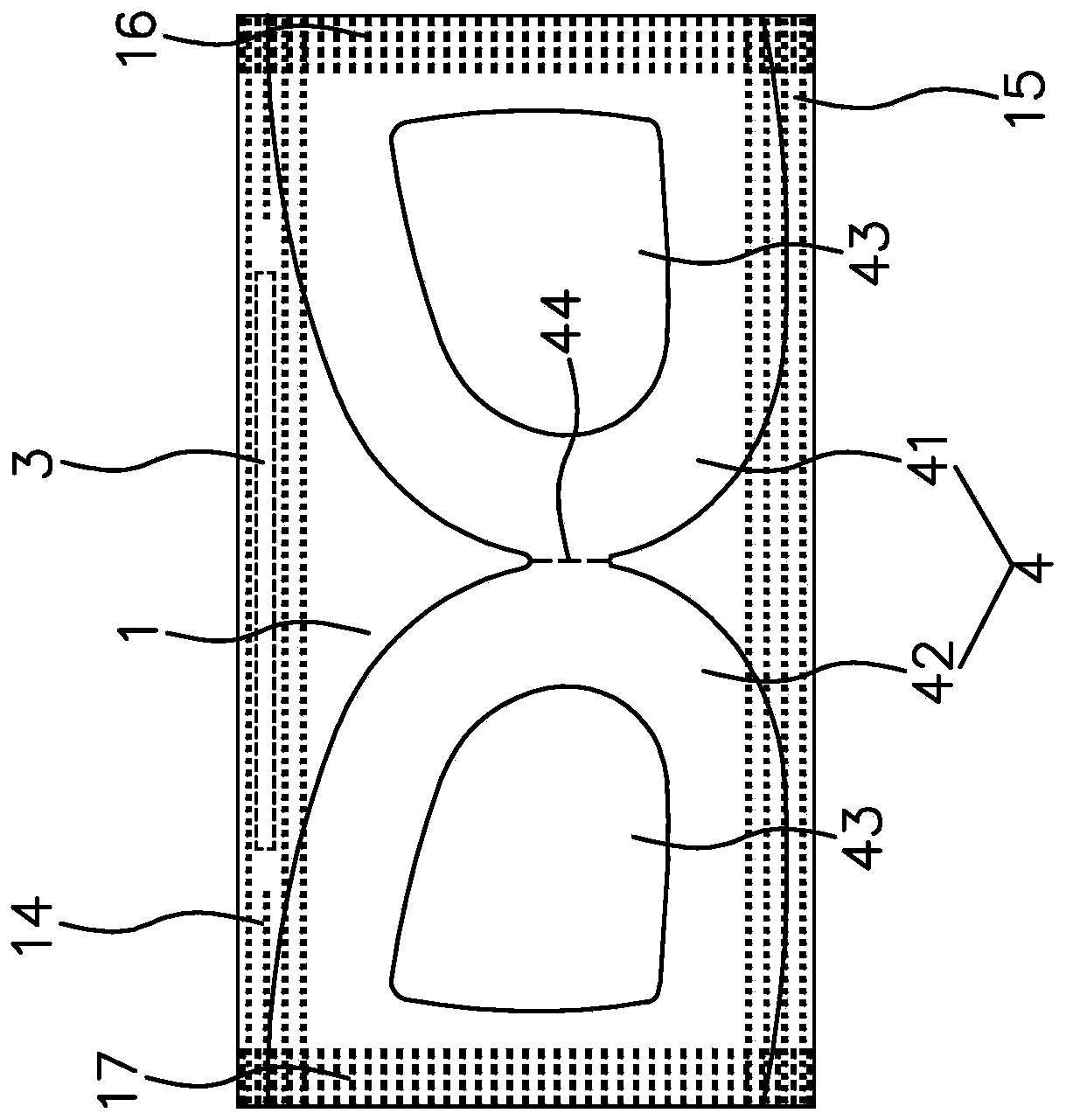

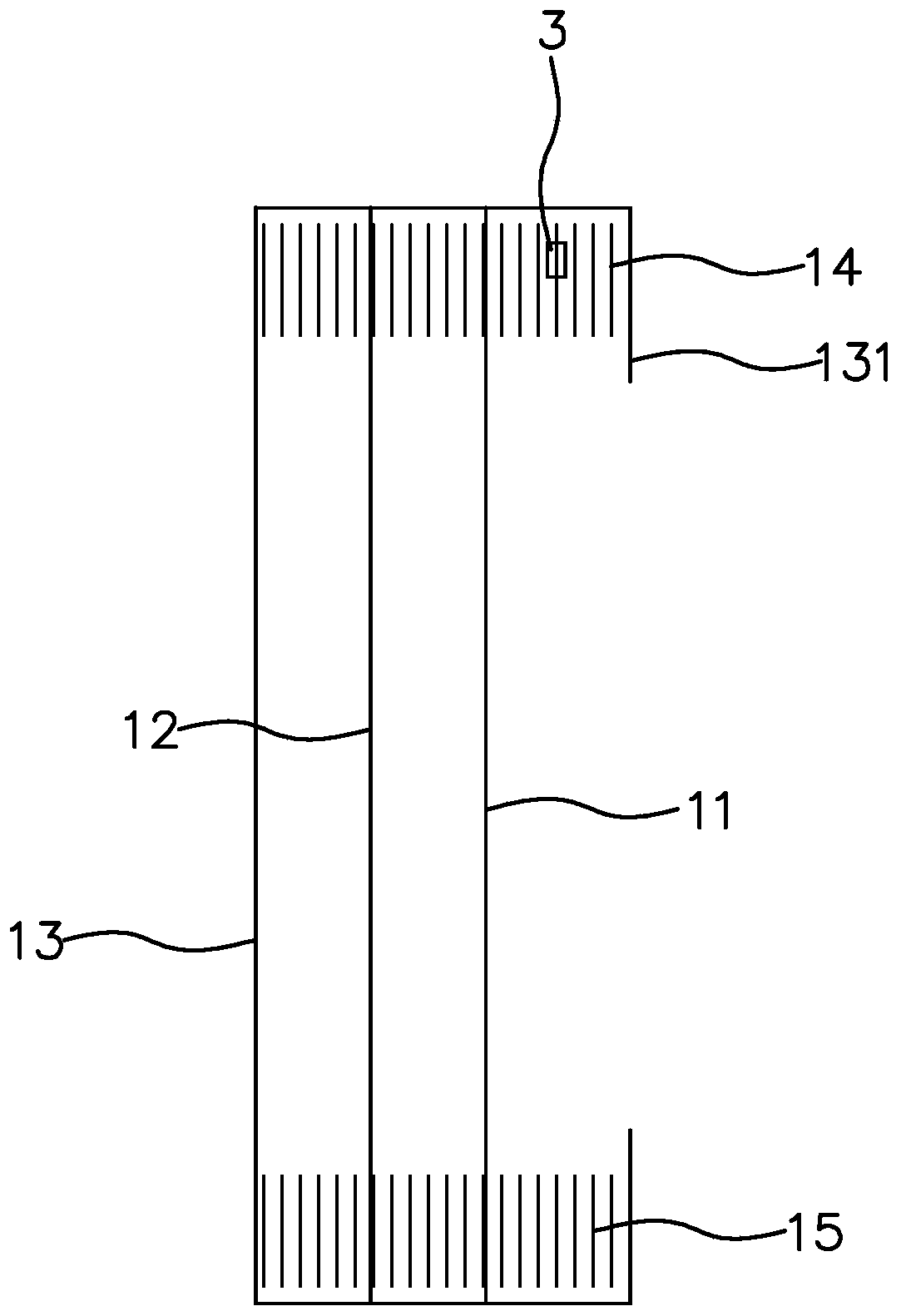

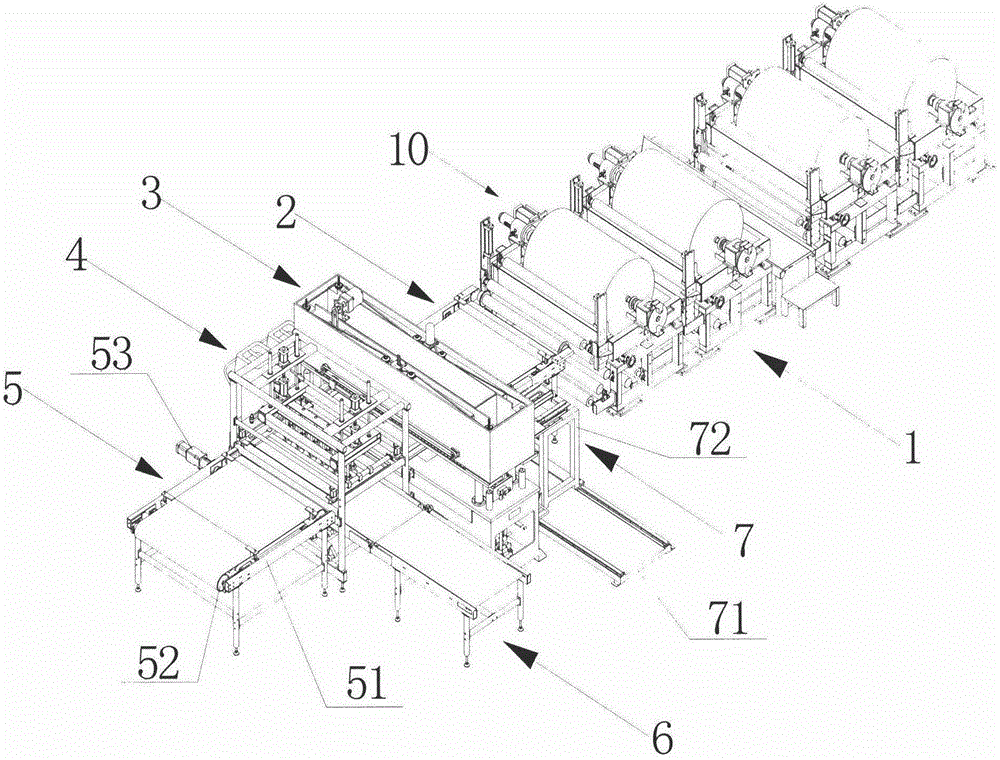

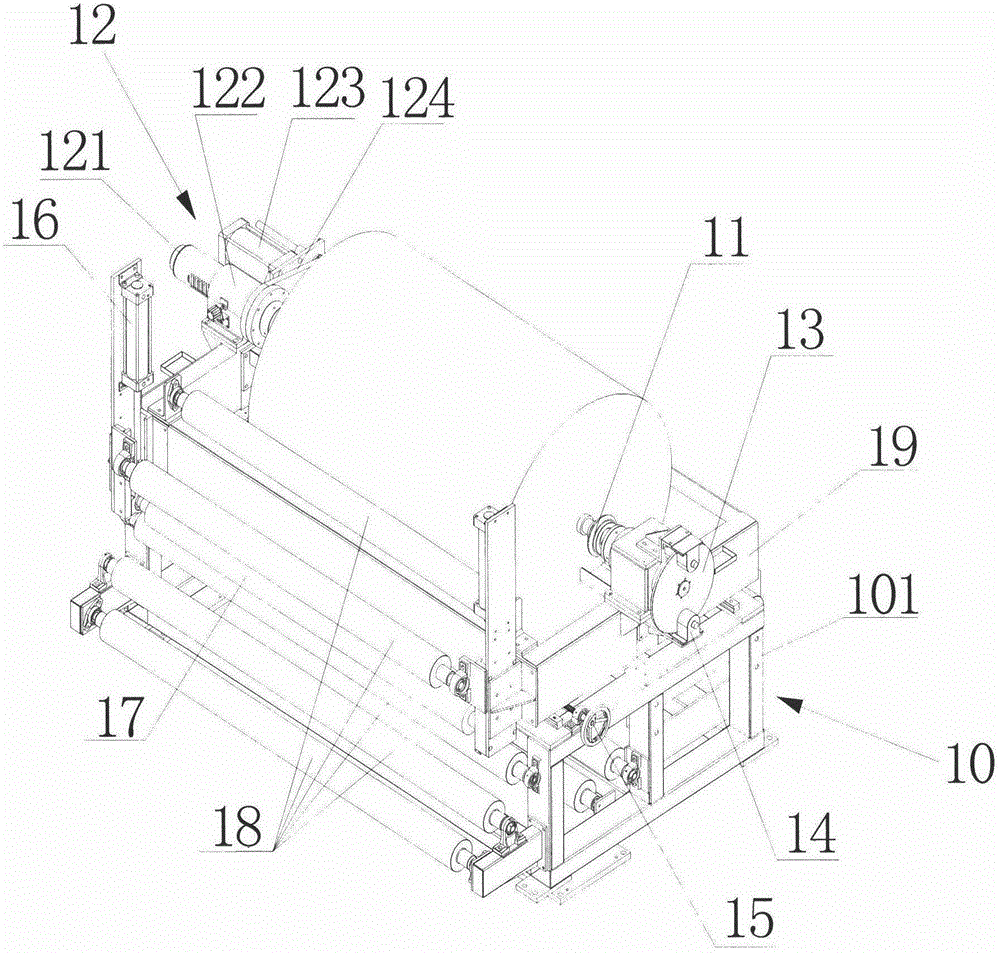

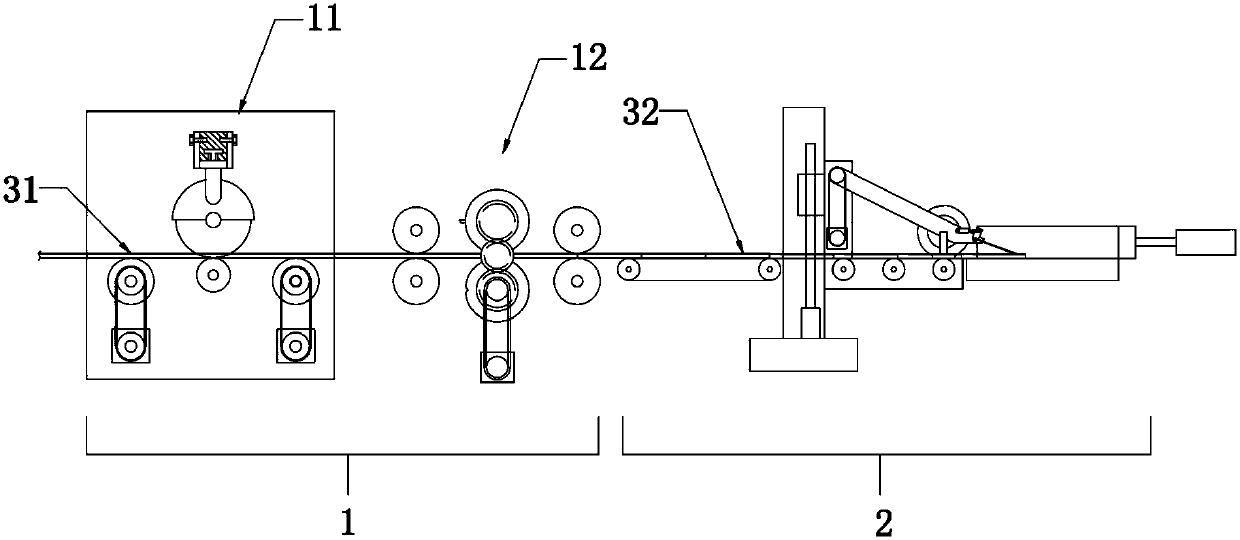

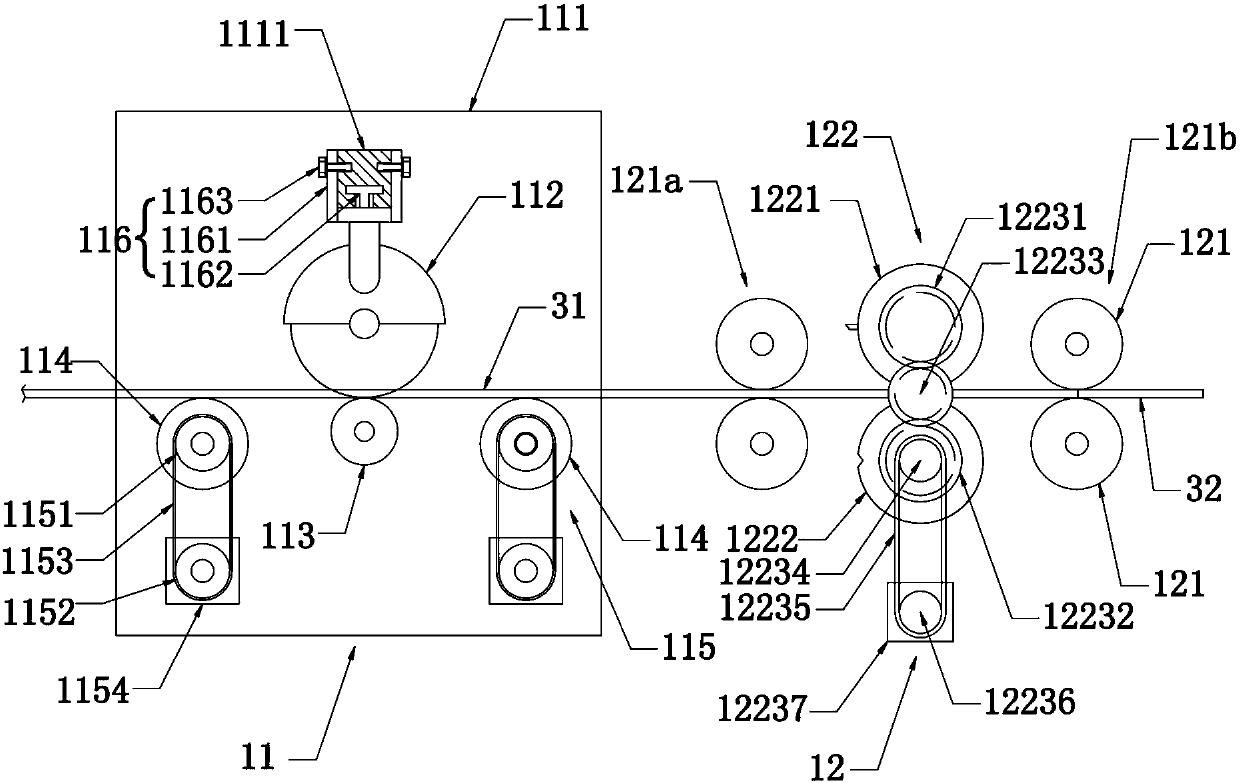

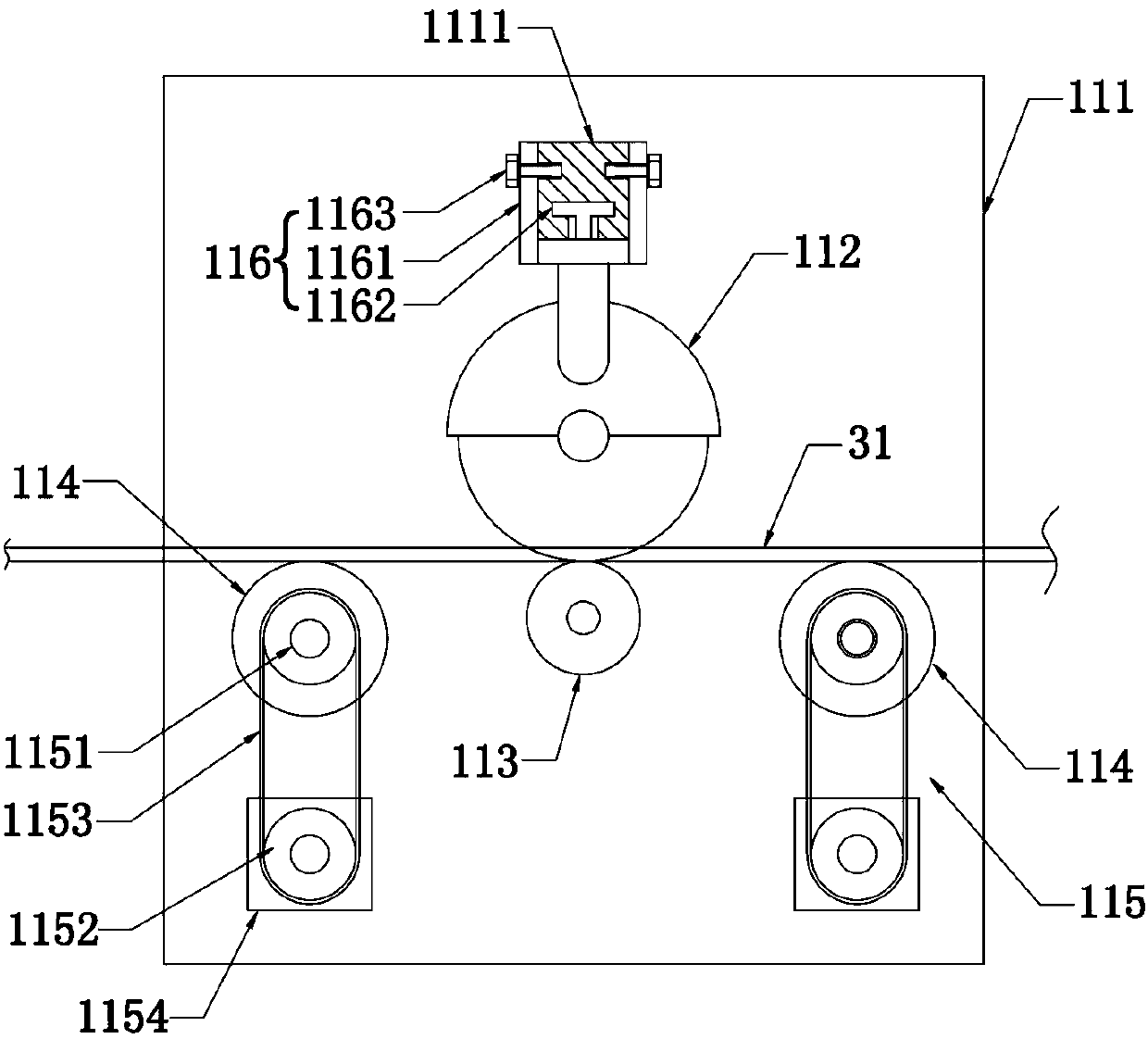

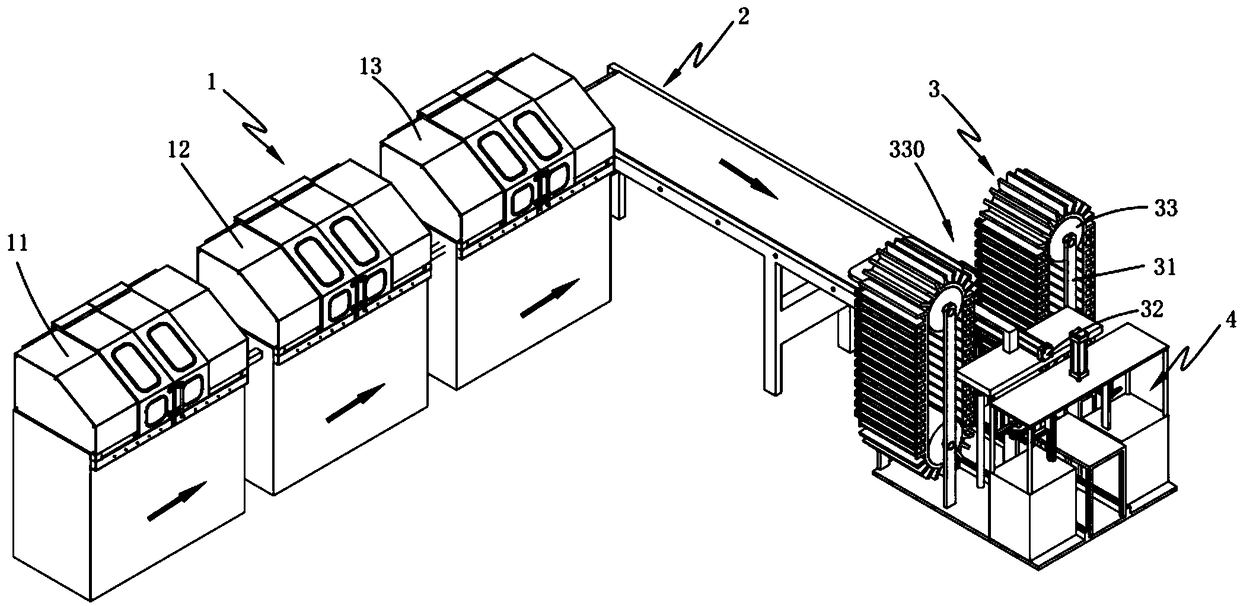

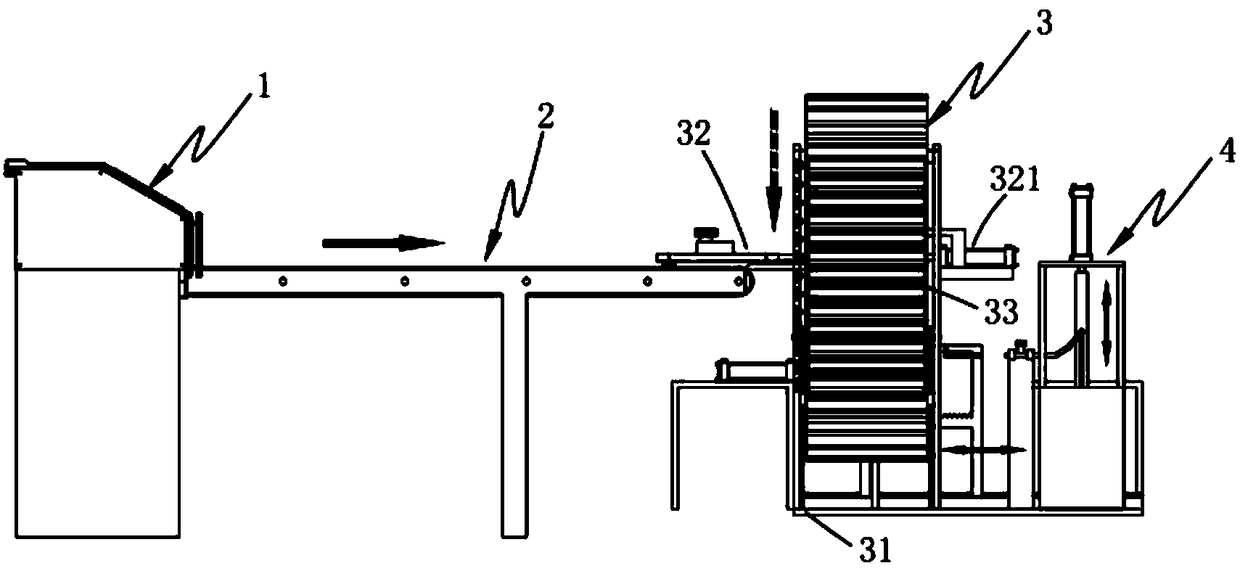

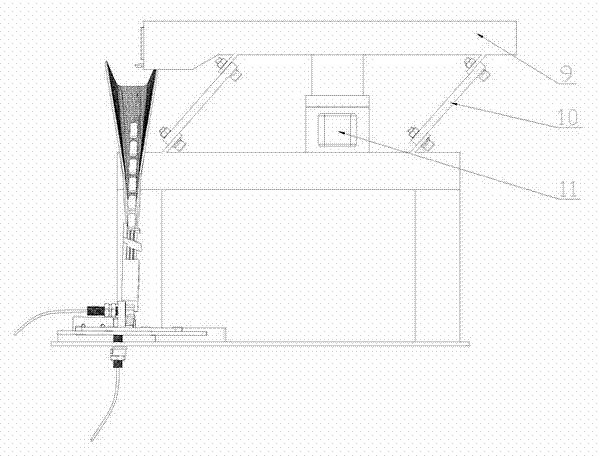

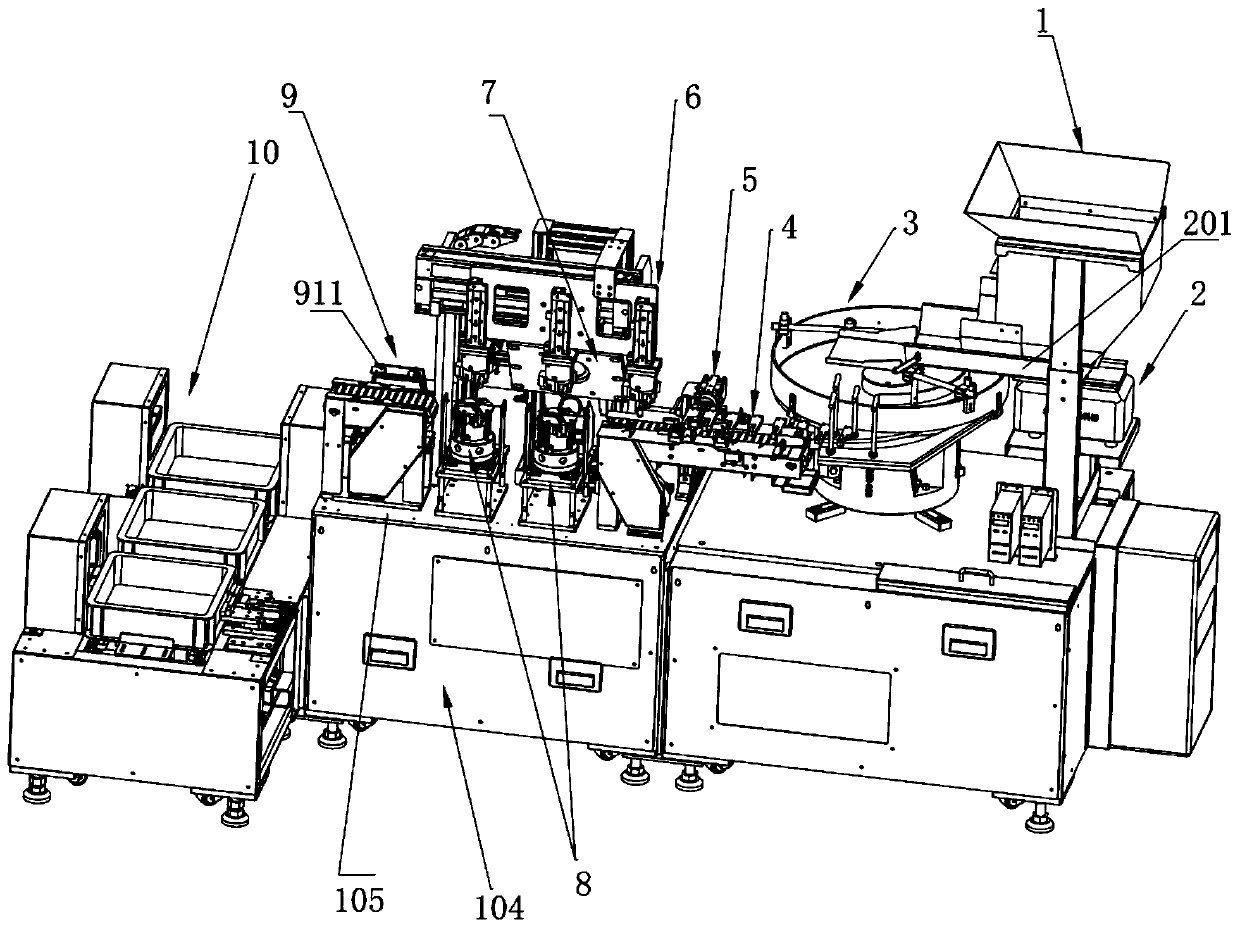

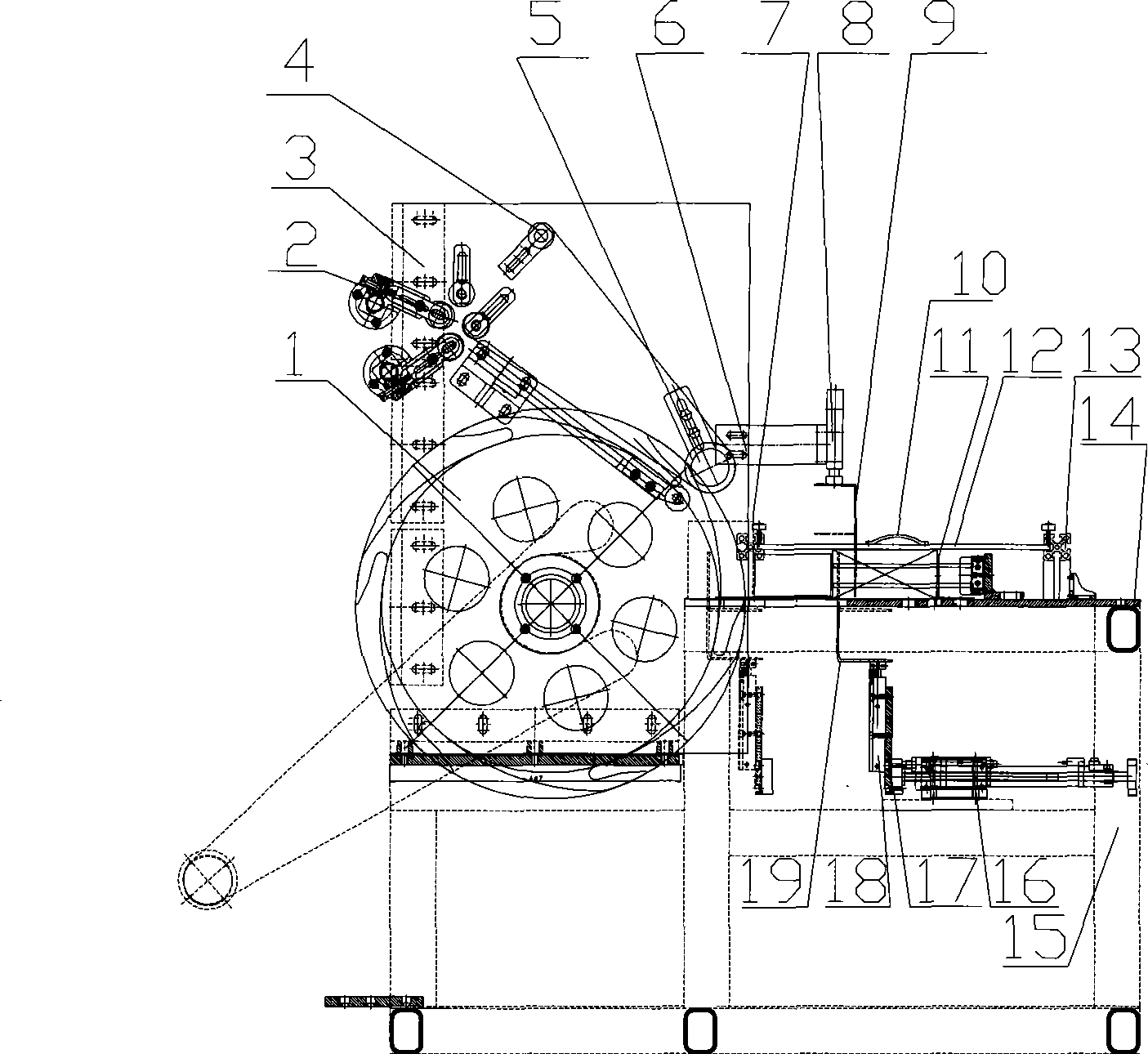

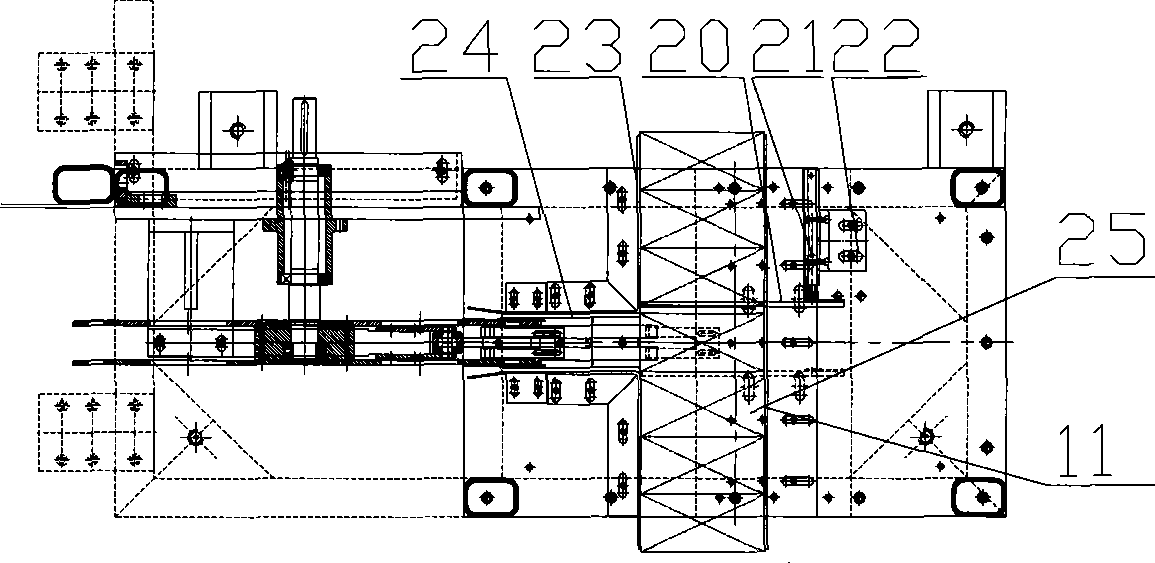

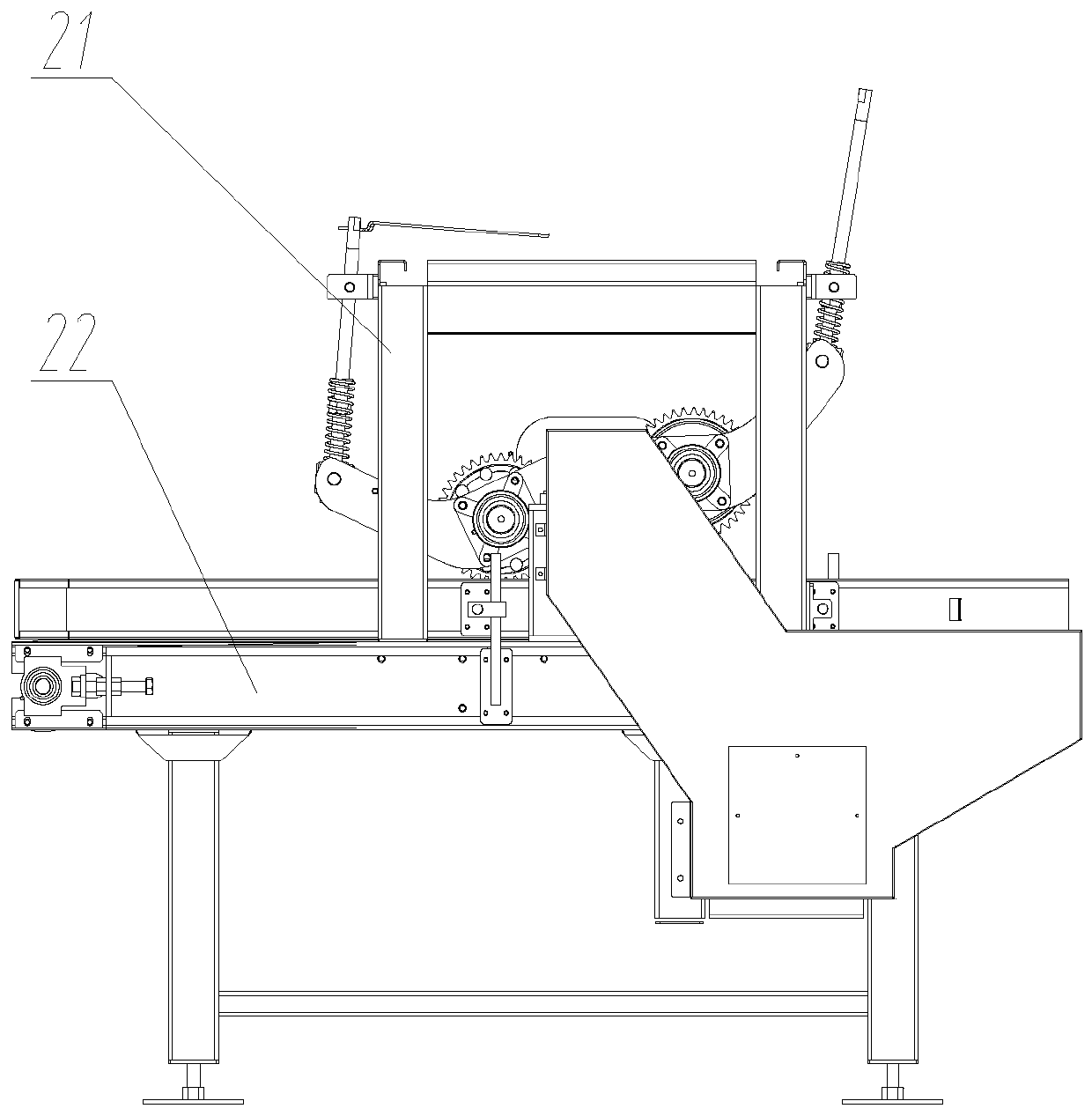

Mask production process and device for implementing process

InactiveCN111150163AConducive to compoundImprove accuracyProtective garmentClothes making applicancesNose clipsProcess engineering

The invention relates to the field of masks, in particular to a mask production process which comprises the following steps: step 1, inputting and compounding more than two layers of filter materials;step 2, forming a pleating part in the middle of the continuous mask raw material; step 3, inputting, cutting off and compounding a nose clamping strip on the mask raw material; step 4, forming a mask body area with an upper fixing edge strip, a lower fixing edge strip, a left fixing edge strip and a right fixing edge strip on the mask raw material; step 5, continuously unwinding, inputting and cutting the lug sheet material to form a continuous lug sheet; step 6, compounding the ear pieces with the mask raw material; step 7, performing thermocompression bonding, and fixing the ear pieces andthe mask raw material; step 8, performing slitting, and forming an independent mask; step 9, outputting the product. The technical problems that ear hanging parts of an existing mask are poor in connection firmness, the production is inconvenient, and the production efficiency is low are solved. Meanwhile, the invention further provides a device for implementing the mask production process.

Owner:QUANZHOU HANWEI MACHINERY MFG

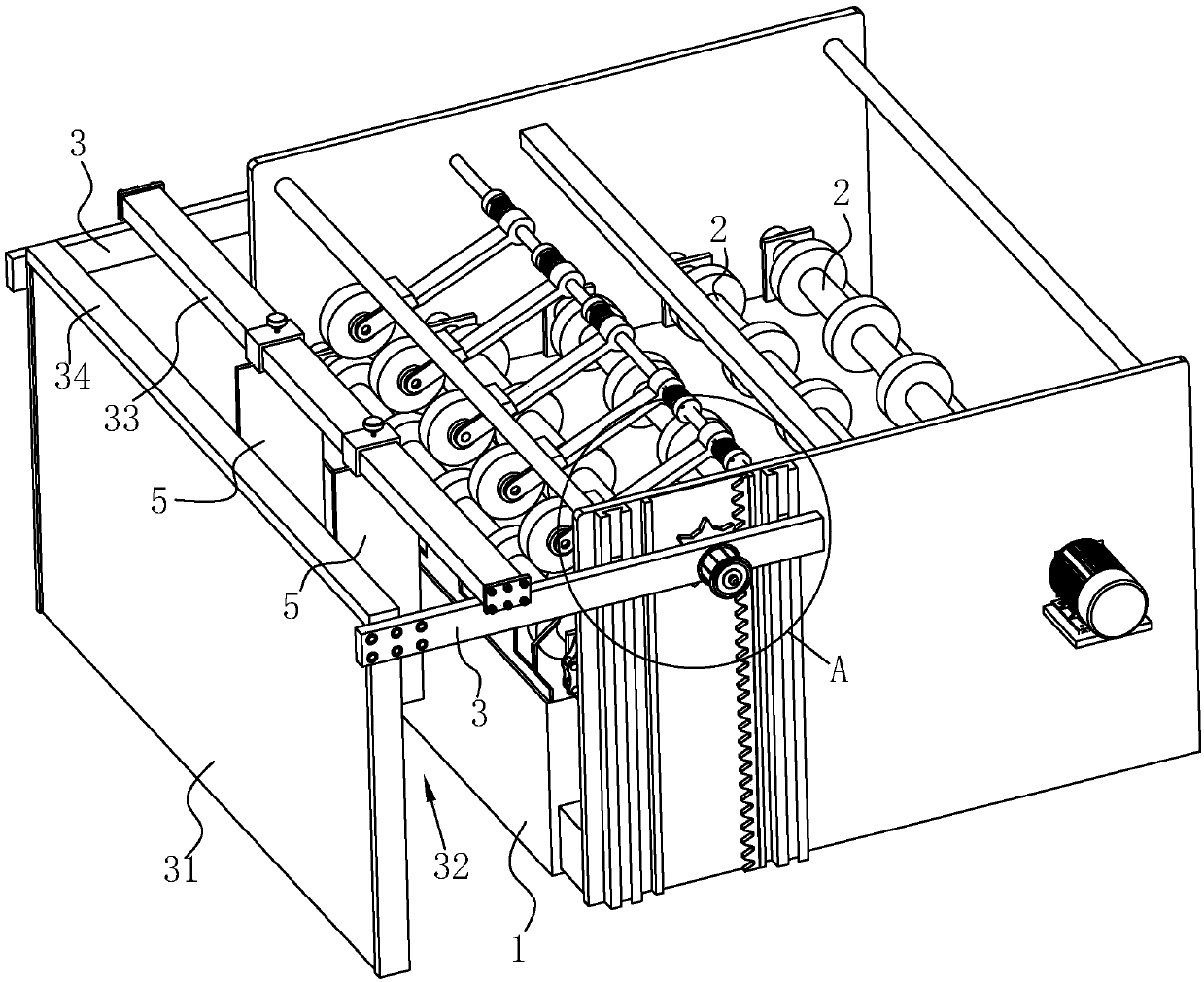

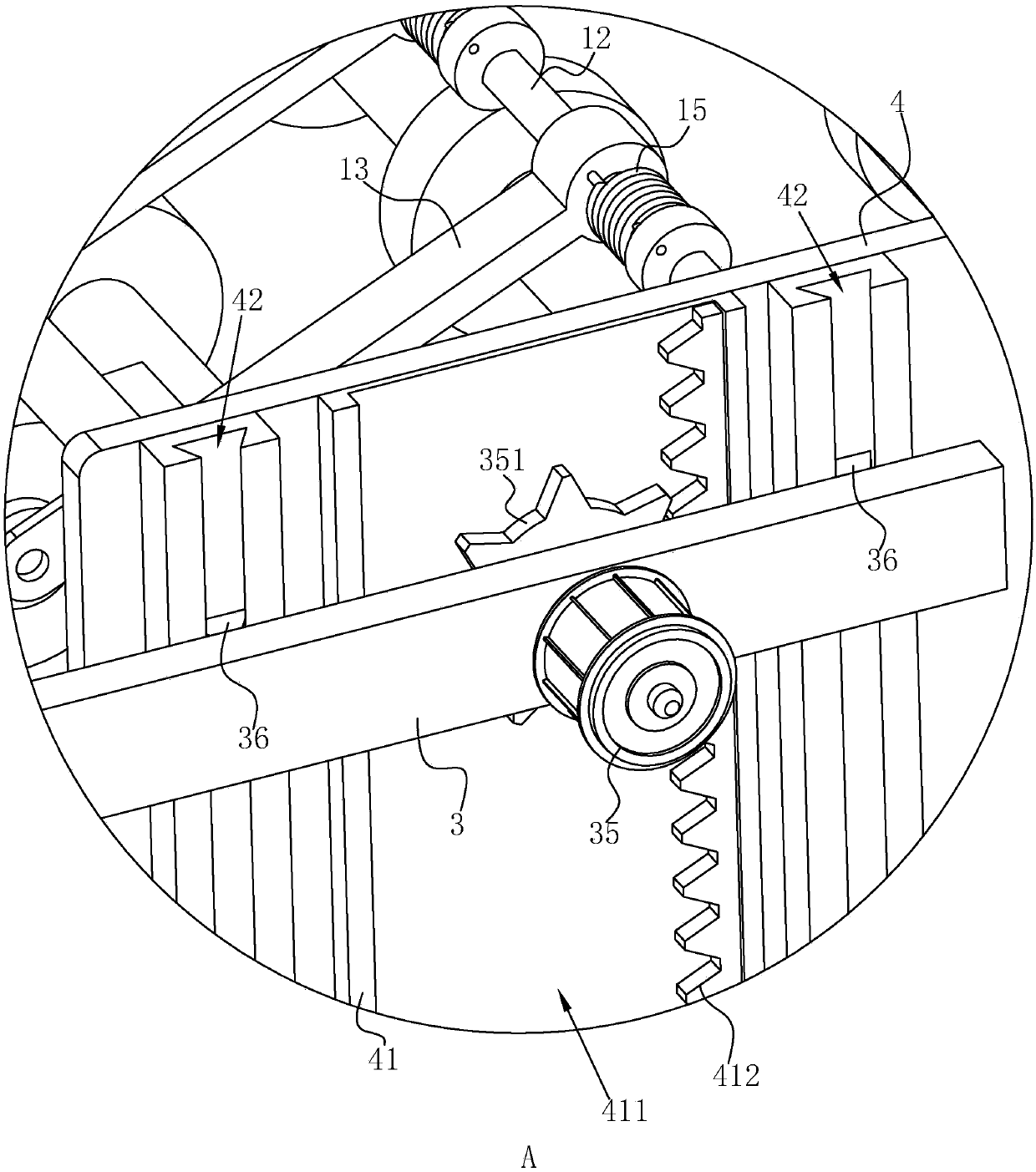

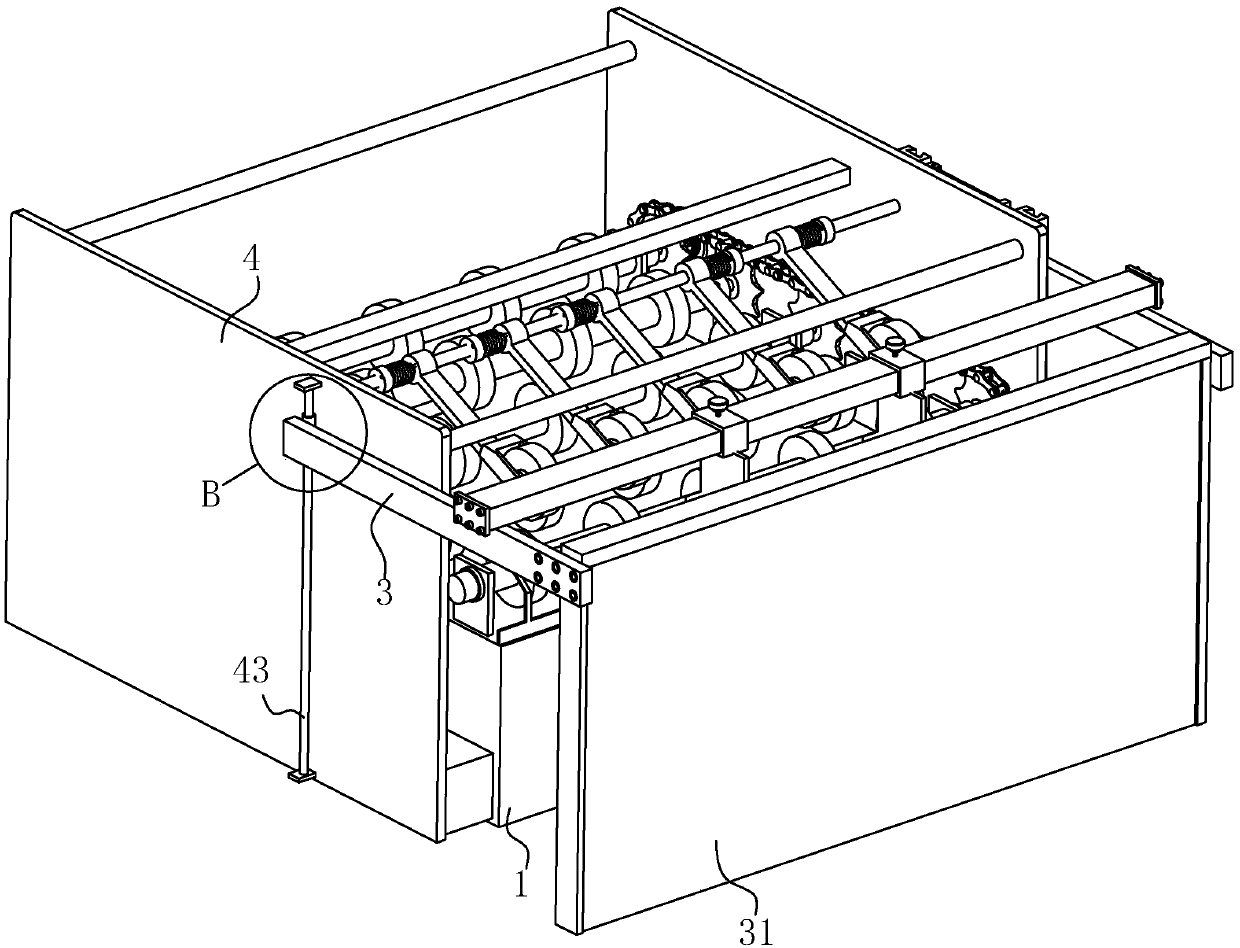

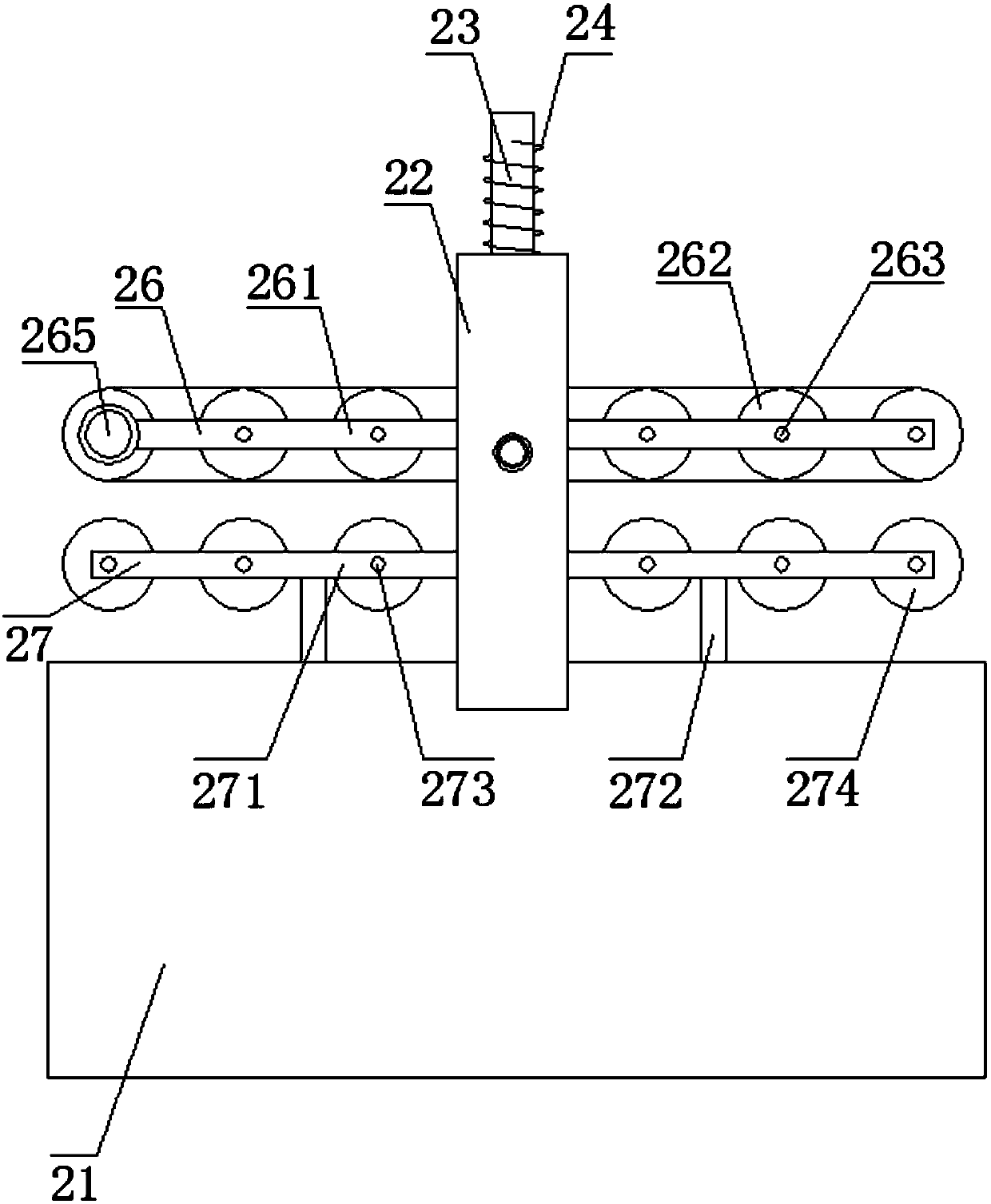

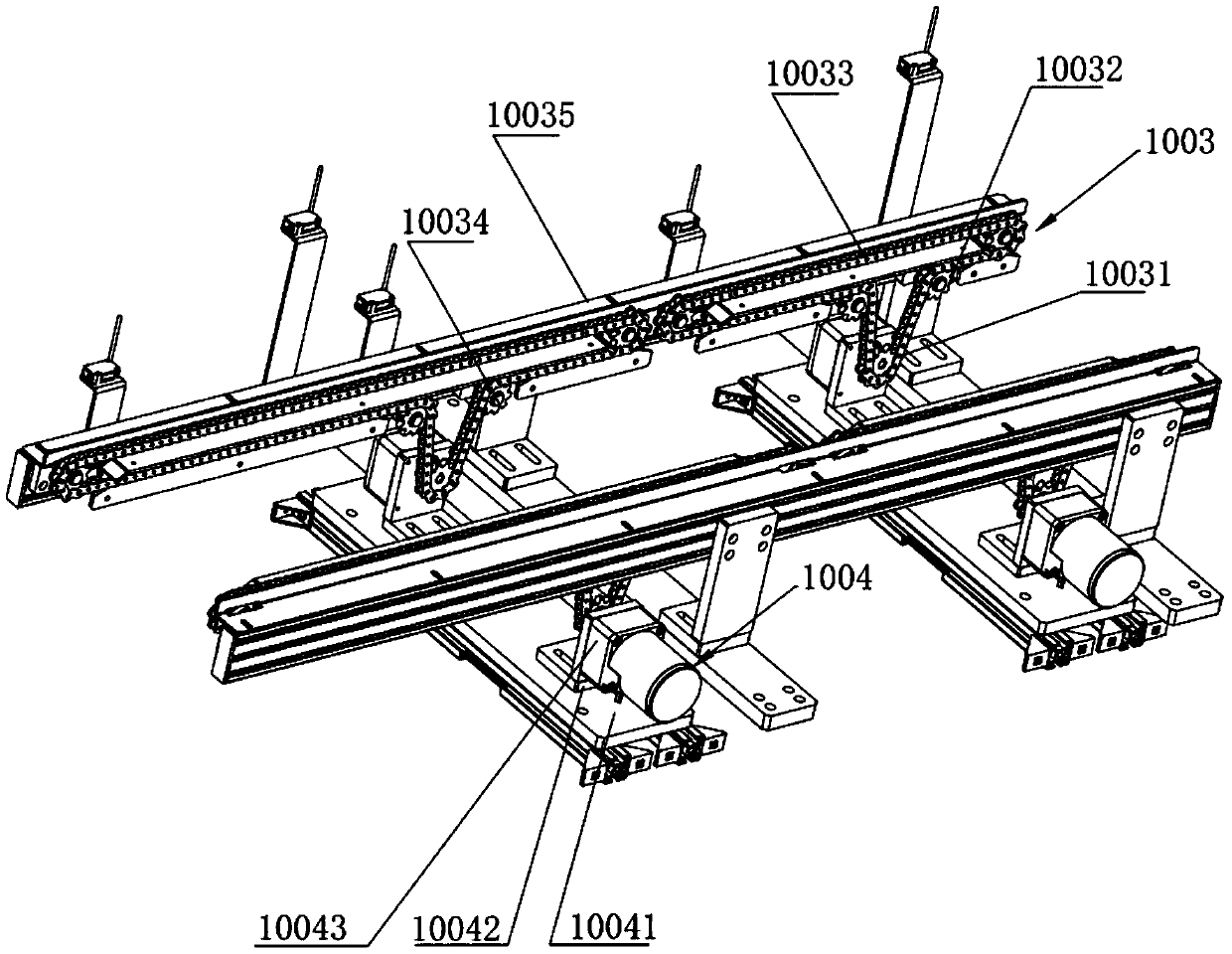

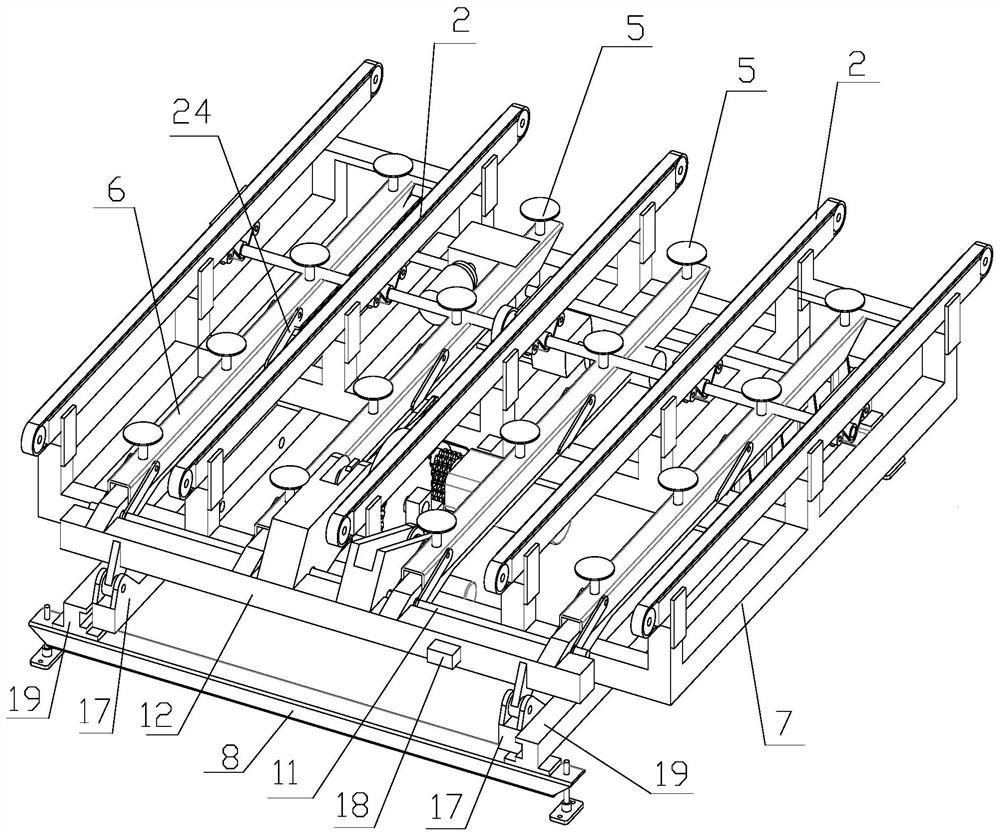

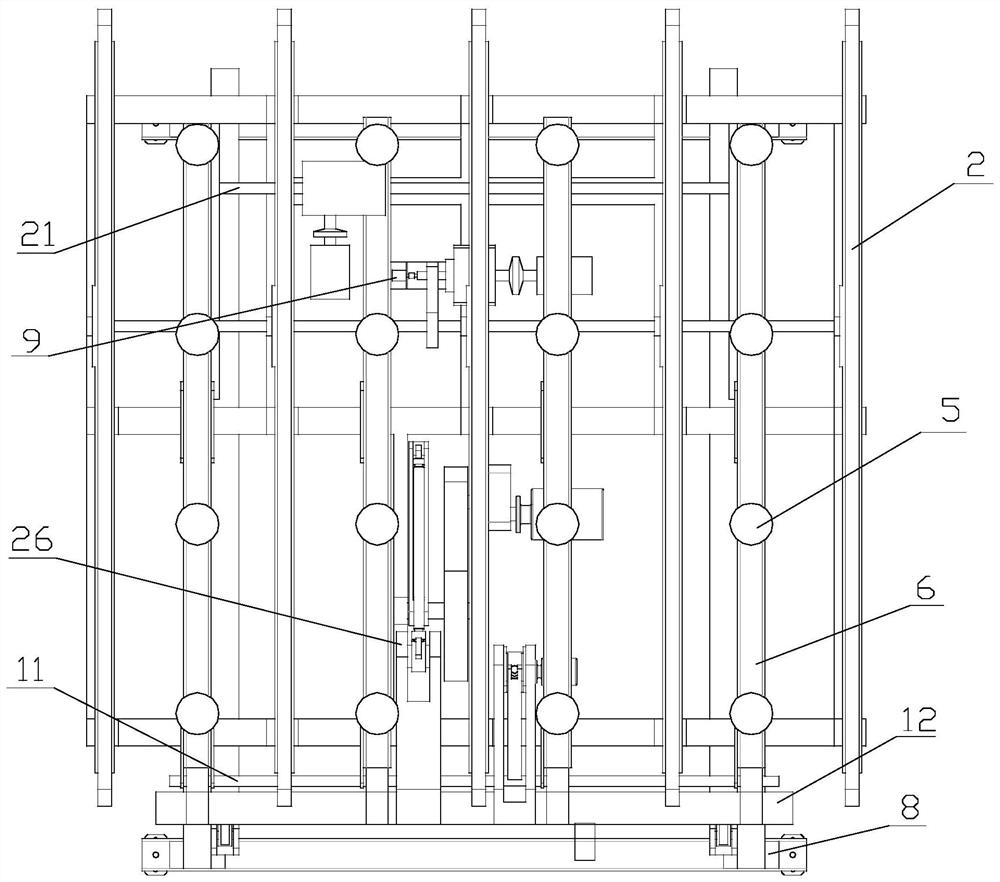

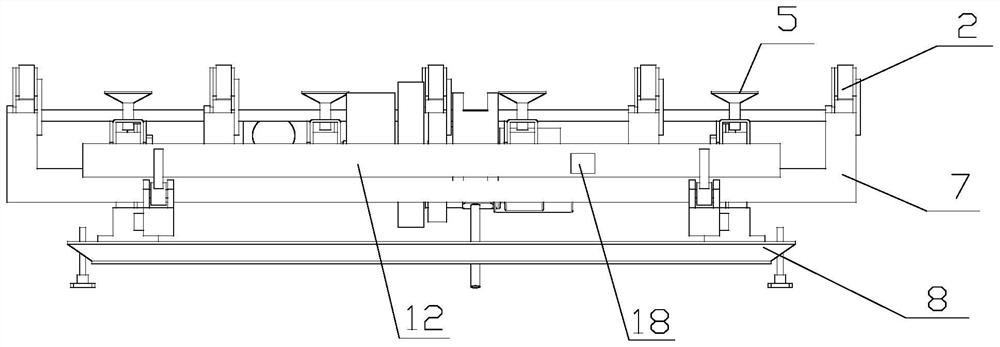

Corrugated paperboard stacking device

ActiveCN109592468ARealize automatic stackingAdjustable distancePile receiversArticle deliveryPaperboardEngineering

The invention relates to a corrugated paperboard stacking device and belongs to the field of corrugated paperboard machining devices. The corrugated paperboard stacking device comprises a machine frame and a conveying device arranged on the machine frame. The conveying device comprises multiple rotating shafts rotationally arranged on the machine frame. The multiple rotating shafts are evenly arranged on the machine frame. The machine frame is provided with a drive assembly used for driving the multiple rotating shafts to rotate in the same direction. Two support plates are arranged on the machine frame and located above the rotating shafts. The length direction of each support plate is identical with the conveying direction of the rotating shafts, and the support plates extend out of themachine frame. A baffle is arranged between the ends, outside the machine frame, of the support plates. A stacking space for containing corrugated paper remains between the baffle and the end walls ofthe machine frame. A cross rod is arranged between the two support plates. The potions, on the two sides of the corrugated paper fallen into the stacking space, of the cross rod are both provided with flattening plates. By the adoption of the corrugated paperboard stacking device, it is not needed to manually stack the corrugated paper, automatic corrugated paper stacking is achieved, and the stacked corrugated paper can achieve the automatic and tidy stacking effect.

Owner:四川瑞森纸业有限公司

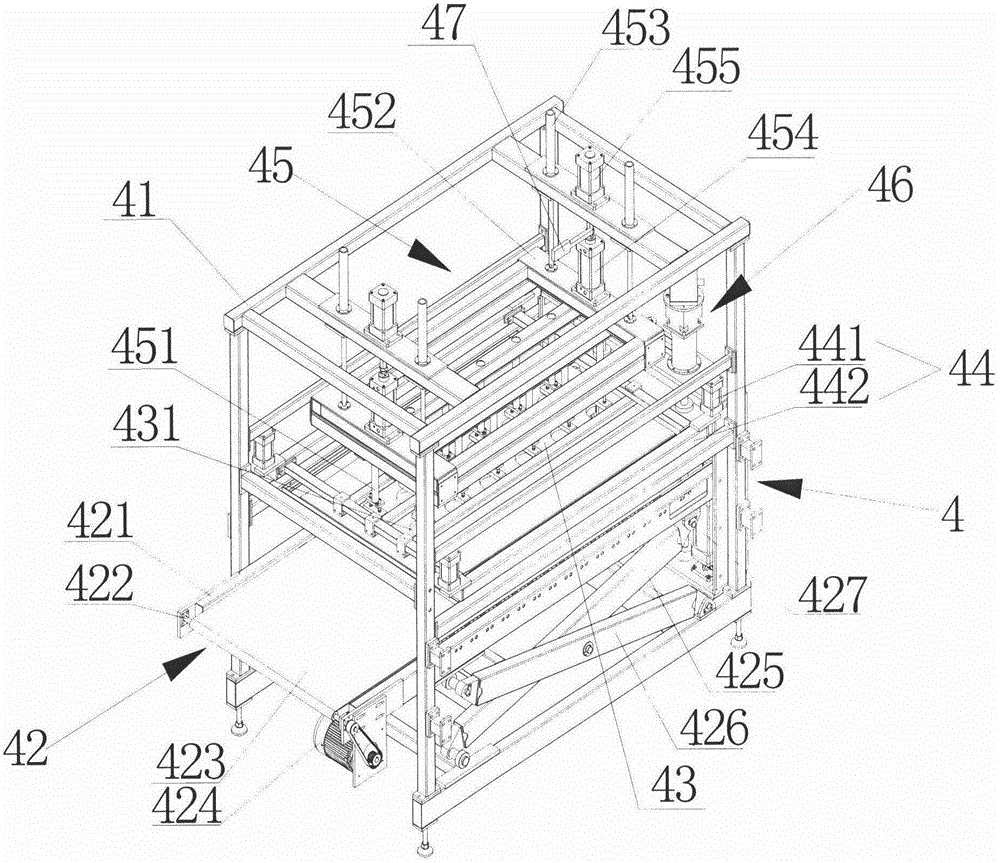

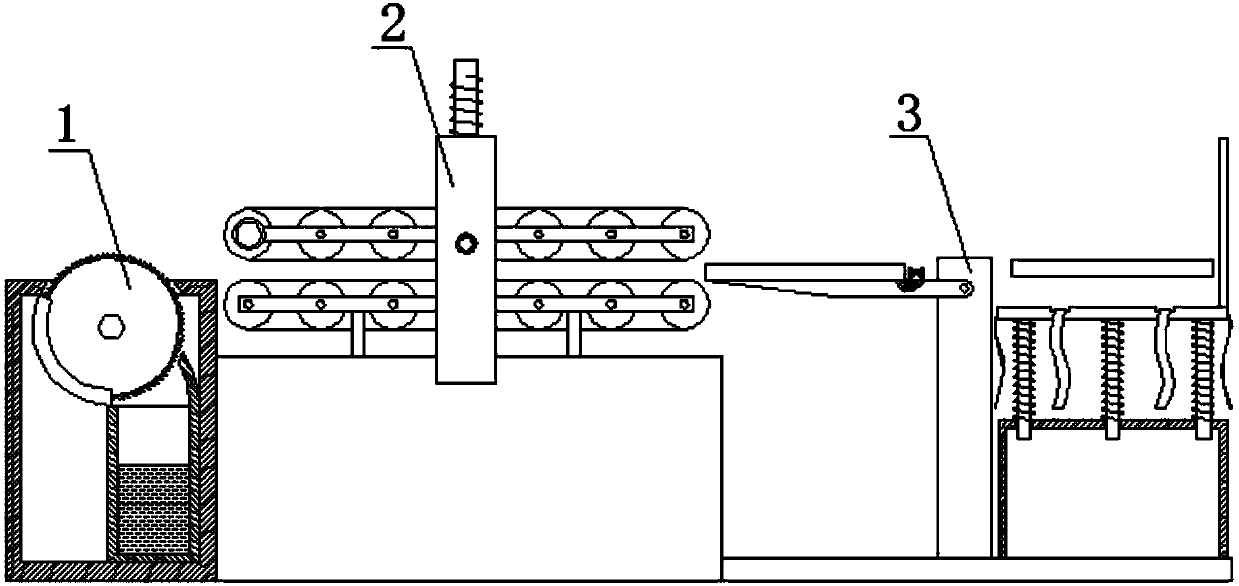

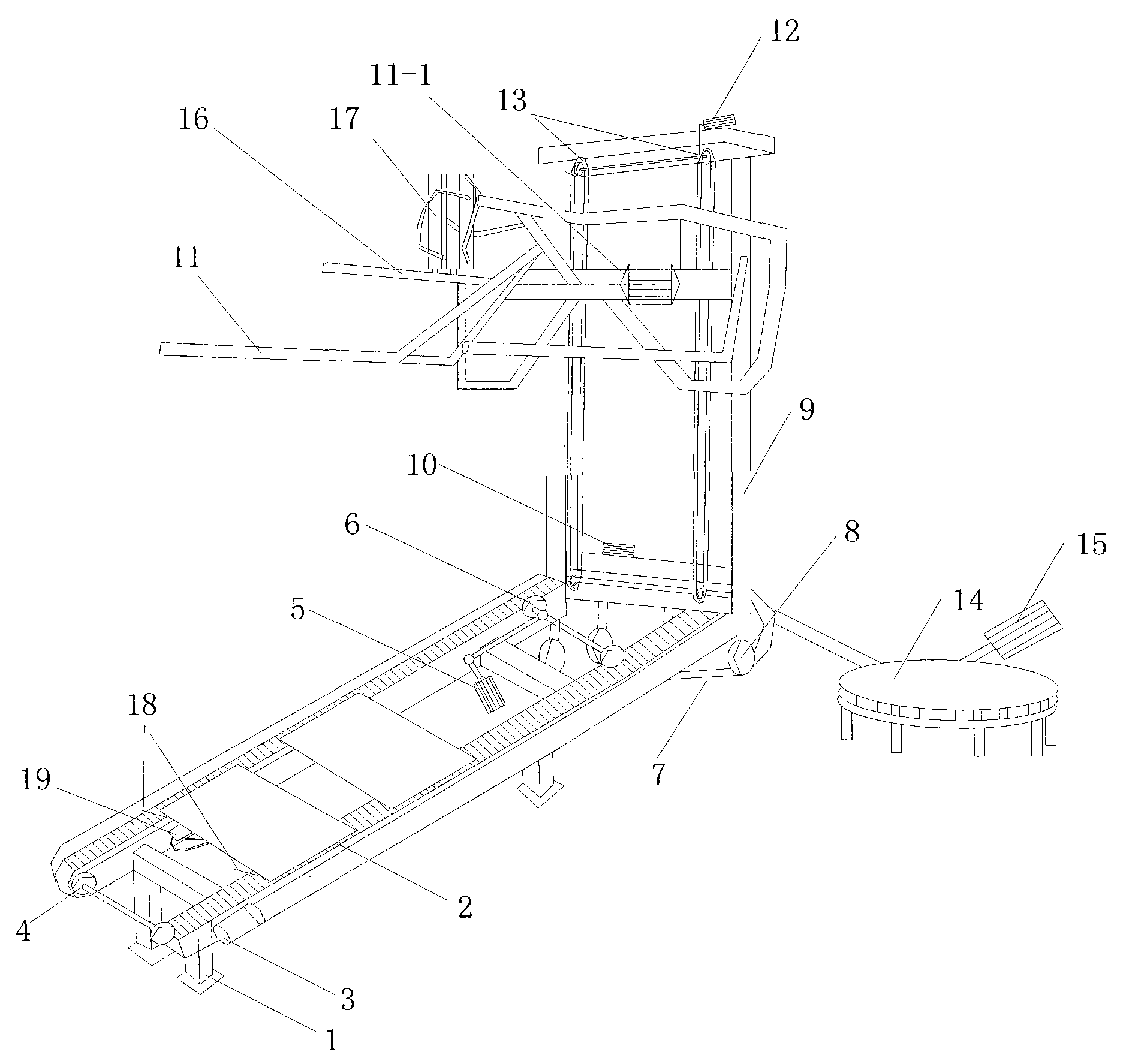

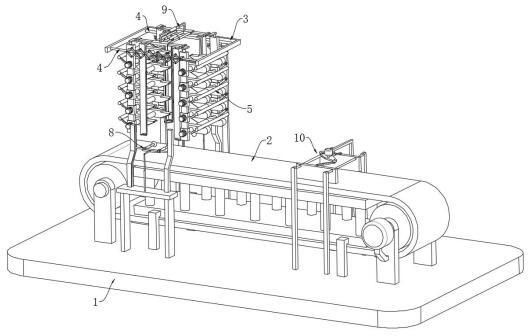

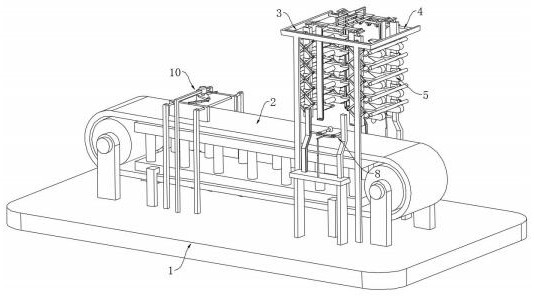

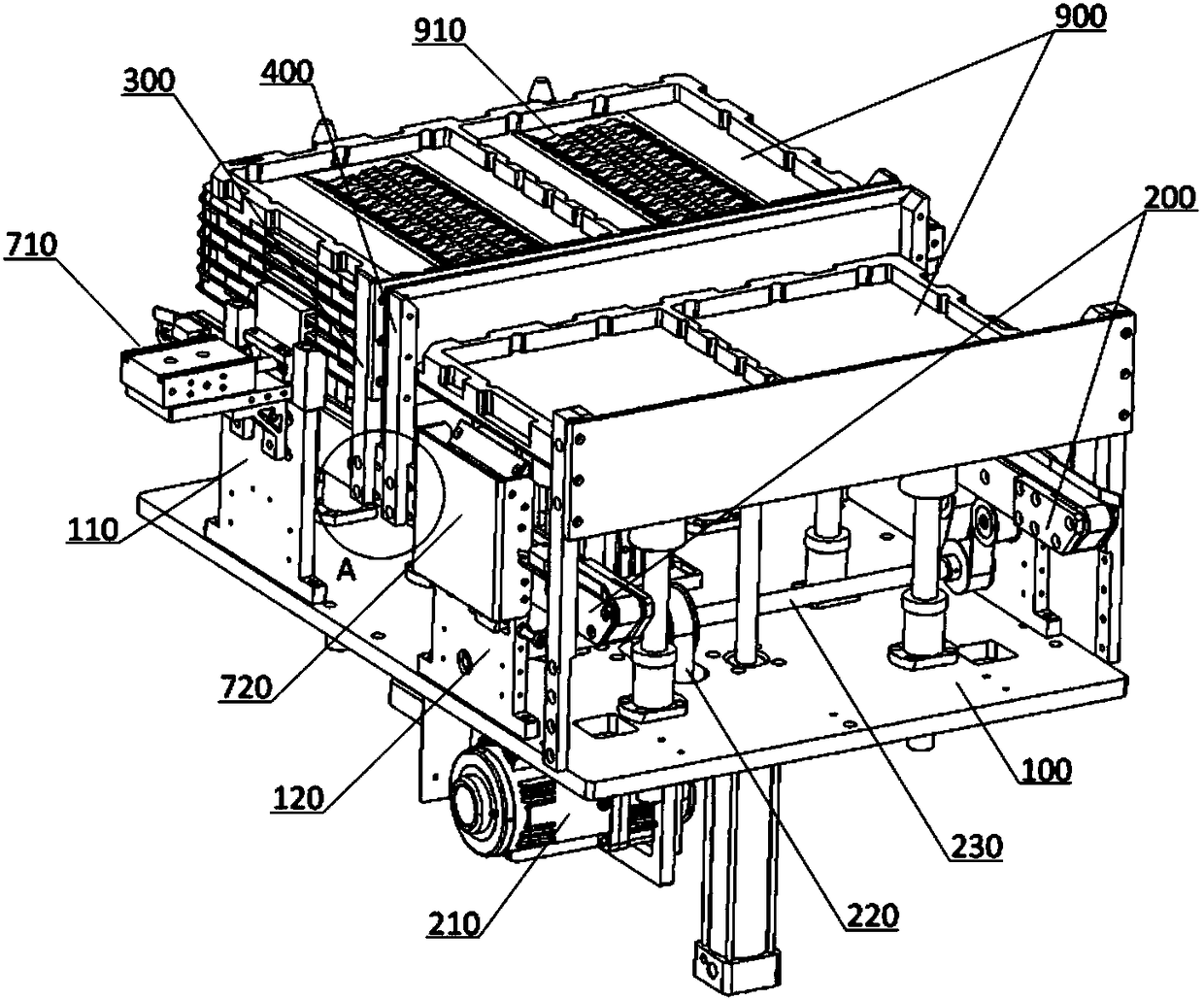

Automatic multilayer abrasive paper blanking device

ActiveCN104385159ARealize automatic stackingAutomate processingAbrasion apparatusGrinding devicesEmery paperEngineering

The invention relates to an automatic multilayer abrasive paper blanking device which comprises a feeding component, a conveying component, a cutting main unit, a stacking component, a waste collecting component and a discharging component. The feeding component, the conveying component, the cutting main unit, the stacking component and the waste collecting component are sequentially arranged, the discharging component is arranged beside the stacking component, the automatic feeding component comprises a plurality of sequentially arranged feeding mechanisms for storing abrasive paper, the stacking component comprises a supporting frame, a height-adjustable lifting mechanism, a knockout die plate, a pressing mechanism, a knockout mechanism, a limiting mechanism and a sensor, the supporting frame is arranged on the ground, the lifting mechanism is arranged in the supporting frame, the knockout die plate is mounted above the lifting mechanism and provided with a plurality of material holes, the pressing mechanism is arranged above the knockout die plate and matched with the knockout die plate to press abrasive paper, and the knockout mechanism is mounted on the supporting frame and can move to penetrate the material holes. By mutually matching the feeding component, the conveying component, the cutting main unit, the stacking component and the waste collecting component as a whole, the abrasive paper is automatically treated.

Owner:YANCHENG HUASEN MACHINERY

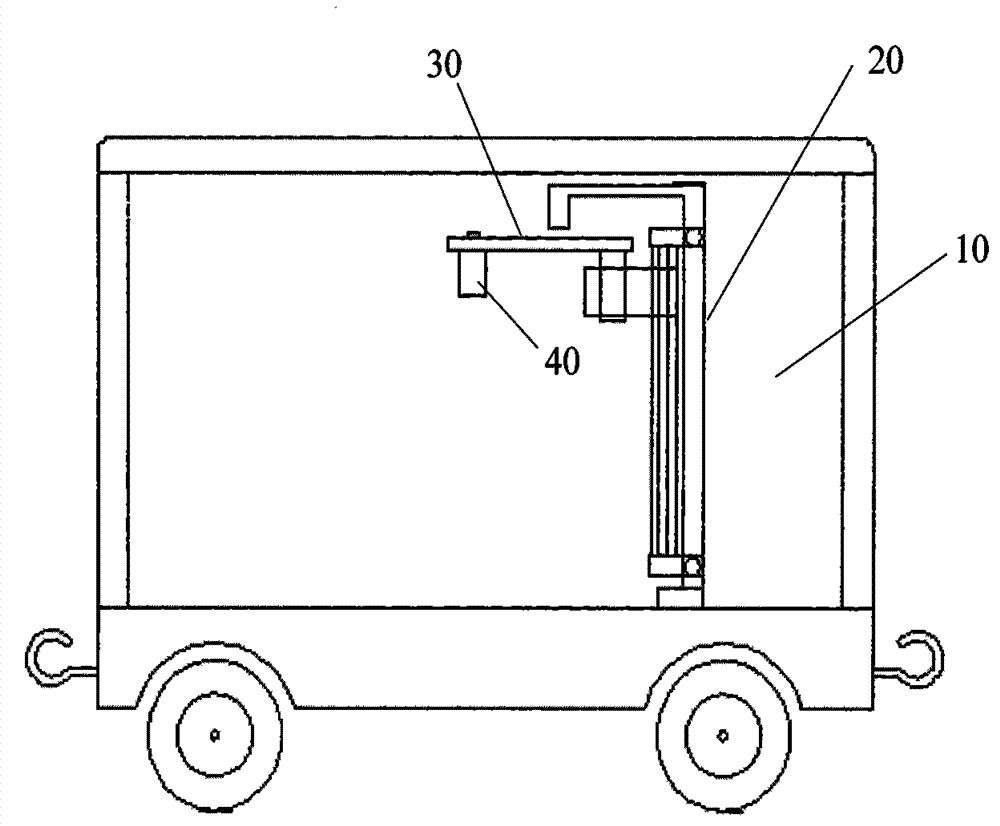

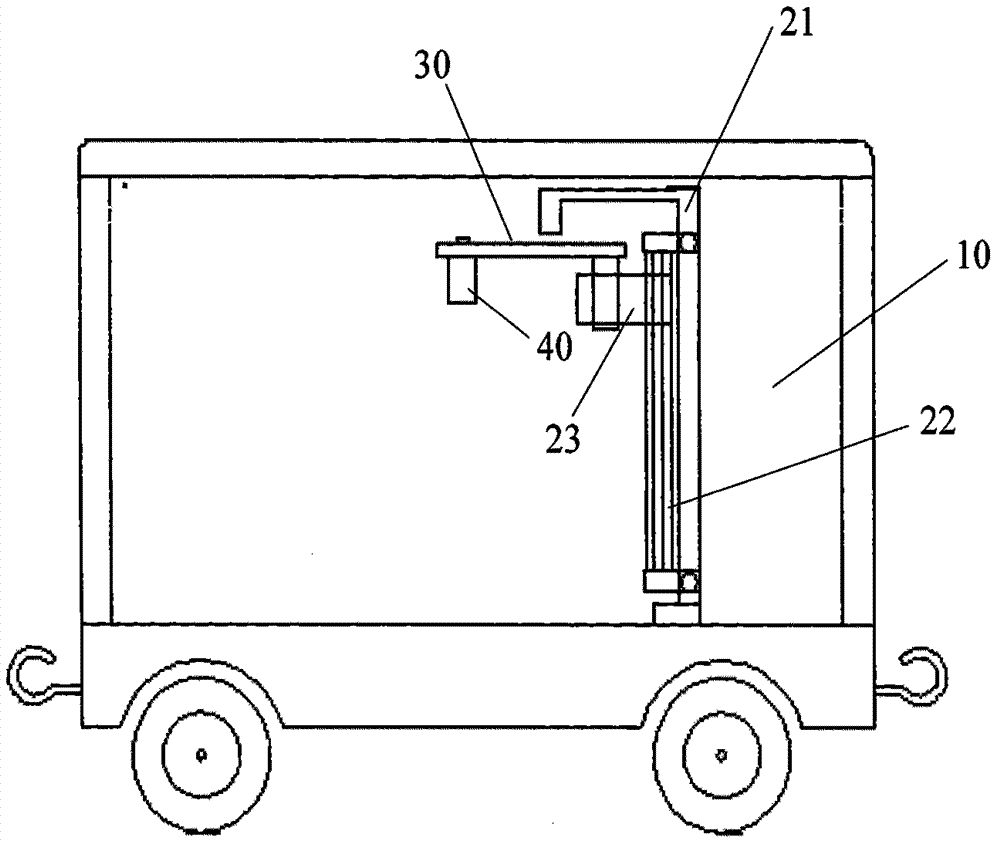

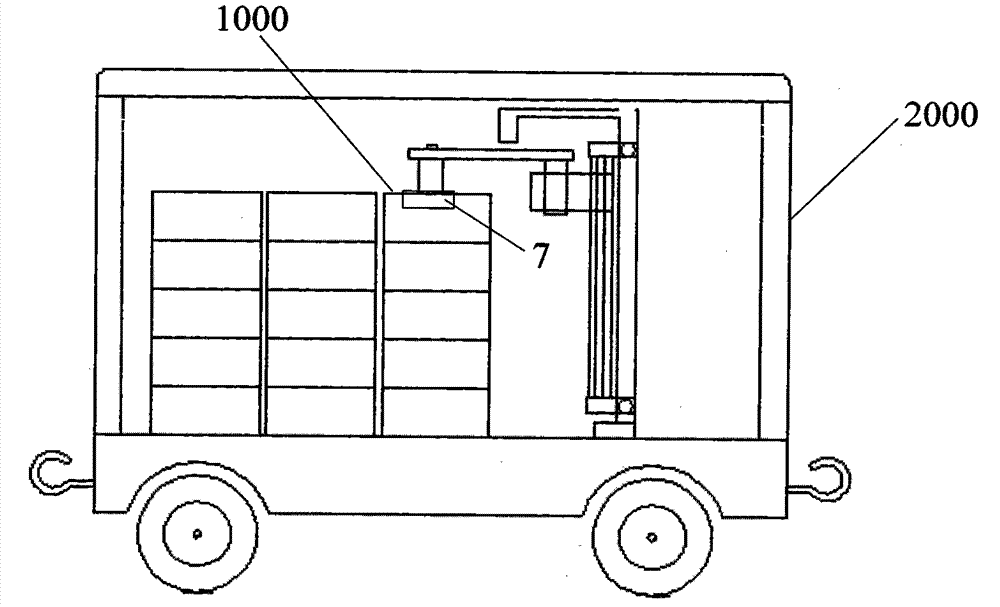

Engineering truck, system and method for operating traffic indicating device

The embodiment of the invention provides an engineering truck, system and method for operating traffic indicating device. The engineering truck comprises a truck body, a moving shaft arranged in the truck body in a moving mode, a swing arm shaft connected with the moving shaft and capable of moving along with the moving shaft and a magnetic head arranged at the end of the swing arm shaft. The magnetic head generates electromagnetic force when powered to attract a metal piece exposed at the top end of the traffic indicating device so that the traffic indicating device can be absorbed to the magnetic head to achieve grabbing of the traffic indicating device. When the magnetic head is powered down, the traffic indicating device absorbed to the magnetic head can be put down to achieve unloading of the traffic indicating device. By means of the engineering truck, system and method for operating the traffic indicating device, the automation degree of stacking and recycling of the traffic indicating device is increased, and stacking and recycling of the traffic indicating device can be achieved conveniently and fast.

Owner:缪明月 +2

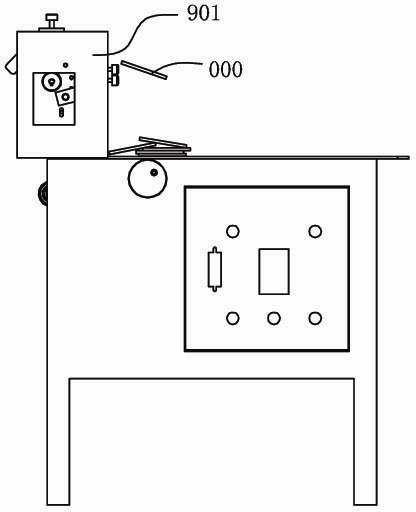

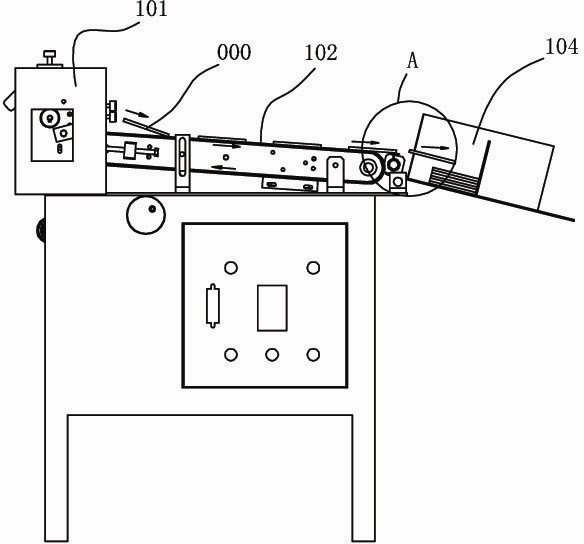

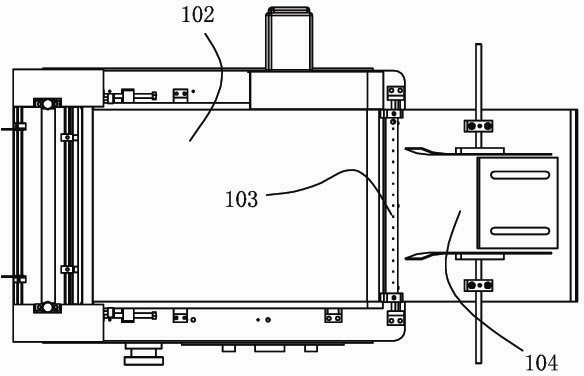

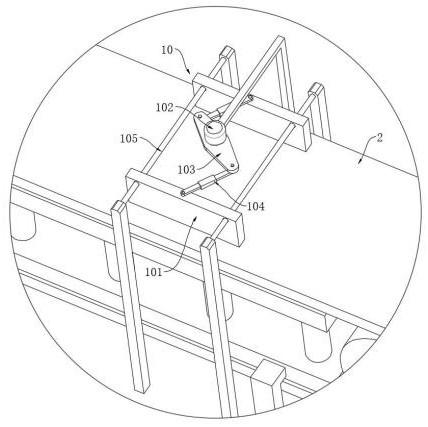

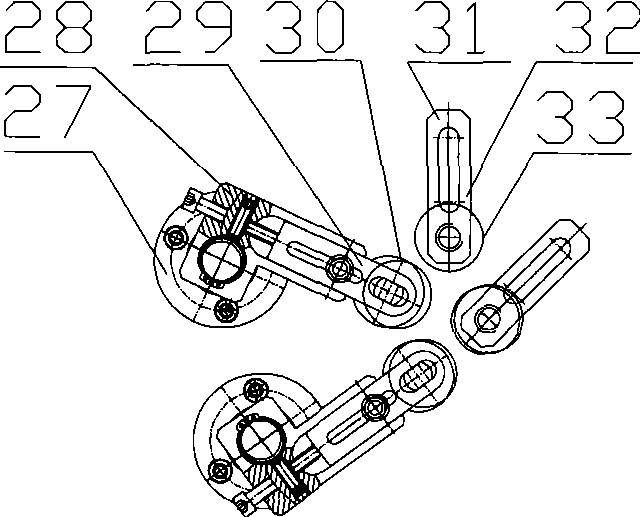

Aggregation device for transverse cutting machine

InactiveCN101979225ARealize automatic stackingSave human effortMetal working apparatusEngineeringConveyor belt

The invention relates to die cutting processing technology, in particular to an aggregation device for a transverse cutting machine in a procedure behind a die cutting machine. The transverse cutting machine comprises a cutting part; the aggregation device comprises a conveyor belt arranged at the front end of the cutting part, an inflator arranged at the front end of the conveyor belt, and an aggregation clamp arranged at the front end of the inflator; the front end refers to the moving direction of cut materials; and the inflator is horizontally arranged, the axle center of the inflator is vertical to the moving direction of the cut materials, and the side wall of the inflator is provided with upward air blowing holes. The aggregation device for the transverse cutting machine can automatically accumulate and stack cut products.

Owner:GUANGDONG FXD INTELLIGENT EQUIP CO LTD

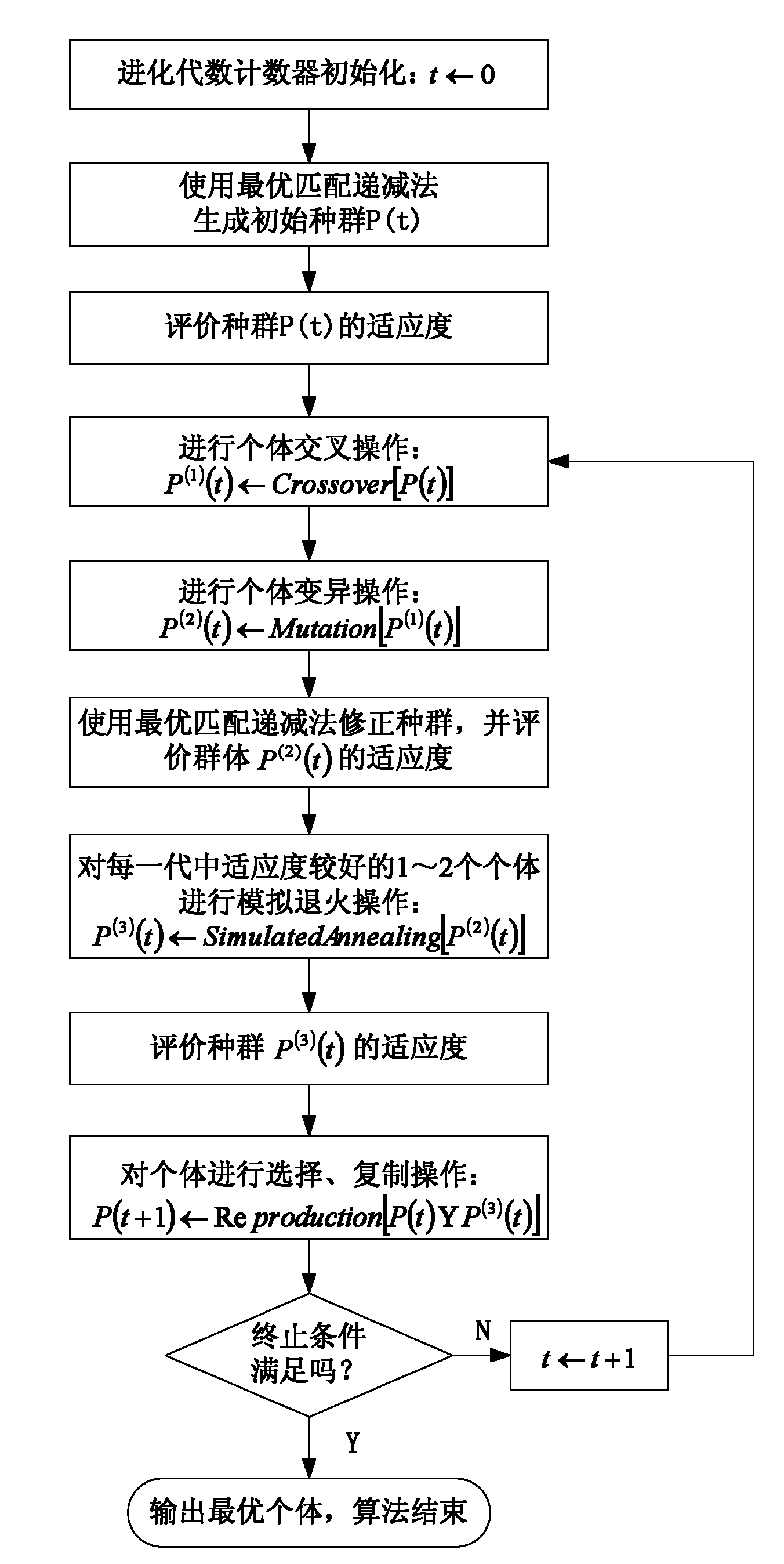

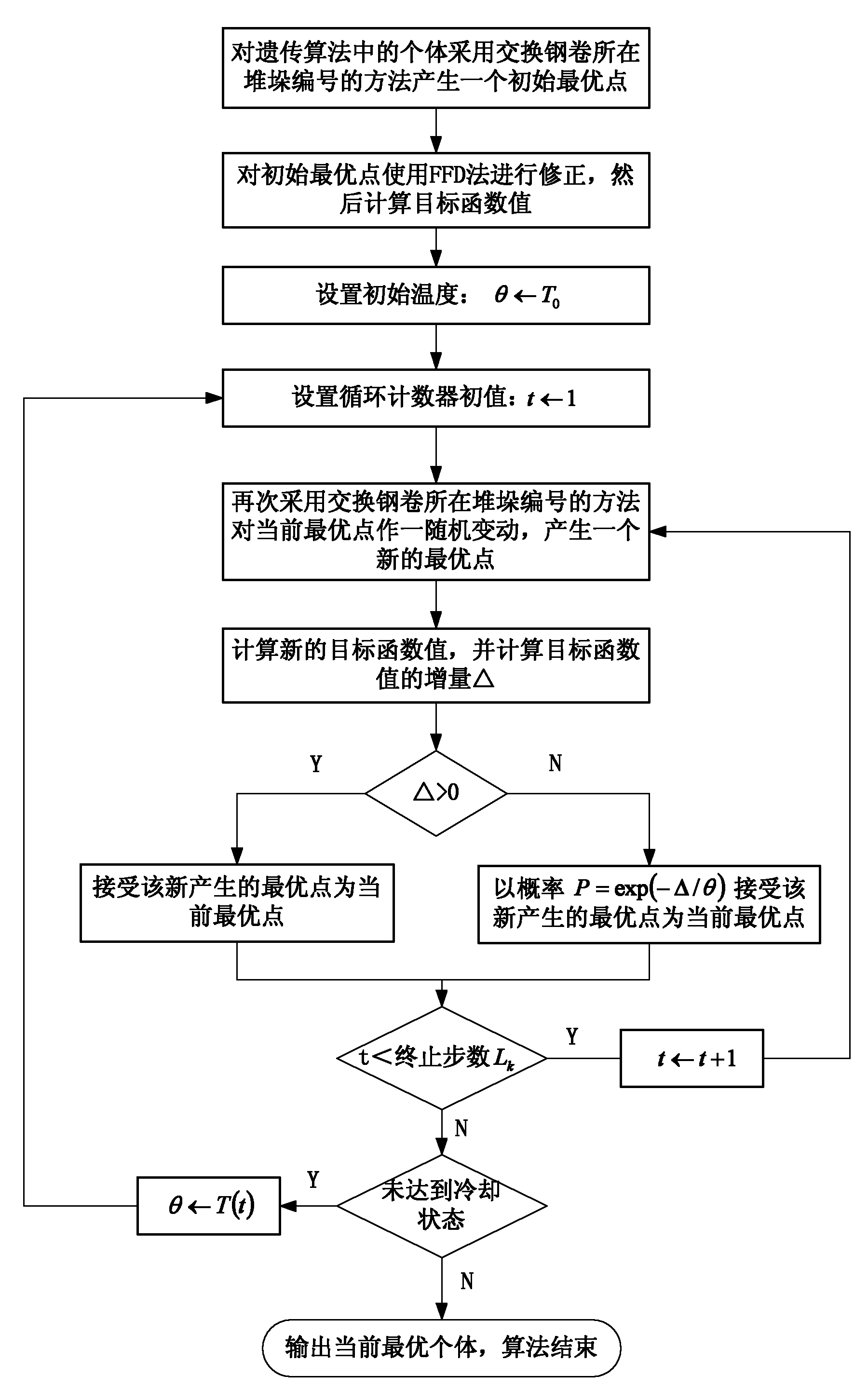

Combinatorial optimization method of steel coil stacking of hood-type annealing furnace

ActiveCN102206741AHigh precisionRealize automatic stackingBell type furnacesHeat treatment furnacesInformatizationMathematical model

The invention relates to the technical field of ferrous metallurgy information technology, and particularly relates to a combinatorial optimization method of steel coil stacking of a hood-type annealing furnace. According to the characteristics of an annealing process of a hood-type annealing furnace, based on the analysis of the effect of steel coil overall dimensions (external diameter, width, thickness, etc.) and steel grades on annealing time and the restriction of various constraint conditions, and aiming at the optimization objects of minimizing stacking number and maximizing furnace stage production efficiency, the invention establishes a mathematical model for the optimization of hood-type furnace stacking, and provides a hybrid genetic algorithm (FGSA) combining algorithms of a first fit decreasing algorithm (FFD), a genetic algorithm (GA), and a simulated annealing algorithm (SA) for the solution of the model. The method can realize the informatization and the automation of hood-type furnace annealing production, reduce the labor intensity of scheduling personnel, increase the production efficiency of production factories, and has the effect of energy saving and consumption reduction.

Owner:WISDRI WUHAN WIS IND FURNACE

Automatic tea fermentation system

PendingCN105851297AAvoid mutual influenceSmall volumePre-extraction tea treatmentBiotechnologyBiochemical engineering

The invention relates to an automatic tea fermentation system. A passage for enabling a fertilization box to pass through is formed in a fermentation tunnel; a pushing device is arranged at one end of the fermentation tunnel; a discharge device is arranged at the other end of the fermentation tunnel; and a water mist spray pipe and a heating device are arranged in the fermentation tunnel. A fermentation method employing the above-mentioned automatic tea fermentation systems comprises the steps of: loading fresh leaves into fermentation tanks; pushing the fermentation tanks into a fermentation tunnel in turn by a pusher; controlling oxygen content, temperature and humidity in the fermentation process; after fermentation, pushing the fermentation tanks to unloading equipment by the pusher, so as to realize automatic tea fermentation. The invention employs a structure containing the fermentation tunnel located in the fermentation chamber cooperated with the pusher, and reduces the volume of the fermentation space, thereby reducing energy consumption radically and reducing the chance of contamination by bacteria as well.

Owner:HUBEI DENGCUN GREEN TEA GRP

Grid automatic stacking device

InactiveCN102491096ARealize automatic stackingSimple structureStacking articlesEngineeringLead Metal

The invention discloses a grid automatic stacking device, which comprises a machine frame and a controller, wherein a grid stacking mechanism and a stacked grid outputting mechanism are arranged on the machine frame; the conveying mechanism is a plane rollway; the stacking mechanism comprises a grid supporting frame and a driving device of the grid supporting frame; and the control device controls the operation of the stacking mechanism and the conveying mechanism according to the detection of the detection device. The device realizes the automatic stacking of grids, reduces the labor intensity of workers, relives the damages of lead metal to the body health of works and creates a condition for the automatic processing grids. Meanwhile, the grid automatic stacking device also has the advantages of simple structure, convenient operation, reliable operation and the like.

Owner:JIANGSU SANHUAN IND HLDG CO LTD

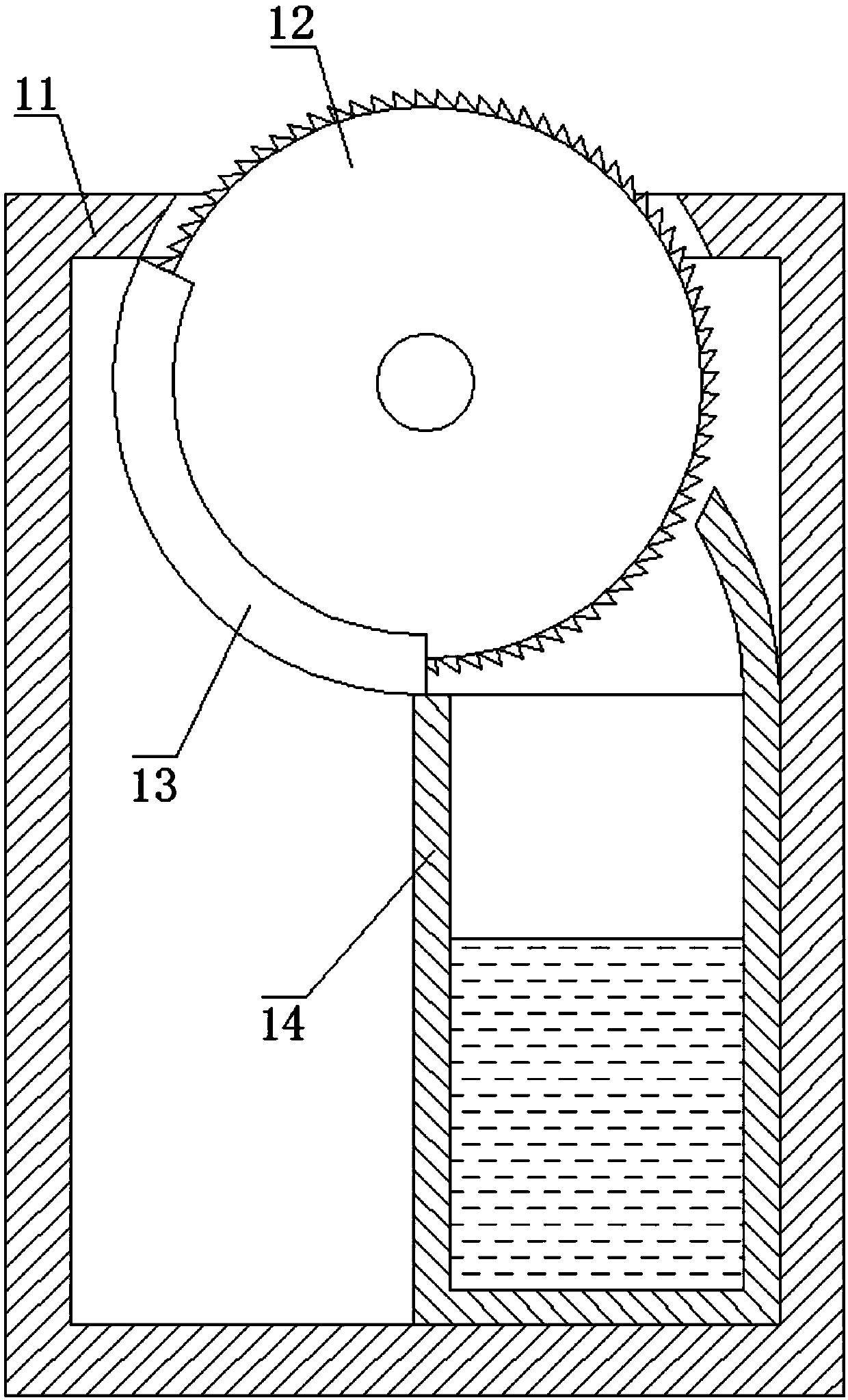

Self-transmission stacking device for sun sheet cutting and flattening

ActiveCN109607140AAvoid burning phenomenonTo avoidEdge grinding machinesGrinding carriagesCombustionEngineering

The invention discloses a self-transmission stacking device for sun sheet cutting and flattening. The self-transmission stacking device comprises a cutting device, a flattening device and a stacking device, wherein the cutting device comprises a mounting box; the inner side wall of the mounting box is fixedly connected with a cutting motor; the output end of the cutting motor is fixedly connectedwith a cutting wheel; a corresponding protective cover is mounted outside the cutting wheel; the lower end of the protective cover is fixedly connected with a water slot; the water slot is fixedly connected to the bottom wall of the mounting box, so that scraps generated during cutting are collected into the water slot, dust and scraps generated during cutting are avoided, and an accident caused by a combustion phenomenon of the scraps is prevented, sun sheets of different thicknesses and different widths can be grinded, compatibility of the machine is improved, and producing and processing efficiency is improved; automatic stacking is realized by additionally arranging structures such as a turnover plate, a trigger device and a stacking platform; and moreover, a worker conveniently packsafter stacking is accomplished, and therefore, the self-transmission stacking device is convenient and quick.

Owner:GUANGDONG GUOWEIXING PLASTIC SCI & TECHCO LTD

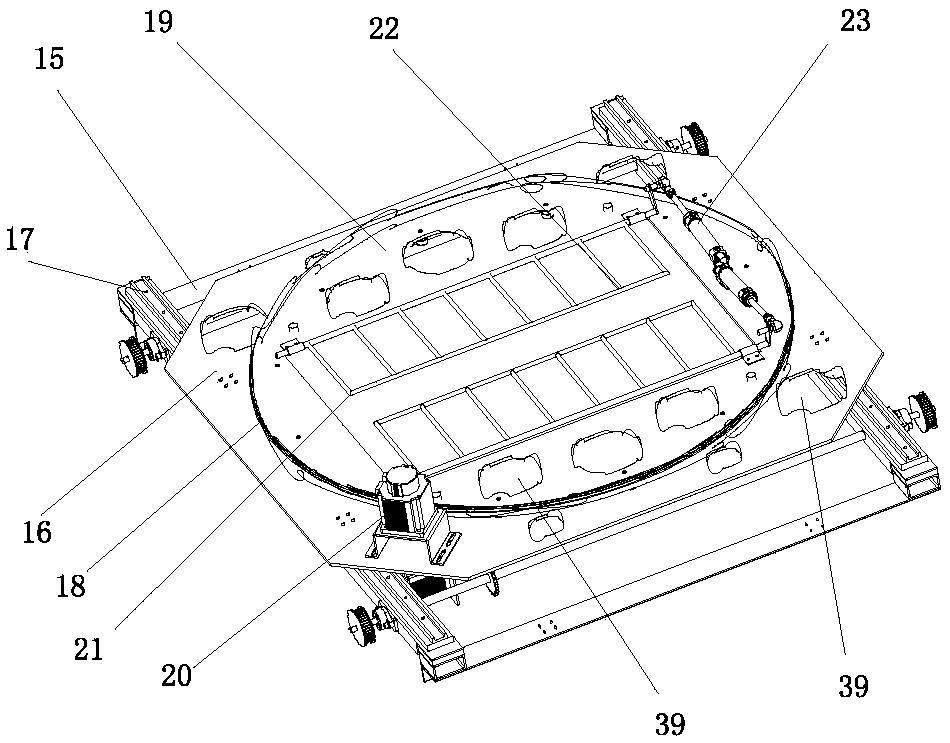

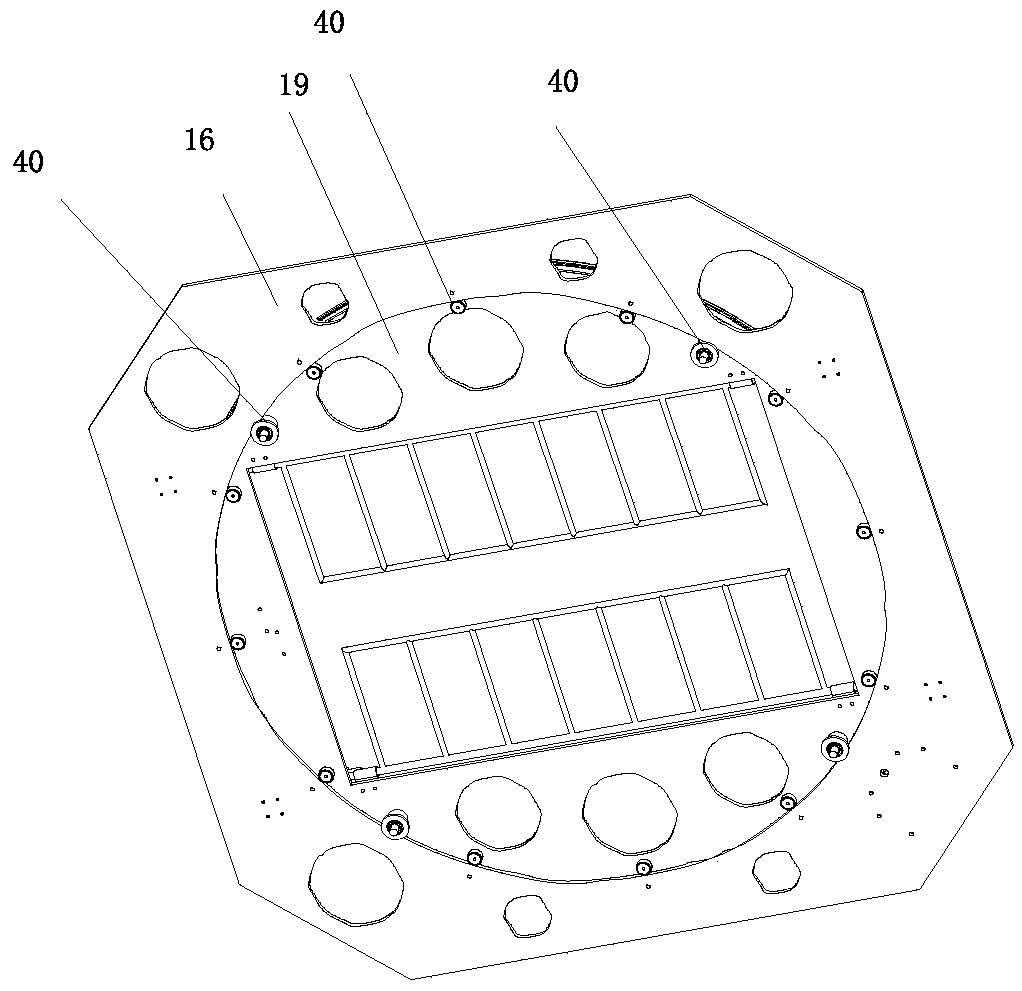

Novel automatic board stacking machine

InactiveCN103950732ASo as not to damageReasonable and novel structure designStacking articlesDe-stacking articlesStack machineEngineering

The invention discloses a novel automatic board stacking machine, and relates to the technical field of mechanical equipment. A conveyor belt is arranged above the frame of a conveyor; the two ends of the conveyor belt are respectively in transmission connection with a driven chain bearing and a driving chain bearing; the central shaft of the driving chain bearing is in transmission connection with a transmission motor; an automatic rotary table resetting switch is arranged on one side of the frame of the conveyor; the frame of the board stacking machine is arranged at the tail end of the conveyor belt; an idler wheel is arranged below the frame of the board stacking machine; a circular track is arranged at the bottom of the idler wheel; the idler wheel is connected with a rotating motor; a lifting motor is arranged at the top of the frame of the board stacking machine; the lifting motor is connected with an automatic board stacking fork through a transmission chain; an automatically-rotating board stacking base is arranged below one side of the frame of the board stacking machine; the automatically-rotating board stacking base is in transmission connection with a motor. The novel automatic board stacking machine is firm and durable; that the novel automatic board stacking machine can automatically stack boards is realized, so that a lot of manpower and material resources can be saved; the novel automatic board stacking machine is low in energy consumption; the boards can be stored orderly and attractively and are not damaged, so that resources are saved.

Owner:江门市康德木业有限公司

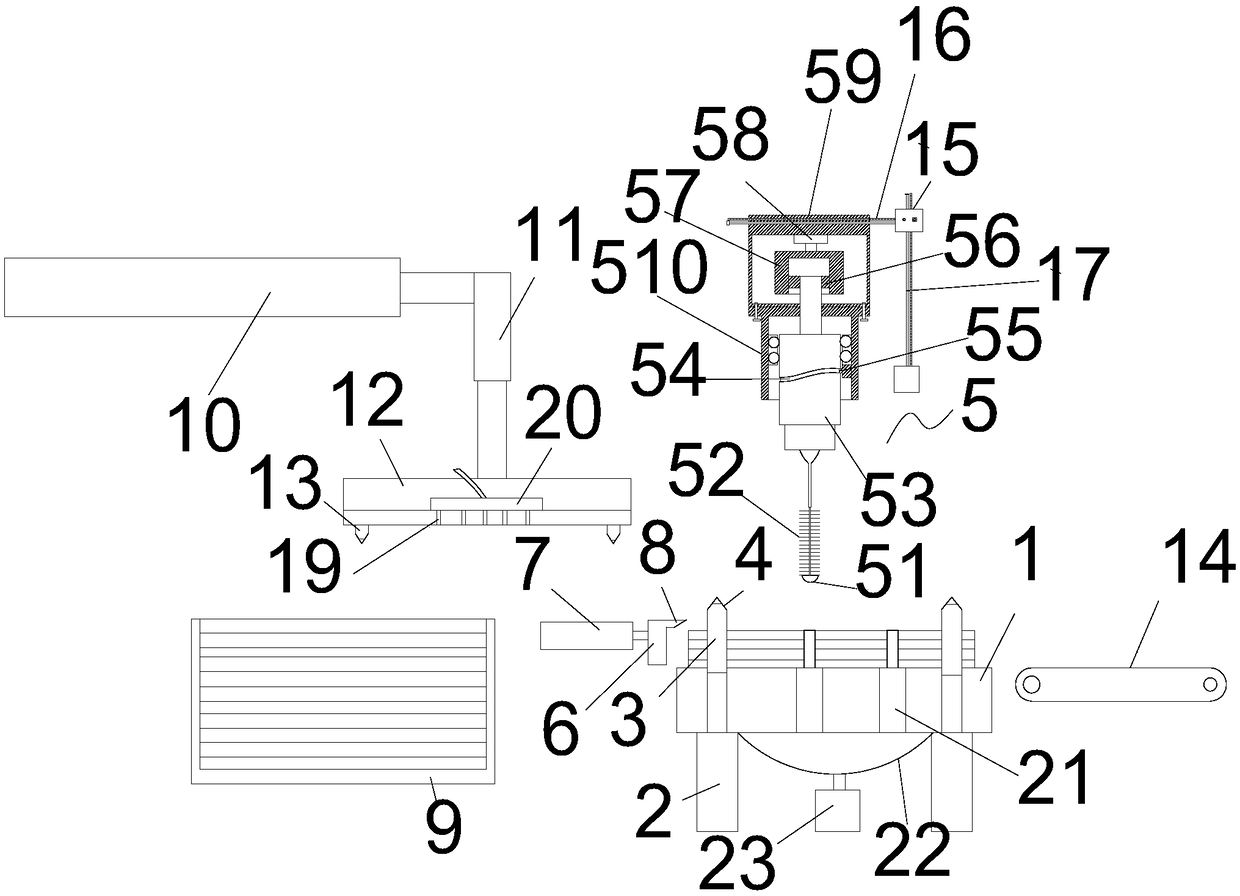

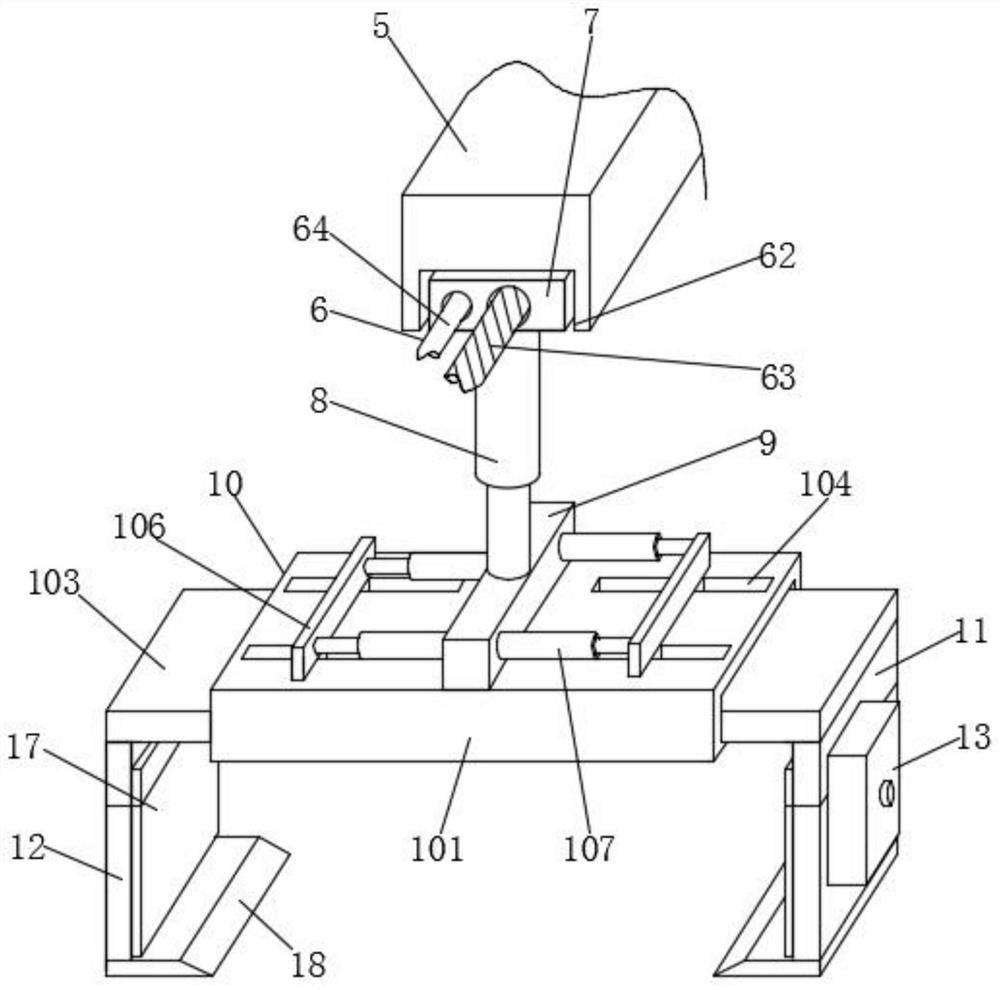

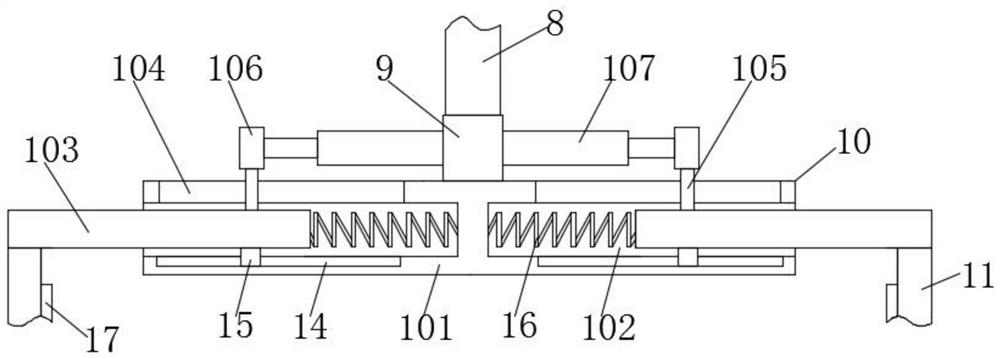

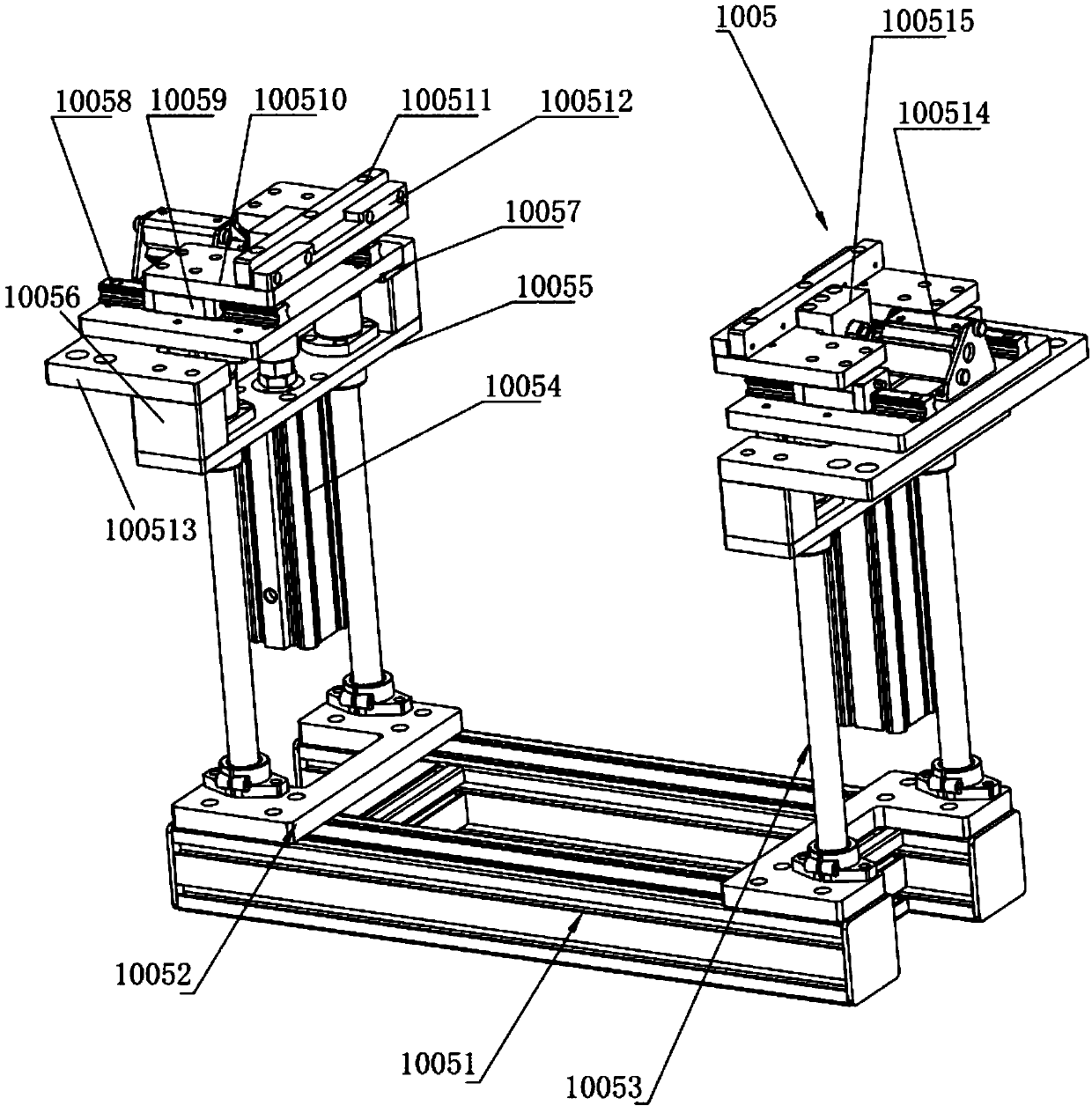

Method and device for achieving batched removing of burrs in hole of PCB based on numerical control machine tool

PendingCN109277899ARealize automatic stackingAchieve grindingEdge grinding machinesGrinding drivesPush and pullNumerical control

The invention discloses a device for achieving batched removing of burrs in a hole of a PCB based on a numerical control machine tool. The device comprises a PCB moving mechanism and a PCB deburring mechanism; the PCB deburring mechanism comprises a machine tool table board, a first push and pull device is arranged at the bottom of the machine tool table board, and is connected with a positioningpin, a first conical part matched with a positioning hole of the PCB is formed on the top of the positioning pin, a deburring drill bit structure is arranged above the machine tool table board, an L-shaped pressing plate is arranged on the side face of the machine tool table board, and is connected with a second push and pull device, a second conical part matched with the PCB is formed on the endface of the L-shaped pressing plate, the PCB moving mechanism comprises a frame for stacking of PCBs and a third push and pull device, and the third push and pull device is connected with a first lifting device. Automatic stacking, grinding and transport of the PCBs can be achieved, the grinding effect is good, and the grinding efficiency is high.

Owner:AOSHIKANG TECH CO LTD

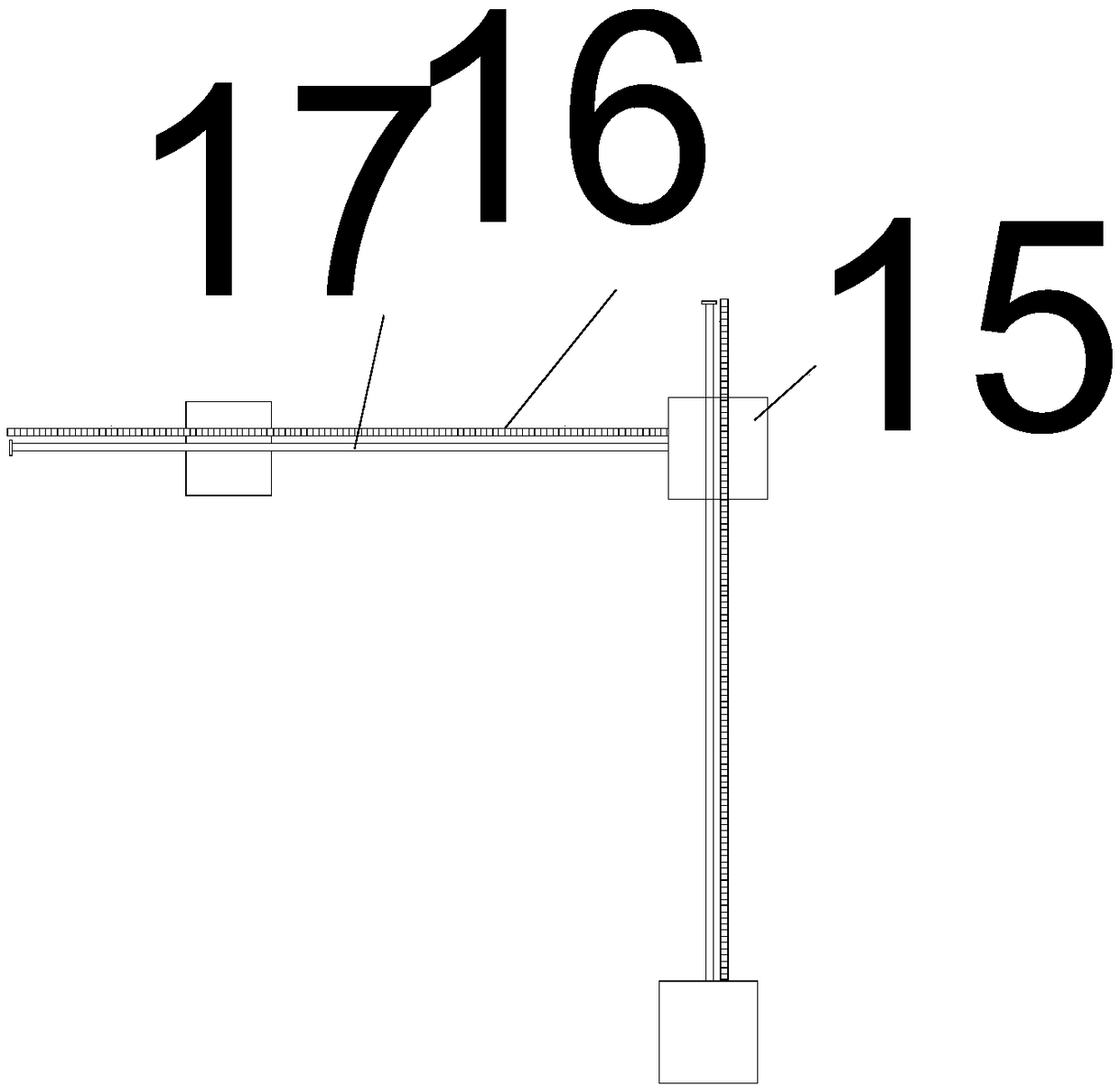

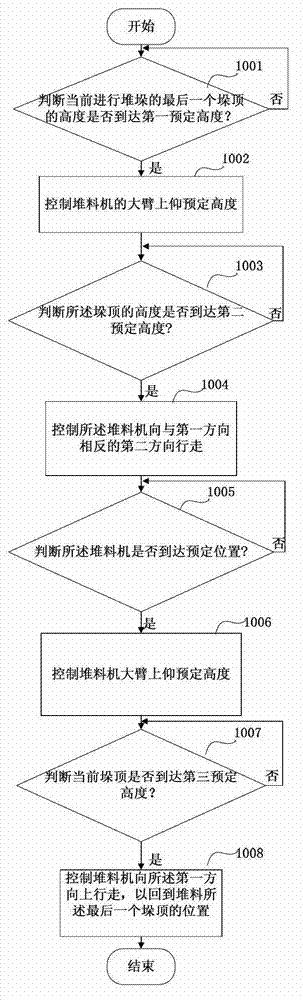

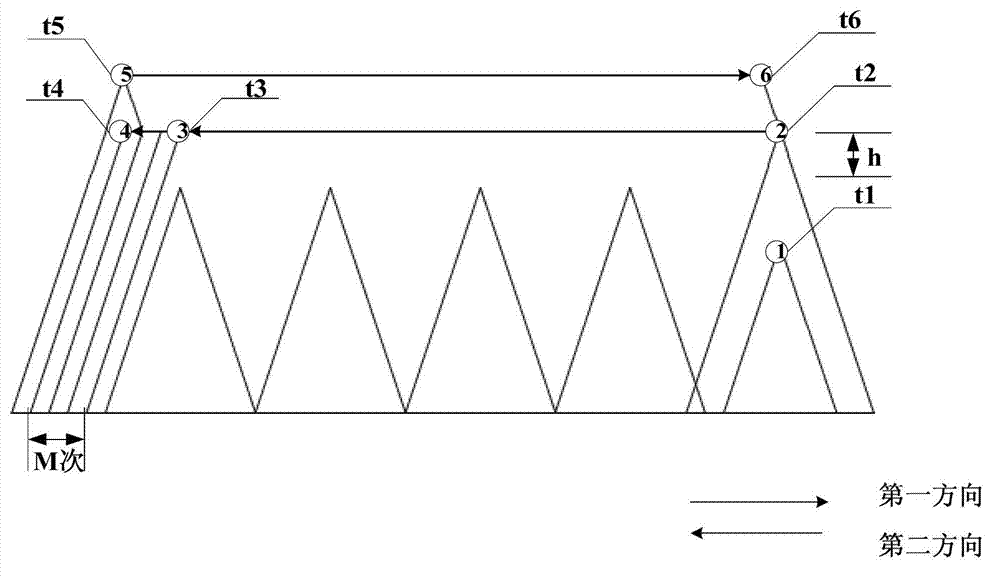

Control method, control device and control system for automatic stacking of stacker

ActiveCN103112729AEasy to operateImprove work efficiencyLoading/unloadingProgramme control in sequence/logic controllersControl systemEngineering

The invention discloses a control method, a control device and a control system for automatic stacking of a stacker. The control method for the automatic stacking of the stacker comprises the steps of receiving an automatic stacking command, controlling a big arm of the stacker to nose up by a predetermined height under the condition that height of the last stack among the stacks which are stacked by the stacker reaches to a predetermined height, controlling the stacker to travel in the second direction opposite to the first direction under the condition that the height of the stack reaches to a second predetermined height, controlling the big arm of the stacker to nose up to a predetermined height under the condition that the stacker reaches to a predetermined position, controlling the stacker to travel towards the first direction under the condition that the height of the present stack reaches to a third predetermined height, and controlling the stacker to return to the position of the last stack. Stacking is carried out when the big arm of the stacker noses up and then the stacker travels.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Logistics stacking machine for logistics transferring of parcels

PendingCN111717670AAchieve grippingRealize automatic stackingConveyorsStacking articlesLogistics managementStructural engineering

The invention belongs to the technical field of logistics transferring, and discloses a logistics stacking machine for logistics transferring of parcels. The logistics stacking machine comprises a stacking platform and a conveying belt. The stacking platform is located in front of the conveying belt and is close to the right side of the conveying belt. First supporting rods are fixedly connected to the rear portion of the top of a conveying belt support. According to the logistics stacking machine for logistics transferring of the parcels, the horizontal distance between two first clamping plates and two second clamping plates can be adjusted through left-right telescopic components, and the distance between the first clamping plates and the second clamping plates can be adjusted through adjustment assemblies, so that parcels with different sizes can be clamped; automatic stacking is realized through the cooperation of the conveying belt, a driving assembly, mounting blocks, first hydraulic push rods, fixing strips, the left-right telescopic components, the first clamping plates, the second clamping plates and the adjustment assemblies, so that labor is saved, the working efficiency is improved, and the problems that an existing logistics stacking machine cannot clamp parcels exceeding the height and length of the clamping plates, and consequentially, the stacking efficiency isaffected, and the practicability of the logistics stacking machine is reduced are solved.

Owner:常州旅游商贸高等职业技术学校

Corrugated paper cutting and stacking integrated equipment

ActiveCN108032550ARealize automatic stackingPrevent movementBox making operationsPaper-makingCircular sawEngineering

The invention discloses corrugated paper cutting and stacking integrated equipment. The corrugated paper cutting and stacking integrated equipment comprises a cutting mechanism and a stacking mechanism which are arranged in sequence. The cutting mechanism comprises a transversely-cutting mechanism and a longitudinally-cutting mechanism which are arranged in sequence according to the material conveying direction. The transversely-cutting mechanism comprises a transversely-cutting mechanism rack, an electric circular saw, a carrier roller, a conveying roller and a conveying roller driving mechanism used for driving the conveying roller to rotate. The stacking mechanism comprises an input conveying belt, a paper receiving platform and an output conveying belt, wherein the input conveying belt, the paper receiving platform and the output conveying belt are in butt joint with each other in sequence. The feeding end of the input conveying belt are in butt joint with the longitudinally-cutting mechanism, and a paper splitting mechanism is arranged between the discharging end of the input conveying belt and the paper receiving platform.

Owner:佛山市三水三丰包装材料有限公司

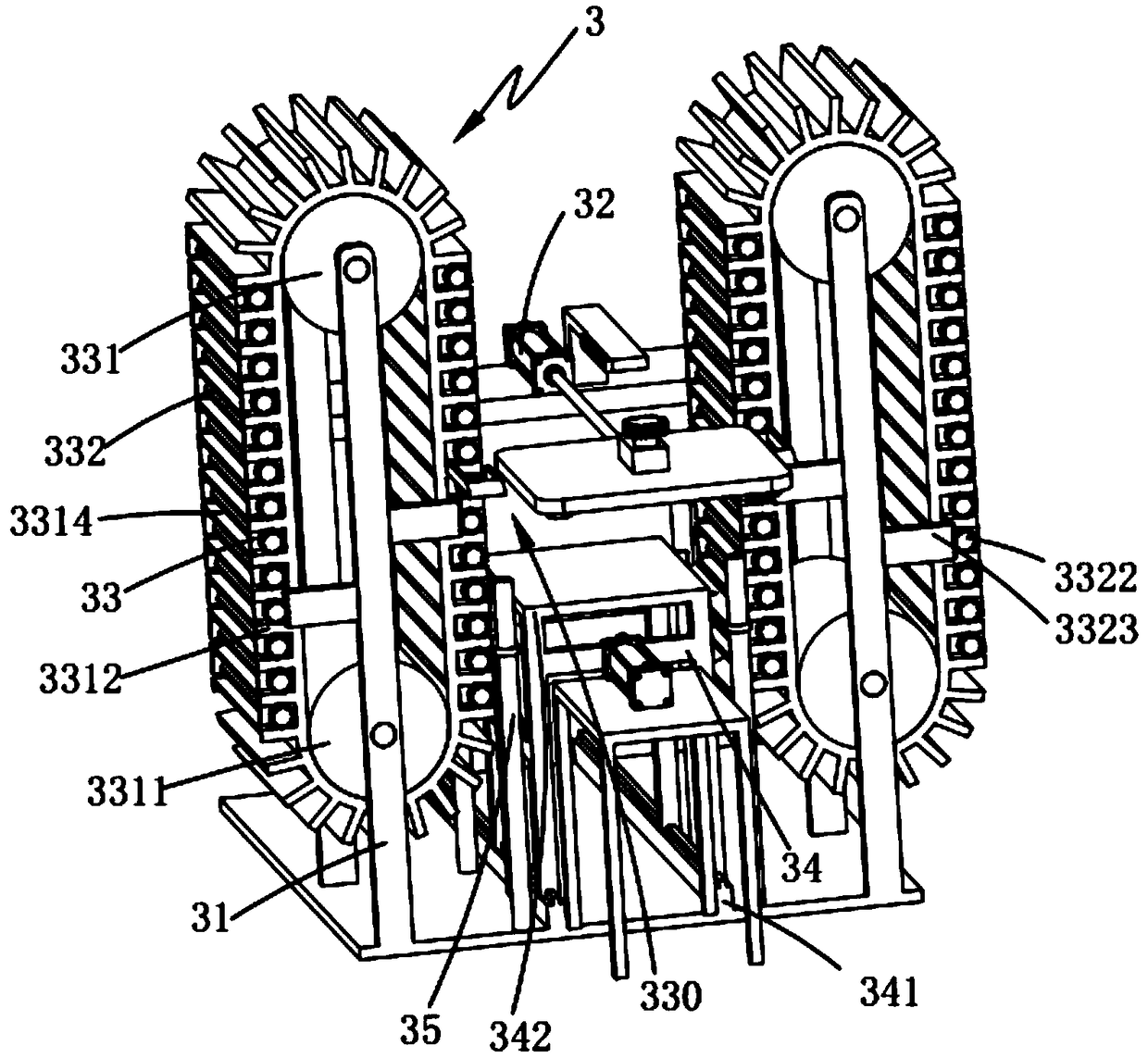

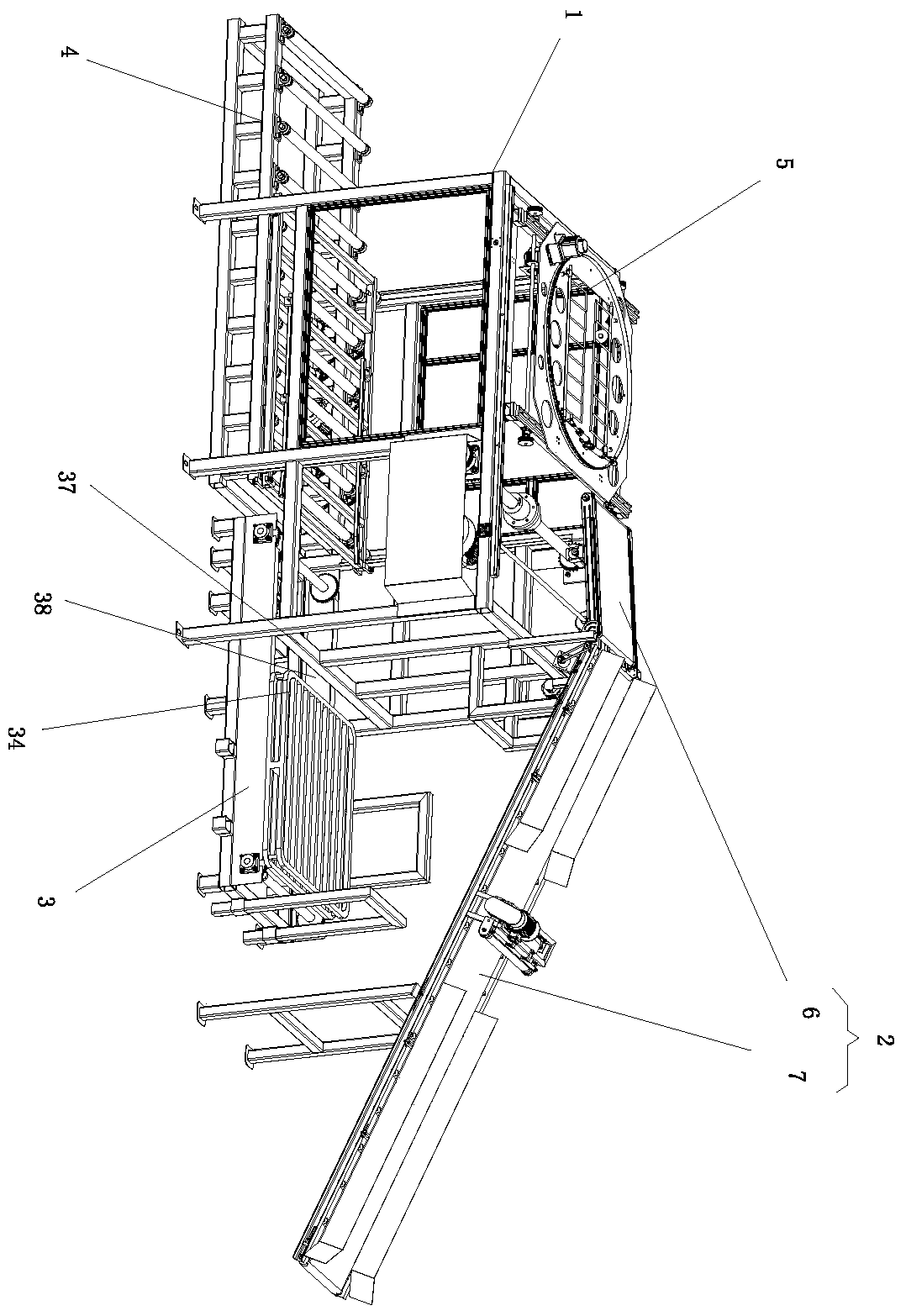

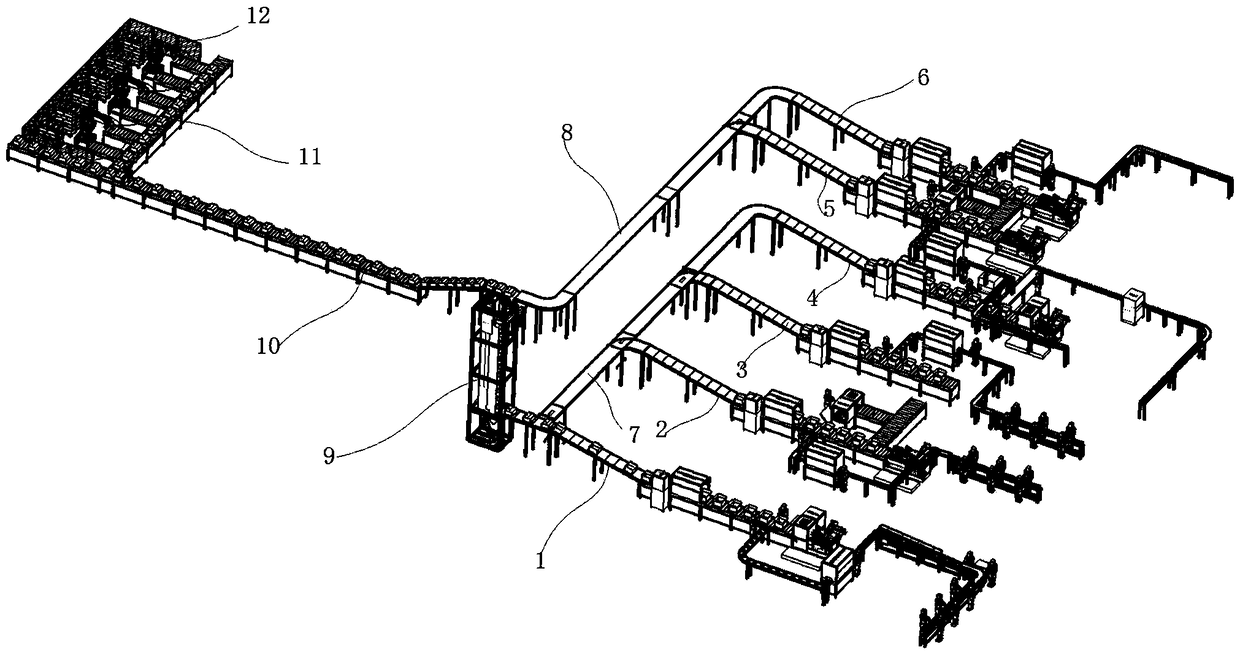

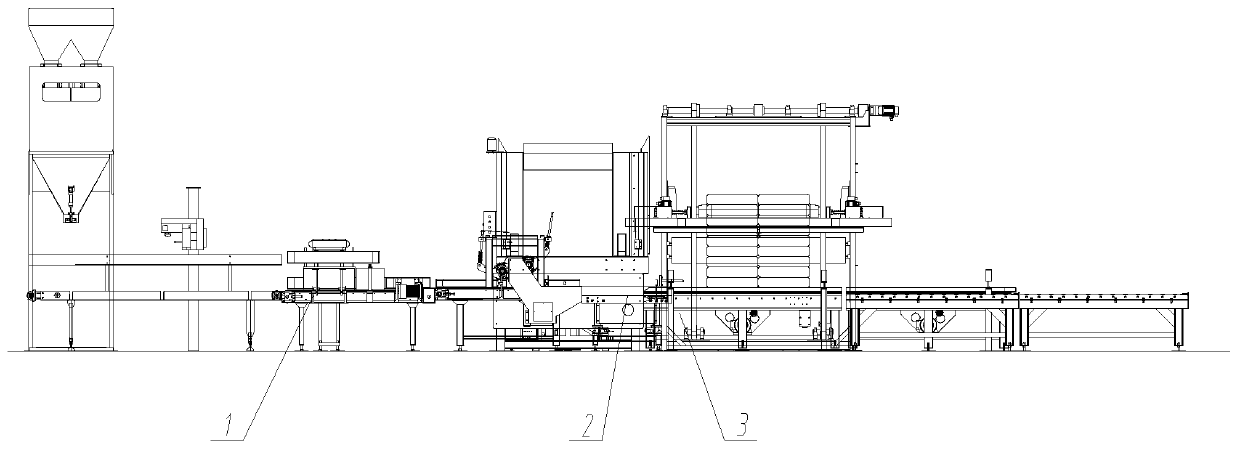

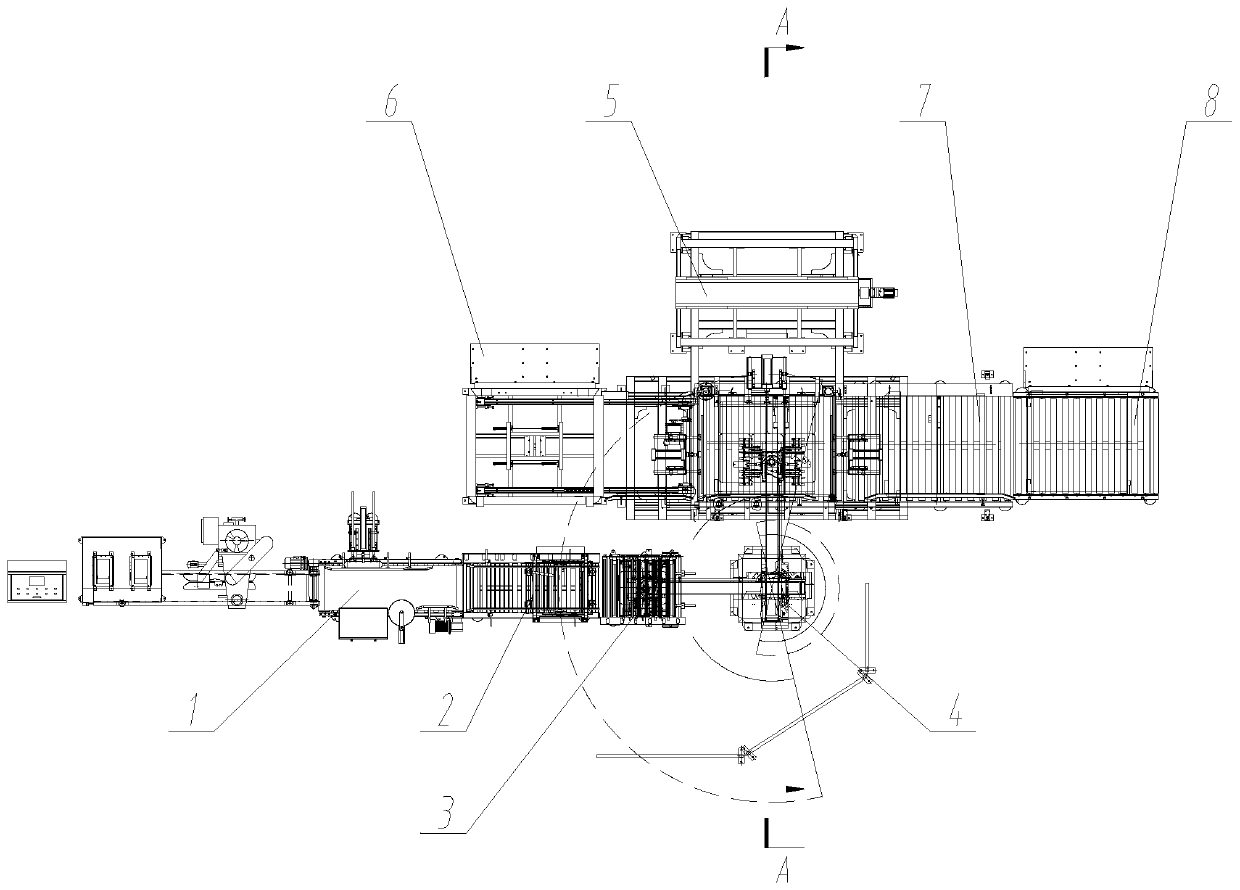

Full-automatic woven bag production line and process

InactiveCN109080223AImprove stacking efficiencyImprove stacking and packaging efficiencyBag making operationsPaper-makingProduction lineEngineering

The invention provides a full-automatic woven bag production line and process. The full-automatic woven bag production line comprises a woven bag forming mechanism, a woven bag conveying mechanism, awoven bag stacking mechanism and a packaging output mechanism. The woven bag stacking mechanism comprises a machine frame, an adsorption transport assembly, rotary finishing assemblies, an output assembly and a buffer assembly, a woven bag finishing space is formed between the rotary finishing assemblies, and the adsorption transport assembly intermittently acts on the right above the woven bag finishing space. The packaging output mechanism is arranged on one side in the output direction of the woven bag stacking mechanism, and comprises a woven bag pile limiting assembly, a packaging assembly and a finished product bearing assembly. The stacked woven bags are output to the packaging output mechanism through the output assembly, and the woven bag pile limiting assembly is matched with thepackaging assembly for pressing linkage to realize the limiting of woven bag piles, while the woven bag piles are packaged, and the buffering assembly is lifted to buffer the woven bags, so that thetechnical problem of low packaging work efficiency in the prior art is solved.

Owner:浙江埃芮克环保科技有限公司

High-speed stacking machine for bagged feed and stacking method thereof

ActiveCN107915058ARealize automatic stackingSmall heightConveyorsStacking articlesStack machineEngineering

A high-speed stacking machine for bagged feed comprises a stacking machine frame, an automatic slideway device, an automatic pallet replacement device and an automatic pallet conveying device. The automatic slideway device is connected with the stacking machine frame. A stacking mechanism is arranged at the upper end of the stacking machine frame. A slideway outlet of the automatic slideway deviceis located above the stacking mechanism. The automatic pallet conveying device is located below the stacking mechanism. The automatic pallet conveying device is located between the automatic slidewaydevice and the automatic pallet replacement device. Automatic stacking can be realized, and the placement position can be adjusted reasonably according to different shapes of bagged feed blocks.

Owner:SCIKOON IND

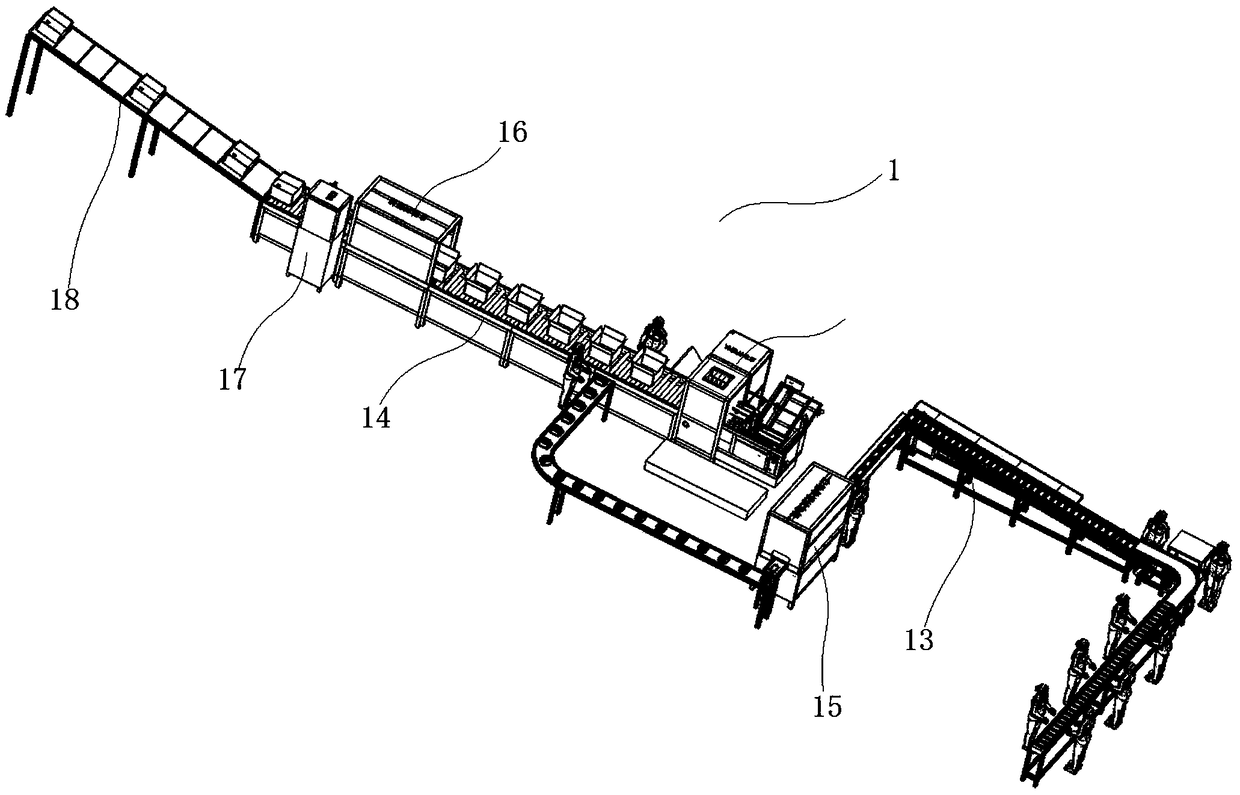

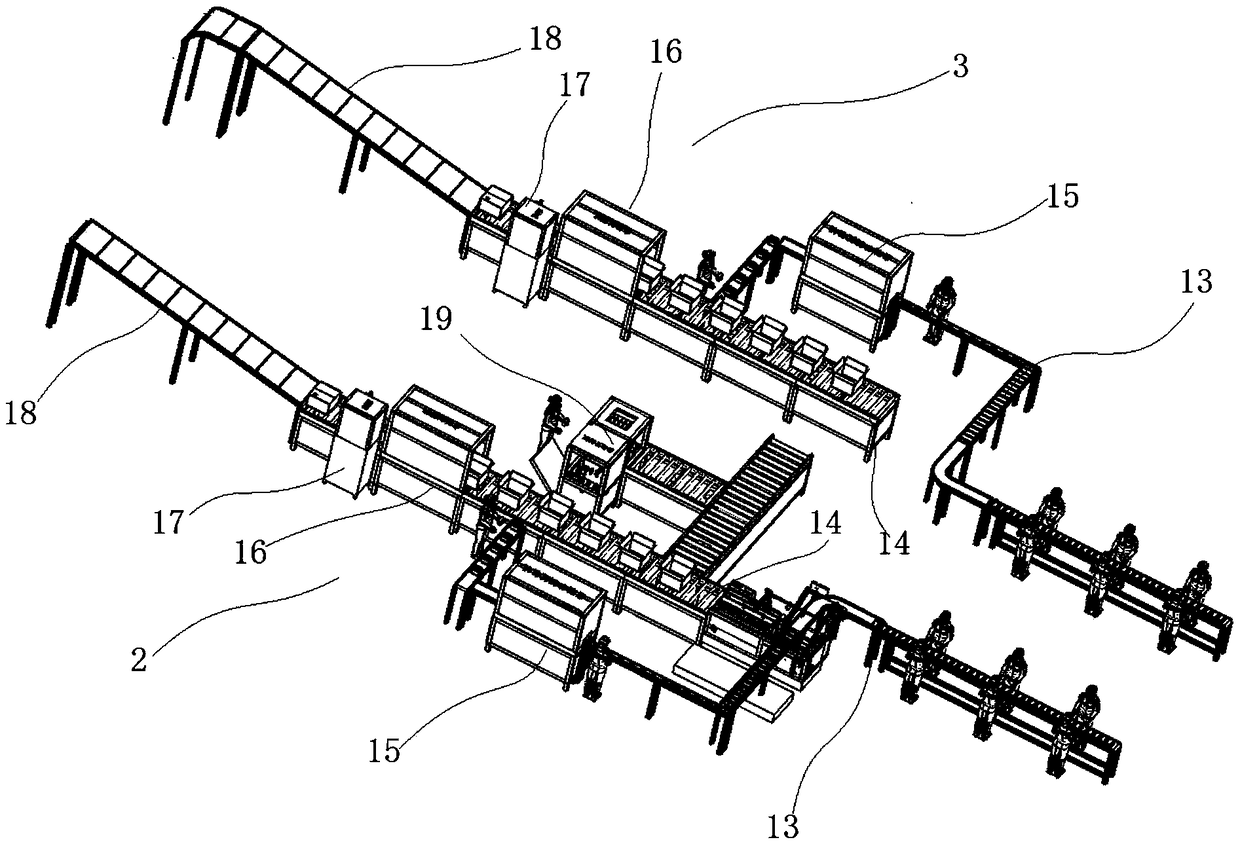

Full-automatic pillow packaging machine for drugs

InactiveCN109018475ARealize automatic stackingStacking articlesDe-stacking articlesEngineeringCarton

The invention provides a full-automatic pillow packaging machine for drugs, and relates to the field of automatic equipment. The full-automatic pillow packaging machine comprises a first packaging line, a second packaging line, a third packaging line, a fourth packaging line, a fifth packaging line and a sixth packaging machine. The first packaging line, the second packaging line, the third packaging line and the fourth packaging line are connected in series through a first connection line. The fifth packaging line and the sixth packaging line are located above the fourth packaging line and are connected in series through a second connection line. The first collection line and the second connection line are connected through a lifting conveying mechanism. A main collection line is arrangedon the other side of the lifting conveying mechanism. A distribution line is arranged at the tail end of the main collection line. A robot stacking mechanism is arranged on one side of the distribution line. According to the full-automatic pillow packaging machine for drugs, cartons are fed automatically and then are automatically opened through an automatic unpacker so as to be conveyed, multi-bag units stacked by the single-bag pillow packaging machine are manually placed in the cartons, and afterwards, the cartons are automatically sealed to be conveyed to the robot stacking mechanism, sothat automatic stacking is achieved.

Owner:DONGGUAN RONGXU AUTOMATION TECH

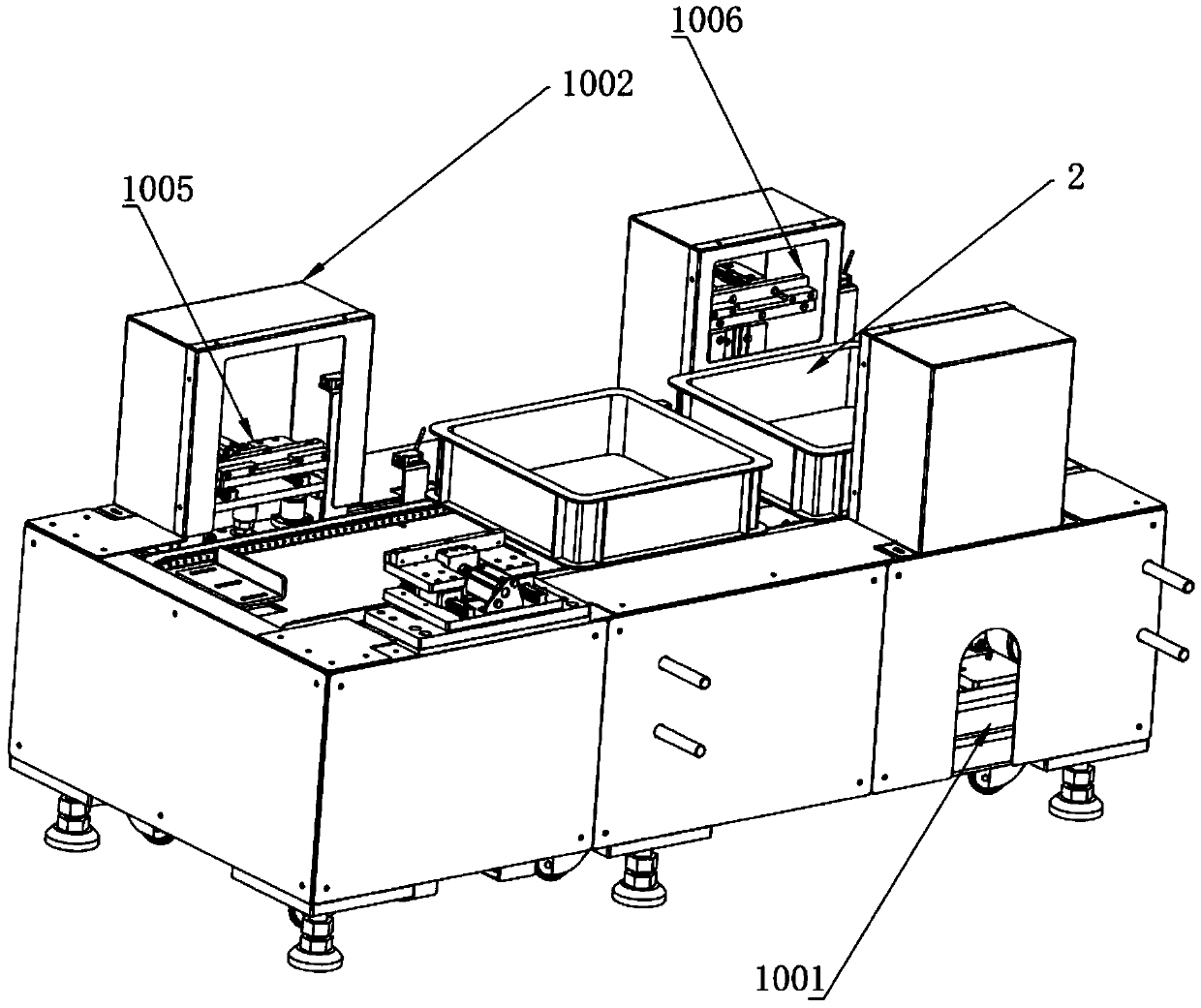

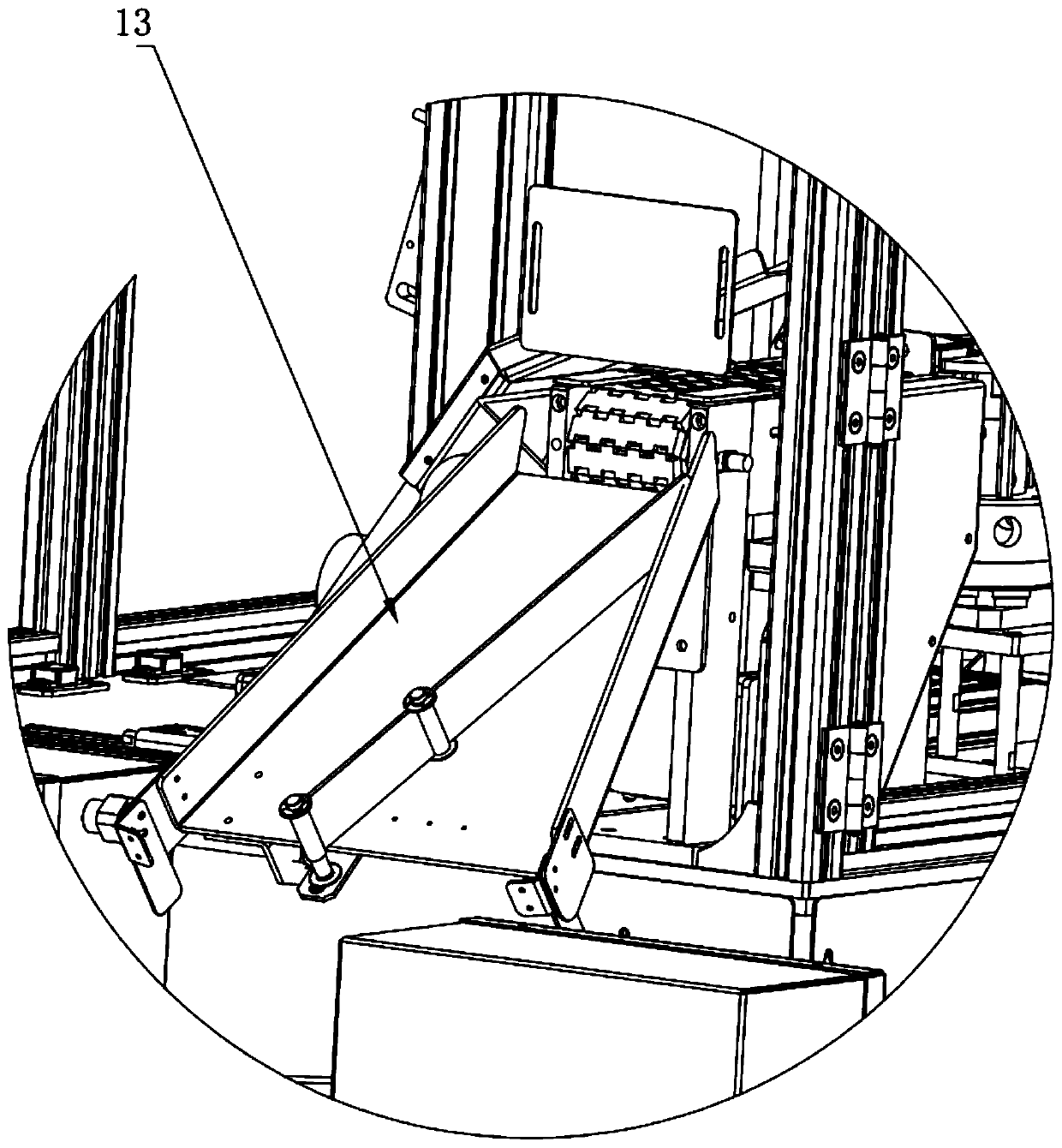

Discharging mechanism for full-automatic laser marking device

PendingCN109650025ARealize automatic unloadingRealize automatic stackingWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryConveyor belt

The invention relates to a discharging mechanism for a full-automatic laser marking device. The discharging mechanism comprises a welding machine frame, wherein a motor assembly, a conveyor belt assembly, a plurality of material boxes, a pair of first tray lifting assemblies, a pair of second tray lifting assemblies, a plurality of blocking assemblies and a jacking assembly are arranged in the welding machine frame, and the motor assembly drives the conveyor belt assembly to move the material boxes positioned on the conveyor belt assembly. The discharging mechanism is simple in structure and convenient to use; and according to the discharging mechanism, the automatic blanking of materials, the automatic stacking of the material boxes and the automatic conveying of the empty material boxescan be realized, the automation degree of the whole discharging process is high, the manpower resource investment of enterprises is saved, time and labor are saved, the labor intensity of workers is reduced, and the production efficiency is greatly improved.

Owner:无锡蓝智自动化科技有限公司

Automatic conveying and screening device for sheet materials

ActiveCN102514943AImprove input efficiencyAvoid stickingStacking articlesJigging conveyorsProcess engineeringMaterial supply

The invention discloses an automatic conveying and screening device for sheet materials, which comprises a sheet material quantity-limiting input mechanism, a status clear-up mechanism, a stacking mechanism, a single output mechanism, wherein the mechanisms are sequentially relevant to each other. The automatic conveying and screening device for sheet materials has the advantages of being simple in structure, easy to arrange, low in cost, high in efficiency, suitable for automatic conveying and screening of various sheet materials and especially suitable for automatic screening material supply of small embedded-block sheets.

Owner:长城汽车股份有限公司平湖分公司

Automatic conveying and stacking equipment for lithium batteries

ActiveCN114379986ANeatly stackedRealize automatic stackingConveyorsFinal product manufactureStructural engineeringTransfer mechanism

The invention relates to the technical field of lithium battery manufacturing, and discloses automatic conveying, stacking and stacking equipment for lithium batteries. The automatic lithium battery conveying, stacking and stacking equipment comprises a bearing plate, a conveying belt mechanism is fixedly installed on the upper end face of the bearing plate, and a transferring mechanism used for transferring lithium battery panels to a stacking mechanism from the conveying belt mechanism is installed on the left portion of the upper end face of the bearing plate and located below the stacking mechanism. The upper end faces of the multiple stages of telescopic mounting plates are jointly connected with a collecting frame mechanism in a clamped mode, and the right portion of the upper end face of the bearing plate is fixedly connected with a straightening mechanism used for adjusting the positions of the lithium battery panels through a supporting rod. And the stacking quality and the stacking efficiency can be effectively improved, the distance between the clamping plates can be adjusted according to the lithium battery panels of different lengths and thicknesses, and the application range is widened.

Owner:徐州林泰新能源有限公司

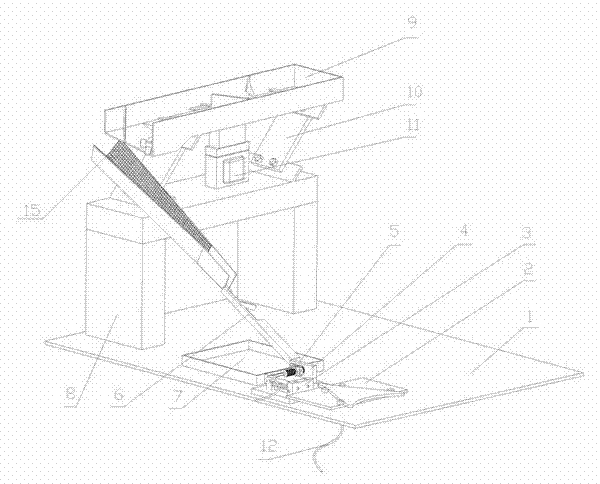

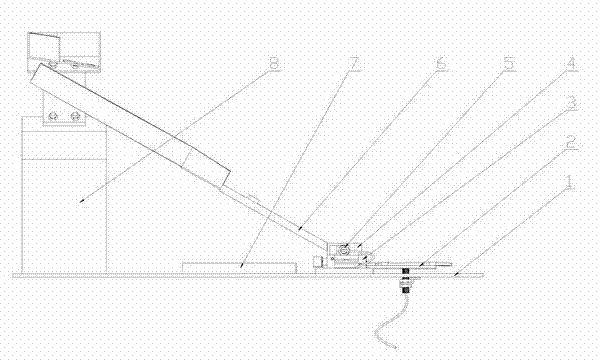

Method and device for automatically stacking plain glass

InactiveCN112124967ARealize automatic stackingAvoid distanceCharge manipulationConveyor partsProduction lineStructural engineering

The invention relates to a method for automatically stacking plain glass. The method includes the steps of placing an L-shaped bracket in front of the tail end of a conveying production line; horizontally moving the glass by a distance of Sn after the glass is conveyed to the tail end of the production line; and sucking the glass by a sucking disc, overturning, and vertically leaning against the L-shaped bracket in sequence. According to the method for automatically stacking the plain glass, the conveying distance of each piece of glass on a conveying belt and the distance Sn of the glass moved horizontally again are calculated by a counting encoder on a rotating shaft of the conveying belt and controlled by a PLC, so that the lower surface of the glass is prevented from being scratched, and the glass is prevented from being scratched by each other during stacking.

Owner:TIANJIN NORTH GLASS IND TECHN

Automatic feeding and discharging device for material trays

PendingCN108313743APrevent mutual stickingGuaranteed continuityDe-stacking articlesConveyor partsEngineeringMaterials processing

The invention discloses an automatic feeding and discharging device for material trays. The automatic feeding and discharging device comprises a bottom plate, two belt line mechanisms, a first material frame, a second material frame, a first jacking mechanism and a second jacking mechanism; each belt line mechanism is arranged above the bottom plate through a first supporting plate and a second supporting plate; the first material frame and the second material frame are arranged on the two belt line mechanisms in parallel; the first material frame is used for containing the material trays loaded with materials, and each first supporting plate is provided with a first bearing mechanism for bearing the material trays loaded with the materials; the second material frame is used for containingthe empty trays, and each second supporting plate is provided with a second bearing mechanism for bearing the empty trays; and the first jacking mechanism is arranged below the first material frame,and the second jacking mechanism is arranged below the second material frame. According to the automatic feeding and discharging device, feeding and automatic stacking of the empty trays in an onlinestate can be realized, continuity of material processing is guaranteed, the production efficiency is improved, and the feeding and discharging device can adapt to the automatic processing of materials.

Owner:深圳市冠阳科技有限公司

Automatic color plate stacking machine

ActiveCN105059993ARealize automatic stackingGuaranteed identityArticle deliveryStack machineEconomic benefits

The invention relates to an automatic color plate stacking machine. The stacking machine comprises a square machine frame, a lifting device, a conveying device, a clamping and horizontally-moving device and a swinging and rotating device. The lifting device is arranged on one lateral side of the square machine frame. The conveying device is arranged at the bottom of the square machine frame. The clamping and horizontally-moving device is arranged at the position, above the conveying device, of the lifting device. The swinging and rotating device is arranged outside the clamping and transversely-moving device. The lifting device can drive the clamping and horizontally-moving device to horizontally move up and down. The outer side of the clamping and horizontally-moving device is connected with the swinging and rotating device. The swinging and rotating device can swing and rotate up and down. When the clamping and horizontally-moving device and the swinging and rotating device are both in the horizontal state, the clamping and horizontally-moving device can horizontally move forwards and backwards on the swinging and rotating device. The stacking machine is scientific in design and can automatically complete stacking of a color steel machine. Manpower and material resources are greatly saved. The work efficiency is improved. The economic benefits of enterprises are improved.

Owner:天津市新宇彩板有限公司

Shaping manipulator for storage battery

PendingCN111591776ARealize automatic stackingReduce manufacturing costStacking articlesDe-stacking articlesControl engineeringManipulator

The invention discloses a shaping manipulator for a storage battery. The shaping manipulator for the storage battery comprises a rack, an overturning manipulator mounted on the rack in a manner of rotating in a direction perpendicular to the transverse direction, and a transverse shaping assembly mounted on the rack in a manner of transversely sliding; and the overturning manipulator is used for receiving stacked parts and longitudinally shaping the stacked parts, and the overturning manipulator rotates to convey the stacked parts to the transverse shaping assembly for transverse shaping of the stacked parts. According to the shaping manipulator, the stacked parts can be reshaped in all directions, and the stacked parts with regular shapes are output, so that the automatic stacking of a stacking manipulator is realized, the labor intensity is reduced, the production efficiency of a continuous plate coating line is improved, and the production cost of an enterprise is reduced.

Owner:中国船舶重工集团衡远科技有限公司

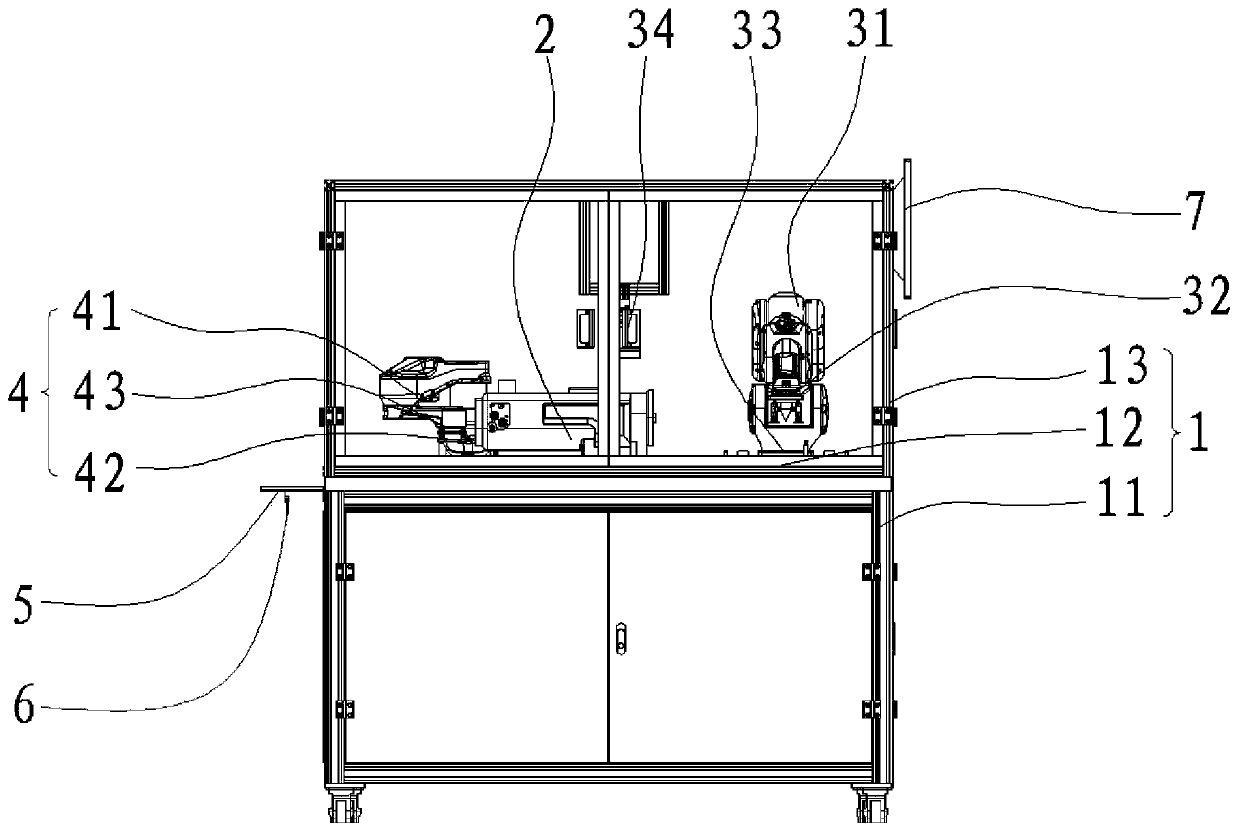

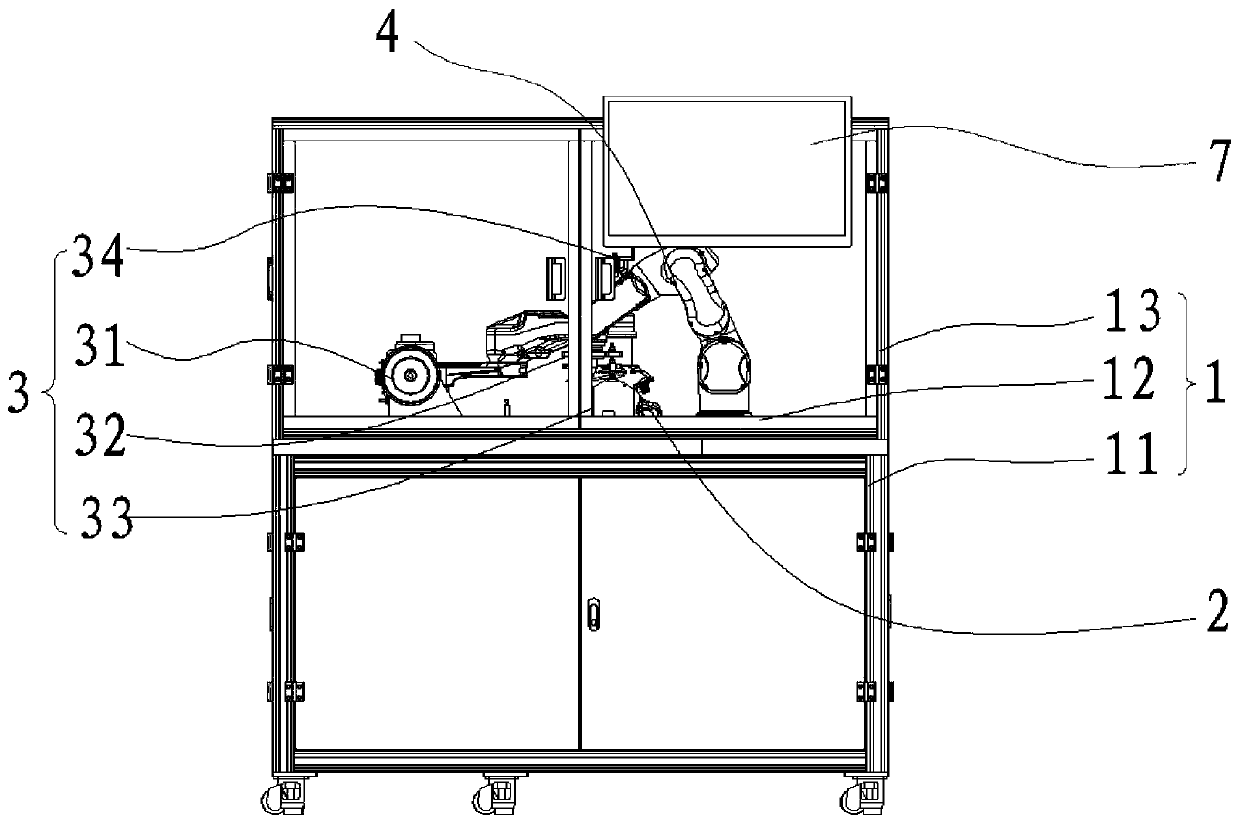

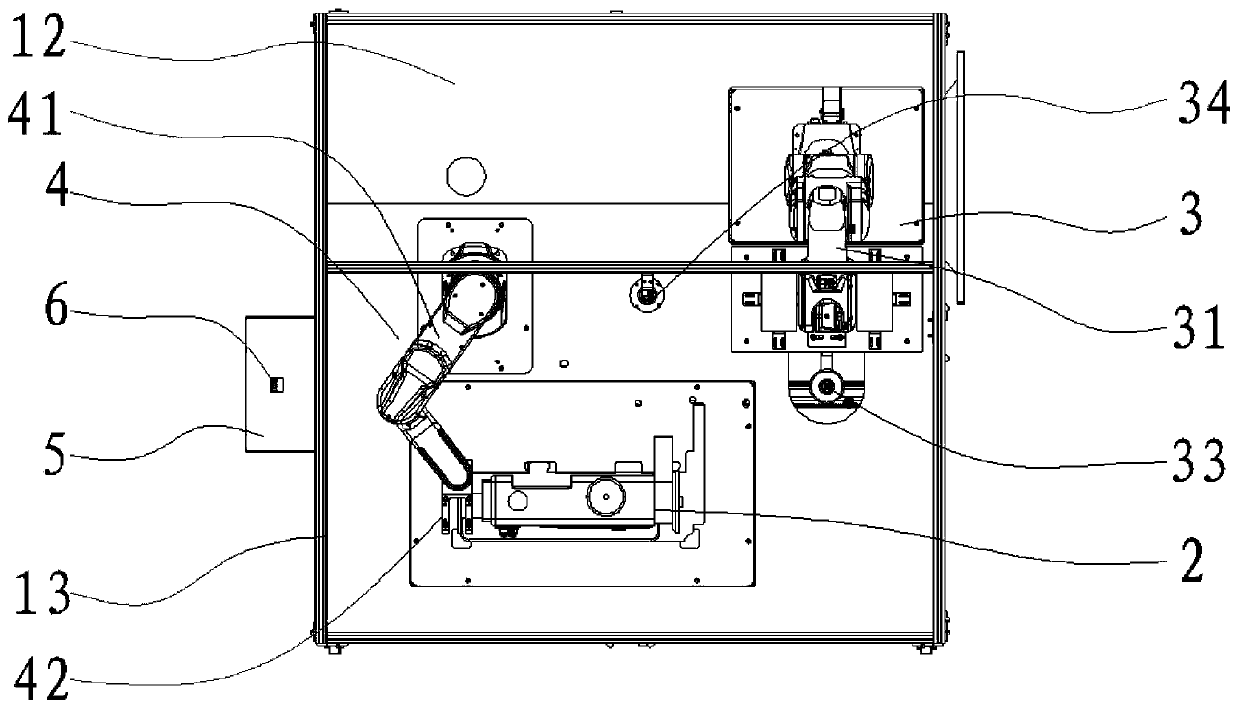

Robotic sewing device

PendingCN110735236AAchieve stackingImprove work efficiencyProgramme-controlled sewing machinesEngineeringSewing machine

The invention relates to the technical field of sewing equipment, in particular to a robotic sewing device. The robotic sewing device comprises a sewing platform, a servo sewing machine, a feeding mechanism, a sewing robot, a platform stacking vision region, a holding platform and a processor. The servo sewing machine is used for sewing cut pieces. The feeding mechanism is used for grasping the cut pieces to a stacking region on the sewing platform to complete stacking of the multiple cut pieces. The sewing robot for conveying the cut pieces stacked on the platform stacking vision region conveys the grasped cut pieces to the servo sewing machine to sew, and conveys the stitched cut pieces to the holding platform. The platform stacking vision region is arranged on the sewing platform. The holding platform is fixed to the sewing platform. The processor is electrically connected with the servo sewing machine, the feeding mechanism and a sewing robot mechanism. The robotic sewing device has the advantages that the feeding mechanism grasps the cut pieces to achieve stacking of the multiple cut pieces, the sewing robot conveys the stacked cut pieces to the servo sewing machine to sew, the stitched cut pieces are conveyed to the holding platform, automatic cut piece stacking, feeding and sewing are realized, and accordingly, the working efficiency of a robot sewing work station is improved.

Owner:重庆智能机器人研究院 +1

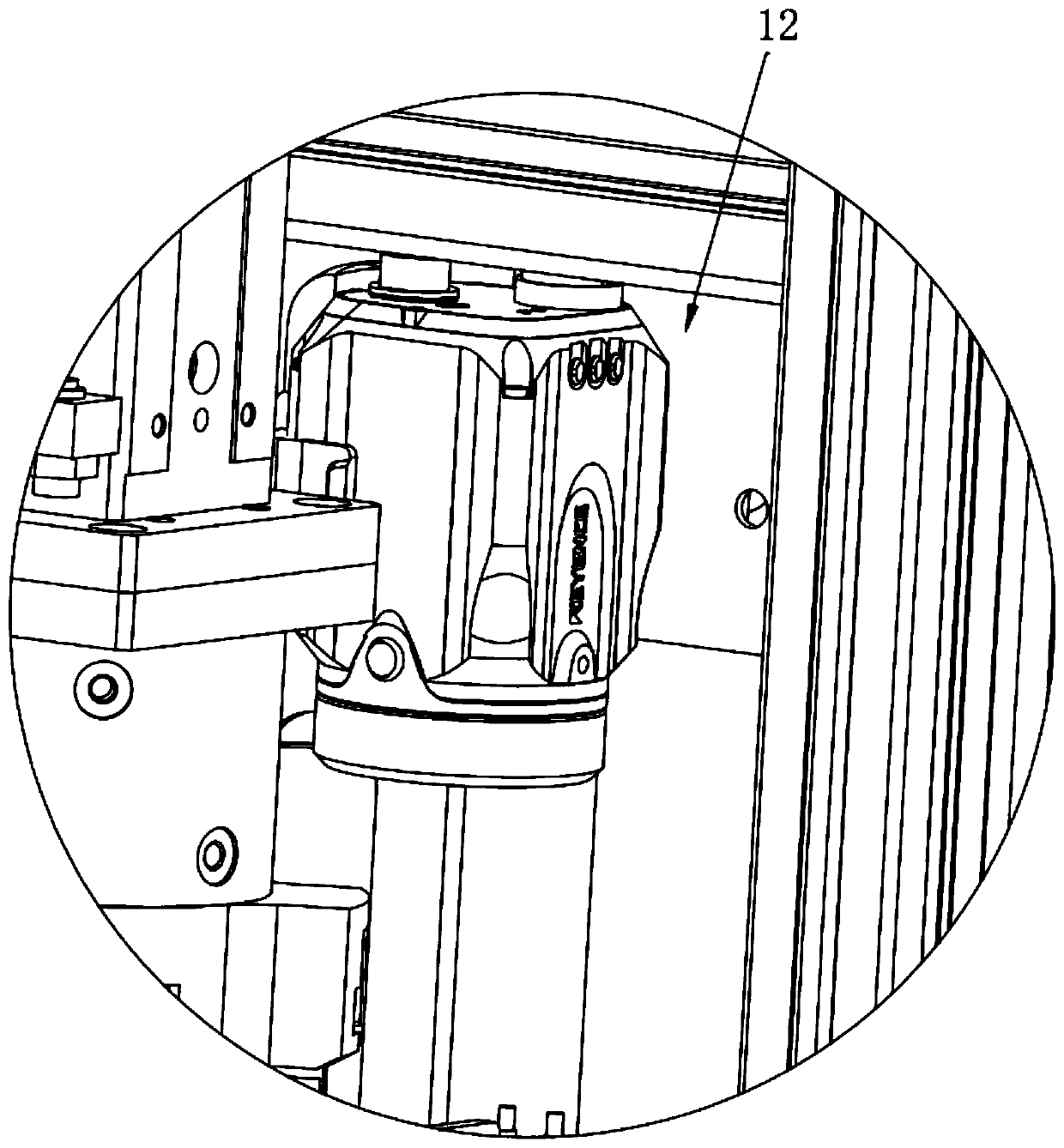

Full-automatic laser marking device for engine cylinder ring

PendingCN109894739ASimple structureEasy to useWelding/cutting auxillary devicesAuxillary welding devicesEngineeringButt joint

The invention relates to a full-automatic laser marking device for an engine cylinder ring. The full-automatic laser marking device is composed of a feeding mechanism, an executing mechanism and a discharging mechanism which are sequentially arranged; the executing mechanism comprises a second welding machine frame and a cover shell assembly, a second working table plate is arranged on the secondwelding machine frame, and a conveying material blocking mechanism, a clamping turnover mechanism, a movable clamping mechanism, a clamping mechanism, a laser marking mechanism, a conveying mechanismand a finished product detection mechanism which are in butt joint with the discharging port of a vibration disc are sequentially arranged on the second working table plate; and a CCD detection cameraand a discharging sliding table used for feeding a material box of the discharging mechanism are further arranged on the cover shell assembly. According to the full-automatic laser marking device, the structure is simple, the use is convenient, and the processes of cylinder ring material part feeding, identification of positive and negative, marking, moving, detecting marking quality, and discharging the material box are fully automated, so that the investment of manpower resources of enterprises is solved, the two hands of workers are liberated, the automation degree is high, time and laborare saved, and the production efficiency of enterprises is effectively improved.

Owner:无锡蓝智自动化科技有限公司

Sheet counter and working method thereof

ActiveCN101439768ARealize automatic stackingMeet the needs of automatic packagingPaper article packagingPackaging automatic controlEngineeringDual axis

The invention relates to a sheet counter capable of arranging a plurality of sheets of sanitary towels into stacks to be conveyed to a packaging bag and a working method for the sheet counter. A belt pulley adjusting mechanism, a small tension pulley and a large tension pulley are arranged above a wheel fork, wherein a supporting plate is arranged between the belt pulley adjusting mechanism and the large tension pulley; two L-type angle plates form a longitudinal passage oppositely; a handle has an L-type structure and the bottom thereof is connected with a piston in a twin cylinder positioned below a working platform; the upper end face of the handle is matched crossly with a through groove in the longitudinal passage and extends out and retracts under the drive of the twin cylinder; the twin cylinder is connected with a piston in a guide rod cylinder through a liner plate; a twin shaft cylinder is connected with a machine frame wallboard through a baffle plate; one end of a limiting plate is connected with the piston in the twin shaft cylinder; the limiting plate surface is used for blocking a port of the longitudinal passage; an upright moving plate and the upright sides of the two L-type angle plates form a transverse passage oppositely; the twin cylinder is positioned on the table top of the working platform; and the piston of the twin cylinder is connected with a push rod of the transverse passage and drives the push rod to move to and fro in the transverse passage.

Owner:HANGZHOU XINYUHONG INTELLIGENT EQUIP CO LTD

Robot packaging and stacking system and use method

PendingCN110481909ARealize sortingAchieve compactionConveyorsPackaging automatic controlEngineeringRobot

The invention discloses a robot packaging and stacking system and a use method. The robot packaging and stacking system comprises a packaging machine, a bag pressing machine, a weighing and conveyingdevice, a stacking robot and a compacting machine. The weighing and conveying device is located on the right side of the bag pressing machine, and the stacking robot is arranged on the right side of the weighing and conveying device. The compacting machine is arranged behind the stacking robot, and a conveying device is arranged on the lower side. The bag pressing machine comprises a supporting frame, a bag pressing assembly and a vibration conveying device. The supporting frame is erected on the vibration conveying device, and a transmission assembly in the bag pressing assembly drives a pressing assembly to carry out rotary bag pressing. The compacting machine comprises a lifting device, a plate drawing device and a push-on device. A lifting platform in the lifting device is arranged onthe lifting frame in a vertical sliding manner through the lifting assembly. A driving assembly controls a supporting plate to relatively move on the lifting platform left and right. According to therobot packaging and stacking system and the use method, the layout is compact, packaging bag material arrangement and compaction are achieved, materials are prevented from being accumulated in packaging bags, the packaging bags are more compact, and weighing is more precise.

Owner:HEFEI EAGLE AUTOMATION ENG TECH +1

Tea fermentation apparatus

ActiveCN108464366AImproved stackingIntelligentPre-extraction tea treatmentContinuous fermentationControl system

The invention discloses a tea fermentation apparatus. The tea fermentation apparatus comprises a rotating mechanism, a fermenting box, a humidifying box, and a control system; the rotating mechanism comprises an electric rotating shaft, a connecting rod I, a connecting rod II, a rotating column I, a rotating column II, and a position locater; and the fermenting box is arranged with a whipping mechanism, a trigger mechanism, a box cover, a fixed column I, and a fixed column II. Piling way of Liubao tea is improved by the tea fermentation apparatus so that temperature and humidity control over piling and fermentation can be suitably performed; moreover, automatic humidifying and heating can be achieved according to different changes of temperature and humidity. In addition, monitoring on Liubao tea becomes more intelligent, and automatic pile turning is realized. The tea fermentation apparatus is capable of carrying out continuous fermentation without stopping caused by different batches. The tea fermentation apparatus realizes refrigeration by adopting dry ice, and thus, the tea fermentation apparatus has the characteristics of high refrigeration capacity, convenient and flexible usage, and fast in mechanical refrigeration and cooling rate; moreover, the tea fermentation apparatus also has the advantages of good refrigeration effect, and convenient storage and transportation.

Owner:防城港市丰禾曲辰农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com