Novel automatic board stacking machine

A stacker, automatic technology, applied in the stacking, transportation and packaging of objects, destacking of objects, etc., can solve the problems of tight human resources, high labor intensity and high cost, and save human and material resources and resources. The effect of waste, neat and beautiful storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

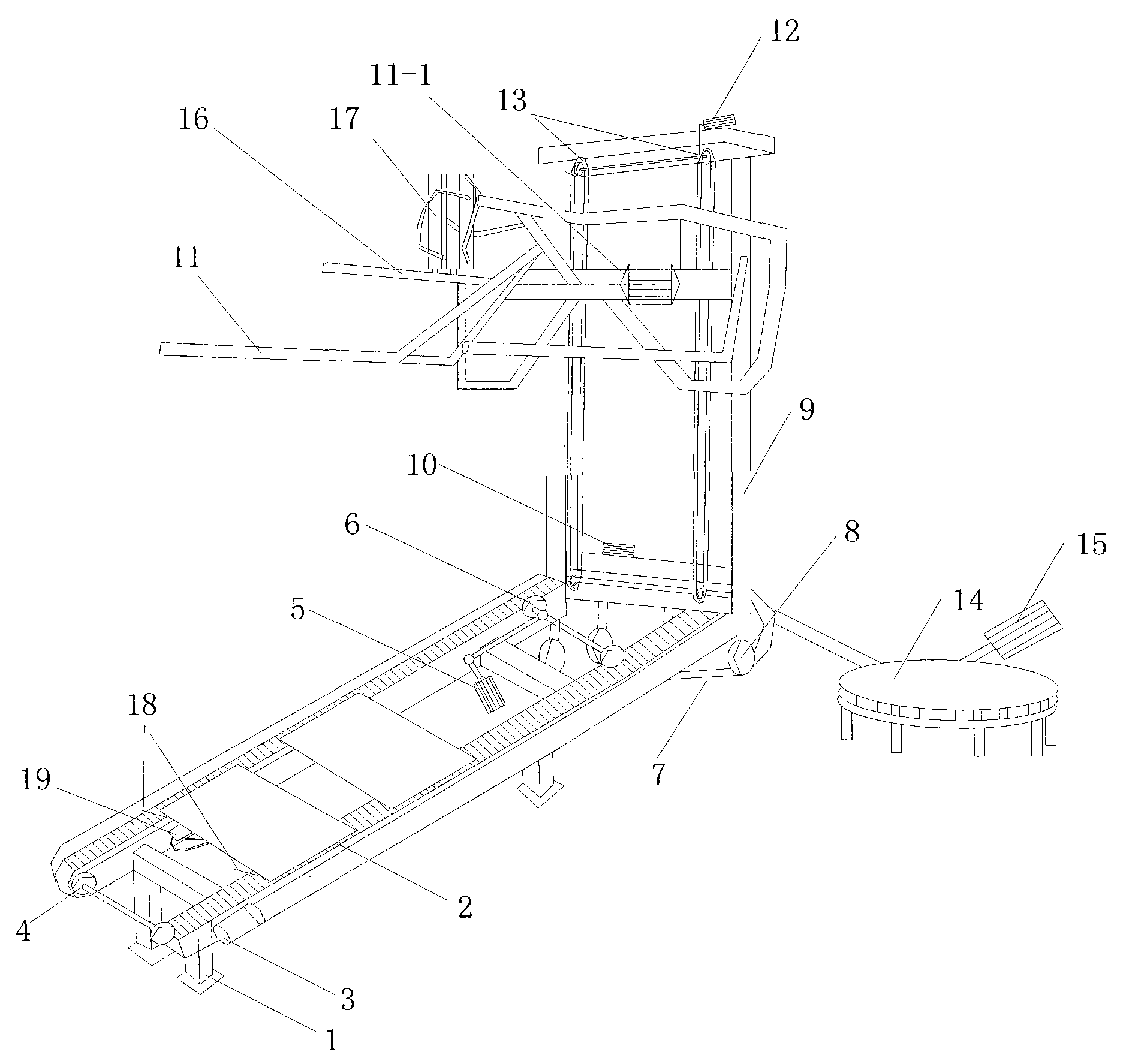

[0011] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: it includes a conveyor frame 1, a conveyor belt 2, a turntable automatic reset switch 3, a driven chain bearing 4, a transmission motor 5, a drive chain bearing 6, a circular track 7, Roller 8, stacker frame 9, rotating motor 10, automatic stacking fork 11, lifting motor 12, transmission chain 13, automatic rotating stacking seat 14, motor 15, bifurcation and merging motor 11-1, connecting rod 16, Platen cylinder 17, stop rod 18 and automatic positioning cylinder 19, conveyor belt 2 is arranged on the top of conveyor frame 1, the two ends of conveyor belt 2 are connected with driven chain bearing 4 and drive chain bearing 6 respectively, and drive chain The central axis of the bearing 6 is connected to the transmission motor 5. One side of the conveyor frame 1 is provided with a turntable automatic reset switch 3. The end of the conveyor belt 2 is provided with a stacker frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com