Patents

Literature

466results about How to "Reasonable and novel structure design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

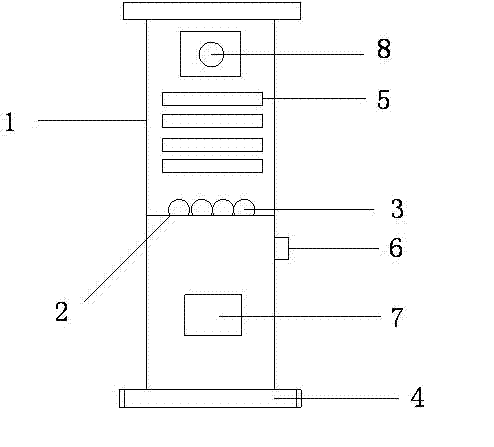

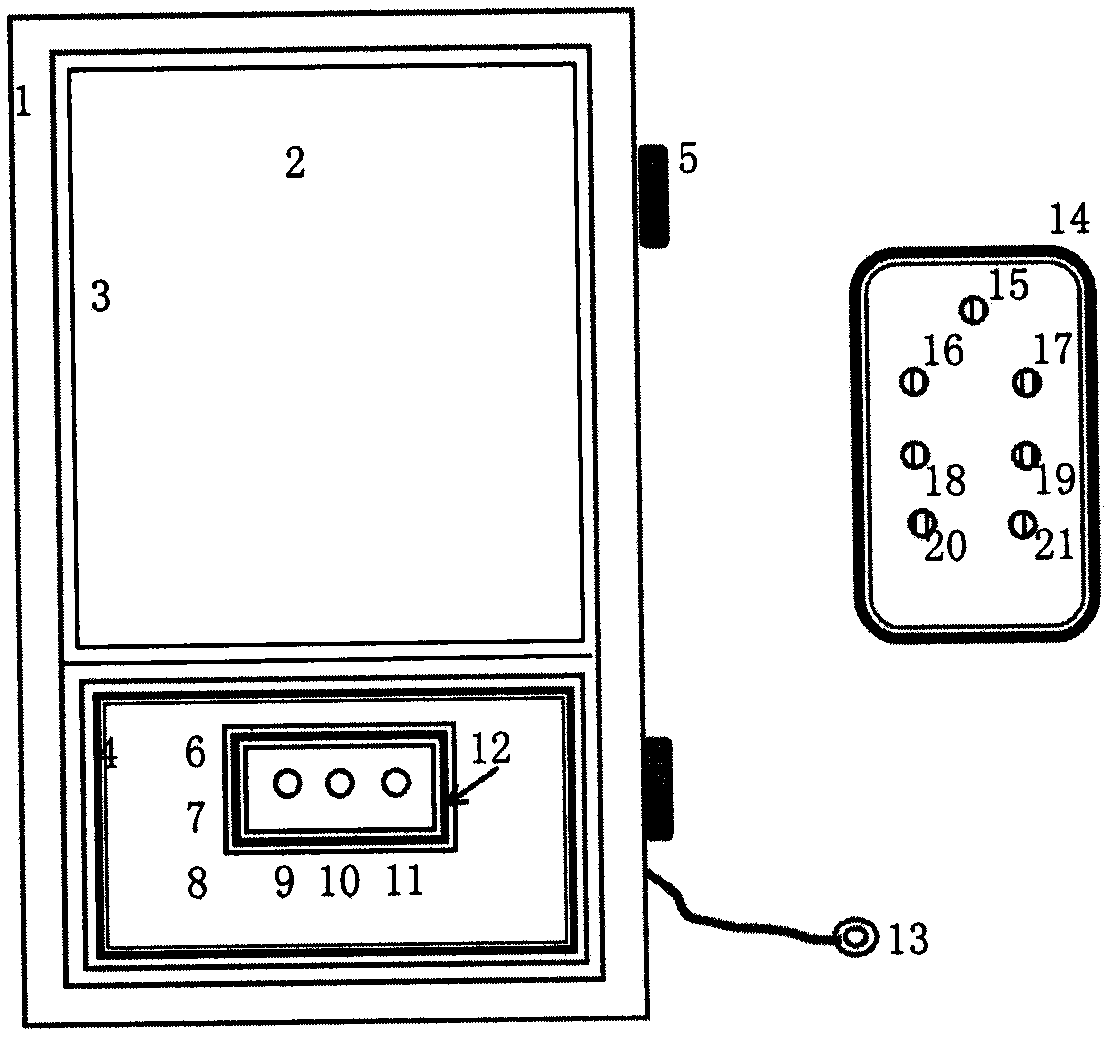

Light emitting diode (LED) lawn lamp with monitoring device

InactiveCN102506348AServe as a reminderReasonable and novel structure designPoint-like light sourceElectric circuit arrangementsEngineeringLight-emitting diode

The invention discloses a light emitting diode (LED) lawn lamp with a monitoring device, which comprises a lamp cylinder, a basal plate, an LED illuminant, a lamp holder, a transparent piece, an infrared induction device and a sound emitting device. The LED lawn lamp with the monitoring device is characterized in that the basal plate is arranged at the middle part of the inner side of the lamp cylinder, the LED illuminant is arranged on the basal plate, the transparent piece is arranged at the middle upper part of the outer wall of the lamp cylinder, the infrared induction device is arranged at the middle lower part of the outer wall of the lamp cylinder, the sound emitting device is arranged at the lower part of the inner side of the lamp cylinder and is connected with the infrared induction device by a conducting wire, the upper part of the lamp cylinder is also provided with a camera, and the camera is connected with the sound emitting device by a conducting wire. According to the LED lawn lamp with the monitoring device, a signal is received by the infrared induction device, and the signal is transmitted to the sound emitting device, so that sound is emitted by the sound emitting device so as to act as a prompting action; meanwhile, the camera extends out, and the operation of shooting is also carried out; and after the operation of shooting is finished, the camera is automatically retracted. According to the LED lawn lamp with the monitoring device, the structural design is novel and reasonable, the installation and the use are convenient, and the application range is extensive.

Owner:SUZHOU JINGLEI PHOTOELECTRIC LIGHTING TECH

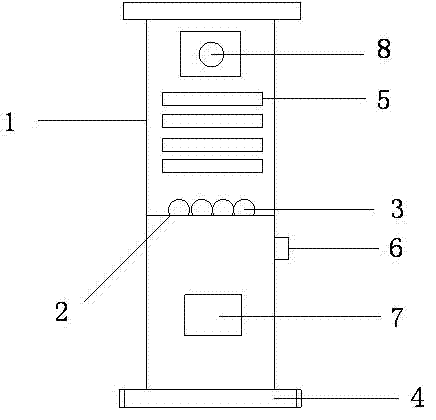

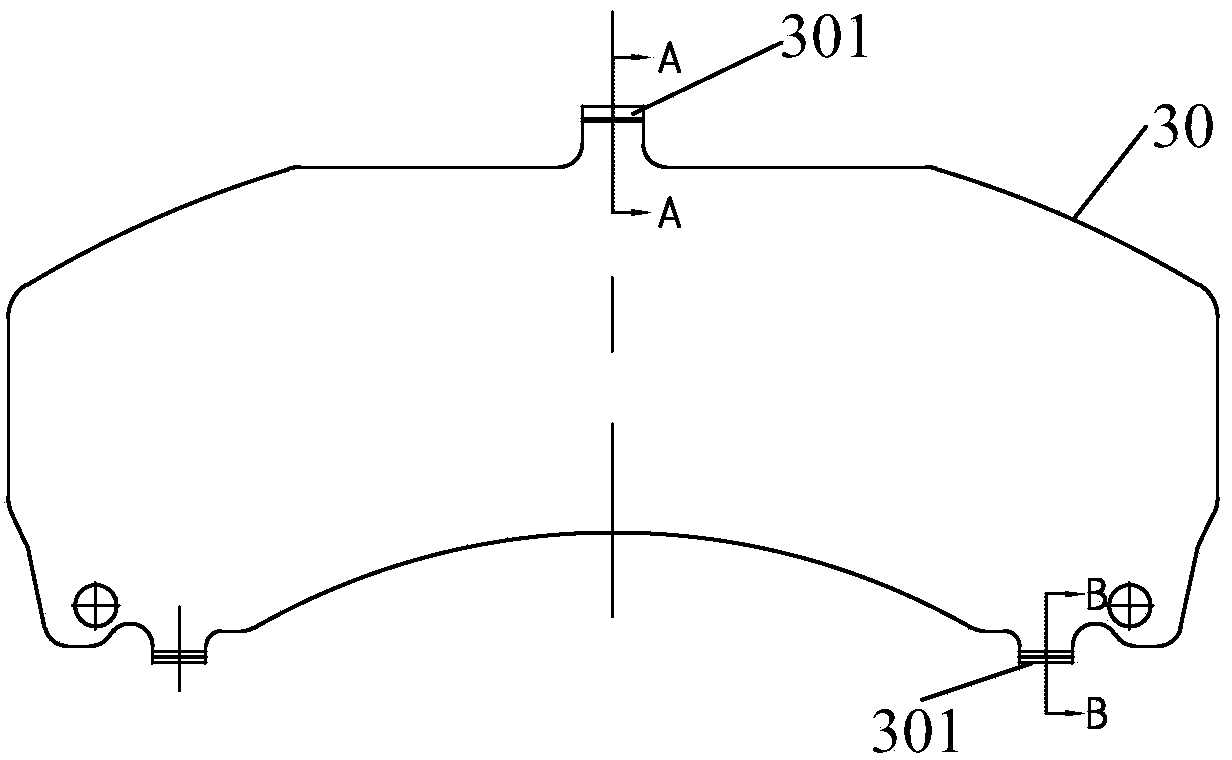

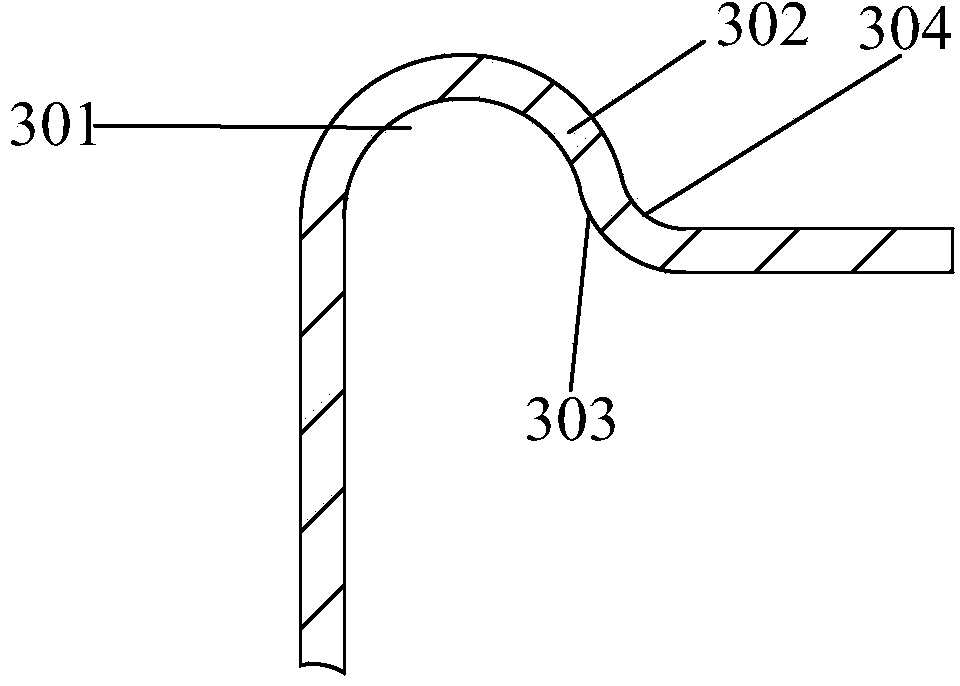

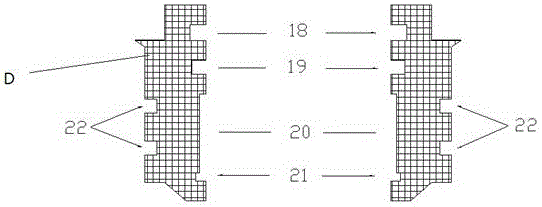

Progressive die of concave bayonet bloop and production method of concave bayonet bloop

ActiveCN103506492AImprove operational safetyStrong order response abilityShaping toolsPunchingEngineering

The invention discloses a progressive die of a concave bayonet bloop and a production method of the concave bayonet bloop. The progressive die of the concave bayonet bloop comprises an upper die and a lower die matched with the upper die, and a bloop material strap goes forward between the upper die and the lower die; in the advancing direction of the bloop material strap, the lower die is sequentially provided with a lower die punching insert core used for punching the bloop material strap, a lower die pre-bending insert core used for concave bayonet half forming, and a lower die blocking foot bending insert core used for blocking foot forming; the upper die is provided with a punching plunger chip matched with the lower die punching insert core, a pre-bending insert core matched with the lower die pre-bending insert core, and a blocking foot bending plunger chip matched with the lower die blocking foot bending insert core. The progressive die is high in production automation degree, productivity and quality of products are greatly promoted, manual operation safety is high, labor intensity is also greatly weakened, manpower and drilling crews are saved, production management is convenient and fast, and customer order response ability is high.

Owner:韶关德嘉汽车零部件有限公司

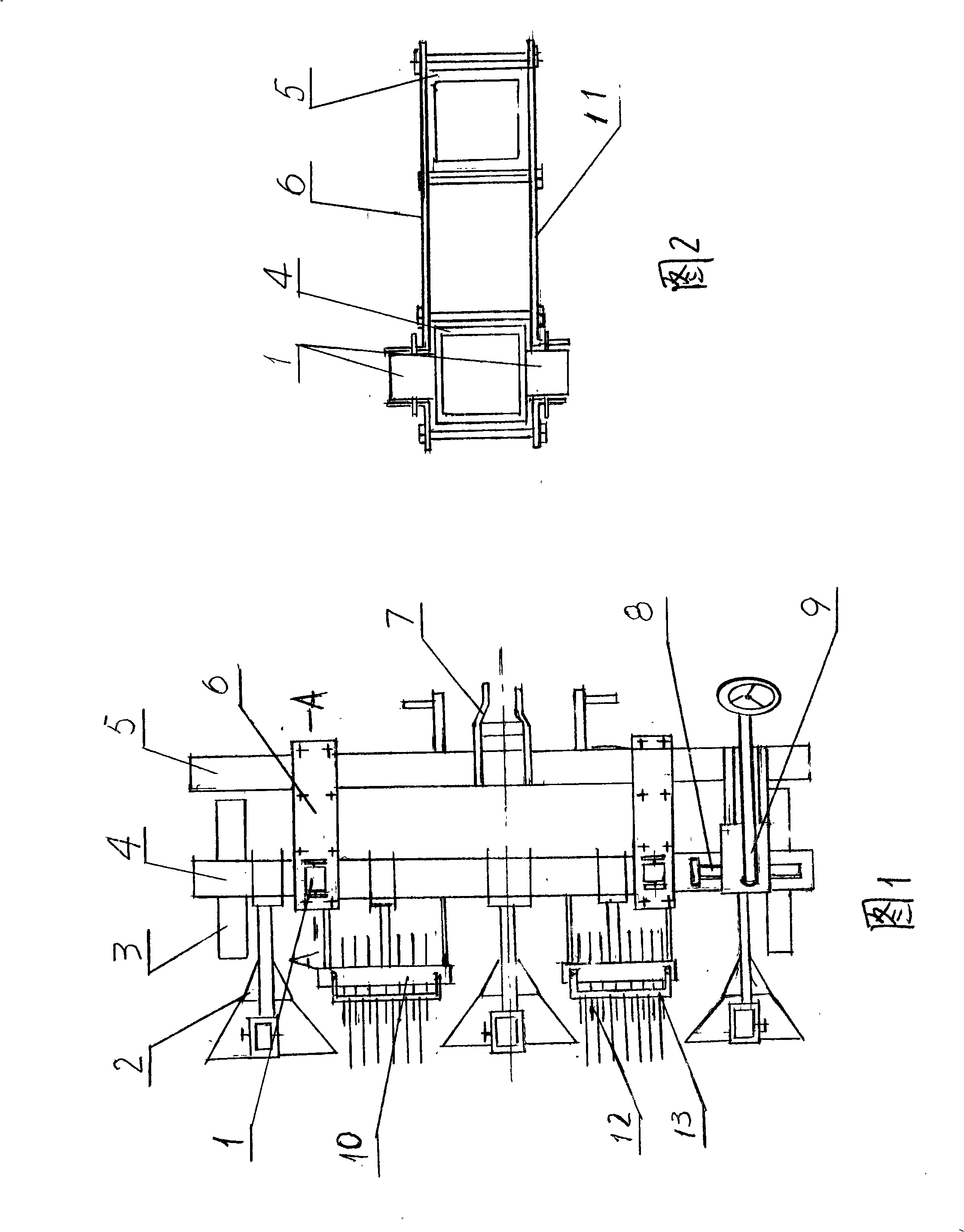

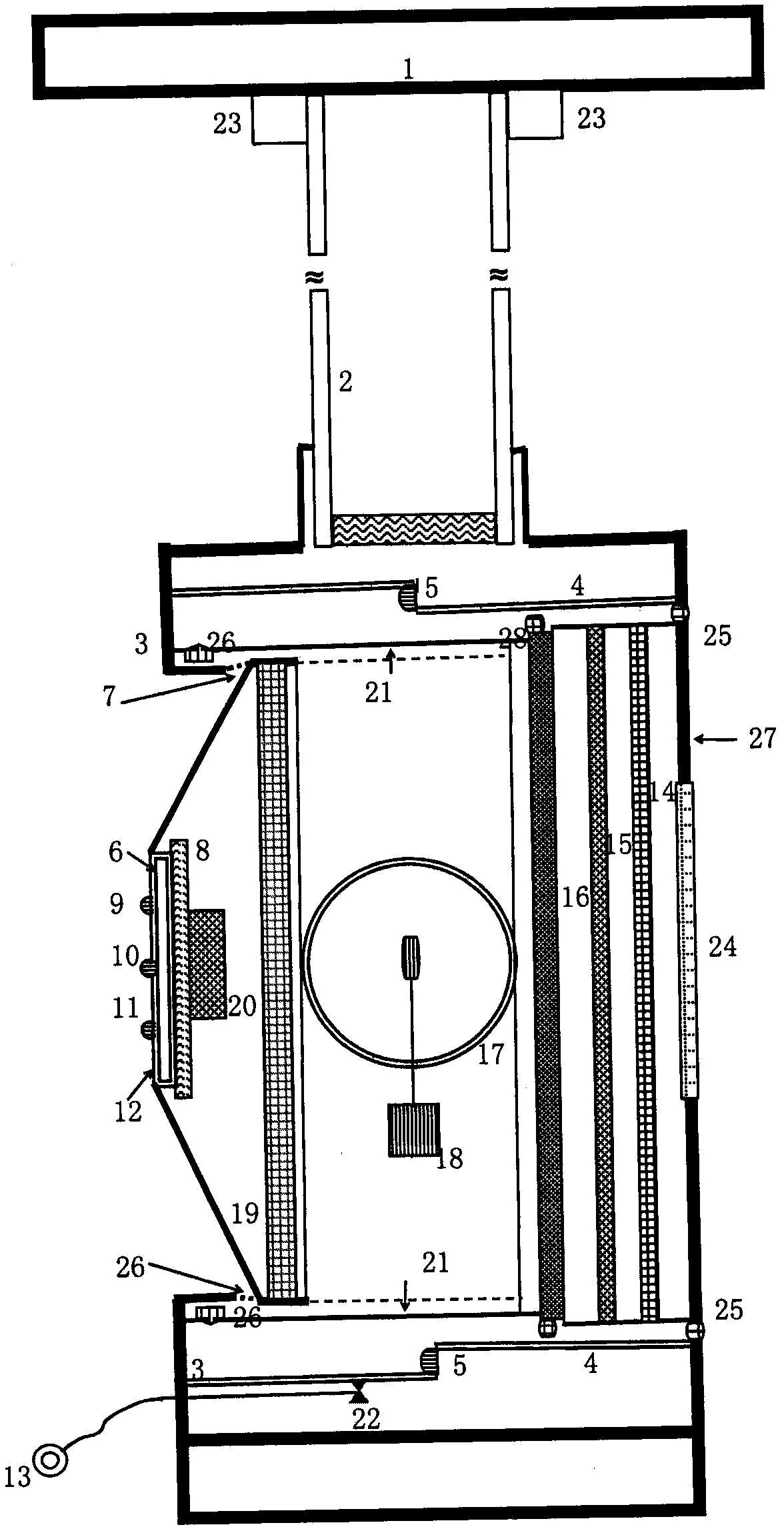

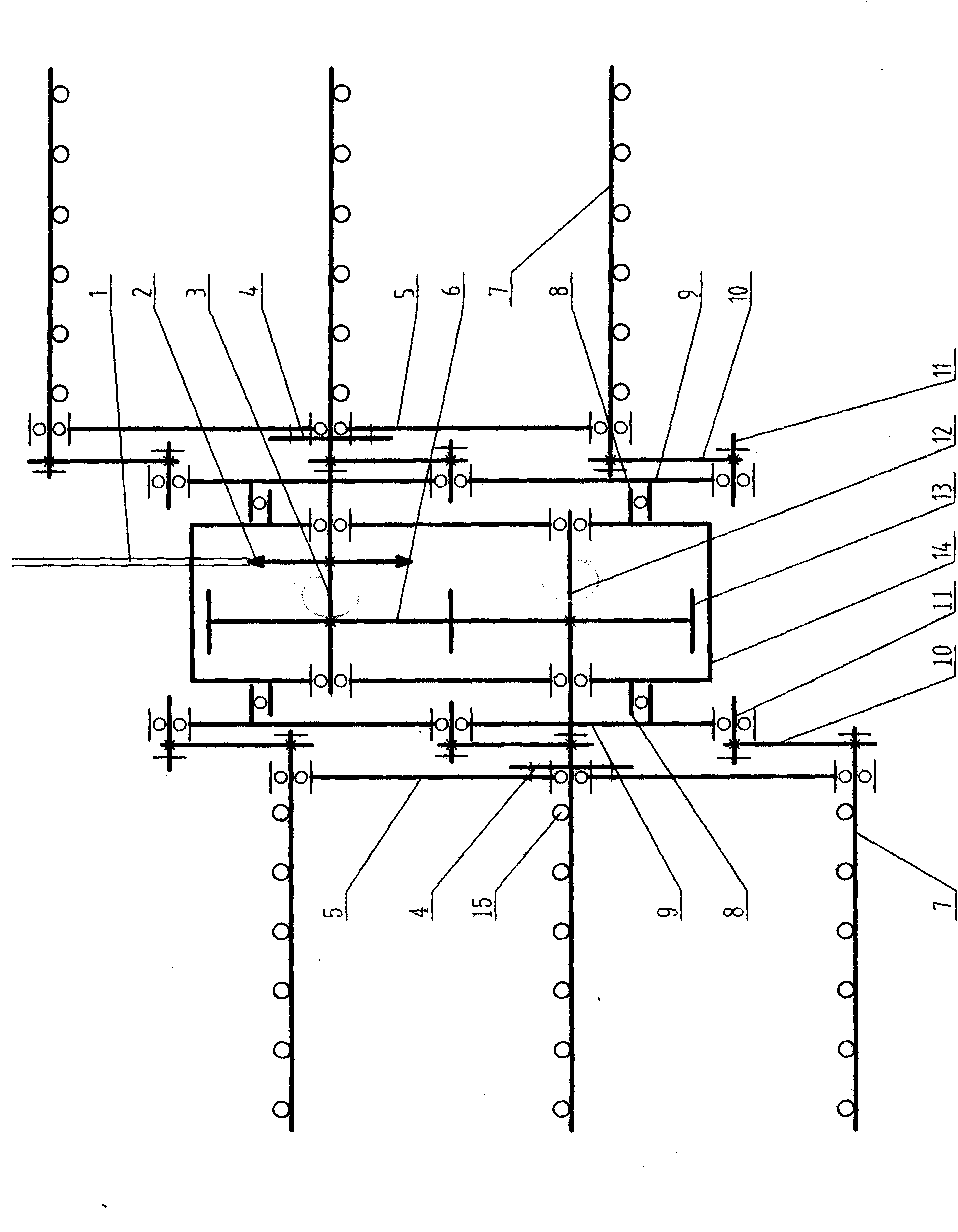

Multi-functional weed and loose soil machine

InactiveCN101331821APromote growth and developmentRaise the ground temperatureSoil-working equipmentsAgricultural engineeringIdler-wheel

The multi-purpose weeding and loose soil machine belongs to the agricultural machinery. An upper fixed connecting plate and a lower fixed connecting plate which are relatively collocated up and down are fixedly arranged on the upper plane and the lower plane at the left side and the right side of a front beam; an idler wheel is arranged on the upper fixed connecting plate and the lower fixed connecting plate; a rear beam is inserted at the position between the upper fixed connecting plate and the lower fixed connecting plate, and the outer surface of the column of the idler wheel on the upper fixed connecting plate is contacted and matched with the upper surface of the rear beam; the outer surface of the column of the idler wheel on the lower fixed connecting plate is contacted and matched with the lower surface of the rear beam; a redirector assembly is fixedly arranged on the front beam; the driving rack of the redirector assembly is connected with the rear beam; a deep loosening and earthing blade assembly is arranged on the rear beam, and the deep loosening and earthing blade assembly is located at the parts of the left side and the right side of a weed extractor assembly; working in the field once, the machine can finish the two operations of weeding as well as deep loosening and ridging and can adapt to the work demand of slopping fields, which is characterized in that the structure is novel and reasonable, the working functions are complete, the working quality is good, the adaptive capacity is strong, the adjustment is simple and convenient, and the use is reliable.

Owner:SUNWU COUNTY NONGFA AGRI MACHINERY

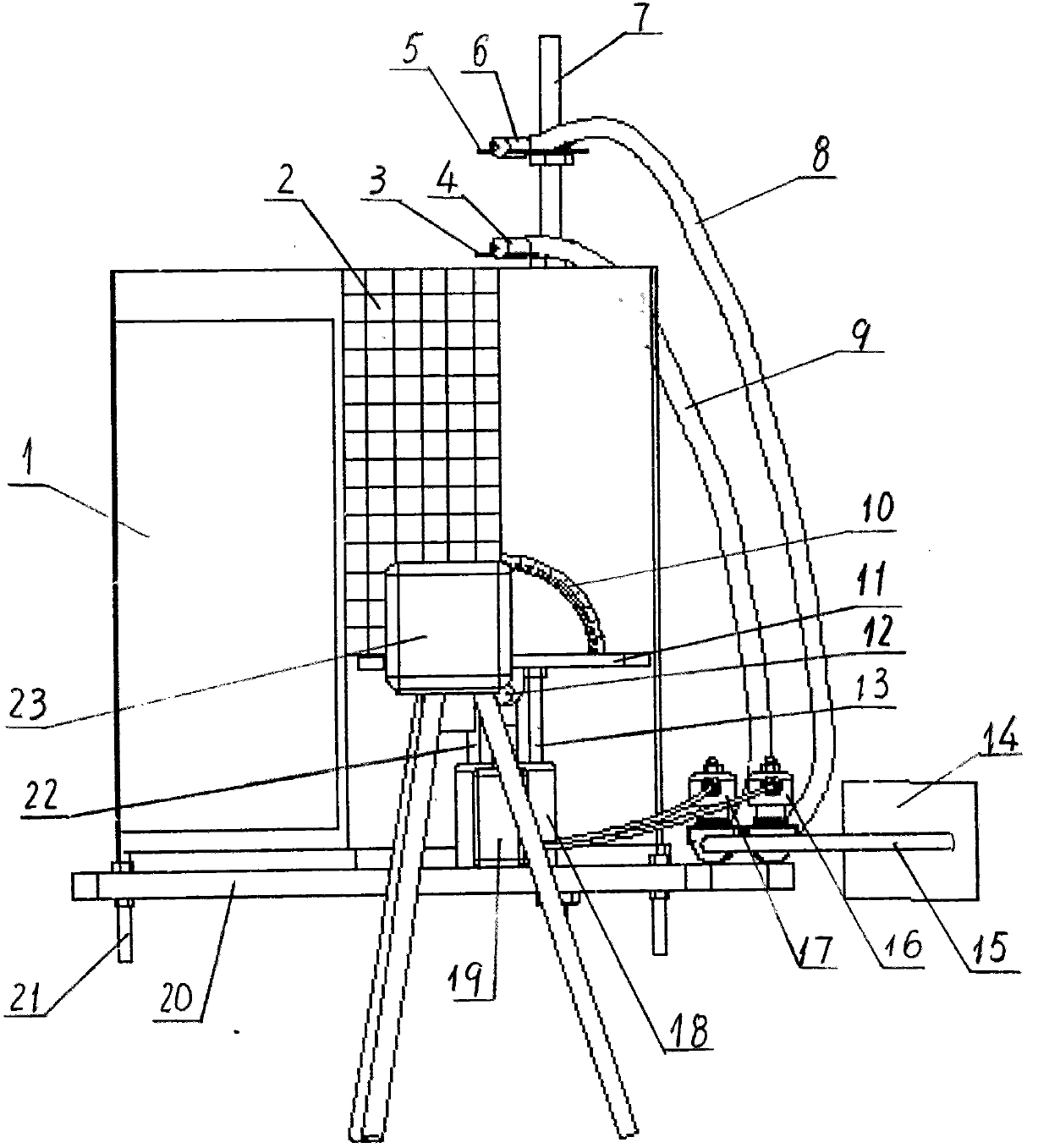

Agricultural material collision recovery coefficient test platform

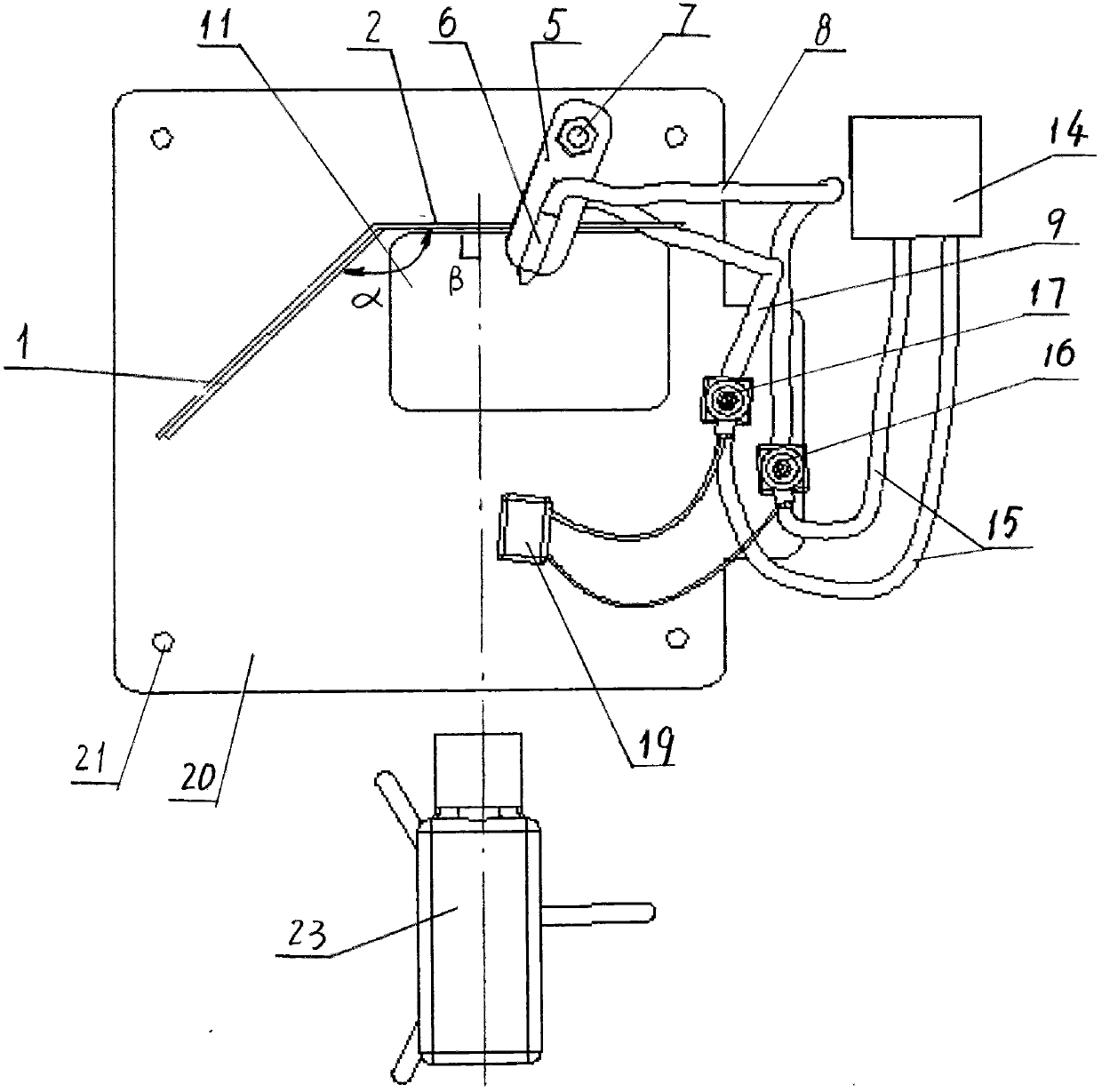

InactiveCN104198146AOvercome and avoid the problem of poor accuracy of test results of collision restitution coefficientImprove test accuracyMachine part testingShock testingPhysical performance testingTime delays

The invention discloses an agricultural material collision recovery coefficient test platform and belongs to physical property test devices. A mirror, a scale wall plate, a height adjusting rod, first and second electromagnetic valves, a support and a time-delay relay are arranged on a base, the mirror and the scale wall plate form a 135-degree included angle to be connected into a whole, the support is hinged to a collision wall plate through a pin shaft, angle adjusting screws A and B are arranged on two sides of the pin shaft on the support respectively, upper and lower supporting plates are disposed on the height adjusting rod, upper and lower adsorption tubes are installed on the upper and lower supporting plates respectively, an air-sucking pump is respectively communicated with the first and second electromagnetic valves through a connecting air tube, a high-speed camera is vertical to the scale wall plate, horizontal adjusting bolt groups are arranged at four corners of the base respectively, the platform can perform testing on collisions of agricultural materials in various forms and conditions and collisions among materials, the structure is novel and reasonable, the adaptive capacity is high, the application range is wide, the usage is reliable, and the test accuracy is high.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

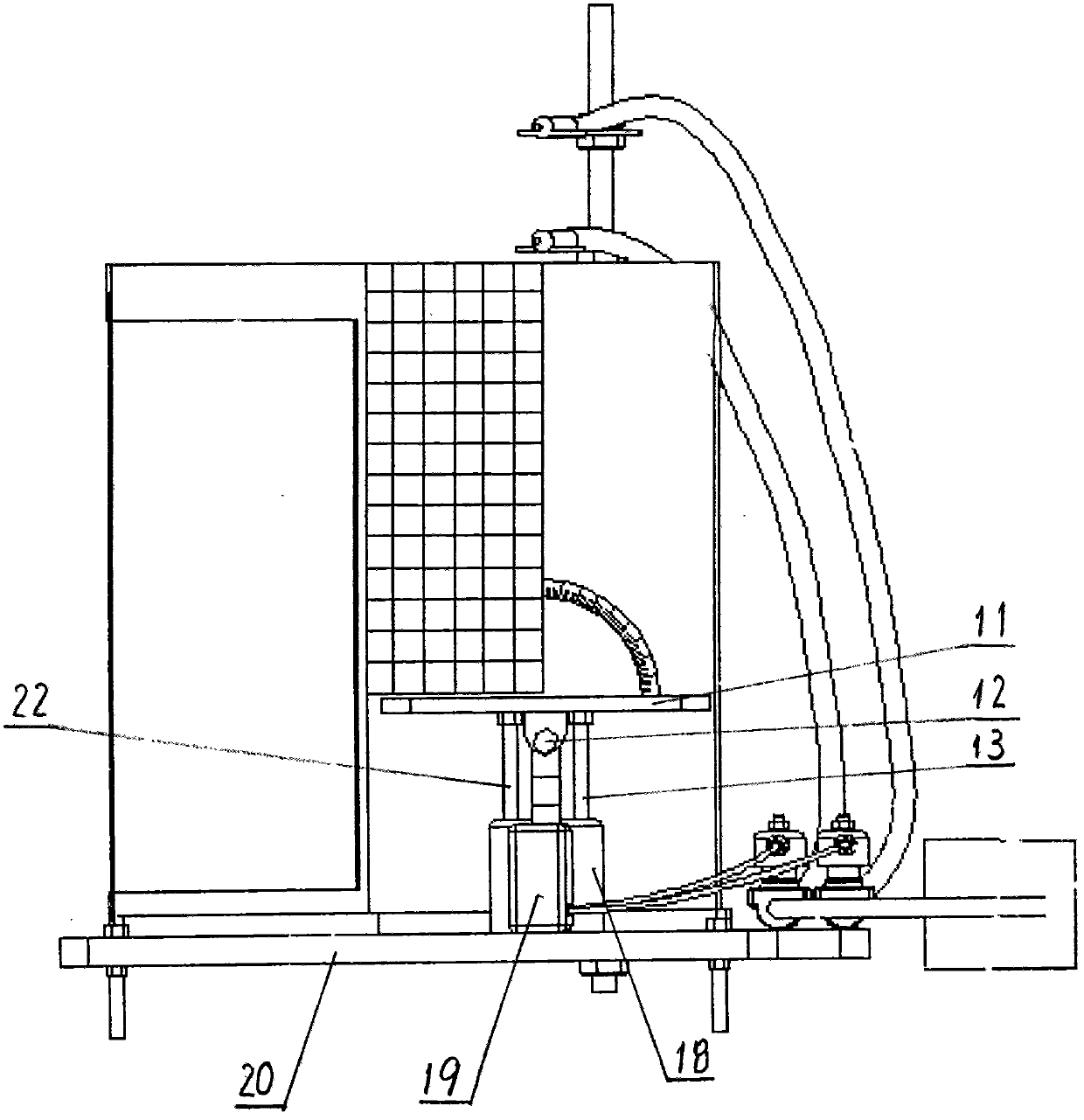

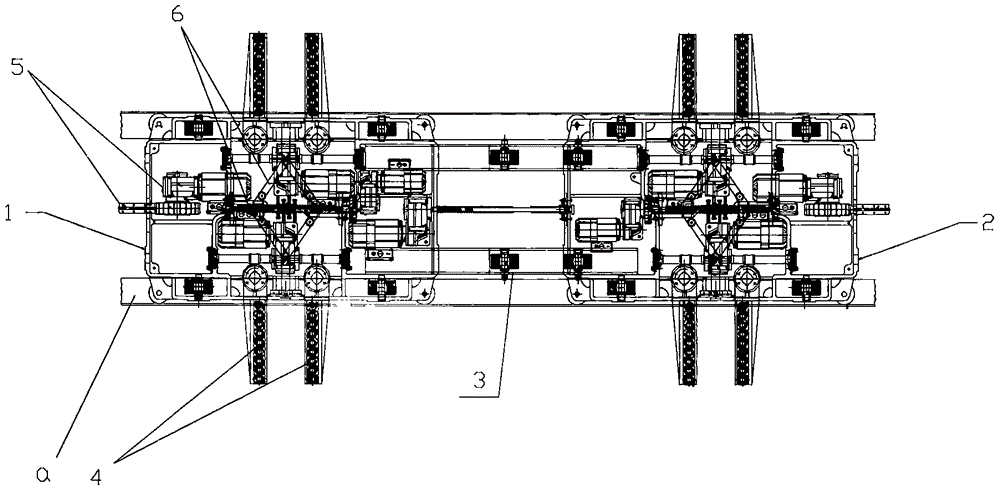

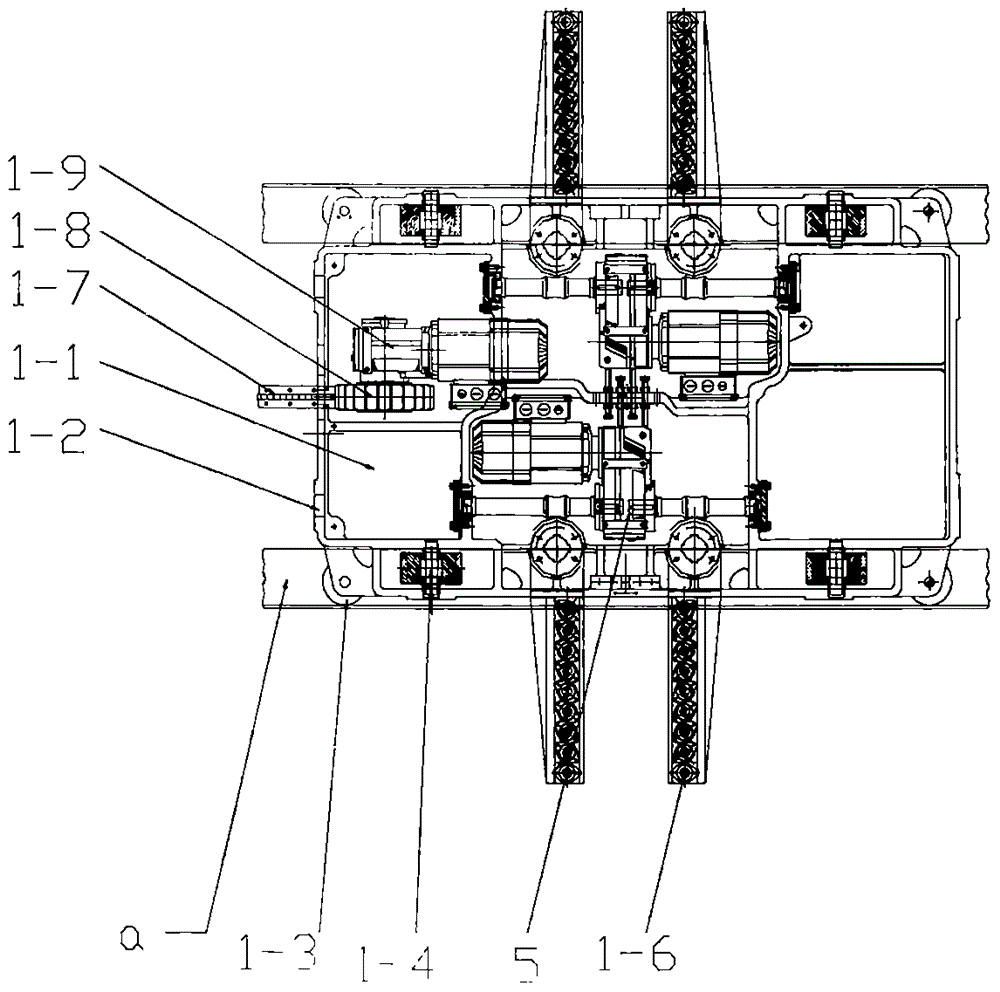

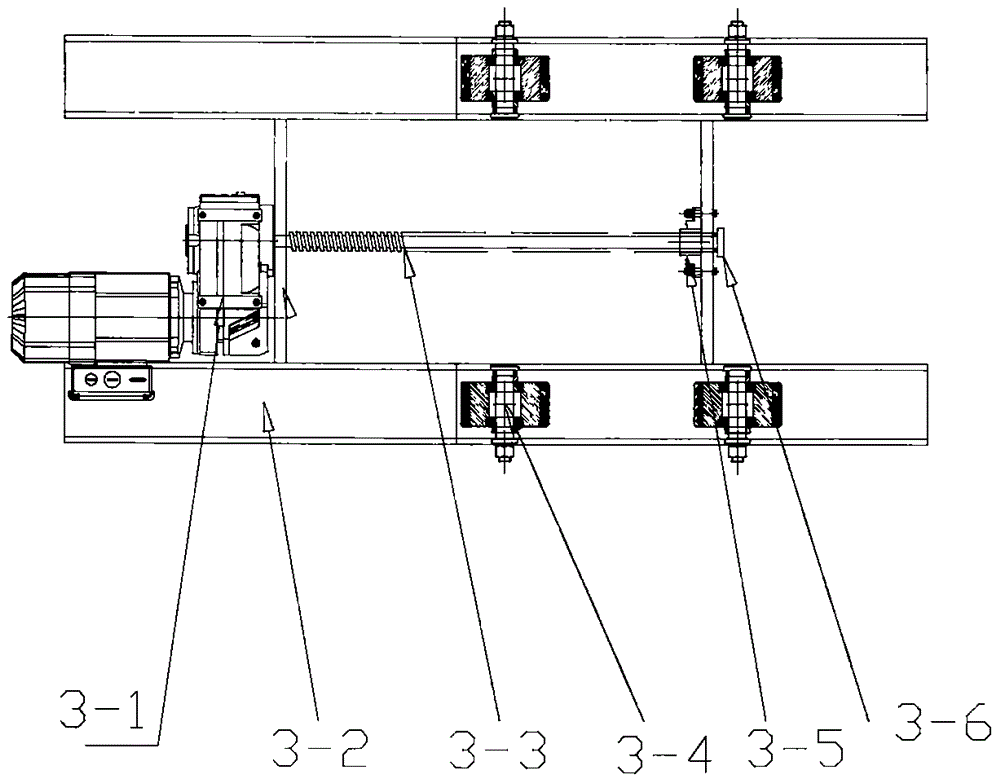

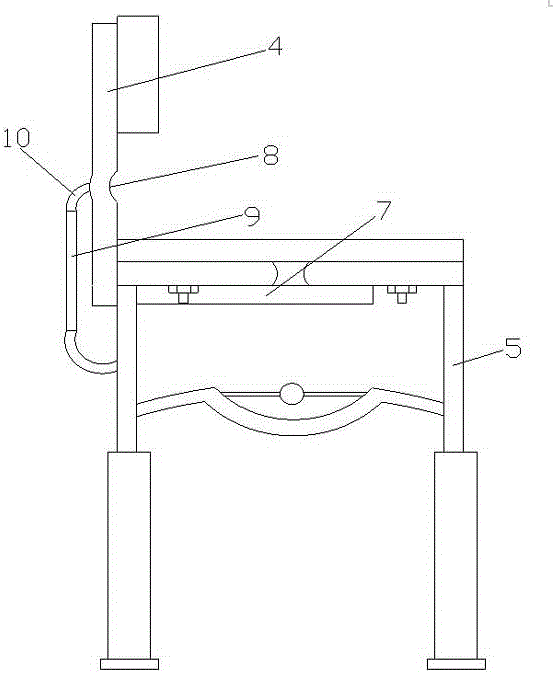

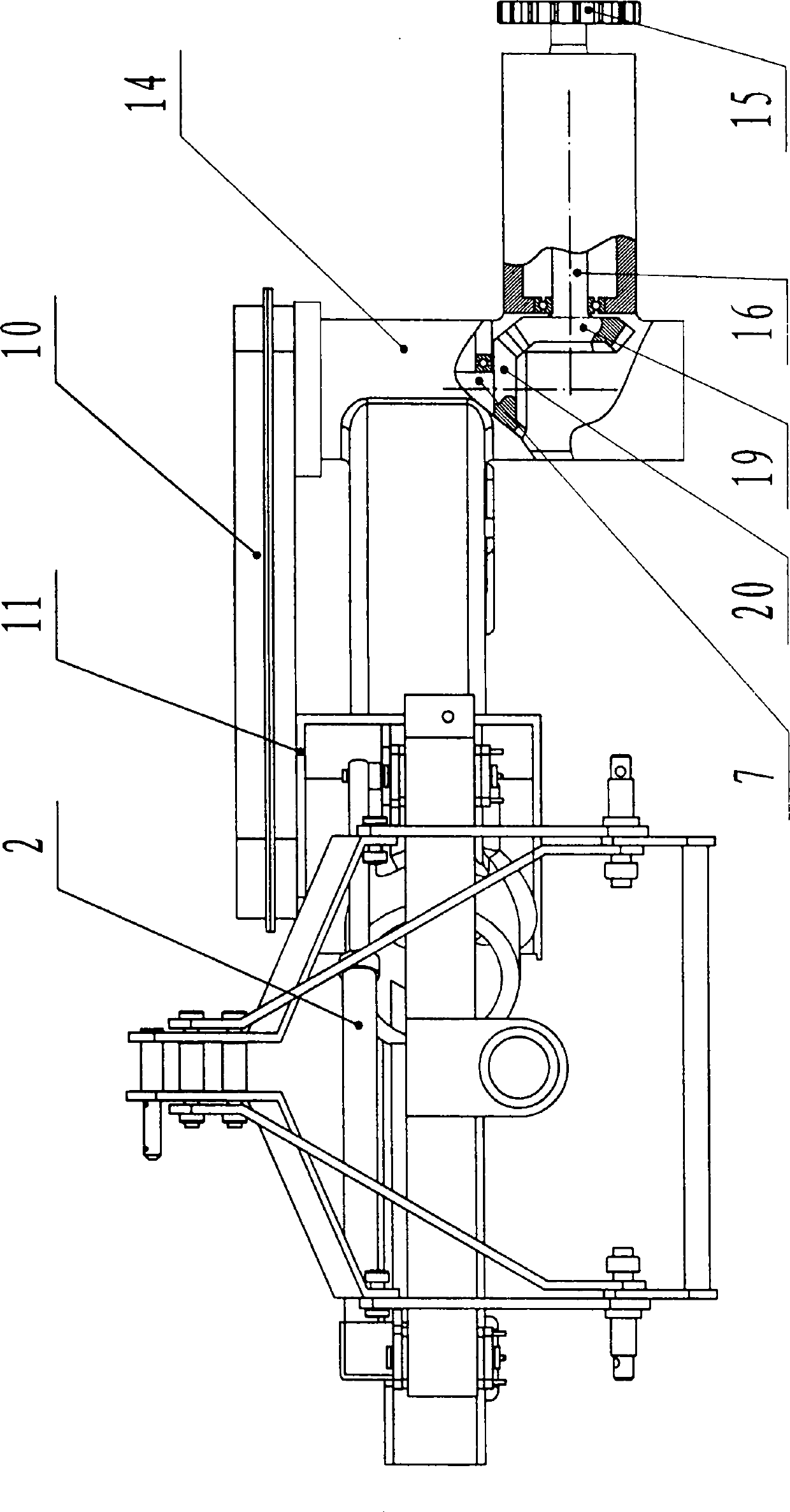

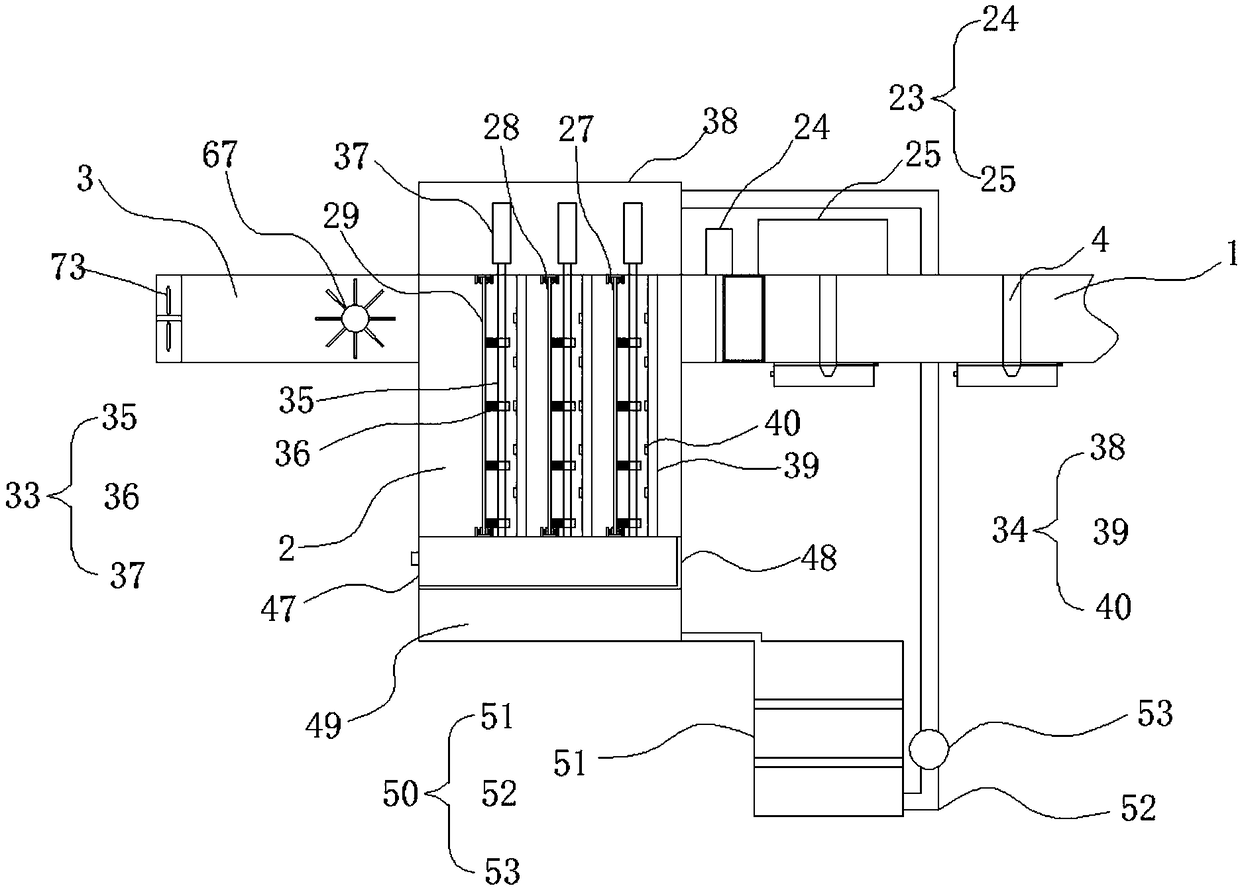

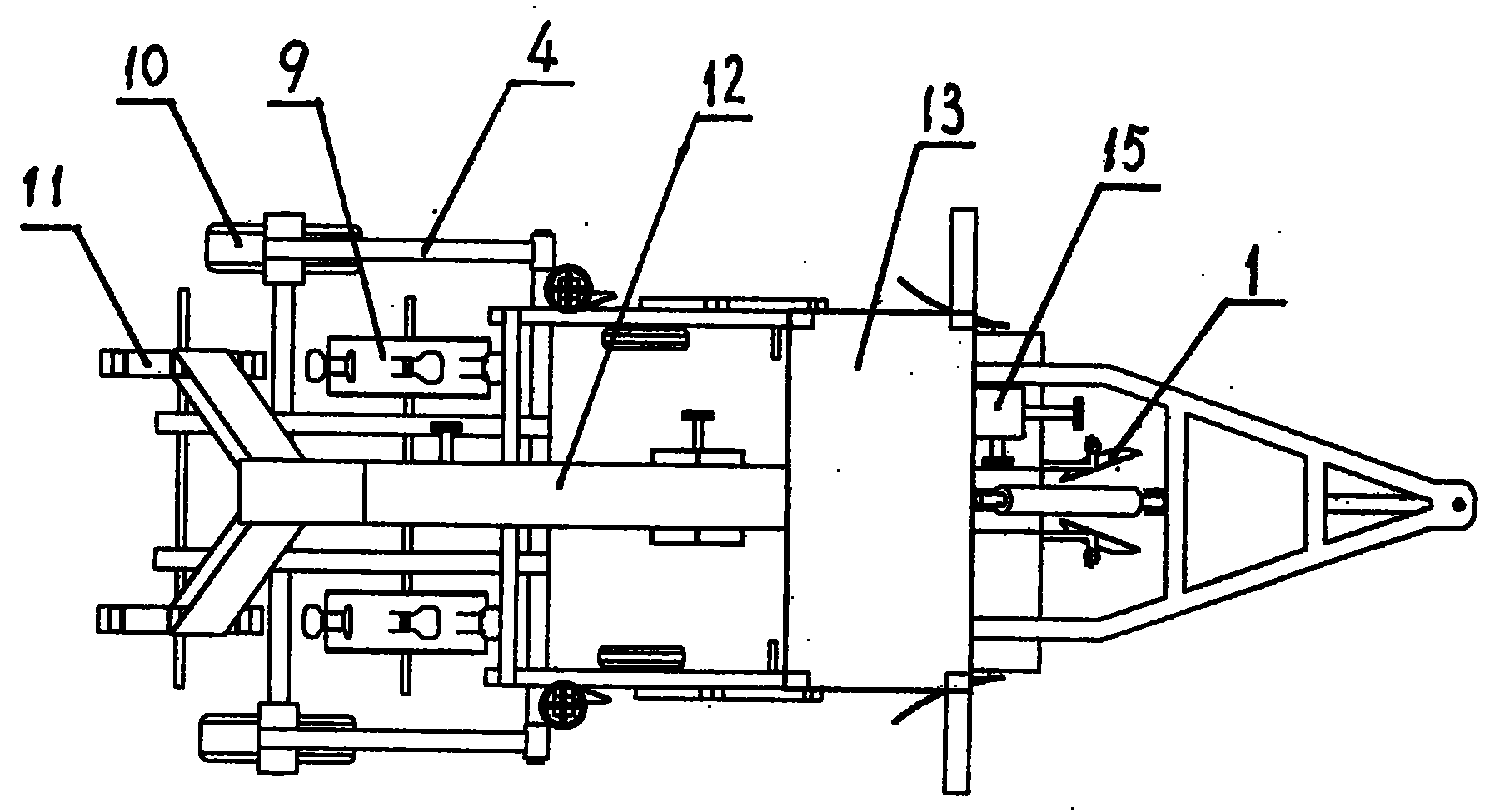

Automobile electric carrying trolley for mechanical stereoscopic garage

InactiveCN105715087AReduce difficultyReasonable and novel structure designParkingsMiscellaneous operationsControl system

The invention discloses an automobile electric carrying trolley for a mechanical stereoscopic garage, relating to the technical field of stereoscopic garages. A front carrying trolley and a rear carrying trolley are correspondingly arranged front and back; the front carrying trolley and the rear carrying trolley are connected by adopting a telescopic connecting mechanism; a vehicle aligning device is arranged in the middle above each of the front carrying trolley and the rear carrying trolley; the front carrying trolley and the rear carrying trolley are identical in structure; the front carrying trolley comprises a planar bearing platform, a vertical bearing platform, a first walking limiting wheel, a second walking limiting wheel, a carrier device, a fixed rack, a walking driving gear and a walking motor; the bottoms of both sides of the front carrying trolley are in sliding connection with a rail through the first walking limiting wheel and the second walking limiting wheel. Drivers are not needed in the whole vehicle parking and taking-out process to carry out miscellaneous operations, such that the electric carrying trolley is time-saving and labor-saving, convenient and efficient, safe and reliable, and remarkable in economic benefit, and therefore the investment is decreased, the difficulty of a control system is reduced, and the reliability is improved.

Owner:WUHAN CARLOS SMART CAR PARKED EQUIP CO LTD

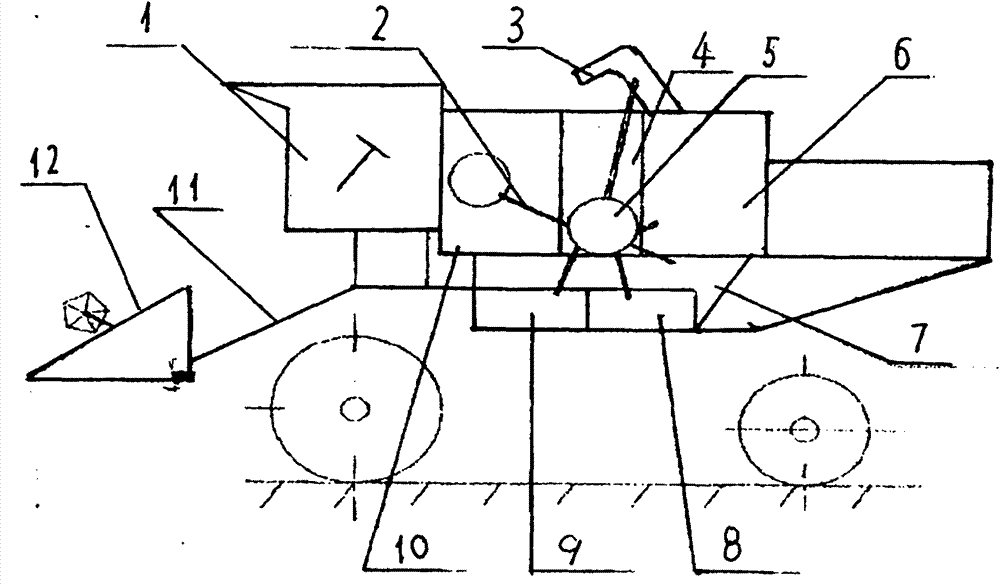

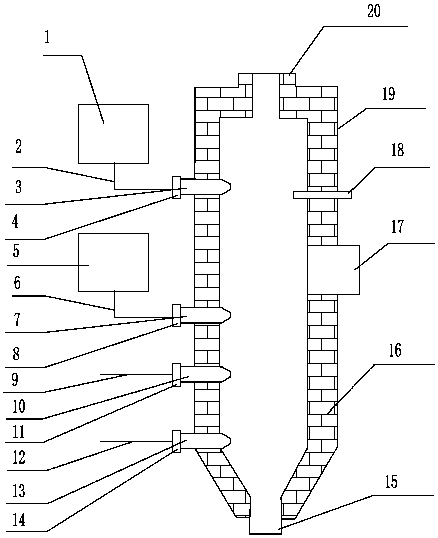

Grain combine harvester with drying function

The invention provides a grain combine harvester with a drying function, and belongs to agricultural machinery. A hot smoke acquiring and distributing device is fitted on a grain harvester combine body and is communicated with a hot smoke exhausting pipe of engine. Hot gas delivering pipes communicate the hot smoke acquiring and distributing device to a threshing device, a separating device, a selecting device, a grain delivering device, a grain bin and a grain discharging device. The heat of hot waste gas exhausted by the engine of the grain harvester combine is utilized, heat is added in each mechanical device for the grains in the grain combine harvester to pass by, accordingly the grains can be dried, parts of free water and combined water in the grains are allowed to evaporate, beneficial conditions are created for post-operation of a drier, and the grain combine harvester has the advantages that novel and reasonable design, fine operating effect, reliability of usage, efficient drying energy and low drying cost.

Owner:侯林山

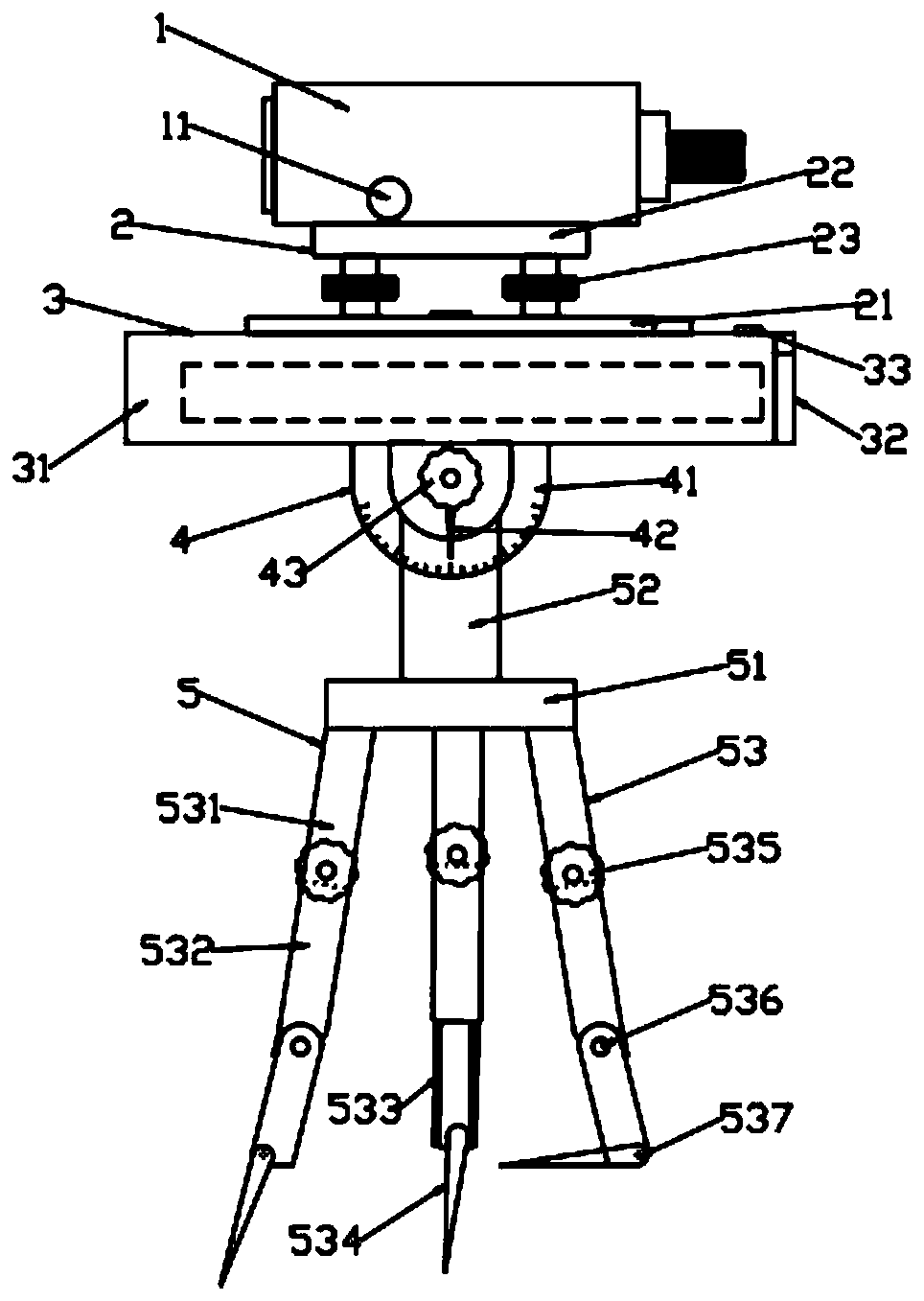

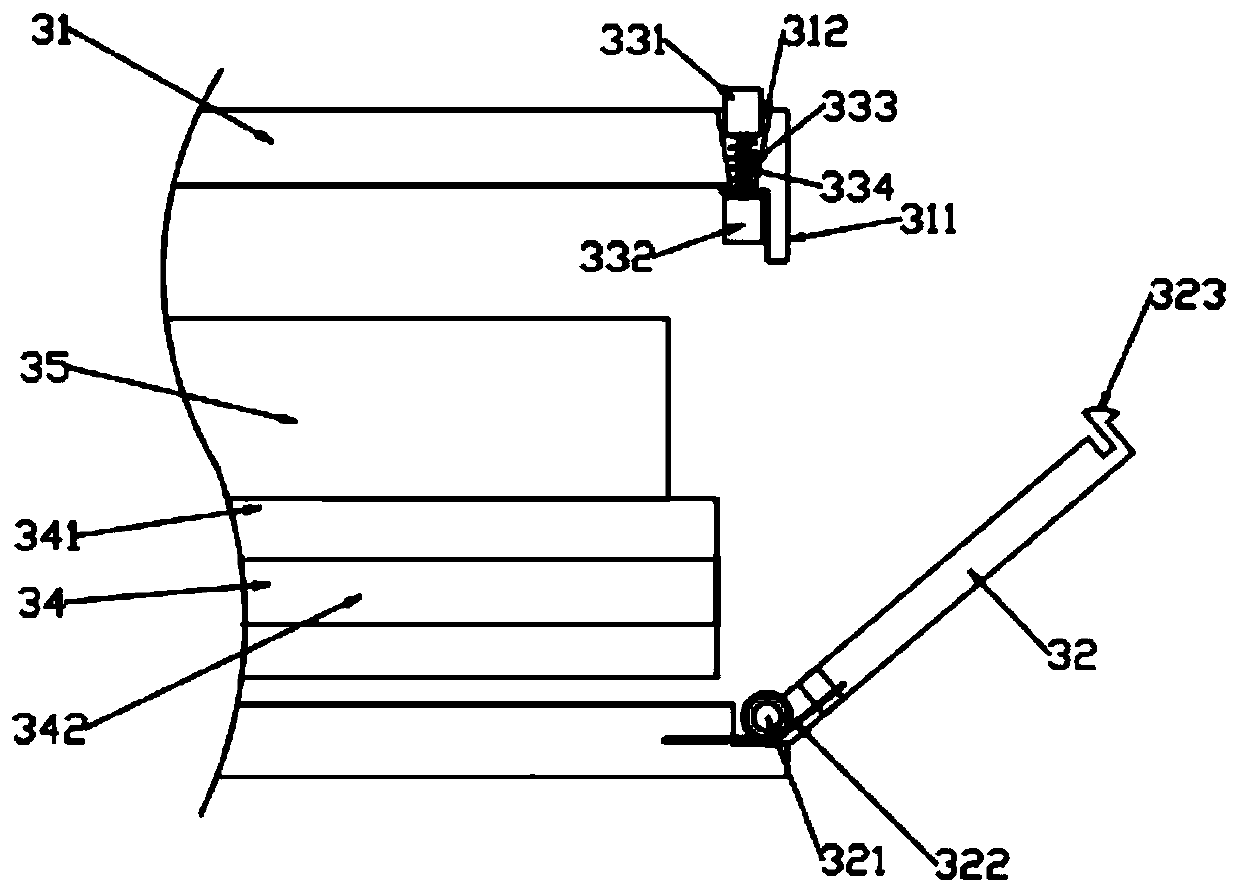

Multifunctional measurement device for construction of civil engineering

PendingCN110411410AReasonable and novel structure designInnovative designSurveying instrumentsHeight/levelling measurementMeasurement deviceData recording

The invention relates to the technical field of civil engineering, in particular to a multifunctional measurement device for construction of civil engineering. The multifunctional measurement device comprises a level gauge, a horizontal adjusting and positioning device, a data recording device, an angle measuring mechanism and a two-purpose adjustable supporting device, wherein the level gauge, the horizontal adjusting and positioning device, the data recording device, the angle measuring mechanism and the two-purpose adjustable supporting device are connected in sequence from top to bottom. The angle measuring mechanism is installed at the upper end of the two-purpose adjustable supporting device, and the angle measuring mechanism and the two-purpose adjustable supporting device are parallelly arranged below the data recording device, so that the data recording device is supported in the vertical direction through the two-purpose adjustable supporting device. Supporting legs of the two-purpose adjustable supporting device are novel in design, U-shaped legs are arranged between telescopic rods and foot margin pins, and the foot margin pins can be folded and stored in the U-shaped legs so that the multifunctional measurement device can be used on a complicated construction site or a smooth ground. Through the arrangement of the data recording device, measured data is conveniently input and recorded. The multifunctional measurement device is novel and reasonable in design, meets the measurement requirements of various road conditions, and is suitable for wide application andpopularization.

Owner:GUANGDONG CONSTR CO LTD OF CHINA RAILWAY NO 3 ENG GRP CO LTD +1

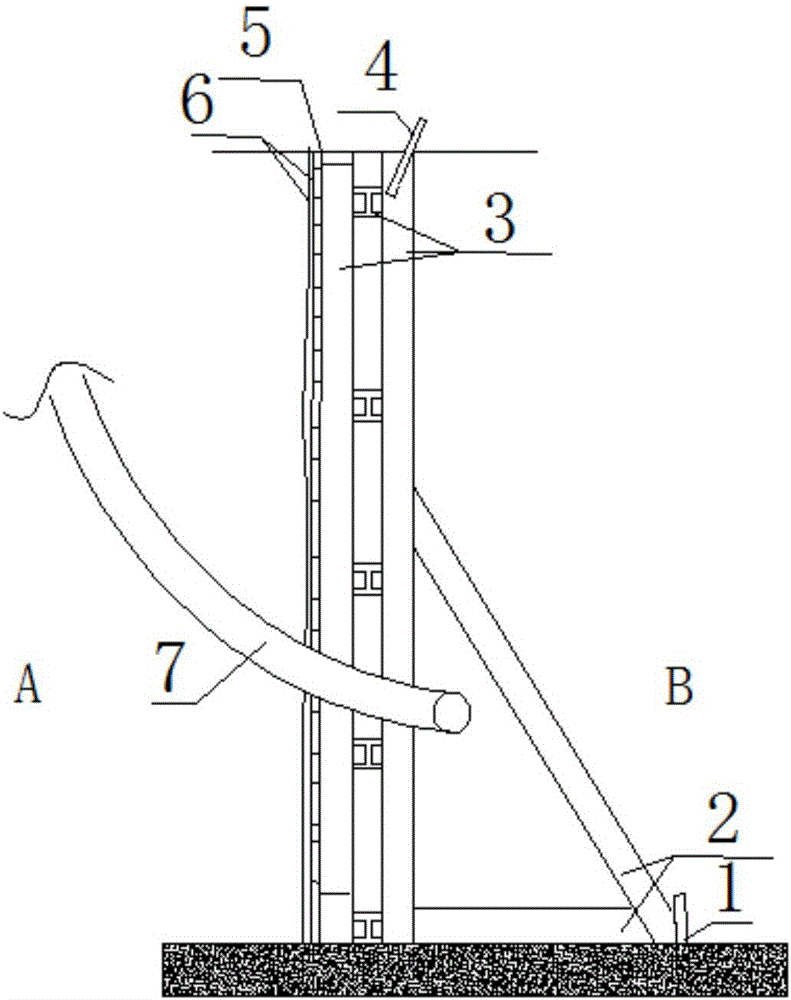

Recyclable steel structure filled retaining wall

The invention discloses a recyclable steel structure filled retaining wall which comprises a composite wall formed by overlaying a plurality of wall fixing round steel bars, an I-shaped steel structural wall, a mesh and water filtering cloth together in sequence, wherein the composite wall is mounted between a goaf and a roadway; I-shaped steel supports and a plurality of supporting and fixing round steel bars are arranged on the back surface of the composite wall for fixation; the composite wall fixing round steel bars are arranged on the periphery of the composite wall at intervals; the tail ends of the composite wall fixing round steel bars are anchored into surrounding rocks to be fixed; the supporting and fixing round steel bars are anchored into the bottom of the roadway; shotcrete is arranged between the composite wall and the roadway. The recyclable steel structure filled retaining wall is novel and reasonable structural design, convenient to construct, high in supporting strength, high in safety performance, good in sand blocking and water filtering effects, capable of being detached and reused, and low in comprehensive cost.

Owner:ANHUI KAIFA MINING IND

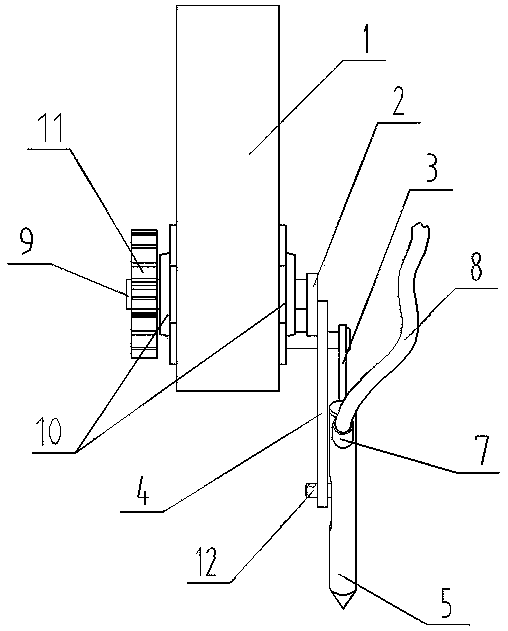

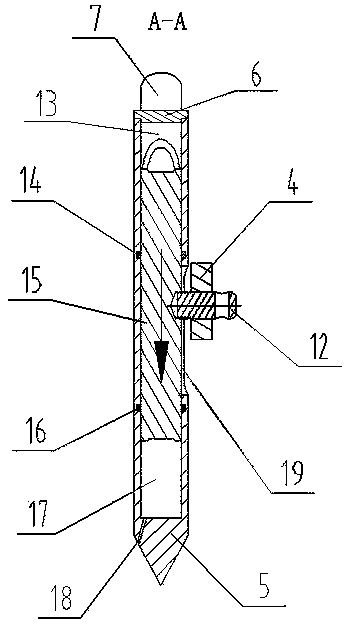

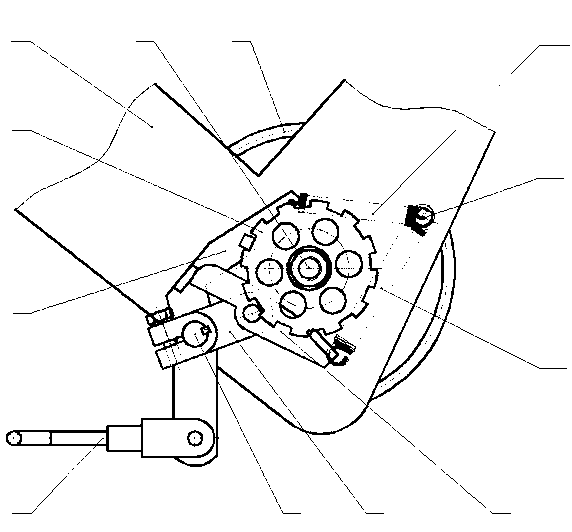

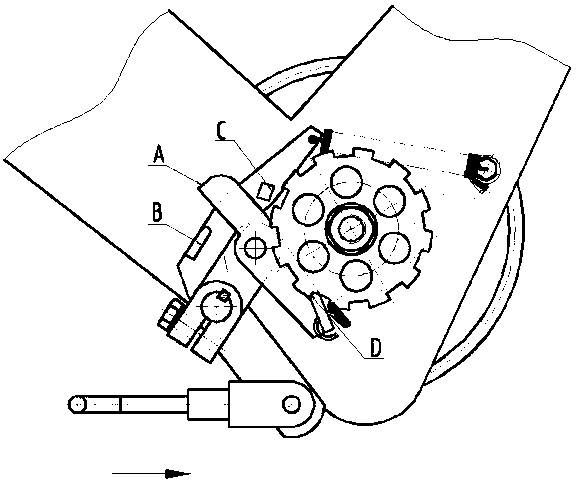

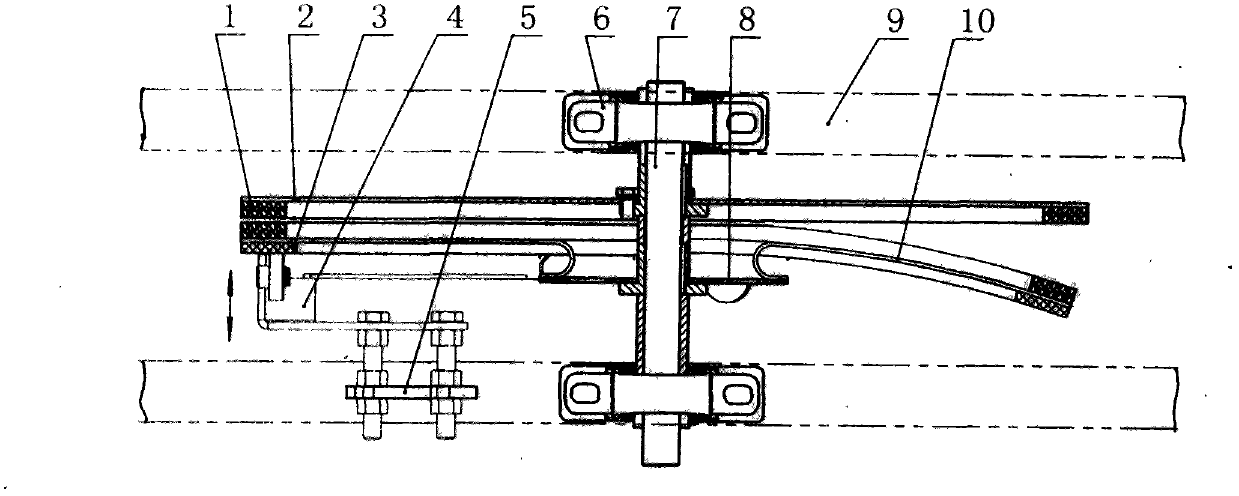

Liquid fertilizer hole prickling and injecting mechanism

InactiveCN107580846AReasonable and novel structure designSmall sizePlantingDirect liquid fertiliser deliveryDrive shaftAgricultural engineering

The invention provides a liquid fertilizer hole prickling and injecting mechanism, and belongs to agricultural machinery. The liquid fertilizer hole prickling and injecting mechanism is characterizedin that transmission shafts are inserted into bearing blocks at the front side and back side of a mounting frame; a driving gear is fixedly arranged at one end of each transmission shaft, and a rockerarm is fixedly arranged at the other end of each transmission shaft; an upper plug is fixedly arranged at the upper end of a fertilizer applying needle casing; a second check valve is axially and movably arranged in a cavity of the fertilizer applying needle casing; a pin shaft is sequentially inserted into a notch slide passage at the side wall of the fertilizer applying needle casing and the second check valve; both ends of a connecting rod are respectively hinged to a pin shaft and the rocker arm; a first check valve is fixedly arranged at the left side of the upper part of the fertilizerapplying needle casing, and the upper end of the first check valve is fixedly arranged on a fertilizer conveying pipe, and is communicated with the fertilizer conveying pipe; one end of a swinging rodis fixedly arranged at the right side of the upper part of the fertilizer applying needle casing, and the other end of the swinging rod is hinged to the mounting frame. The liquid fertilizer hole prickling and injecting mechanism has the characteristics that the synchronous continuous operation of hole prickling and liquid fertilizer injecting is completed by the crank and rocker rod-driven typehole prickling and injecting mechanism; the structure is novel and compact, the operation quality is high, and the reliability in use is realized.

Owner:JILIN UNIV

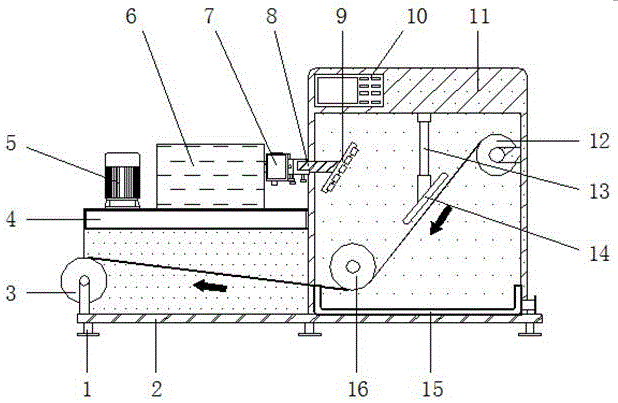

Automated cloth cleaning and drying machine

ActiveCN106436092AEasy dischargeReasonable and novel structure designMechanical cleaningPressure cleaningAgricultural engineeringWater collection

The invention discloses an automated cloth cleaning and drying machine. The automated cloth cleaning and drying machine comprises supports, a base, a cloth rolling roller, a drying device, a water pipe, an operation box, a main body, a feeding roller, a connection rod, a cleaning brush, a water collection tank and a guiding roller. The base is fixed at the top ends of the supports. The cloth rolling roller is arranged on the left side of the base. The drying device is arranged above the cloth rolling roller. The top end of the drying device is connected with a motor. The main body is arranged outside a clean shower. The feeding roller is fixed on the right side of the main body and connected with the guiding roller. The connection rod is mounted between the feeding roller and the guiding roller. The cleaning brush is inlayed at the tail end of the connection rod. The automated cloth cleaning and drying machine has the advantages that the feeding roller and the cloth rolling roller are mounted, defects in the prior art can be overcome, high automation degree is realized, dust ca be cleaned and washed off the surface of cloth by the arranged cleaning brush, simplicity and convenience in operation is realized, and working efficiency is increased greatly.

Owner:WUXI XINGUANG COMP INSTALLATION

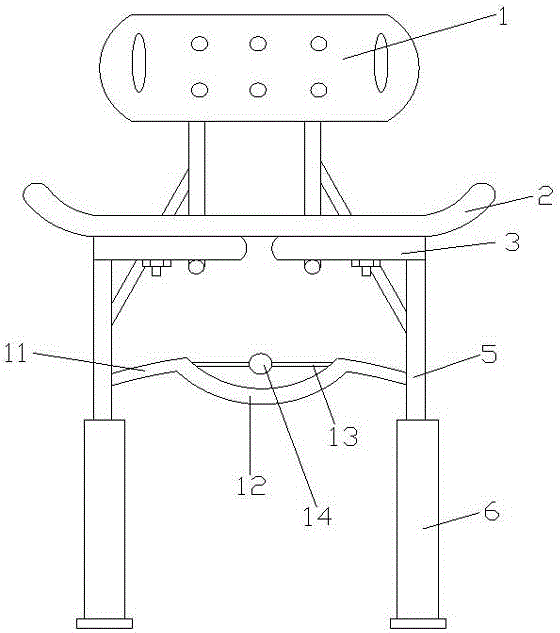

High-strength bathing chair

The invention discloses a high-strength bathing chair, which comprises a back board, a seat board and four supporting legs. A horizontal rod is arranged at the top of the supporting legs, the seat board is arranged on the upper part of the horizontal rod, and the horizontal rod and the seat board are fixedly connected by bolts. ; The rear end surface of the backboard is connected with two parallel backrest rods, and the backrest rods are fixedly connected with the horizontal bar; the backboard and the seat board are provided with a number of water-permeable through holes; the supporting legs include inner pipes and outer The inner tube is sleeved in the outer tube and fixedly connected by bolts, and several positioning holes are arranged on the inner tube and the outer tube. The invention has the advantages that it can overcome the disadvantages of the prior art, and the structural design is reasonable and novel.

Owner:江阴市新盛医疗器材设备有限公司

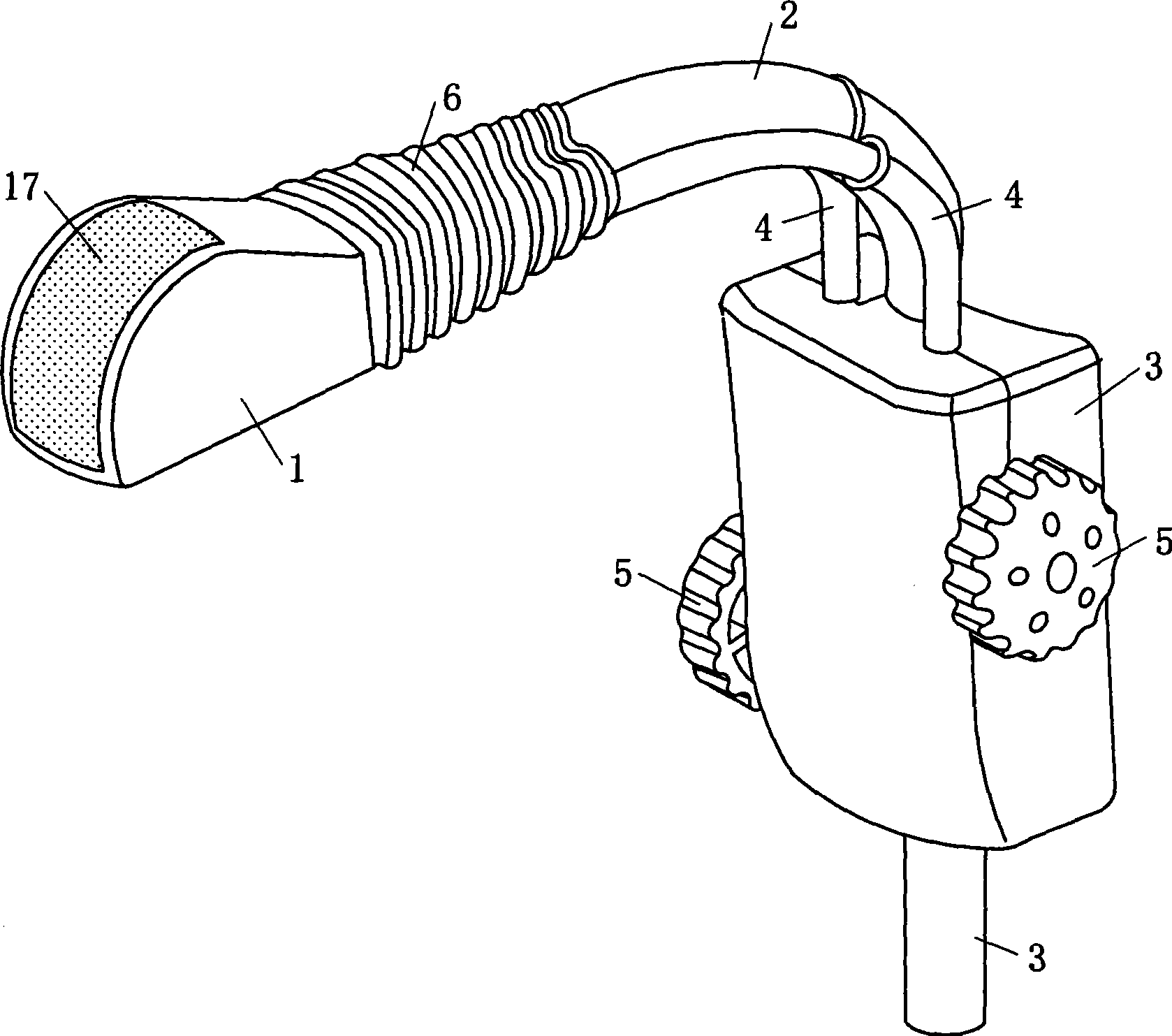

Ultrasonic probe inside vagina with changeable detection direction and device

ActiveCN101411628AEffective Scanning and SurveillanceExpand the scope of clinical applicationSurgeryCatheterUltrasonic sensorLeft direction

The invention relates to a gynaecologic ultrasonic probe capable of changing the direction of a probe body, which comprises the probe body which consists of an ultrasonic sensor and a shell of the ultrasonic sensor, a cable conductor which is connected with the ultrasonic sensor, and a cable conductor shell, wherein a free swinging section is arranged between the probe body shell and the cable conductor shell; and a regulation and control box which is used for controlling rotation of the probe body is arranged on the other end of the cable conductor shell. The ultrasonic probe on the regulation and control box part can efficiently deflect the probe body placed on anterior fornix or posterior fornix in the left direction, the right direction, the up direction, the down direction or the combined direction, not only can efficiently scan and monitor an uterus body on various positions and is suitable to be used for various gynaecologic operations but also can monitor different positions when the same operation is performed and improve the operation efficiency and accuracy, and has good application effect, novel and reasonable structural design, good localizability and convenient use, and is particularly favorable for promotion and implementation.

Owner:河南方正医用电子有限公司

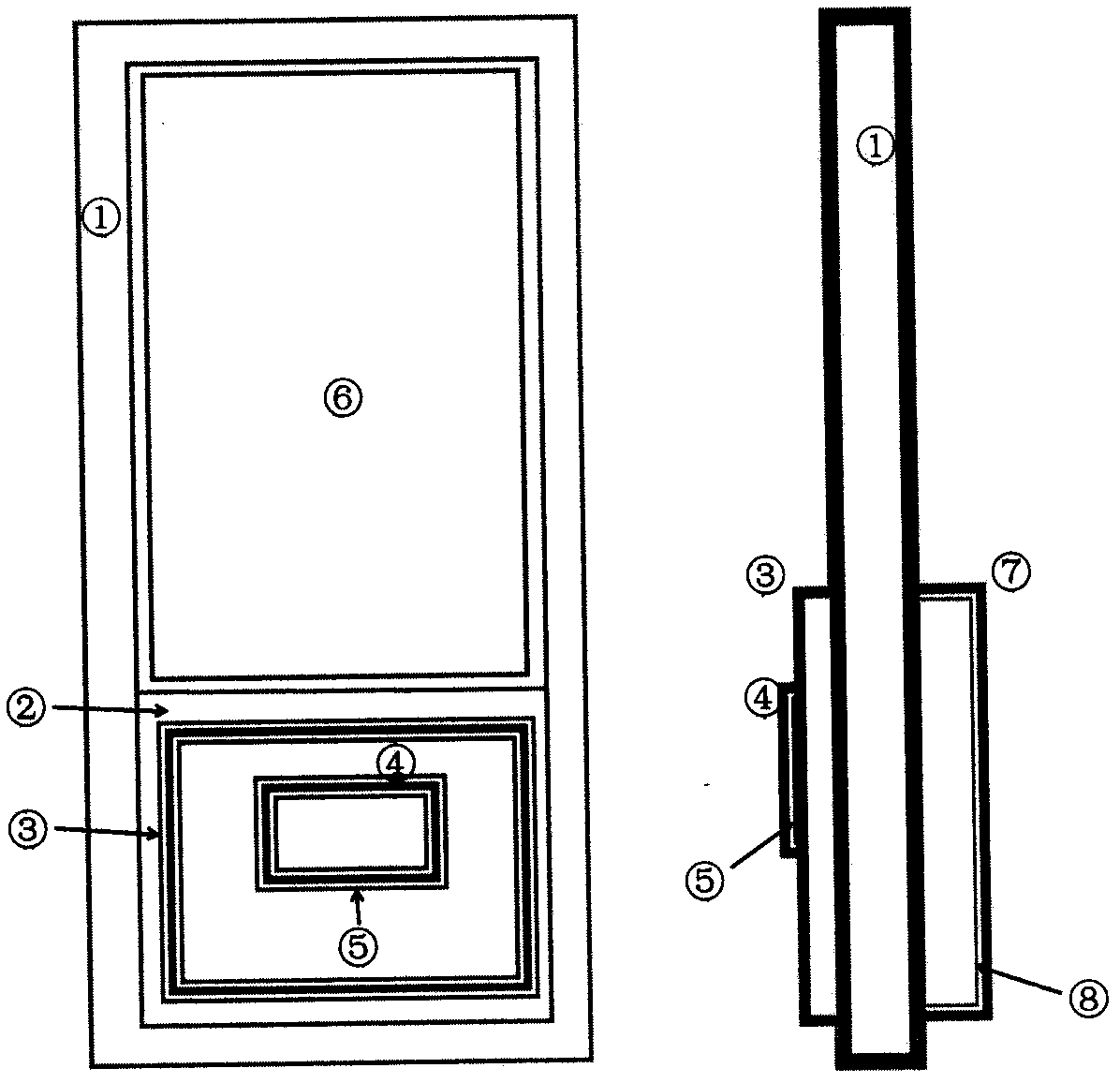

Breathing intelligent air purifying window

InactiveCN108613284AReasonable and novel structure designMeet the needs of pollution controlMechanical apparatusLighting and heating apparatusAir filtrationFresh air

The invention discloses a breathing intelligent air purifying window; in the breathing intelligent air purifying window, the air purifying function and the fresh air circulating ventilation function are combined; and with a building window body as a medium, an air purifying equipment module can be borne to realize overall purification of room space. The breathing intelligent air purifying window comprises a frame of the purifying window, and a purifying equipment module assembled in the frame. The frame is made of an aluminum alloy material; and the purifying equipment module is independentlyand overally assembled in reserved space of the frame to form the whole purifying window with a window body. The purifying window is provided with air filtration, plasma generation, a PTC heating device and an intelligent machine core for air filtration, disinfection, sterilization and provision of warm air during operating. The purifying window can realize outdoor and indoor all-weather air circulating ventilation; sucked indoor air is intelligently and timely breathed outdoors after filtration and plasma disinfection and sterilization by the purifying window; and the breathing intelligent air purifying window can achieve intelligent control of overall room space fresh air, circulating ventilation and temperature and humidity control.

Owner:俞艳芬

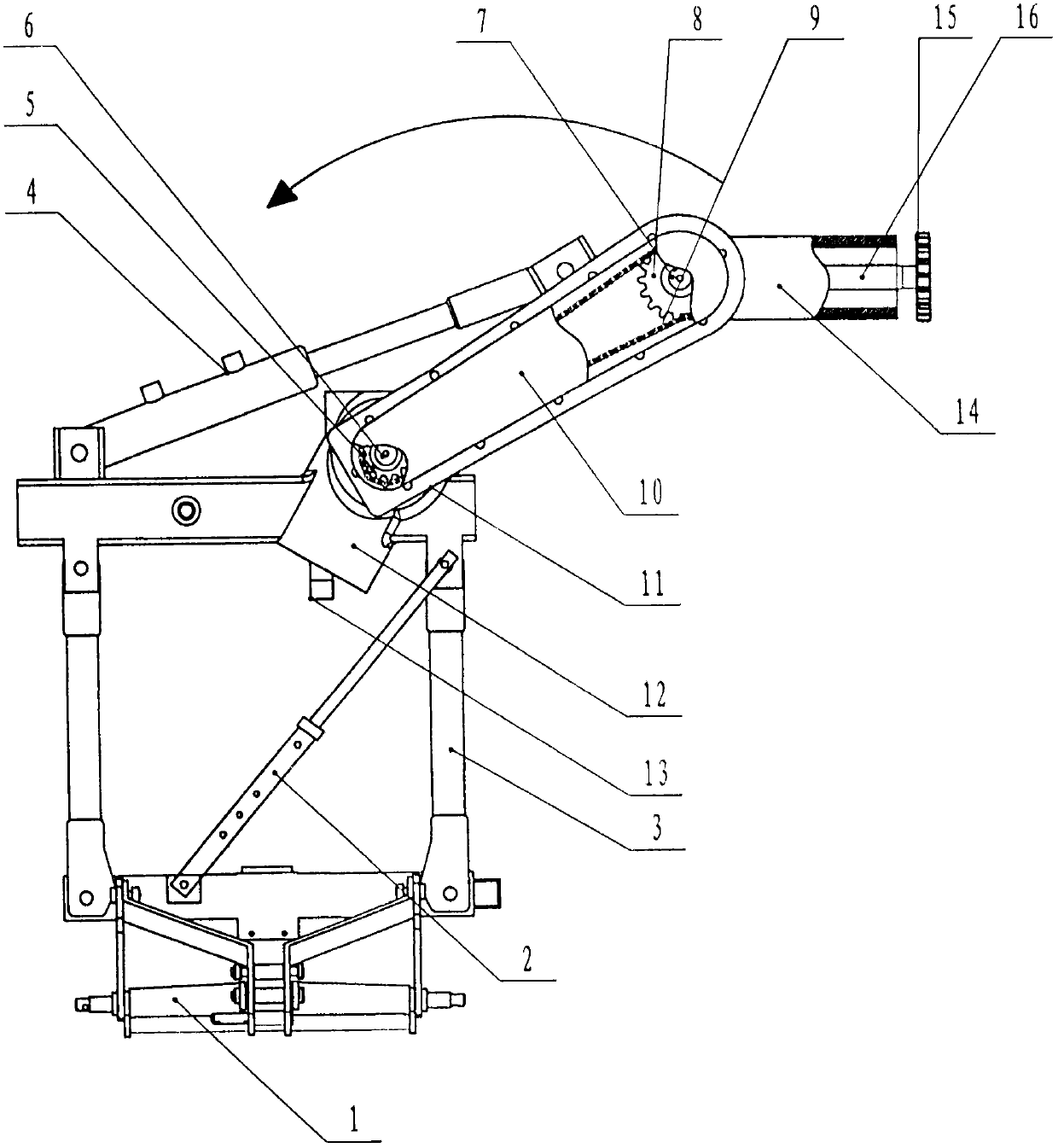

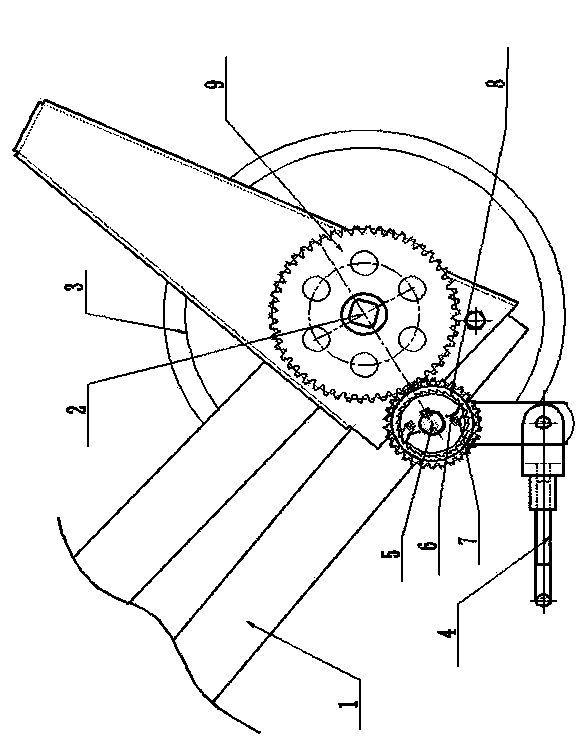

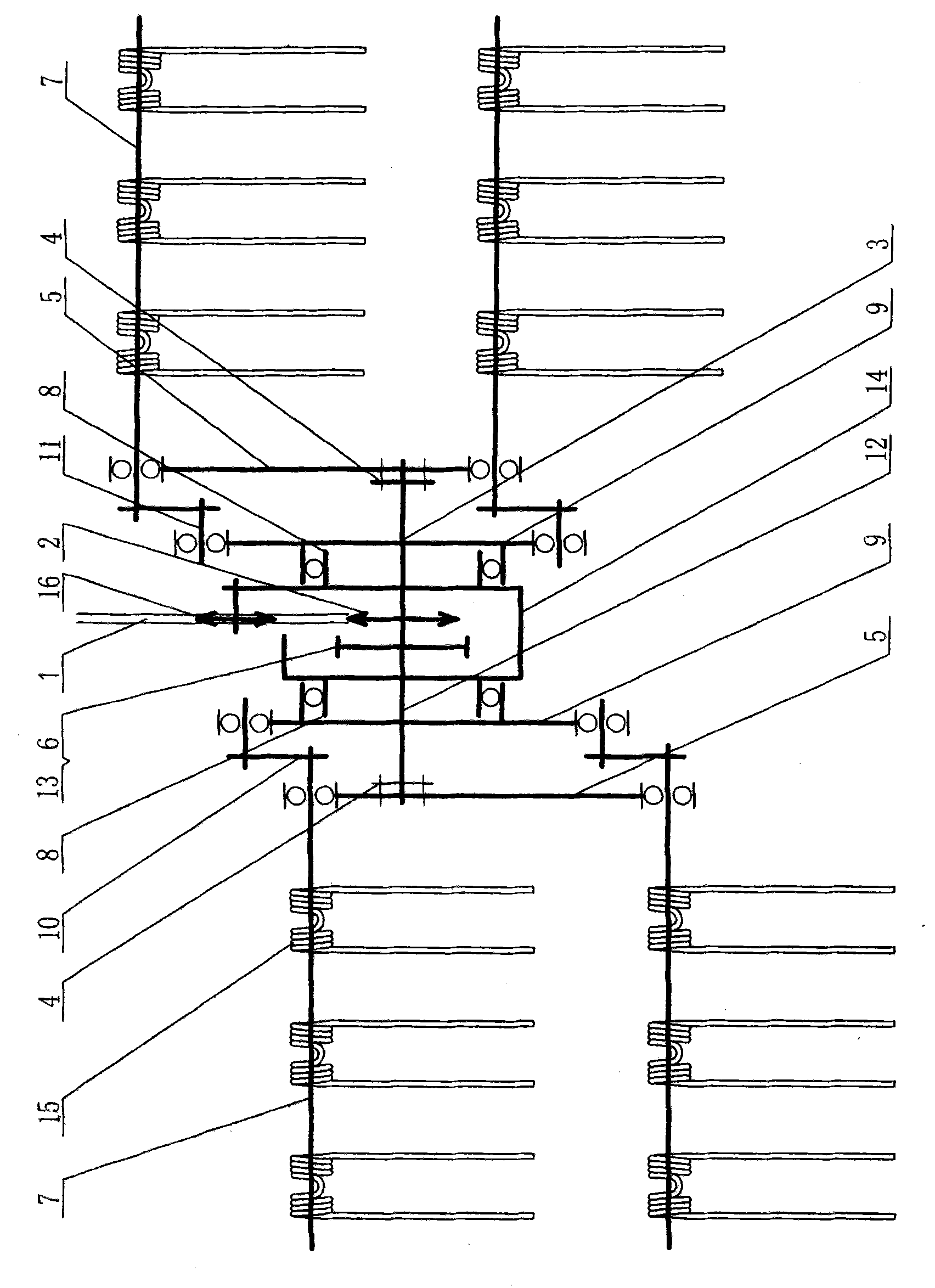

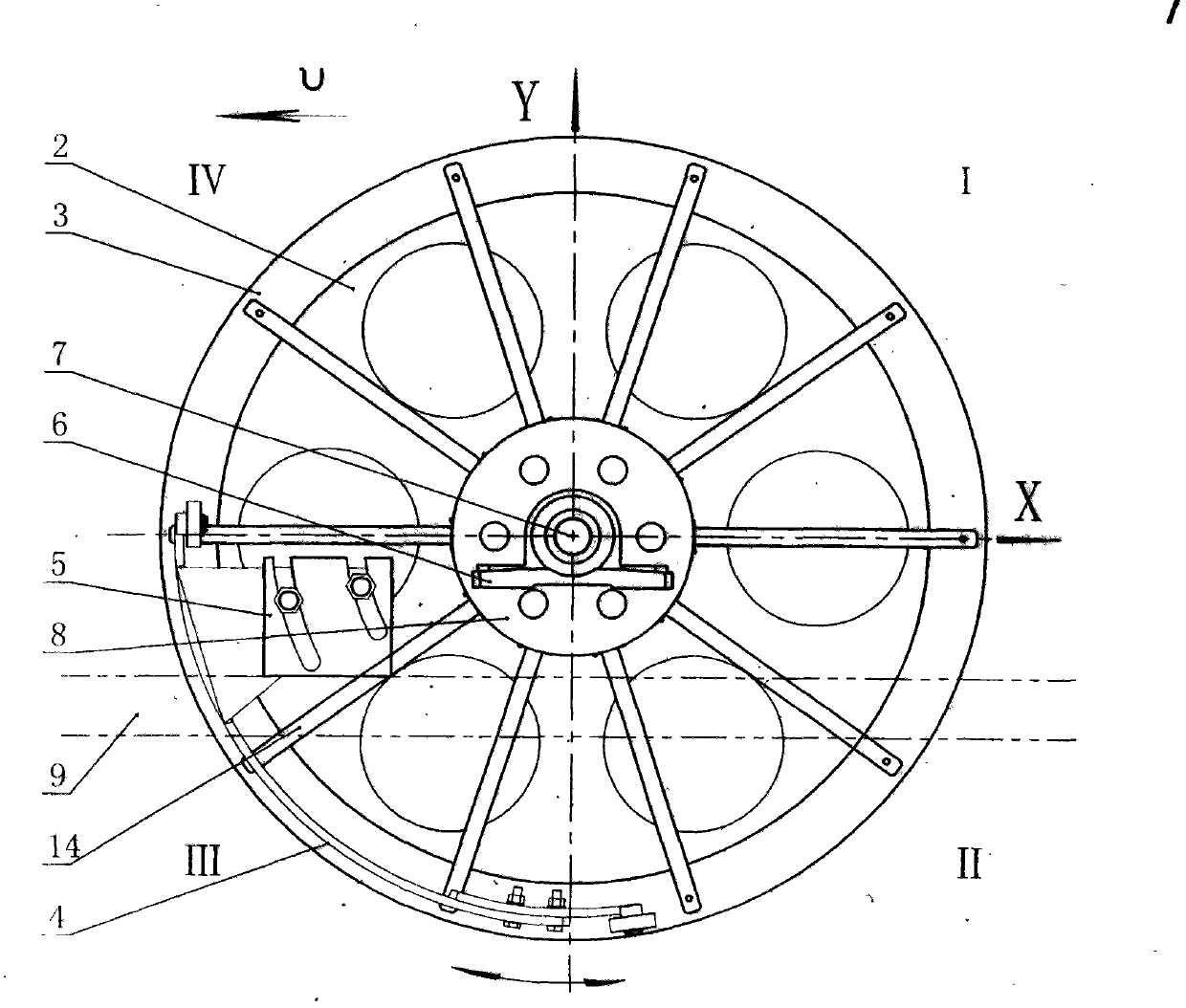

Conjugated cam and planetary gear train combined-type pot-grown rice seedling transplanting mechanism

InactiveCN102893737AReasonable and novel structure designSimple structureGearingTransplantingEngineeringGear train

A conjugated cam and planetary gear train combined-type pot-grown rice seedling transplanting mechanism belongs to agricultural machinery and is formed by assembling a uniform / non-uniform speed driving planetary gear train mechanism, a conjugated cam swinging mechanism and a transplanting arm, wherein power drives the uniform / non-uniform speed driving planetary gear train mechanism to rotate through a central shaft, the uniform / non-uniform speed driving planetary gear train mechanism provides power for the conjugated cam swinging mechanism while pulling the transplanting arm to move, and the conjugated cam swinging mechanism enables a housing of the transplanting arm to rotate relative to planetary gears, so that the movement of the transplanting arm becomes the composition of pulling movement and relative rotation of the uniform / non-uniform speed driving planetary gear train mechanism and sharp points of seedling clamping pieces on the transplanting arm form a movement trajectory in a woodpecker manner, to complete the transplantation of pot-grown rice seedlings. The conjugated cam and planetary gear train combined-type pot-grown rice seedling transplanting mechanism has the characteristics of good operation quality, strong adaptability, simple structure, low cost, reliable working, small vibration and high efficiency.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

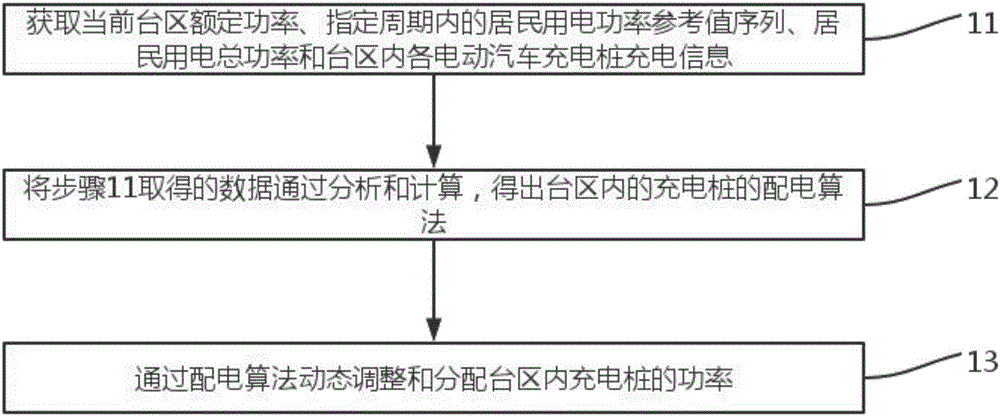

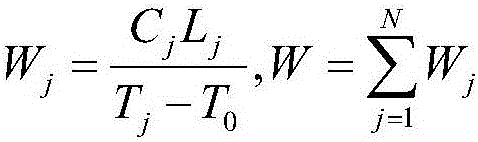

Intelligent power distribution method for charging piles under limited capacity of transformer in court

ActiveCN107528316ARealize smart power distributionReduce capacityCharging stationsSecondary cells charging/dischargingElectricityDistribution method

The invention discloses an intelligent power distribution method for charging piles under limited capacity of a transformer in a court. The method includes the following steps: S1, acquiring the rated power of a current court, the residential electricity power reference value sequence in a specified period, the total power of residential electricity, and the charging information of electric vehicle charging piles in the court; S2, analyzing the data obtained in S1 and carrying out calculation to get a power distribution algorithm for the charging piles in the court; and S3, dynamically adjusting and allocating the power of the charging piles in the court through the power distribution algorithm. The method has the advantage that the method can overcome the defects of the prior art, and is reasonable and novel in design.

Owner:江苏中科瀚星数据科技有限公司

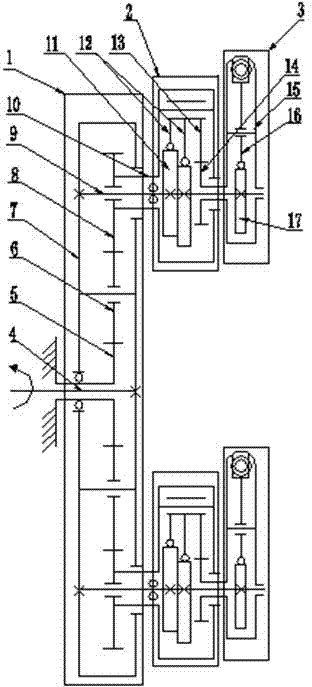

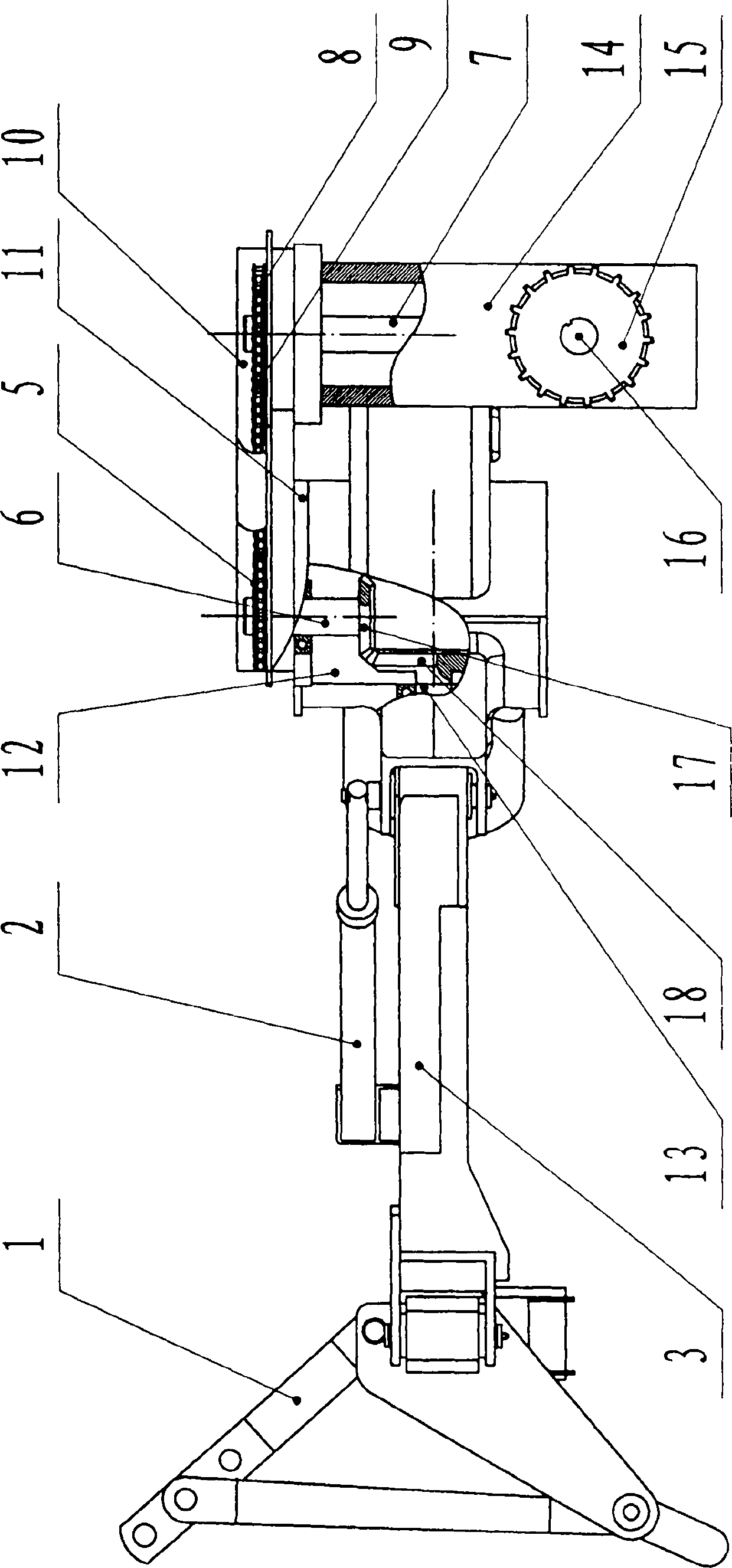

Steering adjustment mechanism for ridge building component of paddy field ridge building machine

InactiveCN104285529AReasonable and novel structure designEasy to adjustGuiding agricultural machinesSprocketEngineering

The invention provides a steering adjustment mechanism for a ridge building component of a paddy field ridge building machine, and belongs to agricultural machines. A main drive box body is fixedly installed on a parallel four-bar suspension frame. A rotating arm plate is hinged to the main drive box body, wherein a sprocket drive box body is fixedly installed on the rotating arm plate. The two ends of a bi-directional hydraulic oil cylinder are hinged to the parallel four-bar suspension frame and the rotating arm plate respectively. A power output drive box body is fixedly installed on the lower side of the rotating arm plate. A power input shaft, a shaft I, a first bevel gear and a second bevel gear are installed inside the main drive box body. A driving sprocket, a chain and a driven sprocket are installed inside the sprocket drive box body. A shaft II, a third bevel gear, a fourth bevel gear and a power output shaft are installed inside the power output drive box body. A power output sprocket is fixedly installed on the outer side end of the power output shaft. The steering adjustment mechanism realizes 180-degree rotation of the ridge building component on the single-side paddy field ridge building machine, completes mechanical work on a ridge at the edge of a paddy field, and is reasonable in structural design, convenient to adjust, high in work efficiency, low in operation labor intensity and reliable in use.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Method for preparing sulfur dioxide by utilizing by-product of coking industry desulfurization system

ActiveCN107804829AReduce moisture contentReasonable and novel structure designSulfur compoundsCombustionSulfur

The invention discloses a method for preparing sulfur dioxide by utilizing the by-product of a coking industry desulfurization system, and relates to the technical field of sulfur dioxide production methods. According to the method, liquid-state sulfur from a sulfur melting system passes through a liquid-state sulfur conveying pipeline, and is subjected to flow rate adjusting through a liquid-state sulfur flow rate control device, and the flow rate-adjusted liquid-state sulfur enters an incinerator through a liquid-state sulfur inlet; a liquid-state by-product salt from a salt extraction system passes through a liquid-state by-product salt conveying pipeline, and is subjected to flow rate adjusting through a liquid-state by-product salt flow rate control device, and the flow rate-adjustedliquid-state by-product salt enters the incinerator through a liquid-state by-product salt inlet; external oxygen is subjected to flow rate adjusting through an oxygen flow rate control device, and the flow rate-adjusted external oxygen enters the incinerator through an oxygen inlet; and the liquid-state sulfur, the liquid-state by-product salt and the external oxygen are subjected to a combustionreaction at a certain temperature in the incinerator, and the generated sulfur dioxide gas is exported through a generated gas outlet. According to the present invention, with the application of themethod to prepare sulfur dioxide, the reactant liquid-state sulfur does not substantially contain water, and the water content of the liquid-state by-product salt is low, such that the generated sulfur dioxide gas has the low water content, and a large amount of dilute sulfuric acid cannot be generated in the acid preparation process of the subsequent system so as to solve the disadvantage of theexisting desulfurization waste liquid-to-acid process.

Owner:杨承诣

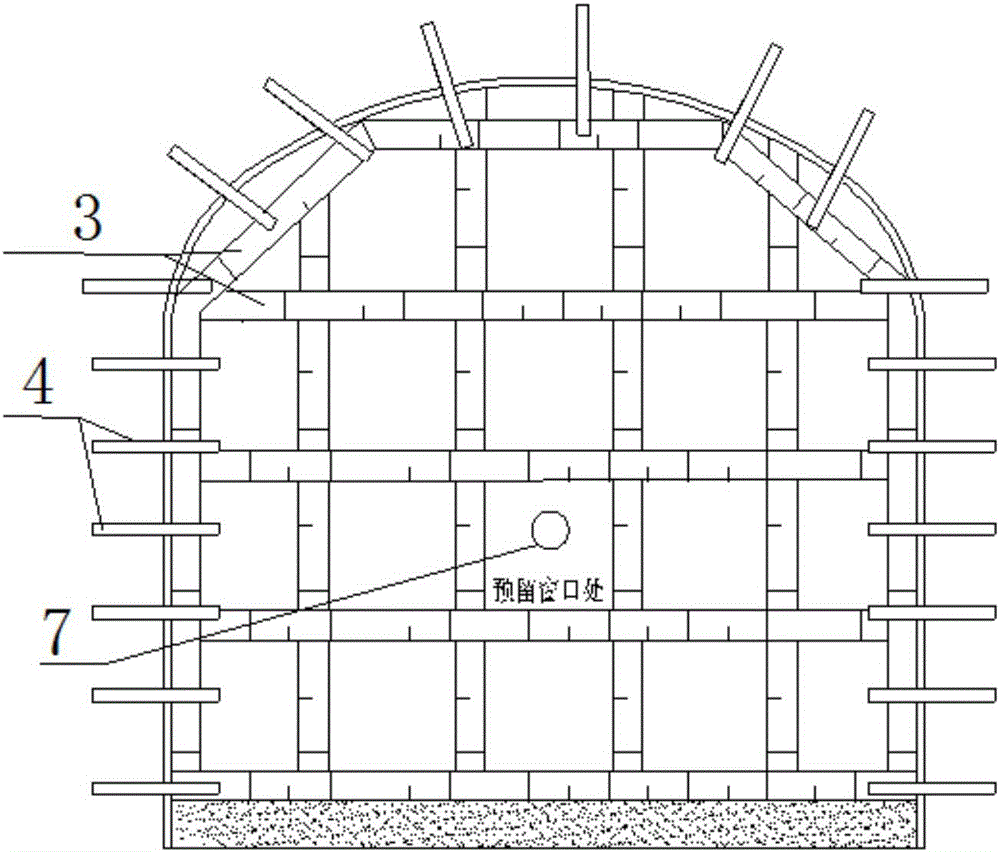

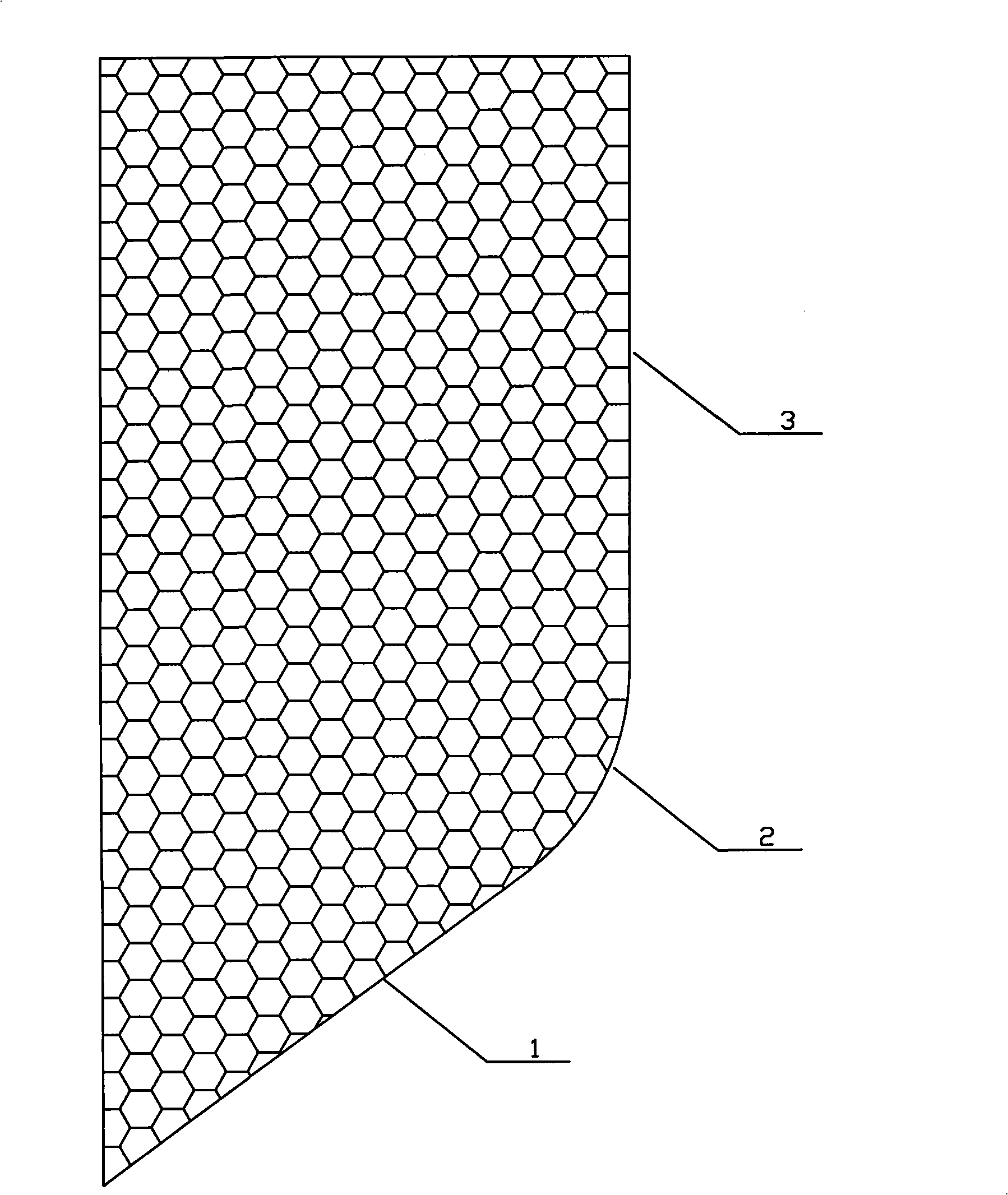

Gear-driven pot seedling transplantation longitudinal seedling feeding mechanism

The invention relates to a gear-driven pot seedling transplantation longitudinal seedling feeding mechanism, and belongs to agricultural machinery. According to the gear-driven pot seedling transplantation longitudinal seedling feeding mechanism, a seedling feeding shaft drive gear is fixed on a seedling feeding shaft and positioned on the outer side of a seedling box side support, a rotation arm shaft welding is matchedly arranged on the seedling box side support and positioned below the side of the seedling feeding shaft, an inner ratchet and outer gear assembly is arranged on the rotation arm shaft welding, a pawl and a spring sheet are fixed on the rotation arm shaft welding, the pawl and the inner ratchet teeth of the inner ratchet and outer gear assembly form snapping contact matching, the spring sheet bears against on the pawl, the outer gear of the inner ratchet and outer gear assembly is engaged with the seedling feeding shaft drive gear, the transmission ratio is 1:2, and a push-pull rod and the rotation arm shaft welding form a hinge connection. The gear-driven pot seedling transplantation longitudinal seedling feeding mechanism has characteristics of novel, reasonable and compact structure design, accurate and stable transmission, low vibration, low noise, less failure, and no damage on the seedling tray.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

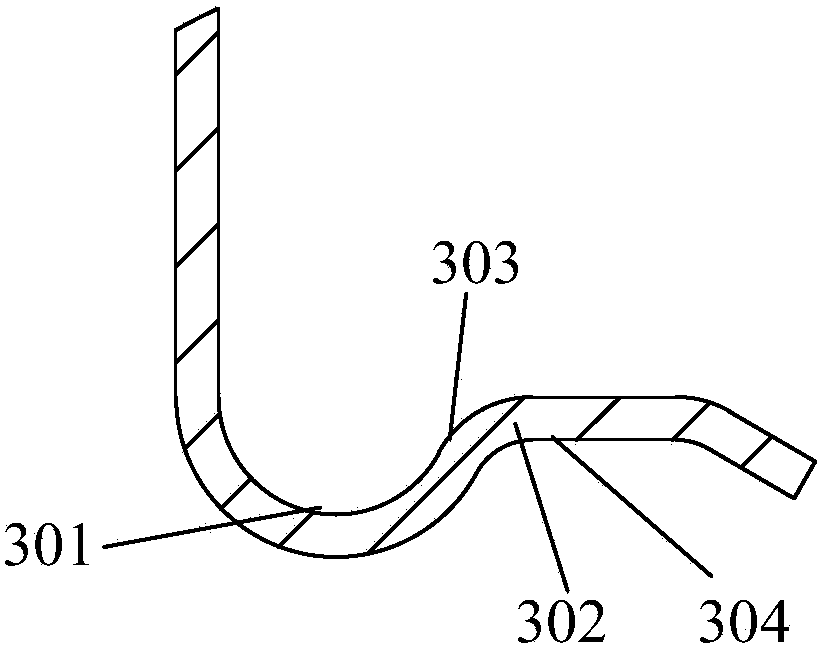

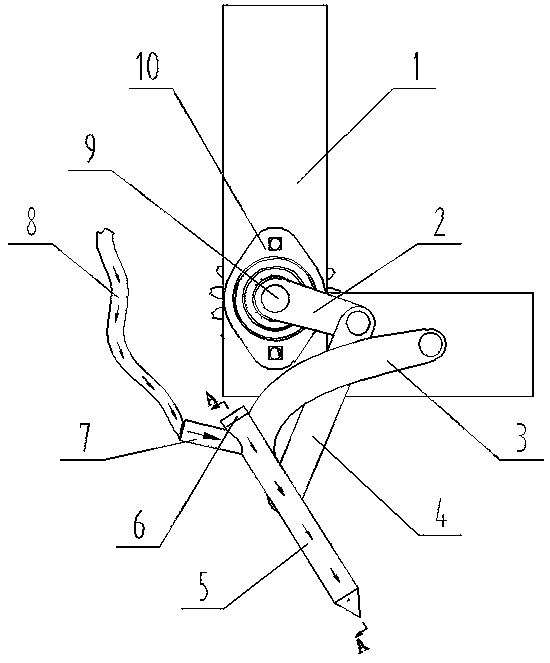

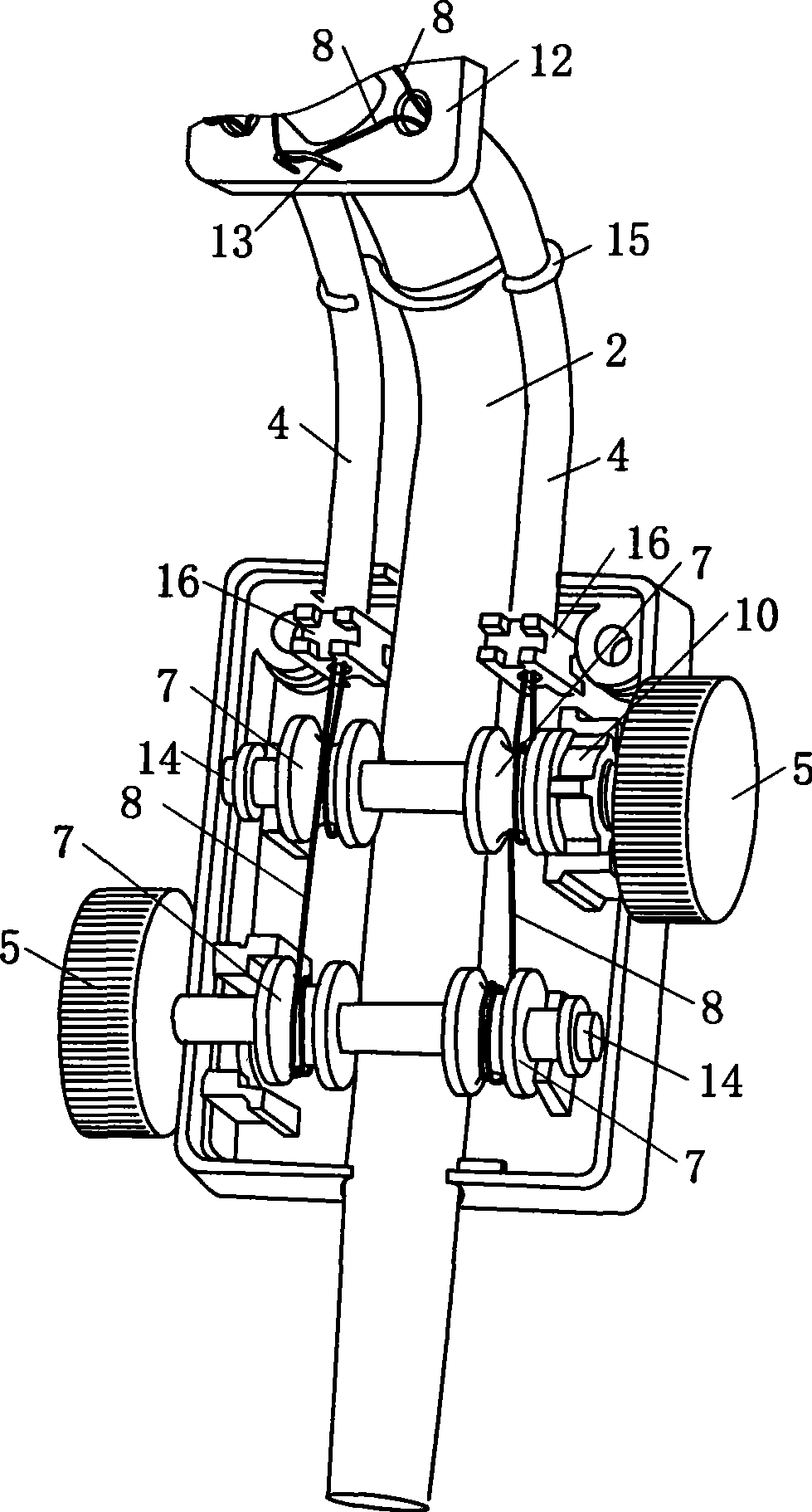

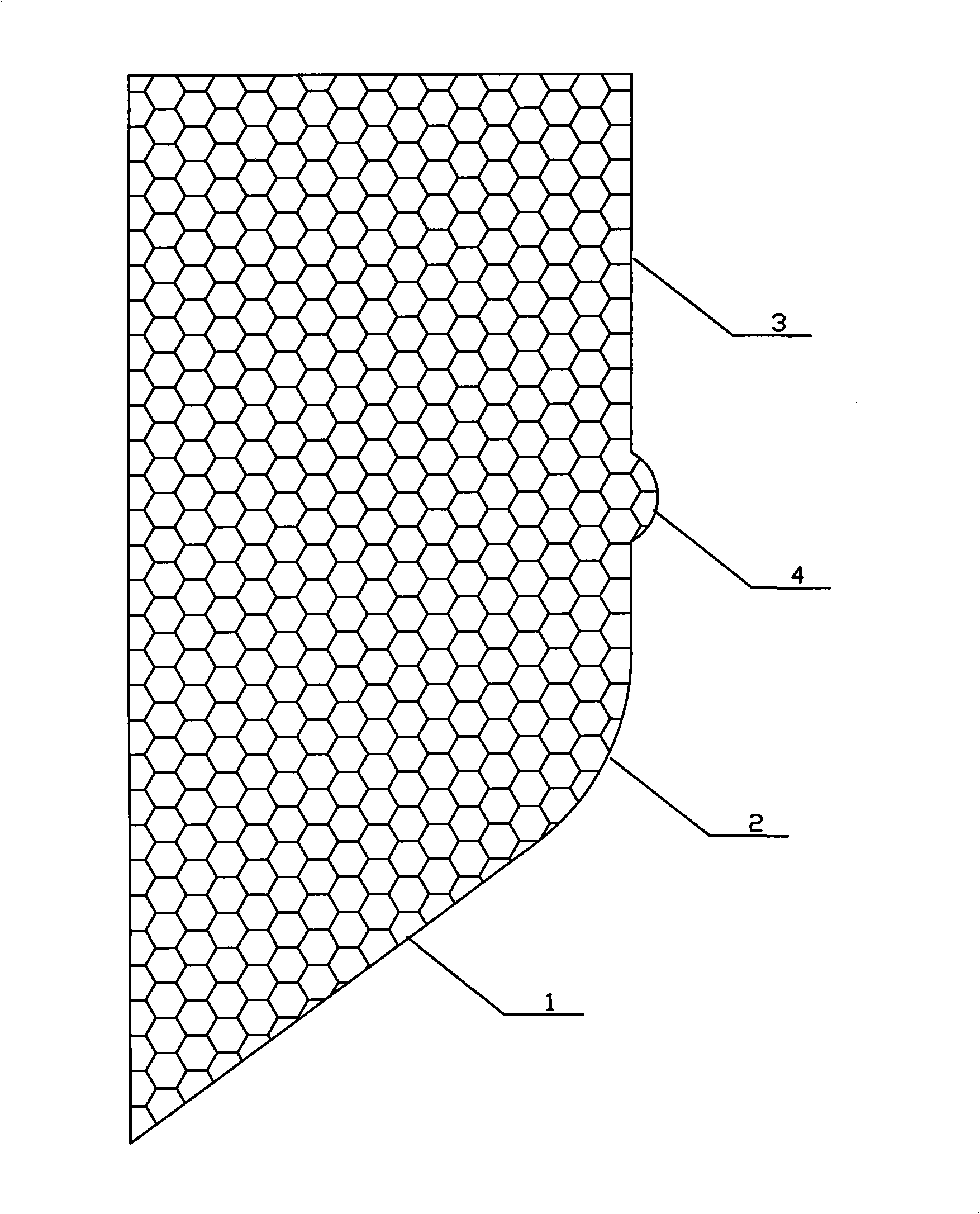

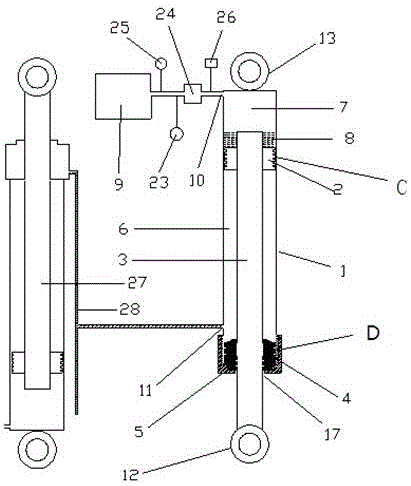

Machine-tooled method for cylinder jacket inner bore surface and fine boring squeezing knife tool

ActiveCN101327527AIncrease tightnessImprove wear resistanceTurning toolsBoring/drilling machinesGas cylinderWear resistant

The invention belongs to the technical field of metal surface mechanical machining. The invention provides a mechanical machining method of the surface of an internal hole of a gas cylinder sleeve, which includes the following steps: a main cutting blade (1) and an auxiliary cutting blade (2) of a cutter are used to perform the major and the remaining cutting tasks; an extruding cone (4) of a smoothing blade (3) is used to extrude the surface of the internal hole of the gas cylinder sleeve after the cutting step, wherein, the smoothing blade (3) levels off the burrs formed in the process and smoothes the protuberances produced in the extrusion of the internal holes of the gas cylinder sleeve by the extruding cone (4). The precision boring cutter smoothing blade (3) is provided with the extruding cone (4), the arc of which increases gradually in the arc direction along the cutter, wherein, the extruding cone (4) has a conical body which is processed through cutting in the oblique direction from the top to the bottom of the conical body; the arc of the cone bottom is 25 to 35 degrees. The processing of the method improves the compactedness of the metal at the surface of the internal hole of the gas cylinder sleeve, thus improving the wear resistant performance of the internal wall of the gas cylinder sleeve and lengthening the service life of the engine.

Owner:洛阳百成内燃机配件有限公司

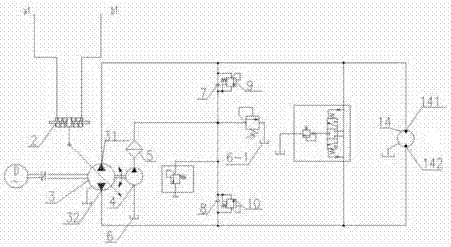

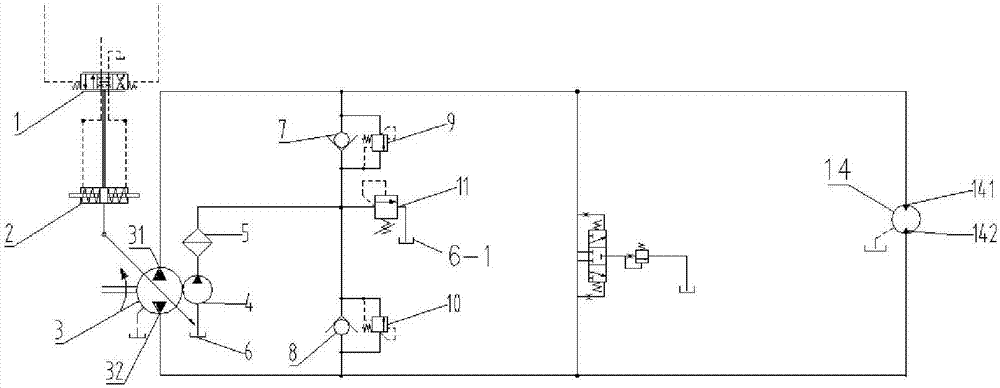

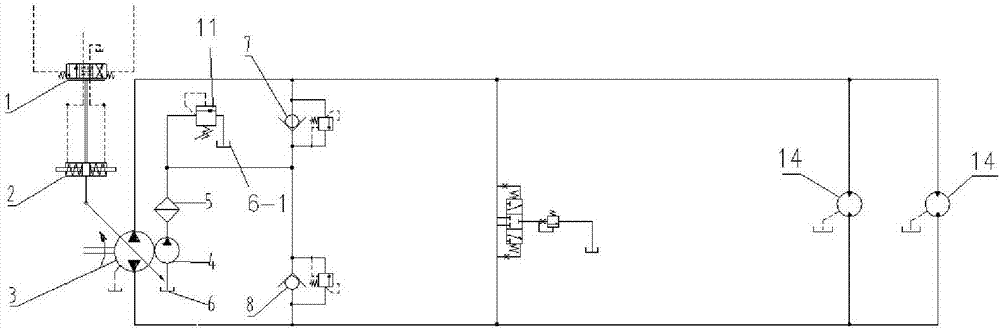

Closed hydraulic system for heading machine

PendingCN106907364AAvoid throttling lossesReasonable and novel structure designServomotor componentsServomotorsMechanical equipmentCoal

The invention discloses a closed hydraulic system for a heading machine and a heading machine using the system and relates the technical field of coal mine mechanical equipment. A main oil pump is a bidirectional variable pump. A first oil opening in the main oil pump communicates with a first end opening of a motor. A second oil opening in the main oil pump communicates with a second end opening of the motor. A pilot control device directly communicates with a main oil pump variable mechanism, and an inlet of a first high-pressure overflow valve and an inlet of a second high-pressure overflow valve are connected with the first oil opening of the main oil pump and the second oil opening of the main oil pump correspondingly. An outlet of the first high-pressure overflow valve and an outlet of the second high-pressure overflow valve are connected with an oil supplementing overflow valve which is connected with a second oil tank. A pilot control element is directly connected with the main oil pump variable mechanism to control the displacement of the main oil pump. The main oil pump is connected with the motor through a pipeline, and a valve throttle is arranged in the middle. Throttling losses of an opening system are avoided, energy consumption is reduced, and reversing impacts are reduced; and power losses of the device are low, the temperature rise of hydraulic oil is low, large-volume oil tank heat dissipation is not needed, only the requirement for oil supplementing needs to be met through to the oil tank volume, and equipment space and weight are saved.

Owner:无锡华瀚能源装备科技有限公司

Dust removal device

ActiveCN108355410AReasonable and novel structure designImprove filtration efficiencyDispersed particle filtrationTransportation and packagingWater circulationElectric energy

The invention provides a specific technical scheme of a dust removal device. The device is characterized by comprising an air channel, a dust removal chamber and an exhaust channel, wherein a plurality of hollow partition boards are arranged in the air channel; the dust removal chamber comprises a first dust removal channel, a second dust removal channel, a grid plate, a first dust removal box anda second dust accumulation box; a sewage tank is arranged at the lower parts of the first dust removal box and the second dust accumulation box; a water circulation device is arranged at the lower part of the sewage box; a power generation device is arranged in the exhaust channel, and a draft fan is arranged at an outlet end of the exhaust channel. The dust removal device is reasonable and novelin structure design, dust-containing airflow is gradually filtered, and the filtration efficiency is improved; besides, an ash removal device and a spraying device are arranged in the dust removal channel, cleaning of a filter net is completed without stopping of the device, and the maintenance cost is reduced; the water circulation device is arranged at the lower part of the dust removal chamber, and reutilization of sewage is realized; the power generation device is arranged in the exhaust channel, air power after purification is sufficiently utilized to realize conversion of electric energy, energy is saved, and the production cost is saved.

Owner:TIANJIN JINHANG COMP TECH RES INST

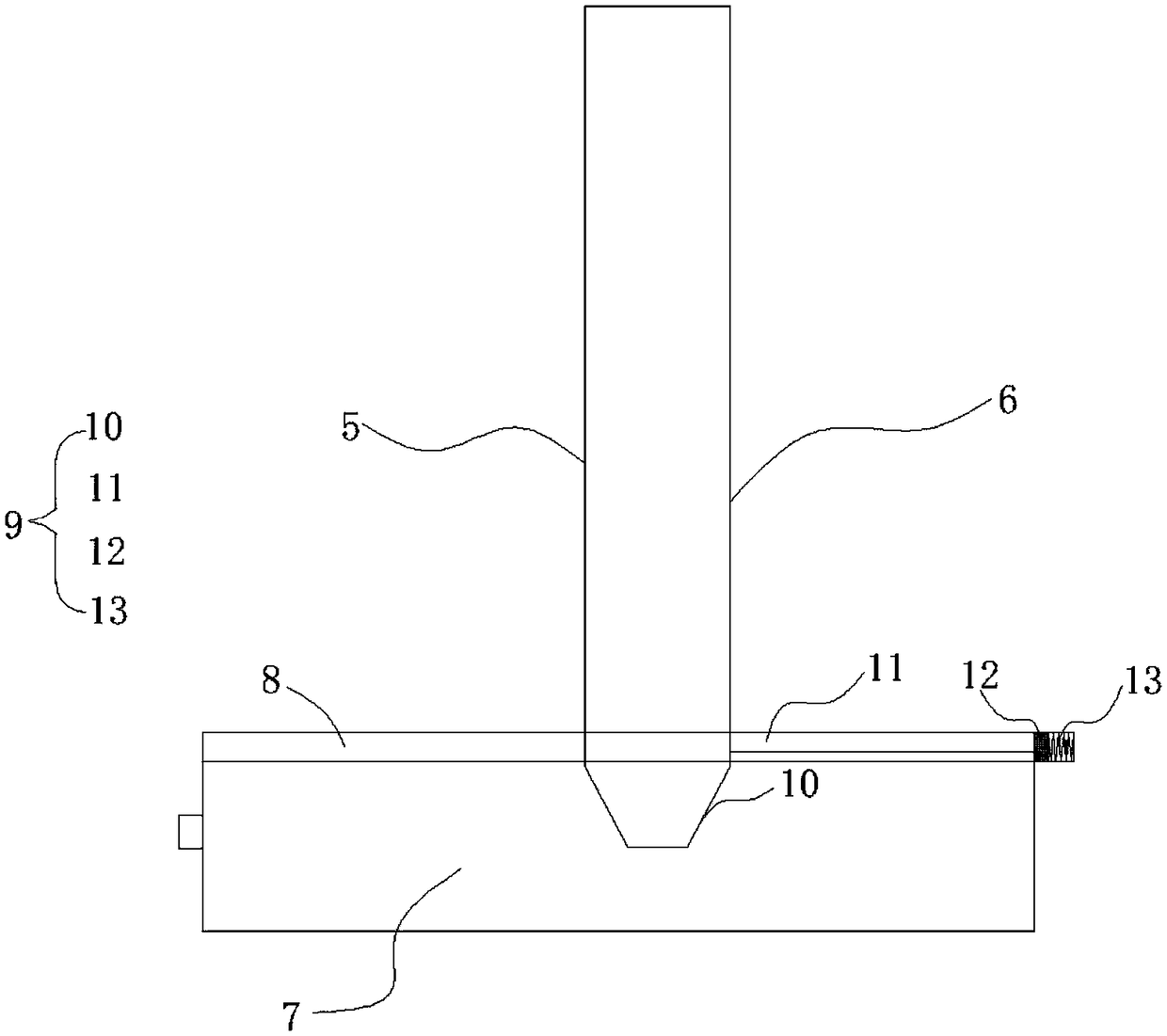

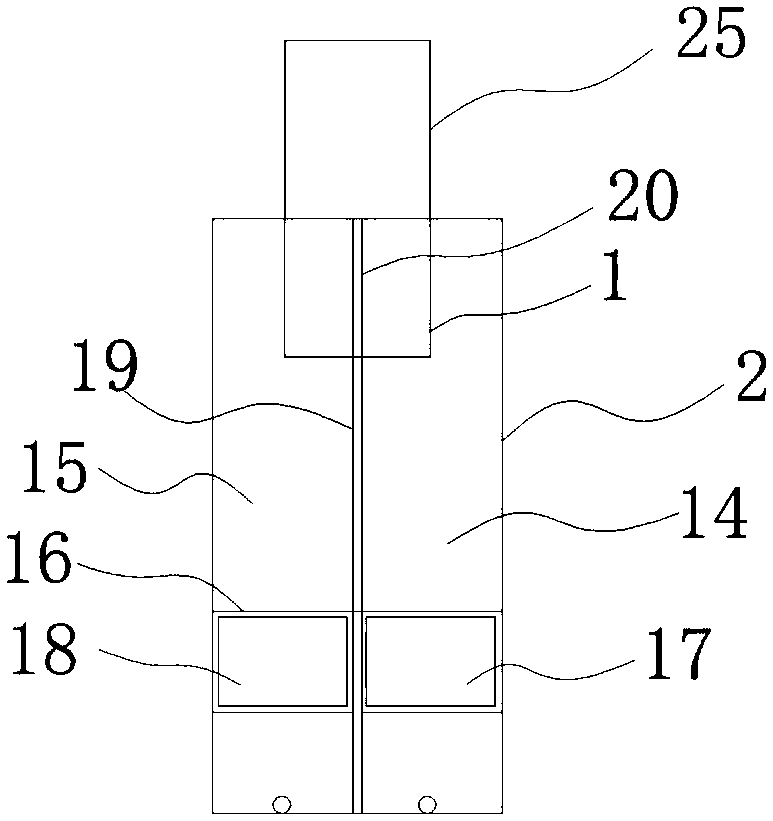

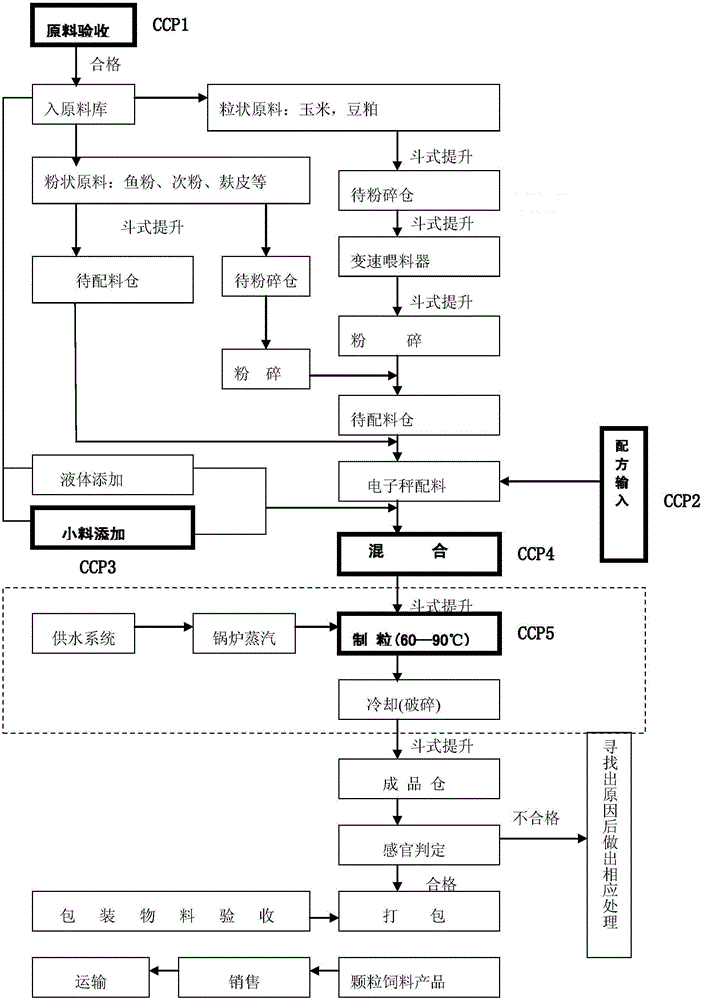

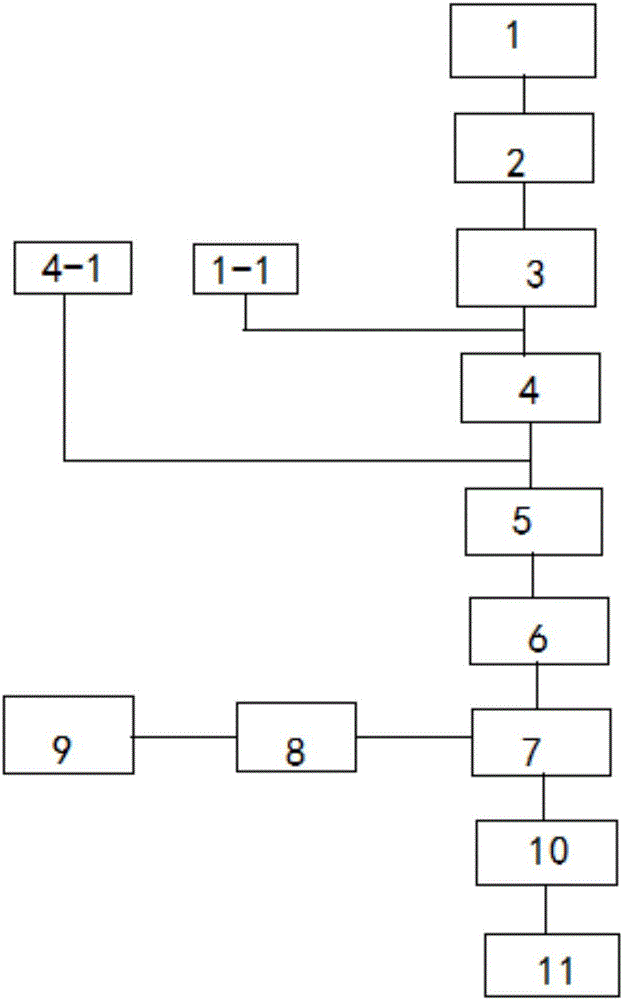

Feed processing system and processing technology

InactiveCN106213547AReasonable and novel structure designHigh degree of mechanizationFeeding-stuffFeed processingProcess engineering

The invention discloses a feed processing system and a processing technology and relates to the technical field of feed processing. A grinding bin, a variable speed feeder and a grinder are sequentially connected; a second grinding bin is connected with the grinder and then connected with a proportioning bin; the proportioning bin is connected with an electronic weighing and batching device; a second proportioning bin is connected with the proportioning bin; the electronic weighing and batching device, a mixing device and a granulating mechanism are sequentially connected; a water supply system is connected with a boiler steam device and the granulating mechanism; and the granulating mechanism, a cooling device and a finished product warehouse are sequentially connected. The degree of mechanization is high, excessive workers do not need to participate in operation, and the manufacturing cost is greatly reduced. Moreover, in the feed preparation process, a process of sequentially grinding and proportioning is adopted, proportioning is accurate, and the proportioning precision is greatly improved.

Owner:河源市瑞昌饲料有限公司

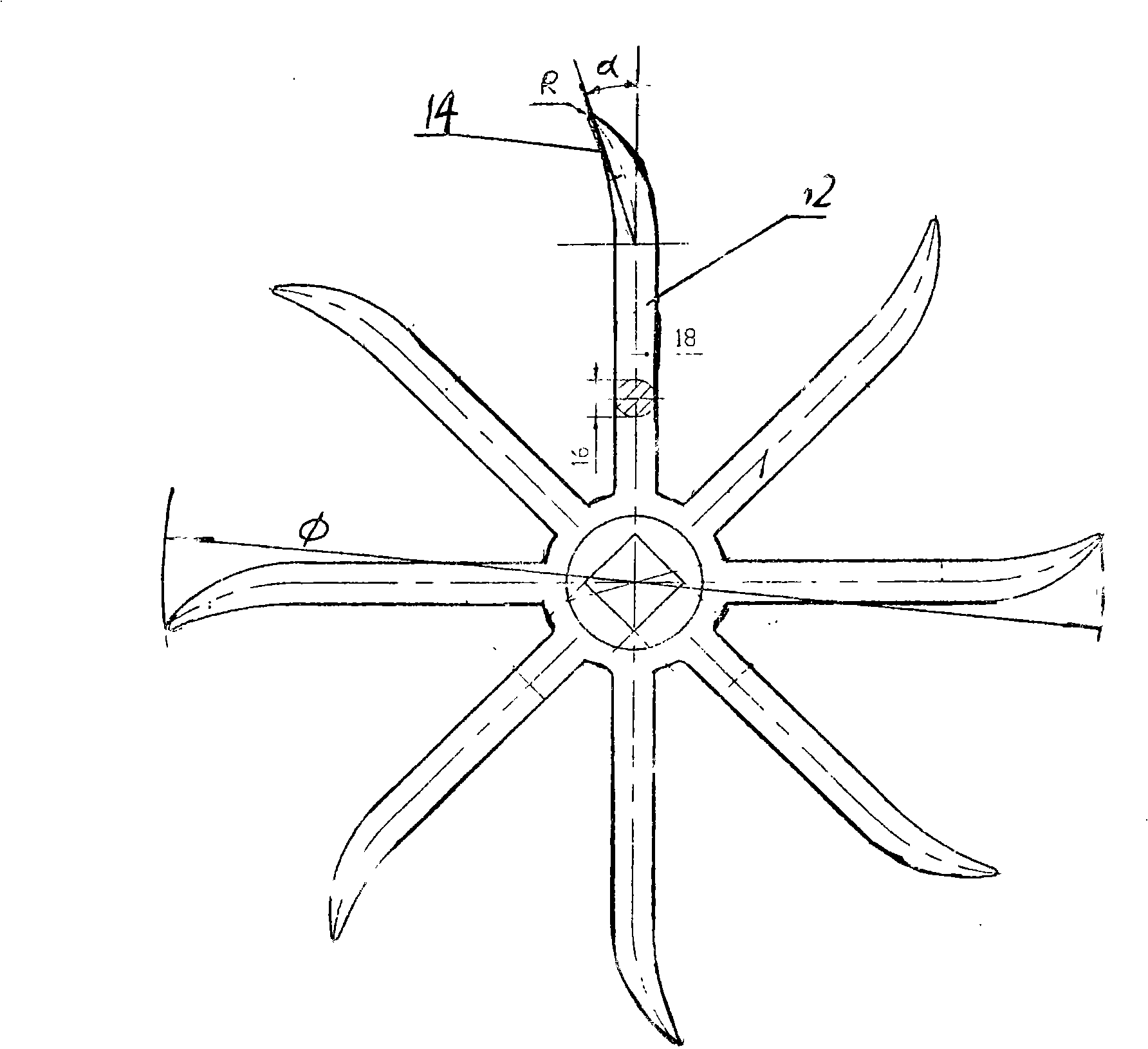

Combined vertical comb-type weeding mechanism for crop seedling with loose soil

The invention relates to a combined vertical comb-type weeding mechanism for crop seedlings with loose soil, which belongs to agricultural machinery. In the technical scheme, a transmission case is provided with a rear power output shaft and a front power output shaft in parallel, the rear power output shaft is provided with a driving sprocket and a driving cylindrical gear, the front power output shaft is provided with a driven cylindrical gear, the outer ends of the front power output shaft and the rear power output shaft are fixedly provided with a comb-type shaft with elastic comb teeth respectively through a flange coupling plate, a circular chute is arranged on outer side faces of the front wall and the back wall of the transmission case, a driven plate is arranged on the circular chute, a pin shaft is arranged on the driven plate, and the two ends of a connecting plate are fixedly connected with the comb-type shaft and the pin shaft respectively. The mechanism can make the elastic comb teeth on the comb-type shaft always maintain the upright state during the operation, has the advantages of novel and reasonable structure, stable insertion of the elastic comb teeth in the soil, high operating quality, high efficiency, low rate of injured seedlings and high adaptability, and can be widely applied in inter-tillage of soybeans, corns, beets, cereals, cotton and other crops.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

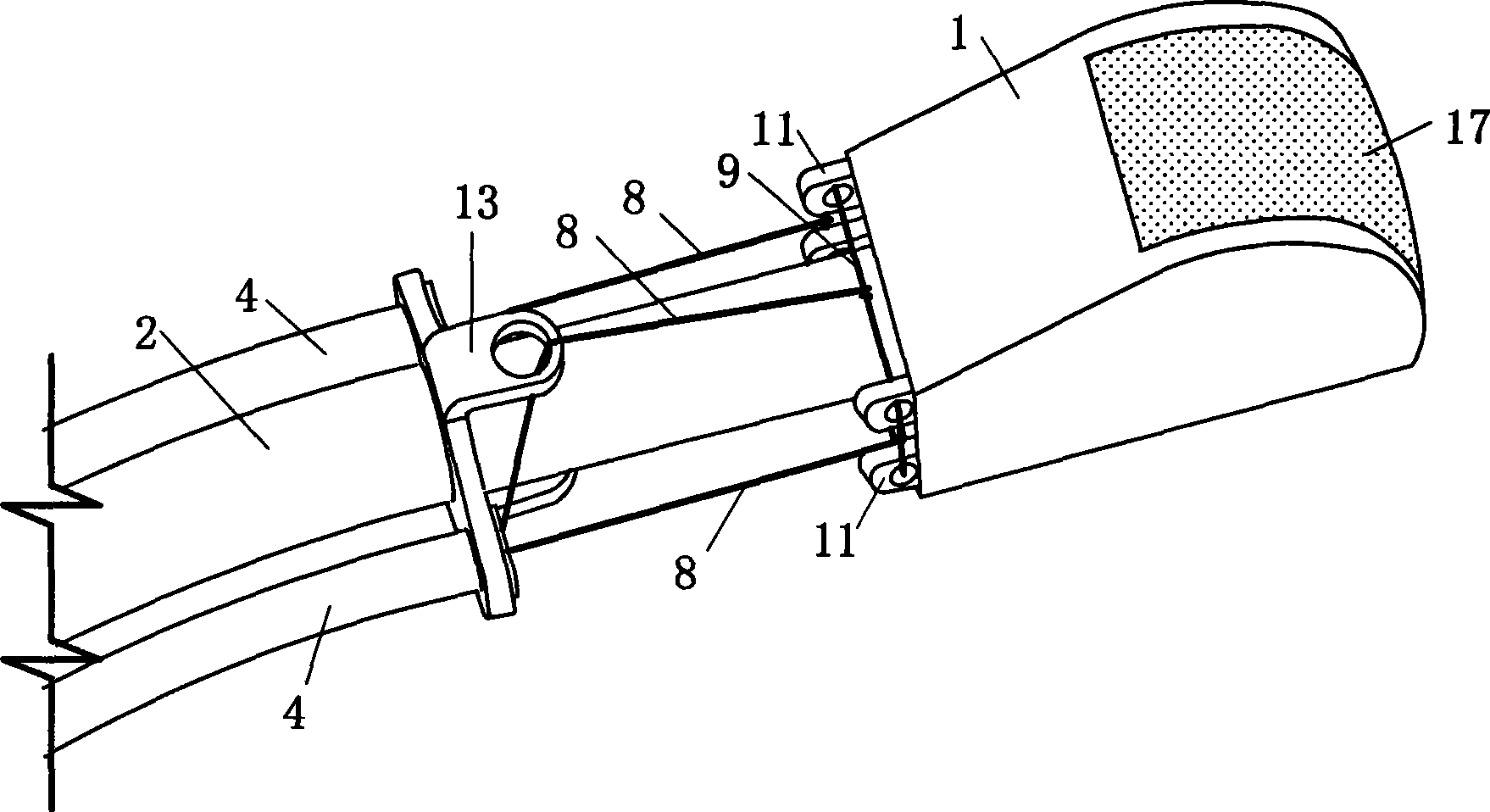

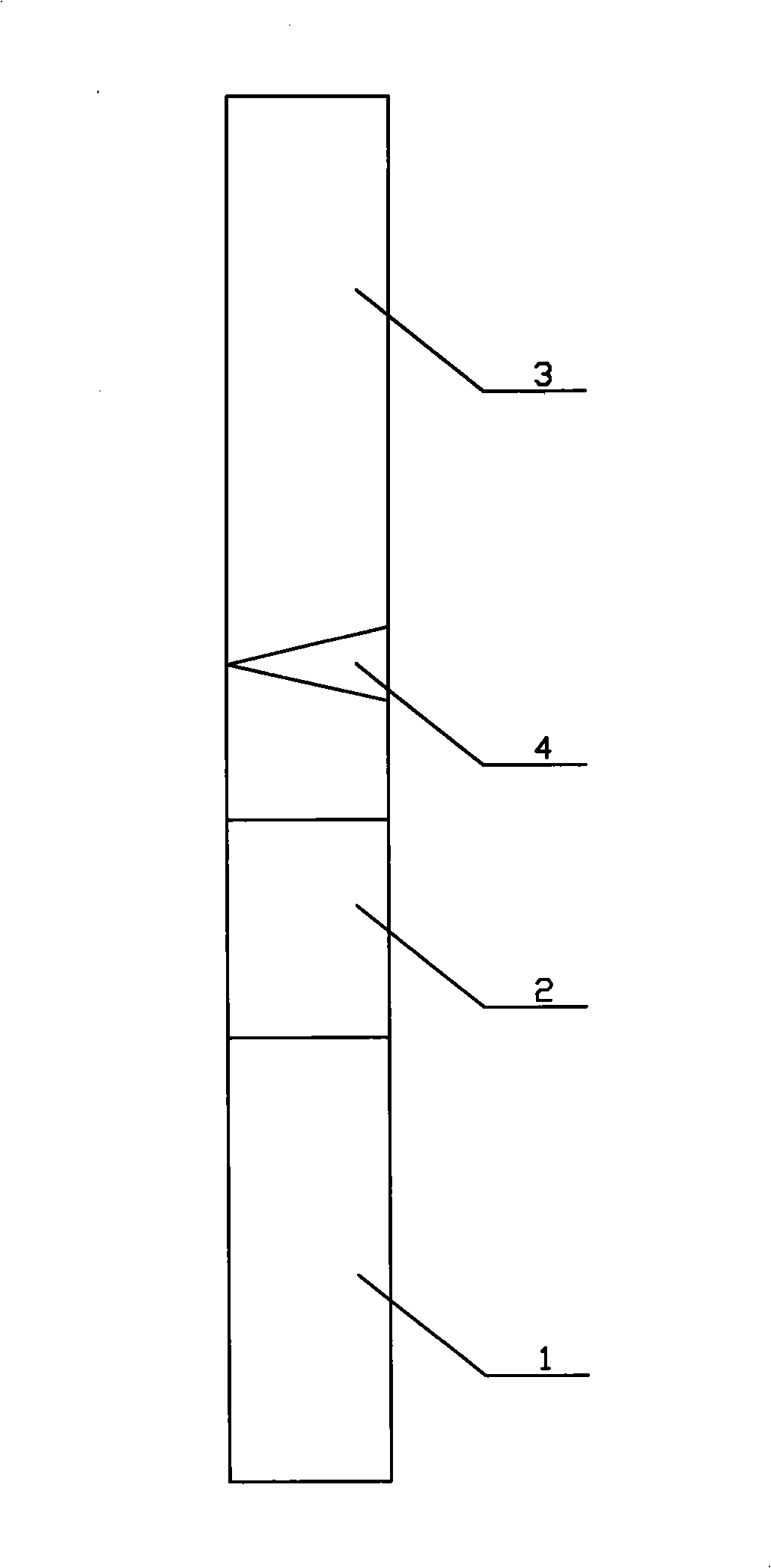

Longitudinal seedling-feeding mechanism for pot seedling transplanting

InactiveCN103190233ALongitudinal conveying pot seedling position is accurateAvoid damageTransplantingPull forceLocking mechanism

The invention relates to a longitudinal seedling-feeding mechanism for pot seedling transplanting, belonging to agricultural machinery. A rotating arm shaft seam is rotatably assembled on a side seedling box bracket; a locating rod is rotatably sleeved on the rotating arm shaft seam; a pull rod base is fixedly mounted on the rotating arm shaft seam; a pull rod is hinged on the pull rod base; one end of the pull rod is matched with the locating rod in an engaging or disengaging manner, and the other end of the pull rod is matched with a ratchet wheel in an engaging manner; a tension spring fixing base is arranged on the side seedling box bracket; two ends of a first tension spring are respectively connected to the pull rod and the tension spring fixing base; two ends of a second tension spring are respectively connected to the locating rod and the tension spring fixing base; the locating rod is matched with the ratchet wheel in an engaging or disengaging manner; and a push rod is hinged on the rotating arm shaft seam. As a ratchet wheel and connecting rod combined locking mechanism is adopted, accumulated errors during continuous pot seedling feeding operations are eliminated; and the longitudinal seedling-feeding mechanism has the characteristics of novel and reasonable structure design, good operation quality, no damage to a seedling tray, small operation fault and reliable use.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

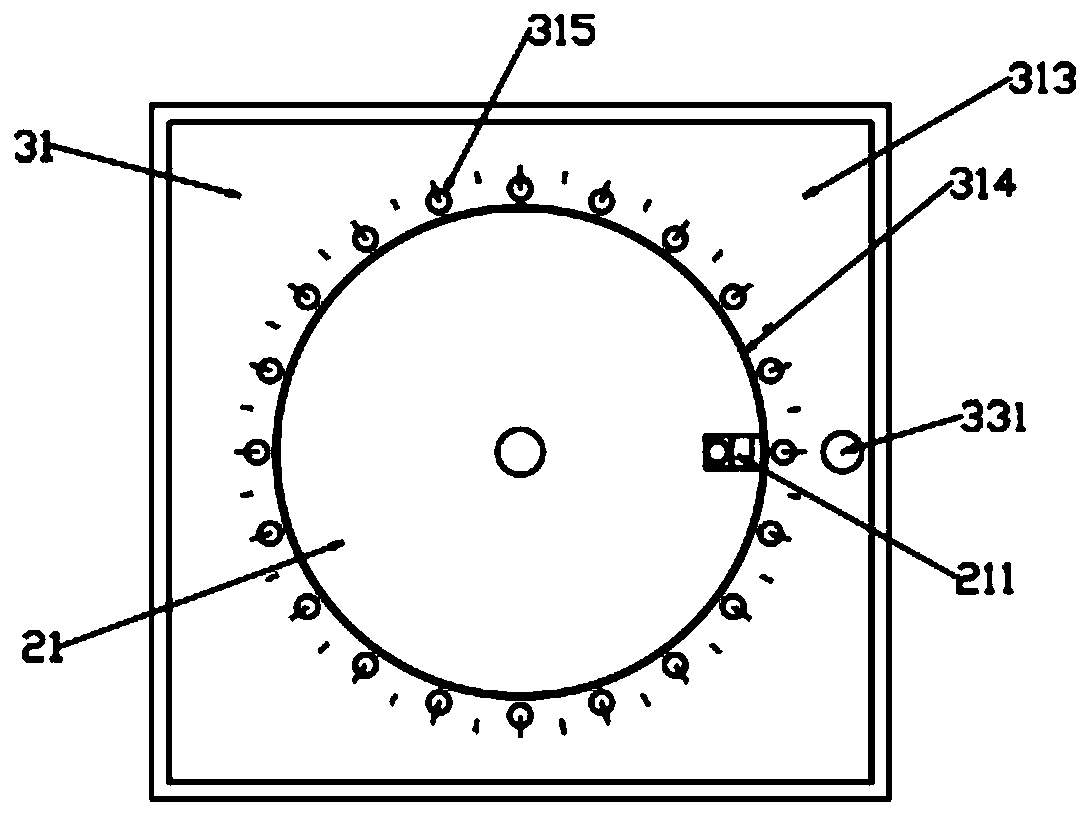

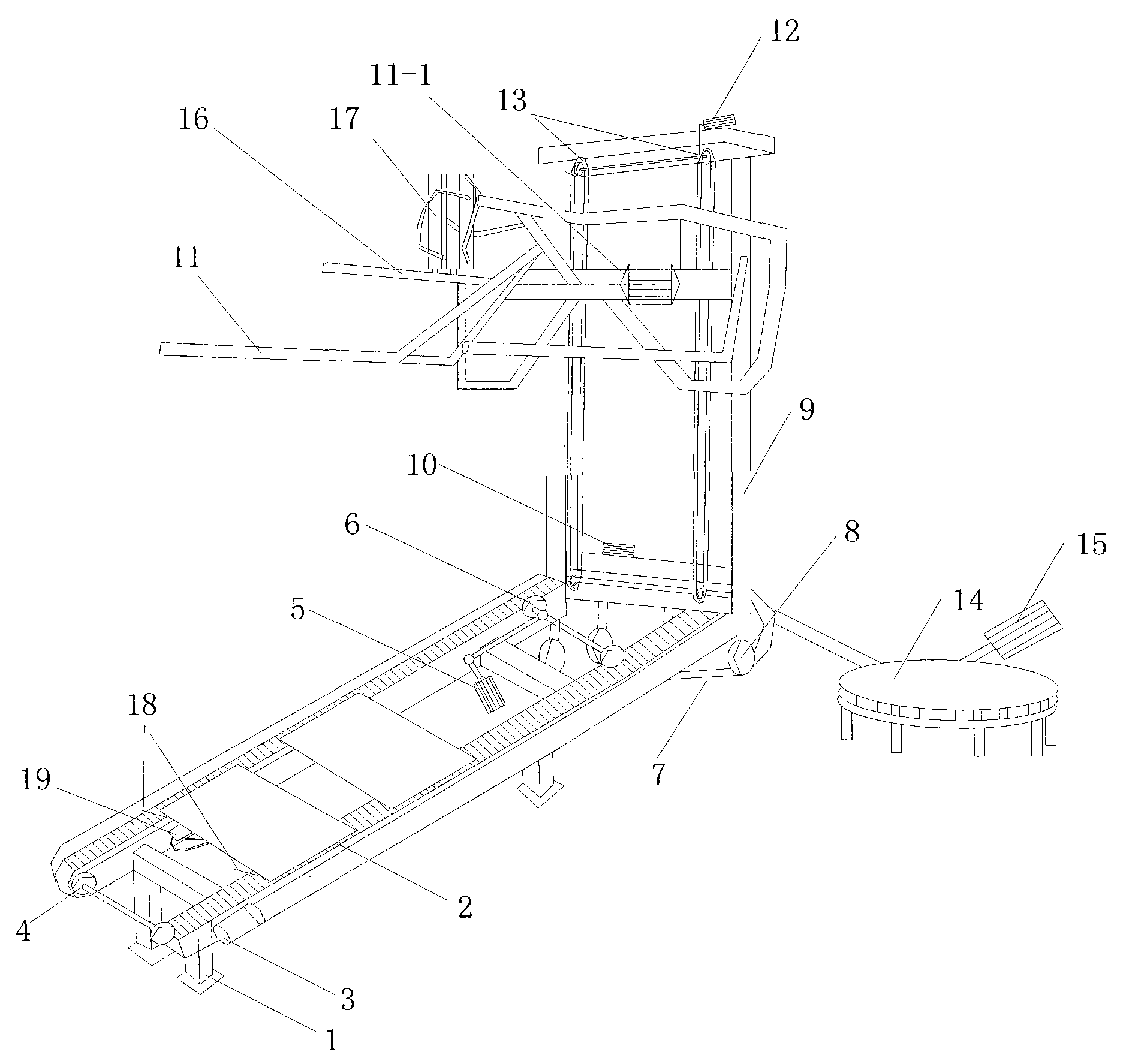

Novel automatic board stacking machine

InactiveCN103950732ASo as not to damageReasonable and novel structure designStacking articlesDe-stacking articlesStack machineEngineering

The invention discloses a novel automatic board stacking machine, and relates to the technical field of mechanical equipment. A conveyor belt is arranged above the frame of a conveyor; the two ends of the conveyor belt are respectively in transmission connection with a driven chain bearing and a driving chain bearing; the central shaft of the driving chain bearing is in transmission connection with a transmission motor; an automatic rotary table resetting switch is arranged on one side of the frame of the conveyor; the frame of the board stacking machine is arranged at the tail end of the conveyor belt; an idler wheel is arranged below the frame of the board stacking machine; a circular track is arranged at the bottom of the idler wheel; the idler wheel is connected with a rotating motor; a lifting motor is arranged at the top of the frame of the board stacking machine; the lifting motor is connected with an automatic board stacking fork through a transmission chain; an automatically-rotating board stacking base is arranged below one side of the frame of the board stacking machine; the automatically-rotating board stacking base is in transmission connection with a motor. The novel automatic board stacking machine is firm and durable; that the novel automatic board stacking machine can automatically stack boards is realized, so that a lot of manpower and material resources can be saved; the novel automatic board stacking machine is low in energy consumption; the boards can be stored orderly and attractively and are not damaged, so that resources are saved.

Owner:江门市康德木业有限公司

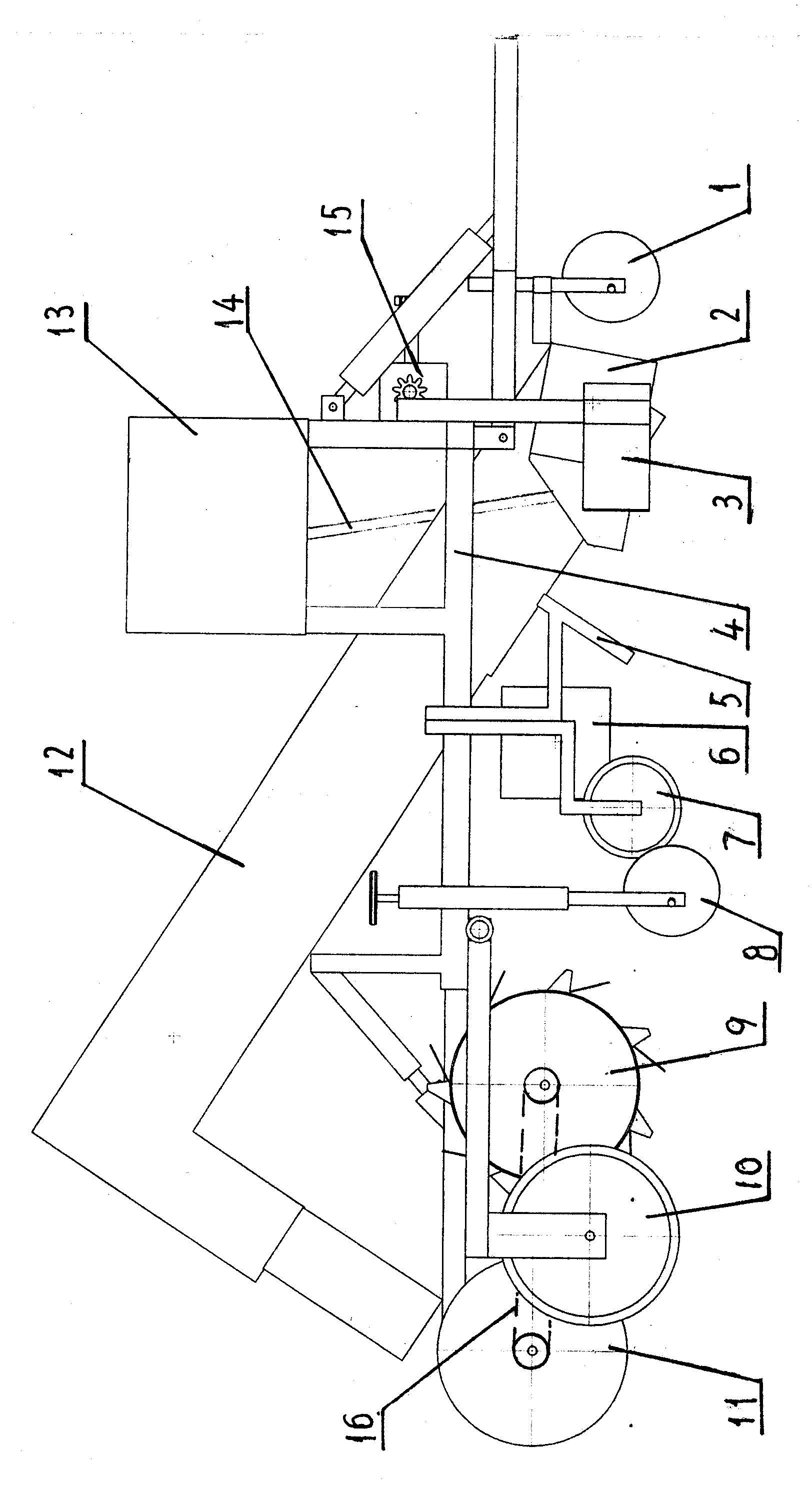

Corn double-ridge film mulching seeding combined planting machine

InactiveCN103583289AReasonable and novel structure designGood seeding qualityPlant protective coveringsFertiliser and seeding apparatusAgricultural engineeringIdler-wheel

The invention discloses a corn double-ridge film mulching seeding combined planting machine, and belongs to agricultural machinery. A soil collector, a chain harrow type soil conveying assembly, a groove earthing idler wheel and a power transmission case are respectively assembled on a machine frame, the soil collector is located in front of a ridge shaper, a soil inlet in the front end of the chain harrow type soil conveying assembly is located in the back side of the soil collector, the power transmission case is connected with the chain harrow type soil conveying assembly in a power transmission mode, the groove earthing idler wheel is assembled behind a duckbilled seeding roller, the duckbilled seeding roller is connected with the groove earthing idler wheel in a power transmission mode through a transmission chain, and a soil outlet in the back end of the chain harrow type soil conveying assembly is located above the groove earthing idler wheel. The corn double-ridge film mulching seeding combined planting machine is novel and reasonable in design, good in seeding operation quality, high in operating efficiency, reliable in usage and small in number of faults.

Owner:齐齐哈尔农利群机械制造有限公司

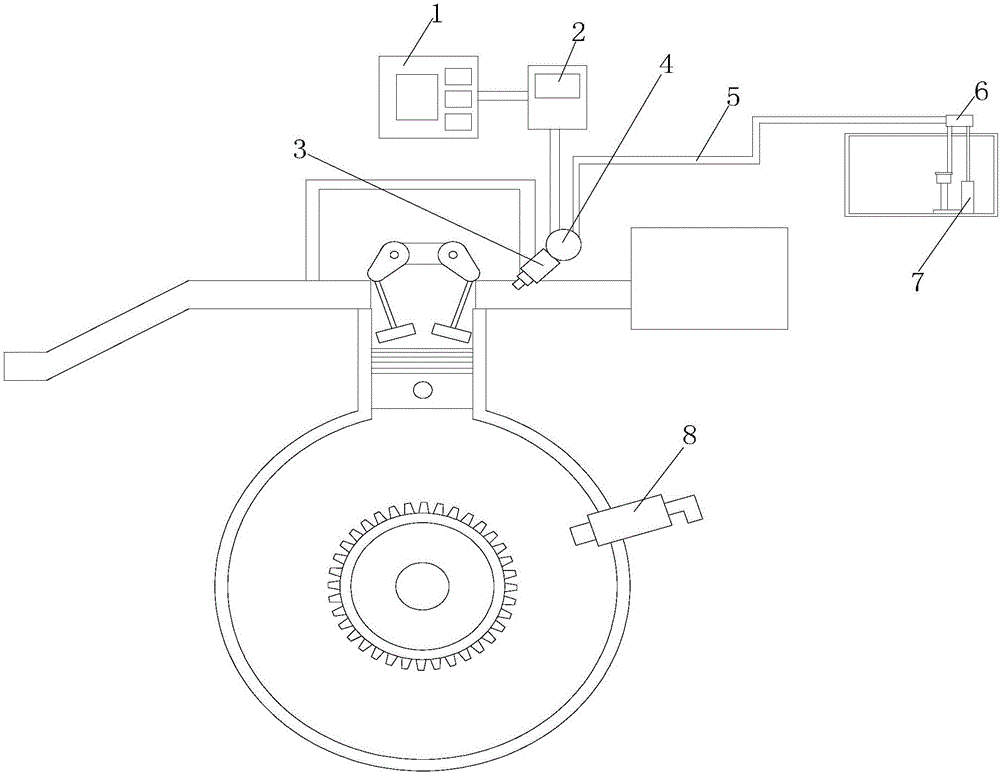

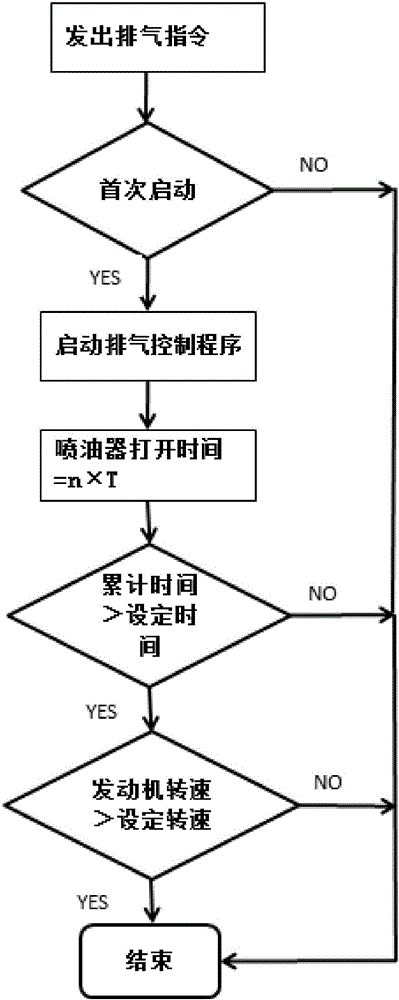

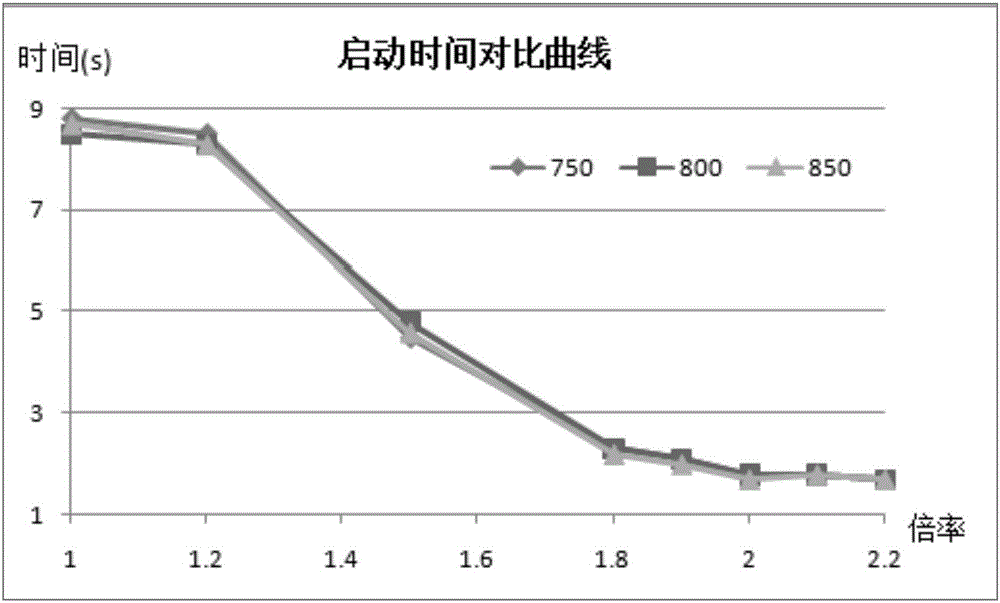

Quick exhaust device for automobile oil way and use method of quick exhaust device

InactiveCN106194534AEasy dischargeSpeed up the pace of offlineElectrical controlFuel injection apparatusFuel filterElectronic control unit

The invention discloses a quick exhaust device for an automobile oil way. The quick exhaust device for the automobile oil way comprises an engine and an instruction sending-out device. The engine is connected with an engine oil way, the instruction sending-out device is connected with an electronic control unit, the electronic control unit is connected with an oil atomizer, the oil atomizer is connected with an oil rail, and the oil rail is arranged on the engine oil way. The engine is provided with a rotation speed sensor, and the rotation speed sensor is connected with the electronic control unit. The oil rail is connected with a fuel filter and an oil pump through the engine oil way. The quick exhaust device has the beneficial effects that the defects of the prior art can be overcome, and the structural design is reasonable and novel.

Owner:HARBIN DONGAN AUTOMOTIVE ENGINE MFG CO LTD

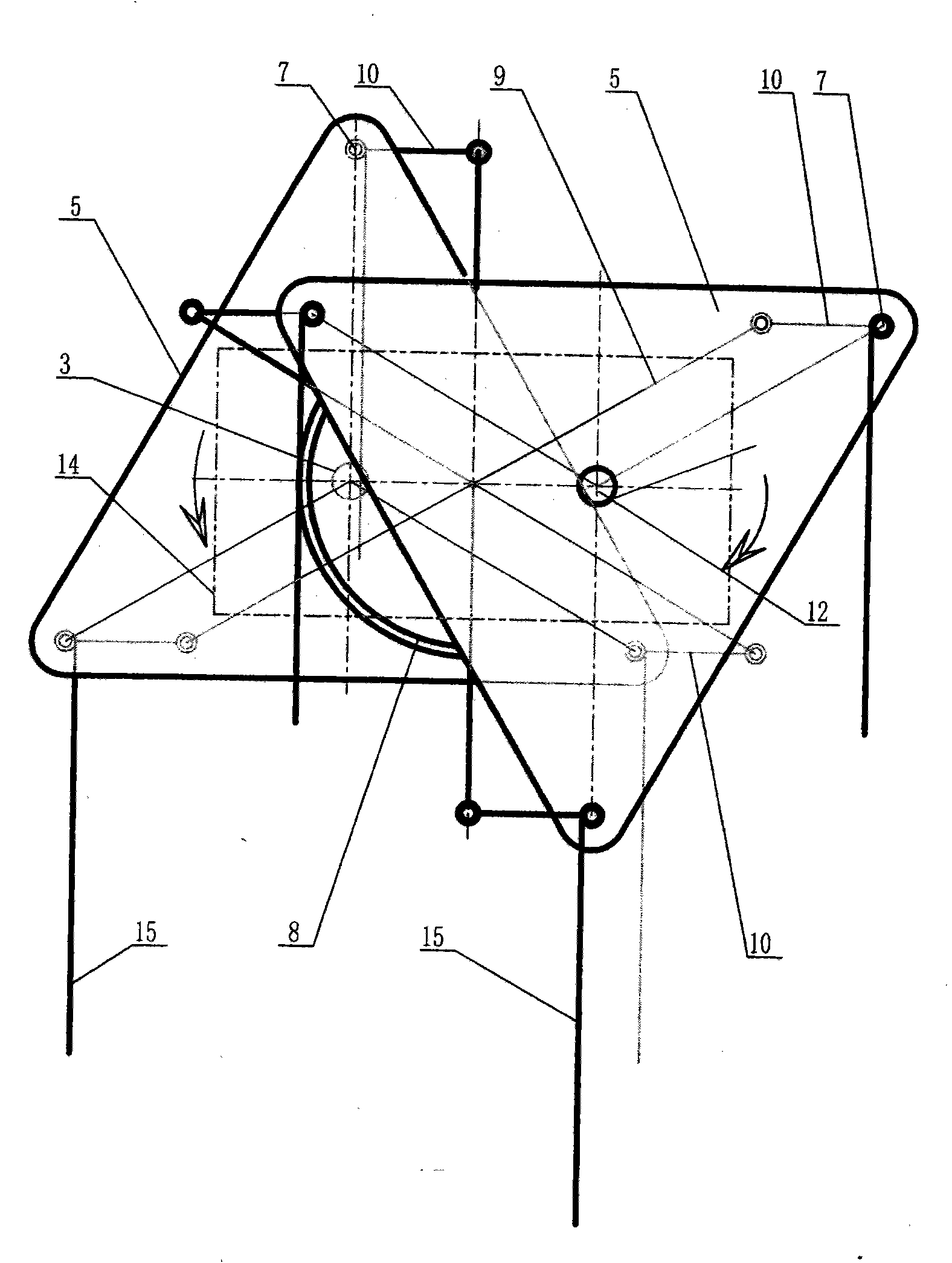

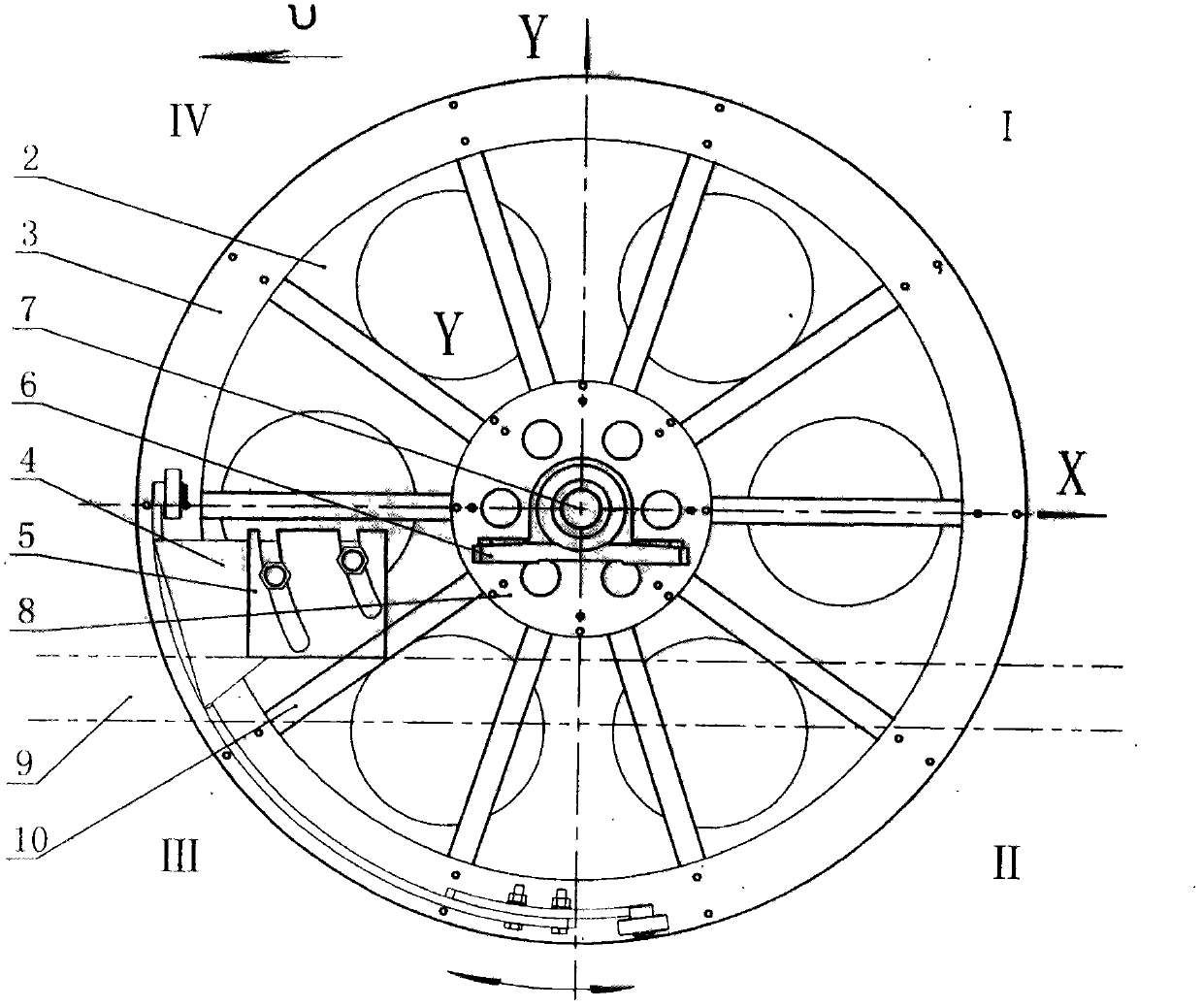

Flexible circular disc type planting device

InactiveCN102598929AReasonable and novel structure designEasy to useTransplantingCircular discDrive shaft

The invention relates to a flexible circular disc type planting device, which belongs to agricultural machinery. A driving shaft is arranged on a machine frame through a bearing seat, a rigid circular disc and a flexible circular disc are fixedly arranged on the driving shaft, plate springs are fixedly arranged in the radial direction on the flexible circular disc and are uniformly distributed in the circumferential direction, an annular elastic connecting plate is fixedly arranged on the outer end edge position of the plate springs, heavy body foam is respectively assembled on the outer end edge positions of the rigid circular disc and the plate springs, an opening degree regulating support seat is fixedly arranged on the machine frame, a pot disc gap regulating assembly is assembled on the opening degree regulating support seat and is in contact matching with the annular elastic connecting plate, or a swinging rod is arranged on the flexible circular disc through a hinging pin, an annular elastic connecting plate is fixedly arranged on the outer end edge position of the swinging rod, the heavy body foam is respectively assembled on the outer end edge positions of the rigid circular disc and the swinging rod, a pressure regulating screw bolt with a press spring is assembled on the rigid circular disc, and the press spring is in contact matching with the swinging rod. The flexible circular disc type planting device has the advantages that the structure is novel and reasonable, the use is reliable, the pot seedling transplanting operation quality is good, the efficiency is high, the faults are fewer, and the application range is wide.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Gas lifting jack for excavator

ActiveCN106429944AReduce output powerSolve the disadvantage of not being able to support the vehicleLifting devicesSoil-shifting machines/dredgersCylinder headGas cylinder

The invention discloses a gas lifting jack for an excavator and relates to the technical field of excavators. A piston rod and a piston are arranged in a cylinder body, one end of the piston rod is connected with the piston, the other end of the piston rod stretches out of one end of the cylinder body, and a first flying ring is arranged at the stretching-out end and connected to a rotary disc big frame of the excavator. The upper portion of the cylinder body is connected with a cylinder head, the cylinder head is fixed into the cylinder body through a cylinder cover, and a second flying ring is arranged at the other end of the cylinder body and connected to a big arm of the excavator. The piston divides the interior of the cylinder body into two cavities, the piston rod is arranged in one chamber serving as a rod end chamber, and the piston rod is not arranged in the other chamber serving as a non-rod end chamber. The rod end chamber is connected with a rod end chamber oil pipe of a big arm oil cylinder of the excavator, the non-rod end chamber is communicated with a high-pressure gas bottle, a first sealing structure is arranged between the piston and the cylinder body, a second sealing structure is arranged between the piston rod and the cylinder head, high-pressure nitrogen is used in the non-rod end chamber for work, hydraulic oil is used in the rod end chamber for work, the output power of an engine is reduced, and lifting force of a working device is improved.

Owner:沈阳双壹市政工程有限公司

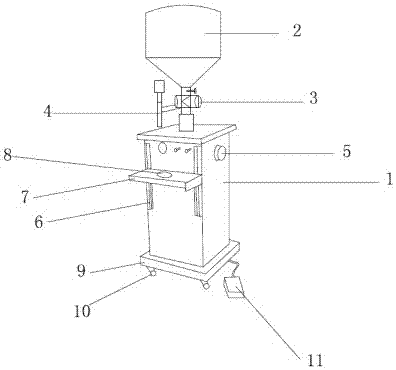

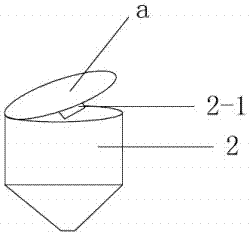

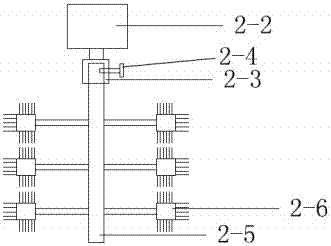

Filling machine for cosmetics

InactiveCN107986212ALow costReduce volumeLiquid fillingFilling device cleaningMedium enterprisesEngineering

The invention discloses a filling machine for cosmetics, and relates to the technical field of packaging machinery. According to the filling machine, the lower portion of a machine body is fixed to abase, a plurality of rolling wheels are arranged at the bottom of the base, a feeding hopper is connected to the upper portion of the machine body, a filling quantity adjusting knob is arranged on theside edge of the machine body, a pneumatic valve is arranged at the bottom end of the feeding hopper, the lower end of the feeding hopper is connected to a pneumatic discharging port, a filling bottle placing plate is arranged below the pneumatic discharging port and is connected to sliding rails in a sliding mode, the sliding rails are arranged on the front side of the machine body, a placing groove is formed in the middle position of the upper portion of the filling bottle placing plate, and a pedal switch is connected to the bottom of the machine body. The filling machine has the advantages that the filling bottle placing plate can slide up and down, the height of the placing plate can be adjusted according to the height of the bottle, in addition, a cleaning device is arranged in thefeeding hopper so that the feeding hopper can be cleaned, and therefore labor can be saved, and the filling machine is small in size, low in manufacturing cost and suitable for small and medium enterprises.

Owner:唐世奎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com