Closed hydraulic system for heading machine

A technology for hydraulic systems and roadheaders, which is applied to fluid pressure actuating system components, mechanical equipment, fluid pressure actuating devices, etc., can solve the problems of low life of open system components, many impurities in hydraulic oil, and large reversing impact. , to achieve the effect of reasonable and novel structure design, reducing energy consumption and reducing commutation impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

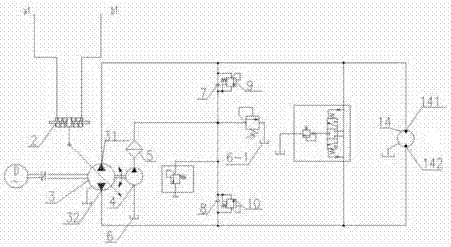

[0021] Specific implementation mode one: as figure 1 As shown, this specific embodiment adopts the following technical solutions: it includes a pilot control device 1, a main oil pump variable mechanism 2, a main oil pump swash plate 3, a charge pump 4, a fine filter 5, a first oil tank 6, and a second oil tank 6- 1. The first one-way valve 7, the second one-way valve 8, the first high pressure relief valve 9, the second high pressure relief valve 10, the oil charge relief valve 11, the motor 14, the motor first port 141, the motor second port Two ports 142, the first oil port 31 and the second oil port 32 of the main oil pump swash plate 3, the main oil pump swash plate 3 is a two-way variable pump, the first oil port 31 on the main oil pump swash plate 3 is connected to the first port 141 of the motor 14 Communication, the second oil port 32 on the main oil pump swash plate 3 communicates with the second port 142 of the motor 14, the pilot control device 1 directly communica...

specific Embodiment approach 2

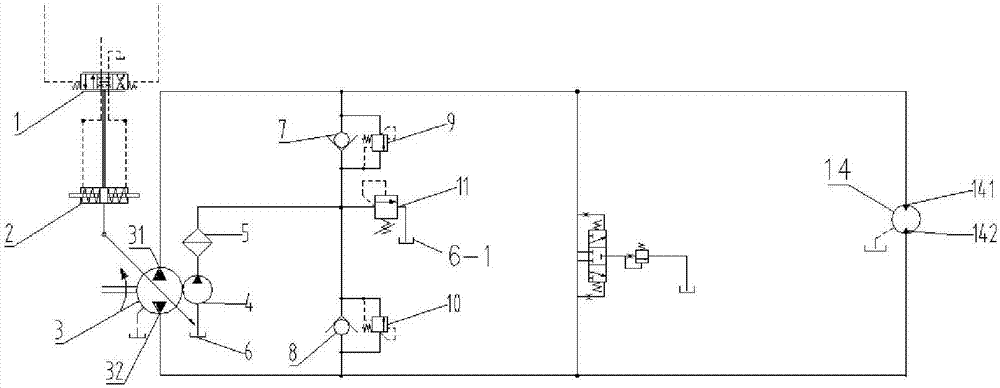

[0023] Specific implementation mode two: as figure 2 As shown, the difference between this specific embodiment and the first specific embodiment is that: the pilot control device 1 is removed, and the variable mechanism 2 is directly controlled by the first control pressure device a1 and the second control pressure device b1, thereby through The control mechanism 2 controls the change of the displacement of the main pump, and other components and connection methods are the same as those in the first embodiment.

specific Embodiment approach 3

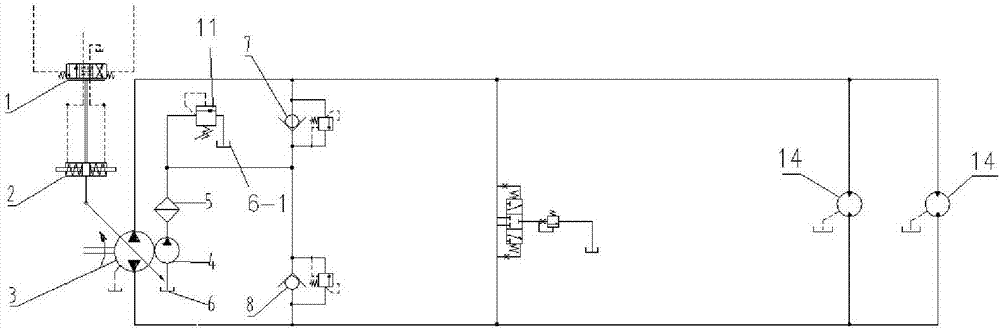

[0024] Specific implementation mode three: as image 3 As shown, the difference between this specific embodiment and specific embodiment one is: the outlet of the fine filter 5 is connected to the oil replenishment overflow valve 11, and the oil replenishment overflow valve 11 is connected to the second oil tank 6-1 connected, and there are two or more motors 14, the inlets of two or more motors 14 are connected together, the outlets of the main oil pump swash plate 3 are connected, and the outlets of two or more motors 14 are connected together, It is connected with the main oil pump swash plate 3 inlet. Other composition and connection methods are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com