Patents

Literature

62results about How to "Avoid throttling losses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

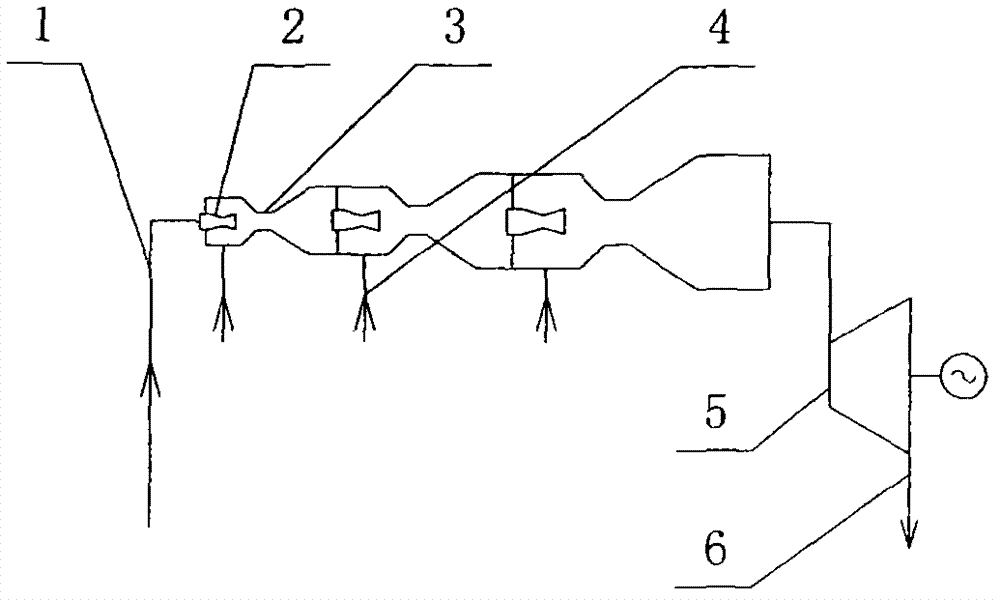

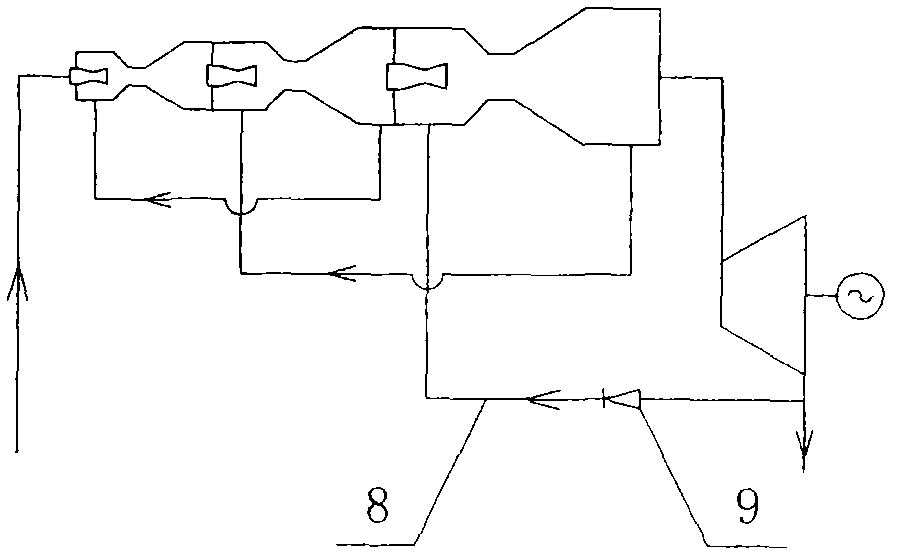

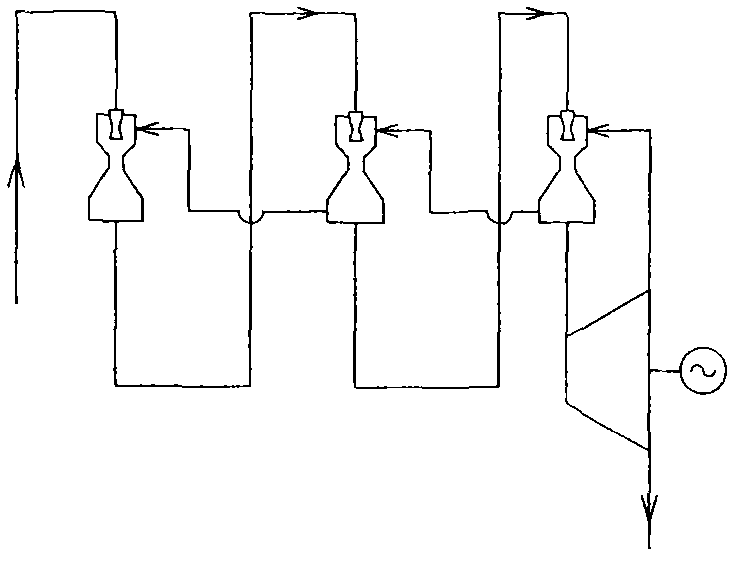

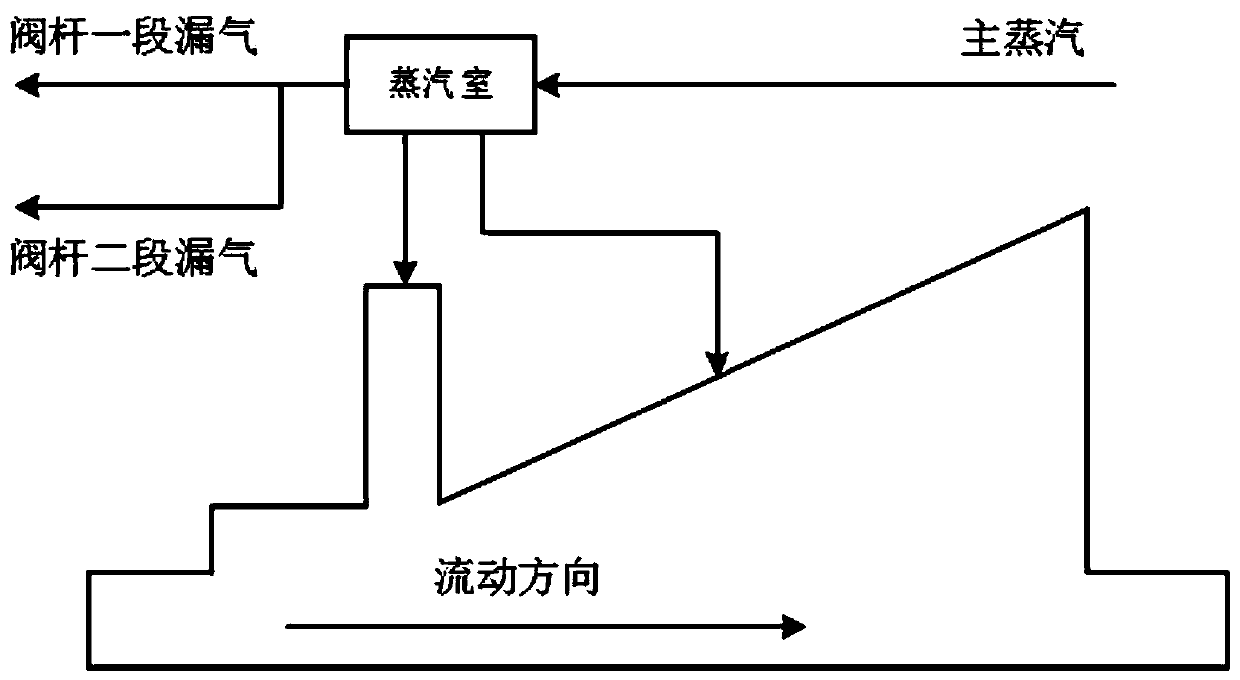

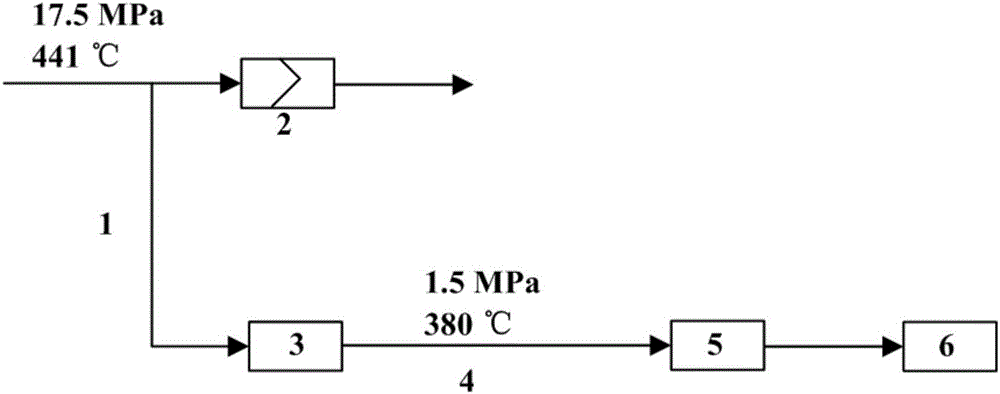

Energy-saving method by adopting jetting exhausting in thermal process

InactiveCN102852567AAvoid direct contactSolve the problem of high parameter operation and low parameter emissionJet pumpsGas turbine plantsThermal energyWater quality

An energy-saving method by adopting jetting exhausting in a thermal process belongs to the field of heat power. A high-parameter power air source is adopted in order to improve thermal efficiency, a jetting exhausting thermodynamic system adopts a circulation exhausting mode, or an over-one-stage multistage jetting exhausting device adopts a mode combining series connection, parallel connection and circulation to form a composite jetting system, and the high-parameter air source enters the jetting exhausting system and a gas turbine to sufficiently act to achieve high-efficiency operation through a mode combining the heat-into-power conversion equipment such as the jetting exhausting system and the gas turbine. In addition, a jetting cooling scheme for reducing throttling loss is provided, the energy-saving method can be popularized to wide energy-saving fields such as various heat and power processes and seawater or other water quality thermal purification systems, and the energy-saving method is high in efficiency and low in cost.

Owner:张玉良

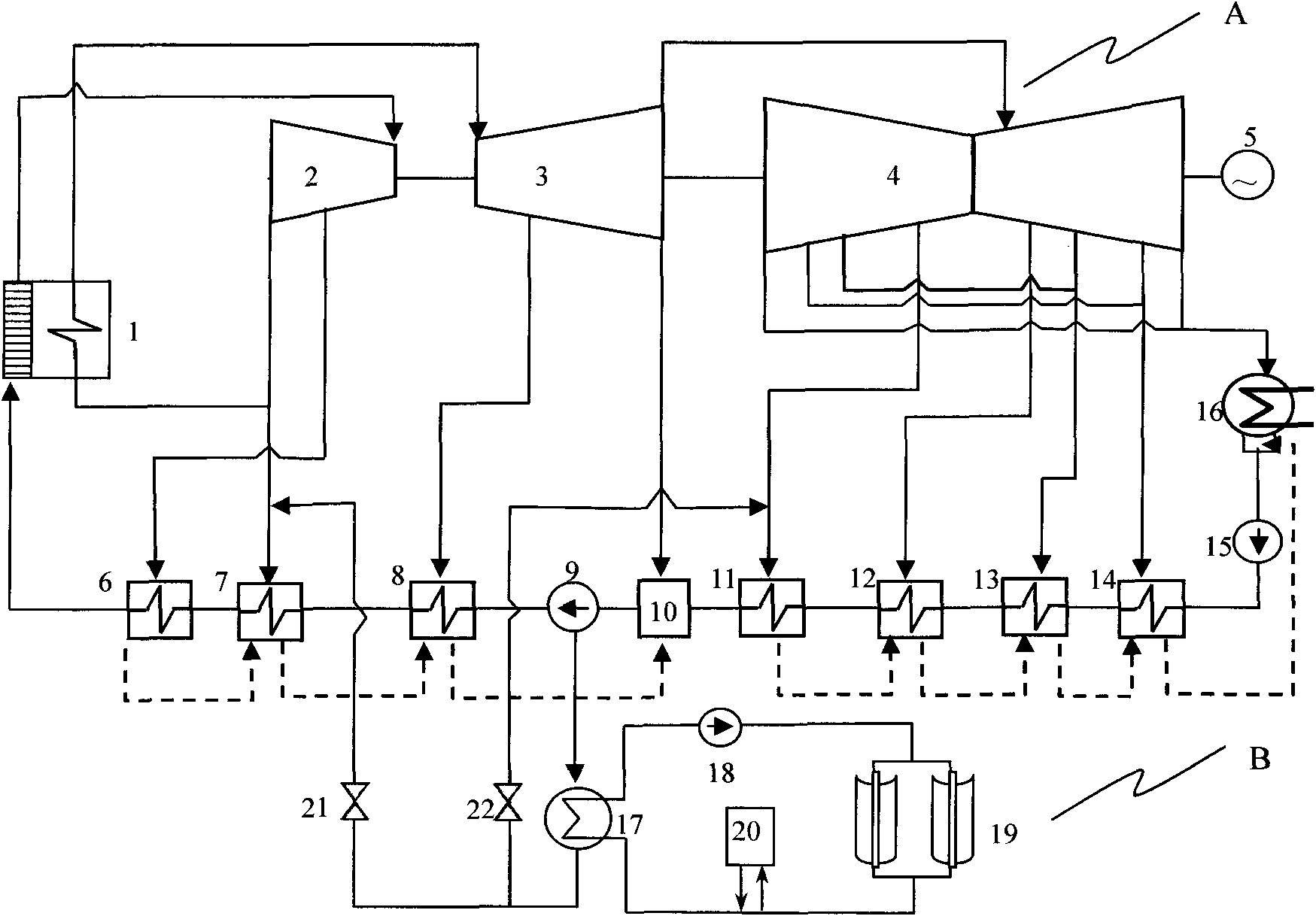

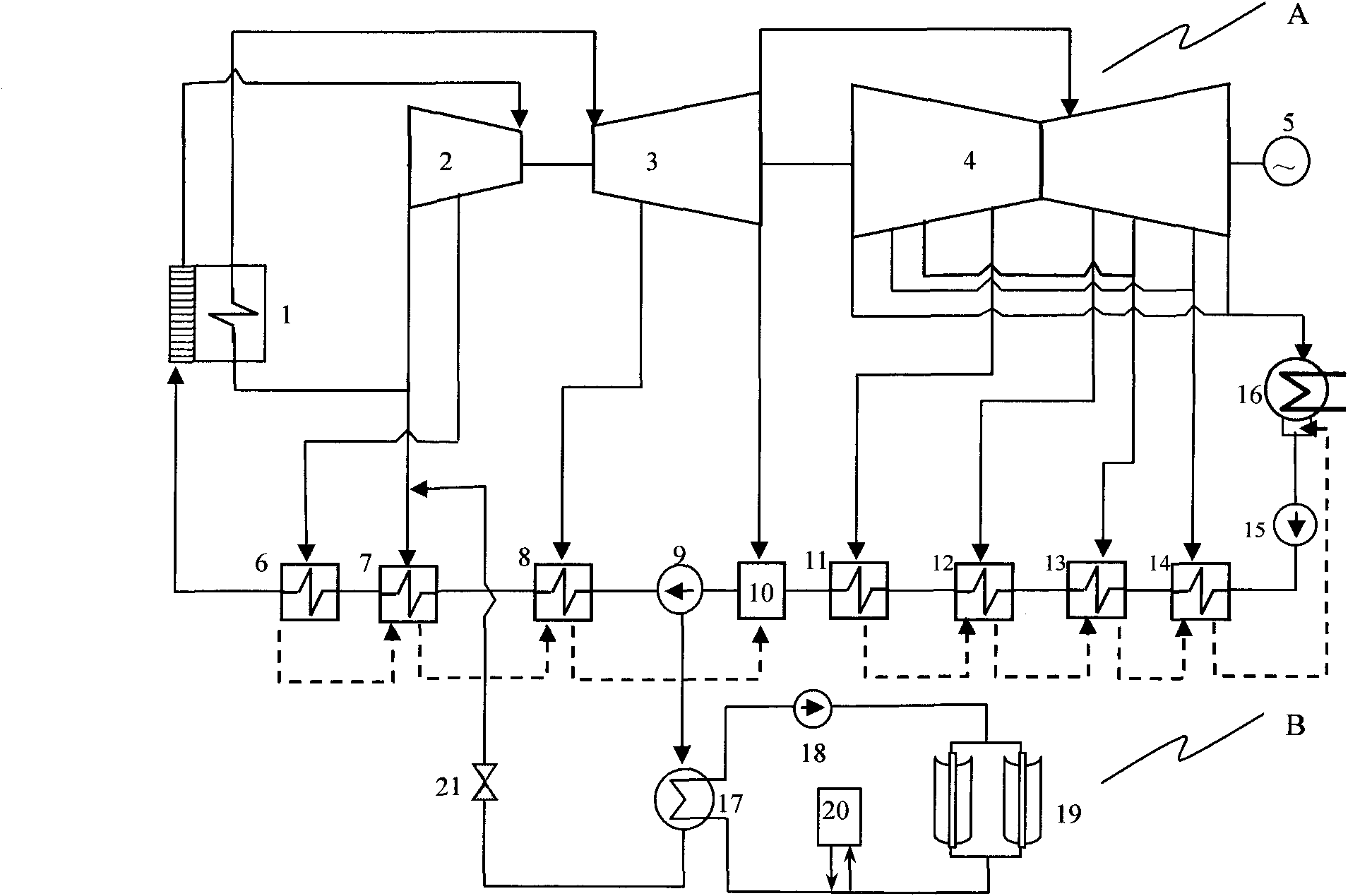

Solar heat collection, energy storage and back heating system applied to thermal generator set

InactiveCN101846044ARealize the goal of energy saving and emission reductionReduce regenerative steam extractionSteam generation heating methodsFrom solar energyClosed loopEngineering

The invention discloses a solar heat collection, energy storage and back heating system applied to a thermal generator set, and belongs to the field of energy conservation and emission reduction of the thermal generator set. The solar heat collection, energy storage and back heating system provided by the invention is connected with the conventional thermal generator set through a pipeline and a valve. The solar heat collection, energy storage and back heating system consists of a heat exchanger, an oil pump, a solar heat collection field, a heat accumulator and a heat exchanger which are connected in turn in a closed-loop mode; a heating working medium input end of the heat exchanger is connected with a center tap of a water supply pump of the thermal generator set; and a heating working medium input end of the heat exchanger is connected with a certain back heating steam extraction pipeline of the thermal generator set. The system can provide qualified heating steam for a certain back-heat heater through proper valve switching operation without changing a thermodynamic system structure of the conventional thermal generator set to stop using back heating extracted steam of a primary steam turbine so that the generating coal consumption of the thermal generator set is reduced and the purposes of energy conservation and emission reduction of the thermal generator set are fulfilled.

Owner:HUAZHONG UNIV OF SCI & TECH

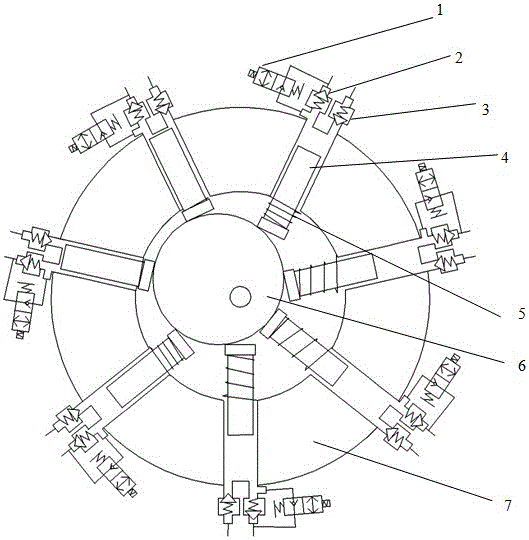

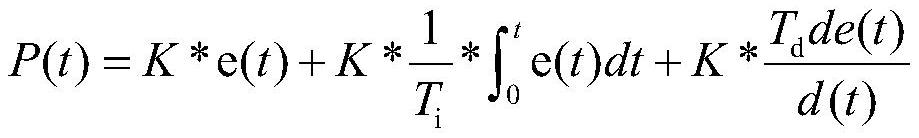

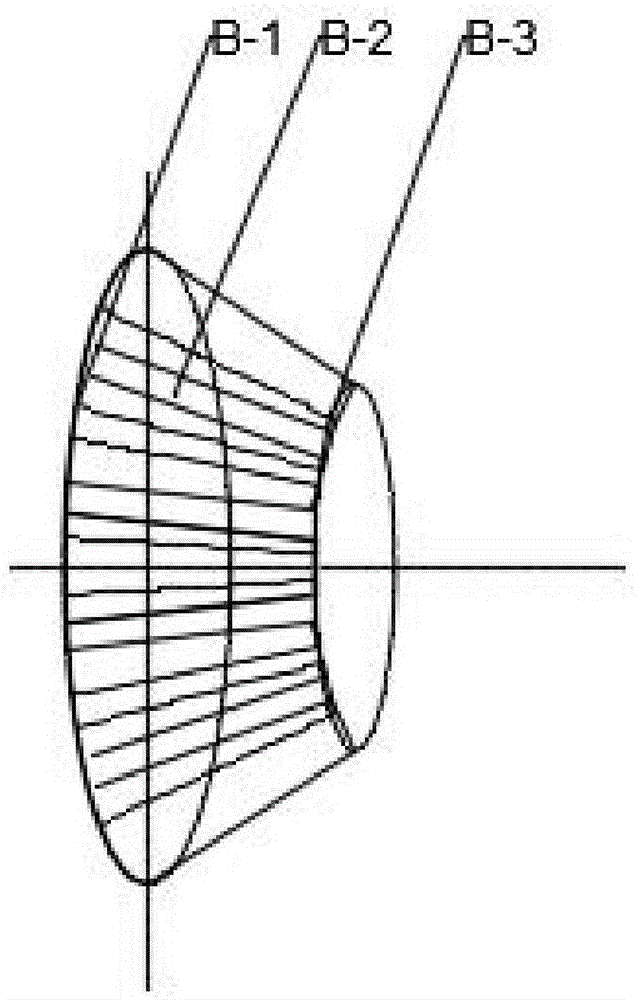

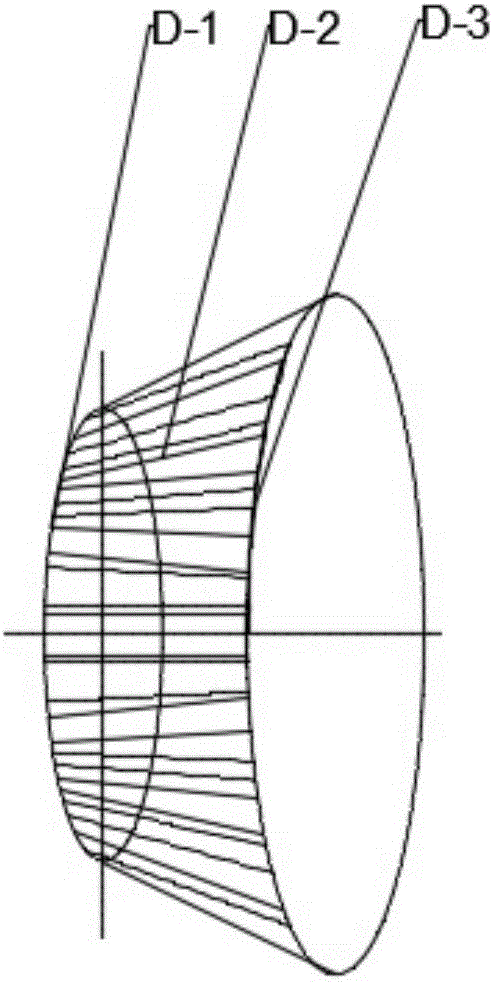

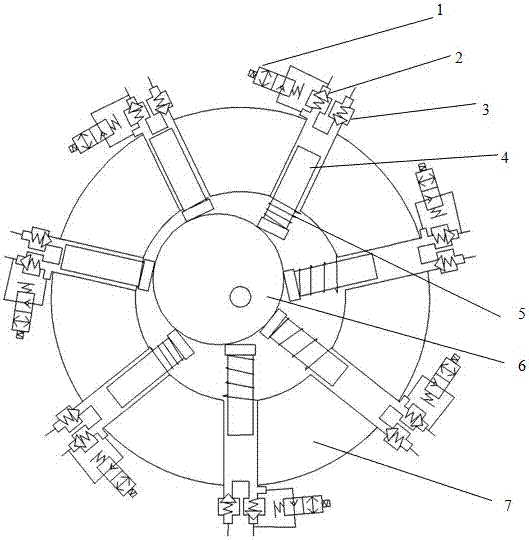

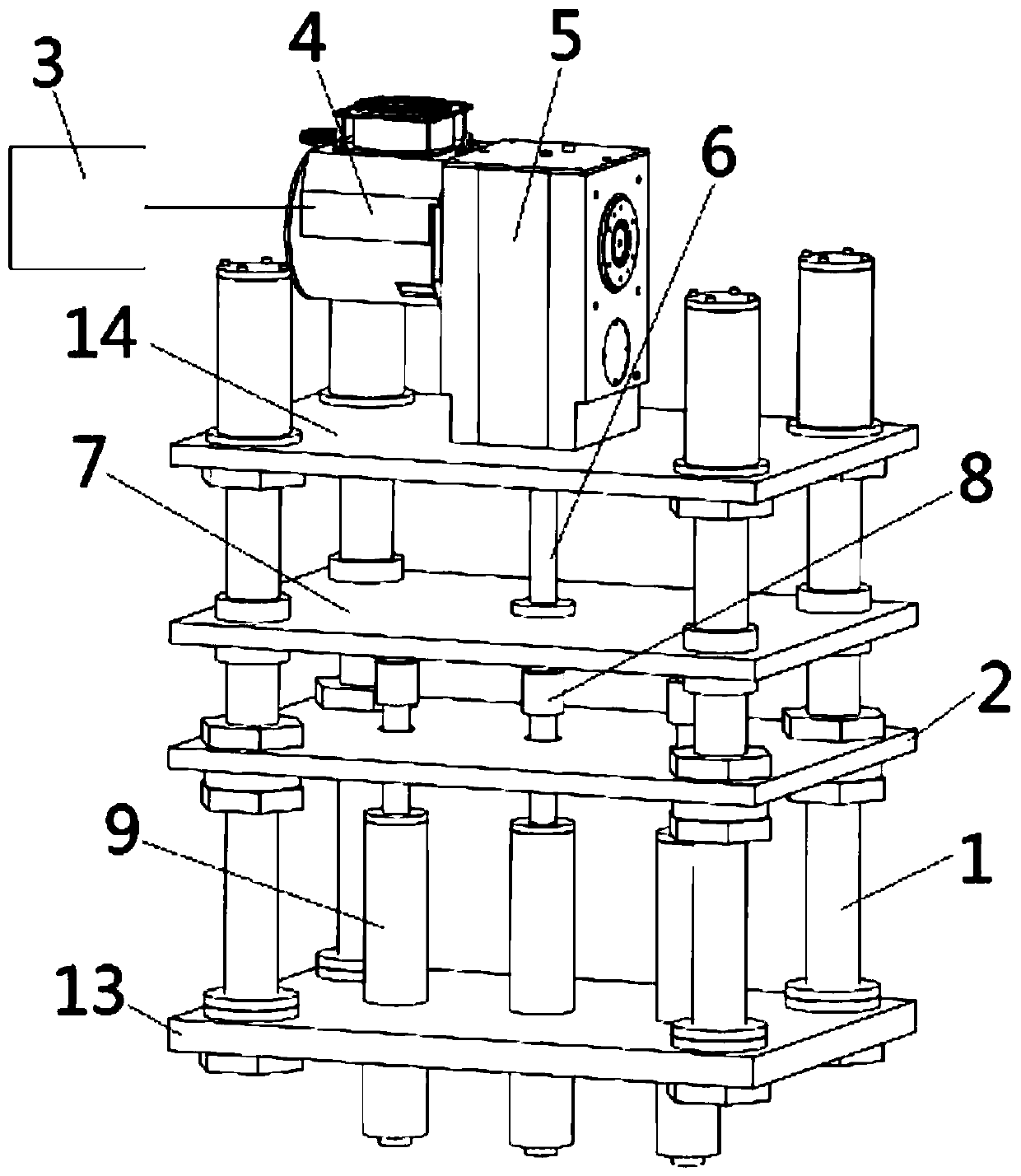

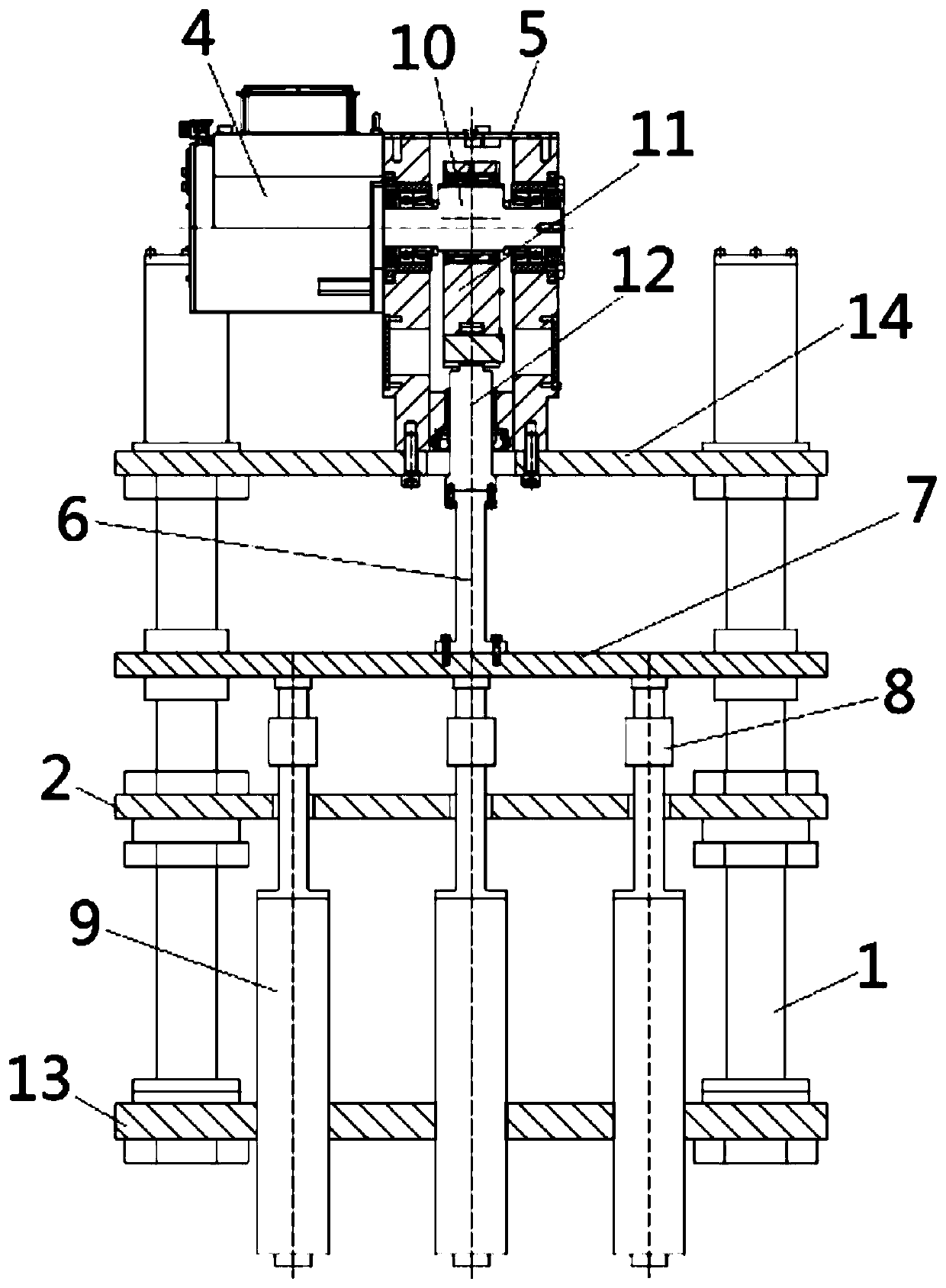

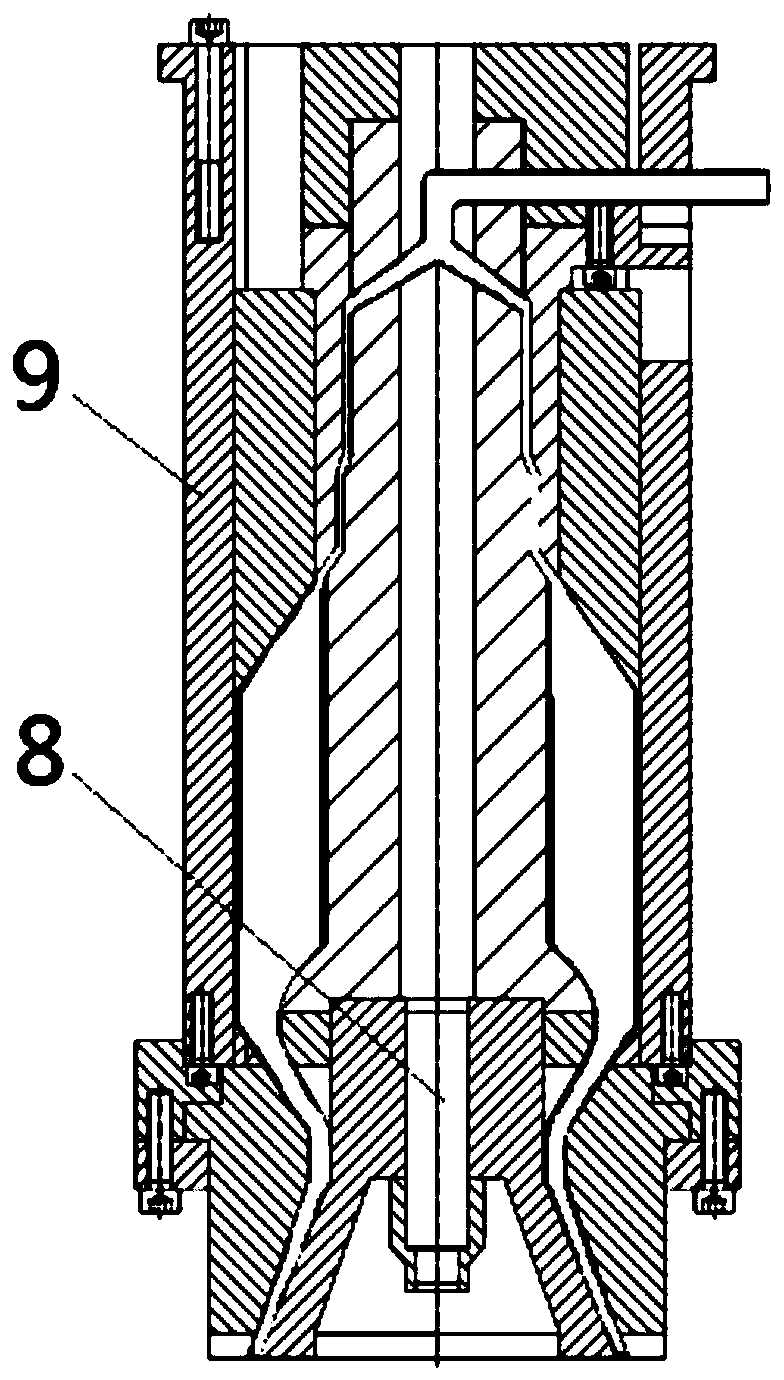

Plunger piston combined type digital variable pump

ActiveCN105134573ADisplacement depends onAvoid throttling lossesPump controlPositive-displacement liquid enginesSolenoid valveFuel tank

The invention discloses a plunger piston combined type digital variable pump. The plunger piston combined type digital variable pump consists of a plurality of plunger pistons, a plurality of oil absorption check valves, a plurality of oil discharge check valves, and a plurality of two-position two-way electromagnetic stop valves, wherein an oil absorption opening of each plunger piston communicates with an oil tank through the oil absorption check valves; an oil pressure opening of each plunger piston communicates with a high-pressure oil path through an oil pressure check valve; and the oil pressure opening of each plunger piston carries out bypass through the two-position two-way electromagnetic stop valves. In work, actual displacement of the digital variable pump is obtained by summing up displacement of all plunger pistons which normally discharge oil; the control on the displacement is realized by regulating the displacement corresponding to single plunger piston through an solenoid valve, so that the displacement changes of the digital variable pump are very quick in response to input of an electric signal, and therefore, requirements of high-frequency response control are satisfied. The plunger piston combined type digital variable pump can be used for effectively solving the defects such as large pressure loss, low frequency response and the like in a large-flow servo and proportional electric hydraulic control system, and achieves the great energy-saving effect.

Owner:王林翔

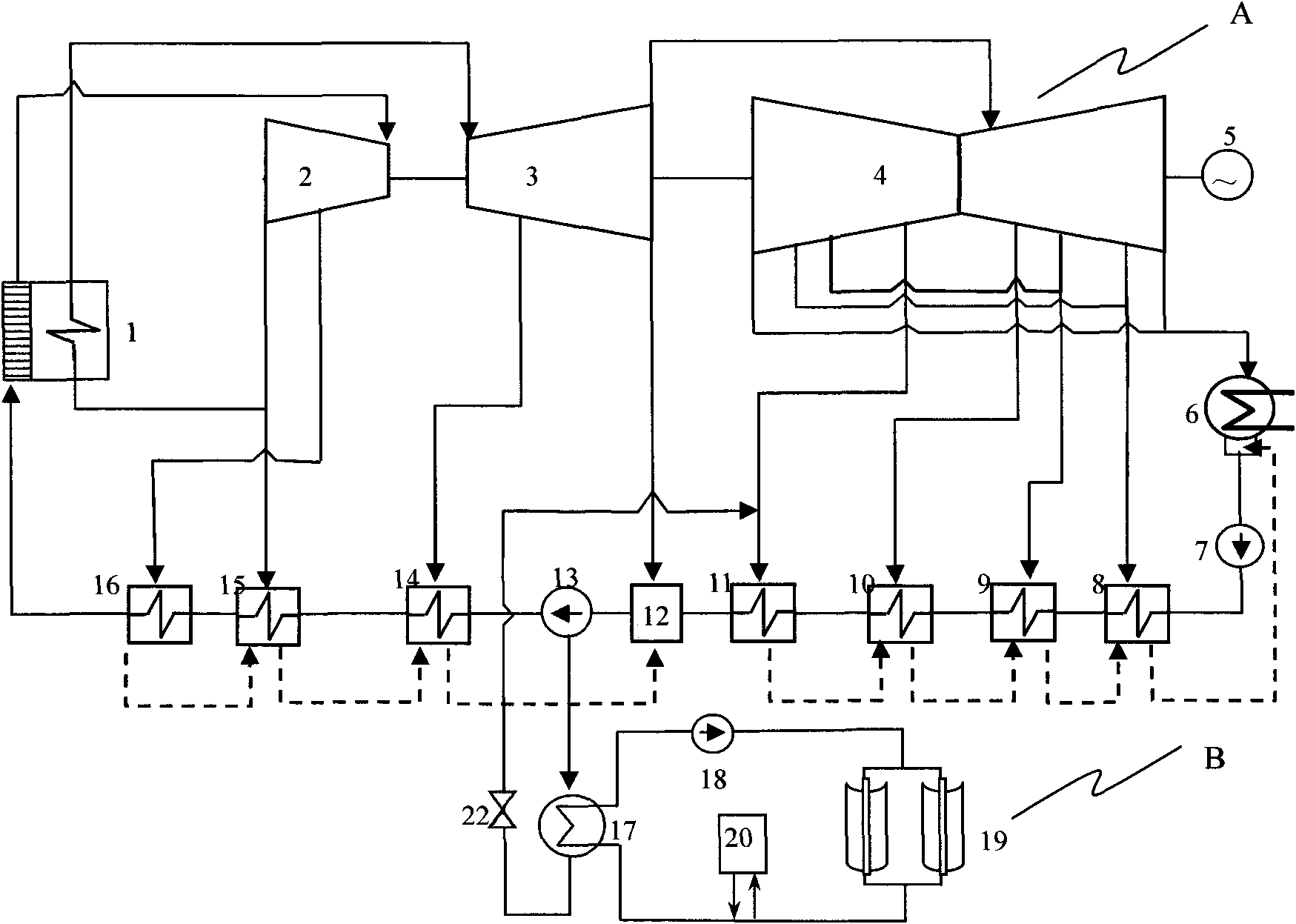

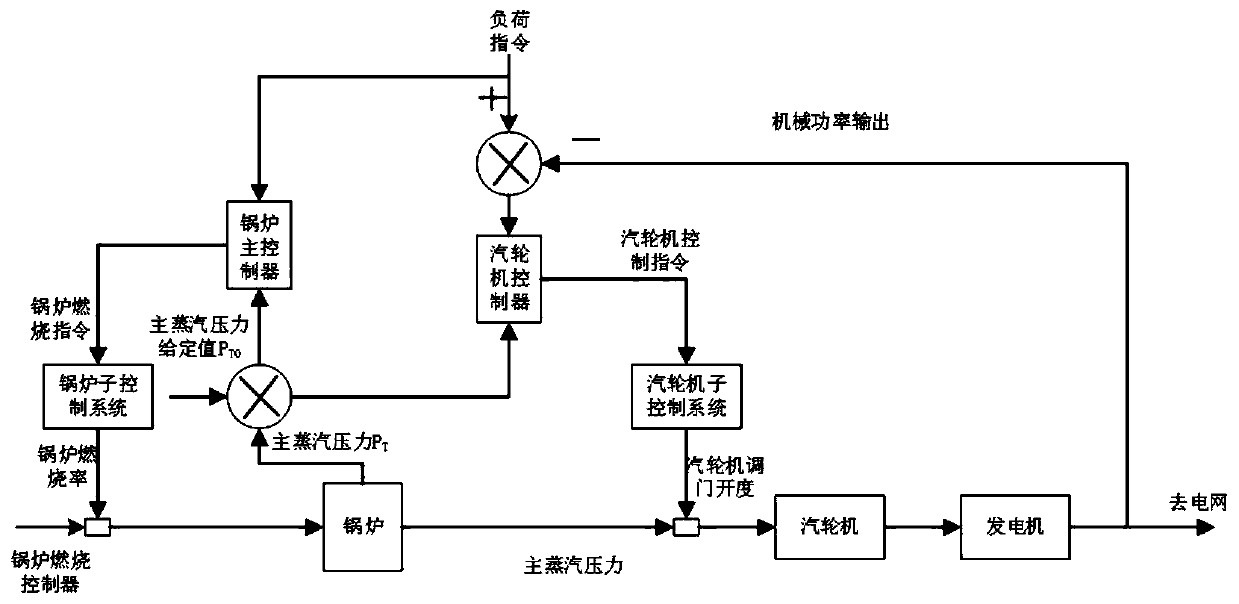

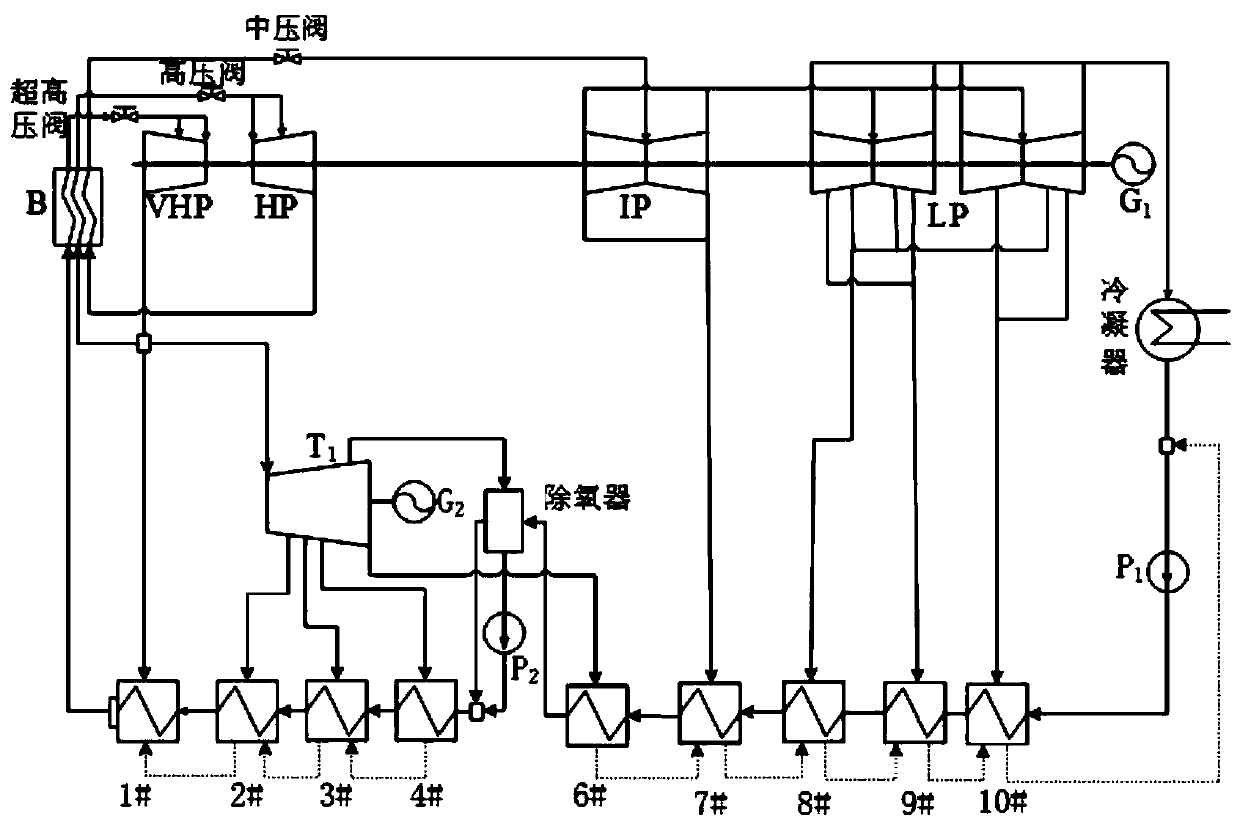

Control system and method for ultra-supercritical secondary reheating unit to participate in power grid primary frequency modulation

PendingCN110792482AAchieve a FMIncrease capacityBoiler controlEngine componentsUltra high pressureControl system

The invention discloses a control system and method for an ultra-supercritical secondary reheating unit to participate in power grid primary frequency modulation. The system comprises an ultrahigh-pressure cylinder regulation valve, a high-pressure cylinder regulation valve, a medium-pressure cylinder regulation valve, a first steam supplementing valve and a second steam supplementing valve; ultrahigh-pressure cylinder regulation valve, the high-pressure cylinder regulation valve and the medium-pressure cylinder regulation valve of a secondary reheating unit can be controlled to simultaneouslyparticipate in power grid primary frequency modulation in a steam supplementing regulation mode. When the practical load of a power grid is higher or lower than a rated load, the frequency of the power grid deflects for 50 HZ; the deflection change of the frequency of the power grid is received by the control system; the opening amplitudes of the ultrahigh-pressure cylinder regulation valve, thehigh-pressure cylinder regulation valve and the medium-pressure cylinder regulation valve are controlled, and the steam inlet flow of each cylinder is changed, so that the mechanical power output of asecondary reheating turbine is changed; and practical power output is matched with the load of the power grid, so that primary frequency modulation of the power grid is realized.

Owner:XI AN JIAOTONG UNIV

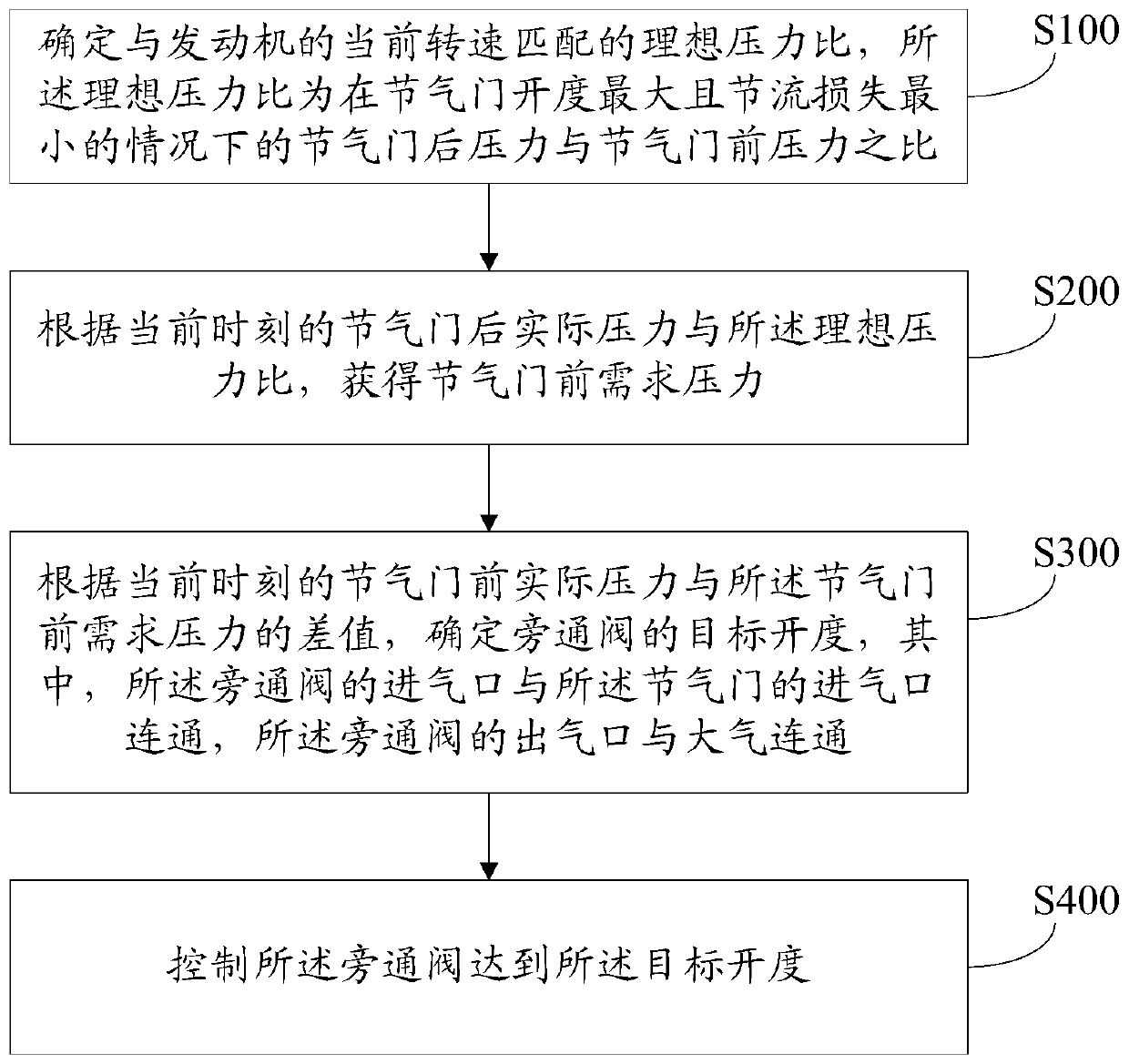

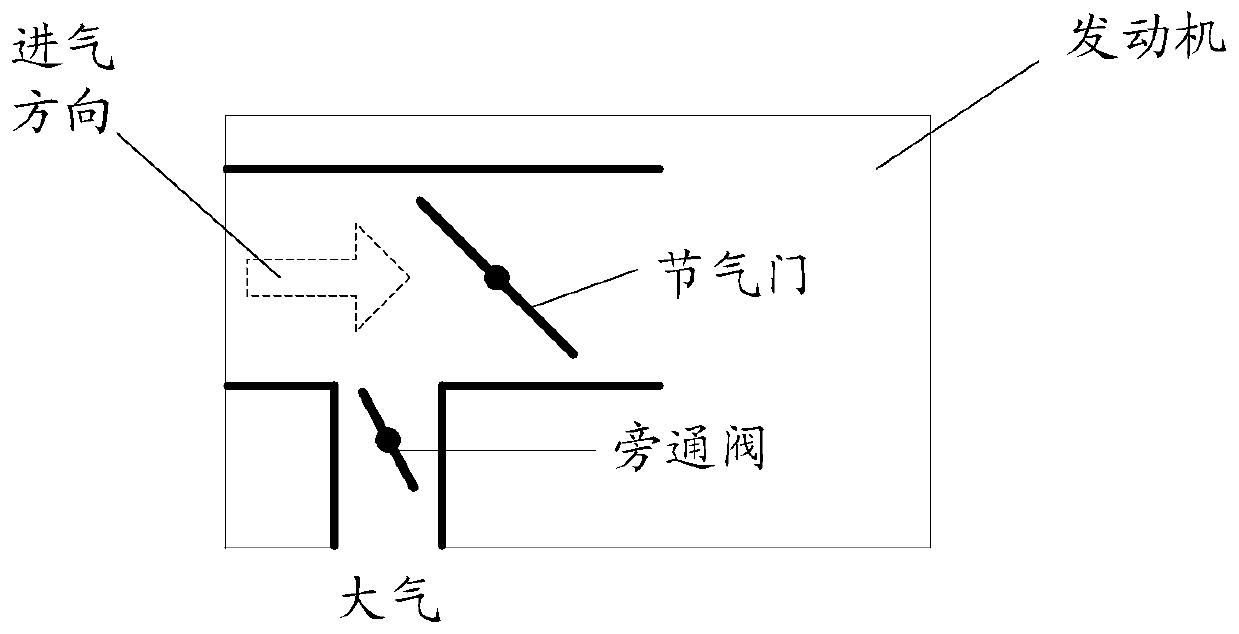

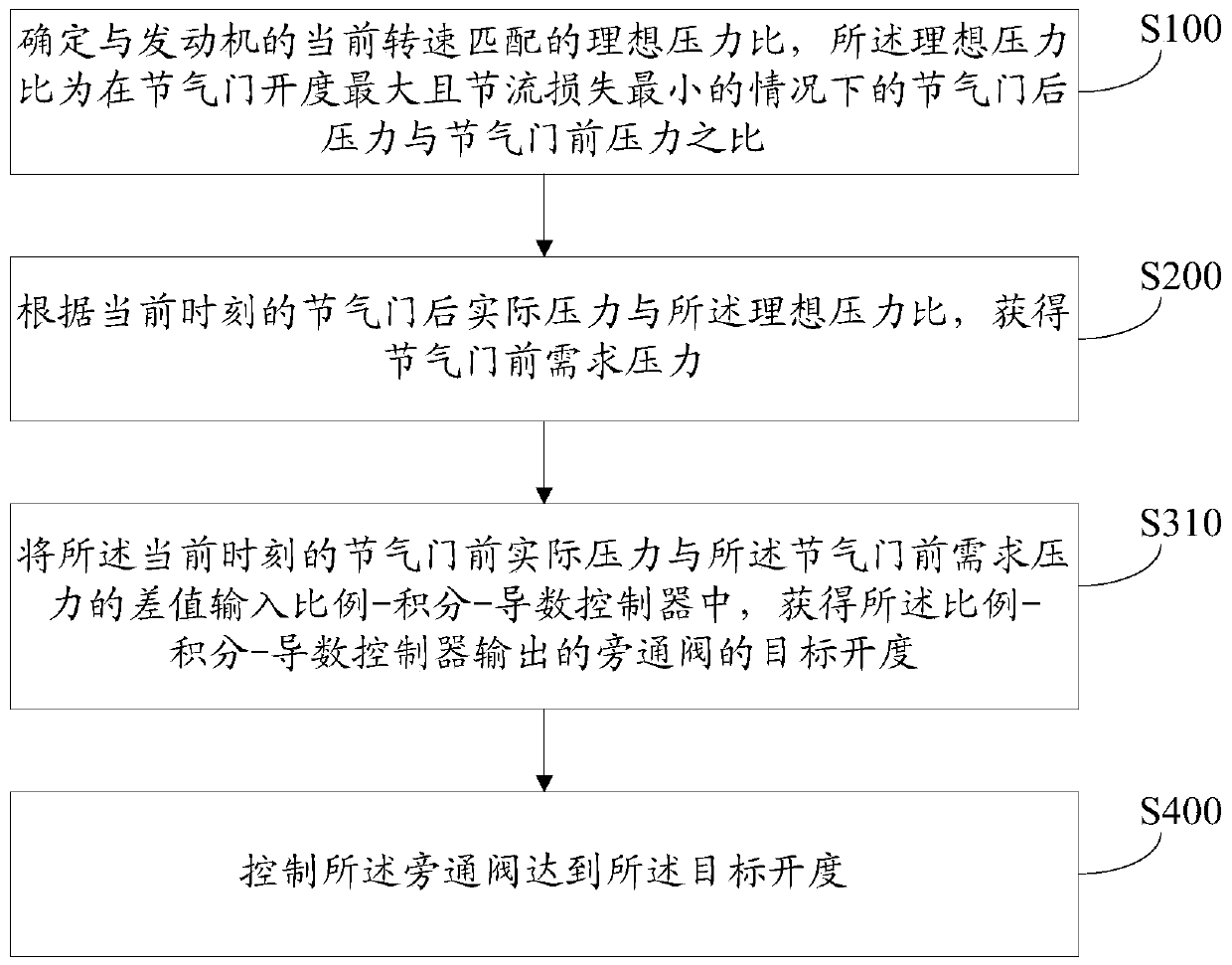

Control method and device of engine, storage medium and computer equipment

ActiveCN110284976AAvoid throttling lossesHigh thermal efficiencyElectrical controlOutput powerControl theoryThermal efficiency

The invention discloses a control method and device of an engine, a storage medium and computer equipment. The ideal pressure ratio matched with the current rotating speed of the engine can be confirmed, and the ideal pressure ratio is the ratio of the back pressure and the front pressure of a throttle valve under the condition that the opening degree of the throttle valve is the maximum and throttle losses are the minimum; the front required pressure of the throttle valve is obtained according to the back actual pressure of the throttle valve at the current moment and the ideal pressure ratio; the target opening degree of a bypass valve is confirmed according to the difference value between the front actual pressure of the throttle valve at the current moment and the front required pressure of the throttle valve, wherein a gas inlet of the bypass valve communicates with a gas inlet of the throttle valve, and a gas outlet of the bypass valve communicates with the atmosphere; and the bypass valve is controlled to reach the target opening degree. The technical means of controlling the opening degree of the bypass valve is adopted, the technical problem that the throttle losses of the engine are increased is overcome, and then the technical effect of improving the heat efficiency of the engine is achieved.

Owner:WEICHAI POWER CO LTD

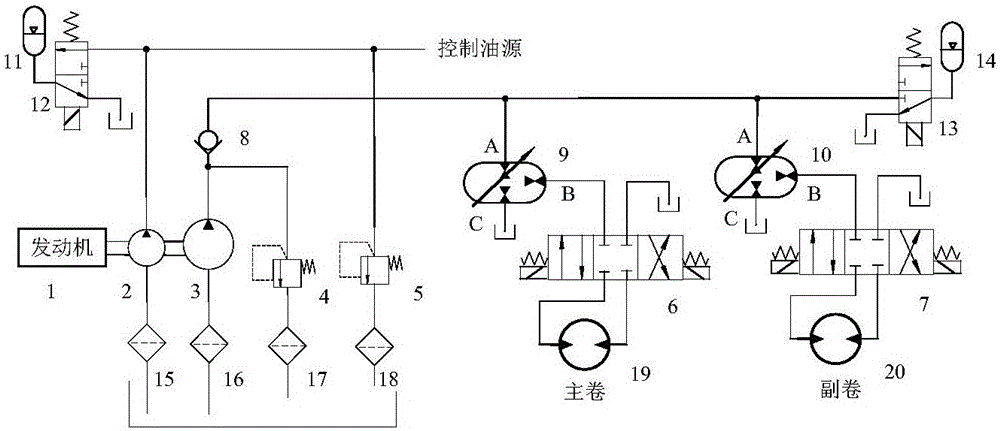

Winch hydraulic system applicable to crawler crane

InactiveCN106185662AReduce installed powerIncrease profitAccumulator installationsServomotorsDrive shaftHigh pressure

The invention discloses a winch hydraulic system applicable to a crawler crane. The winch hydraulic system comprises a control oil way, a high pressure oil way, a control oil way metering pump, a main pump, a one-way valve, a fourth solenoid directional valve, a high pressure accumulator, an engine, a third solenoid directional valve and a low pressure accumulator; the control oil way metering pump is arranged on the control oil way; the main pump, the one-way valve, the fourth solenoid directional valve and the high pressure accumulator are arranged on the high pressure oil way; a driving shaft of the engine is connected with the control oil way metering pump and the main pump; the engine and the main pump are used for supplying power to the crawler crane jointly; the third solenoid directional valve is connected with the low pressure accumulator and an outlet of the control oil way metering pump; the low pressure accumulator is used for stabilizing the pressure of the control oil way; an outlet of the main pump is connected with the one-way valve; the fourth solenoid directional valve is connected with the one-way valve and the high pressure accumulator; and the high pressure accumulator is used for recovering and storing potential energy of a weight when the weight drops, so as to be used for winch movement.

Owner:HUAZHONG UNIV OF SCI & TECH

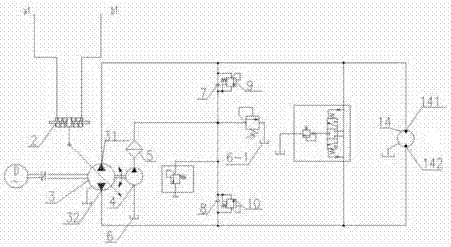

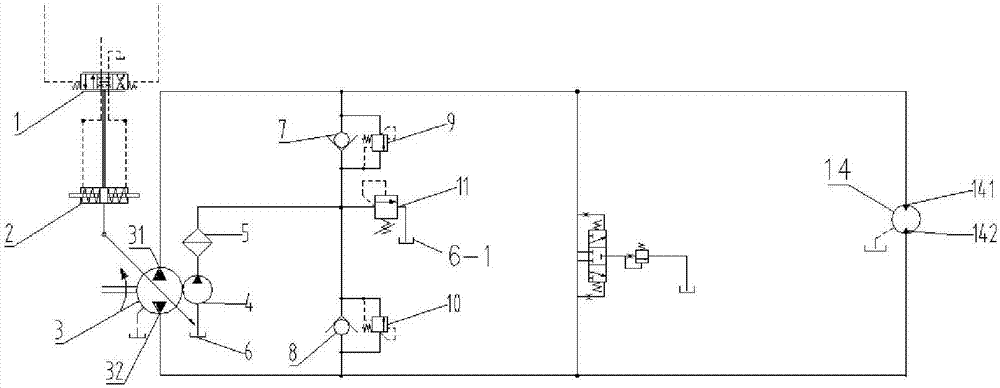

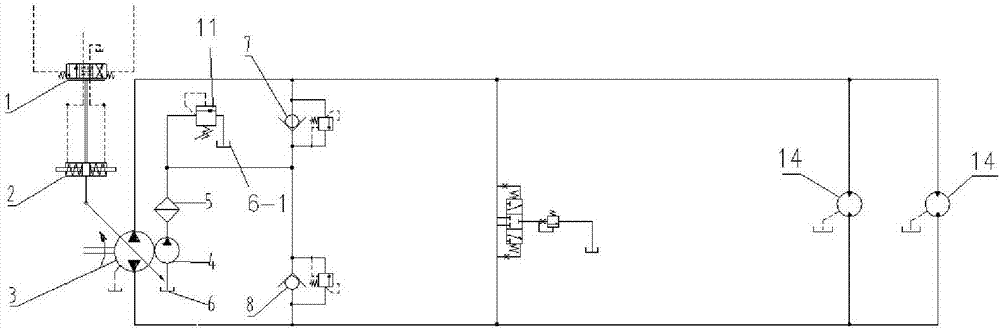

Closed hydraulic system for heading machine

PendingCN106907364AAvoid throttling lossesReasonable and novel structure designServomotor componentsServomotorsMechanical equipmentCoal

The invention discloses a closed hydraulic system for a heading machine and a heading machine using the system and relates the technical field of coal mine mechanical equipment. A main oil pump is a bidirectional variable pump. A first oil opening in the main oil pump communicates with a first end opening of a motor. A second oil opening in the main oil pump communicates with a second end opening of the motor. A pilot control device directly communicates with a main oil pump variable mechanism, and an inlet of a first high-pressure overflow valve and an inlet of a second high-pressure overflow valve are connected with the first oil opening of the main oil pump and the second oil opening of the main oil pump correspondingly. An outlet of the first high-pressure overflow valve and an outlet of the second high-pressure overflow valve are connected with an oil supplementing overflow valve which is connected with a second oil tank. A pilot control element is directly connected with the main oil pump variable mechanism to control the displacement of the main oil pump. The main oil pump is connected with the motor through a pipeline, and a valve throttle is arranged in the middle. Throttling losses of an opening system are avoided, energy consumption is reduced, and reversing impacts are reduced; and power losses of the device are low, the temperature rise of hydraulic oil is low, large-volume oil tank heat dissipation is not needed, only the requirement for oil supplementing needs to be met through to the oil tank volume, and equipment space and weight are saved.

Owner:无锡华瀚能源装备科技有限公司

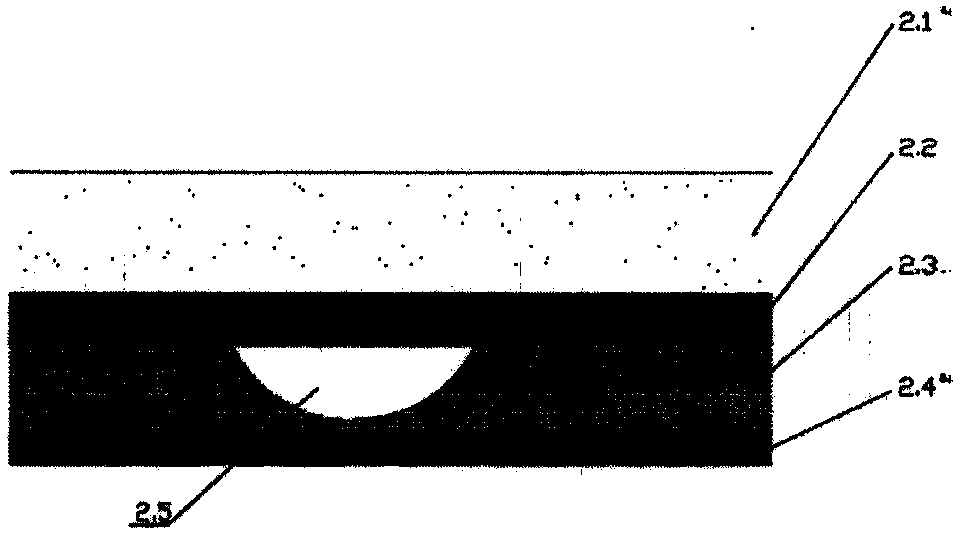

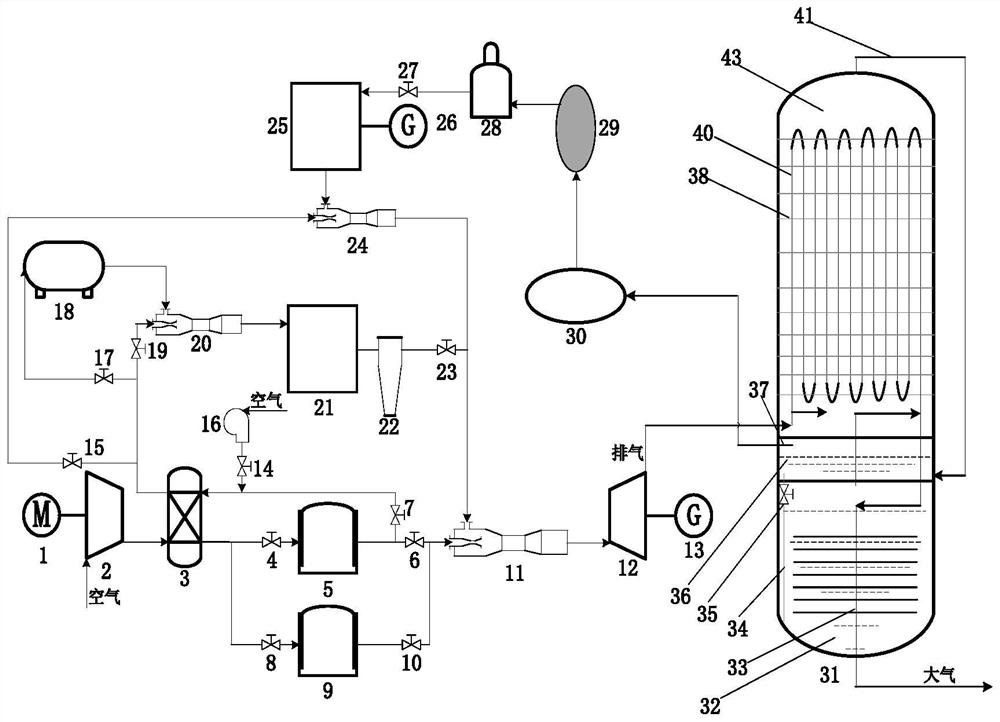

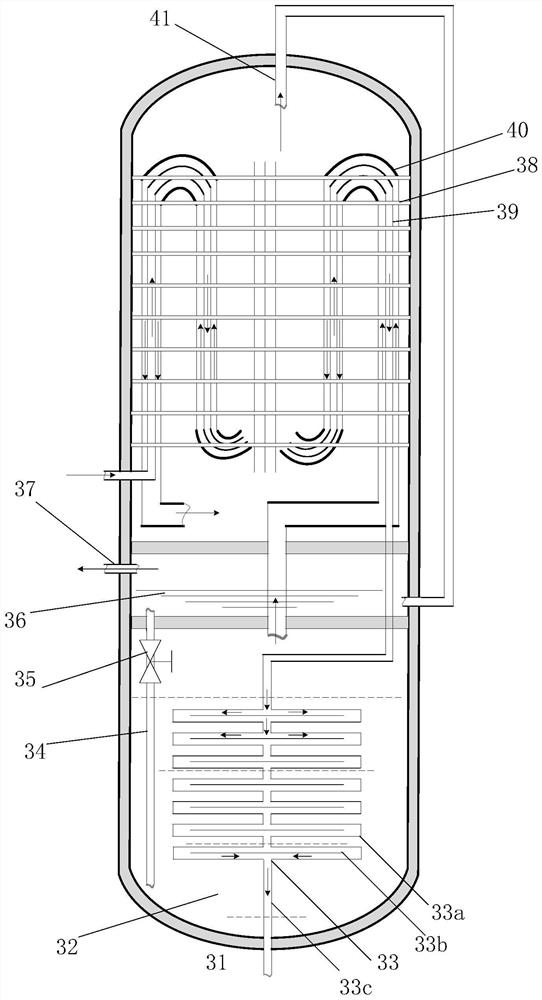

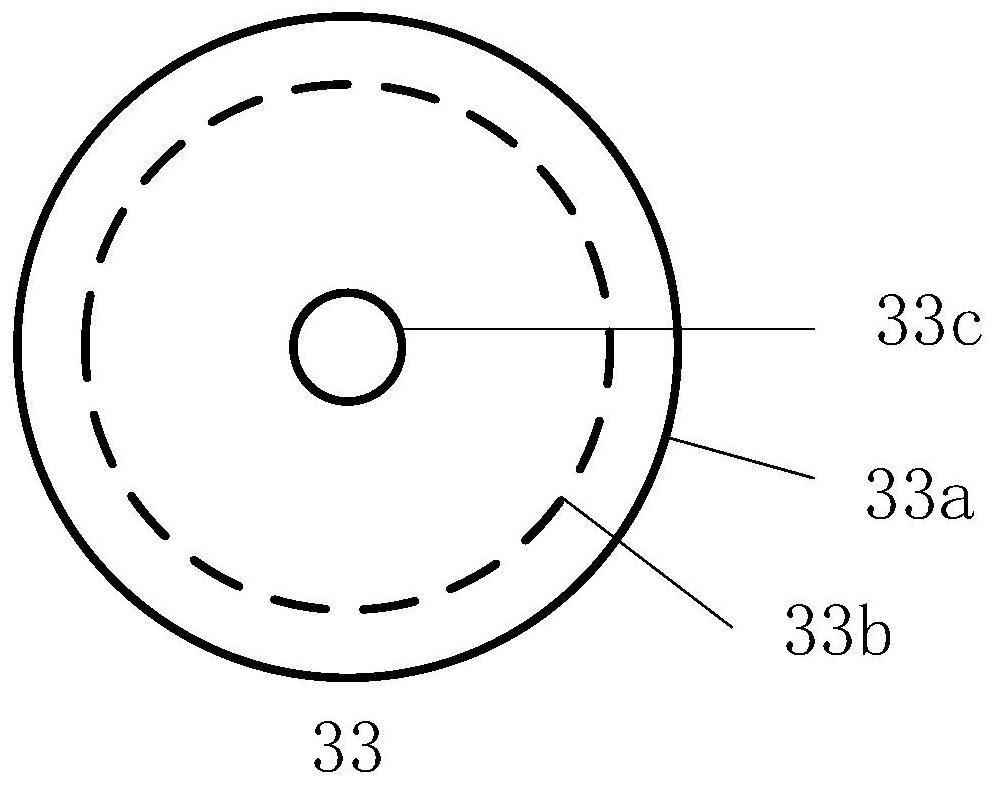

Compressed air energy storage method and energy storage system

InactiveCN109306963AImprove thermal performanceReduce power consumptionEngine fuctionsEnergy efficient heating/coolingThermal energy storageLithium bromide

The invention discloses a compressed air energy storage method. The compressed air energy storage method comprises the following steps that an underground aquifer serves as an air storage chamber of acompressed air energy storage system, and the development and application of the compressed air energy storage system are free from the limitation of geological conditions; the underground aquifer serves as the air storage chamber for storing compressed air, it is guaranteed that in the system energy releasing process, the pressure of the compressed air at an outlet of the air storage chamber isapproximately invariable, and the throttling loss caused by the throttling pressure reducing action of a throttling valve in a traditional compressed air energy storage system is avoided; compressionheat generated in the compression process is absorbed by a heat transferring medium from a heat network heat exchanger and is absorbed in a cooler, and the heated heat transferring medium is used forsupplying heat to heat consumers in a heat supply network; in the energy releasing process, a low-grade heat source is used for heating pre-stage inlet steam of an expansion machine, so that the powercapability of the compressed air can be greatly improved; and steam exhaust of a turbine unit enters a lithium bromide absorption refrigerating machine to serve as a high-temperature heat source of the refrigerating machine, and cooling capacity is supplied outside through the refrigerating machine.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

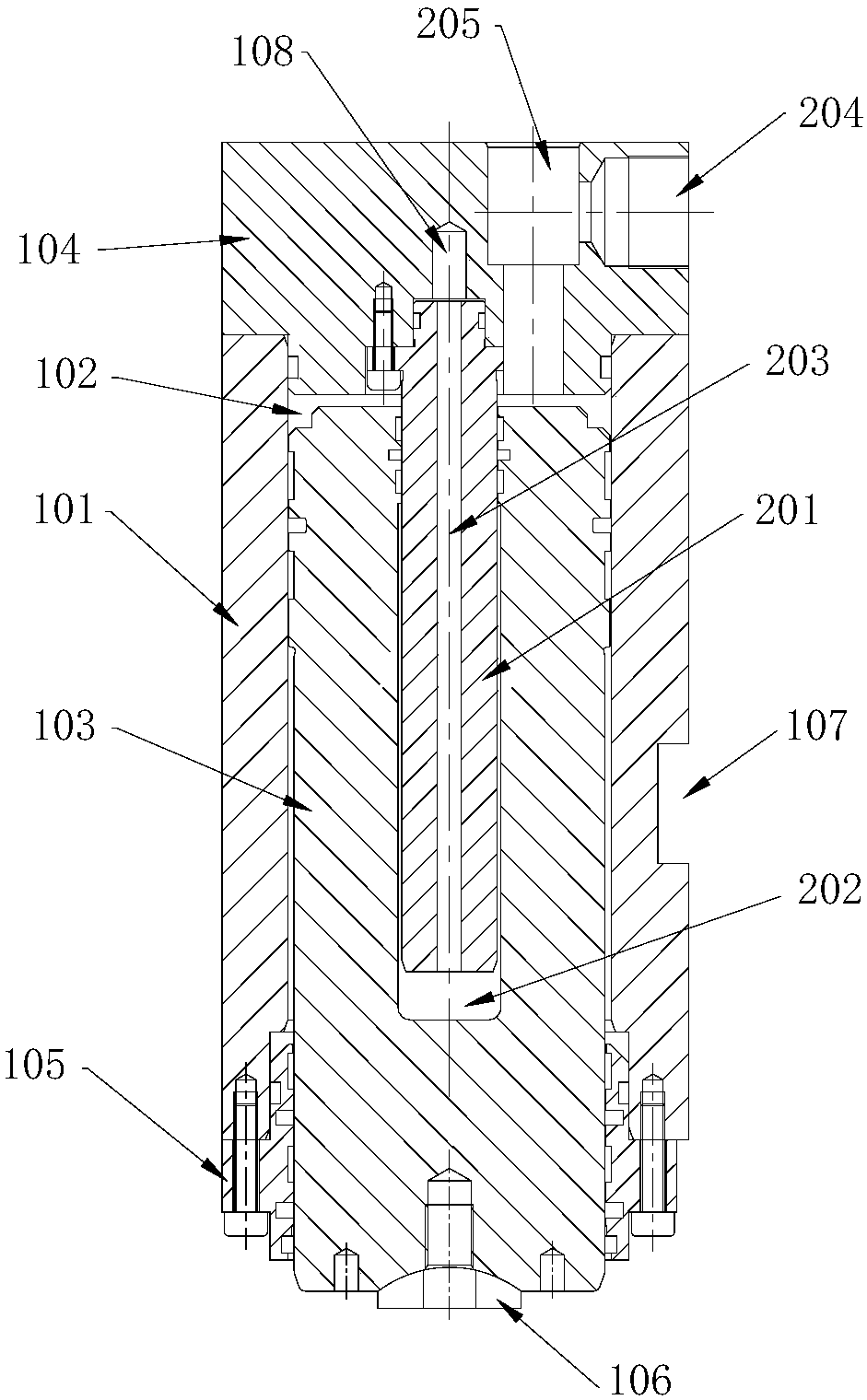

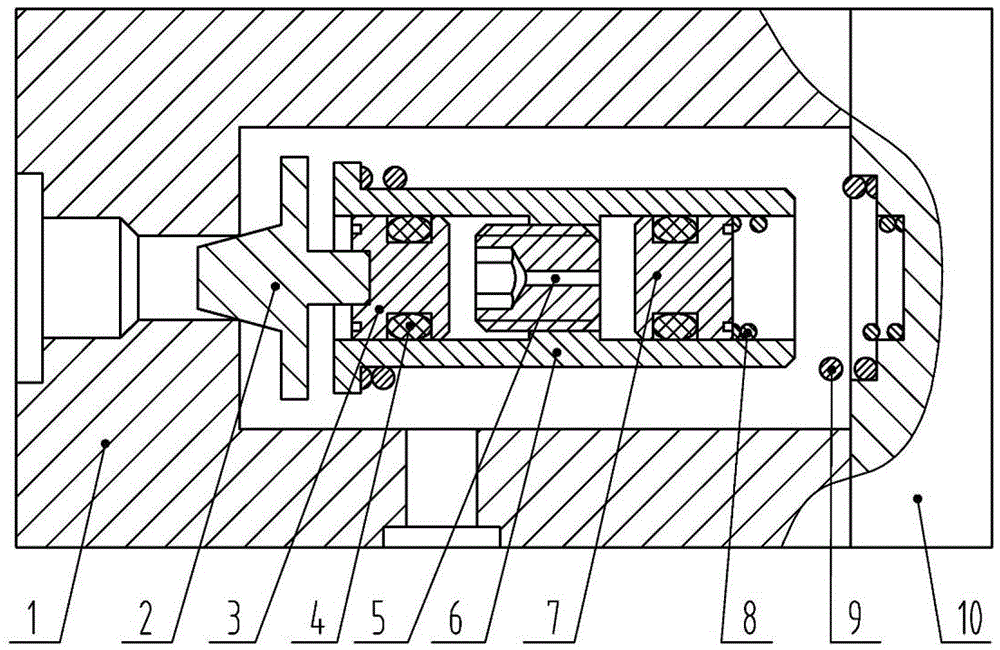

Electro-hydraulic integrated swashplate and plunger type hydraulic transformer

InactiveCN107461370AManual control rotationShorten the lengthFluid-pressure convertersHydraulic motorElectro hydraulic

The invention discloses an electro-hydraulic integrated swashplate and plunger type hydraulic transformer. The electro-hydraulic integrated swashplate and plunger type hydraulic transformer comprises a hydraulic transformer housing, a cylinder block, a valve plate, a plunger, a swashplate, a rear end cover, a swinging hydraulic motor and a flow distribution shaft. The flow distribution shaft serves as a swinging shaft of the swinging hydraulic motor. The flow distribution shaft is connected with the valve plate through a pin shaft and sealing is achieved through contact end faces. Three kidney-shaped flow distribution grooves are formed in the valve plate. Flow distribution grooves matched with the three flow distribution grooves in the valve plate in size are formed in the flow distribution shaft. By the adoption of the electro-hydraulic integrated swashplate and plunger type hydraulic transformer, the swinging hydraulic motor is integrally mounted in a flow distribution shell of the hydraulic transformer, and three oil outlets of the flow distribution shaft are uniformly distributed in the positions with the same axial size of the flow distribution shaft, and the whole length of the hydraulic transformer is reduced effectively; and the valve plate is connected with the flow distribution shaft, the transformer ratio of the hydraulic transformer is increased, the pressure transformation range of the hydraulic transformer is broadened, and the throttling loss is avoided.

Owner:XUZHOU UNIV OF TECH

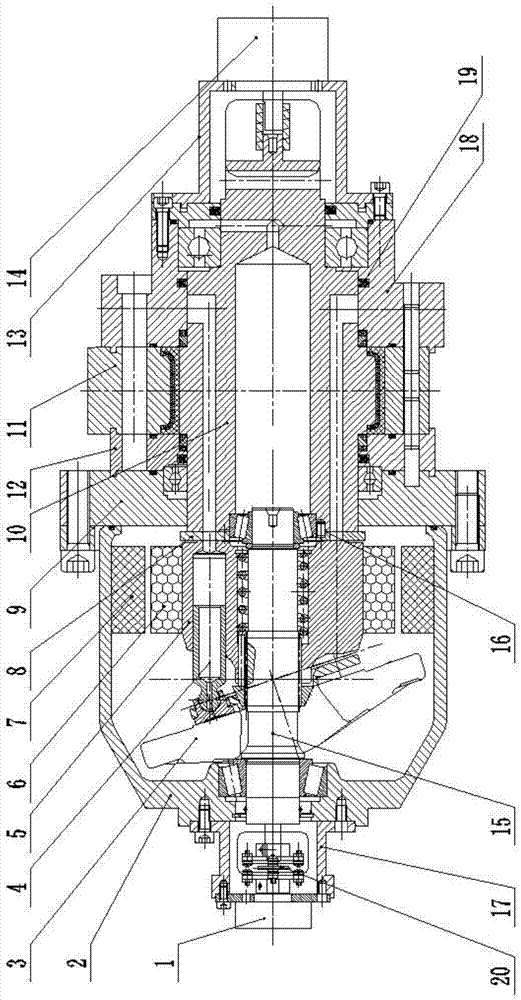

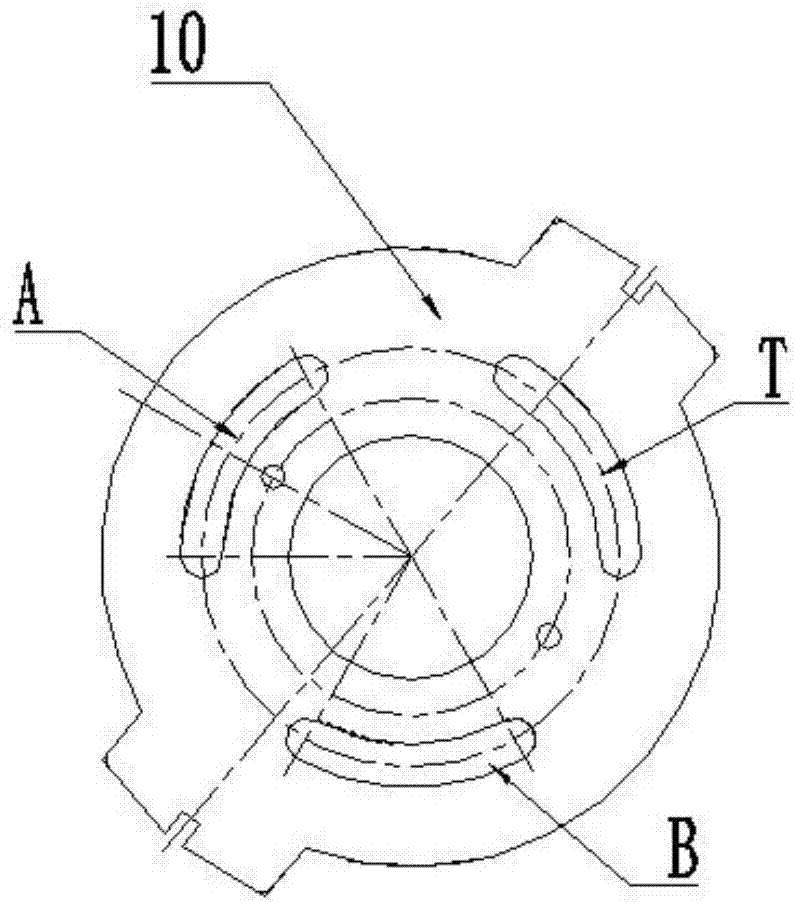

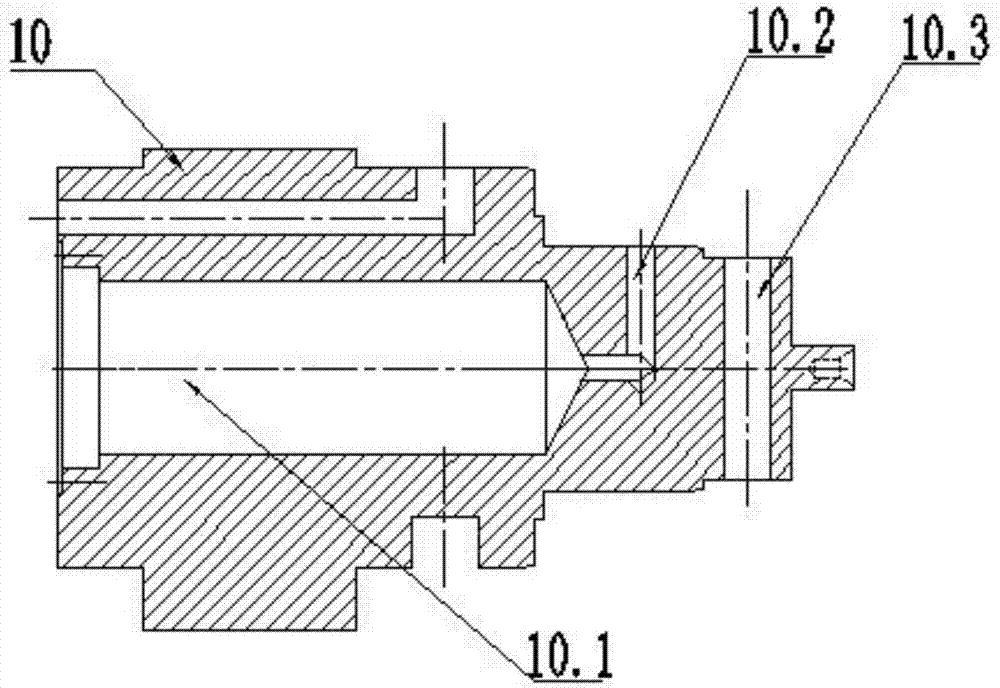

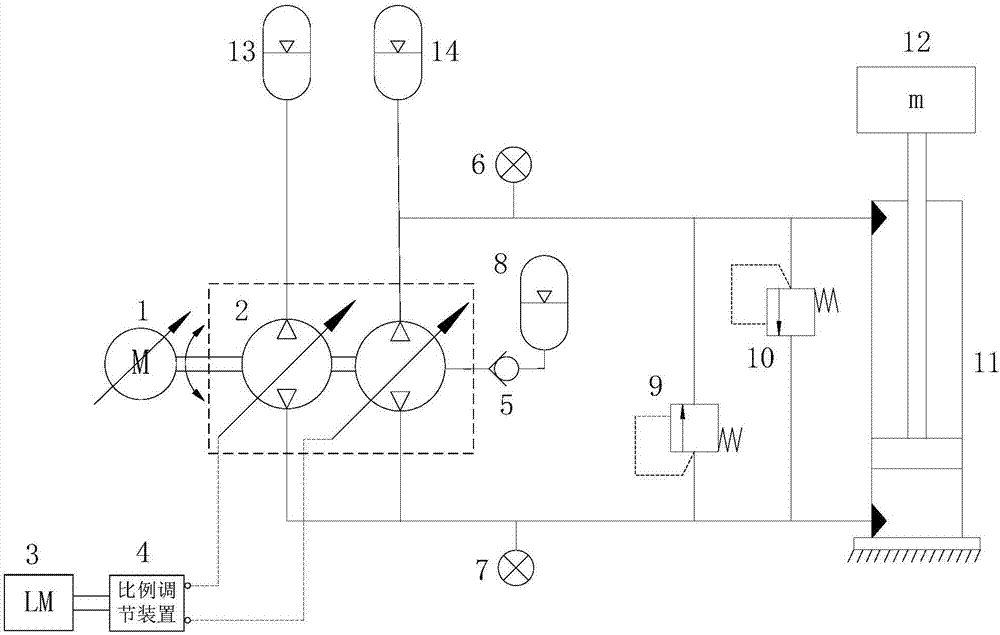

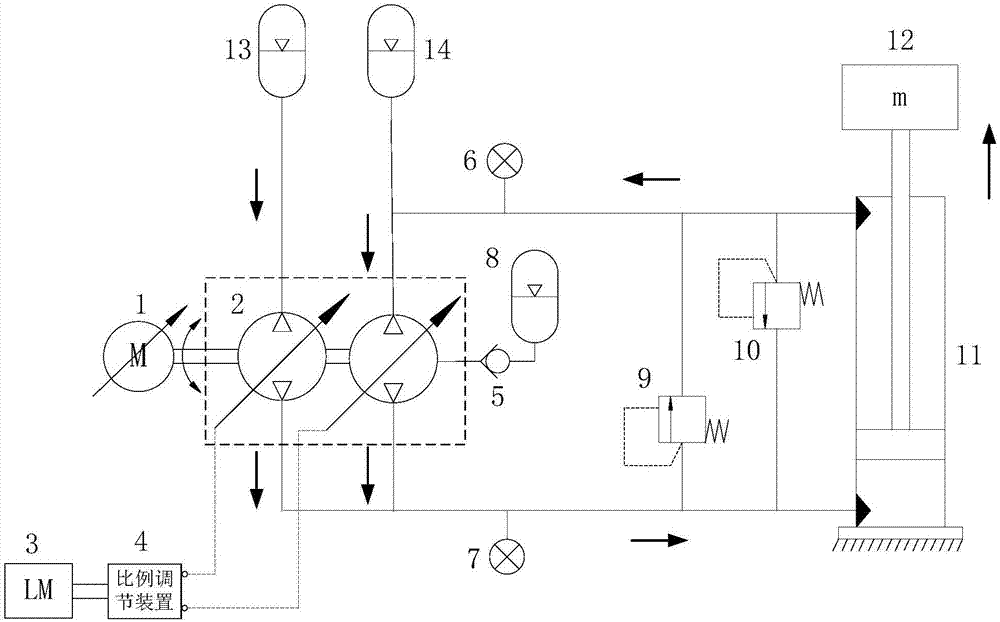

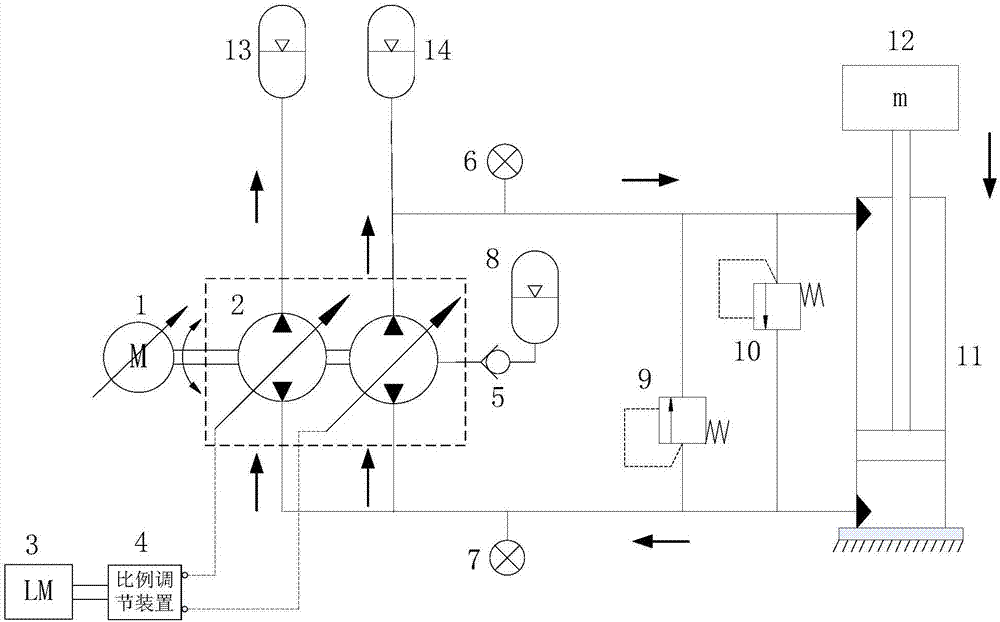

Electric static liquid acting system under gravity load

InactiveCN107131159AAccurate adjustmentOvercome clearance errorMechanical apparatusHydraulic cylinderElectro hydraulic

The invention provides an electric static liquid acting system under a gravity load. The electric static liquid acting system comprises a servo motor connected to a two-way variable duplex pump; two oil inlets of the two-way variable duplex pump are connected with a first energy accumulator and a second energy accumulator correspondingly; the second energy accumulator is connected with a first pressure gauge, and is connected to a rod cavity of an asymmetric hydraulic cylinder; two oil outlets of the two-way variable duplex pump communicate with each other, and are connected with a second pressure gauge; the second pressure gauge is also connected with a rodless cavity of the asymmetric hydraulic cylinder; the upper end of the asymmetric hydraulic cylinder is connected with the gravity load; a linear motor is connected with a proportional adjusting device; and the proportional adjusting device is connected with the two-way variable duplex pump. The problem of asymmetric flows of two cavities of the asymmetric hydraulic cylinder in the electric static liquid system is solved; the linear motor and the proportional adjusting device are used for precisely and quickly adjusting the variable structure of the two-way variable duplex pump; and the electric static liquid acting system is simple in structure, meanwhile, prevents the throttling loss caused by introduction of a control valve into an electro-hydraulic servo variable adjusting mechanism, and further improves the energy efficiency.

Owner:BEIJING JIAOTONG UNIV

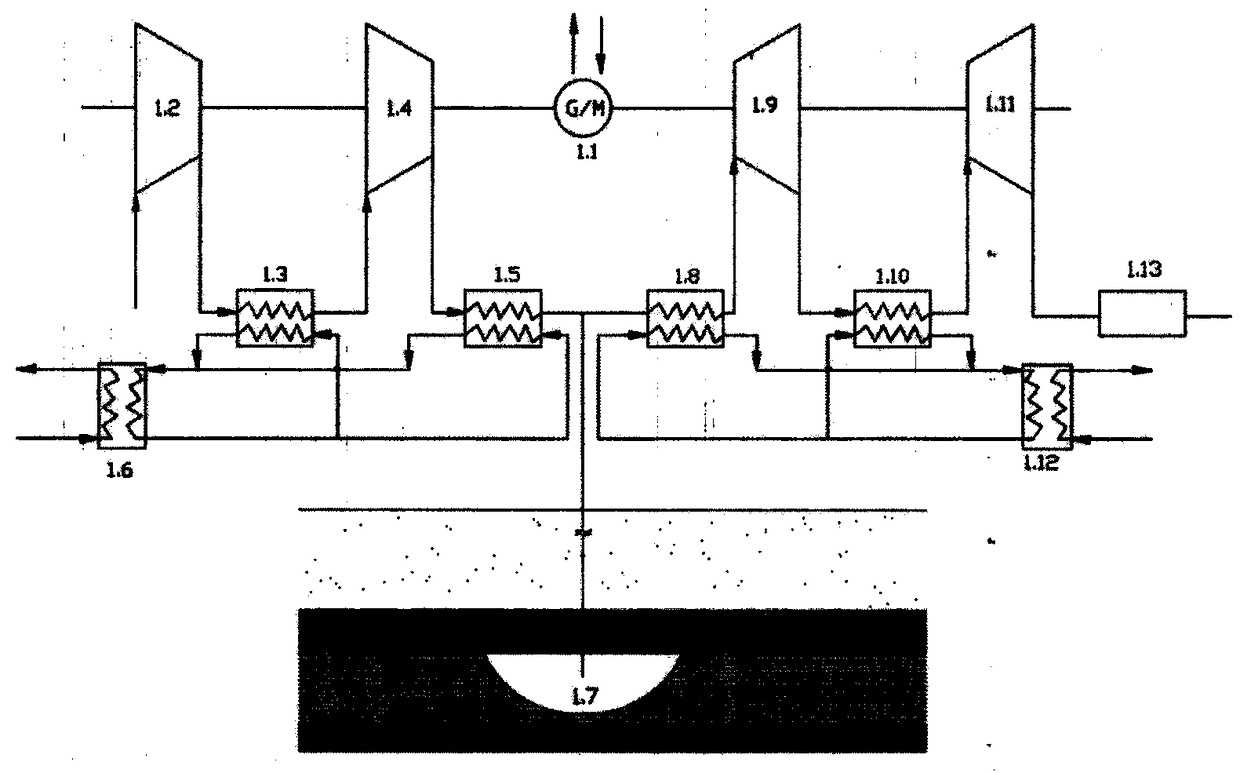

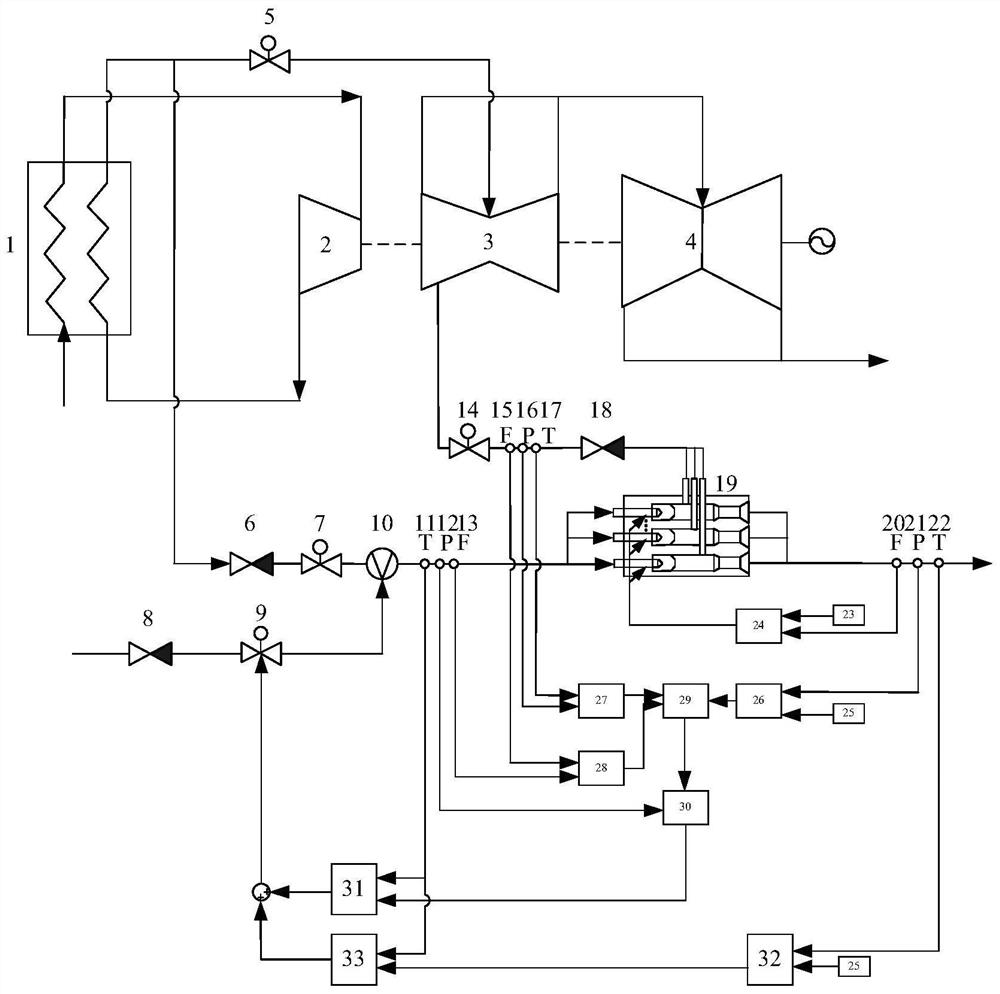

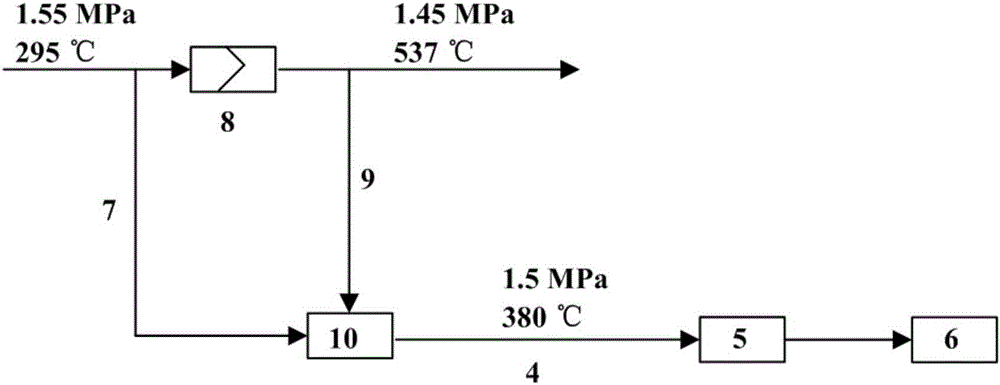

Hot steam re-extraction heat supply control system and method coupled with pressure matcher

ActiveCN112856374AMeet needsAvoid throttling lossesSteam useBoiler controlThermodynamicsLoop control

The invention discloses a hot steam re-extraction heat supply control system and method coupled with a pressure matcher. A multi-nozzle needle valve is coupled to control the pressure matcher, and the flow and pressure of an outlet of the pressure matcher are adjusted by adjusting the opening of the needle valve; meanwhile, two controllers which are connected in series to work are selected to form a double-closed-loop control system, an auxiliary controller is used for performing advanced control on desuperheating water interference, and the influence of the desuperheating water interference on the outlet steam temperature is reduced; and meanwhile, according to a double-closed-loop system, temperature setting feedforward of driving steam is obtained in advance, the disturbance influence caused by parameter changes of the driving steam and suction steam due to working condition changes of a unit can be weakened, and control is more accurate. The problems that the delay of the outlet steam temperature of the pressure matcher and the time constant are very large, the interference effect of desuperheating water is strong and frequent, and the parameter change of driving / suction steam due to the change of working conditions is difficult to accurately control are solved.

Owner:XIAN THERMAL POWER RES INST CO LTD

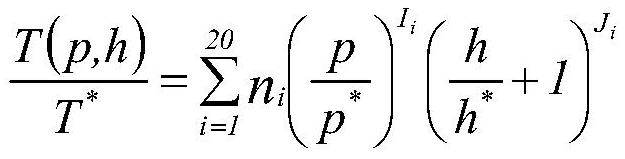

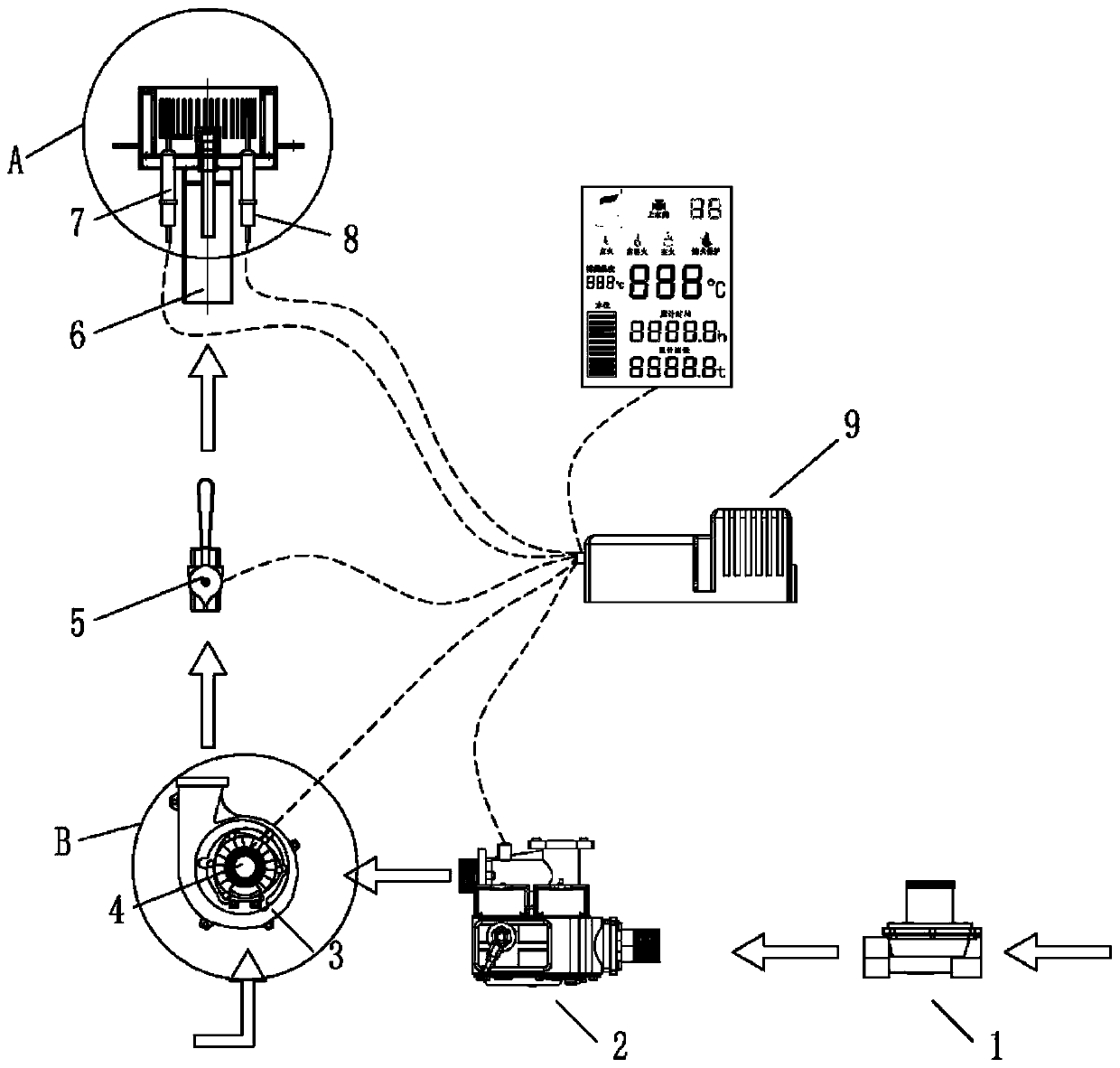

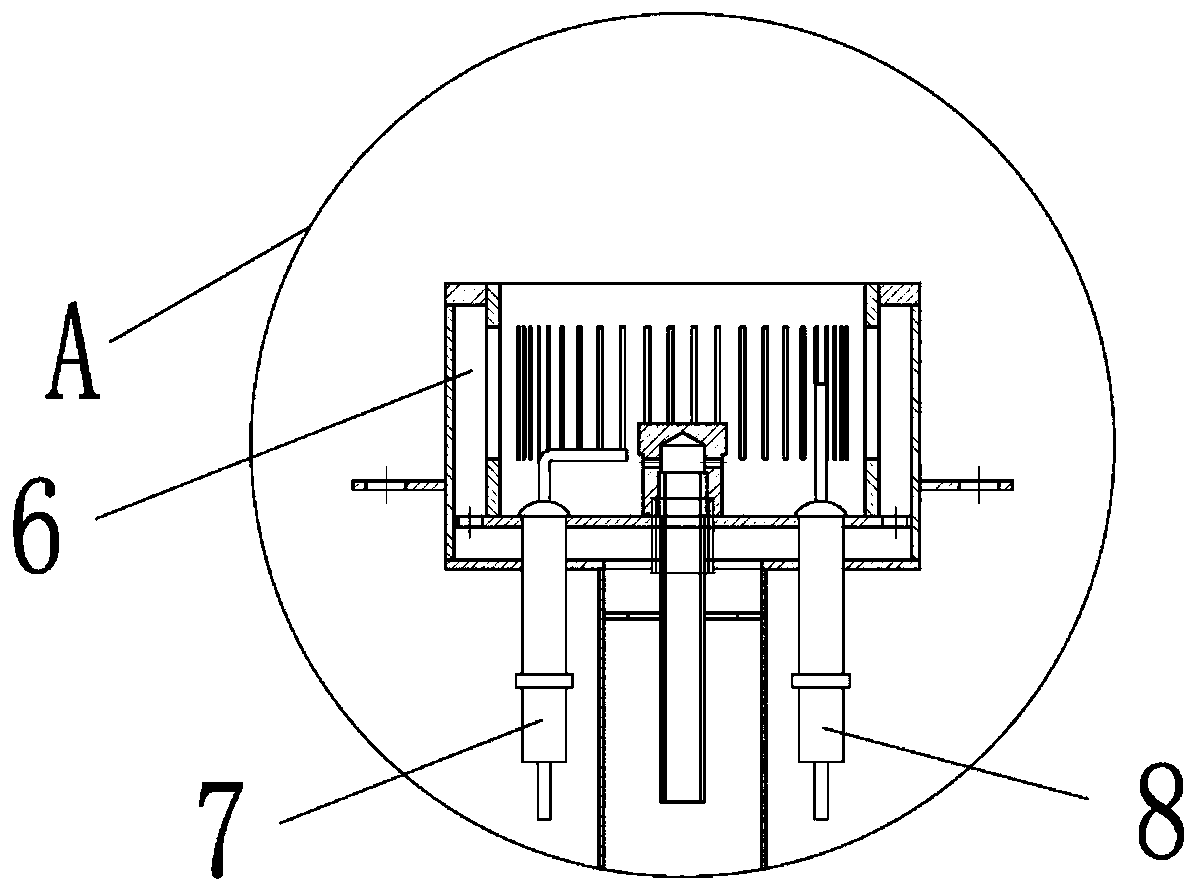

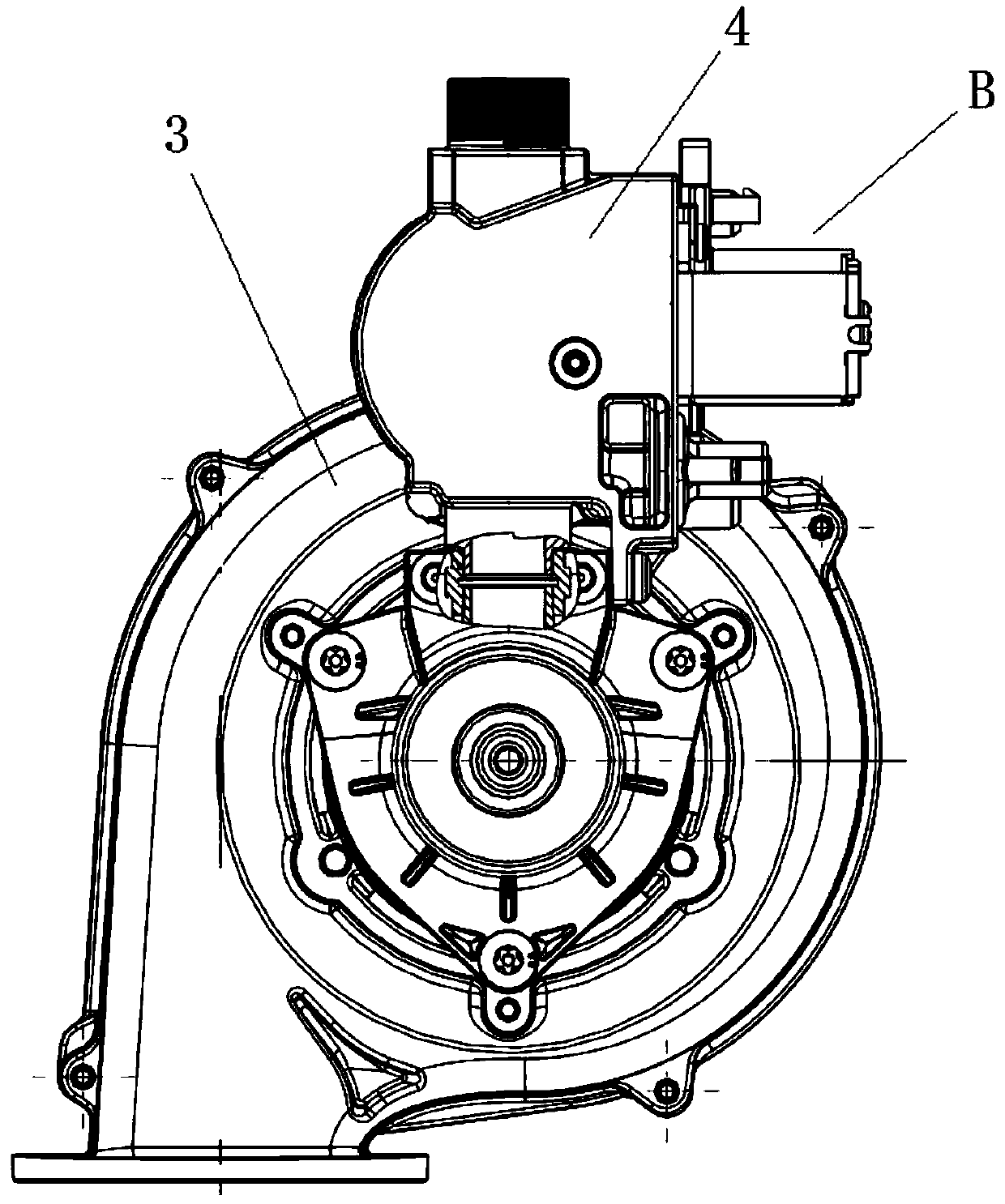

Front pre-mixing combustor used for commercial fuel gas stove

The invention discloses a front pre-mixing combustor used for a commercial fuel gas stove. The front pre-mixing combustor comprises a stove head, an ignition needle, an ion needle, a fuel gas valve, aPWM fan, a Venturi pre-mixer, a zero-pressure header tube fuel gas solenoid valve, a pressure stabilizing vale, a commercial fuel gas stove front pre-mixing controller. The front pre-mixing combustoradopts a front pre-mixing type technology for completely mixing fuels with air before the fuels and the air enter a spray nozzle of a stove head combustion chamber, so that gas molecules are sufficiently stirred and mixed, and therefore, mixing is more complete, combustion speed is not limited by physical conditions such as gas diffusion velocity, combustion speed is higher, efficiency is higher,and emission of harmful CO in smoke gas is reduced. And meanwhile, an automatic pre-mixing technology is applied, so that mixing is guaranteed to be relatively precise. The front pre-mixing combustorguarantees working safety, and is free of phenomena such as flame-lifting, flame-floating and tempering.

Owner:合肥中科顺昌余热利用科技有限公司

Composite compressed air energy storage system and method for coupling methanol reformer with internal combustion engine

ActiveCN114483290AMake full use of high temperature heat dissipationMake the most of heat removalHydrogenInternal combustion piston enginesMethanol waterCombustor

The composite compressed air energy storage system comprises a compressed air energy storage unit, a methanol steam reforming unit, a low-dust combustor unit and an internal combustion engine power generation unit which are mutually coupled, and low-grade compression heat, high-temperature exhaust heat of the internal combustion engine and exhaust heat of an expansion machine are fully utilized; exhaust gas of the expansion machine firstly passes through the methanol steam reaction inner pipe to provide energy for methanol reforming reaction, and then passes through the disc-shaped heat exchanger to evaporate a methanol aqueous solution to generate methanol steam, so that stepped utilization of high-temperature exhaust gas energy of the expansion machine is realized, and the energy utilization efficiency is improved; an external heat source of the reactor is avoided while high-temperature exhaust is utilized, so that the system efficiency is further improved; the mixed gas generated by the reforming reaction passes through the low-concentration methanol aqueous solution in the methanol removal chamber, methanol in the mixed gas is absorbed, heat of the mixed gas is absorbed at the same time, recycling of the methanol and the heat is achieved, and the economical efficiency of hydrogen production through methanol steam reforming is improved.

Owner:XI AN JIAOTONG UNIV

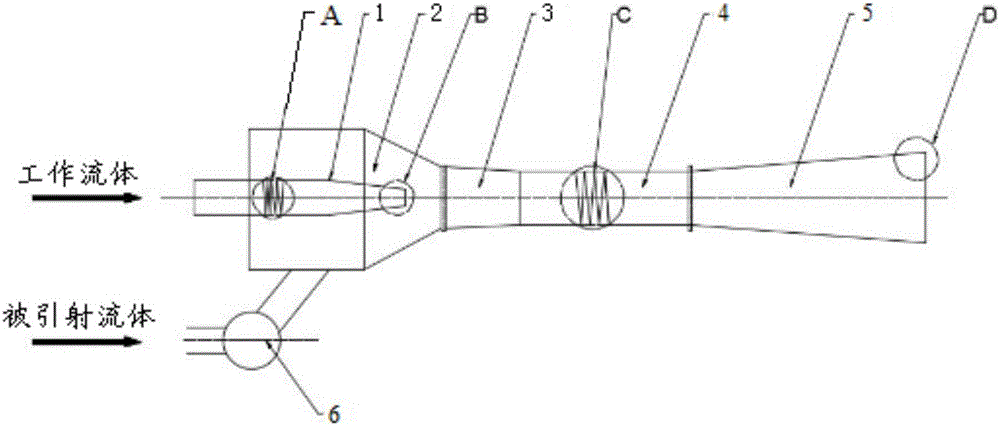

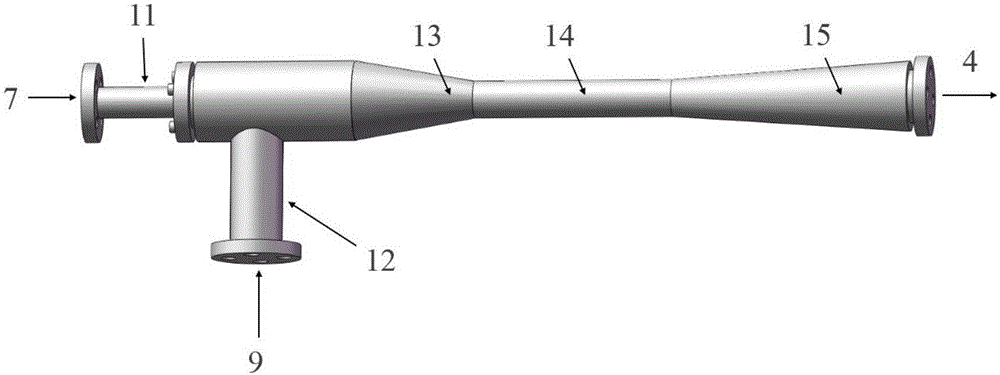

Device used for adjusting basic state parameters of working medium

ActiveCN106678087AWith multi-parameter state adjustment functionAchieving Co-regulationJet pumpsMachines/enginesThroatState parameter

The invention discloses a device used for adjusting basic state parameters of a working medium. The device comprises a working nozzle, a suction chamber, a throat pipe, a diffusion pipe and an injection flash evaporation pipe. The working nozzle is arranged in the suction chamber. The suction chamber is sequentially connected with the throat pipe and the diffusion pipe. The injection flash evaporation pipe communicates with the side portion of the suction chamber through a pipeline. According to the device, the injection and flash evaporation principle is utilized, coordinated adjustment on flow, pressure, temperature, humidity and other parameters of a mixed working medium is achieved, throttling losses generated by a traditional valve in the pressure adjusting process are avoided, and meanwhile enhancing of unit volume working medium acting capability is achieved. Equipment minimization can be achieved, the device can be efficiently applied to the technical fields of humidifying, atomizing, heating, pressure and flow adjusting and the like, the application range is wide, efficiency is high, and operation is convenient.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

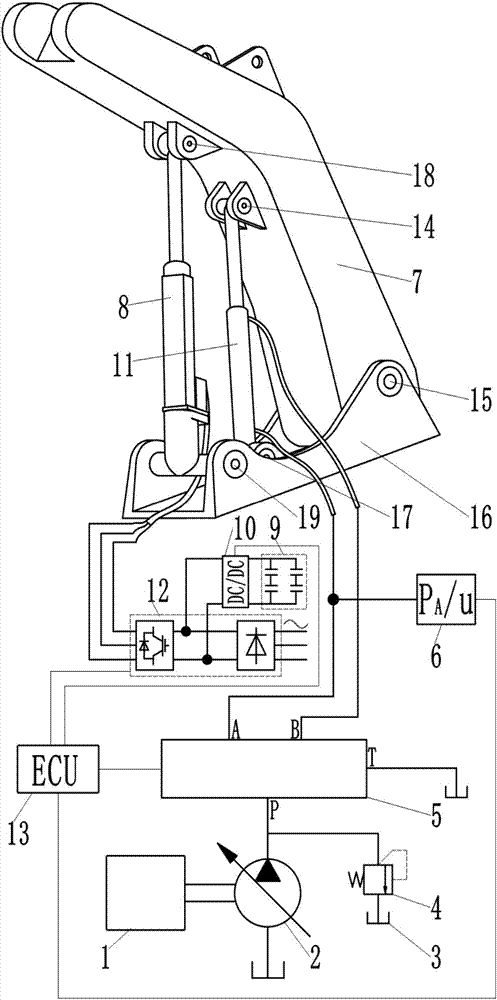

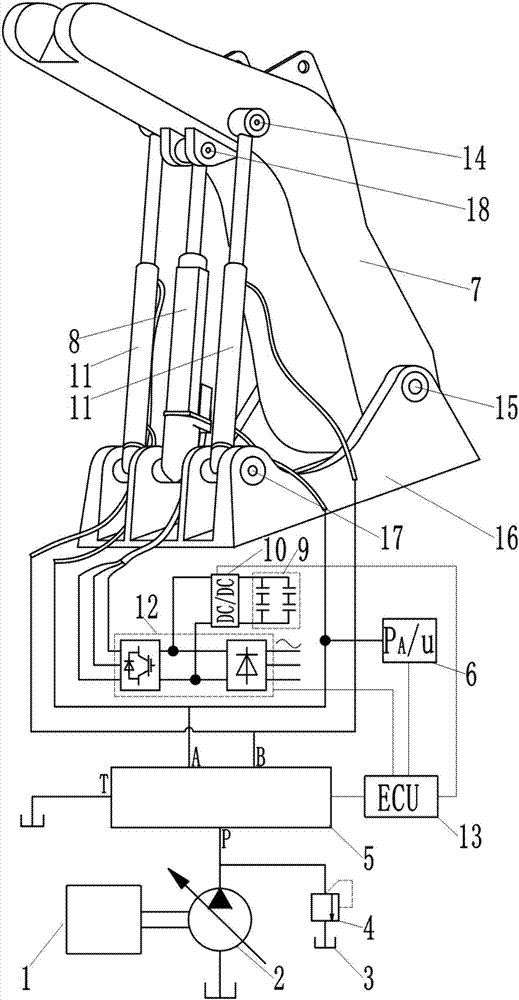

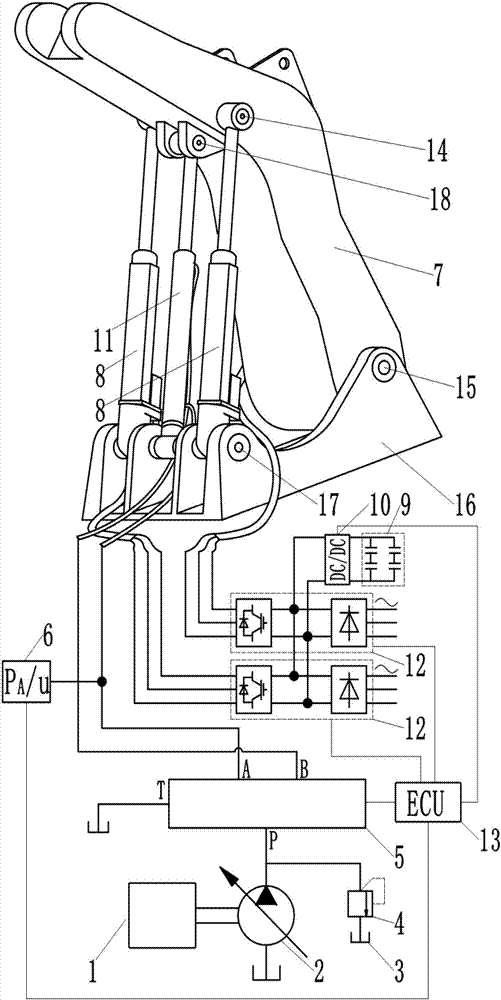

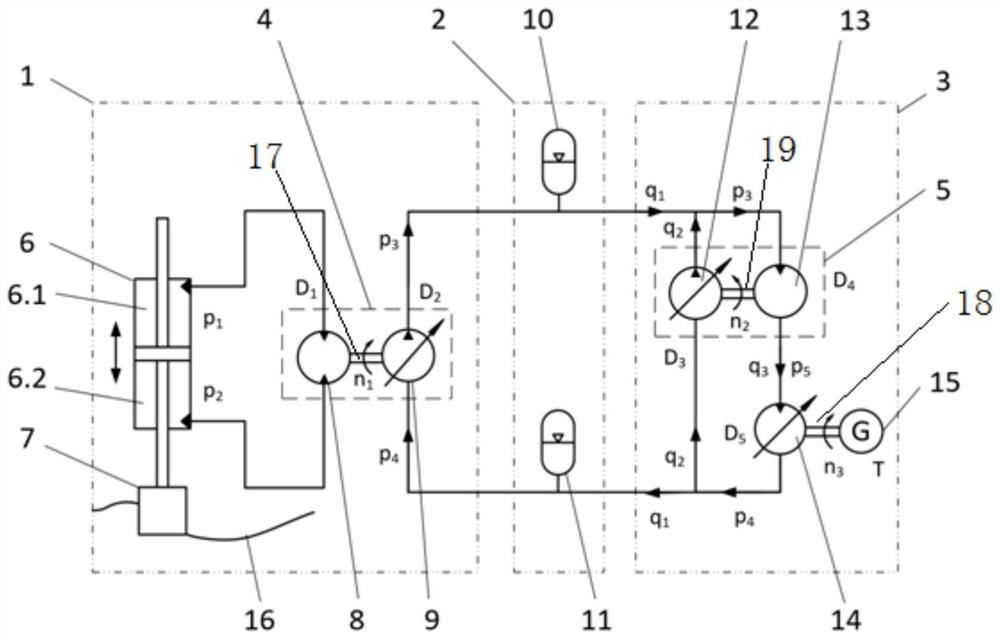

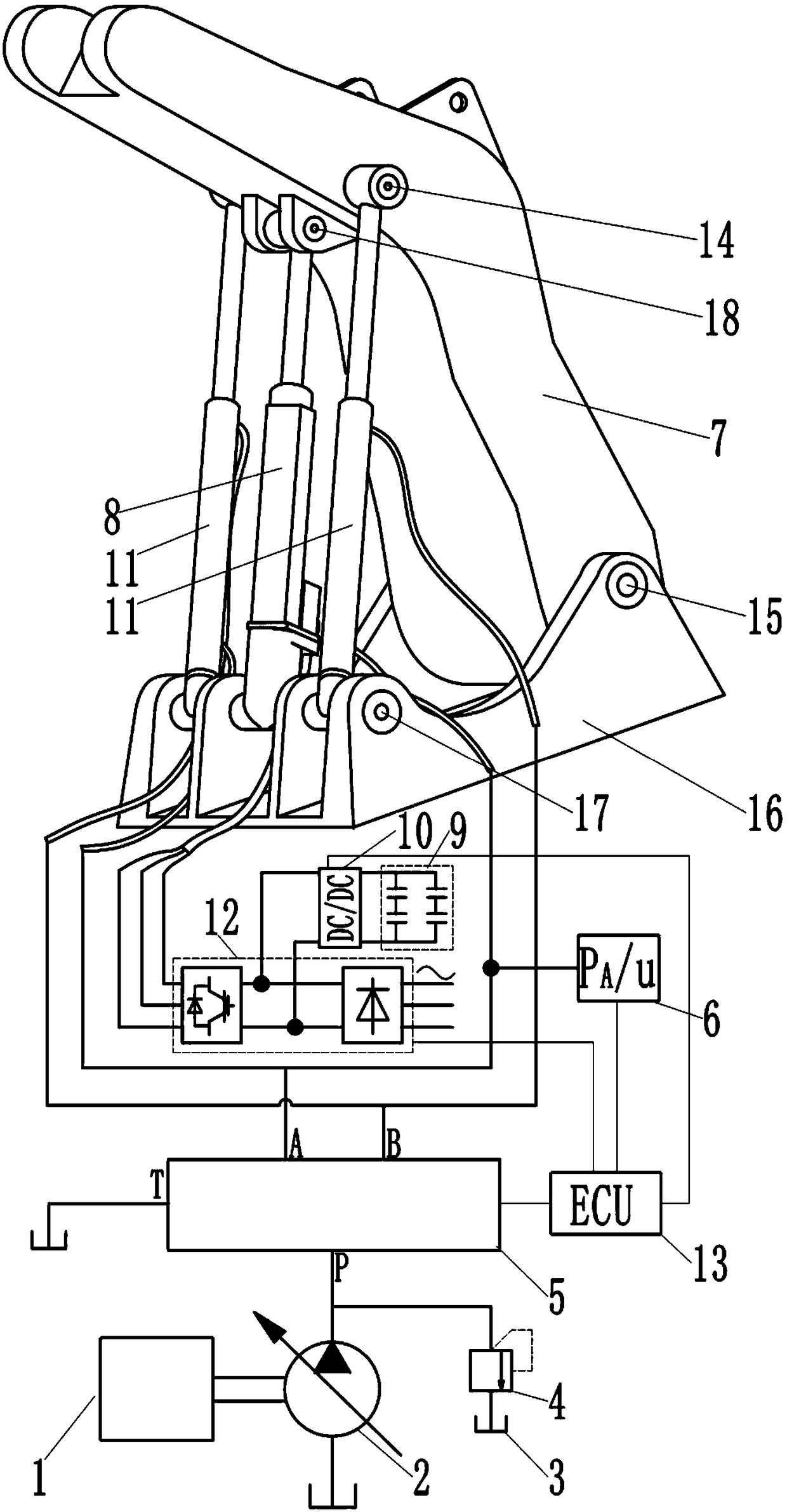

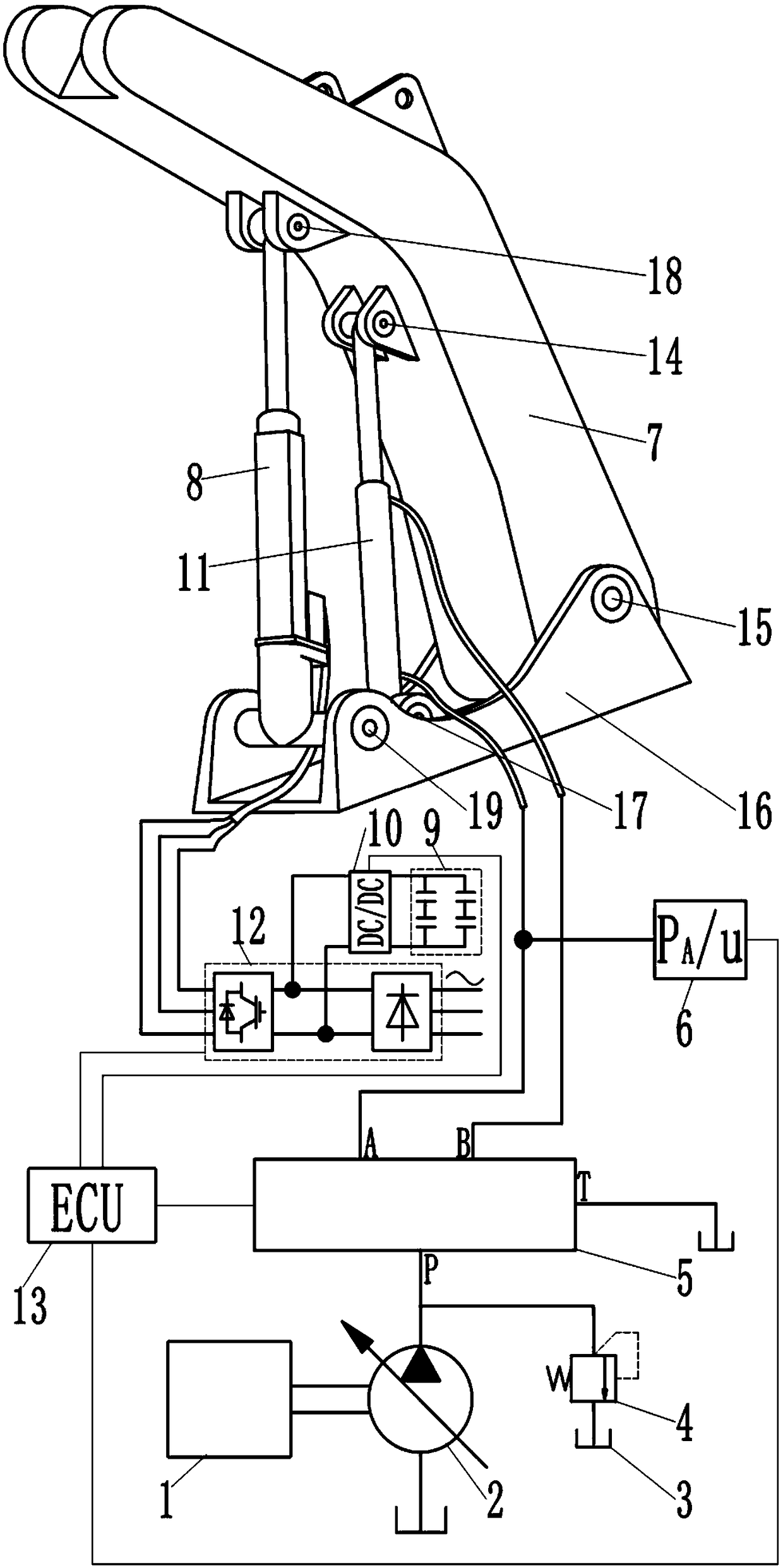

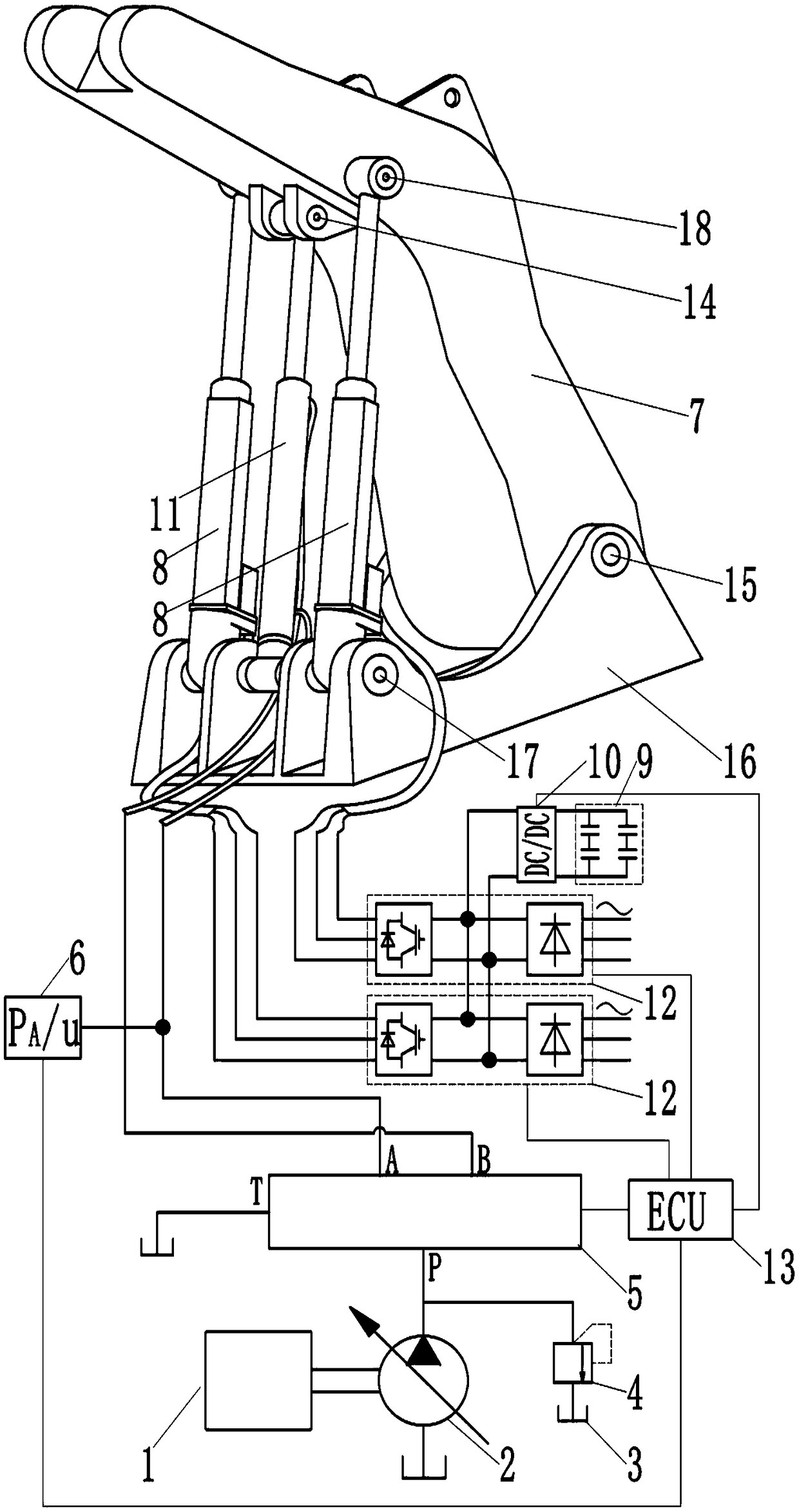

Hydro-electric hybrid energy saving system for lifting mechanism

ActiveCN107235440AAvoid throttling lossesImprove storage utilization efficiencyBatteries circuit arrangementsLifting devicesAutomotive engineeringDrive motor

The invention discloses a hydro-electric hybrid energy saving system for a lifting mechanism. The system is provided with an electric cylinder, an electric speed controller, a two-way DC / DC converter, a super-capacitor module and a pressure sensor; in combination with a corresponding control method, the gravitational potential energy of a movable arm is directly converted into electric energy for charging the super-capacitor module when the movable arm declines; and the super-capacitor module is used for providing the electric energy for a driving motor of an electric cylinder for auxiliary diving when the movable arm rises. The hydro-electric hybrid energy saving system for the lifting mechanism, disclosed by the invention, has the advantages of high storage and utilization efficiency of potential energy of the movable arm, stable output, low installed power, etc.

Owner:TAIYUAN UNIV OF TECH

Hydraulic wave power generation system based on volume adjusting principle

ActiveCN111997824AReduce couplingEasy to controlAccumulator installationsFluid-pressure convertersWave power generationEngineering

The invention discloses a hydraulic wave power generation system based on a volume adjusting principle. The hydraulic wave power generation system is characterized by comprising an energy capturing end, an energy storing end and an output end, the energy capturing end, the energy storing end and the output end are sequentially connected through medium pipelines, the energy capturing end converts wave energy into hydraulic energy and transmits the hydraulic energy to the energy storing end. The energy storing end converts the hydraulic energy with low frequency and high fluctuation into hydraulic energy with high and smooth frequency and then transmits the hydraulic energy with high and smooth frequency to the output end. The output end converts the stabilized hydraulic energy into high-quality electric energy. The multiplex control over hydraulic cylinder acting force, system working pressure and power generator rotating speed is realized in a volume adjusting manner, as a result, compared with a traditional throttling adjusting manner, throttling loss is avoided, conversion efficiency of the power generation system is improved, meanwhile power consumption and frequent pressure fluctuation caused by oil pressure fluctuation initiated by discrete and switching of a hydraulic valve are avoided, and the service life and reliability of all components in the system are increased.

Owner:HEFEI UNIV OF TECH

A plunger combined digital variable pump

ActiveCN105134573BDisplacement depends onAvoid throttling lossesPump controlPositive-displacement liquid enginesSolenoid valveFuel tank

The invention discloses a plunger combined digital variable pump. It consists of multiple plungers, multiple oil suction one-way valves, multiple oil discharge one-way valves, and multiple two-position two-way electromagnetic stop valves. The oil suction port of each plunger is connected with the oil tank through the oil suction check valve; the oil pressure port of each plunger is connected with the high pressure oil circuit through the oil pressure check valve; The two-way cut-off solenoid valve is bypassed; the actual displacement of the digital variable pump is obtained by superimposing the displacements of all normal oil-discharging plungers; the displacement control is adjusted by the solenoid valve to adjust the displacement corresponding to a single plunger Realized, so that the displacement change of the digital variable pump can respond very quickly to the input of the electric signal, thereby meeting the requirements of high-frequency response control. The invention can effectively solve the problems of large pressure loss and low frequency response in the large-flow servo and proportional electro-hydraulic control system, and achieve a large energy-saving effect at the same time.

Owner:王林翔

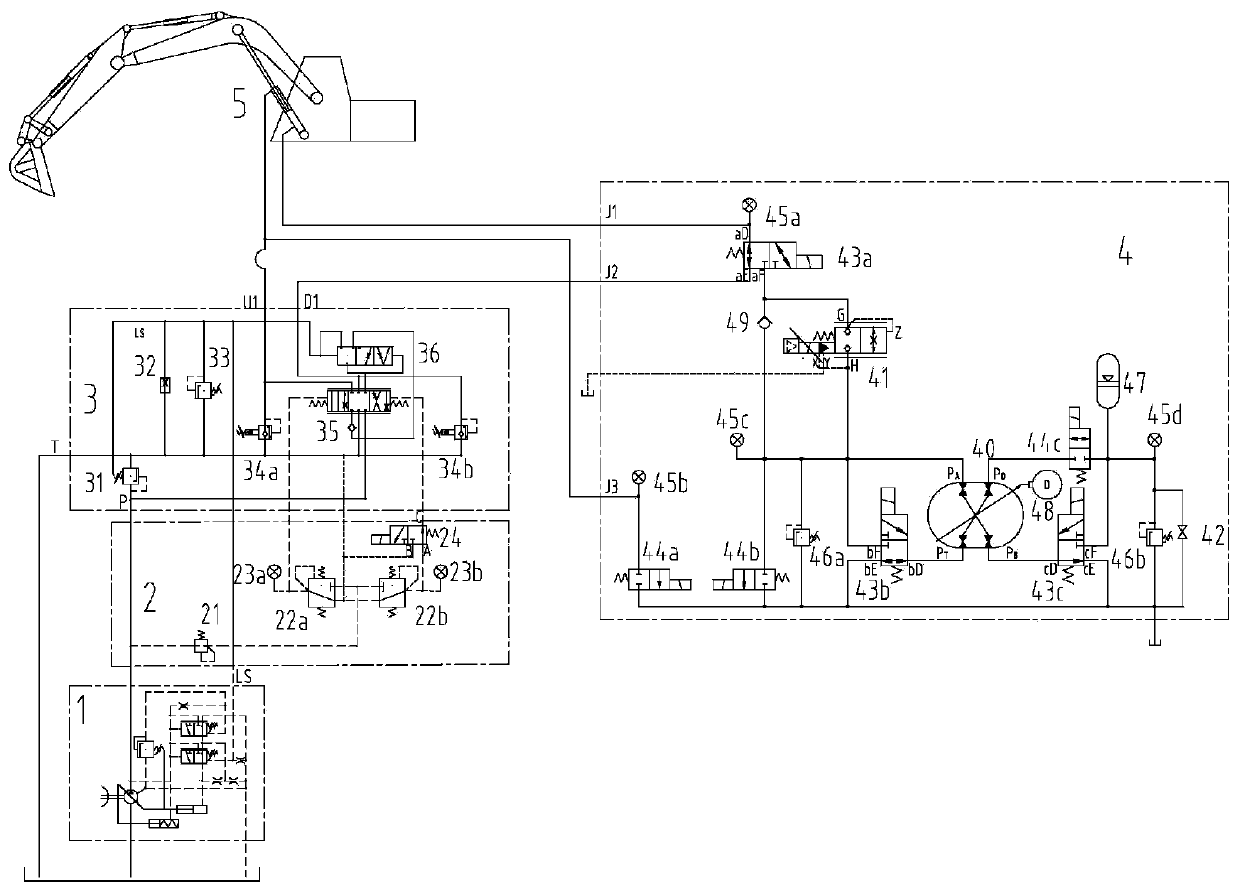

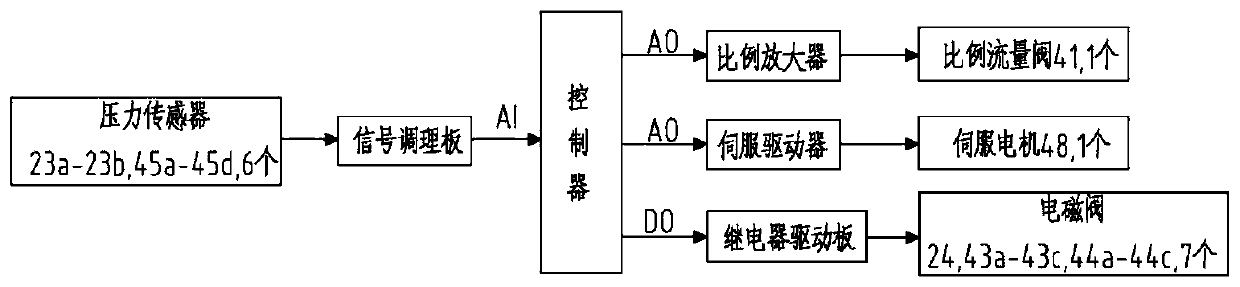

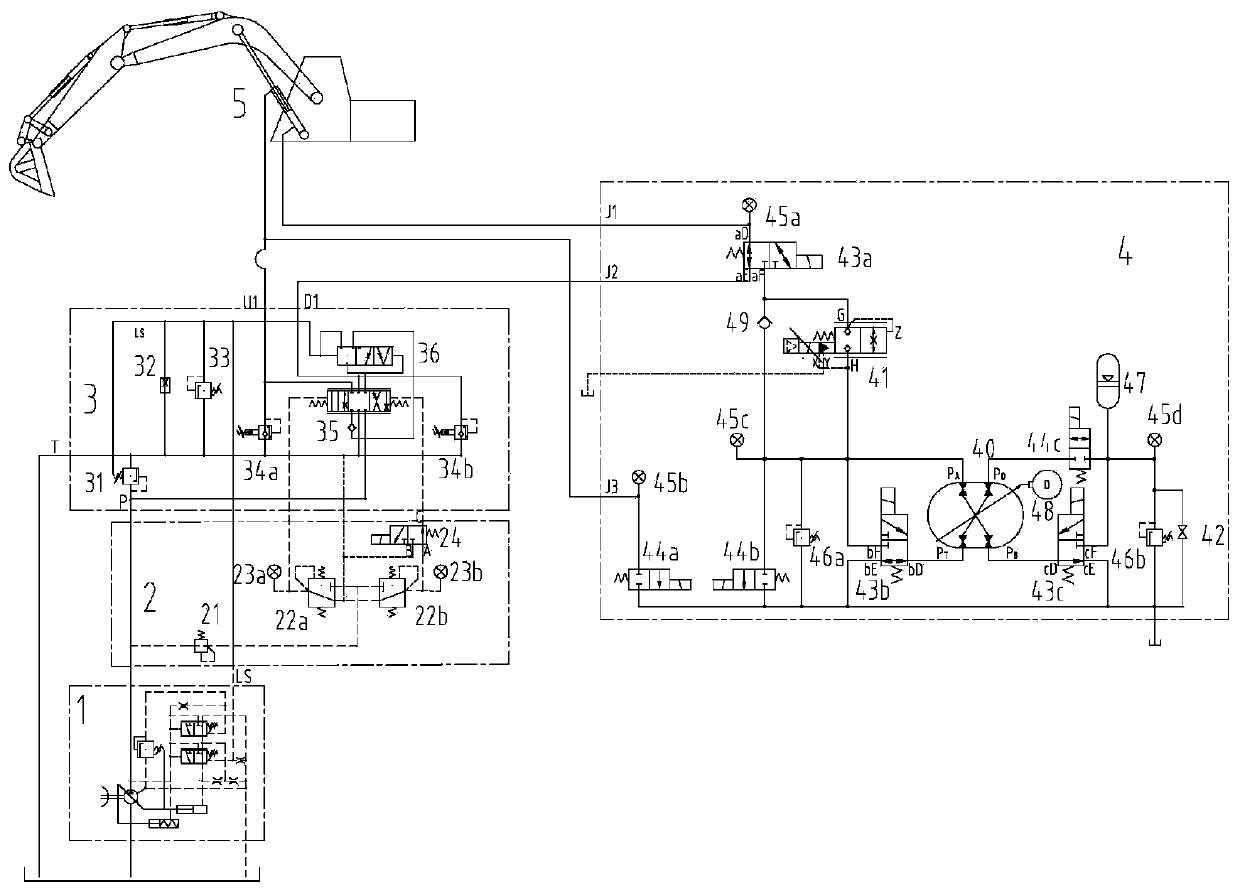

Gravitational potential energy recycling and reutilization energy-saving device based on four-port hydraulic transformer

ActiveCN109914519AMinor changesEasy to install and useSoil-shifting machines/dredgersEnergy recyclingThrottle

The invention discloses a gravitational potential energy recycling and reutilization energy-saving device based on a four-port hydraulic transformer. The device comprises an energy-saving device and aboom cylinder, the energy-saving device comprises the four-port hydraulic transformer, a two-way proportional throttle valve, a two-position three-way reversing valve, a normally-closed electromagnetic valve, an energy storage device and a controller, through the energy-saving device, hydraulic energy obtained through converting of gravitational potential energy in the excavator movable arm descending process is stored in the energy storage device, on the premise of not affecting the excavator operation and movable arm motion stability, energy stored in the energy storage device is released,through pressure transforming of the four-port hydraulic transformer, the energy is used for the excavator movable arm lifting condition, throttling losses generated when oil passes through a hydraulic valve in an original hydraulic system during movable arm descending can be avoided, and the efficiency of the hydraulic system is improved.

Owner:XUZHOU NORMAL UNIVERSITY

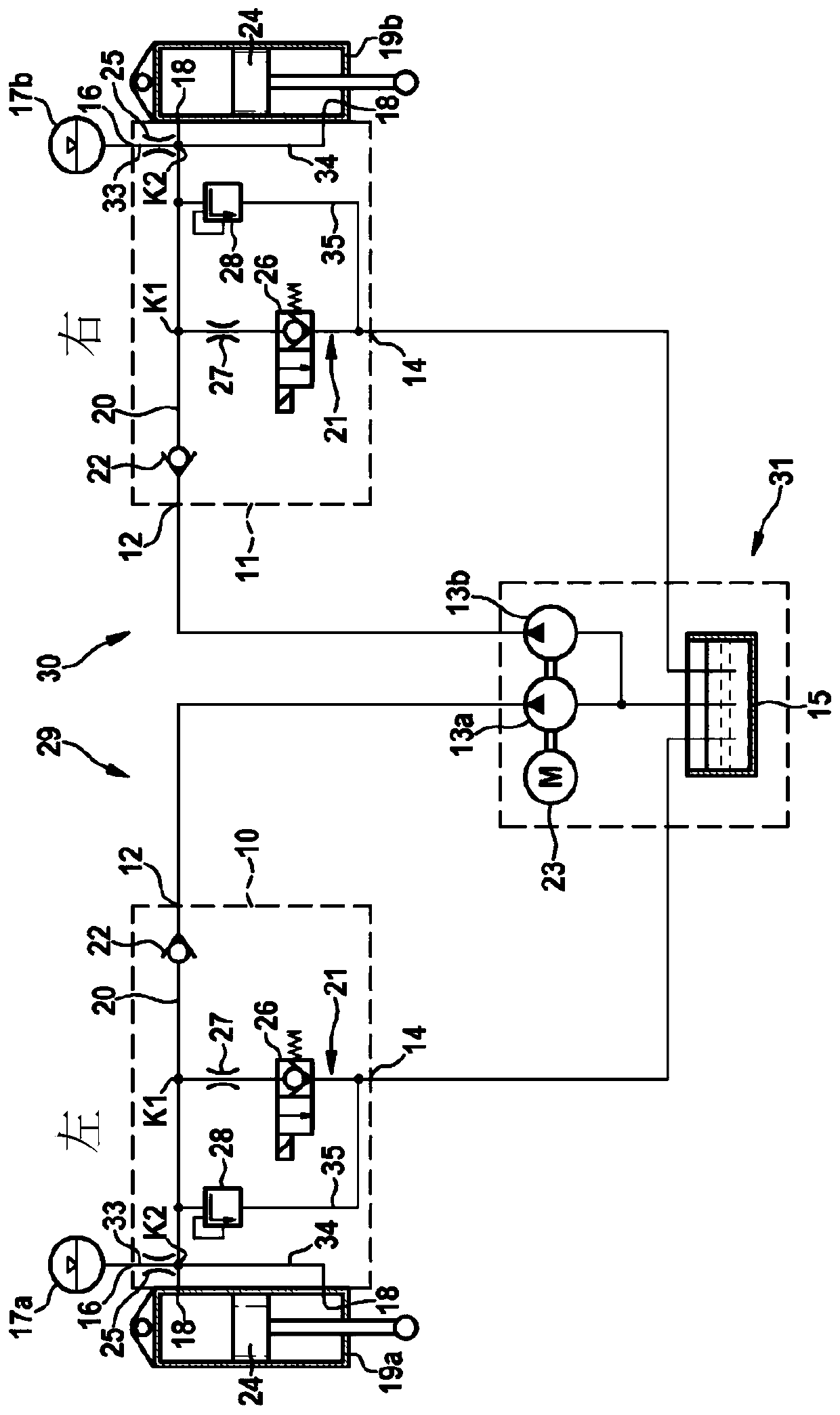

Hydraulic system, hydraulic unit, vehicle, method and use

InactiveCN110541861ACompact structureAvoid throttling lossesServomotor componentsServomotorsHydraulic cylinderDevice form

The invention relates to a hydraulic system, a hydraulic unit, a vehicle, a method and use. The hydraulic system for controlling or adjusting a hydraulic cylinder comprises at least one hydraulic cylinder; at least one hydraulic unit, by means of which the hydraulic cylinder can selectively be connected to a pressure source and a tank; and at least one controlling or adjusting device for controlling or adjusting the supply of hydraulic liquid to the hydraulic cylinder, the controlling or adjusting device forming a first assembly and the hydraulic unit forming a second assembly, and the first assembly and the second assembly are structurally separated from one another and are fluidically connected, wherein the supply of hydraulic liquid to the hydraulic cylinder is predominantly controlledor adjusted, from outside the hydraulic unit by means of the controlling or adjusting device, and the hydraulic unit is rigidly connected to the hydraulic cylinder.

Owner:ARGO HYTOS GRP AG

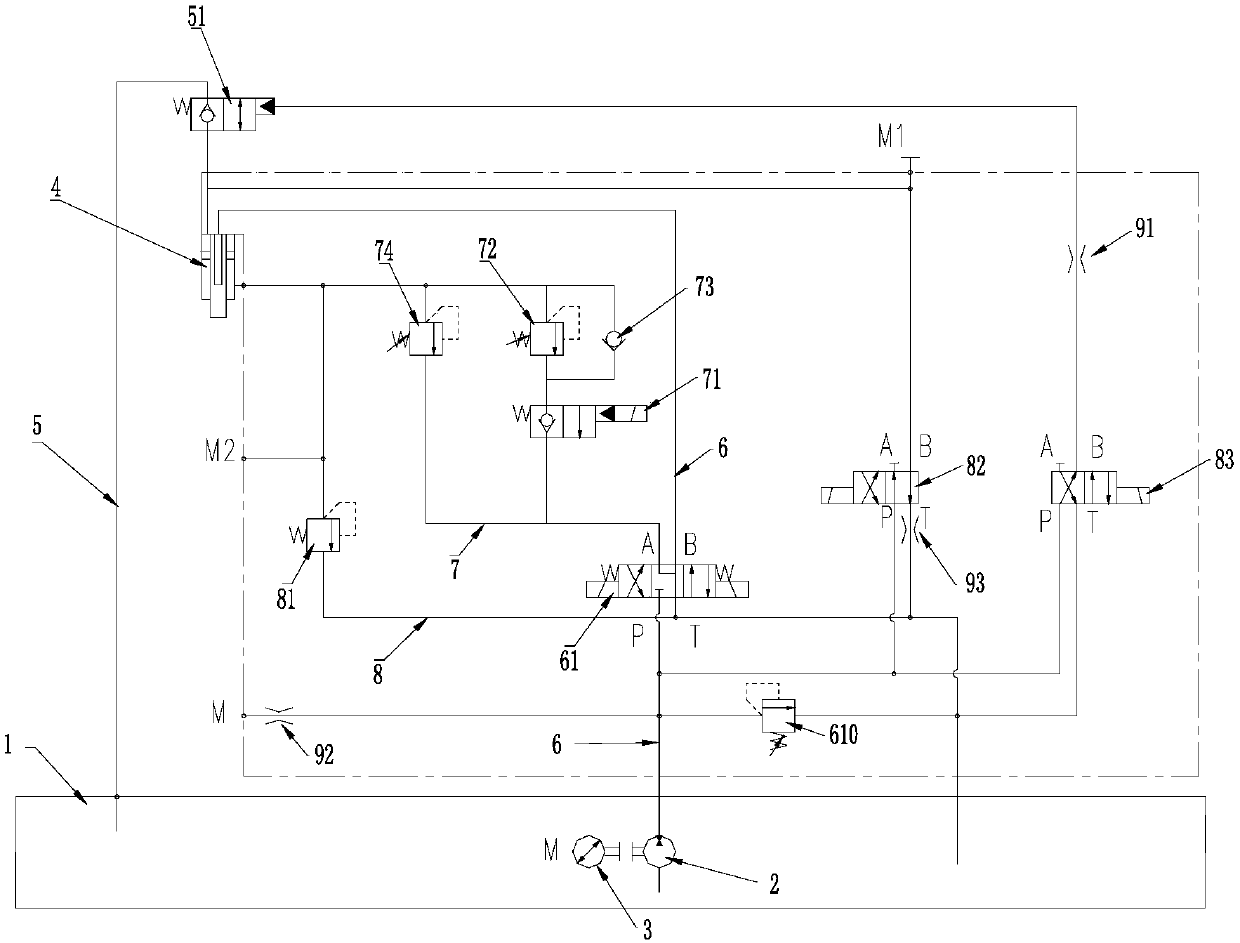

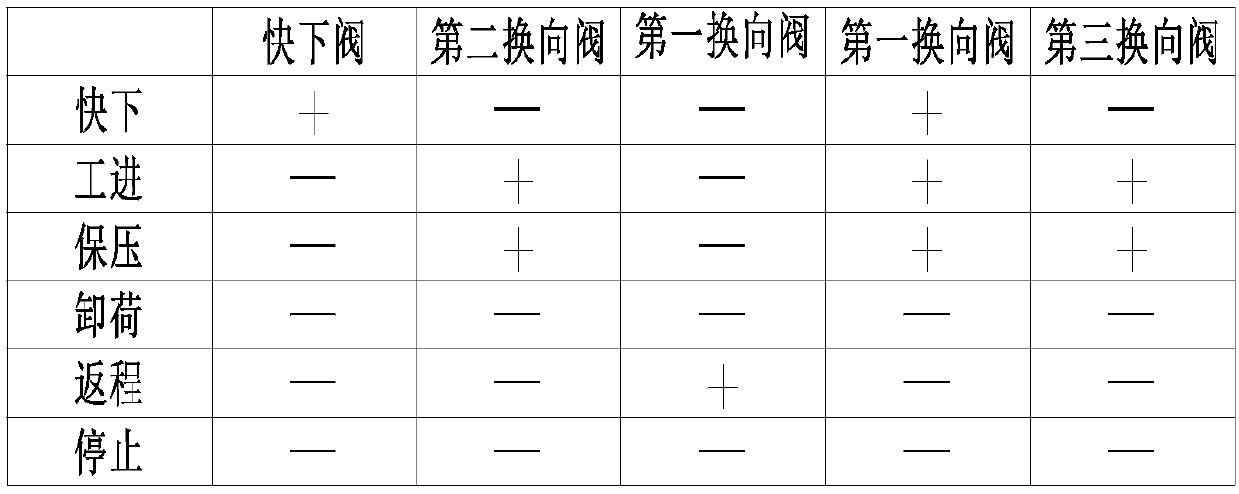

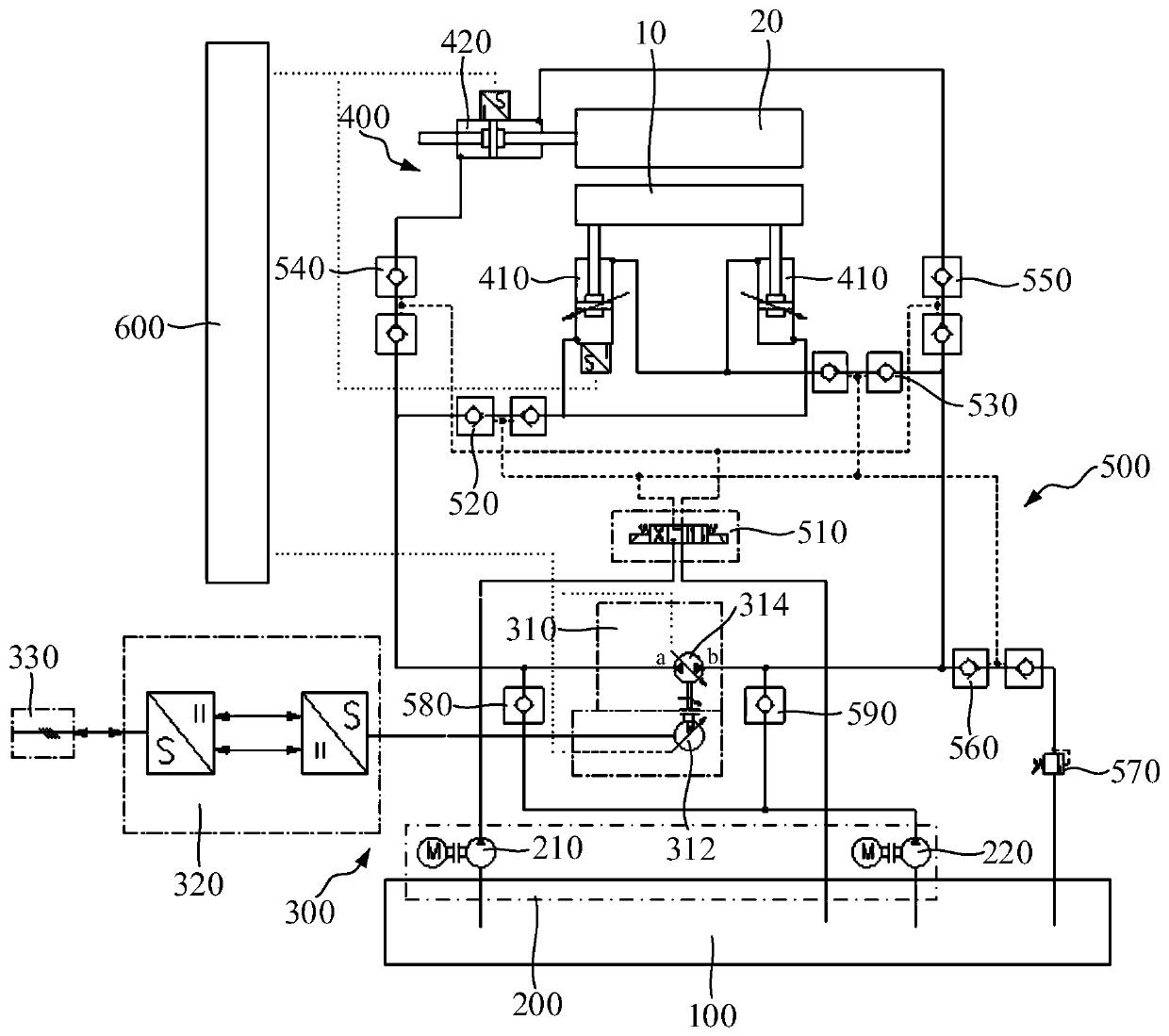

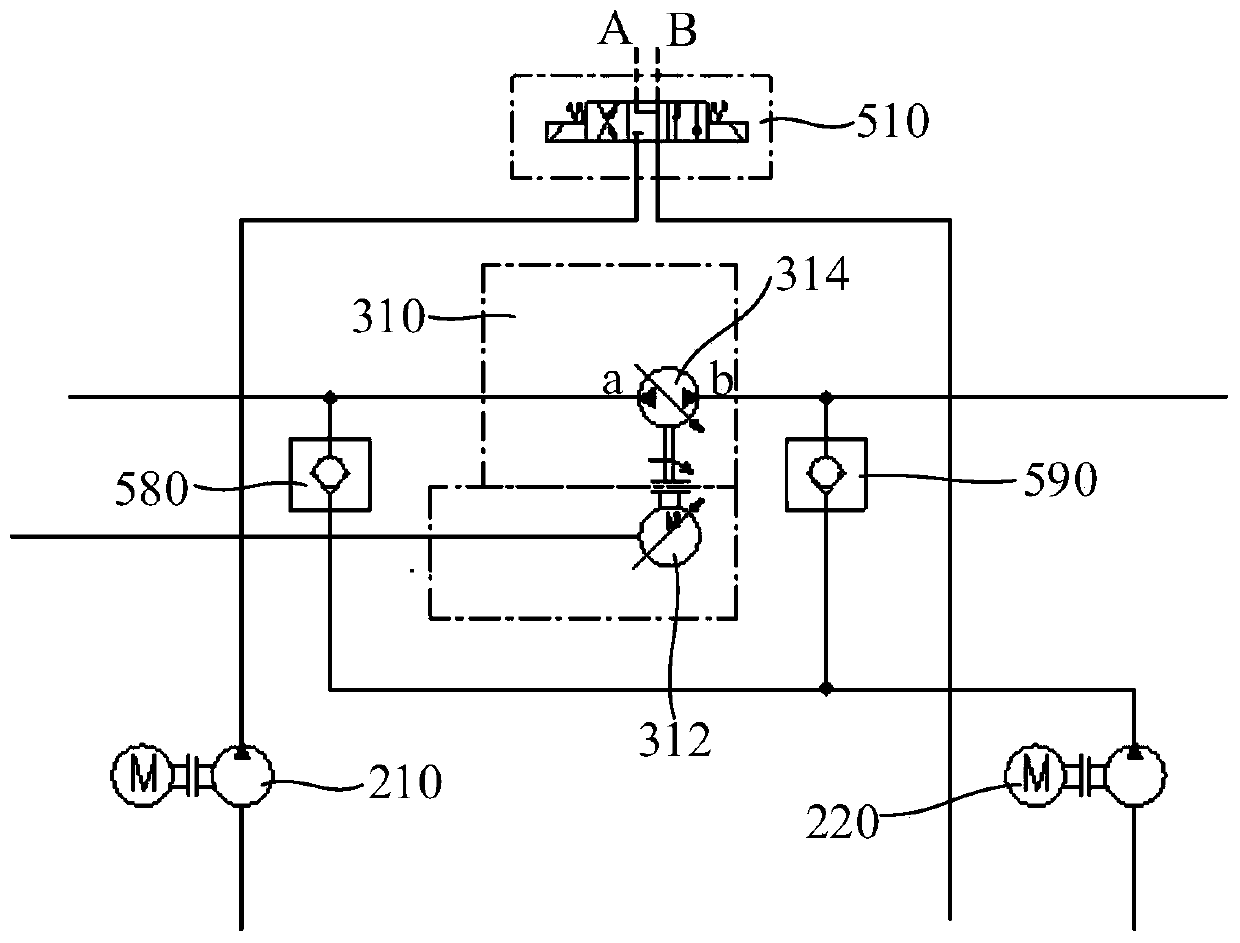

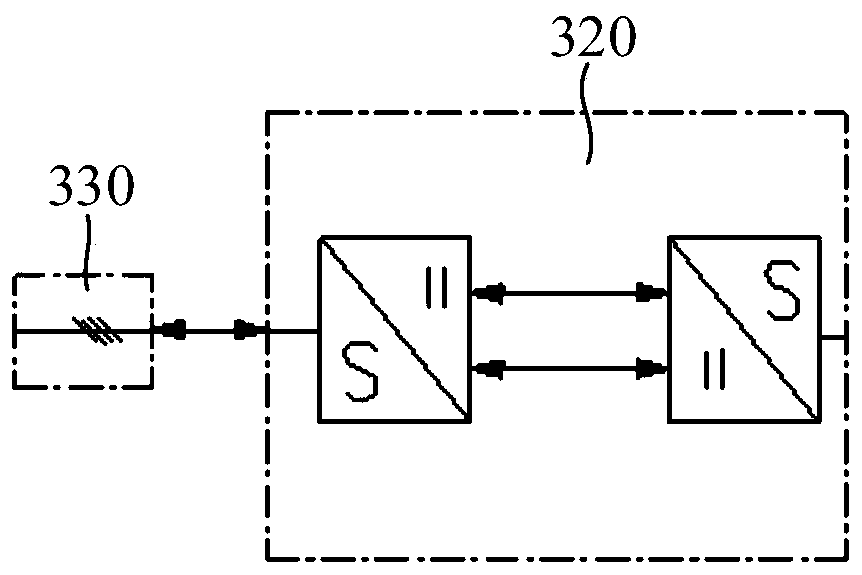

Electro-hydraulic numerical-control synchronous bending machine hydraulic system controlled by double servo pumps

PendingCN107816462AImprove work efficiencySave electricityServomotor componentsServomotorsSafety valveServo

The invention discloses an electro-hydraulic numerical-control synchronous bending machine hydraulic system controlled by double servo pumps. The electro-hydraulic numerical-control synchronous bending machine hydraulic system comprises a speed increasing cylinder, an oil return way, a first oil way, a second oil way and a third oil way. A liquid filling valve is arranged on the oil return way. One end of the oil return way is connected with the speed increasing cylinder, and the other end of the oil return way is connected with an oil tank. The first oil way is provided with a first reversingvalve. One end of the first oil way is connected with the speed increasing cylinder, and the other end of the first oil way is connected with the oil tank. One end of the second oil way is connectedwith the speed increasing cylinder, and the other end of the second oil way is connected with the first reversing valve. The second oil way is provided with a fast downflow valve, an overflow valve, aone-way valve and a back pressure valve. One end of the third oil way is connected with the first oil way and the second oil way, and the other end of the third oil way is connected with the oil tank. The third oil way is provided with a safety valve. A second reversing valve is arranged between the third oil way and the oil return way. A third reversing valve is arranged between the oil return way and the first oil way. By means of the electro-hydraulic numerical-control synchronous bending machine hydraulic system, the noise reduction effect is achieved; and due to the fact that the temperature of hydraulic oil is controllable, the hydraulic oil is long in service life, and thus the environmental protection effect is achieved.

Owner:DERATECH MASCH TOOL (SUZHOU) CORP LTD

Soot blower steam source device utilizing low-temperature reheater access port steam

InactiveCN106090953AWell mixedMeet the steam source parameter requirementsSolid removalWorking fluidEngineering

The invention provides a soot blower steam source device utilizing low-temperature reheater access port steam. The device comprises low-temperature reheater inlet steam, low-temperature reheater outlet steam, an ejector and a steam soot blower air source, wherein the ejector is composed of a high-pressure nozzle, a low-pressure nozzle, a mixing chamber, a mixing chamber throat portion and a diffusion section, the low-temperature reheater inlet steam flows in from the high-pressure nozzle as working fluid, the low-temperature reheater outlet steam is introduced into the mixing chamber from the low-pressure nozzle as driving fluid, and after mixing and pressurization of the ejector, mixed steam sprayed out of a diffusion pipe finally serves as the steam soot blower air source. The structural dimension of the ejector can be optimized through parameter design of the low-temperature reheater inlet steam and the low-temperature reheater outlet steam, so that parameters of mixed steam meet the parameter requirement of the soot blower air source under various load conditions, the problem that high-quality steam is wasted when final-stage superheated steam serves as the soot blower air source is solved, and the economical efficiency of a unit is improved.

Owner:XI AN JIAOTONG UNIV

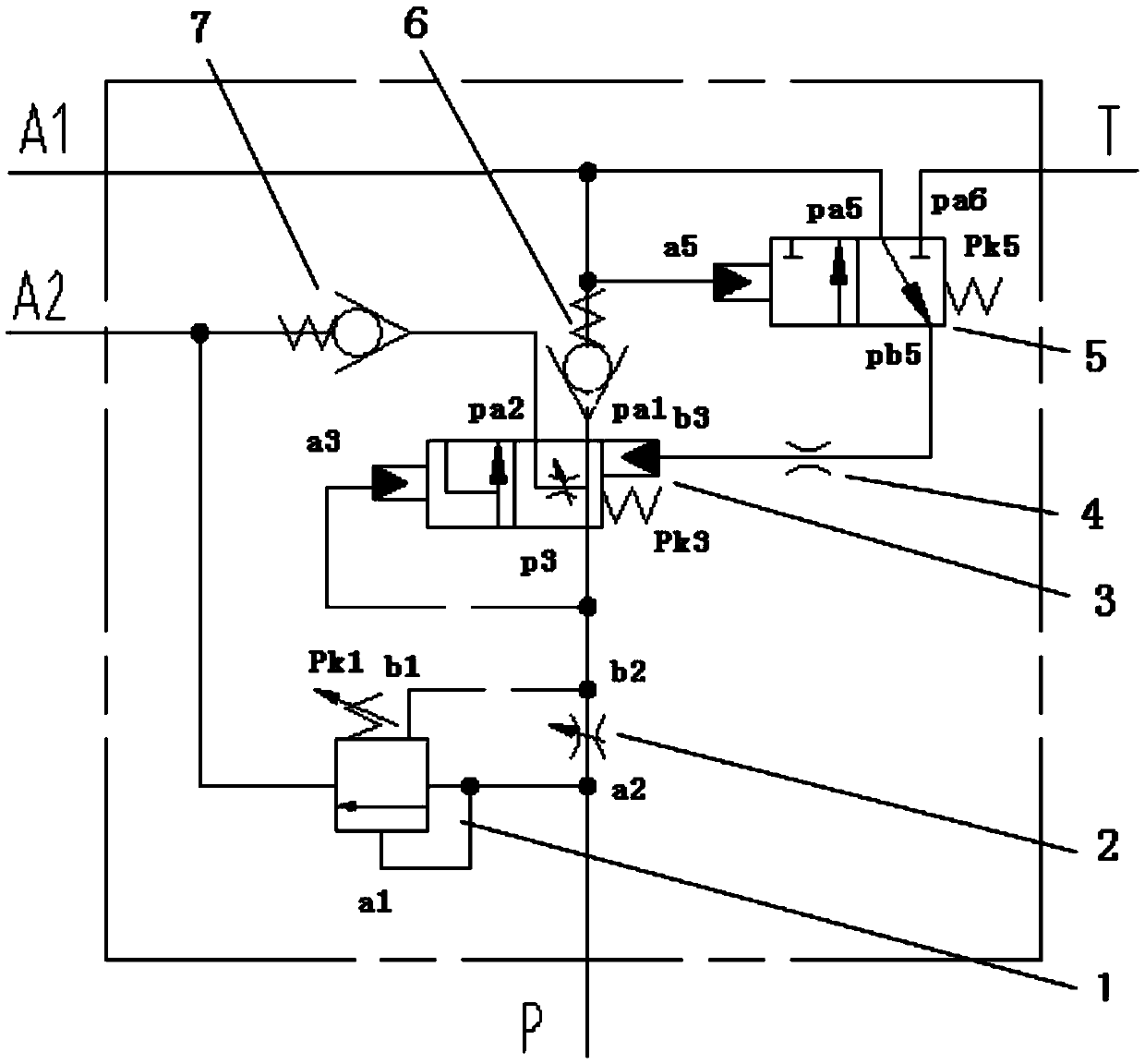

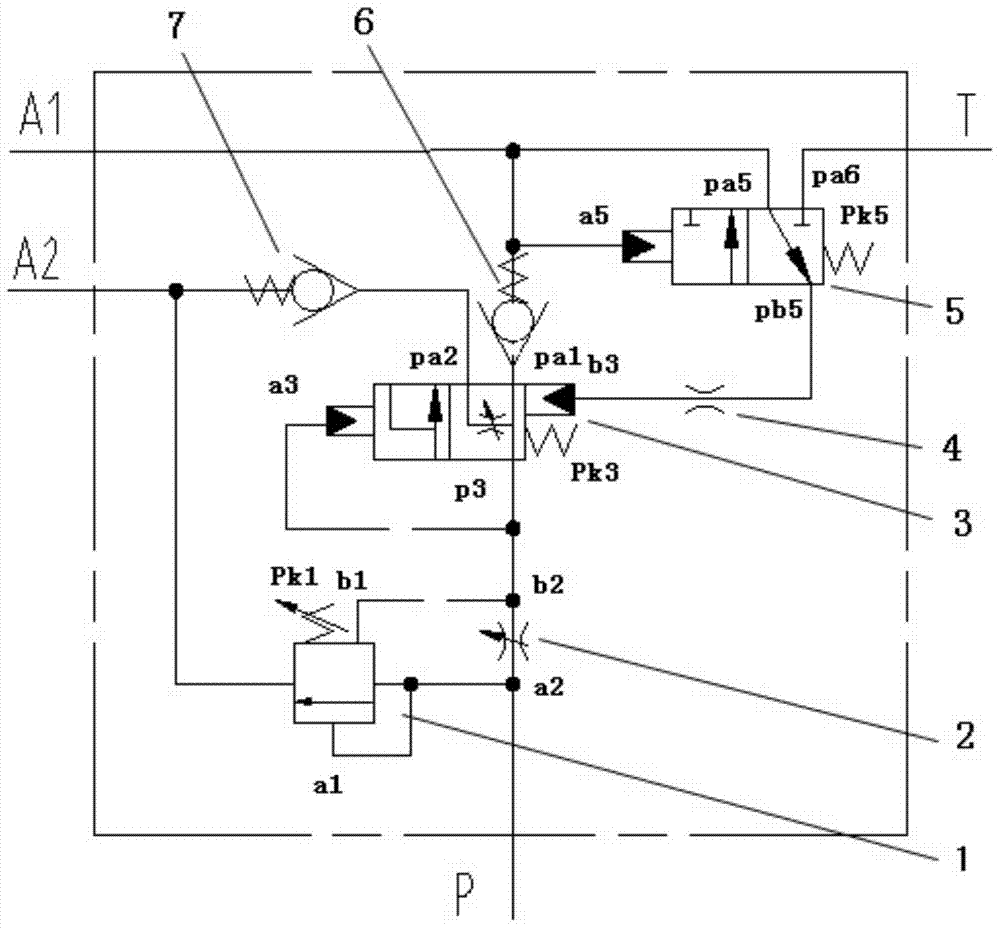

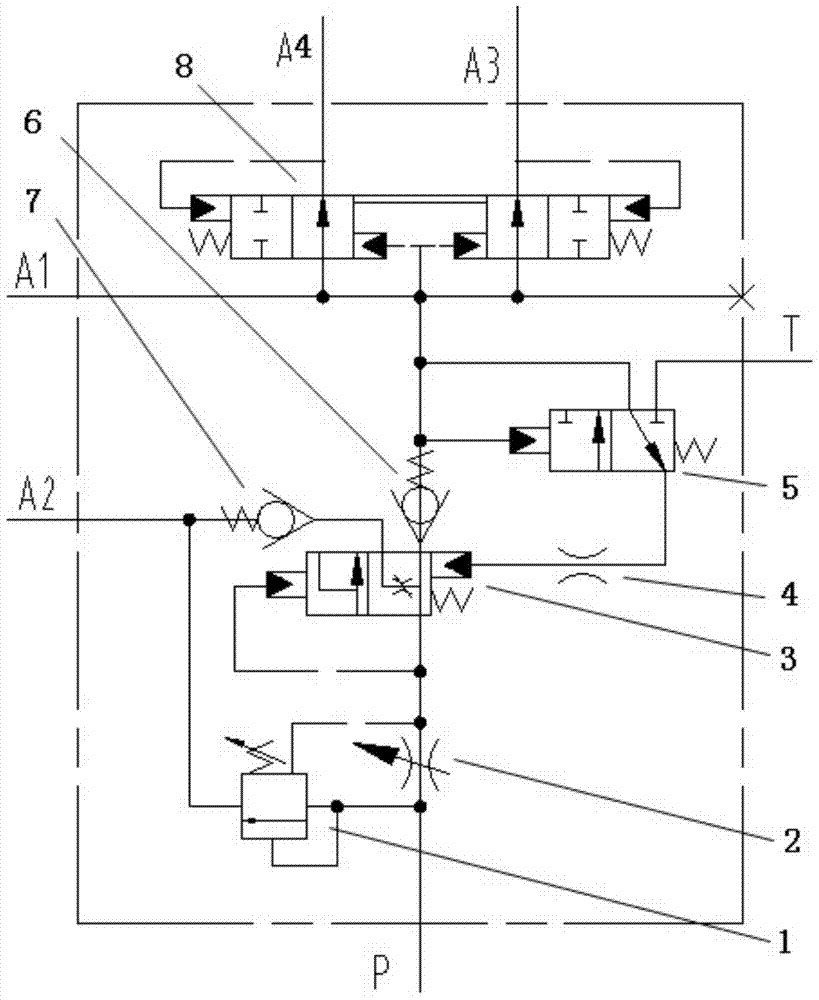

Flow divider priority valve

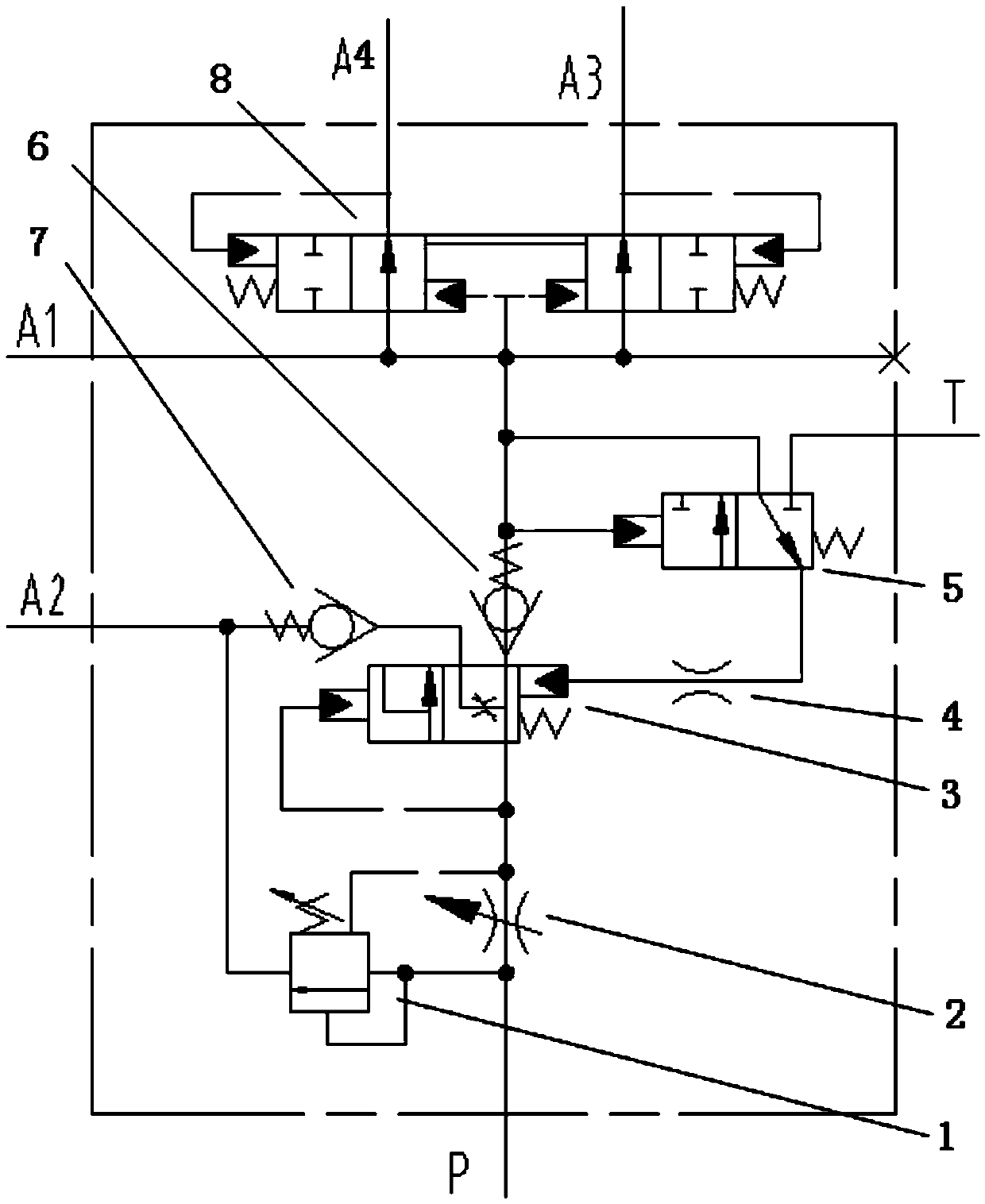

The invention relates to hydraulic elements and provides a flow divider priority valve. The flow divider priority valve aims to solve the problems that a brake pump and a cooling pump are arranged in an existing loading machine, and consequentially the cost is high, and energy saving cannot be achieved. The flow divider priority valve comprises a sequence valve, a throttling valve and a priority valve body, and a priority control valve. The throttling valve is connected with an oil inlet P after being connected with the sequence valve in parallel. An oil outlet of the sequence valve is connected with an output port A2, and the two control ends of the sequence valve are connected with the two ends of the throttling valve. A priority oil outlet of the priority valve is connected with an output port A1, a second oil outlet pa2 of the priority valve is connected with the output port A2, the control end a3 of the priority valve is connected with an oil inlet p3, and the spring cavity control end b3 of the priority valve is connected with an oil port pb5 of the priority control valve. The oil port pb5 and the liquid control end a5 of the priority control valve are connected with the output port A1, and an oil port pb6 of the priority control valve is connected with an oil return port T. The flow divider valve can be applied to a cooling and hydraulic braking system of the loading machine, and oil can be supplied through one hydraulic pump, so that the manufacturing cost is reduced, energy consumption is reduced, and noise is lowered.

Owner:GUANGXI LIUGONG MASCH CO LTD

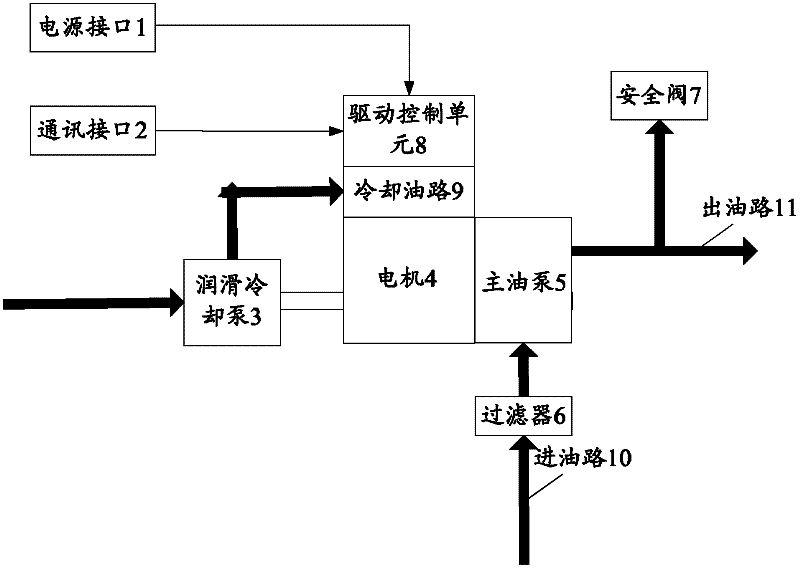

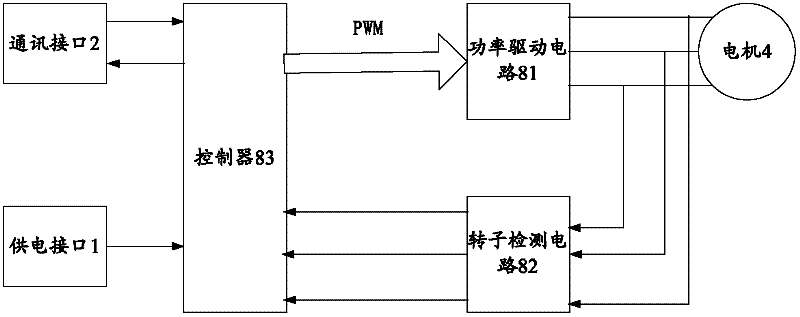

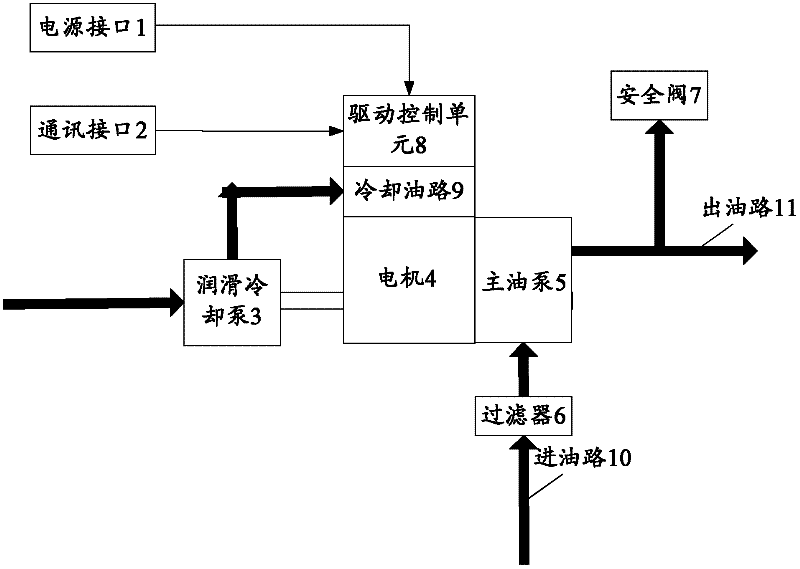

Electric metering pump for aircraft engine

ActiveCN102269146AReduce usageReduce manufacturing costPumpsPositive-displacement liquid enginesAviationFuel tank

The invention discloses an electric metering pump for an aircraft engine. The electric metering pump comprises a power supply interface, a communication interface, a drive control unit, and a lubrication cooling pump, a motor and a main oil pump which are coaxially connected, wherein the drive control unit is connected with the power supply interface and the communication interface and is used for driving the motor to operate and controlling the rotating speed according to a control command; the motor is used for driving the lubrication cooling pump and the main oil pump to rotate; the main oil pump is used for pressurizing oil liquid which flows into the main oil pump; and the drive control unit is used for controlling the oil supply amount of the main oil pump by controlling the rotating speed of the motor. By the electric metering pump, the fuel oil increasing and metering functions of the aircraft engine is realized, the structure of an engine transmission accessory can be eliminated or greatly simplified, and the maximum section area and the weight of the engine can be reduced; in addition, fuel oil does not flow back to an inlet or an oil tank of the pump, so that a hydraulic oil channel is simplified, the energy loss of a system is reduced, the efficiency of the system is improved, and the additional temperature rise of the fuel oil is reduced or eliminated.

Owner:BEIJING POWER MACHINERY INST

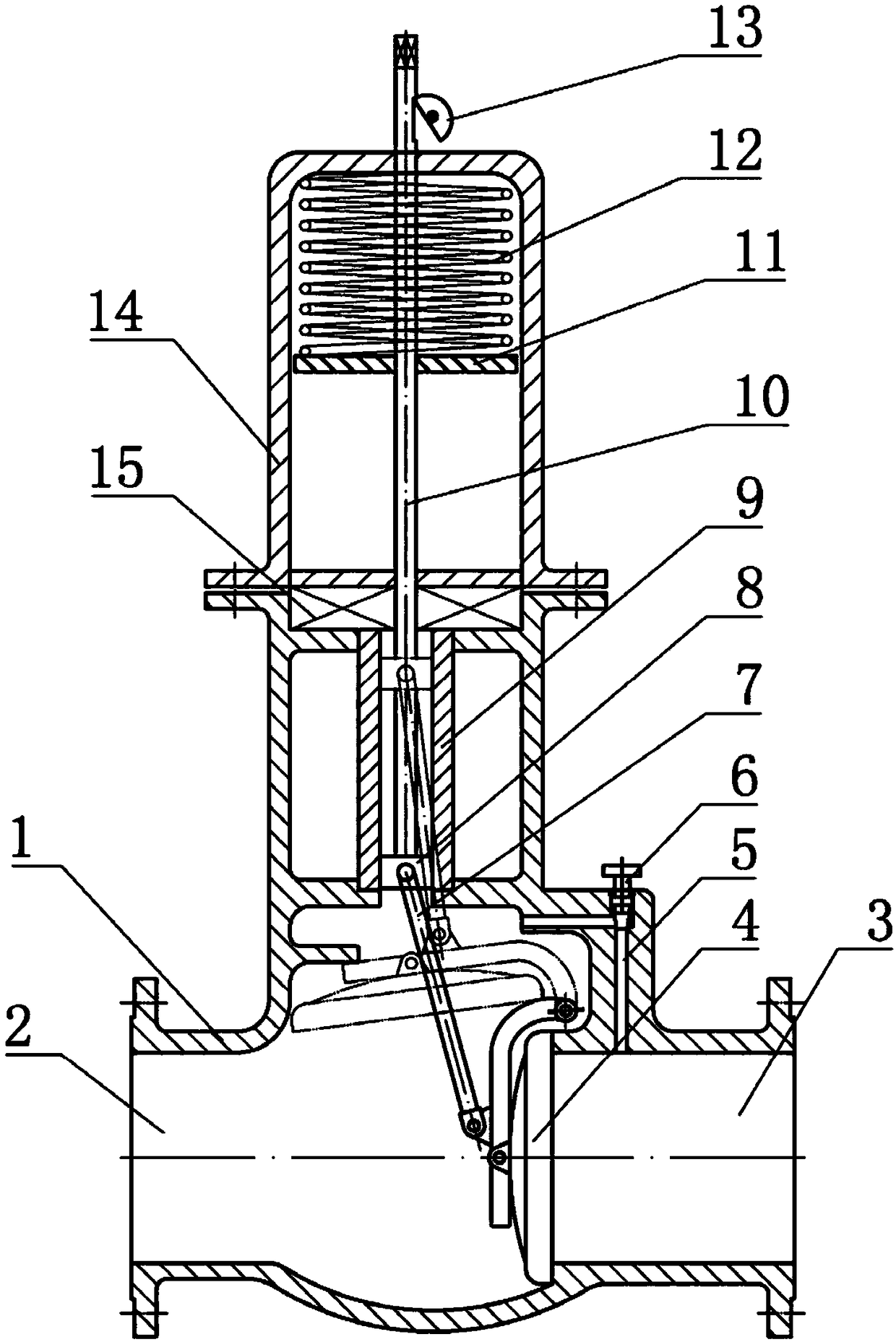

Low resistance loss quick-closing valve and using method thereof

PendingCN109372998AAvoid throttling lossesAvoid Flow Resistance LossEqualizing valvesSafety valvesPore diameterEngineering

The invention discloses a low resistance loss quick-closing valve and a using method thereof. The low resistance loss quick-closing valve is provided with a valve body, a valve clack, a connecting rod, a sliding block, a driving mechanism and a valve rod, wherein an inlet and an outlet are formed in the valve body; the first end of the valve clack is hinged in the valve body; during the overturning process, the valve clack can open or close a passage between the inlet and the outlet; the first end of the connecting rod is hinged to the valve clack; the sliding block is hinged to the second endof the connecting rod; a guide rail is arranged in the valve body; the sliding block can slide in the guide rail; the driving mechanism can drive the sliding block to slide; the valve rod is connected with the sliding block; and the driving mechanism can drive the valve rod to move, so that a stop valve is prevented from throttling loss caused by small pore diameter of a valve seat and from flowresistance loss caused by flowing turning

Owner:安徽新宁能源科技有限公司

Transmission system of stepping mechanism and energy recovery system thereof

PendingCN110030235ASmall footprintStrong adaptability to load feedback power changesBatteries circuit arrangementsSingle network parallel feeding arrangementsElectric machineFrequency conversion

The invention discloses an energy recovery system, further discloses a transmission system of a stepping mechanism, and the transmission system of the stepping mechanism comprises the energy recoverysystem. The energy recovery system comprises a hydraulic power unit, a frequency conversion driving unit and an energy recovery device, wherein the hydraulic power unit comprises a speed regulating motor and a hydraulic pump; the speed regulating motor is connected with the hydraulic pump; the frequency conversion driving unit is connected with the speed regulation motor; the energy recovery device is connected with the frequency conversion driving unit; and the frequency conversion driving unit controls the speed regulating motor to drive the hydraulic pump to operate, the volume speed regulating control is carried out on a hydraulic actuating element, and the hydraulic actuating element is driven to act, so that the load weight under different working conditions is automatically matched,the throttling loss is avoided, the energy-saving effect is achieved, and the control and the structure are simple. When the hydraulic actuating element descends or brakes, the hydraulic actuating element drives the speed regulating motor to be in a power generation state, potential energy and / or kinetic energy of the hydraulic actuating element is converted into electric energy, and the electricenergy is transmitted to the energy recovery device through the frequency conversion driving unit for reuse.

Owner:彭友斌

Integrating device capable of controlling wall thickness of bottle blowing machine with crank connecting rod mechanism driven by motor

The invention relates to a plastic extruding and blowing wall thickness control device, in particular to an integrating device capable of controlling the wall thickness of a bottle blowing machine with a crank connecting rod mechanism driven by a motor. The integrating device comprises a machine frame, wherein a plurality of extruding mold heads for extruding bottle blowing molds are fixed to thebottom of the machine frame; an extruding mold head core rod is arranged in each extruding mold head in a cooperating manner; a servo motor and a crank connecting rod mechanical device are mounted atthe top of the machine frame; the servo motor is connected with a core rod moving mold plate through the crank connecting rod mechanical device, and is used for driving the core rod moving mold plateto move up and down; and the upper ends of the extruding mold head core rods are connected with and fixed to the core rod moving mold plate. The integrating device disclosed by the invention is simplein structure, high in precision of a control device, energy-saving and environmentally-friendly; the motion of the crank connecting rod mechanical device is combined with the motion of the servo motor, so that under the motion requirements of being short in stroke and heavy in load, the integral structure is stable and reliable, and the service life is greatly prolonged; and besides, the curve control is performed by a digital cam which is in servo driving, so that the precision of wall thickness of products is notably improved, and the production efficiency is improved.

Owner:上海弋朋自动化科技有限公司

A hydraulic-electric hybrid energy-saving system for lifting mechanism

ActiveCN107235440BAvoid the loss of multiple conversionsImprove storage utilization efficiencyBatteries circuit arrangementsLifting devicesMotor speedElectric capacity

The invention discloses a hydro-electric hybrid energy saving system for a lifting mechanism. The system is provided with an electric cylinder, an electric speed controller, a two-way DC / DC converter, a super-capacitor module and a pressure sensor; in combination with a corresponding control method, the gravitational potential energy of a movable arm is directly converted into electric energy for charging the super-capacitor module when the movable arm declines; and the super-capacitor module is used for providing the electric energy for a driving motor of an electric cylinder for auxiliary diving when the movable arm rises. The hydro-electric hybrid energy saving system for the lifting mechanism, disclosed by the invention, has the advantages of high storage and utilization efficiency of potential energy of the movable arm, stable output, low installed power, etc.

Owner:TAIYUAN UNIV OF TECH

diverter priority valve

ActiveCN105370650BSatisfy traffic demandSave energyServomotor componentsControl engineeringControl valves

Owner:GUANGXI LIUGONG MASCH CO LTD

A dual-piston independent damping, vibration reduction and pressure regulation equipment

InactiveCN103104567BImprove dynamic stabilityImprove work efficiencyServomotor componentsVibration attenuationEngineering

Disclosed is a double-piston independent damping vibration attenuation pressure regulating device. A non-sealing end of a valve core of the device is connected and fixed with the left end of a piston which is arranged at the front left end of a piston sleeve. A changeable damping hole is formed in the middle portion of the piston sleeve. A changeable cavity is formed in the piston sleeve by the right end of the piston and the left end of the changeable damping hole. Another piston is arranged at the right end of the piston sleeve. Another changeable cavity is formed in the piston sleeve by the right end portion of the changeable damping hole and the left end portion of the second piston. The right end of the second piston is contacted with a spring arranged on the inner side of an end cover. The spring arranged on the inner side of the end cover is sleeved outside the piston sleeve and is contacted with the inner side of a shoulder of the front end of the piston sleeve. The double-piston independent damping vibration attenuation pressure regulating device has the advantages of improving dynamic stability of a pressure valve greatly, enabling the pressure valve to work stably, enabling dynamic features of the pressure valve to be better and easy to stabilize due to the fact that independent damping vibration attenuation pressure regulating technology is adopted, avoiding throttling loss caused by adding a throttling device to a valve, improving working efficiency of parts and a system and improving working reliability of the parts and the system.

Owner:SOUTHWEST JIAOTONG UNIV

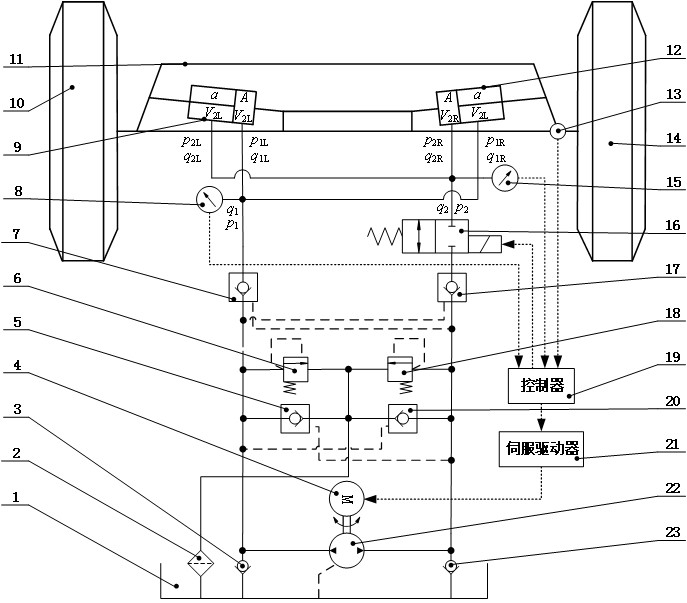

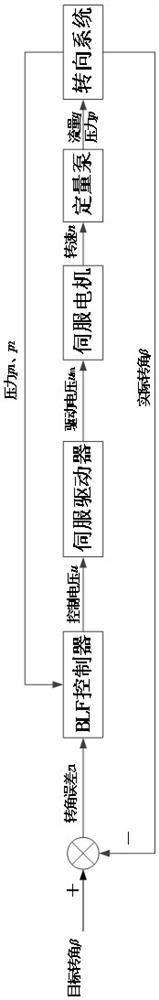

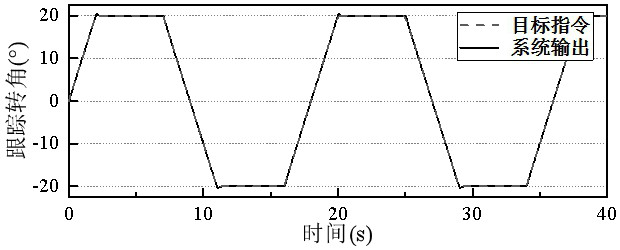

Heavy vehicle electro-hydraulic servo steering system and control method capable of suppressing overshoot

ActiveCN114655306ASave hardware costSave maintenance costFluid steeringAdaptive controlLoop controlSteering wheel

The invention relates to a heavy vehicle electro-hydraulic servo steering system and a control method capable of suppressing overshoot. The heavy vehicle electro-hydraulic servo steering system comprises a hydraulic subsystem, a mechanical subsystem, a data acquisition subsystem and a controller. The data acquisition subsystem is used for acquiring the actual turning angle of a steering wheel and the pressure of each pressure sensor; the controller calculates and outputs control voltage of the servo driver according to the target rotating angle of the system, the actual rotating angle of the steering wheel and the pressure of each pressure sensor so as to control the hydraulic subsystem. According to the invention, corner closed-loop control of the system can be realized, and system overshoot can be reduced while high-dynamic tracking control of the system can be realized.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com