Device used for adjusting basic state parameters of working medium

A technology of basic state and parameters, applied in the direction of machine/engine, non-displacement pump, mechanical equipment, etc., can solve the problems of inability to realize the adjustment of fluid working medium pressure, unsatisfactory technical effect, large throttling loss, etc. Functional ability, wide application range, and the effect of avoiding throttling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

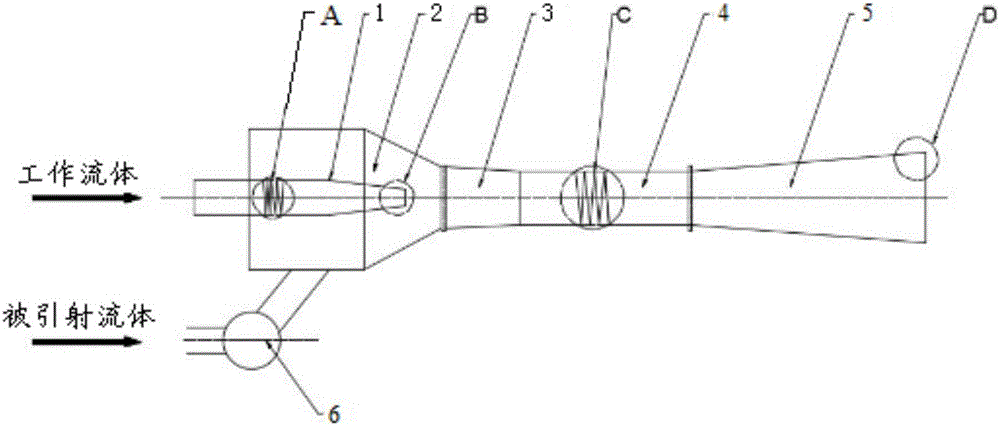

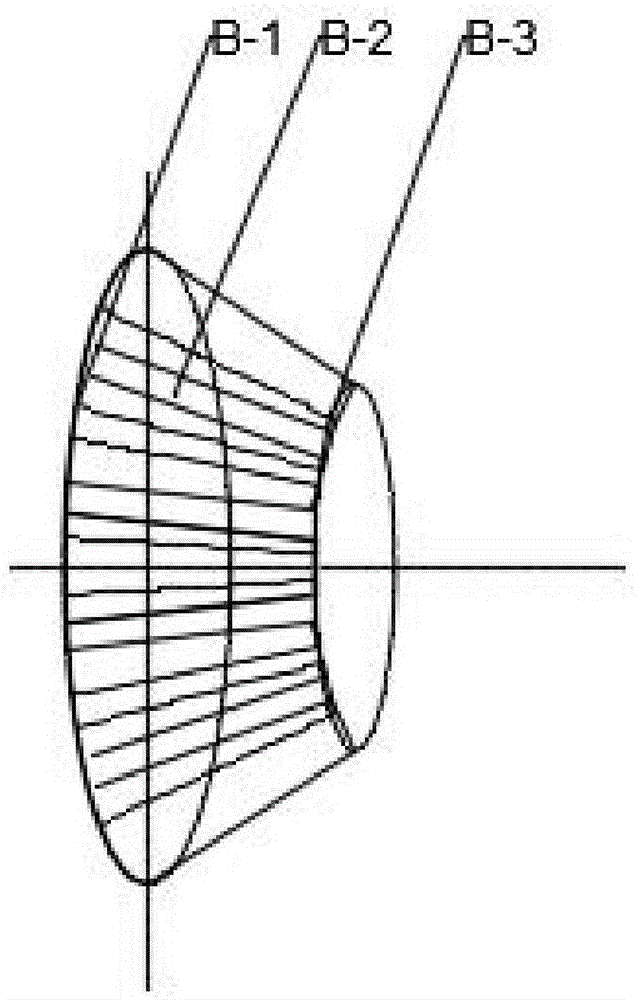

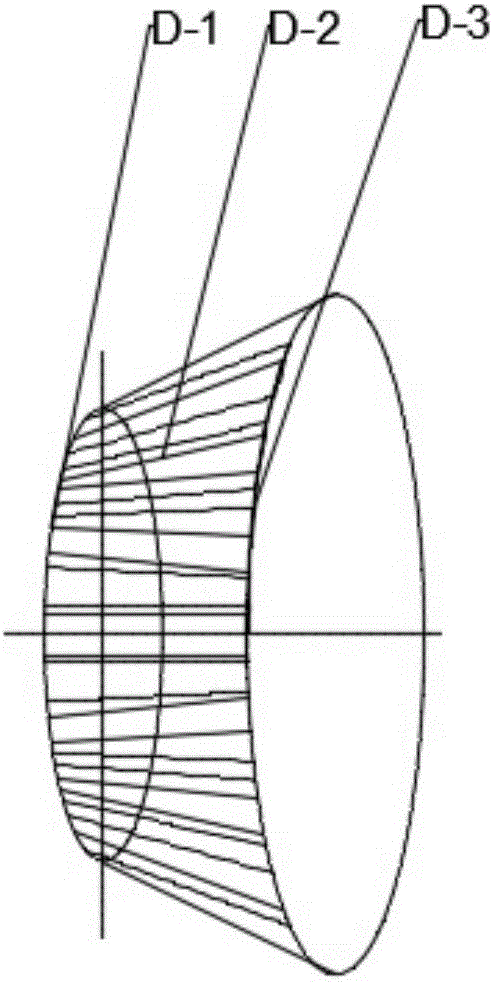

[0036] Such as Figure 1-3 , this embodiment describes in detail the structural features and working principles of the device for adjusting the basic state parameters of the working fluid according to the present invention.

[0037] Such as figure 1 As shown, this embodiment provides a device for adjusting the basic state parameters of the working fluid, including a working nozzle 1, a suction chamber 2, a throat, a diffuser pipe 5 and an injection flash pipe 6, and the working nozzle 1 is set In the suction chamber 2, the suction chamber 2 is sequentially connected to the throat pipe and the diffuser pipe 5, and the injection flash pipe 6 communicates with the side of the suction chamber 2 through a pipeline. The centers of the working nozzle 1, the suction chamber 2, the throat pipe and the diffuser pipe 5 are located on the same straight line.

[0038] Specifically, the suction chamber 2 is a cavity structure, and the working nozzle 1 goes deep into the inner cavity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com