Electro-hydraulic integrated swashplate and plunger type hydraulic transformer

A hydraulic transformer and plunger technology, applied in the direction of fluid pressure converters, mechanical equipment, etc., can solve the problems of unstable output pressure, large volume and weight of the transformer, and small transformation range, so as to improve work efficiency and shorten the overall Length, the effect of improving swing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

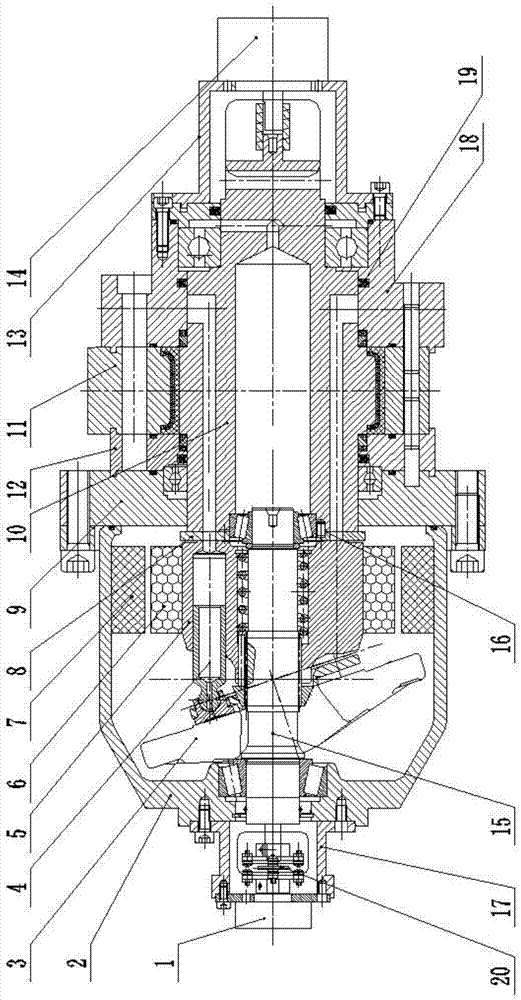

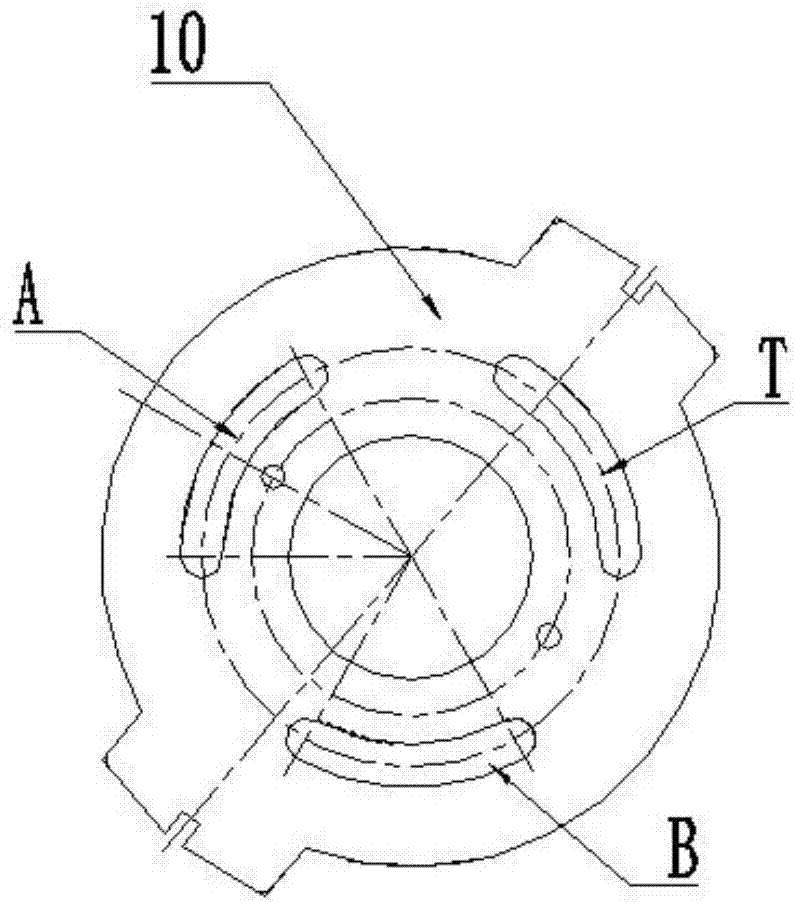

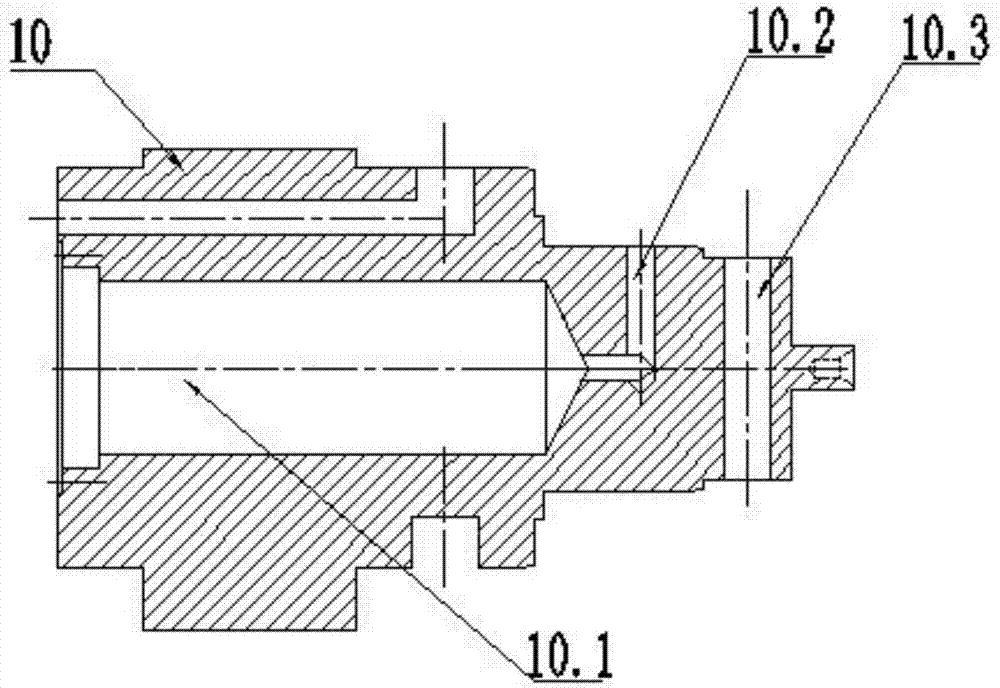

[0025] Such as Figures 1 to 4 As shown, an electro-hydraulic integrated swash plate plunger type hydraulic transformer includes a hydraulic transformer housing 2, a cylinder body 5, a flow plate 8, a plunger 4 and a swash plate 3, and the cylinder body 5 is installed on the output shaft 15 through a spline , the distribution plate 8 is set at one end of the cylinder body 5 and is in sealing contact with the cylinder body 5, the swash plate 3 is set at the other end of the cylinder body 5 and installed on the hydraulic transformer shell 2, there are several plunger cavities in the cylinder body 5, and the plunger 4 is installed in the plunger cavity and one end is in sliding contact with the swash plate 3, and also includes the rear end cover 9, the swing hydraulic motor 11 and the distribution shaft 10, the distribution shaft 10 is the swing shaft of the swing hydraulic mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com