Automobile tire wear test comparison device

A comparison device, a technology for automobile tires, applied in automobile tire testing, measuring devices, vehicle testing, etc., can solve problems such as test errors, low efficiency, and inability to accurately judge the degree of wear by visual observation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

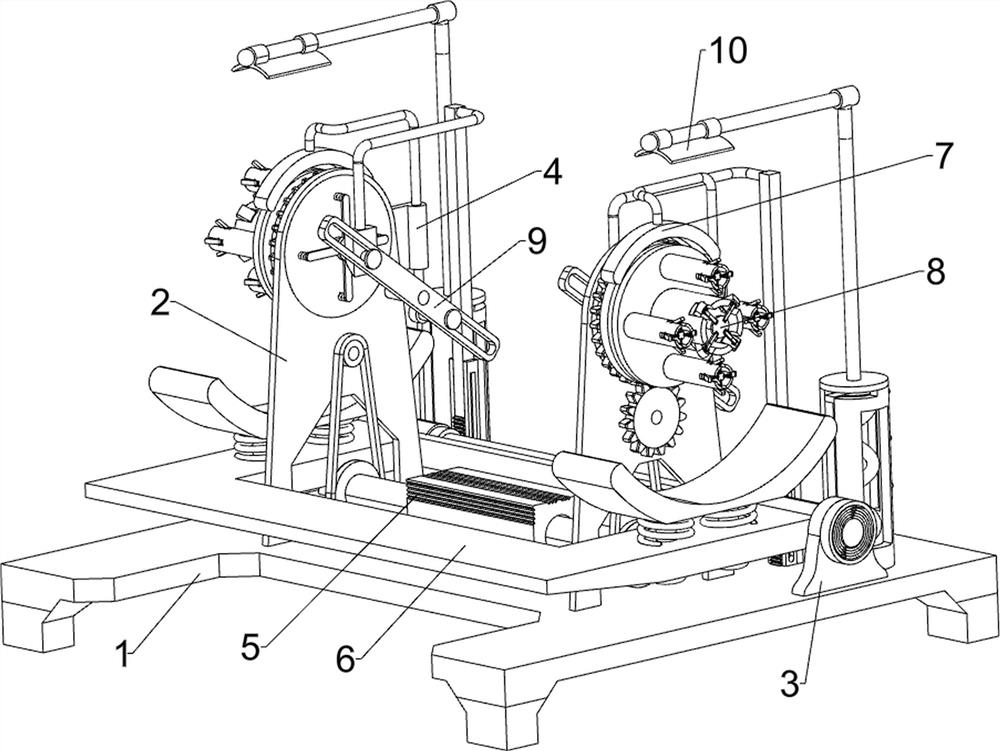

[0030] A kind of automobile tire wear test comparison device, such as figure 1 with figure 2 As shown, it includes a base 1, a support plate 2, a fixed plate 3, a fixed frame 4, a rotating assembly 5 and a friction assembly 6. The support plate 2 is connected to the left and right sides of the top of the base 1, and the left and right sides of the top of the base 1 are connected to The fixed plate 3 is connected with the fixed frame 4 on the rear side of the upper part of the supporting plate 2 on both sides, the rotating assembly 5 is connected in the middle of the top of the base 1, and the friction assembly 6 is connected in the upper part of the fixed plate 3 in a rotatable manner.

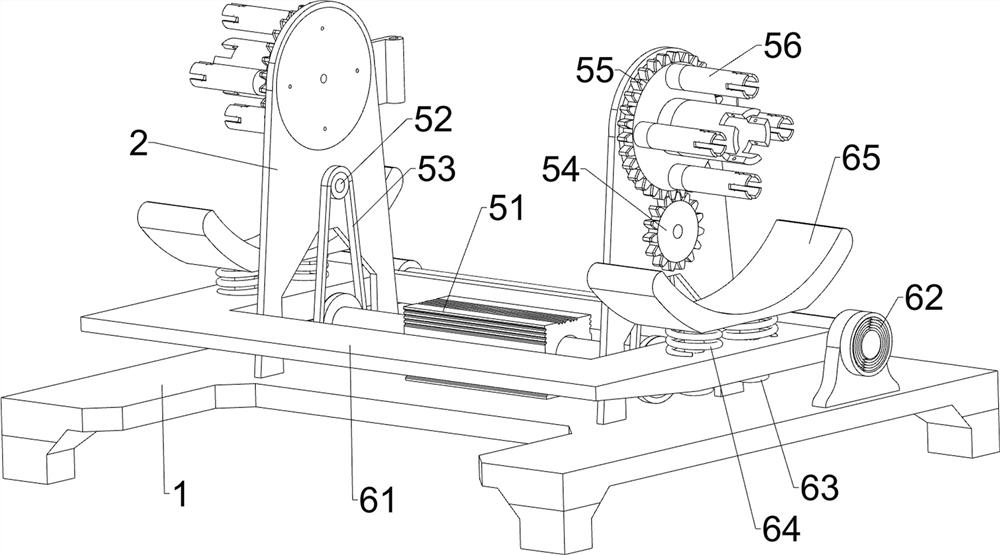

[0031] The rotating assembly 5 includes a biaxial motor 51, a rotating shaft 52, a belt 53, a full gear 54, a gear plate 55, and a positioning shaft 56, and the biaxial motor 51 is installed in the middle of the top of the base 1, and the inner sides of the support plates 2 on both sides are ...

Embodiment 2

[0035] On the basis of Example 1, such as image 3 As shown, a brake assembly 7 is also included. The brake assembly 7 includes a brake disc 71, a caliper 72 and a first carriage 73. The outer sides of the toothed discs 55 on both sides are connected with a brake disc 71. The fixed mounts 4 on both sides A caliper 72 is slidably connected to the middle part, and a first sliding frame 73 is connected to the front side of the calipers 72 on both sides, and the first sliding frame 73 is located directly above the brake disc 71 .

[0036] When the toothed discs 55 on both sides rotate, the first carriages 73 on both sides can be driven downward by manually pressing the calipers 72 on both sides, and the first carriages 73 on both sides move downward together with the brake discs 71 on both sides. The contact makes the toothed disc 55 stop rotating, so that it is more convenient when people want to stop and look at the tire status on both sides, and the rotation of the toothed disc...

Embodiment 3

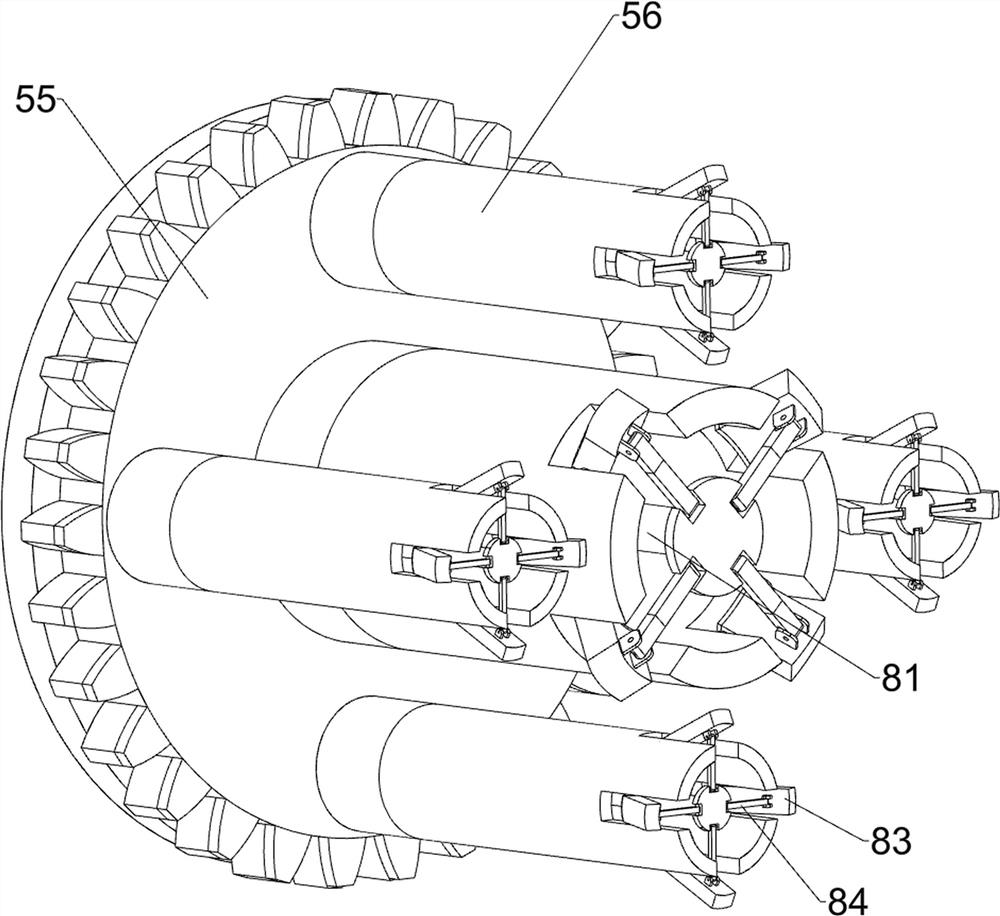

[0038] On the basis of Example 2, such as Figure 4 with Figure 5 As shown, a clamping assembly 8 is also included. The clamping assembly 8 includes a second carriage 81, a second compression spring 82, a block 83 and a second connecting rod 84, and the inner sides of the toothed discs 55 on both sides are slidably connected. There is a second slide frame 81, and a second compression spring 82 is connected between the second slide frame 81 on both sides and the tooth discs 55 on both sides, and the outside of the positioning shaft 56 on both sides is connected with a block 83 in a rotational manner. The inner sides of the clamping blocks 83 are rotatably connected with second connecting rods 84, and the second connecting rods 84 on both sides are rotatably connected to the second sliding frames 81 on both sides.

[0039] When it is necessary to carry out the wear test to the automobile tires, first the tires are manually placed on the positioning shafts 56 on both sides, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com