A plunger combined digital variable pump

A digital variable, combined technology, used in pump control, liquid variable capacity machinery, machines/engines, etc., can solve the problem that the frequency response is difficult to meet the working requirements, and achieve small system pressure loss, simple structure, and overcome frequency Low response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

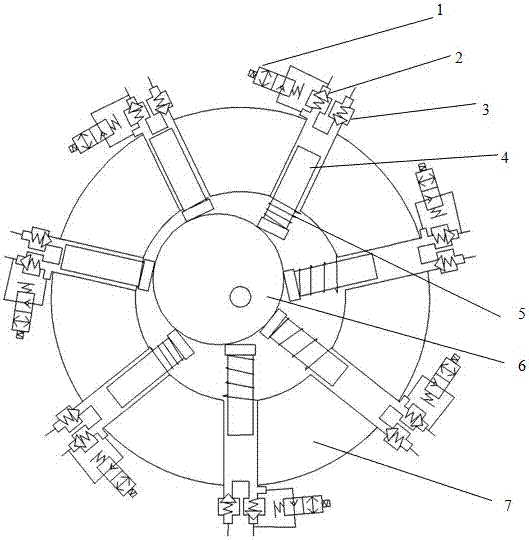

[0025] The design idea of the present invention is illustrated below through a schematic diagram.

[0026] Such as figure 1 As shown, the plunger combined digital variable hydraulic pump of the present invention consists of seven two-position two-way cut-off solenoid valves 1, seven oil suction one-way poppet valves 2, seven oil pressure one-way valves 3, seven plungers 4 , and the plunger return spring 5, the eccentric wheel 6 and the pump body 7 are composed.

[0027] The structure of the whole system is: all the plungers are driven by the eccentric wheel against the force of the return spring, the oil suction port of each plunger is connected with the oil tank, and the connection mode of the oil discharge port of the plunger is determined according to the actual needs. The working volume corresponding to each plunger is connected to the oil tank by a two-position two-way stop type solenoid valve.

[0028] When the digital variable pump is working, the motor drives the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com