A dual-piston independent damping, vibration reduction and pressure regulation equipment

A dual-piston, piston technology, applied in the field of hydraulic components, can solve the problems of difficult pressure valve stability and large overshoot, and achieve the effects of improving pressure stability, small static pressure deviation, and stable volume fluctuations as soon as possible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

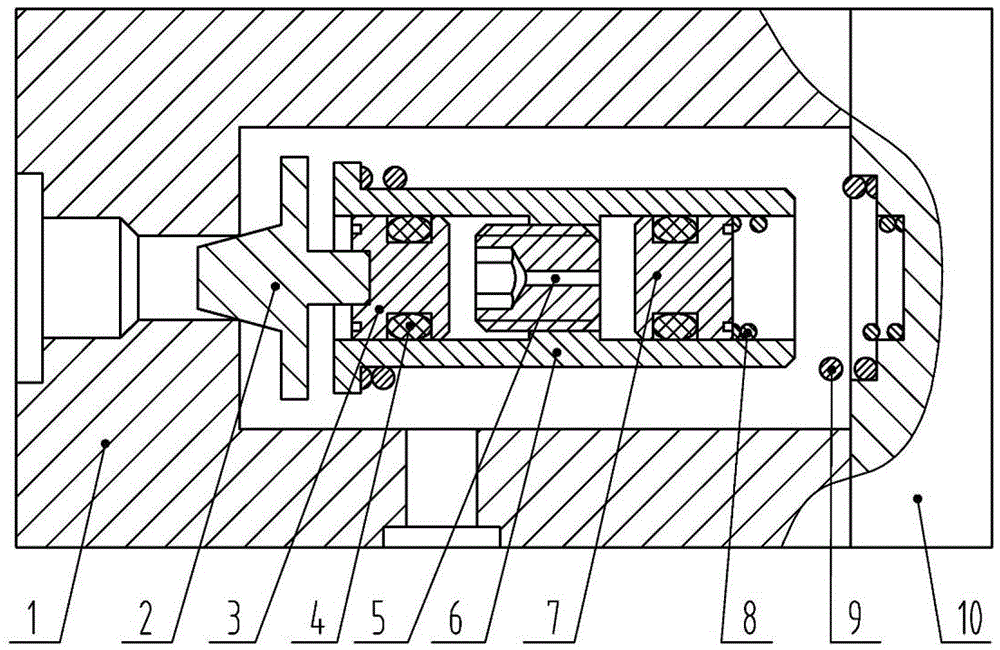

[0018] figure 1 As shown, a specific embodiment of the present invention is: a dual-piston independent damping, vibration reduction and pressure regulating equipment, including a valve body 1, a valve core 2 and a piston-3, the non-sealed end of the valve core 2 and the piston-3 The left end is connected and fixed, the piston one 3 is located at the left front end of the piston sleeve 6, and the middle part of the piston sleeve 6 is provided with a variable damping hole 5, and the right end of the piston one 3 and the left end of the variable damping hole 5 form a variable damping hole 5 in the piston sleeve 6. The volume cavity (called the left volume cavity); the right end of the piston sleeve 6 is provided with a piston 2 7, and the right end of the variable damping hole 5 and the left end of the piston 2 7 form another variable volume cavity (called the left volume cavity) in the piston sleeve 6 It is the right volume chamber), the right end of the piston two 7 is in conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com