diverter priority valve

A technology of priority valve and priority control valve, used in fluid pressure actuating devices, servo motor components, mechanical equipment, etc., can solve the problems of high cost and no energy saving, and achieve the effects of energy saving, noise reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

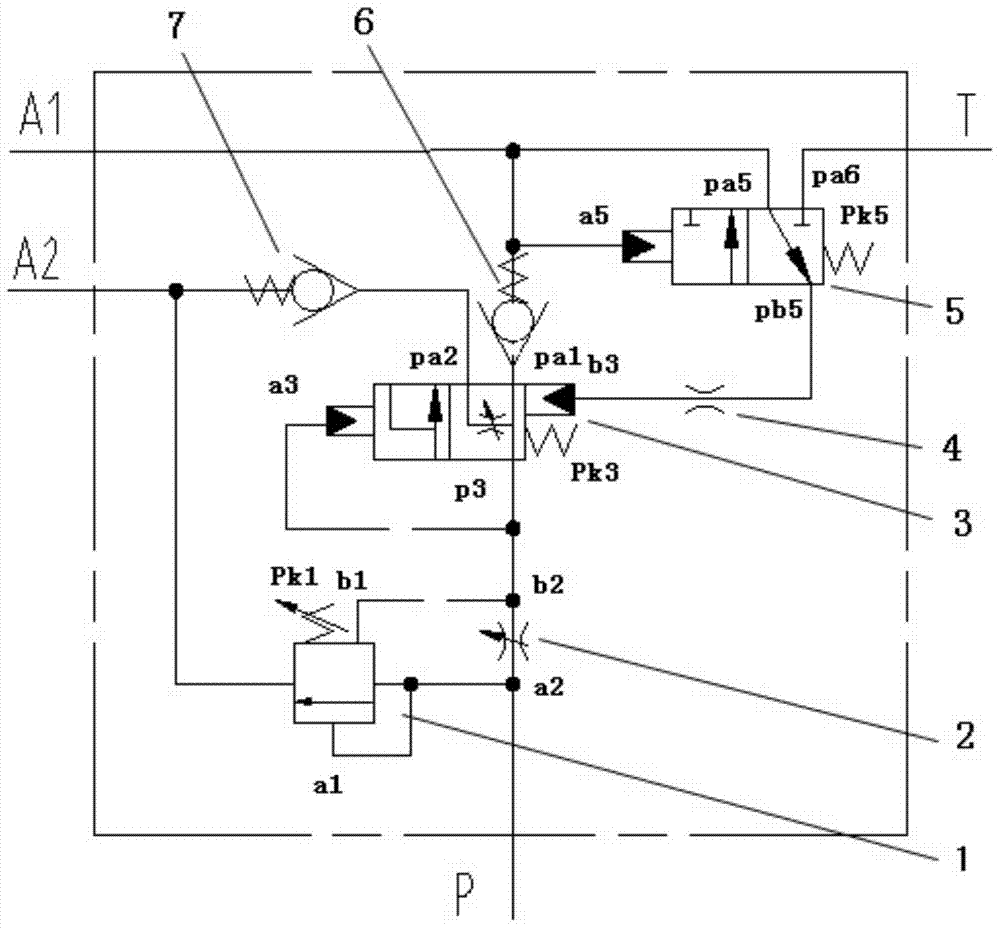

[0028] Such as figure 1 As shown, the diversion priority valve in this embodiment has an oil inlet P port, an oil return T port, an output A1 port, and an output A2 port for connecting with an external oil circuit, and the oil inlet P port is used for connecting with a pressure oil source connections, such as hydraulic pumps. The oil return T port is used to connect with the oil tank circuit. The output A1 port and the output A2 port are respectively used to connect with two hydraulic actuators, and the oil supply priority of the hydraulic actuator connected to the output A1 port is higher than that of the hydraulic actuator connected to the output A2 port, for example In the loader system, the output A1 port can be used to connect with the hydraulic brake system, and the output A2 port can be used to connect with the hydraulic motor cooling system. The priority diverter valve guarantees the oil supply of the hydraulic brake system first, and the excess flow is supplied to t...

Embodiment 2

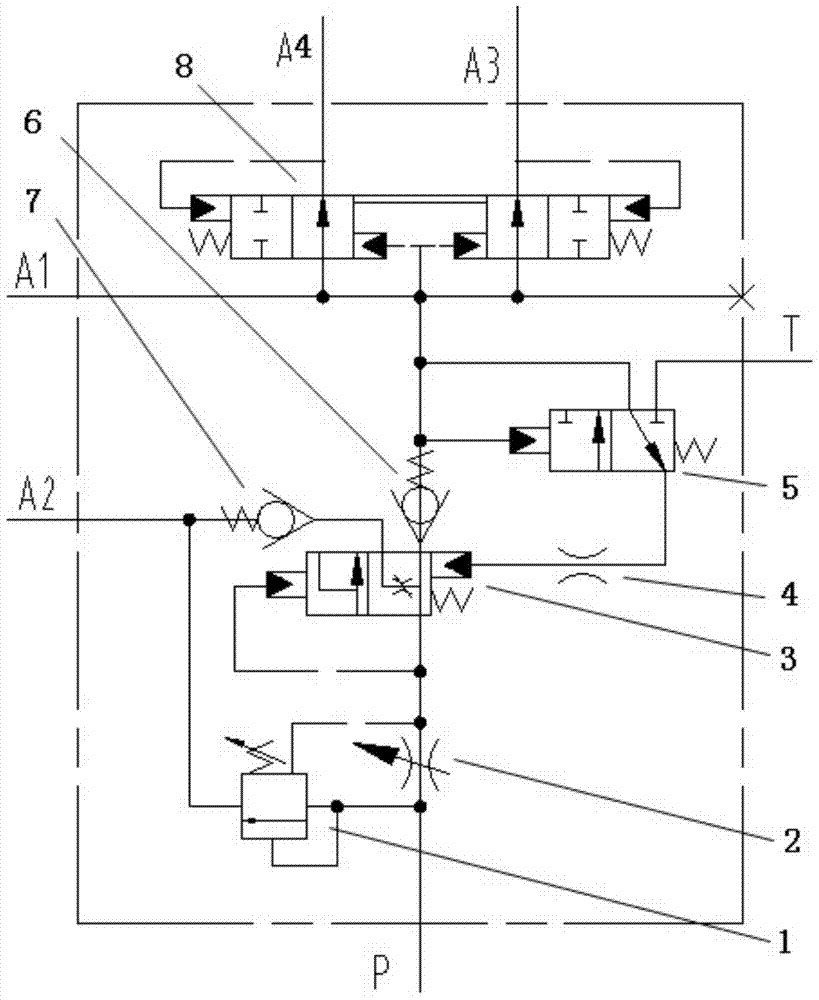

[0036] Compared with the technical solution in Embodiment 1, this embodiment differs in that a pressure reducing valve 8 is connected between the output A1 port and the priority oil outlet pa1 port of the priority valve, through which the pressure reducing valve 8 can output A3 Port and output A4 are connected with the foot brake valve and the accumulator, and the accumulator is charged to store hydraulic energy for the service brake system; the output A1 port is connected with the parking brake valve and supplied to the cylinder of the parking brake system. Oil. The working principle of the priority diverter valve in this embodiment is the same as that of the priority diverter valve in Embodiment 1, and can be used in the hydraulic braking system and hydraulic cooling system of the loader, wherein the output port A2 is connected to the hydraulic motor control valve, The cooling fan hydraulic motor supplies oil, and the output A3 port and output A4 port are connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com