Patents

Literature

243results about How to "Control clearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

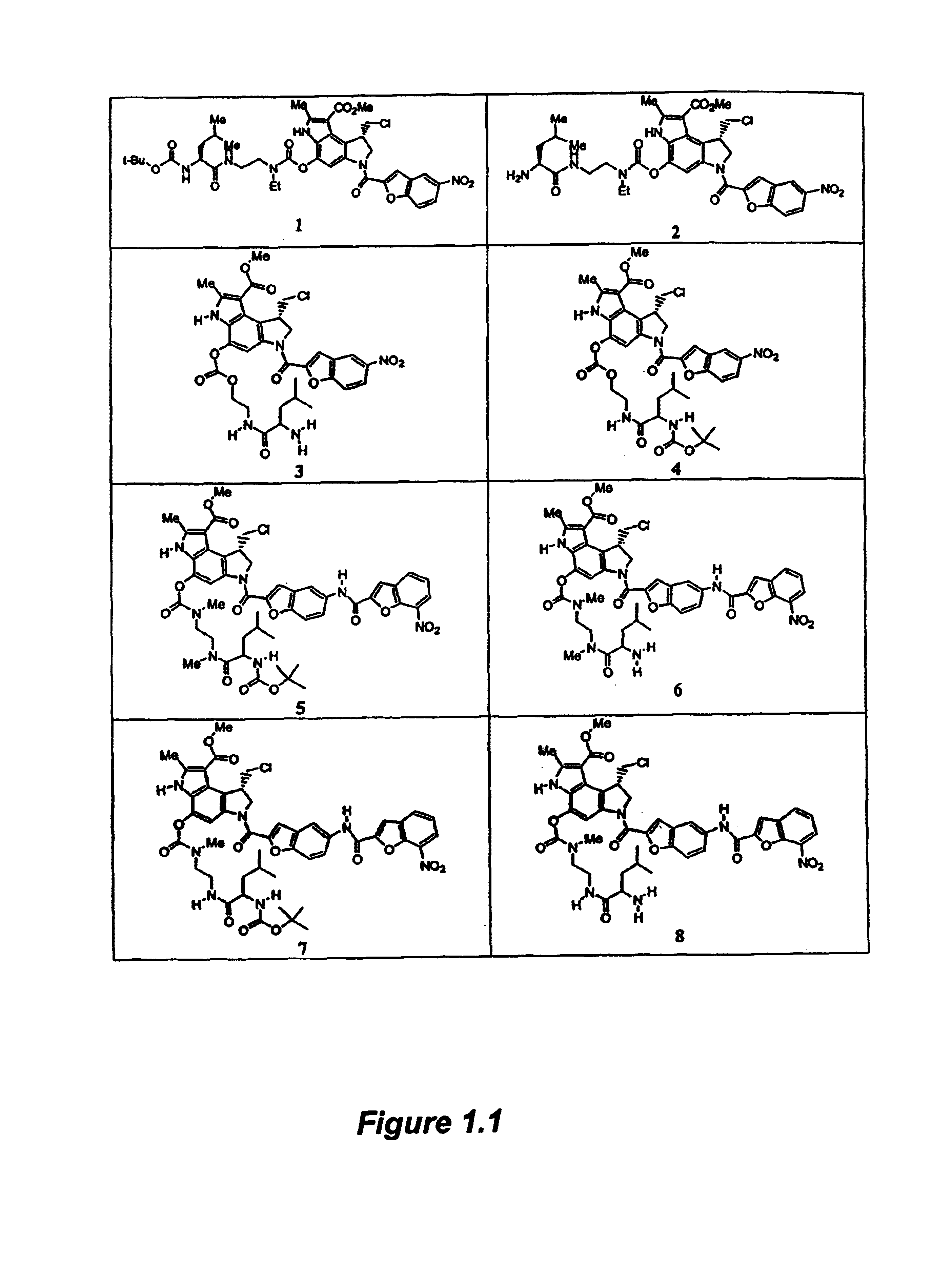

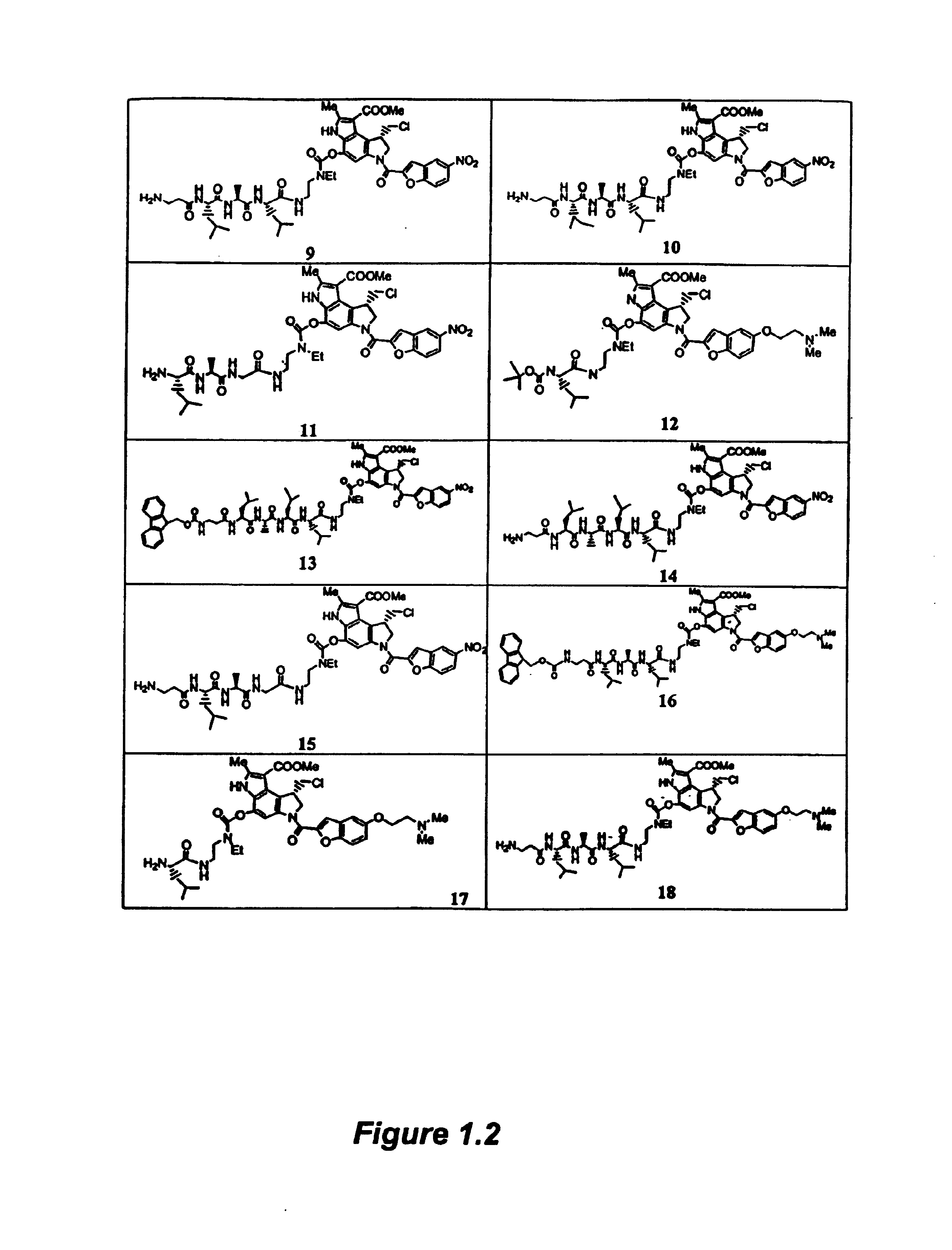

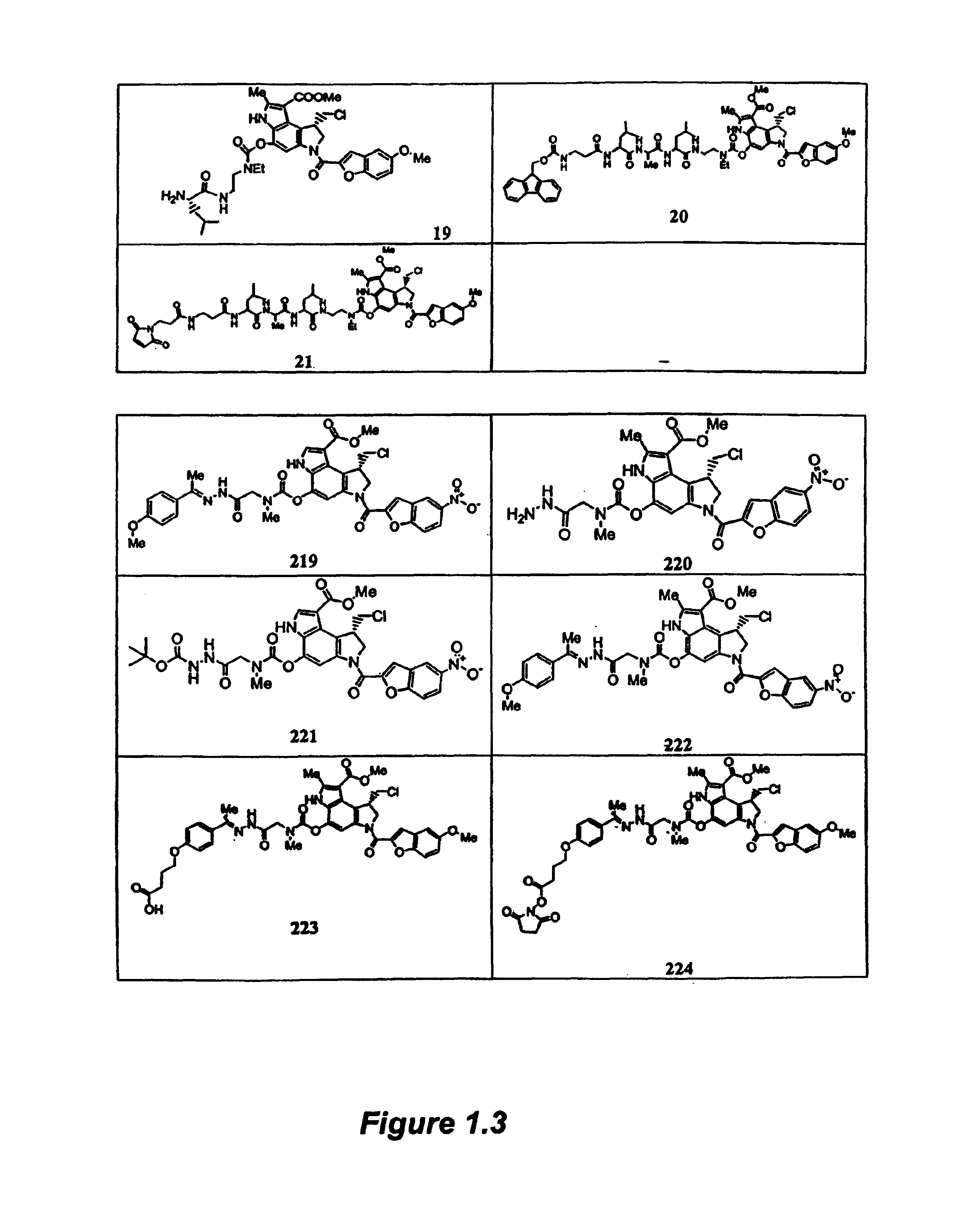

Disulfide prodrugs and linkers and stabilizers useful therefor

The present invention provides analogues of duocarmycins that are potent cytotoxins. Also provided are peptidyl and disulfide linkers that are cleaved in vivo. The linkers are of use in forming prodrugs and conjugates of the cytotoxins of the invention as well as other diagnostic and therapeutic moieties. The invention provides prodrugs and conjugates of the duocarmycin analogues with the linker arms of the invention.

Owner:ER SQUIBB & SONS INC

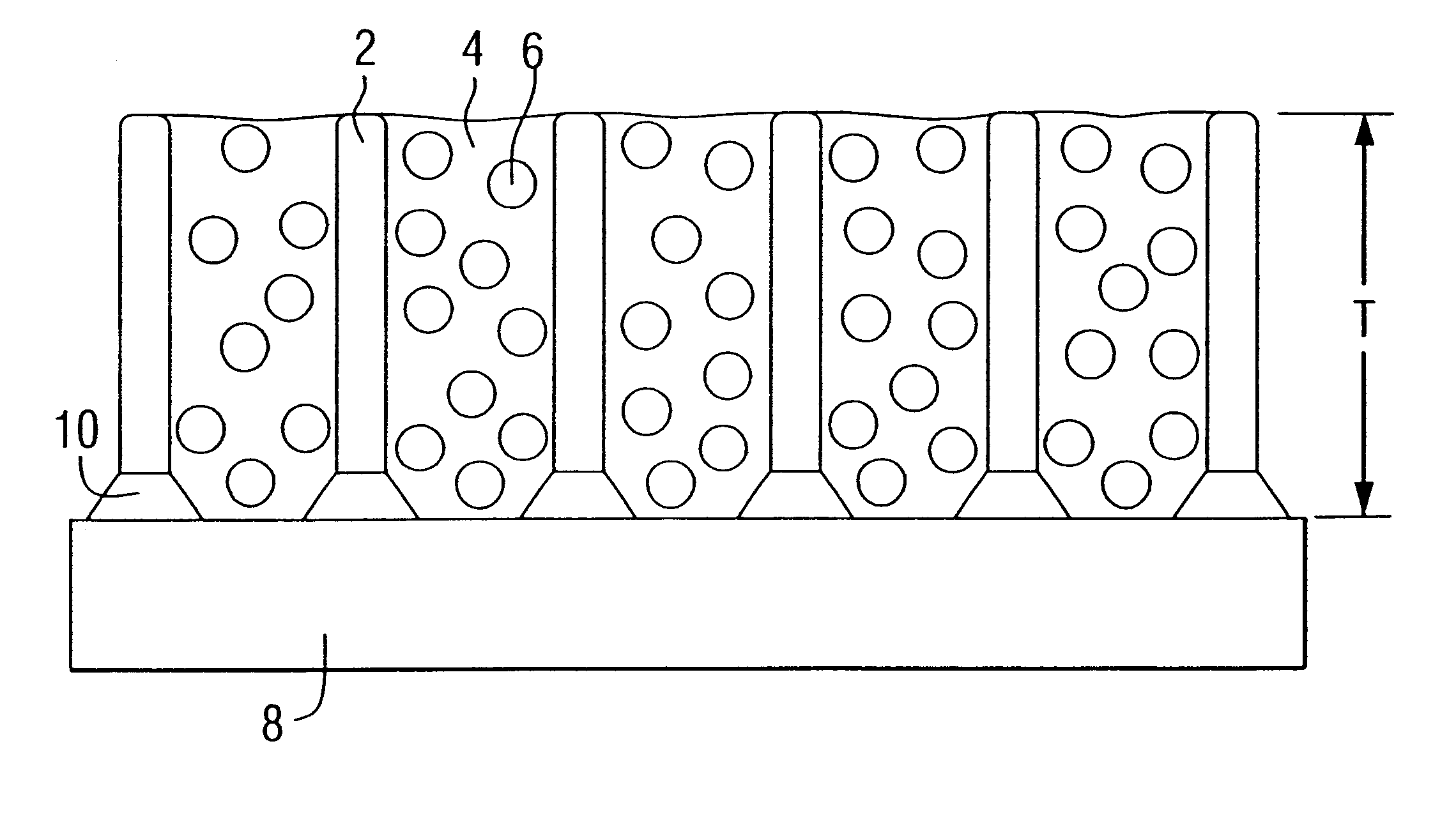

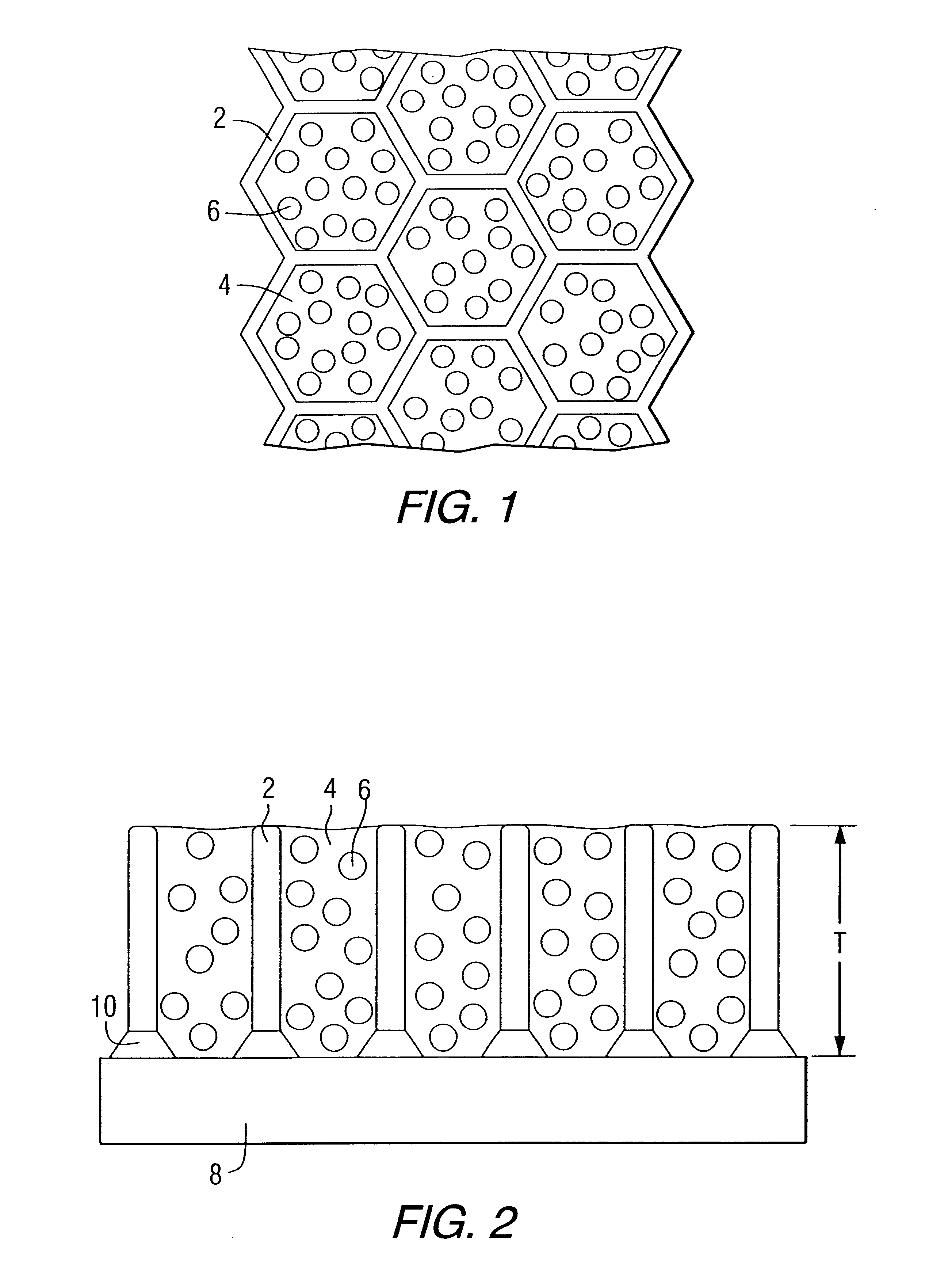

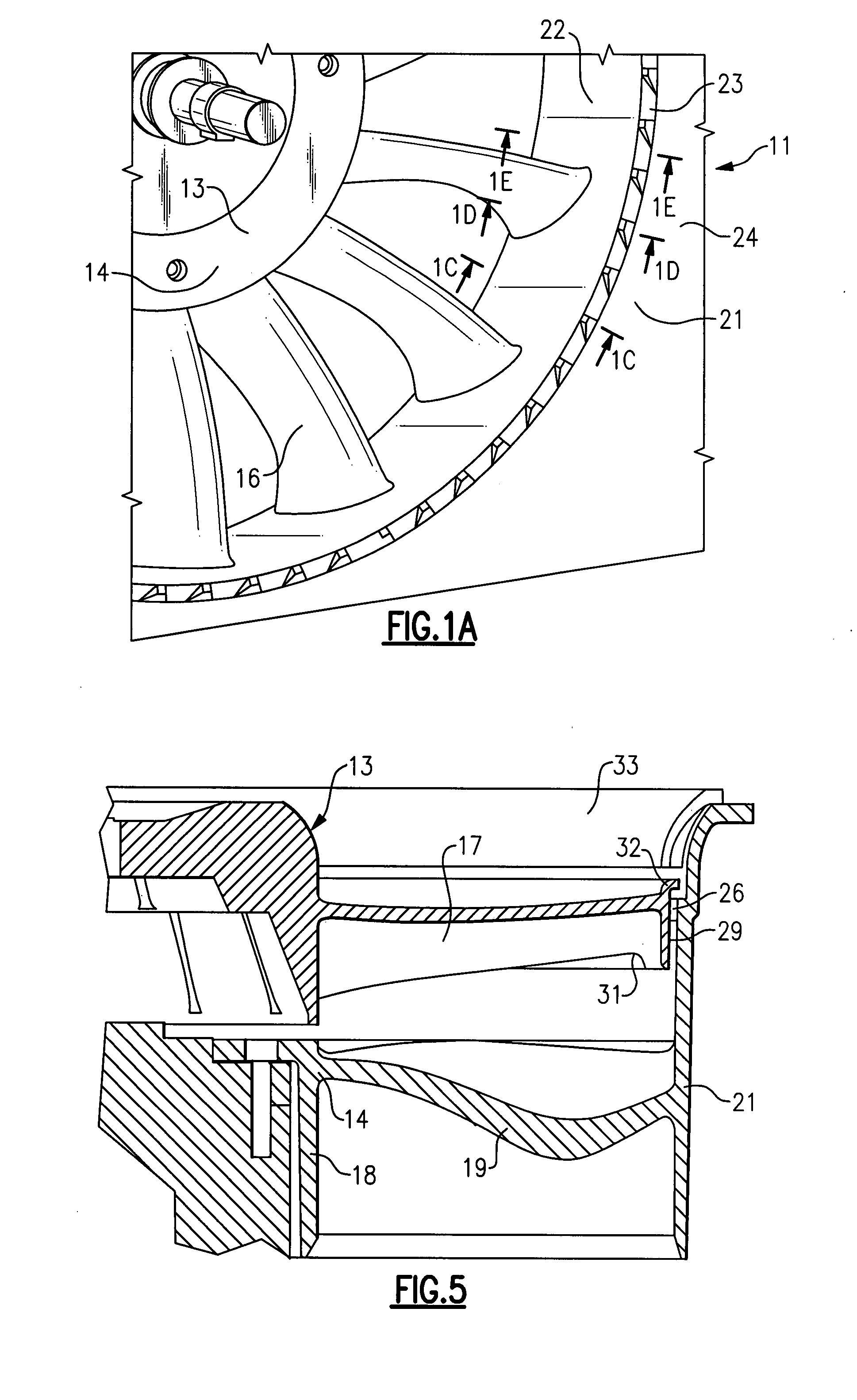

High temperature erosion resistant, abradable thermal barrier composite coating

InactiveUS6235370B1Improve wear resistanceImprove adhesionMolten spray coatingPump componentsCombustorHoneycomb

A composite thermal barrier coating system includes a honeycomb metallic structure filled with high thermal expansion ceramic hollow spheres in a phosphate bonded matrix. The composite thermal barrier coating system may be manufactured to thicknesses in excess of current thermal barrier coating systems, thereby imparting greater thermal protection. Superior erosion resistance and abrasion properties are also achieved. The composite thermal barrier coating is useful on combustion turbine components such as ring seal segments, vane segment shrouds, transitions and combustors.

Owner:SIEMENS ENERGY INC

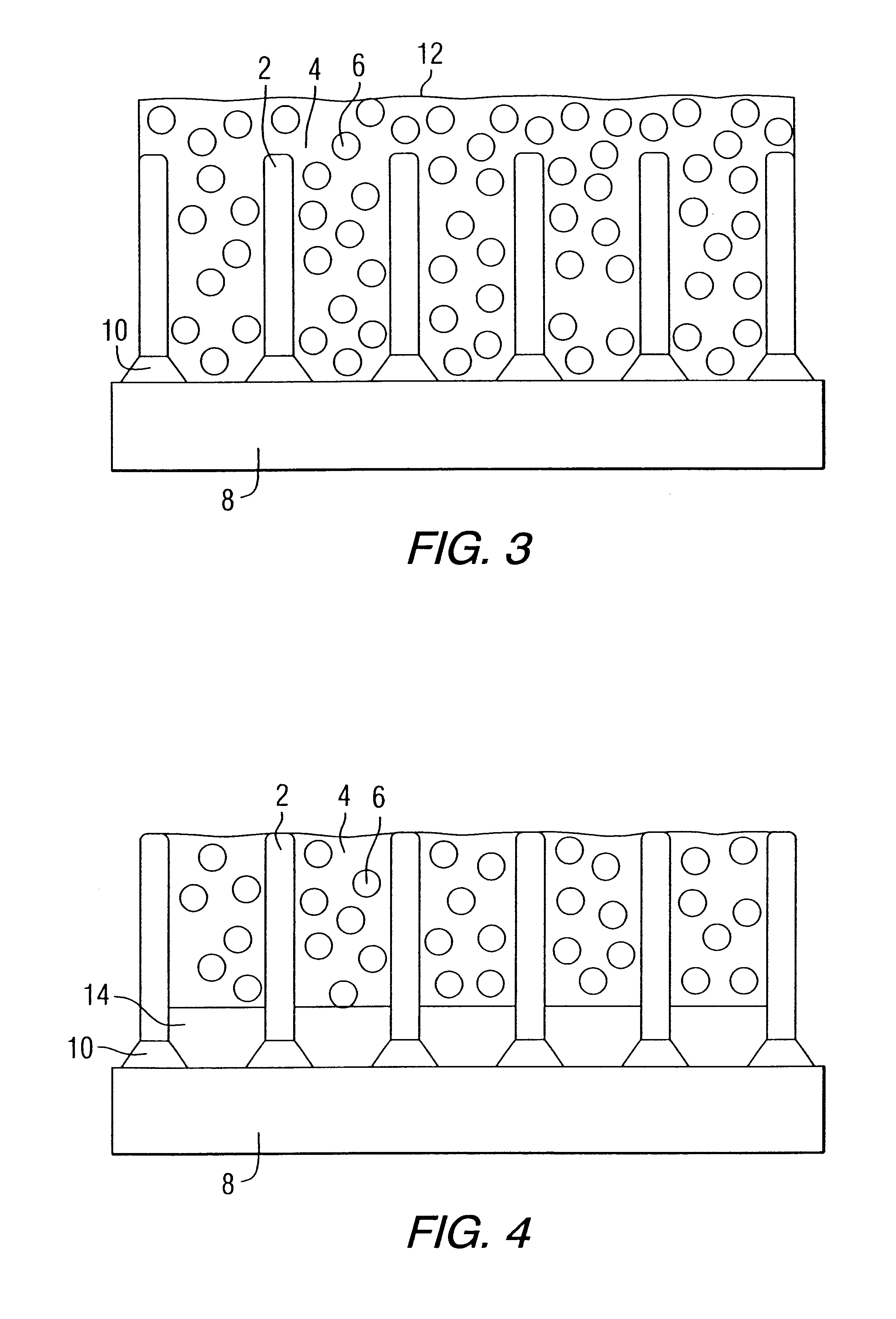

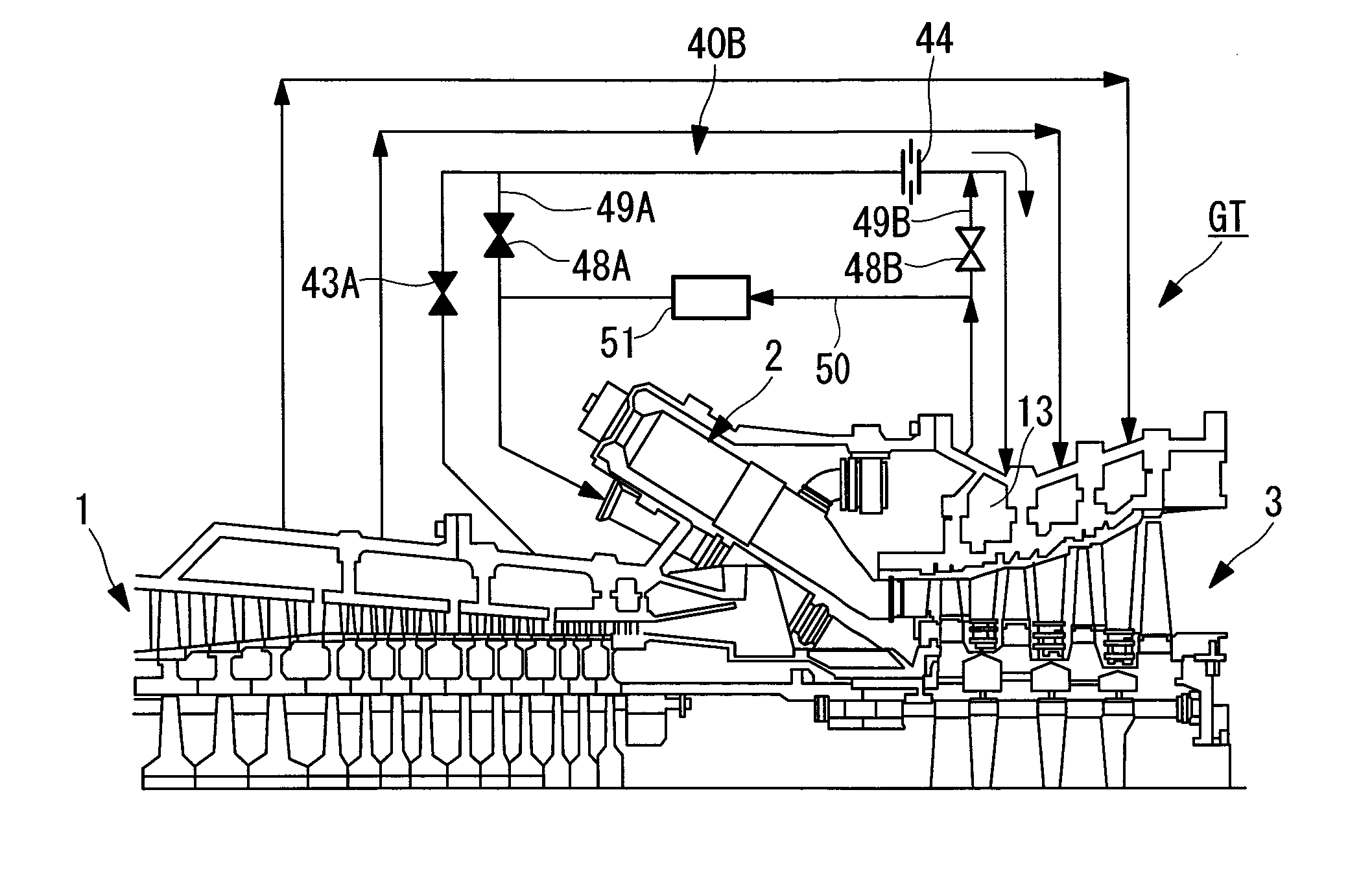

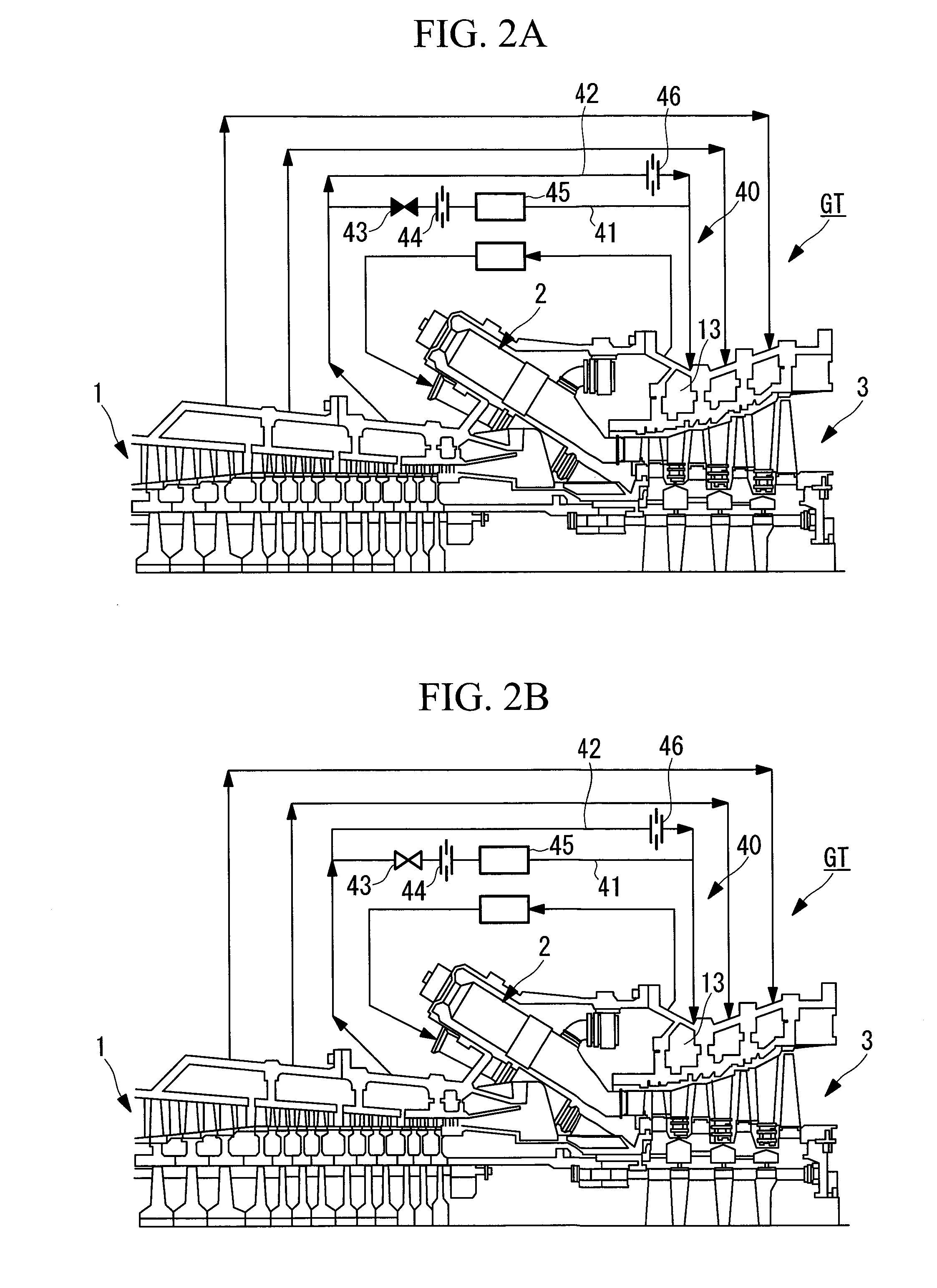

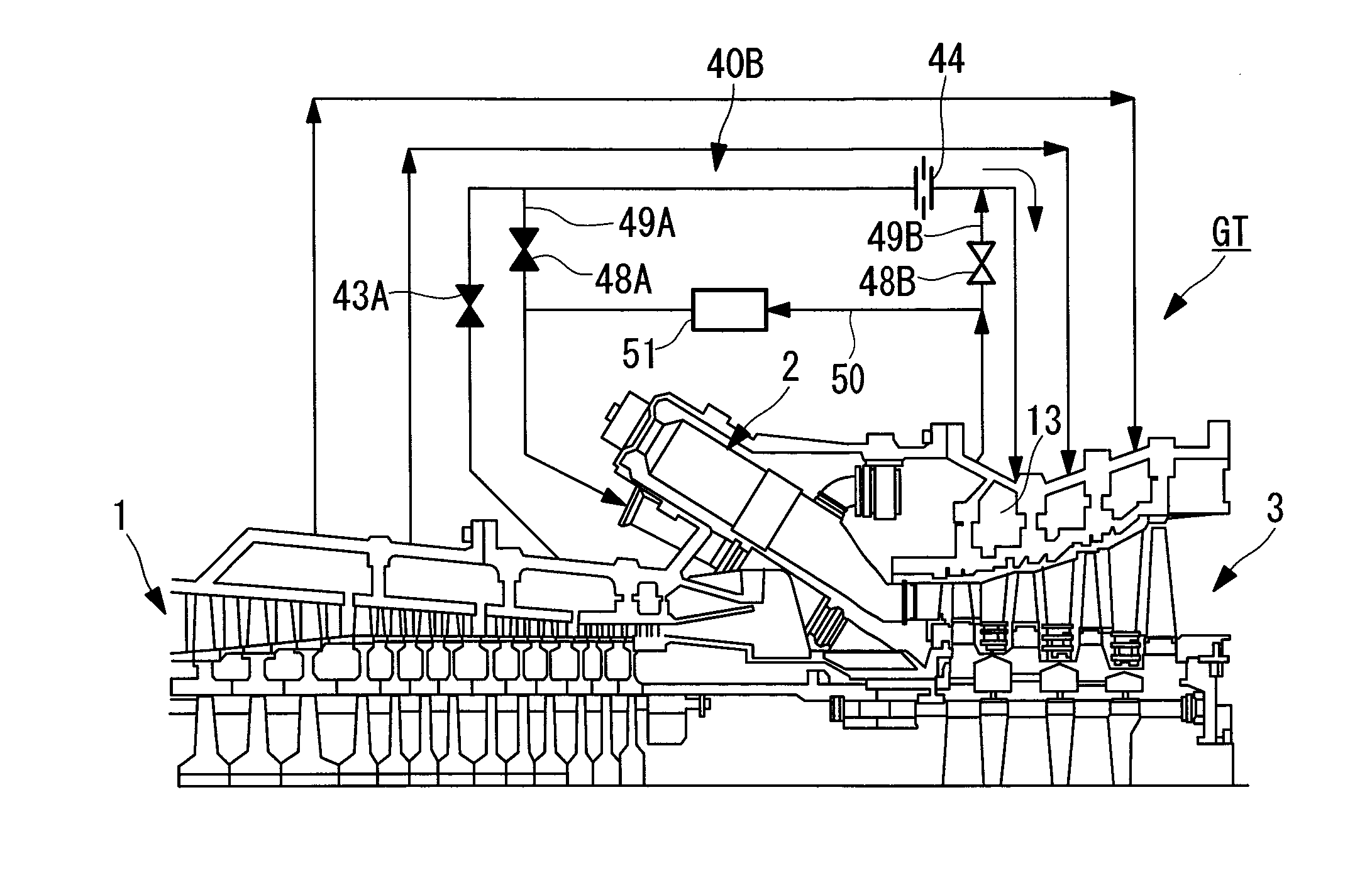

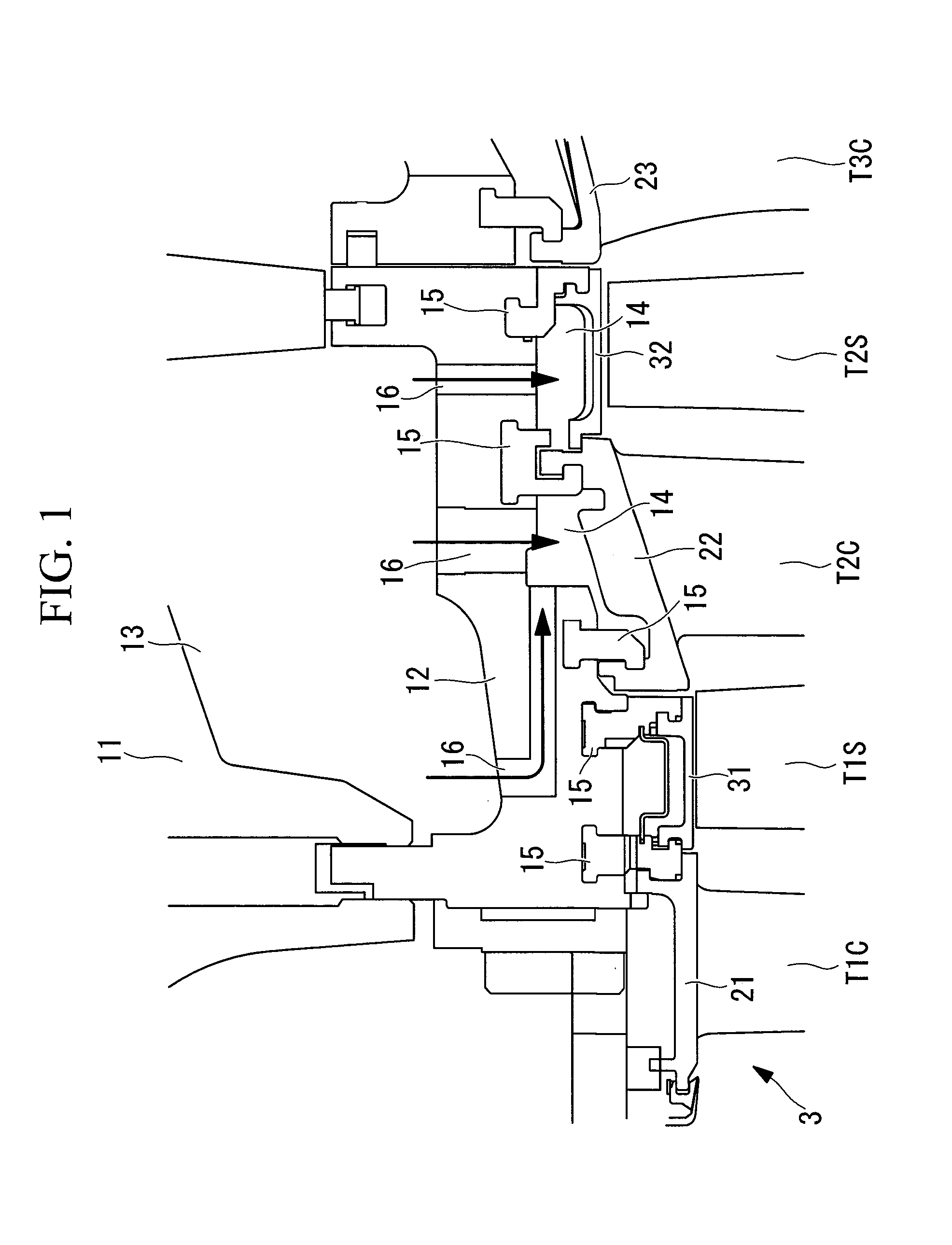

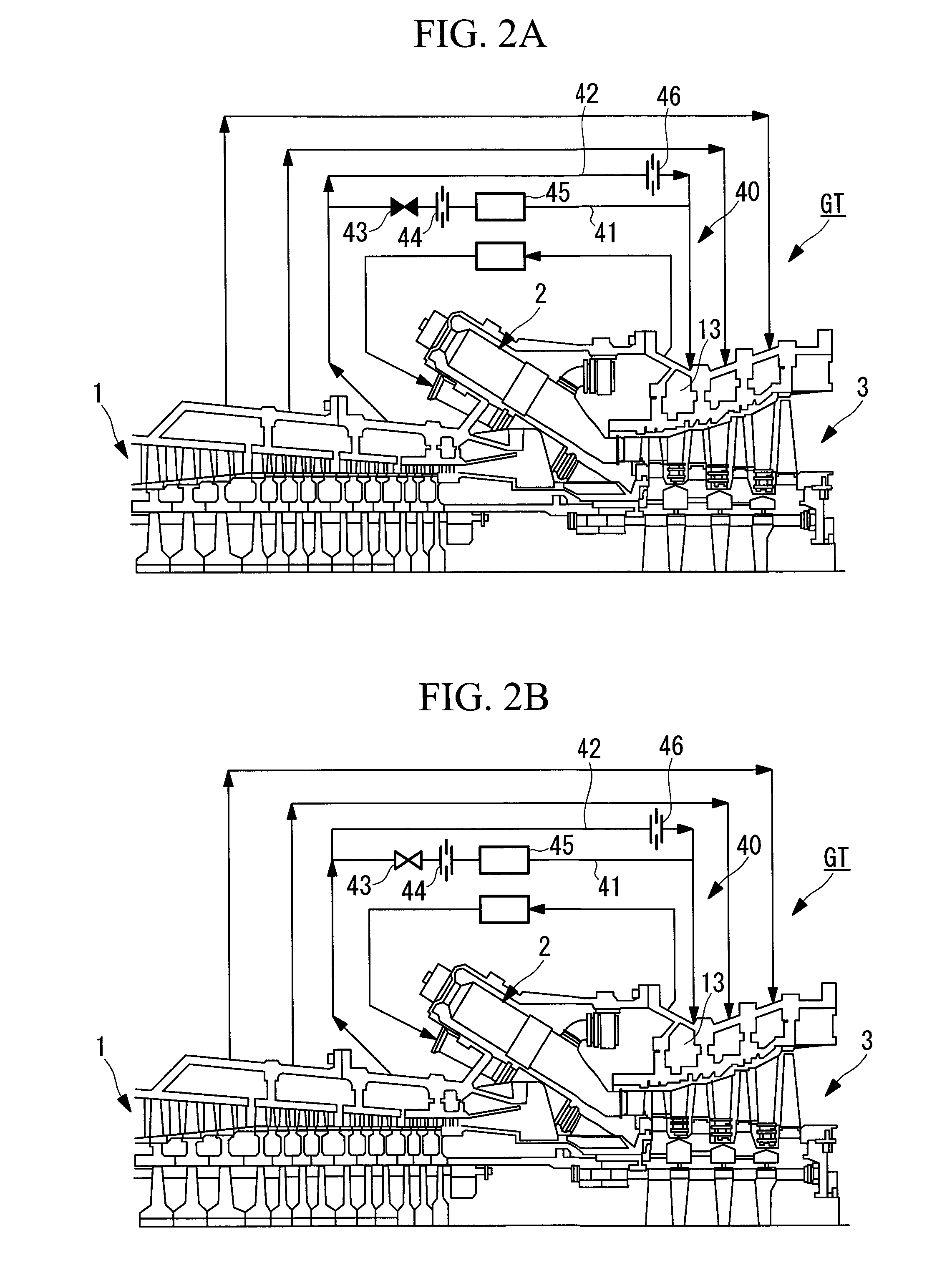

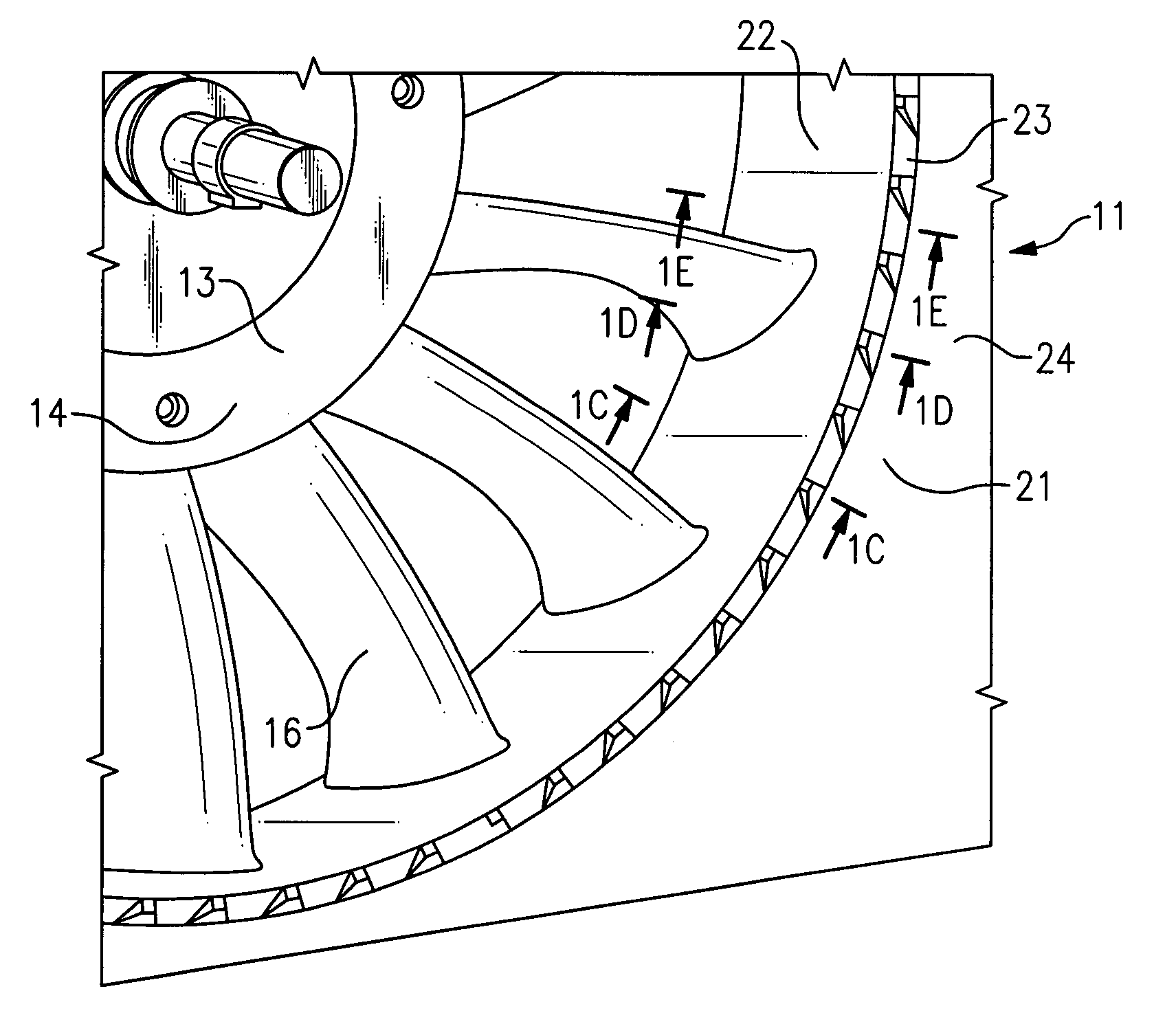

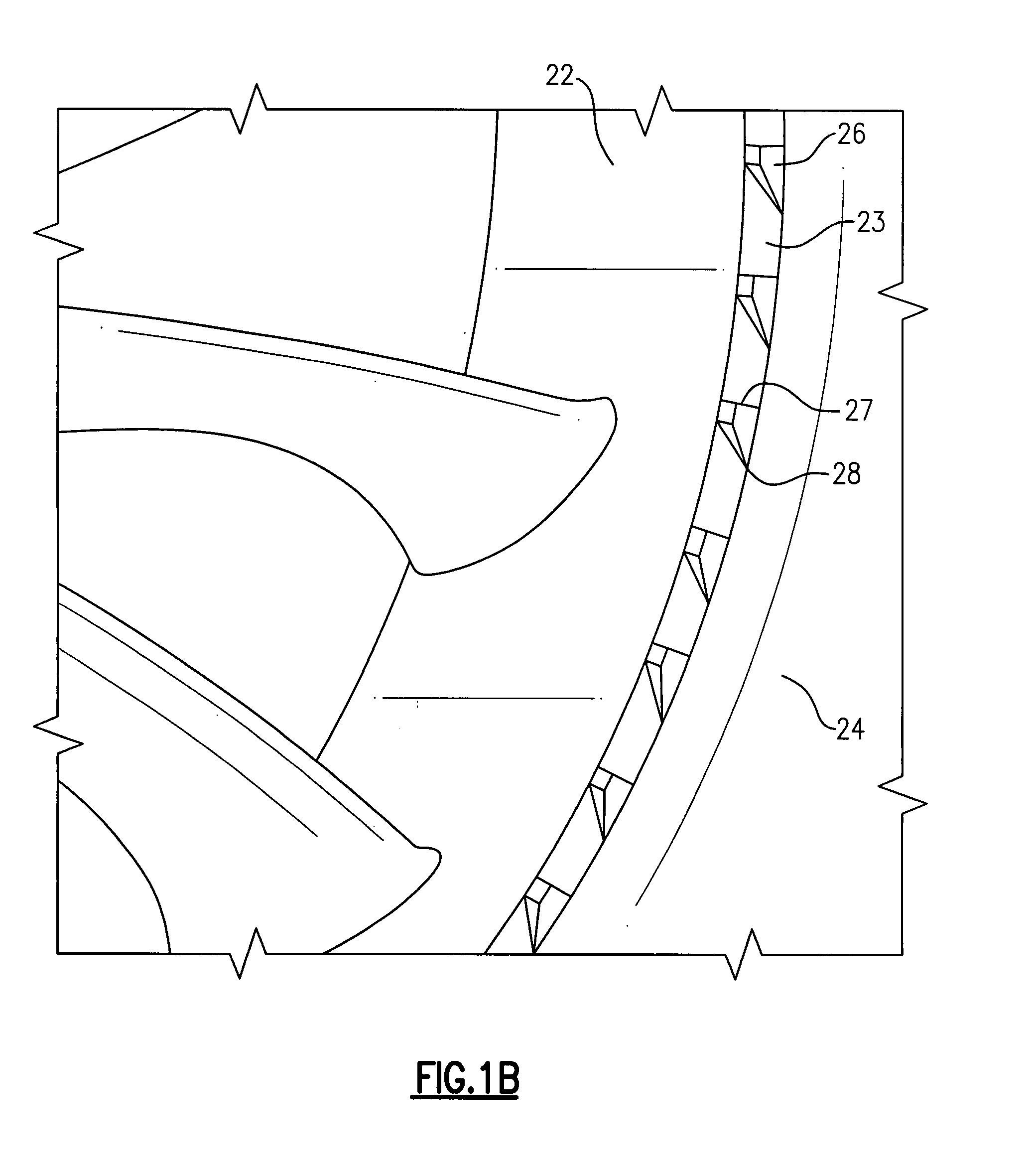

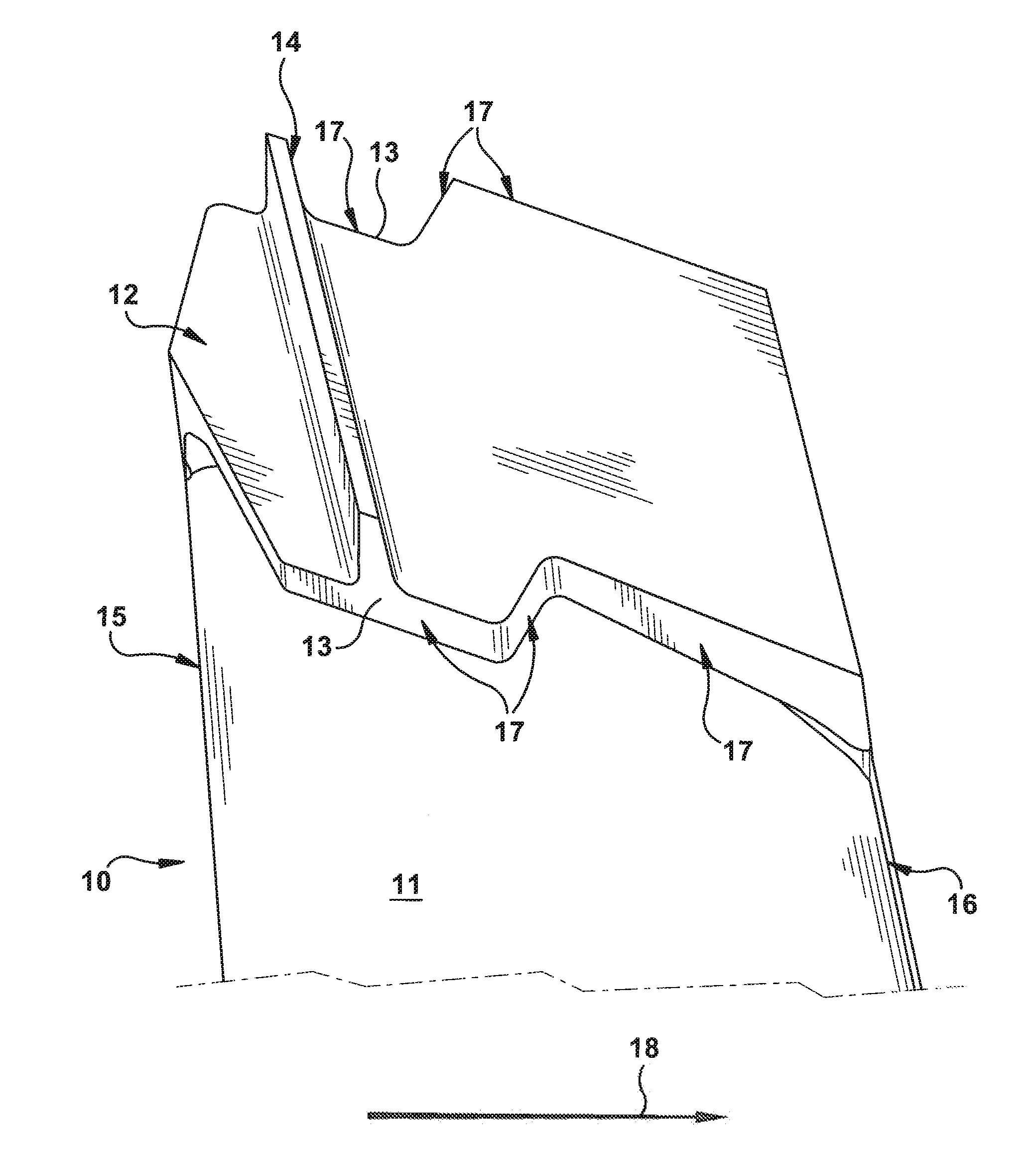

Gas turbine plant

ActiveUS20110135456A1Reducing tip clearanceReduce metal temperaturePump componentsWind motor controlThermal expansionGas turbines

Provided is a gas turbine plant that enables active clearance control for ensuring tip clearance of first-stage turbine rotor blades required during start-up and for achieving the minimum tip clearance during load operation. In a gas turbine plant including a cooler in an air system used for cooling second-stage turbine stator blades, a first-stage segmented ring and a second-stage segmented ring that oppose tips of first-stage turbine rotor blades and second-stage turbine rotor blades are supported by the same blade ring member, and a cooling-air for the second-stage turbine stator blades forms a cooling air flow cooling the blade ring, to control thermal expansion of the blade ring and to control the clearance with respect to the tips.

Owner:MITSUBISHI HEAVY IND LTD

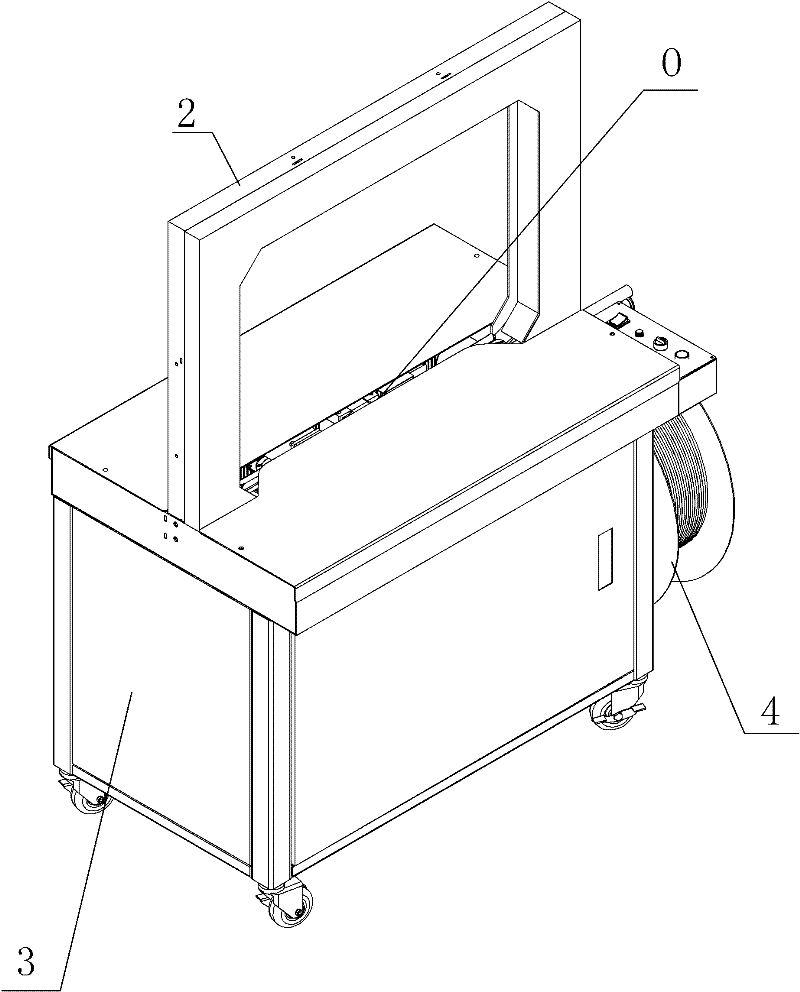

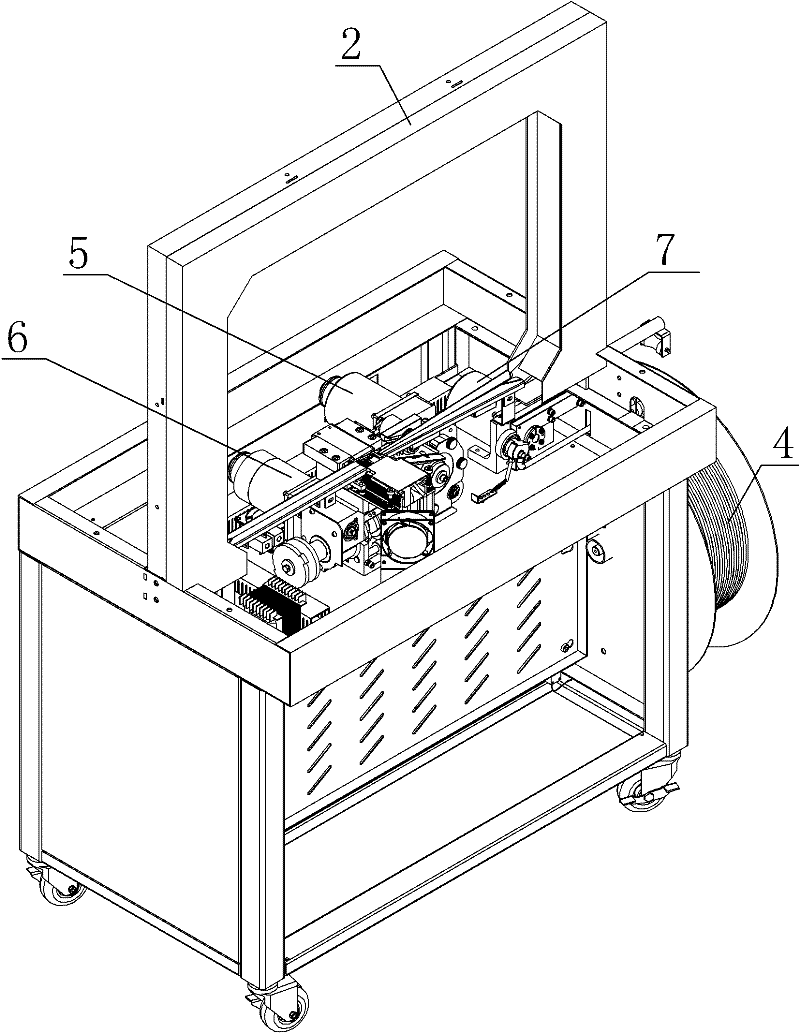

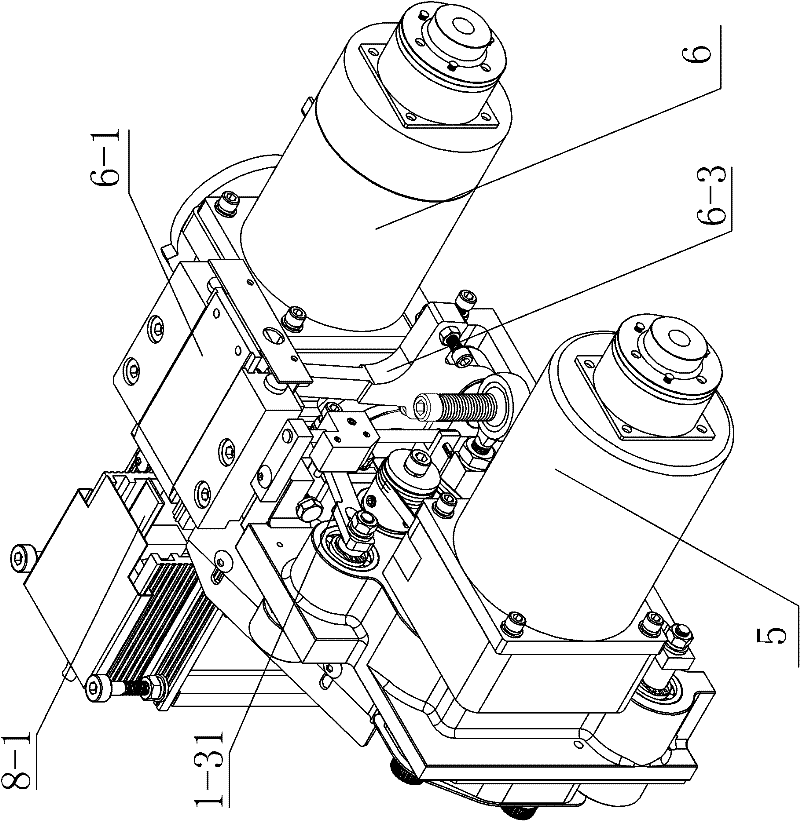

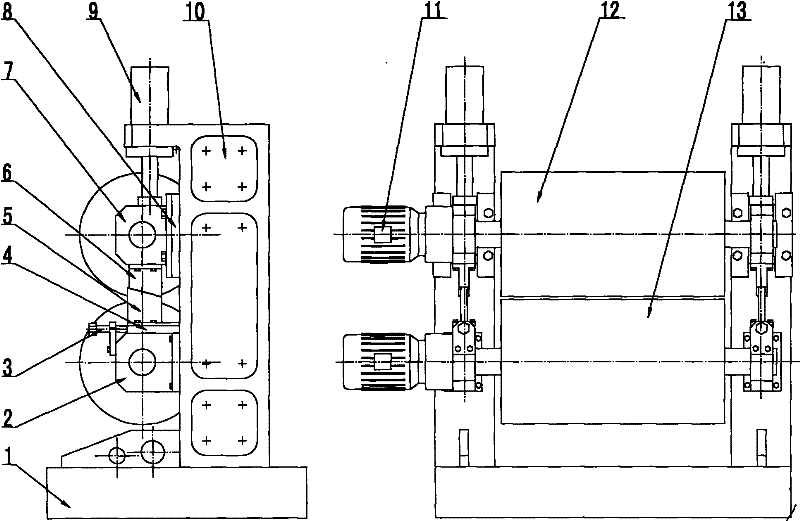

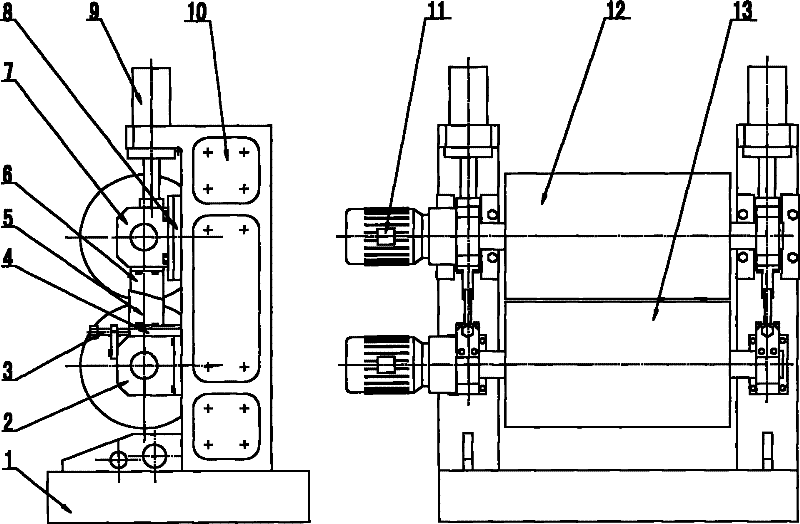

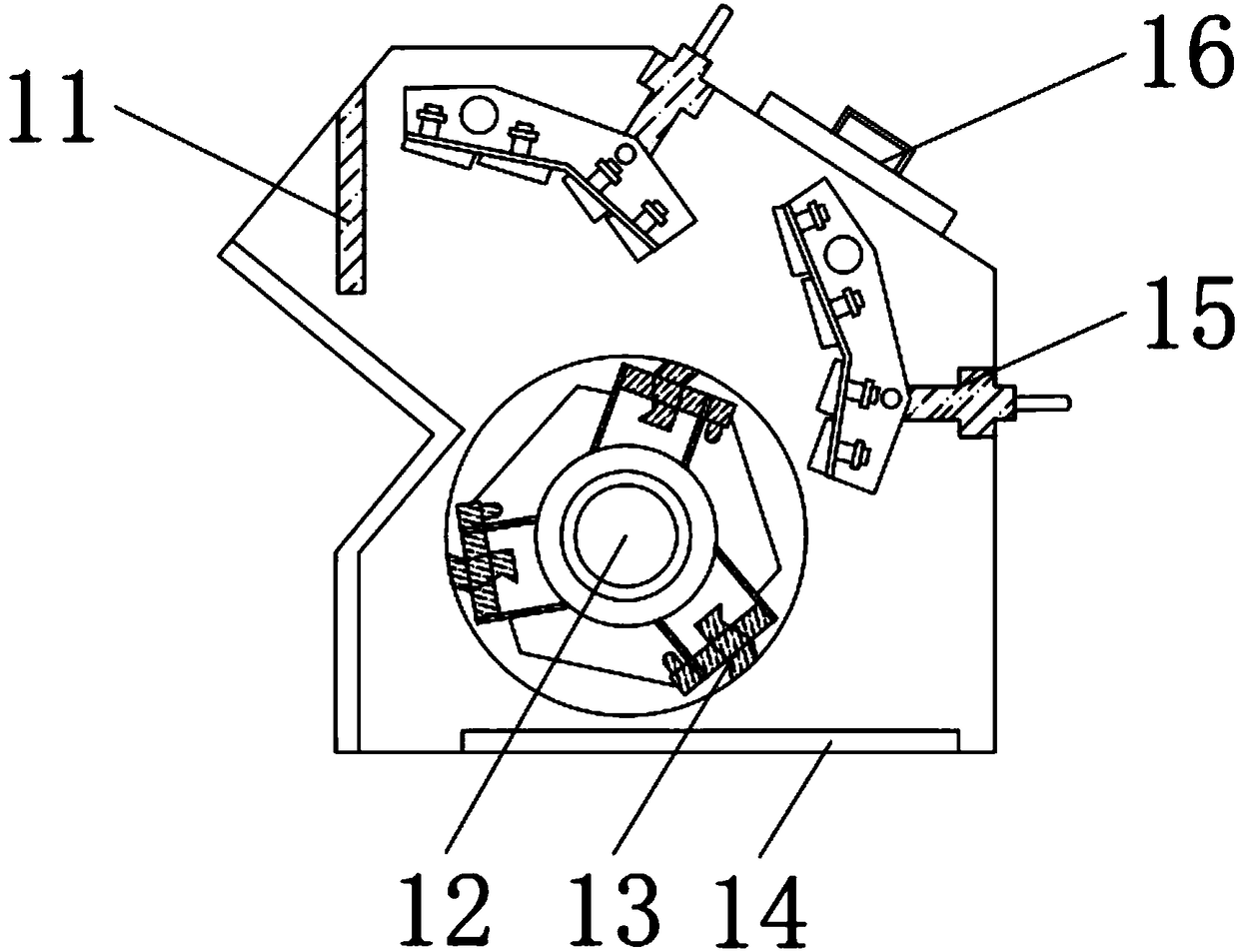

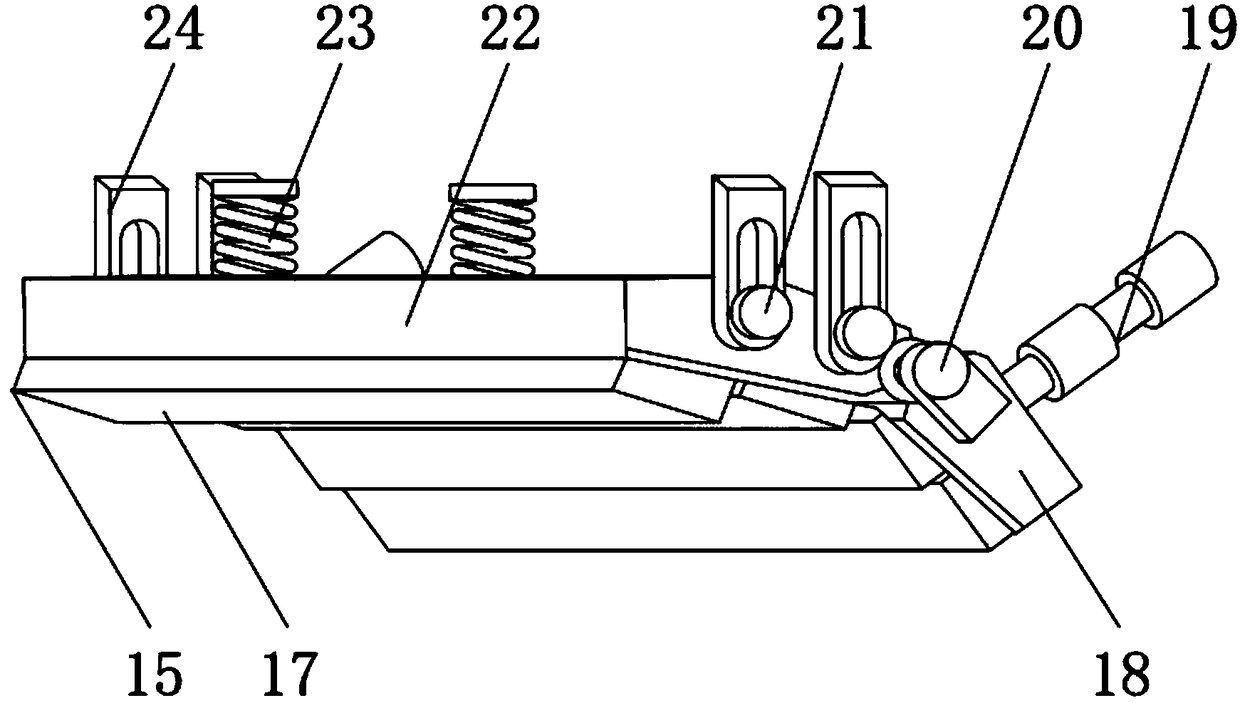

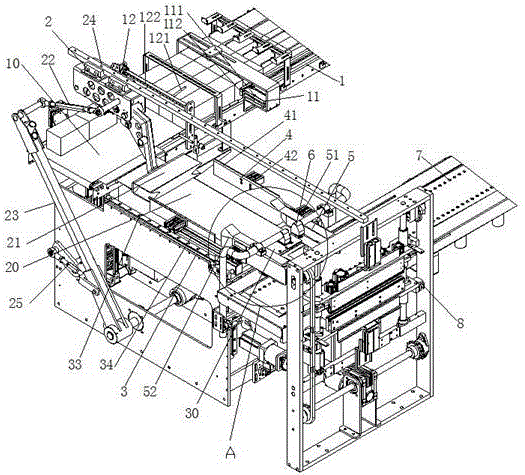

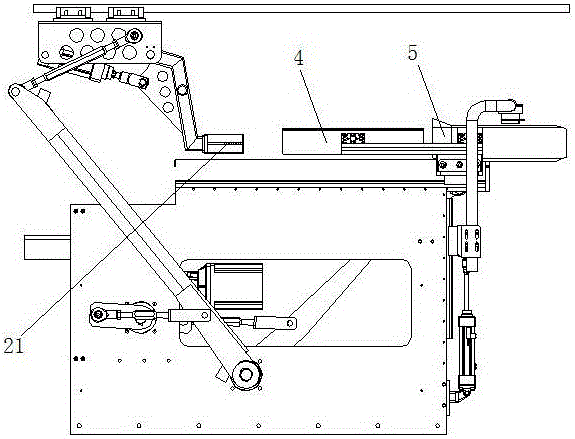

Novel packing machine

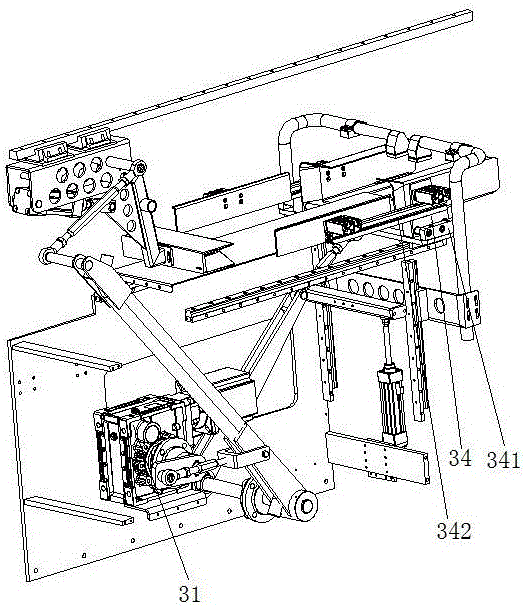

ActiveCN102530291AReasonable configurationEasy to controlBinding material applicationBundling machine detailsFixed frameEngineering

The invention provides a novel packing machine. A vertical mounting plate is arranged at the lower half part of the packing machine, a horizontal mounting plate is fixed at the upper part of the vertical mounting plate, a fixing frame is arranged at the upper half part of the vertical mounting plate and wraps the left part, right part and upper part of an article banding station, the mounting plates and the fixing frame are arranged on a rack of the packing machine, and a tape spool is arranged at the lower part of the packing machine; and a movement of the packing machine and a pre-sending belt device are arranged on the horizontal mounting plate, a retreating belt and tensioning belt device is arranged in the movement of the packing machine and comprises a retreating belt mechanism and a tensioning belt mechanism. According to the novel packing machine, all the functional devices are reasonable in configuration and convenient and simple in control, the packing quality can be improved, and the comprehensive improvement of the packing efficiency and the reliable work can be facilitated.

Owner:HANGZHOU YOUNGSUN INTELLIGENT EQUIP

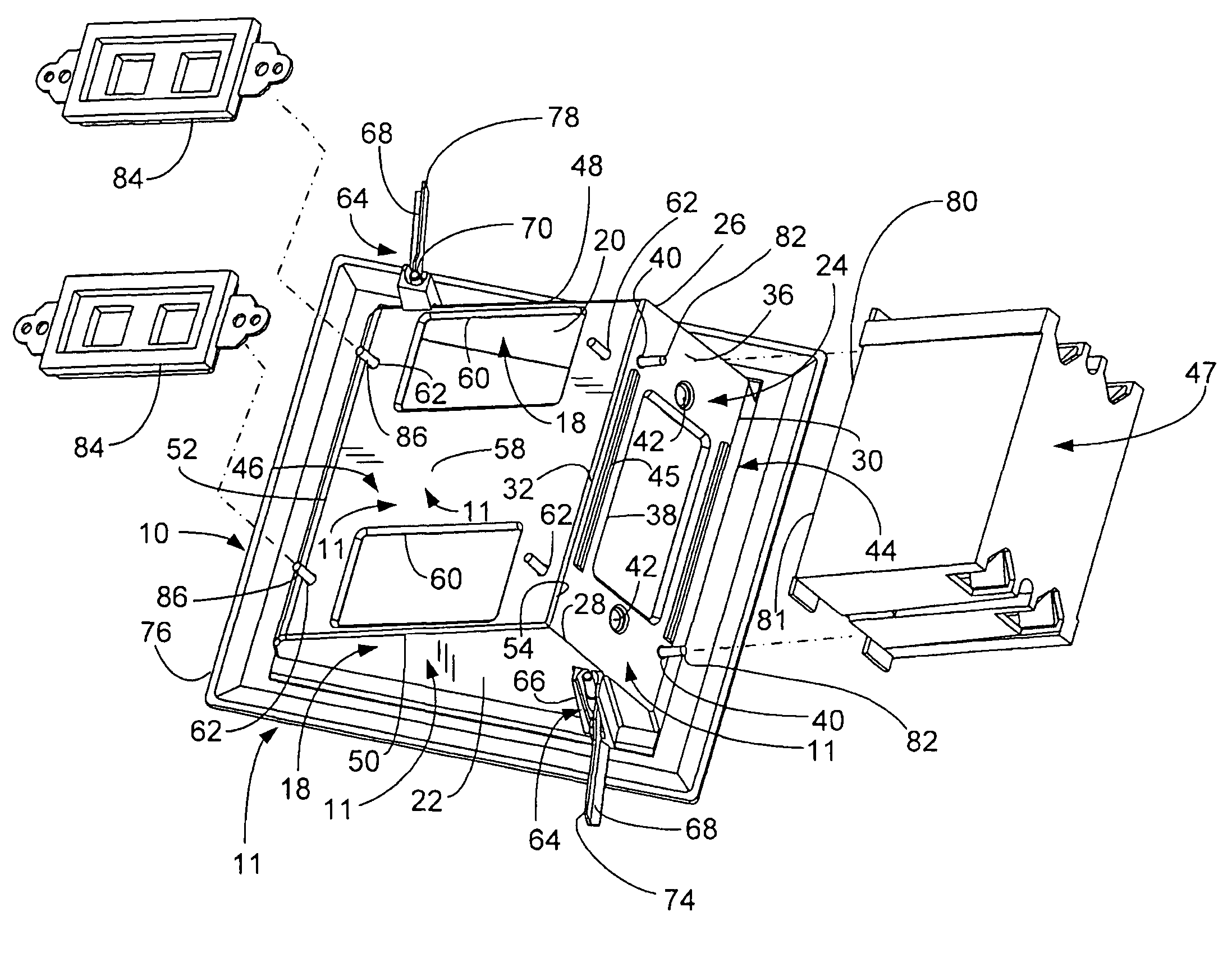

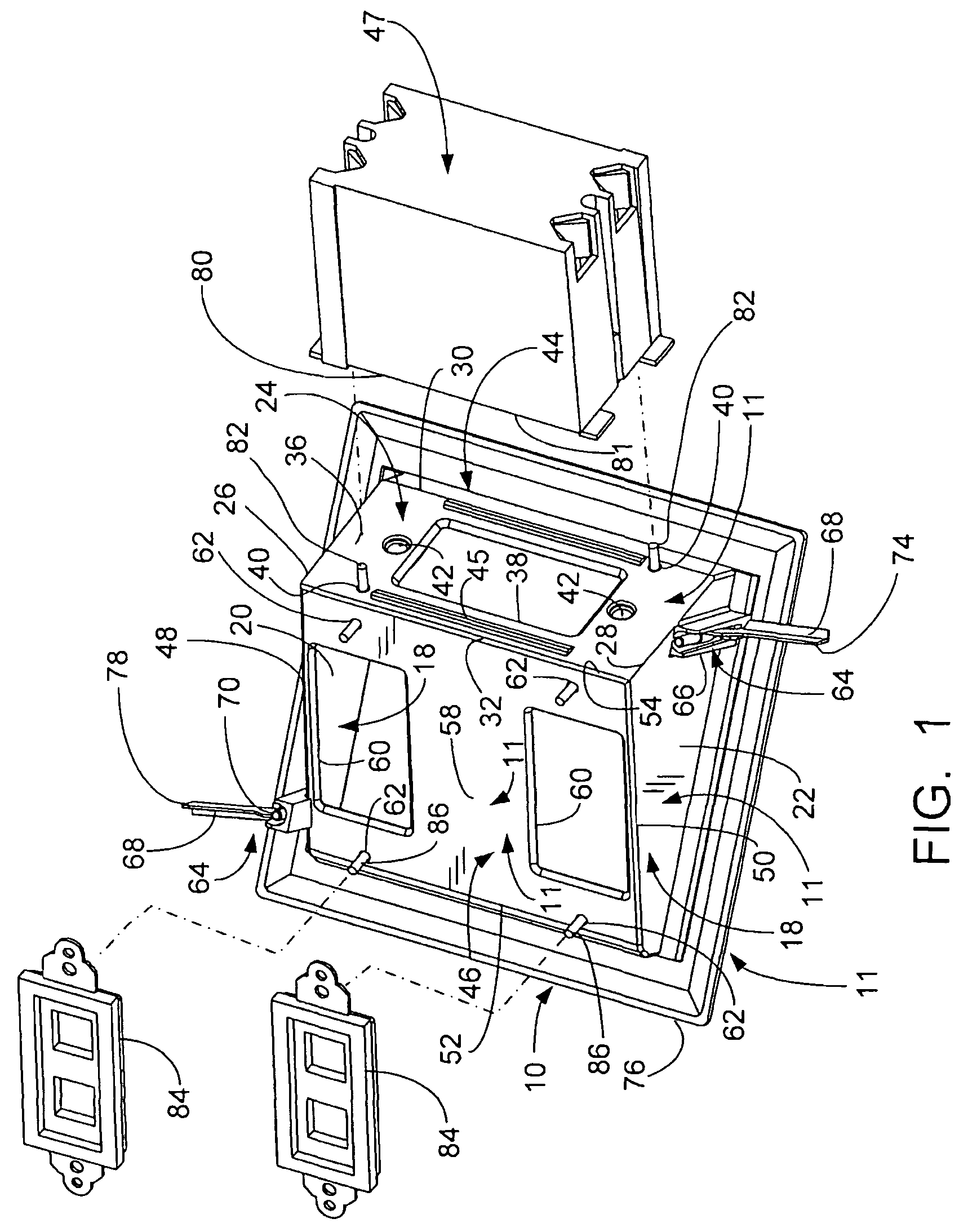

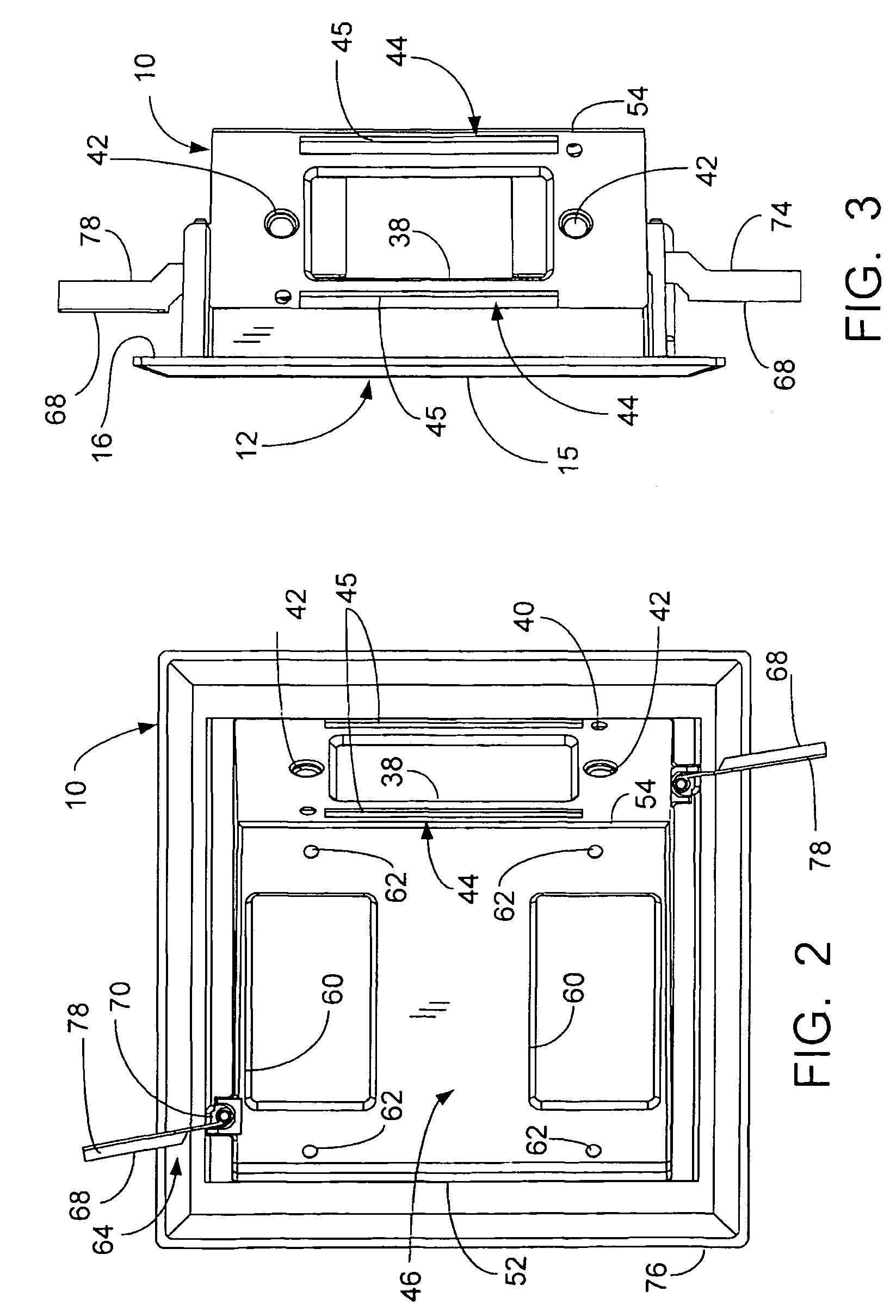

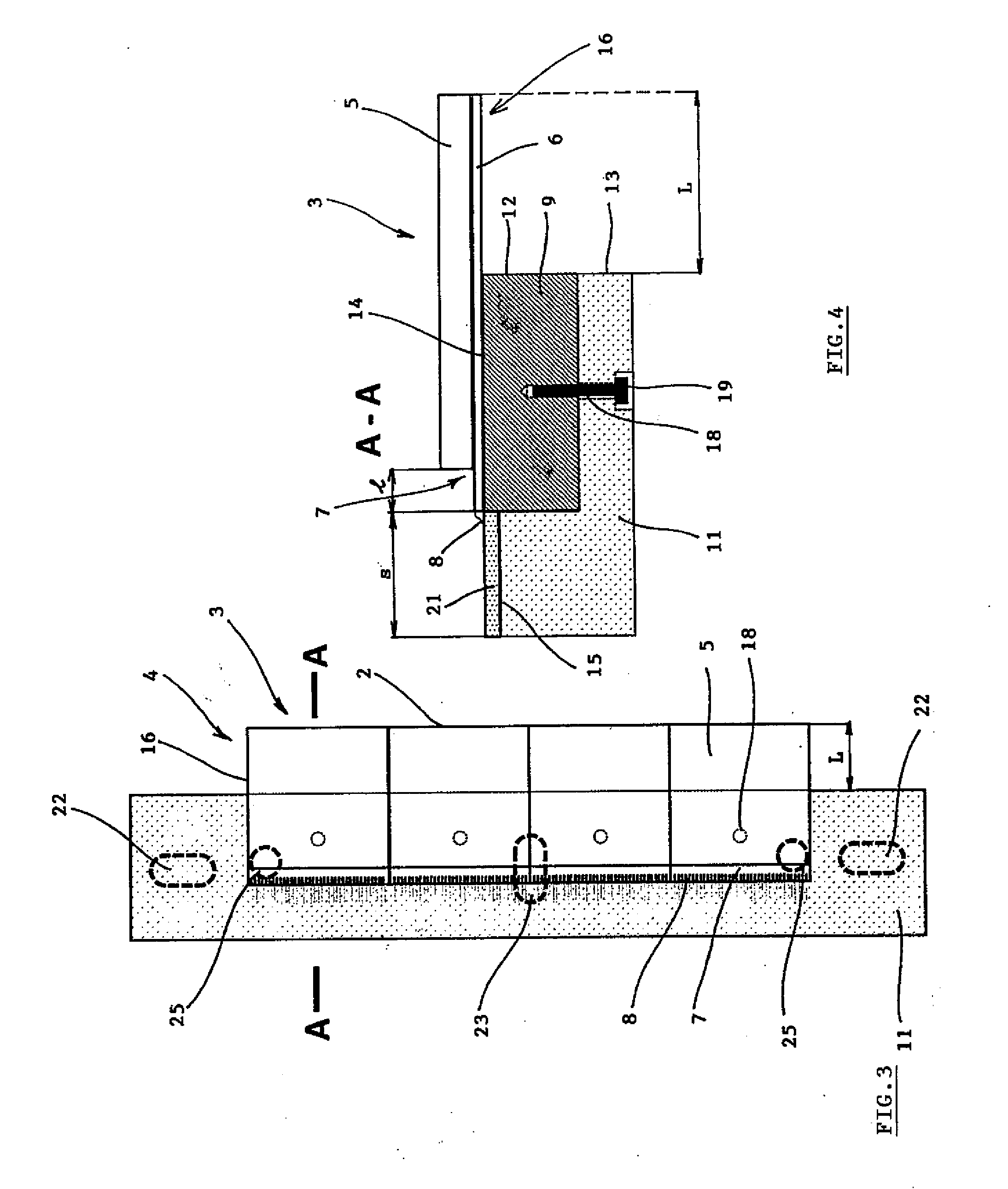

Wall plate bracket

ActiveUS8049107B2Facilitate complianceControl clearanceMachine supportsCouplings bases/casesEngineeringHigh pressure

The wall plate bracket is for a high voltage outlet, and includes a wall plate having front and rear surfaces. The wall plate has an interior opening. A support housing has an inner surface and an interior region bounded by the inner surface. The support housing is connected to the rear surface such that the interior opening provides access to the interior region. The support housing is configured for support of the high voltage outlet within the interior region. A clamp is connected to the wall plate for securing the wall plate to a wall structure. The rear surface of the wall plate may have a rib to limit the clearance between the support housing and rear surface. Alternatively, the clearance may be limited by a recess in the rear surface in which a mounting tab of the support housing is located.

Owner:THOMAS & BETTS INT INC

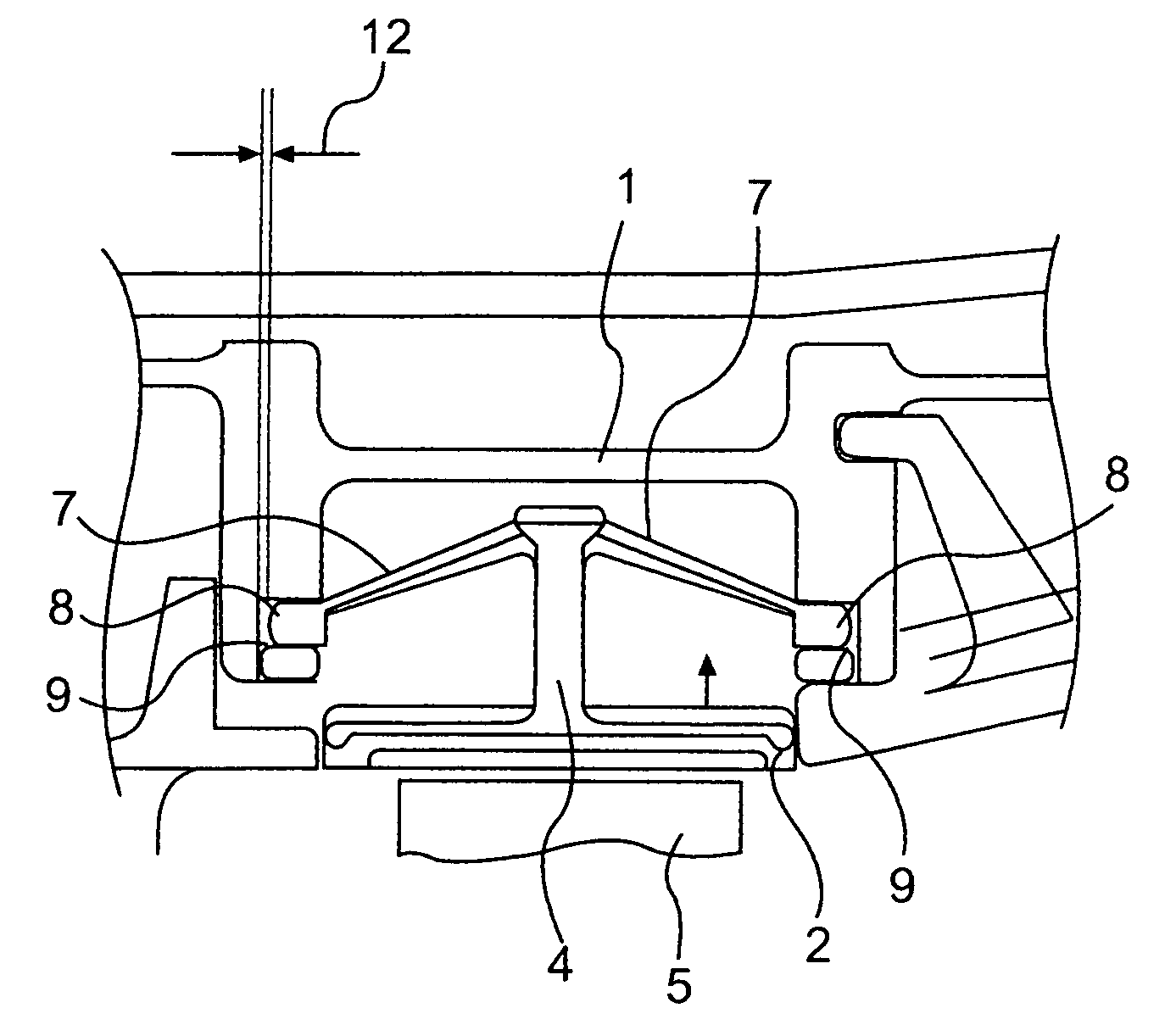

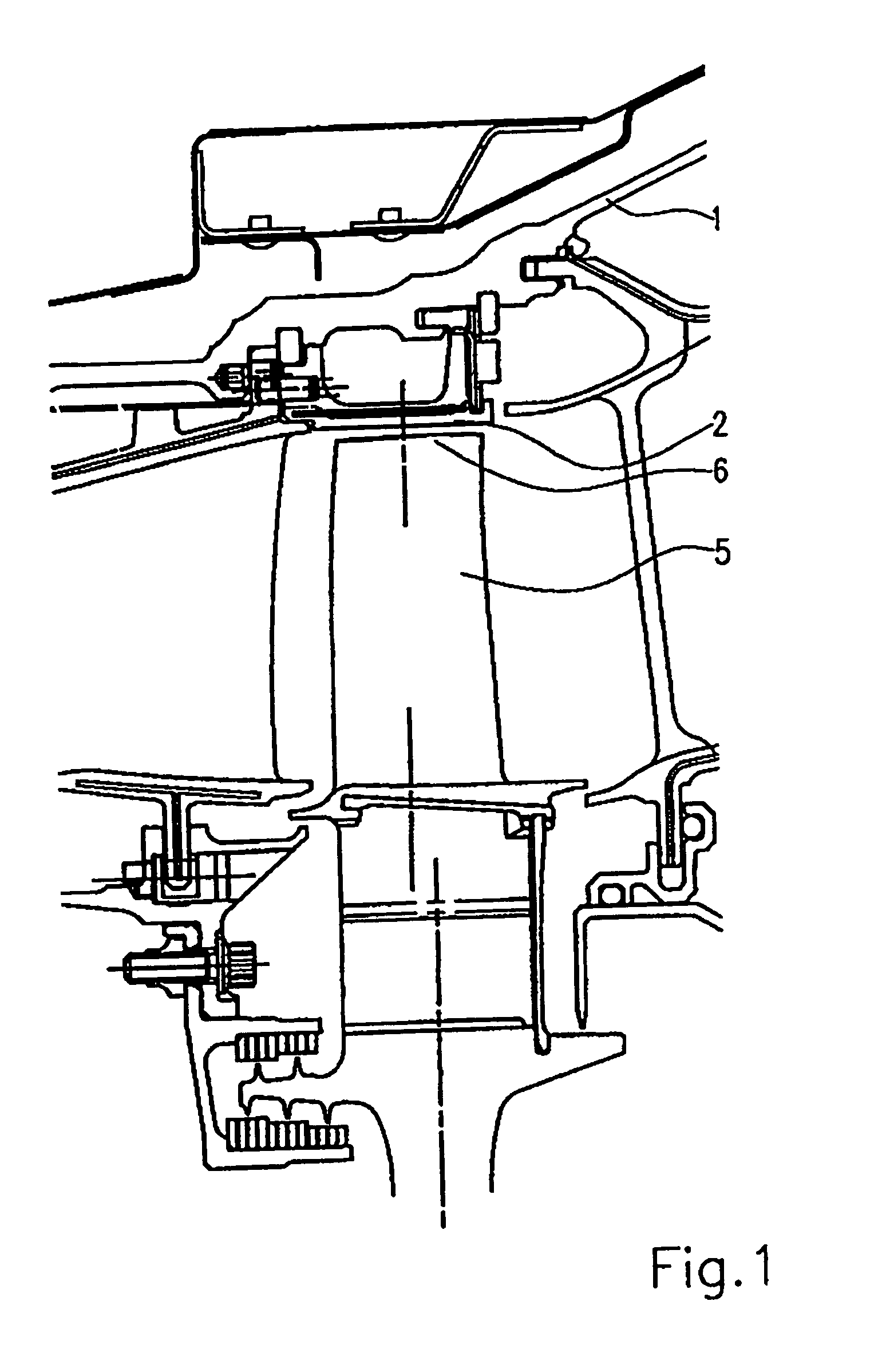

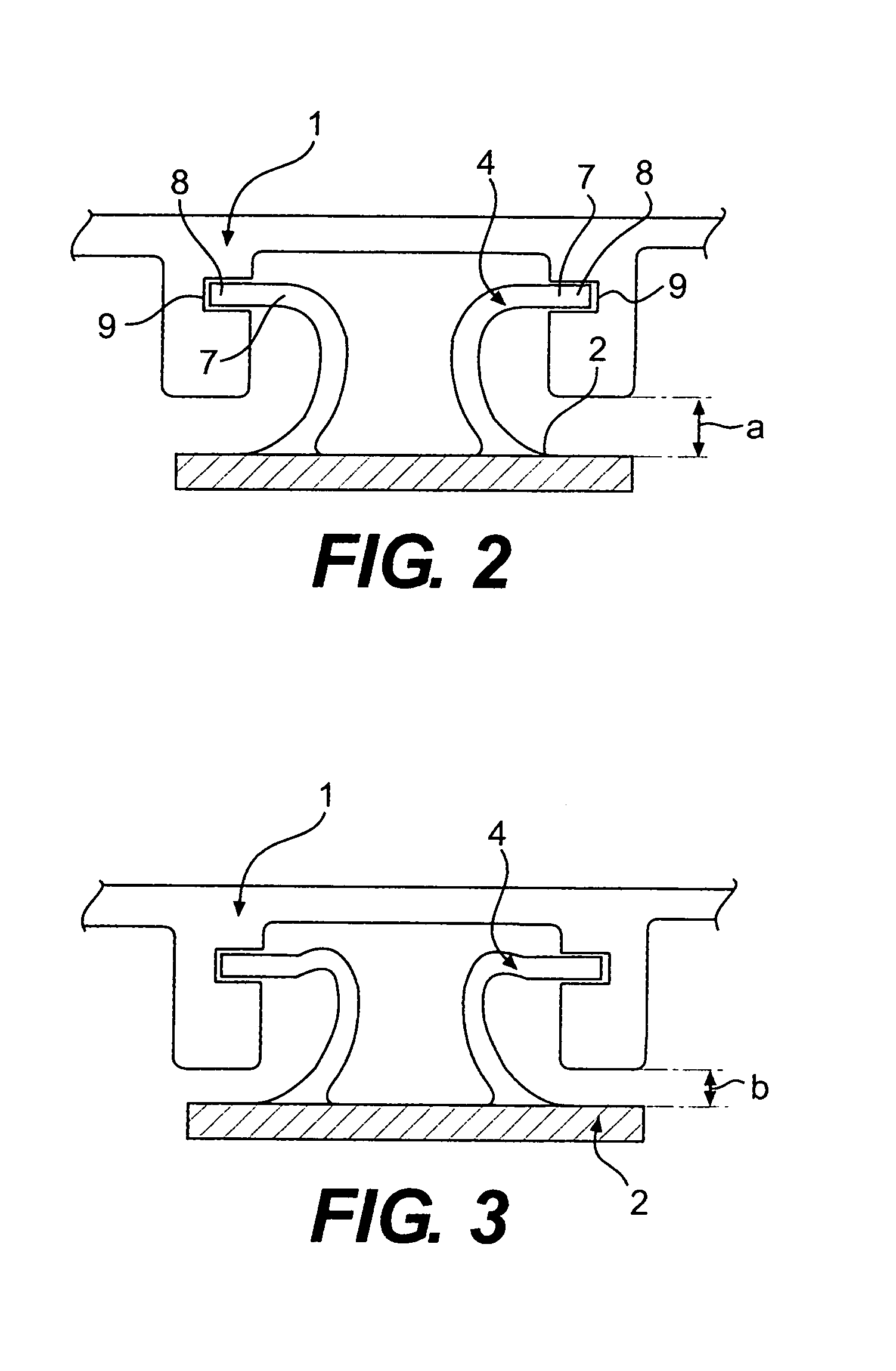

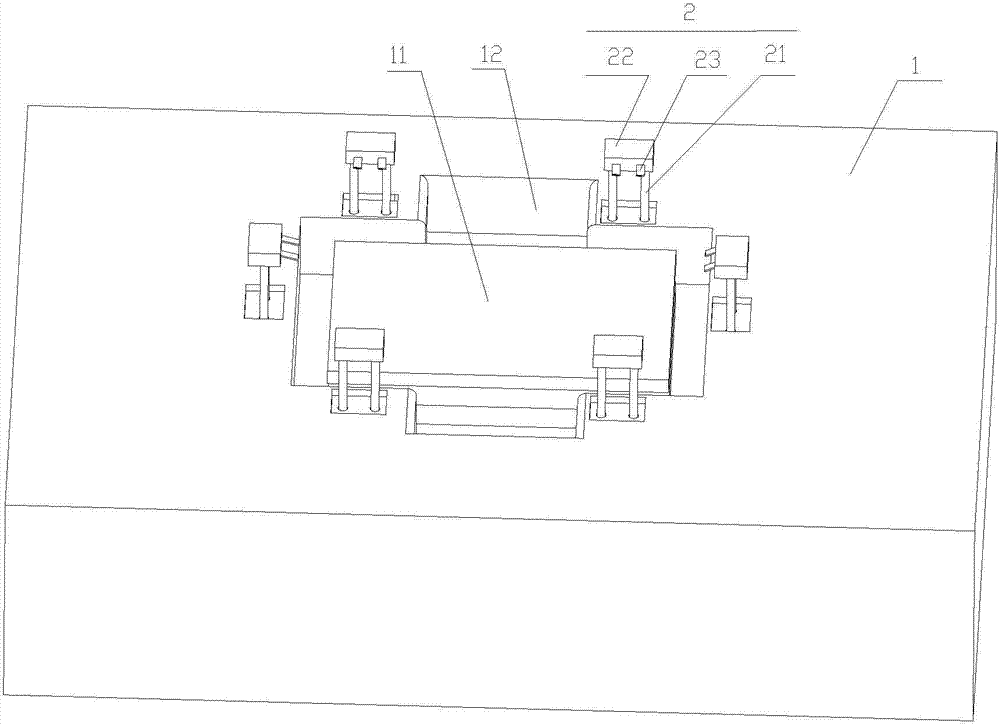

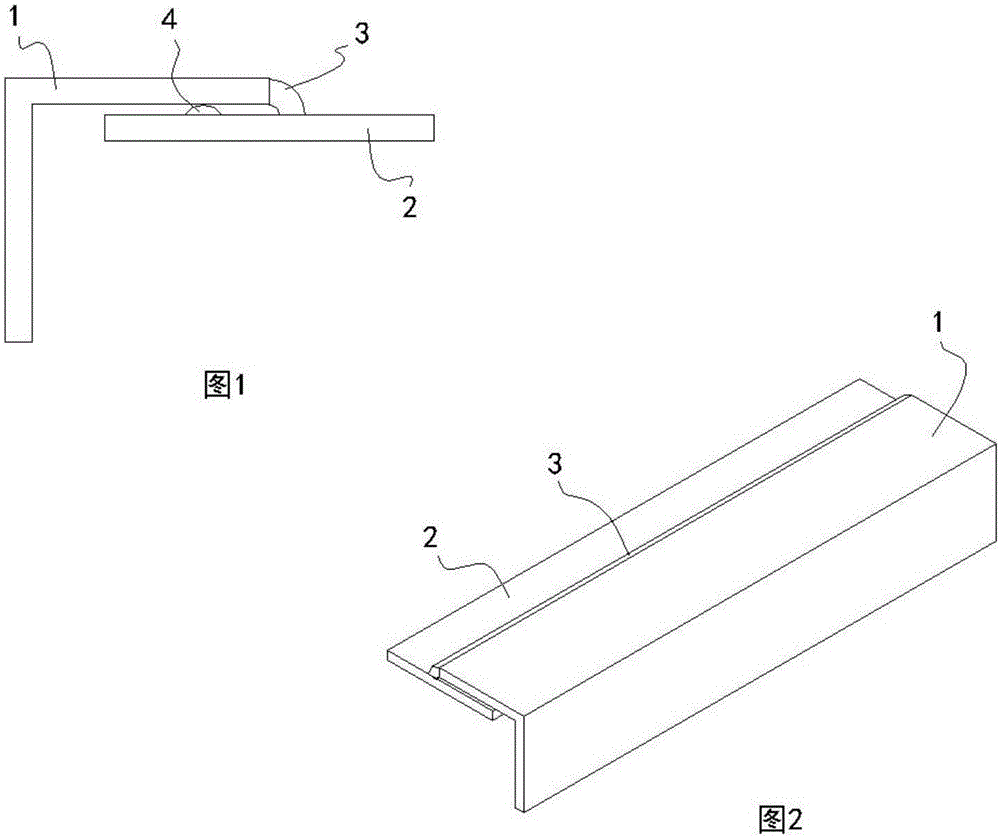

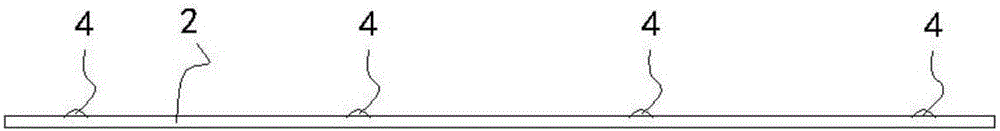

Turbine shroud segment attachment

InactiveUS7189057B2Freedom of movementSimple designPump componentsBlade accessoriesTemperature differenceEngineering

A turbine shroud segment attachment with a casing (1) and several shroud segments (2) arranged in the casing (1), wherein the individual shroud segments (2) are located in the casing (1) with a circumferential clearance (3) between the individual shroud segments (2), in that the clearance (3) is reduced to zero at a given temperature difference between the casing (1) and the shroud segments (2), and in that the shroud segments (2) are retained on the casing (1) by way of an elastically deformable locating arrangement.

Owner:ROLLS ROYCE DEUT LTD & CO KG

Wedge-type gap adjustment mechanism of plastic sheet calender

Owner:ZHANGJIAGANG BEIER MACHINERY

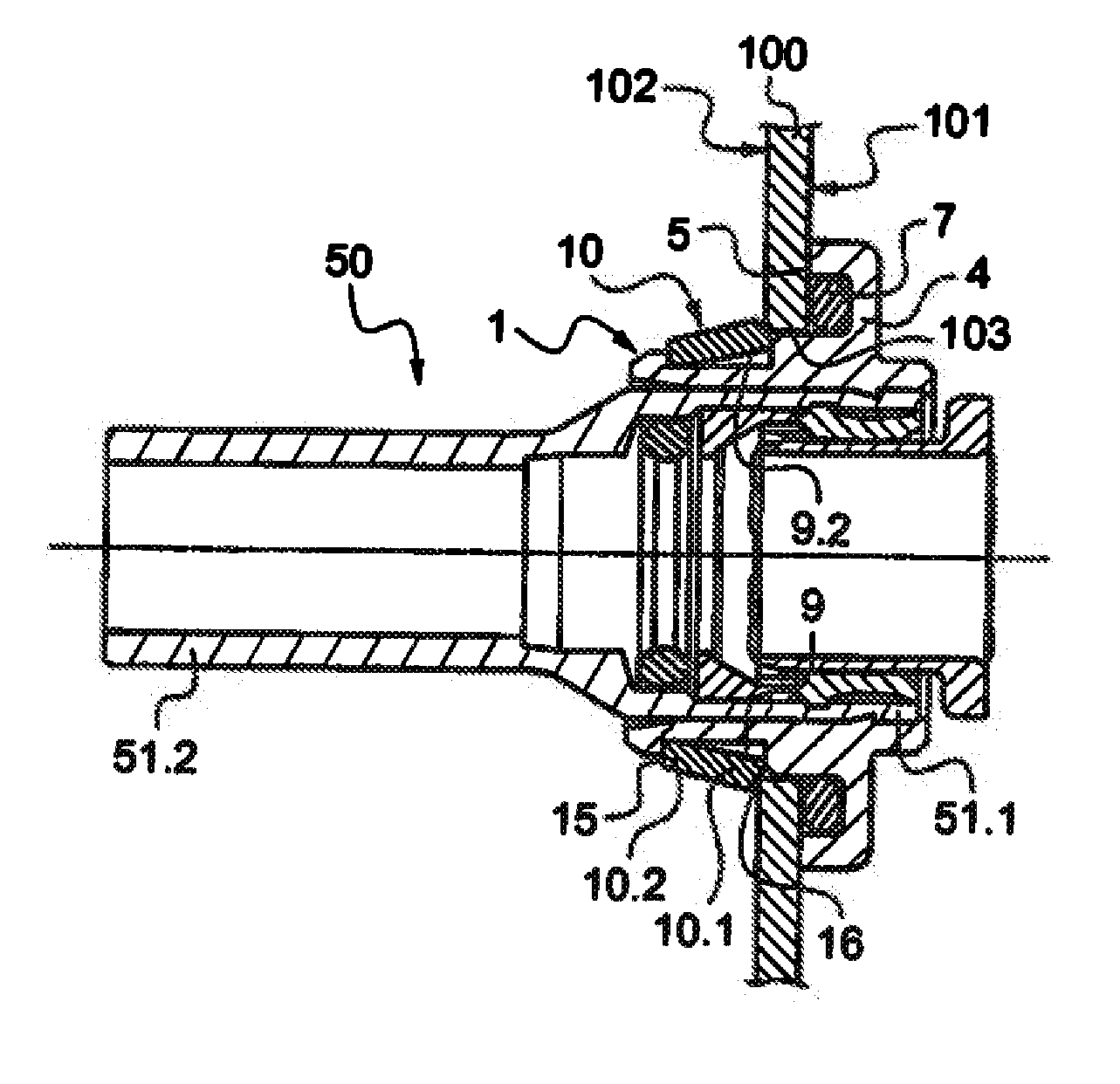

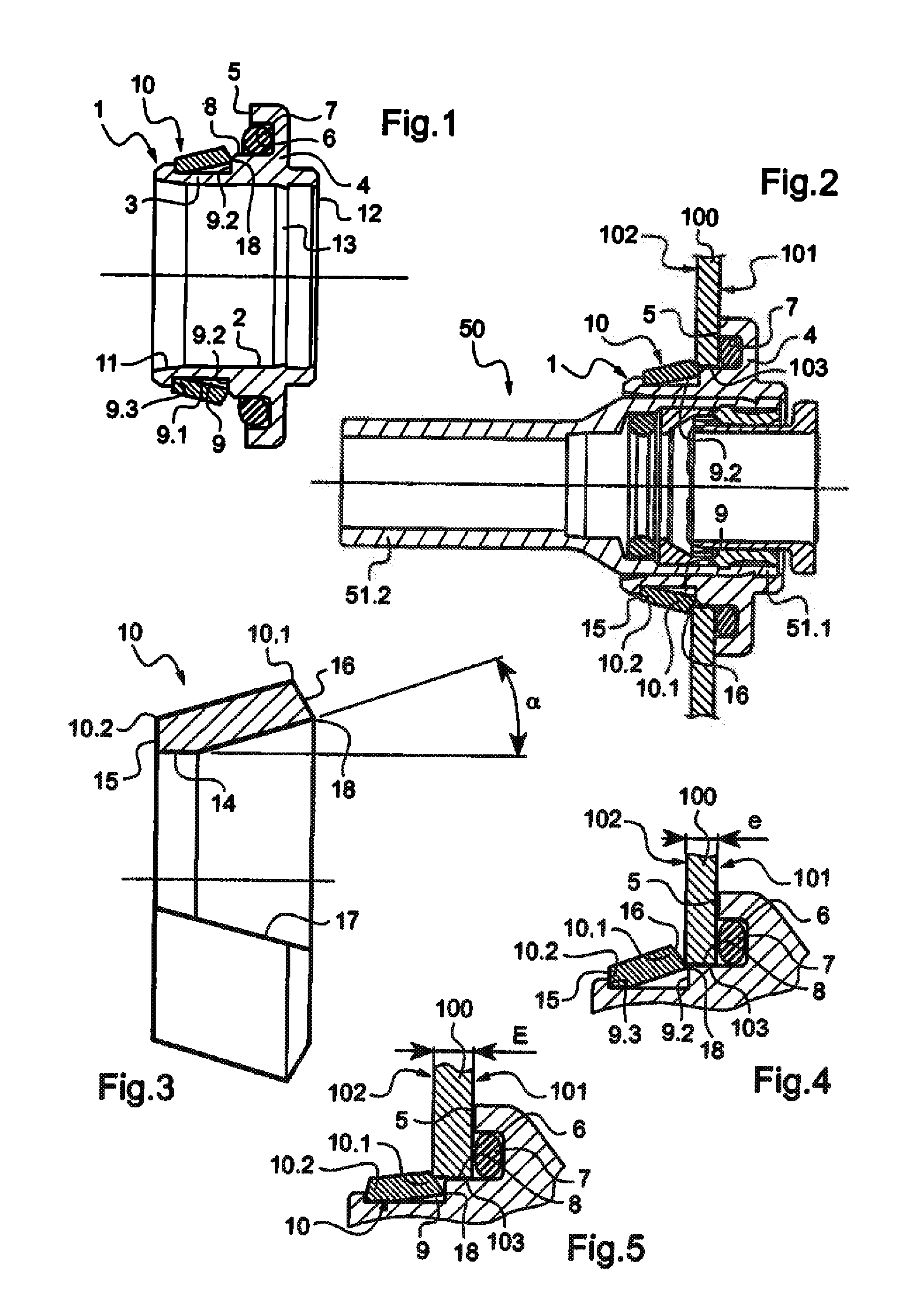

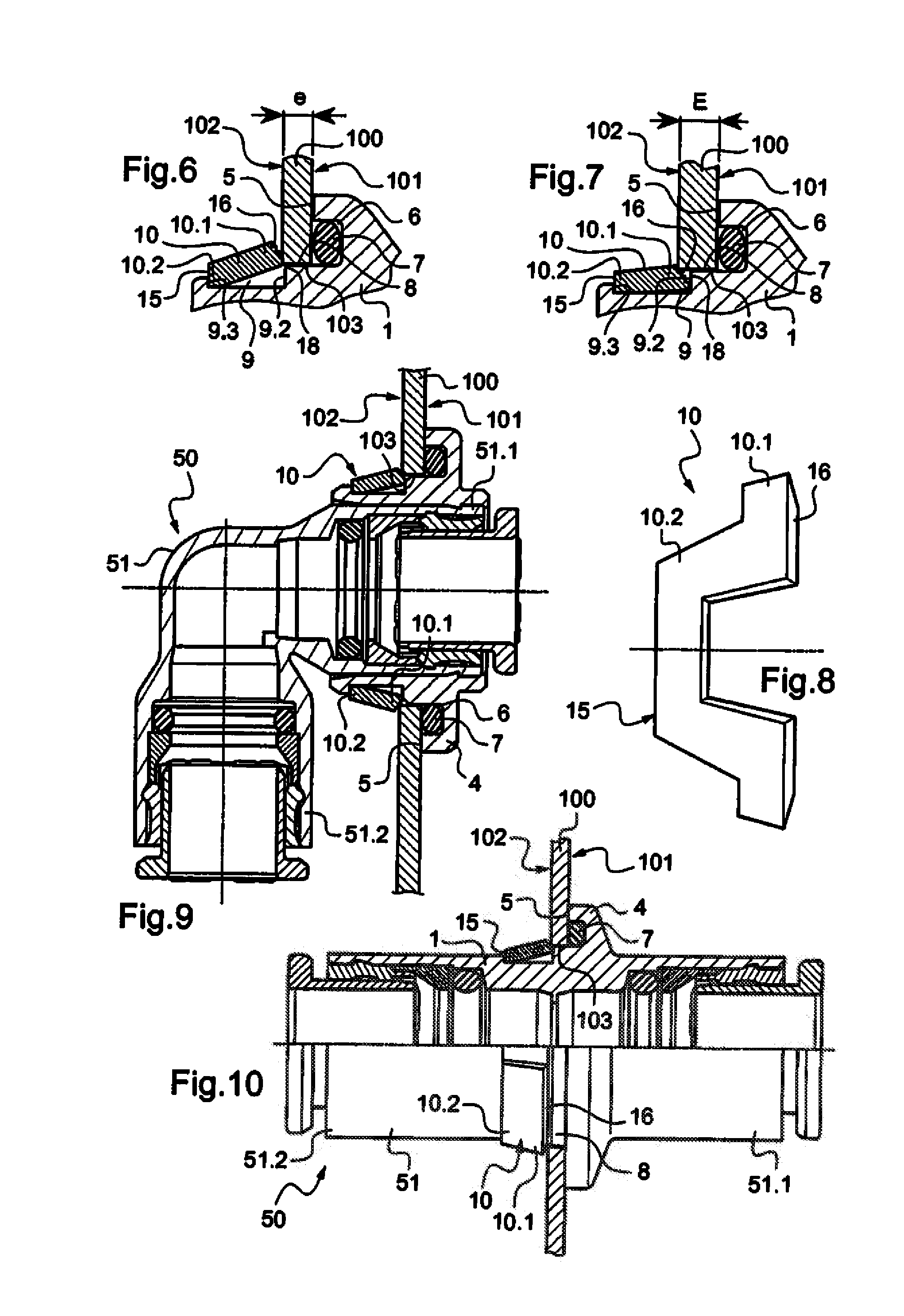

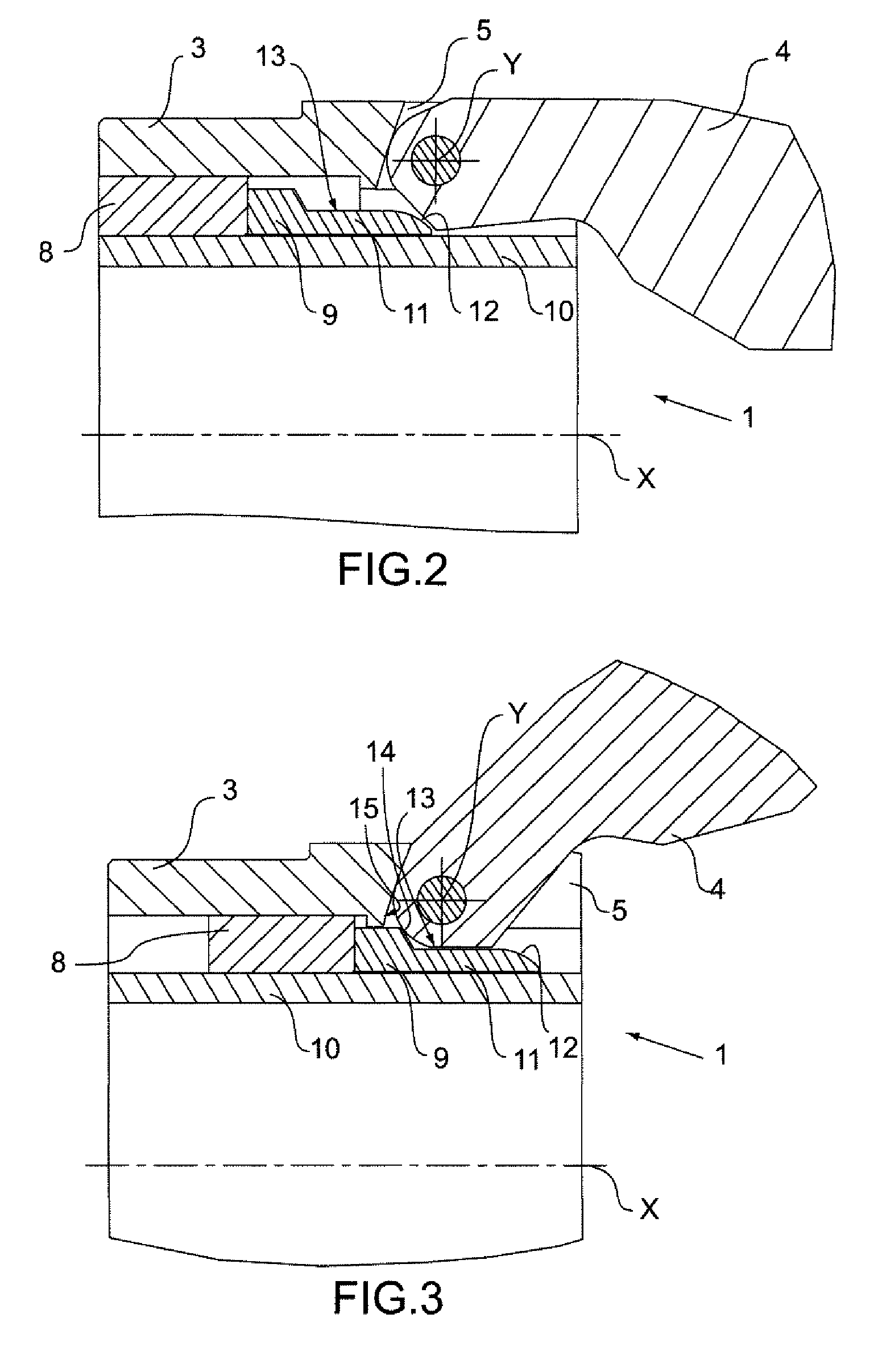

Anchor device for anchoring an element such as a fluid coupling in an opening in a wall

InactiveUS20110318099A1Improve pullout resistanceControl clearancePipesCoupling device detailsFluid couplingEngineering

An anchor device for anchoring an element such as a coupling in an opening in a wall the device including a sleeve for receiving the element, the sleeve being externally provided with a shoulder for bearing against a first face of the wall, and with an anchor member facing the shoulder having a portion that is resiliently movable between a laterally projecting position and a retracted position. The anchor member is a frustoconical ring received in a groove in the outside of the sleeve, the ring having larger end facing the shoulder with a sloping surface which forms the resiliently movable portion and which bears in the laterally projecting position against a zone of intersection between a side surface of the opening and a second face of the wall.

Owner:PARKER HANNIFIN FRANCE

Front-view intelligent anti-glare device of vehicle and manufacturing method of anti-glare mirror thereof

ActiveCN103909868AControl detectionControl Auto SwitchNon-linear opticsOptical viewingEngineeringLight sensing

The invention relates to a front-view intelligent anti-glare device of a vehicle and a manufacturing method of an anti-glare mirror thereof. The front-view intelligent anti-glare device of the vehicle is provided with a control device installed in the support and the anti-glare mirror. The output end of the control device is connected with the input end of the anti-glare device. The control device is provided with an MCU microprocessor, a light sensor, a power supply module and a power supply output control module. The light sensor is provided with a casing and a light sensing mechanism arranged in the casing. The light sensing mechanism is provided with a glare sensor and an environment light sensor. The input end of the MCU microprocessor is respectively connected with the output end of the environment light sensor, the output end of the glare sensor and the output end of the power supply module, and the output end of the MCU microprocessor is connected with the input end of a power supply control module. The output end of the power supply control module is used for being connected with the input end of the anti-glare mirror through an electrode. A monomer molecular coating is added for the anti-glare mirror. The front-view intelligent anti-glare device senses the intensity through the light sensor, the MCU microprocessor receives, processes and sends signals to eliminate glare influence, and the running safety is ensured.

Owner:CHANGZHOU YAPU NEW MATERIALS CO LTD

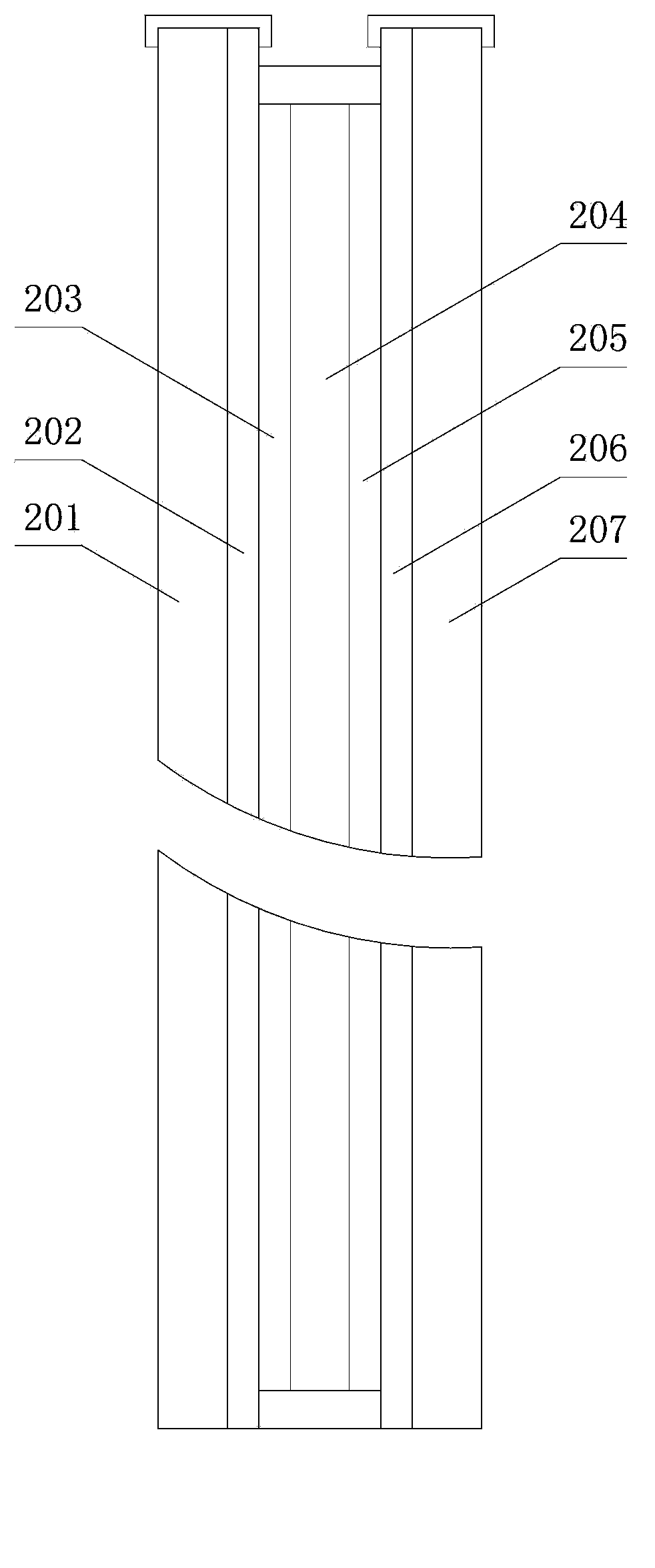

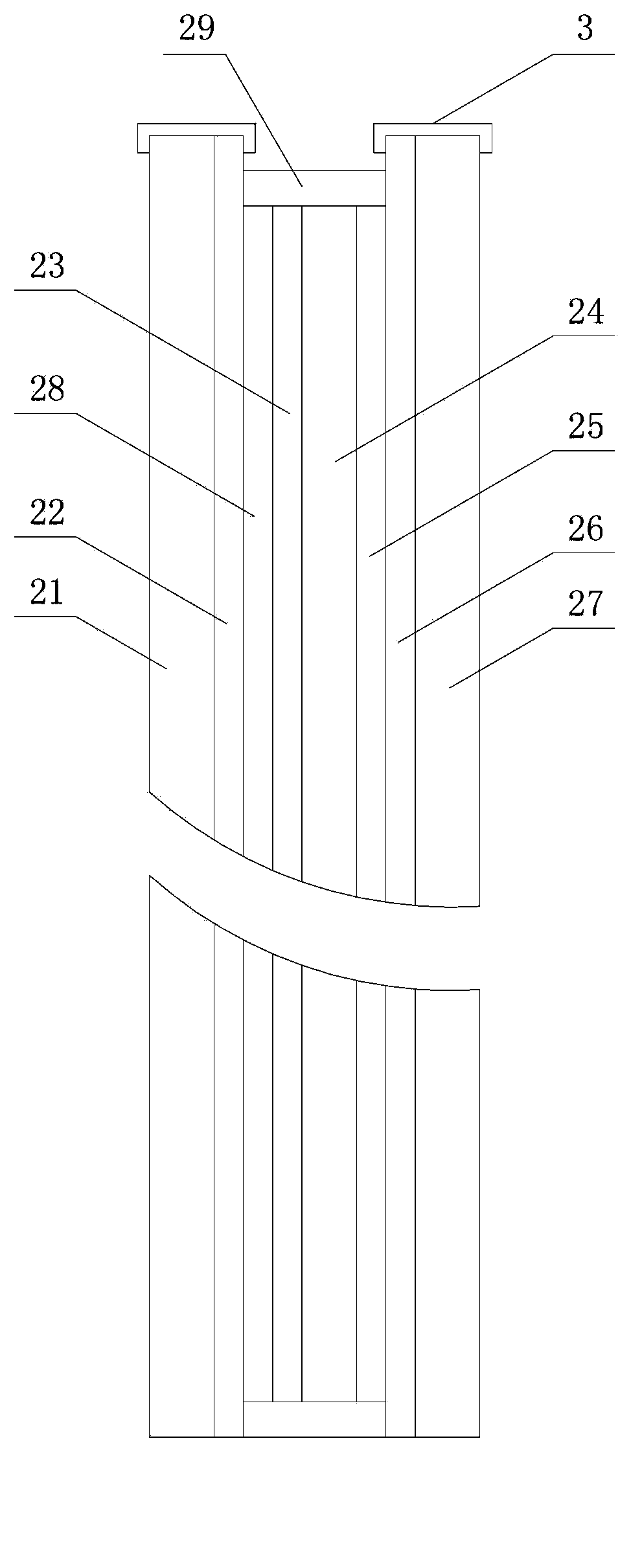

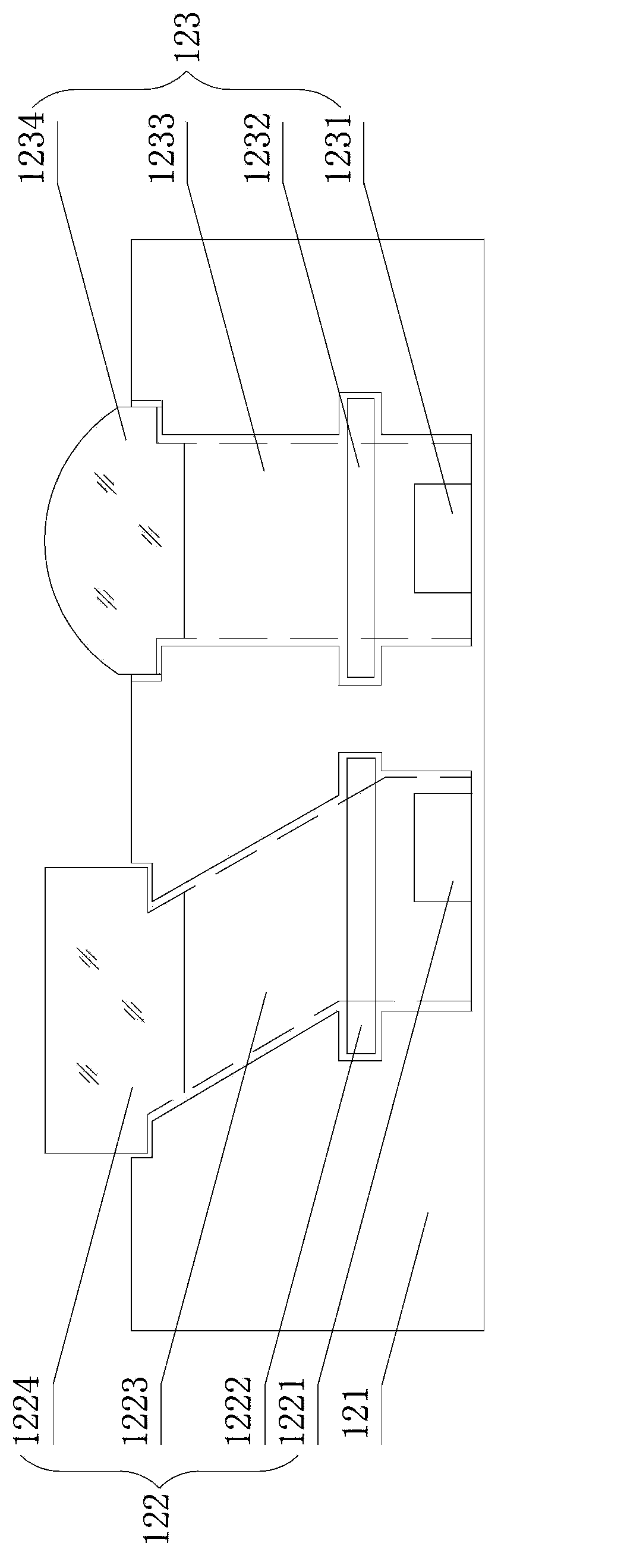

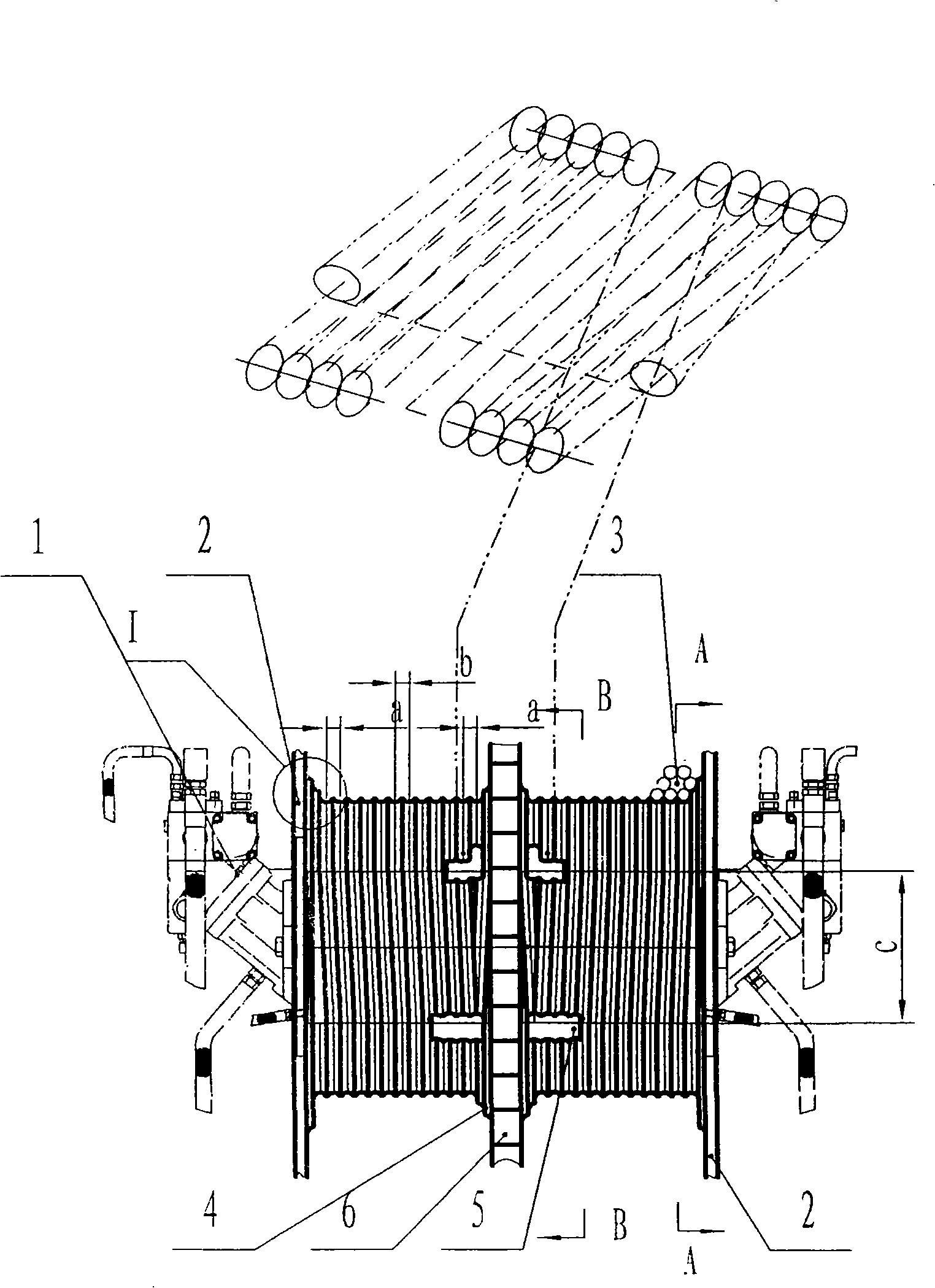

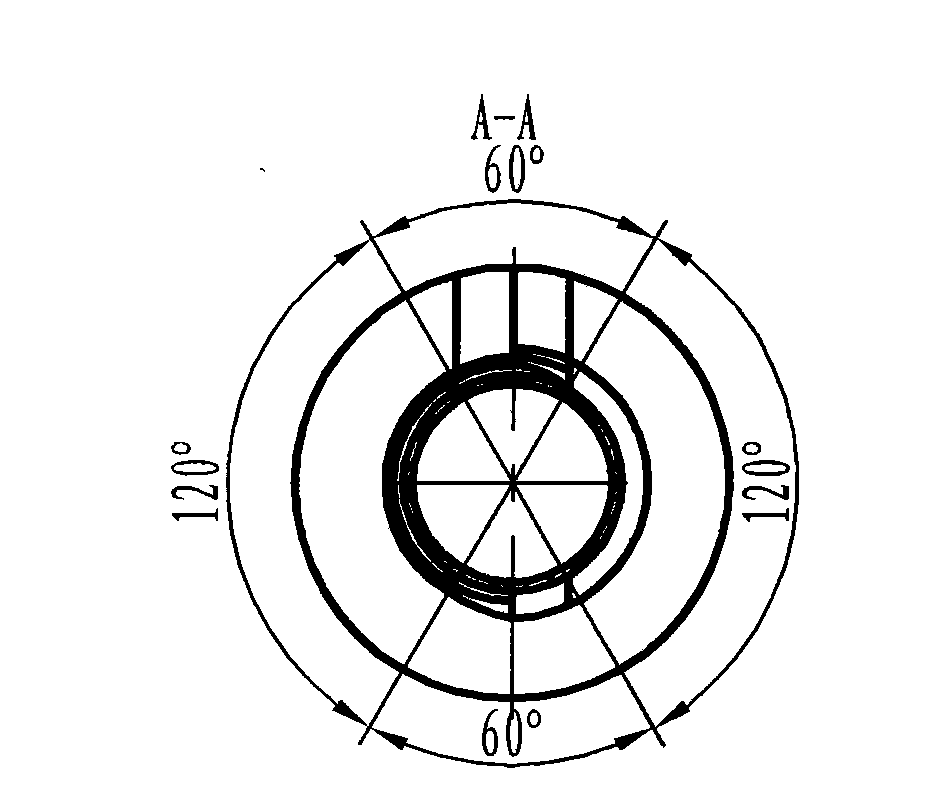

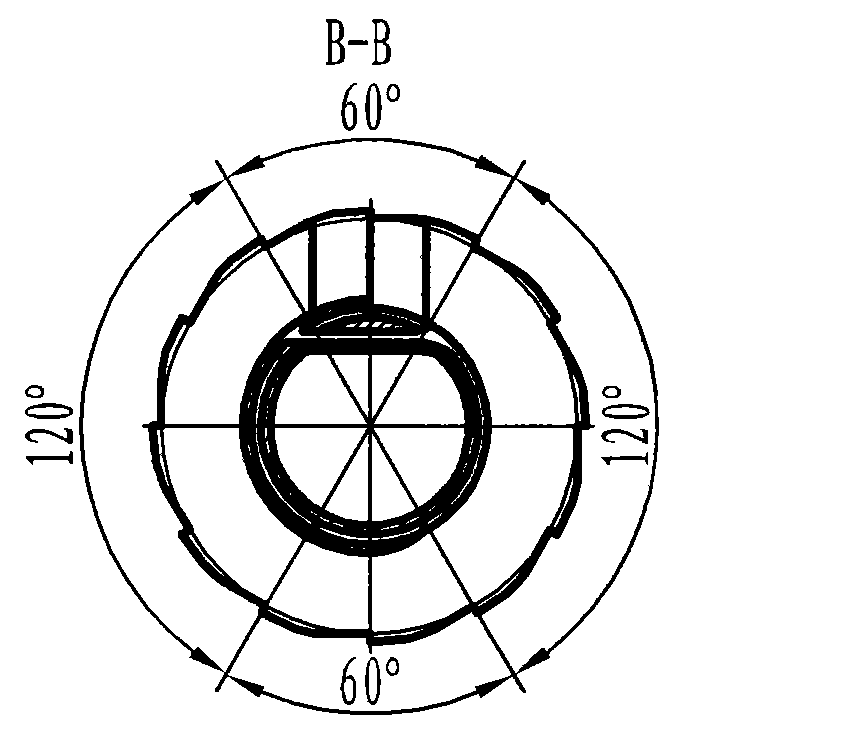

Integral duplex dual-polyline variable-amplitude winding drum of caterpillar crane

The invention relates to an integral duplex dual-polyline variable-amplitude winding drum for a large-tonnage (more than 150 tons) caterpillar crane arm support variable-amplitude device. The integral duplex dual-polyline variable-amplitude winding drum is an integrally casting duplex winding drum, in particular to an integrally casting duplex winding drum with groove turning directions and rope outlets symmetrically distributed at the left side and the right side of a middle baffle plate, wherein the rope outlets are positioned at both sides of the middle baffle plate, the groove turning directions are opposite left and right, grooves are all designed with dual-polyline, and the grooves have compact two-side rope starting parts, loose middle rope arrangement and a rope arrangement lug boss positioned on the middle baffle plate so as to enable wire ropes which are winded on the grooves to have uniform bearing capacity, thus the invention greatly reduces the abrasion among the wire ropes and the axial force of the middle baffle plate; and even if the wire ropes wind with multiple layers, no mutual interference, extrusion and wire rope confusion can be generated, thus the invention achieves the purpose of reducing the volume, prolonging the service life of the wire ropes, reducing the use cost and enhancing the work efficiency.

Owner:LIAONING FUWA HEAVY IND MACHINERY

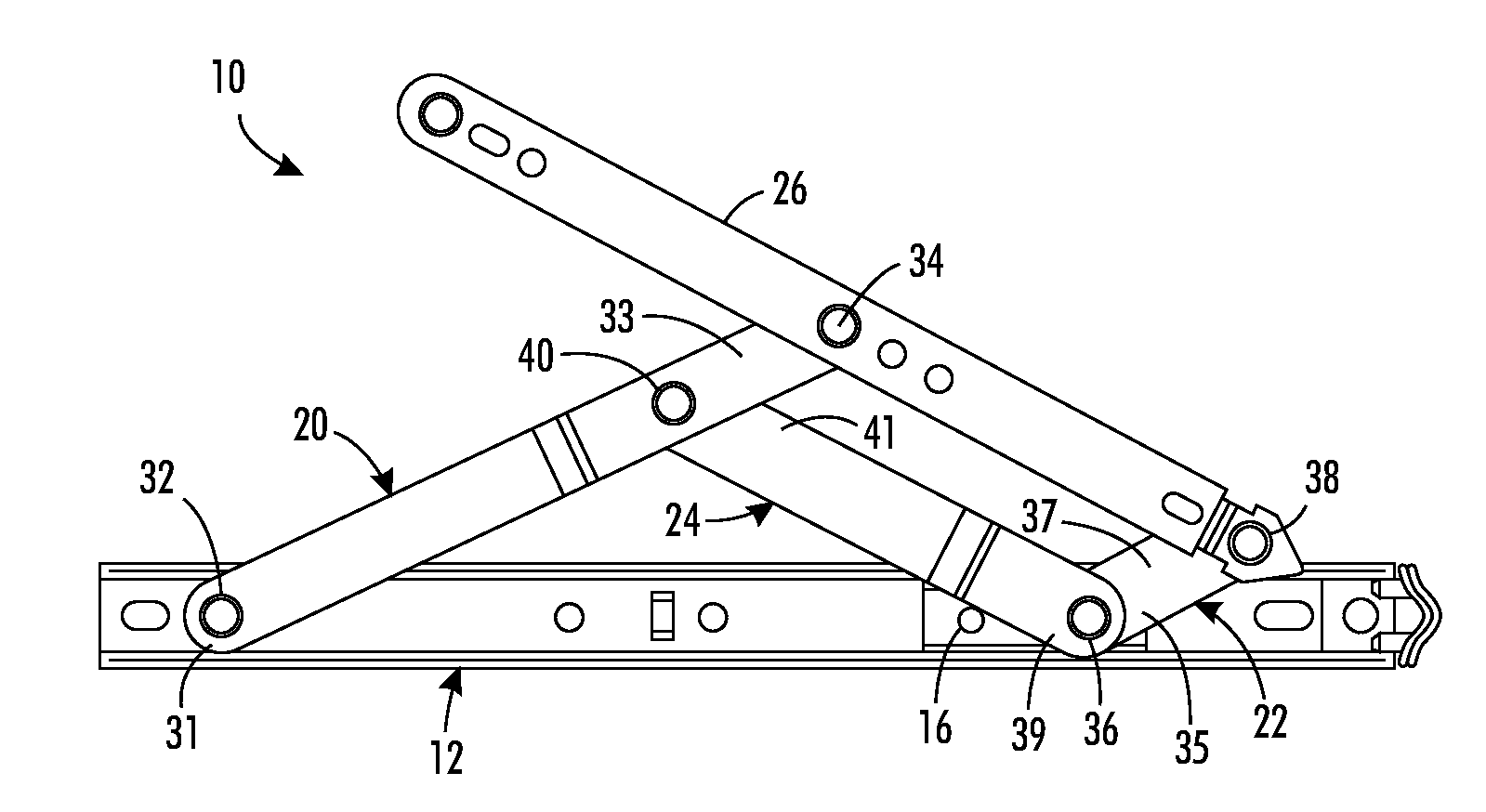

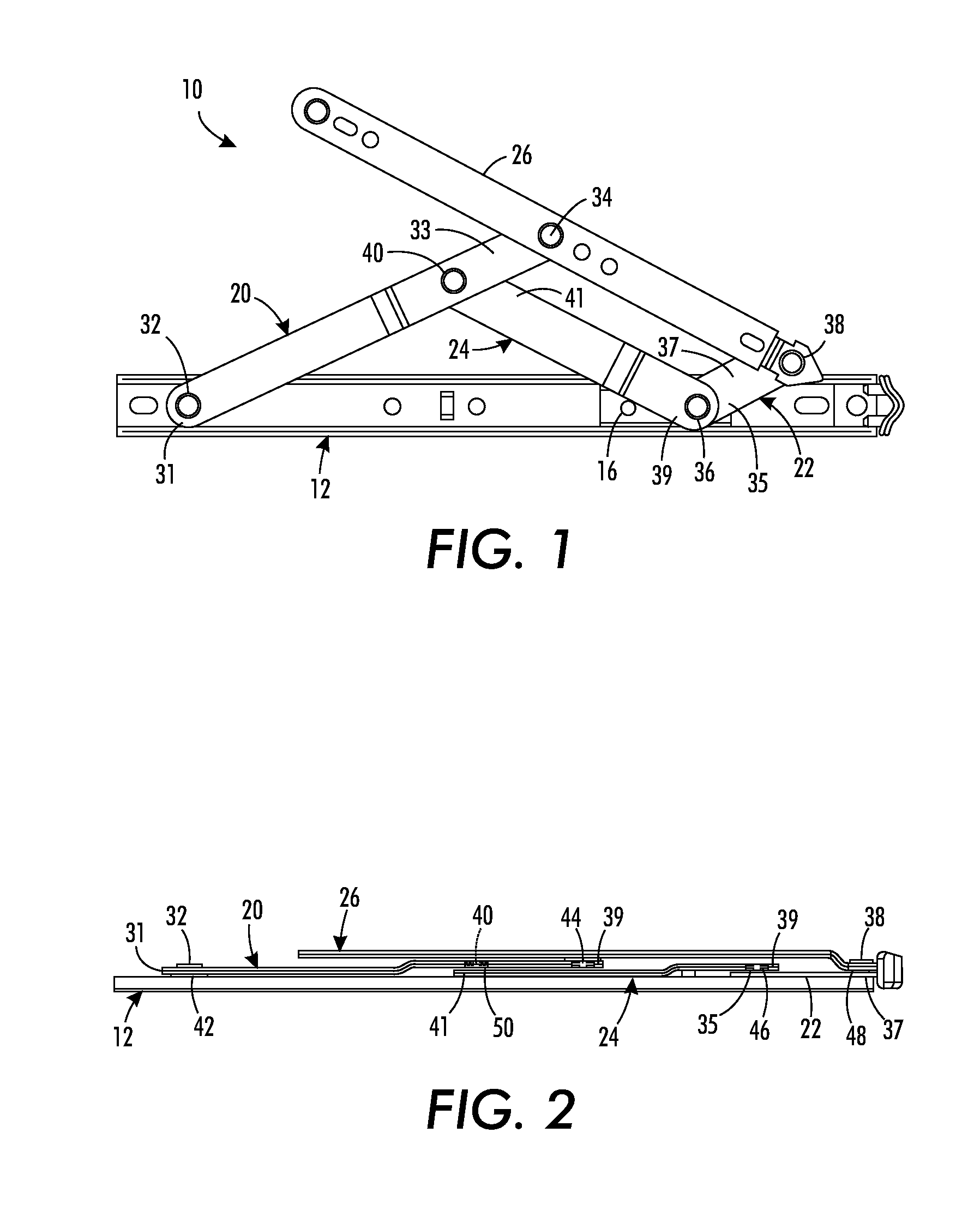

Channel-mounted 4-bar linkage assembly

Owner:CALDWELL MFG NORTH AMERICA

Gas turbine plant

ActiveUS8602724B2Convenience to workControl clearancePump componentsWind motor controlThermal expansionGas turbines

Provided is a gas turbine plant that enables active clearance control for ensuring tip clearance of first-stage turbine rotor blades required during start-up and for achieving the minimum tip clearance during load operation. In a gas turbine plant including a cooler in an air system used for cooling second-stage turbine stator blades, a first-stage segmented ring and a second-stage segmented ring that oppose tips of first-stage turbine rotor blades and second-stage turbine rotor blades are supported by the same blade ring member, and a cooling-air for the second-stage turbine stator blades forms a cooling air flow cooling the blade ring, to control thermal expansion of the blade ring and to control the clearance with respect to the tips.

Owner:MITSUBISHI HEAVY IND LTD

Zinc alloy mold manufacturing process

The invention discloses a zinc alloy mold manufacturing process. The specific steps of the zinc alloy mold manufacturing process are as follows: S1: raw material preparation, S2: smelting, S3: zinc alloy die-casting, S4: cutting, S5: workpiece position measurement Positioning, S6: hole processing, S7: special processing, S8: mold parts processing, S9: assembly, S10: debugging, S11: bonding, S12: storage. In the die-casting process, the present invention adopts low-speed or high-speed casting to fill the mold into the cavity of the mold, and the mechanical properties of the mold are relatively high. Add adhesive to the contact parts of the mold to control the mold gap, so that the mold The service life is greatly improved, and the manufacture of the mold has the advantages of reasonable design, simple operation, safety and practicality, and can be widely used.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

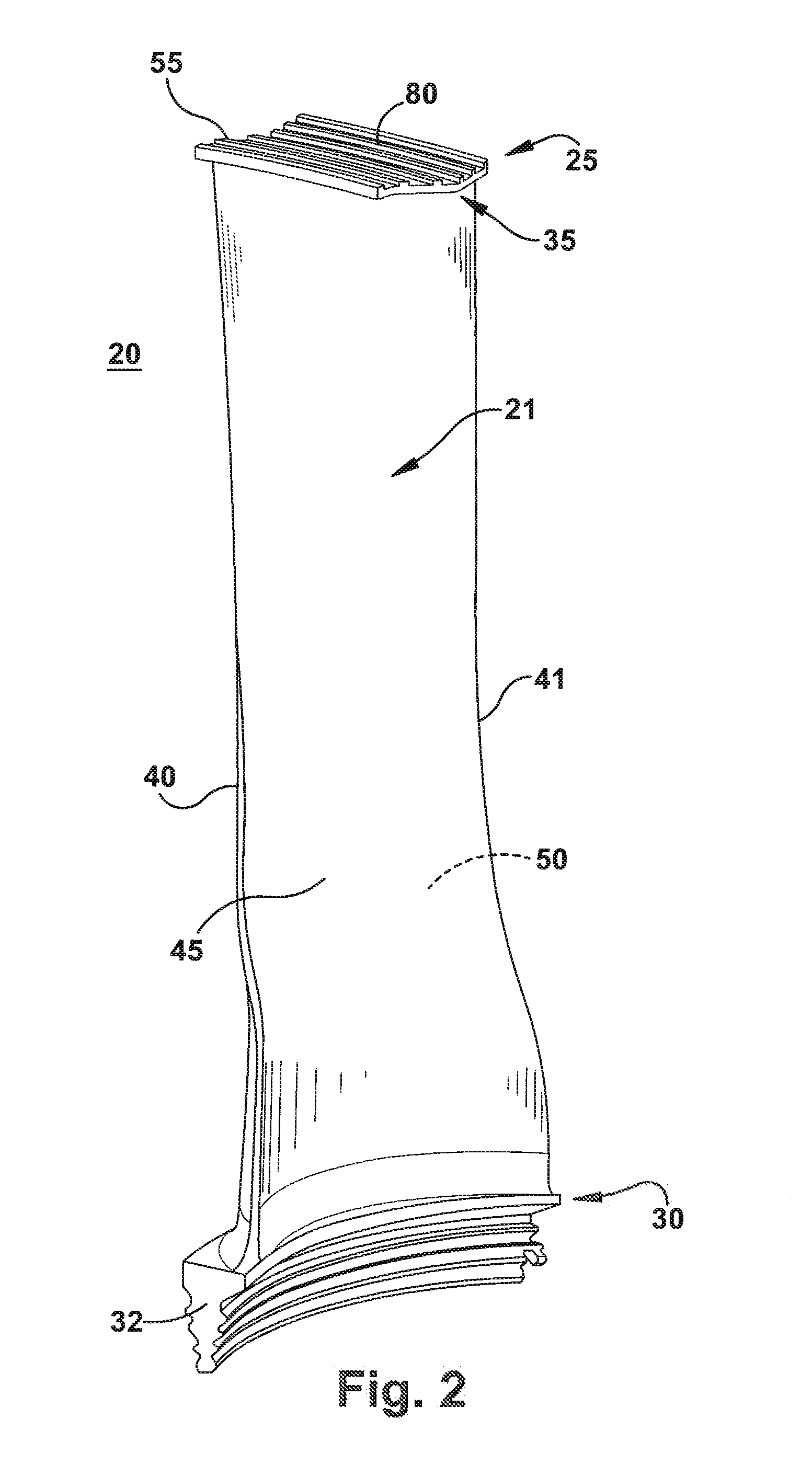

Axial fan casing design with circumferentially spaced wedges

InactiveUS20100040458A1Restriction in clearance flow lossImprove stabilityPump componentsBlade accessoriesEngineeringMechanical engineering

An axial fan assembly including a casing wall with a forward facing step formed therein. Formed on the surface of the step is a plurality of circumferentially spaced wedges which are formed and positioned so as to reduce the swirl flow within the clearance gap between the fan rotor and casing. The wedges are formed so the swirling backflow first encounters a circumferentially tapered face and then an abrupt axially oriented face, thereby substantially removing the swirl component. The wedges have a favorable effect on the flow stability of the fan, thereby extending its operating range. Variations include a fan rotor with a rotating shroud with an outwardly extending portion overlapping the step, and a bellmouth piece at the casing inlet.

Owner:CARRIER CORP

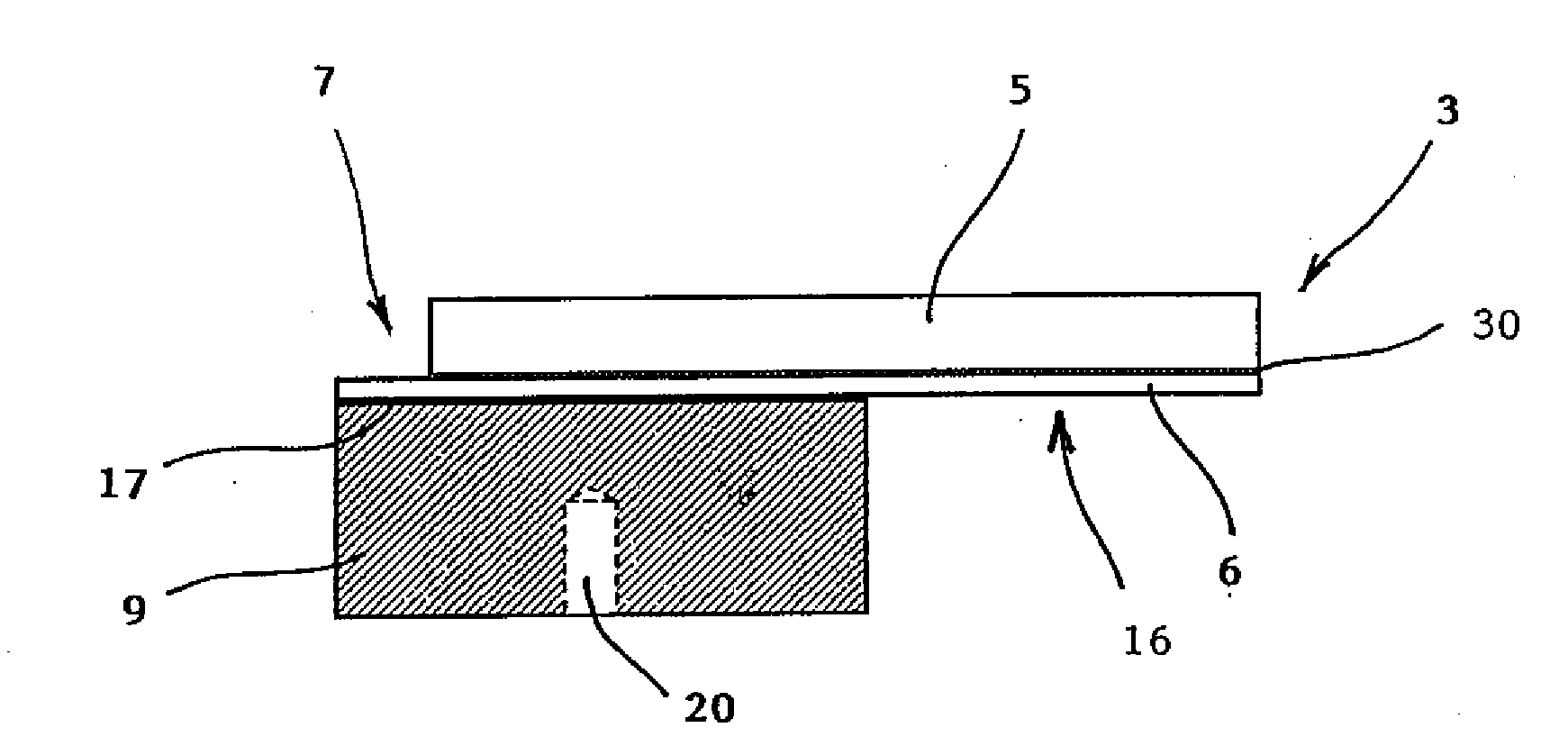

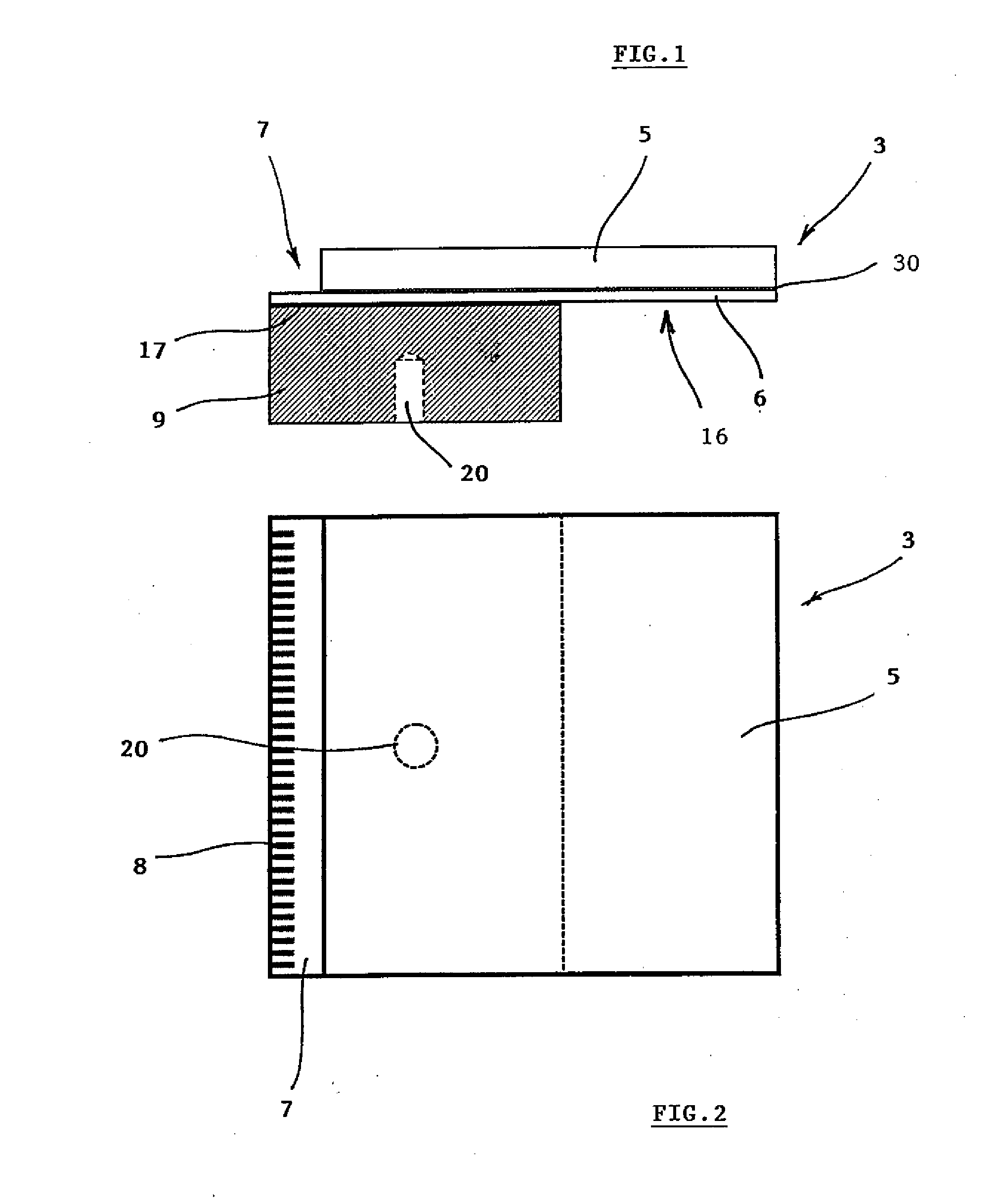

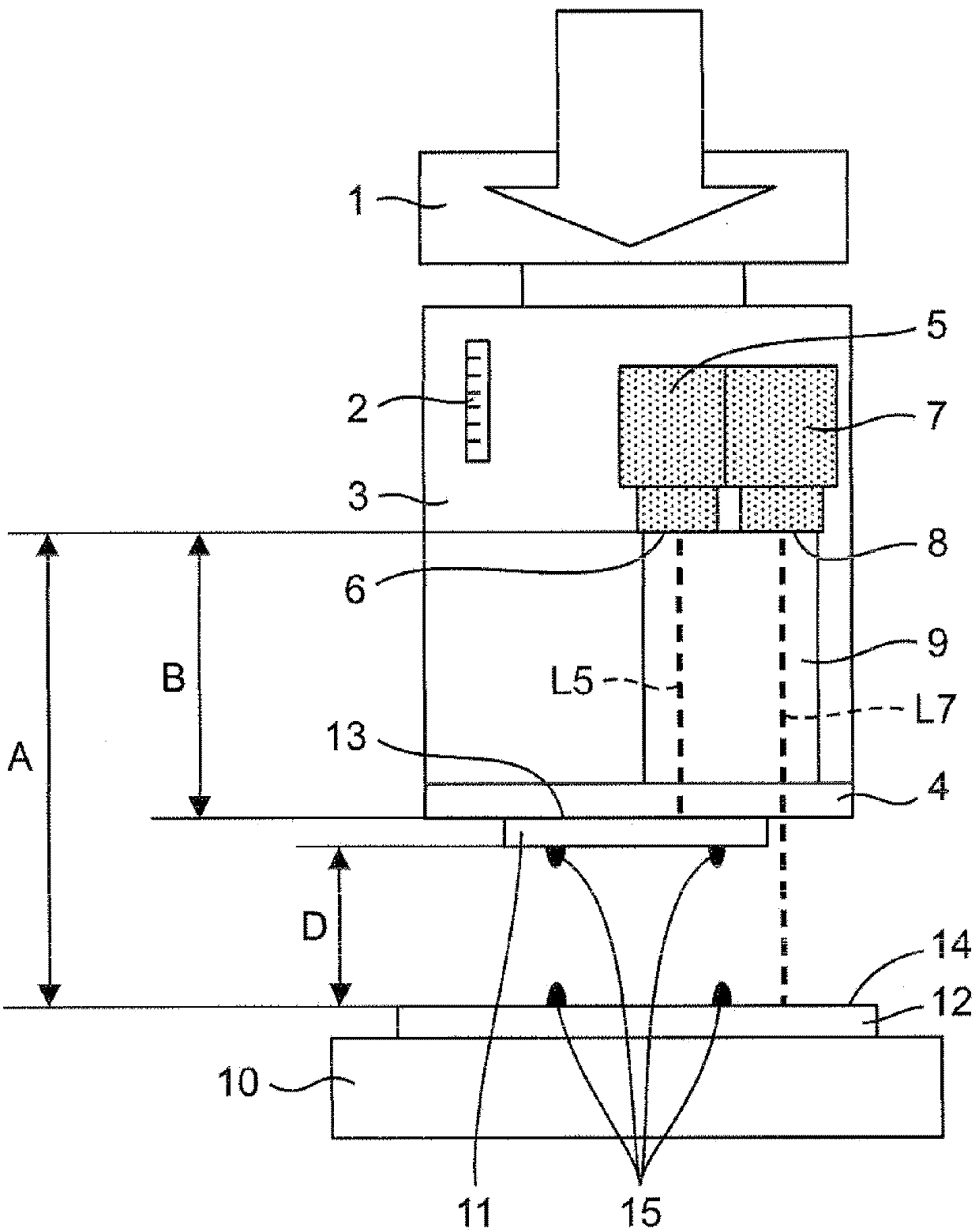

Detector of ionizing radiation enabling a coherent digital image

ActiveUS20160209521A1Control clearanceGap minimizationMaterial analysis using wave/particle radiationSolid-state devicesRadiationIonizing radiation

A detector of ionizing radiation, e.g. x-ray radiation, allowing for the creation of a continuous digital image of a scanned object. The detection surface is formed by a mosaic of detector segments arranged in a matrix and consisted of a sensor layer arranged on a chip reader with the formation of tiers to engage an adjacent detector segment. The sensor layer is active over its entire area, and the matrix is provided with a means for positioning the detector segments to define their mutual lateral clearance less than the size of one pixel. The positioning means preferably comprises a carrier of rows. The resulting detection surface is active over its entire area and allows for the direct creation of continuous digital image without dead zones.

Owner:ADVACAM SRO +1

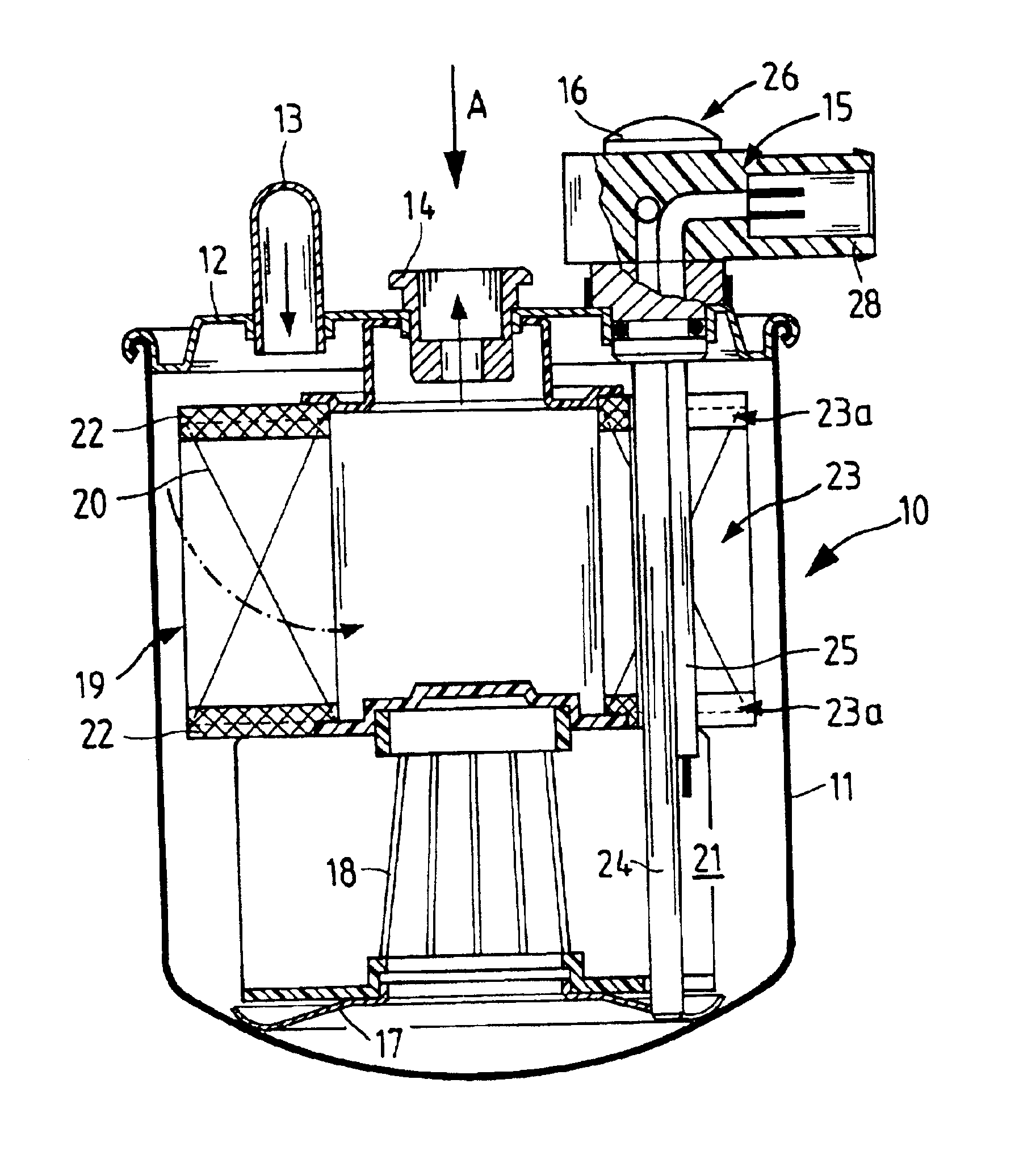

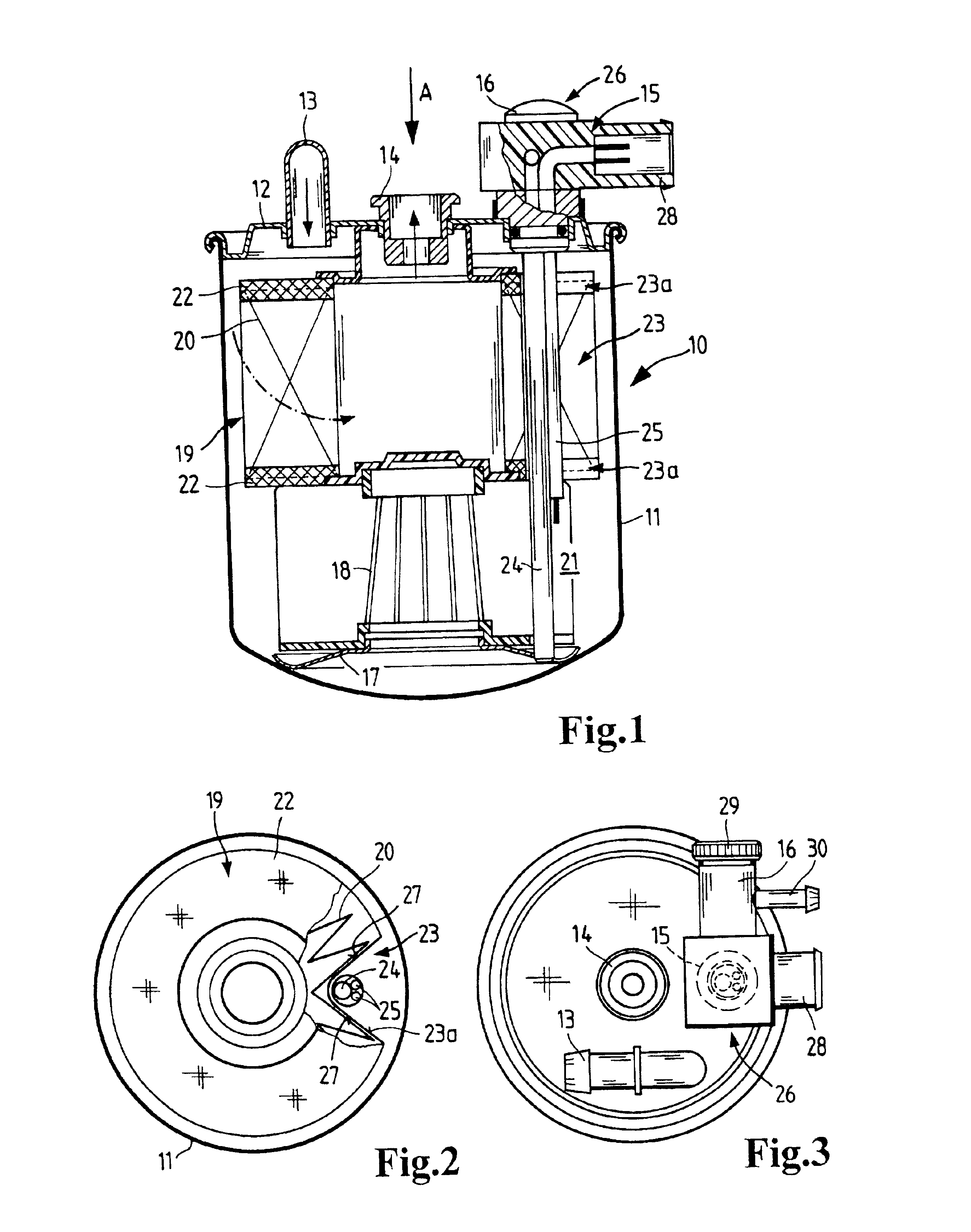

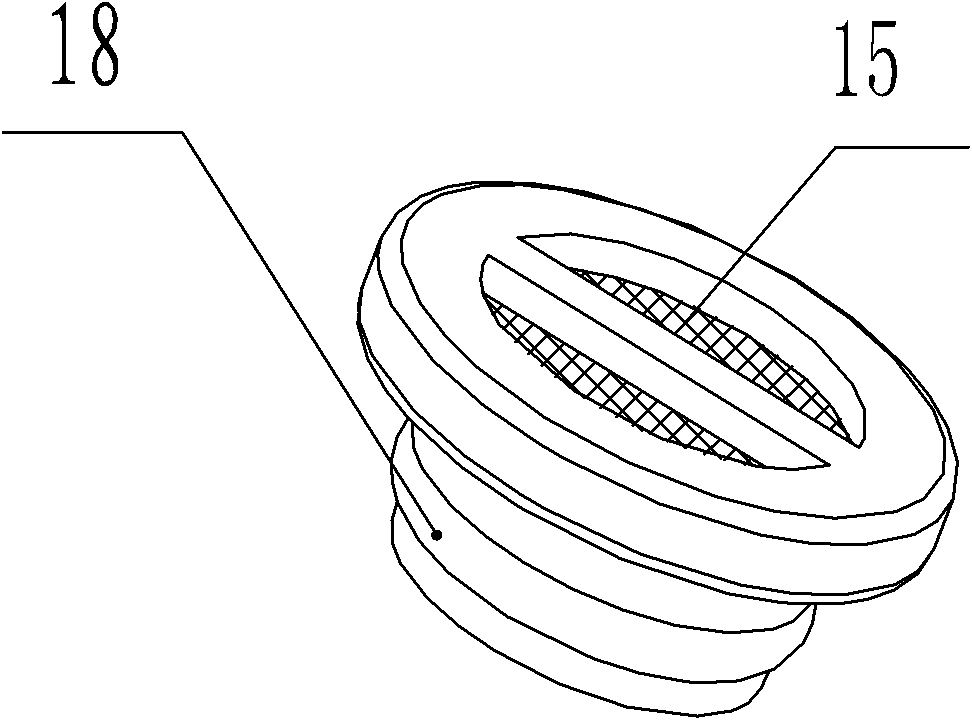

Filter with an annularly constructed filter medium

InactiveUS6852217B2Control clearanceFlexible arrangementSedimentation separationMembrane filtersFilter mediaFuel filter

A filter with a cylindrical filter cartridge in which the filter cartridge has a recess 23, through which functional parts, such as a water level sensor 25 and a water discharge tube 24, can be inserted. This filter may be used, for example, as a fuel filter in which the separated water can be removed from the housing through the functional parts. The functional parts are arranged on a support member 26 and extended through the recess 23, 23a in the filter cartridge 19, and can be accommodated in a space saving manner on the housing cover 12. As a result, the fuel filter can be accommodated particularly in cramped installation spaces in the engine compartment of an internal combustion engine.

Owner:MANN HUMMEL GMBH

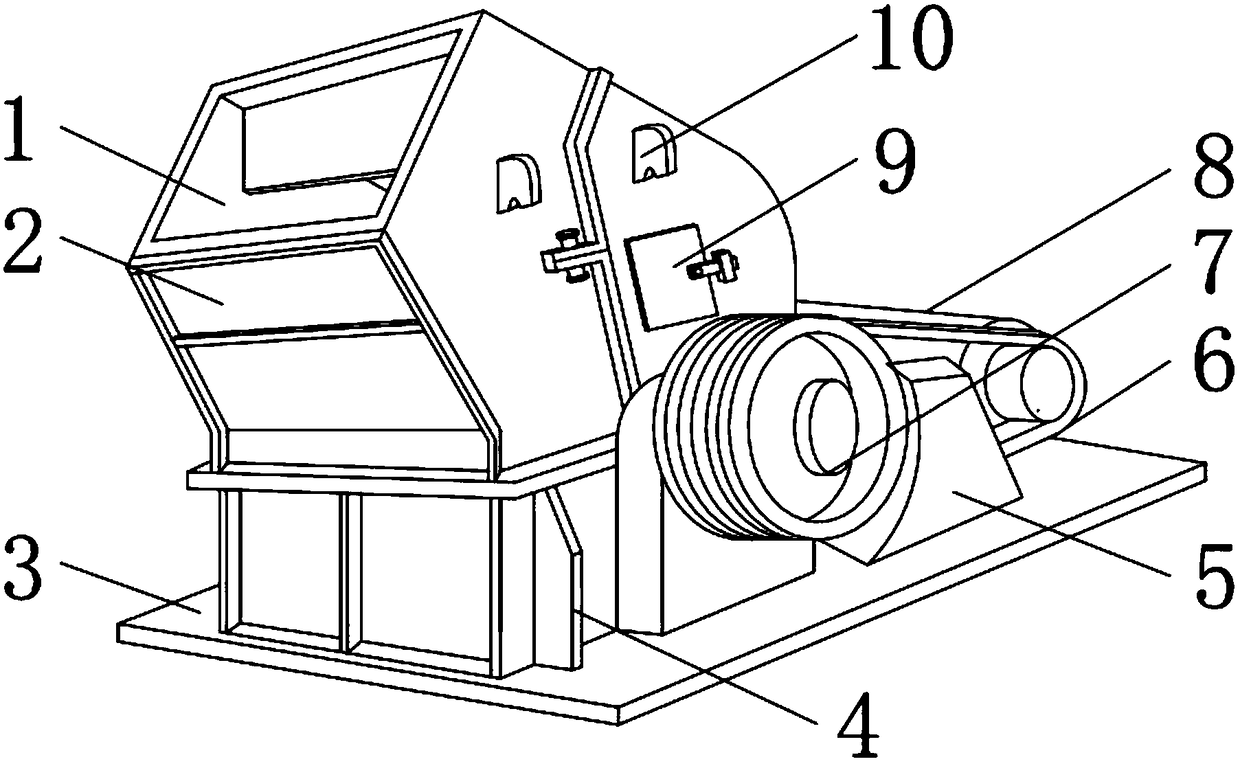

Impact crusher for ore mining

The invention discloses an impact crusher for ore mining. The impact crusher for ore mining comprises a housing, wherein a bottom plate is fixedly connected to the lower end surface of the housing; afixing mounting plate is fixedly connected to the side end surface of the housing; a transmission wheel is rotatably connected to one side, deviated from the fixing mounting plate, of the side end surface of the housing; a conveyor belt is rotatably connected to the outer end surface of the transmission wheel; a motor is rotatably connected to the inner end surface of the conveyor belt; a detecting door is rotatably connected to one side, deviated from the transmission wheel, of the side end surface of the housing; a fixing block is fixedly connected to one side, deviated from the detecting door, of the side end surface of the housing; a feeding port is formed in the upper end surface of the housing; a conveyor belt protecting body is in sliding connection with the upper end surface of thebottom plate; a discharging port is formed in the lower end surface of the housing; a rotating shaft is fixedly connected to the side end surface of the transmission wheel. According to the impact crusher for the ore mining, the conveyor belt is mounted for protecting a crusher body; and the problem that a conveyor belt of a traditional crusher is easily damaged by ore can be solved.

Owner:ANHUI UNIV OF SCI & TECH

Control system of prefabricated bag packing machine

ActiveCN105857649AShort tripPrevent the situation of dumpingSolid materialRolling paperControl system

The invention discloses a control system of a prefabricated bag packing machine and relates to the technical field of mechanical control of packing machines. The control system of the prefabricated bag packing machine comprises a feeding mechanism, a pushing mechanism, a bag stretching mechanism, a bag opening mechanism and a bag conveying mechanism and is characterized by further comprising a clamping mechanism and a translation mechanism. The control system of the prefabricated bag packing machine is applicable to packing machines for packing via prefabricated bags such as small packing machines, medium packing machines and large packing machines and the like; meanwhile, the control system of the prefabricated bag packing machine is also suitable for packing materials such as facial tissues, flat paper, paper towels, blocky foods, drugs, roll paper, unpackaged foods and the like. Through the control system of the prefabricated bag packing machine, the problems that processes in single station of the prefabricated bag packing machine are complex, various packing actions are needed, the travel distance among the stations is long, the equipment occupied area is large, the material is irregular and is easy to pour, the prefabricated bags are easy to break, the material-pushing travel distance is long, the packing effect is poor, and the packaging efficiency is low in the prior art can be solved.

Owner:上海松川峰冠包装自动化有限公司

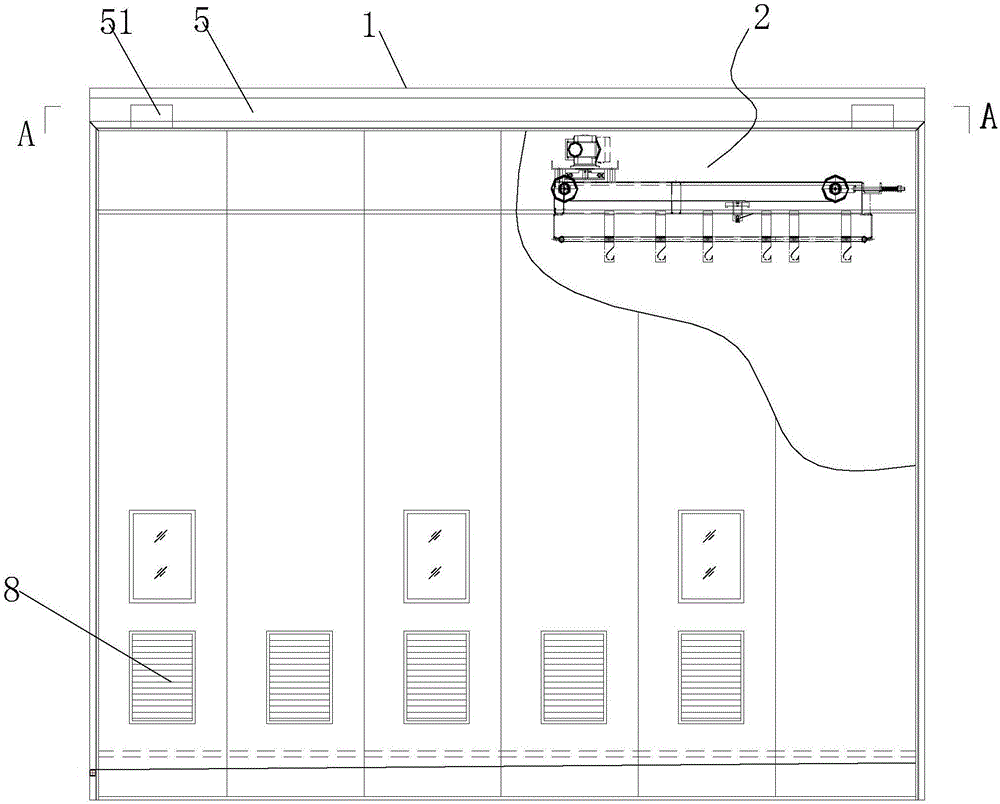

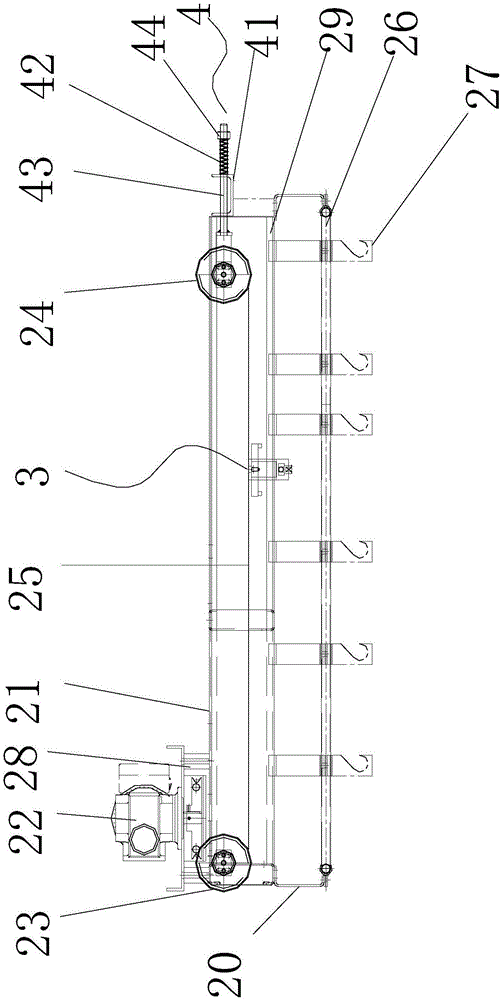

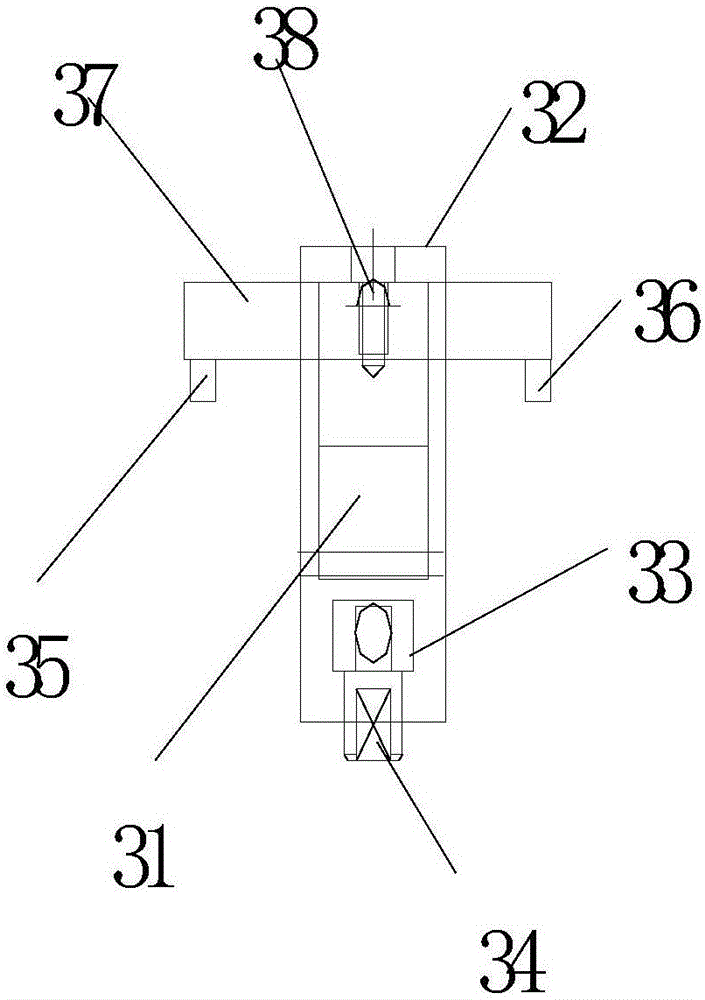

Intelligent wardrobe and method for controlling same

ActiveCN106213824AControl clearanceImprove ventilationWardrobesProgramme control in sequence/logic controllersEngineeringConveyor belt

The invention relates to the technical field of intelligent home, in particular to an intelligent wardrobe and a method for controlling the same. The intelligent wardrobe comprises a wardrobe and a clothing arranging mechanism. The clothing arranging mechanism is arranged inside the wardrobe and comprises a support, a stepper motor, a driving roll, a driven roll, a conveyor belt, a slide rod, hooks and a clothing position judging mechanism; the driving roll and the driven roll are respectively mounted on two sides of the support via bearings, the conveyor belt is wound on the driving roll and the driven roll, the stepper motor is mounted on the support via a reduction gearbox, and the driving roll can be driven by an output end of the reduction gearbox to rotate. The intelligent wardrobe and the method have the advantages that hung clothing can be automatically arranged by the intelligent wardrobe, a clothing room can be effectively ventilated, accordingly, mildew of clothing, damage due to insects and bacterium breeding can be reduced and account for 3% of the original amount as proved via tests, the cost can be reduced by devices of the intelligent wardrobe as compared with the various traditional additional sterilization, heating and ventilating equipment and the like, and the devices only occupy small spaces in the intelligent wardrobe.

Owner:汇森家具(龙南)有限公司

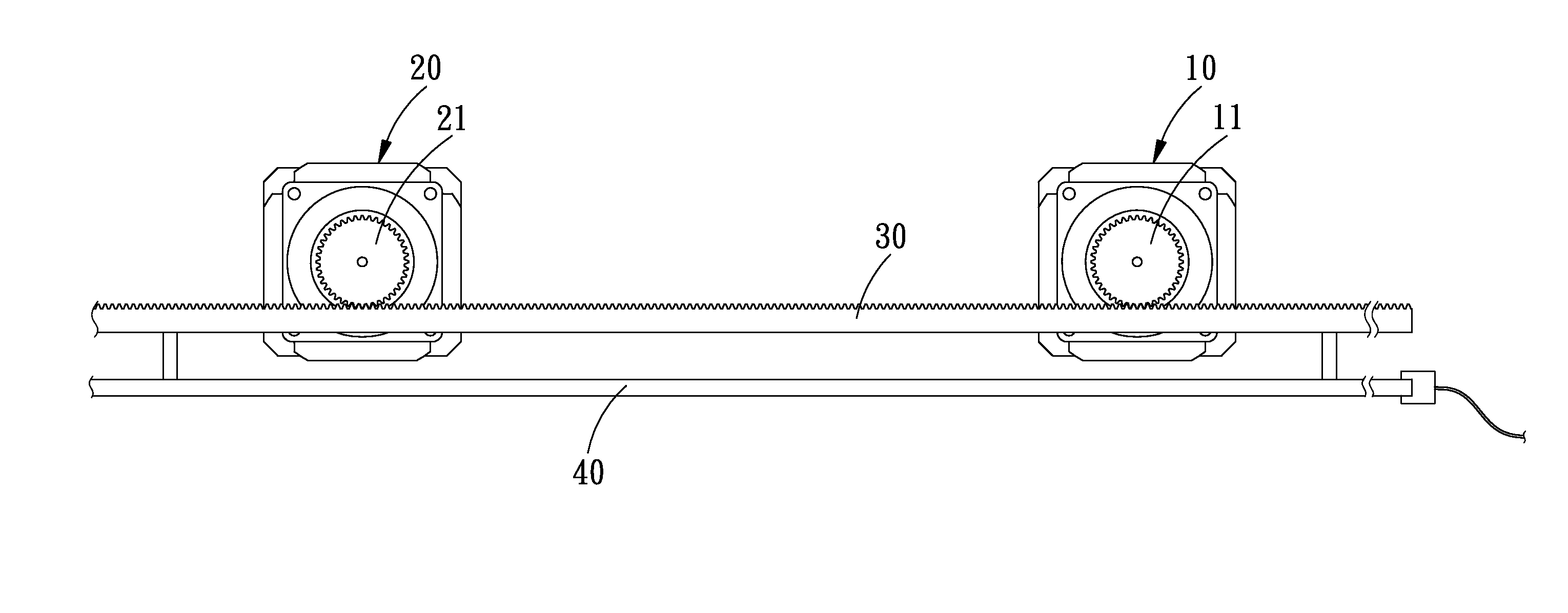

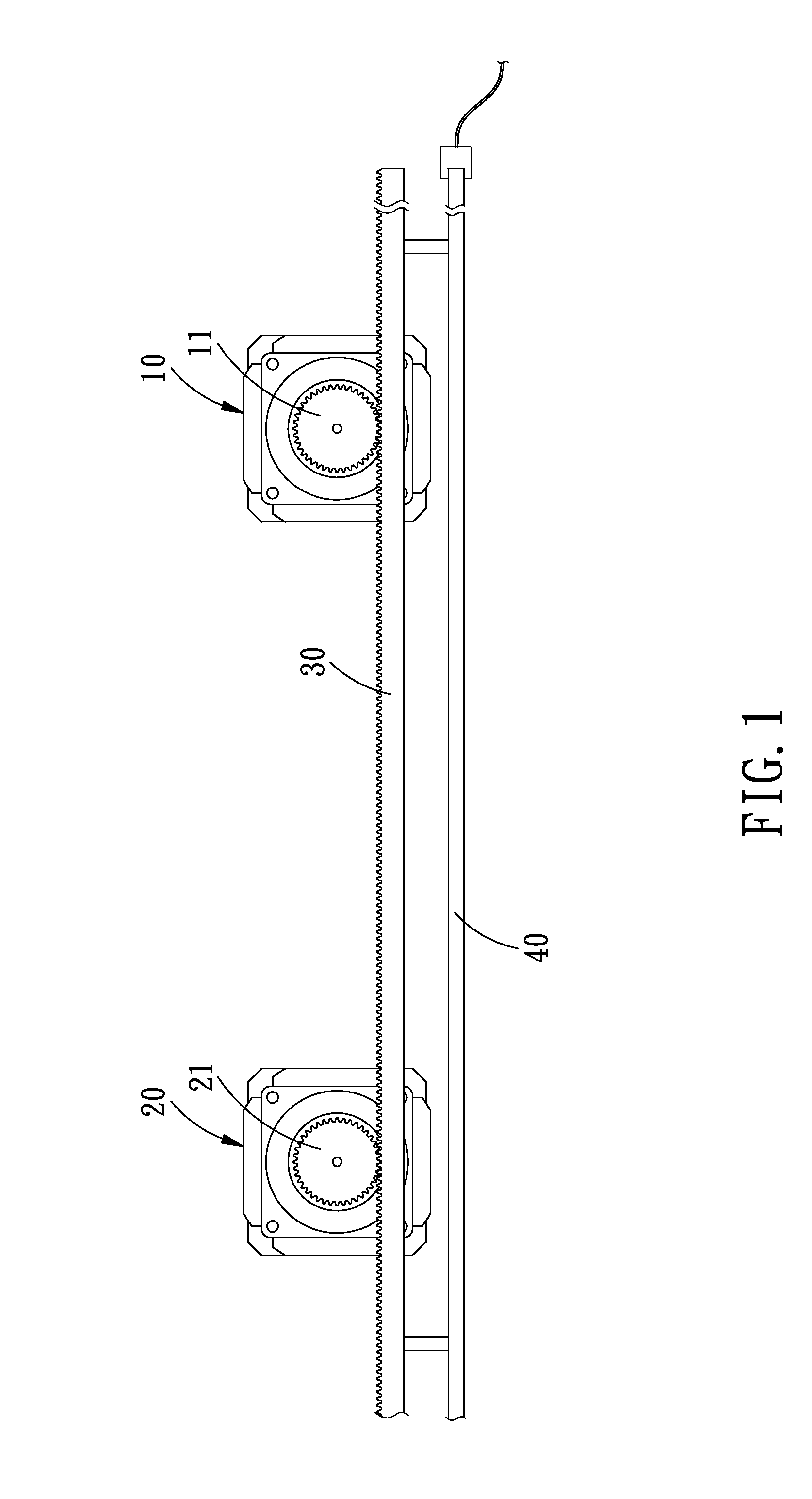

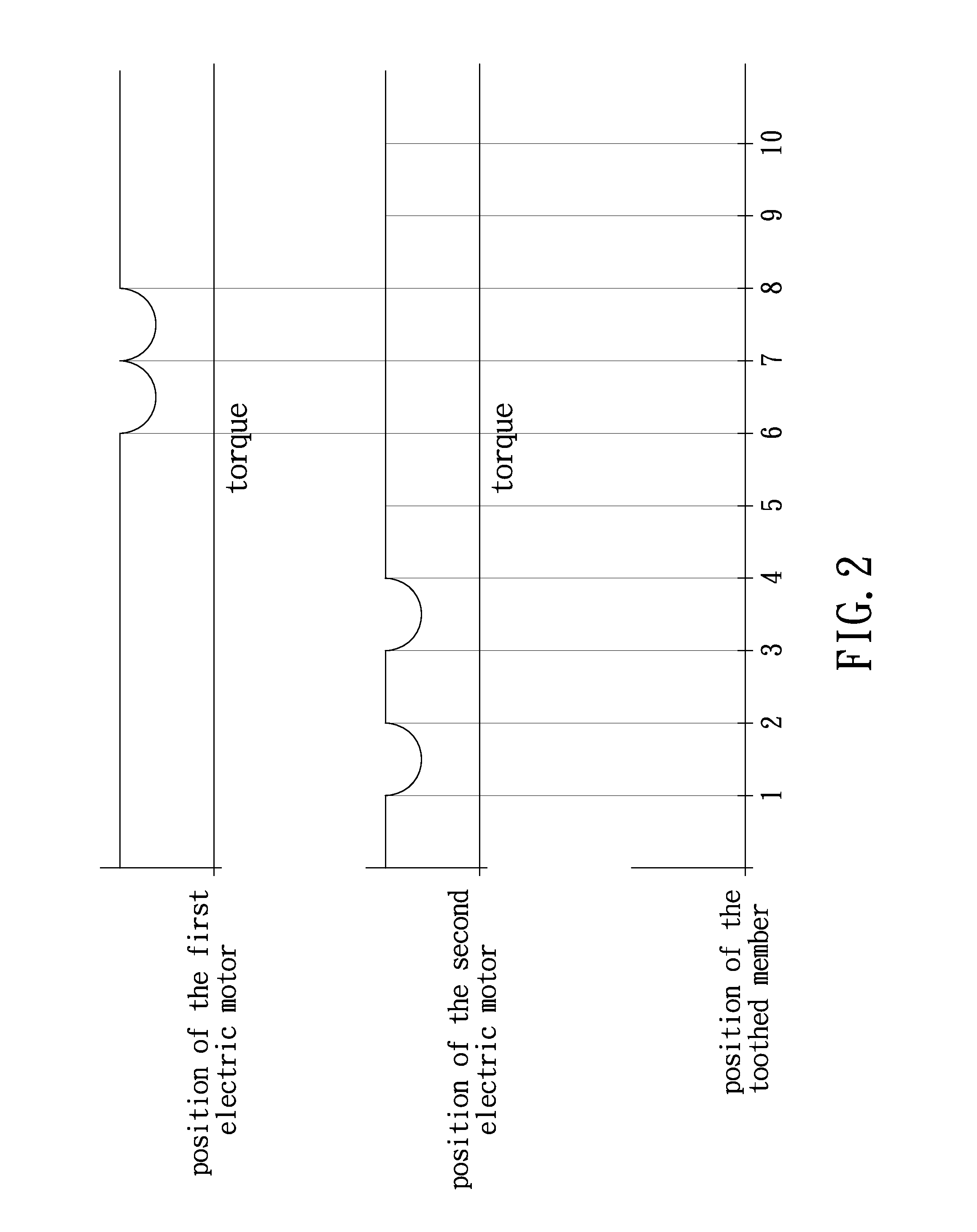

Method for controlling back clearance of a motion transmission apparatus

InactiveUS20130312553A1Eliminate gapsControl clearanceGearing detailsFriction gearingsElectric motorEngineering

A method for controlling back clearance of a motion transmission apparatus, is capable of controlling the generation, reduction and even elimination of a back clearance of a motion transmission apparatus to meet different needs. The motion transmission apparatus comprises: a first electric motor, a second electric motor, and a toothed member engaged with the first and second toothed drive members, when the toothed member needs to be precisely positioned, the back clearance between the second electric motor and the toothed member at different positions of the toothed member will be controlled according to the torque change, so as to consequently change a position offset of the second electric motor with respect to the first electric motor, when the toothed member doesn't need to be precisely positioned, the second electric motor shouldn't be controlled.

Owner:JAN JOHNSON

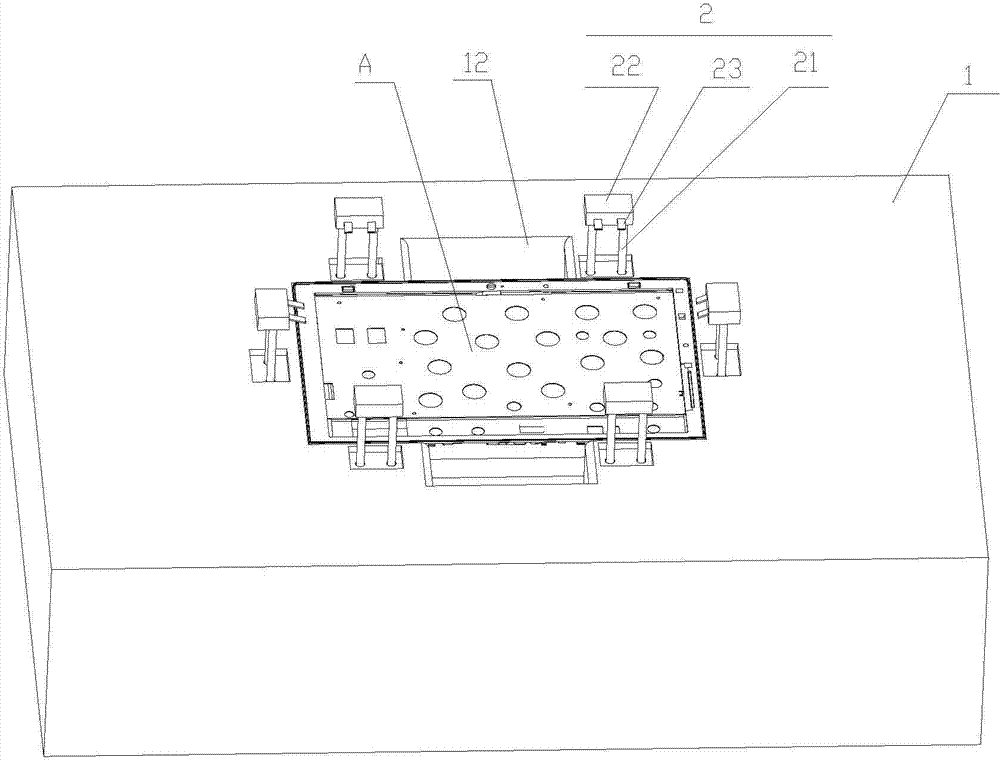

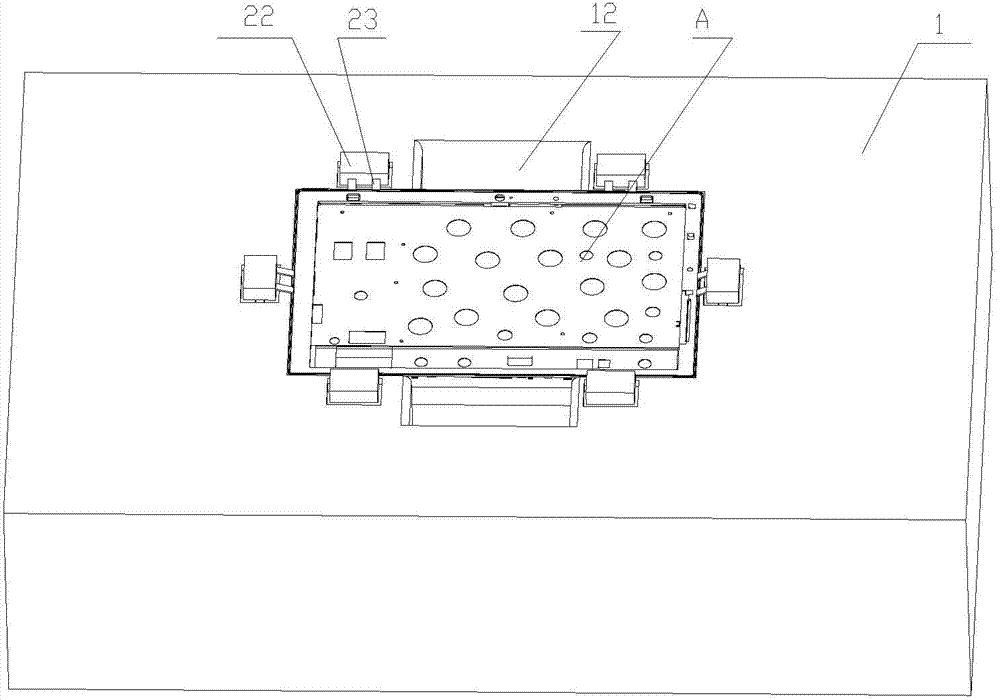

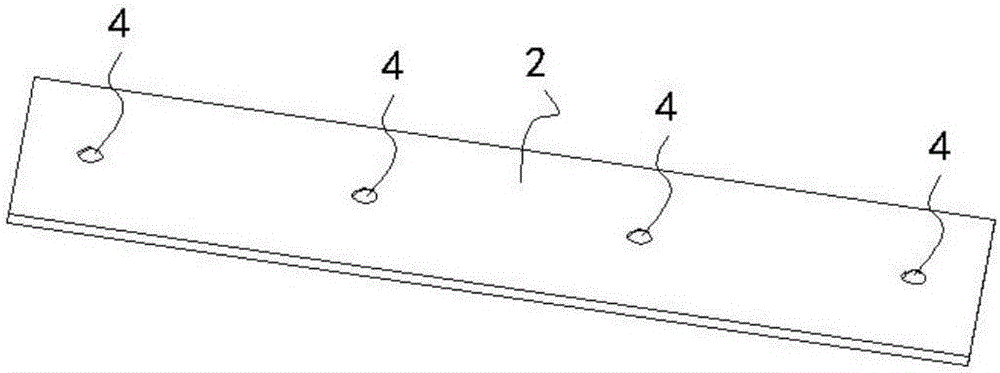

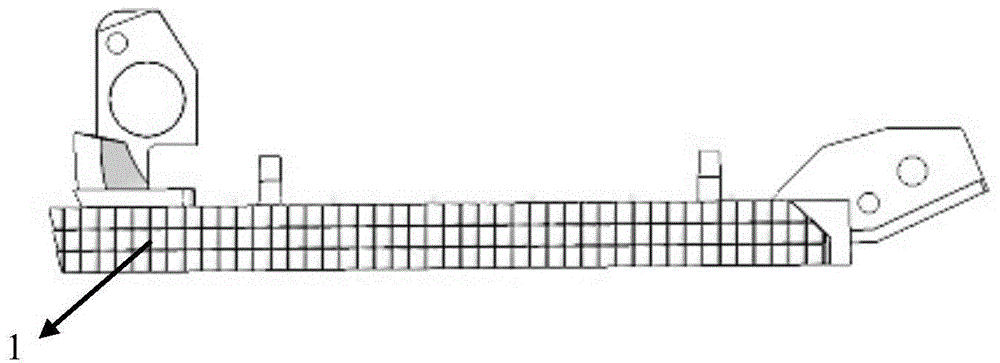

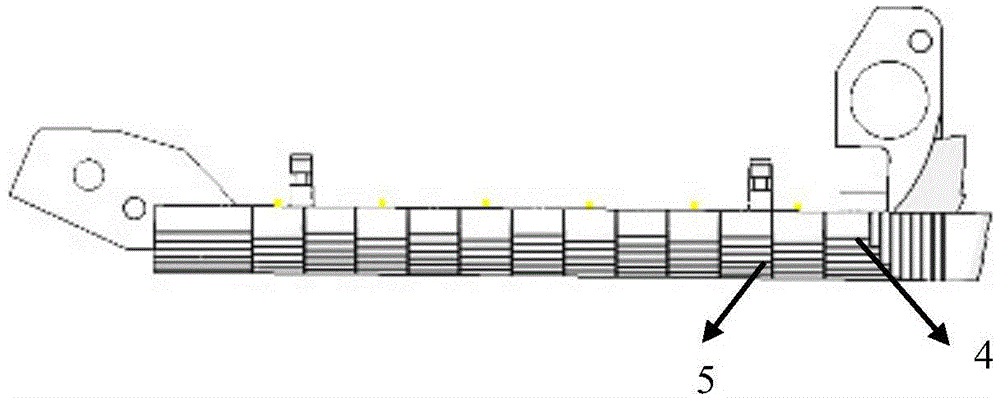

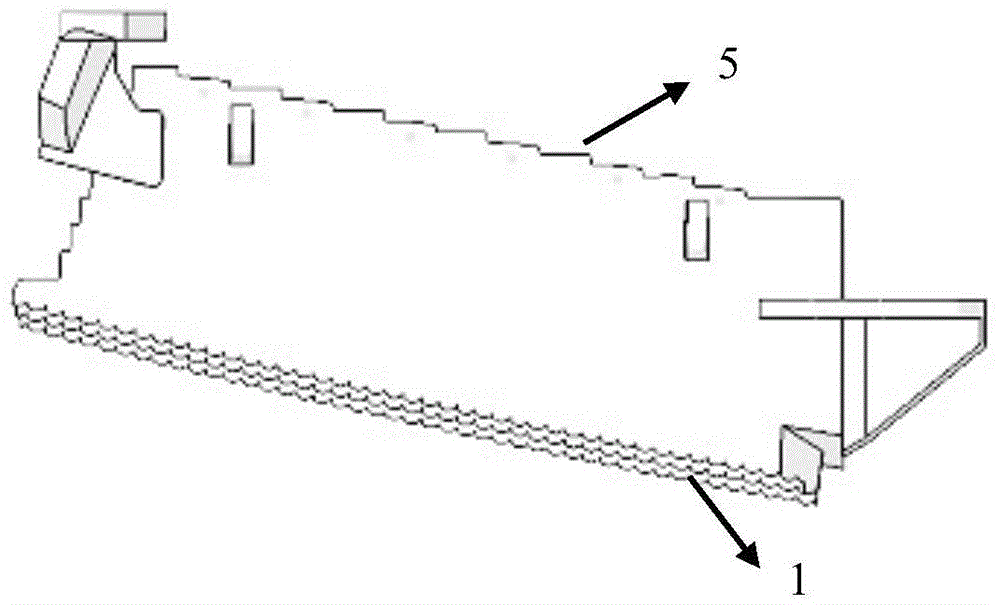

Tablet computer screen pasting jig

ActiveCN104714615AGuaranteed accuracyEnsure stabilityDigital data processing detailsTablet computerEngineering

The invention discloses a tablet computer screen pasting jig used for locating a shell assembly in the screen pasting process. The jig comprises a working table and no less than four locating mechanisms. The working table is provided with a locating groove used for arranging the shell assembly. Each locating mechanism comprises a guide column, a locating block and elastic pieces. The locating blocks are installed on the working table through the guide columns in the mode of being capable of moving vertically and distributed on the periphery of the locating groove. More than one elastic piece is arranged on each locating block. The elastic pieces are located at one side, close to the locating groove, of each locating block. Projections, on the working table, of the elastic pieces are located in the locating groove. By means of the jig, when screen pasting assembly is needed, an electronic product and a shell needing to be assembled or machined can be located fast and accurately, after screen pasting is finished, a locating area is reserved, and taking and placing of the assembled product are facilitated.

Owner:武汉宝龙达信息技术有限公司

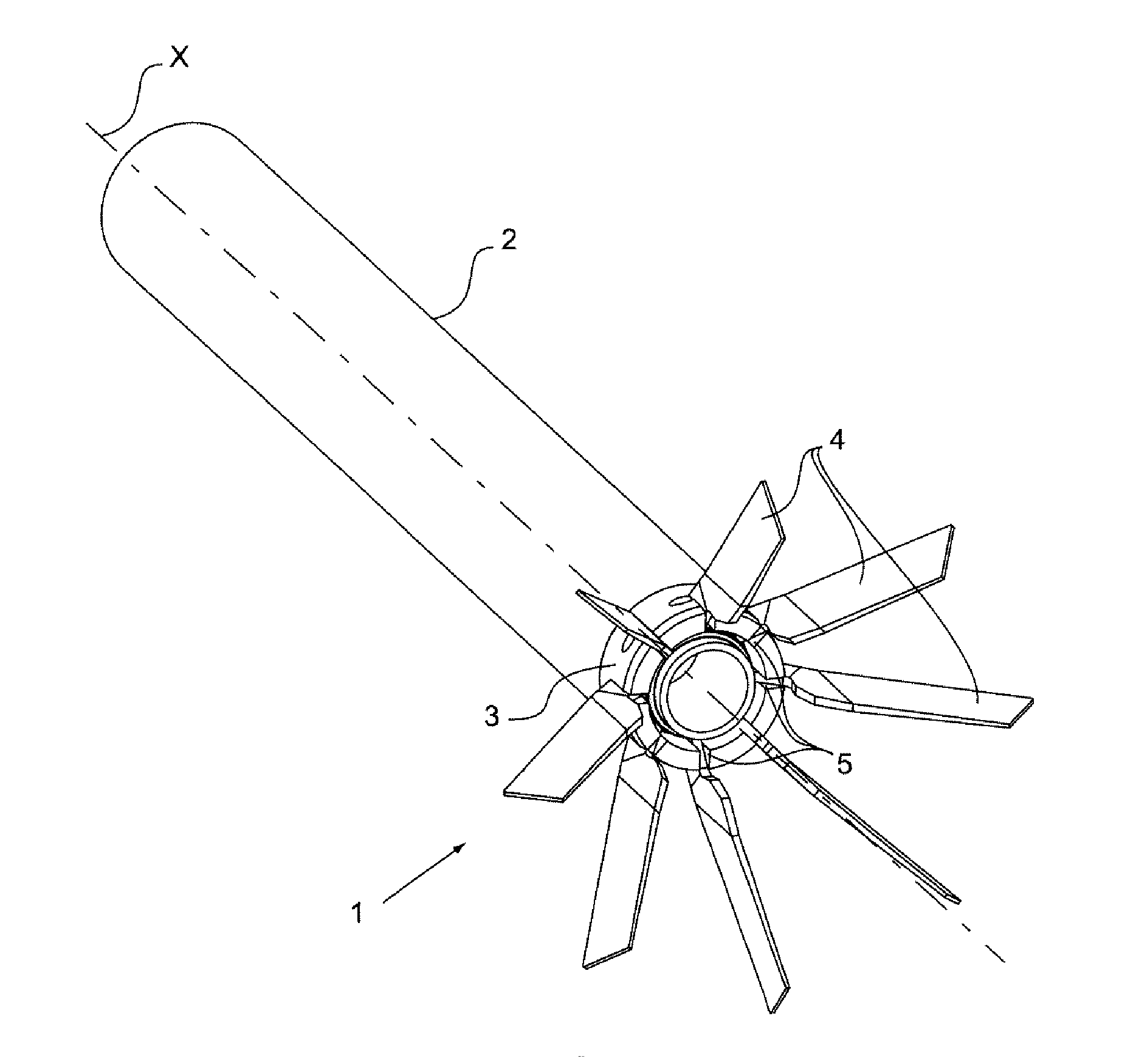

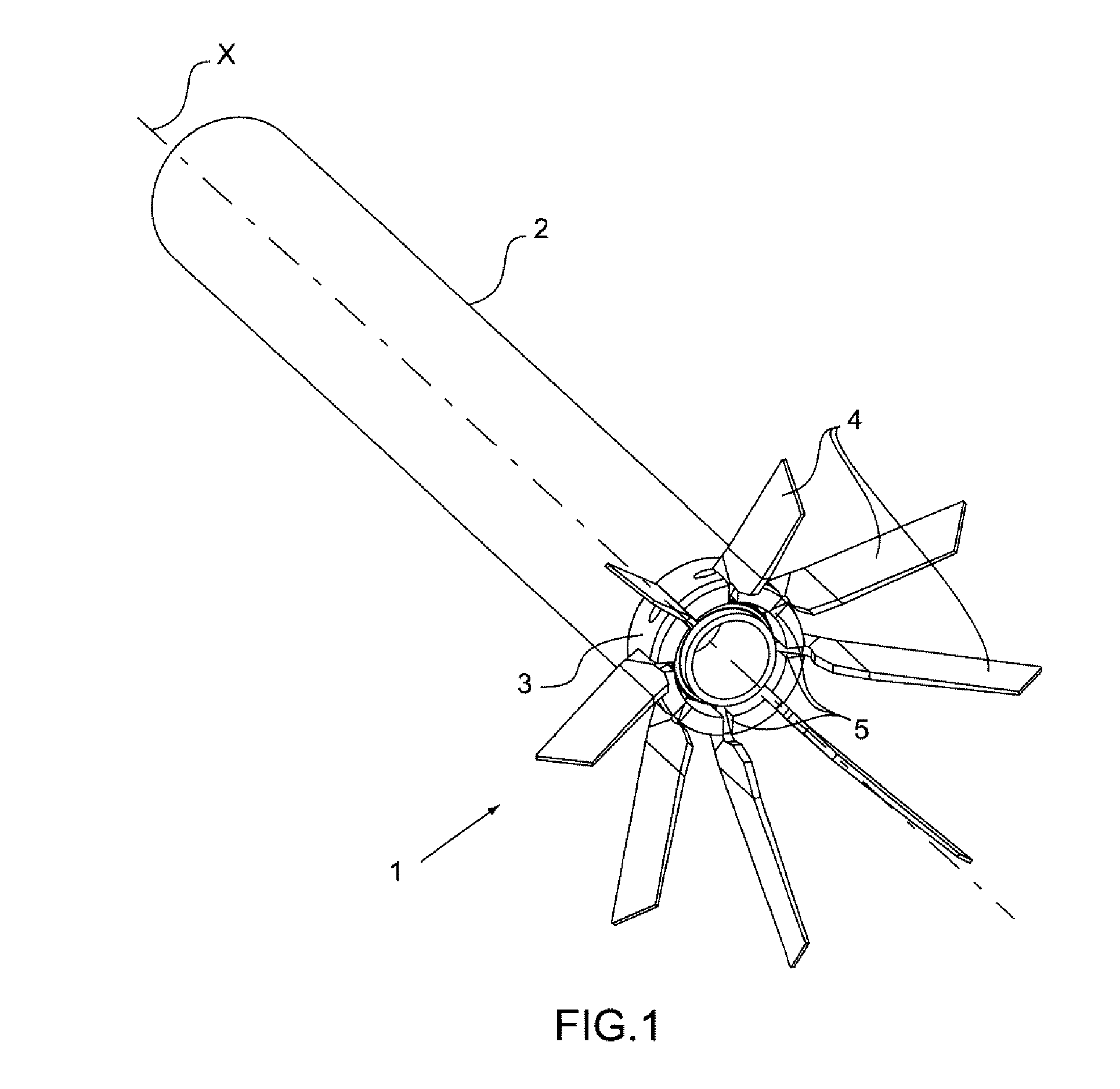

Device for Opening and Locking a Tail Unit for Ammunition

InactiveUS20100308153A1Simple designLimited clearanceSelf-propelled projectilesBearing surfaceEngineering

A device for opening and locking a tail unit is provided. The tail unit includes a body and at least one fin, pivotable relative to the body along a first axis, that has a projection that forms an element. The device comprises a control ring, slidable relative to the body along a second axis, that includes a component, forming an element, that bears against the projection to deploy the fin, the second axis being non-parallel and non-secant to the first axis. A means for shaping one of the elements during translation along the second axis of the control ring towards the projection of the fin is provided on the other element. The body includes a bearing surface to support the fin during shaping, in which the support of the fin on the bearing surface corresponds to the deployed position of the fin.

Owner:TDA ARMEMENTS

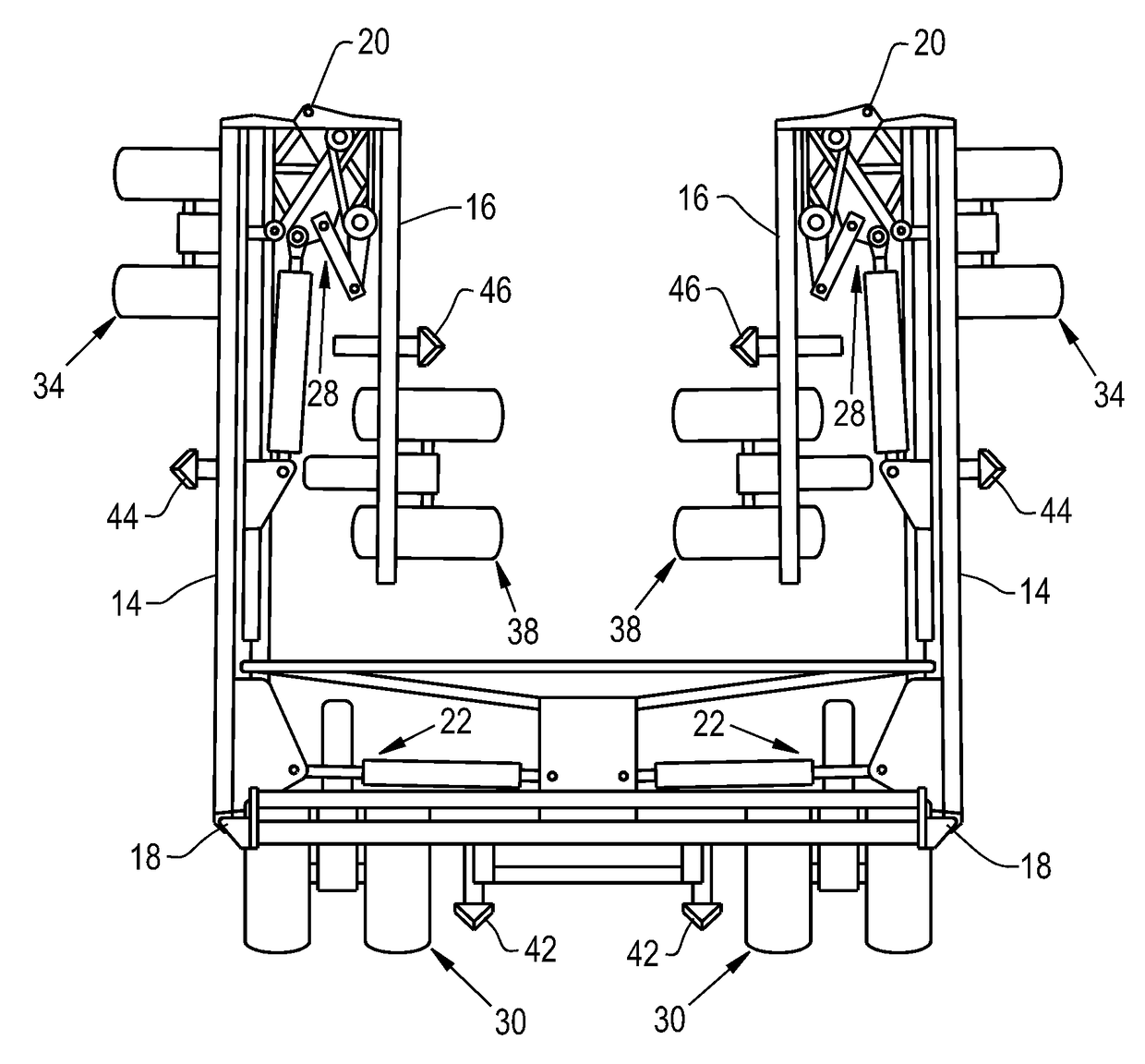

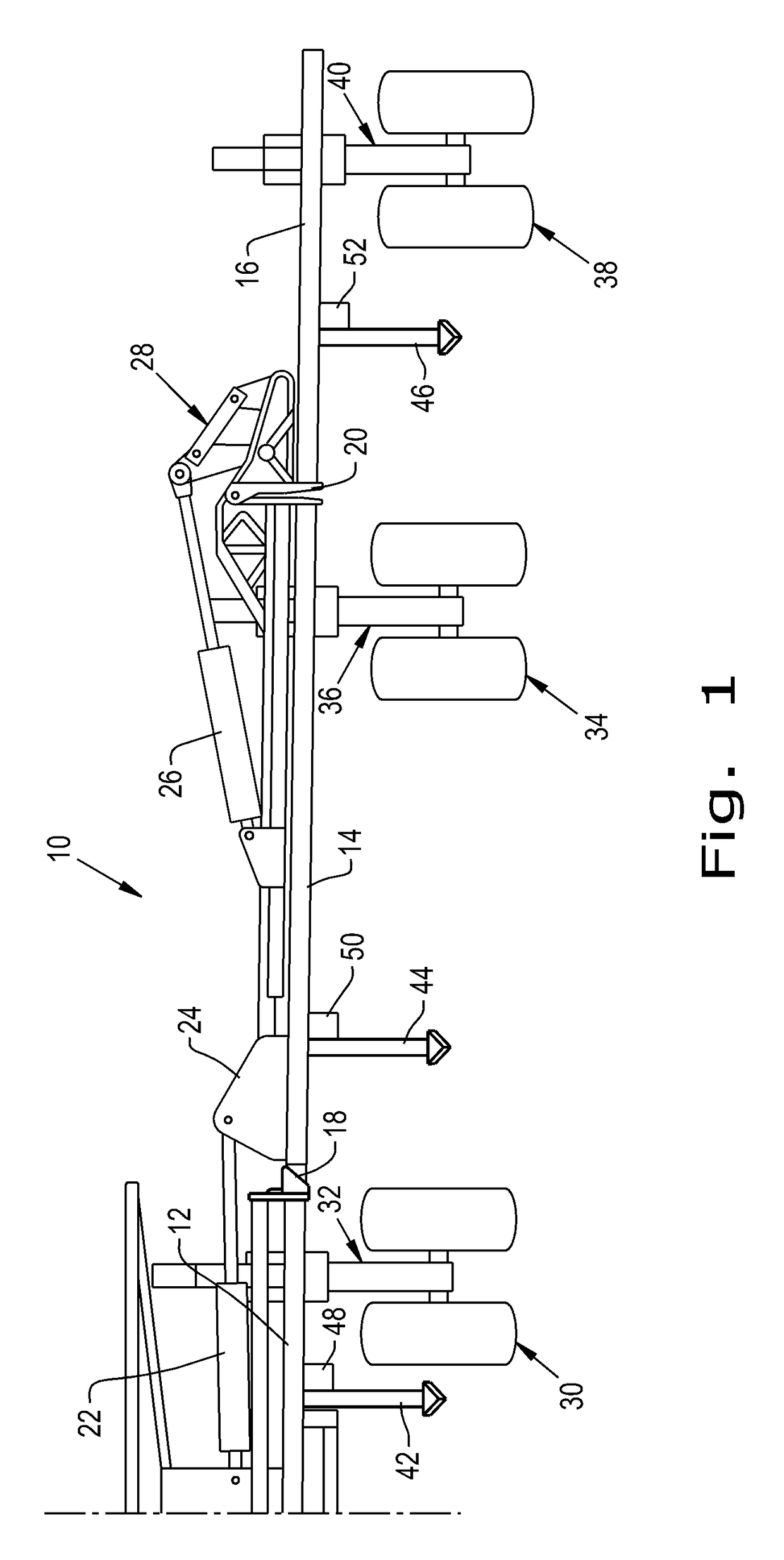

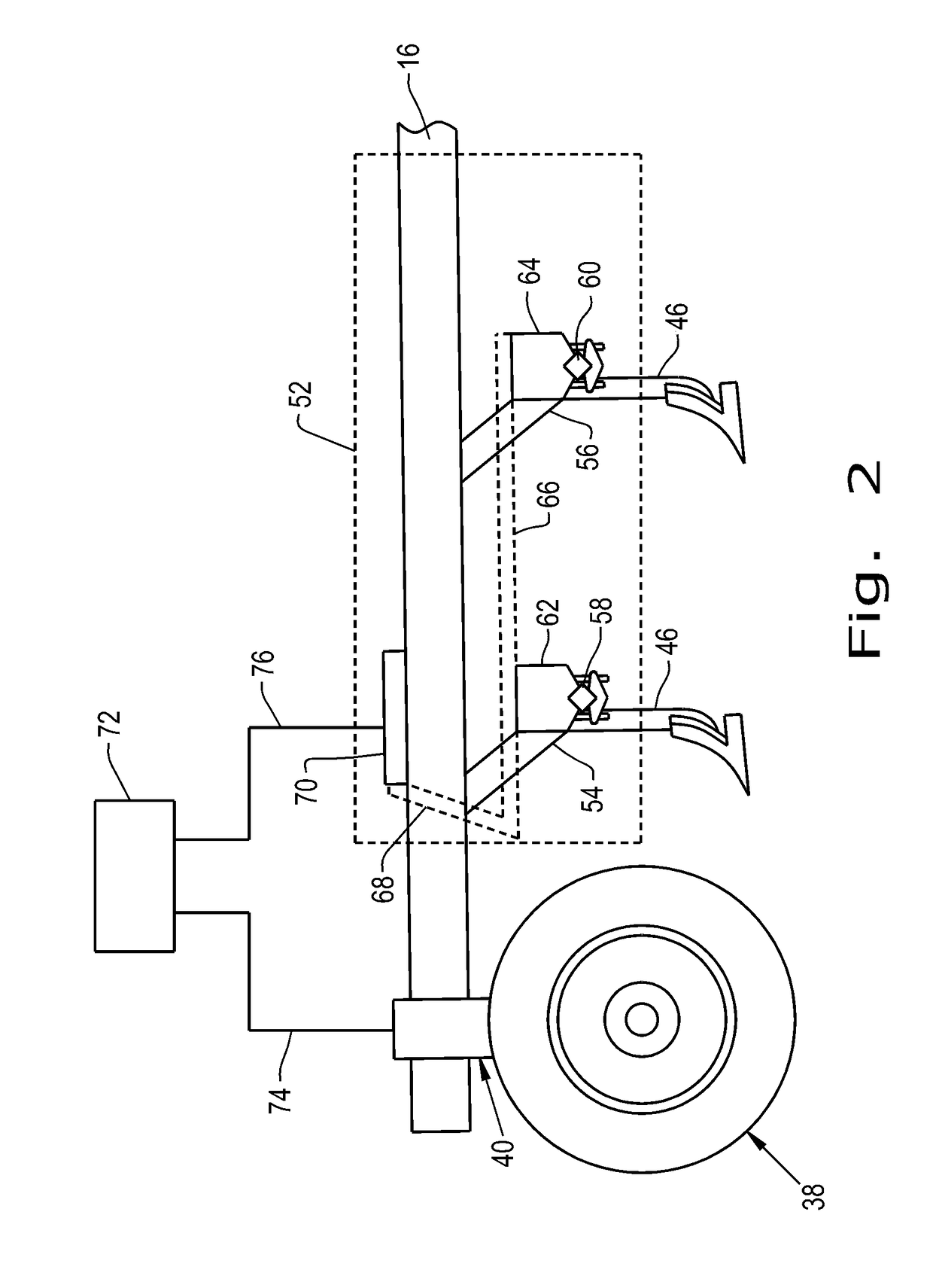

Apparatus and method to minimize transport dimensions of agricultural implements

InactiveUS20180070526A1Rapid and flexible shrinkingControl clearanceAgricultural machinesHarrowsEngineering

Owner:CNH IND CANADA

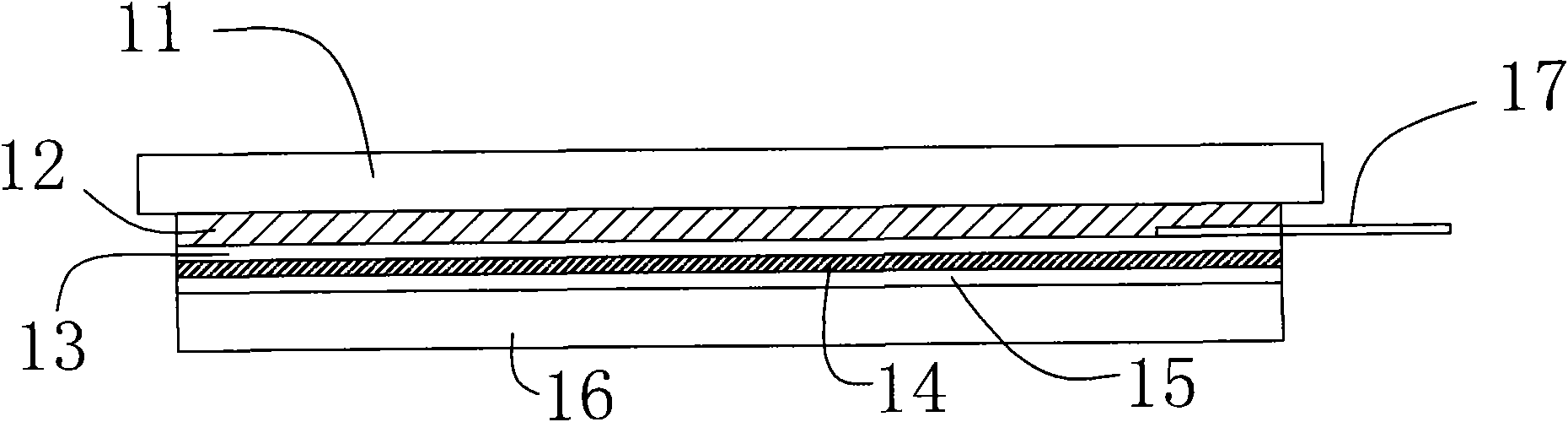

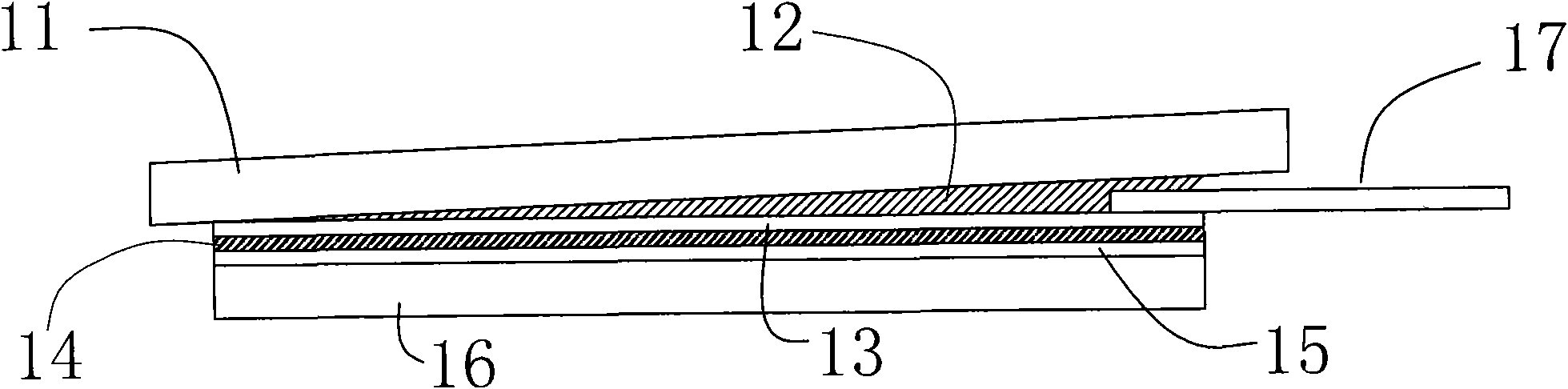

Capacitive touch screen and control method of thickness consistency thereof

InactiveCN101968703AControl clearanceGuaranteed flatnessInput/output processes for data processingFlexible circuitsEngineering

The invention provides a capacitive touch screen and a control method of thickness consistency thereof. The touch screen comprises an upper substrate and a lower substrate which are adhered together through an adhering agent, wherein the adhering agent contains a spacing agent with particle diameter between 2mum and 2mm. The control method sequentially comprises the steps of: adding the adhering agent and the spacing agent on the upper substrate or on the surface of the lower substrate with a flexible circuit board; then adhering the upper substrate and the lower substrate together and ensuring that glue is dispersed and leveled to fill in the adhering surface of the upper substrate and the lower substrate; and curing and preparing the capacitive touch screen, wherein the spacing agent can be firstly dissolved in the solution and can also be directly sprayed on the surface of substrate subjected to dipping the glue, and the spacing agent is mixed with the glue and then dripped or printed on the surface of the substrate. Because of adding the spacing agent with selective particle shape and diameter, the flatness of the two substrates of the touch screen is controlled within not more than + / -1mum, the gap of the two substrates is controlled between 2mum and 2mm, and the thickness consistence of the touch screen can be controlled within not more than + / -0.05mm.

Owner:深圳市中显微电子有限公司

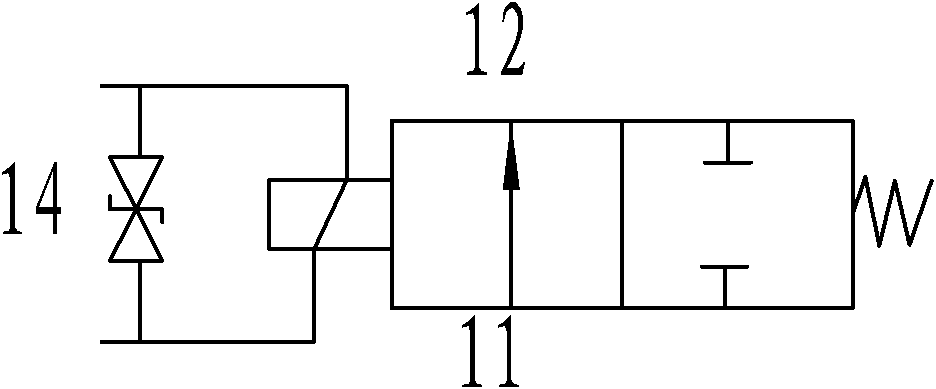

Two-way multifunctional electromagnetic valve

InactiveCN102588612AReduce volumeQuickly control on-offOperating means/releasing devices for valvesLift valveLiquid mediumEngineering

The invention belongs to a two-way multifunctional electromagnetic valve which comprises a valve body and an electromagnet part. The electromagnet part adopts a coil injection-molding assembly; and a TVS (transient voltage suppressor) pipe is arranged in the coil injection-molding assembly. The valve adopts a valve core structure that springs are embedded in a static magnetic core and a dynamic magnetic core and a structure that the static magnetic core is combined with a metal sleeve, has the structure characteristics that a rubber sealing layer at the front end of the dynamic magnetic core simultaneously separates a medium inlet and a medium outlet of the valve body and the medium inlet and the medium outlet are exchangeable, and is an electromagnetic valve which can simultaneously controlled by a direct current signal and a direct current pulse electric signal and further can be simultaneously applicable to a gas medium or a liquid medium, and the medium inlet and the medium outlet of the valve can be used in an exchangeable way.

Owner:WUHAN DONGJIANG FEITE SCI & TECH CO LTD

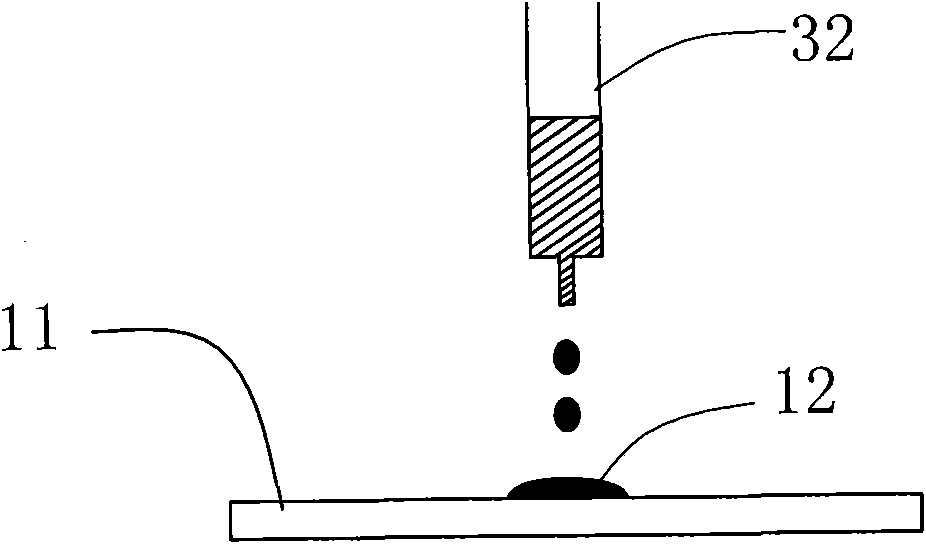

Method for controlling gaps of laser fusion weld plates of aluminum alloy vehicle bodies

InactiveCN106041308AControl clearanceGuarantee welding qualityWelding/soldering/cutting articlesLaser beam welding apparatusOptoelectronicsAluminium alloy

The invention discloses a method for controlling gaps of laser fusion weld plates of aluminum alloy vehicle bodies. Overlap regions are formed between outer plates and inner plates of the laser fusion weld plates, laser fusion weld seams penetrate the overlap regions, and the inner plates and the outer plates are welded with one another. The method for controlling the gaps of the plates is characterized by comprising steps that protrusions are formed on the outer surfaces of the inner plates in the overlap regions, the outer surface of each inner plate refers to the surface of the side, where the corresponding outer plate is located, of the inner plate, the gaps keep in the overlap regions between the clamped outer plates and the clamped inner plates by the aid of the protrusions in laser fusion weld procedures, and the heights of the gaps are the heights of the protrusions. The method has the advantages that the gaps of the laser fusion weld plates can be effectively controlled by the aid of the method, uniform gaps for exhausting hydrogen can be stably formed, and accordingly the weld quality can be guaranteed.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

LED optical structure for car lamps

InactiveCN104696846AContinuous lighting effectReduced distance restrictionsVehicle headlampsPoint-like light sourceLight guideEffect light

The invention discloses an LED optical structure for car lamps. The LED optical structure comprises a pattern structural face which is arranged on the front face of an LED lamp body and used for diffusing light types and an LED light source which is arranged behind the LED lamp pattern structural face. The LED optical structure is characterized in that a light guide inner lens is arranged right behind the LED lamp pattern structural face; the LED light source is arranged on one side of the light guide inner lens, namely, the LED light source is arranged on the rear side of the LED lamp pattern structural face; and a reflecting surface with a free curved surface is formed in the side, corresponding to the LED light source, of the light guide inner lens to ensure that the light from the LED light source reaches the LED lamp pattern structural face of the light guide inner lens after being totally reflected on the reflecting surface with the free curved surface. According to the LED optical structure for car lamps, the composite lighting effects of light sources with different colors are continuous and uniform so as to form continuous and uniform light emitting light bands.

Owner:HASCO VISION TECHNOLOGY CO LTD

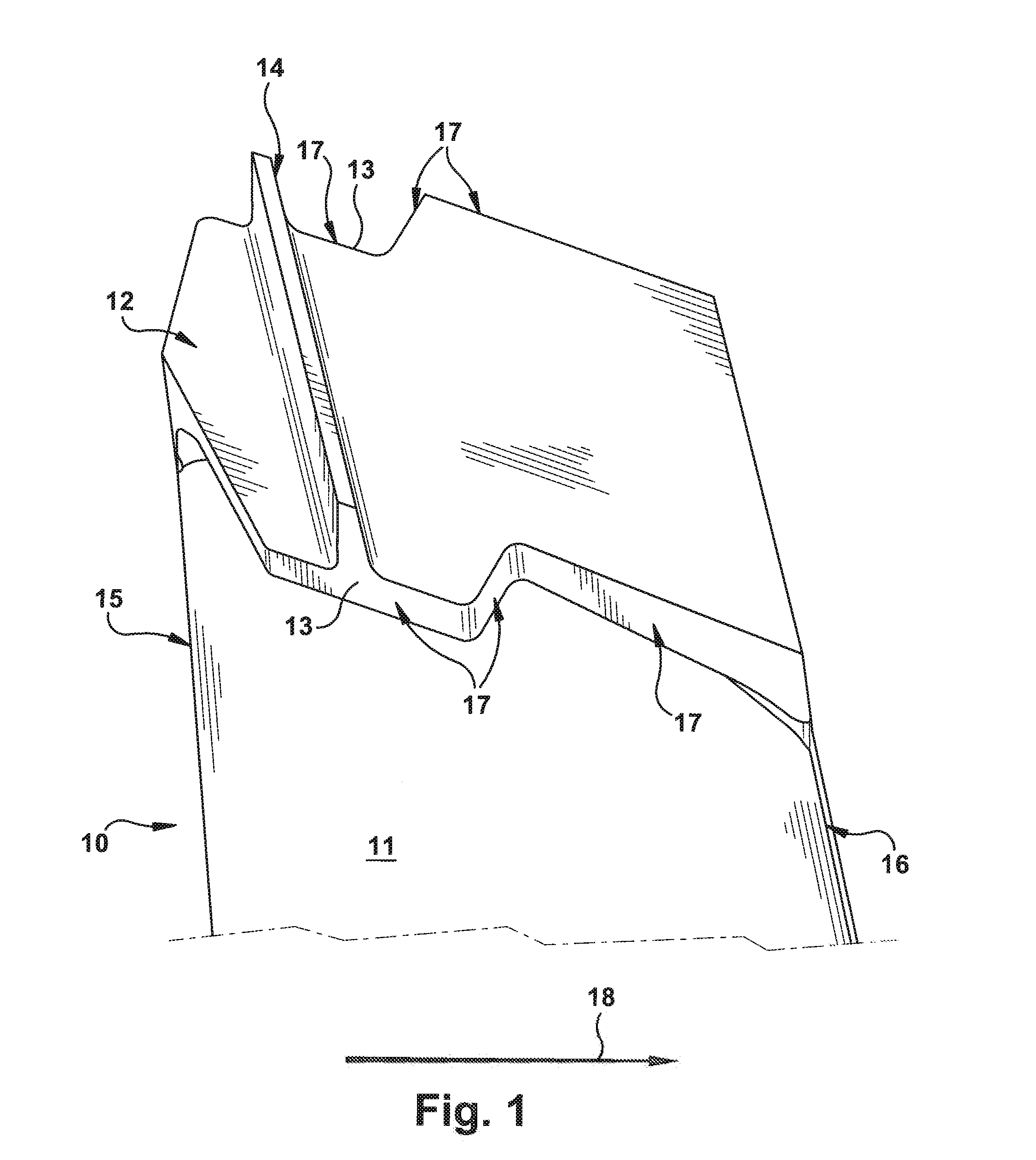

Perforated turbine bucket tip cover

InactiveUS20130259691A1Control flowControl clearancePropellersPump componentsEngineeringLeakage flow

An airfoil with a tip cover surface treatment for reducing leakage flows, minimizing tip vortex size and penetration into main flow that will improve turbine efficiency. The surface treatment for the airfoil tip covers includes a series of concave shapes, such as grooves or holes. These grooves and holes will cause the leakage flow into separate flow paths within the cavities and generate more resistance to leakage flows through the airfoil tip clearance, thereby reducing the leakage mass flow and weakening tip vortex and its interaction with turbine main flows. The material removed from the tip cover provides the additional benefit of reducing the weight of the tip cover, thereby enhancing blade reliability.

Owner:GENERAL ELECTRIC CO

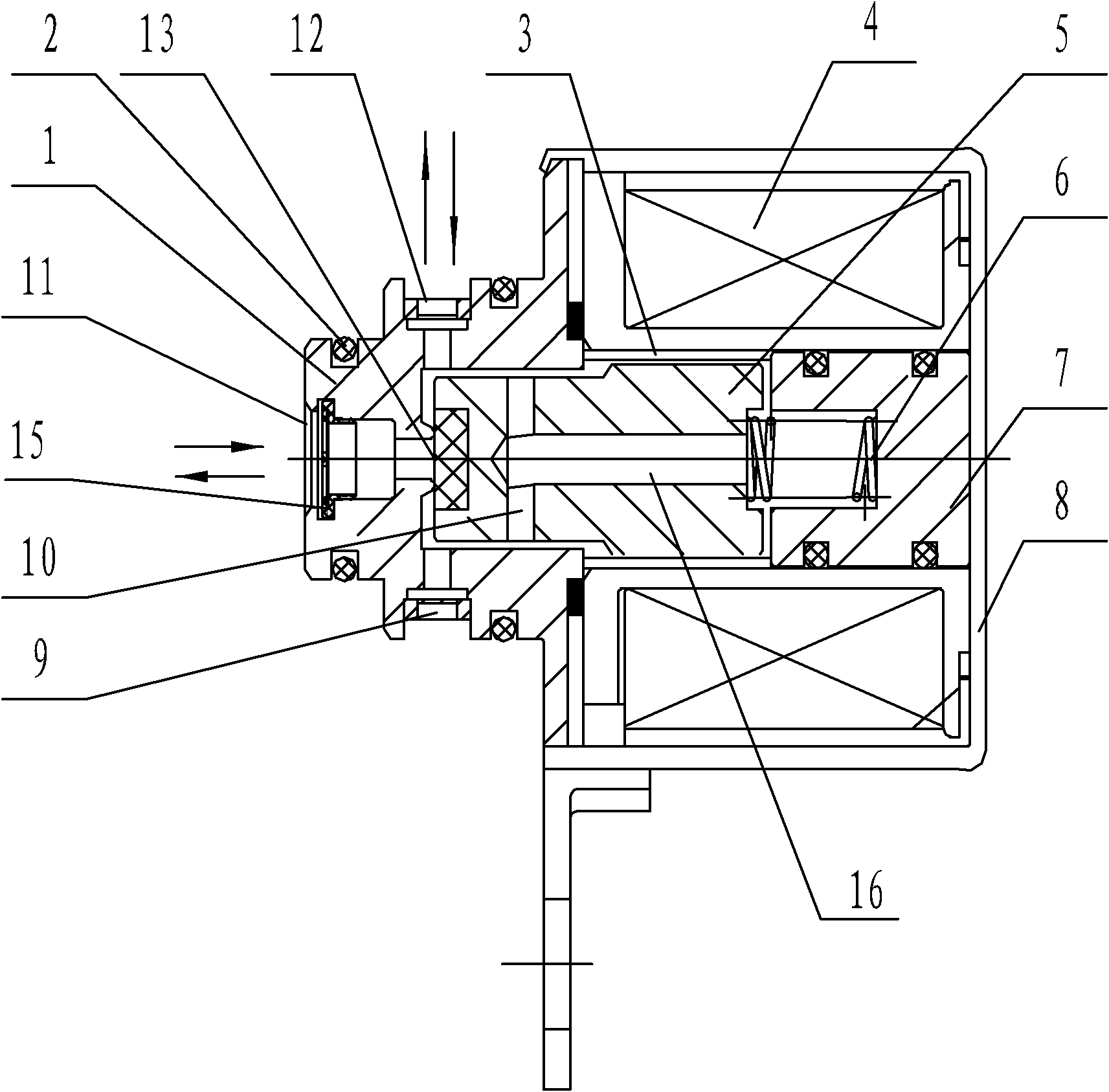

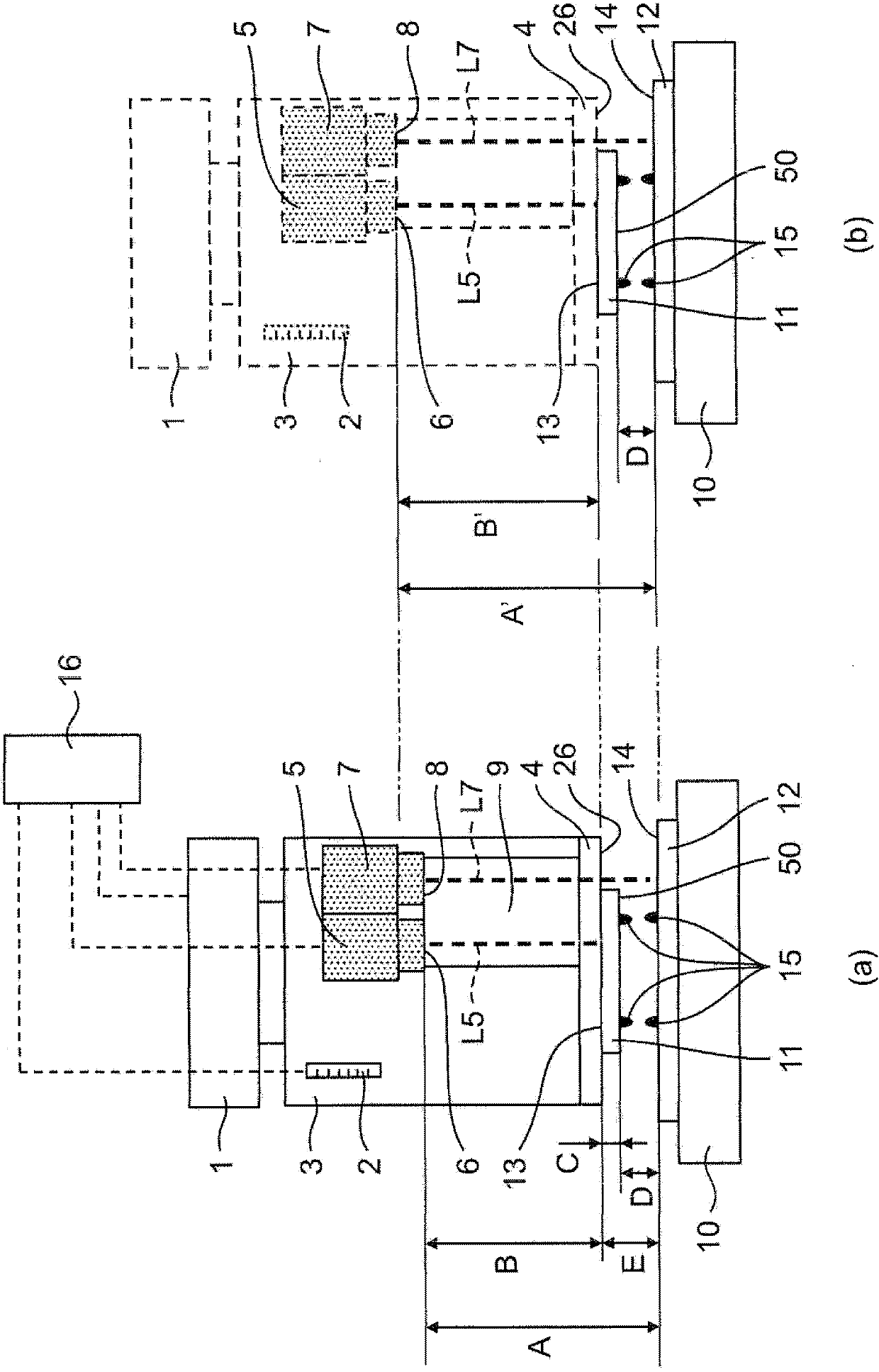

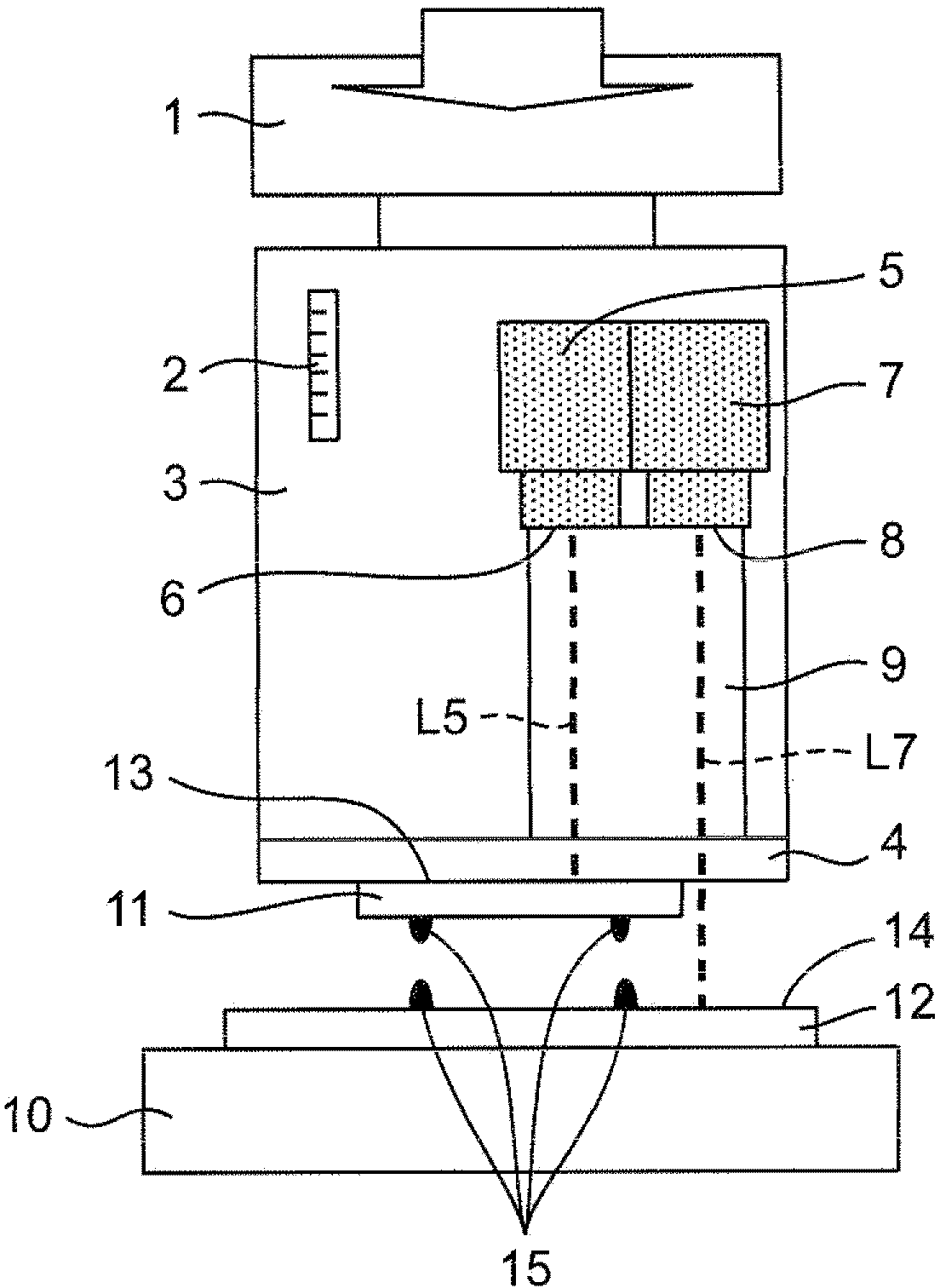

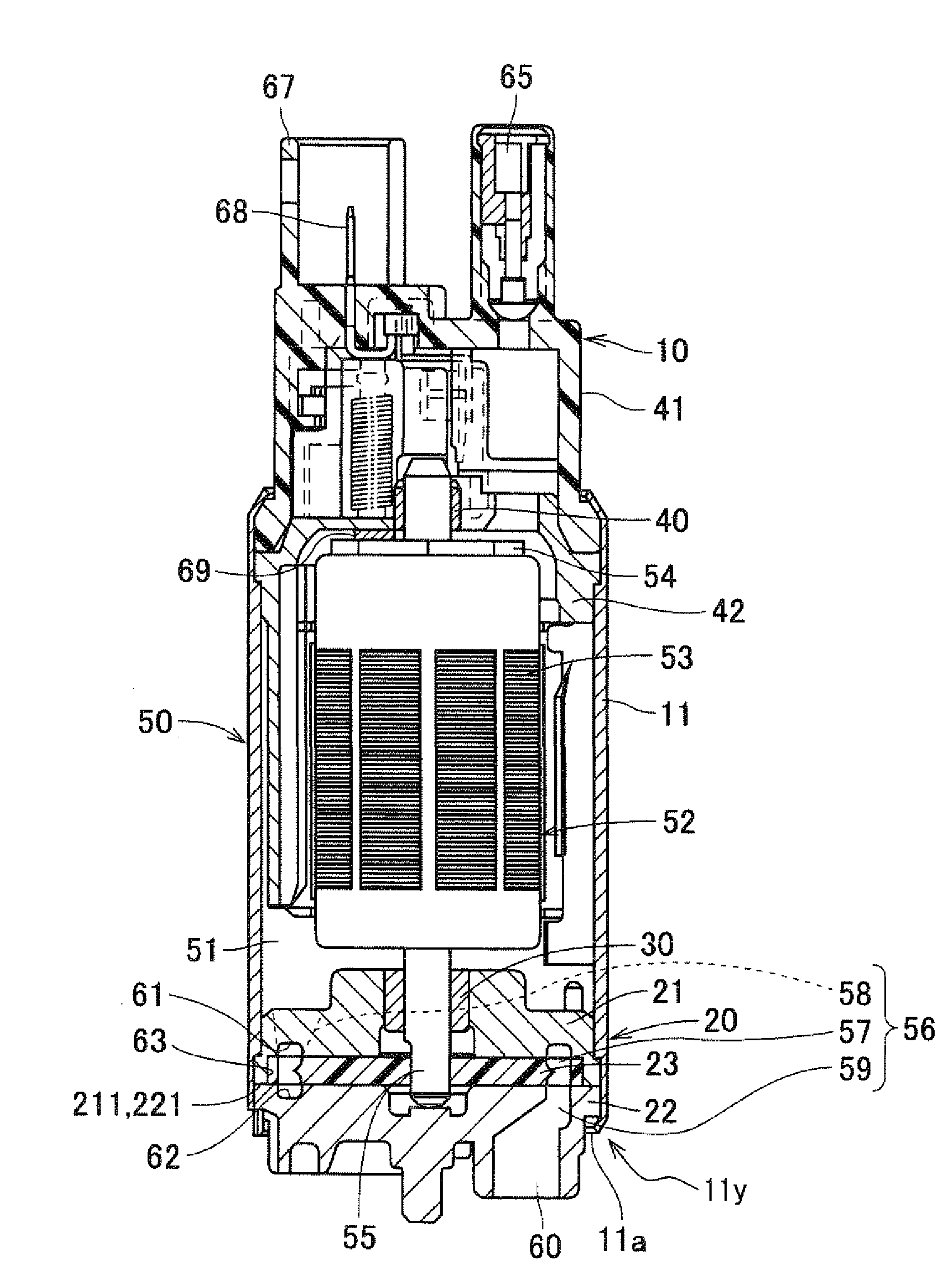

Member mounting method and mounting device

ActiveCN104185384AControl clearancePrinted circuit assemblingElectrical componentsThermal expansionComputer engineering

The present invention aims for providing a mounting method and a mounting device of a member which is capable of mounting gaps of mounting members in high precision without being influenced by a technology in which temperature change of a mounting device exists or thermal expansion of the mounting device caused by long time driving. A distance (B) to a mounting member (11) and the distance from a substrate (12) to the upper surface (14) are measured in the mounting process, and control and mounting are carried out in such a way that the interval (D) of the member is calculated to be a preset value.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

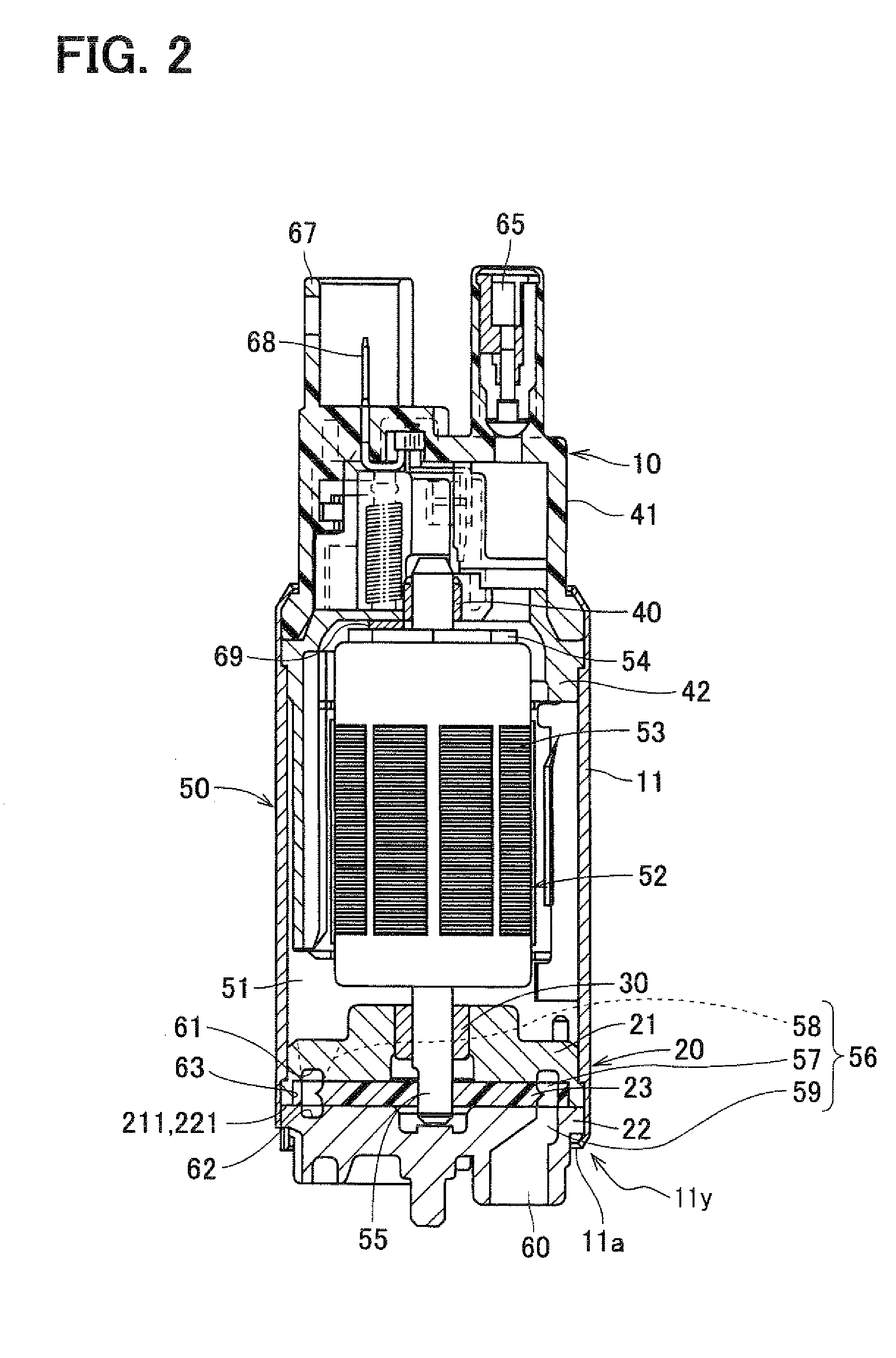

Method and apparatus for manufacturing fuel pump

A cover is inserted into a housing of a fuel pump. Then, a housing-side engaging portion of the housing, which is located at a peripheral edge of an opening of the housing, is heated with a heating means. Thereafter, the housing-side engaging portion is swaged by a punch toward the cover to fix the cover to the housing.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com