Wedge-type gap adjustment mechanism of plastic sheet calender

A technology of gap adjustment mechanism and plastic sheet, which is applied to flat products, household appliances, other household appliances, etc., can solve the problems of inconvenient operation, difficult to control deviation, large number of waste products, etc., and achieves shortened time, reasonable structure and performance, The effect of reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

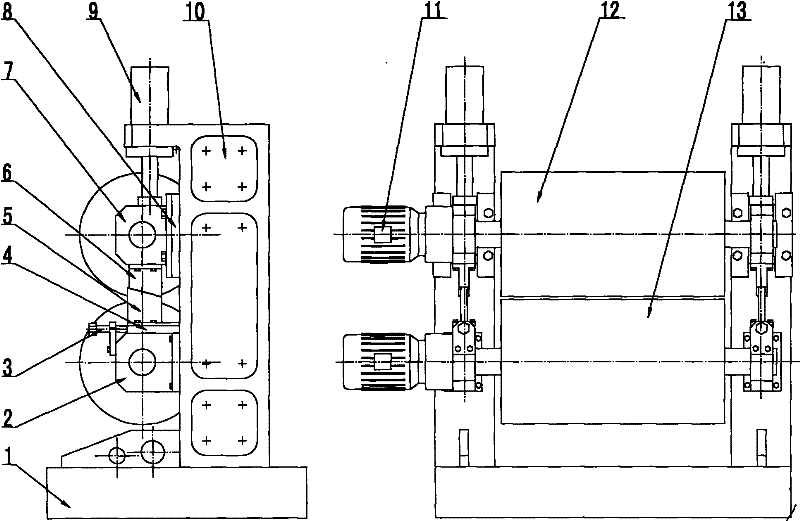

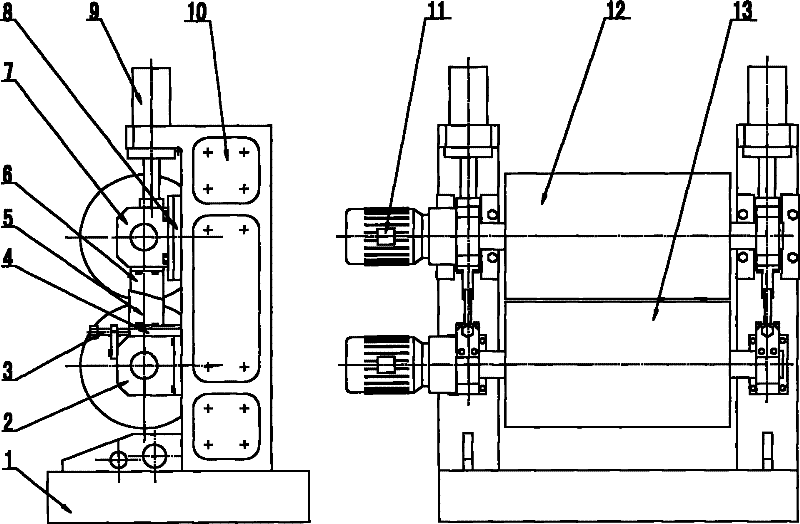

[0011] Two wallboards (10) on the left and right are fixed on the frame (1) to become the body of the calender, and the bottom angle of the lower bearing seat (2) is fixed with the wallboard (10) by bolts and cannot be moved. The upper bearing seat (7 ) has a dovetail grass groove guide rail at the bottom, which cooperates with the lower track (8) of the upper bearing seat and can move up and down in the track of the lower track (8) of the upper bearing seat. The lower track (8) of the upper bearing seat is connected to the wall plate ( 10) Fixed and cannot be moved, the upper roller (12) and the lower roller (13) are respectively supported on the bearings of the upper bearing seat (7) and the lower bearing seat (2) through the roller shaft, and the upper and lower rollers are respectively Driven by two independent driving motors 11, it can be rotated to carry out calendering production of plastic sheets. The upper side of the upper bearing seat (7) is connected with the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com