Control system of prefabricated bag packing machine

A control system and prefabricated bag technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items, can solve the problems of many packaging actions, low packaging efficiency, and poor packaging effects, and achieve a high degree of continuous material pushing and improve packaging. The effect of high efficiency and packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

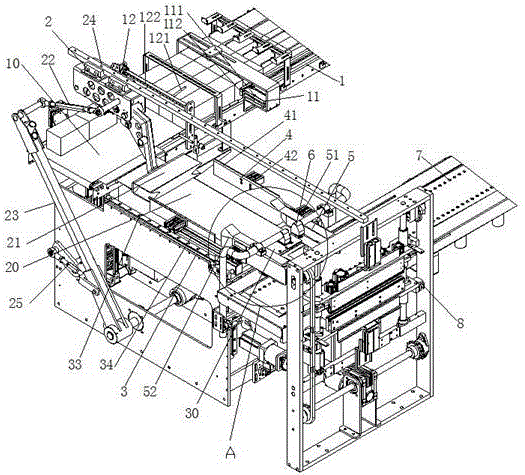

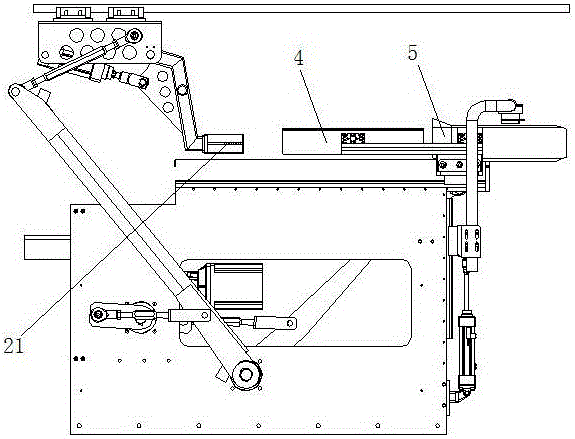

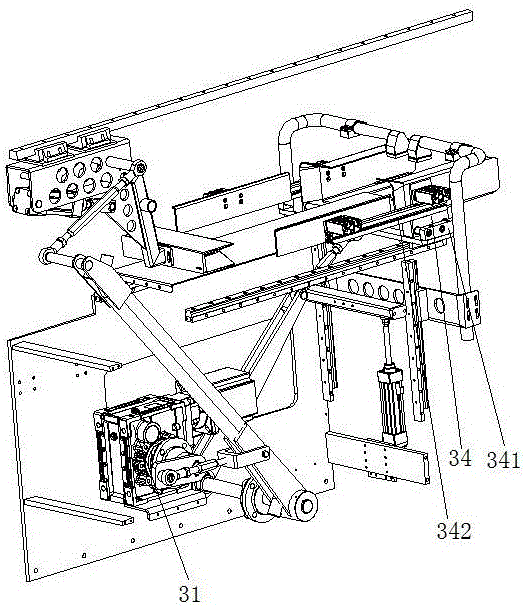

[0093] This embodiment discloses a control system for a prefabricated bag packaging machine, including a feeding mechanism 1, a material pushing mechanism 2, a bag stretching mechanism 5, a bag opening mechanism 6, and a bag feeding mechanism 7, as well as a clamping mechanism 4 and a translation mechanism 3 ;

[0094] The feeding mechanism 1 transports the material to 10 positions to be clamped;

[0095] Driven by the translation mechanism 3, the clamping mechanism 4 clamps and transports the material transported to the station 10 to be clamped to the station 20 to be pushed;

[0096] While the feeding mechanism 1 or the clamping mechanism 4 is in action, the prefabricated bag is transported to the bag opening station 30 by the bag feeding mechanism 7, and the bag opening mechanism 6 opens the pocket of the prefabricated bag;

[0097] While the material is clamped and transported to the station 20 to be pushed, the bag opening mechanism 5 extends into the prefabricated bag a...

Embodiment 2

[0103] This embodiment discloses a control system for a prefabricated bag packaging machine, including a feeding mechanism 1, a material pushing mechanism 2, a bag stretching mechanism 5, a bag opening mechanism 6, and a bag feeding mechanism 7, as well as a clamping mechanism 4 and a translation mechanism 3 ;

[0104] The feeding mechanism 1 transports the material to 10 positions to be clamped;

[0105] Driven by the translation mechanism 3, the clamping mechanism 4 clamps and transports the material transported to the station 10 to be clamped to the station 20 to be pushed;

[0106] While the feeding mechanism 1 or the clamping mechanism 4 is in action, the prefabricated bag is transported to the bag opening station 30 by the bag feeding mechanism 7, and the bag opening mechanism 6 opens the pocket of the prefabricated bag;

[0107] While the material is clamped and transported to the station 20 to be pushed, the bag opening mechanism 5 extends into the prefabricated bag a...

Embodiment 3

[0112] This embodiment discloses a control system for a prefabricated bag packaging machine, including a feeding mechanism 1, a material pushing mechanism 2, a bag stretching mechanism 5, a bag opening mechanism 6, and a bag feeding mechanism 7, as well as a clamping mechanism 4 and a translation mechanism 3 ;

[0113] The feeding mechanism 1 transports the material to 10 positions to be clamped;

[0114] Driven by the translation mechanism 3, the clamping mechanism 4 clamps and transports the material transported to the station 10 to be clamped to the station 20 to be pushed;

[0115] While the feeding mechanism 1 or the clamping mechanism 4 is in action, the prefabricated bag is transported to the bag opening station 30 by the bag feeding mechanism 7, and the bag opening mechanism 6 opens the pocket of the prefabricated bag;

[0116] While the material is clamped and transported to the station 20 to be pushed, the bag opening mechanism 5 extends into the prefabricated bag a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com