Automatic assembling device for elements and assembling method thereof

An automatic assembly and component technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of lower assembly accuracy, lower product quality, long mechanism travel, etc., to improve accuracy, improve product quality, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

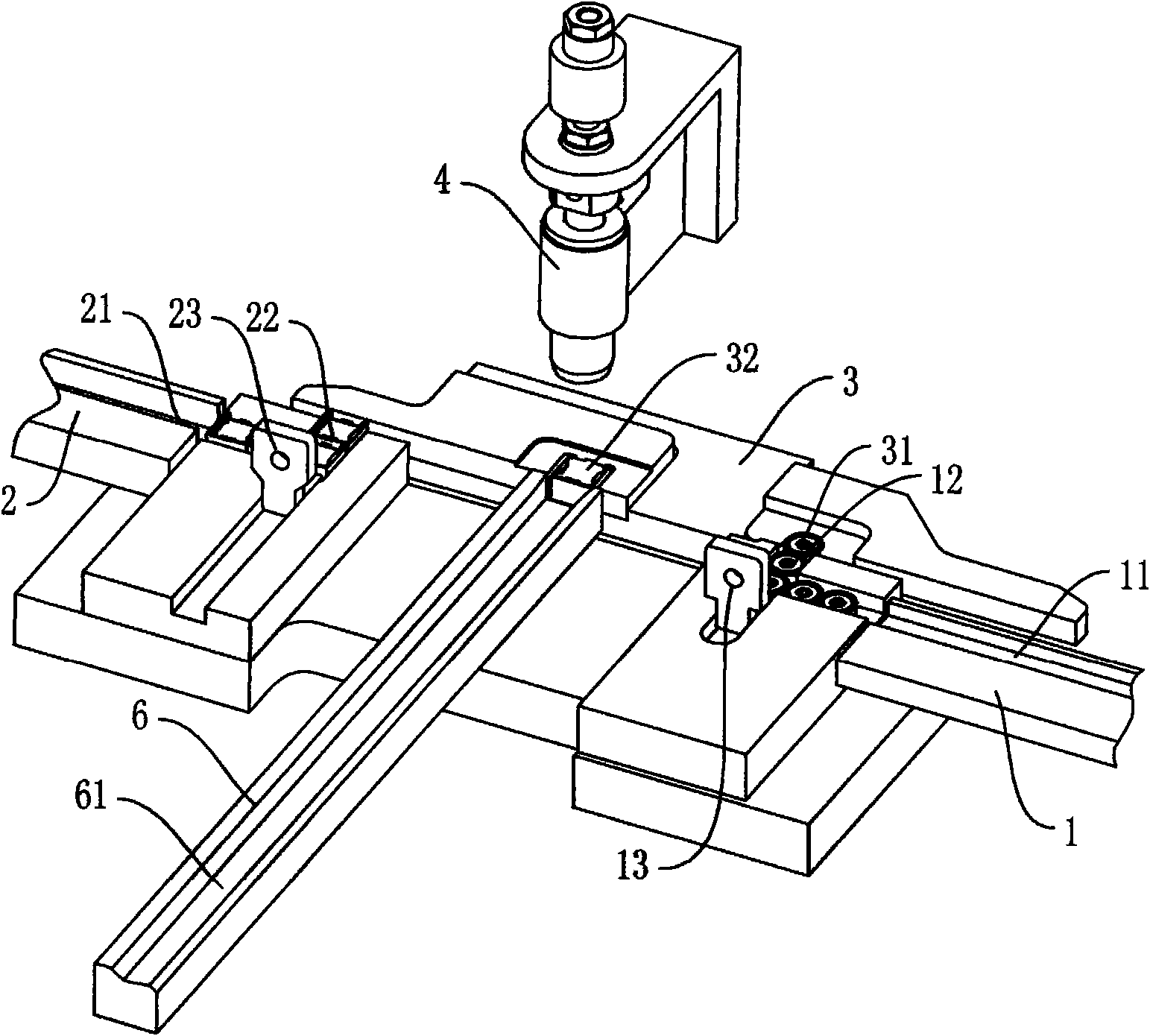

[0029] like figure 1 As shown, the component automatic assembly device is used for the assembly of two kinds of components, including: a reciprocating motion table 3, and the reciprocating motion table 3 is provided with a first component positioning storage device 31 and a second component positioning storage device 32, The first component positioning storage device 31 and the second component positioning storage device 32 are arranged along the reciprocating movement direction of the reciprocating worktable 3; the first component positioning storage device 31 has an outer terminal position and an inner terminal position of the reciprocating motion , the second component positioning storage device 32 has an outer end position and an inner end position of reciprocating movement, and the inner end position of the first component positioning storage device 31 coincides with the inner end position of the second component positioning storage device 32 The first component positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com