Horizontal pressure filter

A filter press, horizontal technology, applied in the field of horizontal automatic filter press, can solve the problems of wasting power, increasing costs, etc., and achieve the effect of simple structure, convenient maintenance, easy maintenance and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

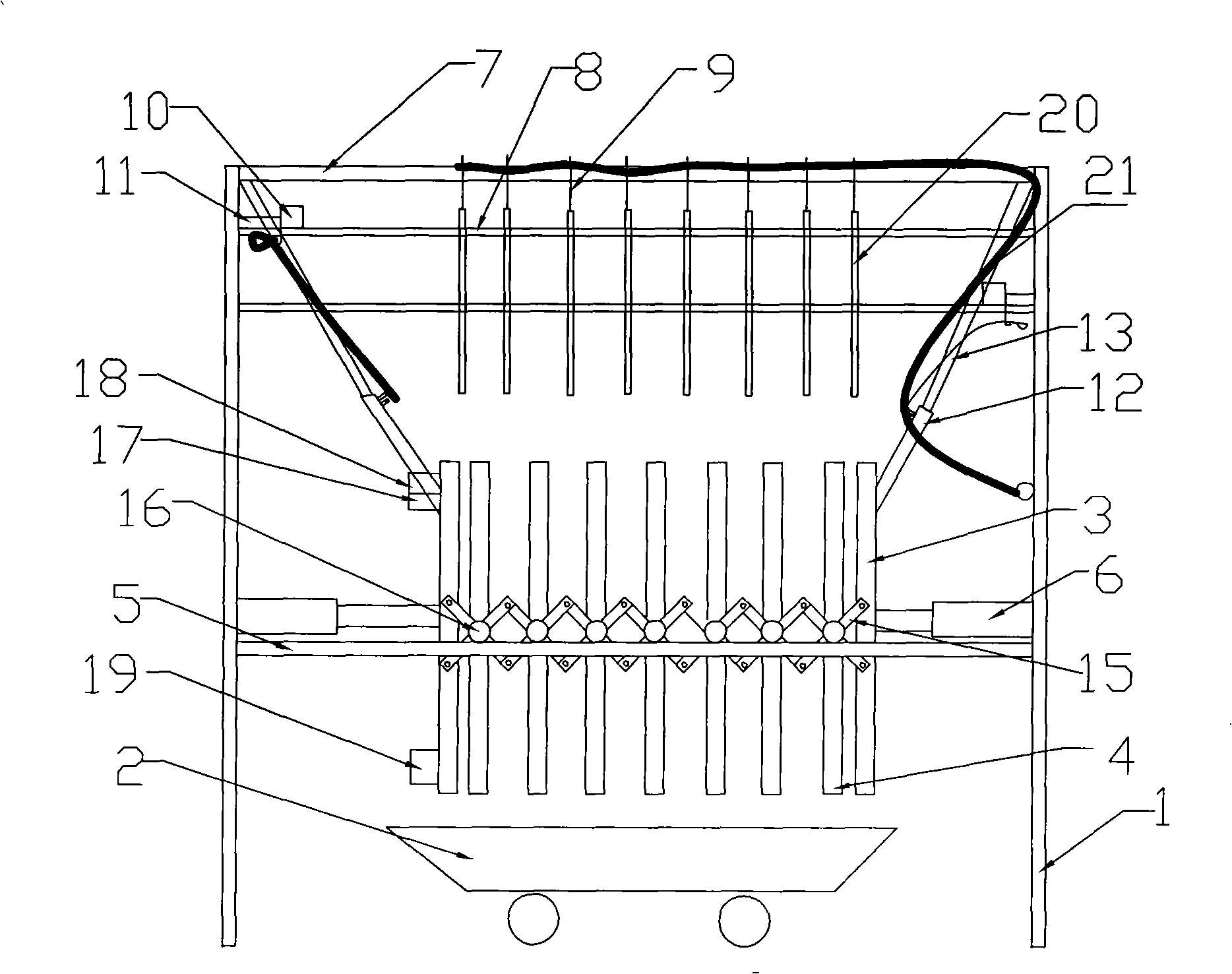

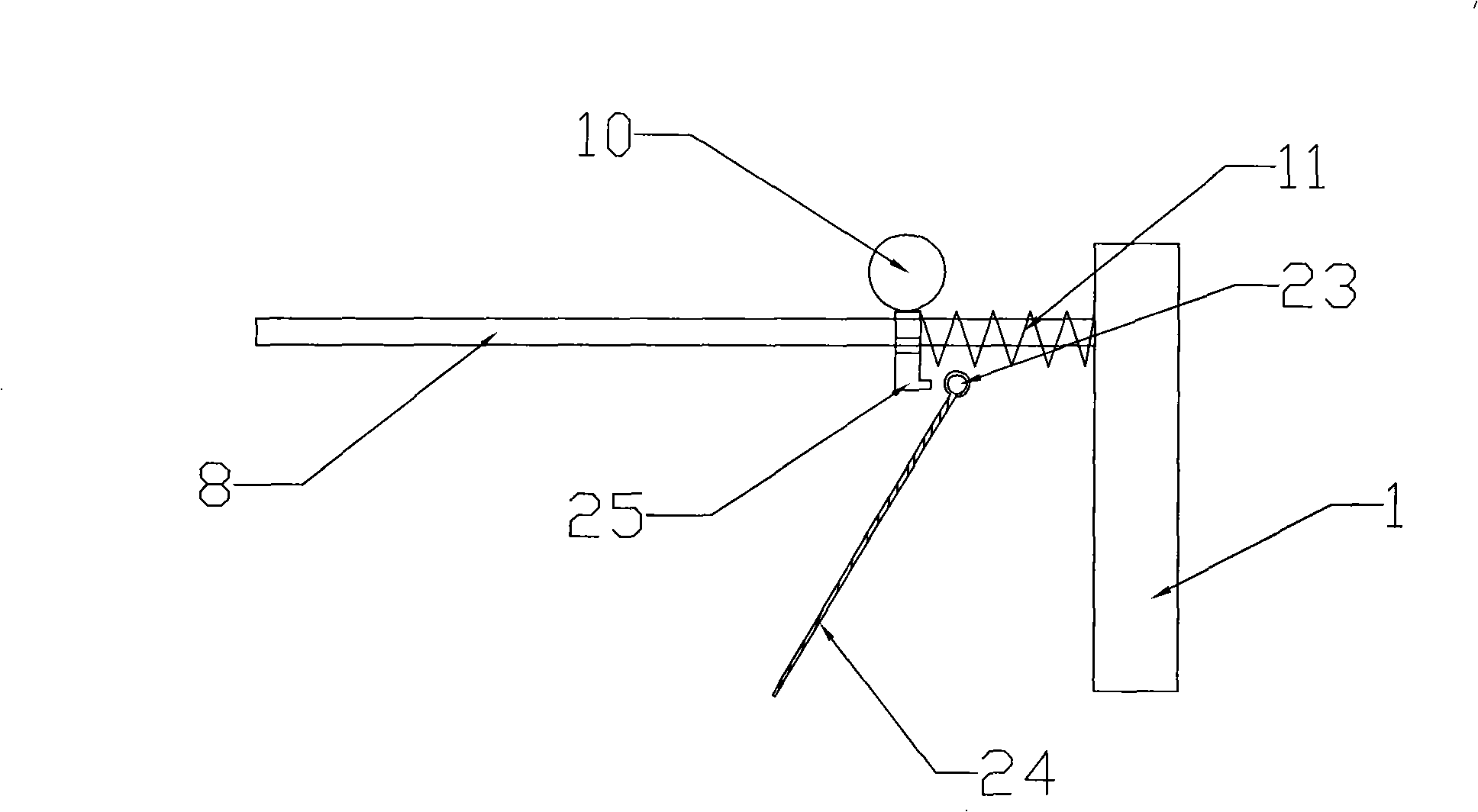

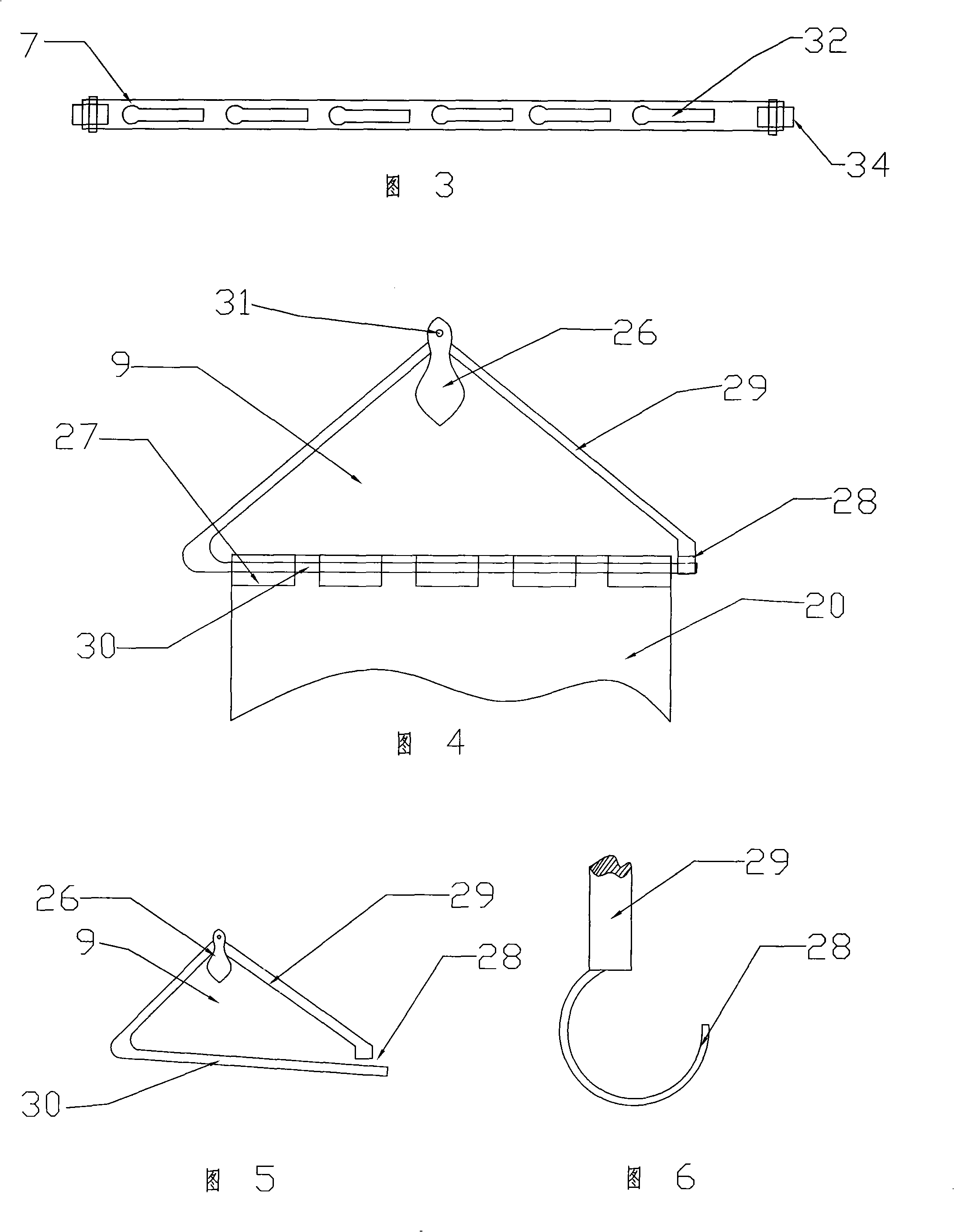

[0035] The present invention adopts the double hydraulic cylinder working mode, such as figure 1 As shown, the main body bracket 1 is composed of two side-by-side frames, two side-by-side guide rails 5 are arranged in the middle of the bracket 1 , and a water spray frame 8 is arranged on the upper part of the bracket 1 . Bearings or round irons 16 are installed on both sides of the plate frame 4, and are vertically framed side by side on the guide rail 5, and each plate frame is connected into a plate frame group by an "X" shaped connecting plate 15. like Figure 9 As shown, the "X"-shaped connecting plate 15 is composed of two connecting pieces 42 connected by a through-shaft at the center. 15 is located between the plate frame 4 and the bearing or round iron 16, the two ends of the "X" shaped connecting plate 15 of the adjacent plate frame 4 are connected together by the pin 43, and the plate frame 4 and the extruded plate 3 are also connected by the "X" ""-shaped connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com