Patents

Literature

158results about How to "Mobile and flexible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

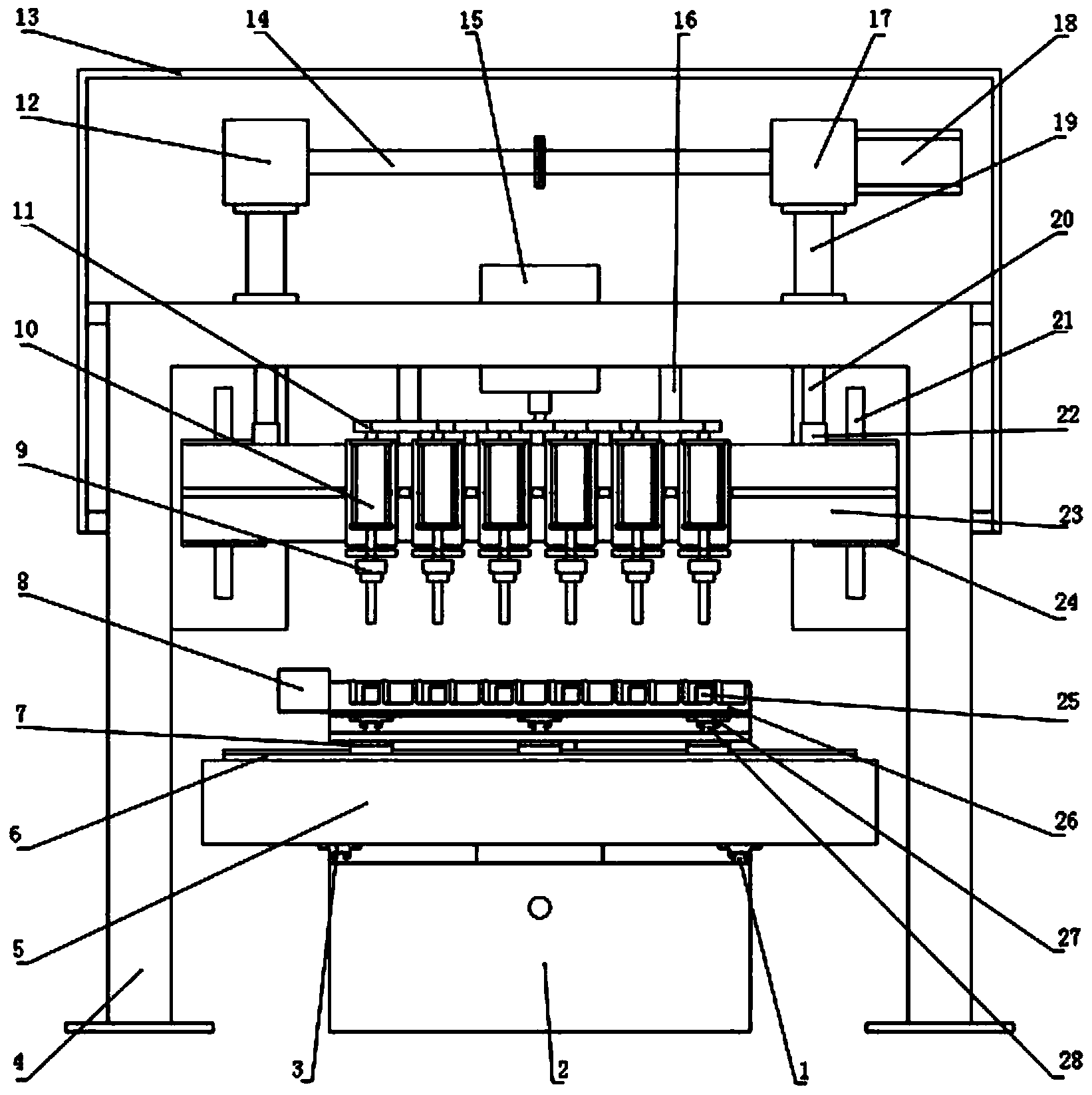

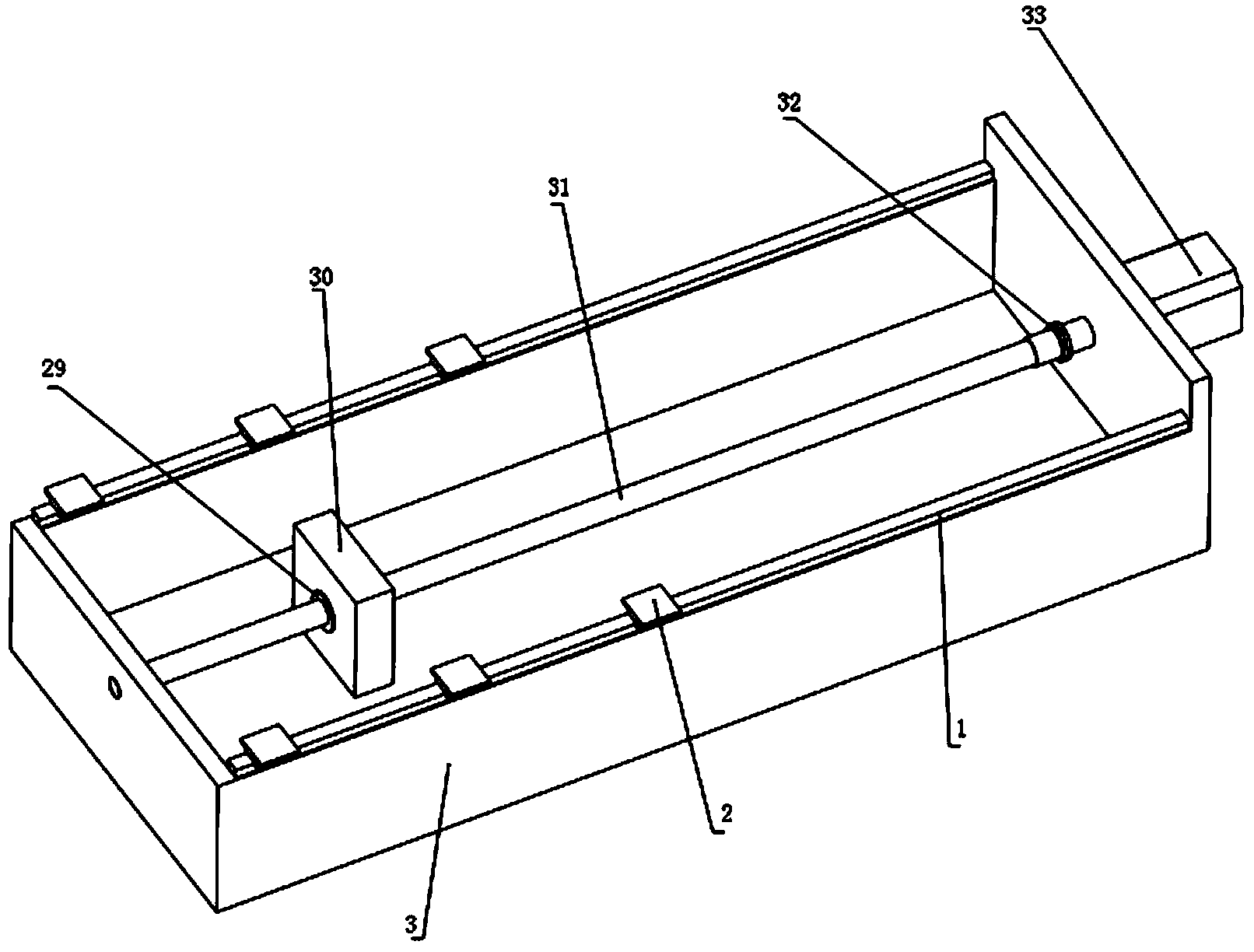

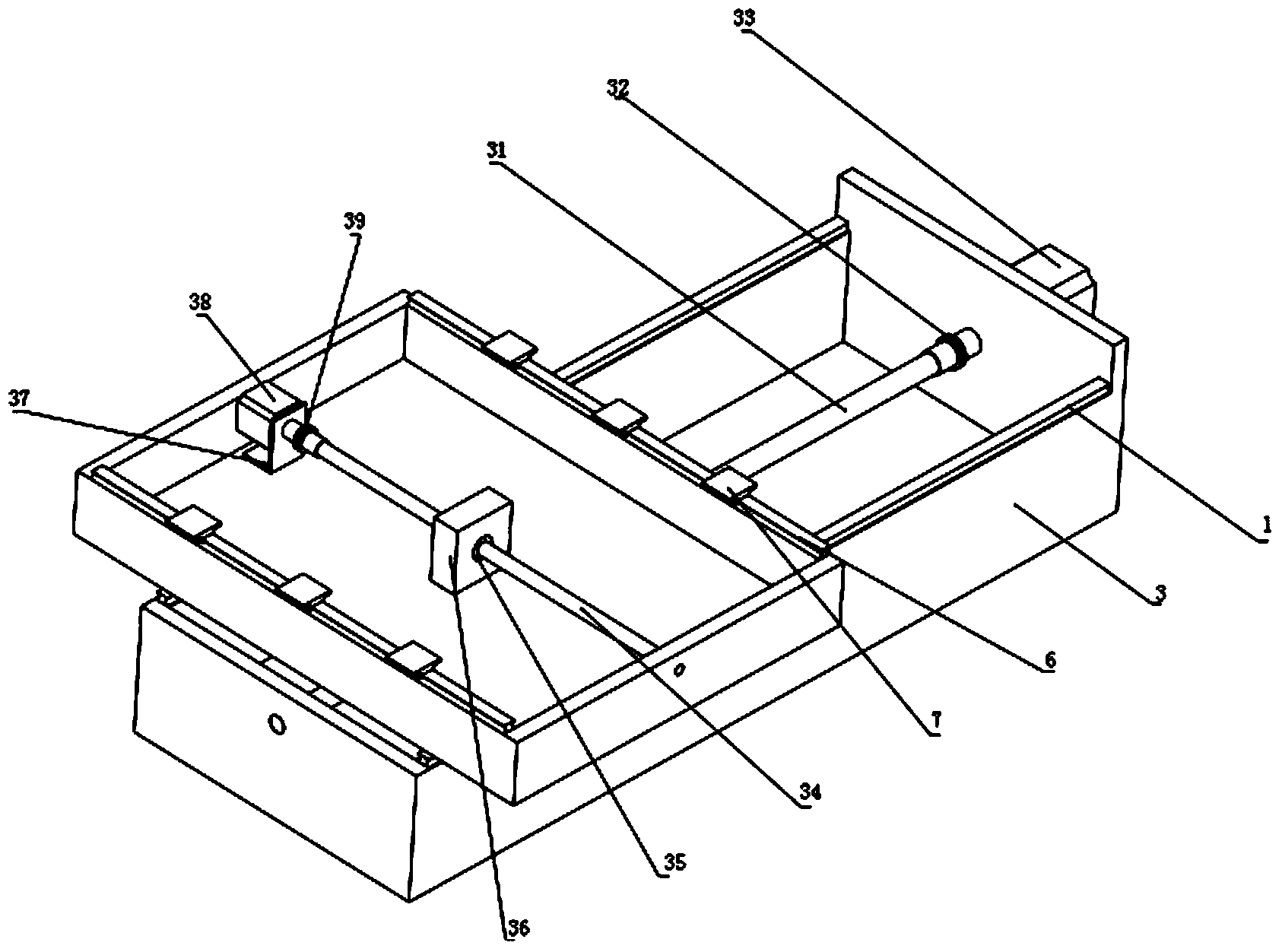

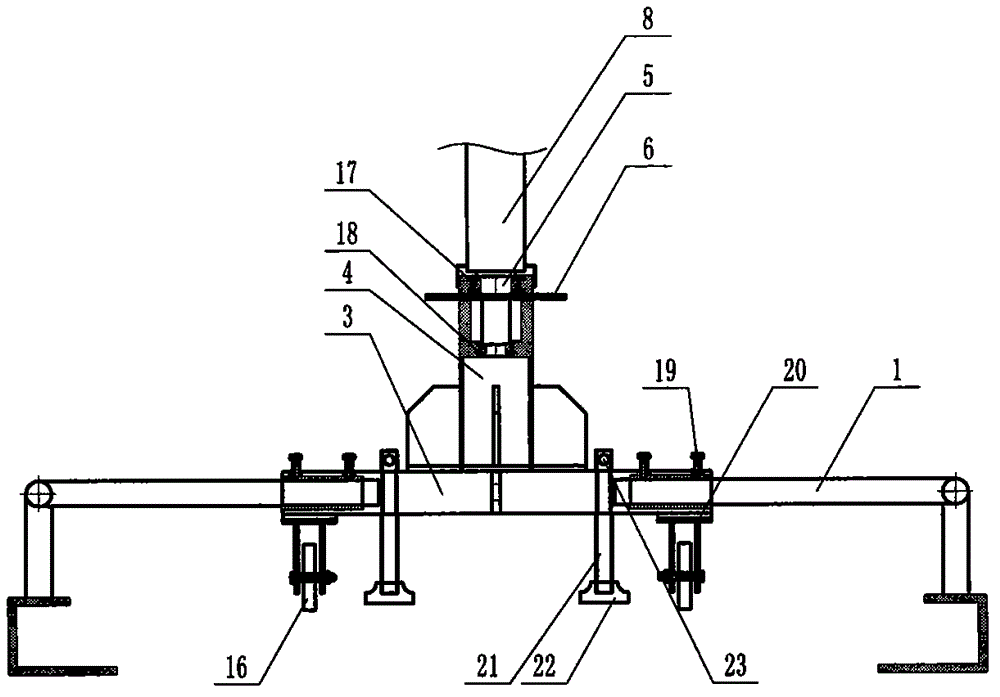

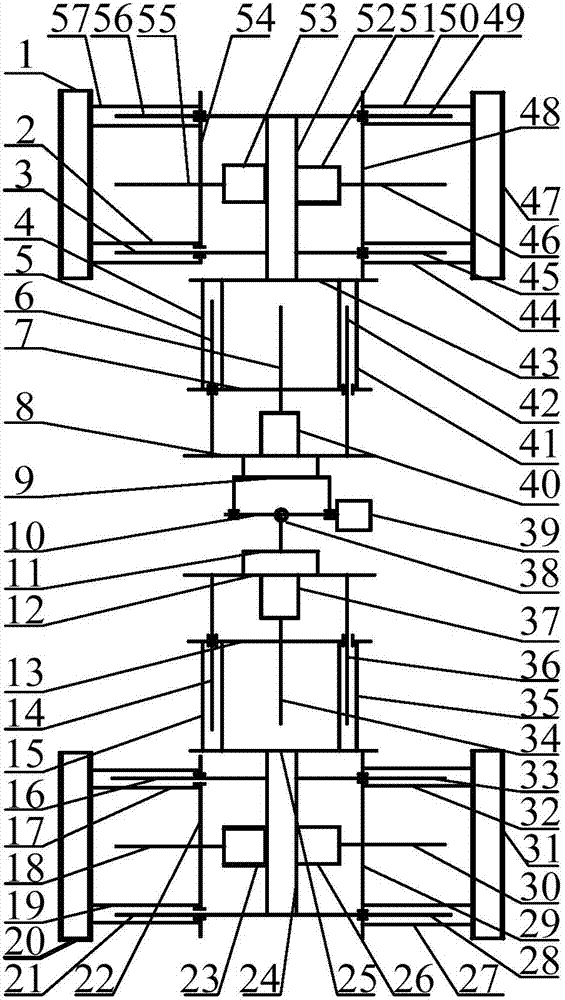

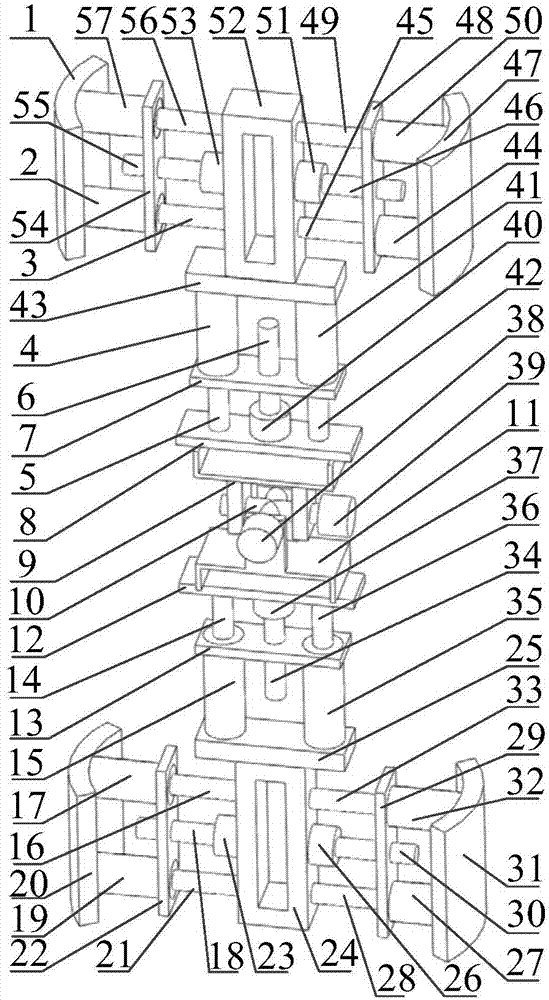

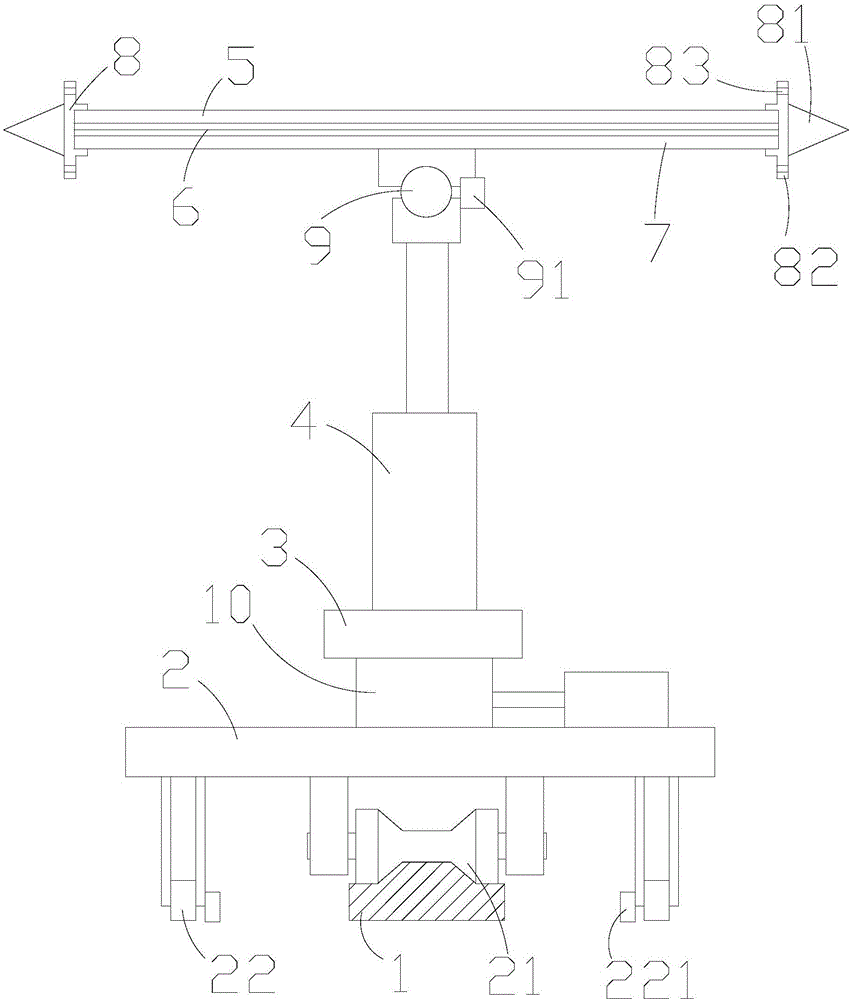

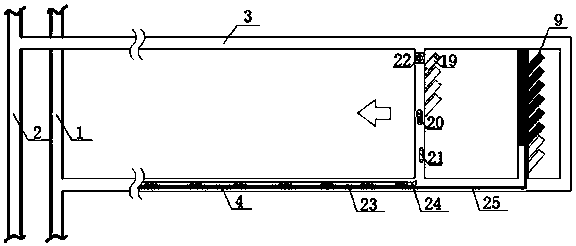

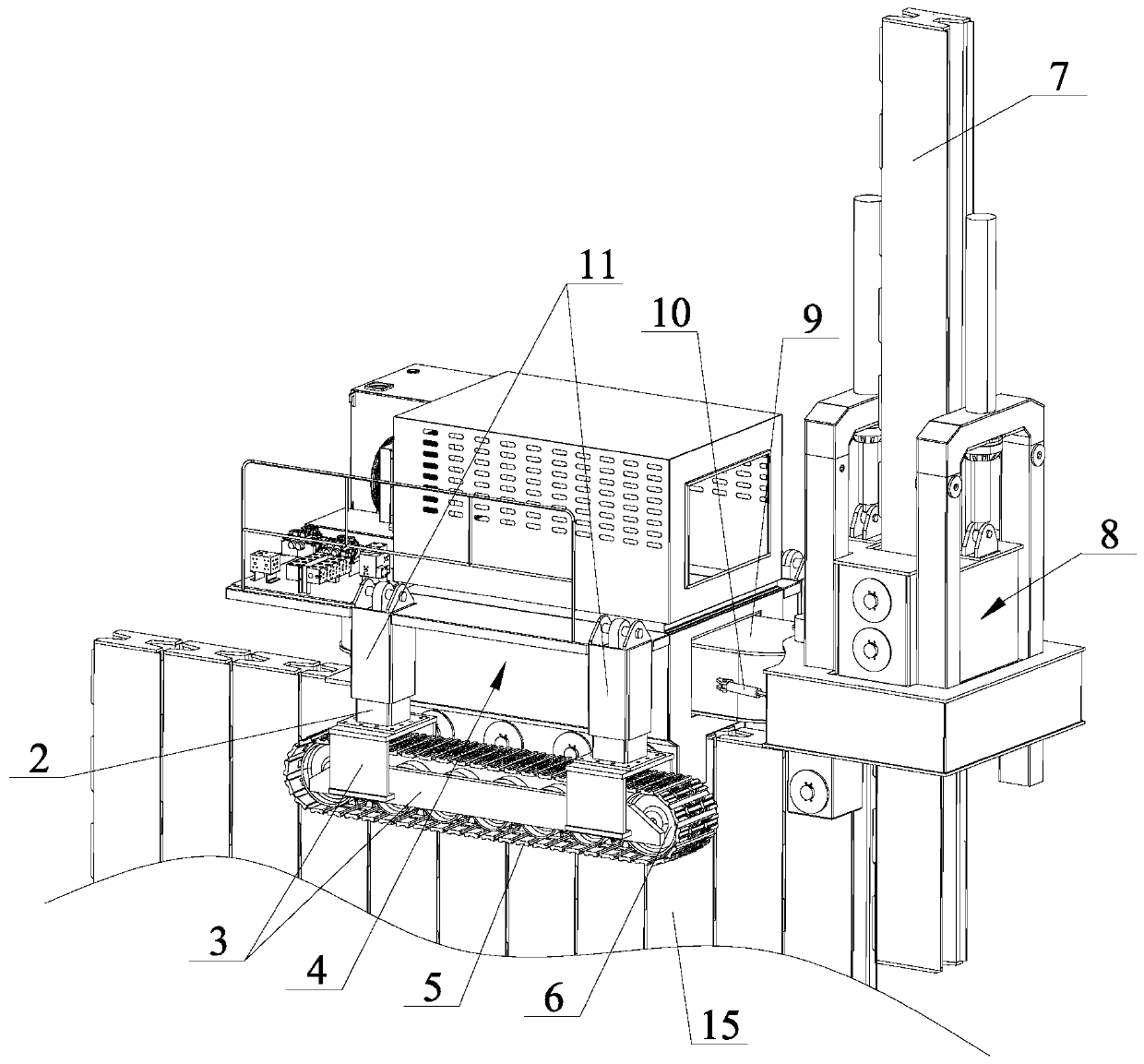

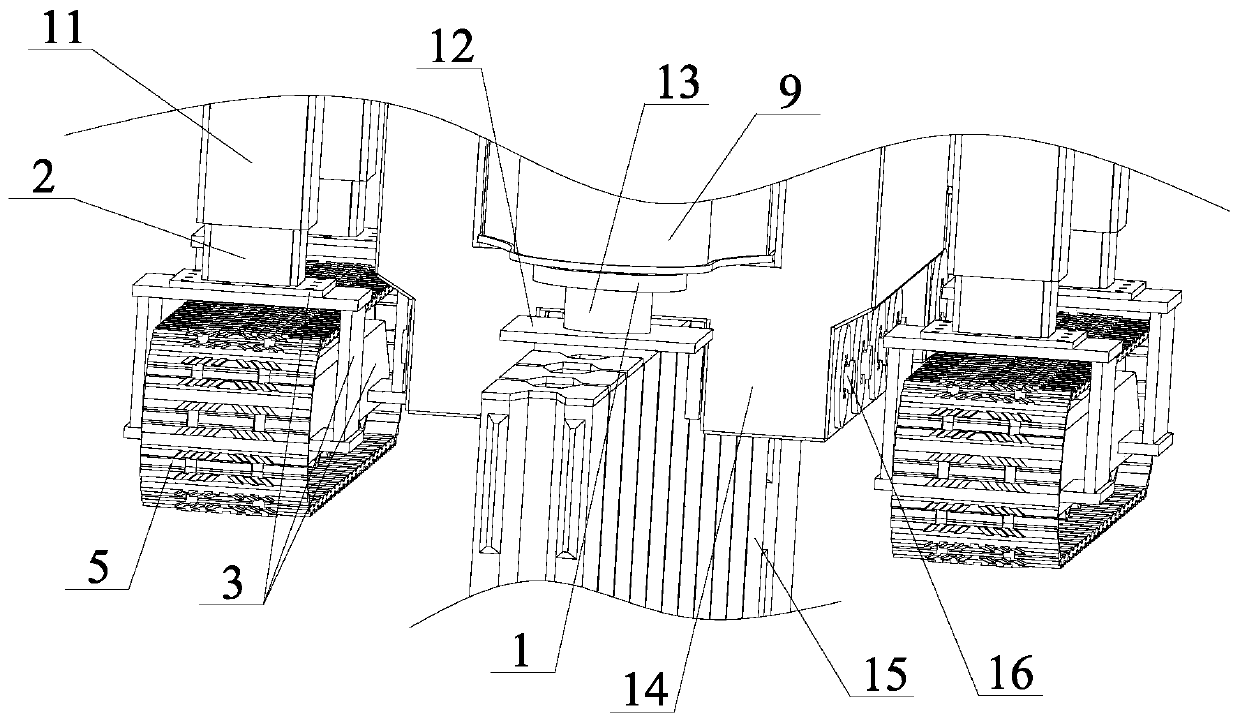

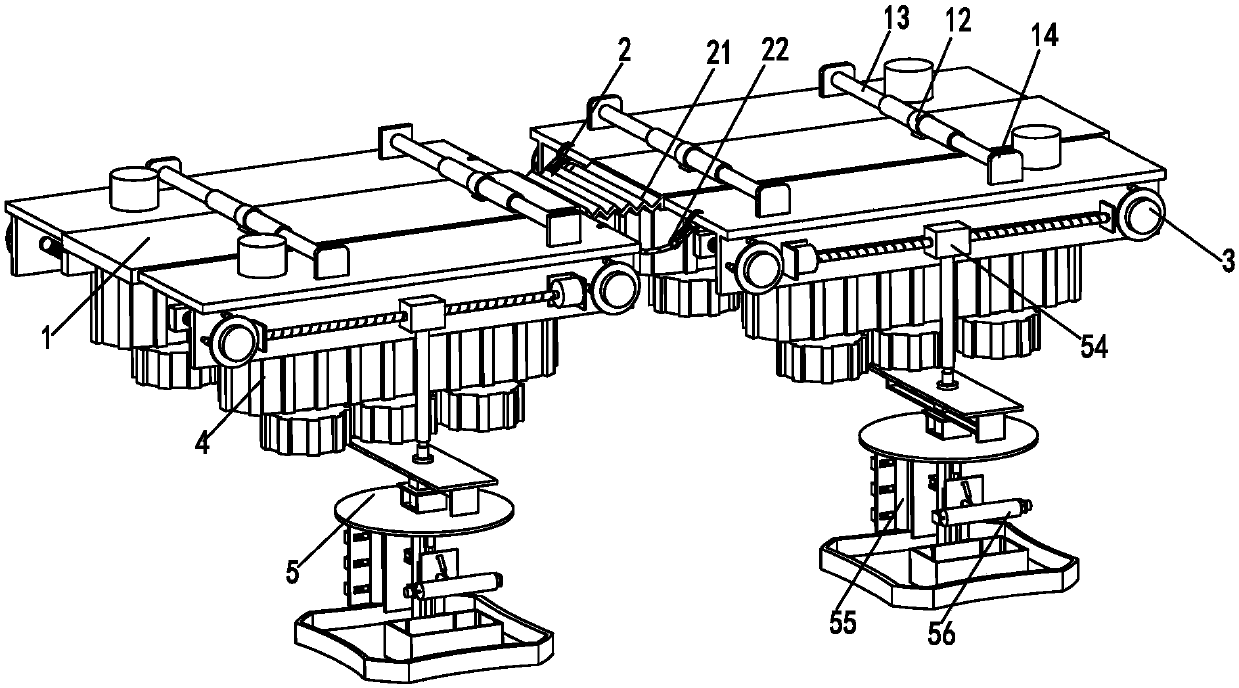

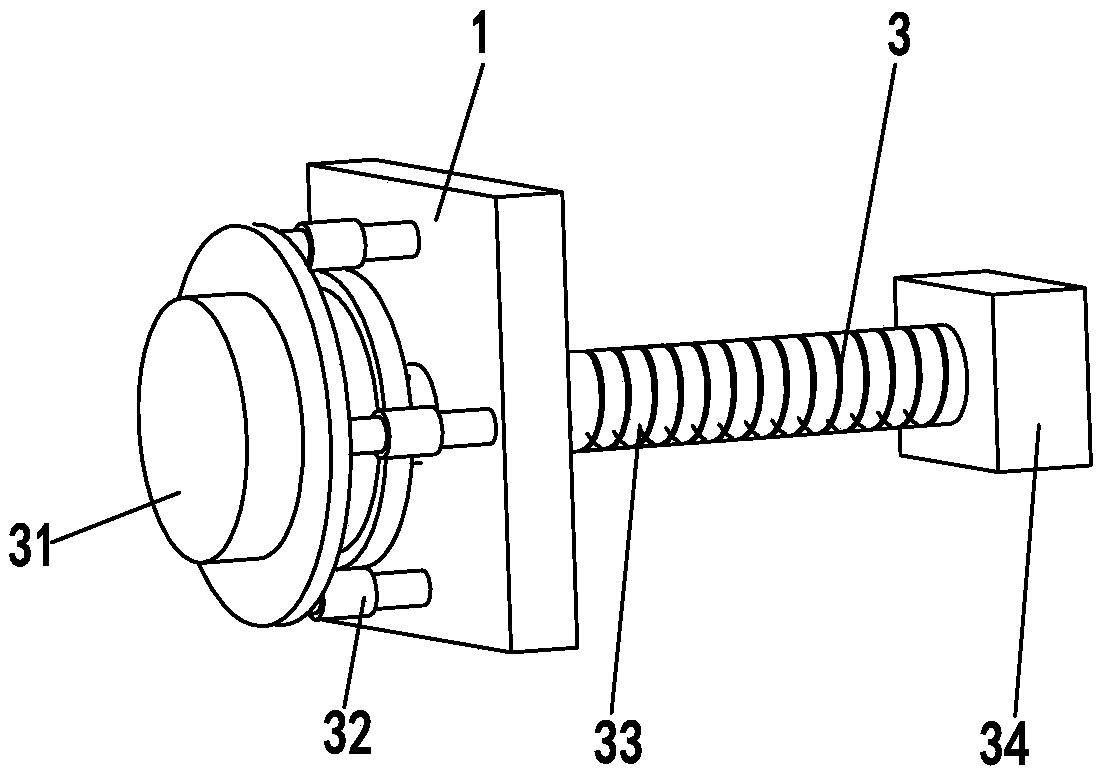

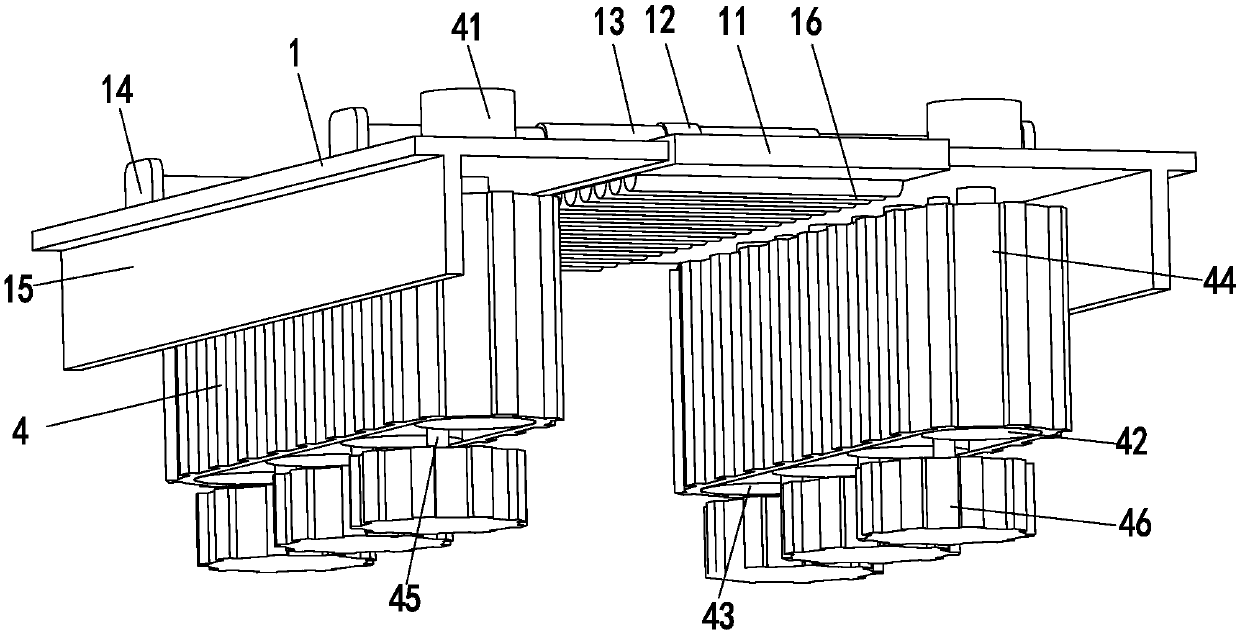

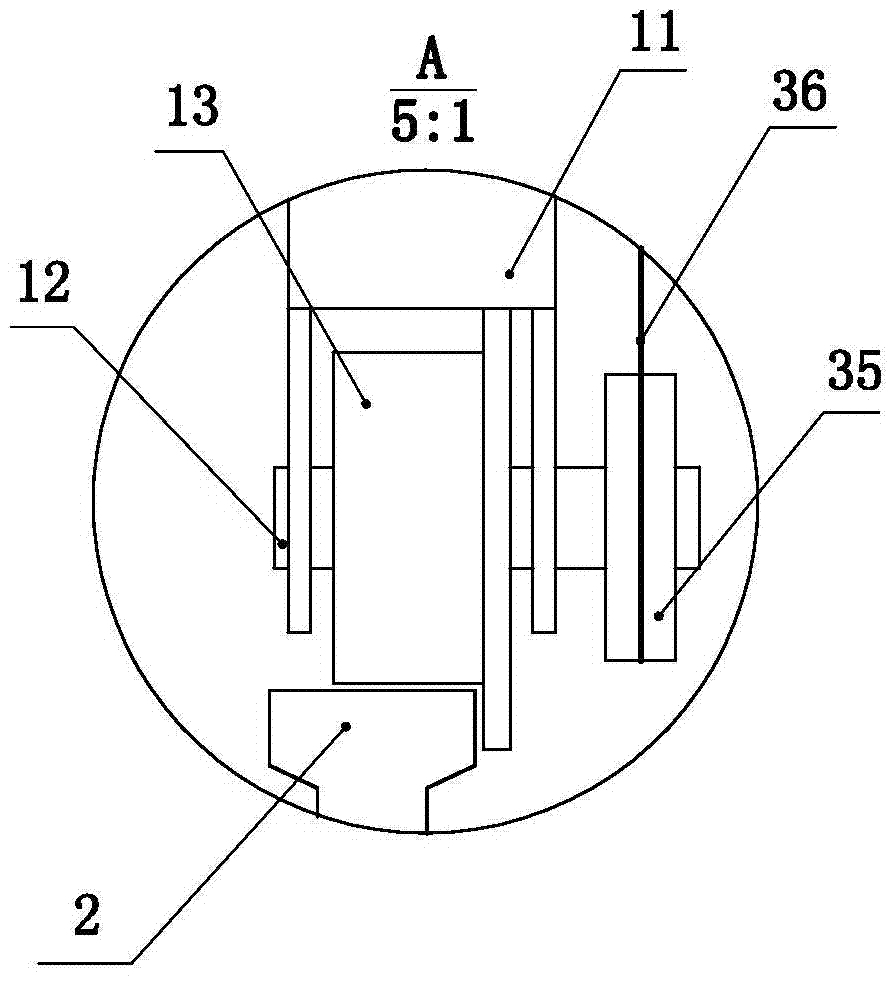

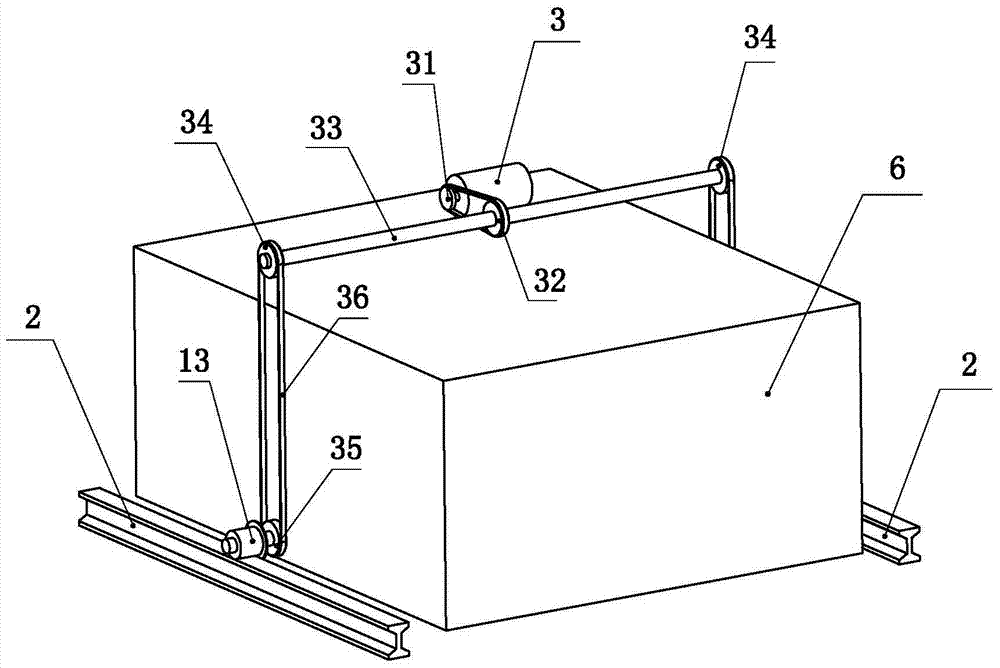

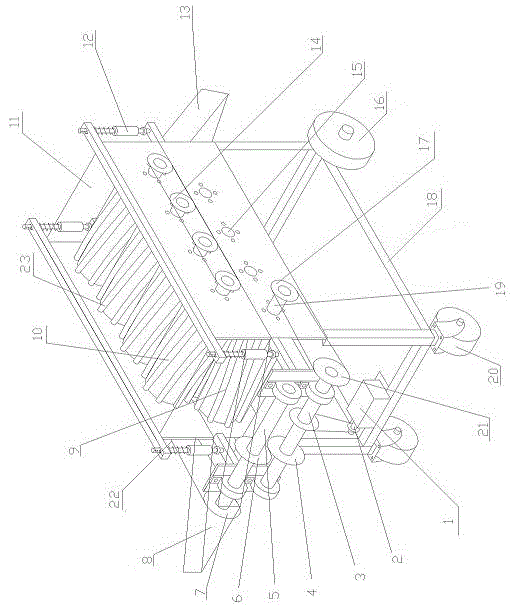

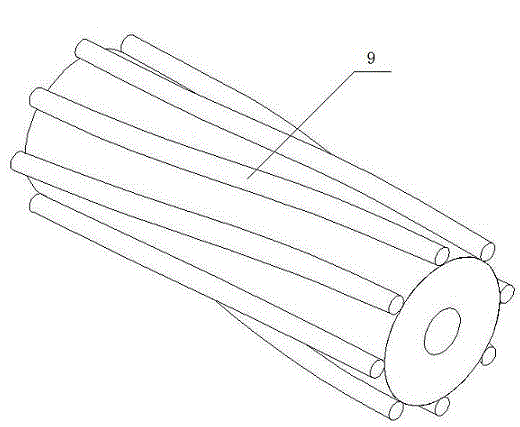

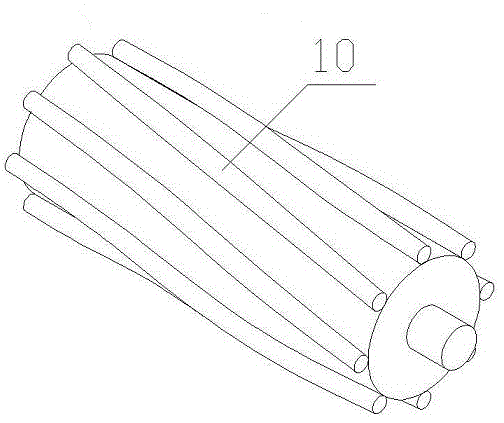

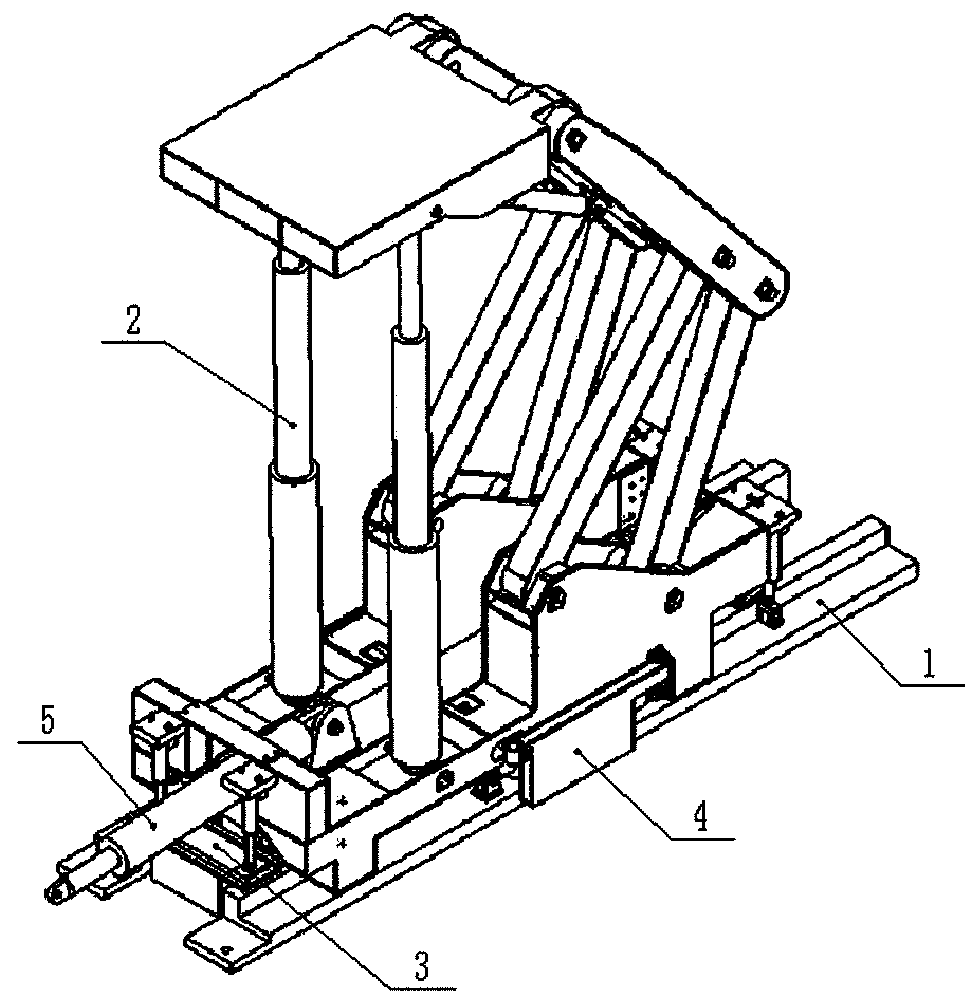

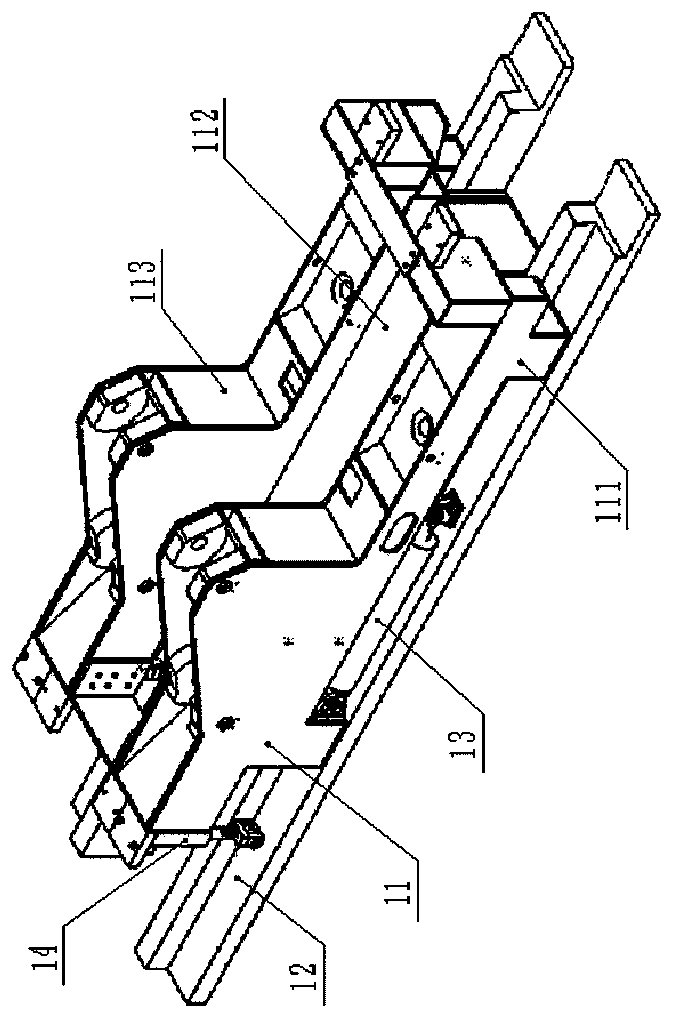

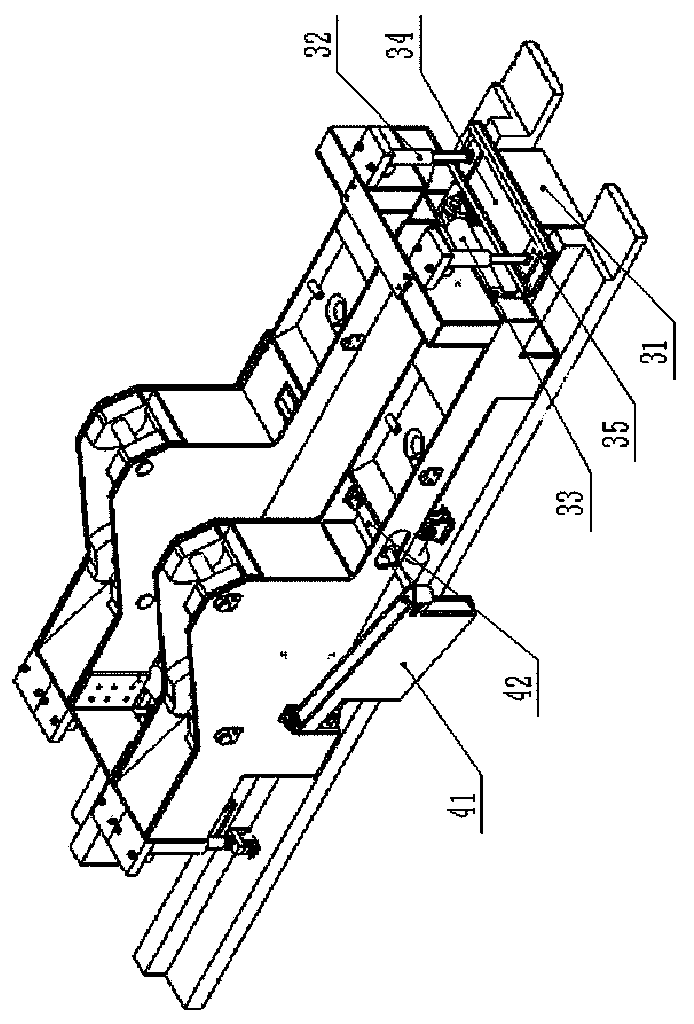

Numerical-control multi-spindle gantry drilling and milling machine tool

ActiveCN103962602ASame feed rateReduce displacementFeeding apparatusDriving apparatusStructural engineeringPower apparatus

The invention discloses a numerical-control multi-spindle gantry drilling and milling machine tool which comprises a gantry. A tool body which enables a workpiece to move in the X direction and the Y direction of the horizontal plane is arranged below the gantry. A clamping device used for clamping the workpiece is arranged on the tool body. A gang drill is arranged on a gantry frame and located on the top of the tool body, wherein the gantry frame and the tool body are relatively and fixedly installed. The gang drill comprises a plurality of drilling and milling devices. The drilling and milling devices are driven by two-stage power devices to move up and down in the vertical direction, two-stage adjustment of the perpendicular distance between the drilling and milling devices and the workpiece is achieved, and the drilling and milling devices are driven by the same driving device to rotate. According to the numerical-control multi-spindle gantry drilling and milling machine tool, working efficiency of mass drilling and milling is greatly improved, and the gap between China and advanced countries is narrowed.

Owner:山东金博利达精密机械有限公司

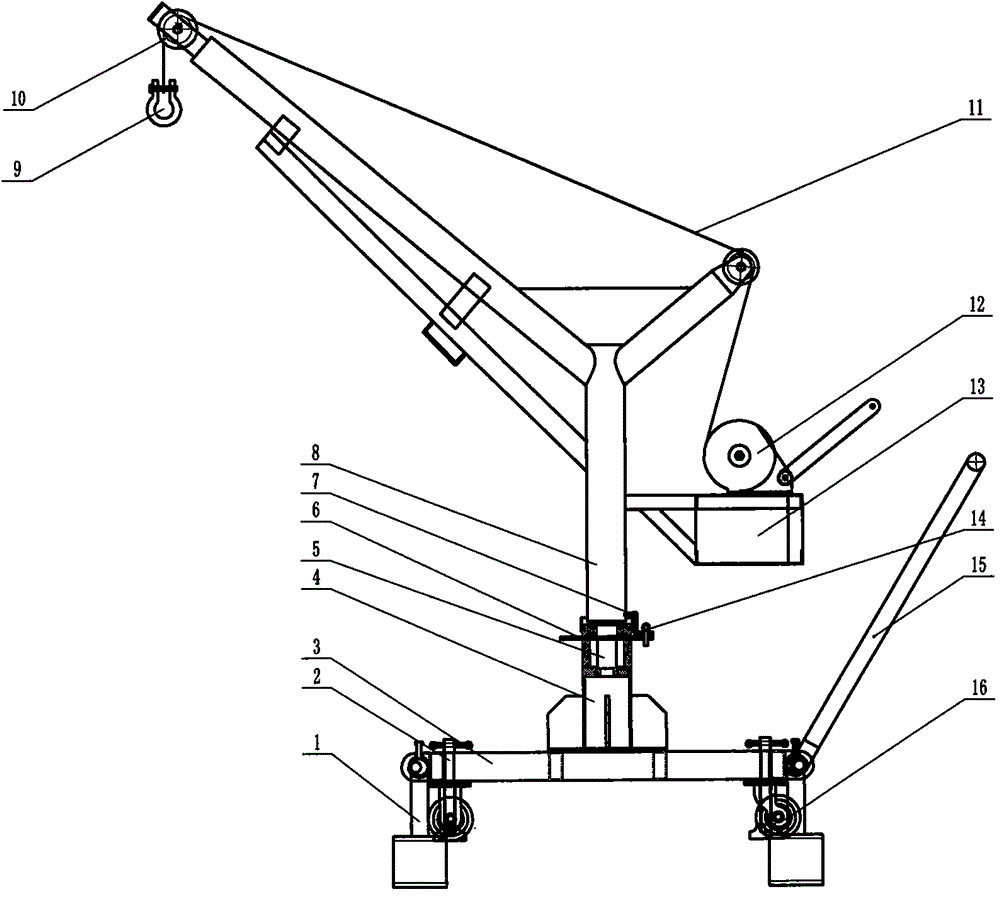

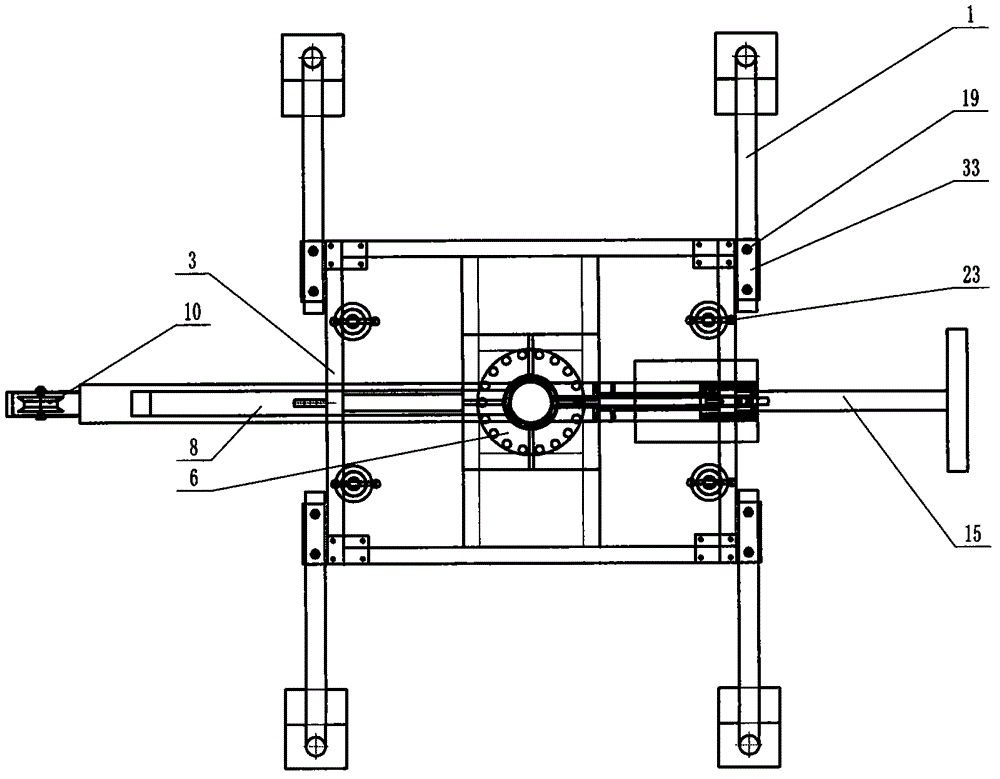

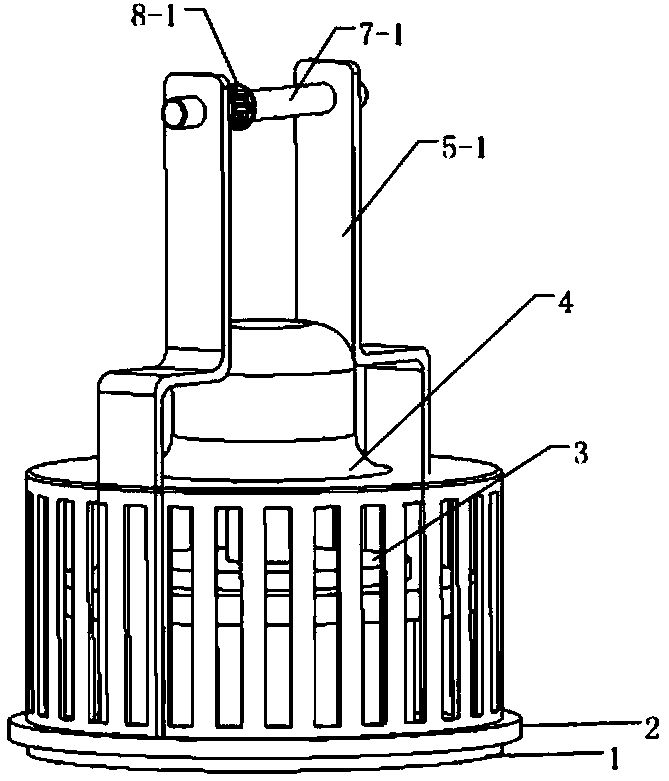

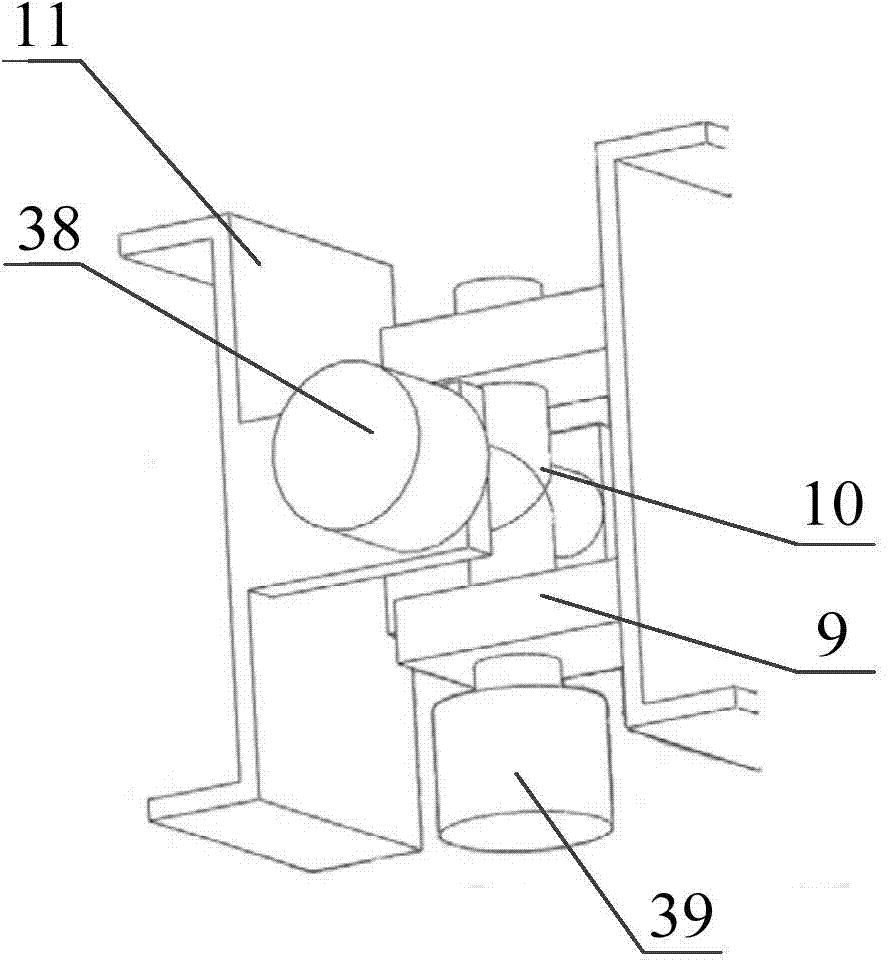

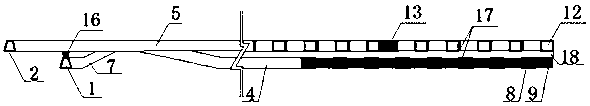

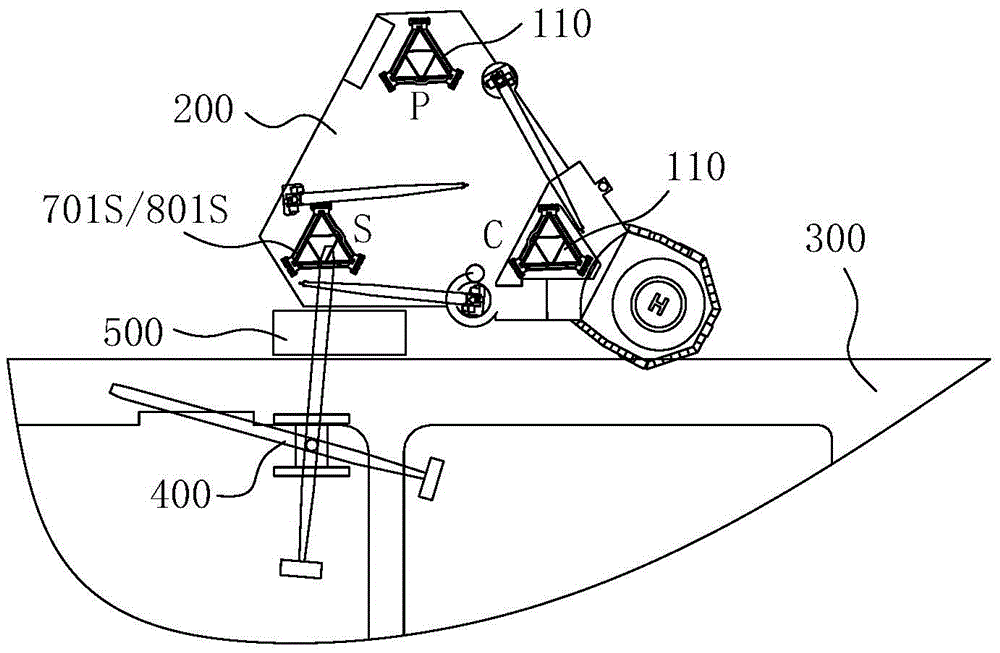

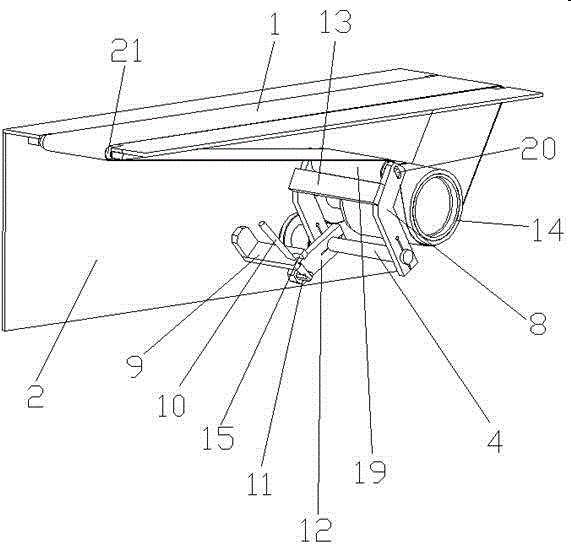

Small movable crane

The invention relates to a small movable crane, which comprises a hoisting device, a counterweight device, a movable pedestal, leading screw supports, and support assemblies. A Y-shaped hoisting hanger of the hoisting device comprises an upper support and a lower support, wherein each end of the upper support is provided with a fixed pulley; the bottom of the lower support is fixed to a rotating shaft, which is inserted into a rotating seat. The rotating seat is fixedly mounted on the center of the movable pedestal; and the counterweight device is arranged at one side of the lower support of the hoisting hanger and is provided with a hand-operated capstan. A steel wire rope is transited via two fixed pulleys, and one end of the steel wire rope is provided with a hook. Every two of the four leading screw supports are symmetrically arranged at front and rear sides of the inner sides of two frames of the movable seat; every two of the four support assemblies are symmetrically arranged at front and rear sides of the outer sides of two frames of the movable seat; and each corner of the movable seat is provided with an omni-directional wheel. The small movable crane has advantages that the crane is small, exquisite, light and convenient, is flexible to move, and is safe and reliable; a large amount of physical power is saved for a maintenance person; the maintenance speed is greatly improved; and an emergency rescuing function of a reaction pool is provided.

Owner:北京市自来水集团门城污水处理有限公司

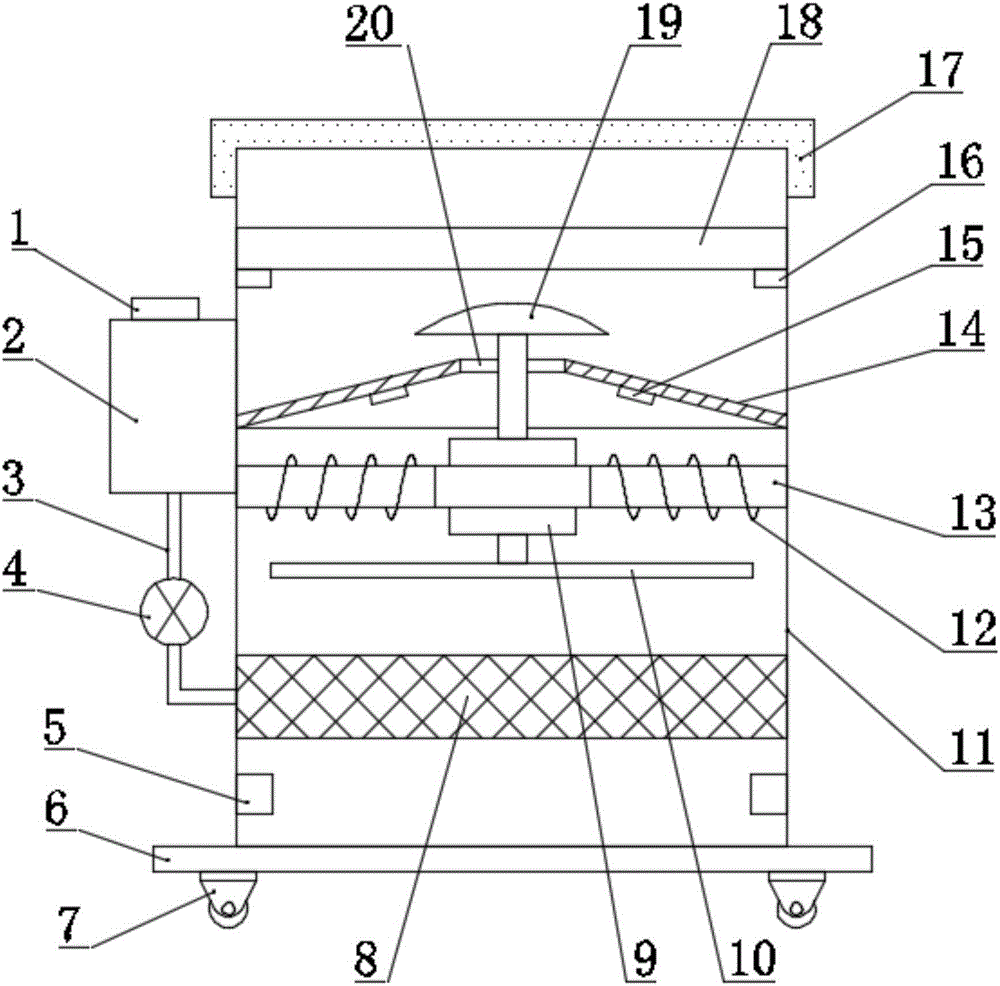

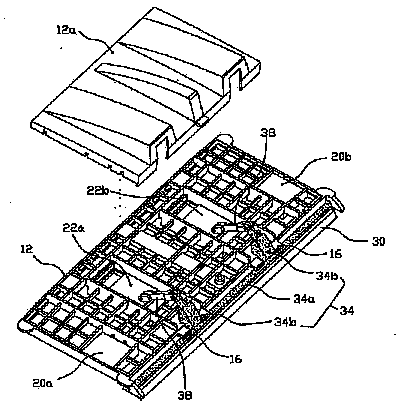

Multifunctional air purifier

InactiveCN107525159AMobile and flexibleIncrease humidityMechanical apparatusLighting and heating apparatusMotor shaftElectric heating

The invention discloses a multifunctional air purifier comprising a purifier main body. A dust collection filter screen is installed on the lower portion of the inner side of the purifier main body. A humidification conveying water pipe connected with the dust collection filter screen is installed on the outer side of the purifier main body and is provided with a humidification water pump. The other end of the humidification conveying water pipe is connected to the bottom of a water tank. A motor support is arranged on the upper side of the dust collection filter screen and in the purifier main body. A double shaft extension motor is installed in the middle of the motor support. A blade is installed at the lower end of a motor shaft of the double shaft extension motor. The motor support is further provided with an electric heating wire. A baffle plate is installed at the upper end of the double shaft extension motor. An air guide cover is further installed between the baffle plate and the motor support. An air purification assembly is installed on the upper side of the baffle plate and in the purifier main body. The multifunctional air purifier is compact in structure and multiple in function, the effects of purification, disinfection, humidification, dehumidification and warm keeping effects can be conducted indoors, and application and popularization are convenient.

Owner:韦人丹

Bionic obstacle-crossing wall climbing robot and obstacle crossing method thereof

The invention discloses a bionic obstacle-crossing wall climbing robot and an obstacle crossing method thereof. The bionic obstacle-crossing wall climbing robot comprises a micro absorption module, a light motion mechanism and a wall climbing robot body. The micro absorption module is connected to the wall climbing robot body through the light motion mechanism. The light motion mechanism is a mechanism with two degrees of freedom and formed by connecting three rods and two drive devices in series. One rod is fixedly connected to the micro absorption module, the other rod is fixedly connected to the wall climbing robot body, the two rods are connected to two ends of the third rod through bearings respectively, the bears are provided with the corresponding drive devices, and the drive devices drive the bearing to rotate so as to drive the micro absorption module and the wall climbing robot body to life and drop. When an obstacle appears, the micro absorption module serves as a 'palm' to absorb on a wall in a manner of static adsorption, and the light motion mechanism serves as a 'long arm' to overturn the wall climbing robot body to cross the obstacle. The bionic obstacle-crossing wall climbing robot can flexibly cross large projections, wide grooves and other obstacles.

Owner:南京赫曼机器人自动化有限公司

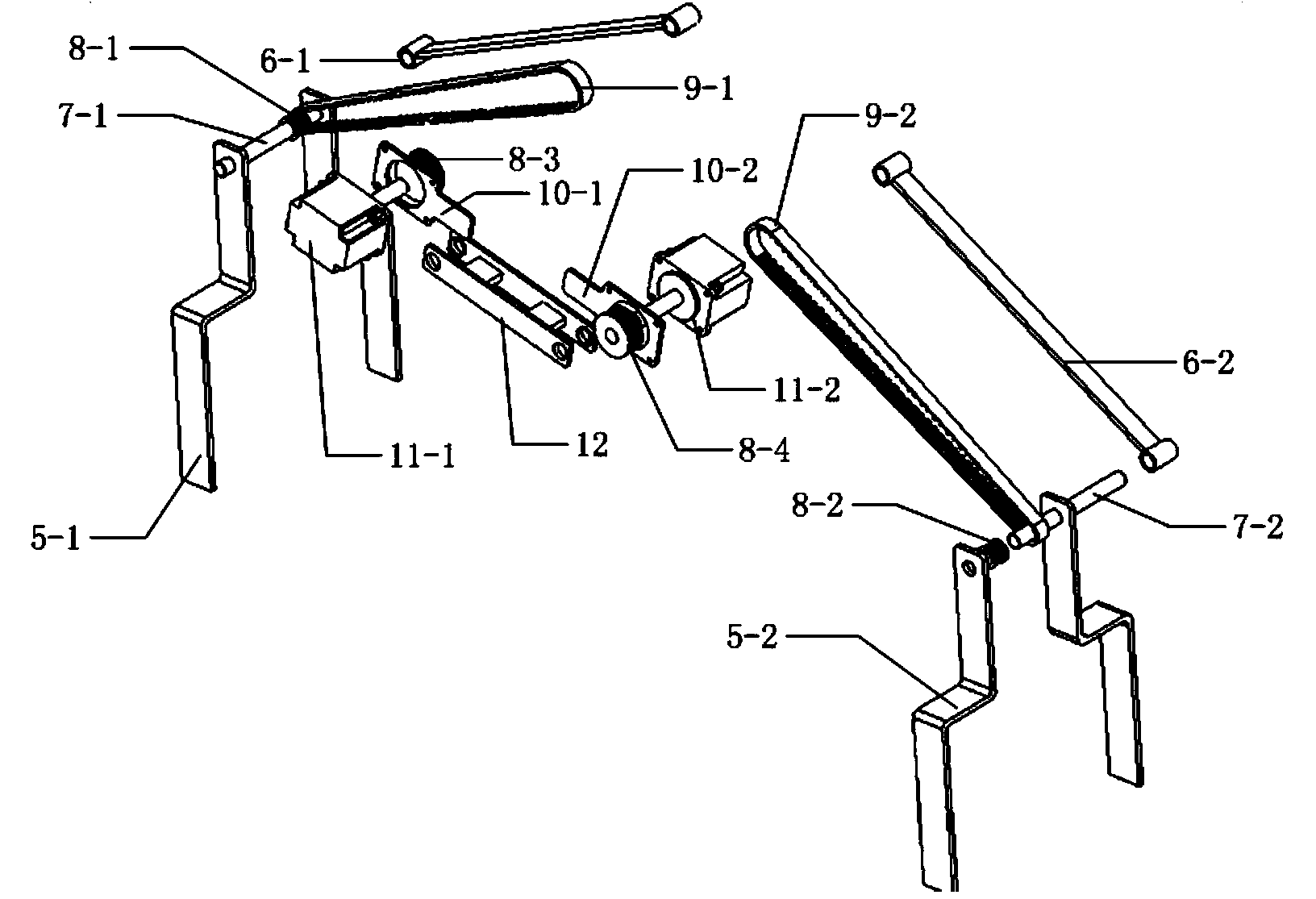

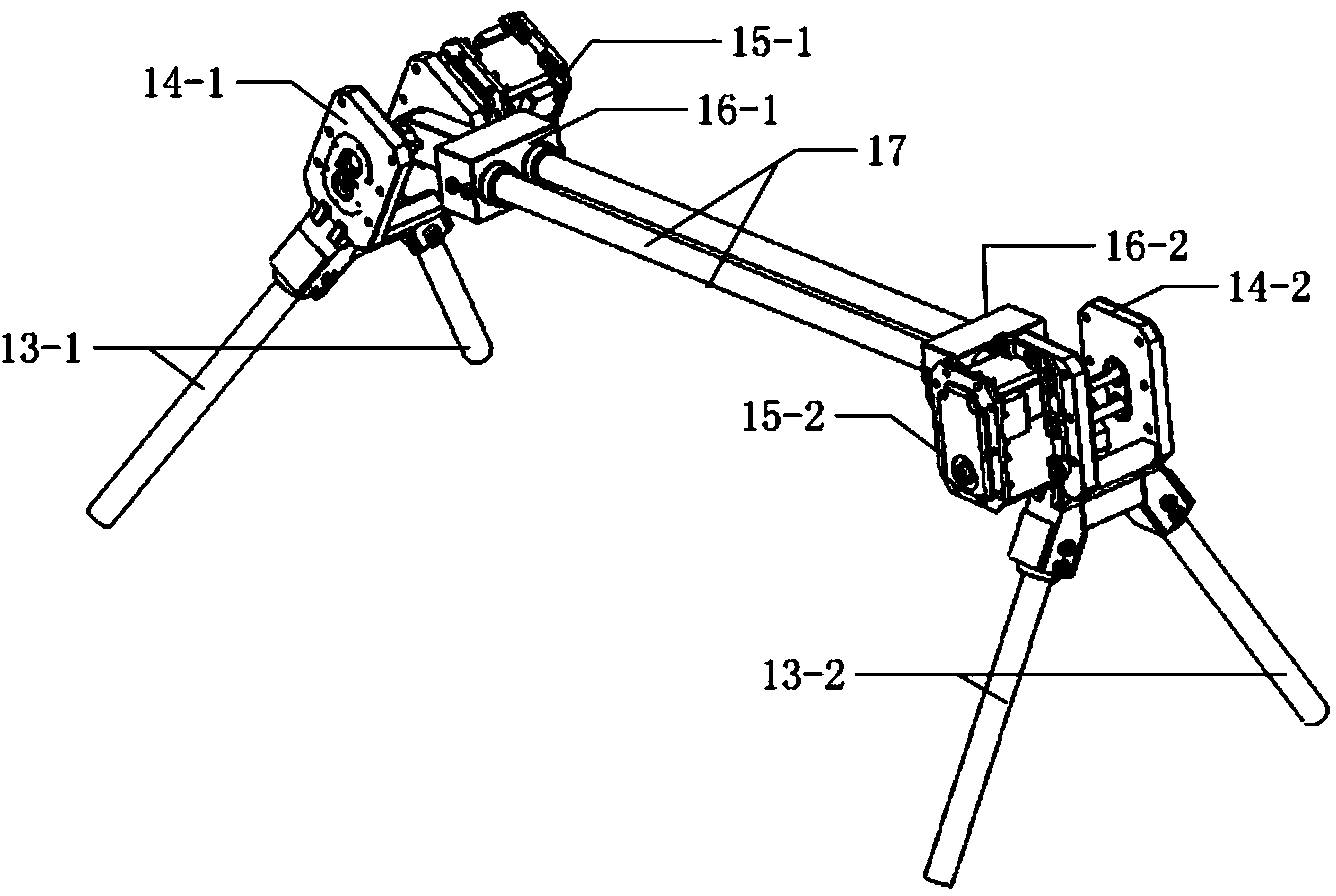

Extensible robot for climbing inner wall of pipeline

The invention provides an extensible robot for climbing an inner wall of a pipeline. The extensible robot comprises a middle connection mechanism, four extensible arms and two extensible mechanisms. Each extensible arm comprises a friction pad, an arm extensible motor, an arm extensible motor holder, an arm extensible pipe connection frame, an arm extensible lead screw, two outer arm extensible pipes and two inner arm extensible pipes. Each extensible mechanism is composed of an arm connection frame, an extensible motor, an extensible motor holder, an extensible pipe connection frame, an extensible lead screw, two outer extensible pipes and two inner extensible pipes. The middle connection mechanism comprises a center rotary frame I, a center rotary frame II, a steering motor I, a steering motor II and a center joint cross. The middle connection mechanism is fixedly connected with the extensible motor holders of the two extensible mechanisms through the center rotary frame I and the center rotary frame II. The arm connection frame of each extensible mechanism is fixedly connected with the arm extensible motor holder of the corresponding extensible arm. Each arm extensible motor holder is symmetrically provided with two extensible arms. The fixed position and the spatial two-freedom-degree rotation of the robot in the pipeline can be achieved.

Owner:三亚哈尔滨工程大学南海创新发展基地

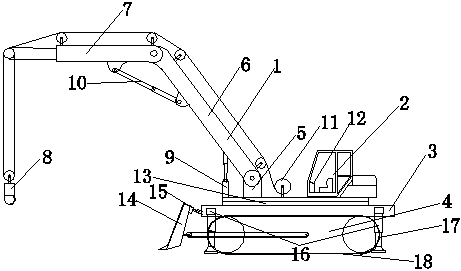

Crane

InactiveCN104261277AExpand the workplaceImprove lifting efficiencyCranesLoad-engaging elementsEngineeringShovel

The invention provides a crane, and belongs to the technical field of engineering machinery. The crane comprises a lifting arm, a driving cab, a machine frame and a walking device, wherein the crane is provided with a push shovel which can level an uneven ground and provide a horizontal support to the crane through stable standing of the crane; the lifting arm consists of multiple movable joints and a hydraulic device, up-and-down and front-and-back movement of a lifting hook can be achieved, the whole lifting arm sits on the rotating hydraulic device, and 360-degree rotation of the lifting arm can be achieved. The crane provided by the invention has a more flexible lifting position, can achieve safe lifting in a variety of complex environments, and has high lifting efficiency and good security.

Owner:XIAN AERONAUTICAL UNIV

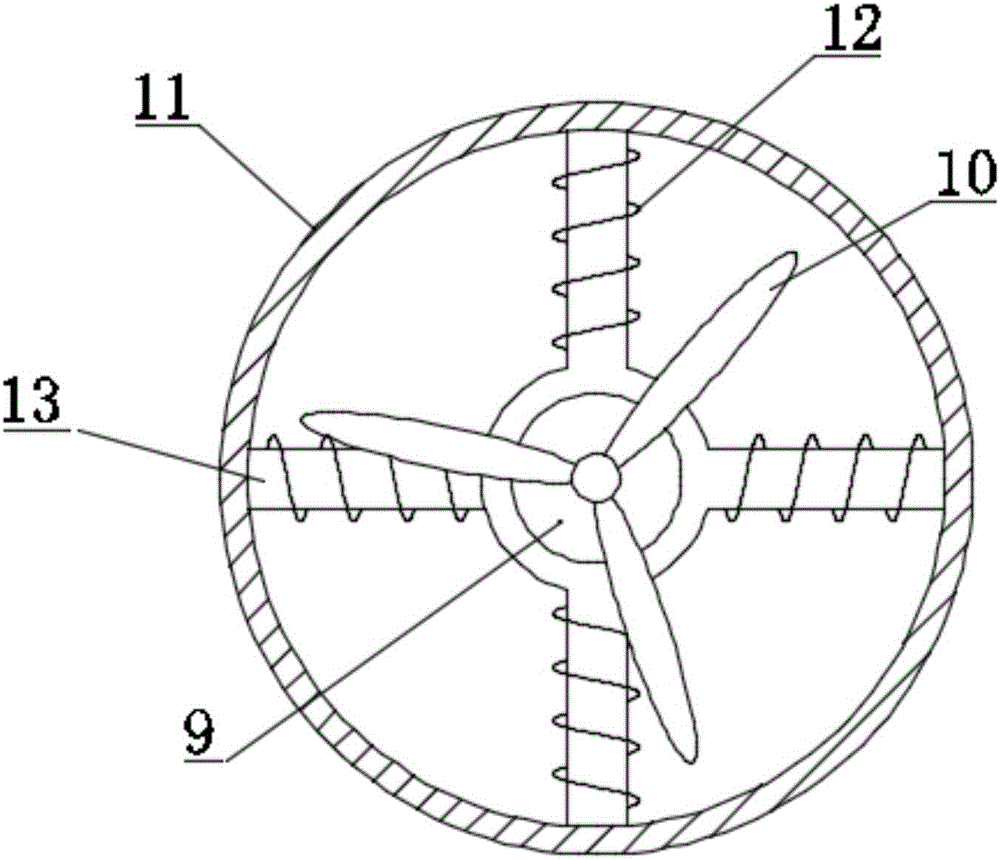

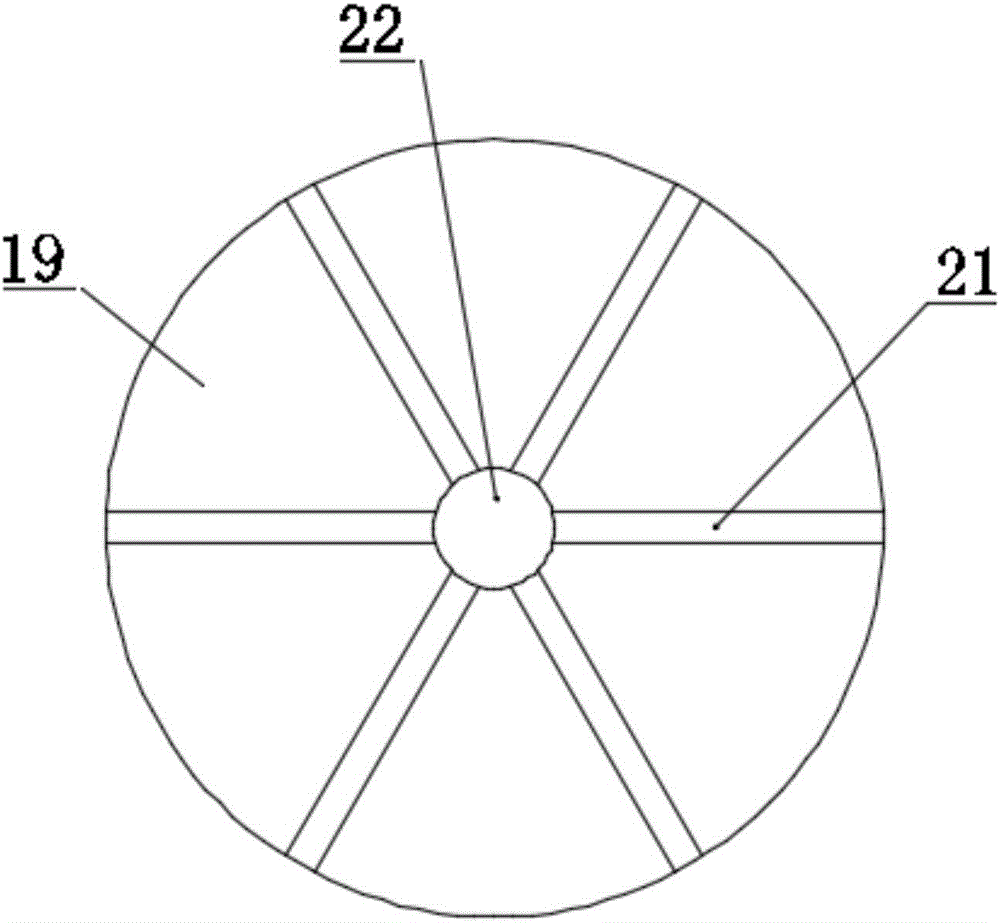

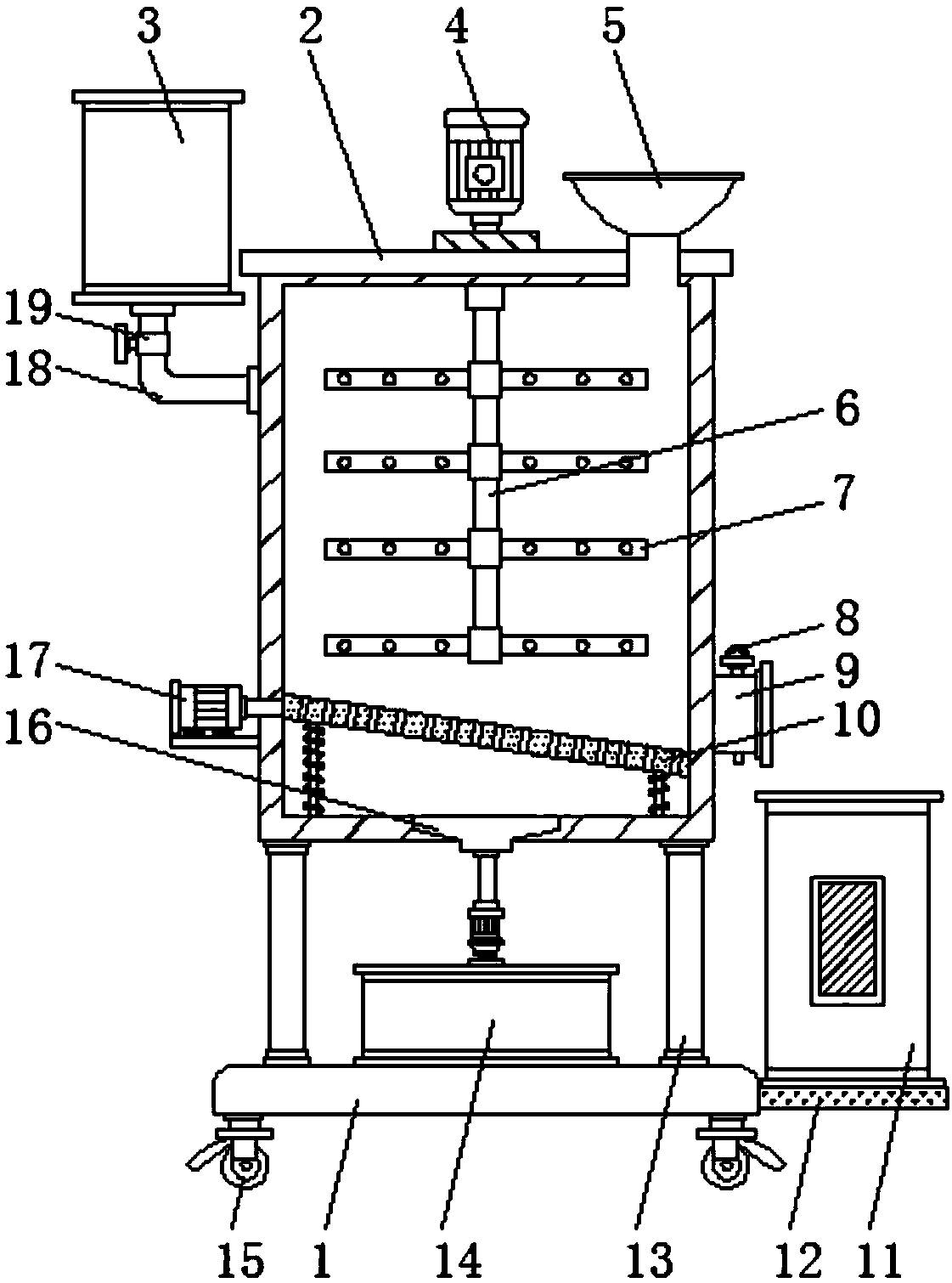

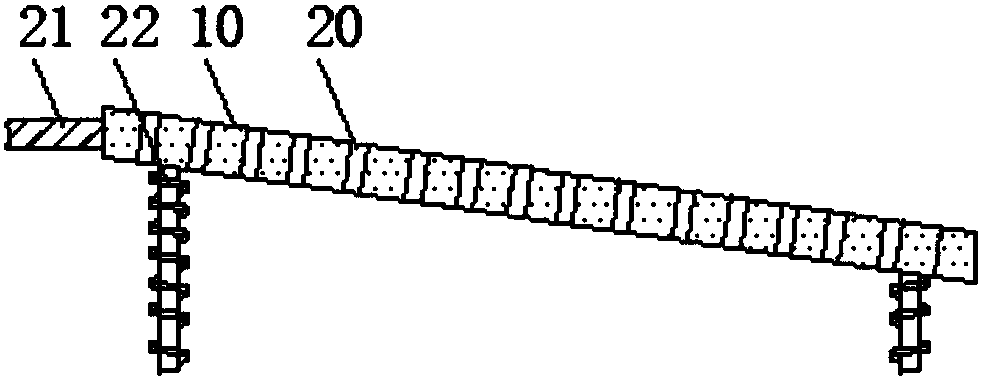

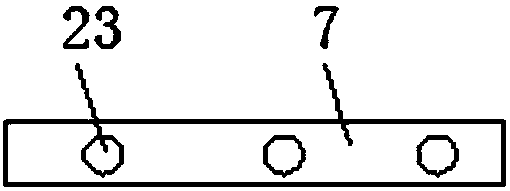

Medicine stirring device for flower seeds

InactiveCN107646243ASimple structureMobile and flexibleSeed coating/dressingAgricultural engineeringSieve

The invention discloses a medicine mixing device for flower seeds, which comprises a base and a mixing drum, a supporting frame is fixed on the top of the base, the mixing drum is arranged on the supporting frame, and an advanced Hopper and stirring motor, the inside of the feed hopper is provided with a miscellaneous net, the upper end of one side of the mixing drum is provided with a medicine storage box, and the bottom of the inner cavity of the mixing drum is provided with a filter sieve plate arranged in an inclined manner , the bottom of the mixing drum is provided with a drug discharge port, and a drug return box is provided below the drug discharge port. The present invention has the advantages of simple structure, convenient use and high drug mixing efficiency. The obliquely arranged filter sieve plate arranged at the bottom of the inner cavity of the mixing drum can not only realize the separation of crop seeds and medicinal liquid, but also facilitate the discharge of seeds, and feed into the hopper. The impurity removal net is provided, which can remove the particle impurities contained in the seeds, and improves the quality of the seeds after mixing the medicine.

Owner:长兴越鑫苗木花卉有限公司

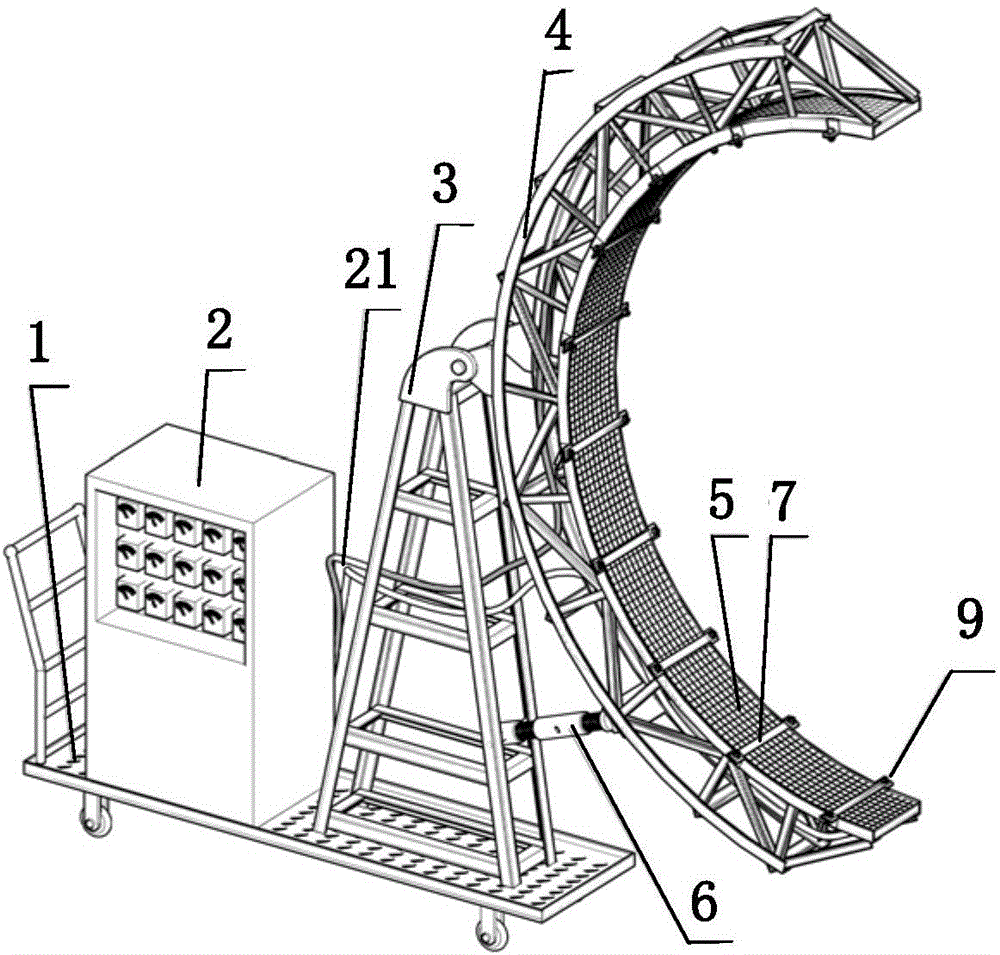

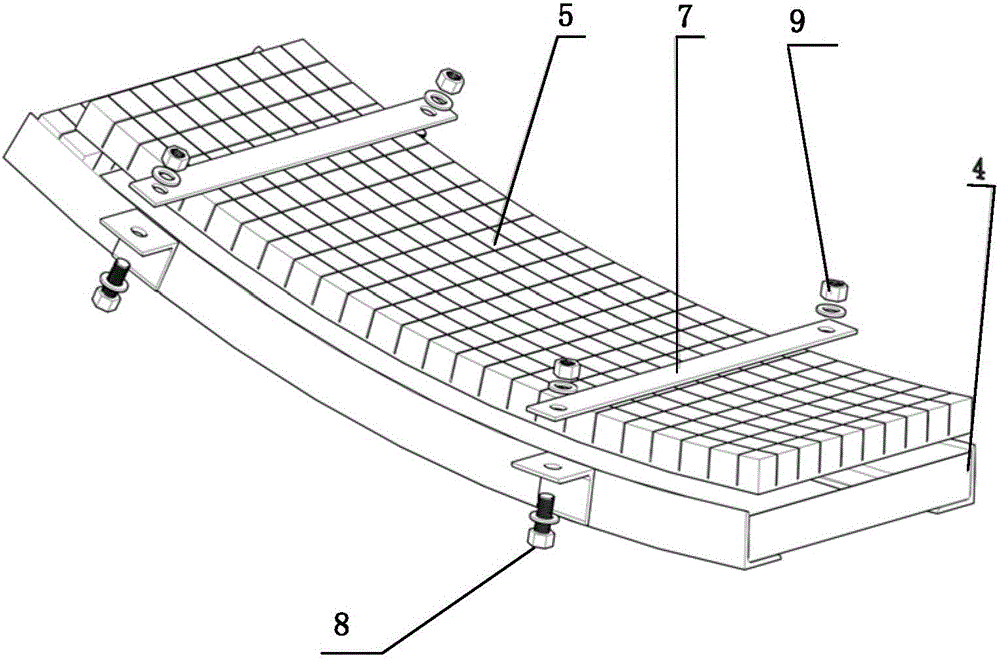

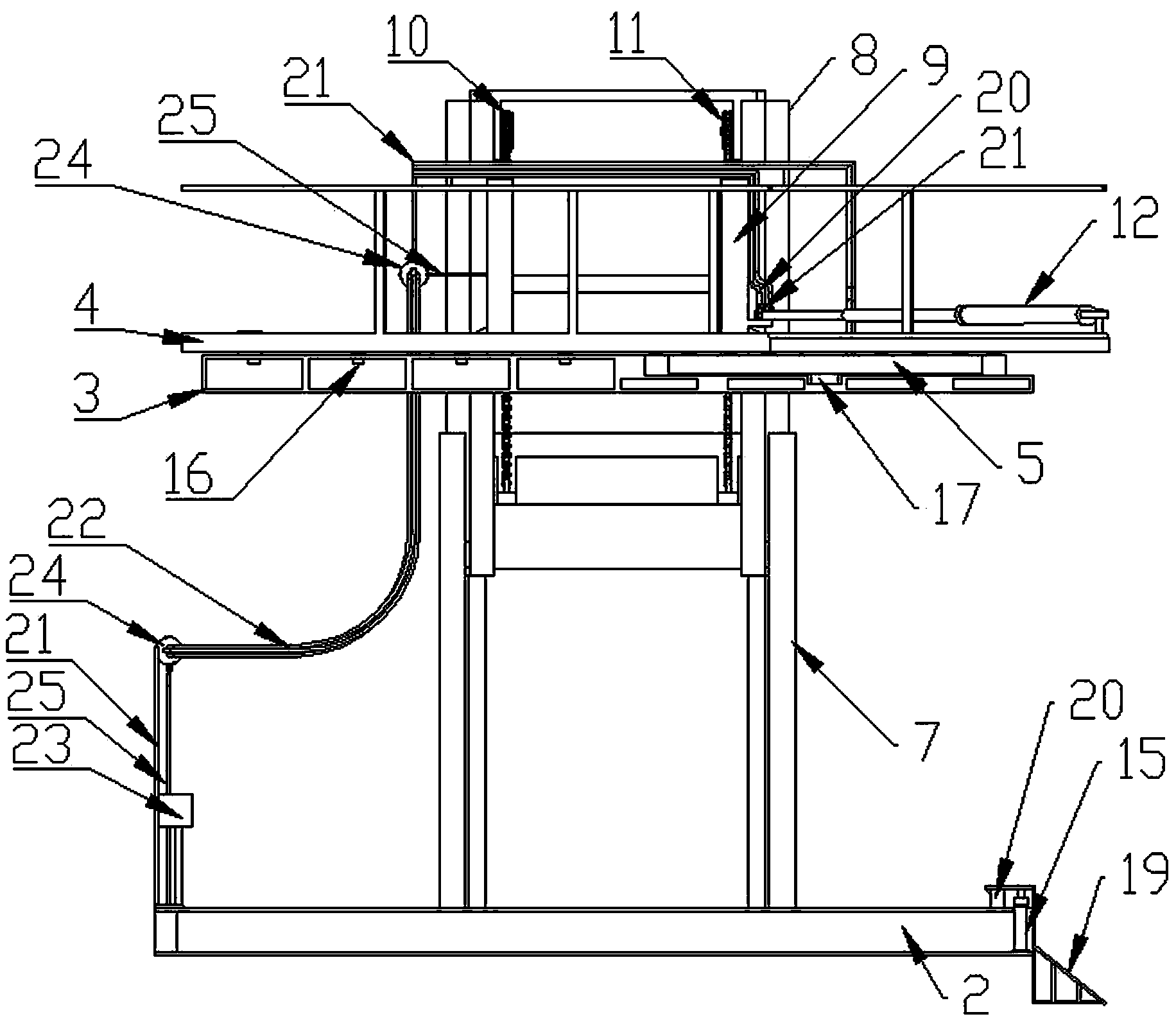

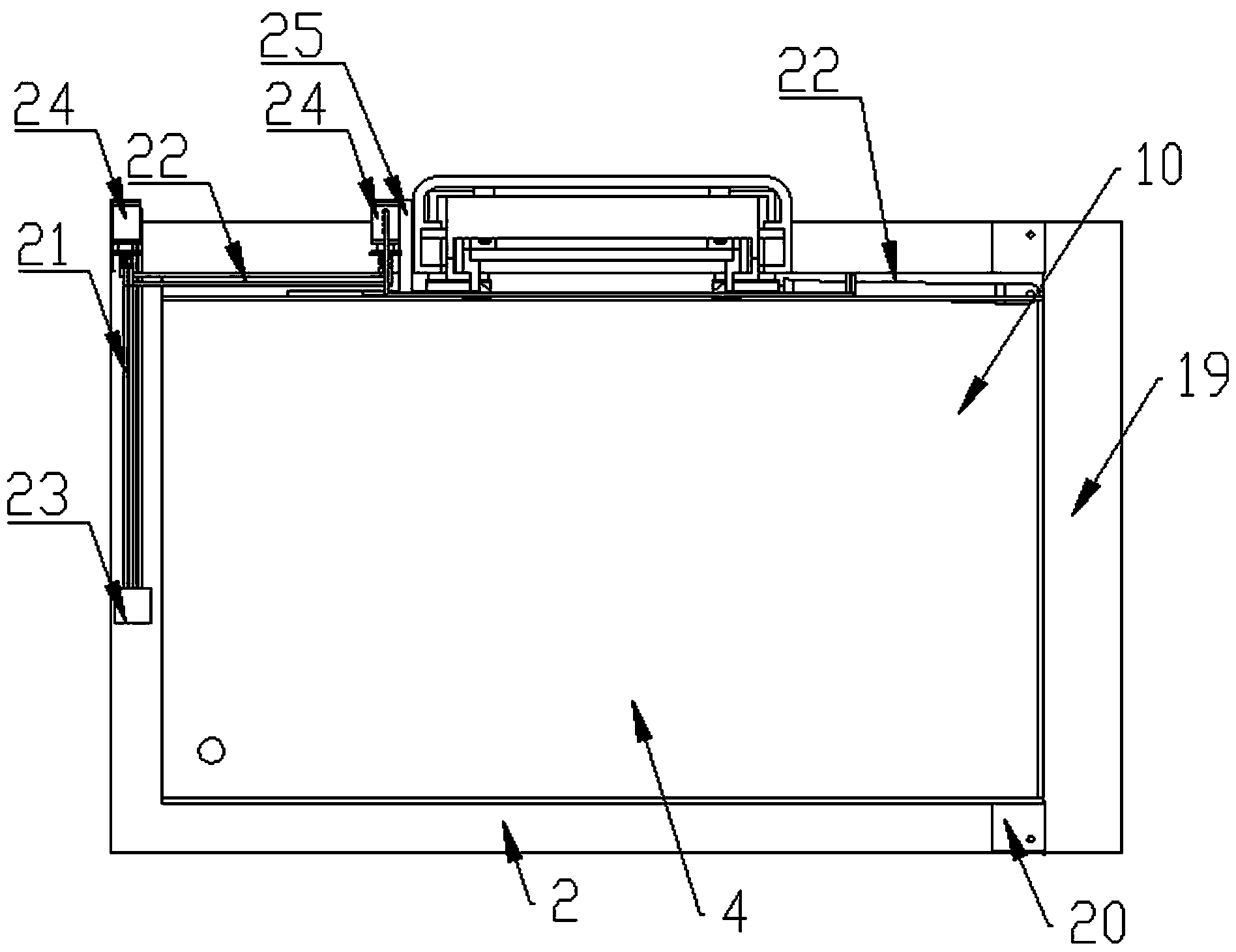

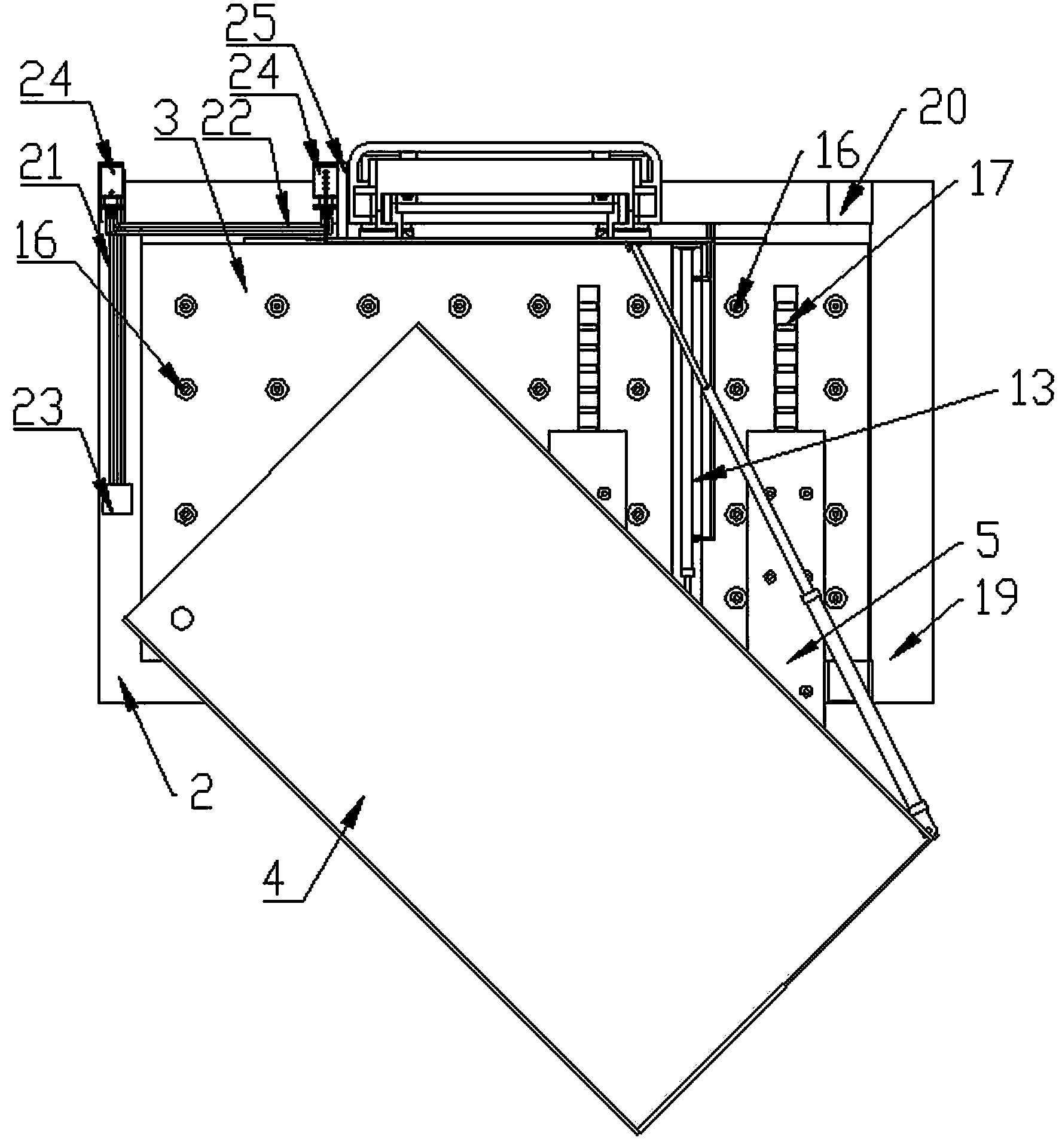

Lift rail-type rotating novel solar photovoltaic power generation system

InactiveCN106411239AAvoid shakingAvoid direct impactPhotovoltaic supportsSolar heating energyChinese charactersGlass cover

The invention discloses a lift rail-type rotating novel solar photovoltaic power generation system, which comprises a single rail, a supporting platform, a base, a supporting rod, a glass cover plate, a cell unit and a lower bottom plate, wherein the supporting platform is arranged on the single rail; the center of the bottom of the supporting platform is provided with at least one V-type rail wheel matched with the single rail; the glass cover plate, the cell unit and the lower bottom plate adopt a frame for fixing to form a whole; the supporting rod is fixedly arranged on the base; the middle of the lower bottom plate is arranged at the top of the supporting rod via a universal head; the outer side of the frame has a cone-shaped structure; a convex edge is arranged at the bottom edge of the frame cone-shaped structure; the supporting rod is a hydraulic lift supporting rod; the base is arranged in the center of the upper part of the supporting platform through a rotating disc; the single rail is a rail group in a shape like a Chinese character fei; and the cell unit can rotate randomly, the angle adjustment and the angle rotation are more accurate, the cell unit can lift freely, the power generation efficiency is high, and as an occlusion area of a side edge is added, the contact area between hail and the solar photovoltaic power generation system is reduced.

Owner:CHENGDU CHUANGHONG TECH

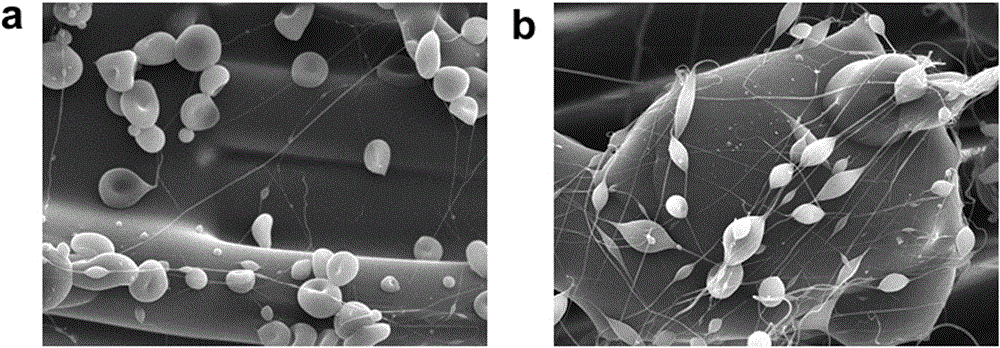

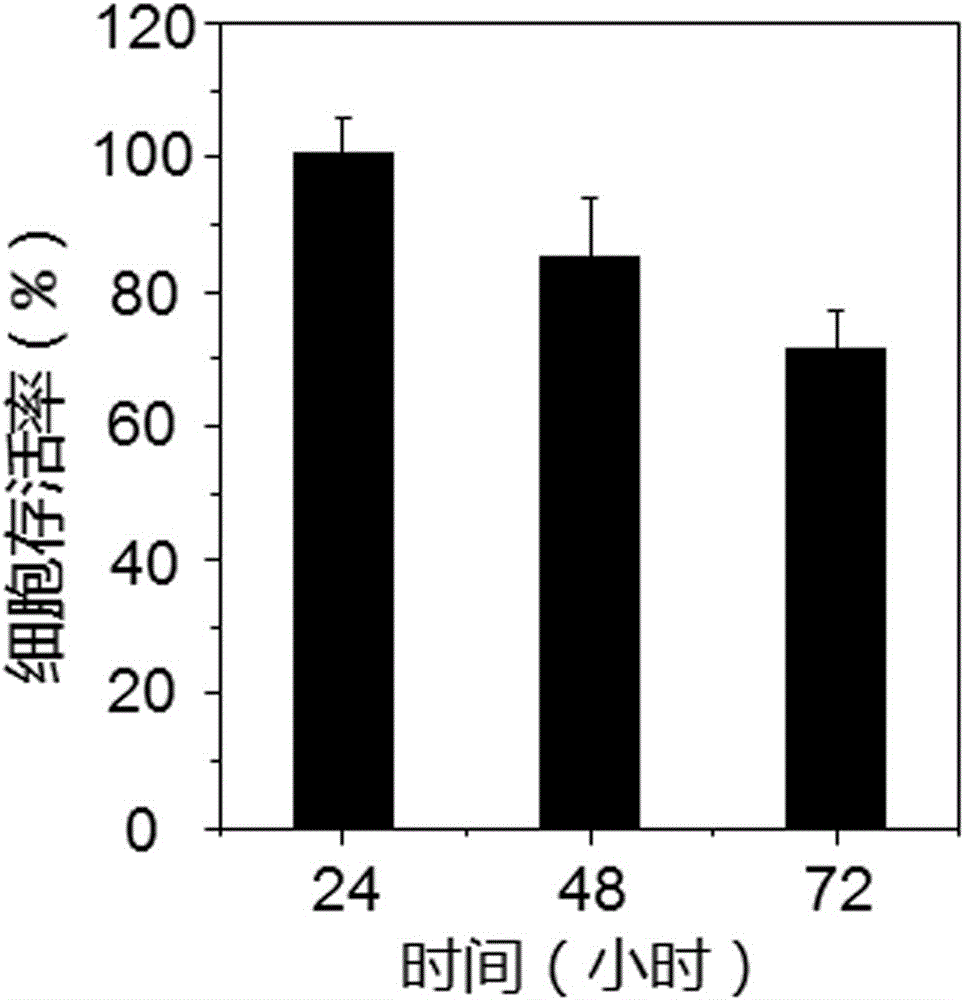

Preparation method of antitumor drug-loaded bead-like nano fibrous membrane

InactiveCN106727447AEasy to prepareMobile and flexibleOrganic active ingredientsPharmaceutical non-active ingredientsSilk clothDrug

The invention discloses a preparation method of an antitumor drug-loaded bead-like nano fibrous membrane. The nano fibrous membrane adopts a biodegradable macromolecular material as a carrier. An antitumor drug and the biodegradable macromolecular material are added into an organic solvent to obtain a spinning stock solution; and then silk cloth is used as a receiver, the spinning stock solution is spun by using a handheld electrostatic spinning instrument, the organic solvent is volatilized, and the antitumor drug-loaded bead-like nano fibrous membrane is prepared. The preparation method has the advantages that the prepared drug-loaded nano fibrous membrane has high antitumor effect, the preparation method is simple, the cost is low and the application prospect is broad.

Owner:SOUTHWEST UNIVERSITY

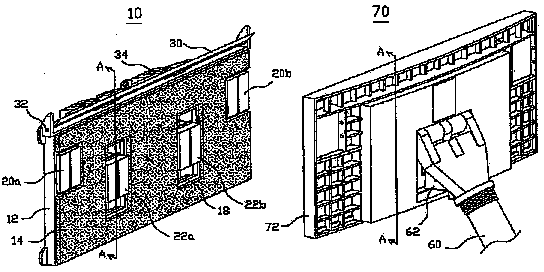

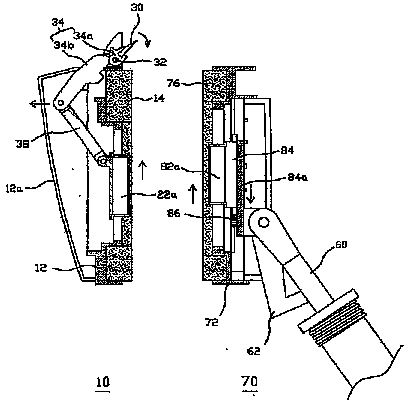

Glass cleaner

The invention relates to a glass cleaner, specifically to a glass cleaner which is attached onto the inner and outer surfaces of a piece of glass by a strong magnetic force and moves to wipe off or wash away stains on the two surfaces of the glass. The invention provides a rubber scraper blade which is capable of flexibly controlling an outdoor cleaning wiper and enabling the outdoor cleaning wiper to attach to or detach from the outdoor glass effectively and flexibly based on needs, thereby cleaning up cleaning fluid remained on the glass. The glass cleaner comprises an outdoor cleaner and an indoor controller. The glass cleaner provided by the invention enables the indoor and outdoor parts to attach onto the glass effectively and move flexibly by the control of the magnetic force of magnets, and enables the rubber scraper blade to contact with or separate from the surface of the glass freely with the employment of the magnetic force of magnet sliding blocks, thereby scraping off the cleaning fluid remained on the glass. In addition, according to the glass cleaner of the invention, the adhesion between the indoor controller and the outdoor cleaner only needs a relatively small number of magnets.

Owner:QINGDAO SPC

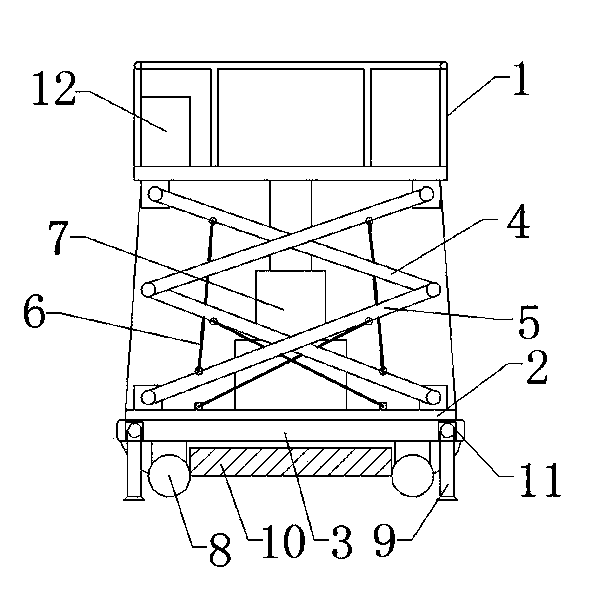

Anti-explosion hydraulic type shear fork elevator

InactiveCN104192760AMobile and flexibleImprove work efficiency and safety performanceLifting framesRotary stageHydraulic pressure

The invention discloses an anti-explosion hydraulic type shear fork elevator. The anti-explosion hydraulic type shear fork elevator comprises a guard bar mechanism, a rotating platform and a chassis, wherein an inner support and an outer support which are hinged to each other are arranged between the guard bar mechanism and the rotating platform; the inner support, the outer support and the rotating platform are connected with an oil cylinder device; a hydraulic mechanism is arranged between the guard bar mechanism and the middle of the rotating platform; the rotating platform is arranged at the upper end of the middle of the chassis; the chassis is provided with moving wheels, hydraulic jacks and a power supplying device; the moving wheels are arranged on the bottom of the chassis; the hydraulic jacks are arranged at the left ends and the right ends of the front side and the rear side of the chassis through supporting devices; and the power supplying device is arranged in the chassis. The anti-explosion hydraulic type shear fork elevator moves with the aid of the chassis, is also provided with a baffle and a control table, can automatically move and turn, moves flexibly and is convenient and labor-saving; the work efficiency and the safety are improved; and the anti-explosion hydraulic type shear fork elevator is simple in structure, convenient to operate and high in anti-explosion effect.

Owner:TAICANG HUANGJING YONGLE AGRI MACHINERY OPERATION SPECIALIZED COOP

Layered separated mining technology with extremely-thick coal seam continuous miner and filling combined

ActiveCN108825237ALess investmentQuick resultsUnderground miningSurface miningMechanizationMineralogy

The invention provides a layered separated mining technology with an extremely-thick coal seam continuous miner and filling combined, and belongs to the technical field of coal mining. The problem that conventional fully mechanized top coal caving or large mining height fully-mechanized coal mining faces can not be arranged on boundary coal of extremely-thick coal seams is solved. An extremely-thick coal seam coal seam with the thickness being 8-13 m is divided into an upper separated layer and a lower separated layer, 3-5.5 m of mining is conducted on the upper separated layer, 3-5.5 m of mining is conducted on the lower separated layer, the thickness of a middle layer is 1-2 m, and coal resources are stoped in a layered mining mode. lower separated layer is mined at first in the way thata continuous miner is adopted to arrange lower separated layer branch roadway mining caverns in a single wing of one side of a lower separated layer branch roadway, which is cooperatively combined with a paste filling mode, and the mode of first jump mining and then filling is adopted; then the upper separated layer is mined, the upper separated layer is mined in a wangeviry mode, upper separatedlayer branch roadway mining caverns are arranged on a single wing of one side of an upper separated layer branch roadway for mining, and stoping is conducted sequentially in a retreating mode. The layered separated mining technology with the extremely-thick coal seam continuous miner and filling combined is reasonable in process, high in mechanization degree and high in working face recovery rate, thereby being a very reliable extremely-thick coal seam coal seam boundary coal mining method.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

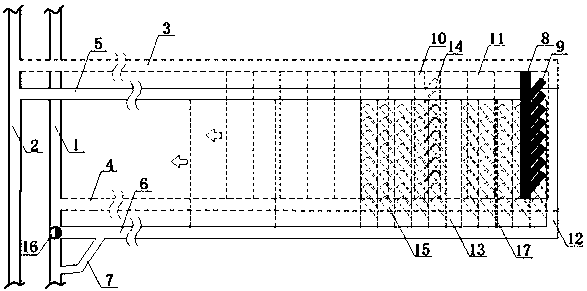

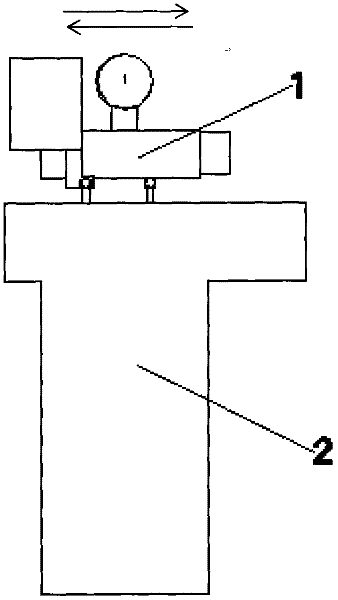

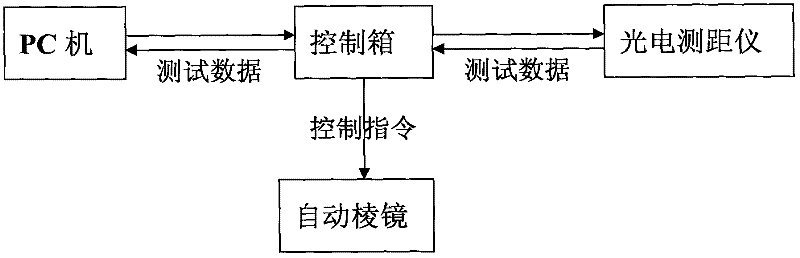

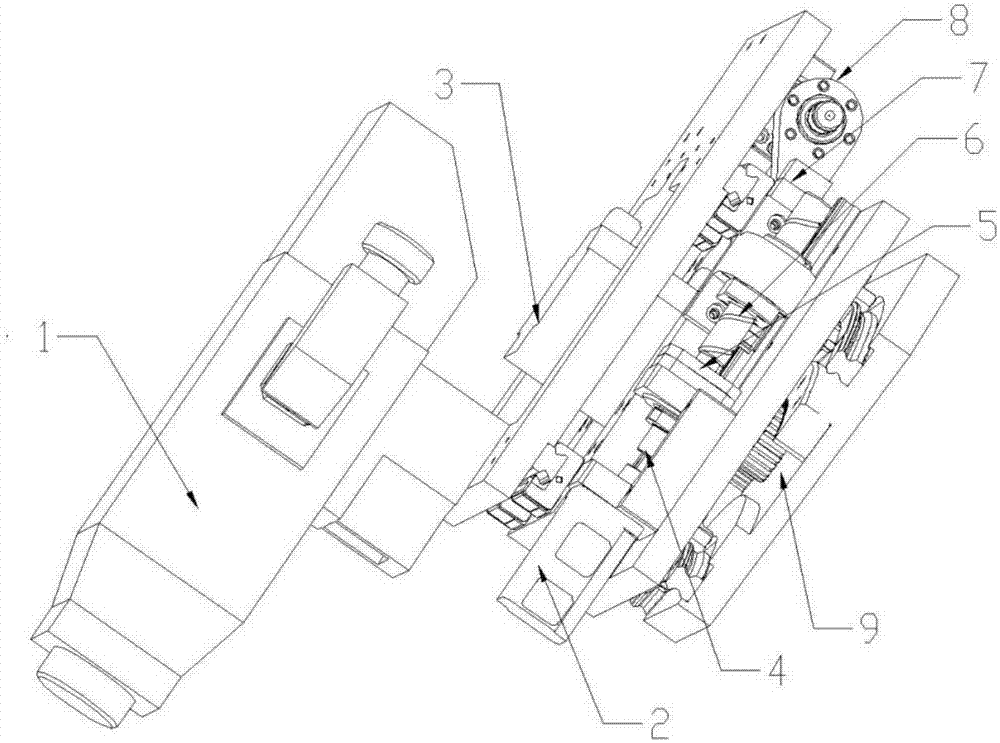

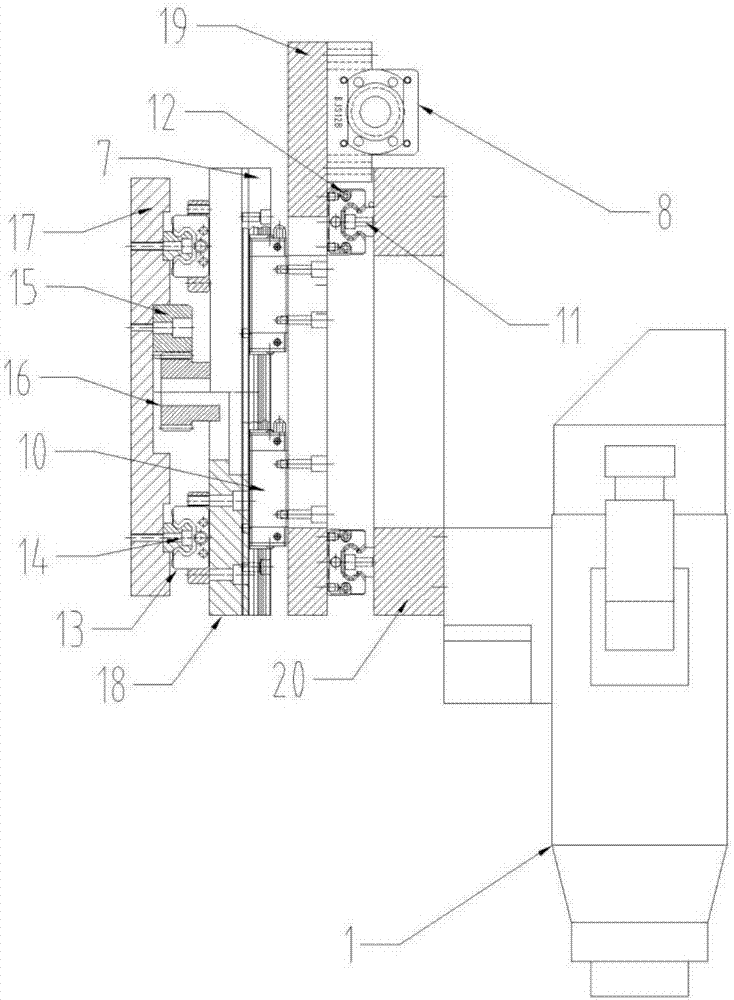

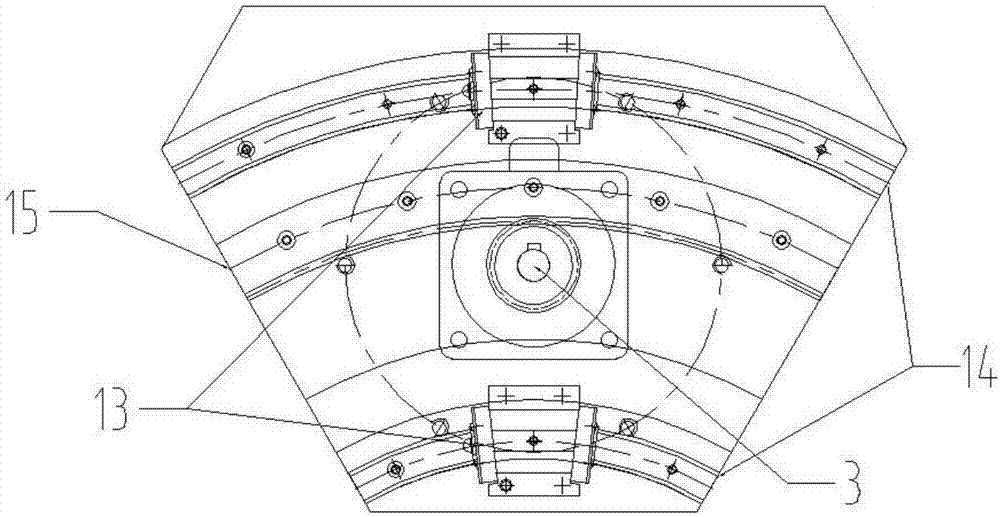

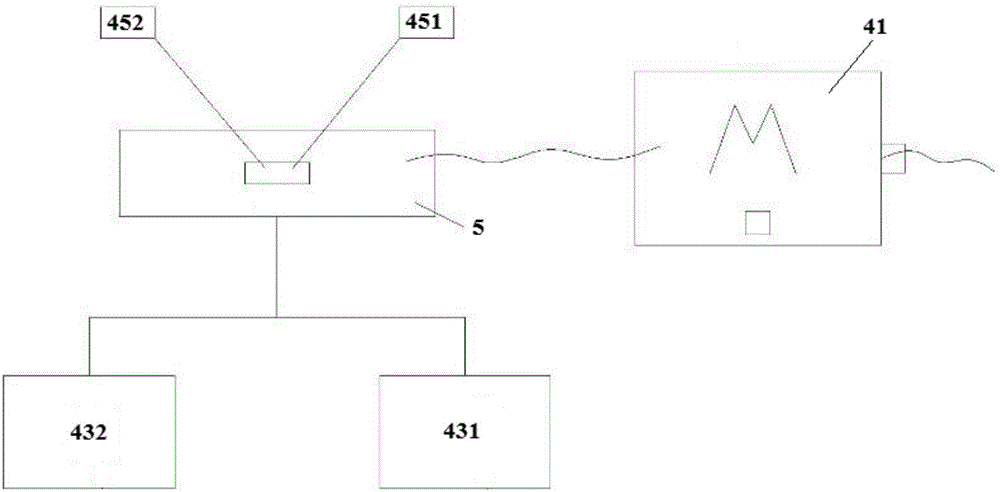

System for automatically detecting periodic error of photoelectric distance measuring instrument

The invention discloses a system for automatically detecting the periodic error of a photoelectric distance measuring instrument. The system comprises a guide rail, distance measuring reflecting prisms, and a detection pier for accommodating the photoelectric distance measuring instrument, wherein the distance measuring reflecting prisms are arranged on the guide rail at intervals according to the periodic error detection requirement. The system for automatically detecting the periodic error of the photoelectric distance measuring instrument is characterized by also comprising a control box and a computer, wherein the distance measuring reflecting prisms are automatic prisms; the computer is connected with the control box; and the control box controls the automatic prisms and the photoelectric distance measuring instrument to be detected. The system for automatically detecting the periodic error of the photoelectric distance measuring instrument has low cost, high efficiency and high automation degree, and can easily and accurately detect the periodic error of the photoelectric distance measuring instrument.

Owner:SUZHOU UNIV OF SCI & TECH

Three-dimensional compensation device for laser welding of complicated joint seam space

PendingCN107378241AMobile and flexibleHigh control precisionLaser beam welding apparatusEngineeringLaser beam welding

The invention belongs to the technical field of laser welding equipment and particularly discloses a three-dimensional compensation device for laser welding of a complicated joint seam space. The three-dimensional compensation device comprises a fixing mechanism, a rotating mechanism and a linear movement mechanism. The fixing mechanism comprises a first fixing plate, a second fixing plate, a third fixing plate and a fourth fixing plate. A rotary guide rail and a rack are arranged on the first fixing plate. A rotary sliding block and a vertical movement guide rail are arranged on the second fixing plate. A vertical movement sliding block and a horizontal movement sliding block are arranged on the third fixing plate. A horizontal movement guide rail and a welding gun are arranged on the fourth fixing plate. The rotating mechanism comprises a rotary servo motor and a gear connected with the rotary servo motor. The rotary servo motor is mounted on the second fixing plate. The gear is engaged with the rack. The linear movement mechanism comprises a vertical movement mechanism and a horizontal movement mechanism. The vertical movement mechanism is arranged on the second fixing plate. The horizontal movement mechanism is arranged on the third fixing plate. The three-dimensional compensation device has the beneficial effects of being flexible to move, high in control accuracy, high in production efficiency, good in welding quality and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

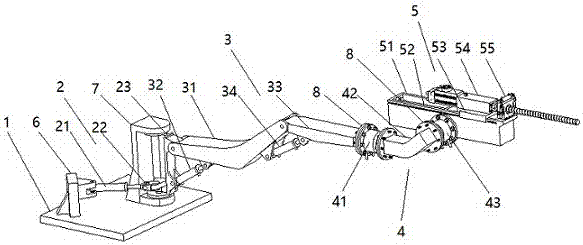

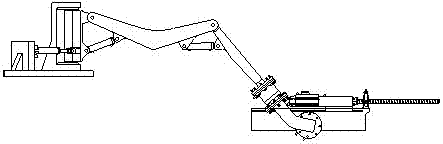

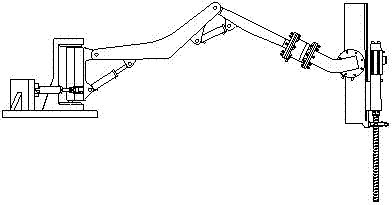

Hydraulic drill arm with multiple degrees of freedom

PendingCN107420034AMobile and flexibleDerricks/mastsDrilling machines and methodsDegrees of freedomMulti degree of freedom

The invention discloses a hydraulic drill arm with multiple degrees of freedom. The hydraulic drill arm comprises a base, a left-right swing mechanism, an up-down swing mechanism, a rotary mechanism and a sliding adjusting mechanism. The left-right swing mechanism is arranged on the base, the up-down swing mechanism is connected with the left-right swing mechanism, the sliding adjusting mechanism is connected with the up-down swing mechanism through the rotary mechanism, a side plate and a fixed rotary frame are also fixedly arranged on the base, and the left-right swing mechanism is connected with the base through the side plate and the fixed rotary frame. Owing to the mode, the hydraulic drill arm with multiple degrees of freedom allows working locations of drill machines to be flexibly determined in narrow spaces, and accordingly, the problems of small movable ranges in exploitation procedures, difficulty in flexibly shifting drill bits of existing drill machines at tail ends by the aid of rotation and movement of first-section drill arms, and operation complexity can be solved.

Owner:GUILIN UNIV OF AEROSPACE TECH

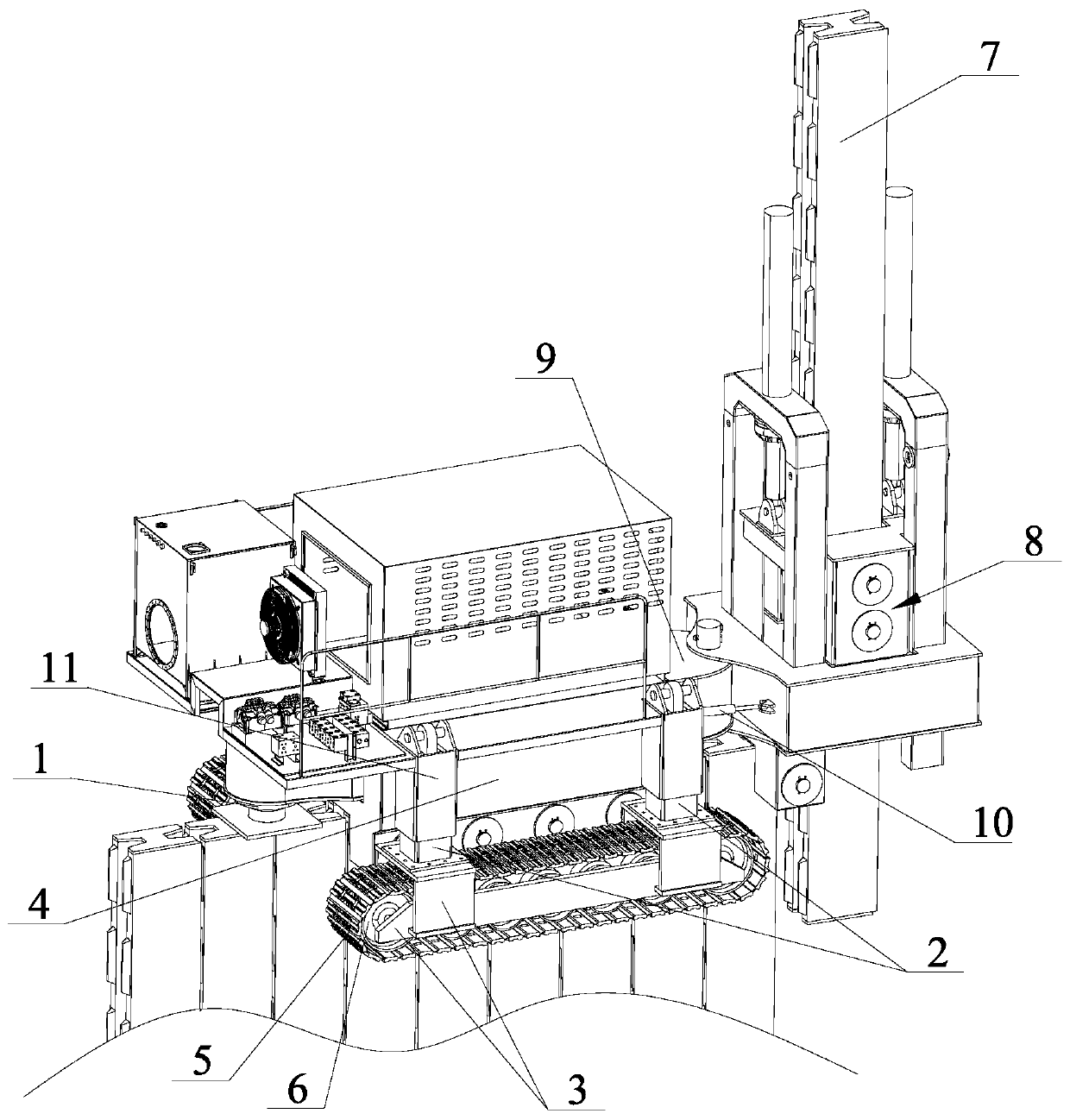

Pile pressing equipment

PendingCN110424389AQuality improvementFlexible and convenient horizontal turningBulkheads/pilesArchitectural engineeringDrilling machines

The invention discloses pile pressing equipment. The equipment comprises a base, first clamping mechanisms fixed to the two sides of the bottom of the base correspondingly, a first lifting oil cylinder fixed to the rear end of the base, a guide rail closed into a middle hole of the base in a sliding sleeving mode, and a horizontal moving oil cylinder which is arranged on the guide rail and the base and used for moving the base or the guide rail front and back. The equipment further comprises a pile pressing device arranged at the front end of the guide rail, and second clamping mechanisms arearranged on the two sides of the bottom of the pile pressing device. The equipment further comprises a crawler device and a lifting device which enable the base and the pile pressing device to be placed at the top of a planted pile. The front end of the guide rail is in the shape of an arc, the rear end of the pile pressing device is hinged to the front end of the guide rail, and turning oil cylinders used for enabling the pile pressing device to turn horizontally are arranged on the two sides of the front end of the guide rail; fixing blocks used for fixing lifting oil cylinders are hinged tothe rear end of the guide rail; and a rotary drilling machine is mounted on the pile pressing device. The pile pressing equipment can travel to the top end of the planted pile and is positioned or moved, and in addition, the pile pressing device can horizontally turn.

Owner:浙江万坚建设有限公司

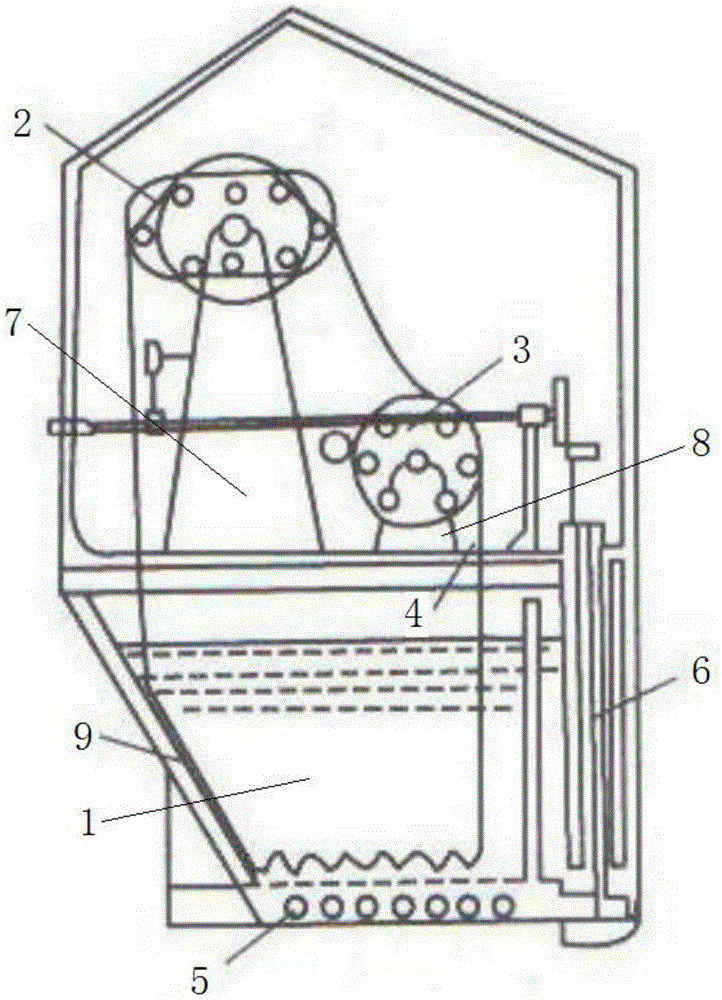

Rope-shaped dyeing machine

InactiveCN104358052AMobile and flexibleReduce energy consumptionTextile treatment containersTextile treatment machine arrangementsEngineeringMechanical engineering

The invention discloses a rope-shaped dyeing machine which comprises a dyeing groove. The rope-shaped dyeing machine is characterized in that the rope-shaped dyeing machine further comprises a driving cloth guiding roller, a driven cloth guiding roller, a cloth distributing crosspiece and a liquid adding pipe, dyeing solution fills in the dyeing groove, a driving support and a driven support are arranged above the dyeing groove, the driving cloth guiding roller is arranged on the driving support and can rotate around the driving support, the driving cloth guiding roller is connected with a motor, the driven cloth guiding roller is arranged on the driven support and can rotate around the driven support, the cloth distributing crosspiece is arranged above the dyeing solution, an inclined board is arranged on one side of the dyeing groove, and the liquid adding pipe used for adding liquid in the dyeing groove is arranged on the inner side of the side board opposite to side of the inclined board. The problems in the prior art that the mechanism of the dyeing machine for pushing fabric to move is complicated, the energy consumed is large, the dyeing solution is not heated, and the dyeing quality is lowered are solved, and the rope-shaped dyeing machine is simple in structure, convenient and fast in fabric moving and good in dyeing effect.

Owner:高雅

Overhaul and transport vehicle and method for water-feeding pump motor

ActiveCN102774624AFlexible and effective transferEffective dodgeMechanical conveyorsAutomotive engineeringSlide plate

Owner:CHINA SHENHUA ENERGY CO LTD +2

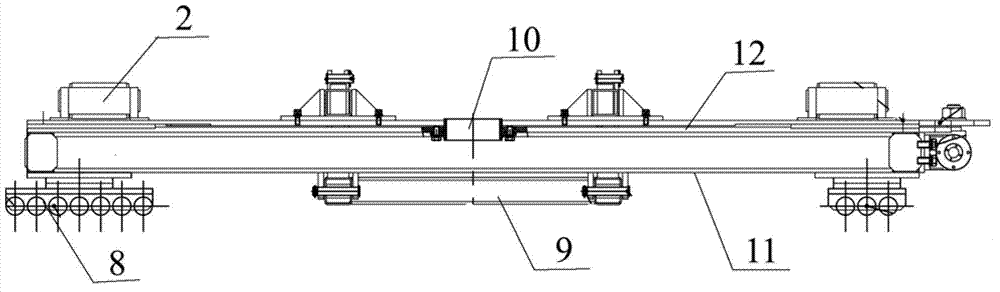

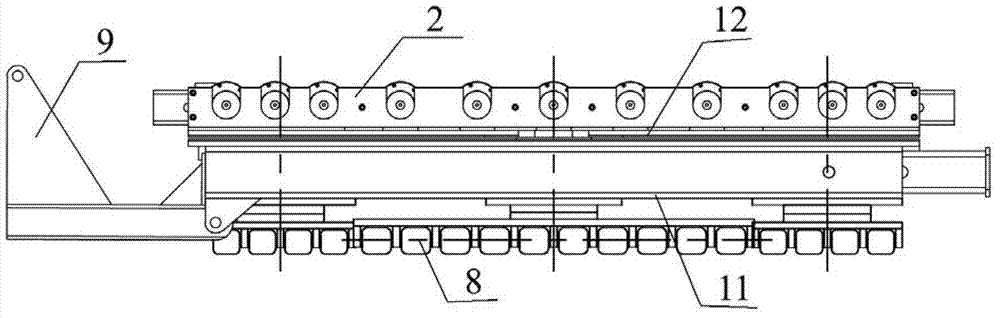

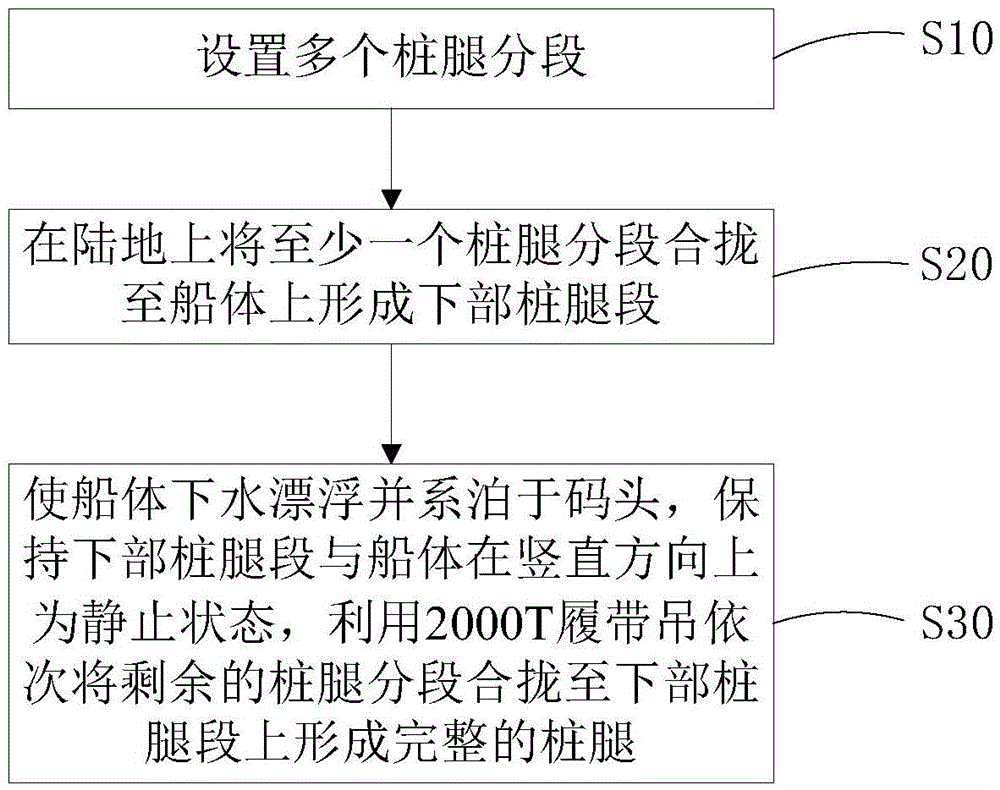

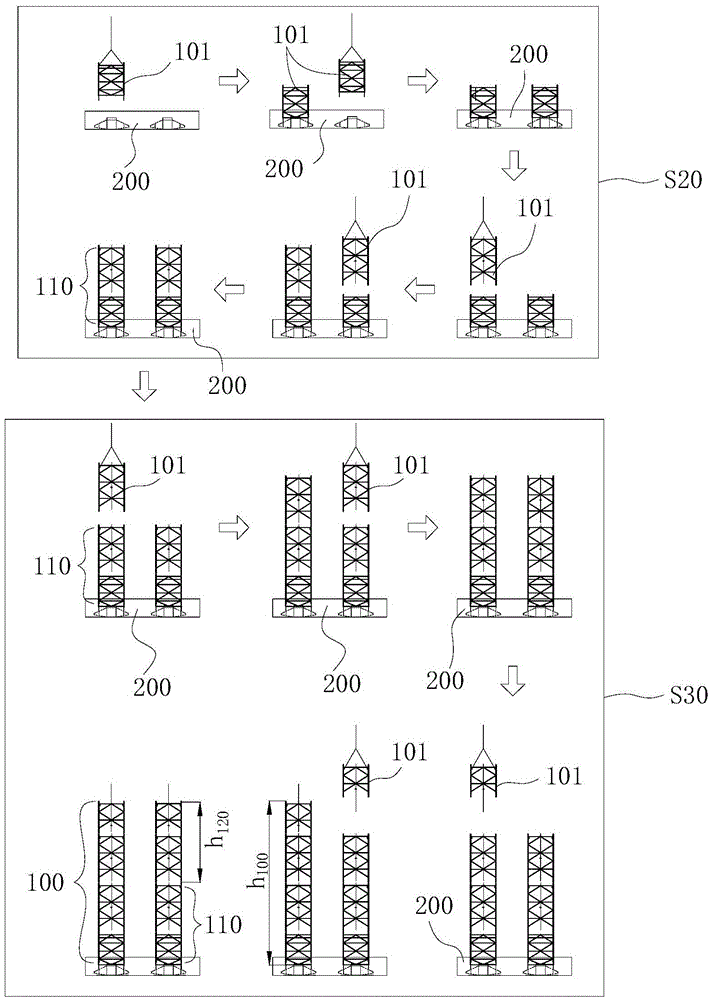

Method for folding self-lifting-type platform truss-type pile legs

InactiveCN105586864AHuge savingsMobile and flexibleArtificial islandsUnderwater structuresStructural engineeringUtilization rate

The invention provides a method for folding self-lifting-type platform truss-type pile legs. The method comprises the following steps: multiple pile leg sections are arranged; at least one pile leg section is folded to a ship body to form a lower part pile leg section on the land; the ship body is launched to float on water and is moored at a dock; lower part pile leg sections and the ship body are kept at a static state in the vertical direction, and the remaining pile leg sections are sequentially folded to the lower part pile leg sections by utilizing a 2000 T crawler crane to form complete pile legs; and the sum of the heights of the pile leg sections which are hoisted and folded through the crawler crane is 15%-16% of the total height of the pile legs. According to the method, overwater hoisting and folding are performed by adopting the crawler crane; the cost for renting a large floating crane and for towing a ship for sailing is omitted, so that the cost is reduced; the crawler crane is flexible for moving, and the utilization rate is high; and pile insertion positioning is not needed, so that the folding cycle is shortened, and the folding efficiency is improved.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +2

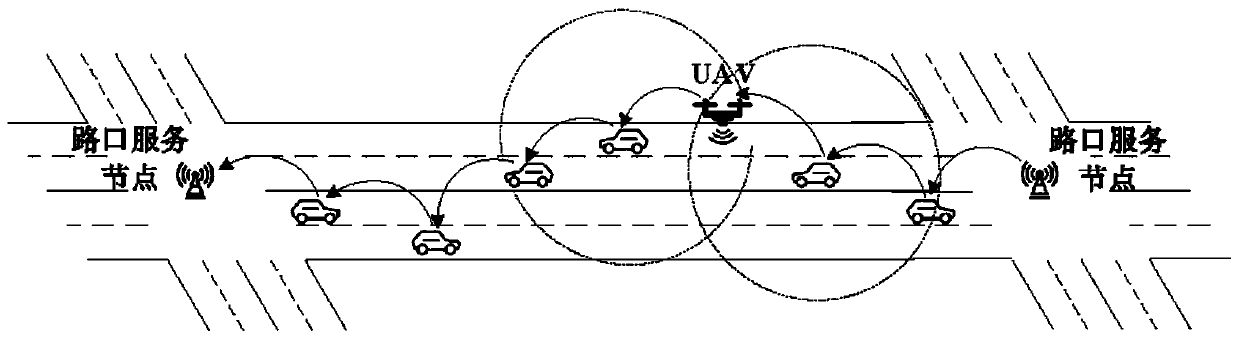

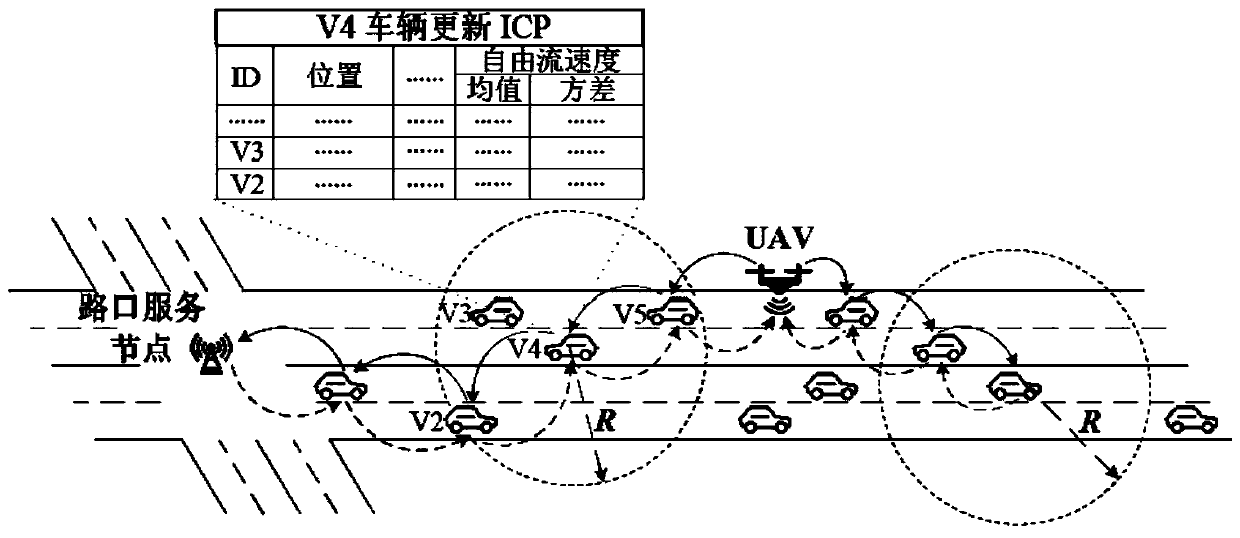

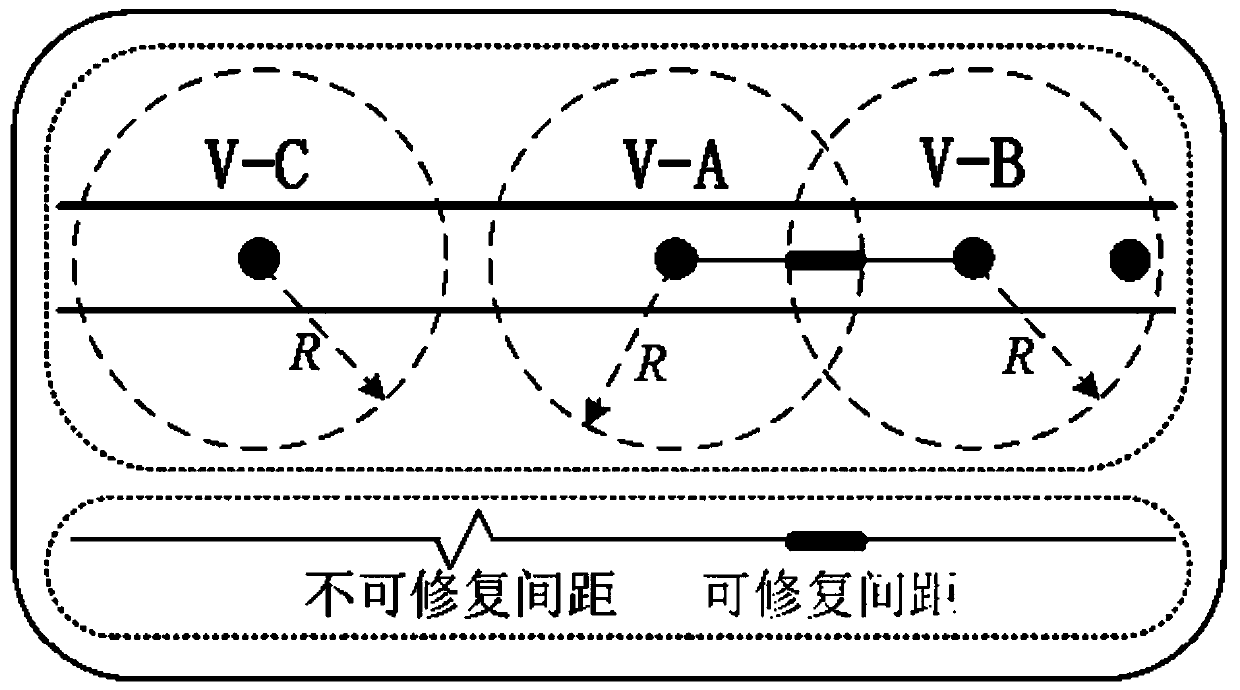

Vehicle ad hoc network road connectivity real-time repair mechanism method based on unmanned aerial vehicle nodes

InactiveCN110958574AEasy to deployStrong space effectParticular environment based servicesNetwork topologiesSimulationUncrewed vehicle

The invention discloses a vehicle ad hoc network road connectivity real-time repair mechanism method based on unmanned aerial vehicle nodes, and relates to the technical field of Internet of Vehiclesand ad hoc networks. The method mainly comprises: obtaining data such as the real-time position and the free flow speed of a current road vehicle based on an unmanned aerial vehicle; calculating the position of the vehicle at each moment in the next period according to the obtained information, and predicting the road multi-hop network communication condition between two intersections according tothe positions; and if the regional network on the road is disconnected in the future period, enabling the unmanned aerial vehicle to calculate an optimal periodic movement strategy according to the current condition to perform bridging repair. According to the mechanism method, only a single unmanned aerial vehicle needs to be configured on a single road to collect vehicle information by means ofa vehicle ad hoc network, calculate the future motion trail of the vehicle to predict the position of the network disconnection area; the optimal real-time moving strategy is calculated in combination the current position, direction and speed of the unmanned aerial vehicle, the possible disconnection area in the future period is repaired to the maximum extent, and the mechanism method provides stable and effective network connectivity support for road vehicle communication when the vehicle flow is small, namely the number of vehicle nodes is small.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Intelligent building decoration equipment capable of conducting secondary painting on outer wall of arc-shaped balcony

InactiveCN107905506ASolve the dangerSolve cleanlinessBuilding constructionsPlane surface grinding machinesEngineeringMobile device

The invention relates to an intelligent building decoration equipment capable of secondary painting on the outer wall of an arc-shaped balcony, including a mounting frame, a connecting device, a limit device, a moving device and a painting device. The number of the mounting frames is two, and the two mounting frames A connecting device is installed between them, two limit devices are installed at the front and rear ends of the mounting frame, a moving device is installed at the lower end of the mounting frame, and a painting device is installed in the middle of the front end of the mounting frame. , Auxiliary agencies, grinding agencies and brushing agencies. The invention can solve the problems of high risk, poor cleanability, low work efficiency, high labor intensity and inconvenient movement in the secondary painting process of the outer wall of the arc-shaped balcony, and can realize automatic grinding and painting of the outer wall of the arc-shaped balcony. It has the advantages of good safety, high cleanliness, high work efficiency, low labor intensity and flexible movement.

Owner:吴丹

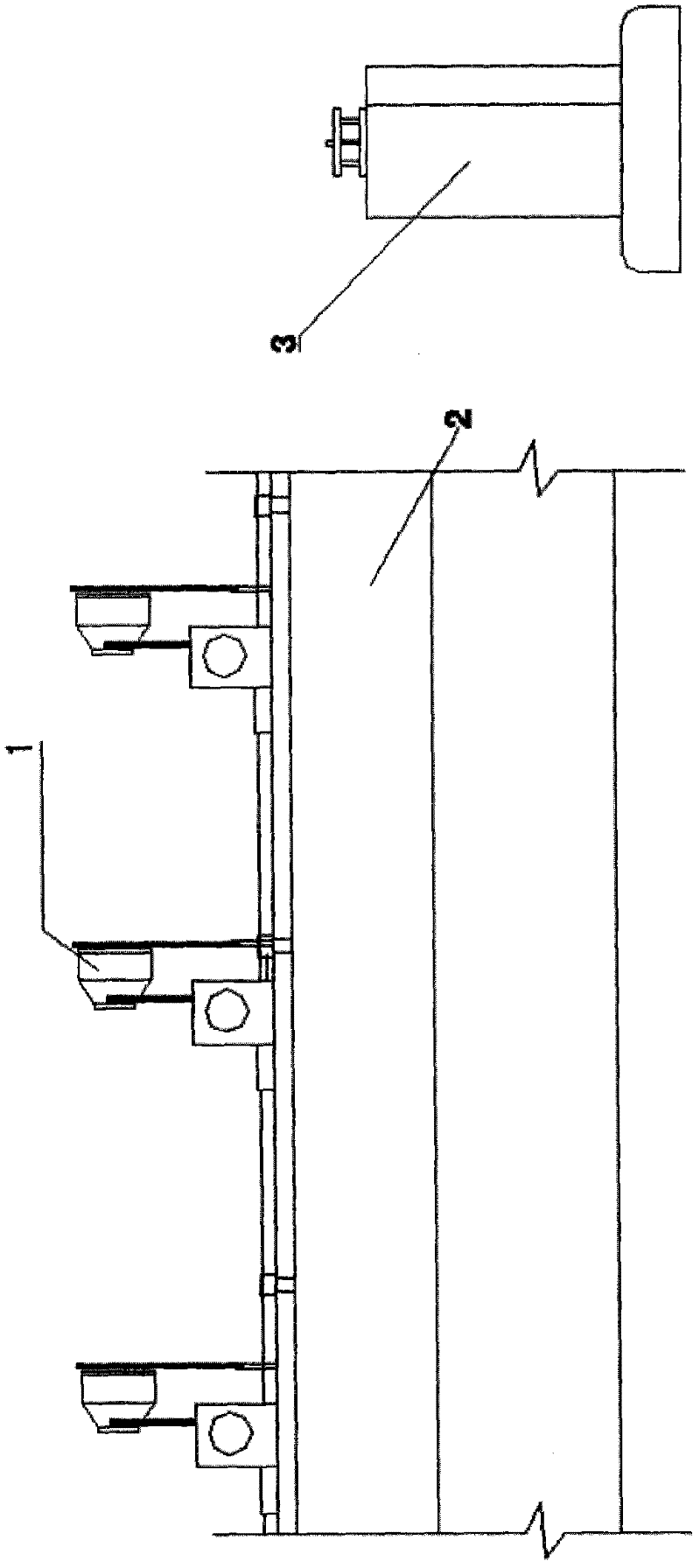

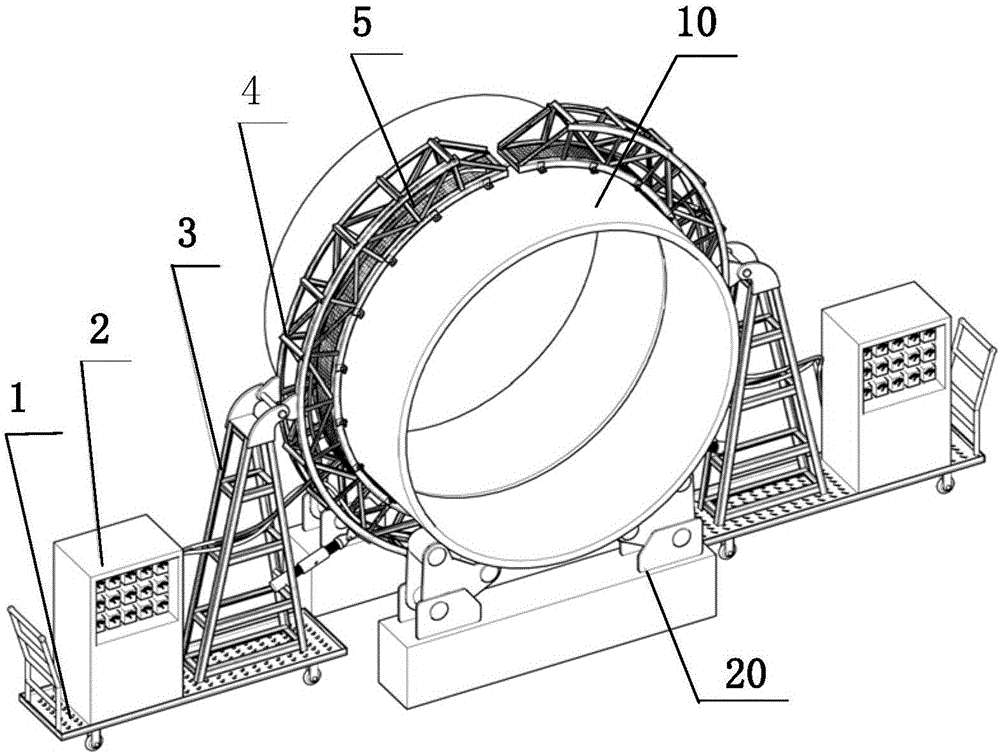

Heating device and method for heating steel pipe circular seams by using heating device

InactiveCN106583973AMobile and flexibleEasy to useWelding/cutting auxillary devicesFurnace typesElectricityEngineering

The invention discloses a heating device and a method for heating steel pipe circular seams by using the heating device. The heating device comprises a moving device, and temperature control equipment, a fixed bracket and a track heating plate bracket arranged on the moving device; the moving device is used for moving the whole heating device; the fixed bracket is fixed on the moving device, and is connected with the track heating plate bracket; the track heating plate bracket is provided with a track heating plate; the shape of the track heating plate bracket is matched with the diameter of a steel pipe; during working, the track heating plate bracket is bonded with the surface of the steel pipe, and the track heating plate heats the steel pipe; and the temperature control equipment is electrically connected with the track heating plate for controlling the heating temperature of the track heating plate. The heating device and the method for heating the steel pipe circular seams by using the heating device are flexible, convenient and efficient in use, and are safe and reliable.

Owner:SINOHYDRO BUREAU 12 CO LTD

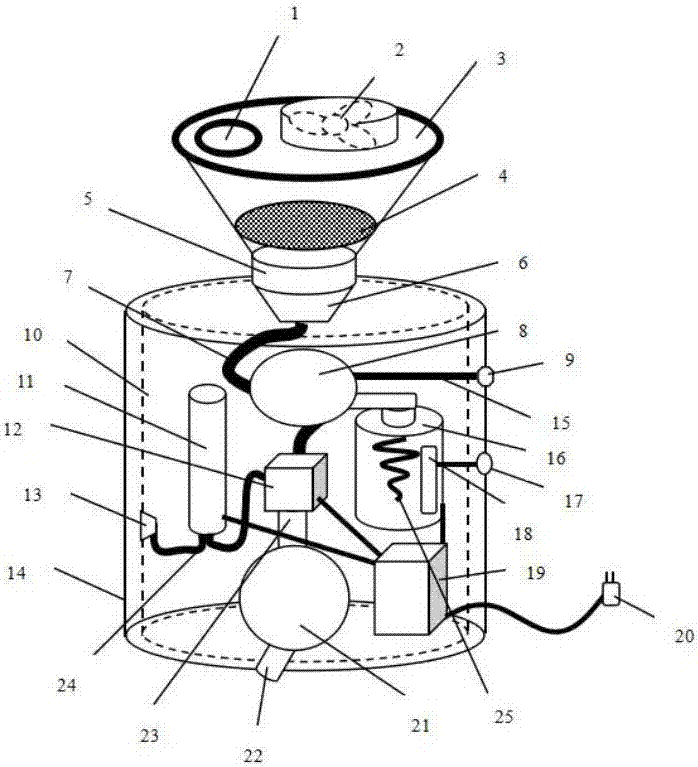

Sterilization treatment device for urine sample in clinical laboratory

The invention discloses a sterilization treatment device for a urine sample in a clinical laboratory. The sterilization treatment device mainly comprises a liquid inlet funnel, an inner shell and an outer shell, wherein the liquid inlet funnel comprises a liquid inlet, a draught fan, a filter net, a deodorizer and a flow valve; the inner shell comprises a liquid inlet pipeline, an autoclaved sterilization boiler, an ozone generator, an ozone disinfector, an exhaust pipe, a pressurizing container, a volume sensor, a power supply, an external power supply plug, a waste liquid storage container, a liquid storage pipeline, an ozone pipeline and an electric heating wire; and the outer shell comprises an exhaust hole, an ozone disinfection spray head, an alarm and a waste liquid draining hole. The sterilization treatment device is small and exquisite and is flexible to move; and after various types of urine samples are collected, the urine samples are filtered, pressured and subjected to autoclaved sterilization and ozone disinfection, so that the safety emission is realized, and no any environmental pollution is caused.

Owner:王名民

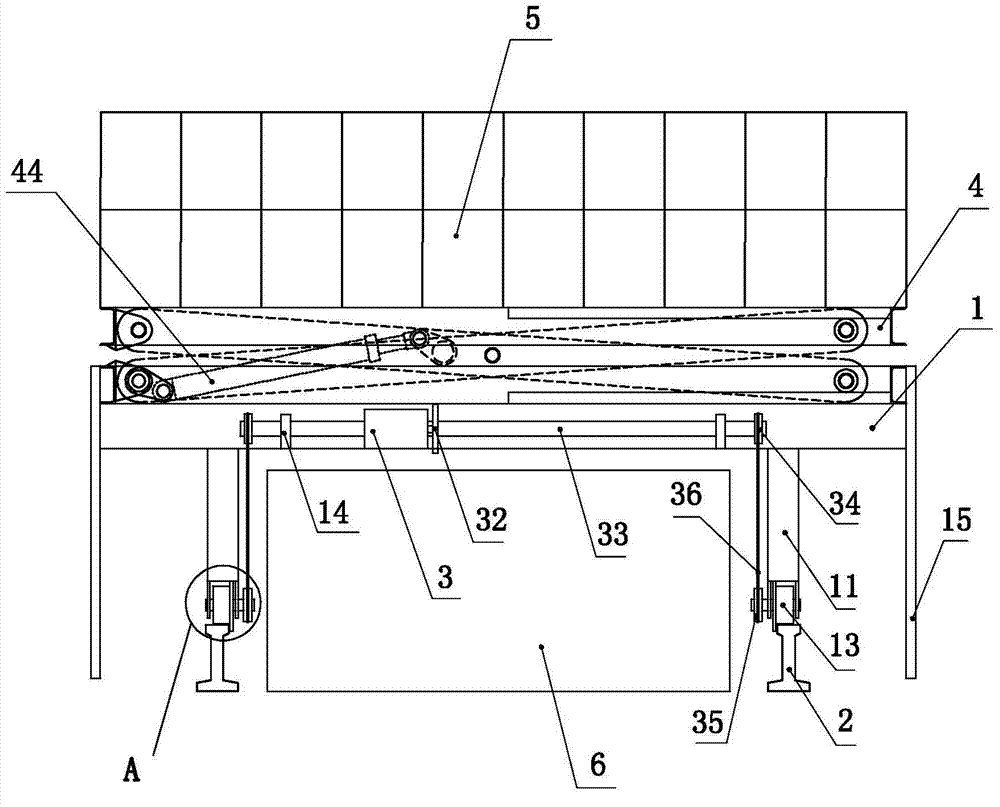

Lifting platform with automatic moving rail

The invention provides a lifting platform with an automatic moving rail, and relates the technical field of lifting machines. The lifting platform with the automatic moving rail is used for solving the problems that an existing moving shear-folk lifting machine cannot span higher height and move on a fixed rail. For the lifting platform with the automatic moving rail, which is provided with the invention, the lifting part comprises a base, a first supporting rod and a second supporting rod which are arranged in an X shape, and a top board which is arranged at the tops of the two supporting rods, supporting legs are arranged at the bottom of the base, rail wheels are respectively arranged at the lower parts of the supporting legs, and the rail wheels can roll on the rail which is laid on the ground so as to drive the lifting part to move. A motor and a transmission mechanism are arranged on the base so as to transmit the rotary motion of the motor to the rail wheels. A guarding fence is arranged on the top board so as to protect operators. The lifting platform with the automatic moving rail, which is provided by the invention, can move forwards and backwards according to the production procedures of products, is flexible to move, and is convenient to operate.

Owner:济南华北升降平台制造有限公司

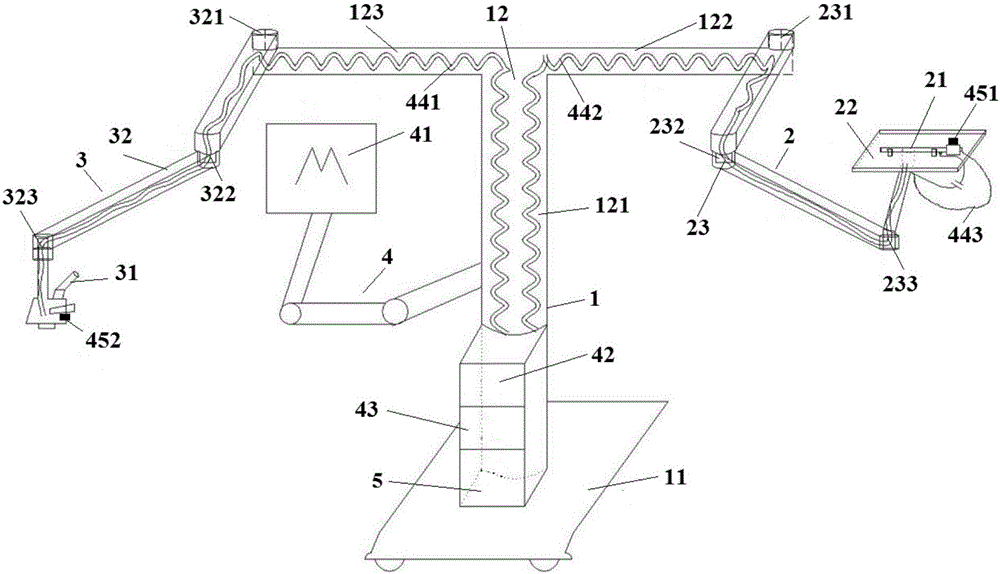

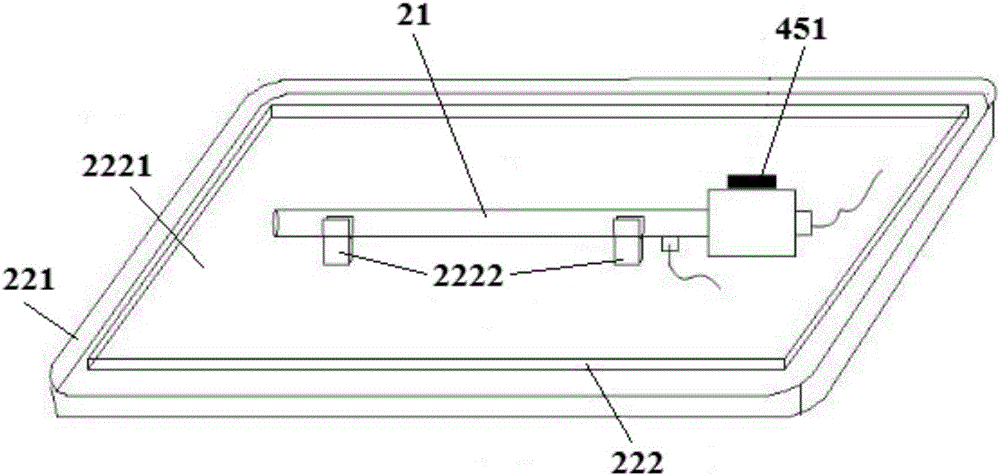

Endoscope and microscope unified body

InactiveCN106308944ALower usage limitReduce restrictionsDiagnosticsSurgical instrument supportMedical equipmentDisplay device

The invention relates to the technical field of medical equipment and particularly relates to an endoscope and microscope unified body. The endoscope and microscope unified body provided by the invention comprises a mounting bracket assembly, an endoscope assembly, a microscope assembly and an image display assembly, wherein the endoscope assembly and the microscope assembly are mounted on the mounting bracket assembly in a mutual noninterference and integrated manner, the endoscope assembly comprises an endoscope, the microscope assembly comprises a microscope, the image display assembly comprises a display, and the display is used for displaying images detected by the endoscope and images magnified by the microscope in a switching manner. According to the endoscope and microscope unified body provided by the invention, the effective integration of the endoscope and the microscope can be achieved, the restriction on the use of the endoscope and the microscope caused by a space of an operating room can be reduced, and the improvement on operation continuity and the shortening of operation time are facilitated.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI

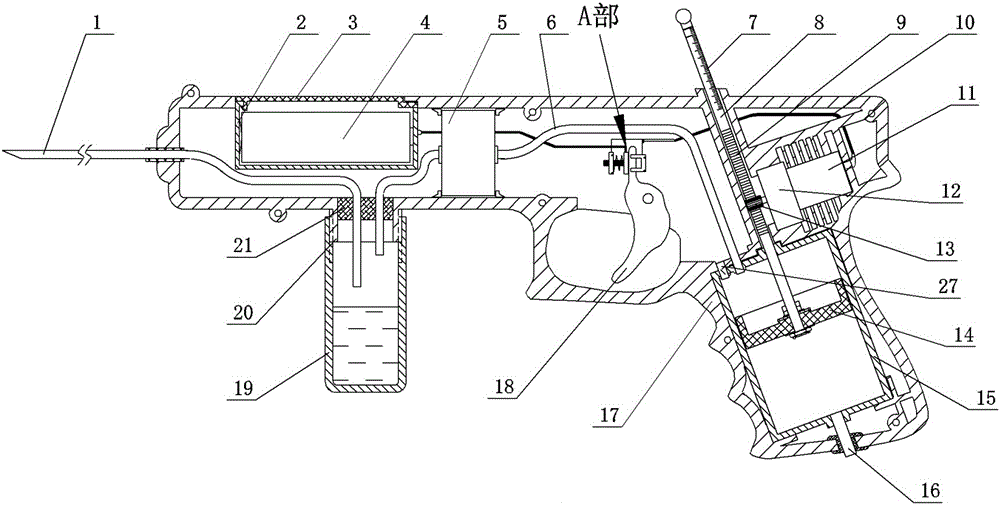

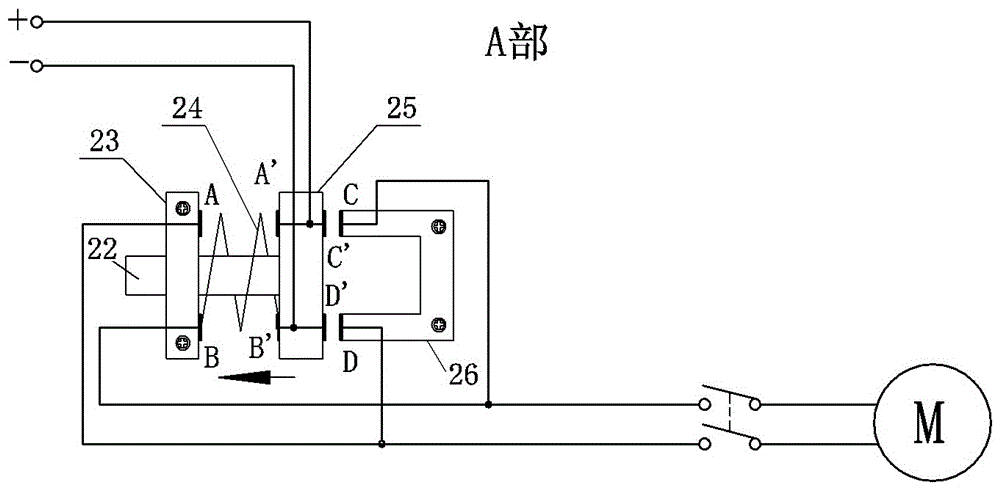

Handheld electric ovum sampling device

The invention discloses a handheld electric ovum sampling device which comprises a negative pressure device and an ovum sampling needle, a negative pressure cylinder is fixedly arranged in a gun body handle inner cavity of the negative device, the negative pressure cylinder is matched with a piston in a sleeved mode, the piston is connected with a slider and provided with a rack, and an output shaft of an electric driving mechanism is provided with a wheel gear which is meshed with the rack; anegative pressure tube connected with the upper cavity of the negative pressure cylinder is communicated with a storage bottle through a filter; the inner end of the ovum sampling needle is located into the storage bottle, and a manual switch powered by electricity to work is arranged. The device is simple in structure and easy to use with high efficiency, the device can be used in a laboratory and taken out to the wild, a culture medium is omitted, and it is convenient for later ovoscopy.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY MEDICINE HENAN ACAD OF AGRI SCI

Rubbing machine for medicinal materials

ActiveCN104457139ASafe to useMobile and flexiblePharmaceutical product form changePreliminary solid treatment for dryingMotor shaftAgricultural engineering

The invention relates to the technical field of agricultural machinery, in particular to a rubbing machine for medicinal materials. The rubbing machine is characterized in that a motor is fixed in the transverse middle of the front end of a lower layer of a frame, a motor shaft is connected with a driving transmission shaft through a pulley, a lower roller driving sprocket is connected with a lower roller driven sprocket arranged at the right end of a lower roller shaft through a belt, a driving guide gear meshes with a driven guide gear arranged on a driven transmission shaft over the driving transmission shaft in the vertical middle of the front of the frame, an upper roller driving sprocket arranged at the right end of the driven transmission shaft is connected with an upper roller shaft main sprocket through a chain. Upper and lower rollers with moderate sizes and moderate speeds rotate relatively, medicinal material can be effectively rubbed when passing between the upper and lower rollers, and the internal structure of the medicinal material is kept intact; a gap between the upper and lower rollers can be adjusted into a moderate rubbing gap by adjustment of a screw, and the medicinal material is never damaged by crushing or rubbing.

Owner:青海林丰农牧机械制造有限公司

Crossheading roadwayalternating circulation self-moving railtype hydraulic support

ActiveCN110259498AWith traction functionRealize self-moving functionMine roof supportsJackscrewHeel structure

The invention discloses acrossheading roadway alternating circulation self-moving rail type hydraulic support, and belongs to coal mine machines. The technical problem of providingthe crossheading roadway alternating circulation self-moving rail type hydraulic supportcapable of self-moving and with good stability and varied azimuth is to be solved; according to the technical scheme,the crossheading roadway alternating circulation self-moving rail type hydraulic support comprises a stepping structure, a lifting jacking structure, a steering structure,anti-heel structures, and a traction jack; the stepping structure structurally comprises two parallelly arranged rails,a bracket base is placed on the two rails, two advancing jacks are mounted corresponding to the two rails, two bottom lifting jacks are vertically mounted at the front end of the bracket base, piston rods of the bottom lifting jacksare lowered downward, and rollers are arranged at the end parts; the lifting jacking structure is mounted on the bracket base; a steering structure is mounted atthe front and rear ends of the bracket base are respectively equipped with, and two sets of the anti-heel structures are respectively mounted on both sides of the bracket base, and the traction jack is arranged parallel to the track and used for installing with an equipment train; and thehydraulic support is used in coal mine roadways.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Arrangement line conveying belt tensioning mechanism

PendingCN106742273AMobile and flexibleLarge adjustment rangeConveyorsPackagingEngineeringMechanical engineering

Owner:SHANDONG SONGYUAN AUTOMATION EQUIP

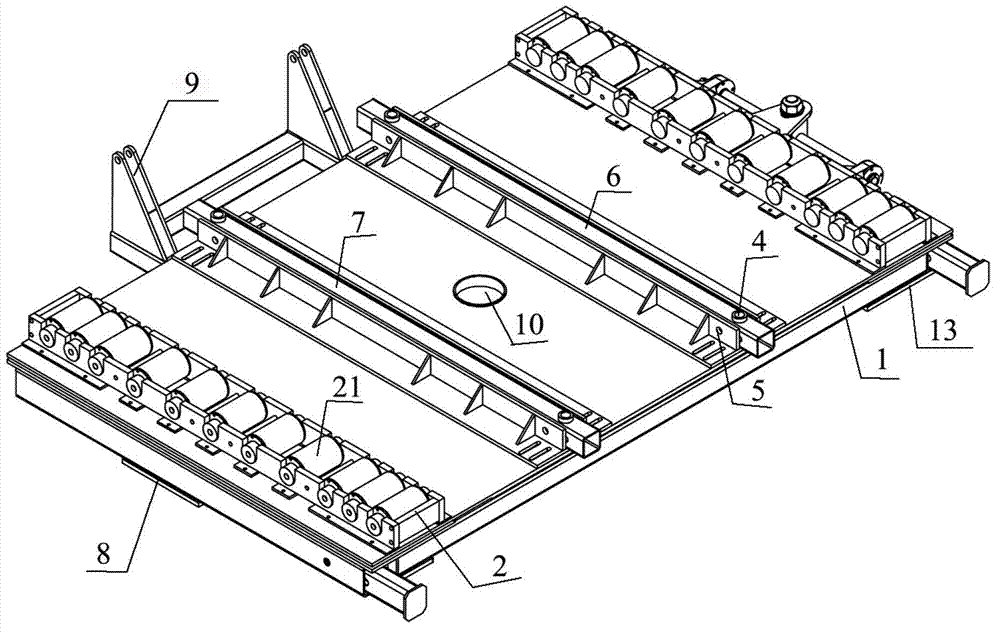

Lifting rotating device for vehicle storing and fetching of three-dimensional garage

ActiveCN104314343AEnsure the center of gravity is balancedEasy accessParkingsMechanical engineeringEngineering

The invention discloses a lifting rotating device for vehicle storing and fetching of a three-dimensional garage. The lifting rotating device comprises a base, a lifting frame, a supporting carrier plate, a rotating carrier plate and an extensible bridging carrier plate, the lifting frame is fixed on the base, the supporting carrier plate is arranged above the base and fixedly connected with the lifting frame, the rotating carrier plate is arranged above the supporting carrier plate, and the extensible bridging carrier plate is arranged between the supporting carrier plate and the rotating carrier plate. During vehicle storing and fetching, the extensible bridging carrier plate extends out to be connected on a parking platform of the three-dimensional garage in an overlapped manner, and the rotating carrier plate rotates onto the extensible bridging carrier plate and corresponds to the parking platform. The lifting rotating device can be used for the three-dimensional garages different in building style, quick vehicle storing and fetching can be realized, and the problem that a vehicle storing and collecting system is only suitable for annular multilayer three-dimensional garages in the prior art is solved.

Owner:喻建康

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com