Numerical-control multi-spindle gantry drilling and milling machine tool

A technology of drilling and milling machine tools and gantry, which is applied to the components of boring machines/drilling machines, boring/drilling, drilling/drilling equipment, etc. Quantity, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

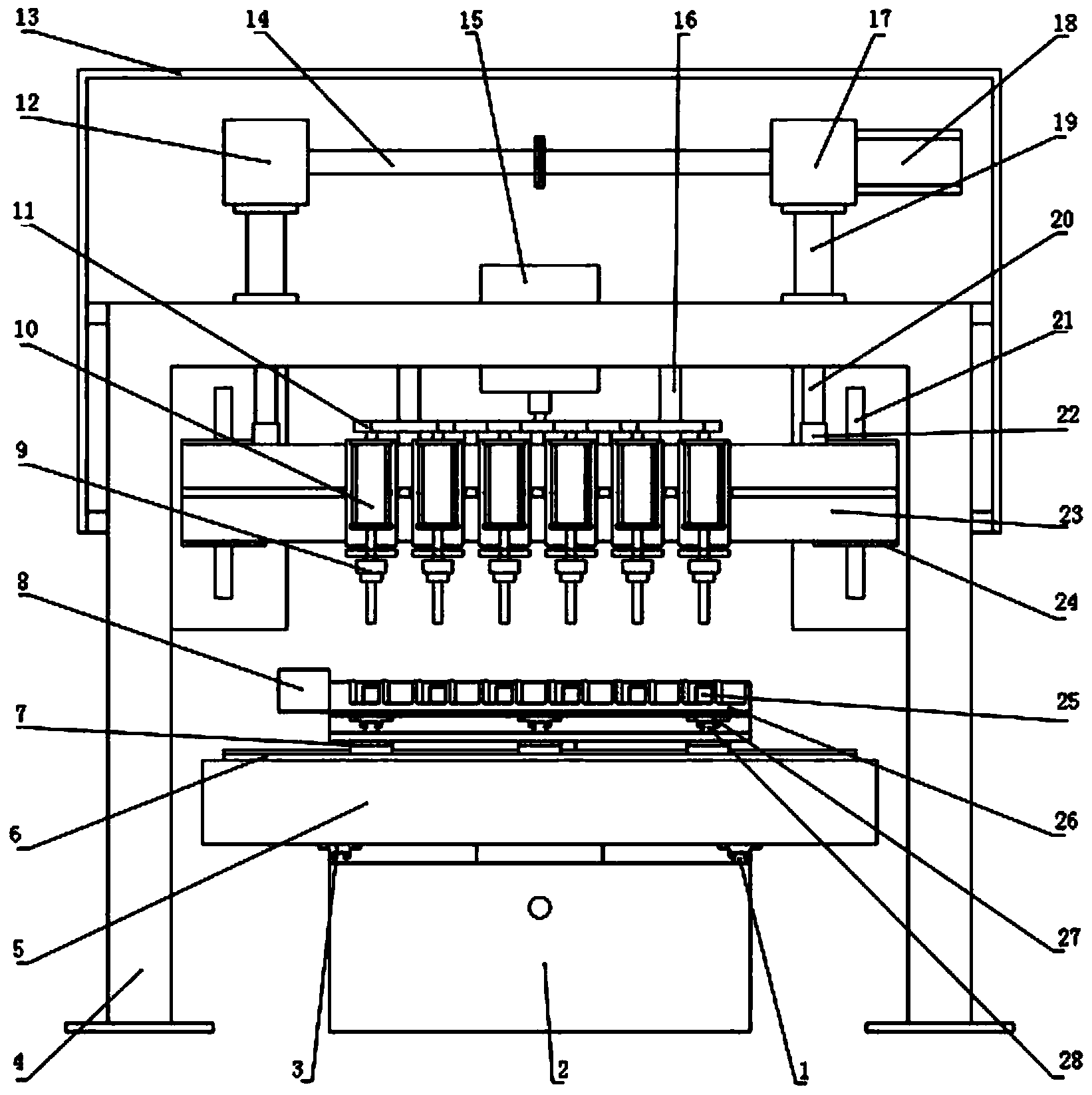

[0029] Figure 1-4 It is a specific embodiment shown, the CNC multi-axis gantry drilling and milling machine tool, including a gantry 4, the gantry 4 is provided with a shield 13, under the gantry 4 is provided with X direction and The bed that moves in the Y direction; the bed is provided with a clamping device for clamping the workpiece, and a row of drills 9 is arranged opposite to it on the bed, and the row of drills 9 is driven by two-stage power to move vertically Moving up and down in the vertical direction, the row drill 9 is driven by the same driving force to rotate.

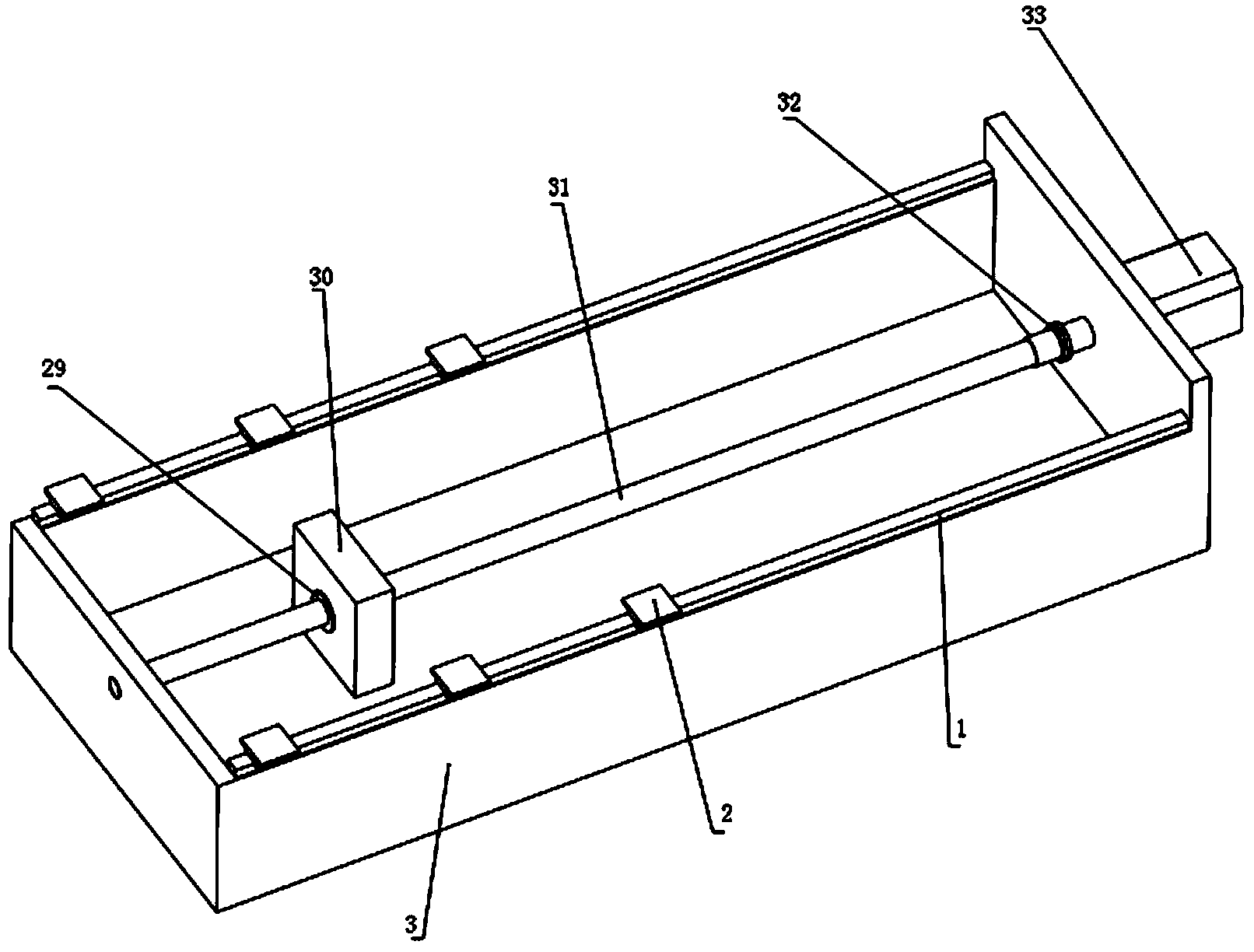

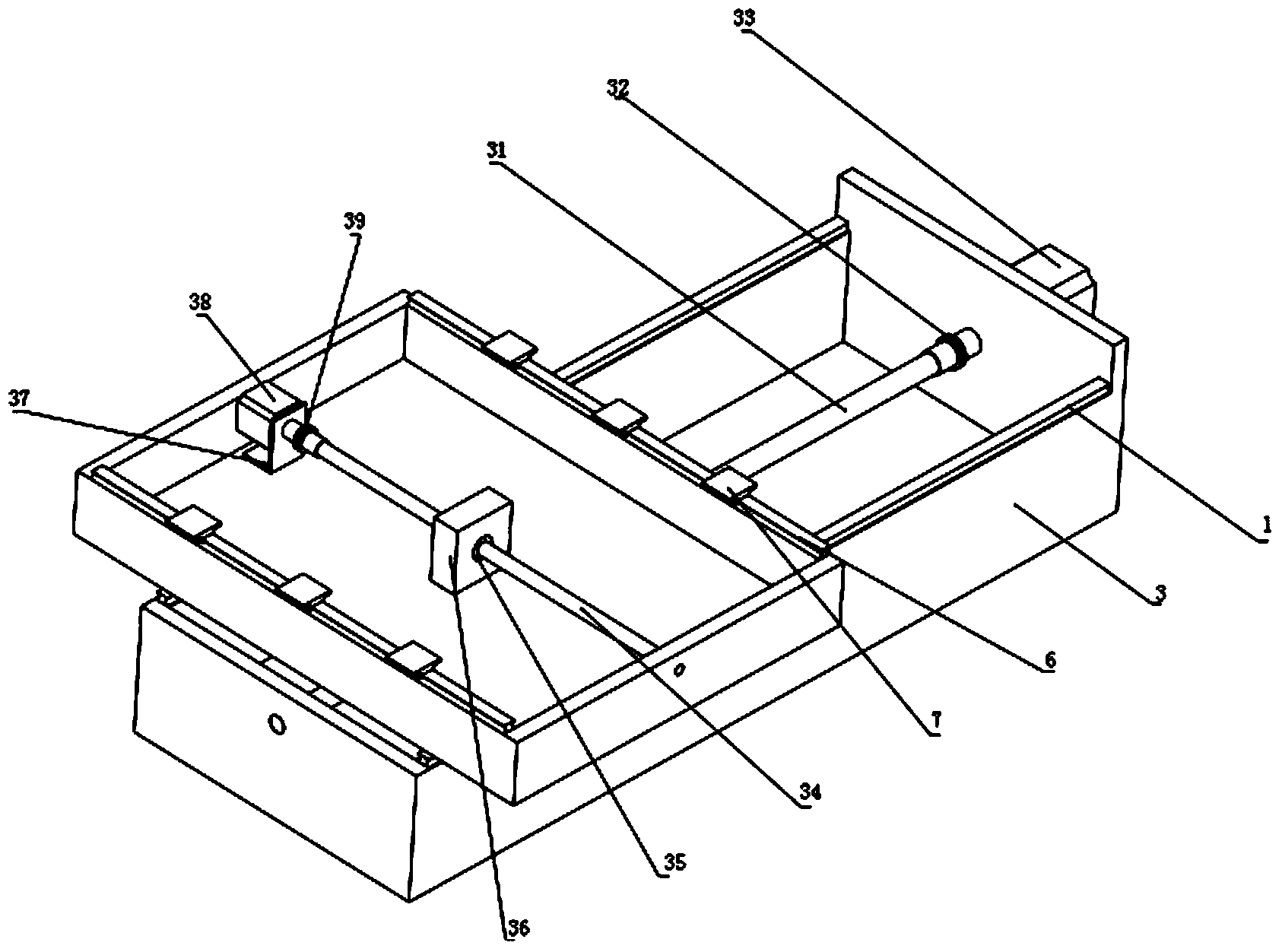

[0030] The bed includes an X-direction bed 2 and a Y-direction bed 5. The Y-direction bed 5 can move back and forth along the X-direction bed 2, and the top of the Y-direction bed 5 is provided with a And the clamping device used to clamp the workpiece.

[0031] The X-direction bed 2 is provided with two mutually parallel X-direction rails on both sides, an X-direction slider 3 is arranged on the X-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com