Patents

Literature

407 results about "Perpendicular distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Perpendicular distance. In geometry, the perpendicular distance between two objects is the distance from one to the other, measured along a line that is perpendicular to one or both.

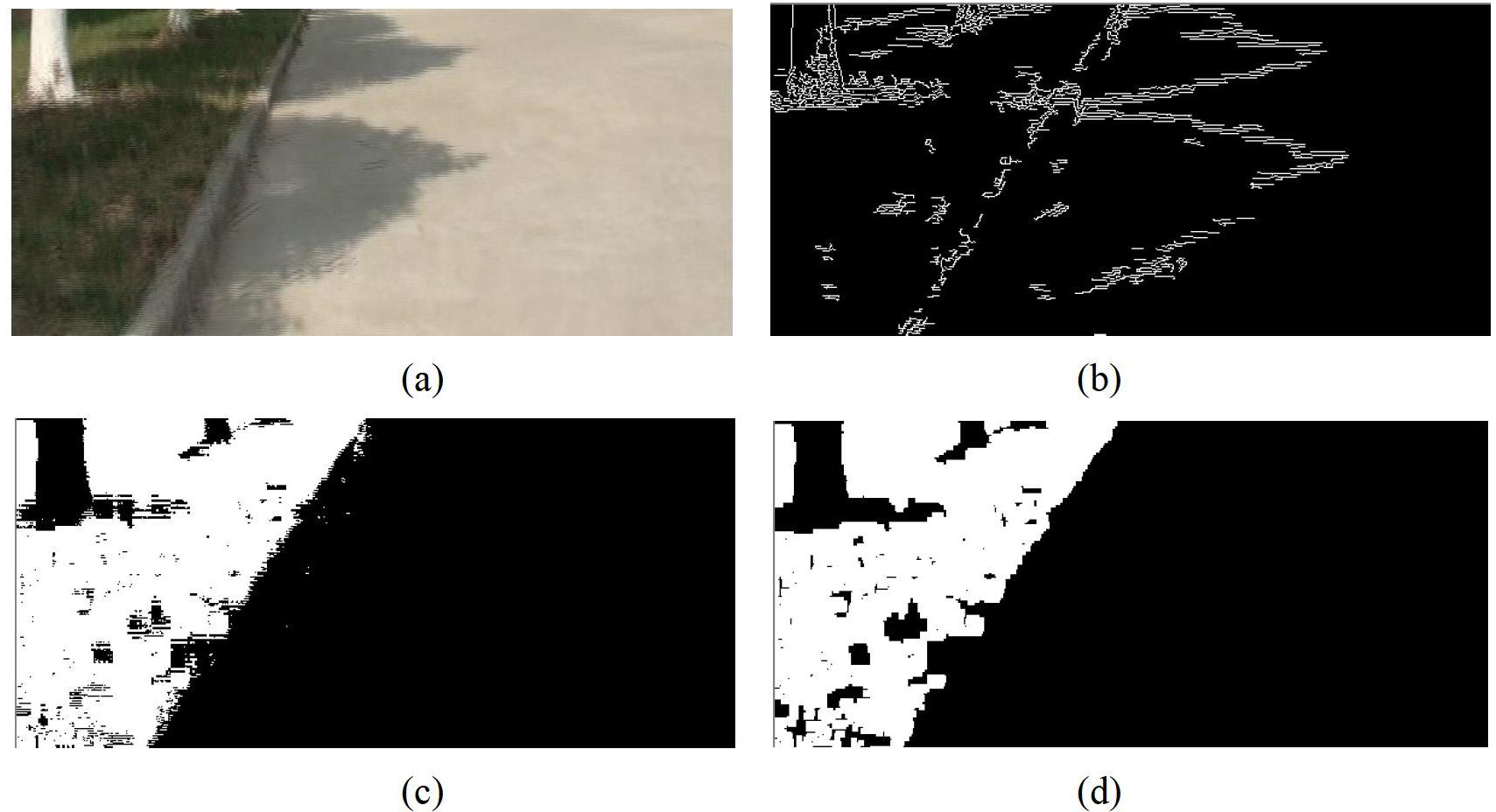

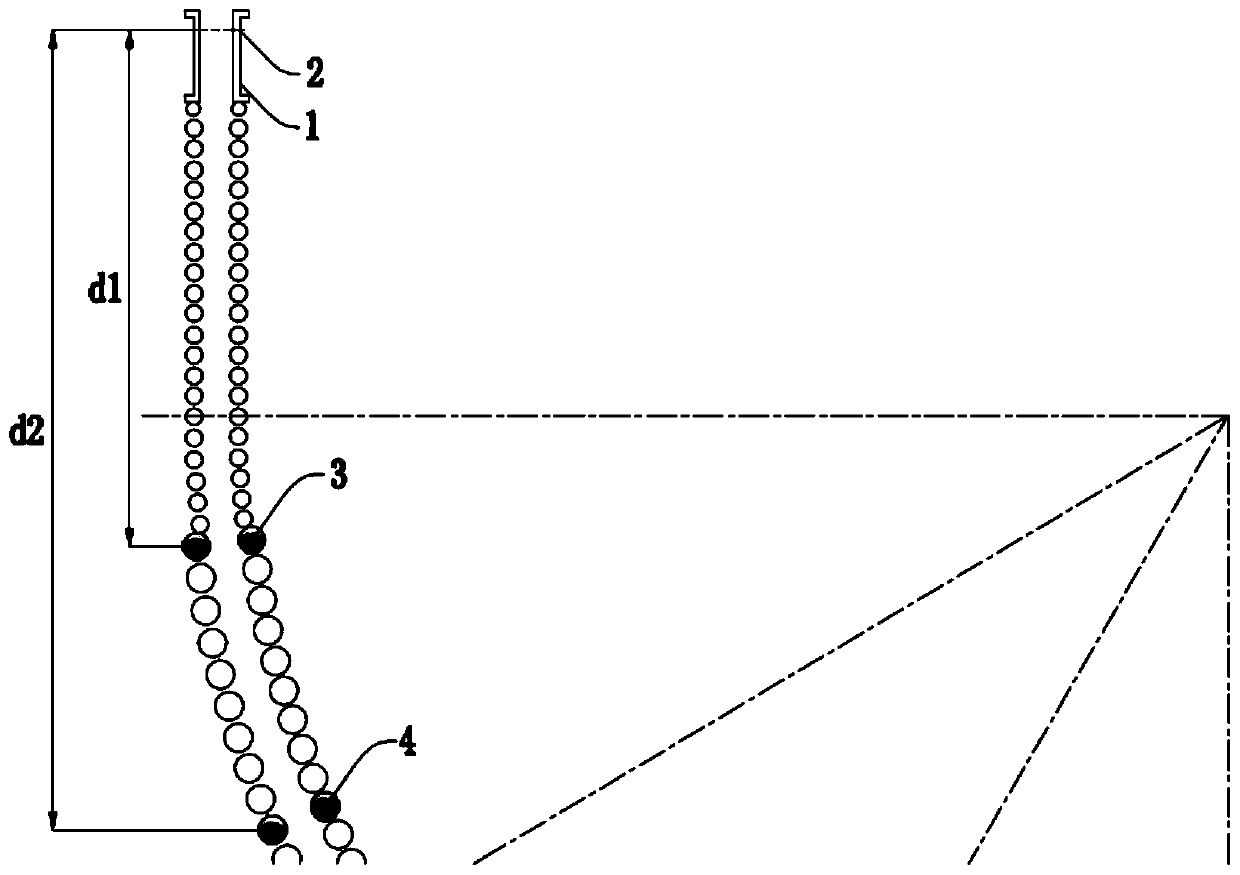

Method based on monocular vision for detecting and roughly positioning edge of road

InactiveCN102682292AAdaptableImprove versatilityCharacter and pattern recognitionNavigation instrumentsMachine visionVisual perception

The invention discloses a method based on monocular vision for detecting and roughly positioning the edge of a road, and relates to the field of machine vision and intelligent control. Aiming at a continuous road with different edge characteristics, two road edge detection methods are supplied and suitable for semistructured and nonstructured roads and can be applied to vision navigation and intelligent control over a robot. The invention provides a method for detecting the edge of the road based on colors and a method for detecting the edge of the road based on threshold value partitioning. On the basis of the obtained edge of the road, an image is subjected to inverted perspective projection transformation, so that a front view is transformed into a top view; and according to a linear corresponding relation between a pixel and an actual distance in the image, a perpendicular distance from the current position of the robot to the edge of the road and a course angle of the robot can be calculated. The method is easy to implement, high in anti-interference performance, high in instantaneity and suitable for the semistructured and nonstructured roads.

Owner:TSINGHUA UNIV

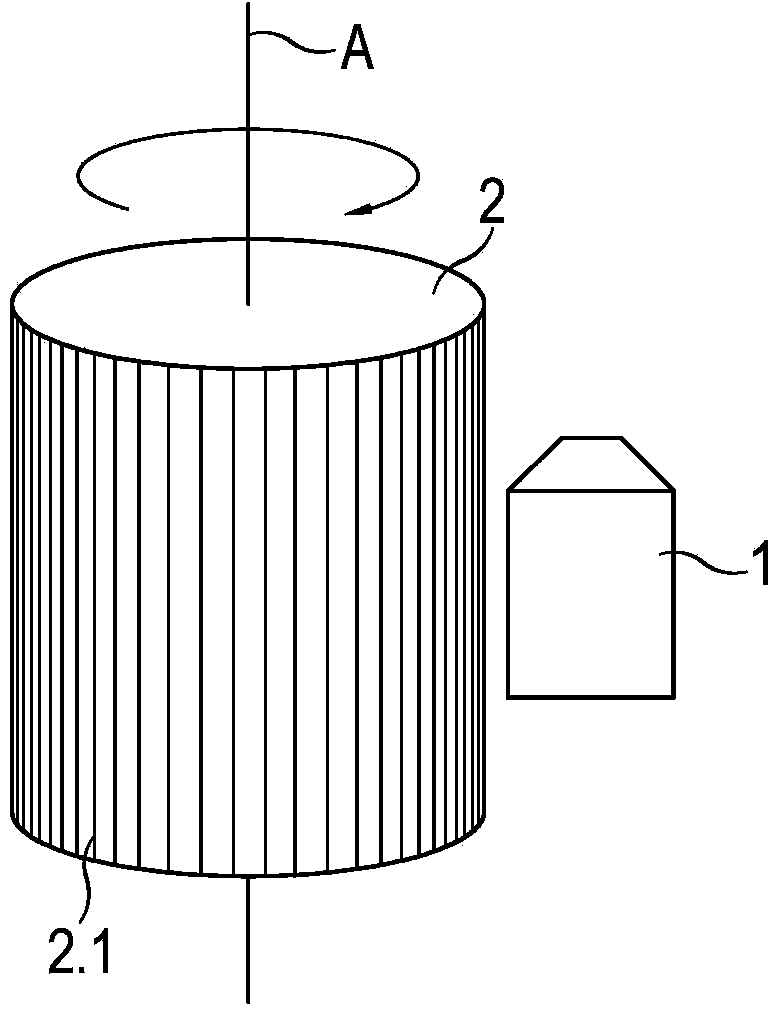

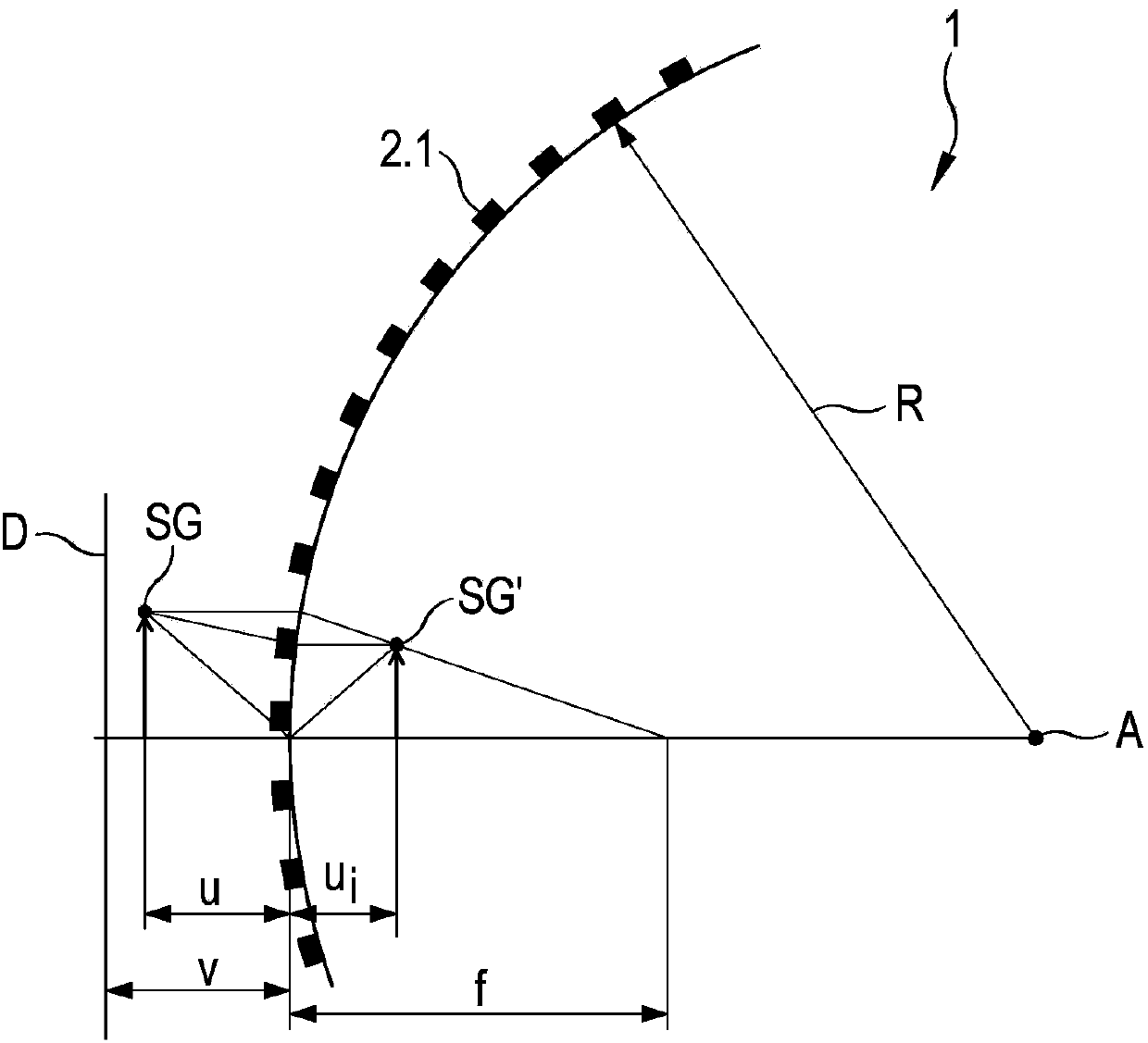

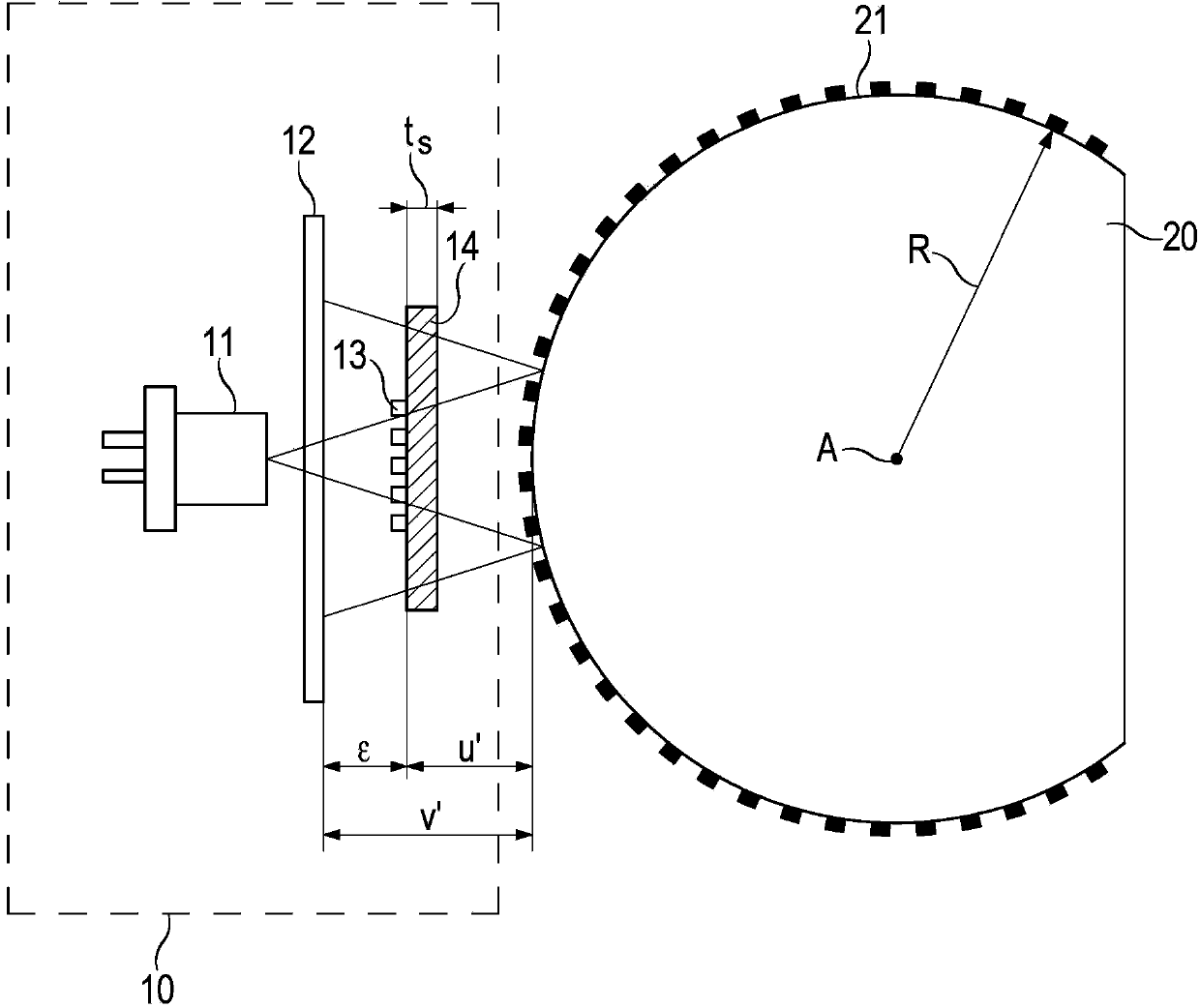

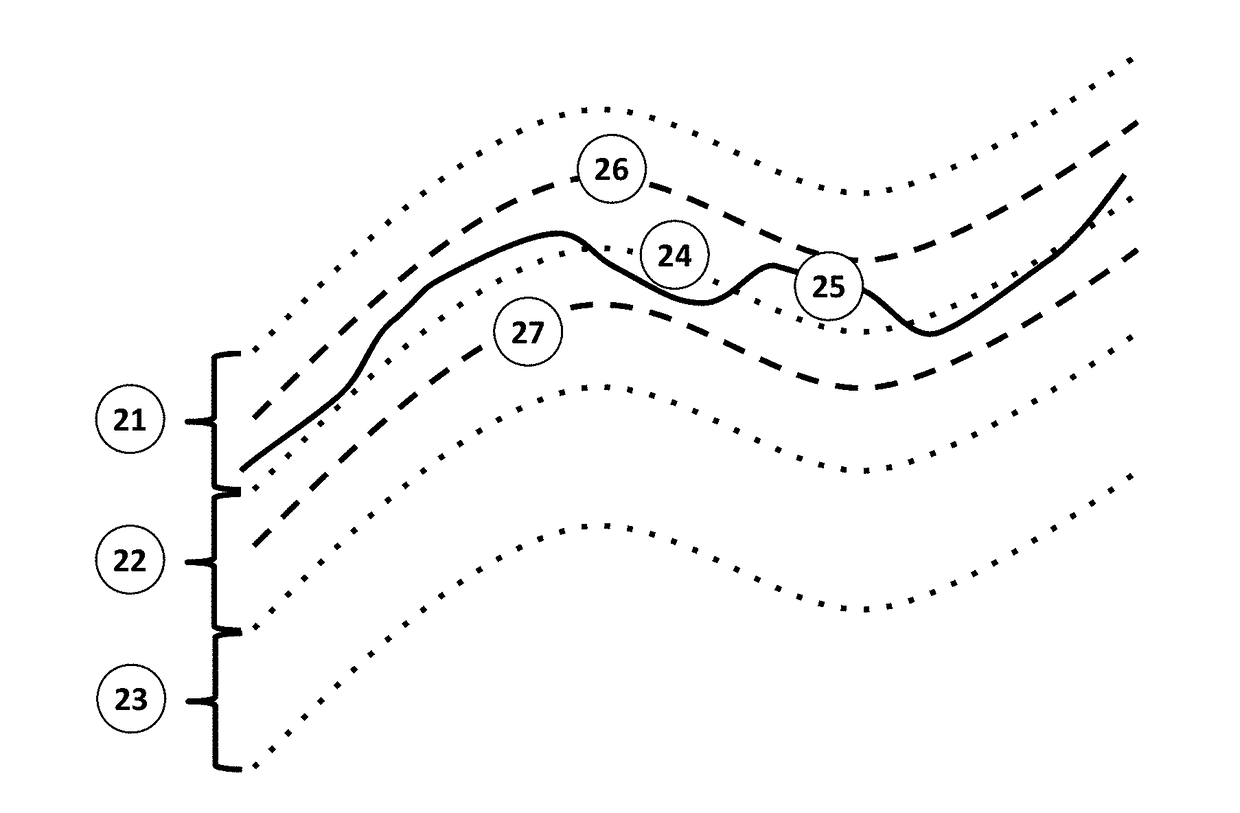

Position-measuring device

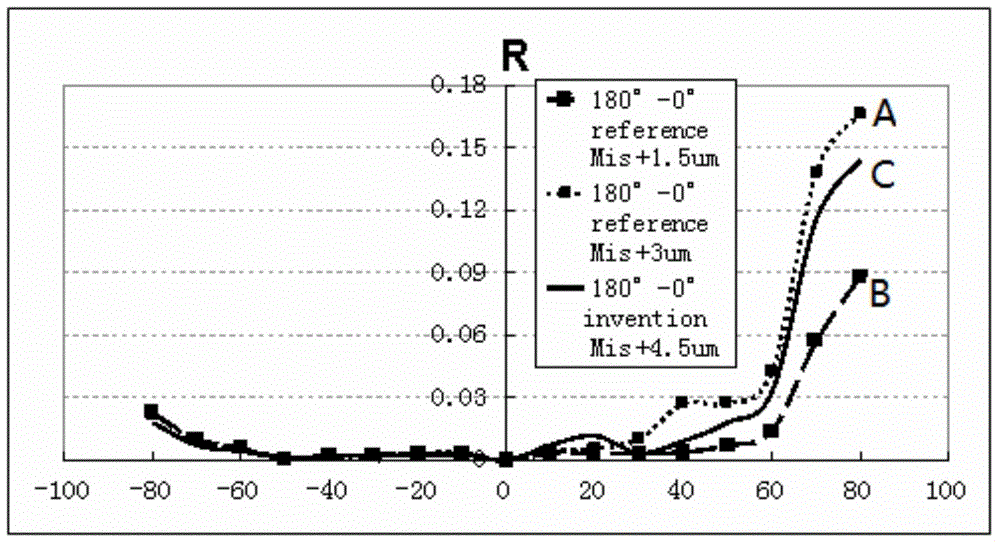

ActiveCN103852090AEasy to installThe scanning signal is stableConverting sensor output opticallyGratingLight beam

The present invention relates to a position-measuring device. The position-measuring device includes a cylindrical object rotatable about a longitudinal axis and comprising circumferential annular reflection measuring graduation; and a scanning unit which is static in relative to the object which is arranged in a rotatable manner, and used for optical scanning of reflection measuring graduation. The scanning unit includes a light source, a transmission grating and a detector. The light beam transmitted by the light source goes through the grating, and then is reflected to the reflection measuring graduation. Backward reflection along the direction of the detector is achieved through the reflection measuring graduation, and a position signal relating to rotation is generated by the light beam. An optically effective perpendicular distance between the detector and the reflection measuring graduation is selected to be one of greater or less than an optically effective perpendicular distance between the transmission grating and the reflection measuring graduation depending on a radius of the cylindrical object.

Owner:DR JOHANNES HEIDENHAIN GMBH

Plank for interior use

InactiveUS20050136234A1Advantageous cost priceGood pricePaper/cardboard layered productsConstructions elementsSolid woodEngineering

The present invention is a plank incorporating a base layer with a thickness ranging from 12 to 25 mm, a solid wood top layer, with a thickness ranging from 4.6 to 6 mm, glued to base layer, wherein the base layer is made of a wood based compound, also containing non flammable polymers, hardeners, etc., wherein the wood content of the compound is at least 2% by volume and 95% by volume at maximum, wherein the wood and the polymers are distributed homogeneously, or distributed, depending only on the perpendicular distance to the glued surface, wherein the glue between base layer and top layer is a non flammable glue. The plank of the invention combines the stability and homogeneity of the base layer with the appearance of a solid plank, and moreover has a flame retardant effect, caused by the structure of the product and by the use of fire retardant polymers.

Owner:HAK GIJSBERTUS +1

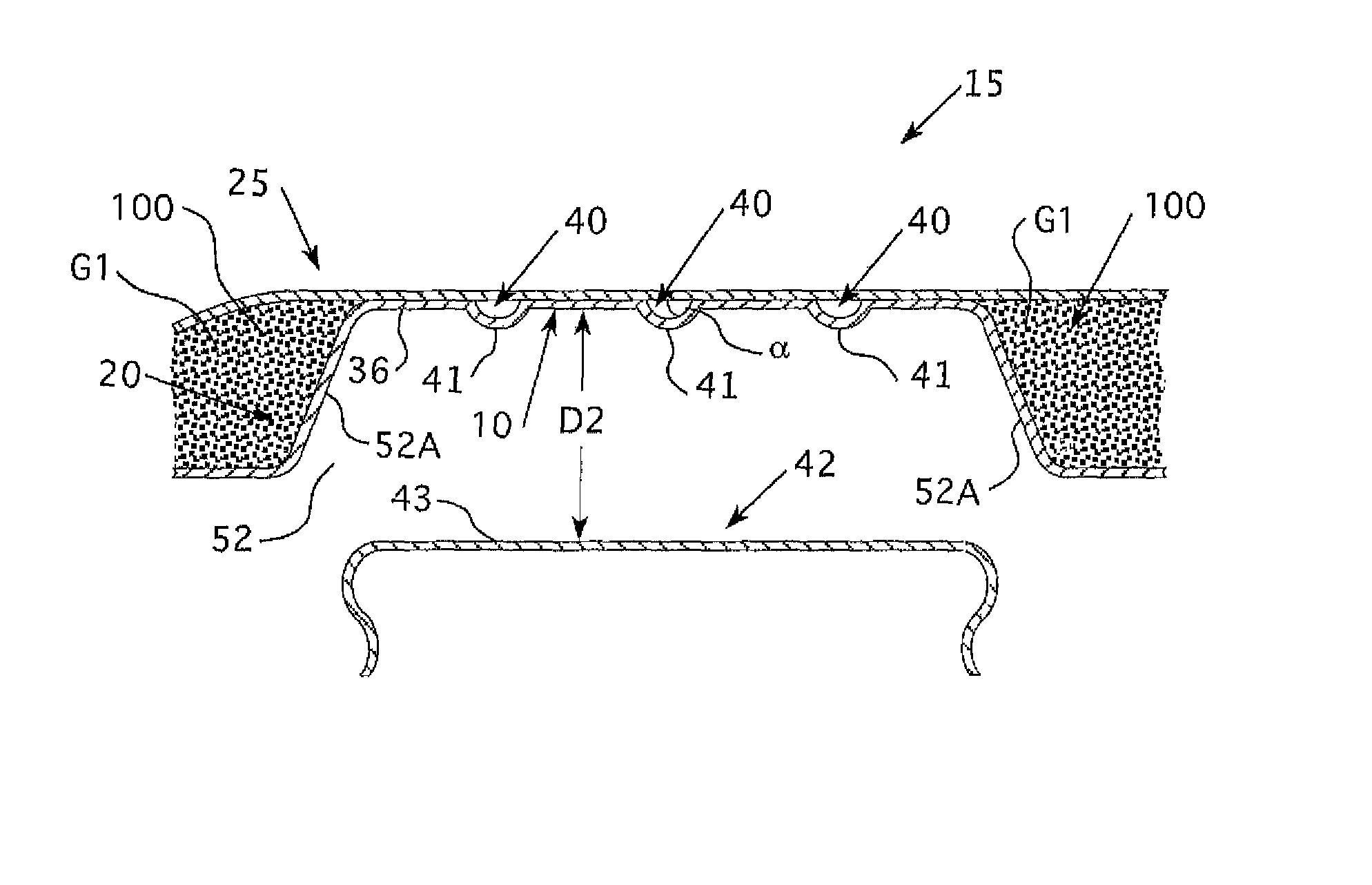

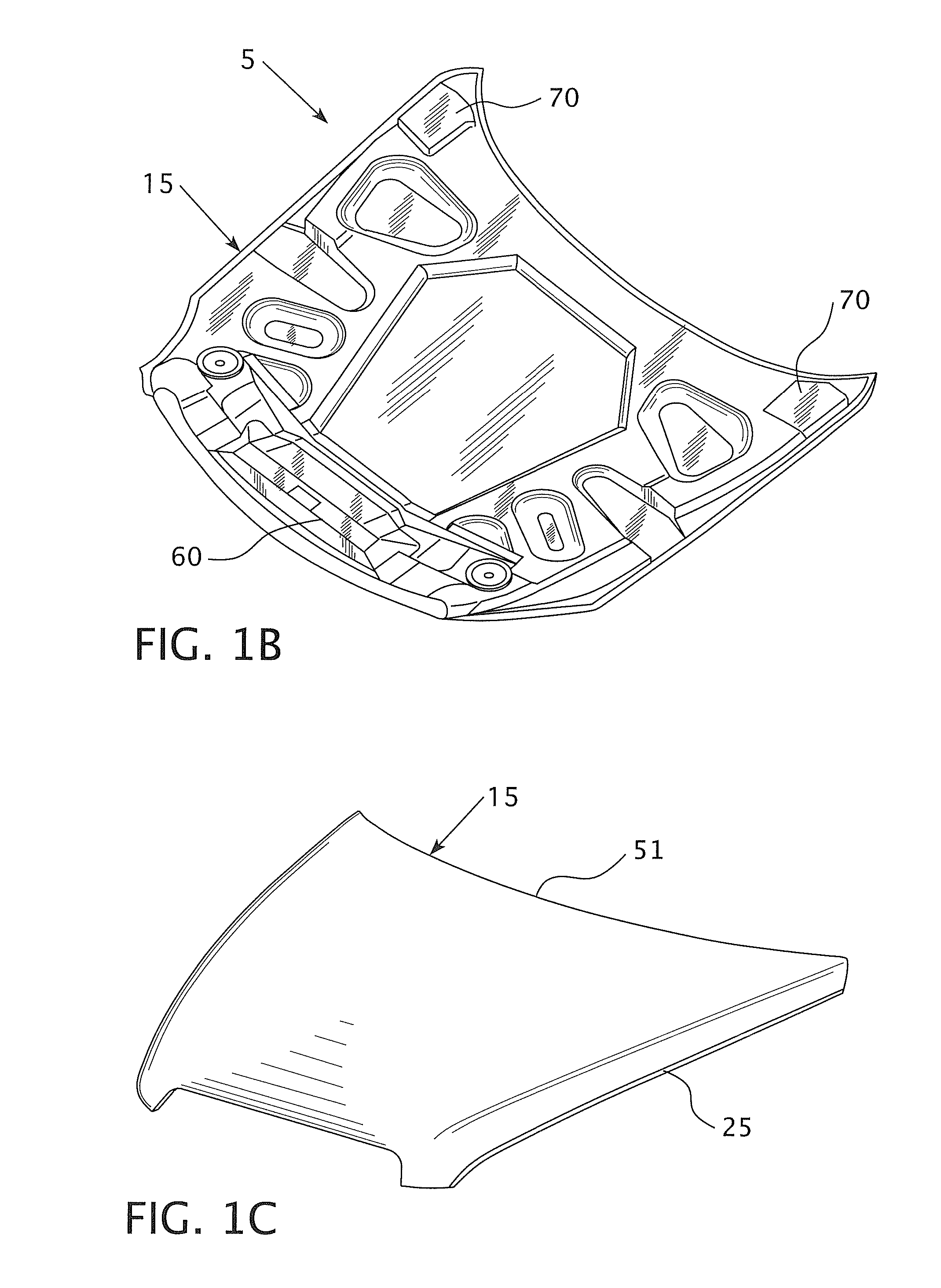

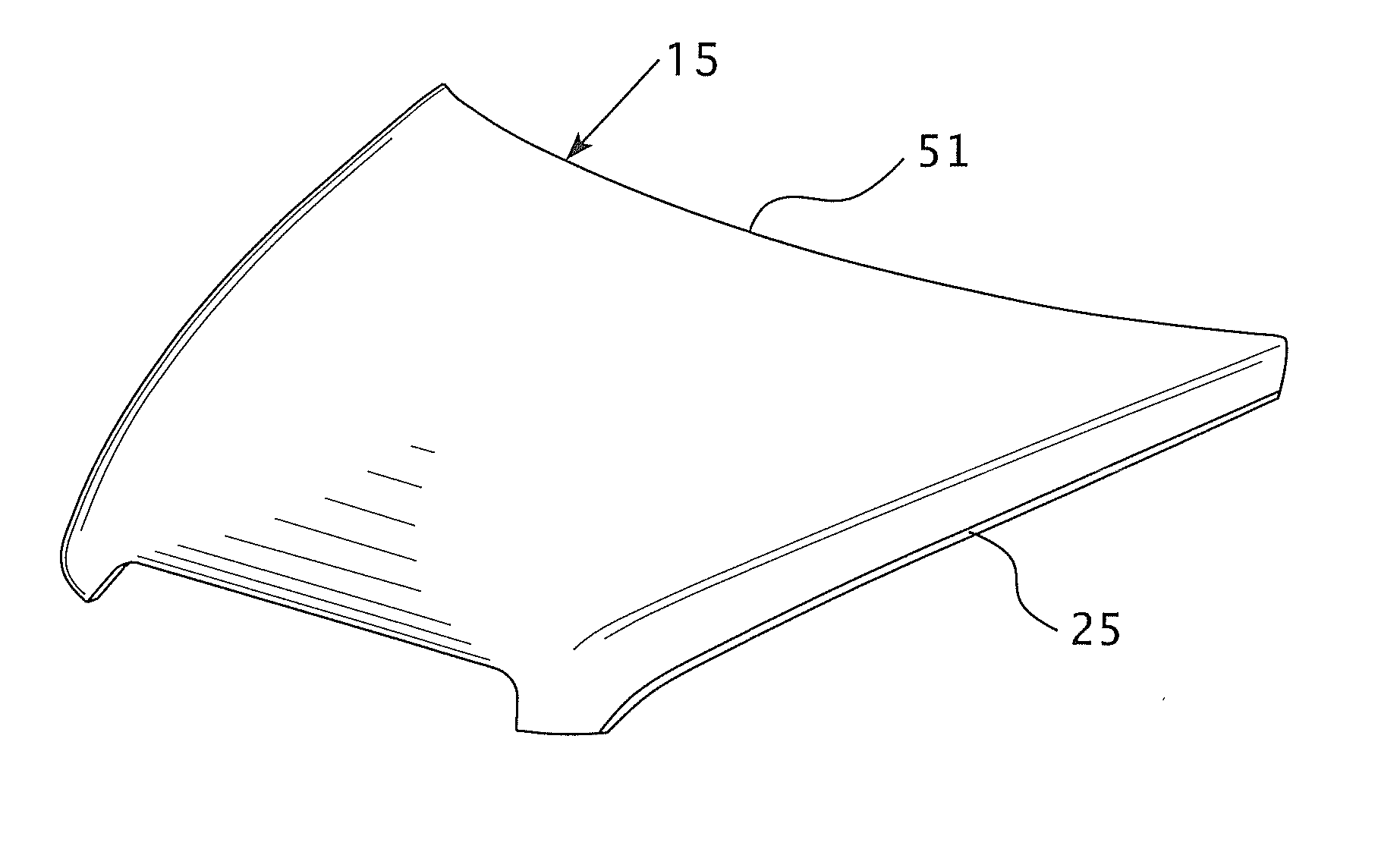

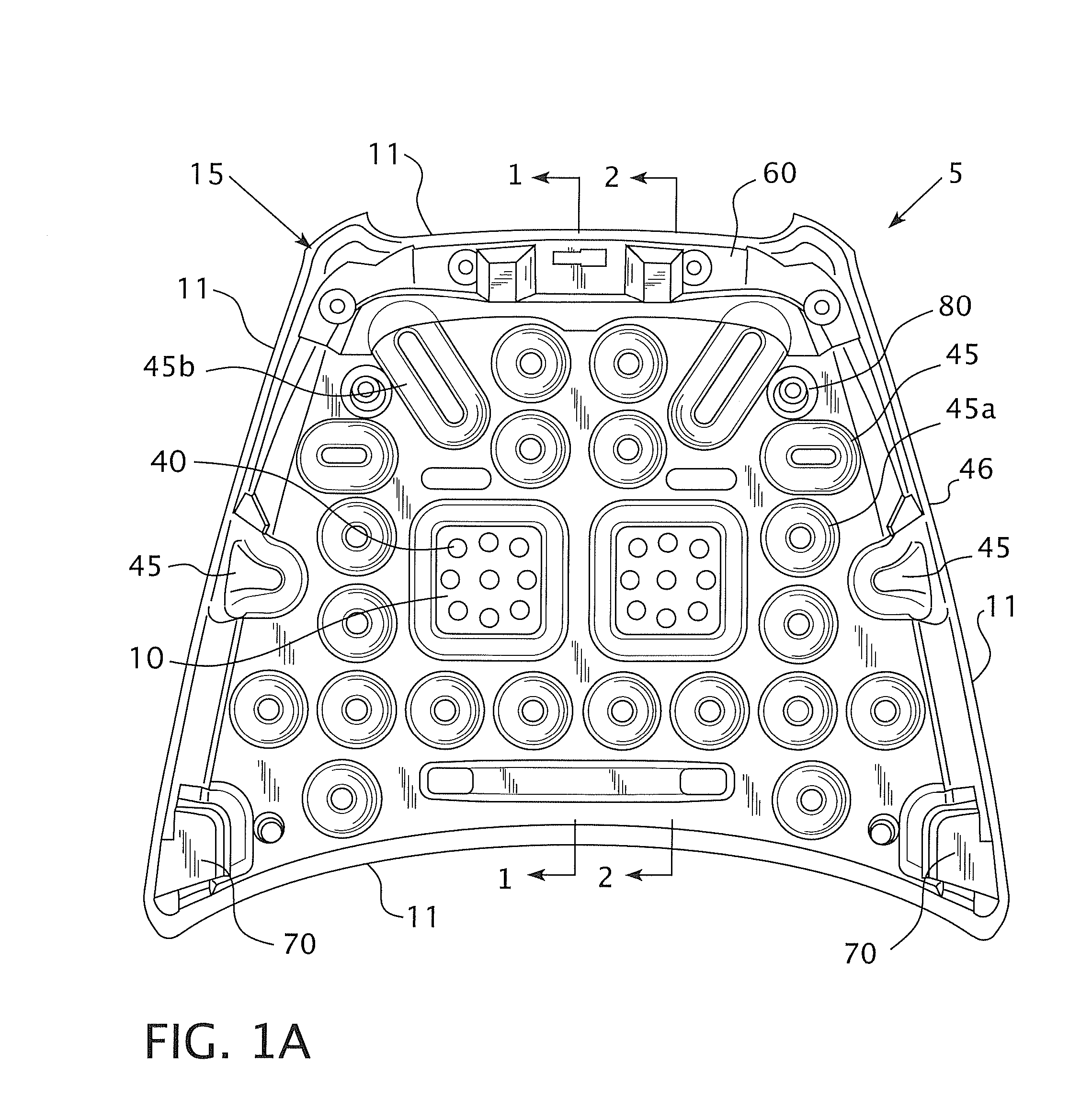

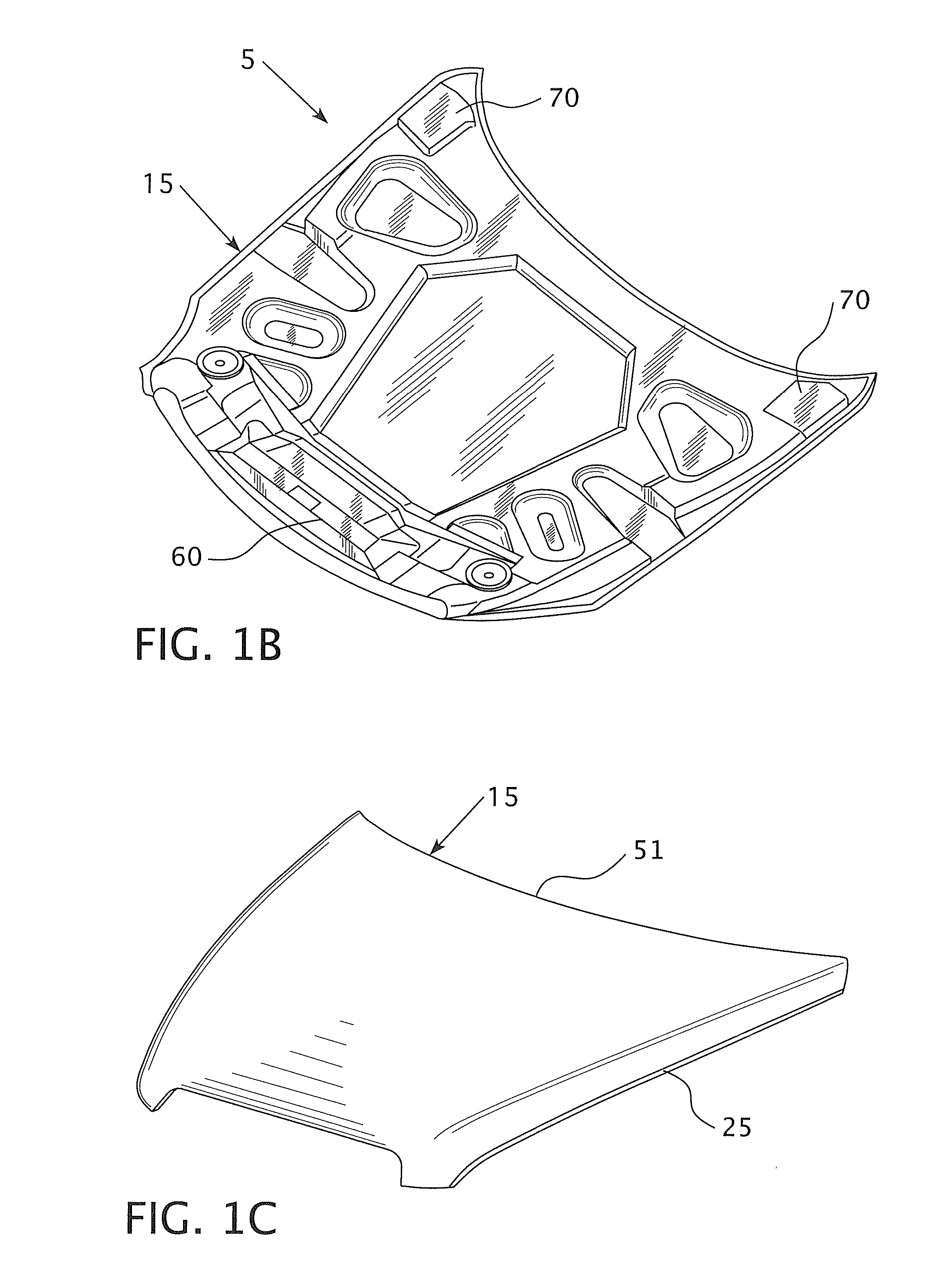

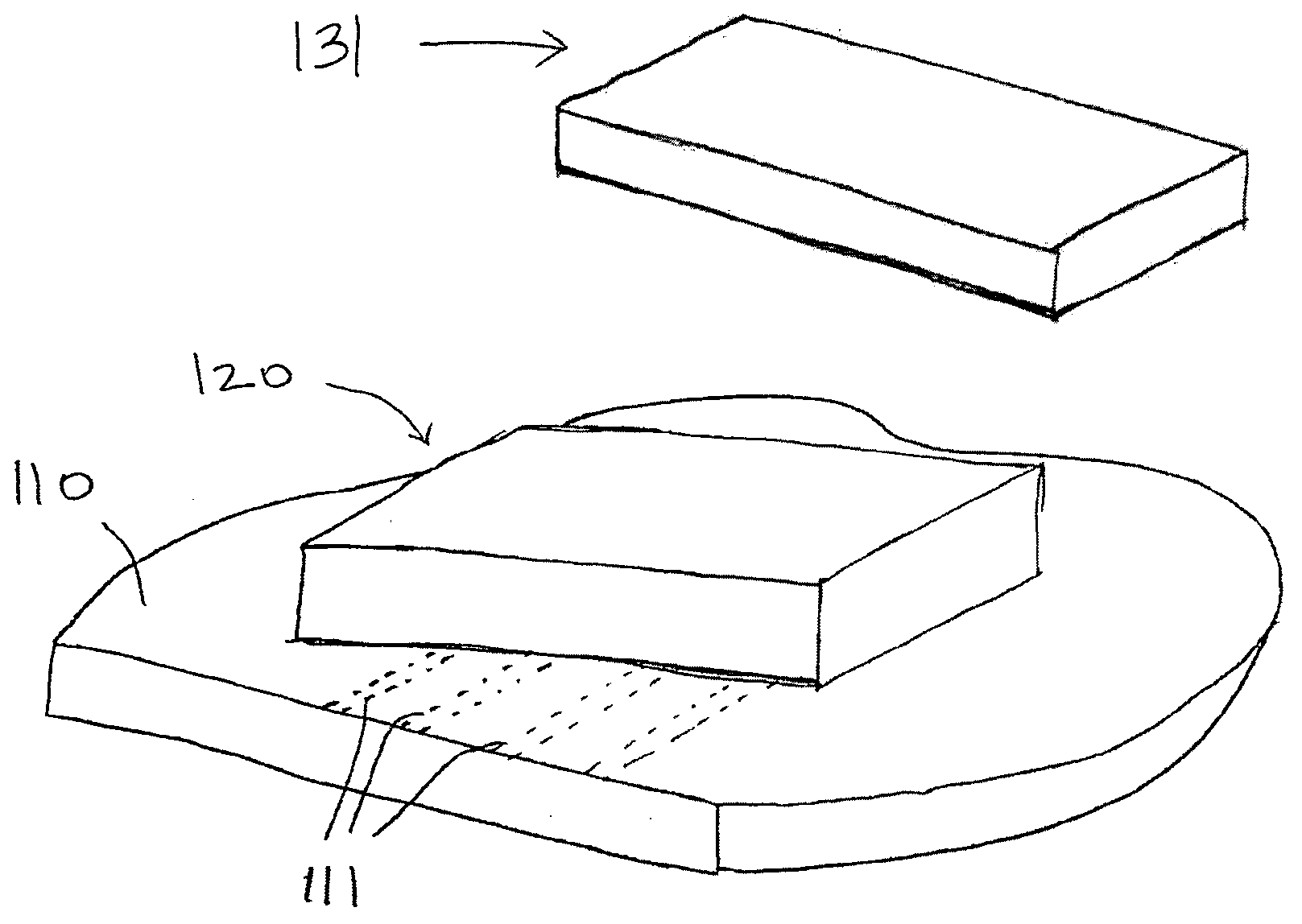

Pedestrian safe automotive hood having reinforcing foam

InactiveUS8052198B2Keep distanceVehicle seatsPedestrian/occupant safety arrangementMechanical engineeringPedestrian

The present invention provides a thin vehicle closure panel design that substantially reduces a thickness (panel gauge plus the perpendicular distance or depth between the panels) of a vehicle hood (5) and the impact effect on the head of a pedestrian struck by a motor vehicle. In one embodiment, the vehicle hood (5) includes a hood shell (15) including an outer panel (25) and an inner panel (20); a unitary foam core (100) positioned between and bonded to the outer (25) and / or the inner panel (20) of the hood shell (15); and at least one recess (10) that corresponds to an underhood component (42). In another aspect of the invention, a vehicle hood (5) is provided in which a latch attachment member (60) and / or hinge members (70) are attached to inner surface (50) of the inner panel (20) of the hood shell (15).

Owner:ARCONIC INC

Pedestrian safe automotive hood having reinforcing foam

InactiveUS20100140979A1Keep distanceVehicle seatsPedestrian/occupant safety arrangementMobile vehicleEngineering

The present invention provides a thin vehicle closure panel design that substantially reduces a thickness (panel gauge plus the perpendicular distance or depth between the panels) of a vehicle hood (5) and the impact effect on the head of a pedestrian struck by a motor vehicle. In one embodiment, the vehicle hood (5) includes a hood shell (15) including an outer panel (25) and an inner panel (20); a unitary foam core (100) positioned between and bonded to the outer (25) and / or the inner panel (20) of the hood shell (15); and at least one recess (10) that corresponds to an underhood component (42). In another aspect of the invention, a vehicle hood (5) is provided in which a latch attachment member (60) and / or hinge members (70) are attached to inner surface (50) of the inner panel (20) of the hood shell (15).

Owner:ARCONIC INC

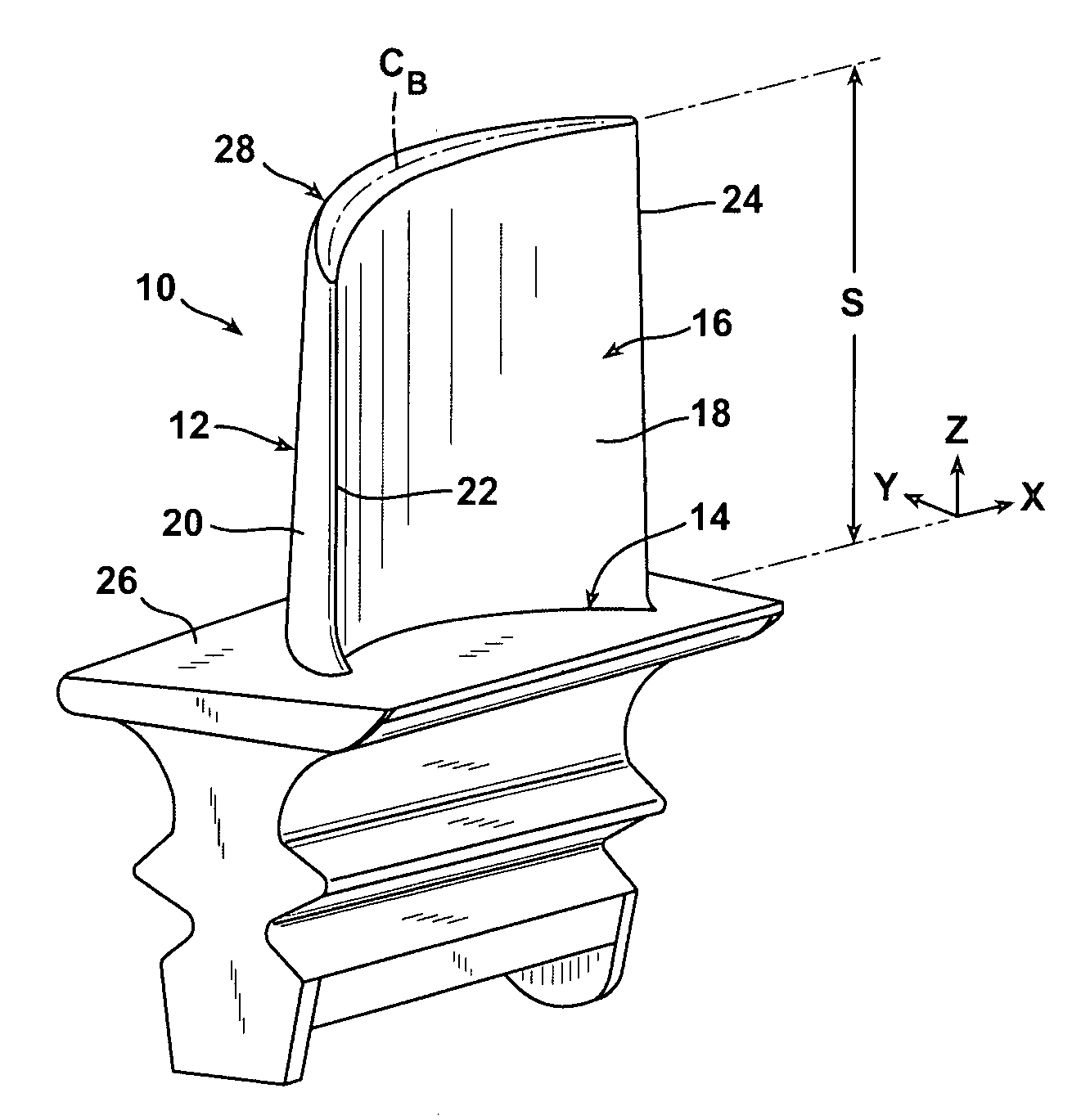

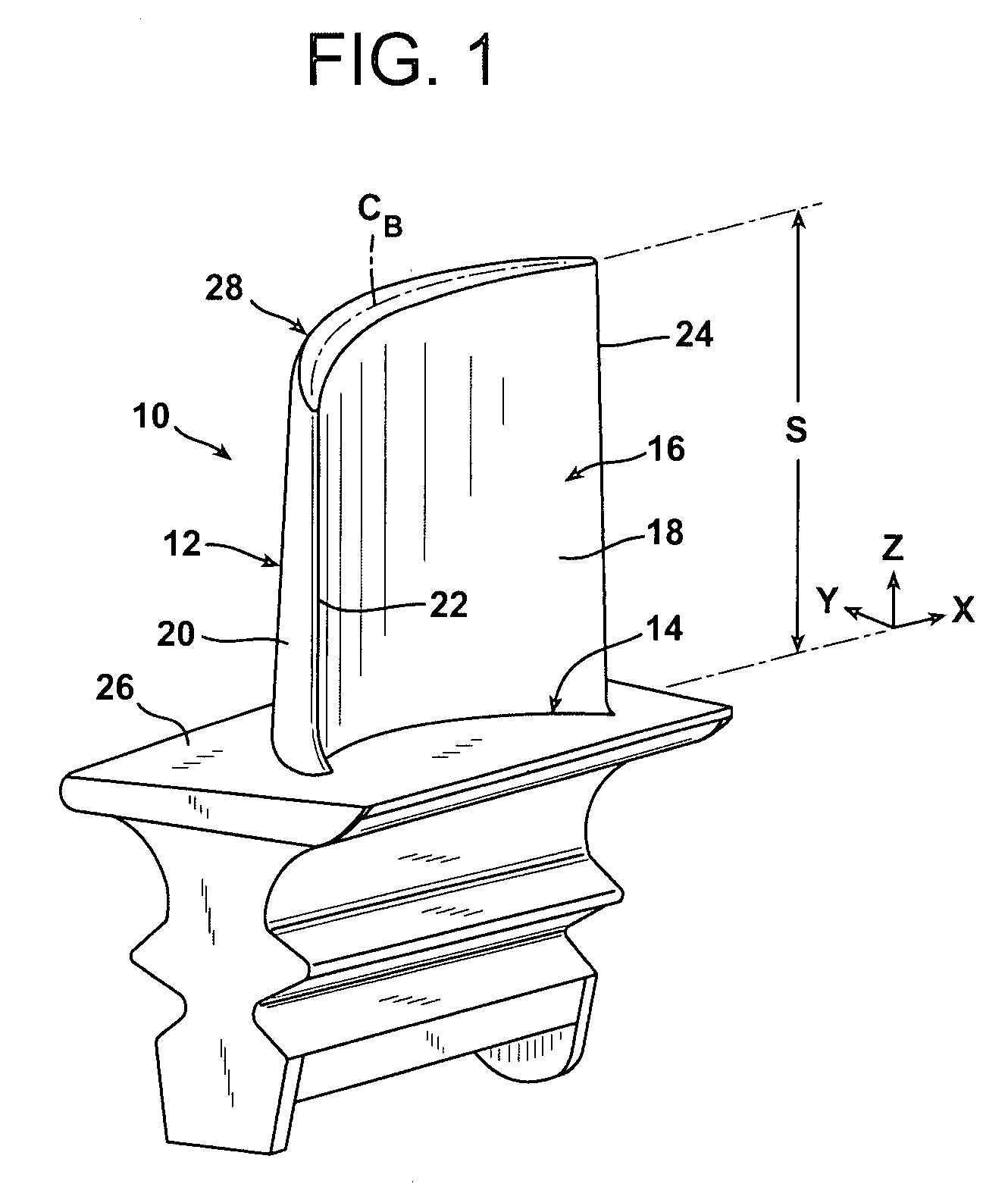

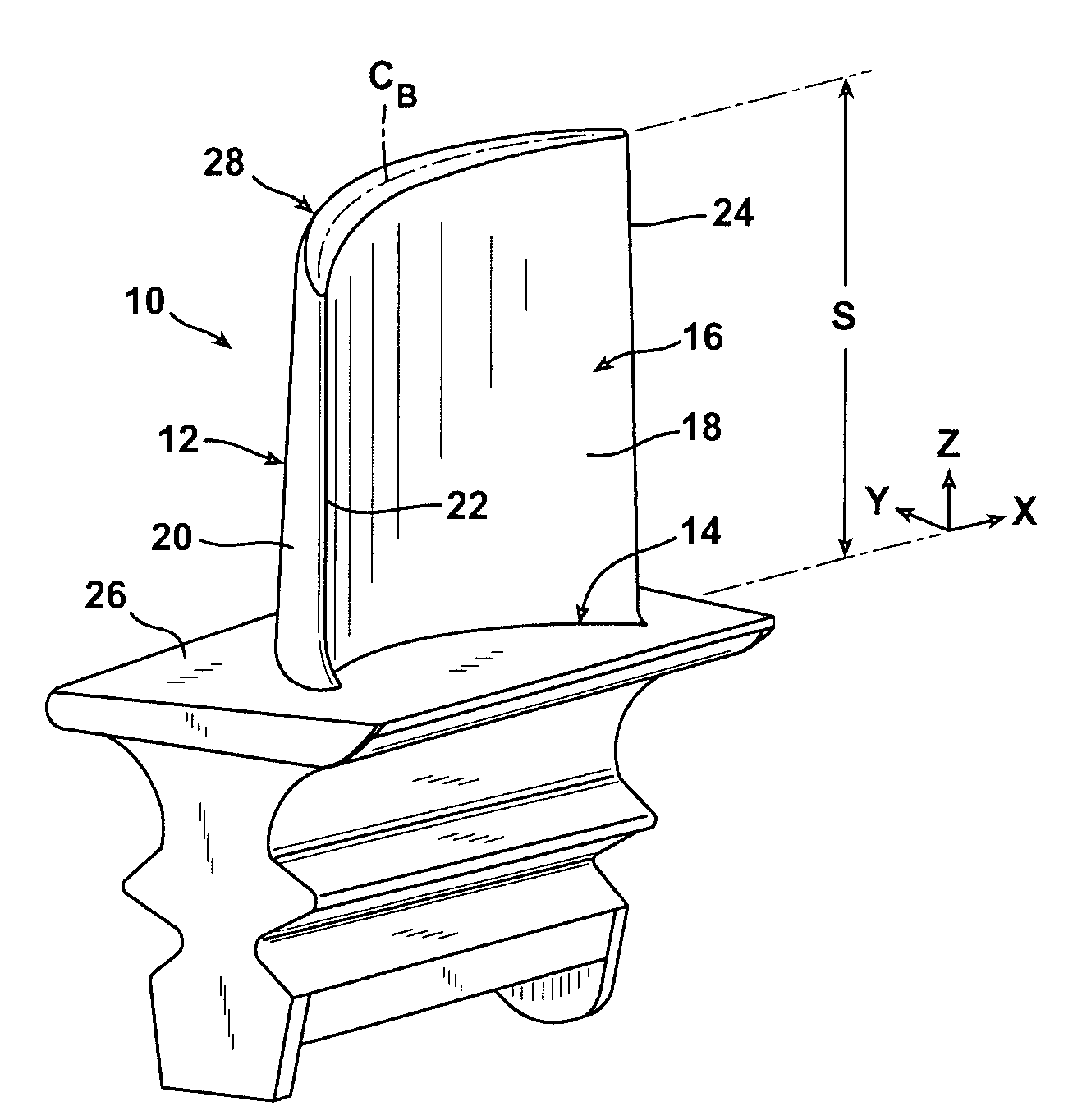

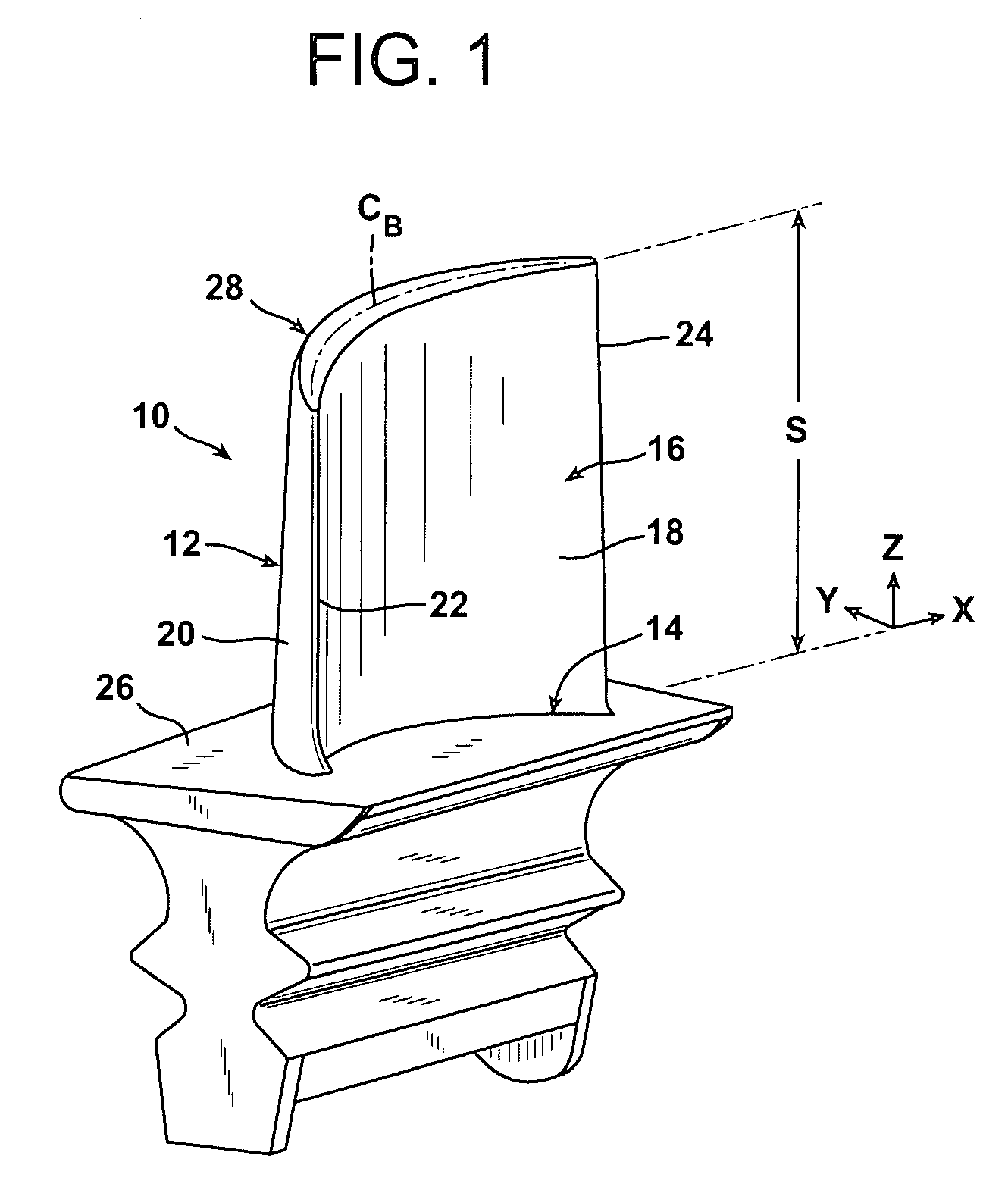

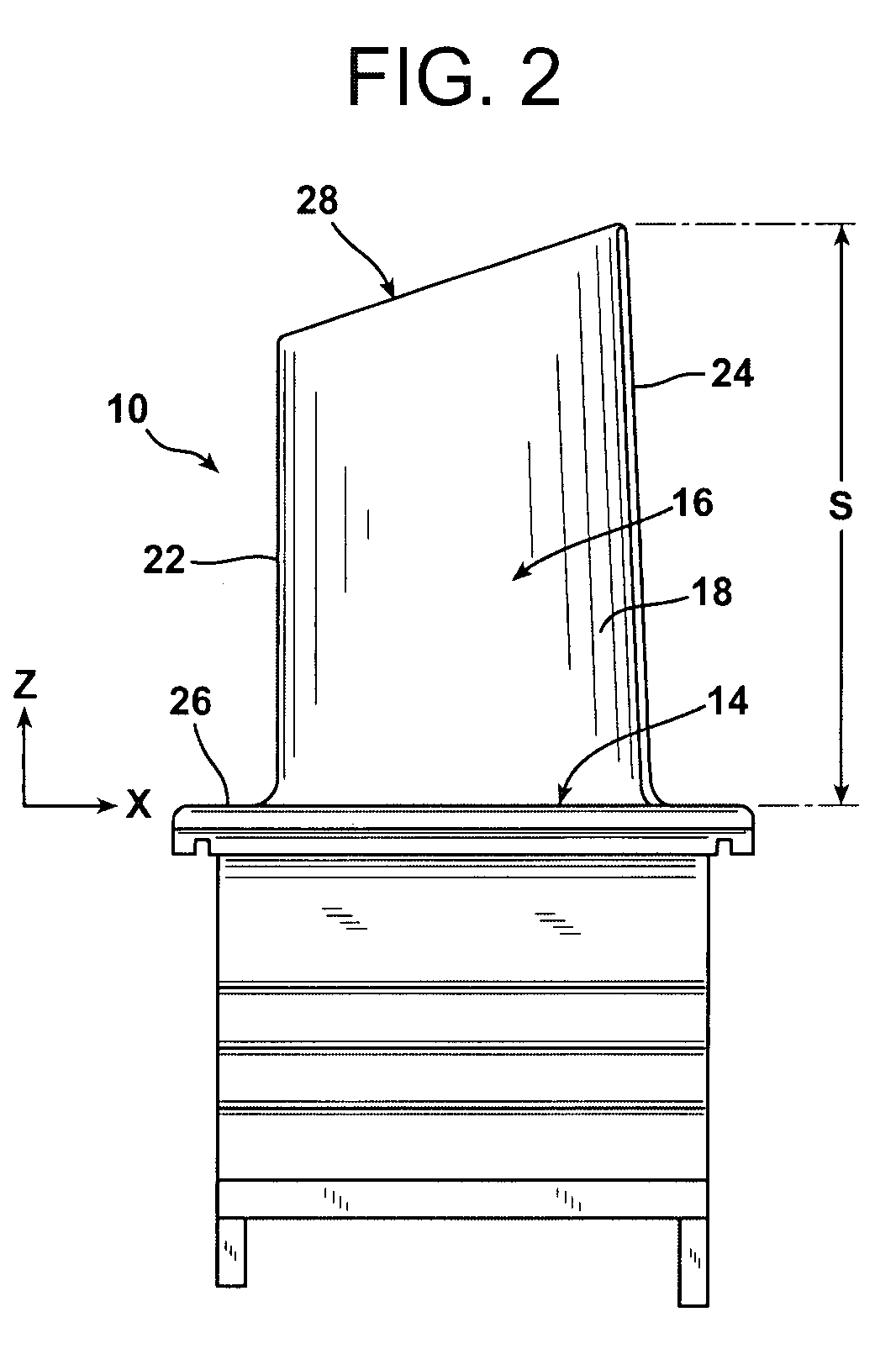

External profile for turbine blade airfoil

InactiveUS20080273984A1Join smoothlyEngine manufactureOther chemical processesLeading edgeTurbine blade

A turbine blade including an airfoil having a pressure sidewall and a suction sidewall joined together along an upstream leading edge and a downstream trailing edge. The leading edge and trailing edge are formed as substantially straight edges, and portions of the pressure sidewall and suction sidewall adjacent the trailing edge form substantially planar surfaces. The airfoil has an uncoated nominal profile substantially in accordance with Cartesian coordinate values of X, Y and Z set forth in Table 1 wherein Z represents a perpendicular distance from a plane normal to a radius of a turbine centerline and containing the X and Y values with the Z value commencing at zero in the X, Y plane at a radially innermost aerodynamic section of the airfoil, and X and Y represent coordinate values defining the airfoil profile at each distance Z which, when connected by smooth continuing arcs, define profile sections at each distance Z.

Owner:SIEMENS ENERGY INC

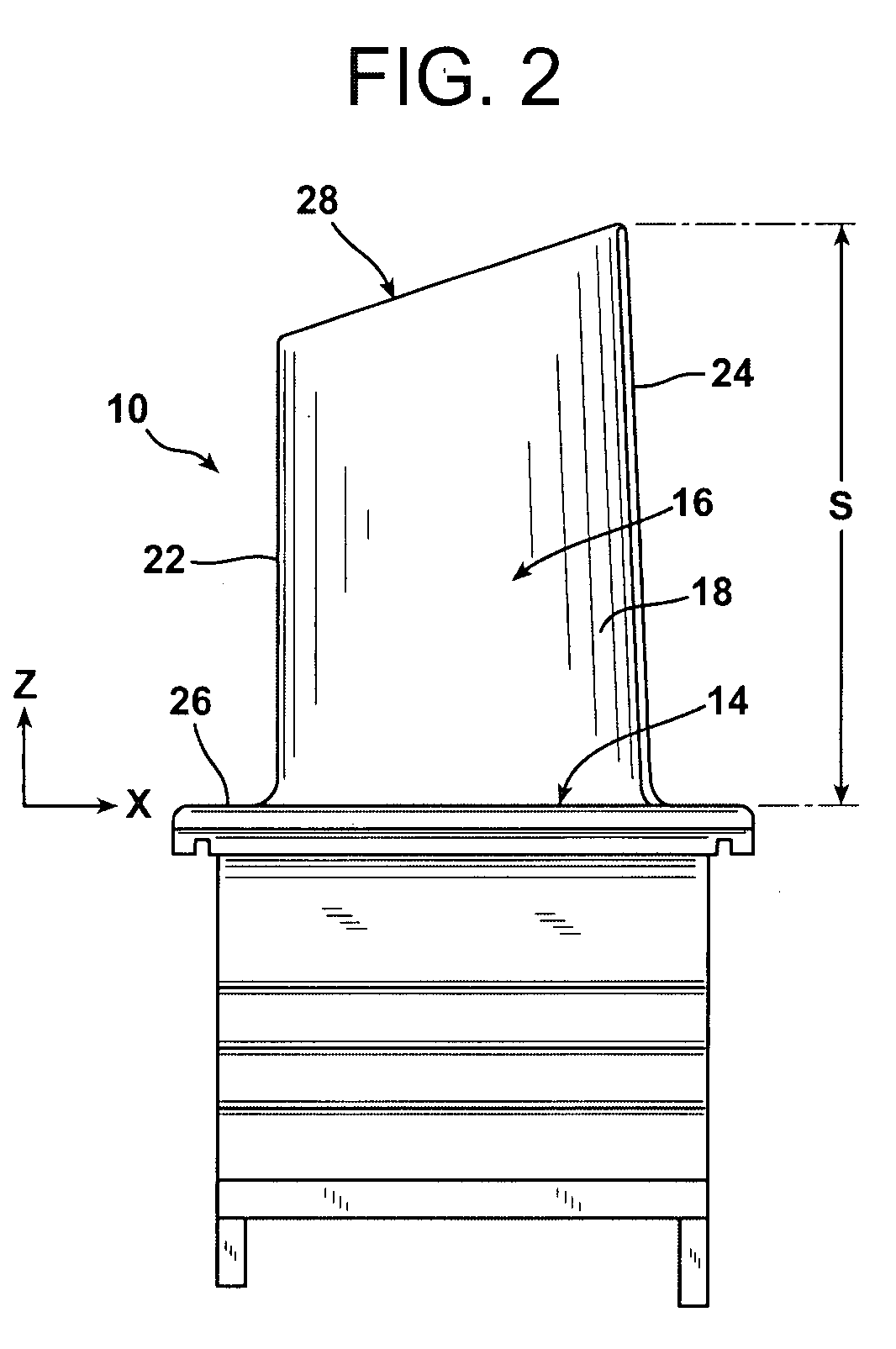

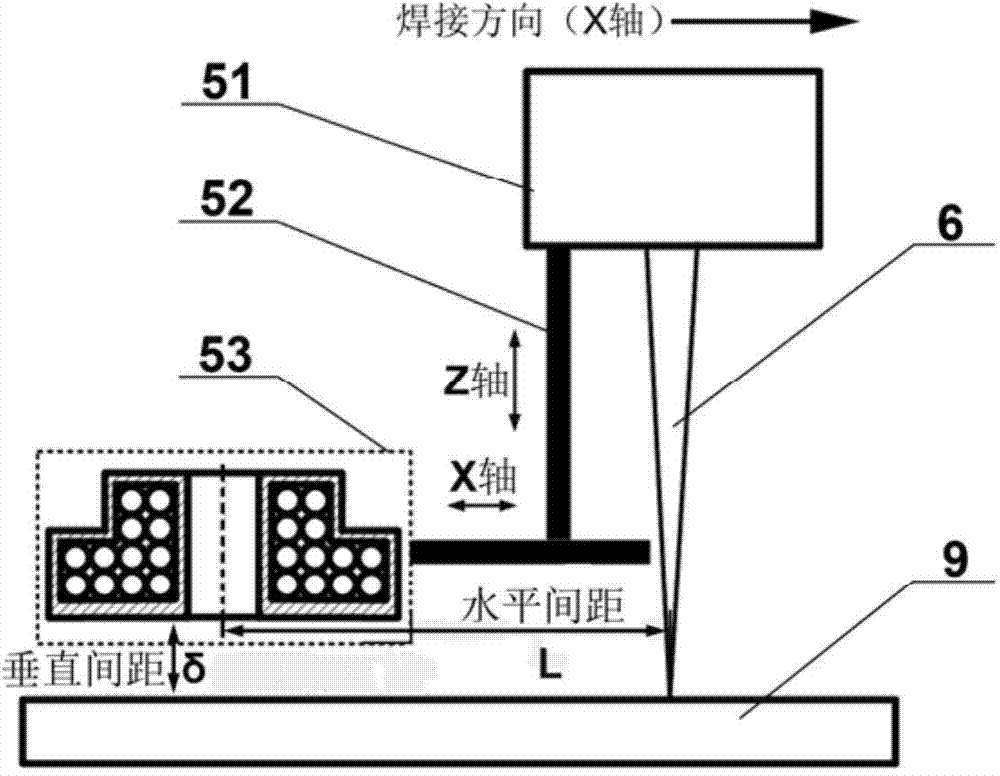

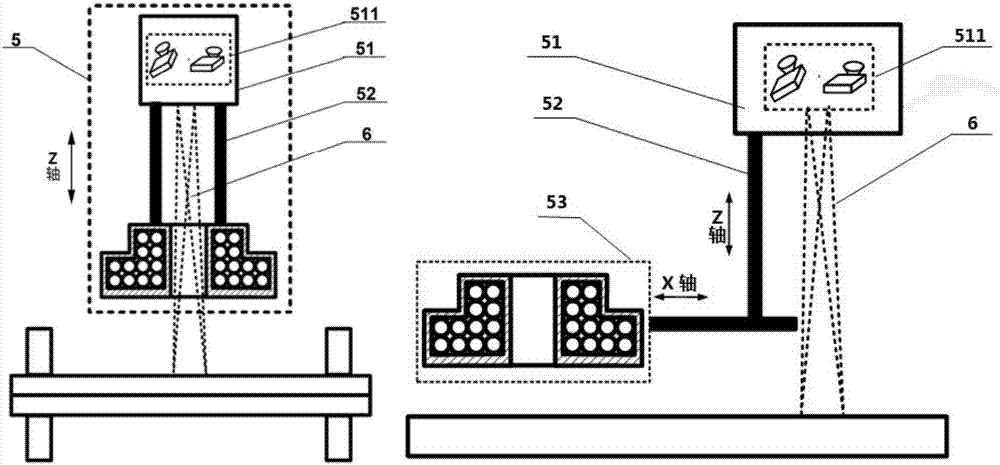

Pulsed high magnetic field auxiliary laser welding method and device

ActiveCN103769746AImprove fatigue strengthSmall structural deformationLaser beam welding apparatusStructural deformationStress concentration

The invention discloses a pulsed high magnetic field auxiliary laser welding method and device. The method and device can be applied to laser spot welding and seam welding. According to the method, in the overall welding process, laser beams are emitted to a workpiece to form a welding connector, a high pulsed magnetic field is exerted to the welding connector which is just solidified and the surrounding area, the pulsed magnetic field generates pressure stress on the surface of the workpiece to enable the connector area to have plastic deformation, residual stress is released to lower the degree of stress concentration and the degree of structural deformation of the welding connector, and the fatigue strength of the welding connector is improved. The device comprises a laser, a pulsed magnetic field generator, a numerical control system, an optical transmission system and a laser pulsed magnetic field composite processing head. The processing head is used for integrating the laser beams and the high pulsed magnetic field, and regulating the perpendicular distance between an electromagnetic conversion device and the surface of the workpiece and the horizontal distance between the electromagnetic conversion device and the laser beams. By means of the pulsed high magnetic field auxiliary laser welding method and device, structural deformation can be lowered, welding quality and processing efficiency are improved, and the processing effect which is superior to that of an existing laser welding process is achieved.

Owner:武汉飞能达激光技术有限公司

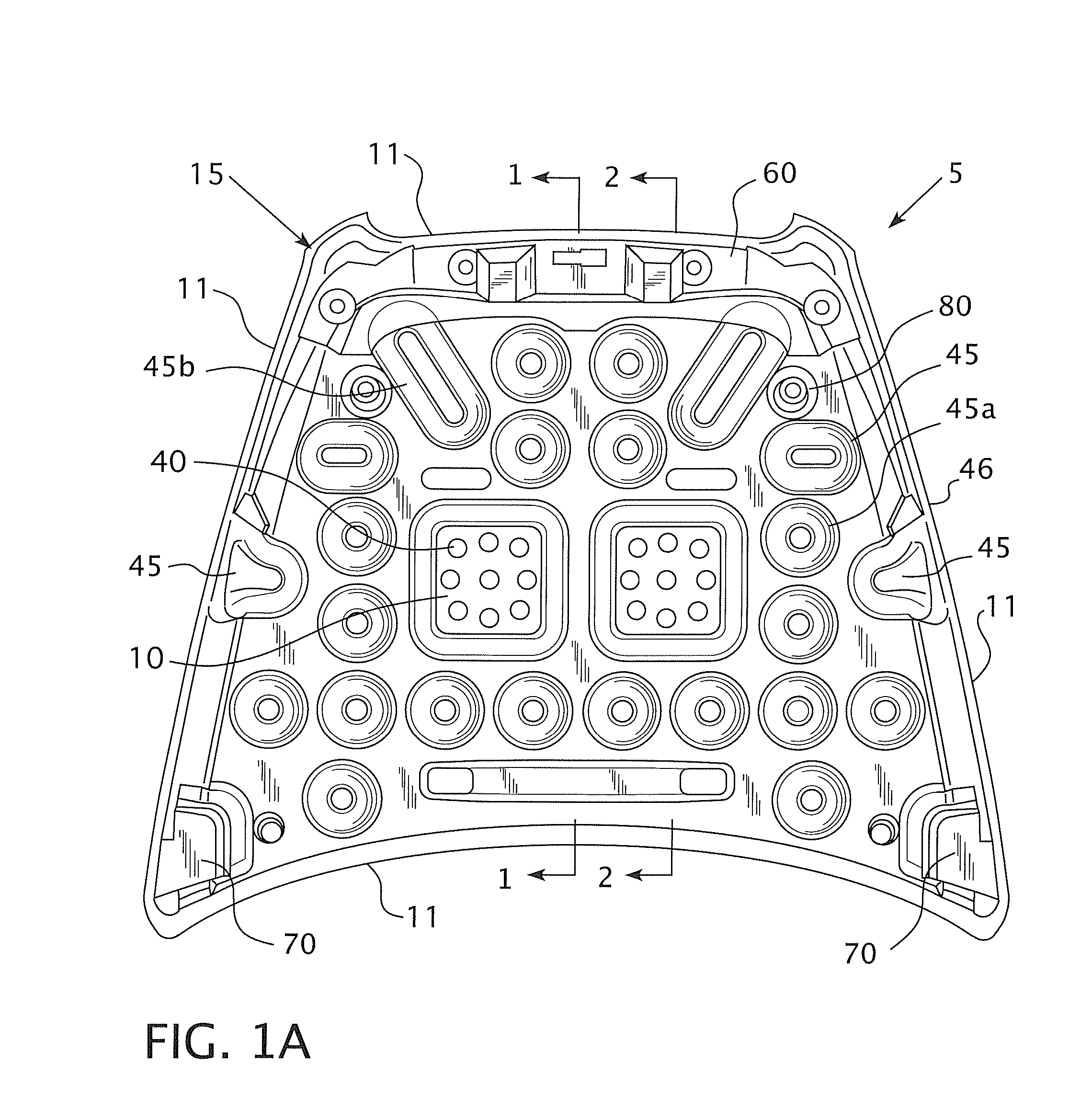

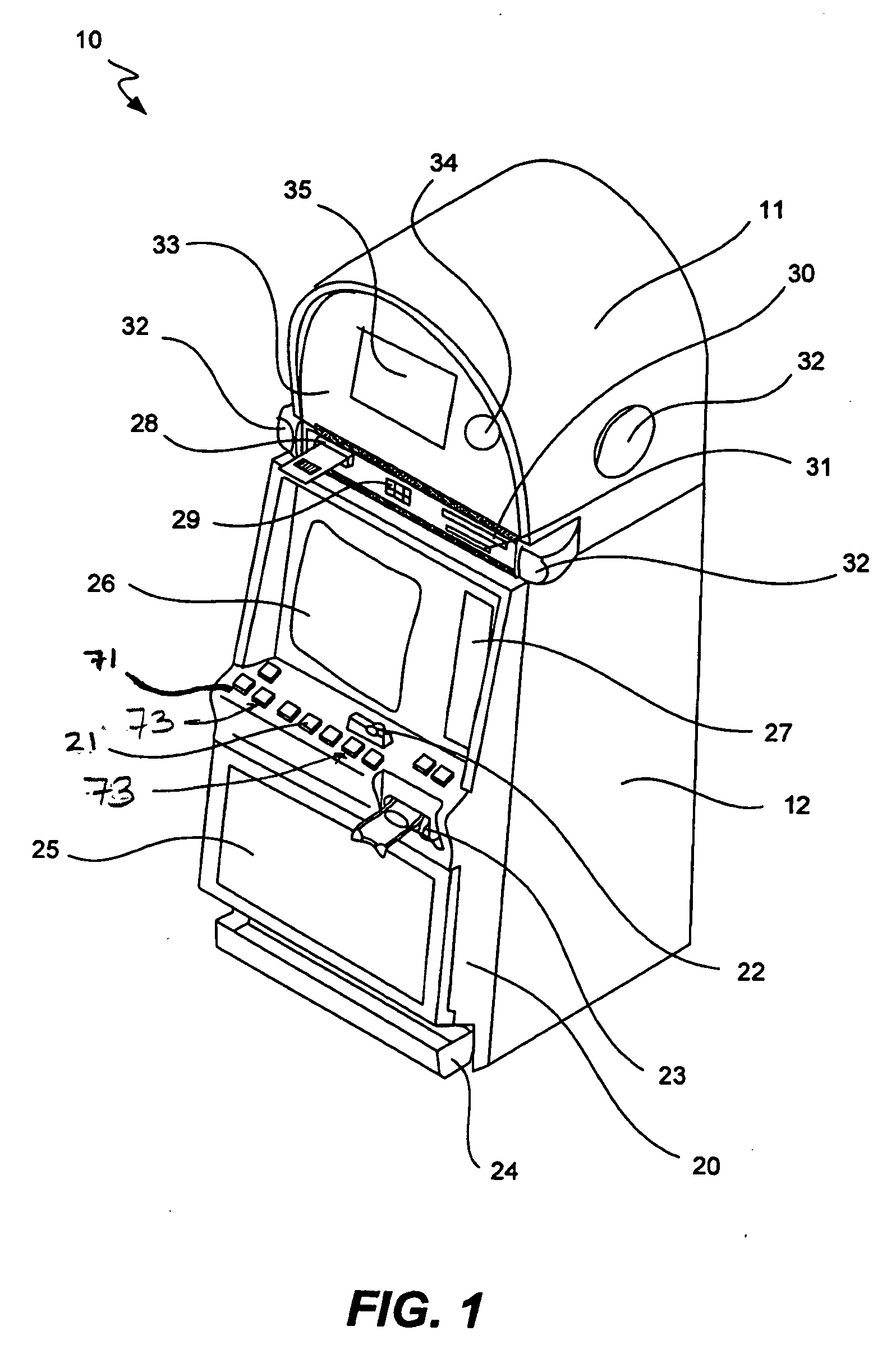

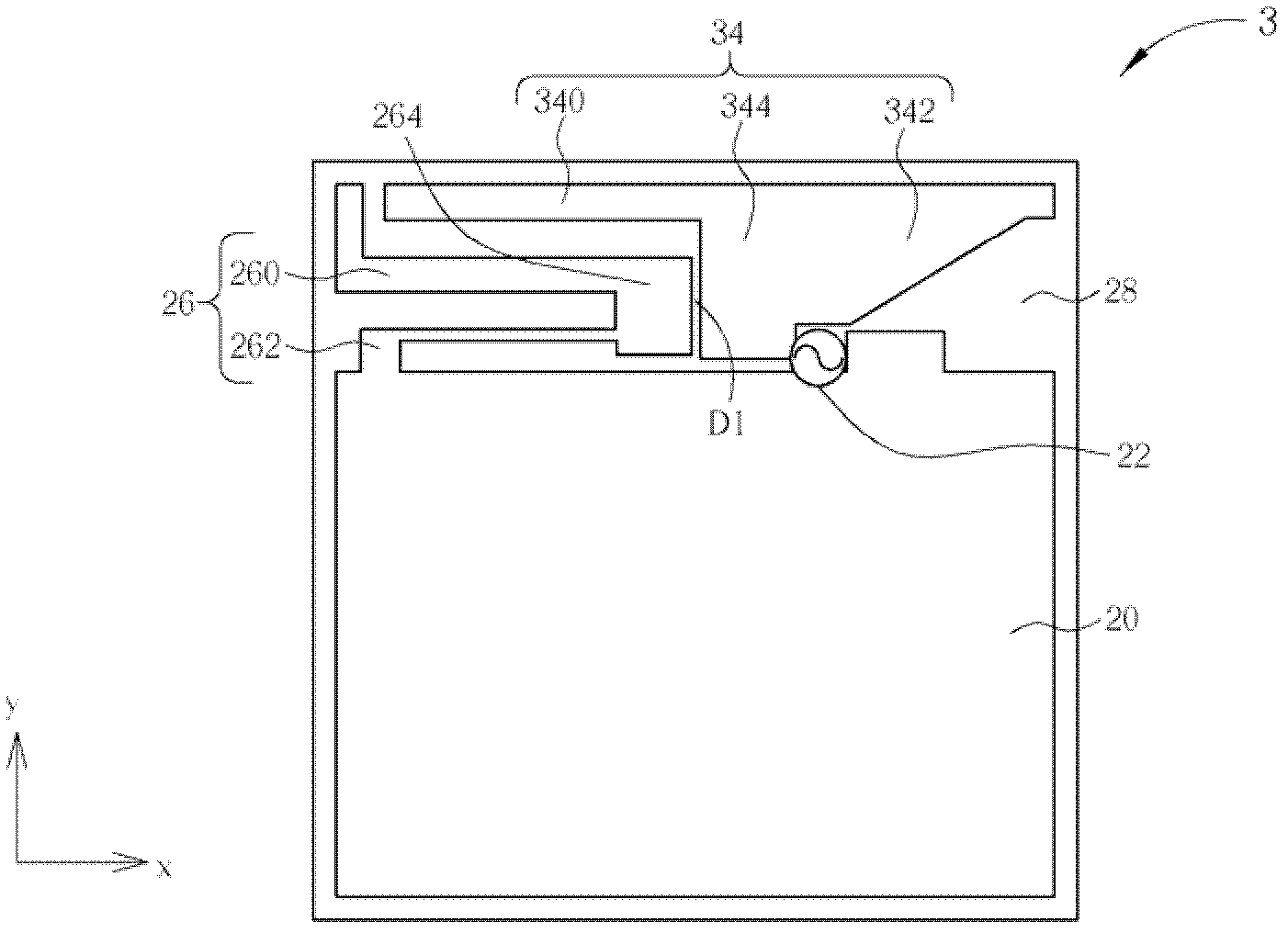

Systems and methods for improving a button assembly

ActiveUS20090131168A1Manufacture be streamlinedUse be streamlinedLegendsKey modulesLight emitting deviceBiomedical engineering

A button assembly is described. The button assembly includes a light emitting device that emits light. The button assembly further includes a lens cap that protects the light emitting device from being damaged. The lens cap has a top surface, a first cap side, a second cap side, a third cap side, and a fourth cap side. The second cap side connected to the first cap side, the third cap side connected to the second cap side, and the fourth cap side connected to the first cap side and the third cap side to form a plane. A first perpendicular distance between the plane and a first point on the top surface is different than a second perpendicular distance between the plane and a second point on the top surface. Additionally, a system for increasing life of a pixel is described.

Owner:IGT

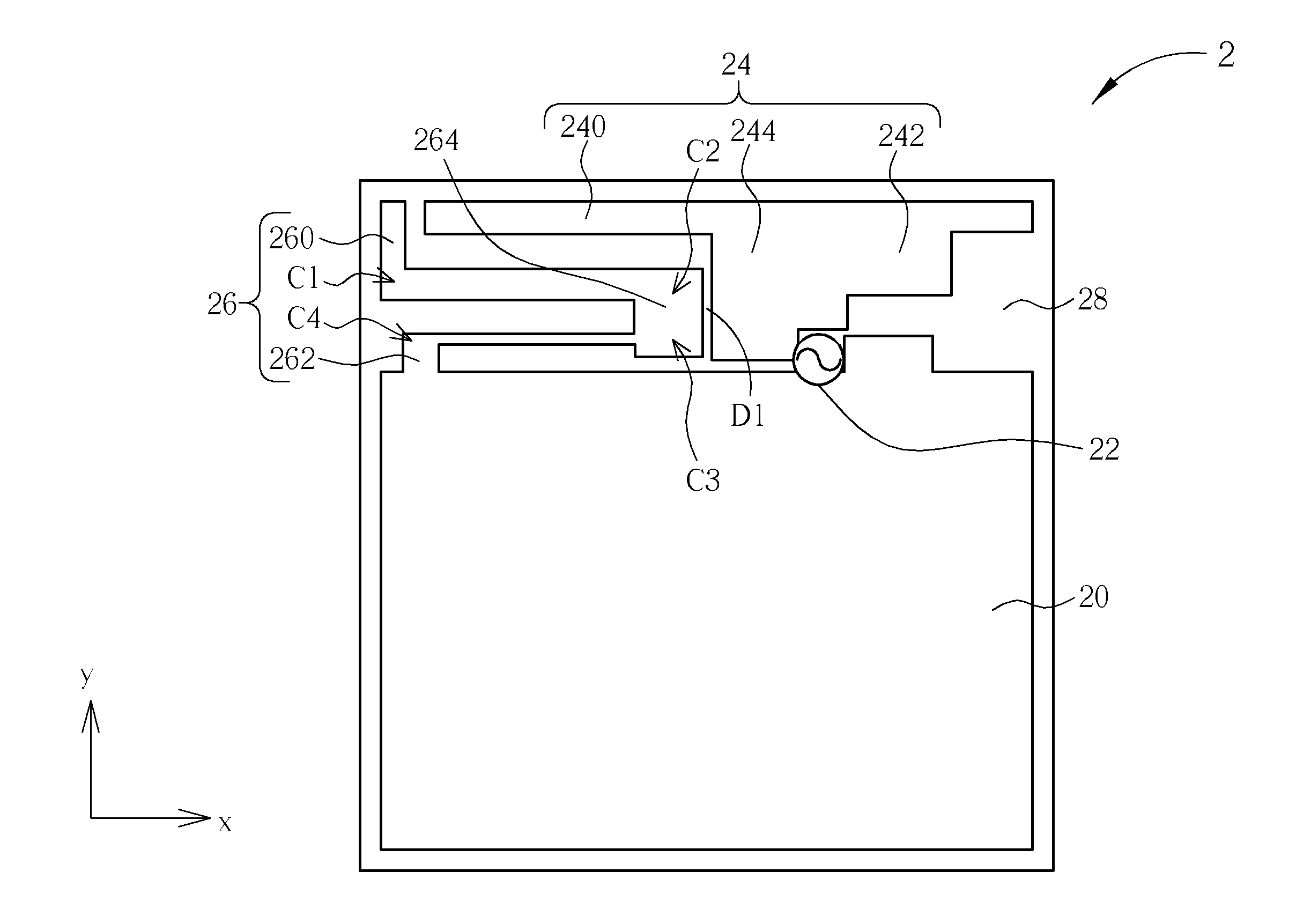

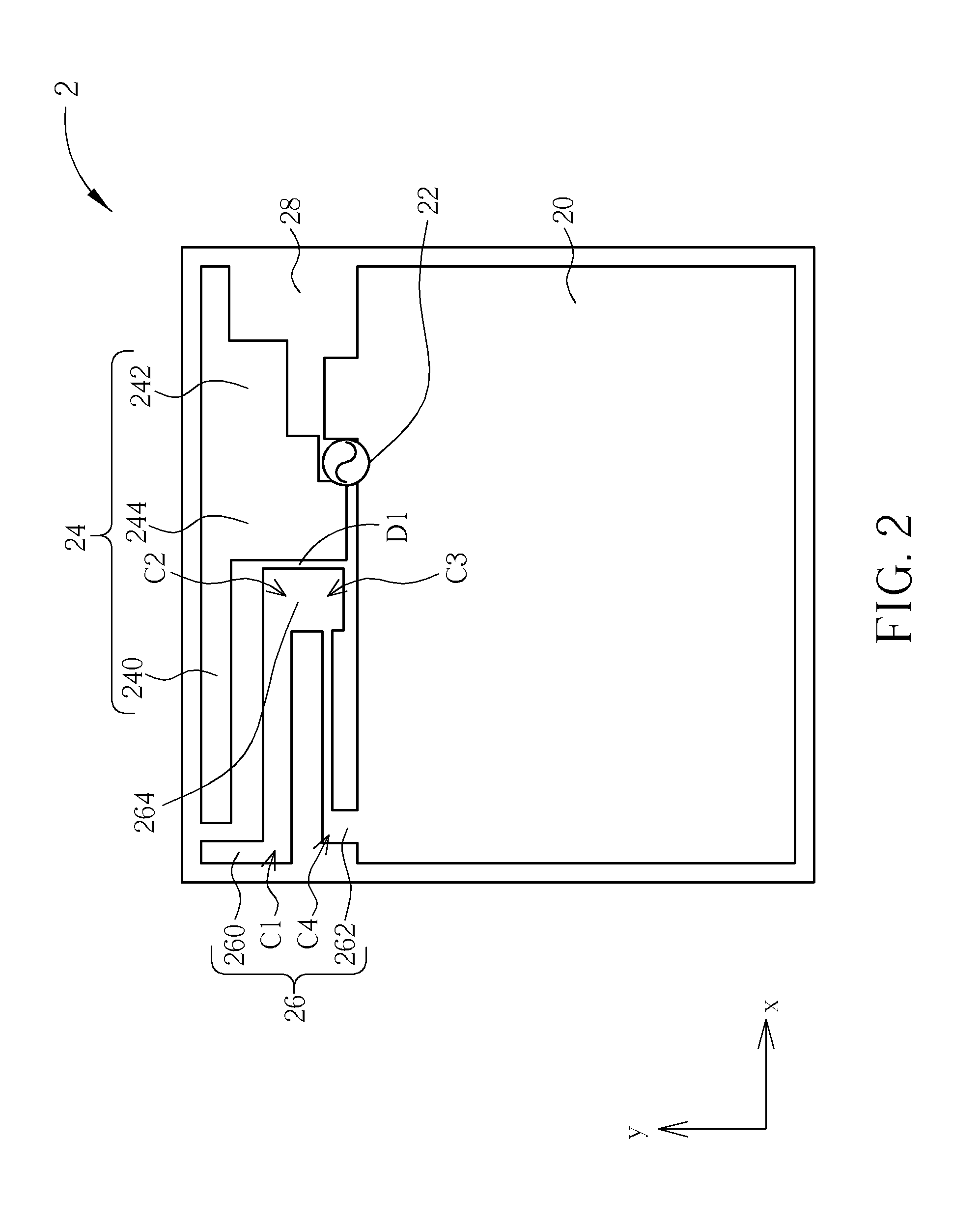

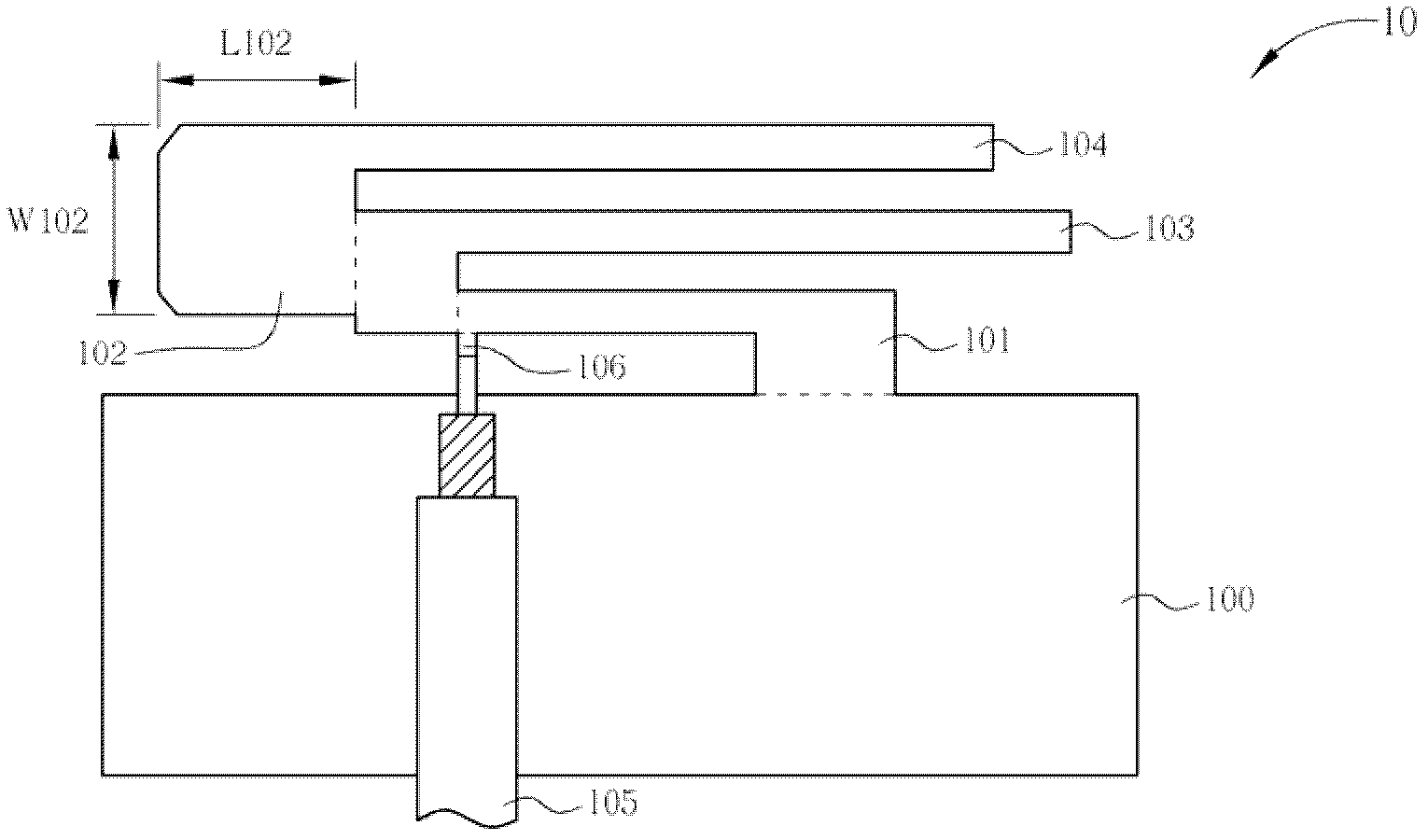

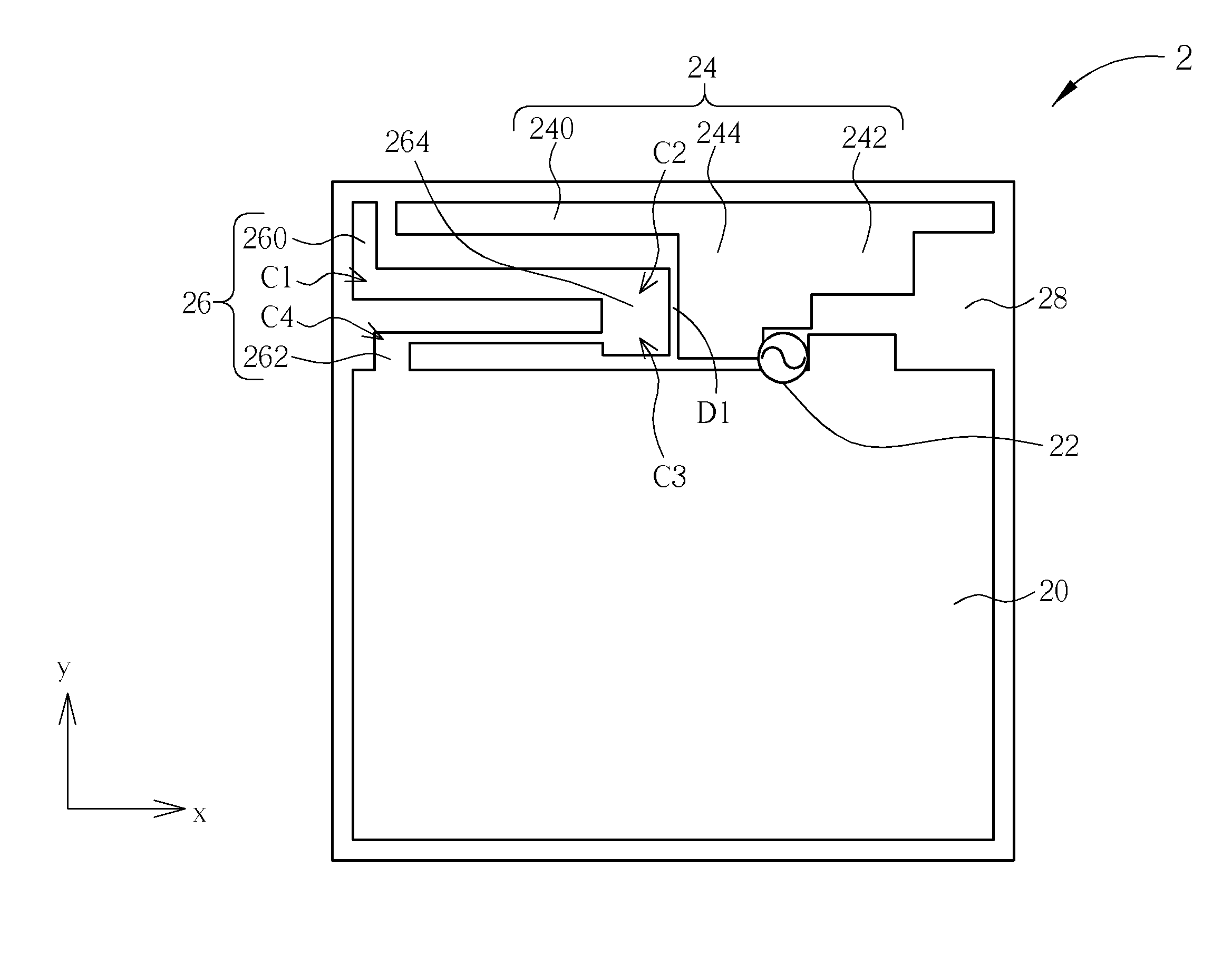

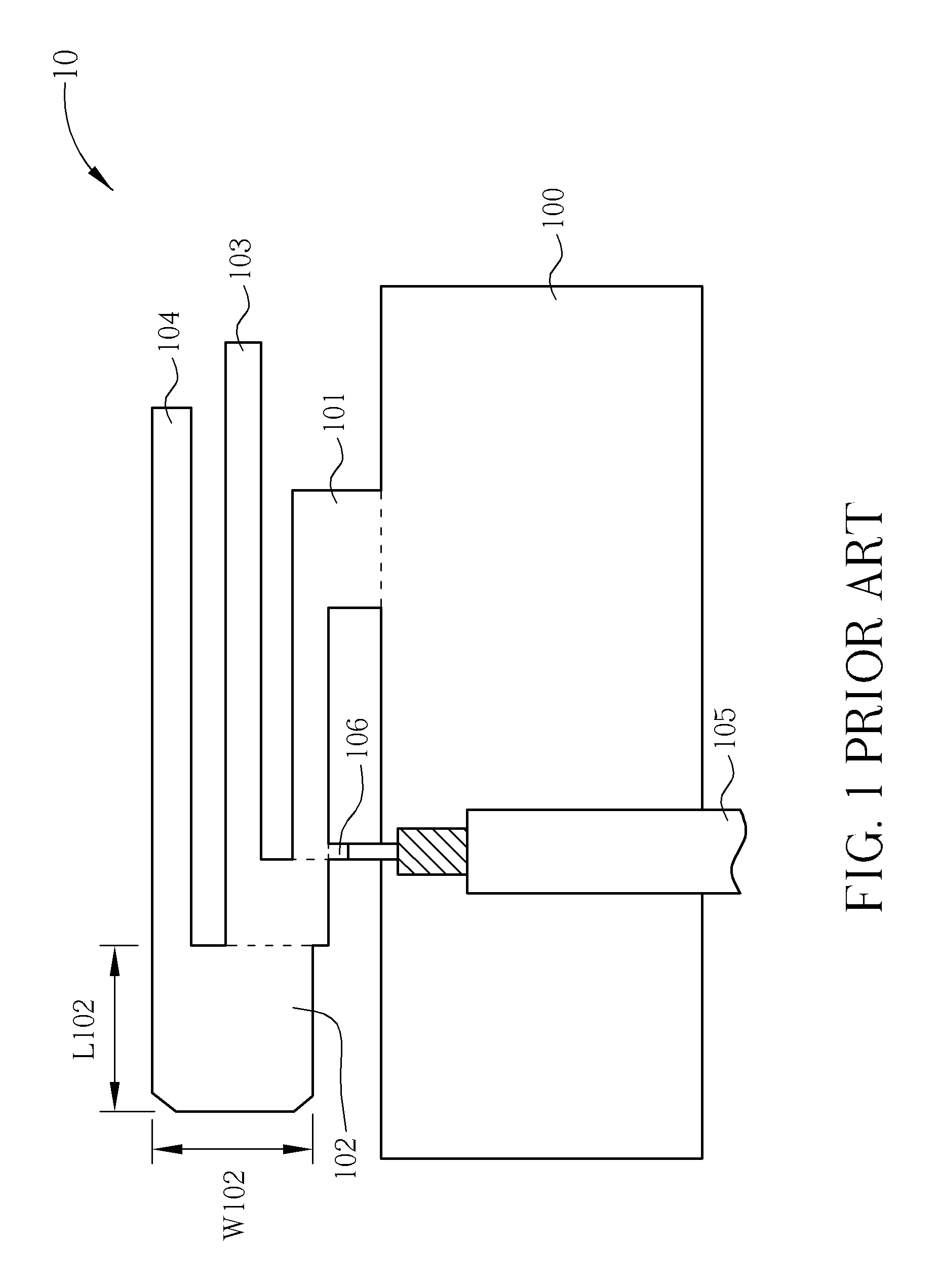

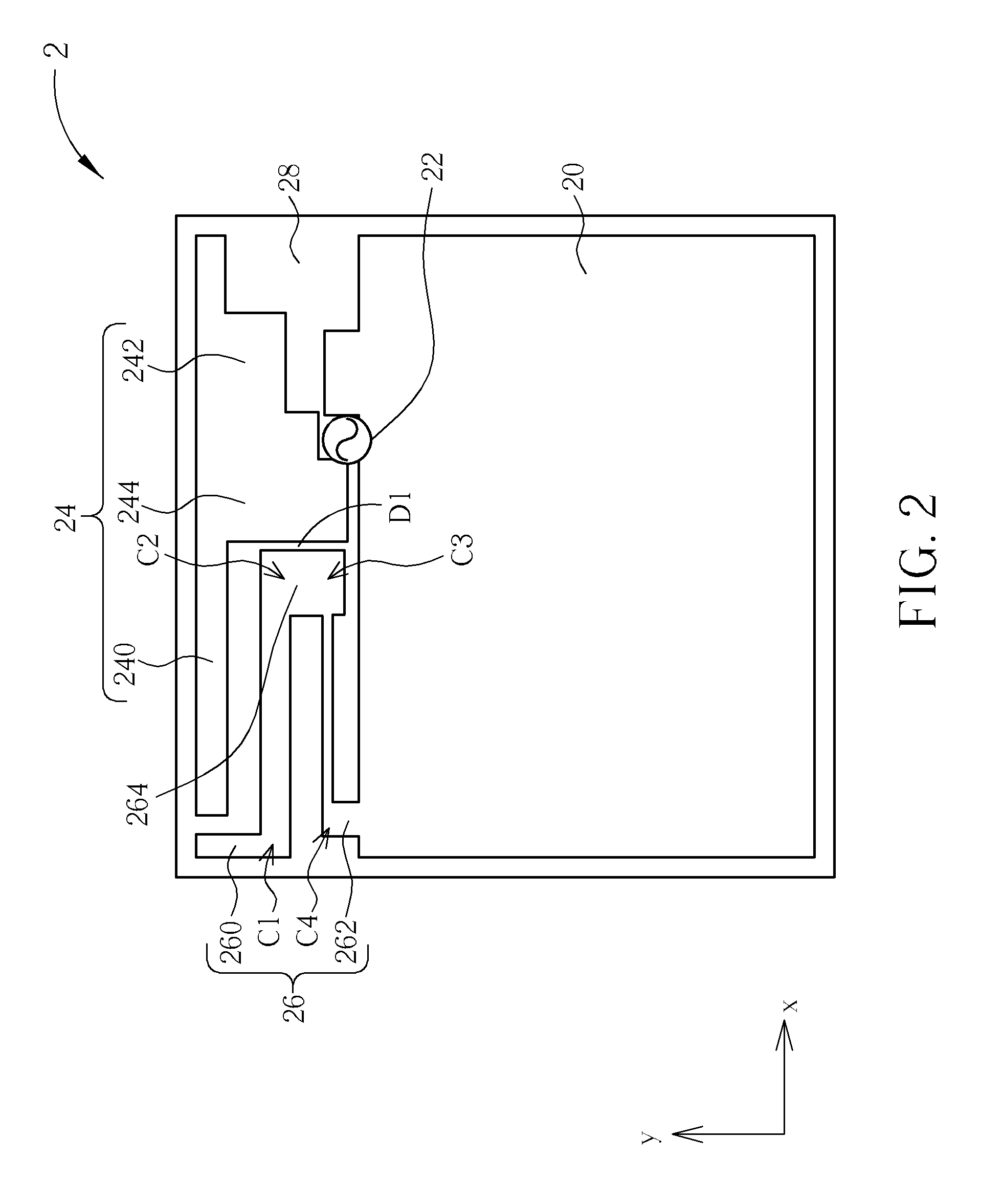

Wideband Antenna

ActiveUS20130207861A1Simultaneous aerial operationsRadiating elements structural formsRadio frequency signalEngineering

A wideband antenna includes a grounding unit electrically connected to a ground, a feed-in source for transmitting and receiving radio frequency signals, a first radiating body including a first radiating unit extending along a first direction, a second radiating unit extending along a second direction opposite to the first direction, and a conducting unit extending along a third direction, and a second radiating body including a short-circuit unit electrically connected to the grounding unit, a third radiating unit including a branch to generate a coupling connection effect with the conducting unit via a first distance, wherein an average perpendicular distance between the second radiating body and the grounding unit is smaller than an average perpendicular distance between the first radiating body and the grounding unit.

Owner:WISTRON NEWEB

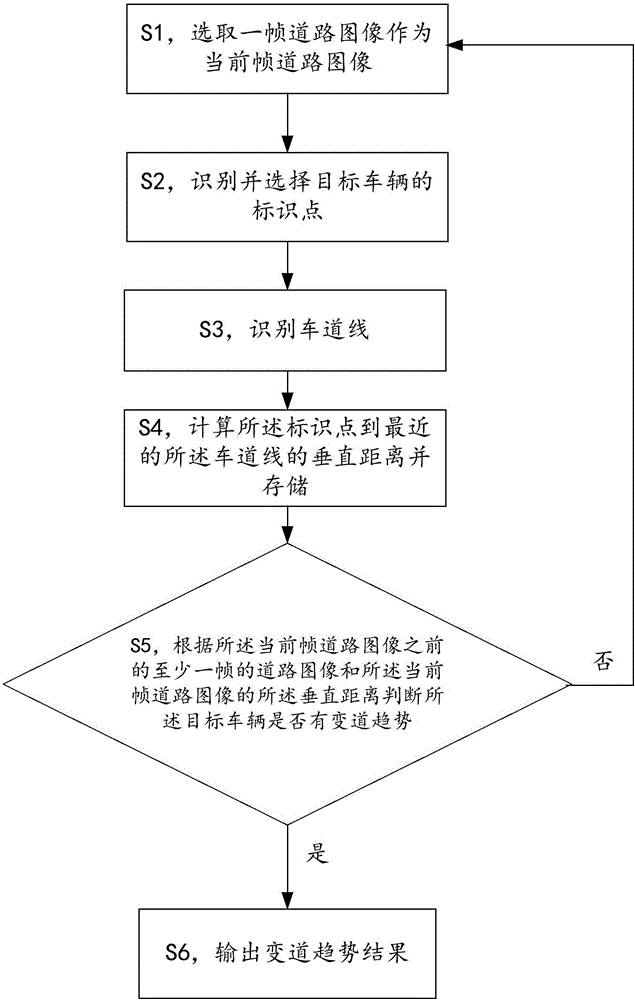

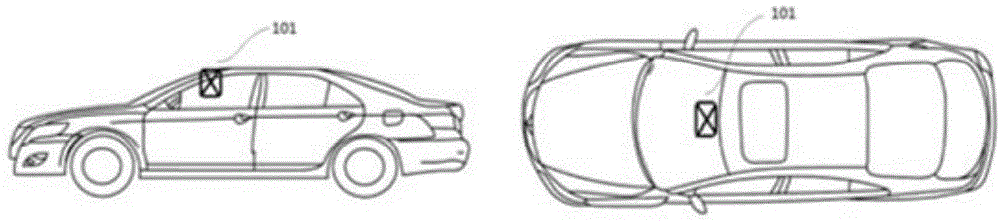

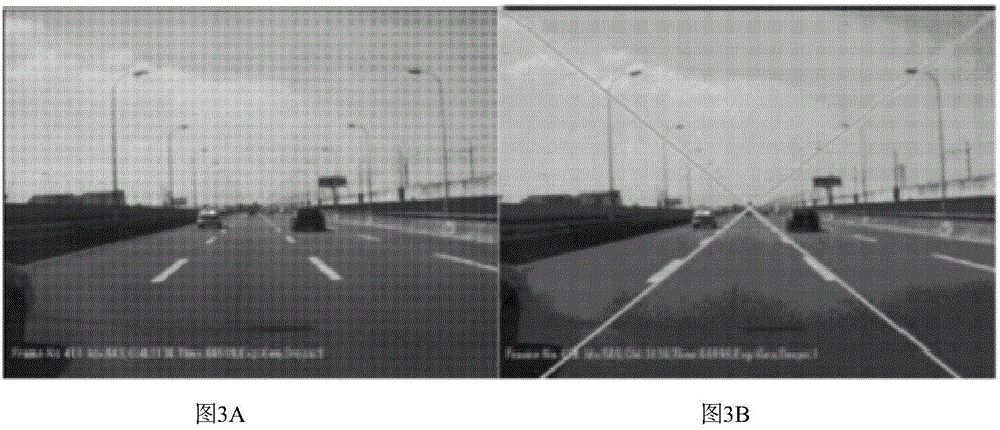

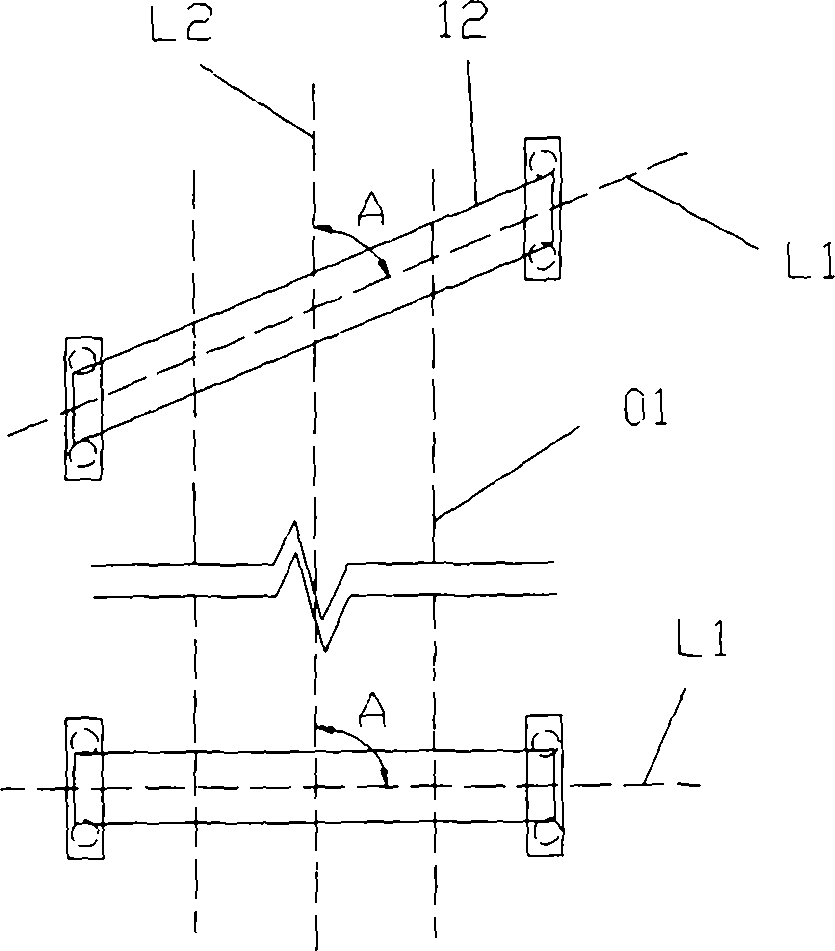

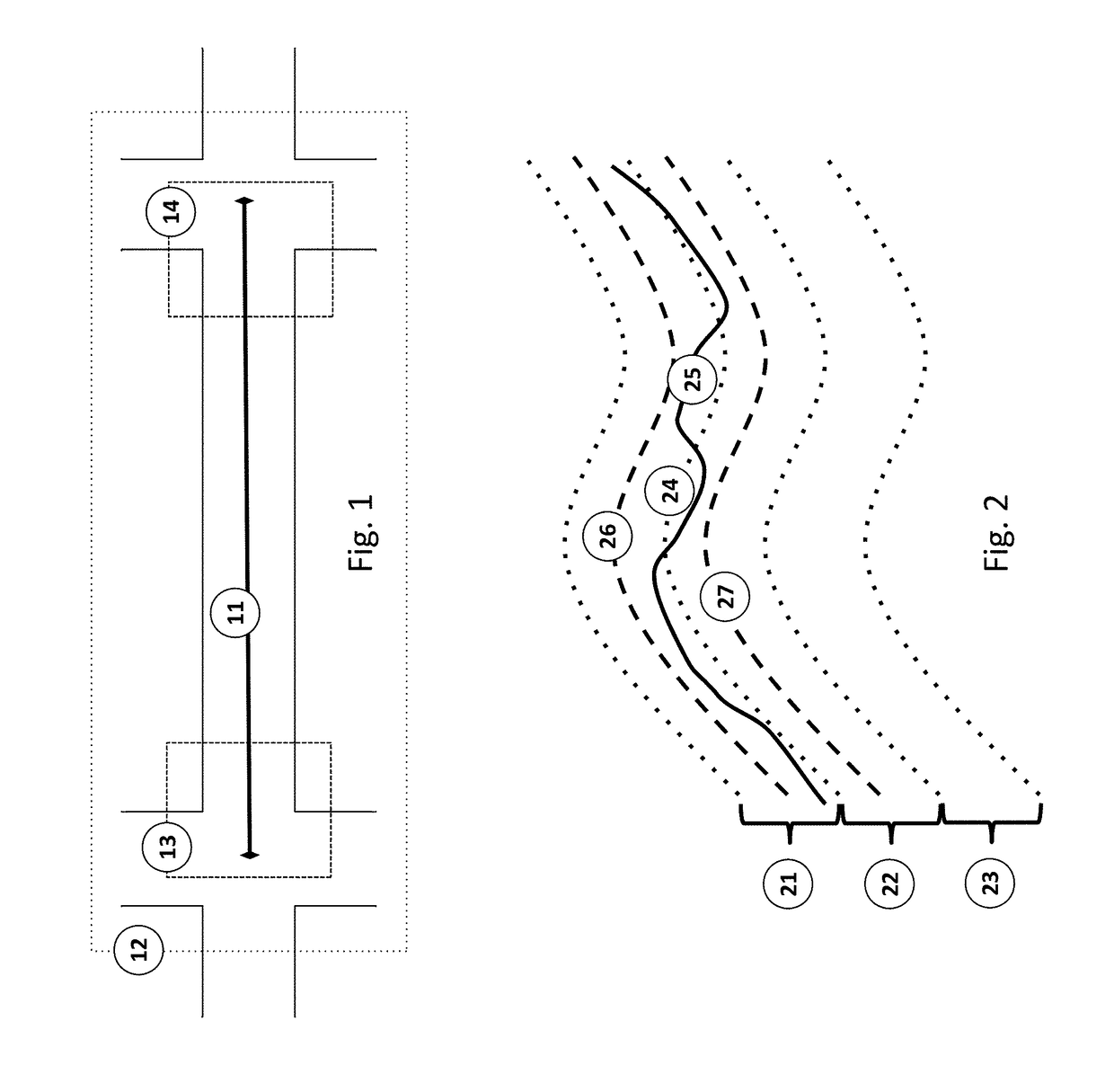

Judgment method and device for lane changing trend of vehicle and computer storage medium

ActiveCN106647776APosition/course control in two dimensionsVehiclesPerpendicular distanceReal-time computing

An embodiment of the invention provides a judgment method and device for lane changing trend of a vehicle and a computer storage medium. The judgment method for the lane changing trend of the vehicle comprises the following steps: selecting a frame of road image as a current frame of road image; recognizing and selecting an identification point of a targeted vehicle; recognizing a lane line; calculating a perpendicular distance from the identification point to the lane line and storing the perpendicular distance; and judging whether the targeted vehicle has the lane changing trend or not according to a perpendicular distance between at least one frame of road image prior to the current frame of road image and the current frame of road image, if the targeted vehicle has the lane changing trend, outputting a lane changing trend result, and if the targeted vehicle does not have the lane changing trend or the lane changing trend cannot be judged, repeating the above steps. According to the embodiment, transverse lane changing trend of the targeted vehicle can be effectively predicted in time, and therefore, danger of lane changing of the targeted vehicle to a current vehicle is avoided effectively.

Owner:UISEE TECH BEIJING LTD

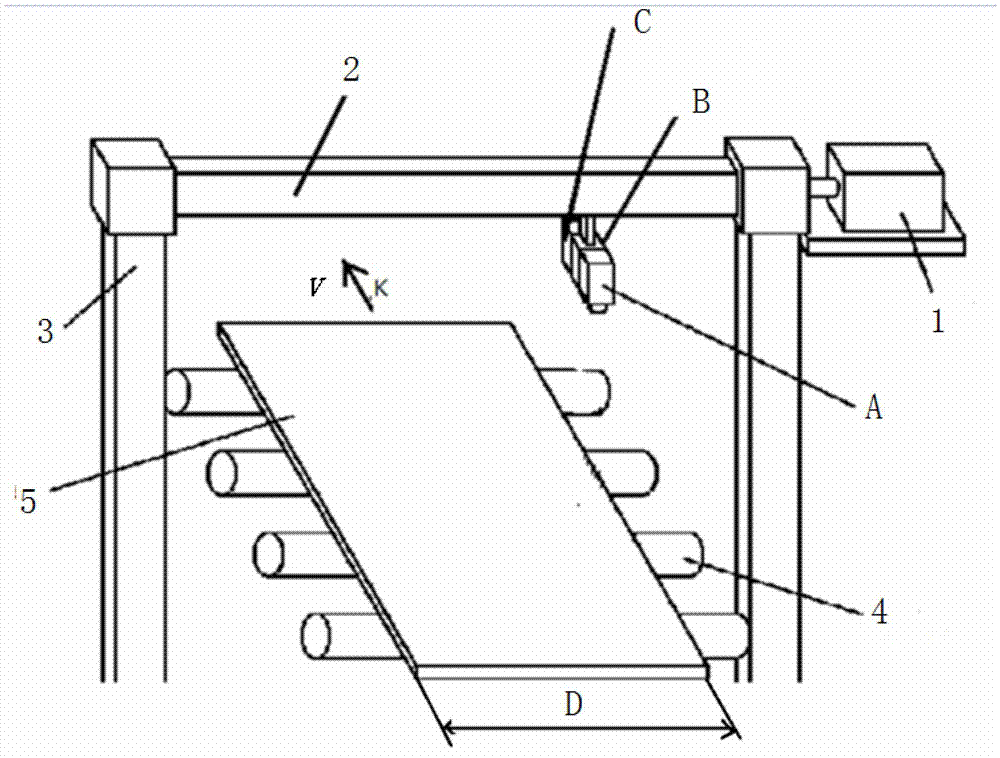

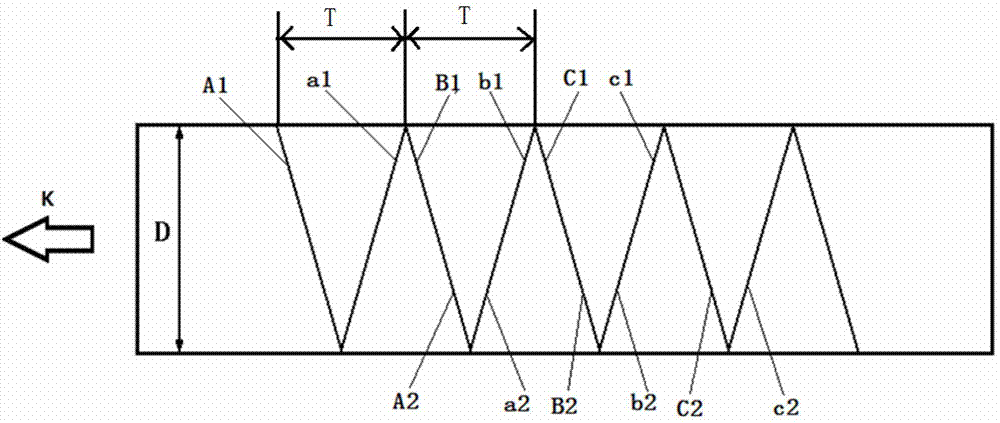

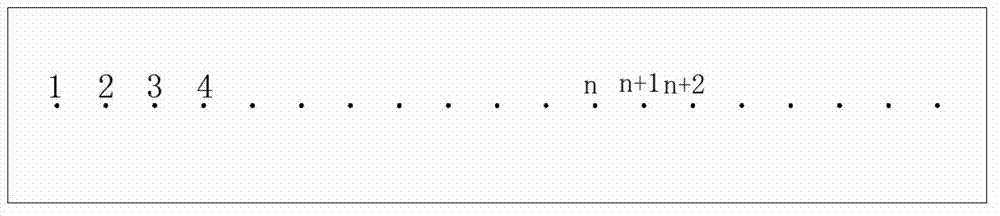

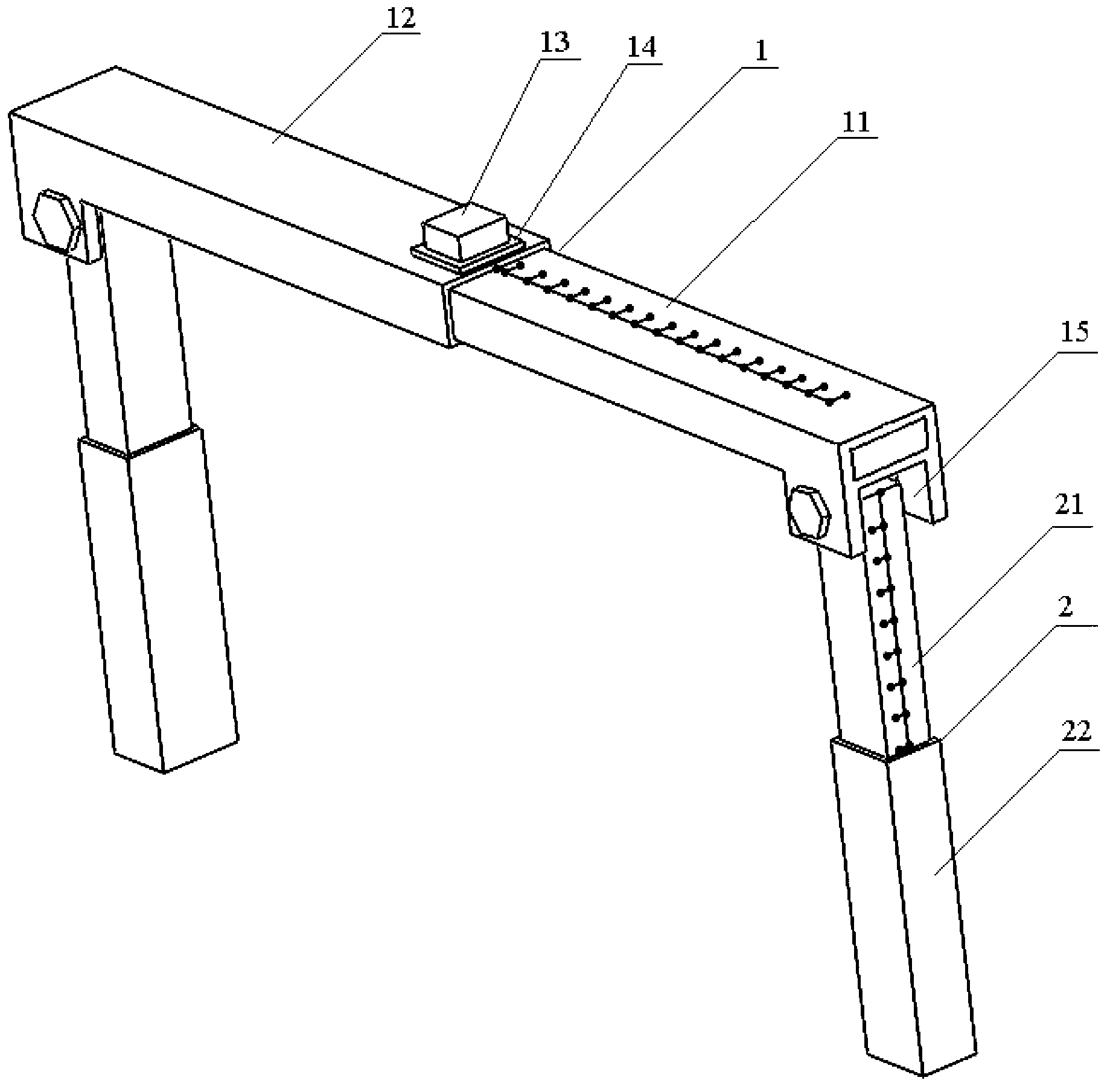

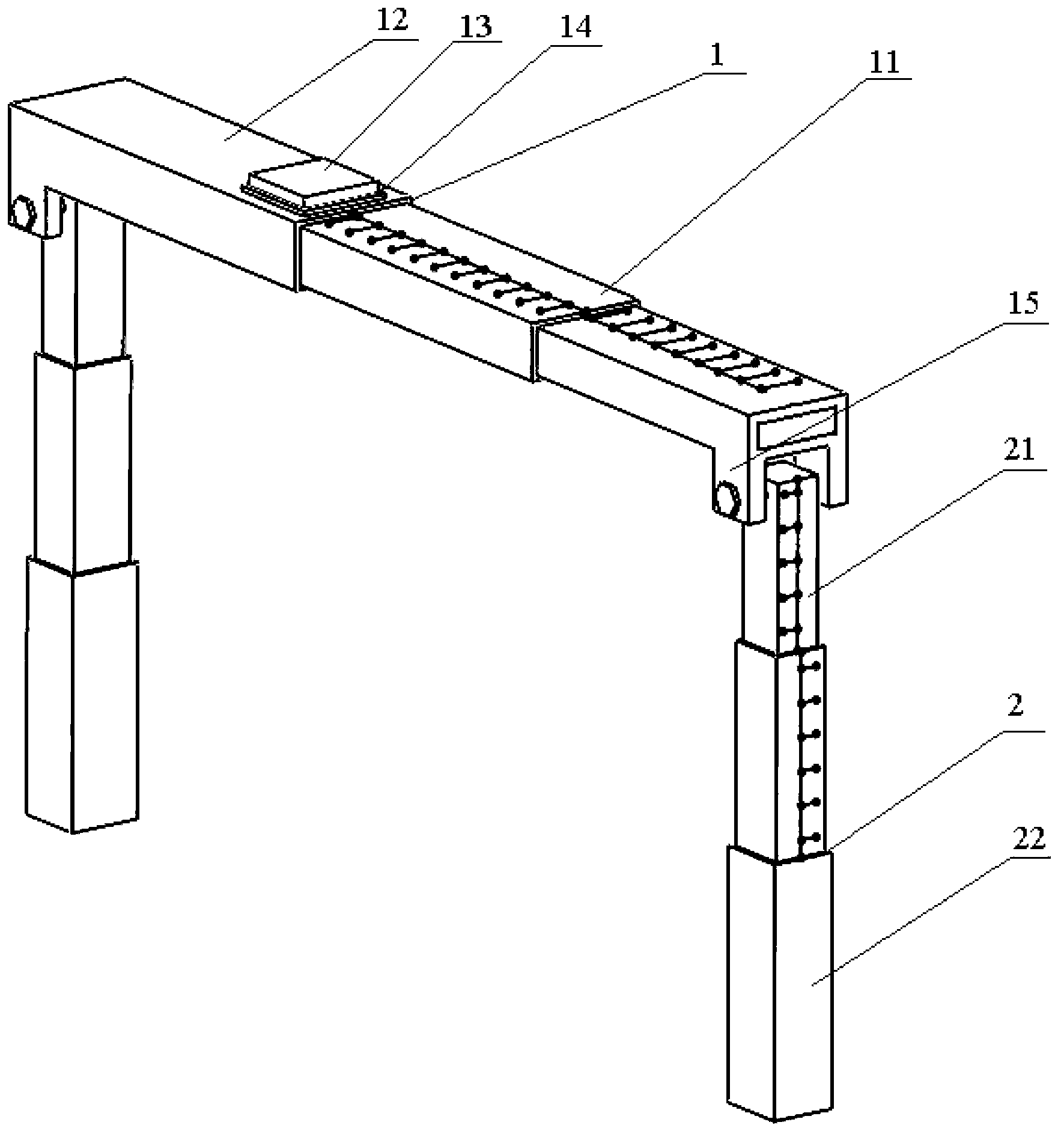

Device and method for detecting panel strip shapes

InactiveCN103486995ARealize detectionSimple structureMeasurement devicesMeasuring instrumentReciprocating motion

The invention discloses a device and method for detecting panel strip shapes, and belongs to the technical field of metal panel detection. The device is characterized in that as is shown in the picture 1, a machine frame (3) is installed above a transverse striding conveying roller way (4), a rail is arranged below an upper beam (2) of the machine frame (3), and a first distance measuring instrument (A), a second distance measuring instrument (B) and a third distance measuring instrument (C) which serve as a whole are installed inside the rail below the upper beam (2) side by side and can be driven by a stepping motor (1) to do reciprocating movement. The distance between probes of every two adjacent distance measuring instruments is T. The direction in which a panel (5) is conveyed on the conveying roller way (4) is perpendicular to the direction of the rail below the upper beam. The operating method comprises the steps that firstly, in the process of conveying the panel, the three distance measuring instruments do once stroke on the rail by double width value of the panel to measure the perpendicular distance between each point in the panel and the distance measuring instruments; secondly, the measured distance value is recorded; thirdly, the detected and recorded data of each point are corrected and calculated. The device for detecting the panel strip shapes has the advantages of being simple in structure, low in manufacturing cost and reliable in operation, the strip shapes can be detected under the dynamic situation, and high measuring precision can be achieved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

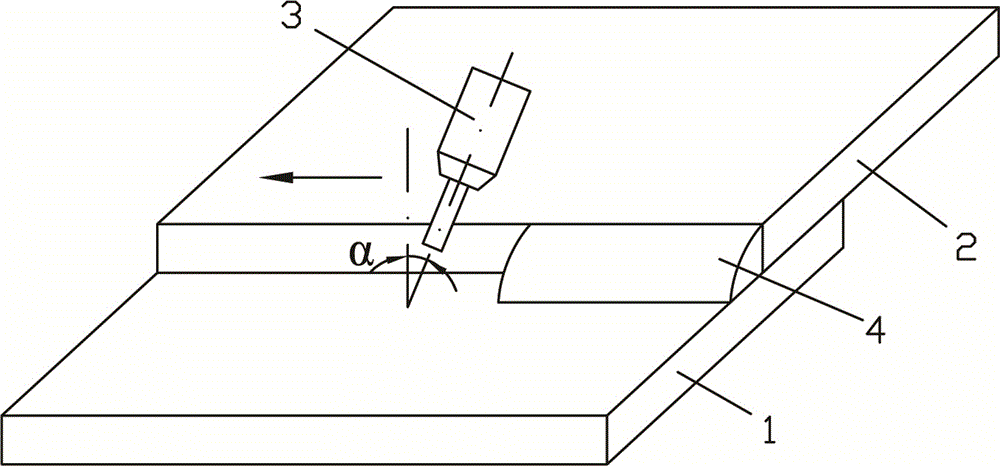

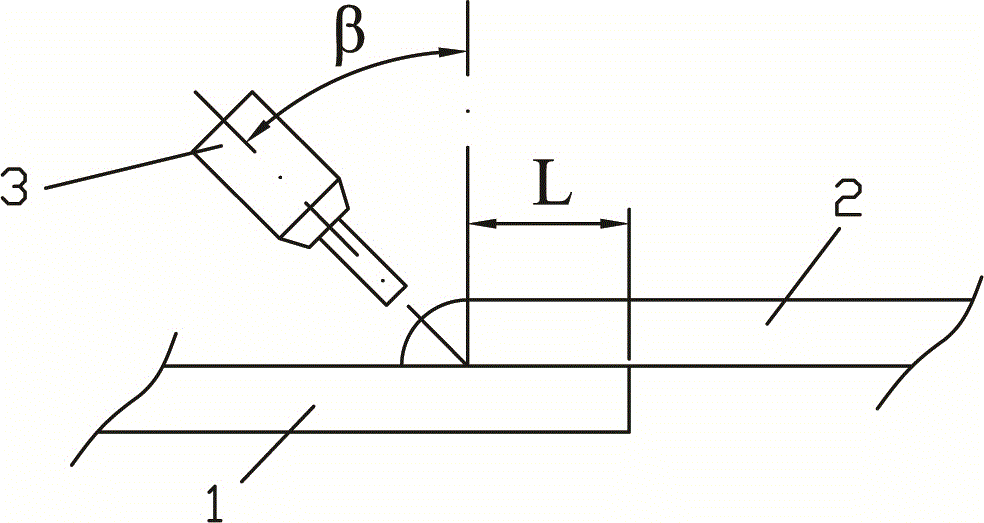

Method for preparing steel-aluminum dissimilar metal overlap joint by adopting CMT technology

InactiveCN106624281ALow heat inputIncrease heat inputArc welding apparatusWelding/soldering/cutting articlesMetalPerpendicular distance

The invention provides a method for preparing a steel-aluminum dissimilar metal overlap joint by adopting the CMT technology. The method comprises the following steps: an aluminum alloy plate is placed on a galvanized steel plate in an overlap manner and fixed by utilizing a fixture, wherein the overlap amount ranges between 5 mm and 20 mm; and a CMT welding machine is utilized, a welding gun is inclined towards the aluminum alloy plate to form an angle of 1-45 degrees with the vertical direction, the welding gun is inclined towards the forward direction by 5-30 degrees, the perpendicular distance between the welding gun and the galvanized steel plate is 10-20 mm, and the welding speed is 0.4-1.0 m / min. According to the method provided by the invention, the CMT technology is improved based on an original MIG welding power source, thereby converting molten droplet transfer into cold metal transfer, and reducing the metal spatter when the heat input during a welding process is reduced; and accordingly, the method is very suitable for welding of the aluminum alloy plate and the galvanized steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

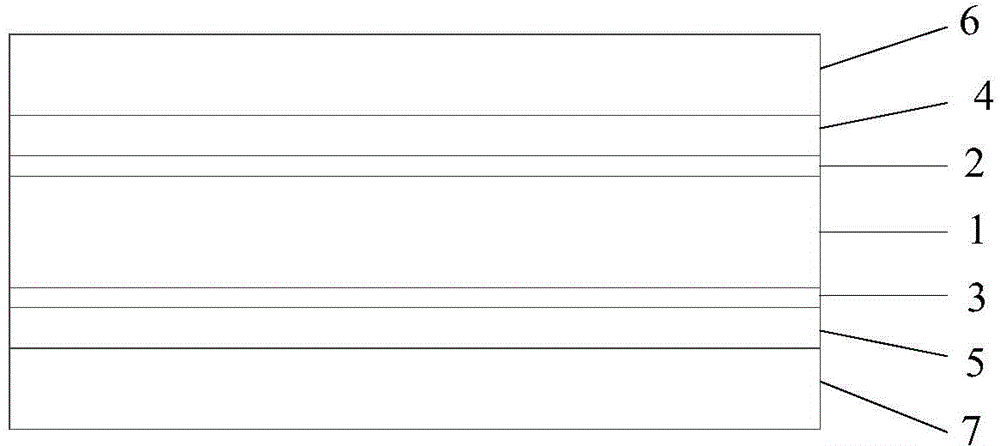

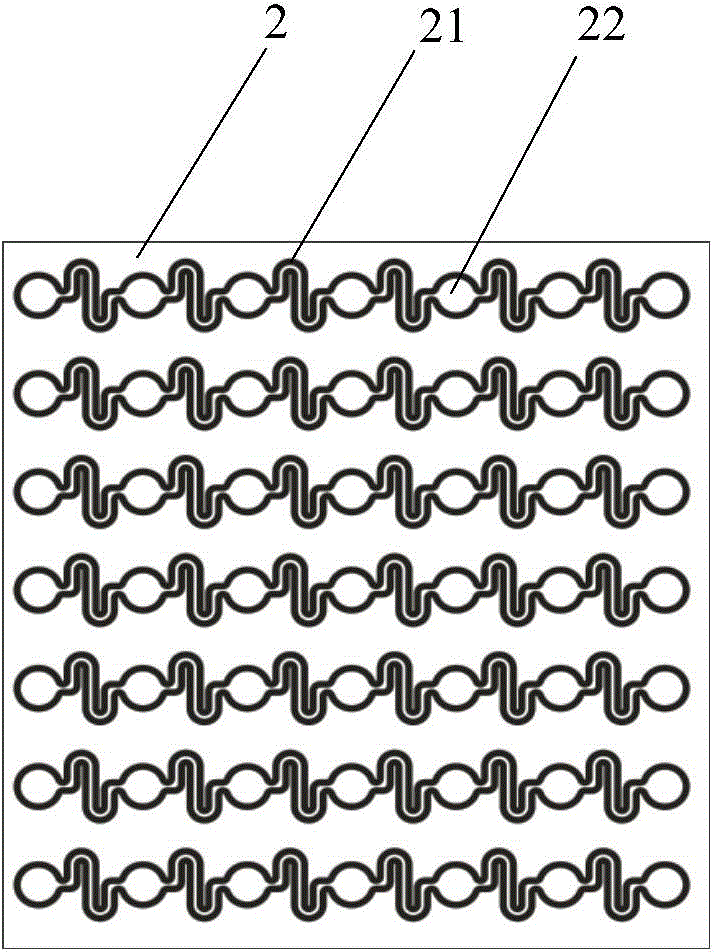

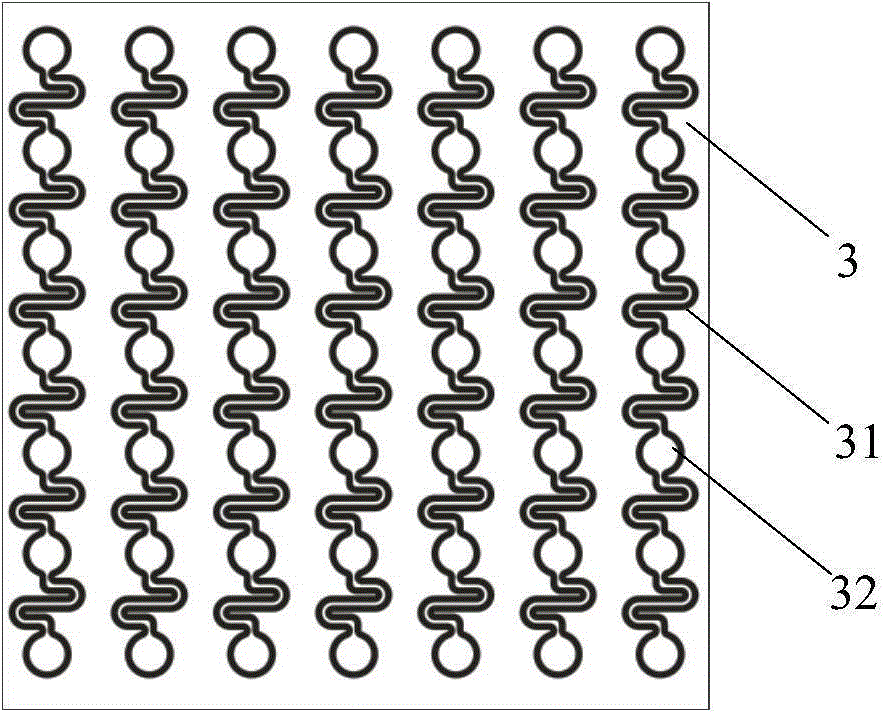

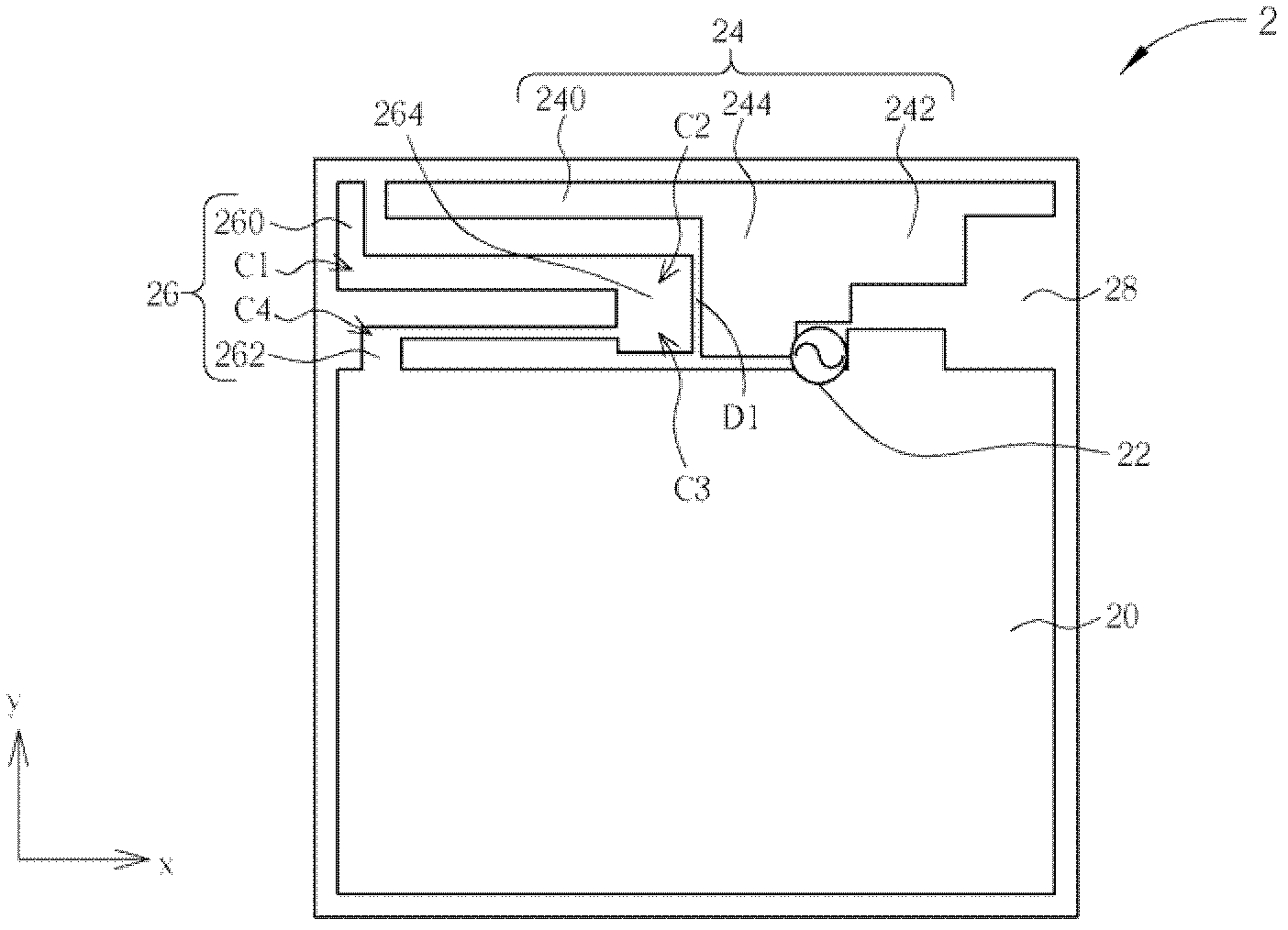

Stress sensor, preparation method and electronic skin

ActiveCN106153219AAccurate detectionImprove detection accuracyForce measurementFluid pressure measurement using capacitance variationCapacitanceForce sensor

The invention relates to the field of sensor technology, and discloses a stress sensor, a preparation method and an electronic skin. The stress sensor includes: a dielectric layer (1), used for elastic deformation under the action of an external force; at least one first electrode unit ( 2), having stretchability, disposed on the upper surface of the dielectric layer (1); and at least one second electrode unit (3), having stretchability, disposed on the dielectric layer (1) The lower surface of the first electrode unit (2) and the second electrode unit (3) cross relatively to form a capacitor array; under the action of an external force, the vertical distance of the corresponding relative intersection changes, so that the capacitance on the corresponding capacitor Variety. The stress sensor of the invention can accurately detect the variation of capacitance and has high detection precision.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

External profile for turbine blade airfoil

A turbine blade including an airfoil having a pressure sidewall and a suction sidewall joined together along an upstream leading edge and a downstream trailing edge. The leading edge and trailing edge are formed as substantially straight edges, and portions of the pressure sidewall and suction sidewall adjacent the trailing edge form substantially planar surfaces. The airfoil has an uncoated nominal profile substantially in accordance with Cartesian coordinate values of X, Y and Z set forth in Table 1 wherein Z represents a perpendicular distance from a plane normal to a radius of a turbine centerline and containing the X and Y values with the Z value commencing at zero in the X, Y plane at a radially innermost aerodynamic section of the airfoil, and X and Y represent coordinate values defining the airfoil profile at each distance Z which, when connected by smooth continuing arcs, define profile sections at each distance Z.

Owner:SIEMENS ENERGY INC

Spirit level for power transmission line n-shaped rod construction

ActiveCN103322875AEasy to measureEasy to storeMechanical depth measurementsMechanical clearance measurementsArchitectural engineeringMeasuring ruler

The invention discloses a spirit level for power transmission line n-shaped rod construction. The spirit level for power transmission line n-shaped rod construction comprises a span measuring ruler used for measuring the horizontal distance between two rod pits of an n-shaped rod and two depth measuring rulers arranged on the end portions of the span measuring ruler respectively. The span measuring ruler comprises a ruler sleeve and a telescopic ruler core sleeved inside the ruler sleeve. The outer surface of the ruler core is provided with a scale. A level gauge is arranged on the outer surface of the ruler sleeve. The depth measuring ruler comprises a lower ruler and a telescopic upper ruler sleeved inside the lower ruler. The outer surface of the upper ruler is provided with a scale. The spirit level for power transmission line n-shaped rod construction is convenient to use and capable of directly measuring the horizontal distance between the two rod pits and the perpendicular distance between the bottom faces of the two rod pits, offering instructive parameters for n-shaped rod construction, omitting a large number of calculation processes and improving the construction efficiency to a large extent. In addition, the spirit level for power transmission line n-shaped rod construction further has the advantages of being small in error, easy to transport and store and the like.

Owner:STATE GRID CORP OF CHINA +2

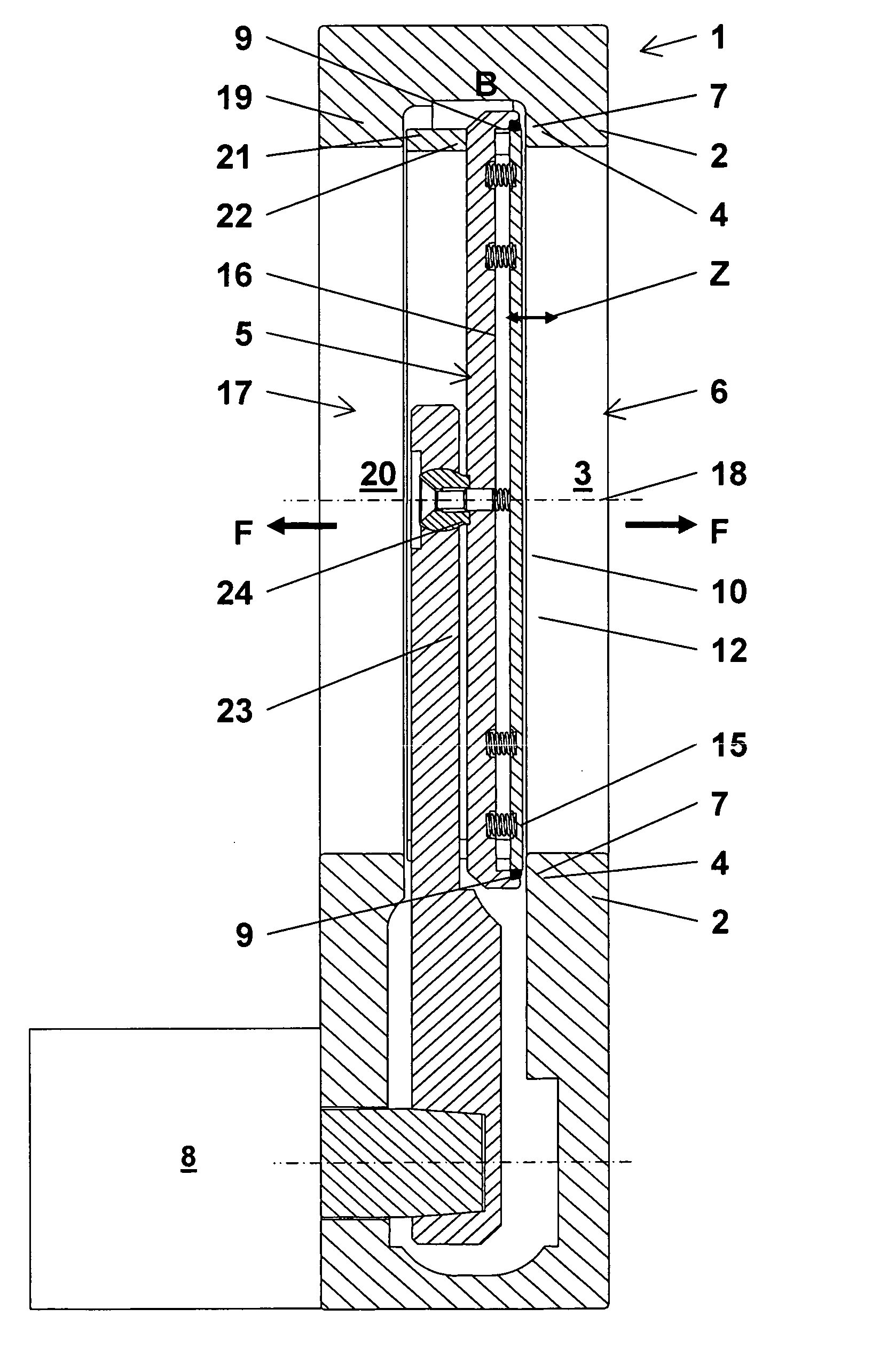

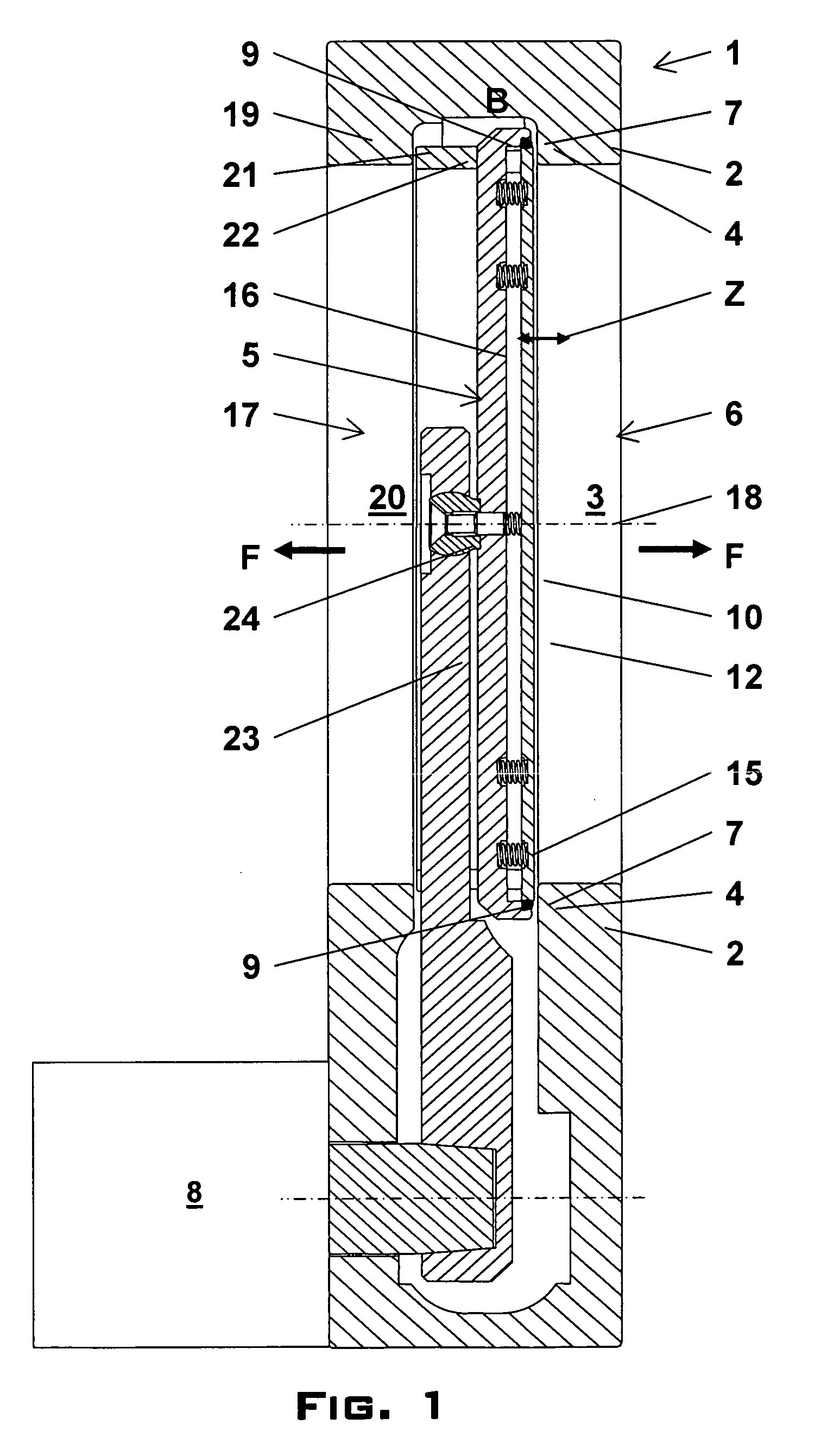

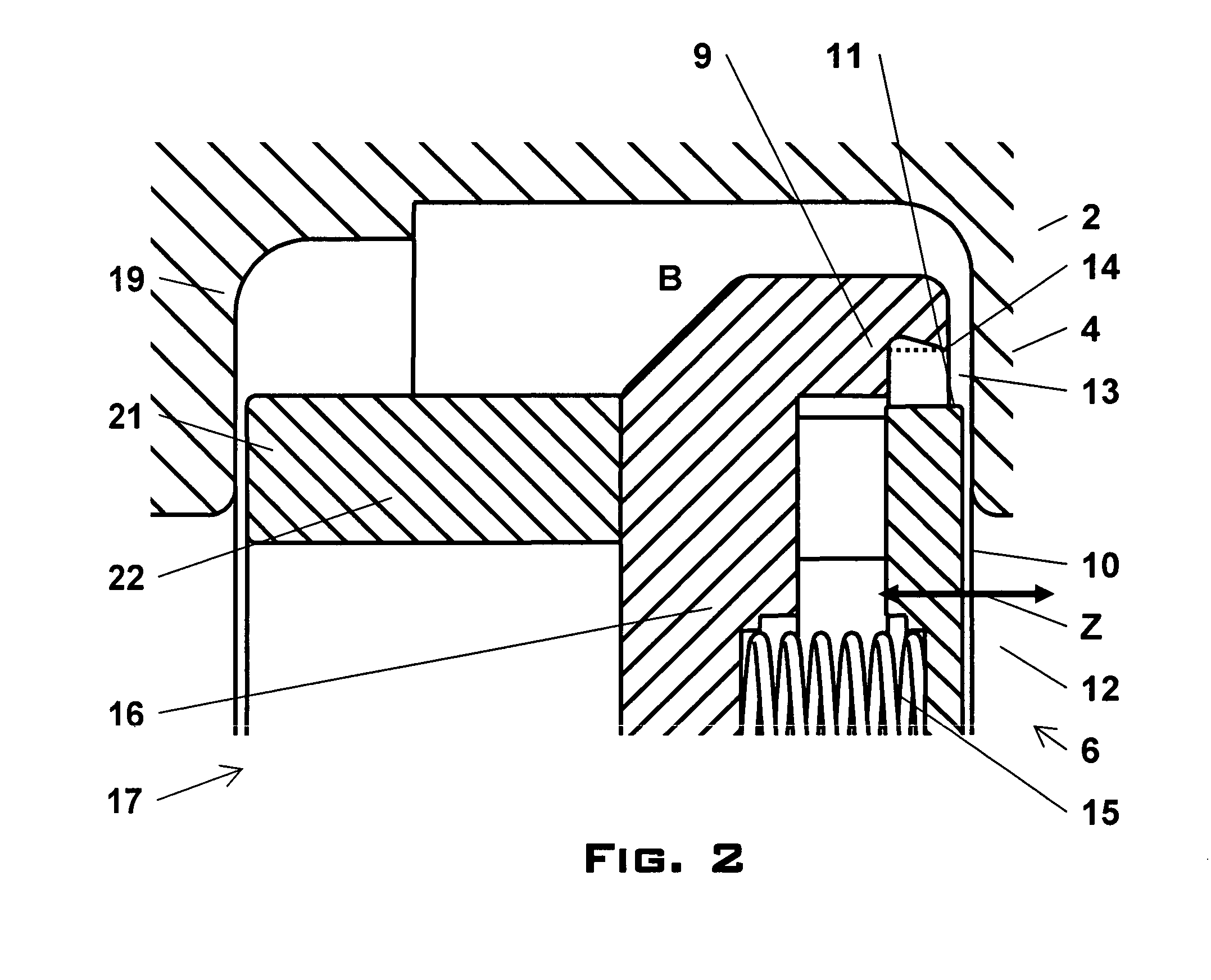

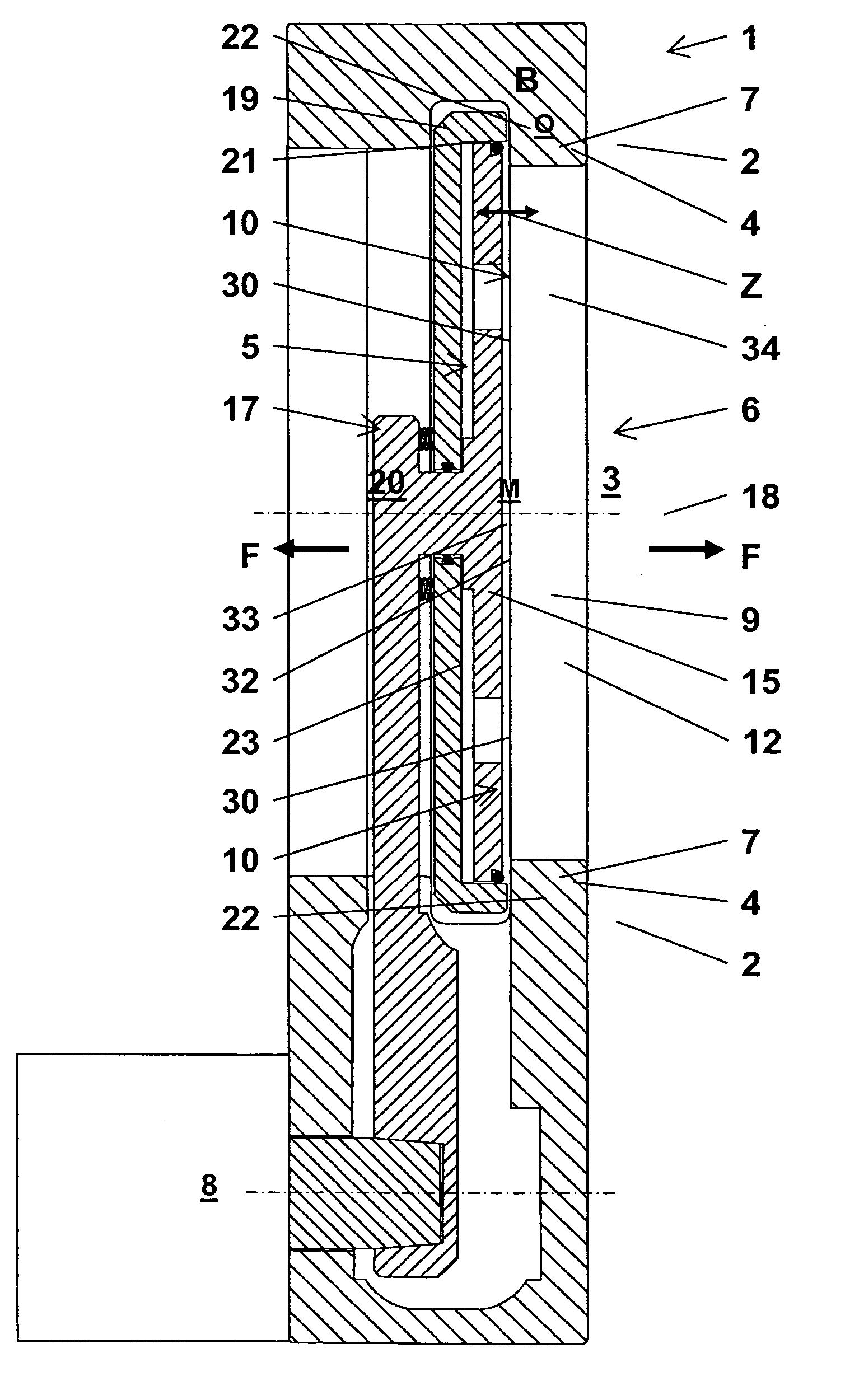

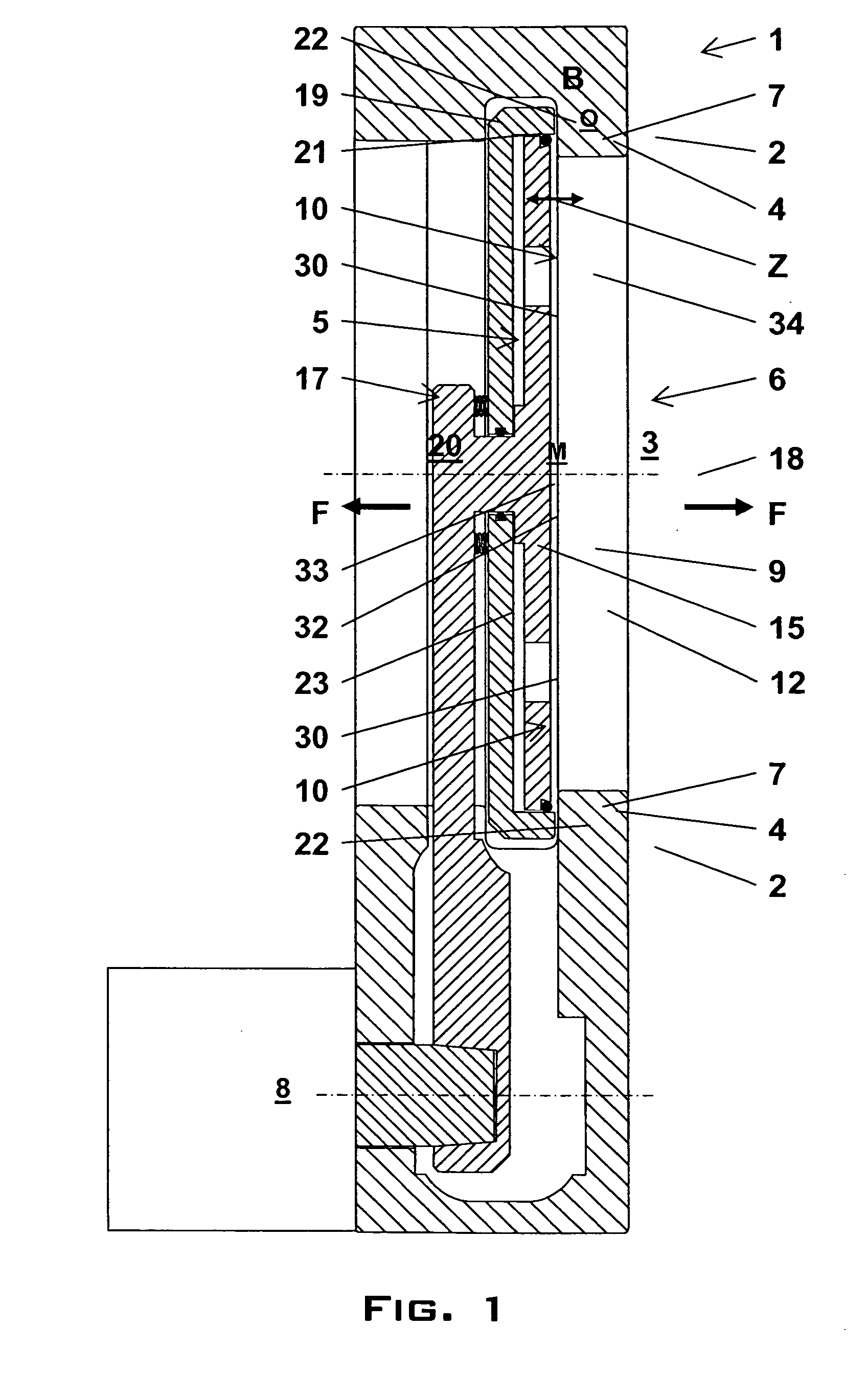

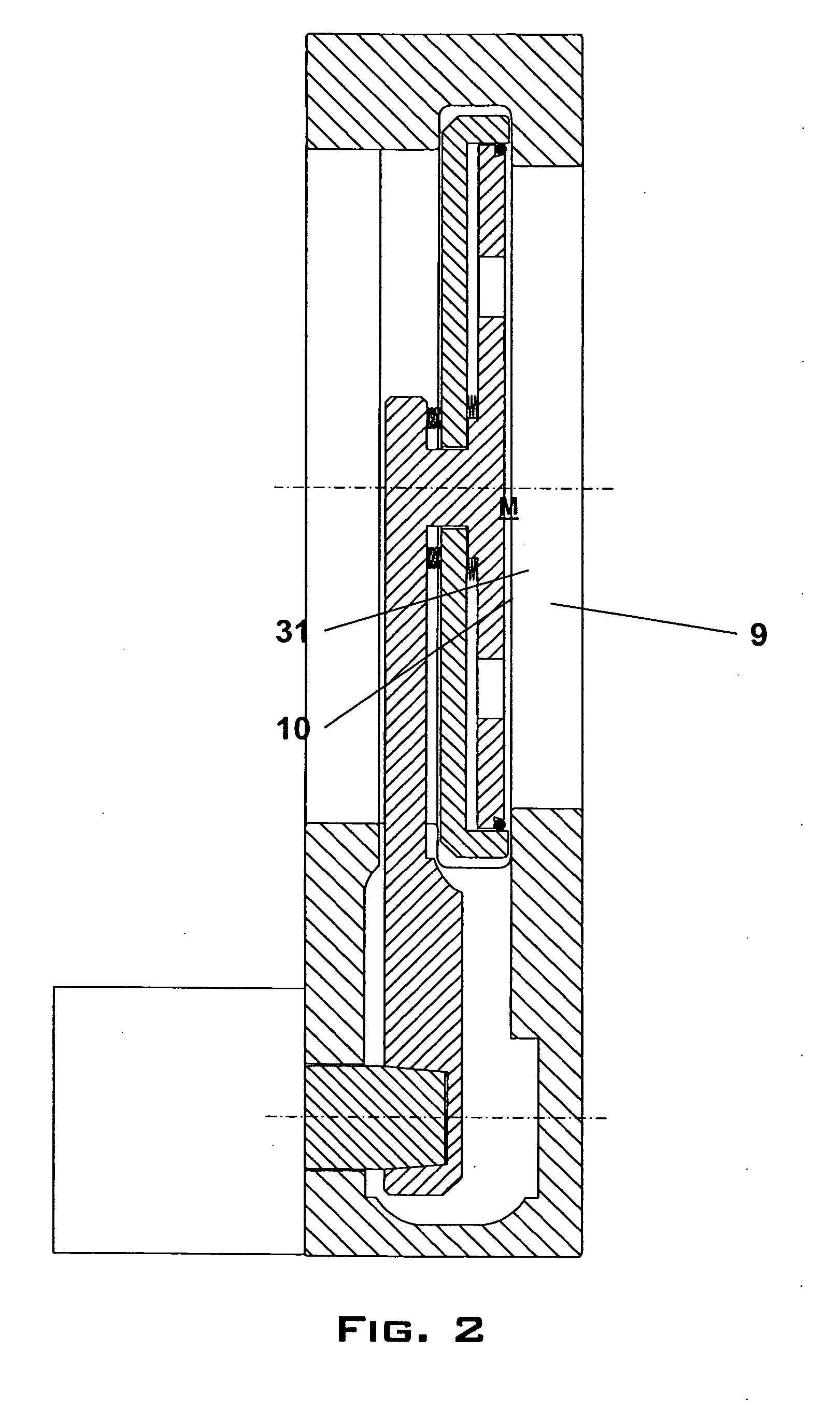

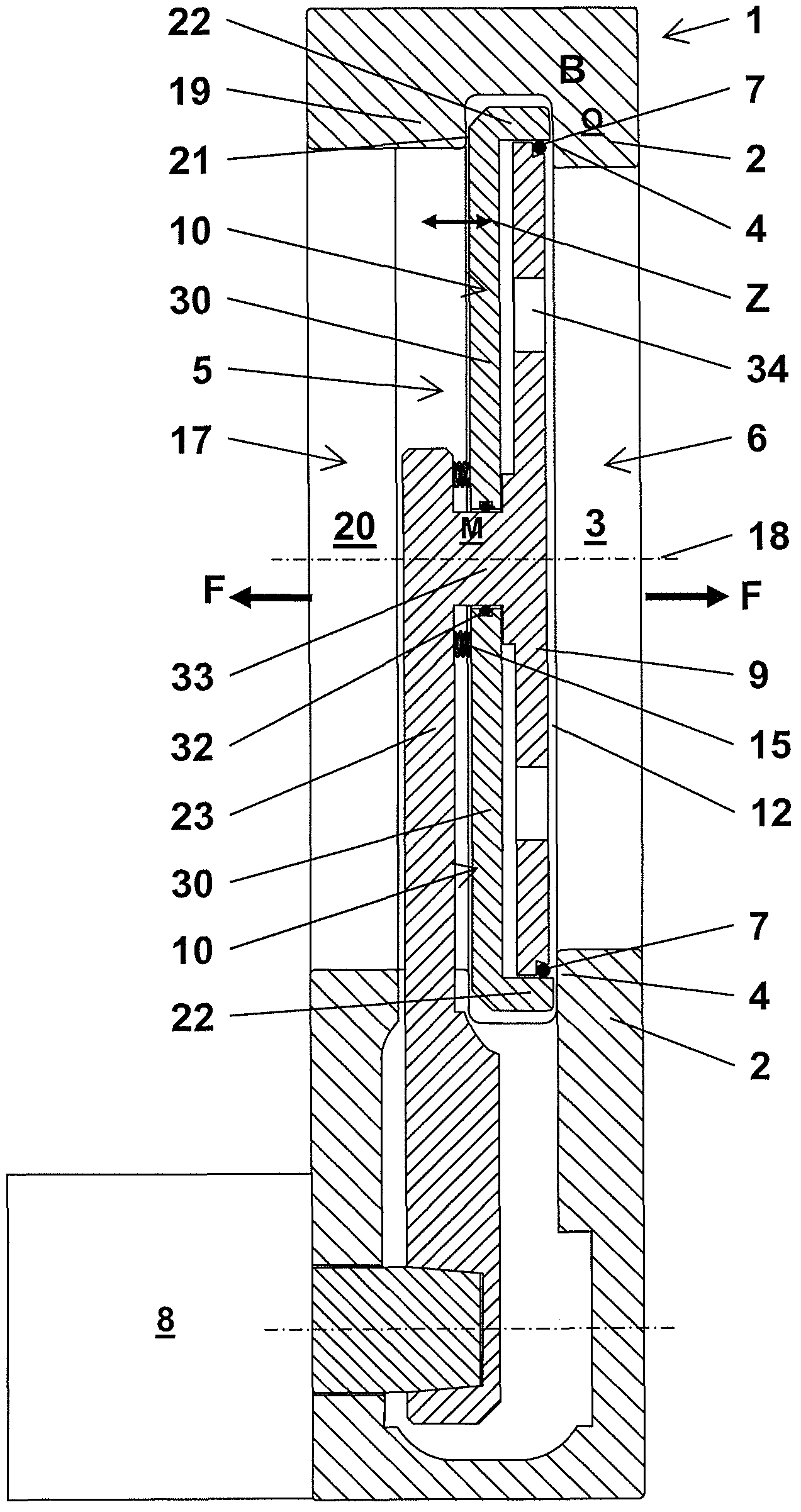

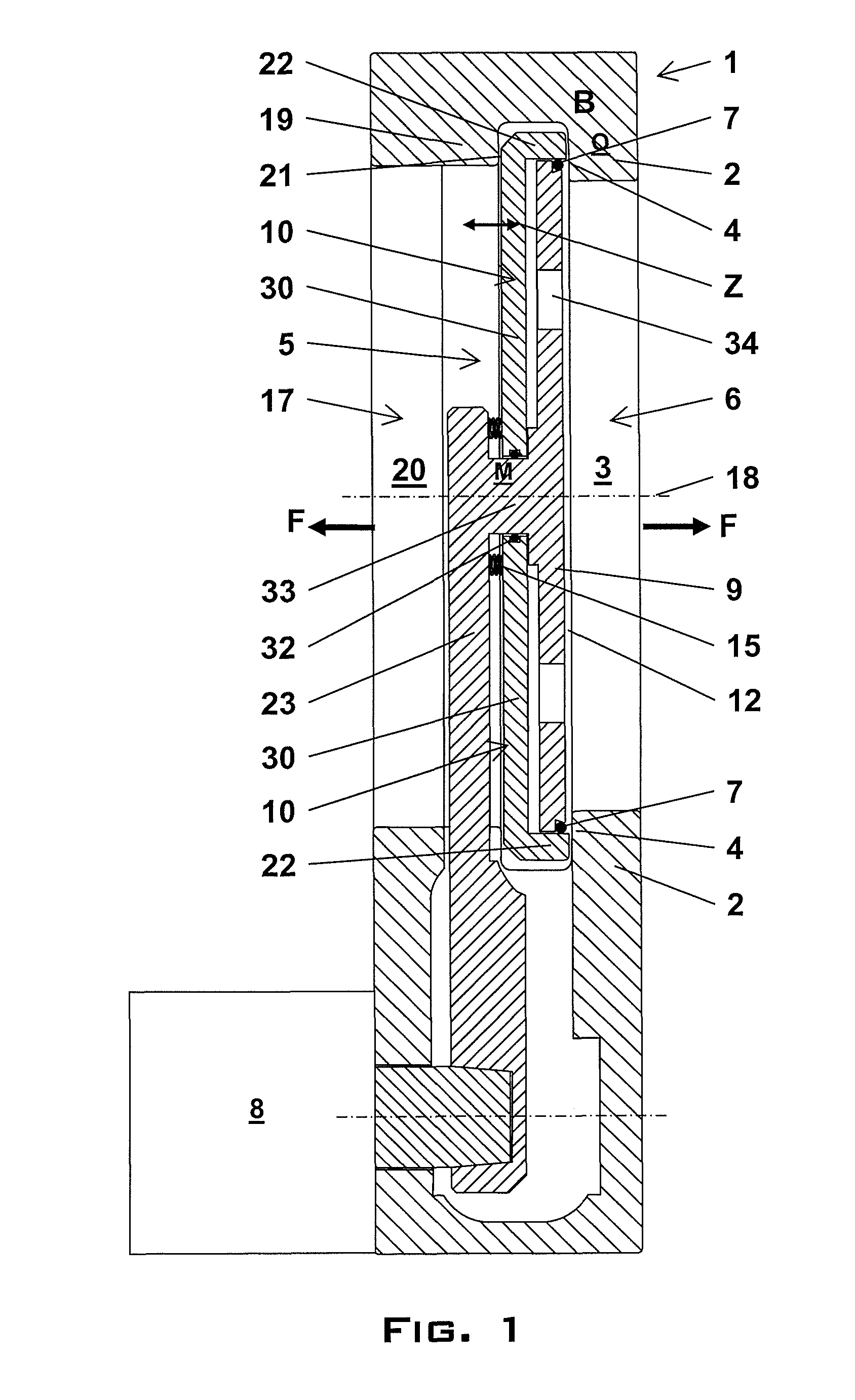

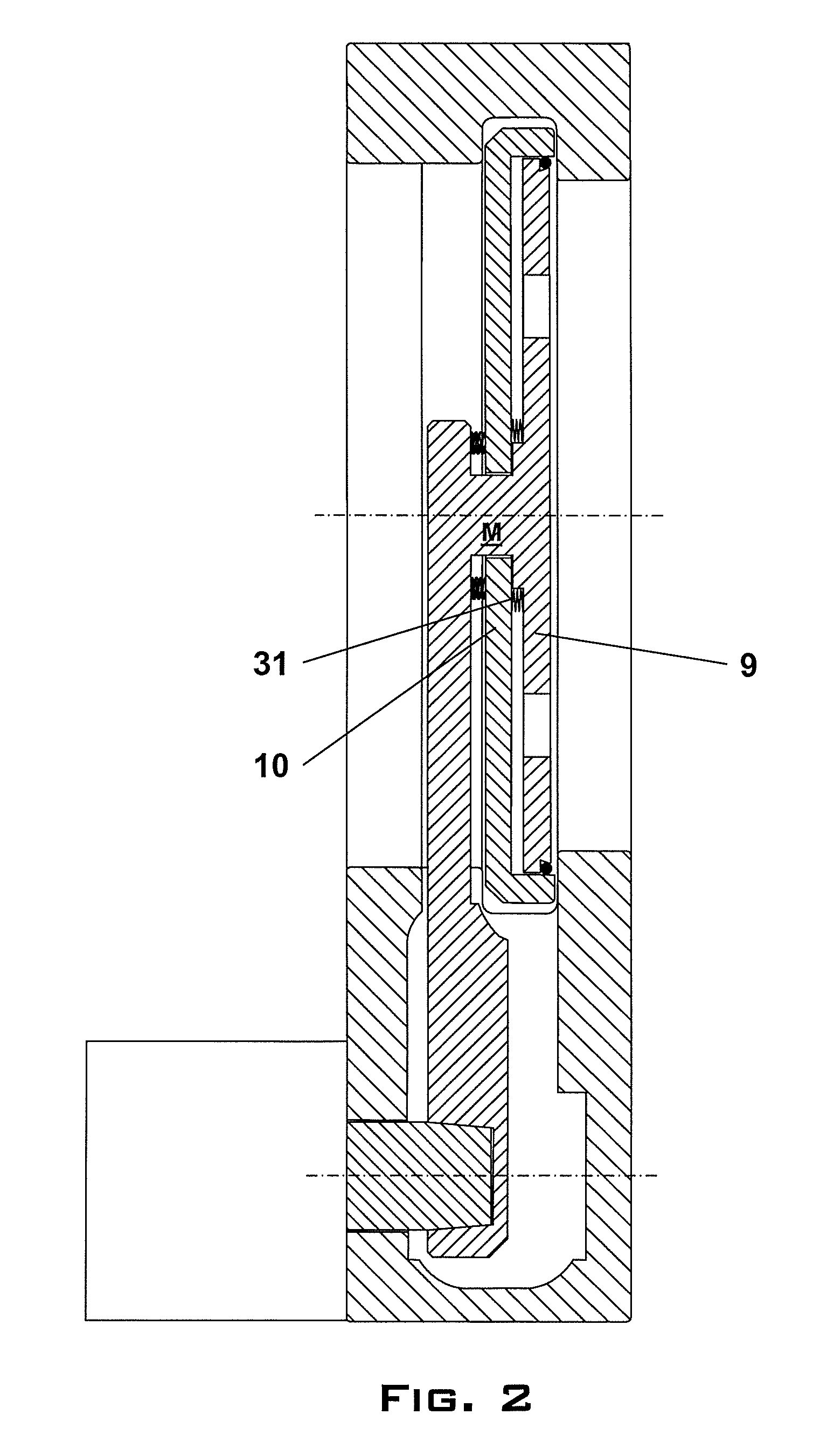

Valve for essentially gastight closing a flow path

ActiveUS20070138424A1Simple and compact designEasy maintenanceSlide valveLift valveCircular discPressure difference

The invention relates to a valve, in particular a shuttle or sliding valve, for essentially gastight closing of a flow path (F). The valve includes a valve housing (1;1a) having a first wall (2) which has a first opening (3) and a first valve seat (4), a valve disk (5) having a closing side (6) with a sealing ring (7) and at least one drive (8). Through the drive (8), the valve disk (5) is pivotable or displaceable from an opened position (A) essentially parallel to the first valve seat (4), and the perpendicular distance between the valve disk (5), and the first valve seat (4) can be reduced so that, in the closed position (C), the flow path (F) is closed essentially gastight by an axially sealing contact between the sealing ring (7) and the first valve seat (4). The valve disk (5) includes an outer disk section (9), which is connected to the drive (8) and fixes the sealing ring (7) in the perpendicular direction to the first valve seat (4), and an inner disk section (10) which has an outer circumferential area (11) and which is mounted so as to be movable relative to the outer disk section (9) in a direction (Z) essentially perpendicular to the first valve seat (4). The outer circumferential area (11) is enclosed essentially gastight with an inner seal by the sealing ring (7). Thus, in the closed position (C), a pressure difference at the valve disk (5) acts essentially on the inner disk section (10) so that the inner disk section (10), decoupled from the outer disk section (9), is supported perpendicularly on a section of the valve housing (1), in particular the first valve seat (4) or a lateral groove (27).

Owner:VAT HLDG AG

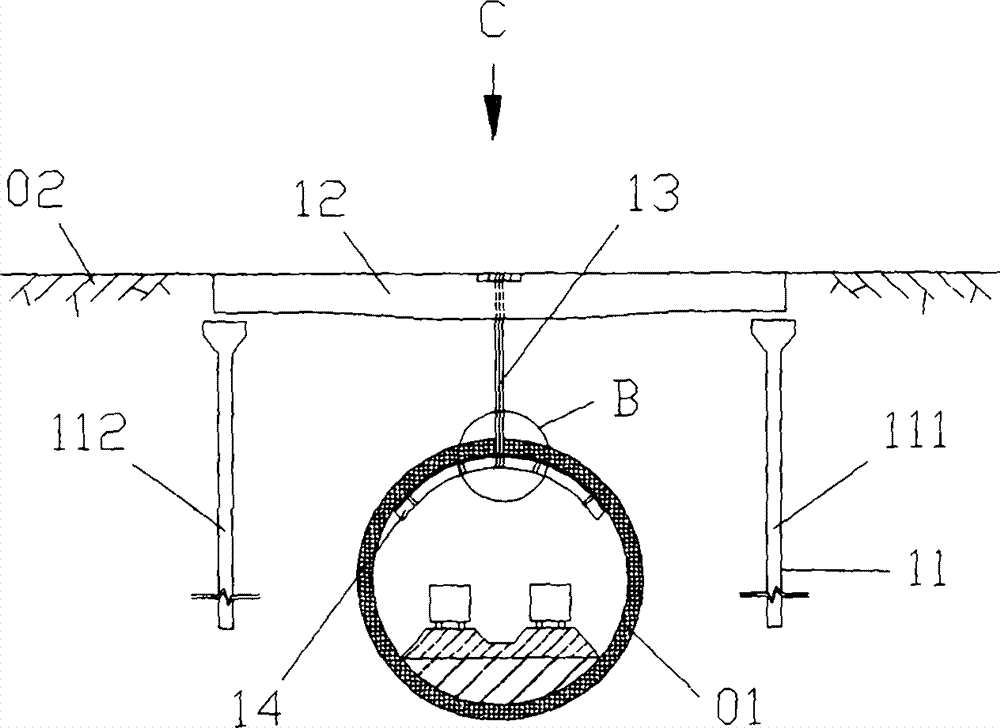

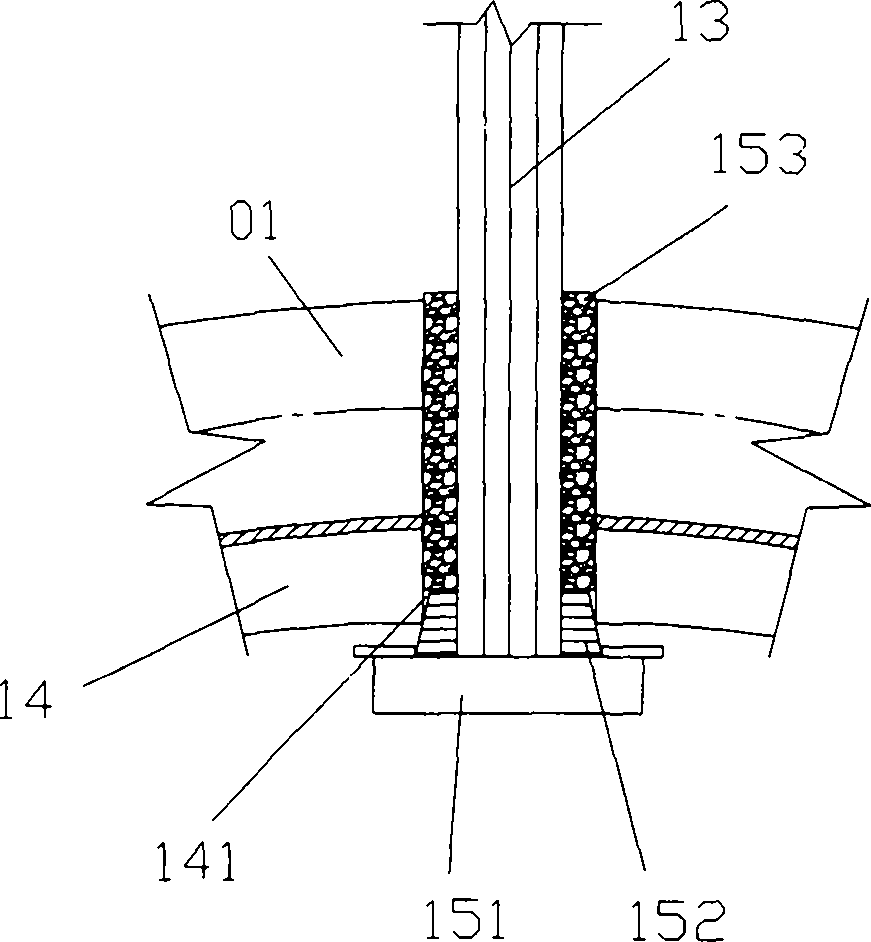

Tunnel settlement protecting device and construction method thereof

InactiveCN104120731ASolve the problem of long-term settlementGuaranteed stabilityFoundation engineeringTunnelsLine structurePerpendicular distance

The invention provides a tunnel settlement protecting device. The protecting device comprises protection single pieces. The protection single pieces comprise pile foundations, supporting beams, traction devices and supporting components. The supporting components are matched with the inner wall of a tunnel lining structure in shape. The pile foundations comprise first single pieces and second single pieces, wherein the first single pieces and the second single pieces are arranged on the two sides of the tunnel lining structure. The two ends of each supporting beam are arranged on the corresponding first single piece and the corresponding second single piece respectively. The minimum perpendicular distance between the first single pieces and the tunnel lining structure and the minimum perpendicular distance between the second single pieces and the tunnel lining structure are 1 m-10 m. The upper ends of the traction devices are fixed to the supporting beams, and the lower ends of the traction devices are throughout the tunnel lining structure and then are fixed to the supporting components. The overall structure is simplified, overall stability of the tunnel lining structure in the processes of holing and follow-up operation can be guaranteed, the problem that a tunnel settles for a long time on a soft soil layer is solved effectively, and maintaining cost is reduced. The invention further provides a construction method of the tunnel settlement protecting device, construction is convenient, and practicability is high.

Owner:黄俊文

Broadband antenna

ActiveCN103259076ABest VSWRSimultaneous aerial operationsRadiating elements structural formsCouplingBroadband

A broadband antenna comprises a grounding component electrically connected to one grounding end, a feed-in source used for receiving a wireless signal, a first radiating body, a second radiating part, a conductive component, a second radiating body and a third radiating part, wherein the first radiating body comprises a first radiating part extending in the first direction, the second radiating part is extended in the opposite direction of the first direction, the conductive component is extended in the second direction, the second radiating body comprises a short circuit component electrically connected with the grounding component, the third radiating part comprises a subsection which keeps a first distance with the conductive component, and the first distance makes the third radiating part and the conductive component generate a coupling connecting effect, wherein the average perpendicular distance from the second radiating body to the grounding component is smaller than that from the first radiating part to the grounding component.

Owner:WISTRON NEWEB

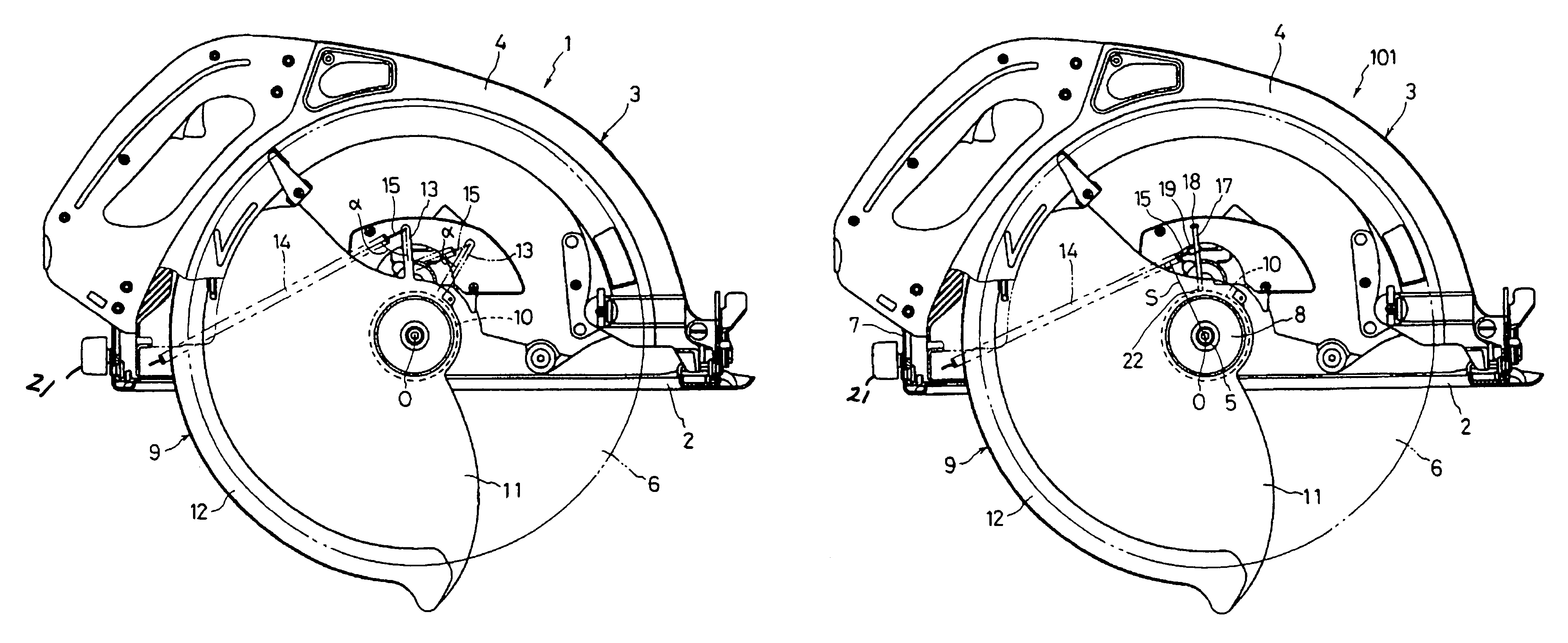

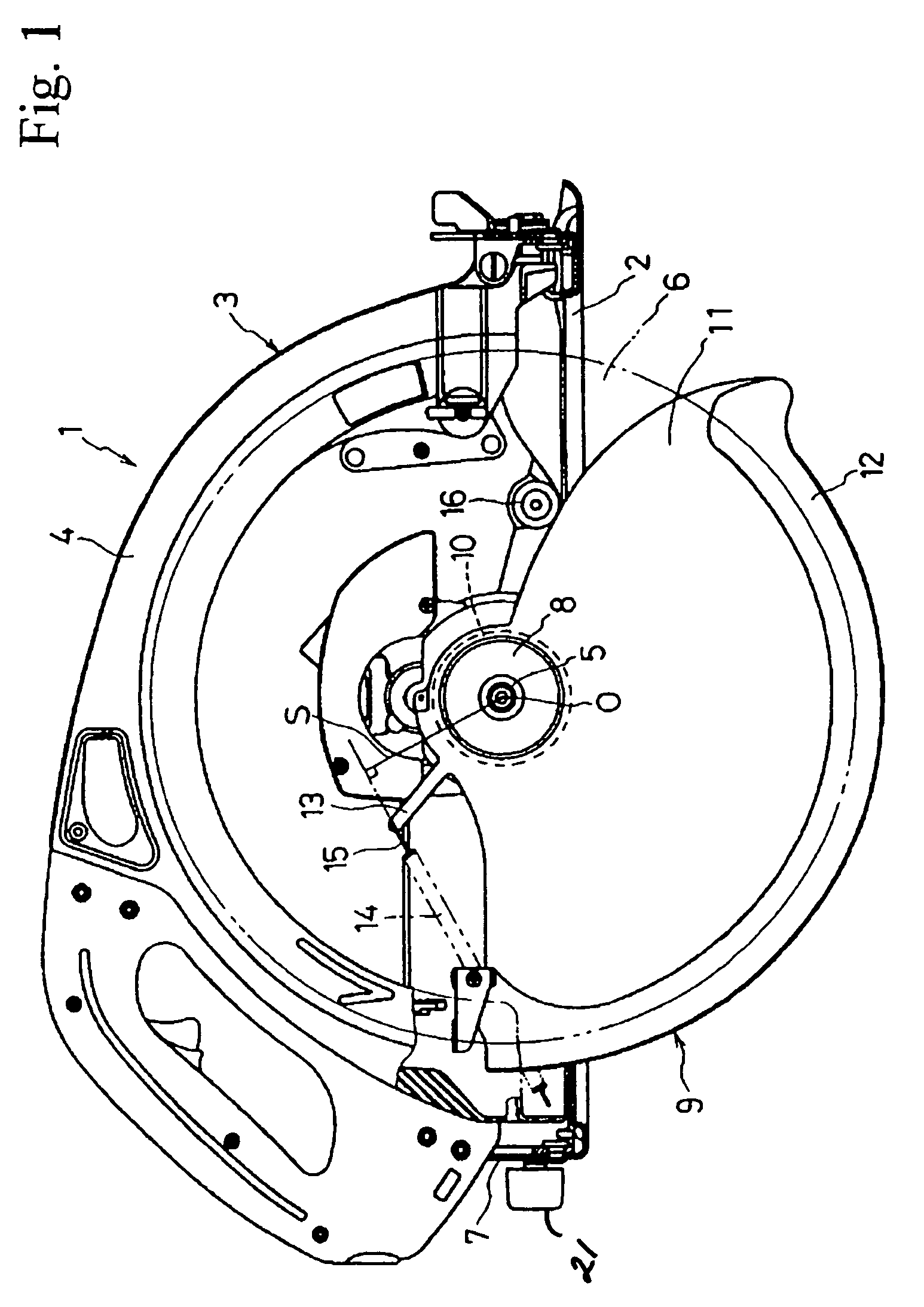

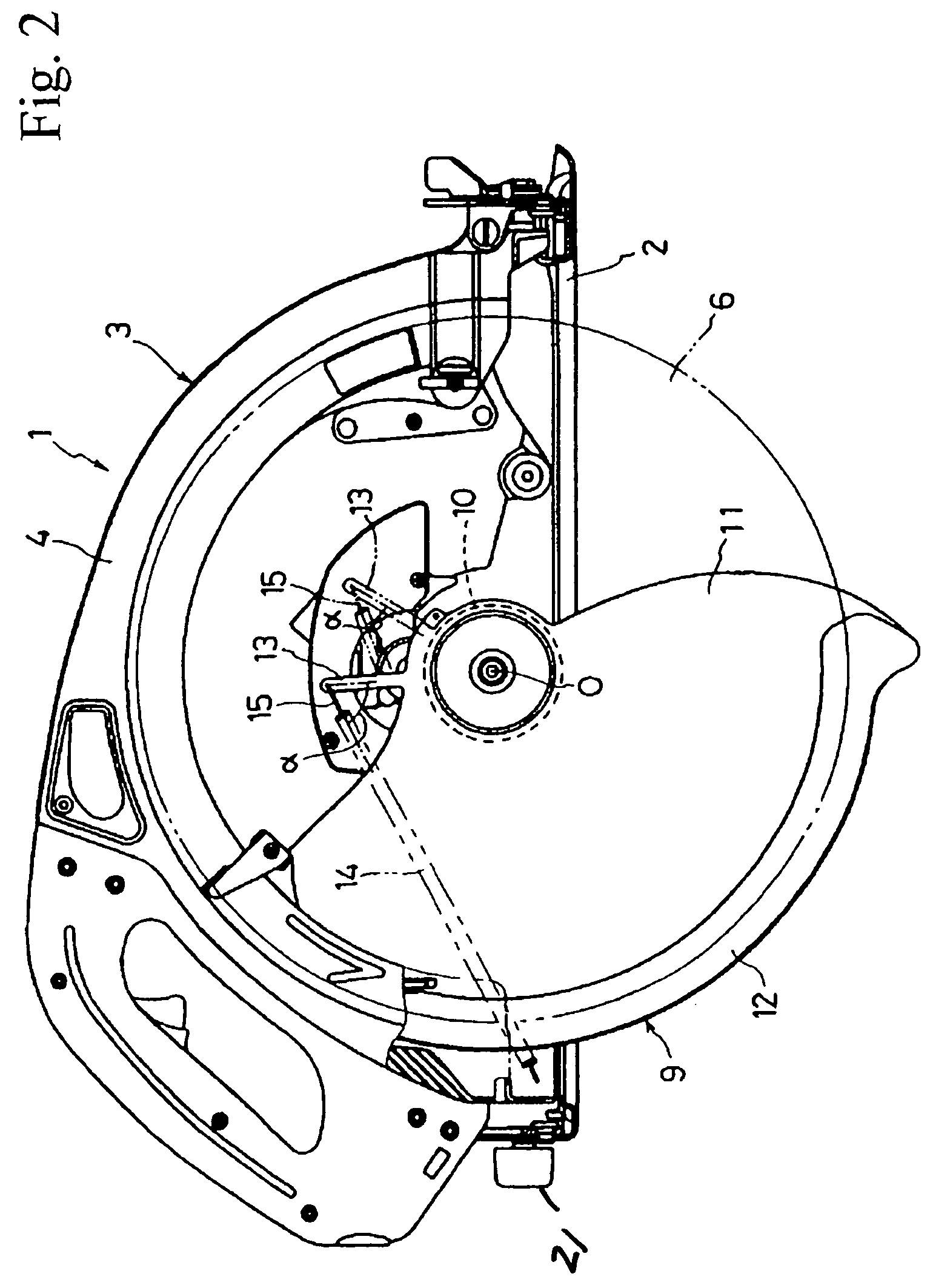

Circular saw with an improved lower blade guard

InactiveUS7089671B2Avoid accidental rotationWithout compromising handling comfortMetal sawing devicesMetal sawing accessoriesLine of actionCircular saw

A circular saw (1) includes a base plate (2) and a saw blade assembly (3) including a lower blade guard (9) for covering a saw blade (6). The blade guard includes a sleeve portion (10) rotatably fitted on a bearing box (8) coupled to the saw blade assembly and a sectoral portion (11) extending radially from the sleeve portion in the rear of the blade. A connecting bar (13) projects radially rearward from the sectoral portion. A spring (14) is stretched between the top of the connecting bar (13) and a lower rear portion of an upper blade guard (4) close to the base plate. When not in use, torque, generated as the product of the spring's tensile force and the perpendicular distance (S) from the line of action or the force to the axis of rotation (O), rotates the blade guard to a closed position.

Owner:MAKITA CORP

Wideband antenna

ActiveUS8779989B2Simultaneous aerial operationsRadiating elements structural formsRadio frequency signalBroadband

A wideband antenna includes a grounding unit electrically connected to a ground, a feed-in source for transmitting and receiving radio frequency signals, a first radiating body including a first radiating unit extending along a first direction, a second radiating unit extending along a second direction opposite to the first direction, and a conducting unit extending along a third direction, and a second radiating body including a short-circuit unit electrically connected to the grounding unit, a third radiating unit including a branch to generate a coupling connection effect with the conducting unit via a first distance, wherein an average perpendicular distance between the second radiating body and the grounding unit is smaller than an average perpendicular distance between the first radiating body and the grounding unit.

Owner:WISTRON NEWEB

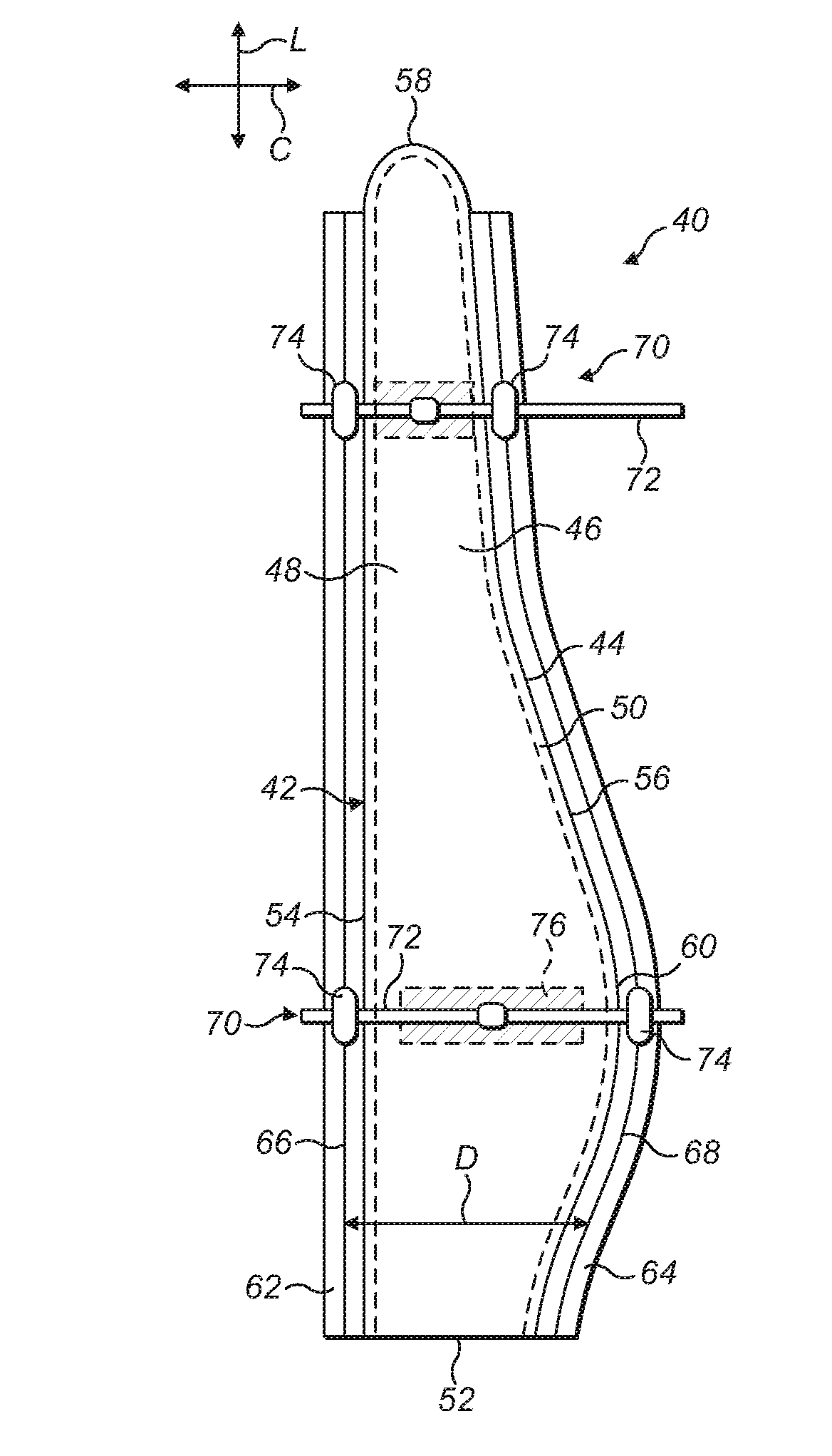

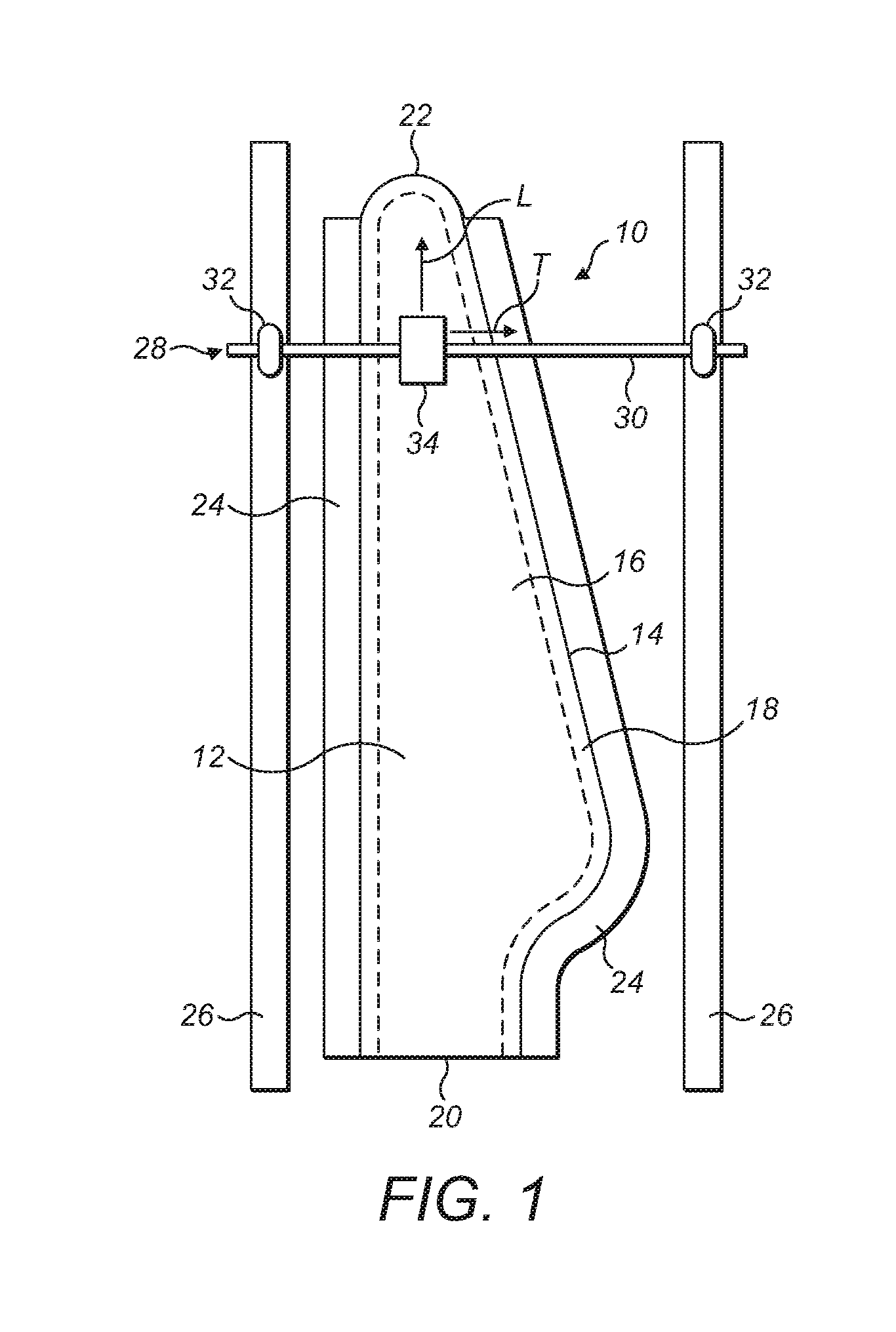

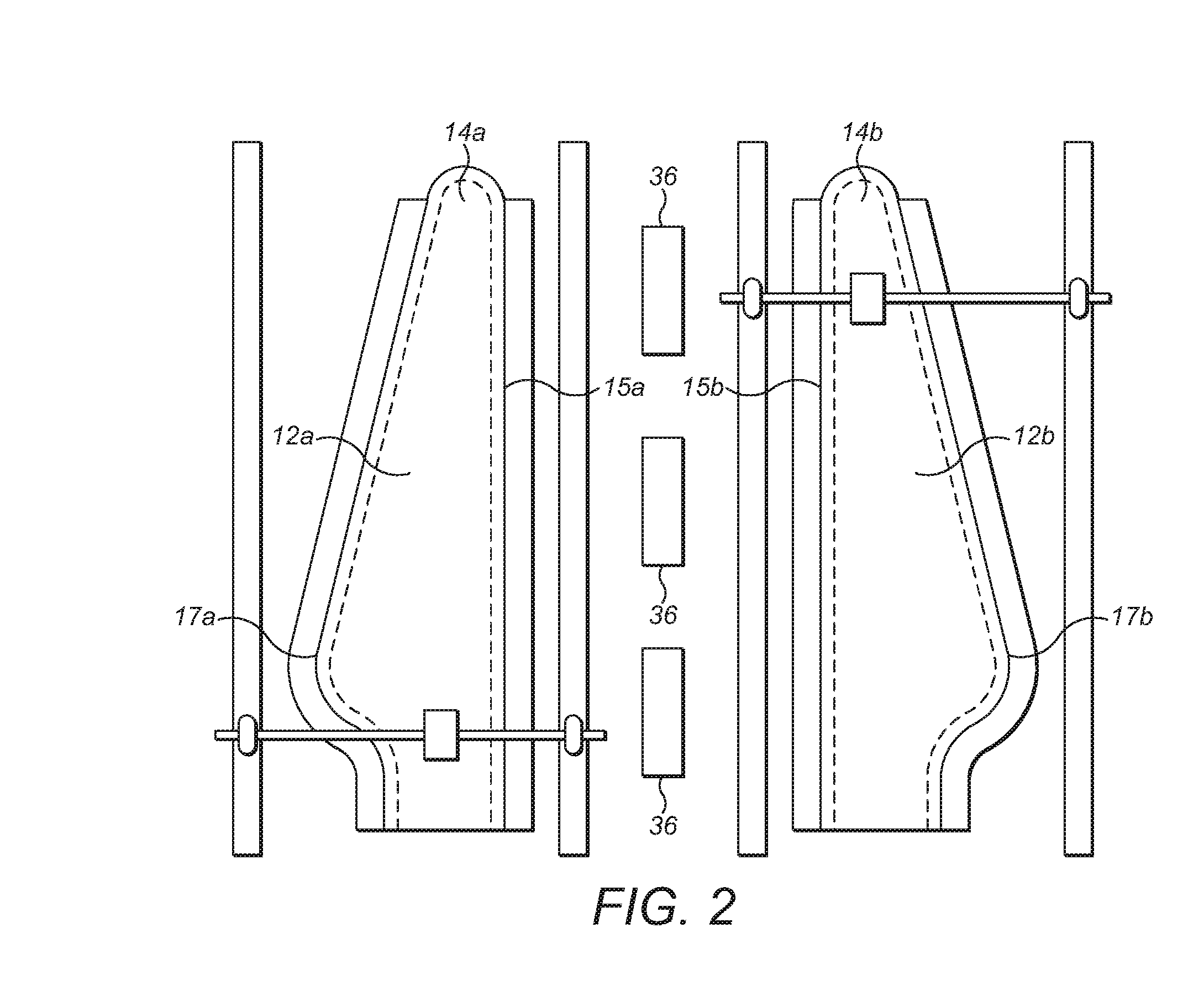

Improvements relating to the manufacture of wind turbines

ActiveUS20160354984A1Less floor spaceReduce required factory spaceEngine manufactureFinal product manufactureEngineeringTurbine

A production system for a wind turbine component is described. The system includes an elongate mould assembly extending in a longitudinal direction, the mould assembly comprising a mould surface and having a width that varies in the longitudinal direction. First and second tracks are defined respectively on opposite longitudinal sides of the mould surface. The perpendicular distance between the respective tracks varies along the length of the track. A transport assembly is moveable relative the mould assembly in the longitudinal direction. The transport assembly includes a pair of side supports arranged to move along the respective tracks, and a gantry supported above the mould assembly by the side supports. The gantry extends transverse to the longitudinal direction. The transport assembly is configured such that the side supports move relative to one another in a direction transverse to the longitudinal direction in accordance with the varying distance between the tracks as the transport assembly moves in the longitudinal direction.

Owner:VESTAS WIND SYST AS

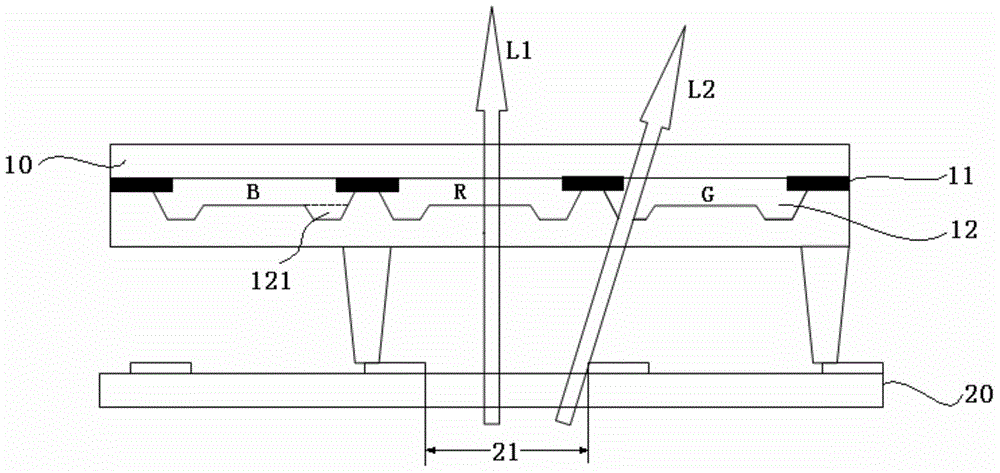

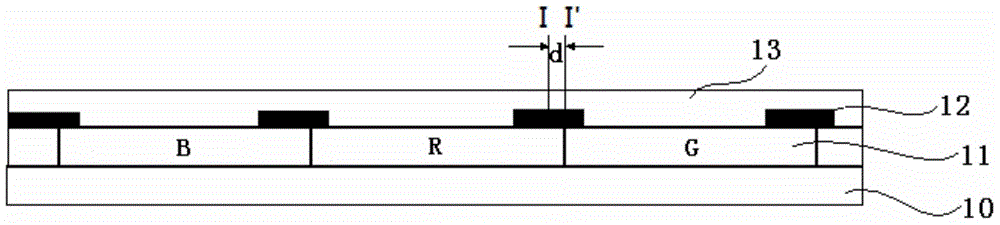

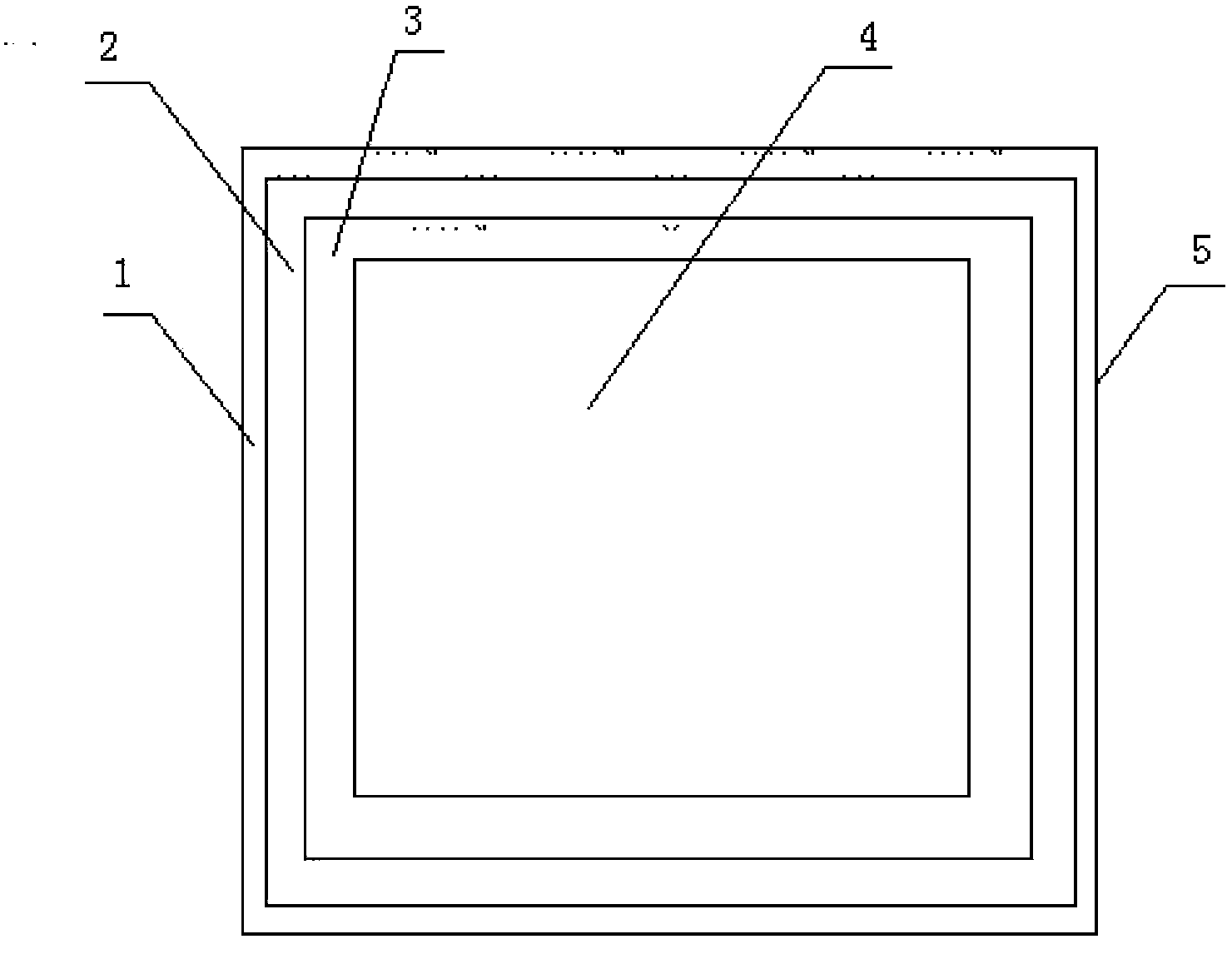

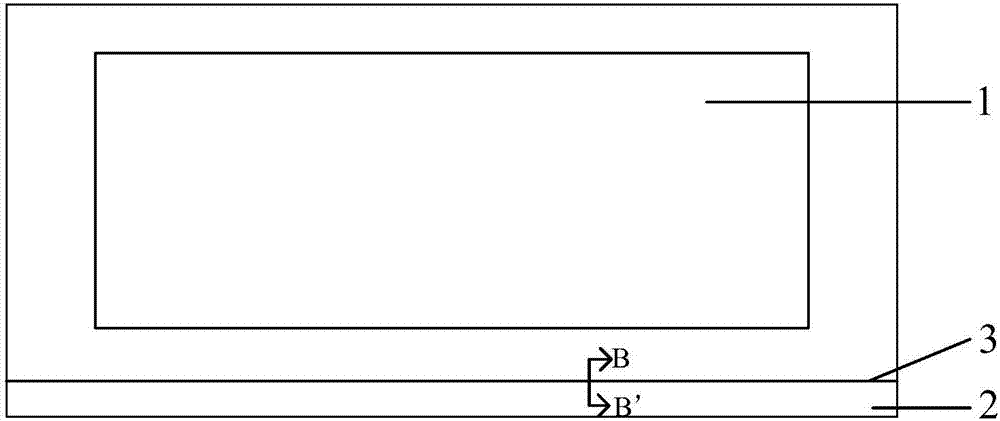

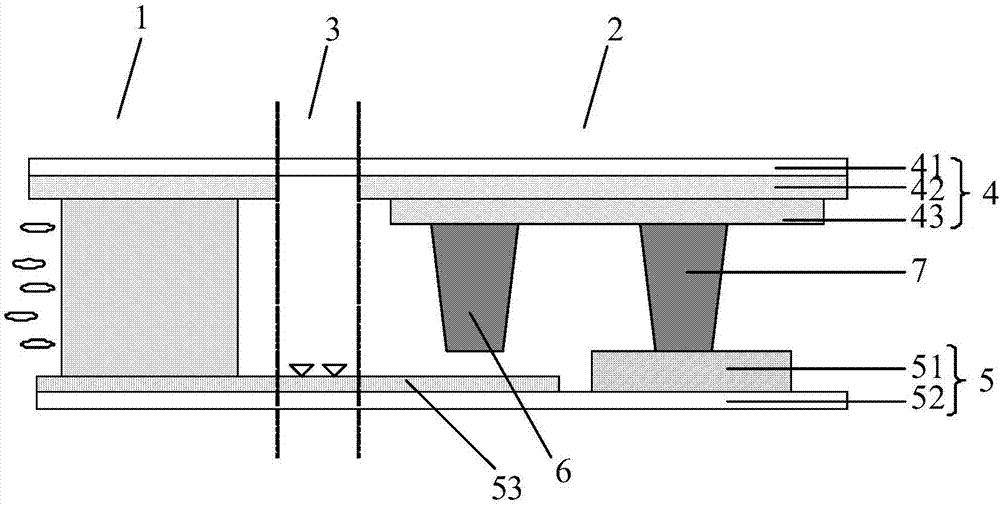

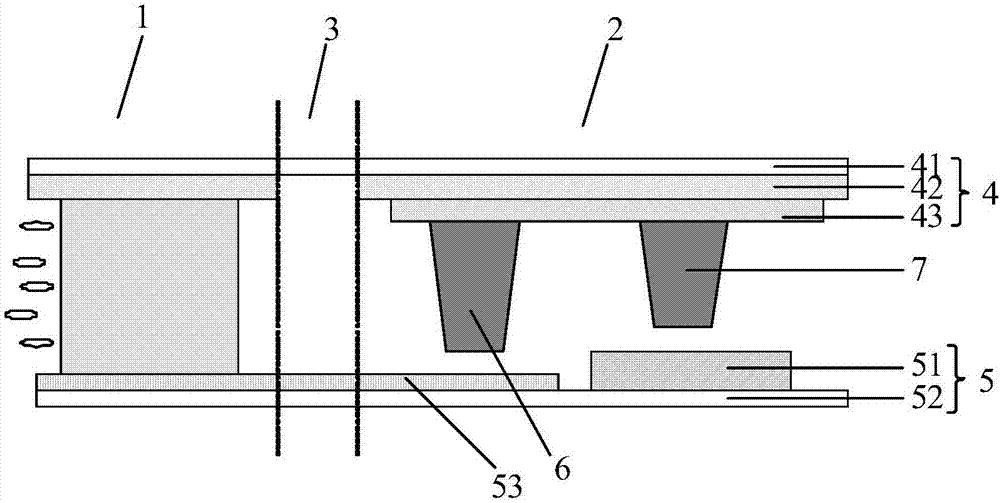

Colored film substrate, manufacturing method thereof and display device

InactiveCN103941462AShorten the vertical distanceQuality improvementNon-linear opticsDisplay deviceOptoelectronics

The invention discloses a colored film substrate. The colored film substrate comprises a substrate body, a color resistor layer and black matrixes, wherein the color resistor layer is directly arranged on the substrate body and comprises color resistors of different colors, and the black matrixes are directly arranged on the color resistor layer and arranged between every two adjacent color resistors. Due to the fact that the color resistor layer is directly formed on the substrate body and then the black matrixes are arranged on the color resistor layer, the perpendicular distance between the black matrixes and an array substrate is shortened, when light reaches the colored film substrate, unexpected emergent light is shielded through the black matrixes, the color cast phenomenon is reduced, the quality of displayed pictures is improved, and the yield of products is increased.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

Pendulum and slide gate vacuum valve

ActiveUS20070138426A1Simple and compact designEasy maintenanceSlide valveLift valveEngineeringPressure difference

The invention relates to a valve, in particular a pendulum or slide gate valve, for essentially gastight closing of a flow path (F). The valve includes a valve housing (1) having a first wall (2) which has a first opening (3) and a first valve seat (4), a valve plate (5) having a closing side (6) with a first sealing ring (7) and at least one drive (8). By action of the drive (8), the valve plate (5) is pivotable or displaceable from an opened position (A) essentially parallel to the first valve seat (4), and the perpendicular distance between the valve plate (5), and the first valve seat (4) can be reduced so that, in the closed position (C), the flow path (F) is closed essentially gastight by an axially sealing contact between the first sealing ring (7) and the first valve seat (4). The valve plate (5) includes support part (9), which is connected to the drive (8) and fixes the first sealing ring (7) in the perpendicular direction to the first valve seat (4), and a sealing part (10) which has an inner circumferential area (11) and which is mounted so as to be movable relative to the support part (9) in a direction (Z) essentially perpendicular to the first valve seat (4). The inner circumferential area (11) encloses the first sealing ring (7) in an essentially gastight way with an inner seal. Thus, in the closed position (C), a pressure difference at the valve plate (5) acts essentially on the sealing part (10) so that sealing part (10), decoupled from the support part (9), is supported perpendicularly on a section of the valve housing (1), in particular the first valve seat (4) or a lateral groove (27).

Owner:VAT HLDG AG

Pendulum and slide gate vacuum valve

ActiveUS7802772B2Simple and compact designEasy maintenanceSlide valveLift valvePressure differencePerpendicular direction

Owner:VAT HLDG AG

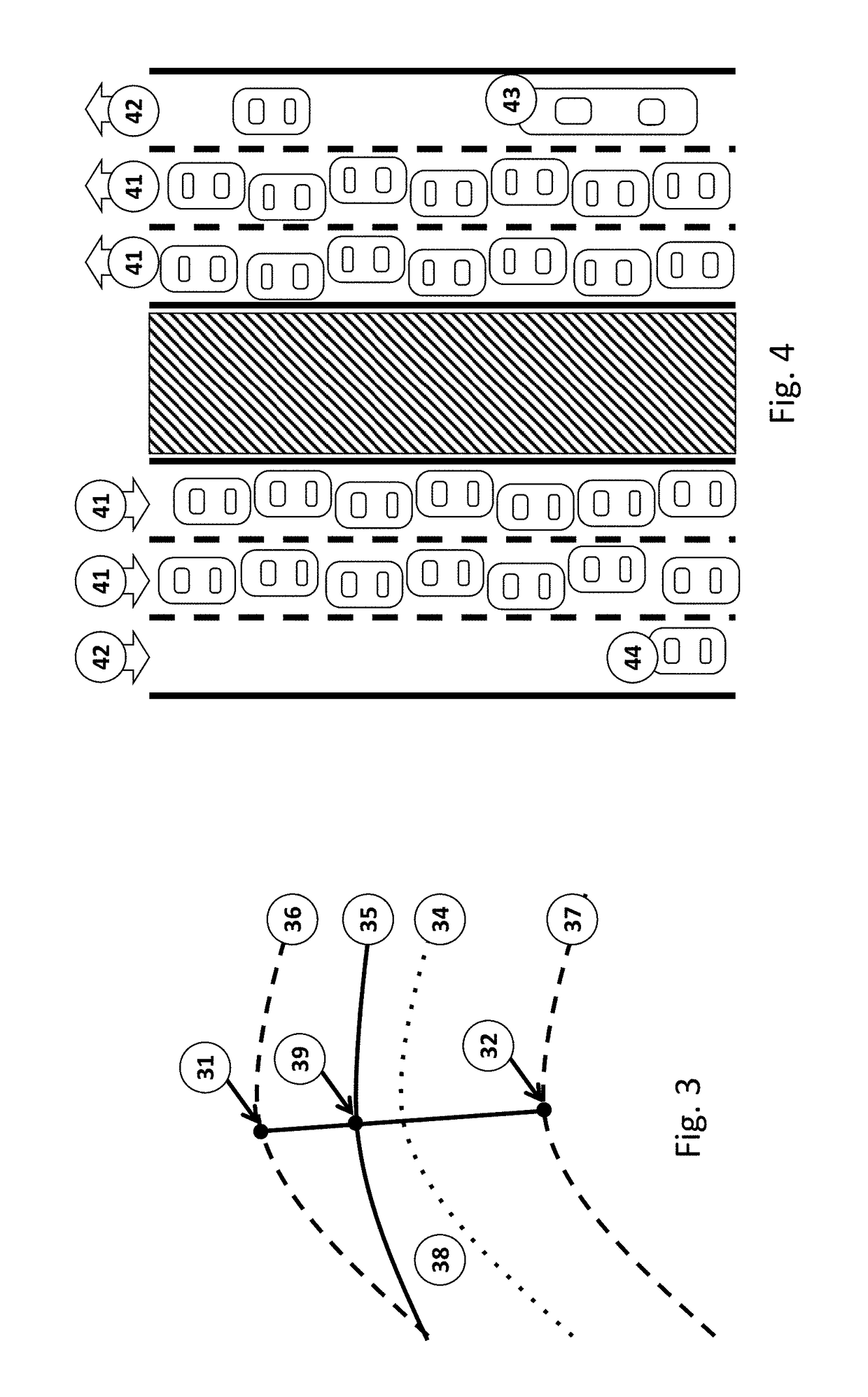

Method of autonomous lane identification for a multilane vehicle roadway

ActiveUS20180122154A1Improve charging effectEasy to identifyInstruments for road network navigationTicket-issuing apparatusEngineeringSignal source

A method is provided for identifying whether a vehicle has entered, departed, or stayed in a target lane as opposed to an adjacent non-target lane of a segmented roadway. Signals are received from at least one signal source at a receiver within, attached to or integrated into the vehicle marking the geographic position of the vehicle at a sampling rate in a detailed travel path. At each sampled point in the travel path, the method compares the standard perpendicular distance between:the vehicle and the target lane centerline (d1); andthe vehicle and the non-target lane centerline (d2);It is assessed that the vehicle is in the target lane if the distance d1 is less than the distance d2, and otherwise, it is assessed that the vehicle is in the non-target lane. From a time (t1) at which the vehicle is assessed to be departing from the target lane, each such sampled point is deemed to be an excursion point and the excursion point departure distances are summed until the vehicle is assessed to return to the target lane, or the detailed travel path ends, at a time (t2); andif:the sum of the excursion point departure distances is less than a threshold distance, orthe time from t1 to t2 is less than a threshold time,the vehicle is treated as having remained in the target lane, and otherwise, the vehicle is treated as having changed to the non-target lane between time t1 and t2. A related system is also provided.

Owner:APPLIED TELEMETRICS HLDG INC

Rice field composite ecological system

InactiveCN103404400AIncrease economic outputReduce usageClimate change adaptationPisciculture and aquariaAquatic productHorticulture

The invention discloses a rice field composite ecological system which comprises a soybean planting area, a first rice planting area, a special type aquatic product aquiculture area and a second rice planting area. The soybean planting area, the first rice planting area, the special type aquatic product aquiculture area and the second rice planting area are sequentially arranged from one side of a rice filed to the other side, opposite to the side, of the rice filed. The soybean planting area is located on the ridge of the rice field, the first rice planting area is located at the periphery of the rice field and within the ridge of the rice field, the groove margin close planting mode is adopted in the first rice planting area, the special type aquatic product aquiculture area is located between the first rice planting area and the second rice planting area, the special type aquatic product aquiculture area is in a ring type, the perpendicular distance between the special type aquatic product aquiculture area and the ridge of the rice field is 60cm, and the large-ridge double-line planting mode is adopted in the second rice planting area.

Owner:句容市苏苑稻米专业合作社

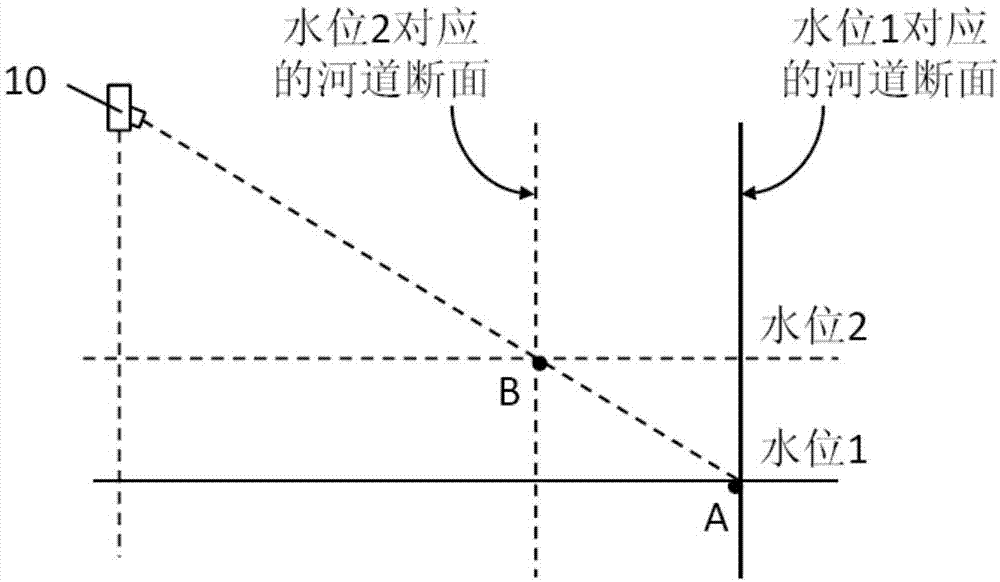

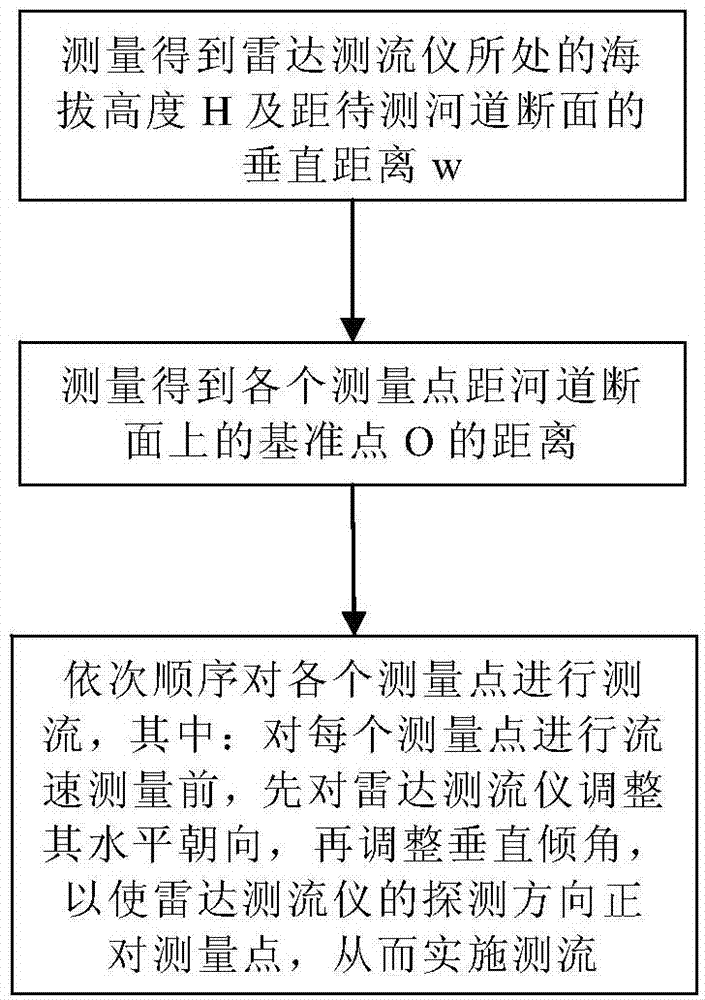

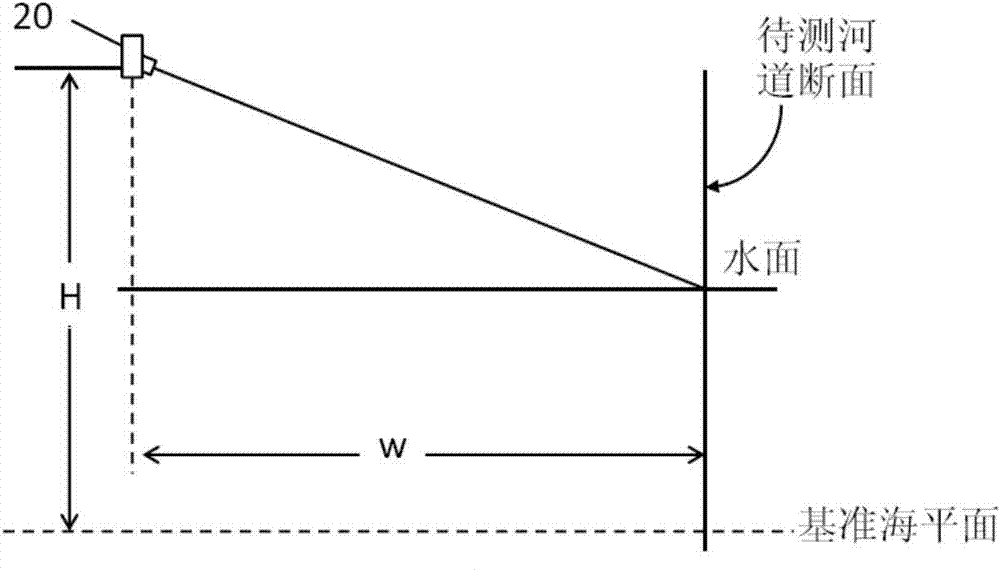

River cross section multipoint flow-measuring method based on fixed points

ActiveCN103792533ATruly reflect the flow rateEliminate biasOpen water surveyWater resource assessmentRadarMeasurement point

The invention discloses a river cross section multipoint flow-measuring method based on fixed points. The method is implemented based on a radar flow-measuring meter which is fixedly installed above a river. The method comprises the steps that the altitude H of the place where the radar flow-measuring meter is located and the perpendicular distance w between the radar flow-measuring meter and the river cross section to be measured are obtained through measurement; the distance between each measuring point and the datum point O on the river cross section is obtained through measurement; flow measurement is conducted on all the measuring points in sequence, wherein before the flow velocity of each measuring point is measured, the horizontal orientation of the radar flow-measuring meter is adjusted first, and then the perpendicular dip angle of the radar flow-measuring meter is adjusted, so that the detection direction of the radar flow-measuring meter is right opposite to the measuring point, and flow measurement is conducted. The river cross section multipoint flow-measuring method is only based on one radar flow-measuring meter, and multipoint flow-measuring operation can be realized at multiple measuring points on the same river cross section just through adjustment of the horizontal orientation and the perpendicular dip angle of the radar flow-measuring meter.

Owner:北京艾力泰尔信息技术股份有限公司

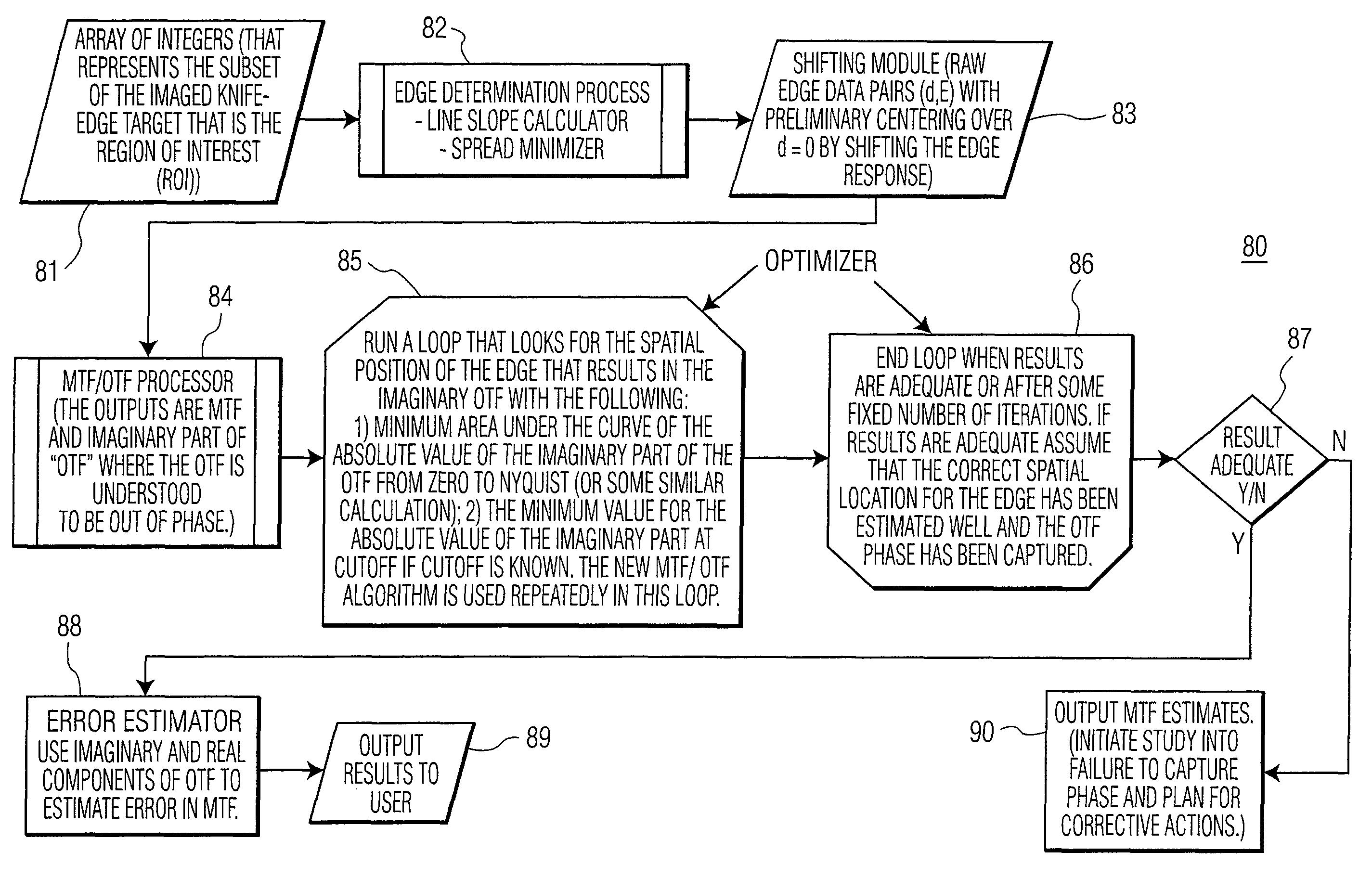

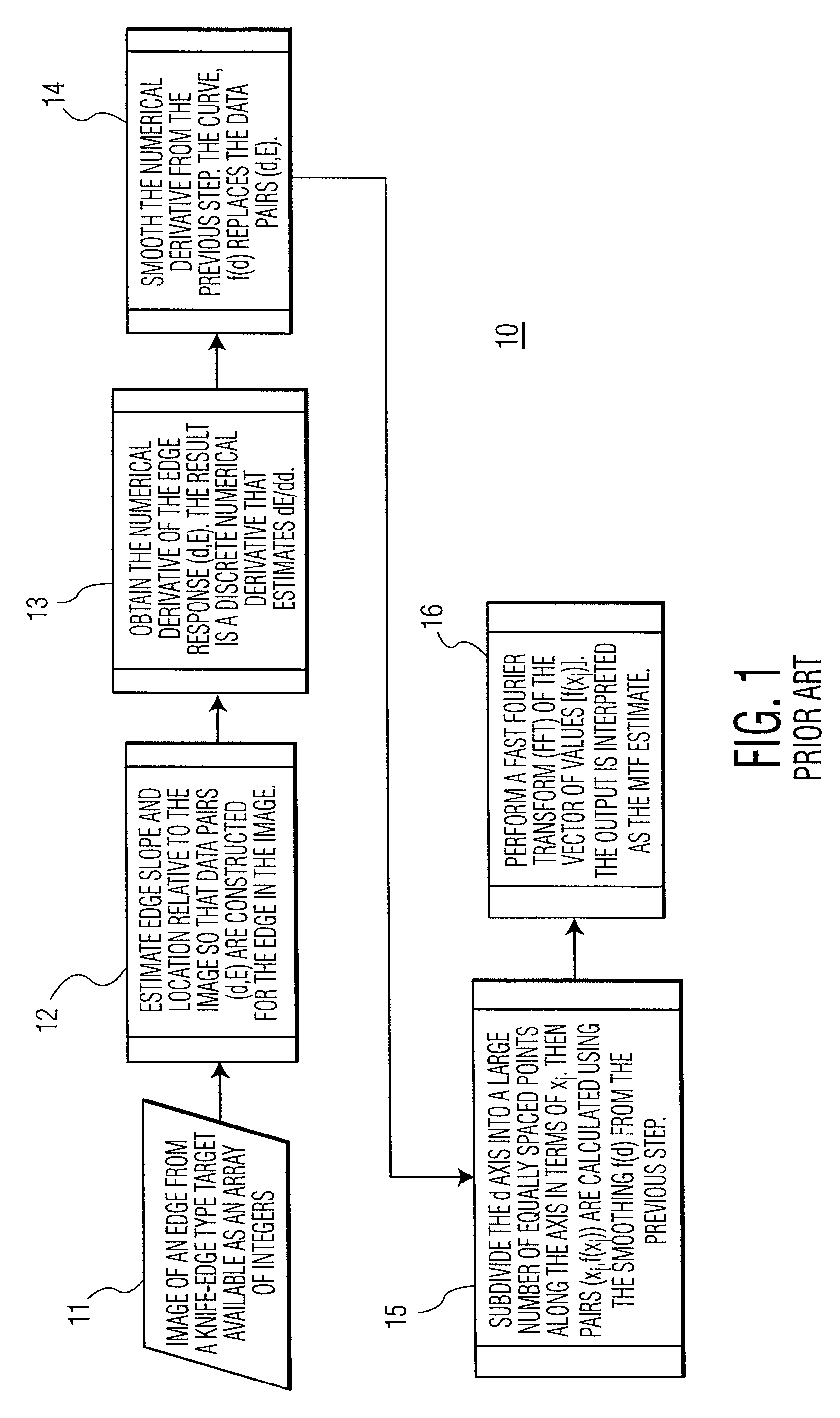

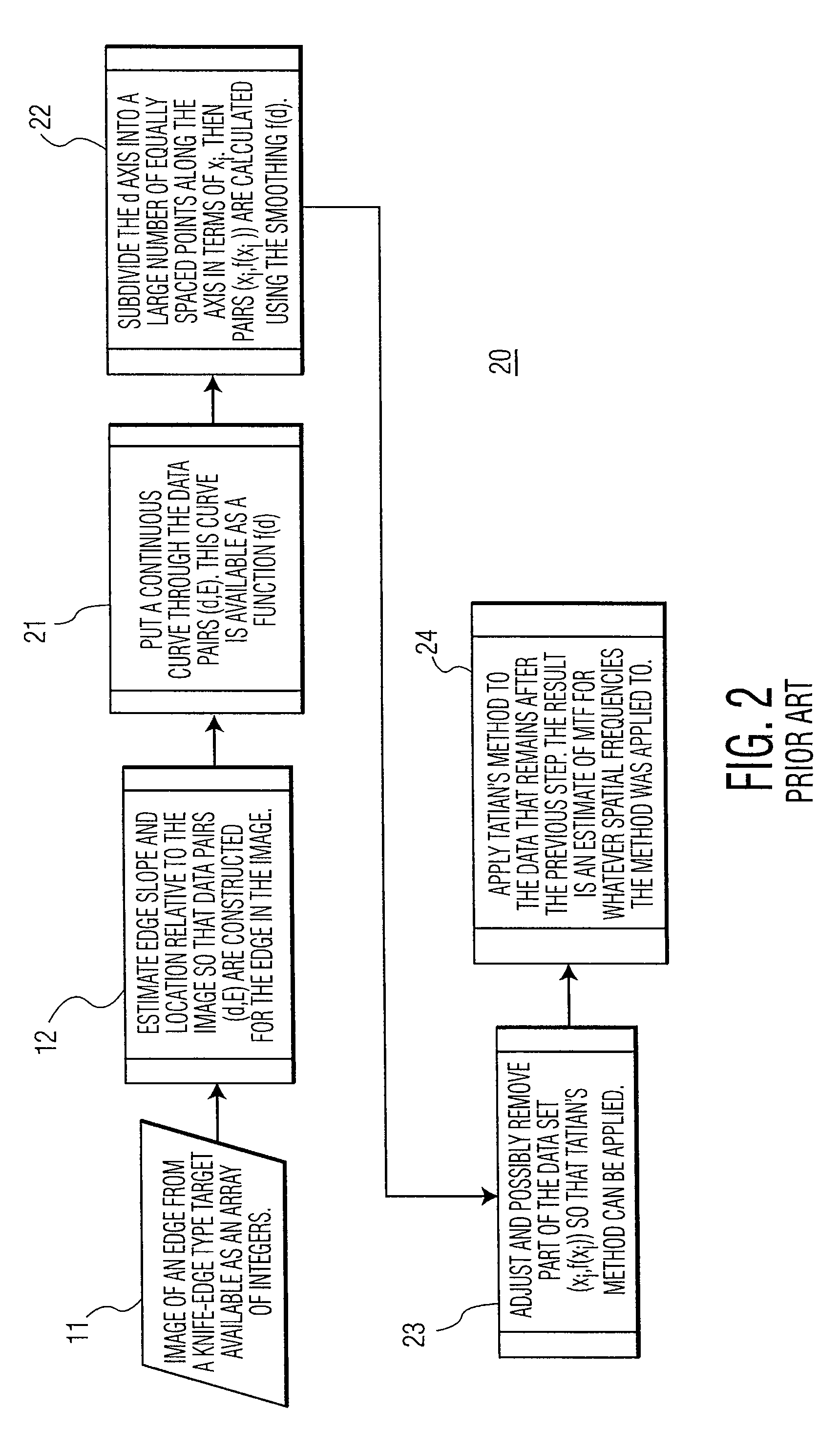

Obtaining an optical transfer function (OTF) from an edge in a sampled image data set

ActiveUS7783440B1Minimize spreadingMinimize the imaginary portion of the OTFSpectral/fourier analysisTelevision systemsData setAlgorithm

A method for obtaining a modulation transfer function (MTF) of a knife-edge target imaged by an electro-optical device is described. The method includes the steps of: (a) obtaining edge response data points, where a data point includes a perpendicular distance, d, to the knife-edge target; and (b) constructing a sequence of line slopes of the edge response data points, where a line slope includes a spread of edge response data points. The method then selects a line slope that minimizes the spread of edge response data points, and calculates the MTF, based on the edge response data points included in the selected line slope. The MTF is provided to a user. An edge response data point is defined by a pair of values of (d, E) of a pixel, where distance, d, is the shortest distance between the pixel and a line slope and the pixel has an intensity value, E.

Owner:HARRIS CORP

Display panel mother board and manufacturing method of display panel

InactiveCN106873251AReduce generationReduce foulingGlass severing apparatusMetal working apparatusEngineeringPerpendicular distance

The invention provides a display panel mother board, and belongs to the technical field of display. The problem that during cutting of an existing display panel mother board, due to the fact that supporting force is not uniform, cutting cracks are worsened is solved. The display panel master board comprises a first substrate and a second substrate which are oppositely arranged. The first substrate and the second substrate each comprise a display area and a non-display area located on the outer side of the display area; in the non-display area of the first substrate, a first spacer and a second spacer are sequentially arranged in the direction away from the display area; the perpendicular distance d1 between the end face, close to the second substrate, of the first spacer and the surface, close to the first substrate, of the second substrate is equal to a perpendicular distance d2 between the end face, close to the second substrate, of the second spacer and the surface, close to the first substrate, of the second substrate, so that the pressure borne by the position, corresponding to the first spacer, of the first substrate and the pressure borne by the position, corresponding to the second spacer, of the first substrate are uniform when a display panel is formed by cutting the display panel mother board.

Owner:BOE TECH GRP CO LTD +1

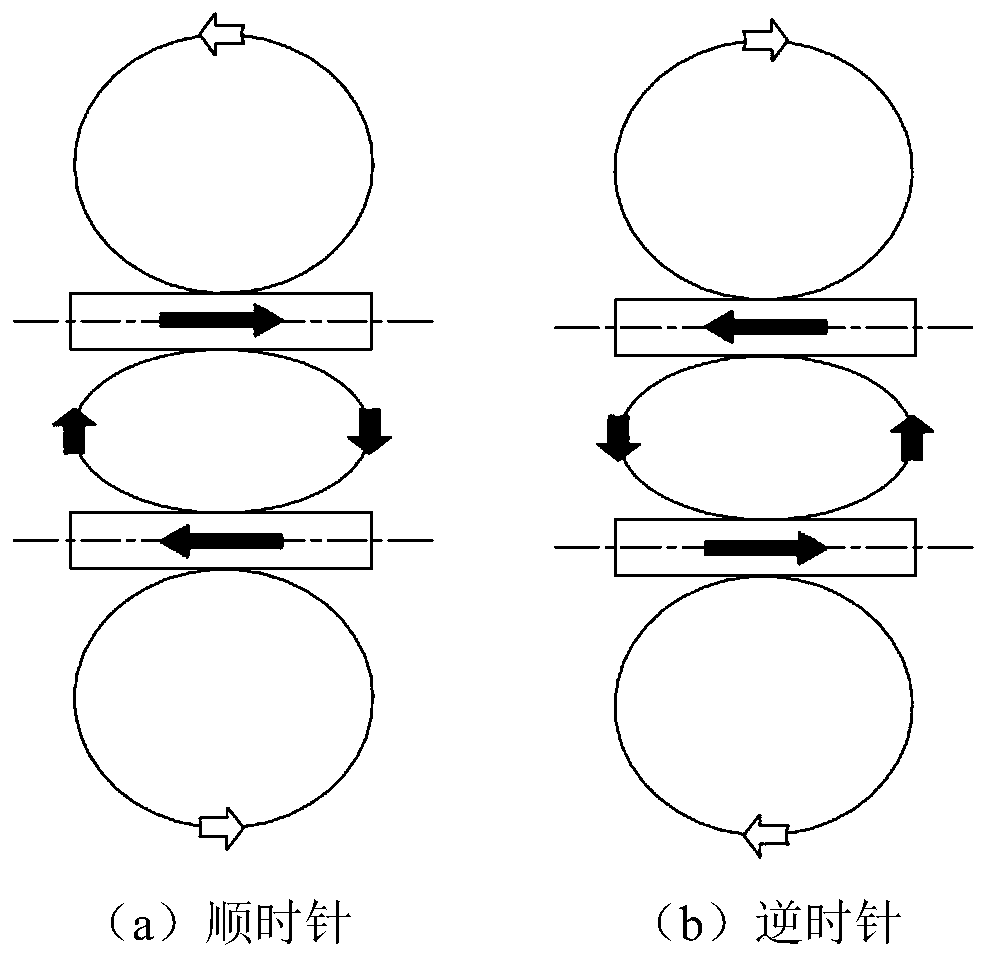

Method of improving center segregation quality of hypo-peritectic steel casting slabs

The invention discloses a method of improving center segregation quality of hypo-peritectic steel casting slabs, and belongs to the technical field of slab continuous casting. According to the method,two pairs of electromagnetic stirring rollers are arranged in a secondary cooling zone, and the two pairs of electromagnetic stirring rollers are installed at corresponding positions 3.5 to 8 m perpendicular distance from a crystallizer meniscus; the two pairs of electromagnetic stirring rollers are arranged in a three-ring manner; magnetic field directions generated by the electromagnetic stirring rollers are changed at intervals of 15 seconds; the current of the first pair of electromagnetic stirring rollers is 200 to 300 A, and the frequency is 2 to 4 Hz; the current of the second pair ofelectromagnetic stirring rollers is 300 to 400 A, and the frequency is 3 to 5 Hz; and meanwhile, the dynamic soft reduction technology is employed for processing nearby a solidification end point, thereduction interval of dynamic soft reduction is arranged at a position that the solid fraction of each casting slab is 10 % to 80 %, the reduction rate is 0.8 to 1.5 mm / m, and the total reduction amount is 4.0 to 5.5 mm. The method disclosed by the invention is capable of stably controlling center segregation of the hypo-peritectic steel casting slabs to be C 0.5 to C 1.5; hot charge rolling is realized on all the hypo-peritectic steel casting slabs; and tensile layering and rupturing of hot-rolled coils (plates) is eliminated.

Owner:MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com