Patents

Literature

168results about How to "Shorten the vertical distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

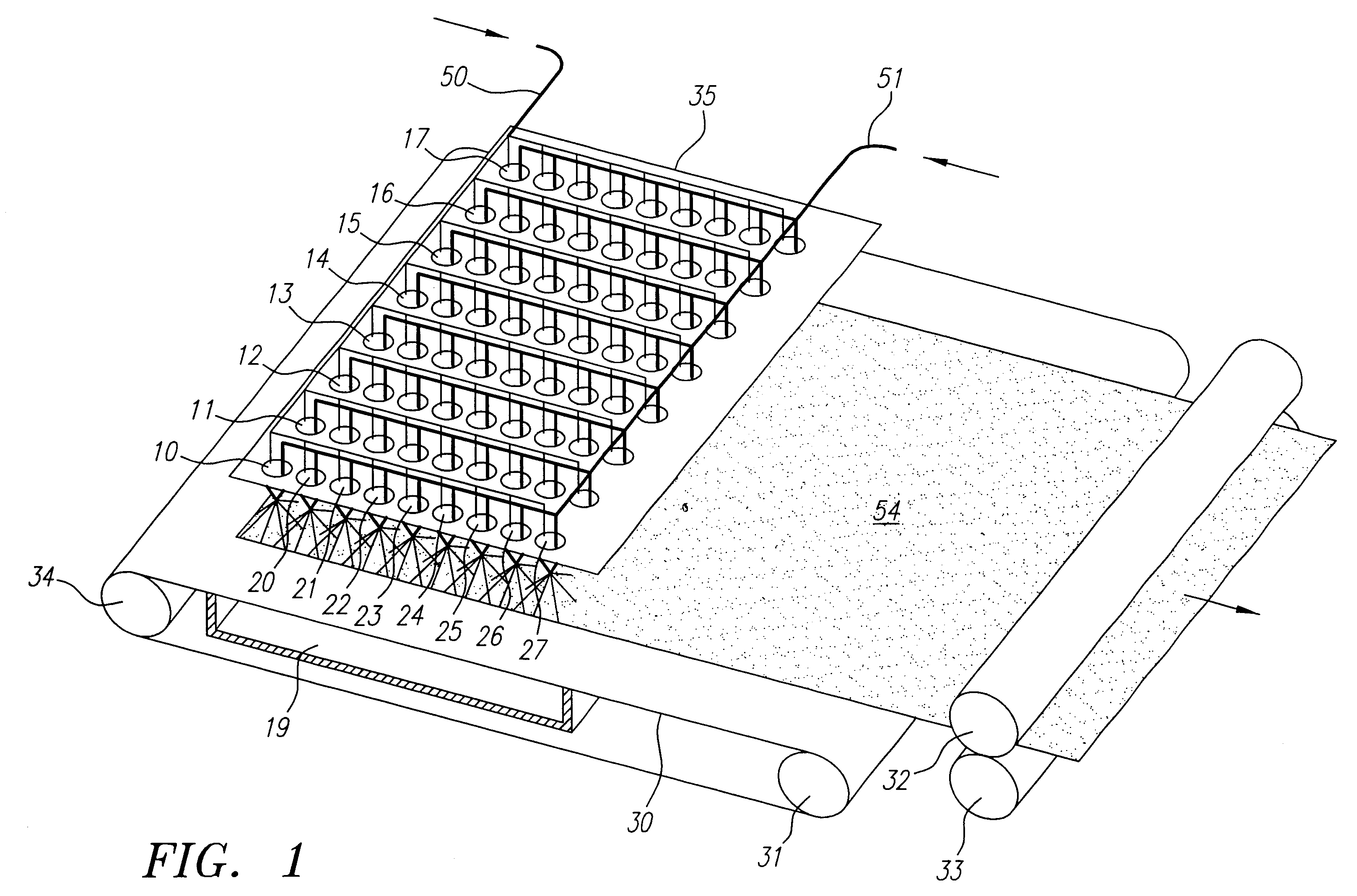

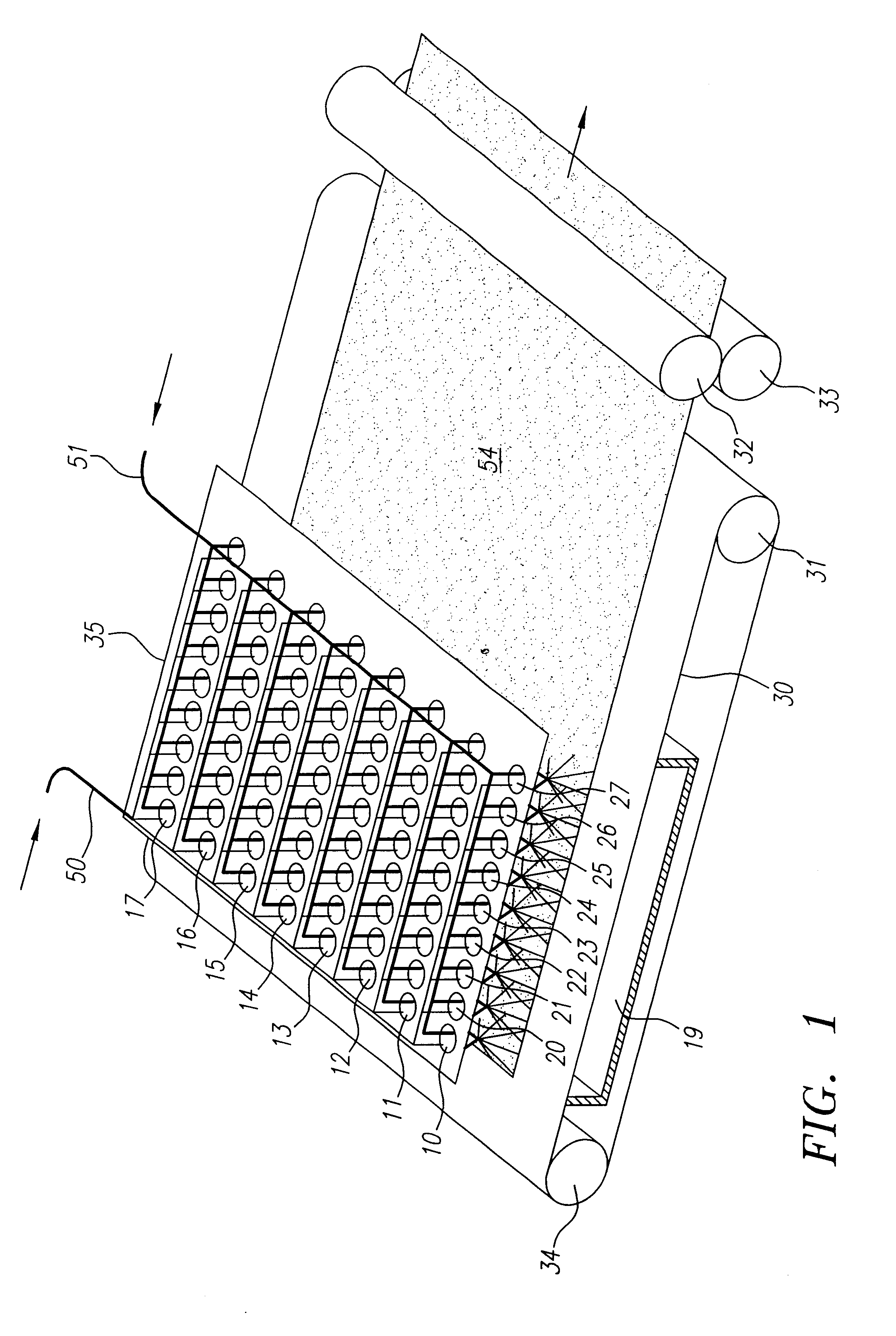

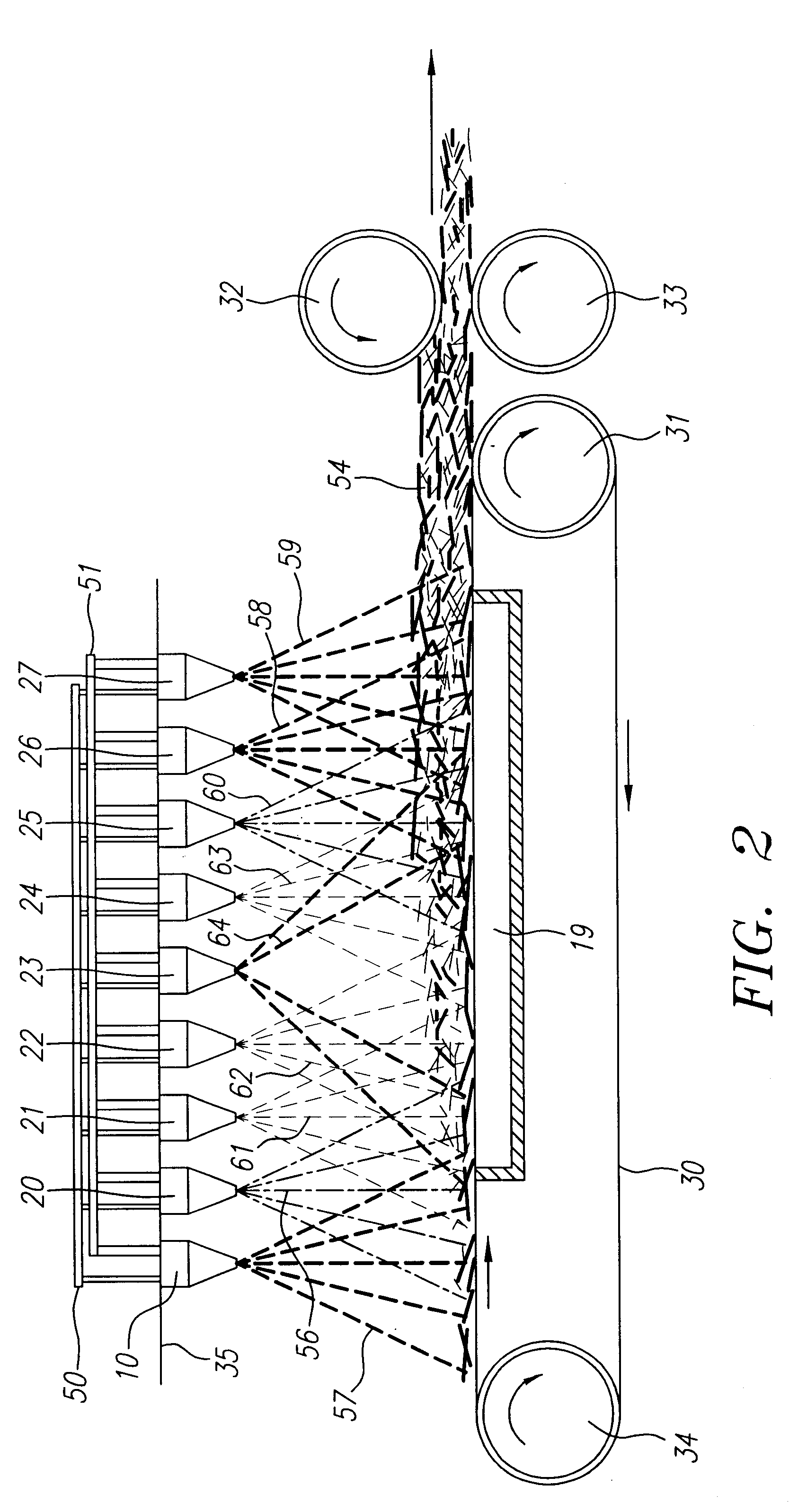

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6315806B1Increase distanceReduce resistanceFilament/thread formingLoose filtering material filtersMean diameterFiber

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

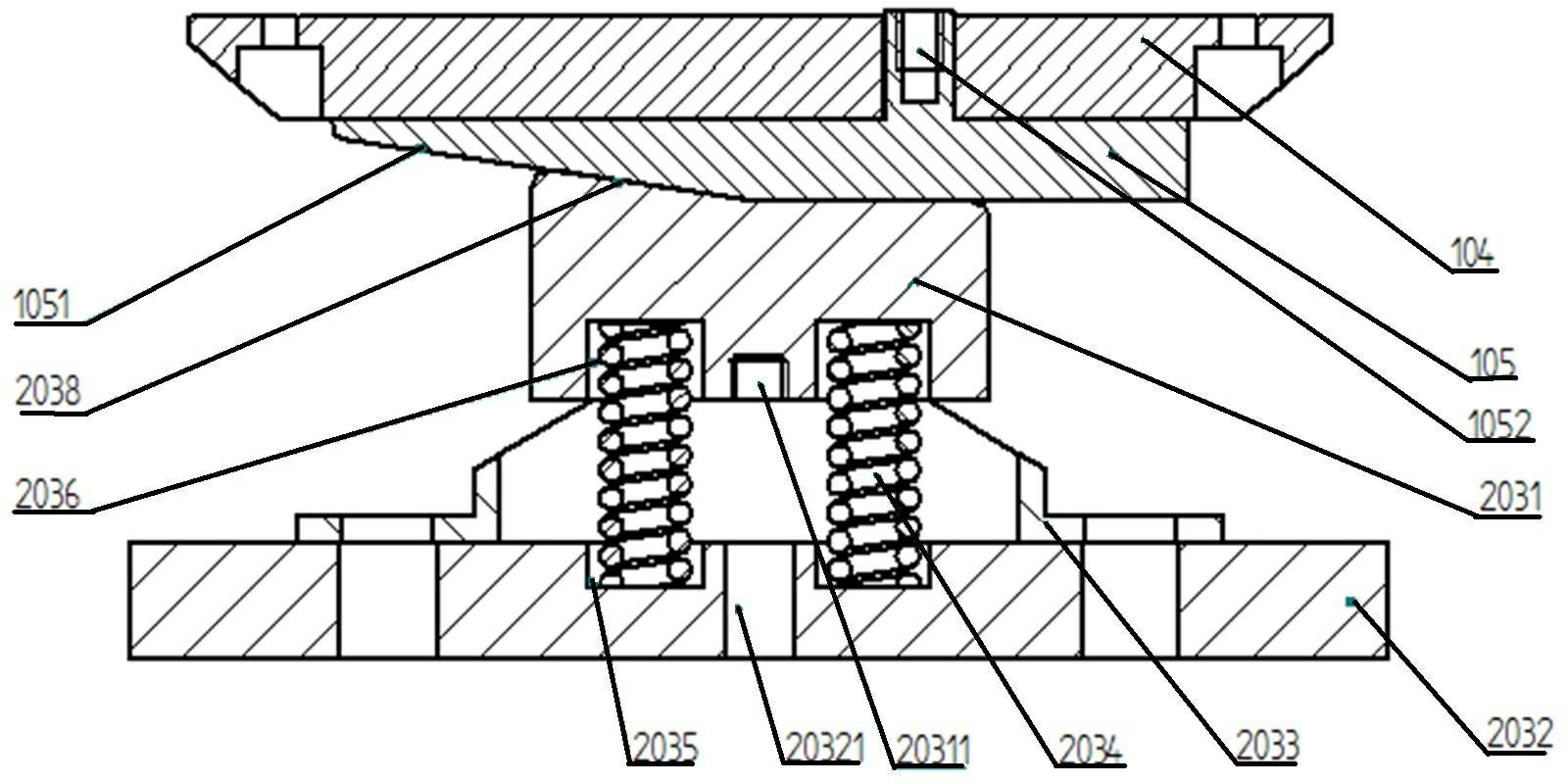

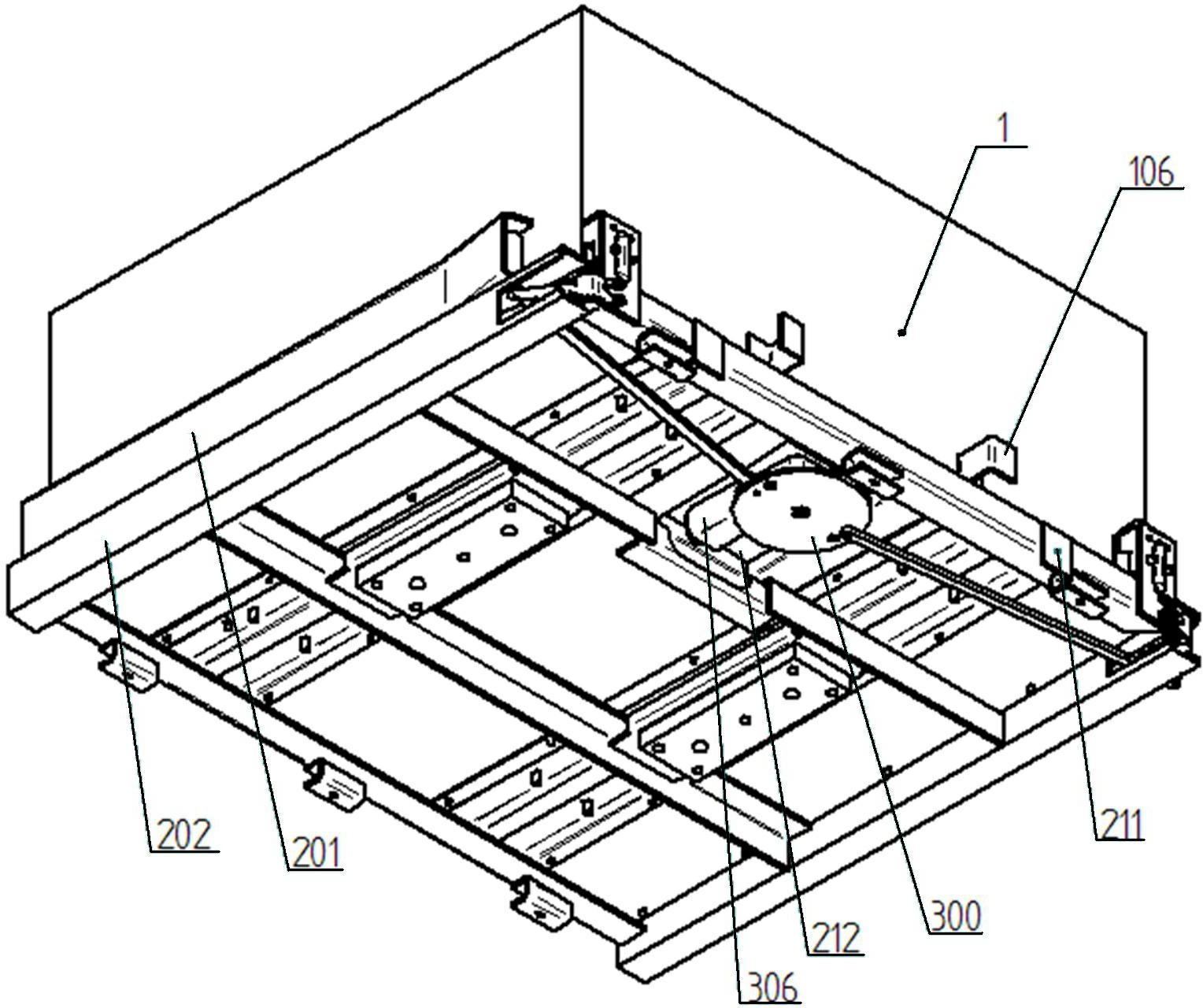

Bottom power taking self-locking electric bus battery box system capable of quickly changing battery

ActiveCN102303589AEasy to installPositioning constraints resolvedElectric propulsion mountingElectric vehicle charging technologyElectricityPower battery

The invention discloses a bottom power taking self-locking electric bus battery box system capable of quickly changing a battery. The system comprises a battery box (1), a tray (2) used for bearing the battery box and arranged on an electric bus, mobile equipment (4) for conveying the battery box, and a grabbing device (5) arranged on the mobile equipment; and a battery box locking and unlocking device (3) is arranged on the tray. Through the system, automatic assembly of the battery box in the electric bus battery box system is realized, and the problems of over positioning, deformation of power wire connection pegs, breakage, arc discharge, welding, difficulty in automatically realizing unlocking due to impact of the battery box to a bolt of a locking mechanism in jolt and deformation of the battery box due to impact in jolt. The system is reasonable, reliable, simple and compact in structure, and can full-automatically, quickly and conveniently realize quick change of the power battery.

Owner:KUNMING SHIPBUILDING EQUIP

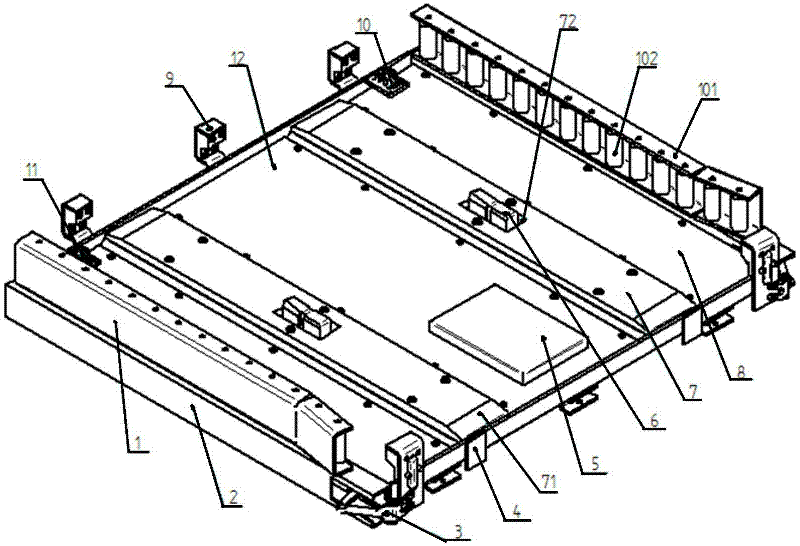

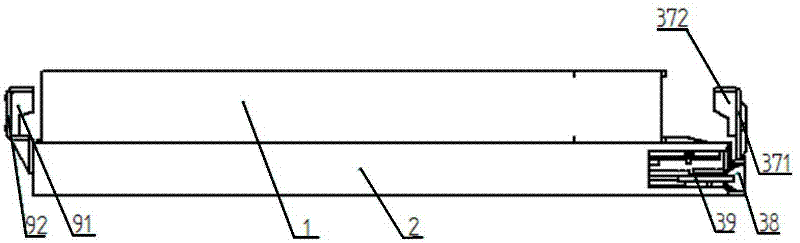

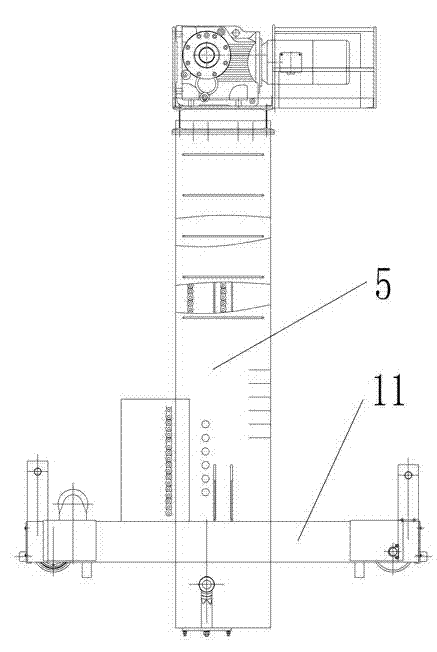

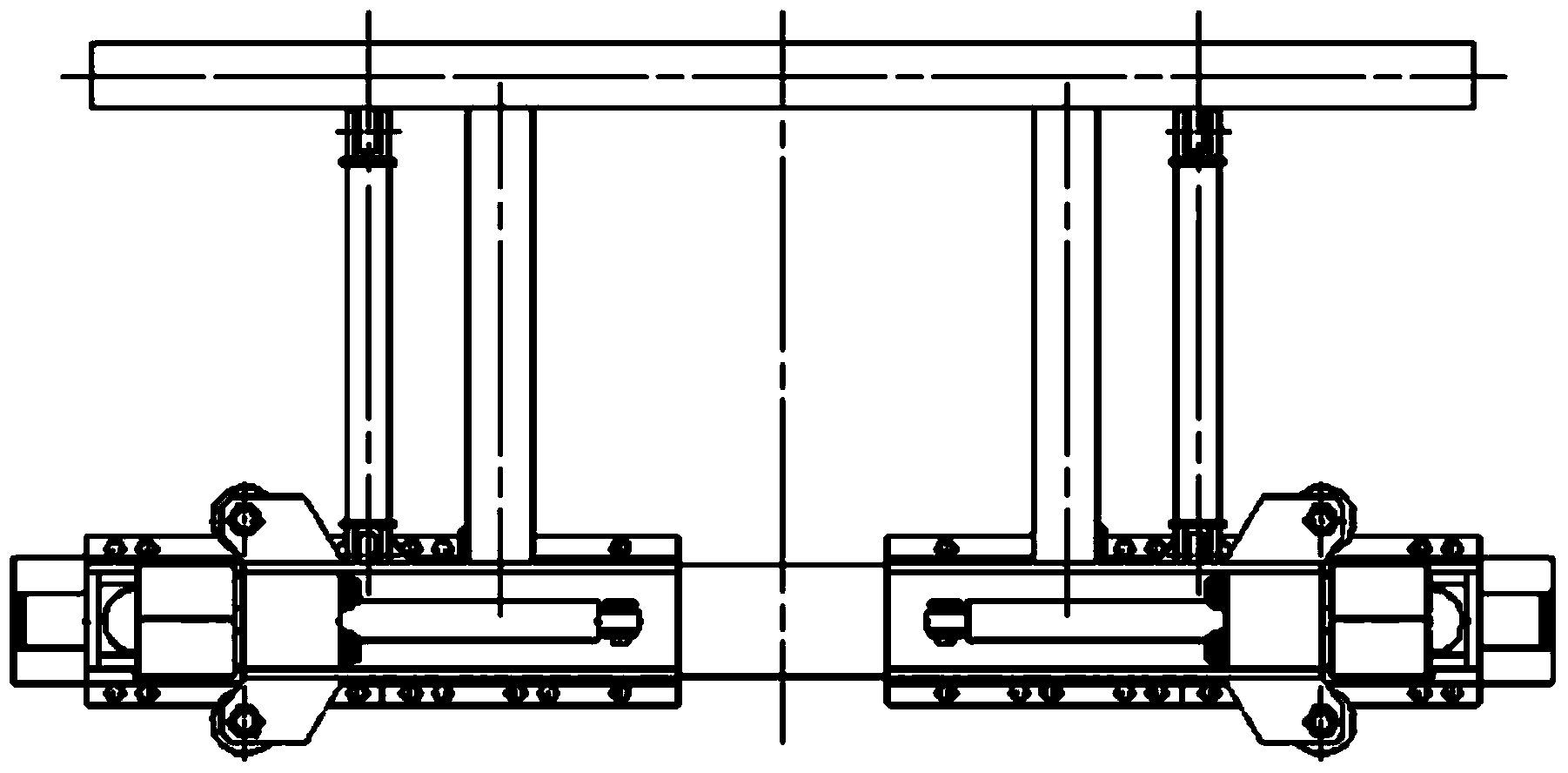

Sliding bottom electricity-taking and self-locking electric bus battery quick-change pellet device

ActiveCN102343894APositioning constraints resolvedAvoid the problem of severe squeezing that cannot be unlockedCharging stationsElectric propulsion mountingElectricityEngineering

The invention provides a sliding bottom electricity-taking and self-locking electric bus battery quick-change pellet device. The electric bus battery quick-change tray device comprises a pellet and a locking and unlocking mechanism (3) mounted on the pellet. According to the invention, the battery box can be correctly positioned and reliably locked reasonably; the force is reasonably applied to the battery box; simple structure and simple and reasonable power wire splicing mode are obtained; and the arc discharge phenomenon can be effectively prevented.

Owner:KUNMING SHIPBUILDING EQUIP

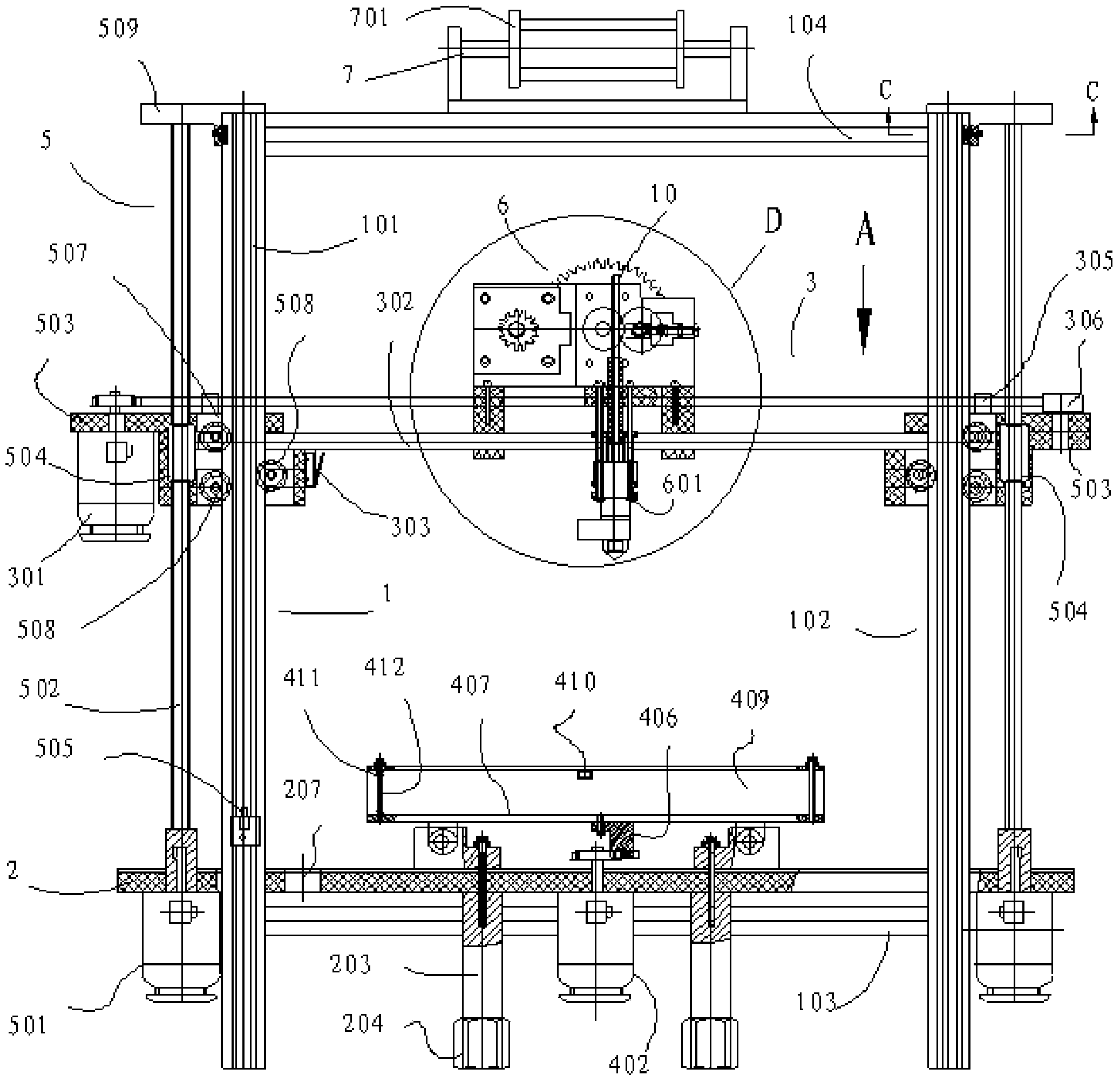

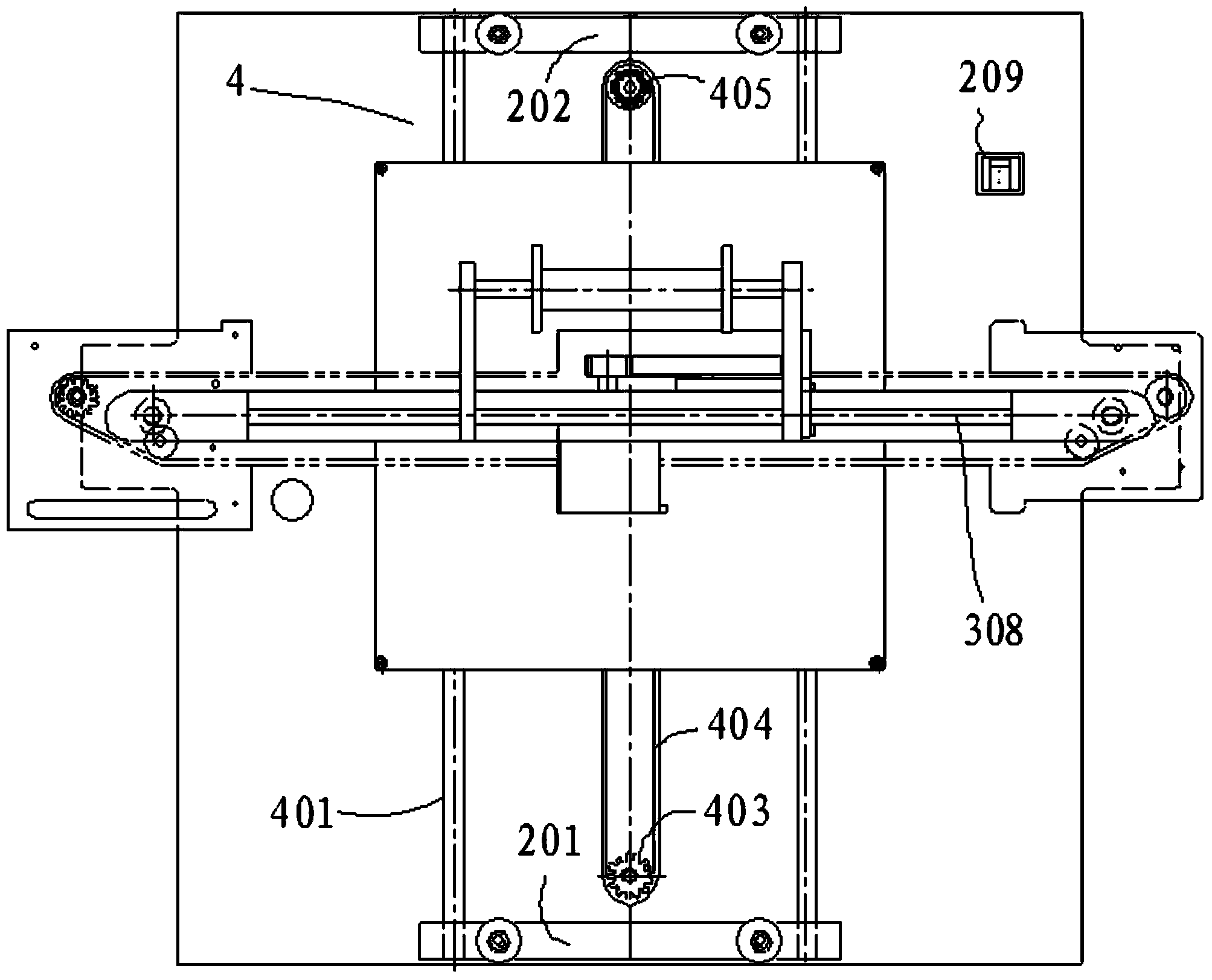

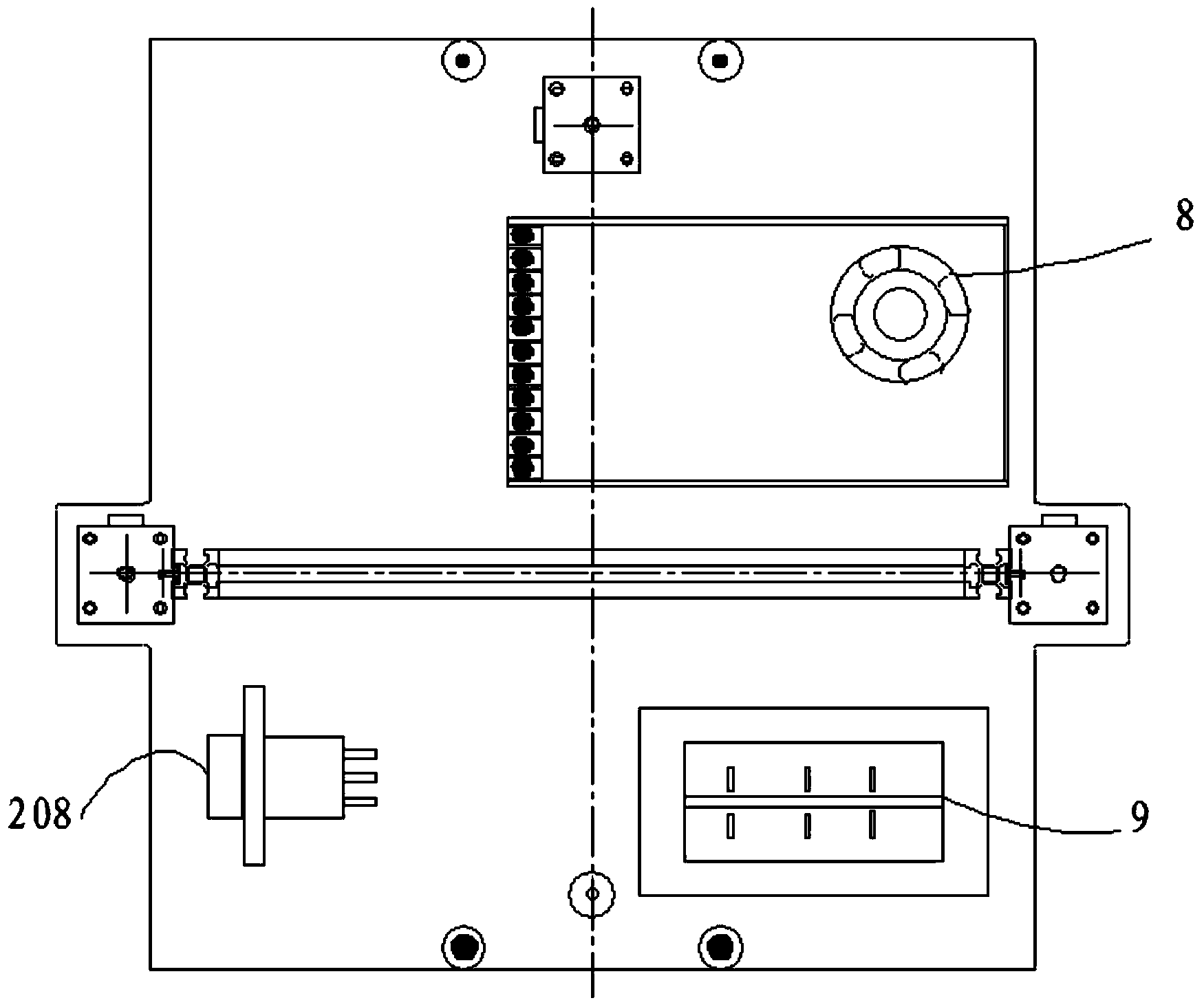

Three-dimensional (3D) printer

The invention discloses a three-dimensional (3D) printer which comprises a rack, a base, an X-axis movement system, a Y-axis movement system, a Z-axis movement system and a printing device, wherein the rack comprises a left upright post, a right upright post, an upper connecting plate and a lower connecting plate; the upper connecting plate and the lower connecting plate are connected with the left upright post and the right upright post, respectively; the base is connected with the lower connecting plate; the upper connecting plate is connected with a printing supplies connecting rack; the printing supplies connecting rack is connected with a printing supplies fixing disc; the printing device is connected with the X-axis movement system; the X-axis movement system is connected with the Z-axis movement system; the Z-axis movement system is connected with a guide rail of the left upright post and the right upright post; the Y-axis movement system is connected with the base; the X-axis movement system is provided with an X-axis movement guide rail through which the printing device moves; a power supply and a controller which are connected with each other are arranged at the bottom of the base; the controller is connected with the X-axis movement system, the Y-axis movement system, the Z-axis movement system and the printing device. The 3D printer is simple and compact in structure, small in size and low in manufacturing cost.

Owner:UNIV OF JINAN

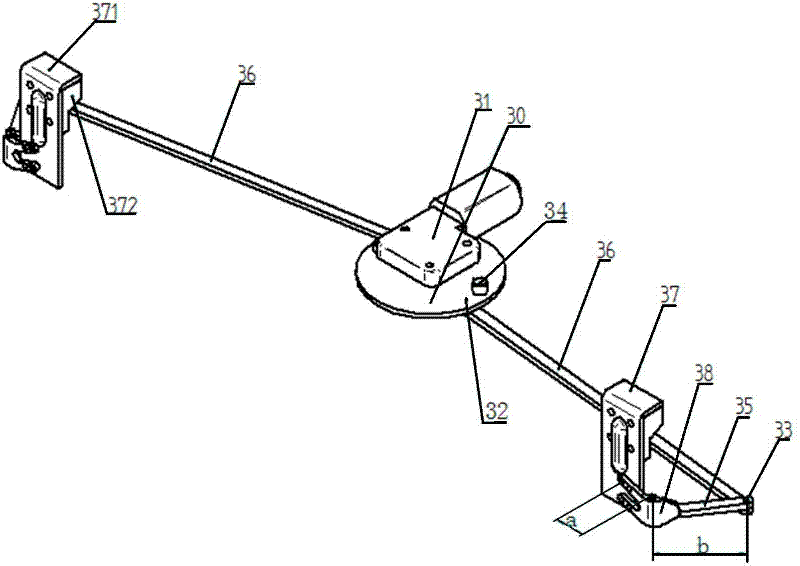

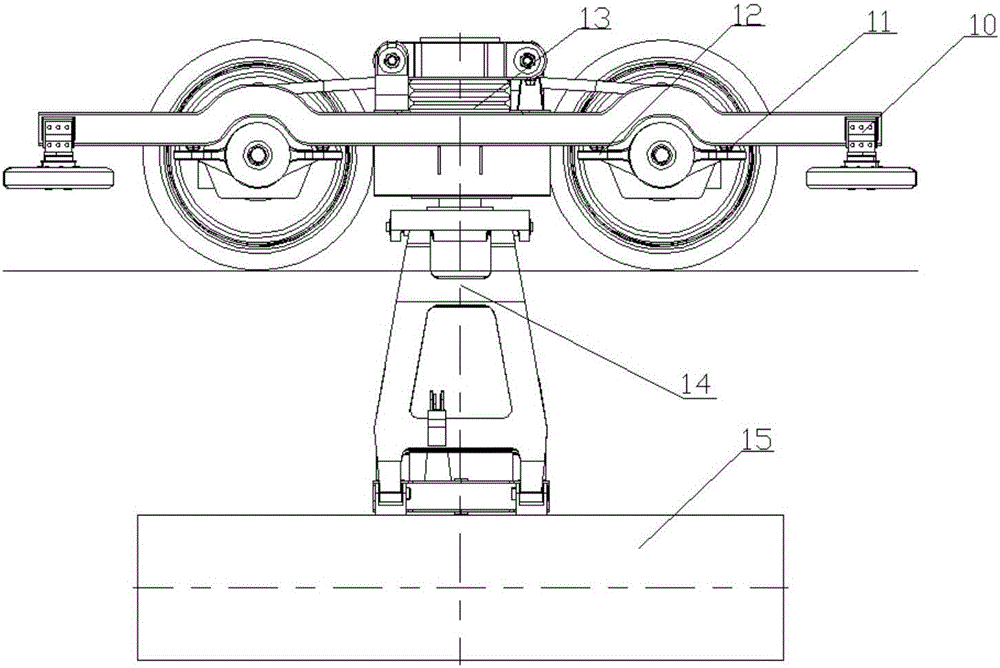

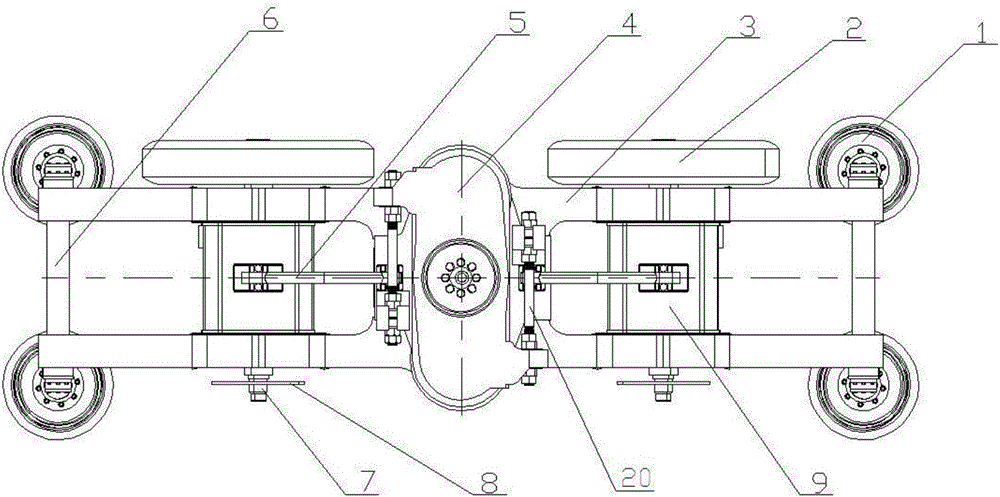

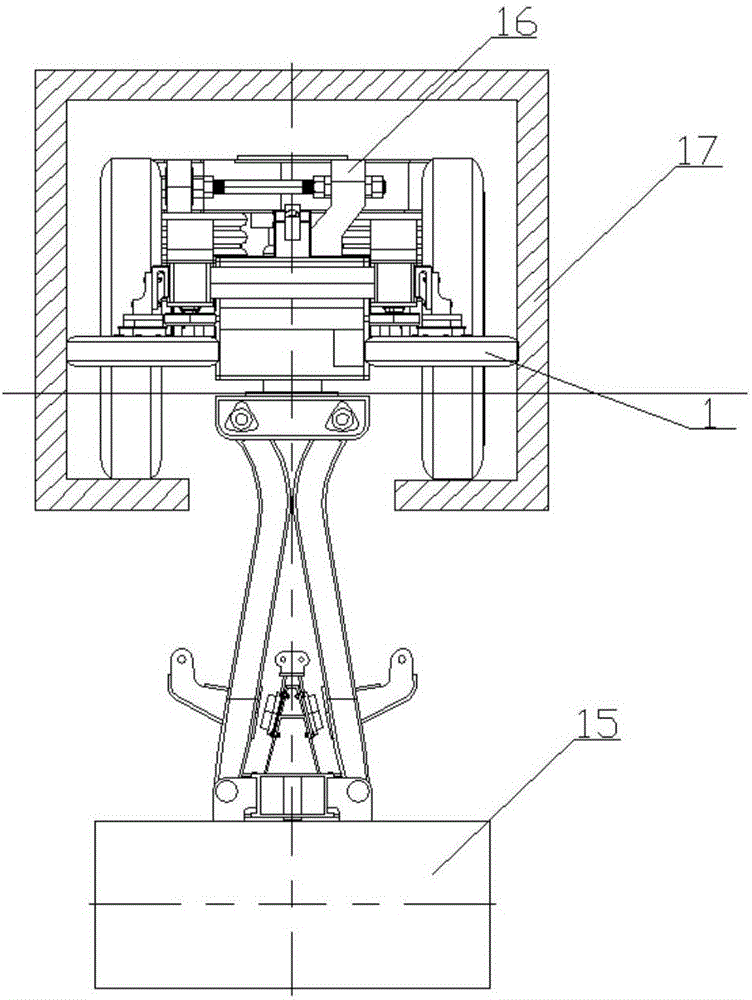

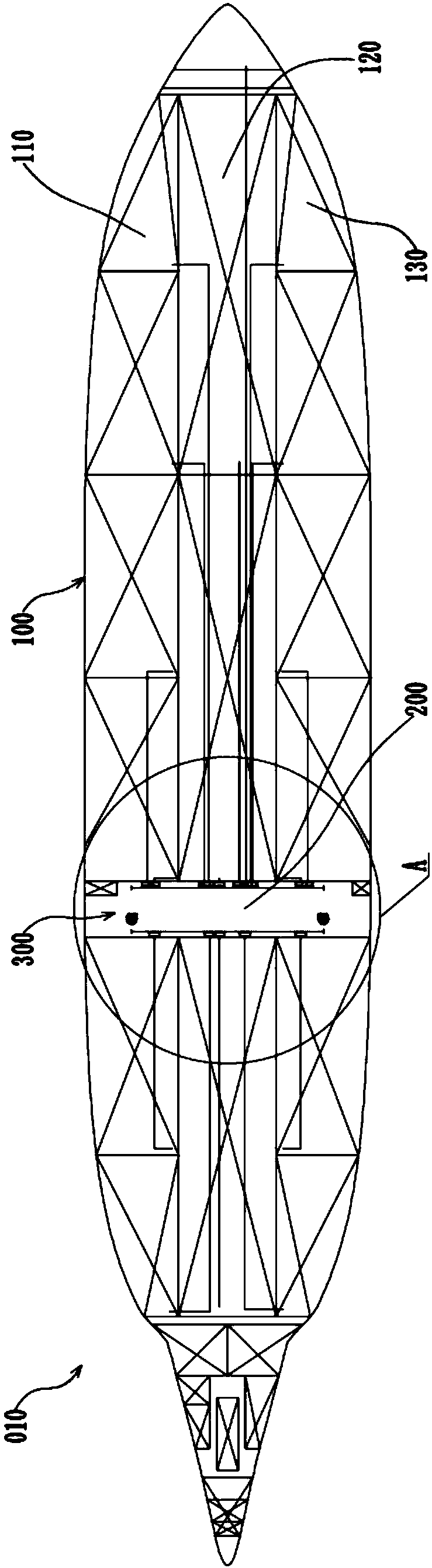

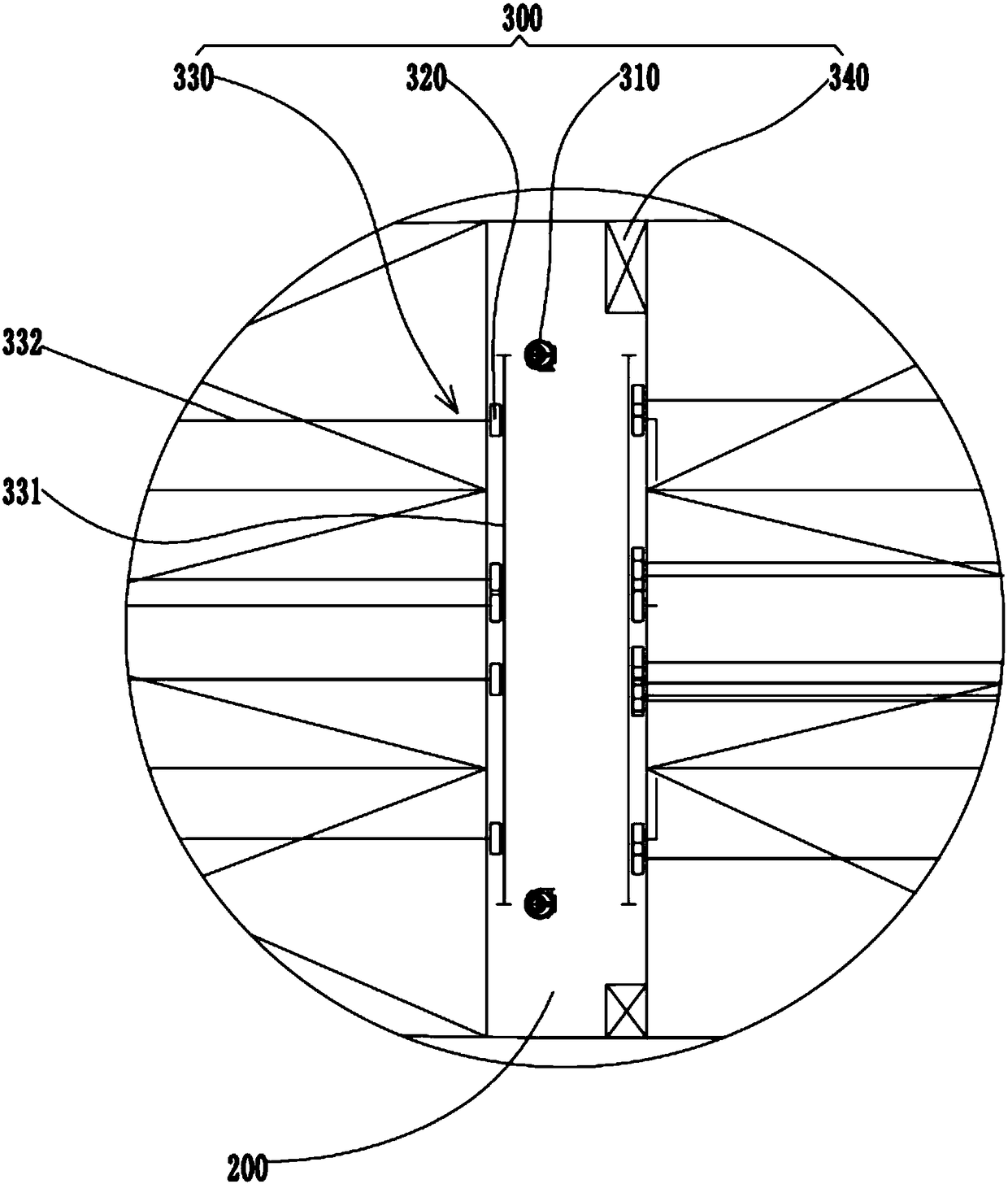

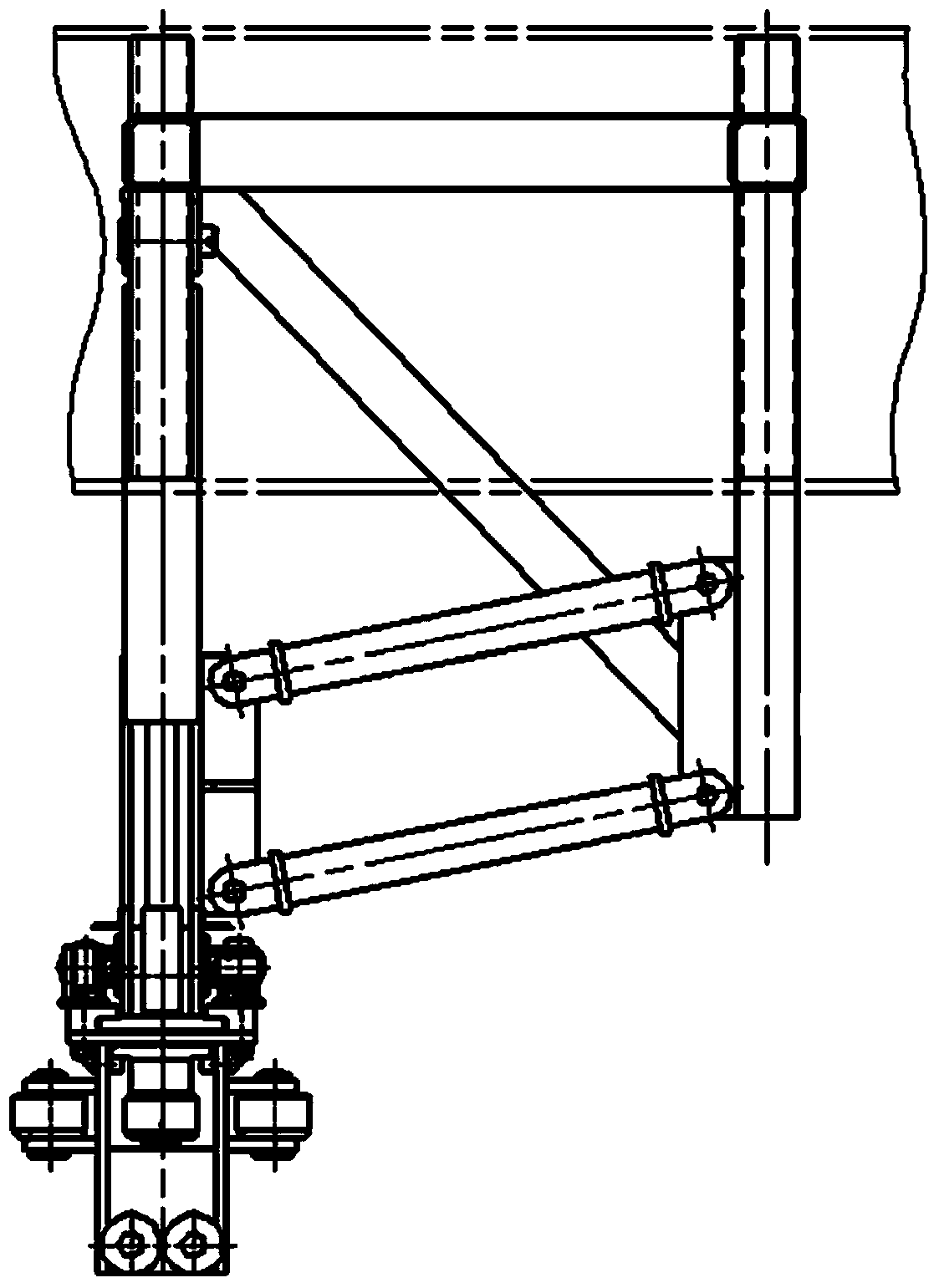

Inner rotor direct-driving type structure of suspension type single-rail train

ActiveCN106114525AImprove conversion efficiencySmall sizeElectric locomotivesElevated railway with suspended vehicleAir springAir suspension

The invention provides an inner rotor direct-driving type structure of a suspension type single-rail train. The structure comprises a framework of a bogie, wherein the framework of the bogie comprises a side frame, cross beams and a framework center platform; an air spring and a sleeper beam are arranged on the framework center platform; transverse pull rods are arranged on the front side and the back side of the sleeper beam; the sleeper beam is press-fitted on the air spring; a suspension device is a four-connecting-rod mechanism; a pair of traveling wheels is transversely arranged on each of outer sides of the side frame; guiding wheels are arranged at two ends of the side frame; and an inner rotor type permanent-magnet motor for providing rotating power for the traveling wheels is arranged between each pair of the transverse traveling wheels. According to the structure, the inner rotor type direct-driving motors are used as driving devices of the bogie, so that the energy conversion efficiency is greatly improved; and meanwhile, the size and the heating value of the motors are reduced, the structure of the bogie is simplified, the reliability of the bogie is improved, the maintenance cost is reduced, and noise caused by the bogie during running is reduced.

Owner:SOUTHWEST JIAOTONG UNIV

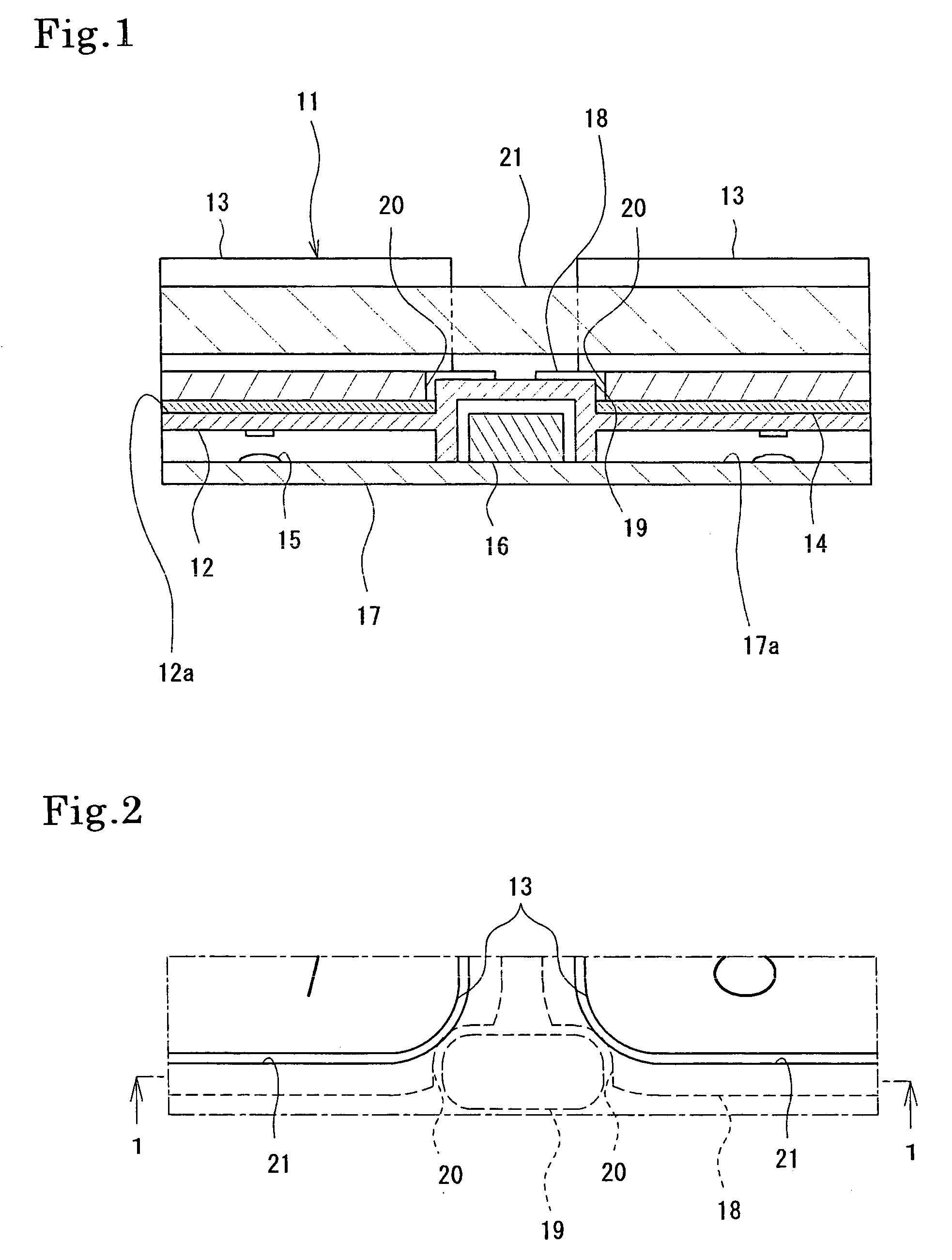

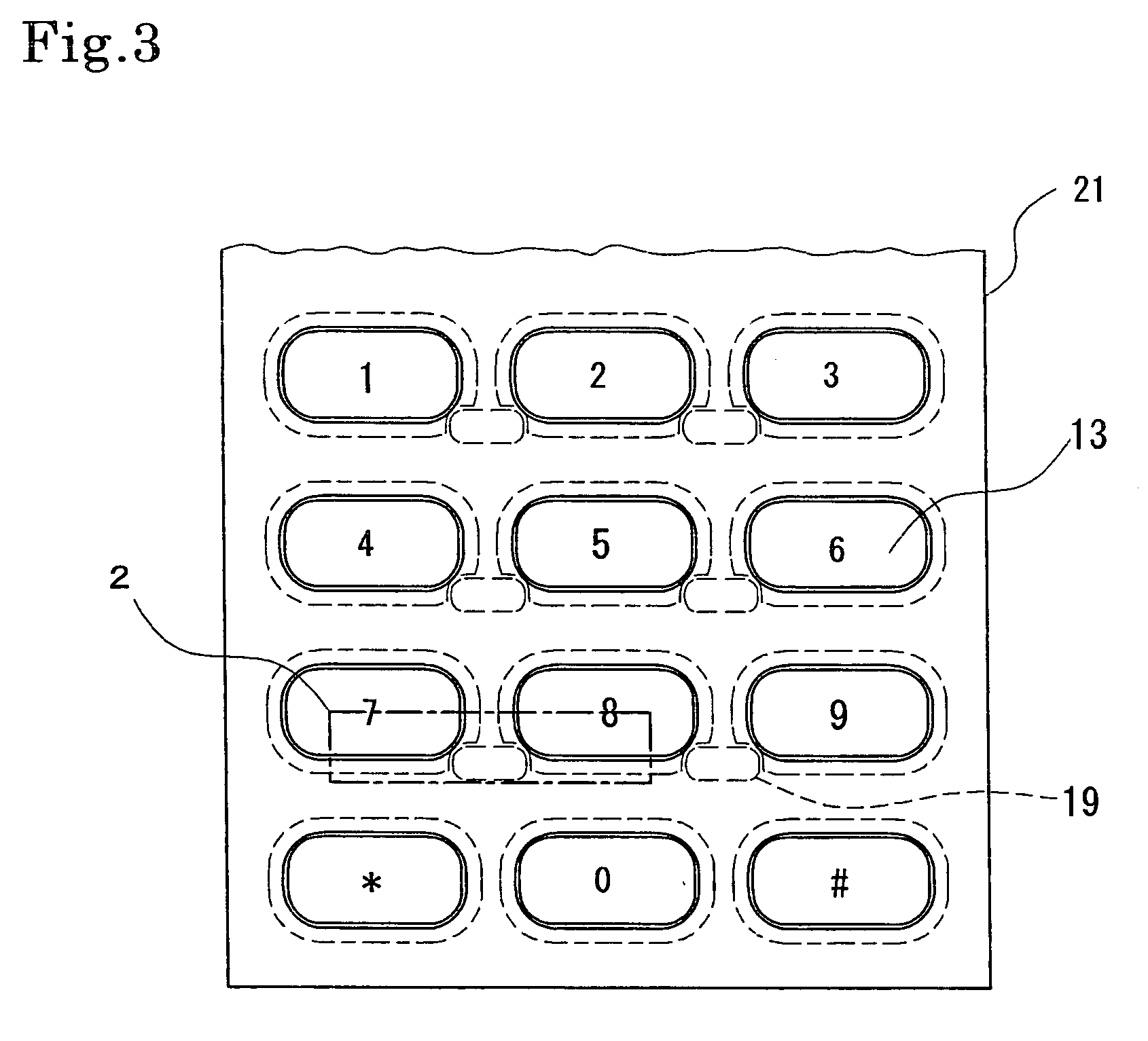

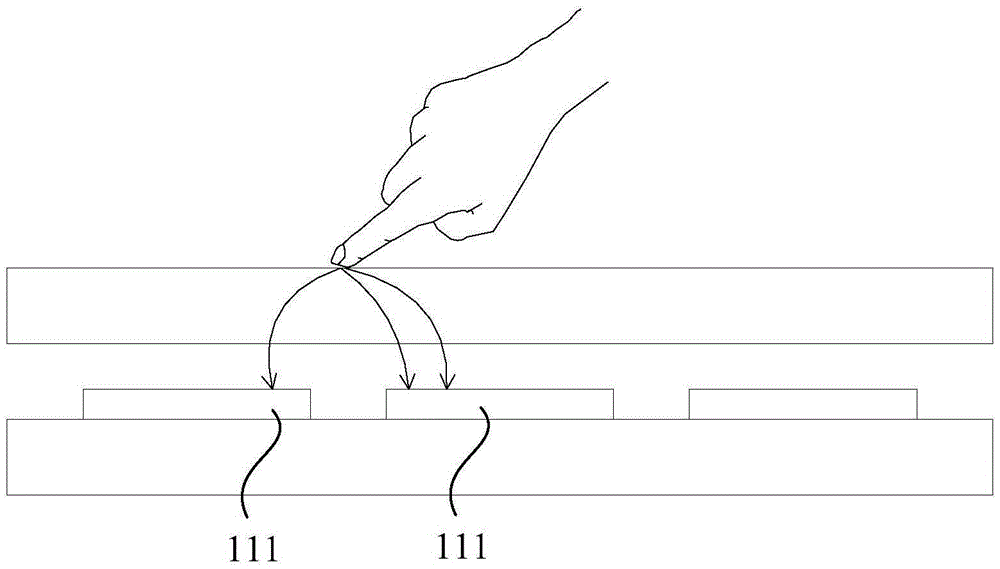

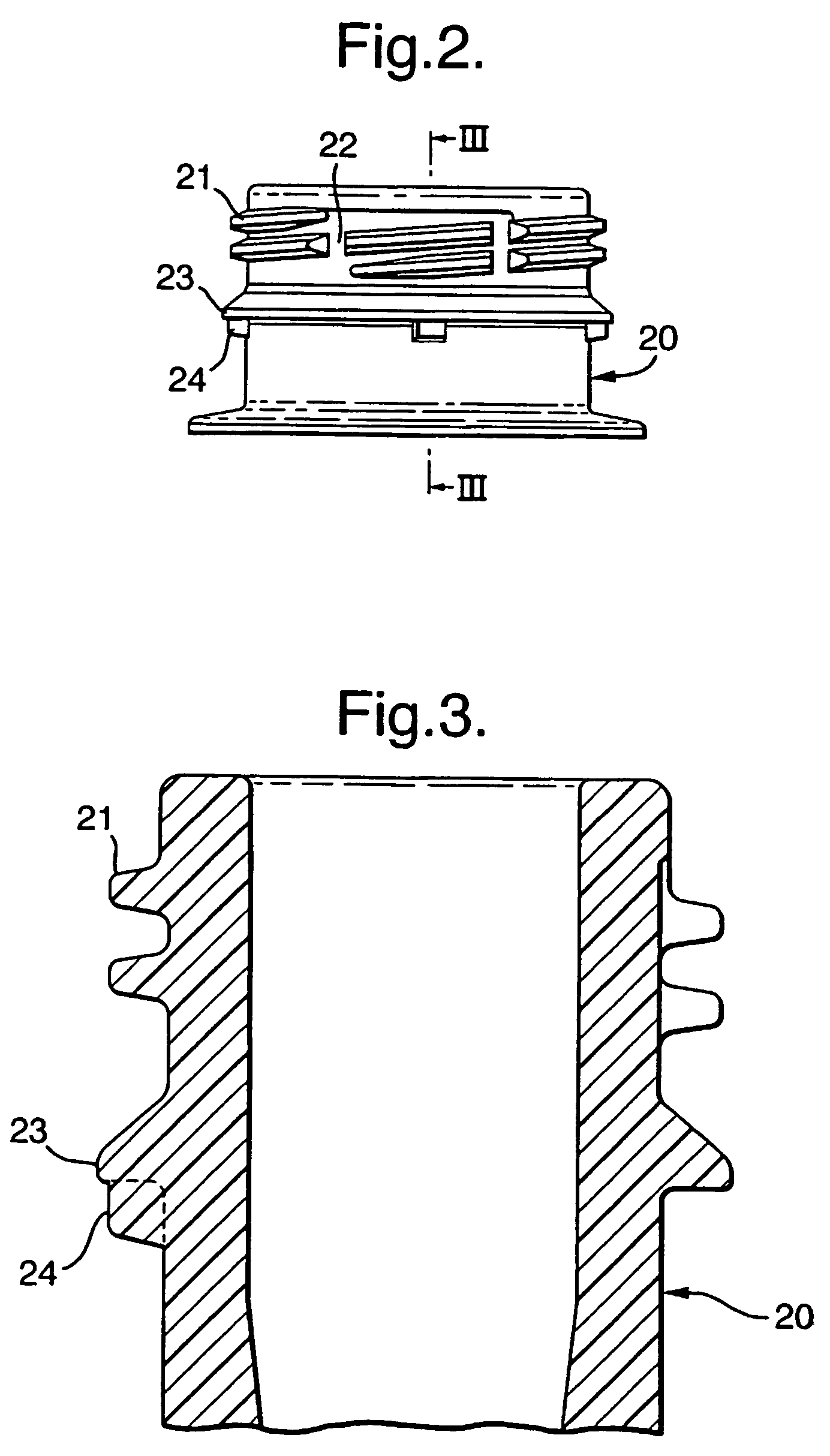

Key pad, resin key top injection mold, and resin key top manufacturing method

InactiveUS7014377B2Small sizeReduce thicknessMeasurement apparatus componentsLegendsEngineeringMechanical engineering

Owner:POLYMATECH CO LTD

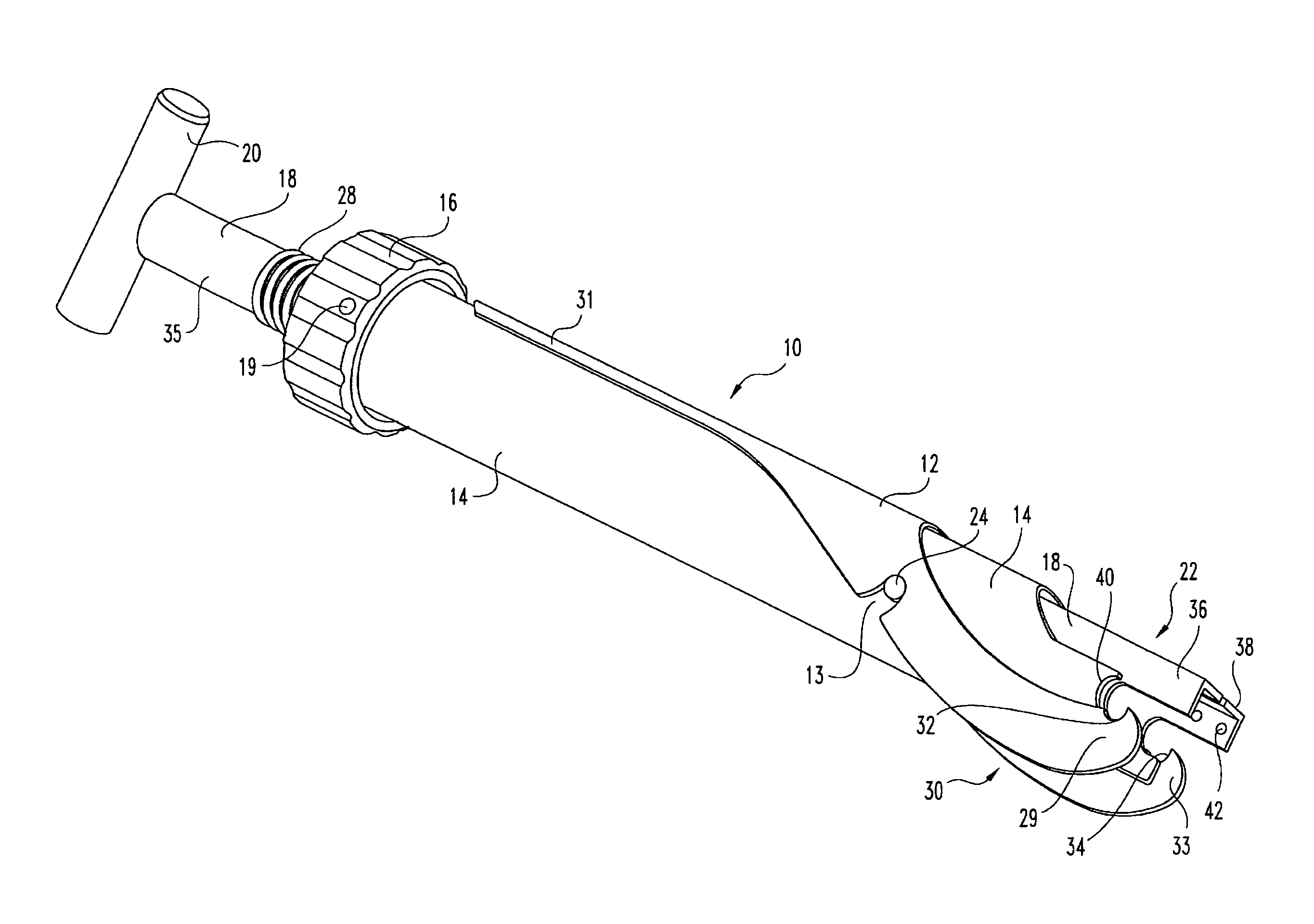

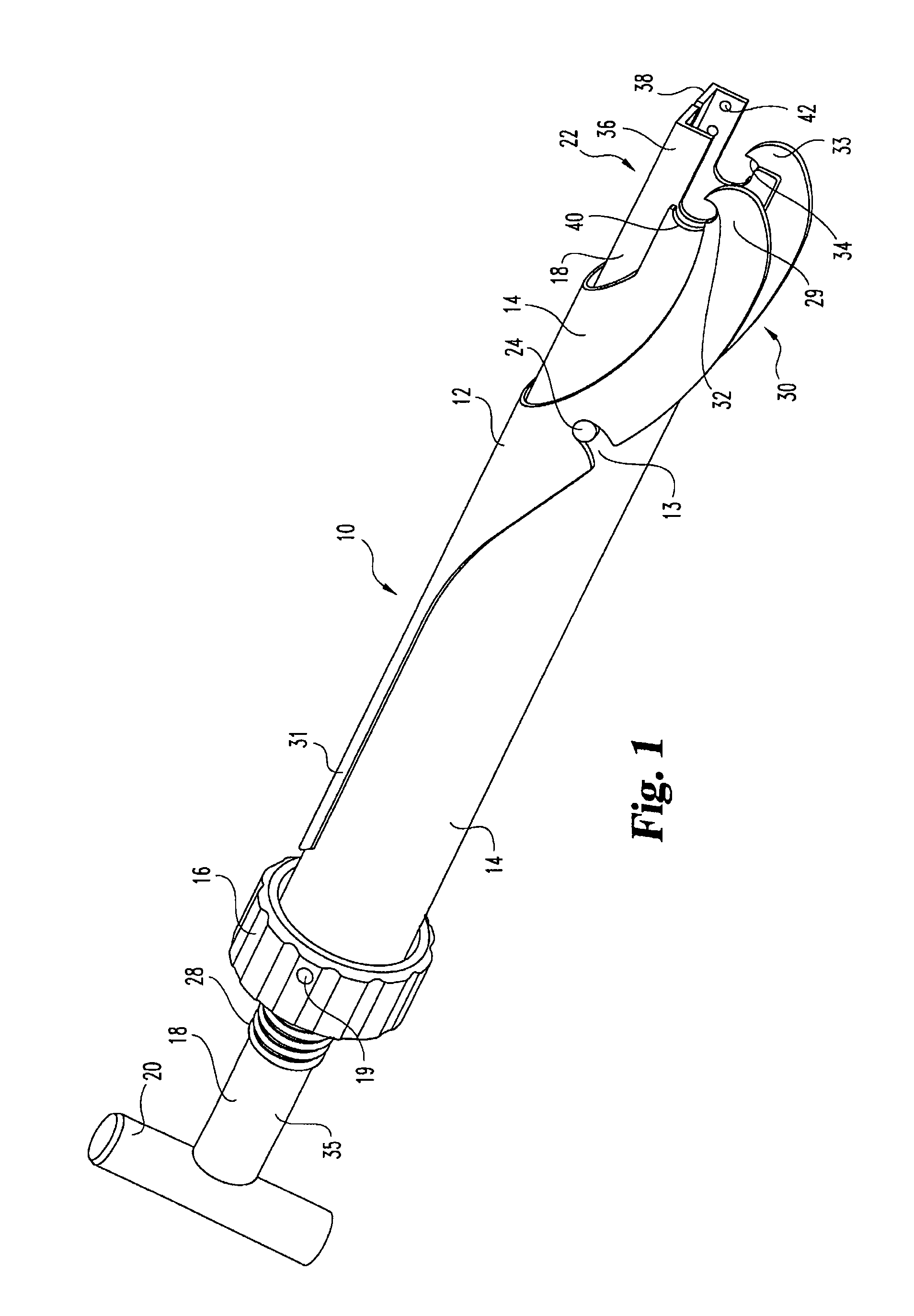

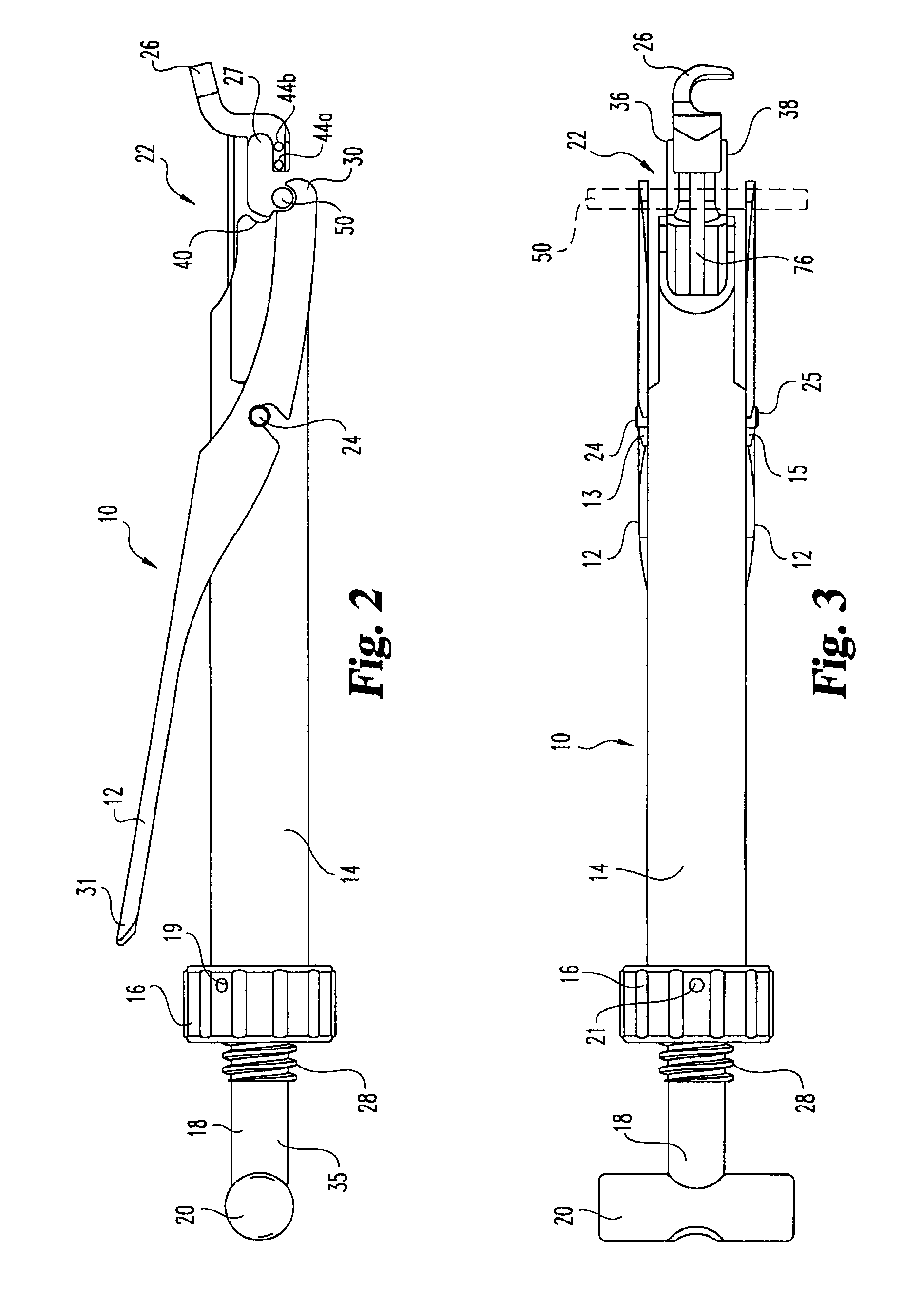

Rod introduction apparatus

InactiveUSRE43526E1Shorten the vertical distanceInternal osteosythesisFastenerBiomedical engineering

Owner:WARSAW ORTHOPEDIC INC

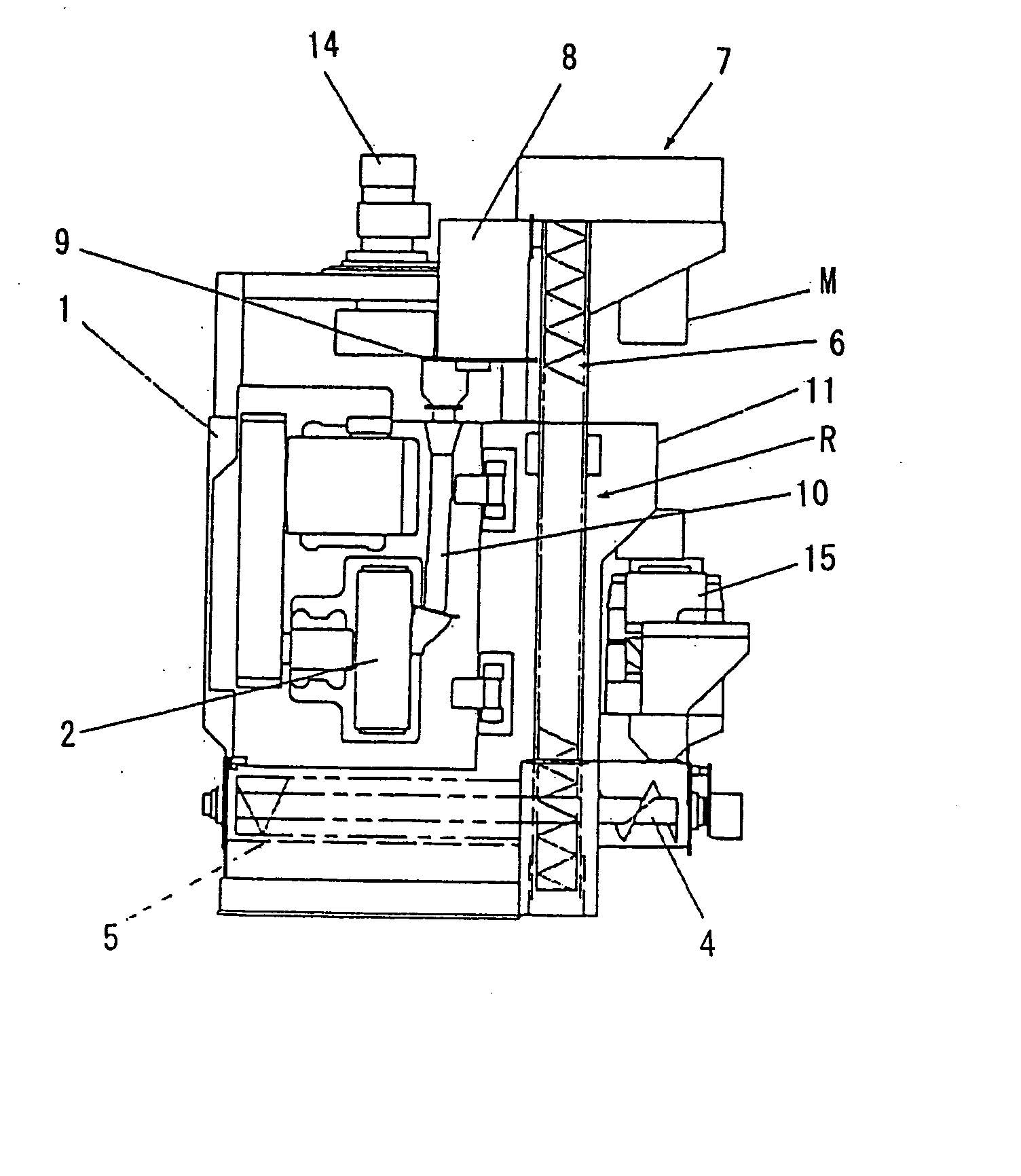

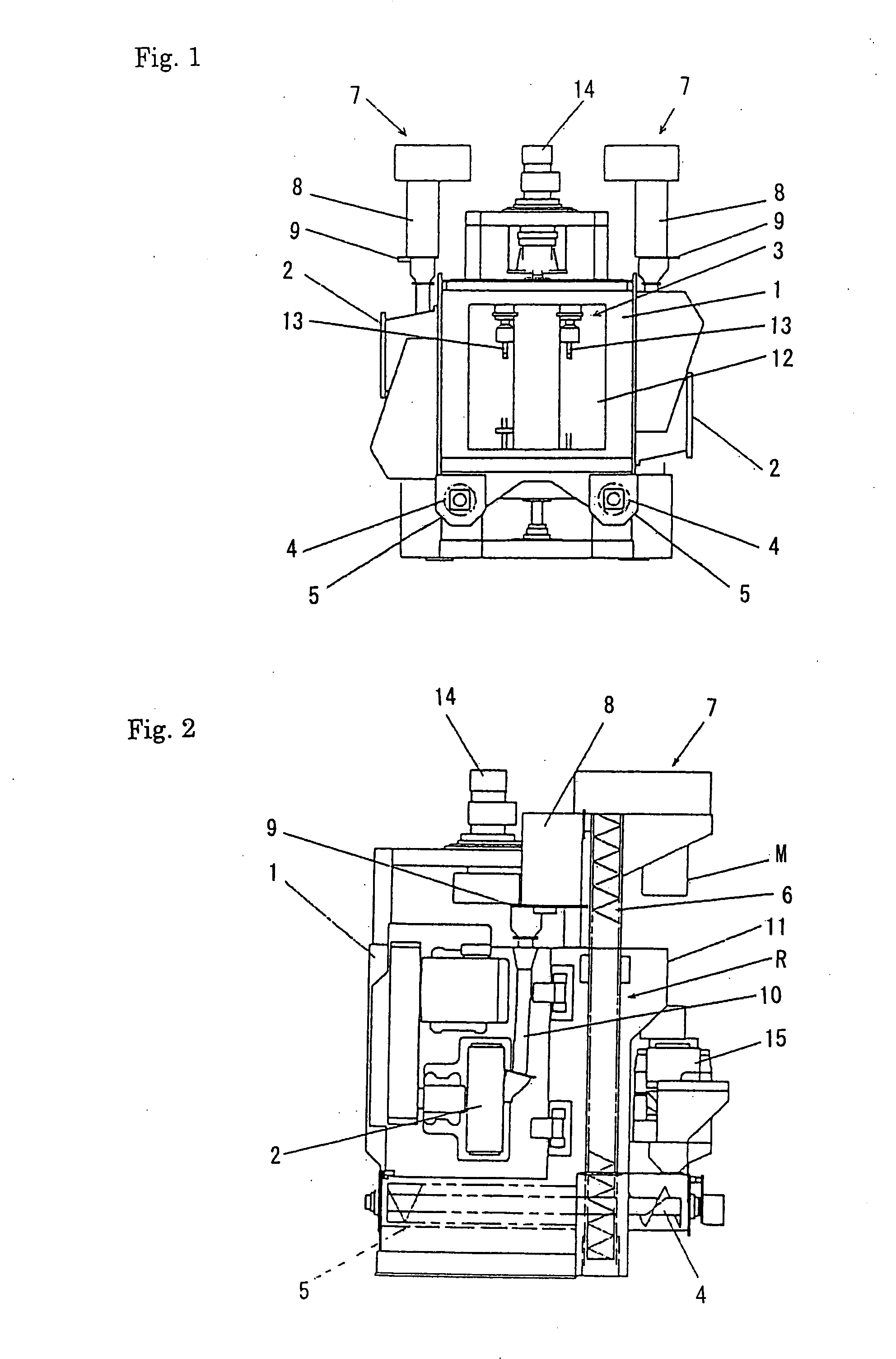

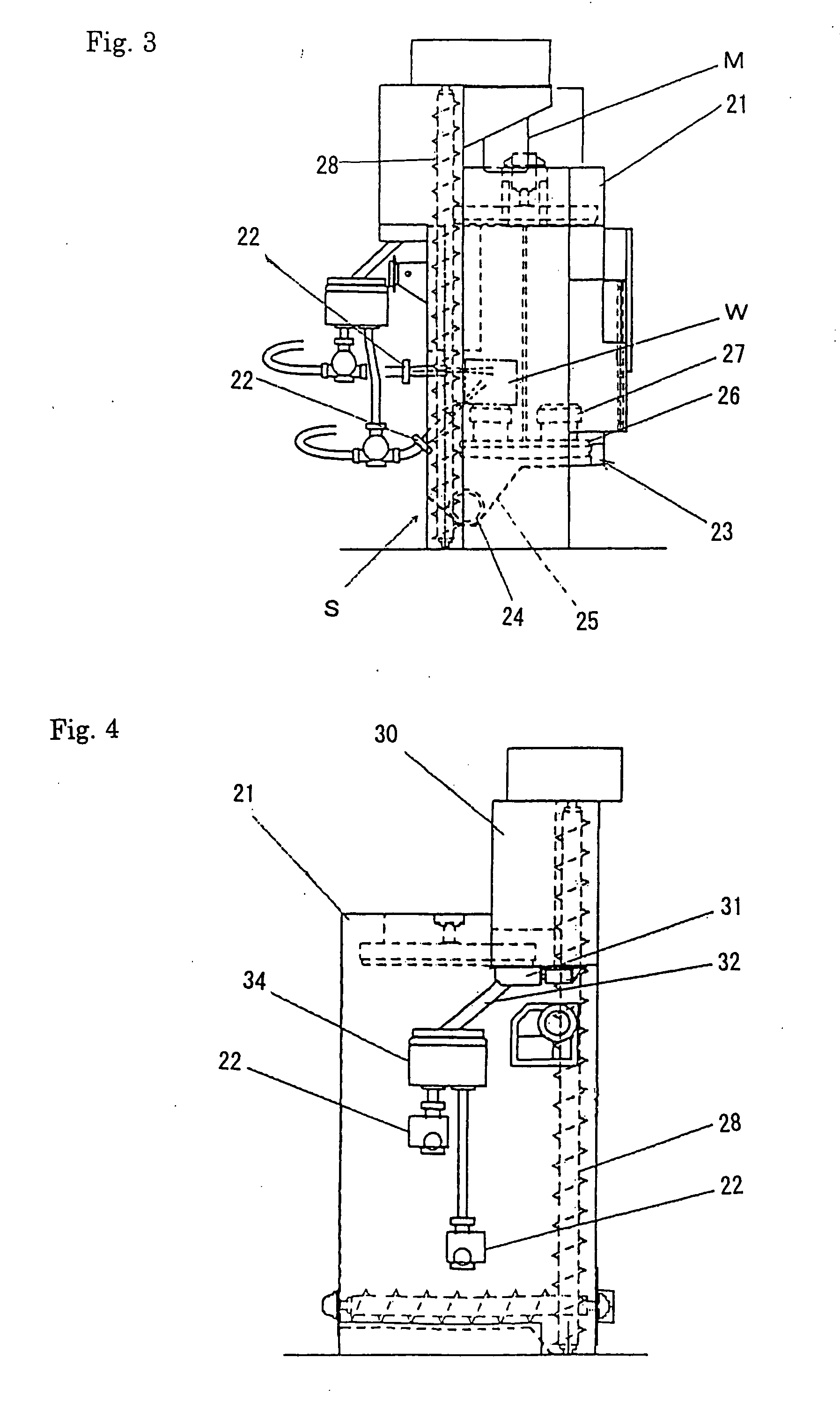

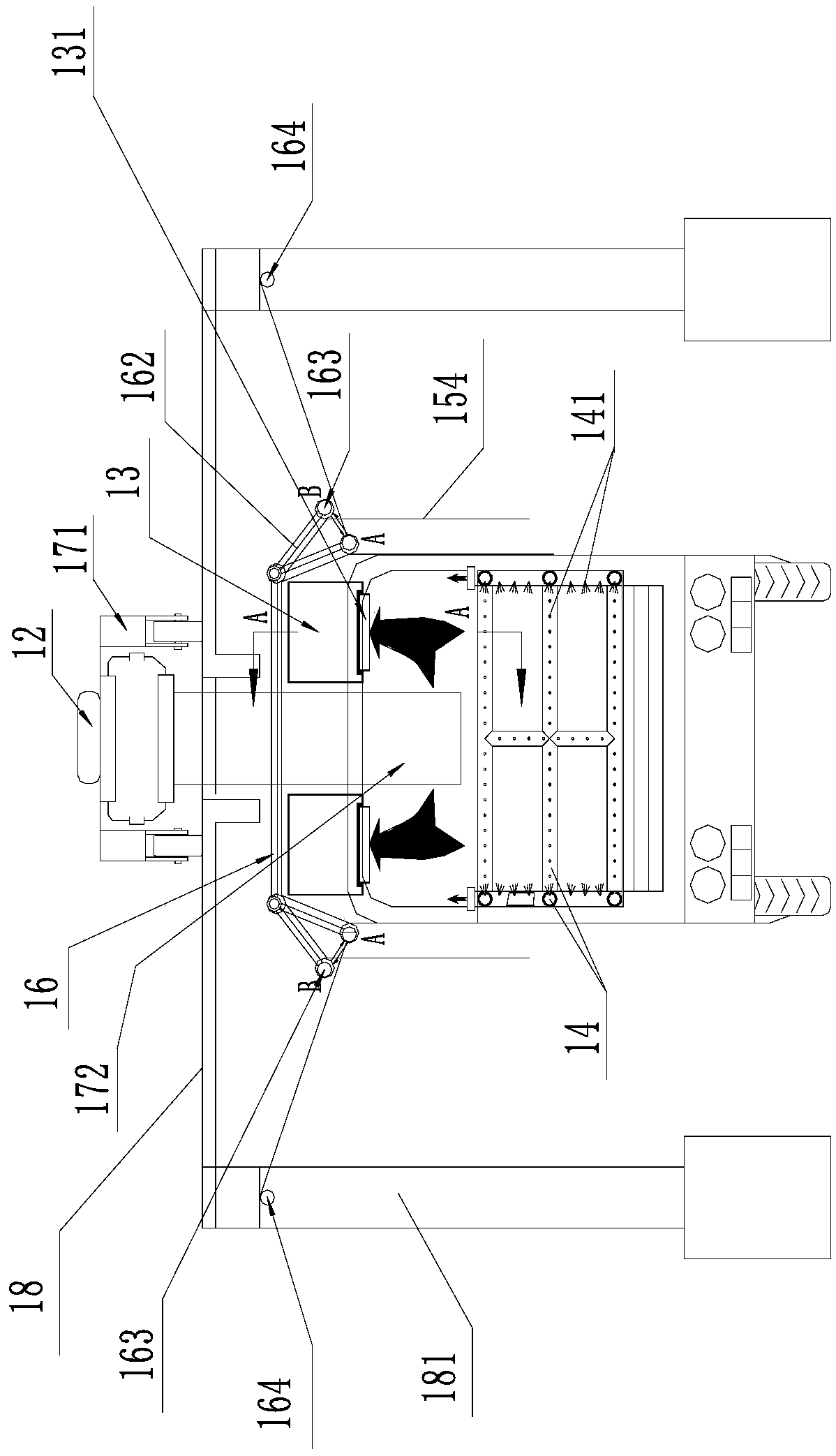

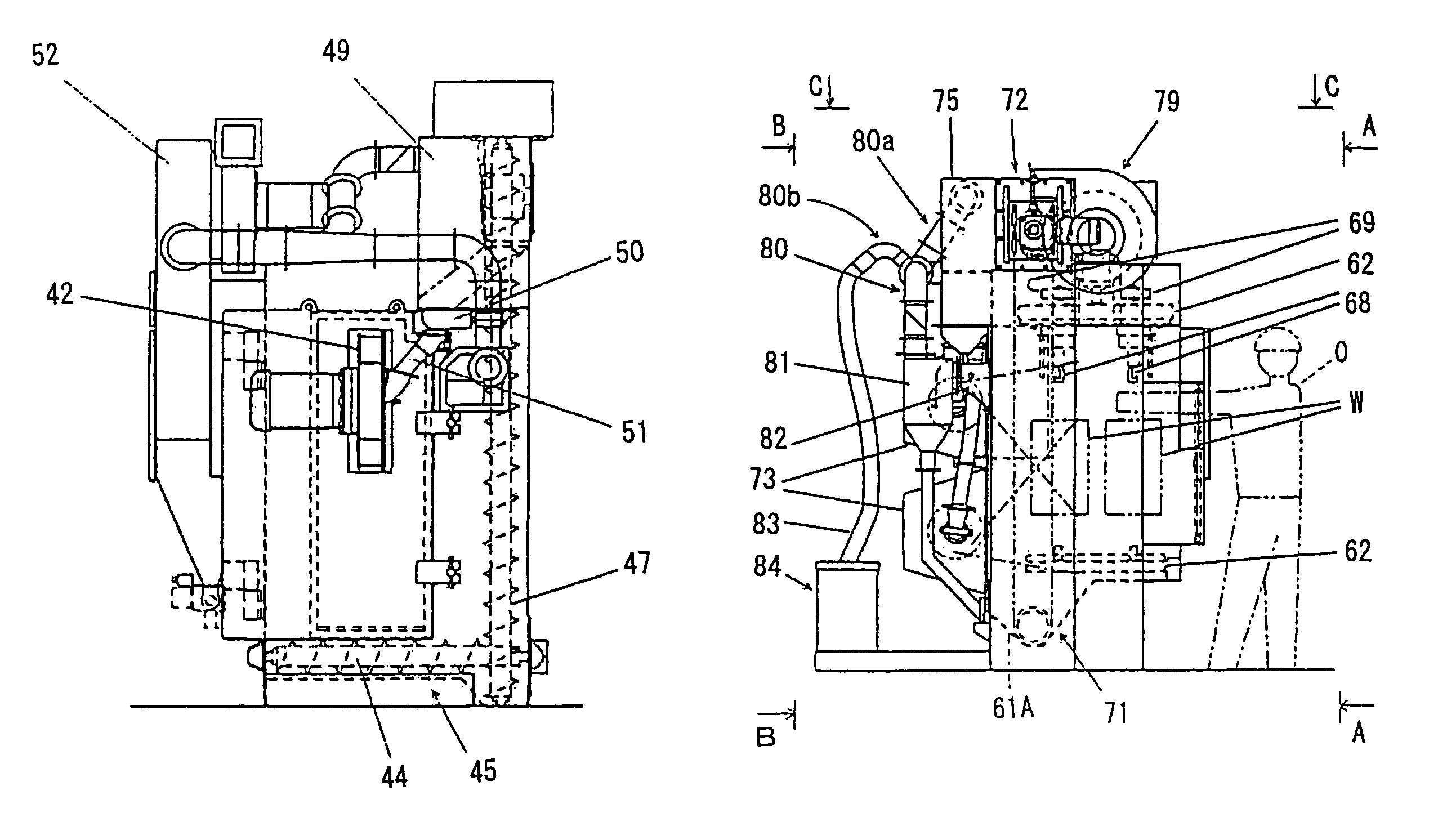

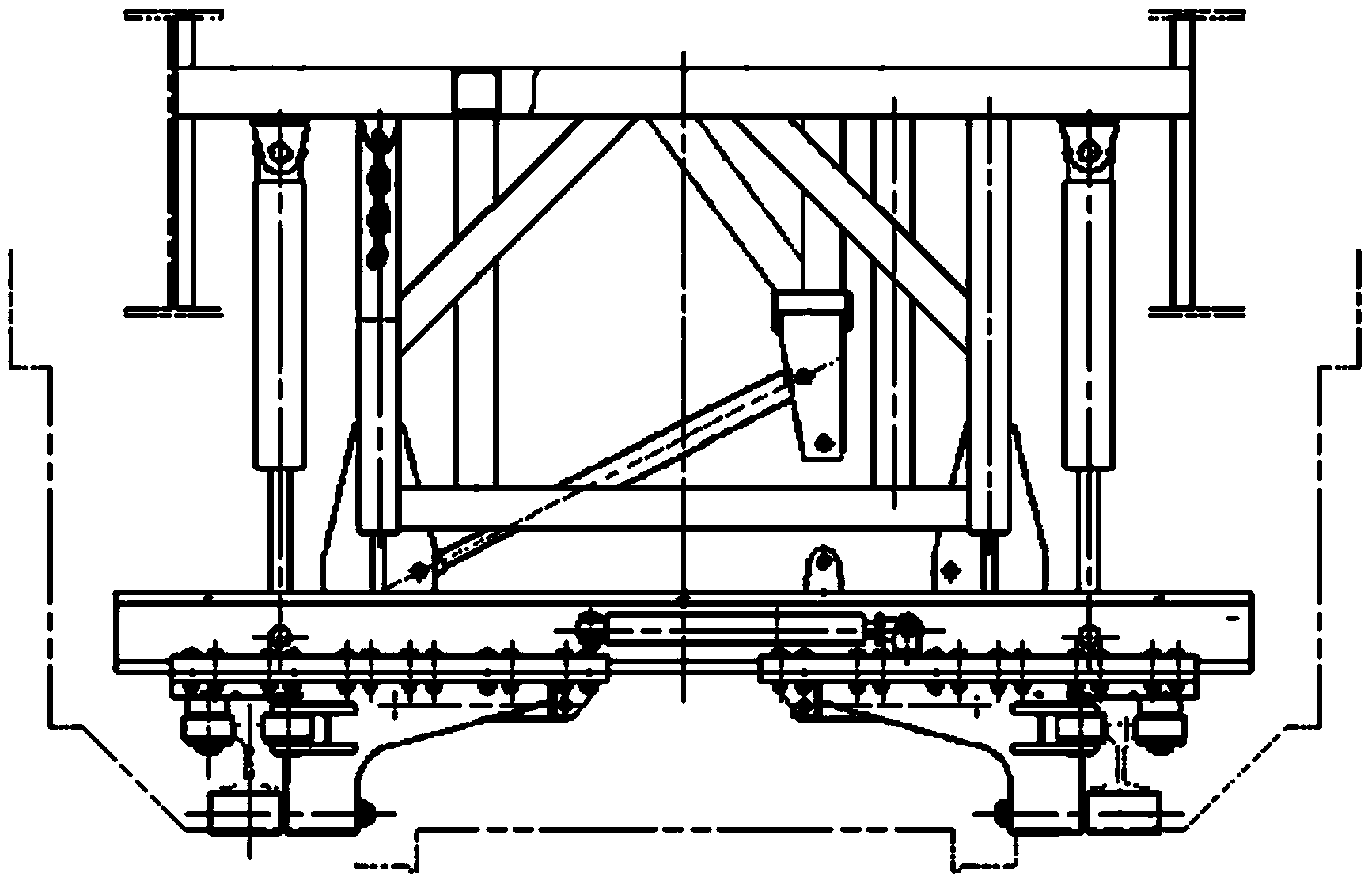

Apparatus For A Shot Peening Treatment

Impeller-type ejectors (2) are installed on the surfaces on both sides of a cabinet (1) defining an ejection chamber in the cabinet. Shots ejected from the ejectors (2) to a workpiece and fallen are conveyed in the horizontal direction by a horizontal screw conveyor (4) positioned above the lower end of the cabinet (1) and then conveyed upward by a vertical screw conveyer (5) whose base end is above the lower end of the cabinet (1). The shots pass from the upper section of the vertical screw conveyer (5) through a chute (8) to reach an opening / closing gate (9). When the gate (9) is opened and the shots are supplied to the ejectors (2) for re-ejection, a portion of the shots is caused to overflow from the gate (9). The overflowed shots are caused to pass through a separator (11) and a sieve device (15) to remove impurities and then returned to the horizontal screw conveyor (4).

Owner:SINTOKOGIO LTD

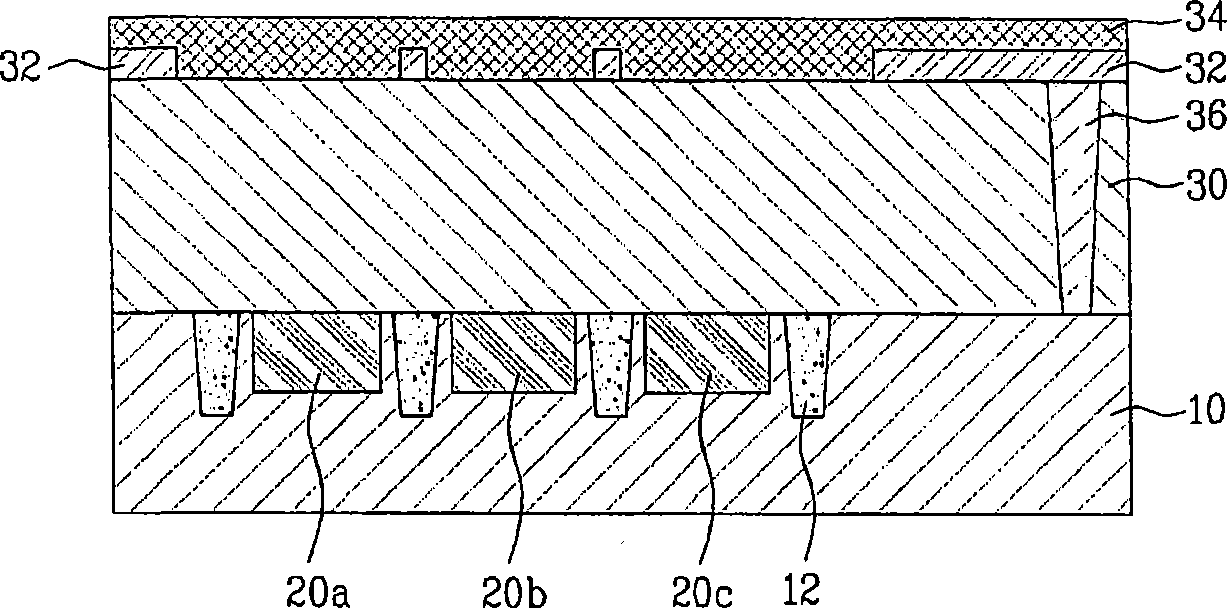

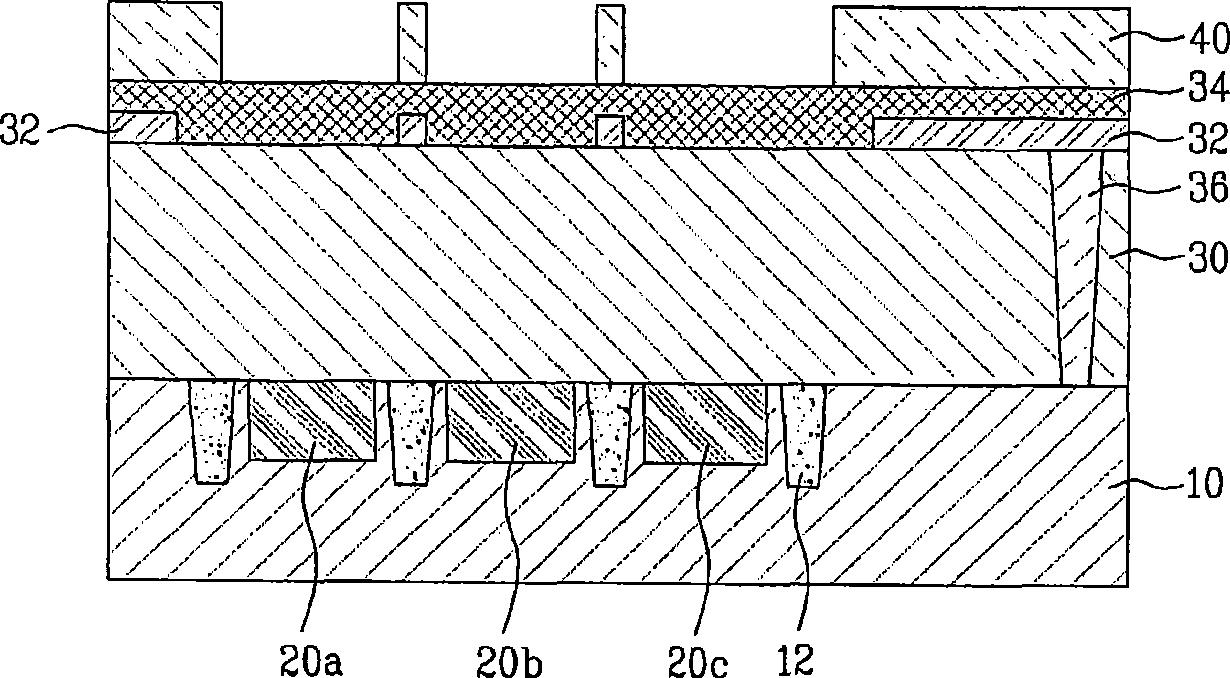

Three-dimensional vacuum sensor and manufacturing method thereof

ActiveCN102923644AMiniaturizationIncrease the upper limit of pressure measurementDecorative surface effectsSolid-state devicesHeat conductingEngineering

The invention provides a three-dimensional vacuum sensor and a manufacturing method of the three-dimensional vacuum sensor. A thermo-electric pile and a heater manufactured by adopting the method are located on different planes, and the thermo-electric pile is arranged on the heater, thus the miniaturization of the thermo-electric vacuum sensor can be further implemented. The shorter vertical distance between the micro heater to a substrate can be obtained by adopting a dry etching release structure through controlling the etching opening and the etching time, the pressure measurement upper limit of a heat conducting vacuum gauge can be improved, the problem of adhesion of a structural layer and the substrate can be avoided, and the rate of finished production of the devices can be improved. Due to the additional arrangement of a silicon cover plate, the thermal conductivity of the gas can be enhanced, and the sensitivity of the heat conducting vacuum gauge on the higher gas pressure end can be improved. In addition, the materials of the semiconductor substrate, the thermo-electric pile and the micro-heater and the preparation technology adopted in the invention are commonly used in the semiconductor process and can be easily compatible with the existing CMOS (complementary metal oxide semiconductor) process.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

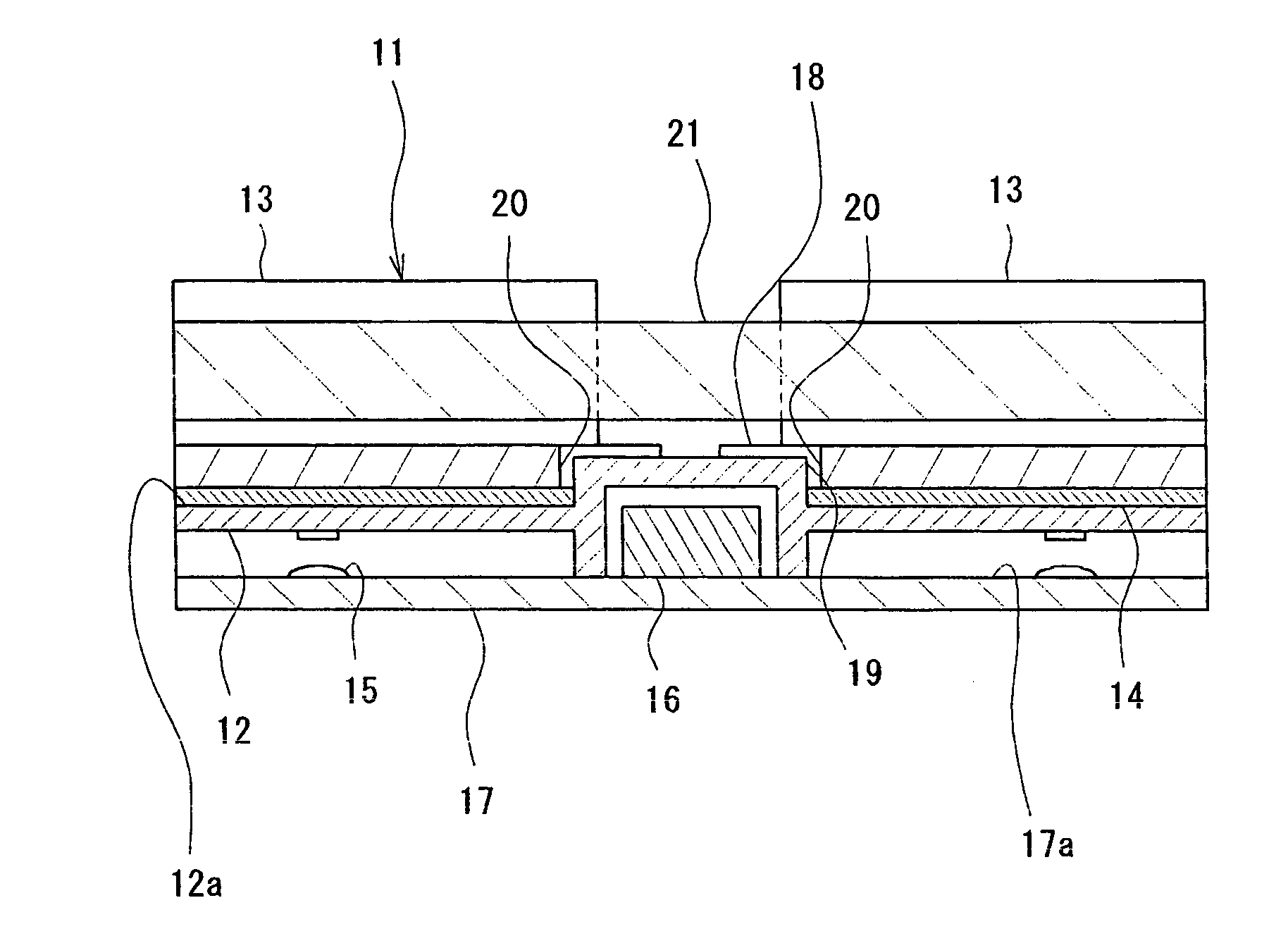

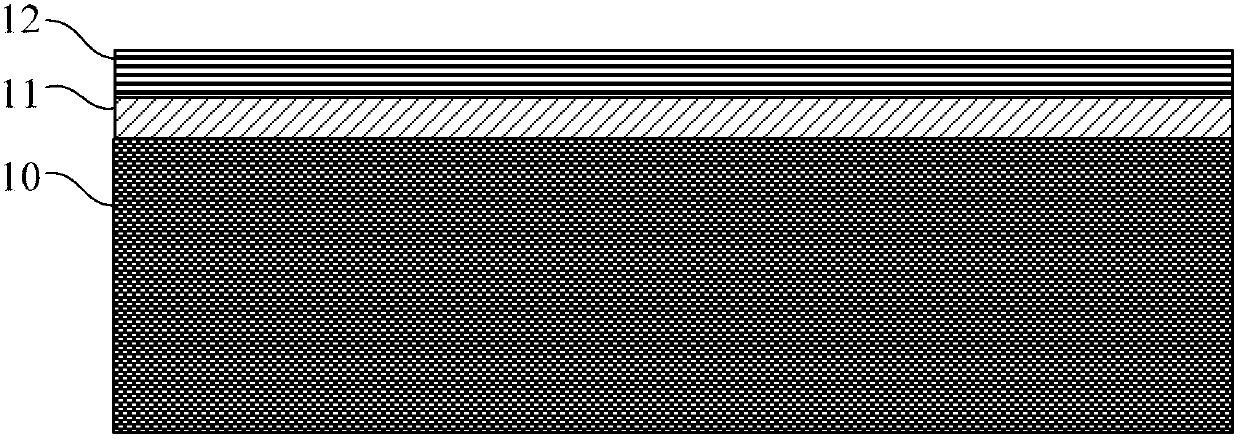

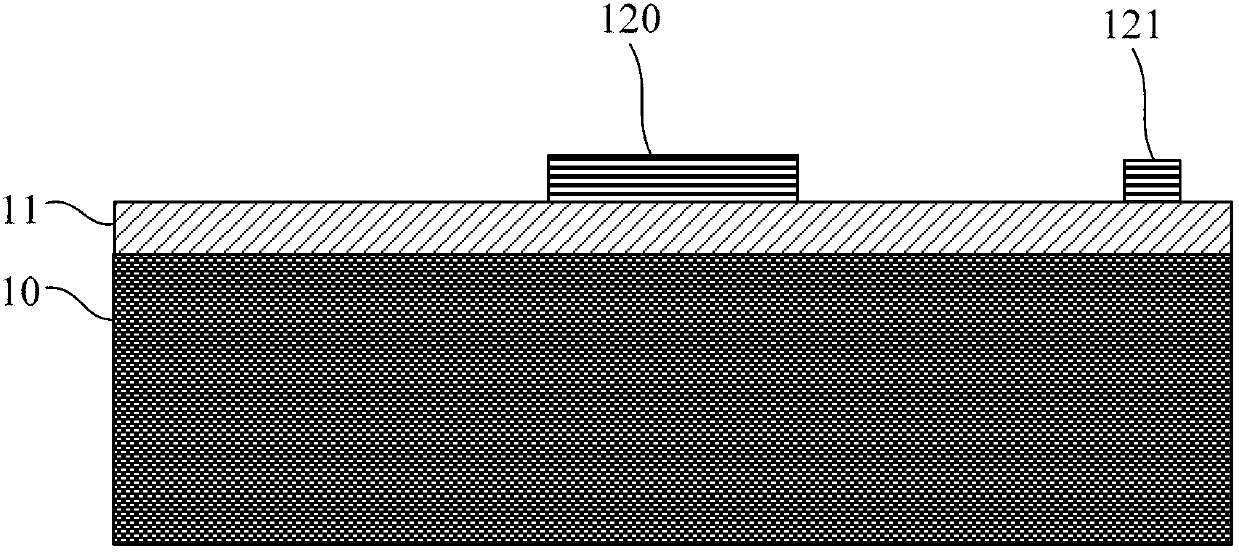

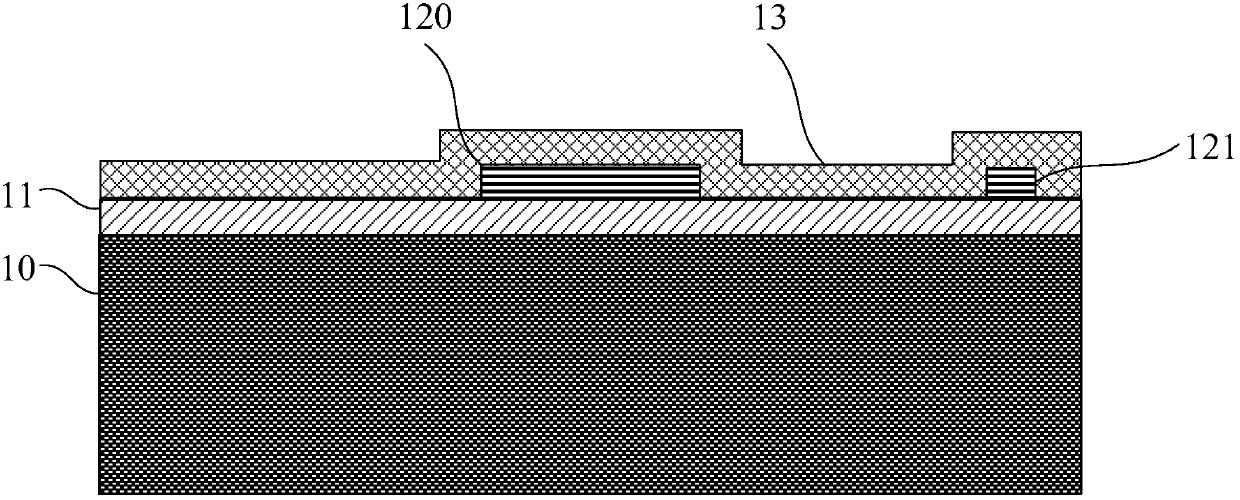

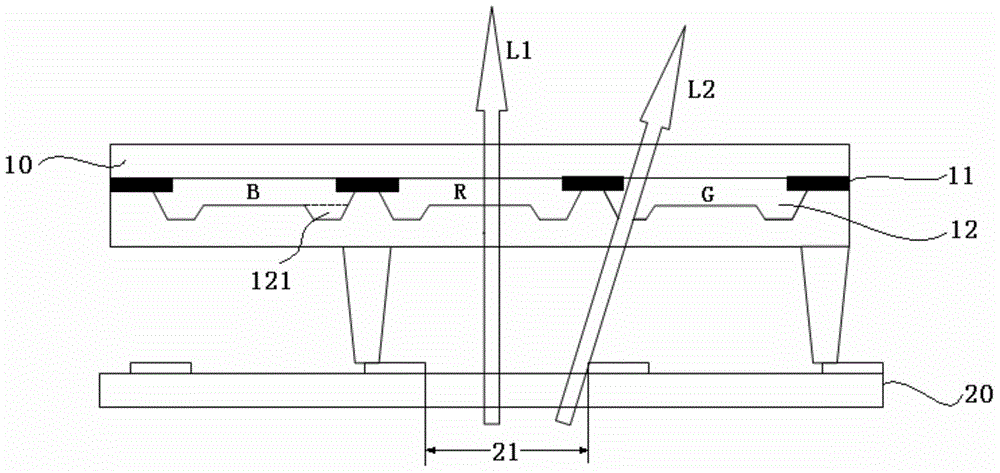

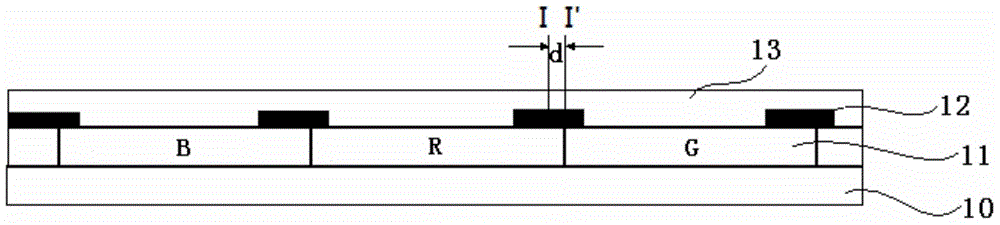

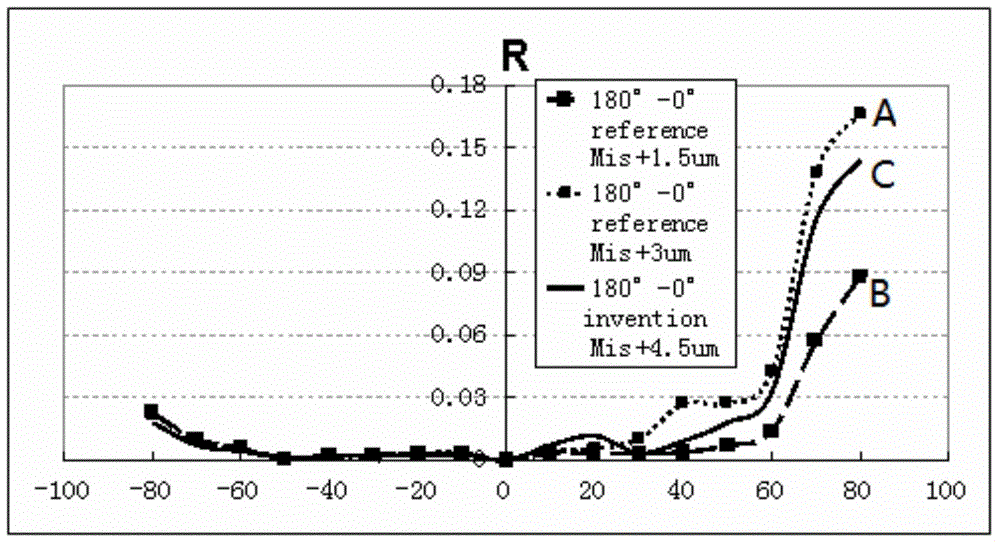

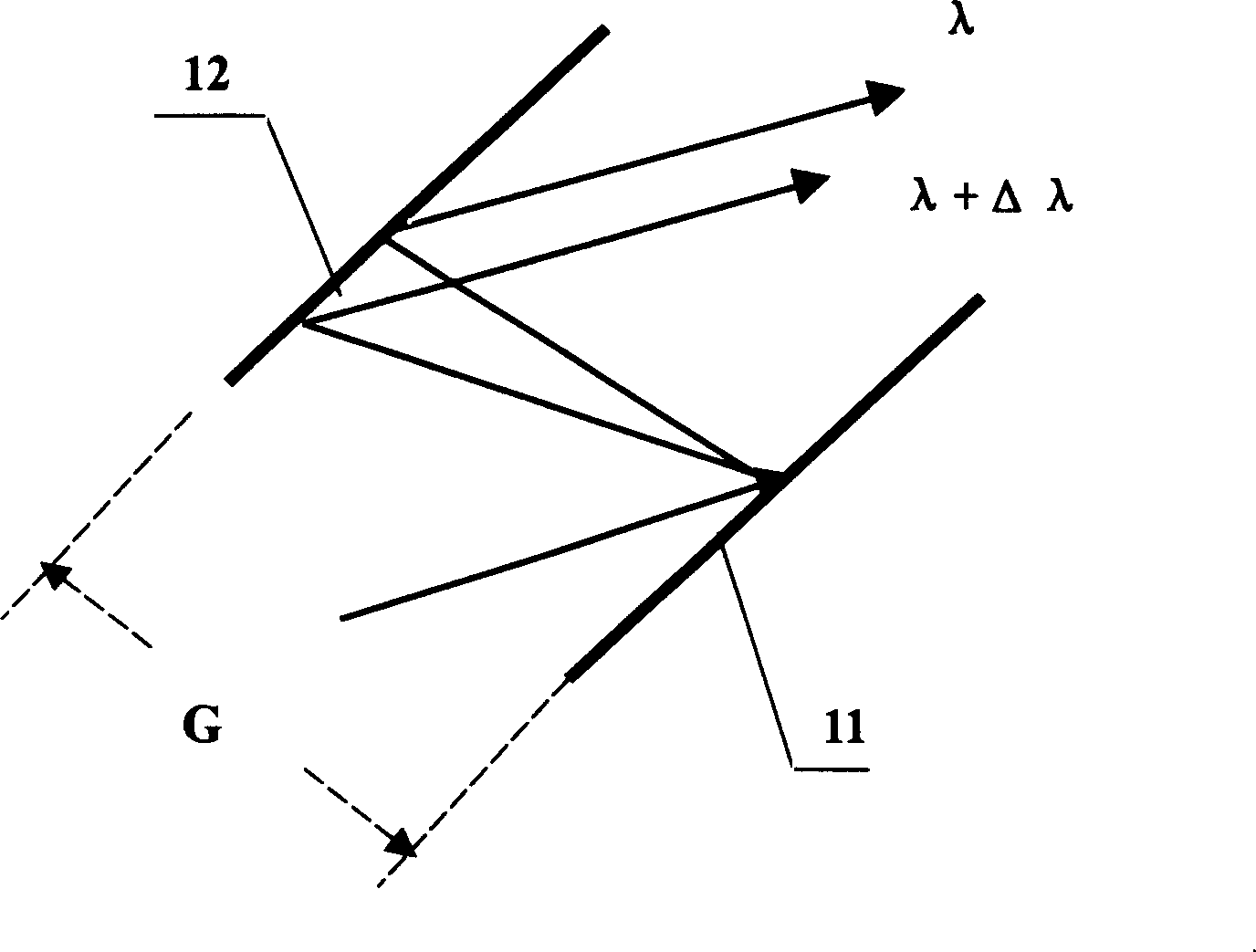

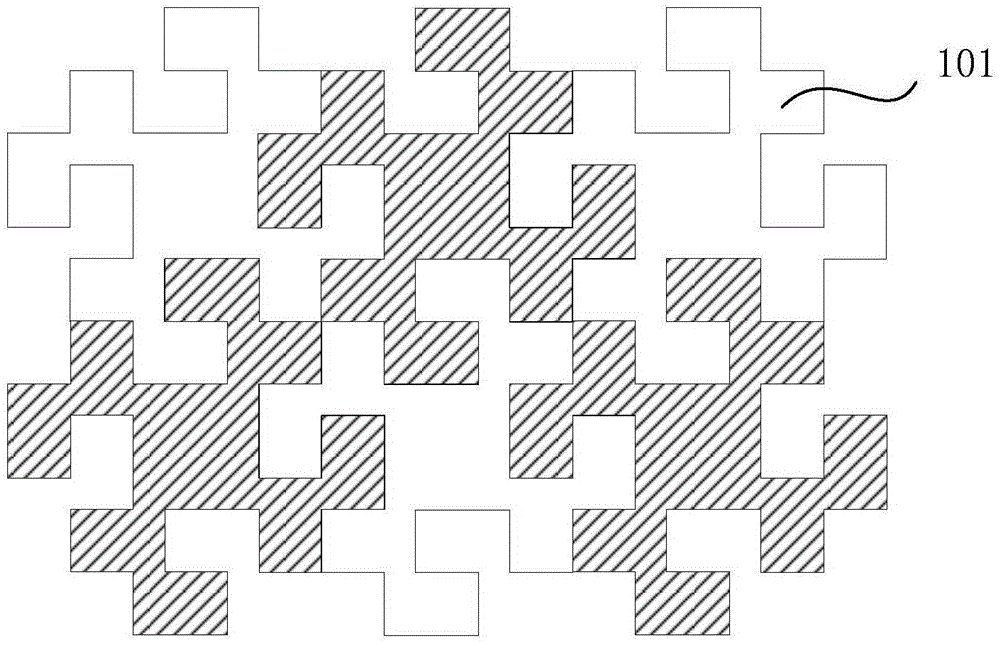

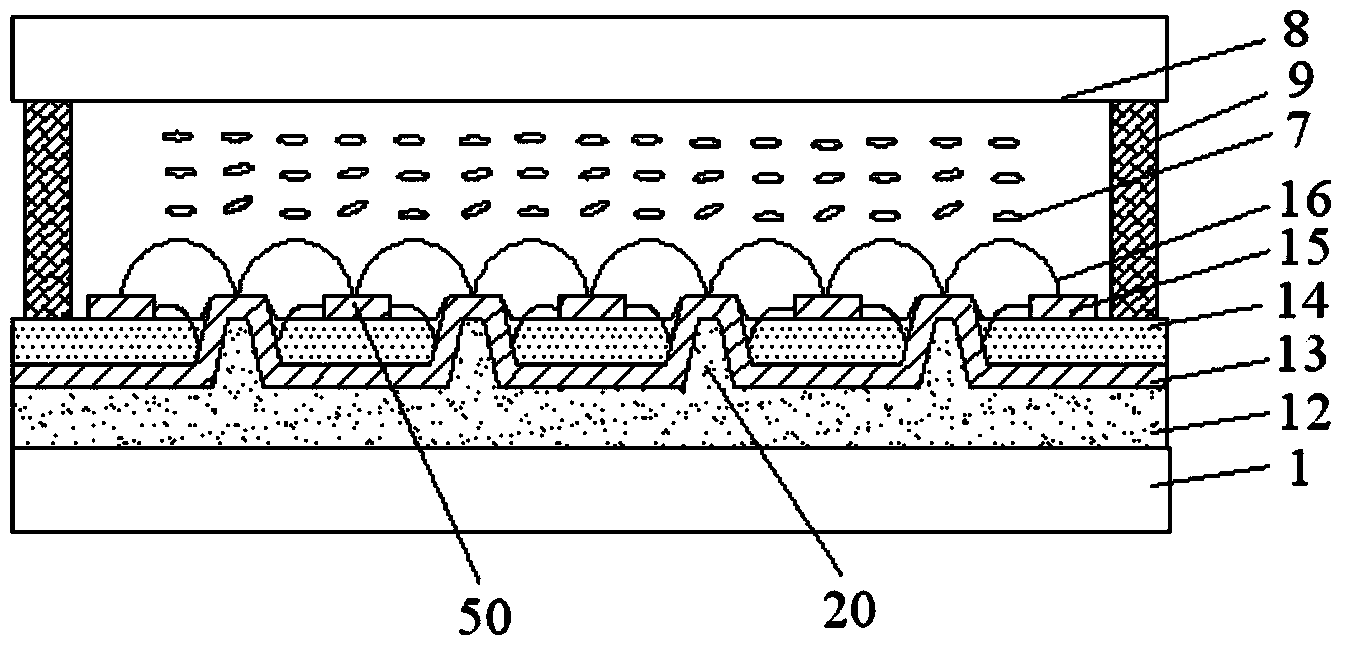

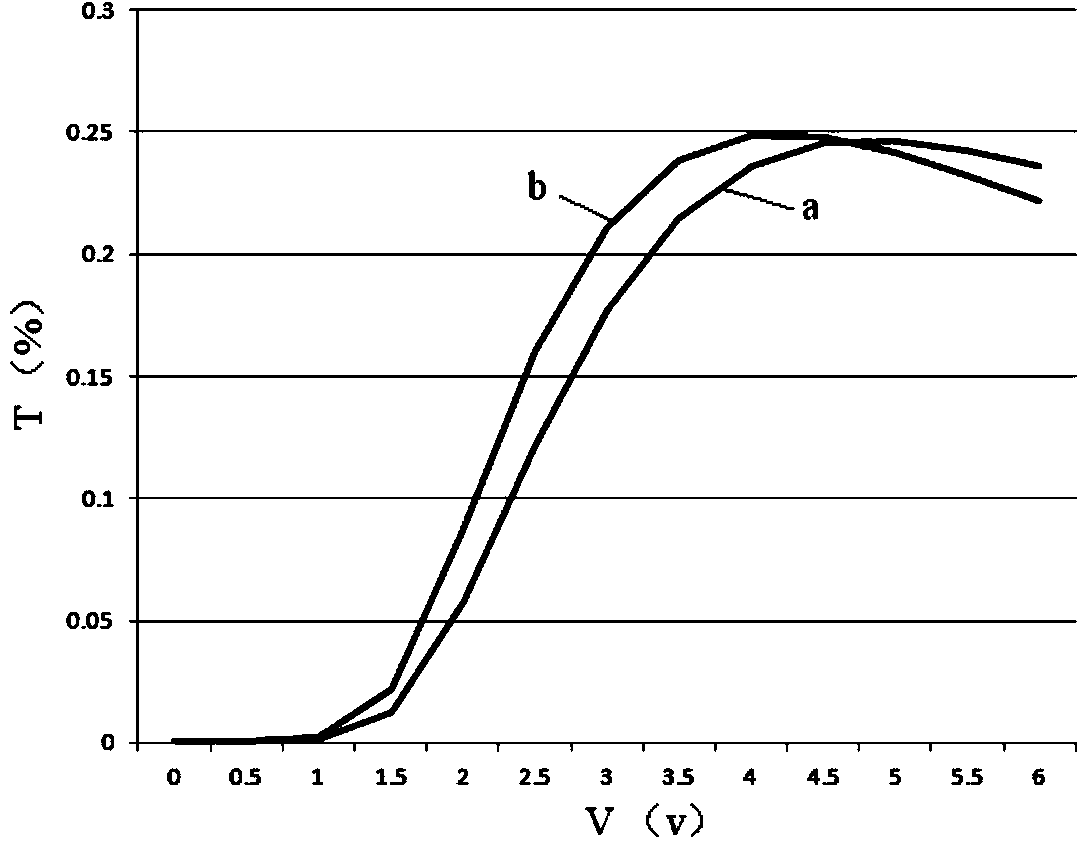

Colored film substrate, manufacturing method thereof and display device

InactiveCN103941462AShorten the vertical distanceQuality improvementNon-linear opticsDisplay deviceOptoelectronics

The invention discloses a colored film substrate. The colored film substrate comprises a substrate body, a color resistor layer and black matrixes, wherein the color resistor layer is directly arranged on the substrate body and comprises color resistors of different colors, and the black matrixes are directly arranged on the color resistor layer and arranged between every two adjacent color resistors. Due to the fact that the color resistor layer is directly formed on the substrate body and then the black matrixes are arranged on the color resistor layer, the perpendicular distance between the black matrixes and an array substrate is shortened, when light reaches the colored film substrate, unexpected emergent light is shielded through the black matrixes, the color cast phenomenon is reduced, the quality of displayed pictures is improved, and the yield of products is increased.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

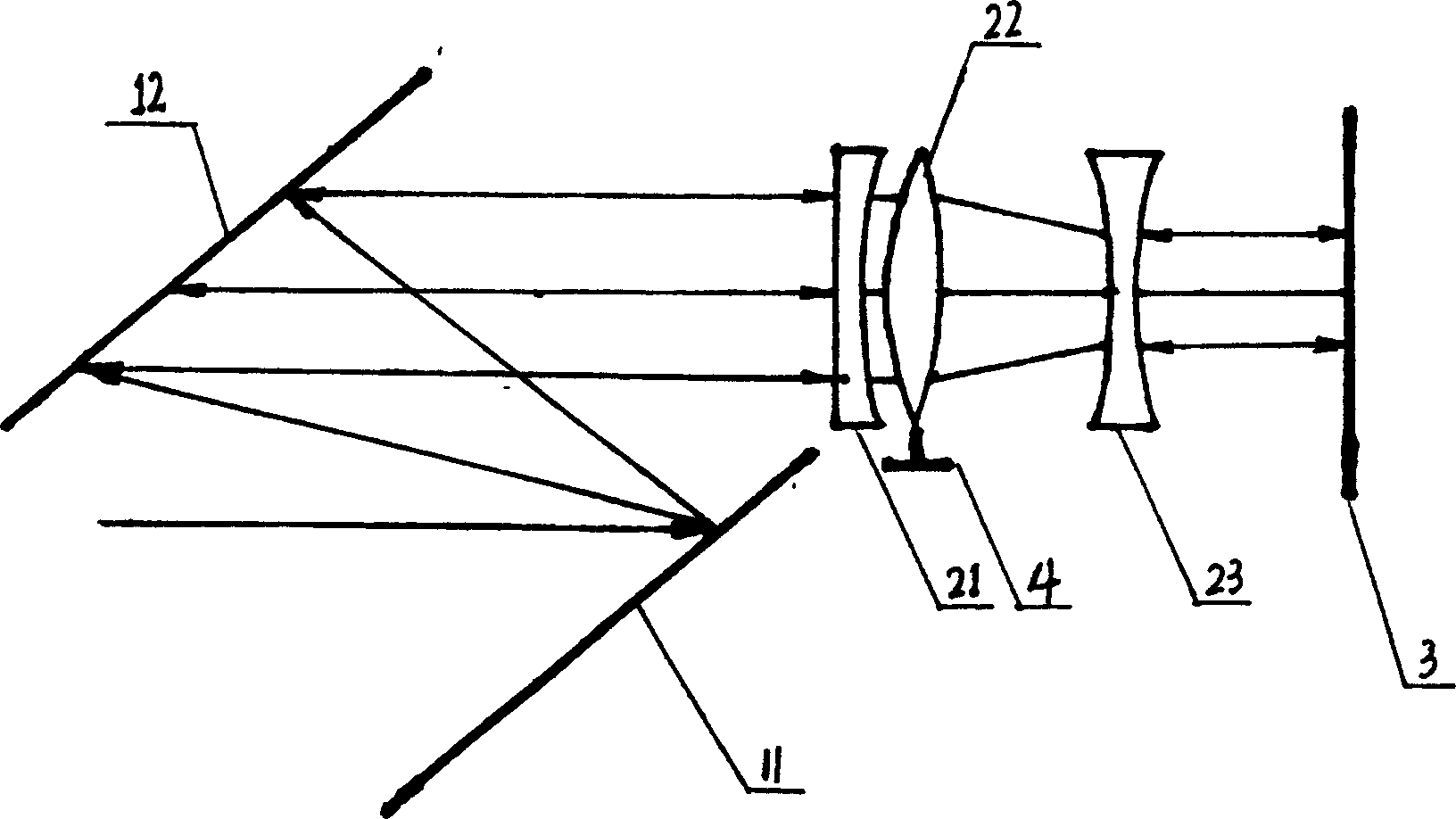

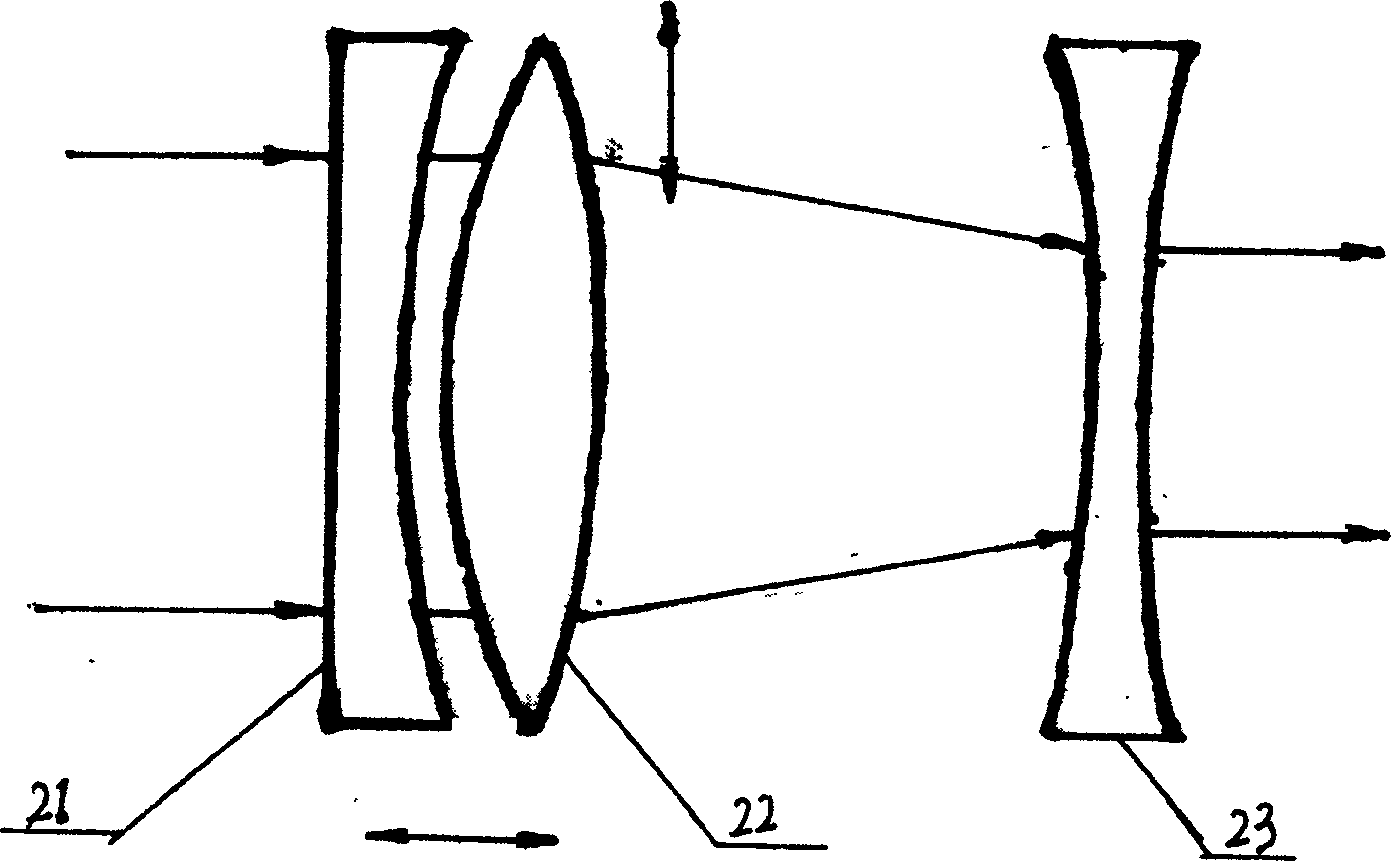

Chirp pulse compressor

InactiveCN1564051ADispersion does not affectEasy to adjustNon-linear opticsOptical elementsGratingLenticular lens

Chirp pulse shortener includes grating pair parallel each other, telescope system and holophote. The telescope consists of plano concave lens, biconvex lens and biconcave lens in sequence. The biconvex lens is placed in a manual translation desk movable in height and along rotation axis. Combination lens composed of plano concave lens and biconvex lens is virtual confocal with biconcave lens. The invented chirp pulse shortener compensates second order, third order and fourth order dispersions effectively without generating obvious energy loss and waveform distortion, and compression ratio is doubled.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

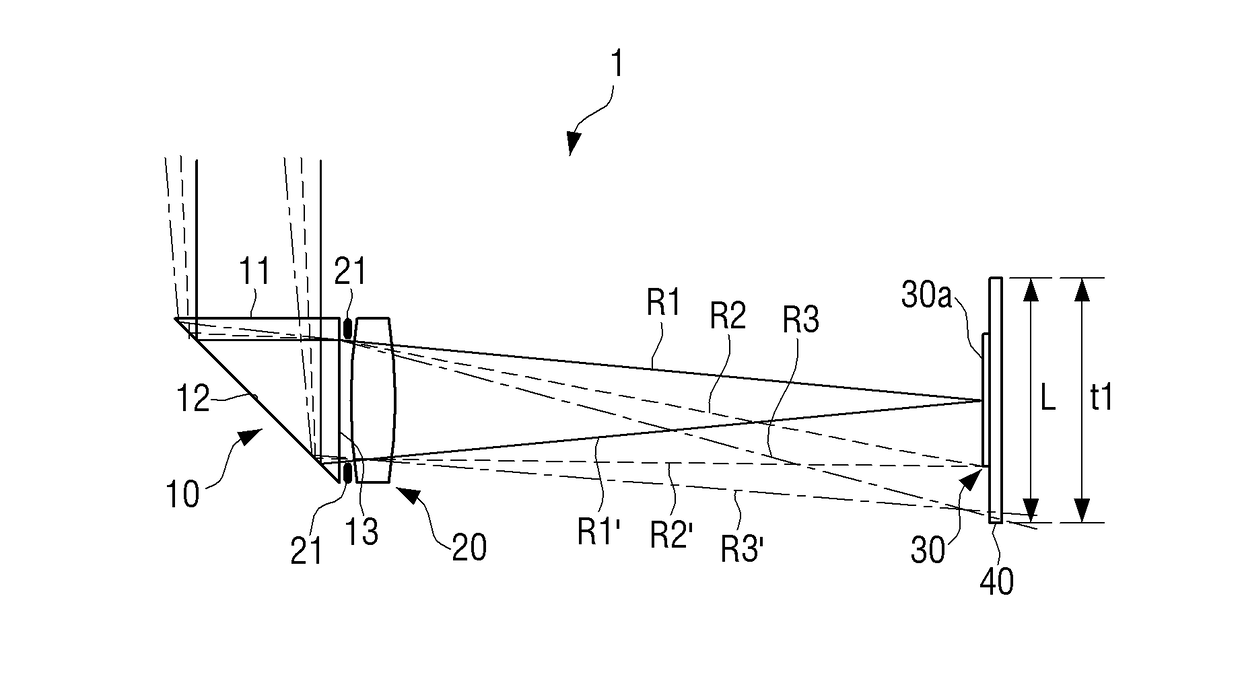

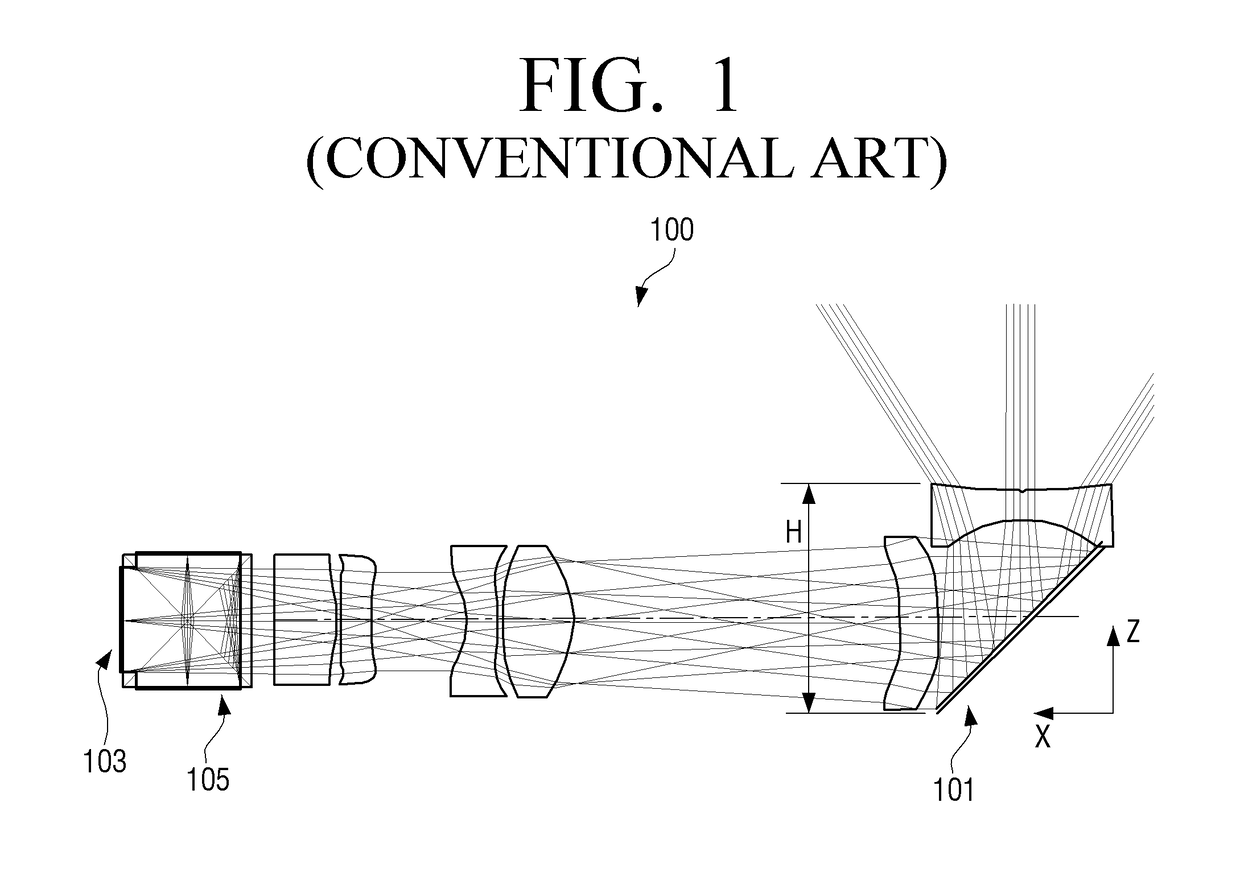

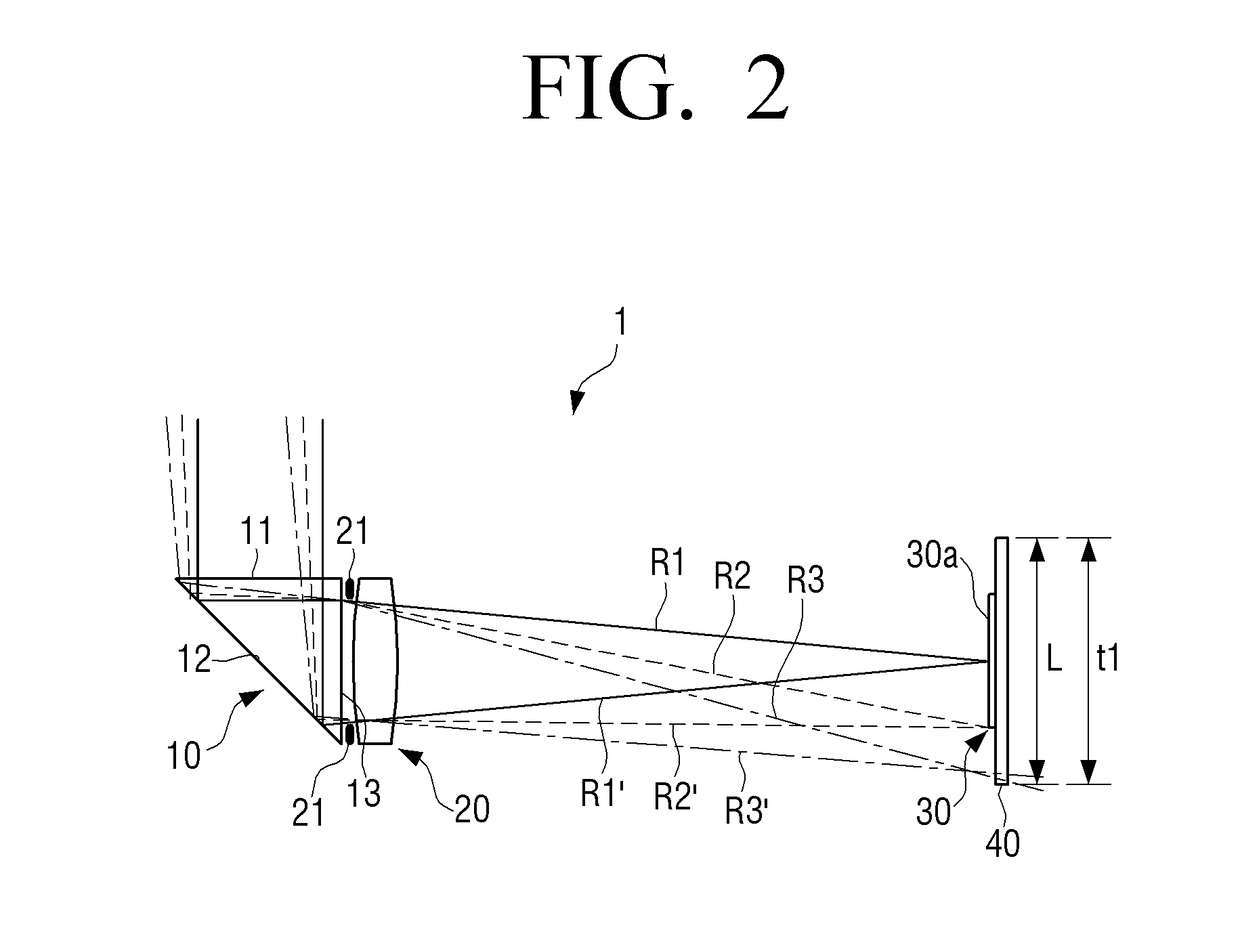

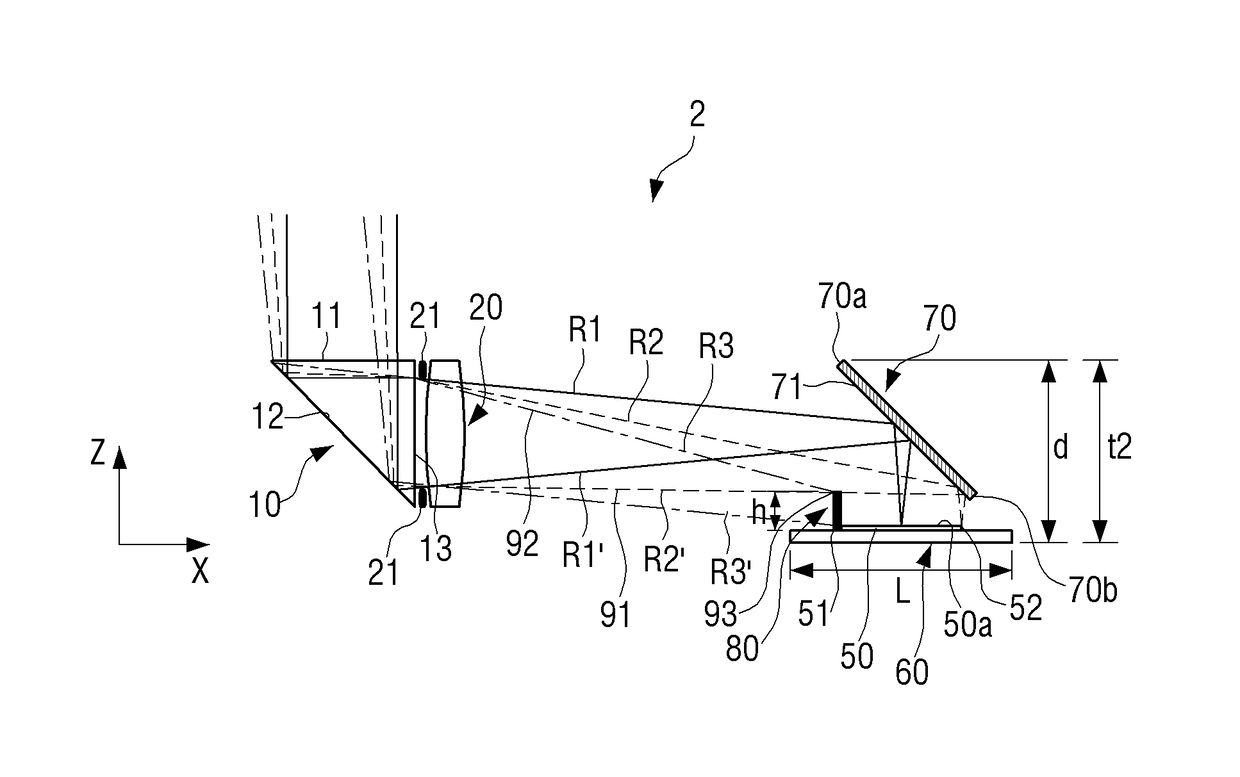

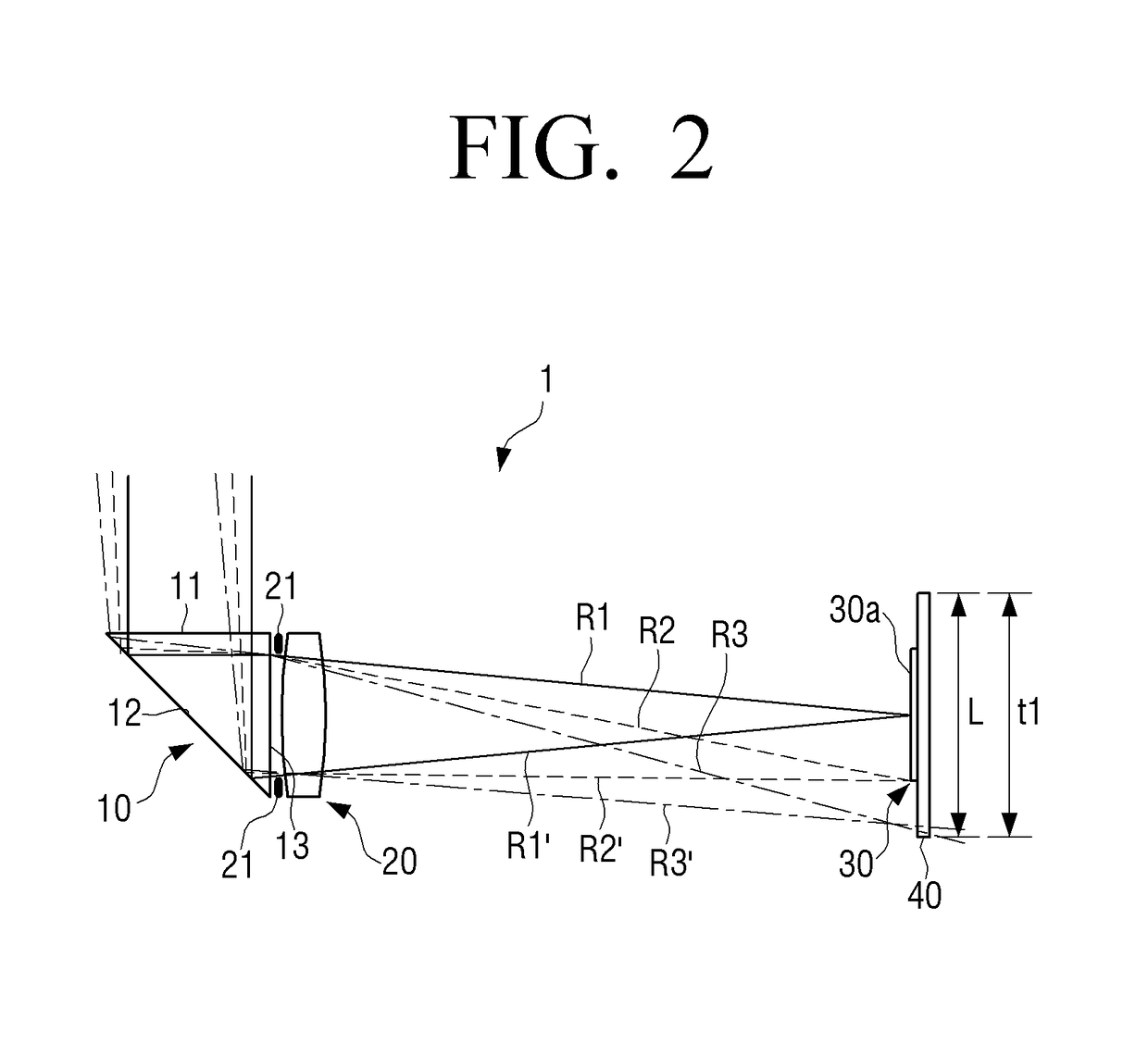

Reflecting imaging apparatus and mobile device having the same

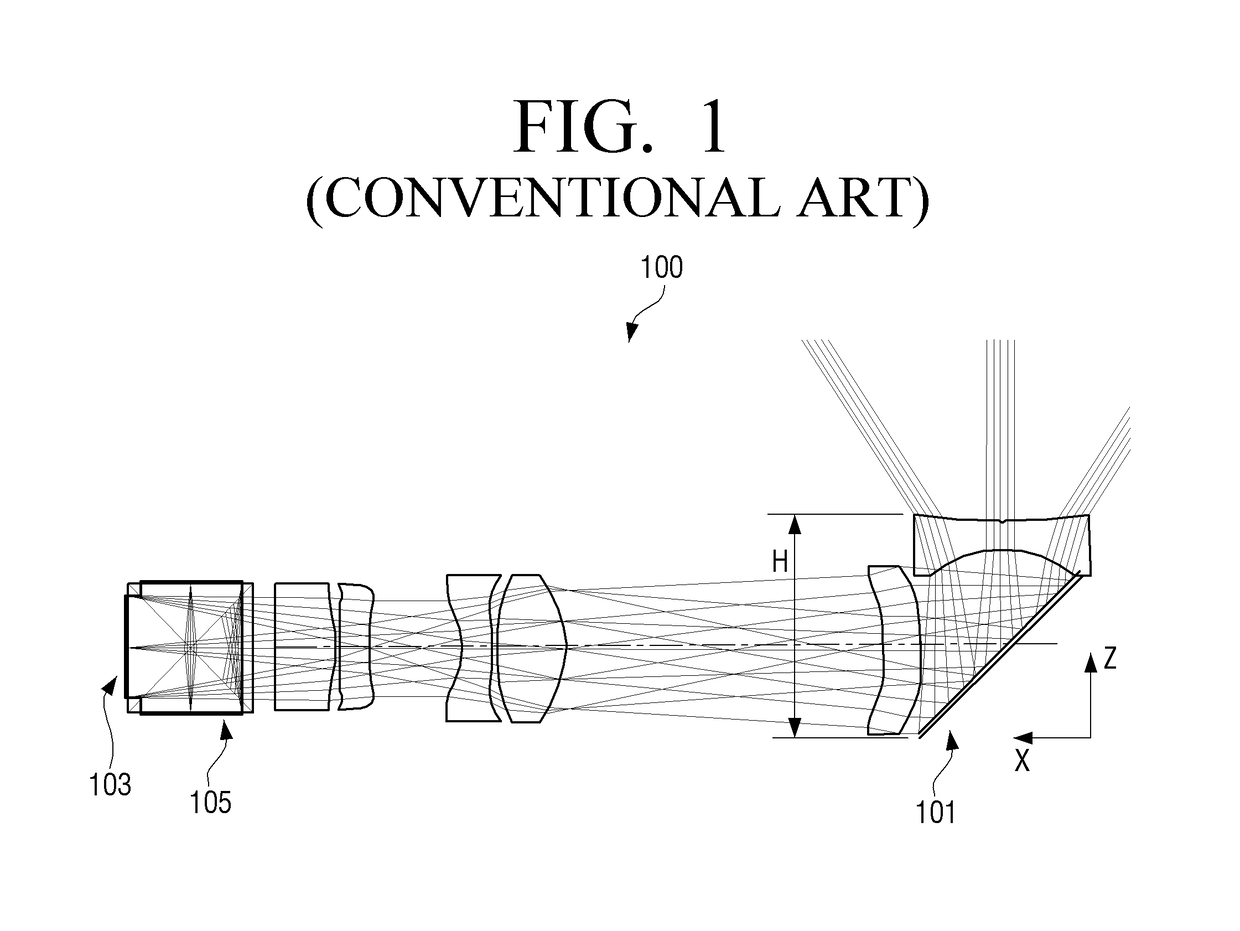

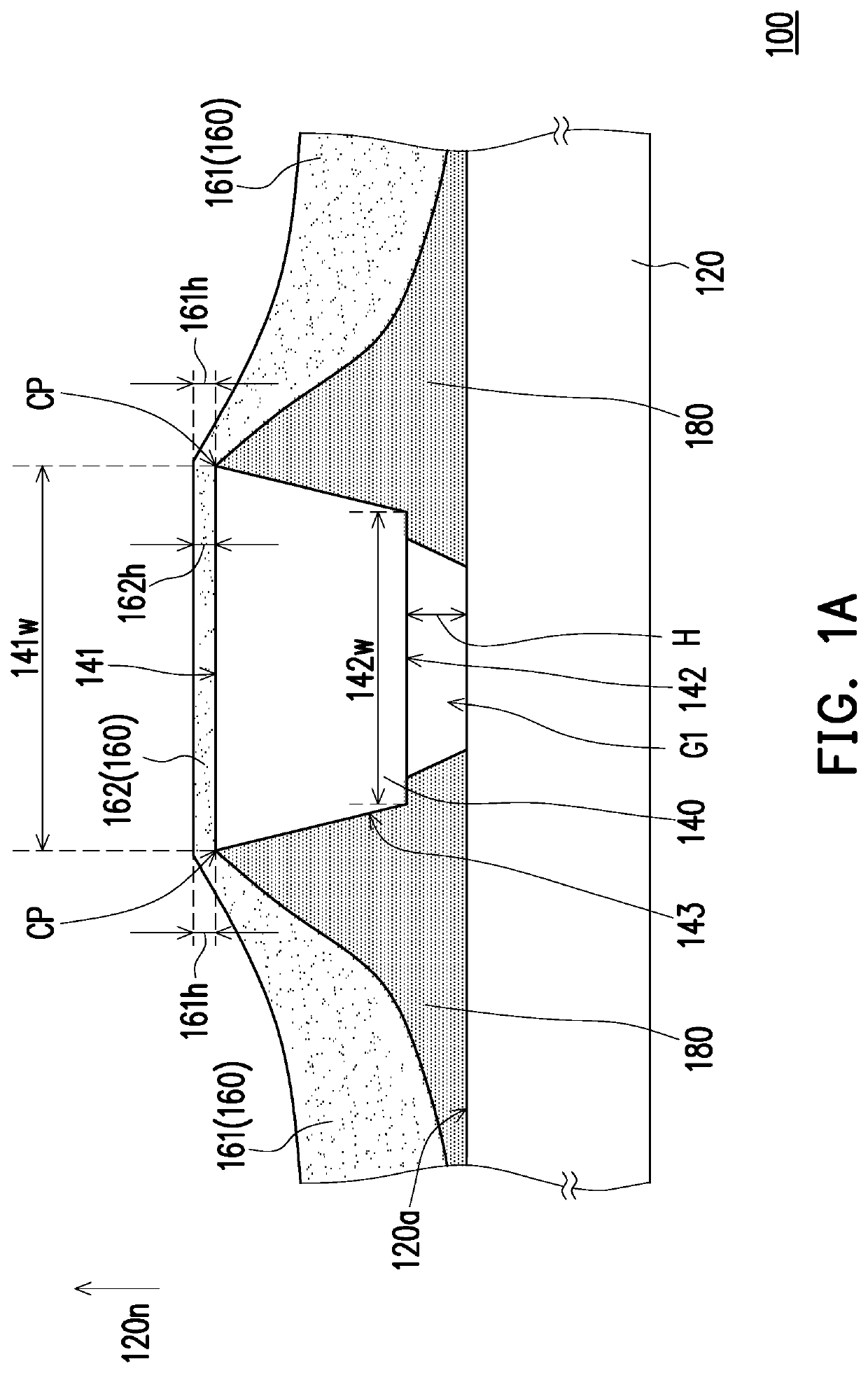

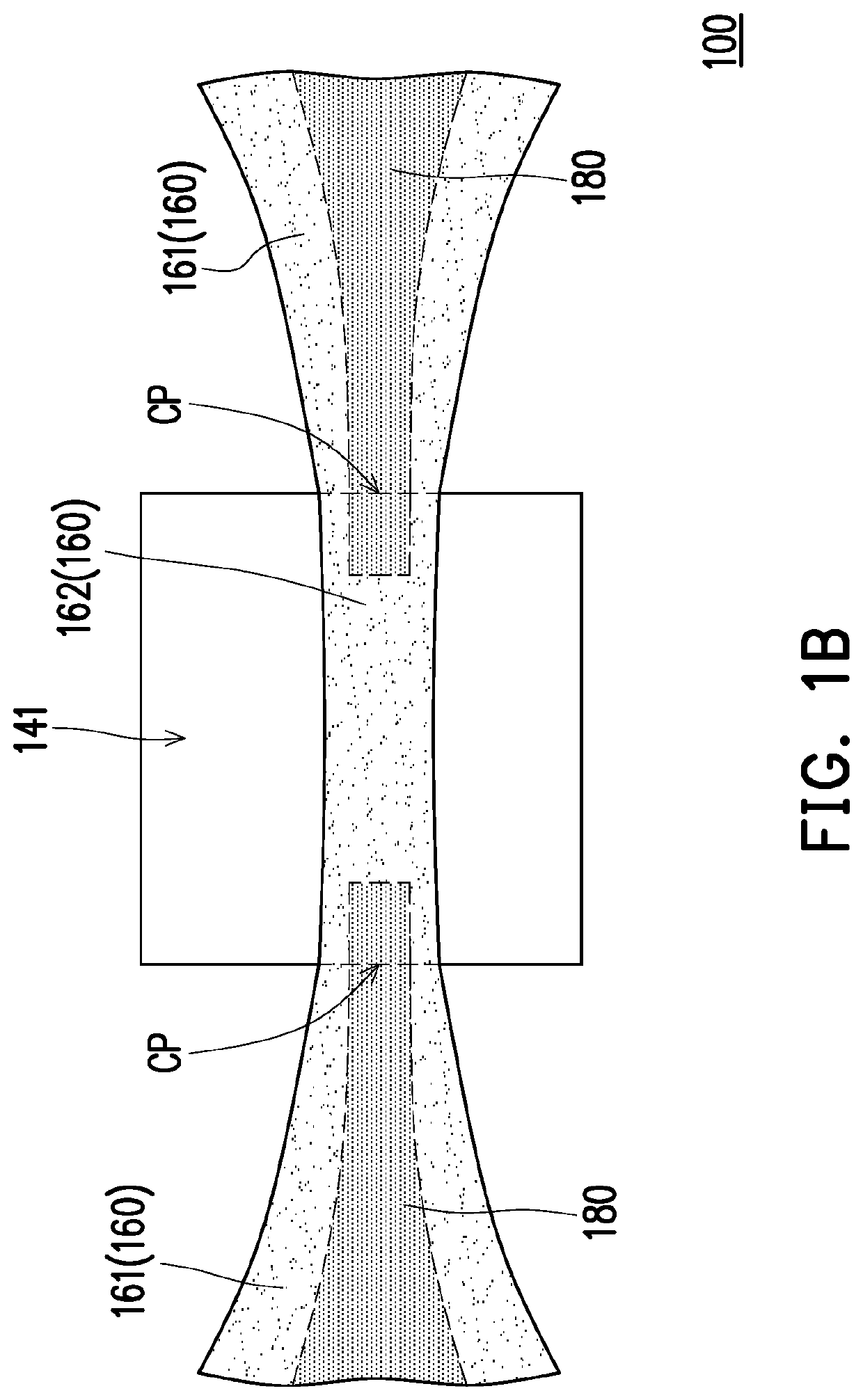

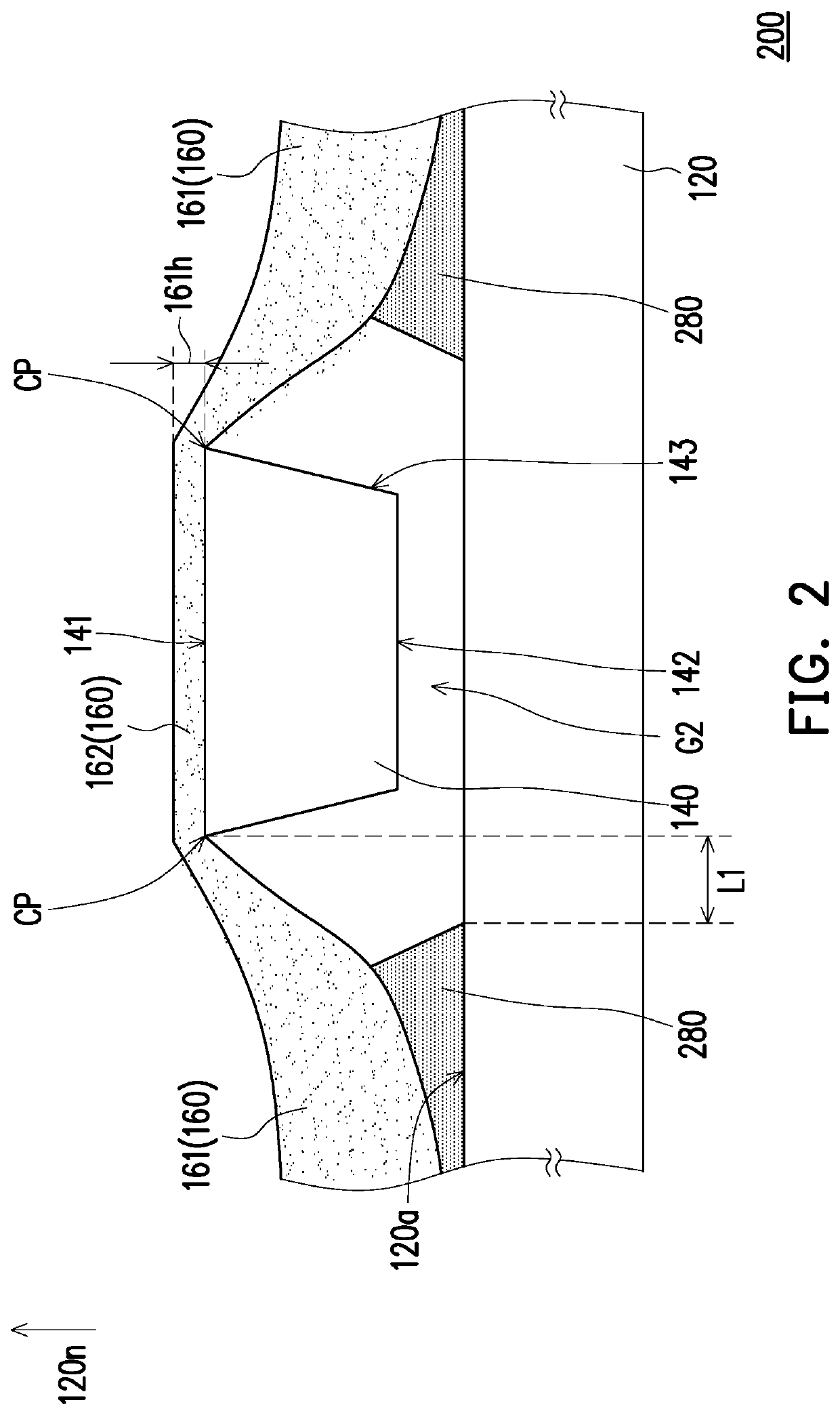

ActiveUS20170131526A1Shorten the vertical distanceReduce stray lightTelevision system detailsColor television detailsImage sensorStray light

A reflection type imaging apparatus includes a deflector that reflects light incident from an outside; a reflecting mirror that reflects the light reflected by the deflector in a direction parallel to a direction in which the light is incident on the deflector; an image sensor that is disposed below the reflecting mirror and arranged perpendicular to the direction in which the light is incident on the deflector, wherein the light reflected by the reflecting mirror is focused on the image sensor; and a stray light blocking member disposed at one side of the image sensor facing the deflector, the stray light blocking member configured to block stray light rays from the deflector from being directly incident on the image sensor.

Owner:SAMSUNG ELECTRONICS CO LTD

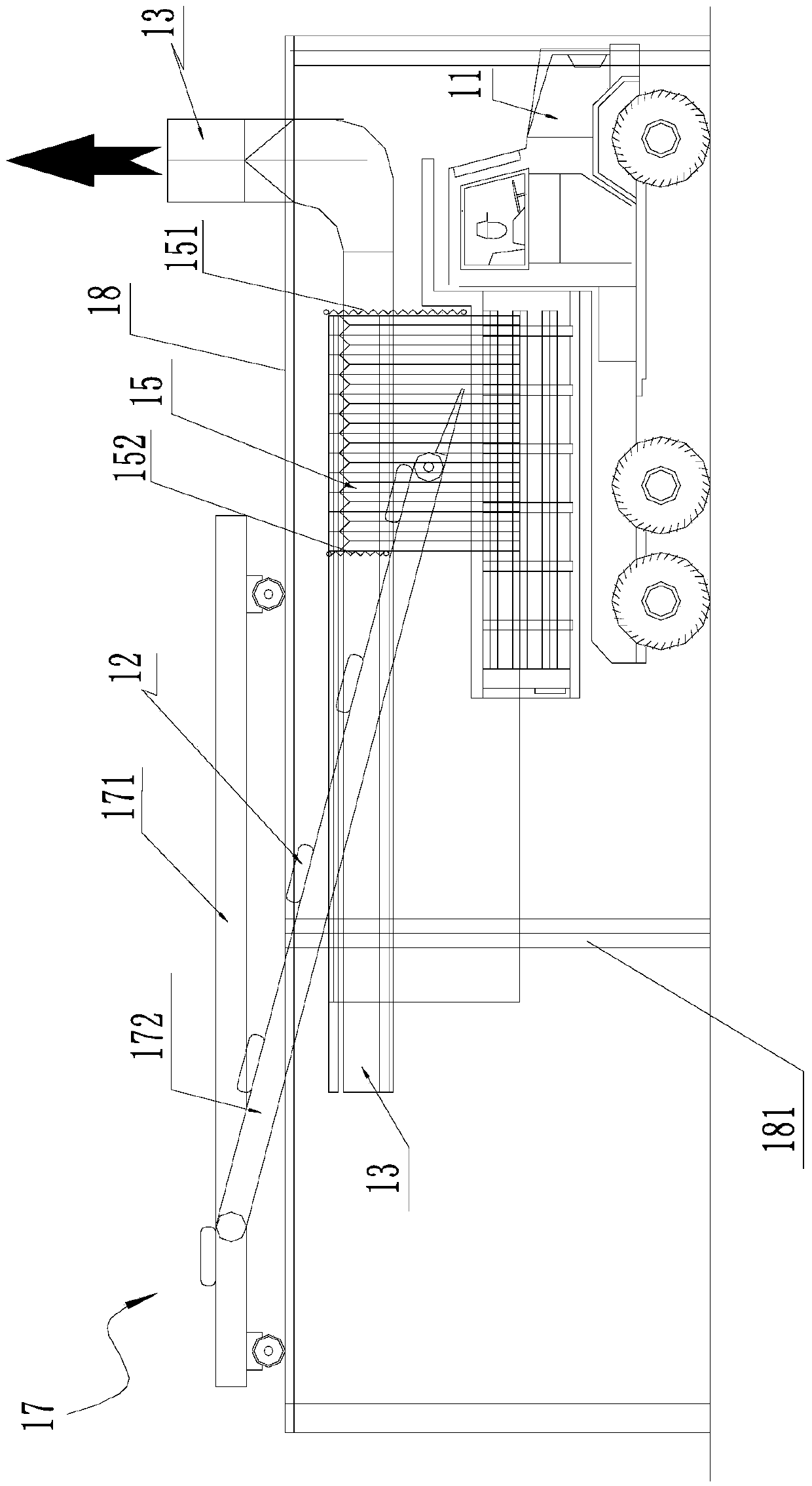

Truck loading dust collecting system

InactiveCN105523398AGuaranteed vacuuming effectPush down easilyLoading/unloadingNational standardEngineering

The invention discloses a truck loading dust collecting system for collecting dust generated by loading dust bags in a loading truck. The truck loading dust collecting system comprises a negative-pressure dust collecting device and a dust sucking pipe, wherein the negative-pressure dust collecting device includes a negative-pressure generator, and a negative-pressure dust collecting pipe connected with the negative-pressure generator; the internal of the negative-pressure dust collecting pipe is in a negative-pressure state; one end of the negative-pressure dust collecting pipe extends above a carriage of the loading truck, and is provided with a dust collecting port towards a carriage; the dust sucking pipe is arranged along the inner wall of the side wall of the carriage of the loading truck, and is communicated with the negative-pressure dust collecting pipe through a joint; and multiple dust sucking ports are formed in one side, towards the dust bags, of the dust sucking pipe. The technical problem to be solved by the invention is to overcome the defect of bad dust pollution around and in the carriage caused by low dust collecting quantity of a traditional truck loading dust collecting device; and the invention provides the truck loading dust collecting system capable of greatly increasing the dust collecting quantity and enabling the content of dust in the truck loading environment to accord with the national standard.

Owner:高玉宗

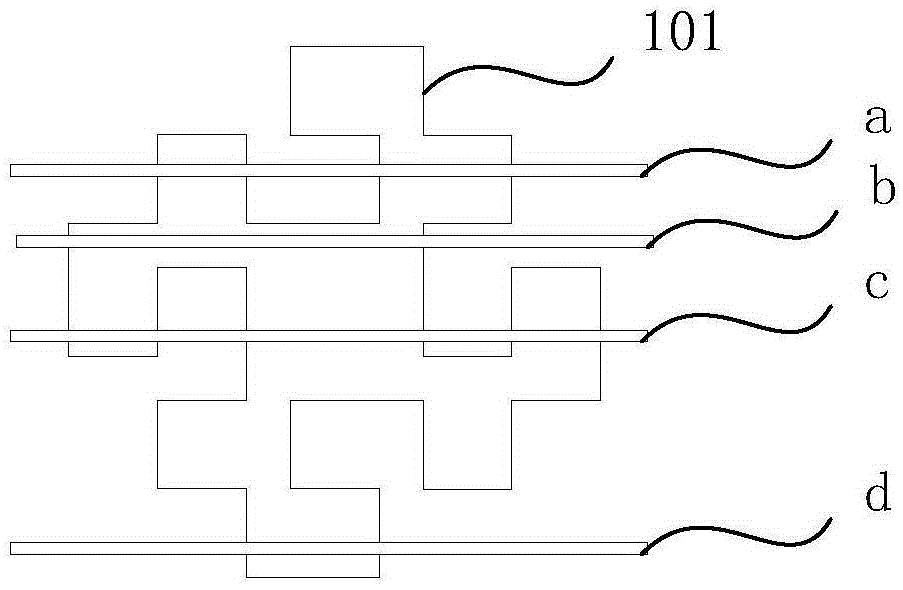

Display panel and display device

ActiveCN105677126AShorten the vertical distanceReduce the difficulty of judgmentNon-linear opticsDigital output to display deviceCapacitanceCoupling

The invention discloses a display panel and a display device. The display panel comprises a first baseplate and a second baseplate opposite to the first baseplate, wherein the first baseplate comprises a plurality of touch-control electrodes distributed in an array manner; the second baseplate comprises a plurality of touch-control auxiliary electrodes, and each touch-control auxiliary electrode and parts of two adjacent touch-control electrodes are overlapped in a projection manner in the direction perpendicular to the second baseplate, wherein the overlapped parts of the touch-control auxiliary electrode and the touch-control electrodes are the same in shape. When touch operation is generated in the display panel, coupling capacitance is formed between a touch-control medium and the touch-control auxiliary electrodes, further coupling capacitance is formed between the touch-control auxiliary electrodes and the touch-control electrodes, which is equivalent to reduction of the perpendicular distance of the touch-control medium and the touch-control electrodes; one time of touch operation can correspond to more touch-control electrodes, and the touch-control position judgment difficulty and the touch-control operation accuracy requirement are reduced.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

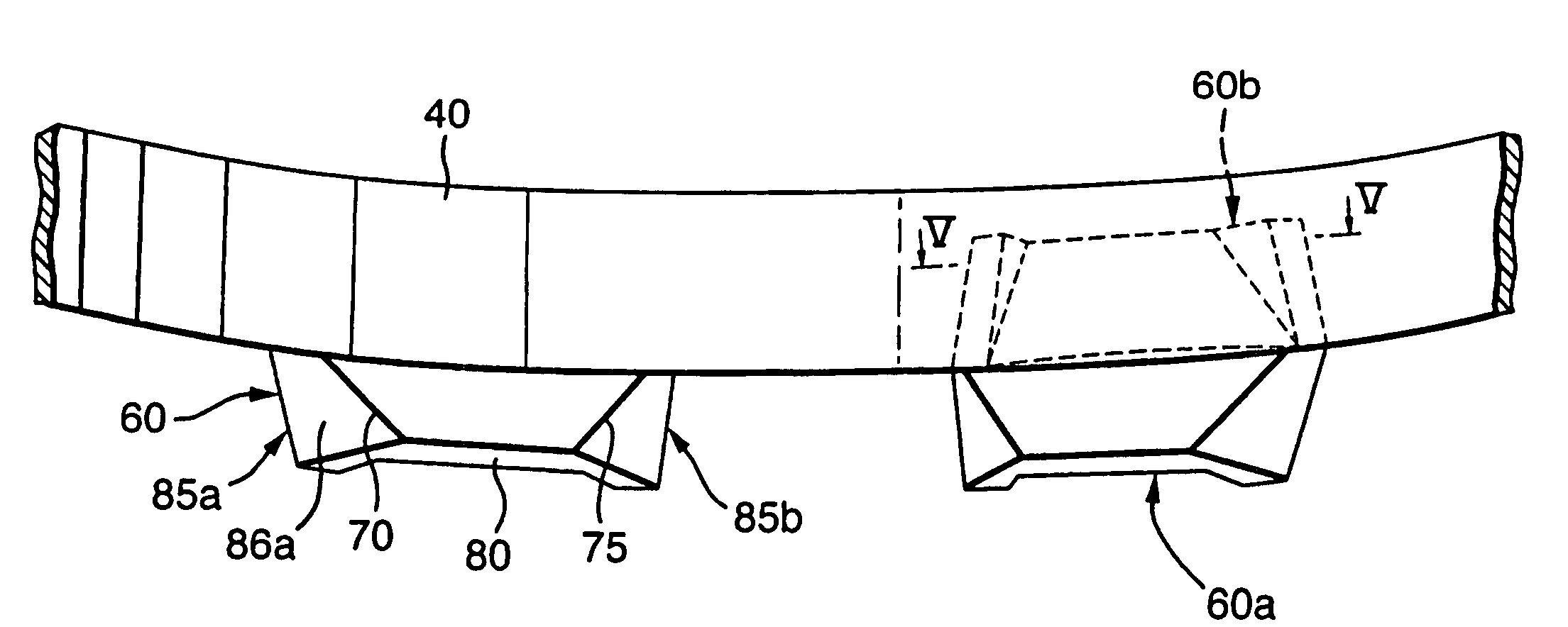

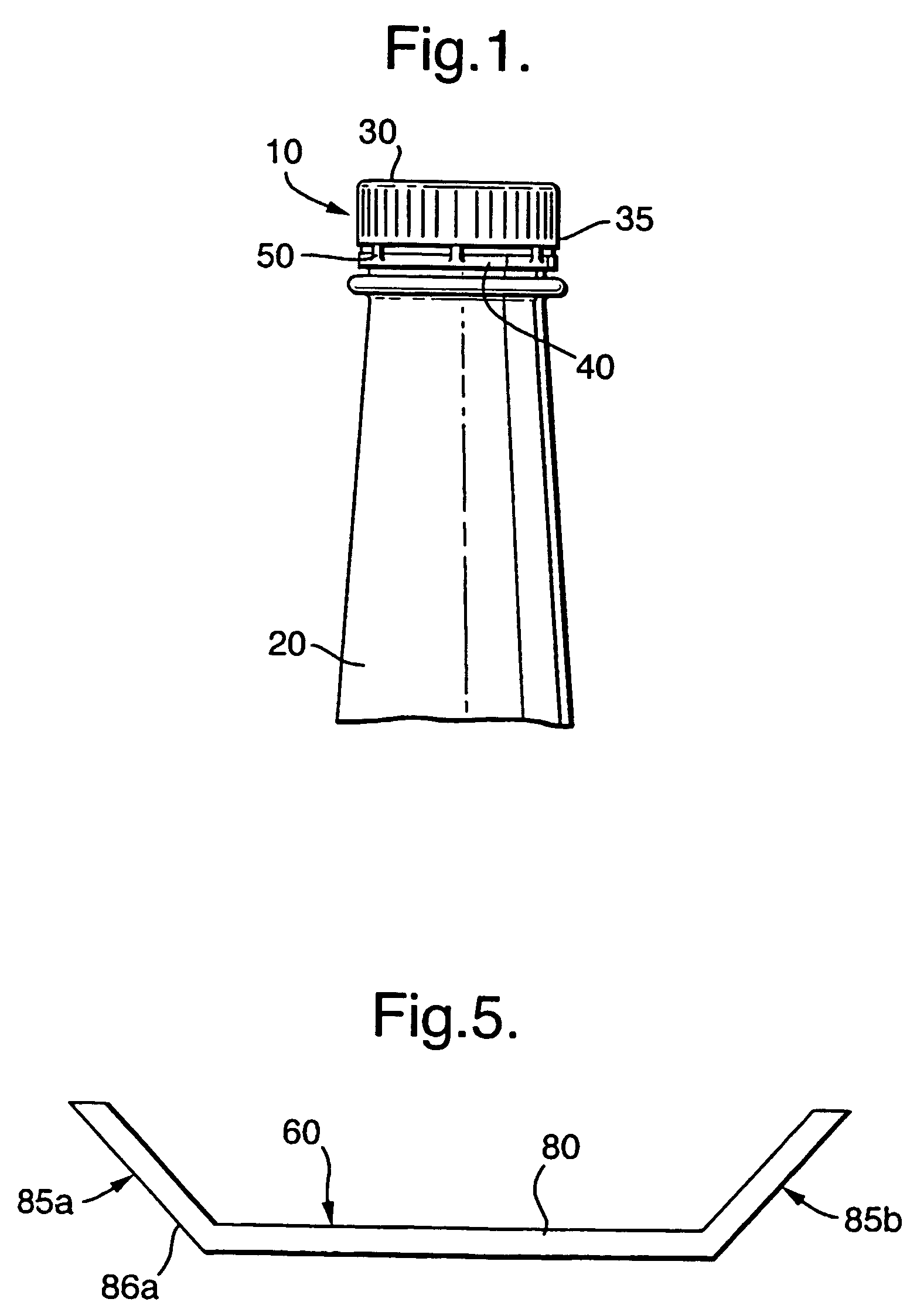

Closure cap

InactiveUS7445130B2Reduce the angleShorten the lengthCapsClosure using stoppersEngineeringMechanical engineering

A closure (10) is provided and includes a tamper-evident band (40). The band (40) has a plurality of retaining flaps (60) which engage under a container neck annular retaining bead (23) when the closure is first applied. The flaps have a ratchet surface (86a, 190) for engaging a complimentary surface on the container neck (20). The flaps also have spacer means (85a, 85b, 186) for pushing them into a more vertical inclination under the bead (23). The ratchet arrangement and spacer means ensure reliable separation of the tamper-evident band (40).

Owner:OBRIST CLOSURES SWITZERLAND GMBH

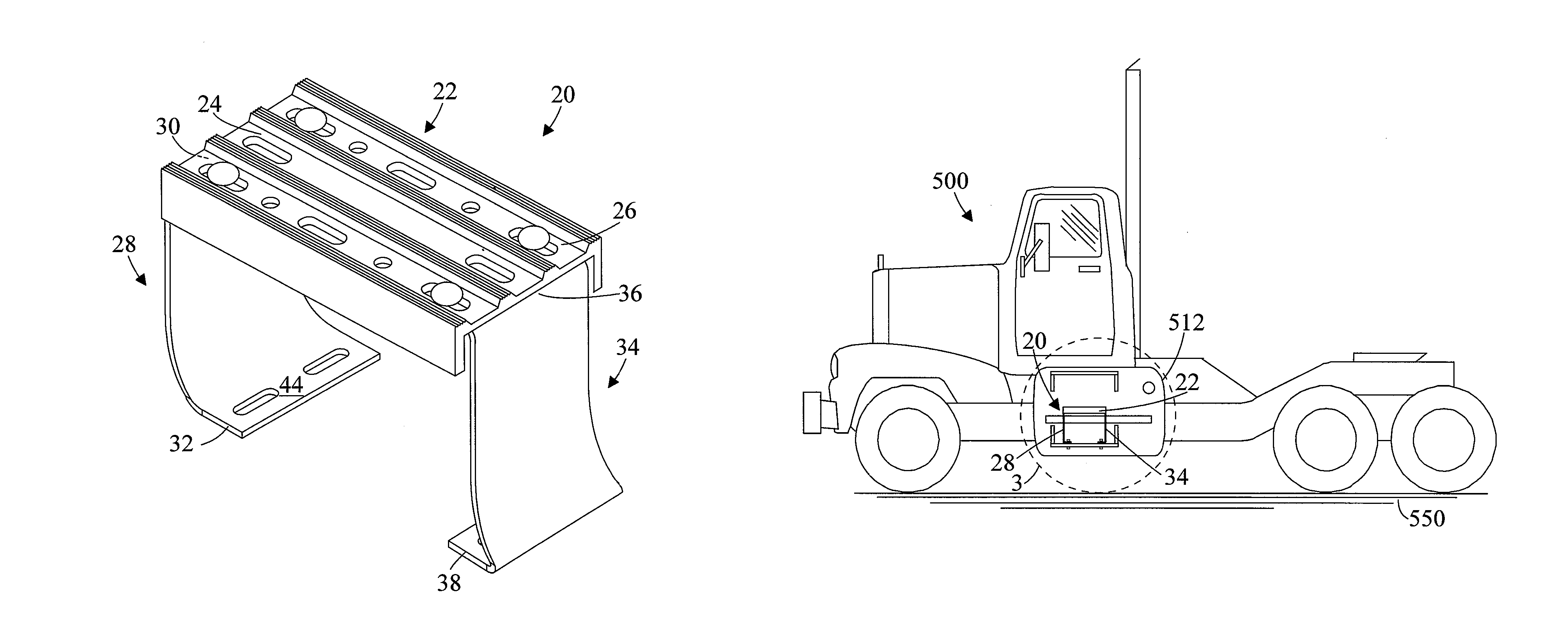

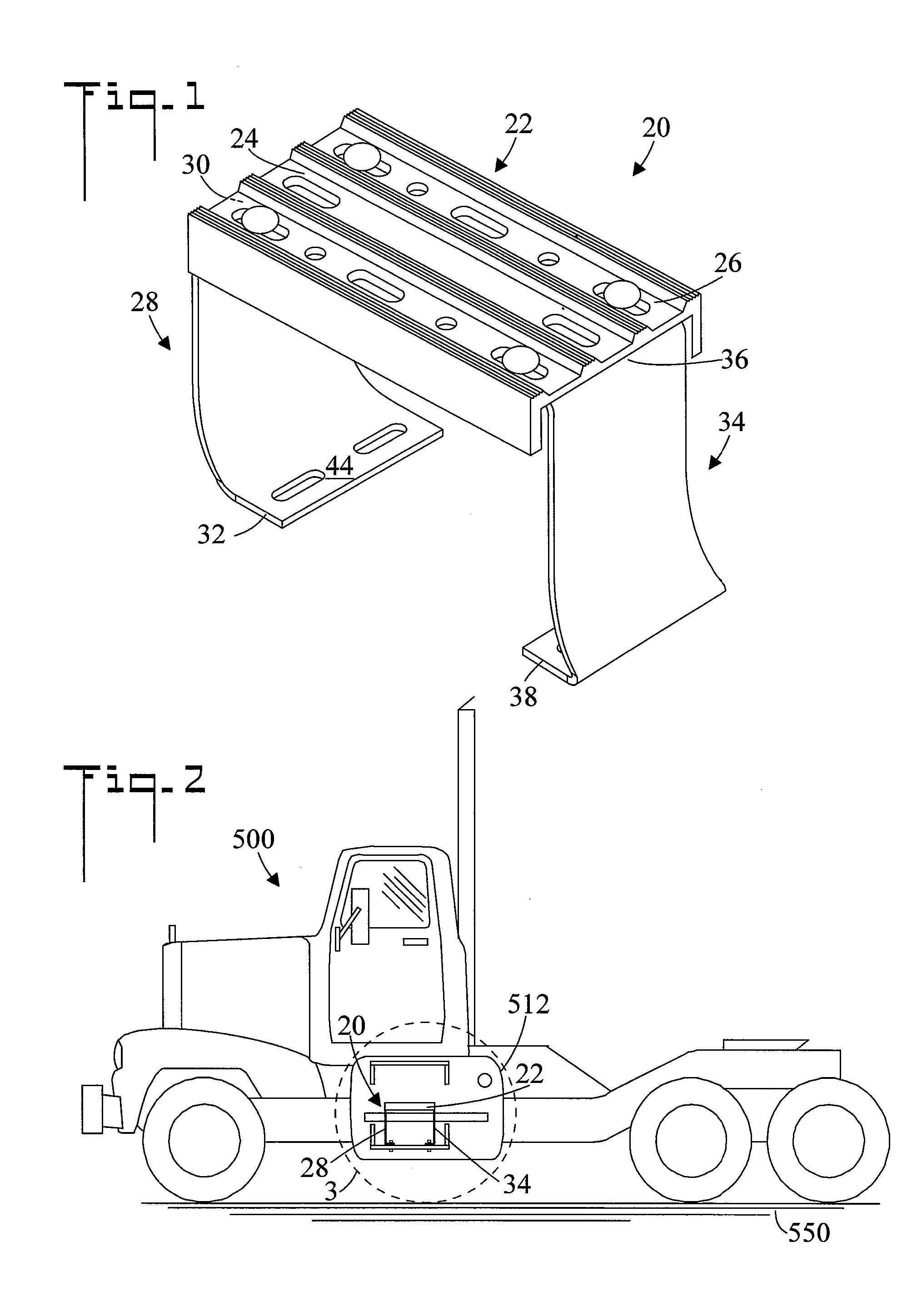

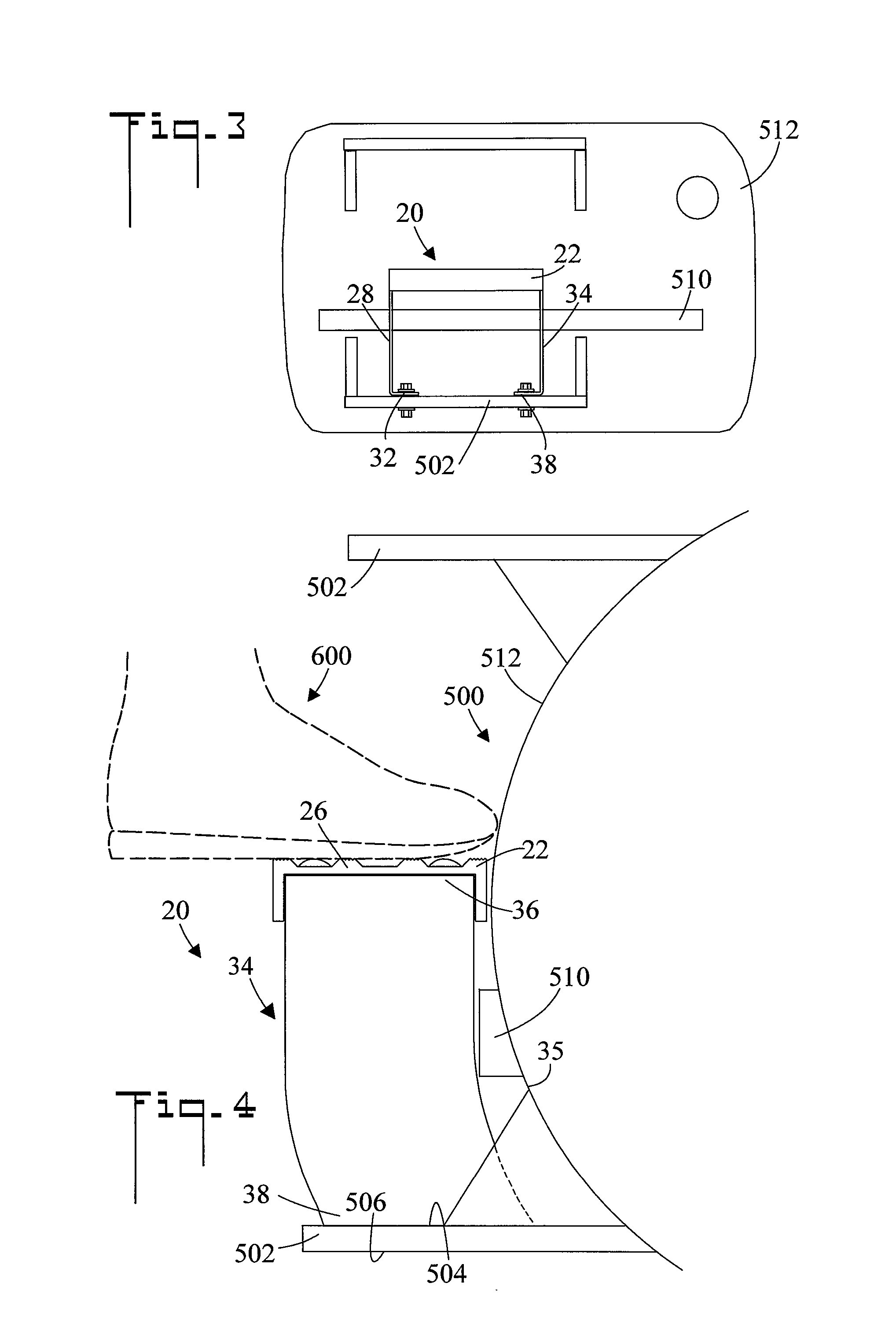

Supplemental step assembly for a vehicle and method of use

ActiveUS9156405B1Shorten the vertical distanceReduce physical strainSteps arrangementStep heightProjection direction

A supplemental step assembly for a vehicle having a vehicle step includes a step which has a first end and an opposite second end. A first side member has a first step end which is connectable to the first end of the step, and an opposite first vehicle step end which is connectable to the vehicle step, the first step end being offset from the first vehicle step end. A second side member has a second step end which is connectable to the second end of the step, and an opposite second vehicle step end which is connectable to the vehicle step, the second step end being offset from the second vehicle step end. The supplemental step assembly can be connected to the step of the vehicle in either an upward projecting direction or a downward projection direction. The supplemental step assembly provides an additional step which reduces the vertical step height and facilitates entry of the vehicle.

Owner:LEVESQUE GUY CHARLES

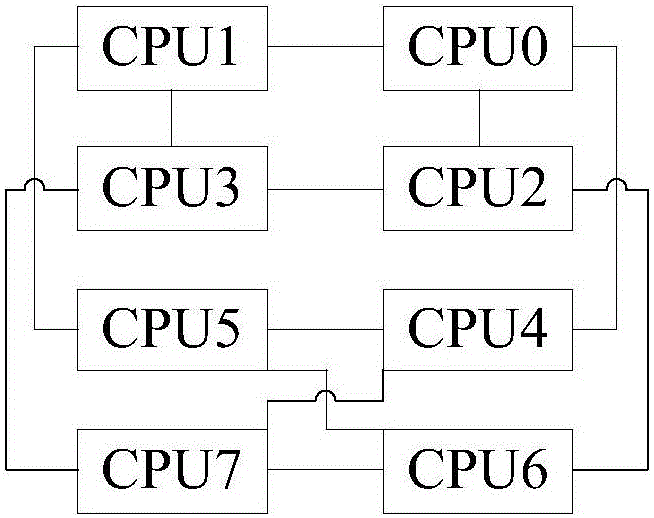

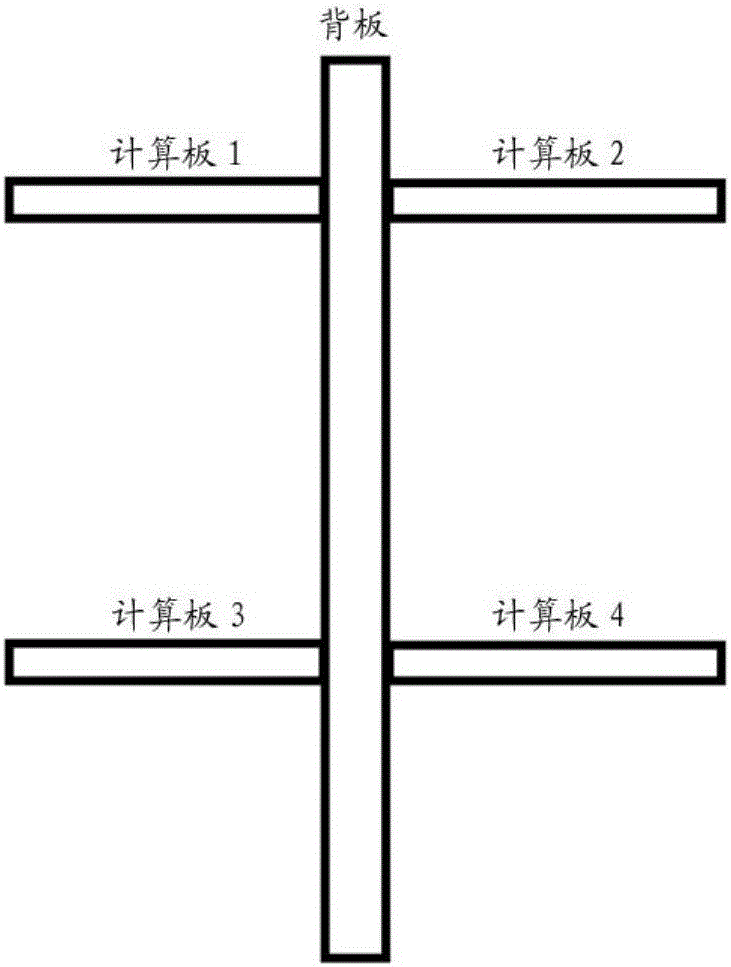

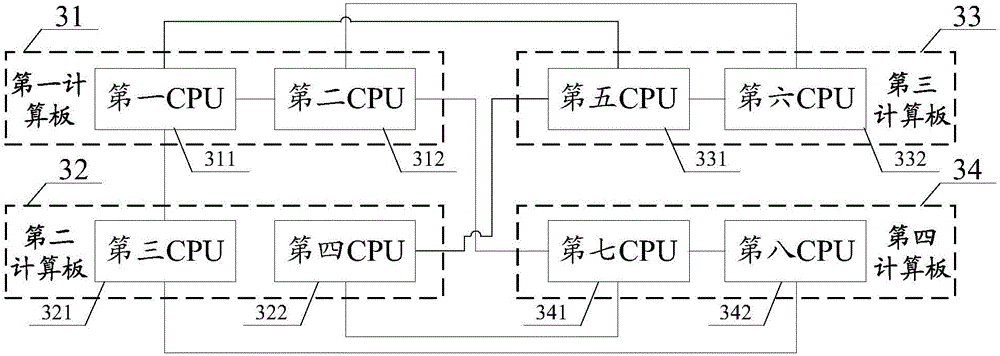

Eight-way server based on connector via hole design

ActiveCN105760340AEfficient signal transmissionShorten the vertical distanceMultiple digital computer combinationsEngineeringBackplane

The invention discloses an eight-way server based on connector via hole design. The eight-way server comprises four calculating boards; each calculating board is provided with two CPUs, two of the calculating boards are located on one side of a backing board of the eight-way server, and the other two of the calculating boards are located on the other side of the backing board of the eight-way server; one side of the backing board is further provided with a first backing board connector, the other side of the backing board is provided with a second backing board connector, and the first backing board connector and the second backing board connector share a same connector hole site located on the backing board. According to the eight-way server, the four calculating boards are evenly distributed on the two sides of the backing board, the backing board connector on one side of the backing board and the backing board connector on the other side of the backing board share the same connector hole site located on the backing board, therefore, the connected bus distance on the backing board is decreased by the longitudinal distance of one calculating board, the physical length of connected buses is decreased, the signal integrity is improved, and the server can conveniently achieve effective signal transmission.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

Array substrate, manufacturing method of array substrate and display panel

InactiveCN104298018AShorten the vertical distanceIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsUltimate tensile strength

Owner:BOE TECH GRP CO LTD +1

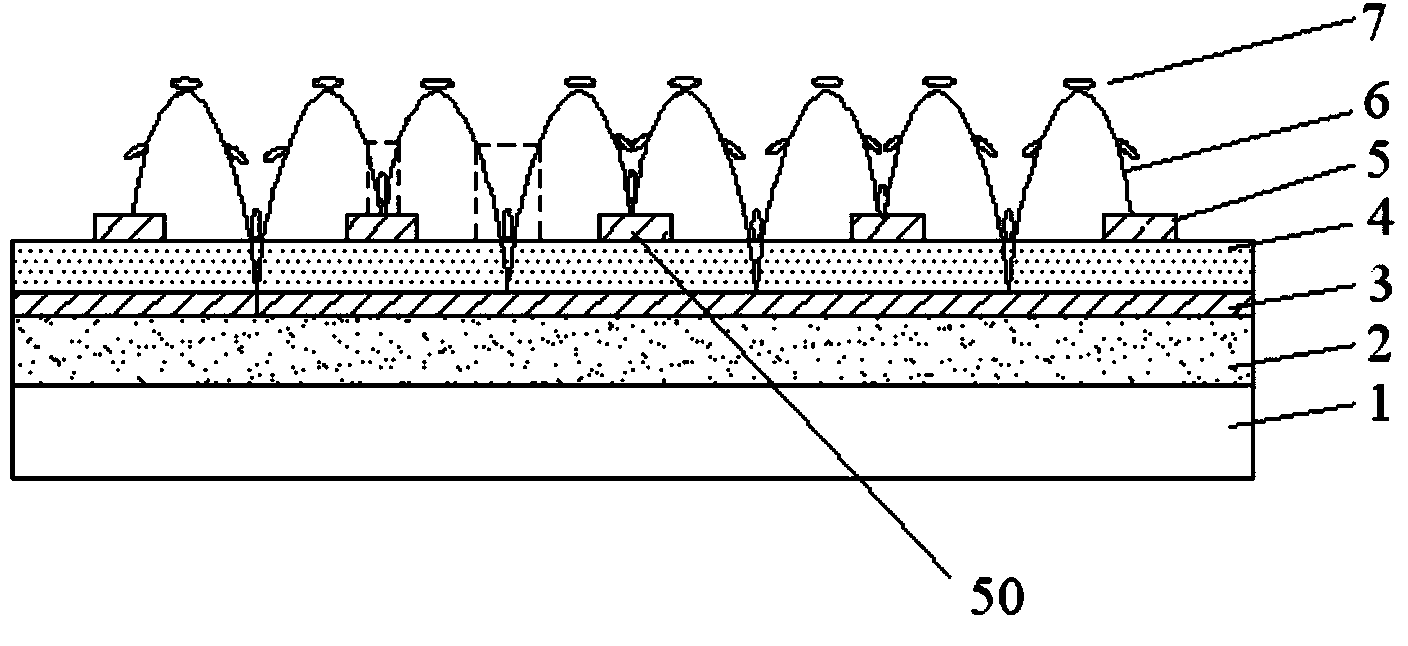

Asymmetrical multichip system level integrated packaging device and packaging method for same

InactiveCN102403308AHigh speedHigh densitySemiconductor/solid-state device detailsSolid-state devicesHigh densityResistance capacitance

The invention discloses an asymmetrical multichip system level integrated packaging device, which comprises a top chip, a bottom chip, a substrate and connecting wires, wherein the substrate is placed below the bottom chip, the dimension of the top chip is smaller than that of the bottom chip, connecting pads or connecting soldering flux bumps are arranged on the bottom chip, a pad face of the top chip is arranged downwardly, a pad face of the bottom chip is arranged upwardly, the bottom chip is placed on the substrate, the pads of the top chip and the top chip are in face-to-face bonding, and the bottom chip is connected with the substrate through the connecting wires. The invention further discloses a packaging method for the asymmetrical multichip system level integrated packaging device. The asymmetrical multichip system level integrated packaging device is low in cost and has the advantages of high density, high frequency and low signal RC (resistance-capacitance) delay.

Owner:SHANGHAI XINCHU INTEGRATED CIRCUIT

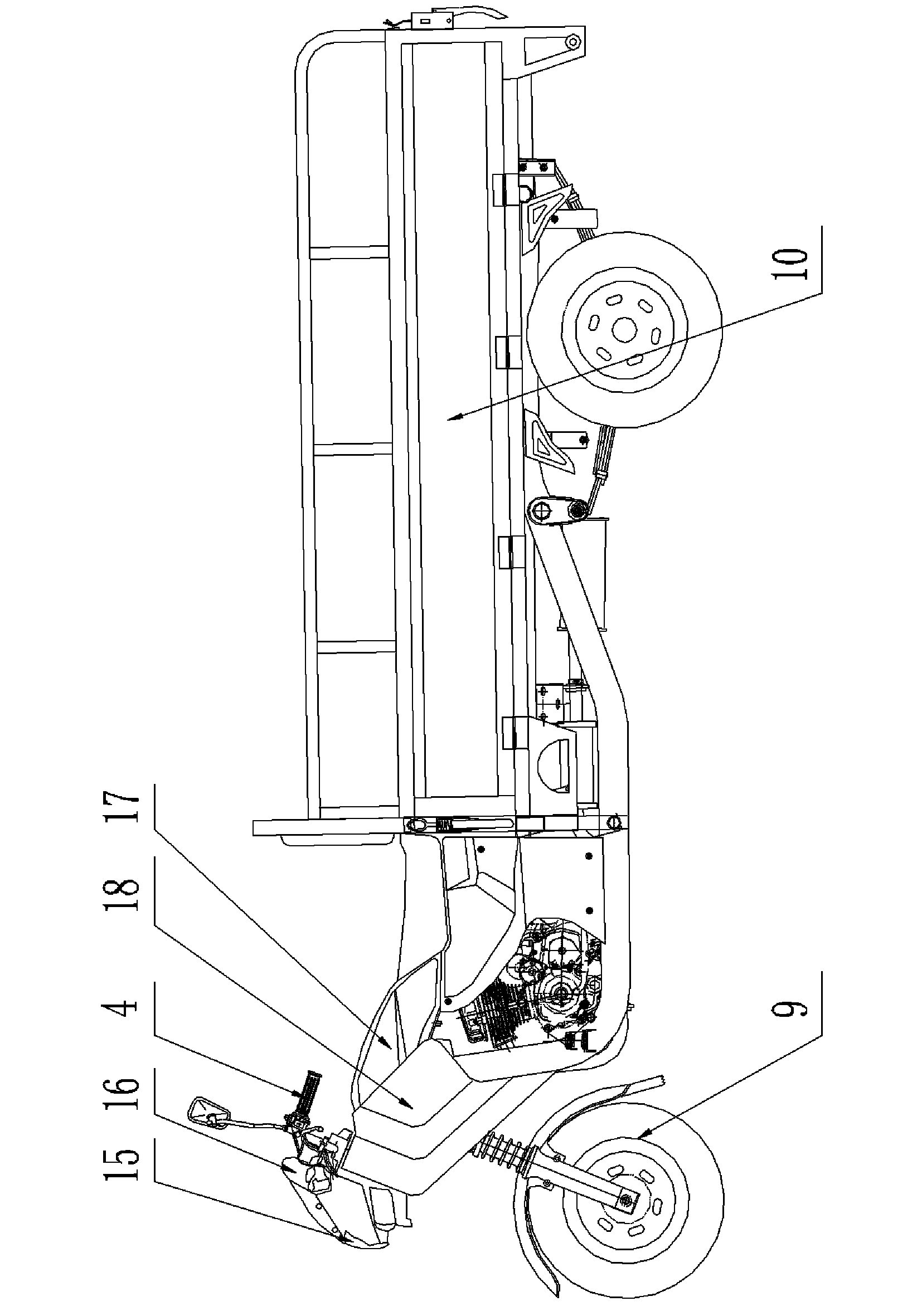

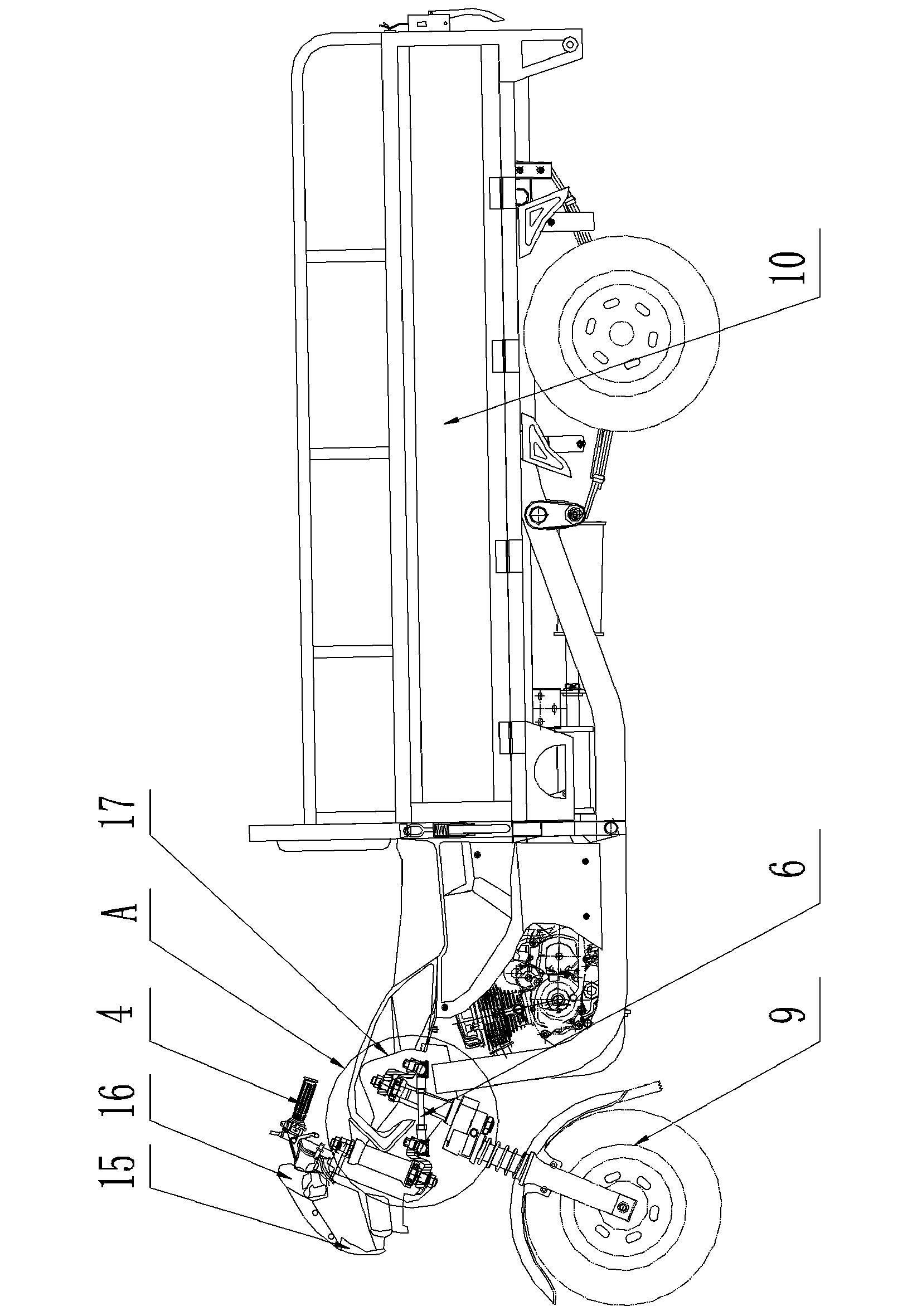

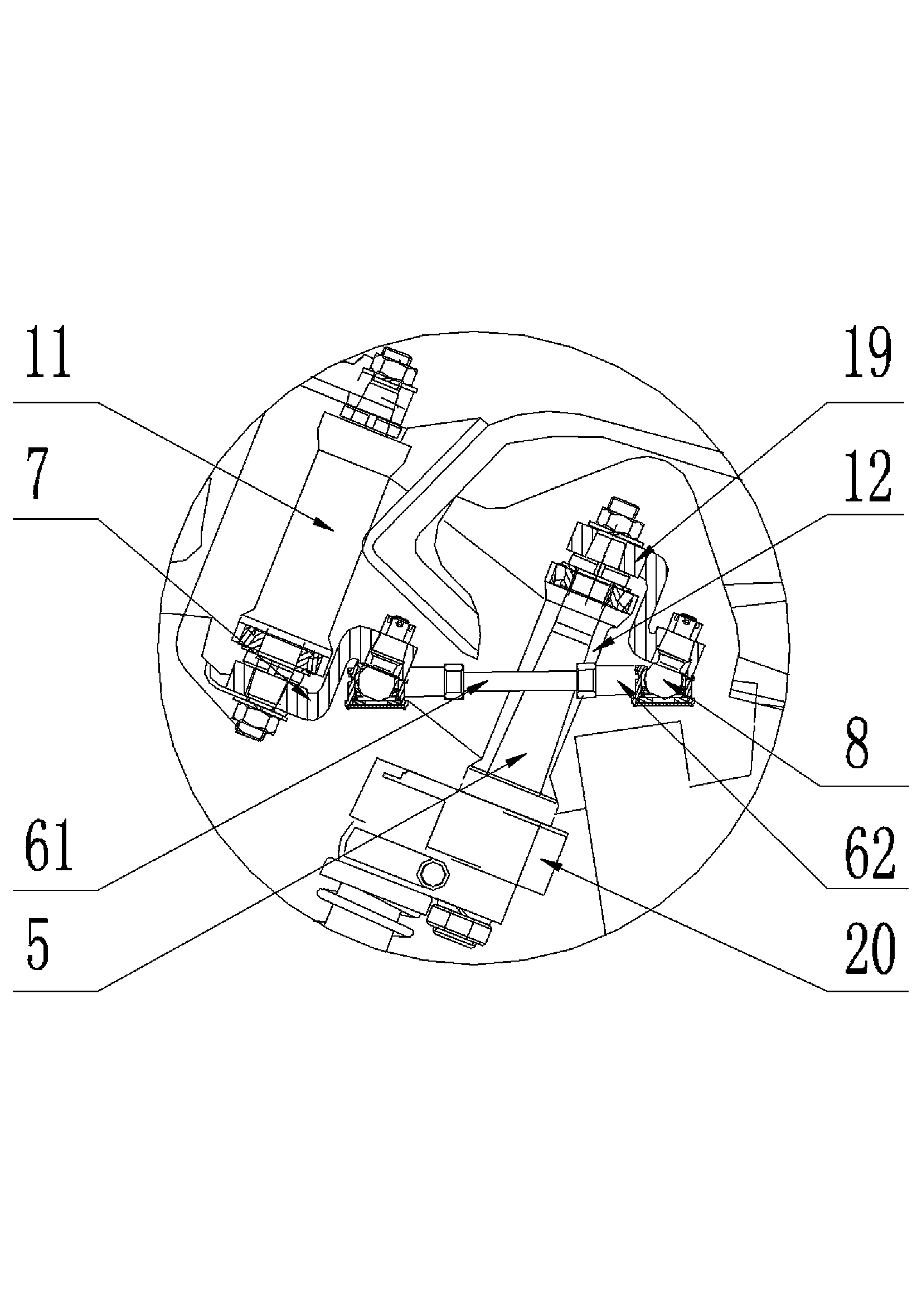

Right three-wheeled motorcycle

ActiveCN103192917AShorten invalid lengthConducive to driving safetyPassenger cyclesChain/belt transmissionVehicle frameControl engineering

The invention discloses a right three-wheeled motorcycle. The right three-wheeled motorcycle comprises a frame with a main beam and a container support beam, wherein a headstock stand pipe for installing a steering post is welded at the front end of the main beam; a handle pipe steering post for installing a handle pipe is rotatably matched in the headstock stand pipe; a handle pipe is arranged at the upper end of the handle pipe steering post; a front fork stand pipe for installing a front fork steering post is welded on the main beam at the back of the headstock stand pipe; a front fork steering post is rotatably matched in the front fork stand pipe; and the handle pipe steering post is connected with the front fork steering post through a linkage device. Compared with a conventional right three-wheeled motorcycle, the front fork steering post of the motorcycle moves backward, so that the invalid length between the front end of a front wheel and the front end of a head lamp of the right three-wheeled motorcycle is shortened; and therefore, a container of the right three-wheeled motorcycle can be lengthened within the specified overall length of the motorcycle, the transportation efficiency can be improved, and the requirements of customers can be met.

Owner:CHONGQING ASTRONAUTIC BASHAN MOTORCYCLE MFG

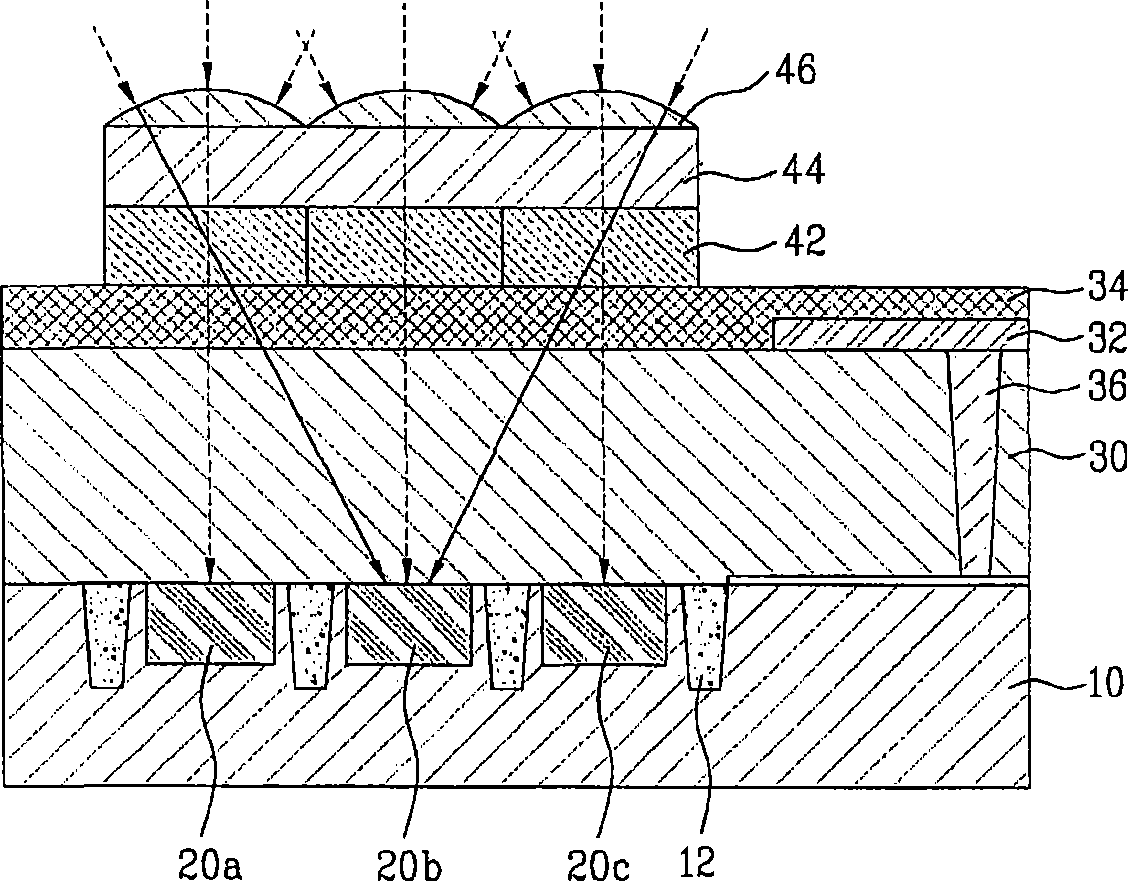

Image sensor and fabricating method thereof

InactiveCN101447496AImprove light gathering efficiencyImprove sensitivitySolid-state devicesSemiconductor/solid-state device manufacturingImage sensorEngineering

An image sensor and fabricating method thereof may include a semiconductor substrate, a plurality of photodiodes formed on and / or over the semiconductor substrate, a first insulating layer formed on and / or over the semiconductor substrate including the plurality of photodiodes, at least one metal line formed on and / or over the first insulating layer, a second insulating layer having a plurality of wells formed on and / or over the plurality of photodiodes, a plurality of color filters formed by embedding color filter layers in a plurality of the wells, and a plurality of microlenses formed on and / or over the color filters.

Owner:DONGBU HITEK CO LTD

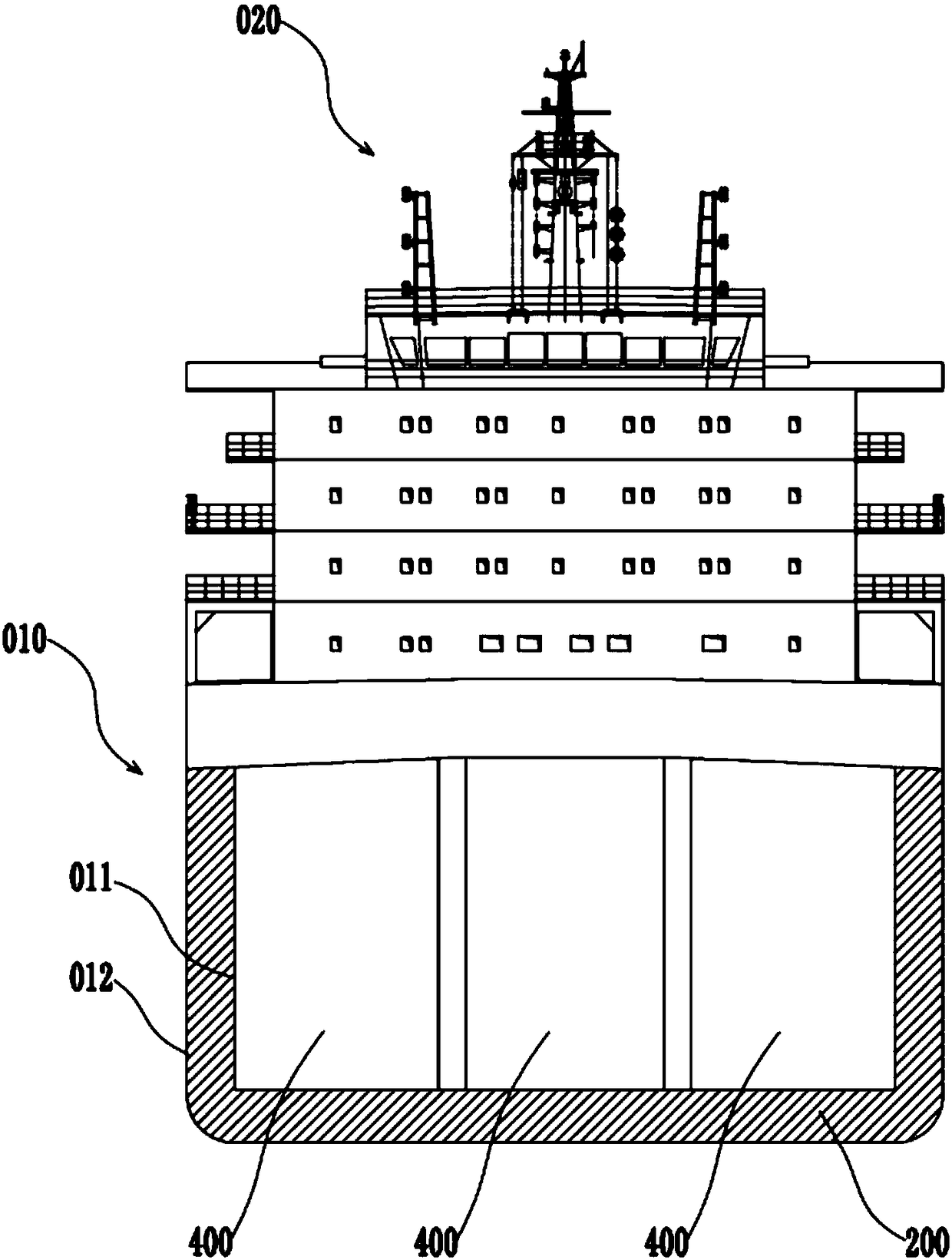

Ship

ActiveCN108569372ARealize the water injection operationAchieve drainageHull interior subdivisionSelf-bailing equipments/scuppersEnvironmental engineeringBallast tank

The invention discloses a ship, relates to the technical field of navigation equipment and is designed to solve the problems of larger occupied space and maintenance inconvenience caused by unreasonable arrangement of a ballast pump. The ship comprises a ship body and a water ballast system, wherein the ship body comprises a cargo hold area, a ballast pump room and a plurality of water ballast tanks, the ballast pump room is located in the cargo hold area, the water ballast system comprises a ballast pump arranged in the ballast pump room, and the ballast pump is communicated with each water ballast tank through a ballast pipeline and is used for injecting water into each water ballast tank or discharging water in each water ballast tank. The ship is used for overcoming the defect that thespace of the ship body is occupied due to unreasonable arrangement of the ballast pump room in the prior art, meanwhile, the risk of damage of the ballast pump due to long-term soaking is reduced.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

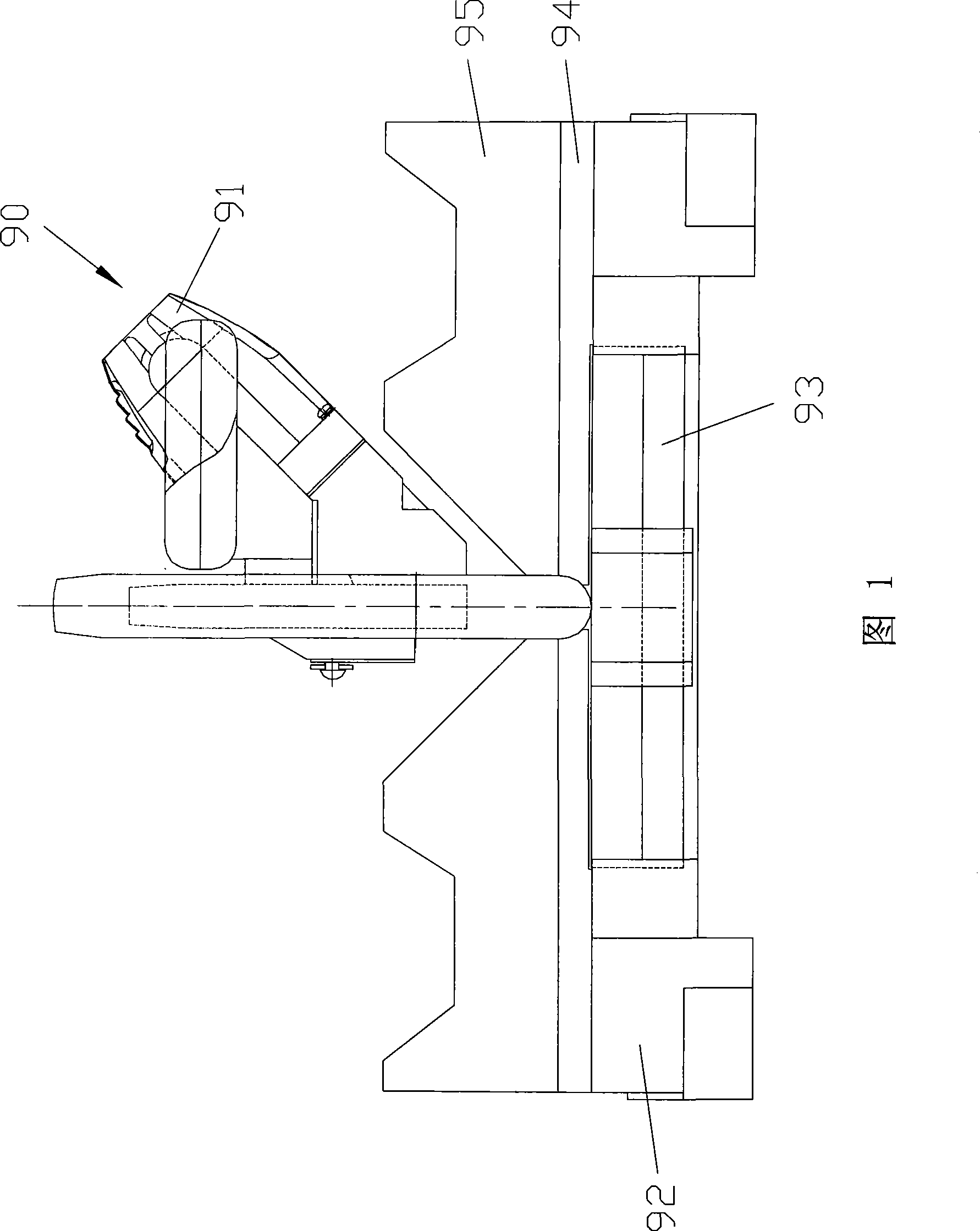

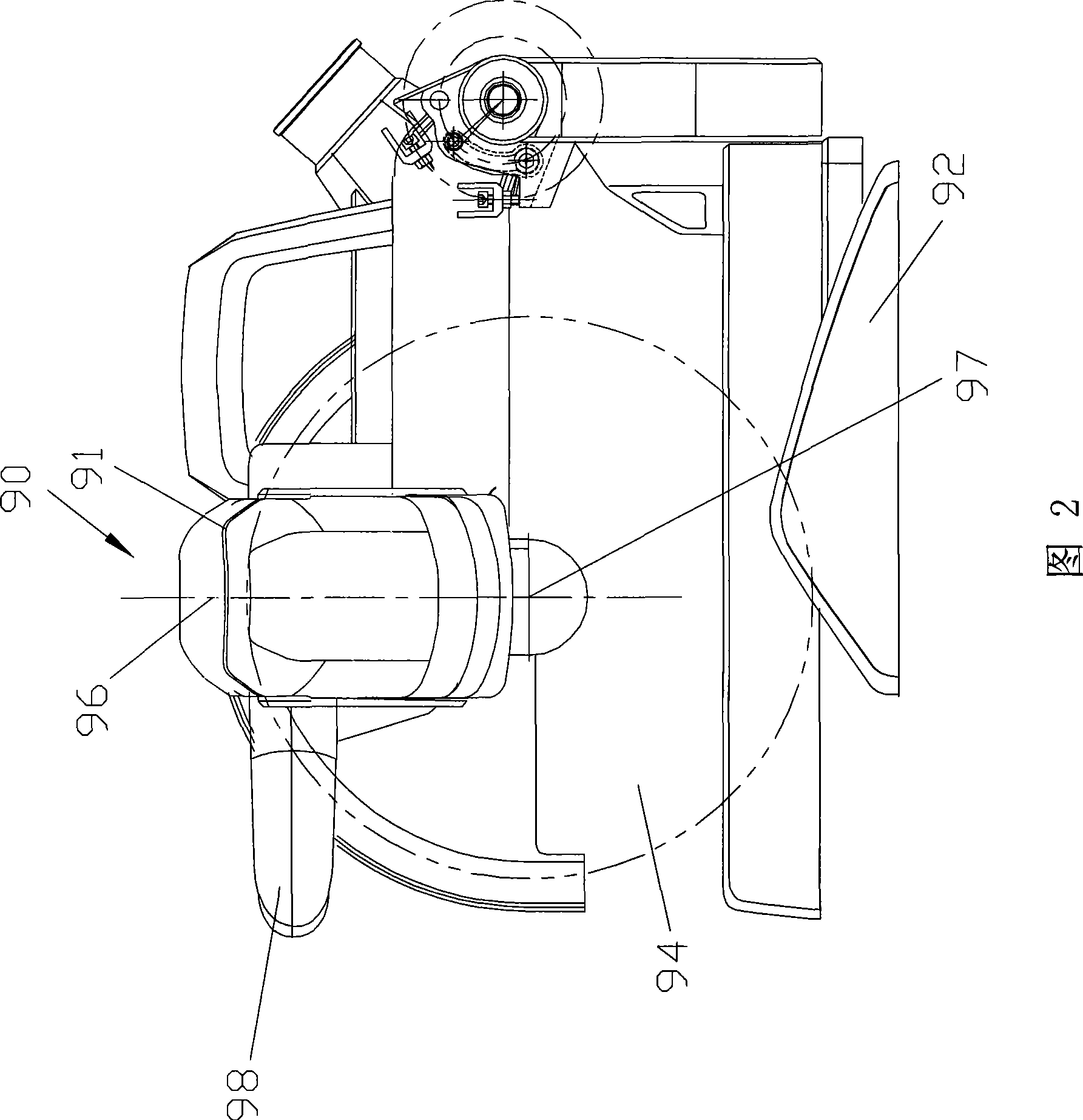

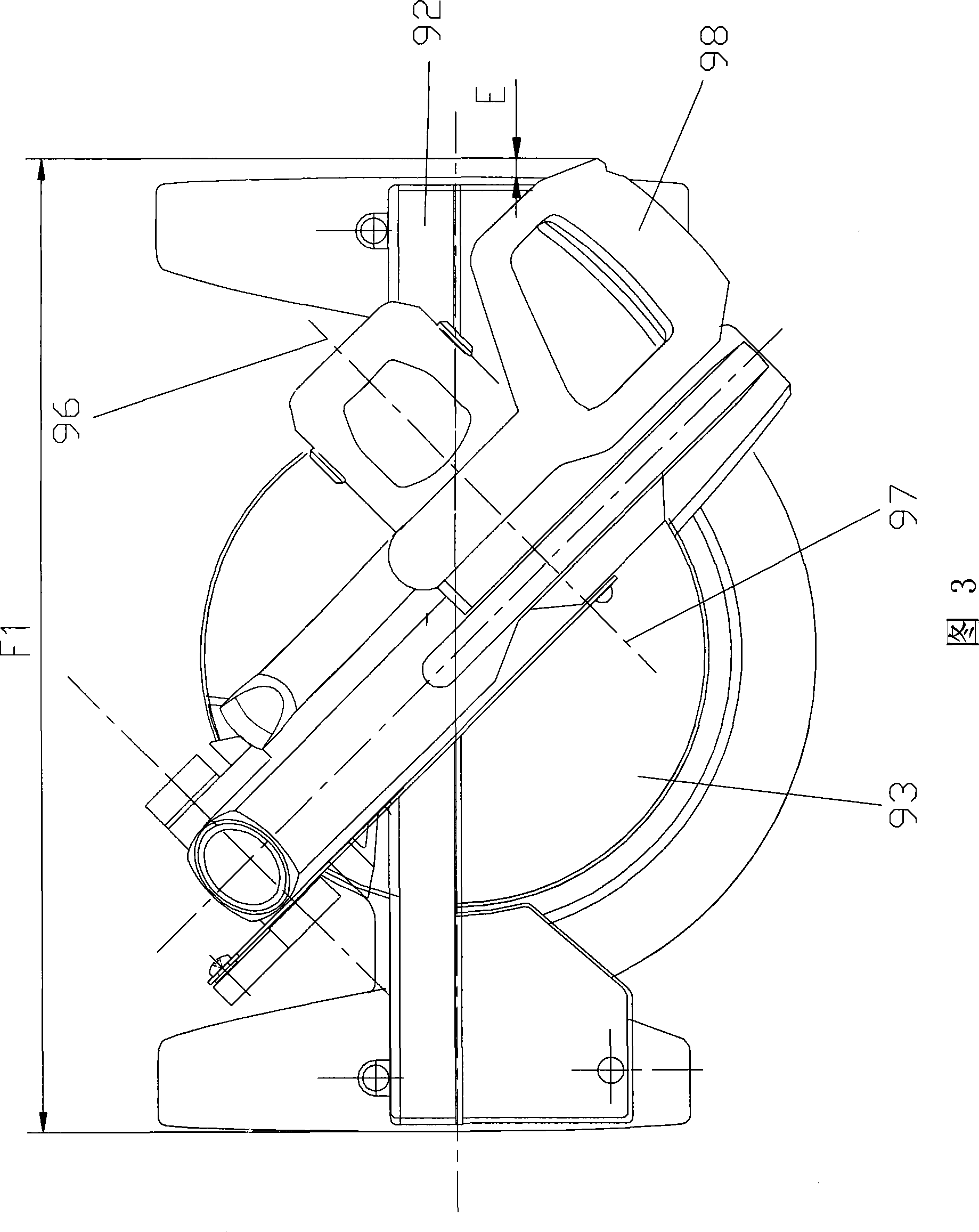

Bias cutter

InactiveCN101450398AReduced packaging volumeShorten the vertical distanceMetal sawing devicesGear wheelElectric machinery

The invention provides an oblique cutting machine, which comprises a base, a support arm in match connection with the base, as well as a sawing mechanism in movable match connection with the support arm. The sawing mechanism comprises a round saw blade, a motor and a transmission mechanism; the motor is obliquely arranged on one side of the round saw blade and is in match connection with a motor output shaft; and the round saw blade is in match connection with a saw-blade shaft, wherein the motor output shaft is obliquely arranged backwards relative to the saw-blade shaft. Therefore, the motor is also arranged relatively behind the oblique cutting machine, so as to reduce packaging volume and cost, shift the gravity center of the sawing mechanism, shorten force arm and increase the life span of a torsional spring of the sawing mechanism. In addition, as a hypoid gear is utilized as the transmission mechanism, the oblique cutting machine can reduce noise during cutting operation and is smooth in transmission, so as to improve cutting precision.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

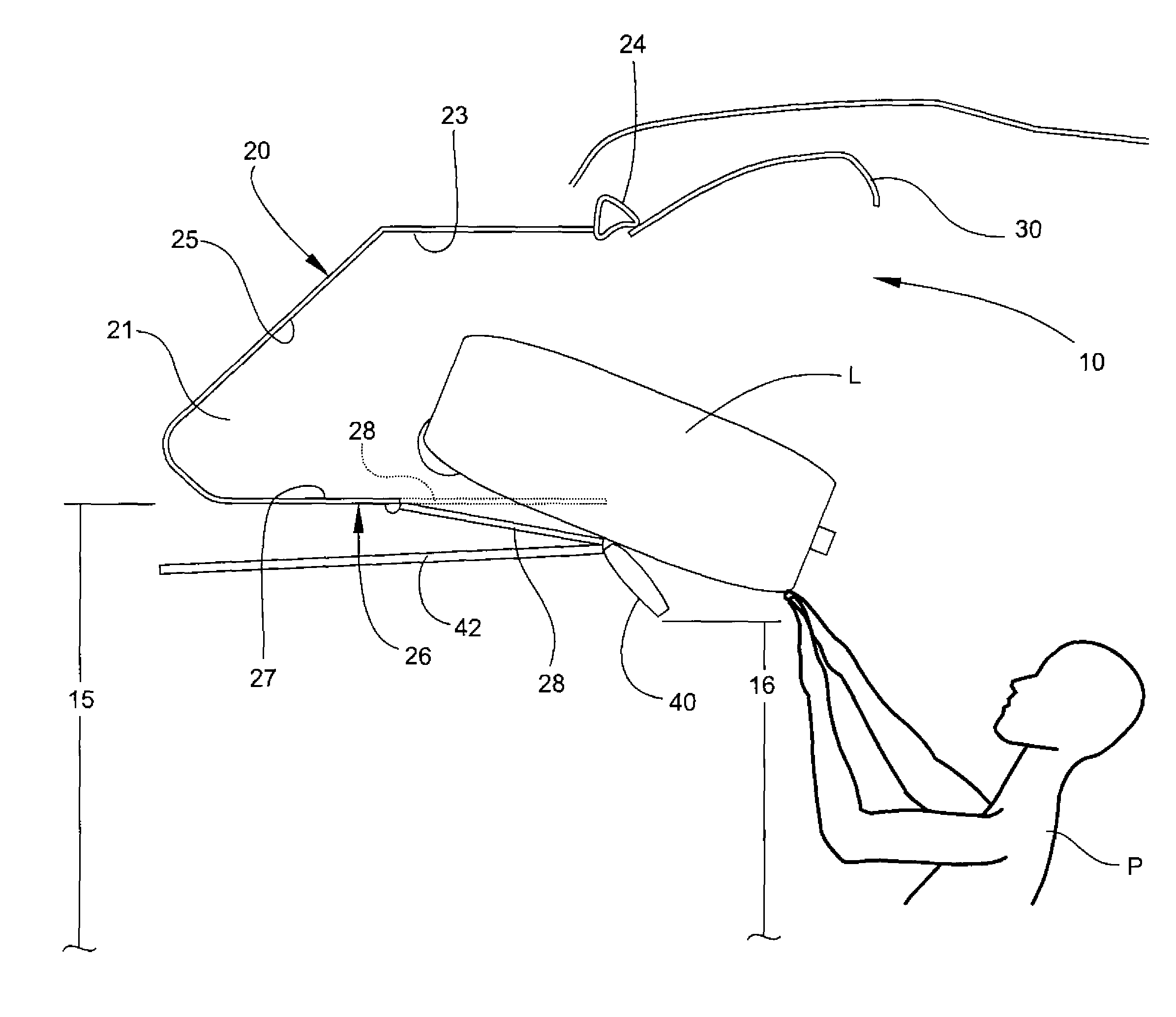

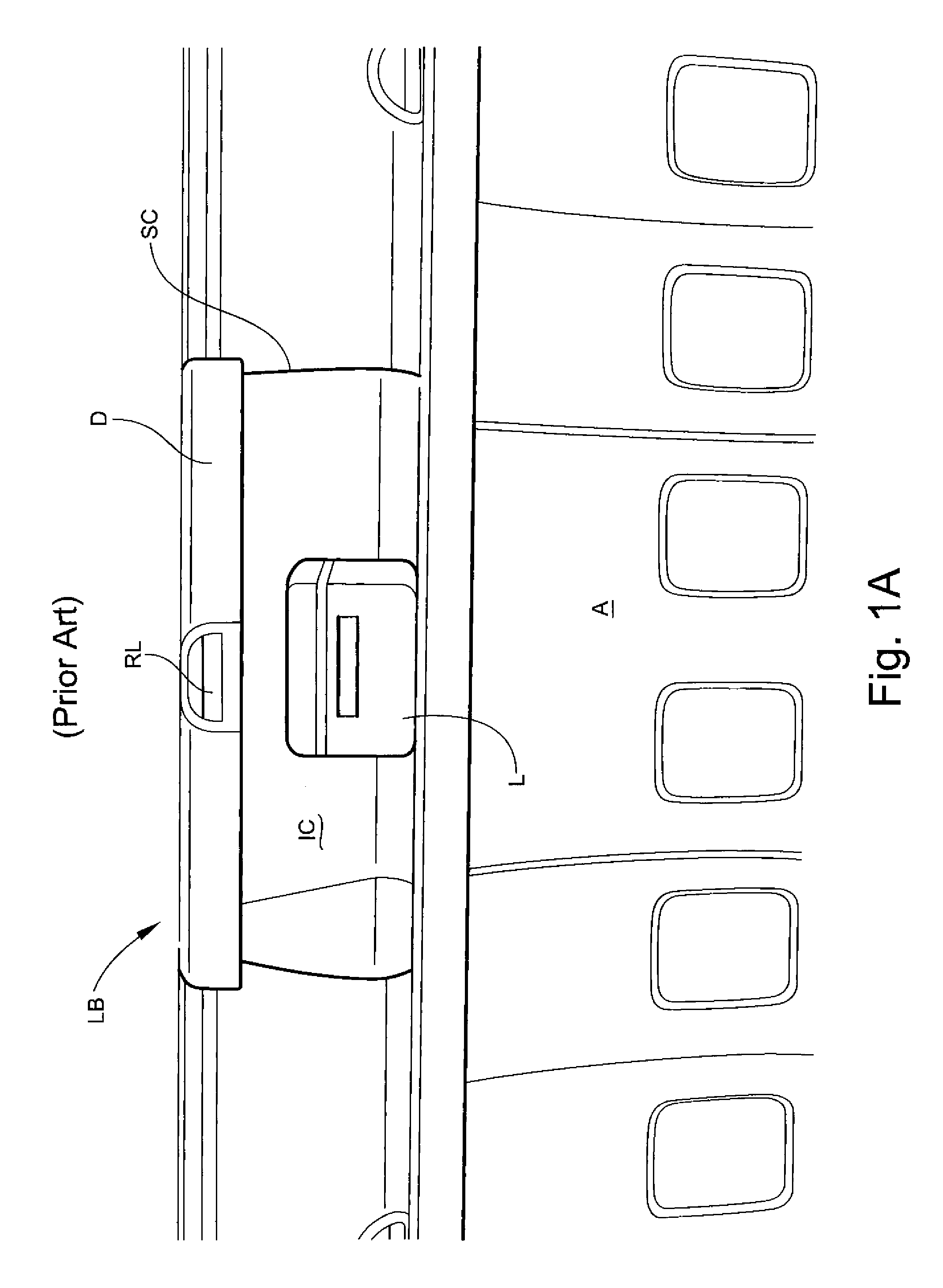

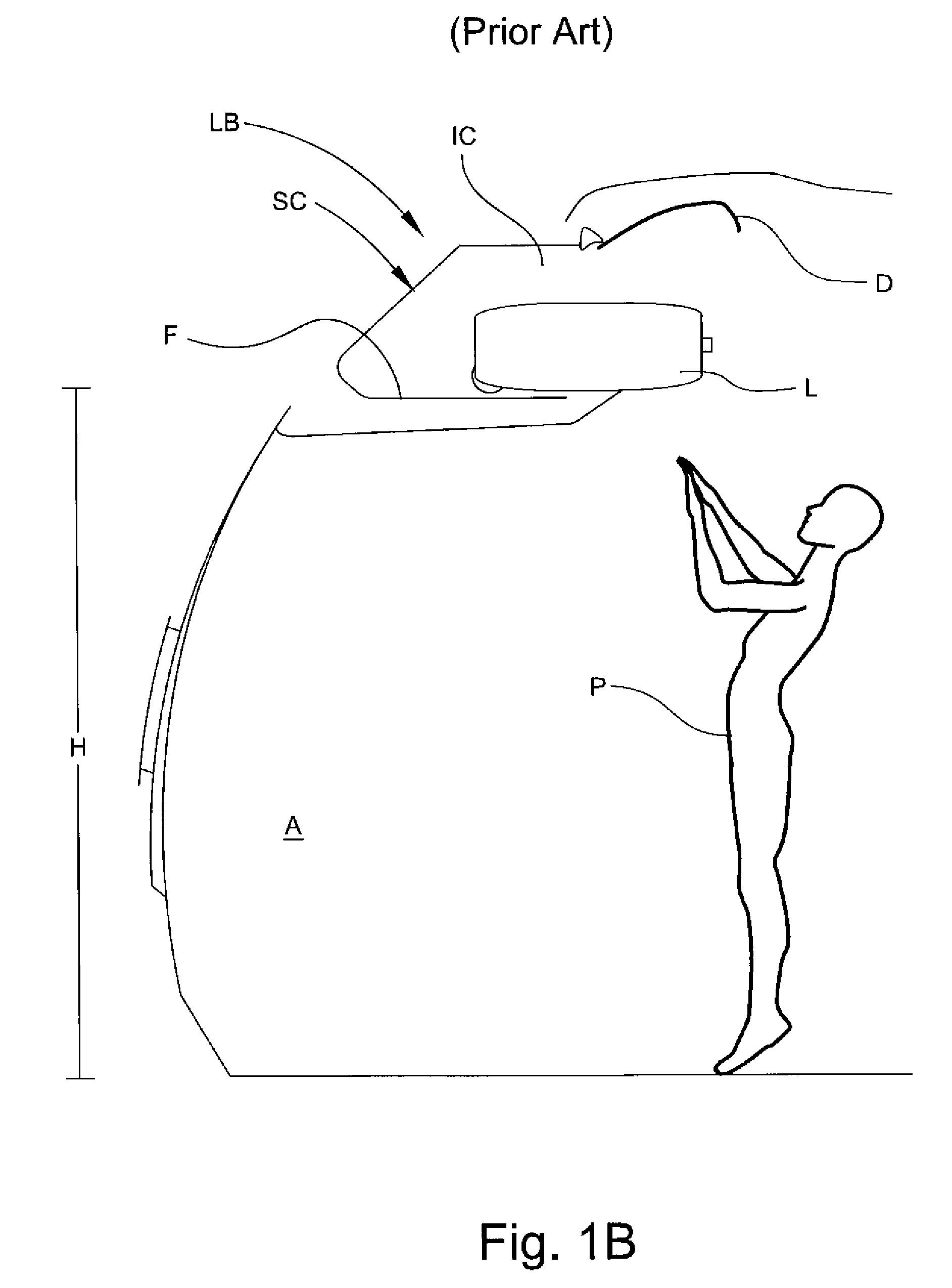

Overhead luggage bin for aircraft interior

ActiveUS8038098B2Shorten the vertical distanceBurglar alarm by hand-portable articles removalFuselagesEngineeringStowage

An overhead luggage bin for an aircraft interior includes a stowage compartment, an upper door movably attached to the stowage compartment and a lower door movably attached to the aircraft interior, the upper door and the lower door being moveable between a closed position and an opened position. A floor of the stowage compartment includes a first portion and a second portion movably attached to the first portion that defines a ramp surface with the lower door in the opened position for improved accessibility. An overhead luggage bin is provided with handles at opposed ends of the stowage compartment and includes one or more non-linear ridgelines and / or increased reflectance on an exterior surface for a more aesthetically pleasing appearance. An overhead luggage bin includes an RFID reader for providing increased RFID functionality. An overhead luggage bin includes a stowage compartment having an integrated handrail.

Owner:BE AEROSPACE INCORPORATED

Reflecting imaging apparatus and mobile device having the same

ActiveUS10082649B2Shorten the vertical distanceReduce stray lightTelevision system detailsColor television detailsMobile deviceStray light

A reflection type imaging apparatus includes a deflector that reflects light incident from an outside; a reflecting mirror that reflects the light reflected by the deflector in a direction parallel to a direction in which the light is incident on the deflector; an image sensor that is disposed below the reflecting mirror and arranged perpendicular to the direction in which the light is incident on the deflector, wherein the light reflected by the reflecting mirror is focused on the image sensor; and a stray light blocking member disposed at one side of the image sensor facing the deflector, the stray light blocking member configured to block stray light rays from the deflector from being directly incident on the image sensor.

Owner:SAMSUNG ELECTRONICS CO LTD

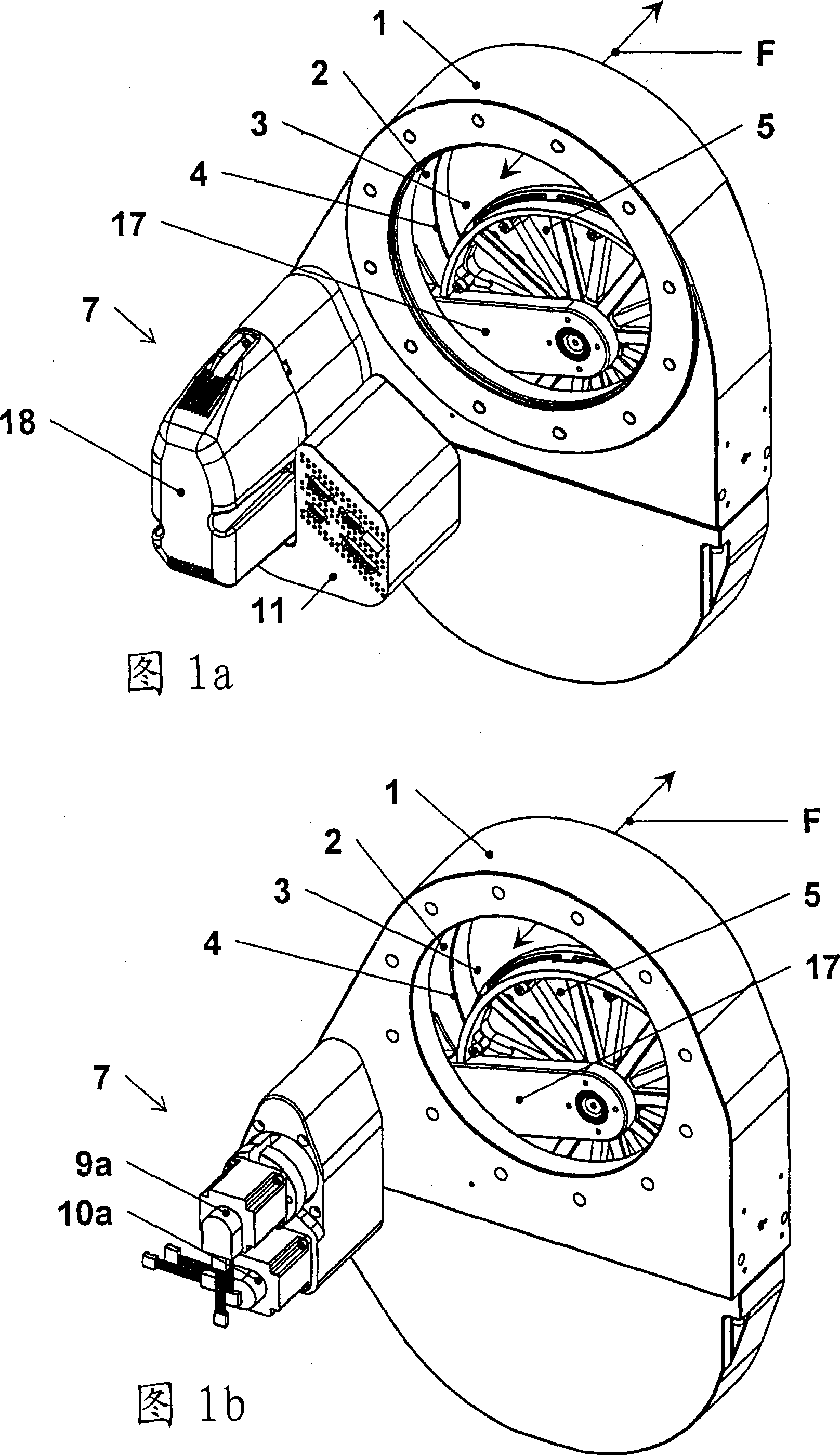

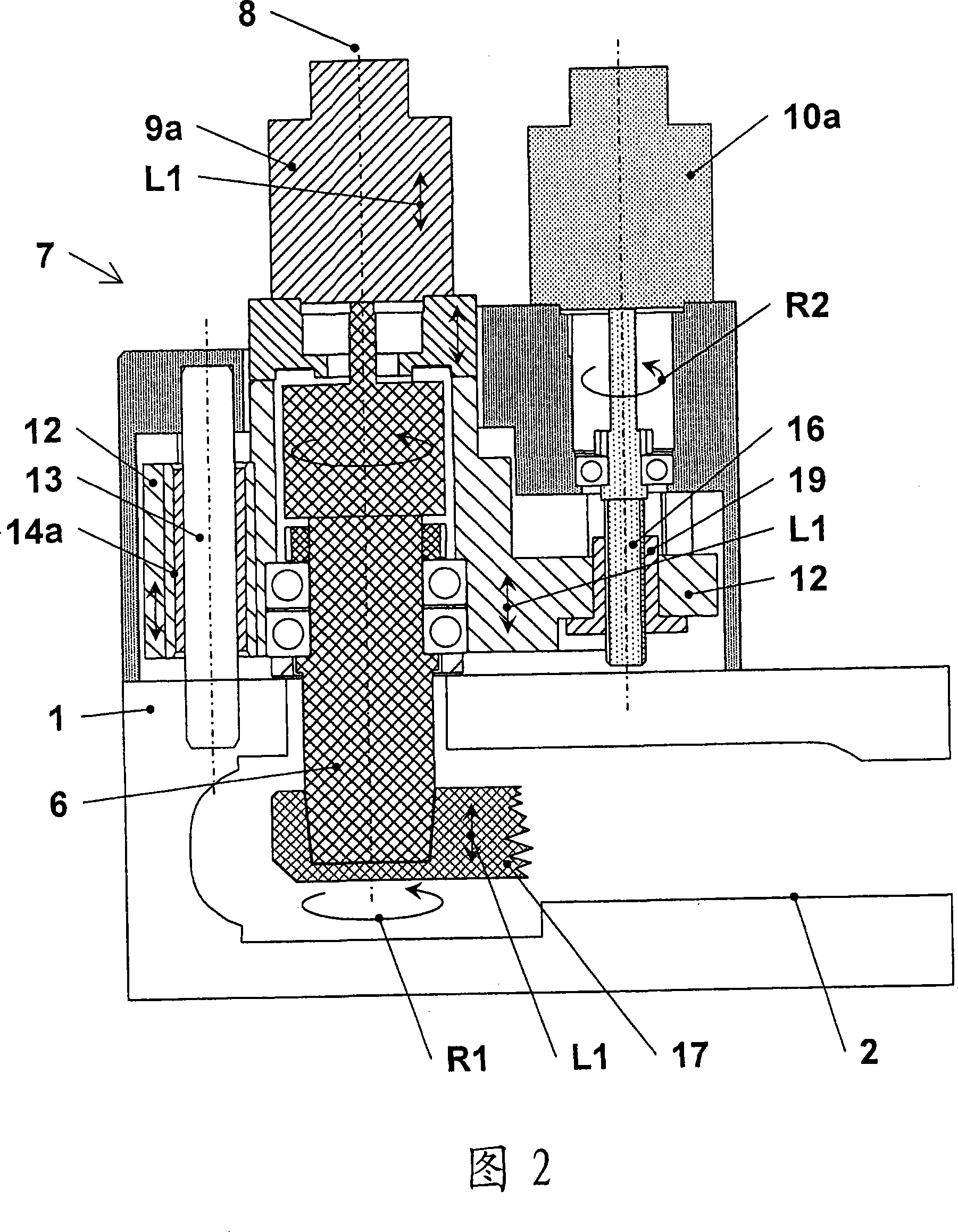

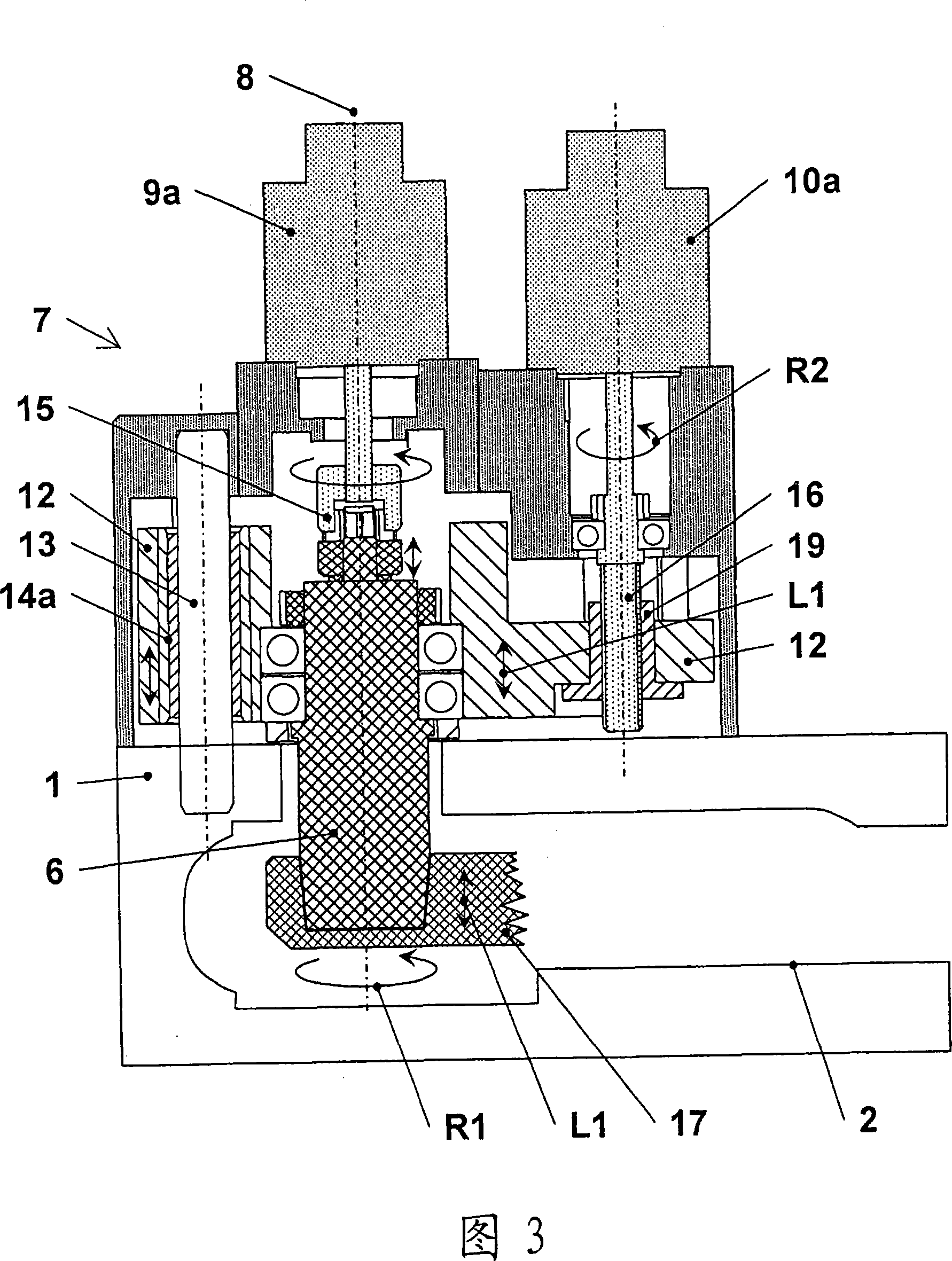

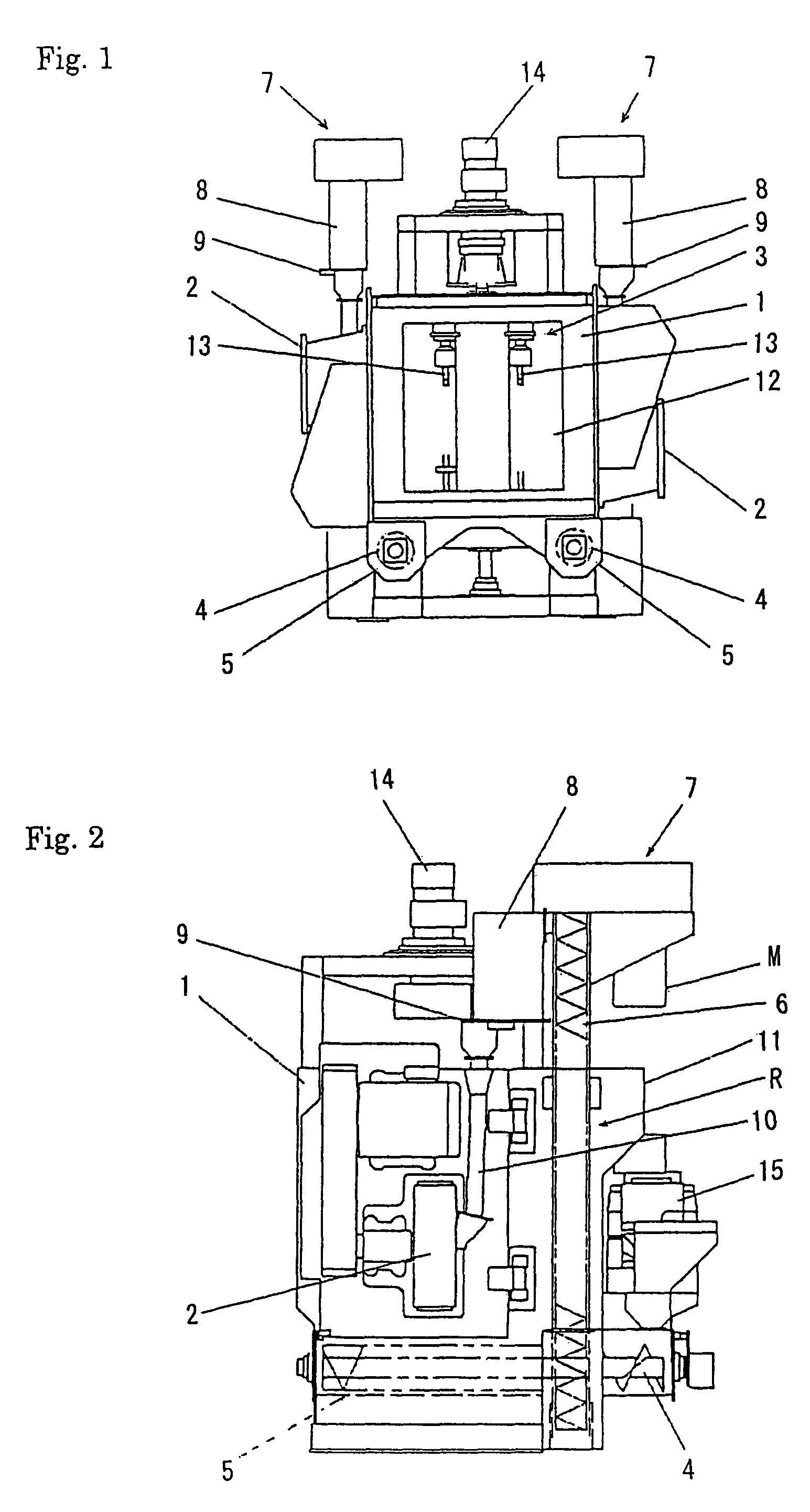

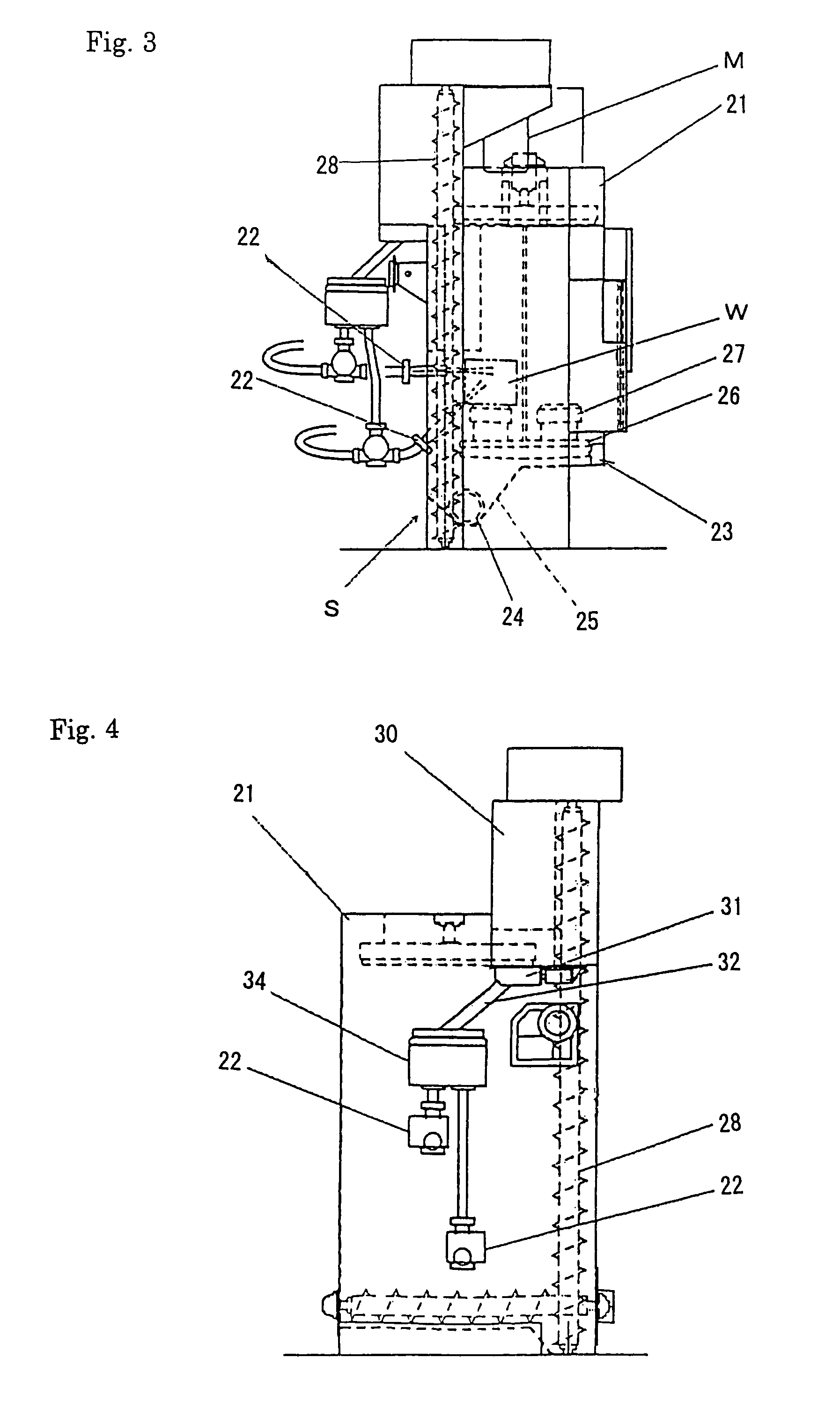

Shuttle valve having two drives

ActiveCN101109451ASimple designEasy maintenanceOperating means/releasing devices for valvesSlide valveLinear motionEngineering

The invention relates to a shuttle valve for interrupting a flow path (F), comprising a valve housing ( 1 ) having a valve seat ( 4 ) surrounding an opening ( 3 ) for the flow path (F). A valve disc ( 5 ) is arranged on a rotatably mounted shaft ( 6 ). By means of a drive unit ( 7 ), the valve disc ( 5 ) can be swivelled along a defined displacement curve (K 1; K 2; K 3 ) from an opened position and leaving the flow path (F) unobstructed over the cross-section of the first opening ( 3 ) by a rotational movement about the pivot axis ( 8 ) of the shaft ( 6 ) and can be moved by a linear movement parallel to the pivot axis ( 8 ) in the direction of the valve seat ( 4 ) into a closed position so that the flow path (F) is sealed gas-tight by a sealing contact between the valve disc ( 5 ) and the valve seat ( 4 ). According to the invention, the drive unit ( 7 ) has a first drive ( 9 a) for carrying out the rotational movement about the pivot axis ( 8 ) and a second drive ( 10 a) for carrying out the linear movement parallel to the pivot axis ( 8 ). By means of a control unit ( 11 ), the first drive ( 9 a) and the second drive ( 10 a) can be actuated so that a variable displacement curve (K 1; K 2; K 3 ) can be produced.

Owner:VAT HLDG AG

Apparatus for a shot peening treatment

A shot-peening device(s) is installed on a side of a cabinet defining an ejection chamber in the cabinet. Shots ejected from the device to a workpiece fall and are conveyed in a horizontal direction by a horizontal screw conveyor positioned above a lower end of the cabinet and then conveyed upward by a vertical screw conveyor whose base end is above the lower end of the cabinet. The shots pass from an upper section of the vertical screw conveyor through a chute to reach an opening / closing gate. When the gate is opened and the shots are supplied to the device(s) for re-ejeciton, a portion of the shots is cause to overflow from the gate. The overflowed shots are caused to pass through a separator to remove impurities and then returned to the horizontal screw conveyor.

Owner:SINTOKOGIO LTD

Structure with micro device

ActiveUS20190363000A1Raise transfer toHigh yieldSolid-state devicesSemiconductor/solid-state device manufacturingEngineering

Owner:PLAYNITRIDE

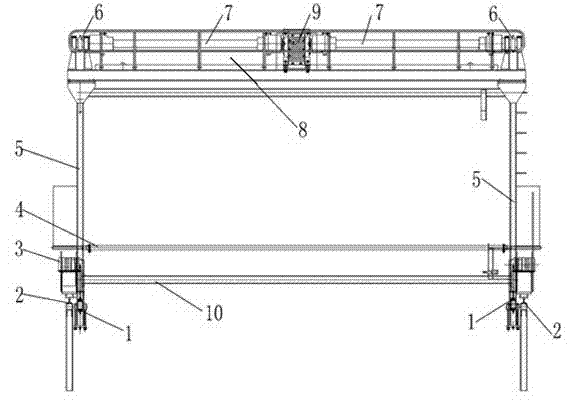

Gantry crane

ActiveCN102923582AShorten the vertical distanceNo added weightLoad-engaging girdersTrolley cranesSprocketThrough transmission

The invention relates to a gantry crane. The gantry crane comprises a gantry, wherein the gantry comprises two columns and a main beam; the two columns are arranged left and right at intervals; the main beam is bridged at the upper ends of the two columns; the gantry crane also comprises a hanging beam with length extending in the left-right direction; the hanging beam is used for installing corresponding hangers; the two ends of the hanging beam are respectively assembled on the two columns via corresponding guide structures by moving vertically in a guided manner; the gantry is provided with one or at least two transmission chains connected with the hanging beam through transmission so as to drive the hanging beams to go up and down; and the gantry is also provided with a chain wheel driving mechanism for driving one transmission chain to make cyclic action or all the chains to make cyclic action synchronously. The gantry crane provided by the invention can reduce the vertical distances between the main beam and the corresponding hangers.

Owner:NUCLEON XINXIANG CRANE

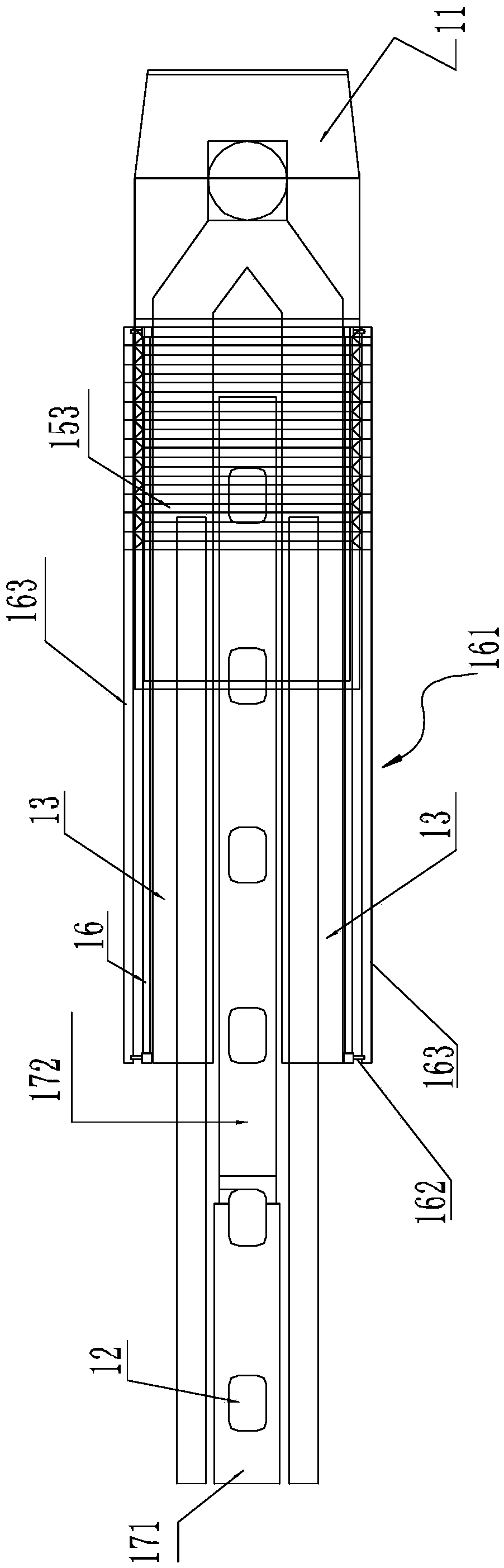

Steel rail collecting and placing device

ActiveCN104264548AQuick releaseReduce auxiliary timeRailway track constructionMoving rail partsEngineeringMechanical engineering

The invention discloses a steel rail collecting and placing device. The steel rail collecting and placing device comprises a positioning assembly and a steel rail clamping assembly; the positioning assembly comprises a guiding base, a lifting frame assembly and a perpendicular oil cylinder; the steel rail clamping assembly comprises first sliding blocks and second sliding blocks which are arranged on lower portions at two ends of a guide base in pairs and a first transverse oil cylinder and a second transverse oil cylinder; a positioning plate is arranged on the lifting frame assembly; the guide base perpendicularly moves along the positioning plate under pushing of the perpendicular oil cylinder; combination bodies of the first sliding blocks and the second sliding blocks transversely move along the length direction of the guide base under pushing of the first transverse oil cylinder; the second sliding blocks transversely move relative to the first sliding blocks under pushing of the second transverse oil cylinder. The steel rail collecting and placing device can conveniently and safely clamp and move the steel rail according to the rail replacement requirement, effectively controls the acting force for clamping the steel rail and well adapts to the railway rail change requirement.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com