Three-dimensional vacuum sensor and manufacturing method thereof

A technology of a vacuum sensor and a manufacturing method, which is applied in the fields of vacuum technology and micro-electromechanical systems, can solve problems such as a large distance from a heater to a substrate, low measurement accuracy, and narrow measurement range, and achieve an increase in the upper limit of pressure measurement, sensitivity, and Yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] As shown in the figure, the present invention provides a method for preparing a three-dimensional vacuum sensor, the method comprising the following steps:

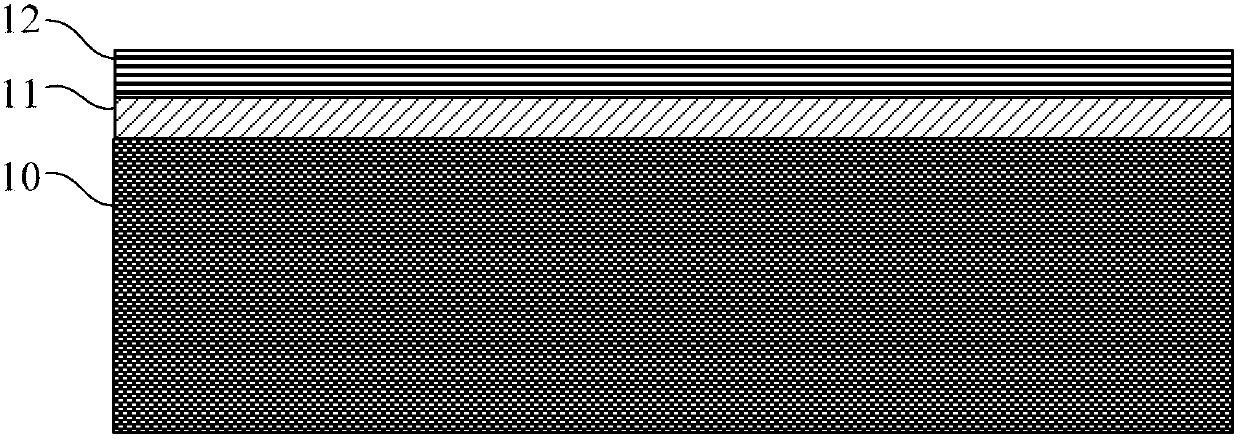

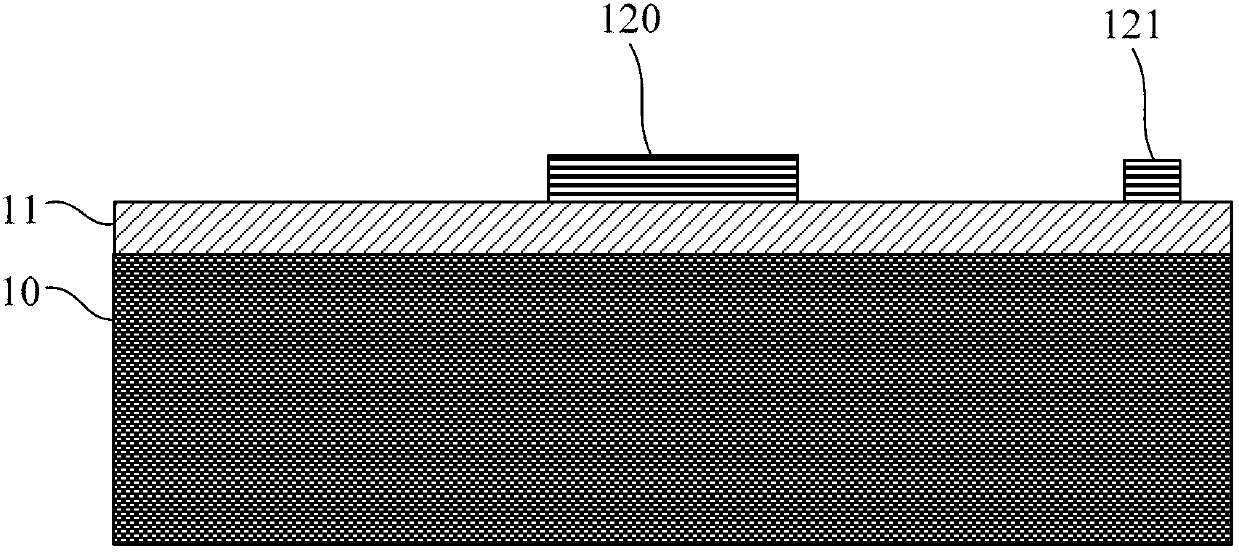

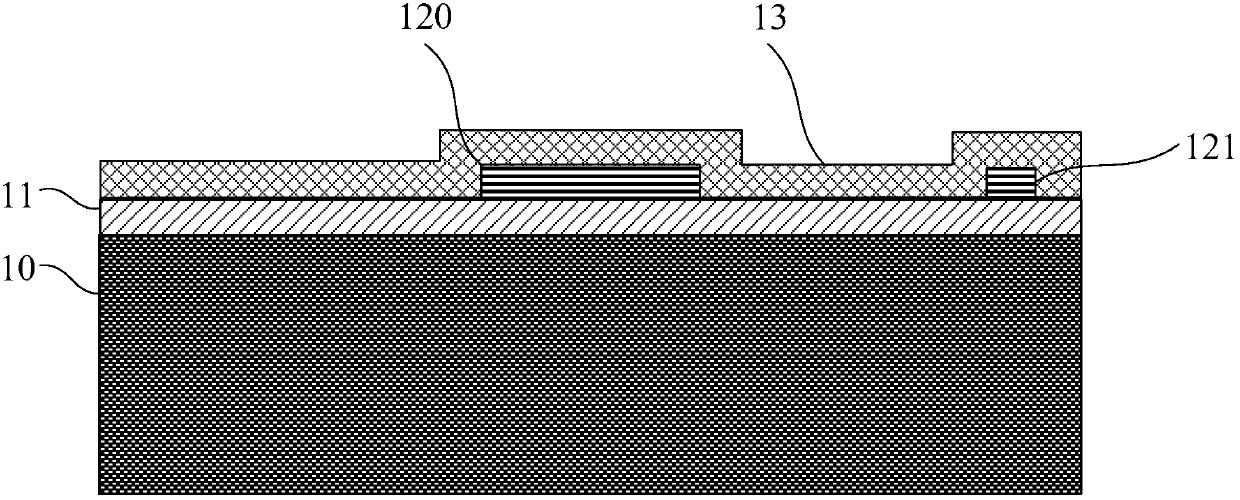

[0071] S1: if Figure 1a As shown, a semiconductor substrate is provided, and the semiconductor substrate can be an SOI substrate, or a common silicon wafer, and the common silicon substrate 10 is tentatively selected in this embodiment. A first silicon oxide layer 11 is prepared as a first dielectric layer on the silicon substrate 10 by a thermal oxidation process, and then a polysilicon layer 12 is deposited on the first silicon oxide layer 11 by an LPCVD process; then ion implantation is used The polysilicon layer 12 is doped by the process to make it conductive as the first conductive layer. The doped ions can be N-type or P-type ions. For example, the commonly used dopants for N-type doping are phosphorus, arsenic, etc., P The commonly used dopant for type doping is boron, indium, gallium, aluminum, or boron ...

Embodiment 2

[0089] like figure 2 As shown, the present embodiment provides a structure of a three-dimensional vacuum sensor, at least comprising: a semiconductor substrate 1', a first support film 2', a micro heater 3', a second support film 4', a thermopile (not shown ) and cover plate 6′.

[0090] The semiconductor substrate 1' has a groove 10', and the semiconductor substrate 1' can be a common silicon substrate or an SOI substrate; the first supporting film 2' wraps the micro heater 3', and with the side wall of the periphery of the groove 10' as a support, it is suspended above the groove 10'; the first supporting film 2' is a composite film, and the first supporting film 2' in this embodiment is A composite film with a sandwich structure comprising the first silicon oxide layer 20', the first silicon nitride layer 21', and the second silicon oxide layer 22' in sequence from bottom to top. better control. But it is not limited thereto. In other embodiments, the first support film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com