Array substrate, manufacturing method of array substrate and display panel

A technology for array substrates and display panels, applied in semiconductor/solid-state device manufacturing, instruments, semiconductor devices, etc., can solve the problem of reducing the driving voltage of the insulating layer, and achieve the enhancement of horizontal electric field strength, high brightness, and weakening of vertical electric field strength distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

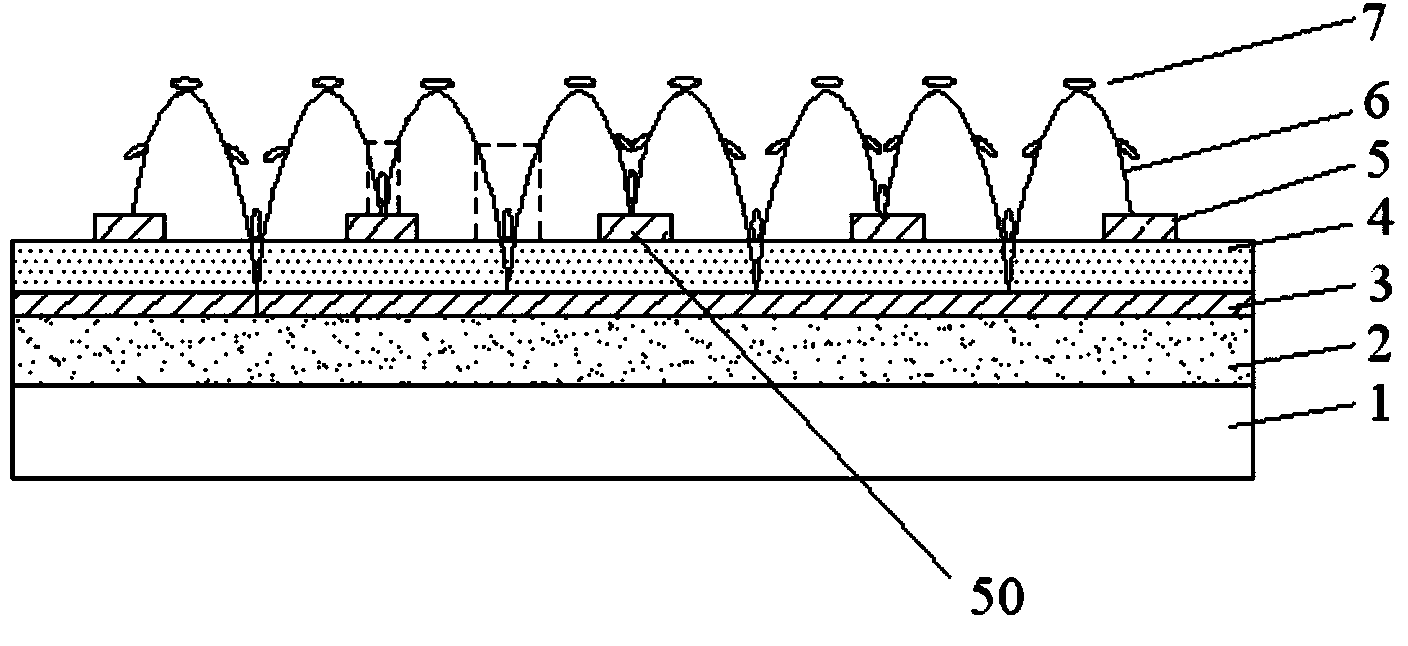

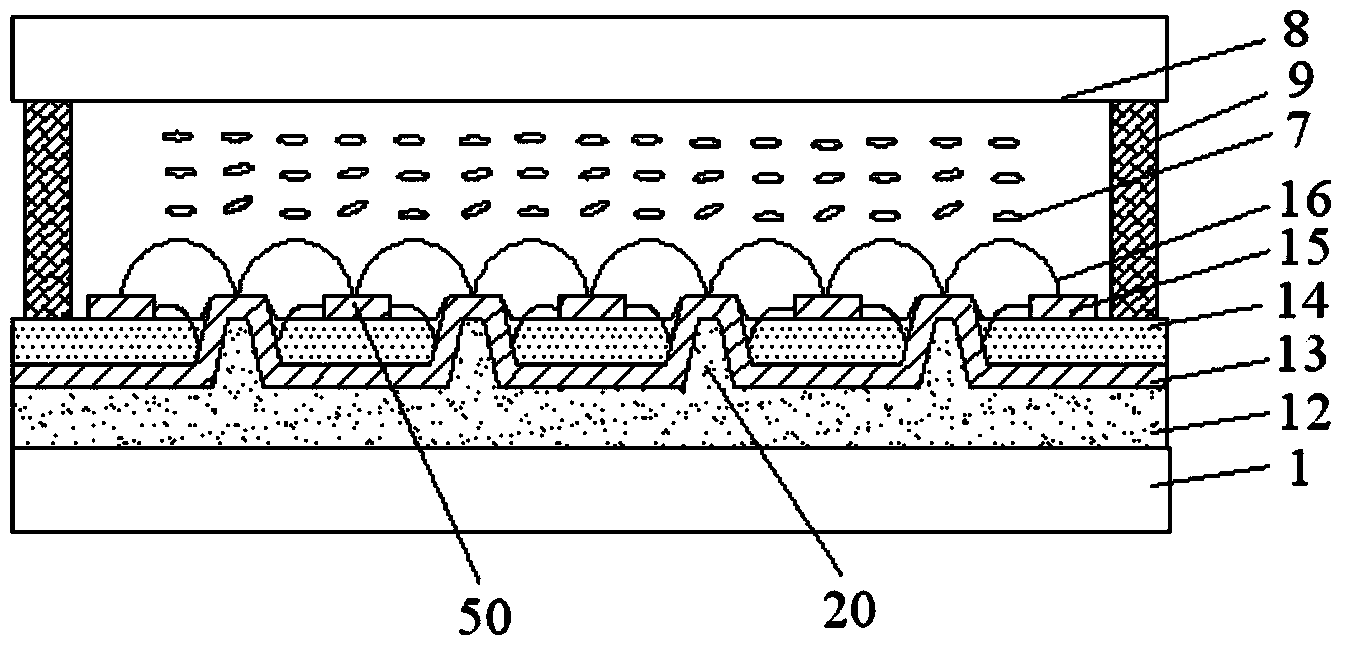

[0031] The present invention firstly provides an array substrate, such as figure 2 As shown in , the array substrate includes a planar layer 12 , a first electrode layer 13 , an insulating layer 14 and a second electrode layer 15 sequentially located above the base substrate 1 (the "base substrate" here includes a thin film transistor array). The second electrode layer 15 includes a plurality of electrode strips 50 , the planar layer 12 includes a plurality of protrusions 20 protruding toward the second electrode layer 15 , and at least a part of the first electrode layer 13 is formed on the protrusions 20 .

[0032] The present invention improves the design o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com