Gantry crane

A gantry crane and gantry technology, applied in the direction of cranes, trolley cranes, load hanging components, etc., can solve the problems of reduced lifting height of spreaders, inability to meet use requirements, and increased crane weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

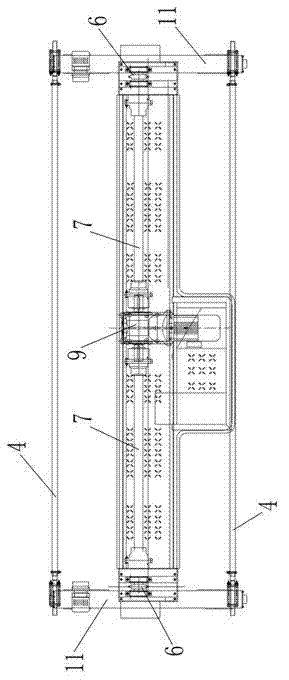

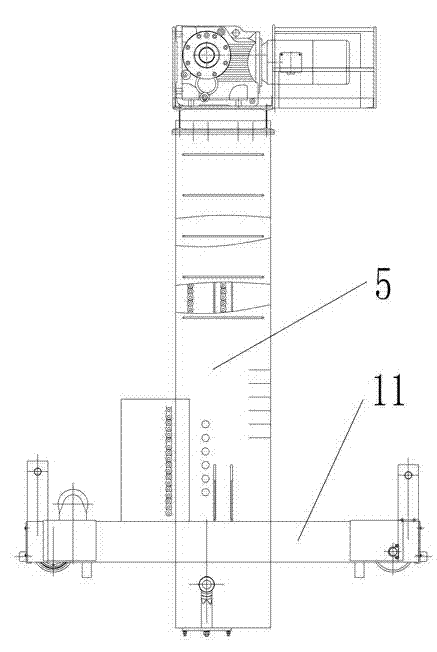

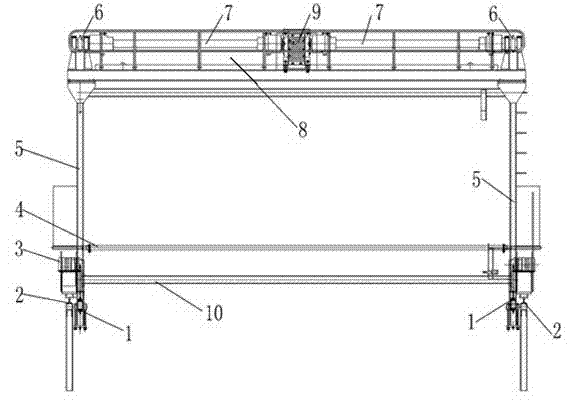

[0017] An example of a gantry crane Figure 1~3 As shown: it includes two guide rails 2 arranged side by side at intervals from left to right and the guiding direction extends along the front and rear directions. The two guide rails 2 are equipped with a gantry for guiding and moving. 3 and a displacement detection device for detecting the moving stroke of the gantry. The gantry includes uprights 5 which are respectively guided and moved and assembled on corresponding guide rails 2 and a main girder 8 bridging the upper ends of the two uprights 5 . The two ends of the beam 10 are assembled on the two uprights 5 through the corresponding guide structure to guide and move in the up and down direction. The guide structure includes a guide with the slots on the two uprights 5 facing opposite and the guiding directions extending in the up and down direction. The left and right ends of the suspension beam 10 are respectively guided and inserted into the guide grooves of the corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com