Patents

Literature

167results about How to "Reduce fermentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

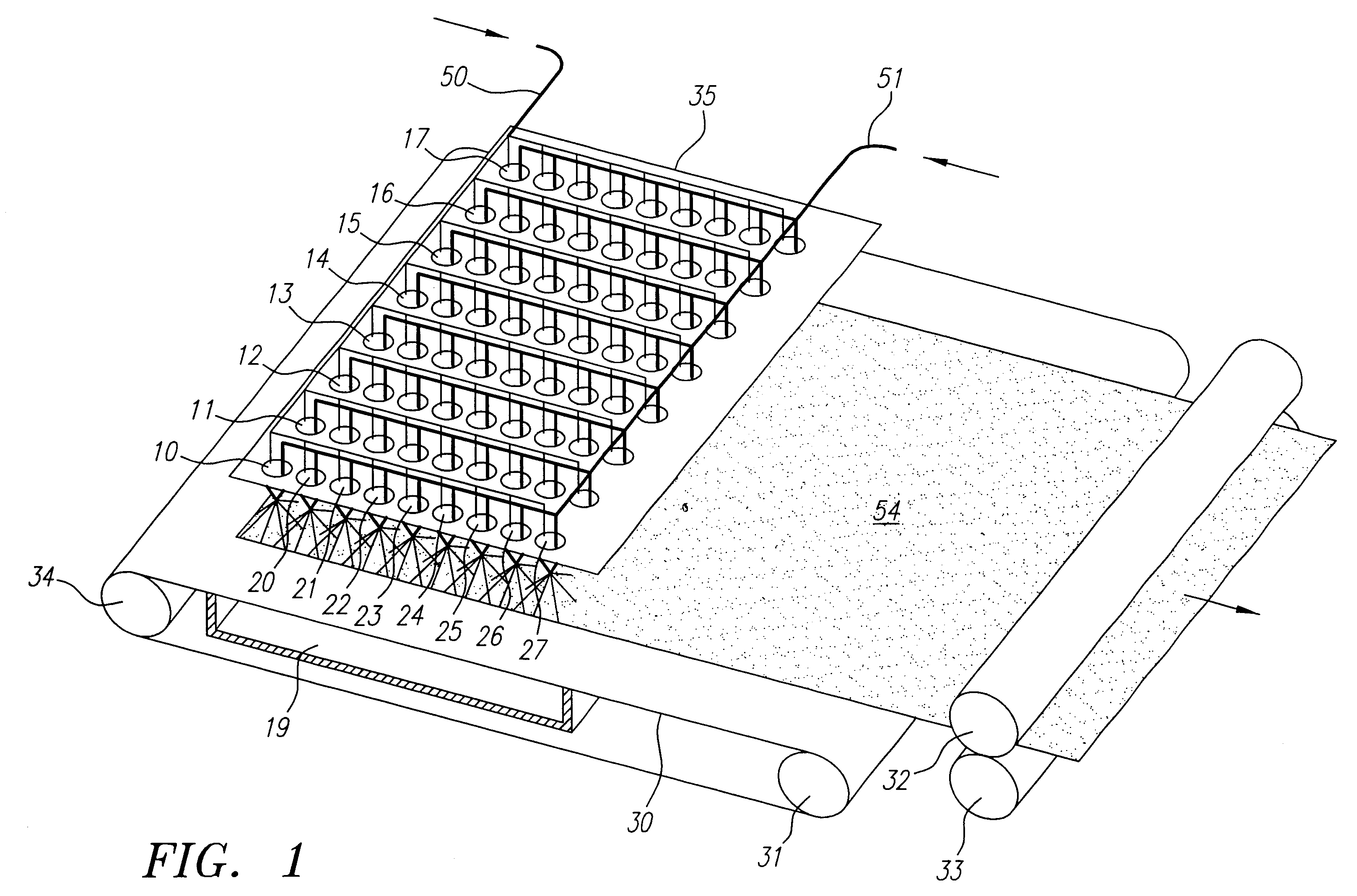

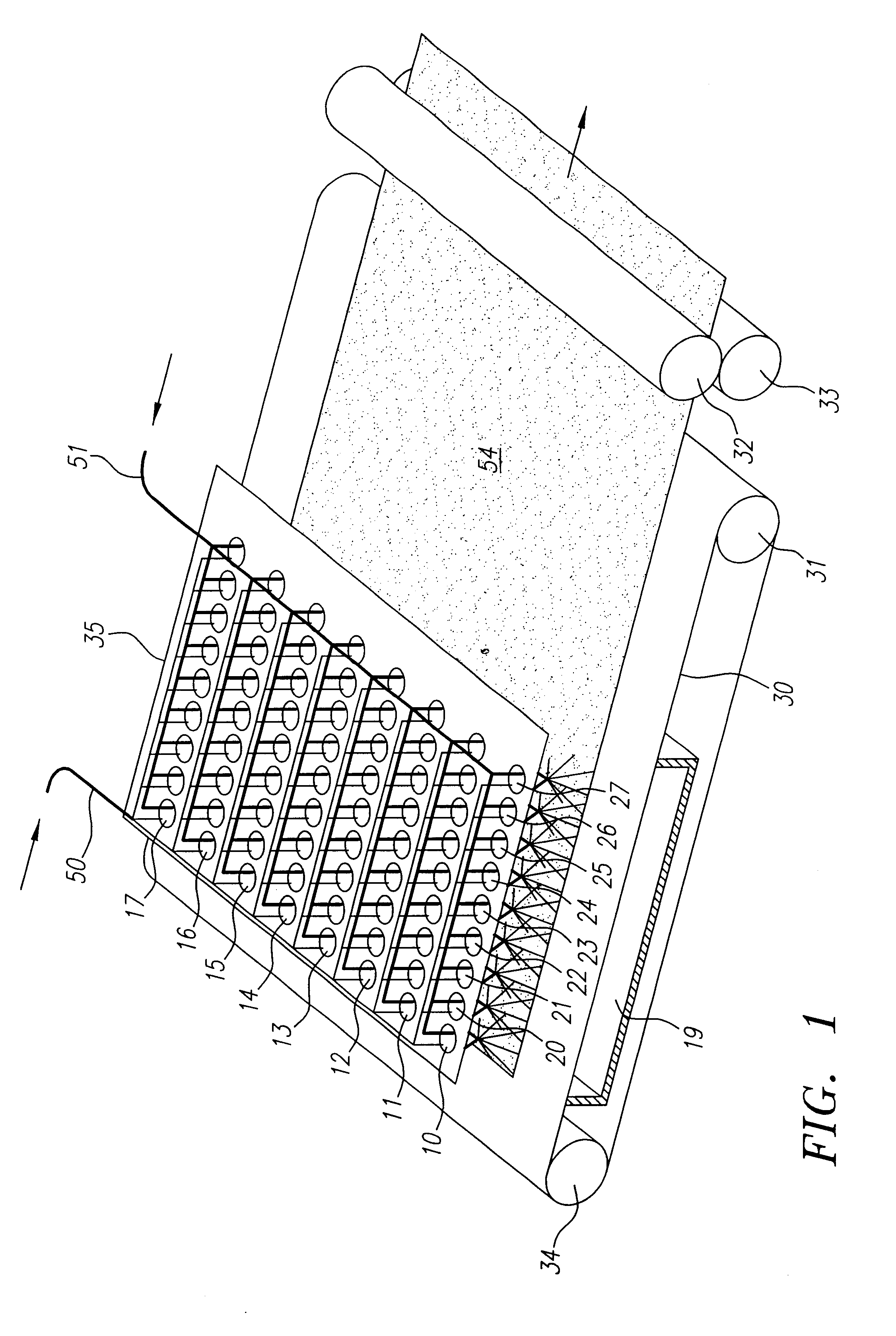

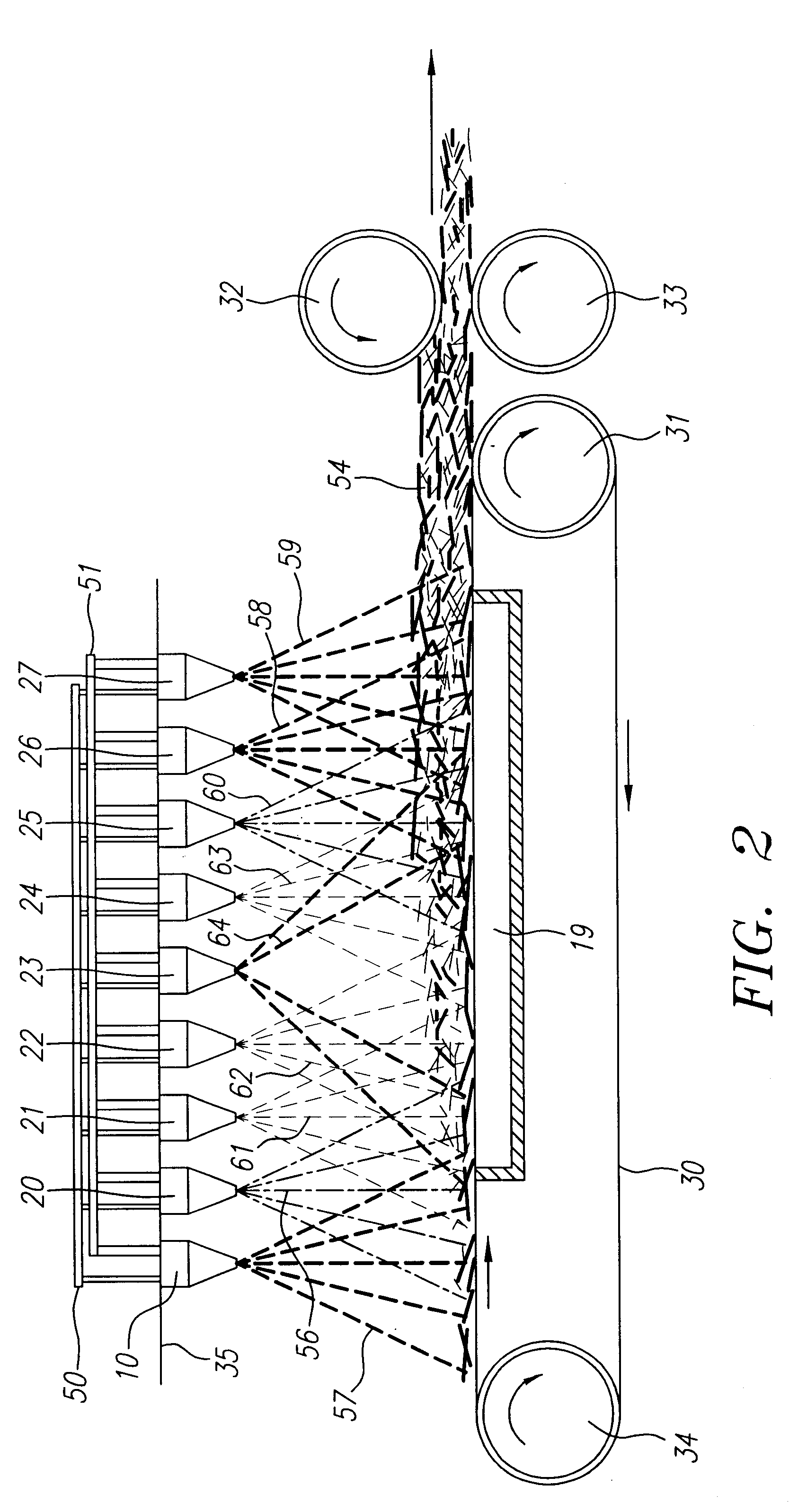

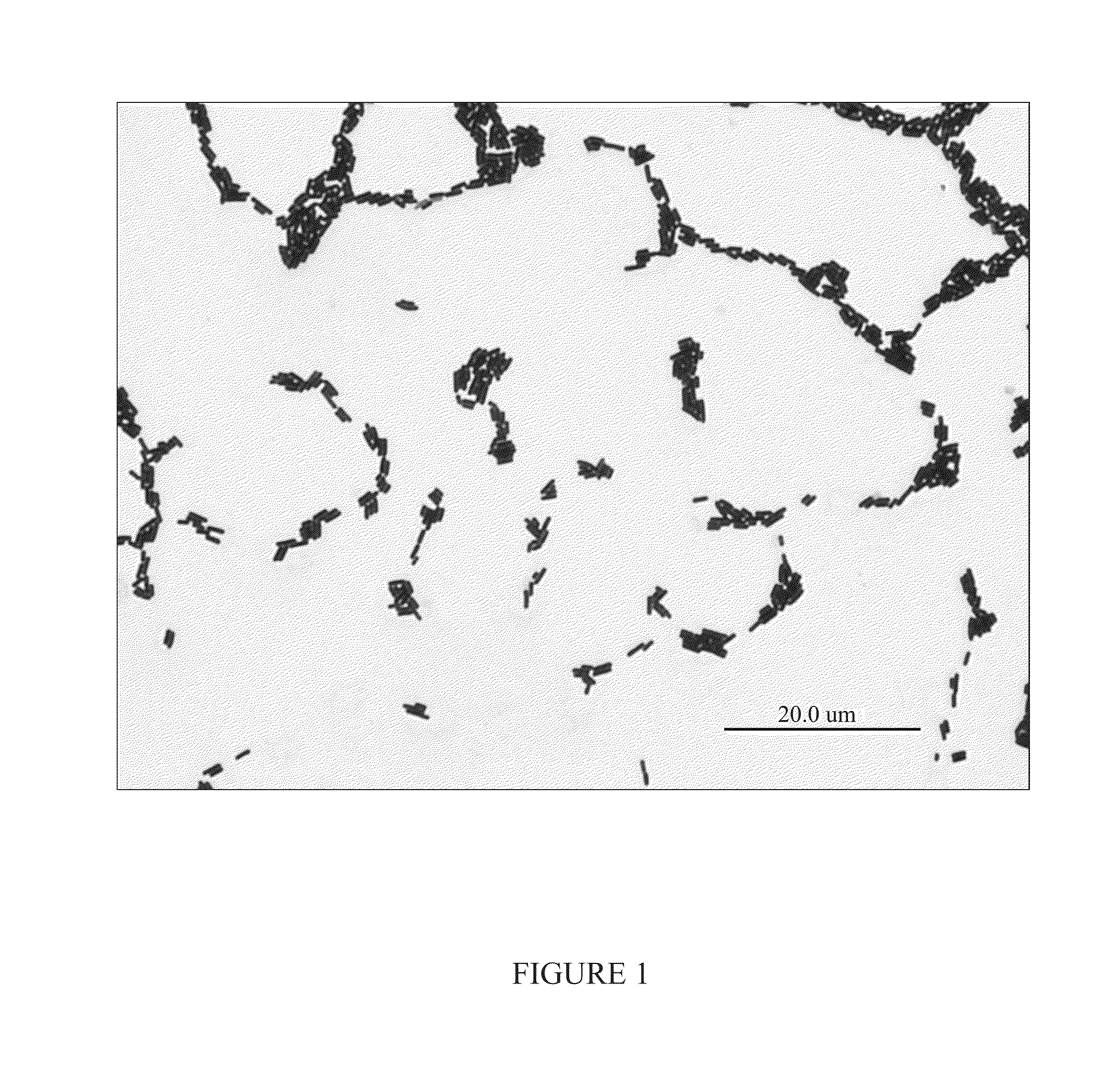

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6315806B1Increase distanceReduce resistanceFilament/thread formingLoose filtering material filtersMean diameterFiber

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

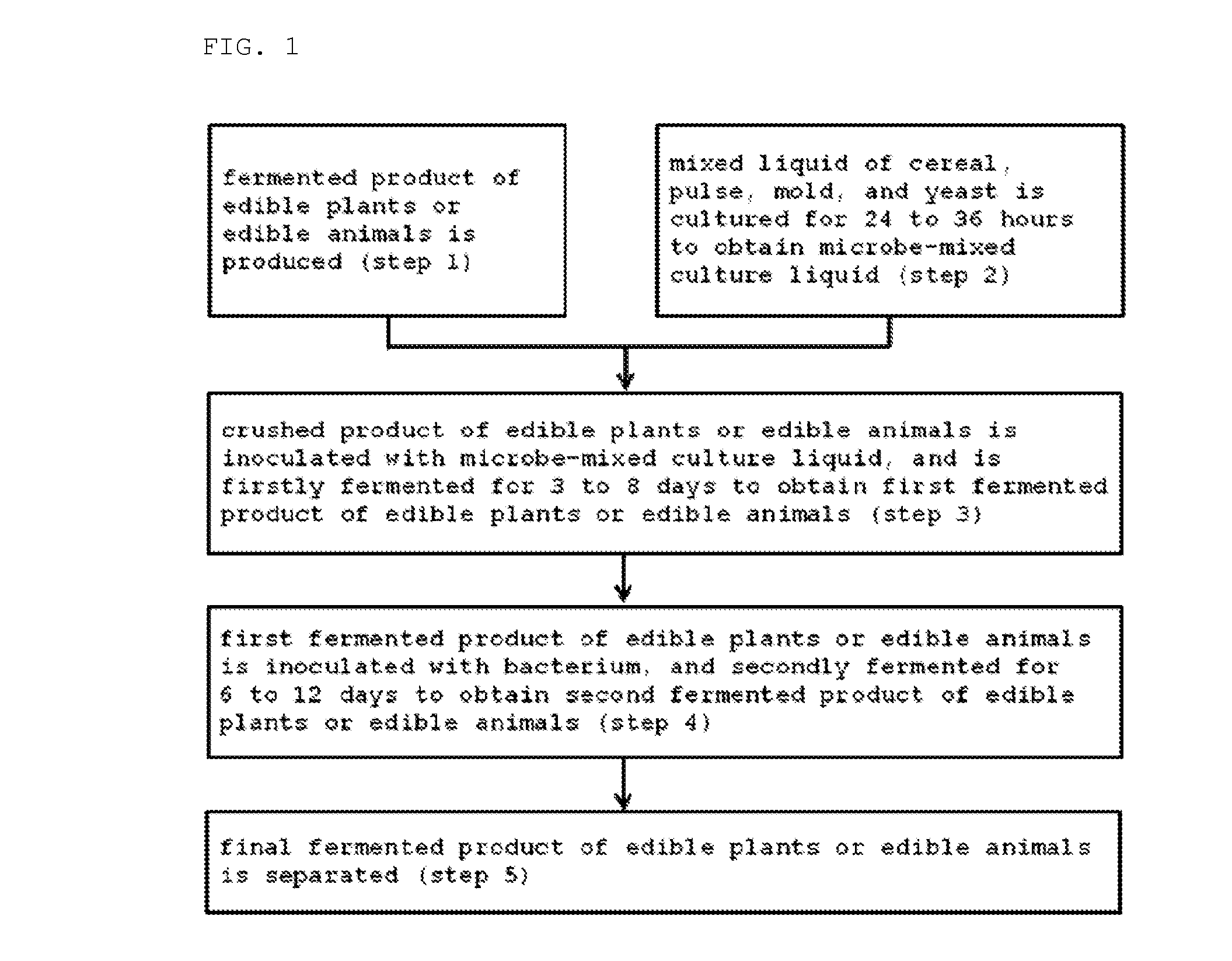

Method for producing fermented edible plants or edible animal/plants, fermented edible plants or edible animal/plants produced by same, and foods containing same

ActiveUS20100316763A1Increase heightPrevent invasionDough treatmentEdible seed preservationFood flavorOrganism

The present invention relates to a method for producing fermented edible plants or edible animal / plants, to fermented edible plants or edible animal / plants produced by same, and to foods containing same. The method for producing fermented edible plants or edible animal / plants includes the steps of: producing crushed edible plants or edible animal / plants; culturing a liquid mixture of grains, saccharides, filamentous fungi, and yeast for 24 to 36 hours to produce a mixed microbial broth; inoculating the edible plants or edible animal / plants with the mixed microbial broth, and firstly fermenting the edible plants or edible animal / plants for 3 to 8 days to produce first fermented edible plants or edible animal / plants; and inoculating the first fermented edible plants or edible animal / plants with bacteria, and secondly fermenting the first fermented edible plants or edible animal / plants for 6 to 12 days to produce second fermented edible plants or edible animal / plants. Whereby, a fermentation period can be shortened, and food deterioration and the growth of pathogenic microorganisms can be suppressed. Further, adding the fermented edible plants or edible animal / plants produced by the above-described method into foods can provide storage stability, increase bioavailability, and improve flavor.

Owner:PHARVIS R&D KOREA

Manufacture of polytrimethylene ether glycol

InactiveUS7157607B1Increase productionReduce fermentationOrganic compound preparationMixingOrganic solventEther

A process of manufacture of polytrimethylene ether glycol comprising:(a) polycondensing reactant comprising diol selected from the group consisting of 1,3-propanediol, 1,3-propanediol dimer and 1,3-propanediol trimer or mixtures thereof in the presence of acid polycondensation catalyst to form polytrimethylene ether glycol;(b) adding water to the polytrimethylene ether glycol to form an aqueous mixture;(c) heating the aqueous mixture to hydrolyze acid esters formed during the acid catalyzed polycondensation;(d) adding to the hydrolyzed aqueous mixture organic solvent that is miscible with polytrimethylene ether glycol to form (i) organic phase containing the polytrimethylene ether glycol and residual acid polycondensation catalyst from the polycondensing and (ii) aqueous phase;(e) separating the aqueous phase and the organic phase;(f) adding base to the separated organic phase to neutralize the residual acid polycondensation catalyst by forming salts of the residual acid polycondensation catalyst;(g) separating the organic phase into (i) liquid phase comprising the polytrimethylene ether glycol, the organic solvent and any residual water, and (ii) solid phase comprising the salts of the residual acid polycondensation catalyst and the base which is unreacted; and(h) removing the organic solvent and the residual water from the liquid phase to obtain polytrimethylene ether glycol.

Owner:EI DU PONT DE NEMOURS & CO

Probiotic fruit and vegetable enzyme drink and preparation method thereof

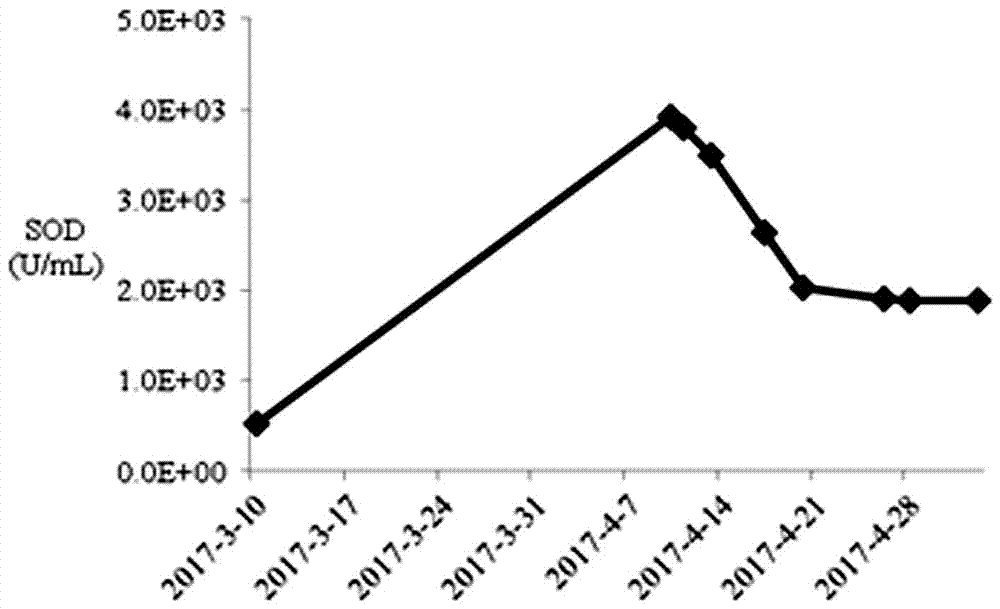

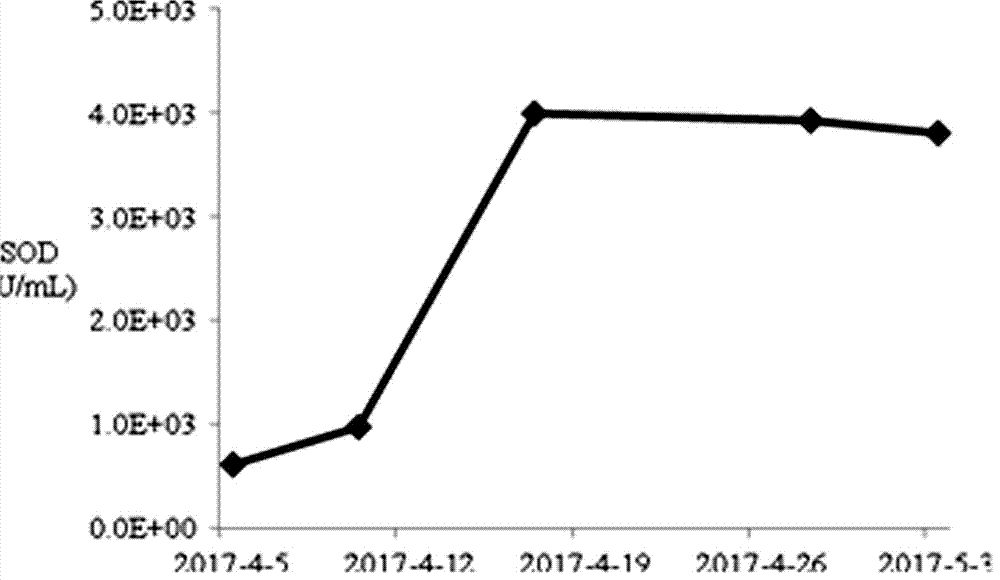

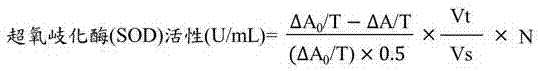

PendingCN107348272AHigh activityHigh nutritional valueFood ingredient for microbe protectionNutritive valuesLactobacillus paracasei

The invention provides a probiotic fruit and vegetable enzyme drink and a preparation method thereof. Fruits and vegetables as well as four-in-one PPHR Lactobacillus powder (including Lactobacillus paracasei, L. plantarum, L. helveticus and L. rhamnosus) are mixed and the obtained mixture is fermented, and the obtained fermented product is the probiotic fruit and vegetable enzyme drink. Compared with the prior art, the preparation method has the advantages that the fermentation process can be shortened, the fermentation process can be simplified, the nutritional value of fruit and vegetable juice can be increased, the fruit and vegetable juice is endowed with higher oxidation resistance, and the application range of Lactobacillus in food, particularly drinks, is broadened.

Owner:恒利康生物科技股份有限公司

Kitchen garbage disposal method

ActiveCN107824601AImprove processing efficiencyFull recoveryBio-organic fraction processingSolid waste disposalLitterReclaimed water

The invention relates to a kitchen garbage disposal method. The kitchen garbage disposal method adopts a kitchen garbage disposal device which comprises a crushing chamber, a disinfection chamber, a fermentation chamber, a separation chamber, a drying chamber, a sewage treatment cavity, a compression chamber and an organic fertilizer storage box. Through such steps as crushing, disinfection, fermentation, solid-liquid separation, sewage treatment, drying, compression and storage, solids of kitchen garbage form an organic fertilizer, liquid is processed to obtain reclaimed water, produced gas forms marsh gas, and therefore, full recycling and reusing of kitchen garbage are truly realized.

Owner:广东人峰实业有限公司

Prebiotic effect of sialyllactose

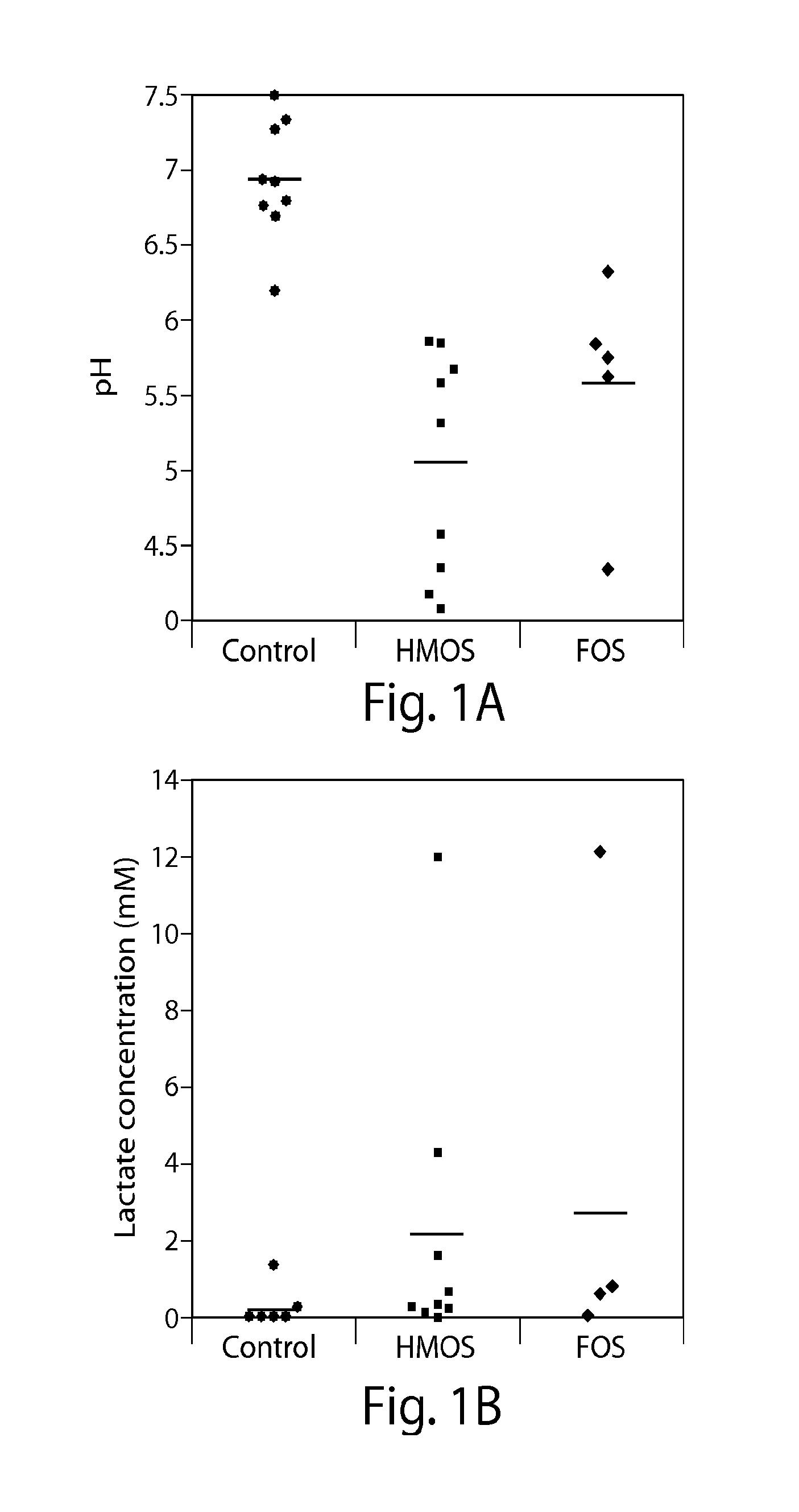

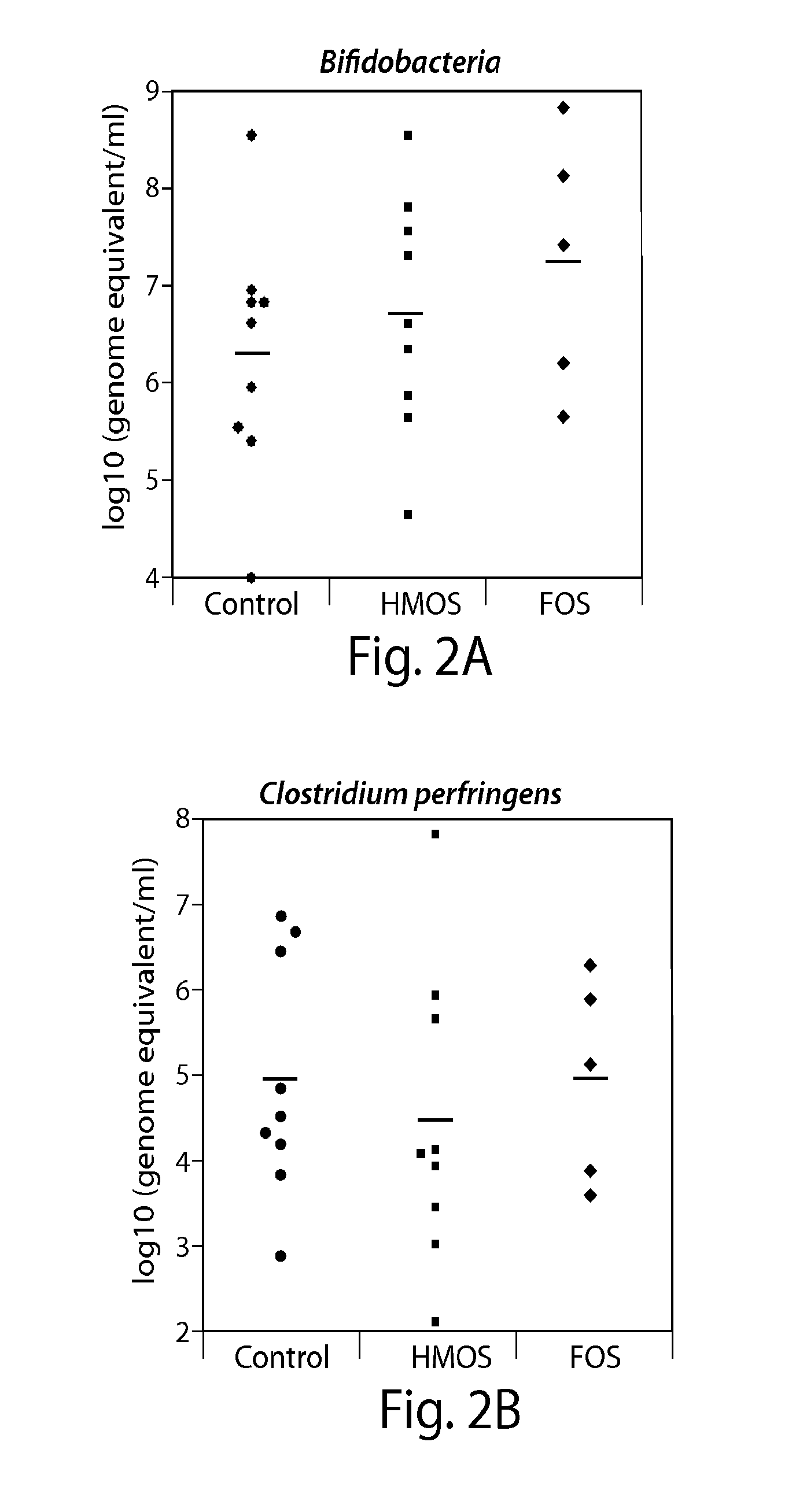

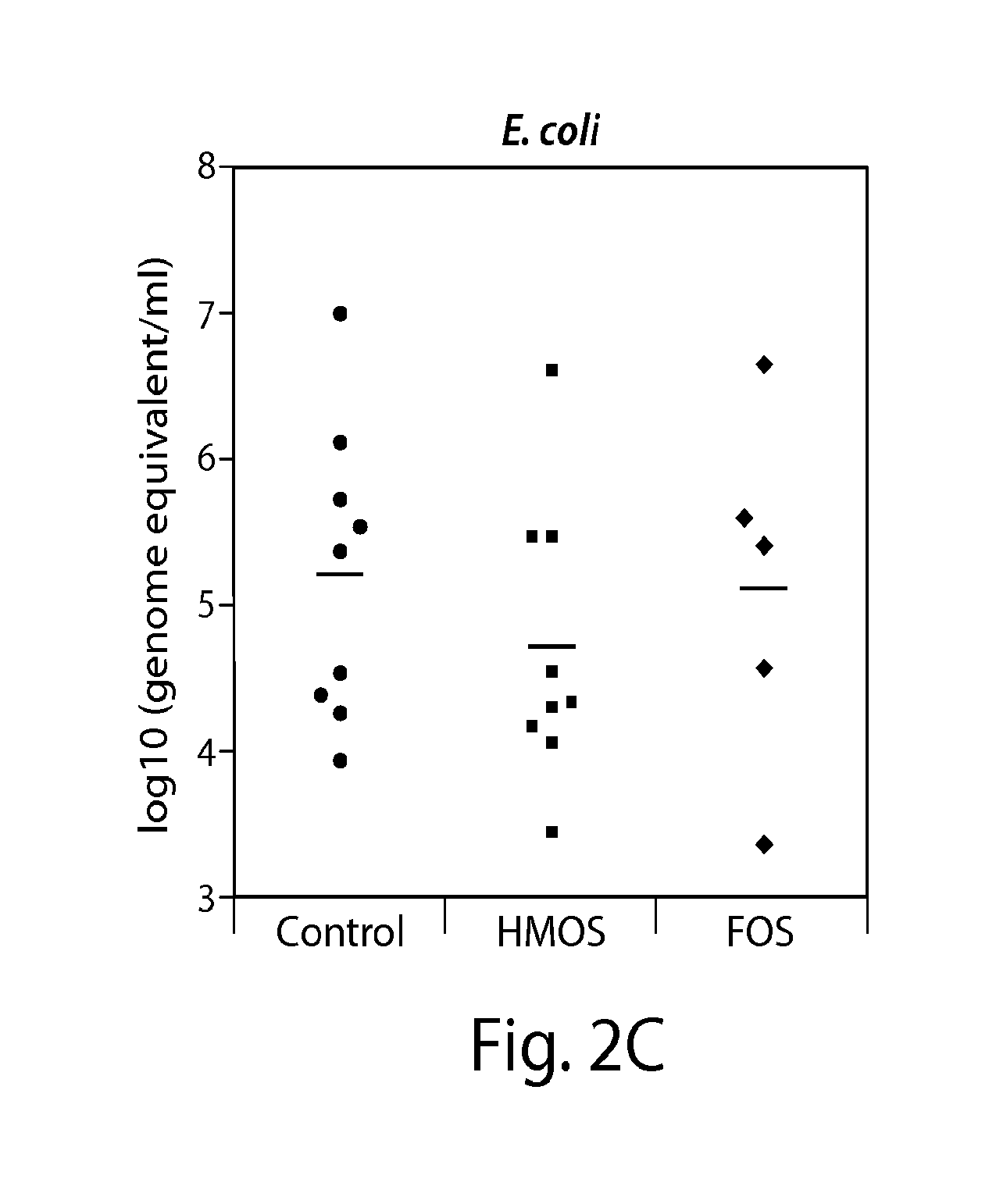

InactiveUS20150265661A1Promote growthHigh prebiotic effectBiocideOrganic active ingredientsBacteroidesOligosaccharide

Provided herein are prebiotic compositions comprising a combination of oligosaccharides such as sialyated oligosaccharides and fusocylated oligosaccharides, and uses thereof in stimulating the proliferation of beneficial intestinal micro biota, for example, of bifidobacteria, and / or in decreasing the abundance of enteric pathogens. The prebiotic compositions can further contain a probiotic, which can be a population of bifidobacteria, lactobacilli, Bacteriodes fragilis, Bacteriodes thetaiotaomicron, Enterococcus faecalis (pro biotic strains thereof), Staphylococcus epidermides, Enterobacter aerogenes, Enterobacter cloacae, or related bacteria having similar functions.

Owner:BOSTON COLLEGE

Pyridocarbazole derivatives having cGMP-PDE inhibitory activity

InactiveUS6018046ALow selectivityEasy to useBiocideOrganic chemistryIschemic Heart DiseasesActive ingredient

PCT No. PCT / JP97 / 01829 Sec. 371 Date Jan. 29, 1998 Sec. 102(e) Date Jan. 29, 1998 PCT Filed May 29, 1997 PCT Pub. No. WO97 / 45427 PCT Pub. Date Dec. 4, 1997The invention relates to novel pyridocarbazole derivatives having highly selective action in inhibiting cyclic GMP-phosphodiesterase (hereinafter abbreviated as cGMP-PDE), processes for producing such derivatives, agents containing at least one of such derivatives as an active ingredient for preventing and / or treating pulmonary hypertension, ischemic heart diseases or diseases against which the cGMP-PDE inhibitory action is effective, and intermediates useful for the production of pyridocarbazole derivatives.

Owner:MOCHIDA PHARM CO LTD

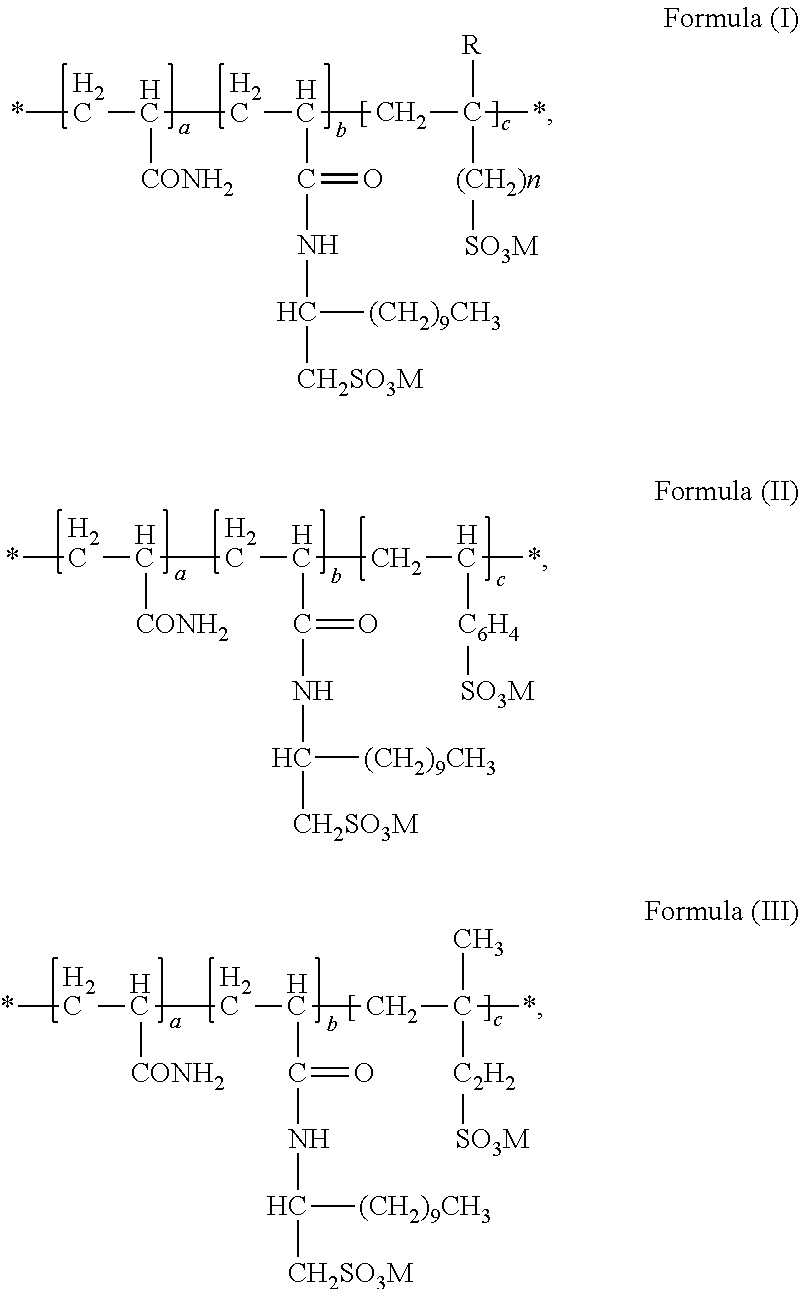

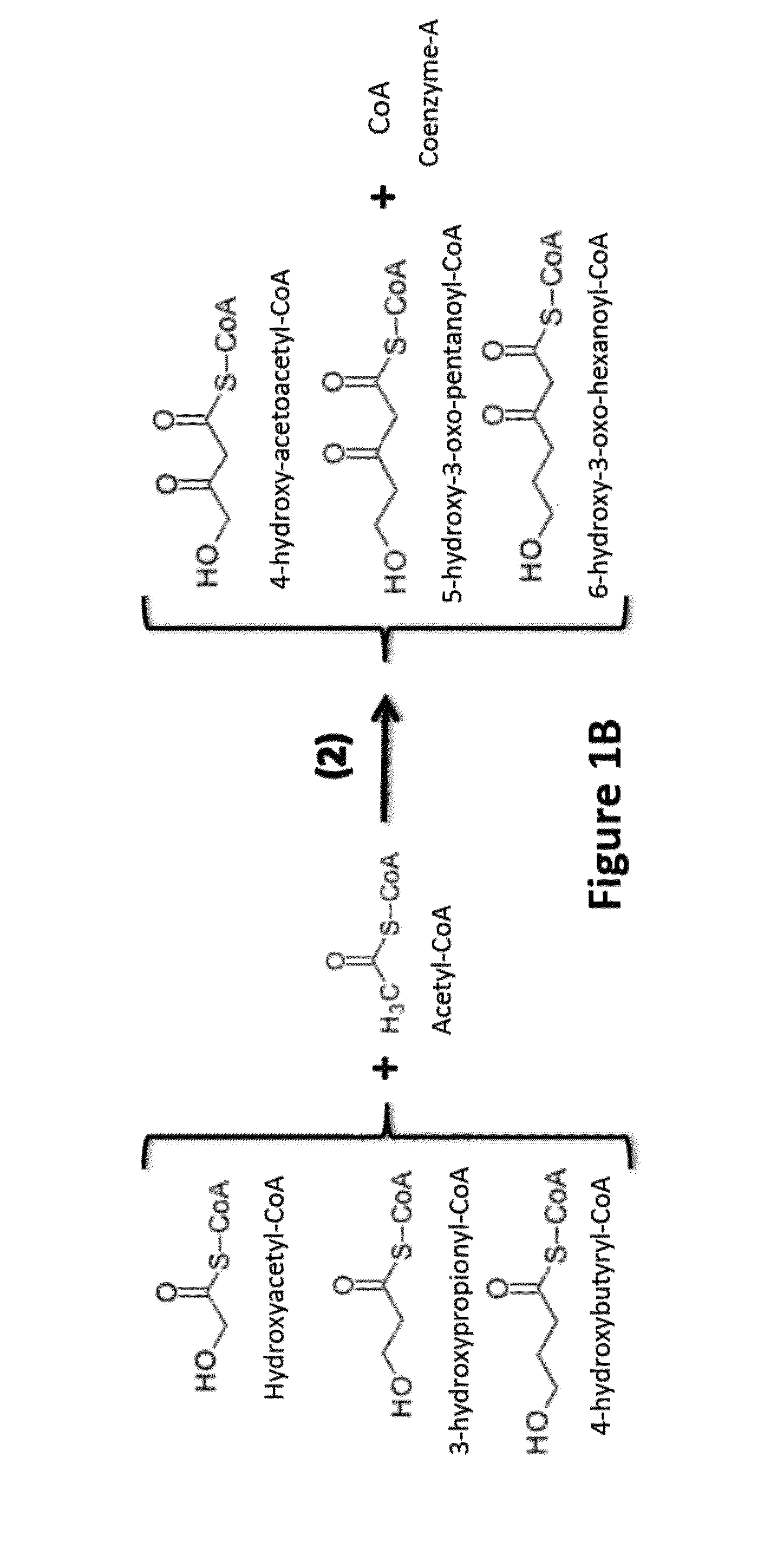

Dispersant and a drilling fluid containing the same

InactiveUS20130079257A1Low viscosityEliminate the effects ofTransportation and packagingMixingFiltrationSulfamic acid

The present invention provides a dispersant and a drilling fluid containing the dispersant. The dispersant comprises the product obtained from the reaction of water, lignin, phenol, sulfonating agent, telogen and catalyst at 140-220° C., preferably at 160-180° C.; the catalyst is one or more selected from the group consisting of sulfamic acid, p-toluenesulfonic acid and benzenesulfonic acid. The dispersant provided by the present invention not only can significantly lower the viscosity of the drilling fluid but also plays a role in reducing filtration loss.

Owner:CHINA PETROCHEMICAL CORP +1

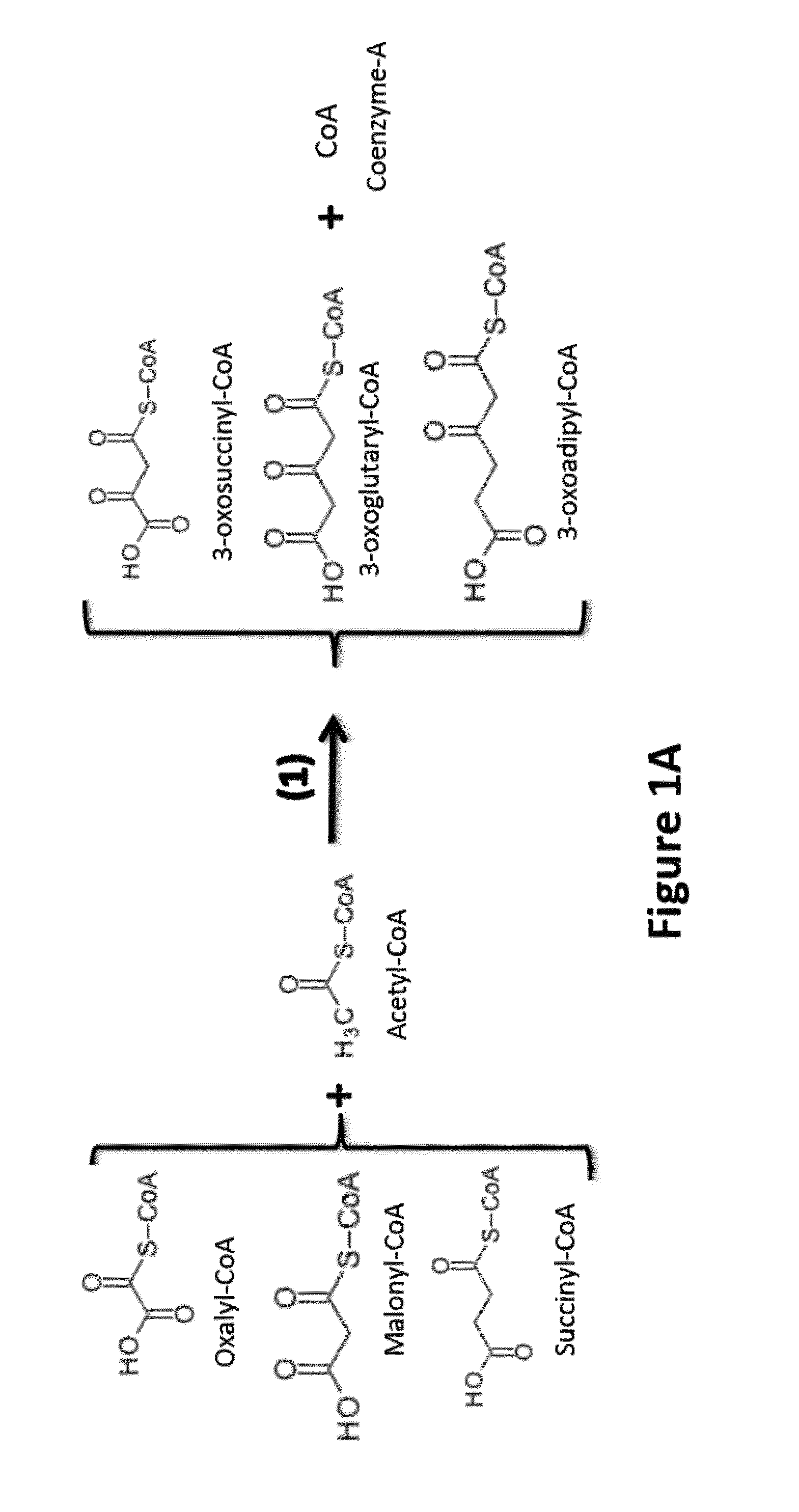

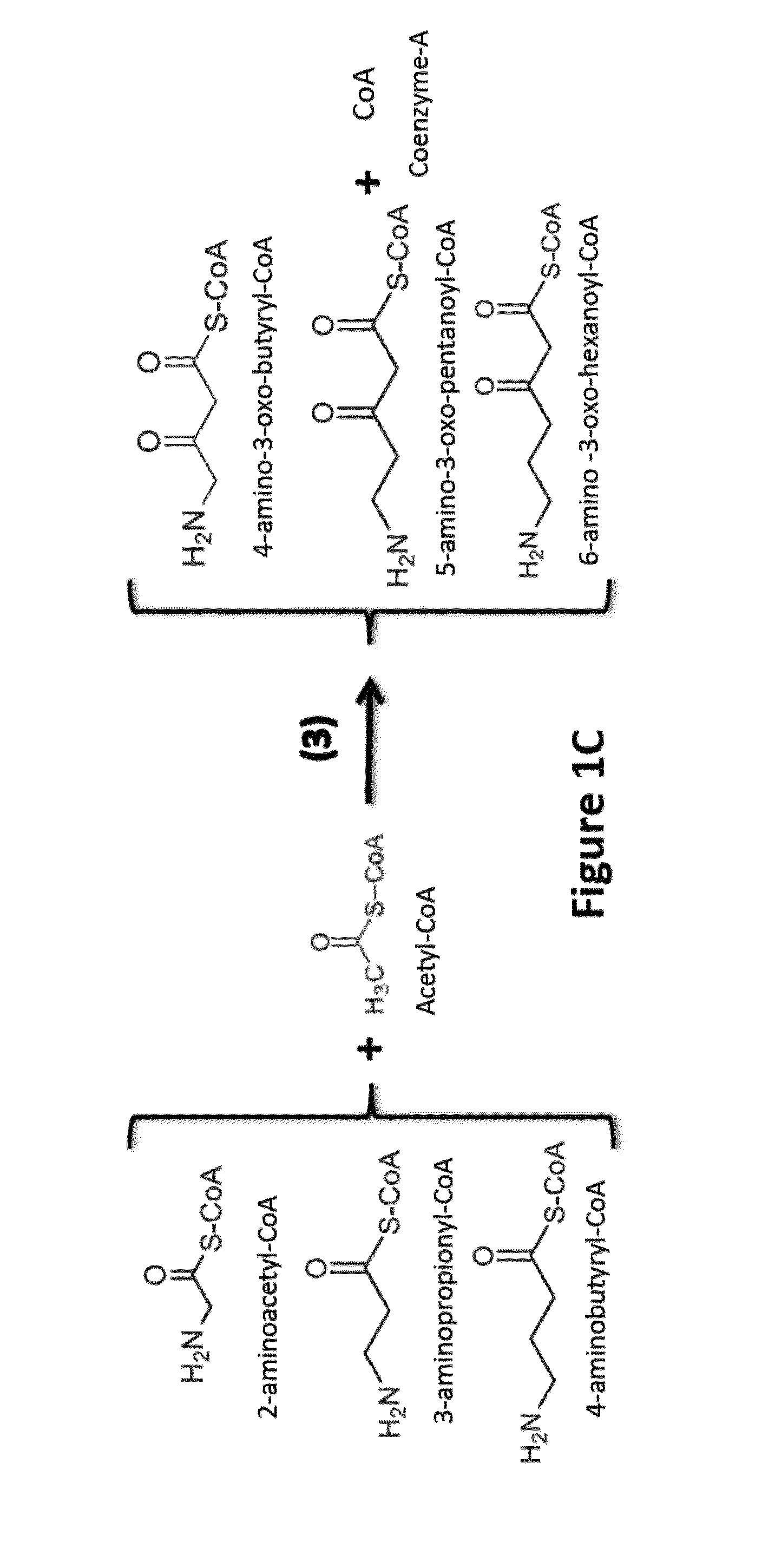

Functionalized carboxylic acids and alcohols by reverse fatty acid oxidation

ActiveUS20140273110A1Reduce expressionReducing lactate productionBacteriaHydrolasesAlcoholBeta oxidation

Bacteria that run the beta oxidation cycle in reverse anabolic direction are provided, along with many novel primers to start the reverse cycle, pathways to make such primers, and a large variety of products produced thereby. Methods for making desired product by using such primers in the reverse pathway are also disclosed.

Owner:RICE UNIV

Method for improving forage nutritional value of cottonseed meal through microbial fermentation

InactiveCN104186957AImprove the nutritional value of feedHigh protein contentAnimal feeding stuffBiotechnologyCellulose

The invention utilizes a microbial fermentation technology to improve the forage nutritional value of the cottonseed meal, so as to improve the forage quality of the cottonseed meal, increase the addition proportion in the forage and realize the promotion of the protein nutritional value and the feeding value of the cottonseed meal, aiming at the disadvantages that cottonseed meal is rich in antinutritional factors of free gossypol, cellulose, oligosaccharide, phytic acid and the like, the protein quality is relatively poor and the content of essential amino acids of methionine and the like is low and unbalanced, so that the large-scale forage of cottonseed meal is restricted. The method for improving forage nutritional value of cottonseed meal through the microbial fermentation adopts the technology of 'composite enzymatic hydrolysis and multi-strain three-step solid-state fermentation', so as to prepare the fermented cottonseed meal product that is high in the free gossypol, cellulose degradation degree and the protein content; the cottonseed meal product is rich in nutritional ingredients of probiotics, vitamins, enzyme, amino acid, short peptide, high-grade protein and the like; the method for improving the forage nutritional value of cottonseed meal through the microbial fermentation has the advantages of prompting growth and development, improving the utilization ratio of the forage, enhancing immunization, improving intestinal micro ecology, preventing diseases and the like. The method for improving forage nutritional value of cottonseed meal through the microbial fermentation adopts the solid-state fermentation; the manufacturing technology is simple; the energy consumption is low; zero environmental pollution is generated; and the investment is small. Therefore, mass production is easy.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

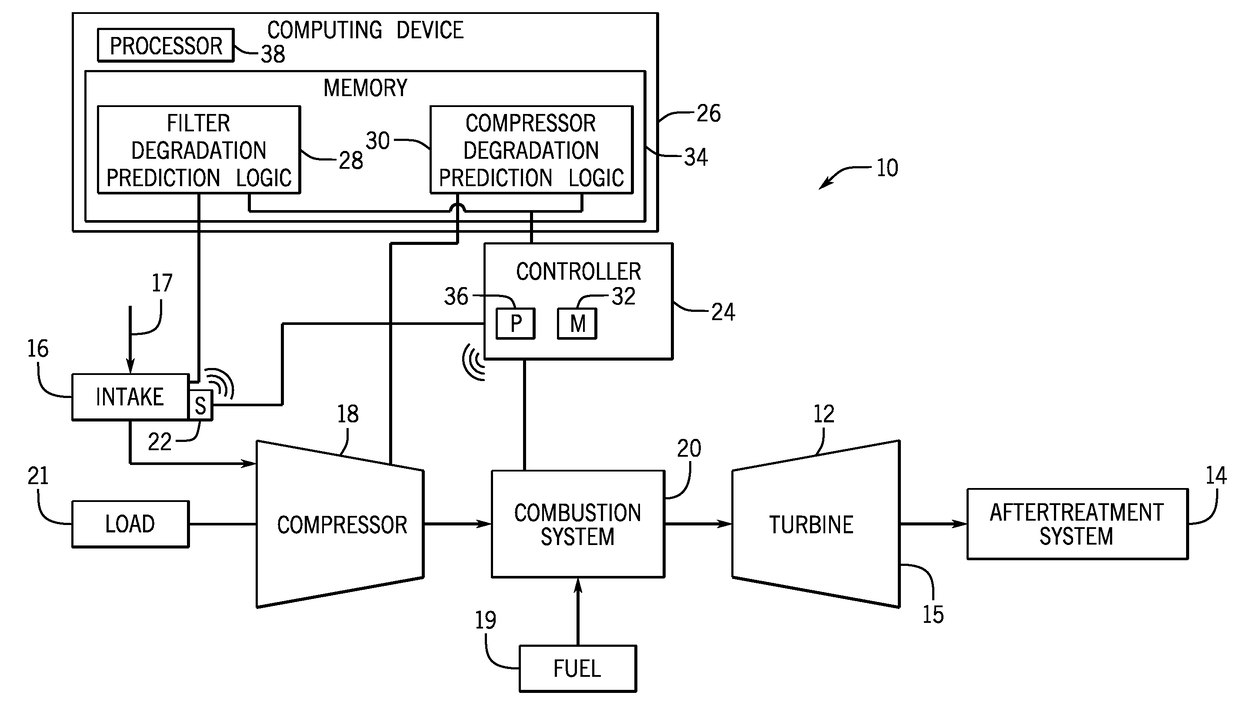

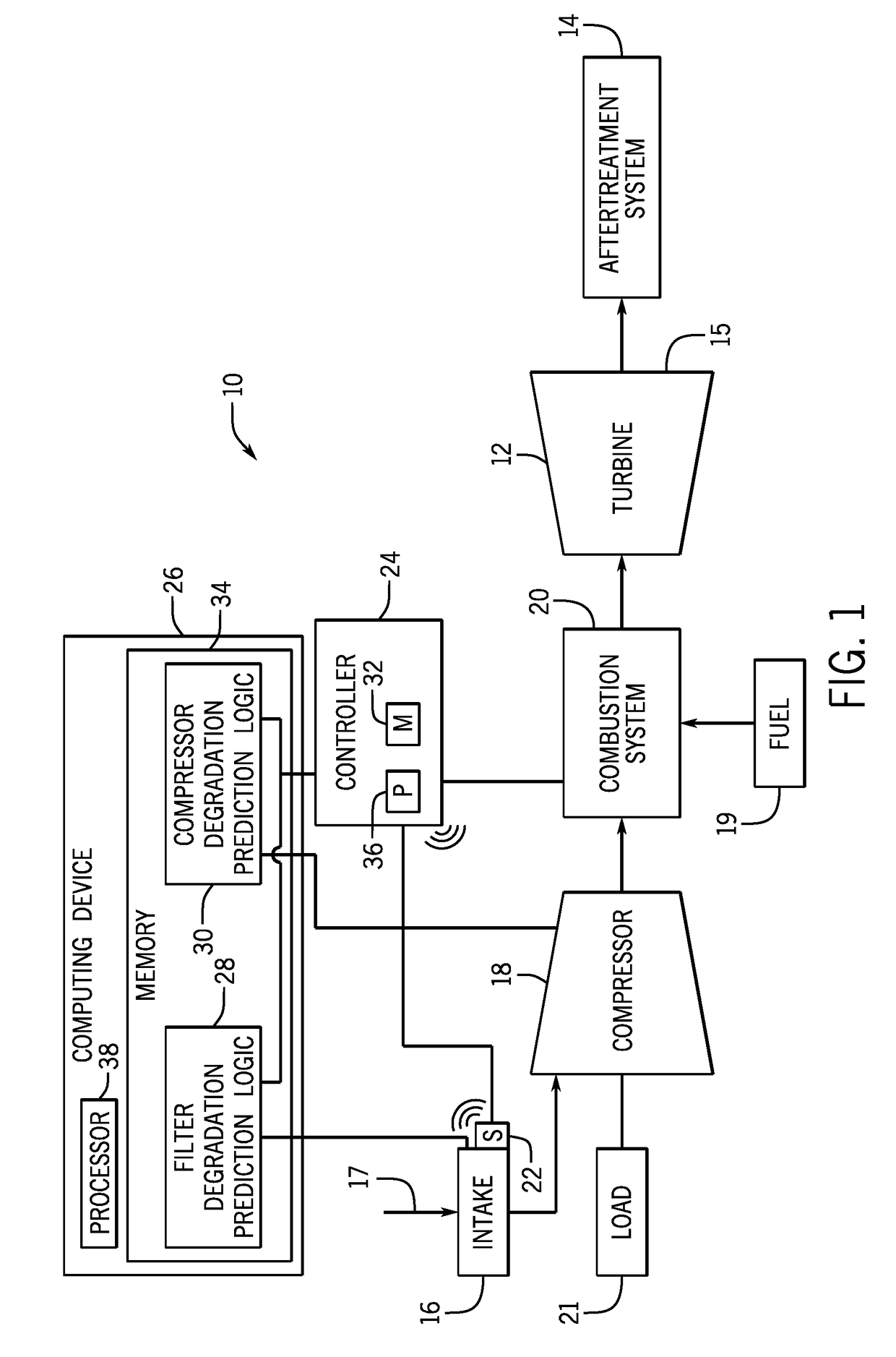

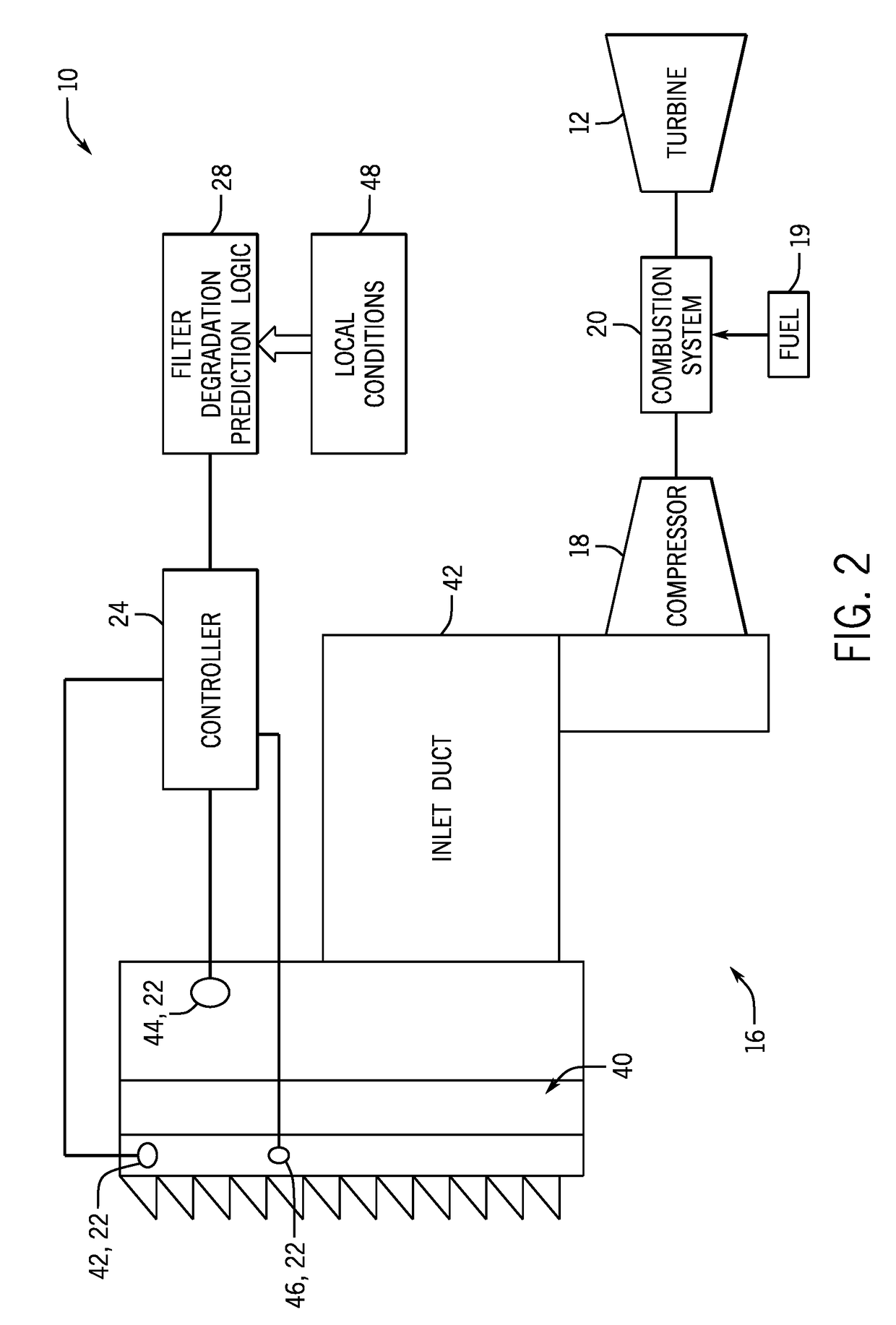

System and method for condition-based monitoring of turbine filters

InactiveUS20180073386A1Reduce the possibilityImprove performanceGas-turbine engine testingDispersed particle filtrationFiltrationCondition based monitoring

In one embodiment, a turbine system includes an intake section including a filter house, the filter house including at least one filtration stage, each of the at least one filtration stage, including a filter. The turbine system also includes one or more sensors disposed in the intake section, and a processor configured to receive performance data related to testing conditions of the intake section, sensor data from the one or more sensors, local conditions data, or some combination thereof, predict a filter degradation rate for the filter using a filter degradation prediction model that provides a function of performance of the filter based on the performance data, the sensor data, the local conditions data, or some combination thereof, and perform one or more preventative actions based on the filter degradation rate prediction.

Owner:GENERAL ELECTRIC CO

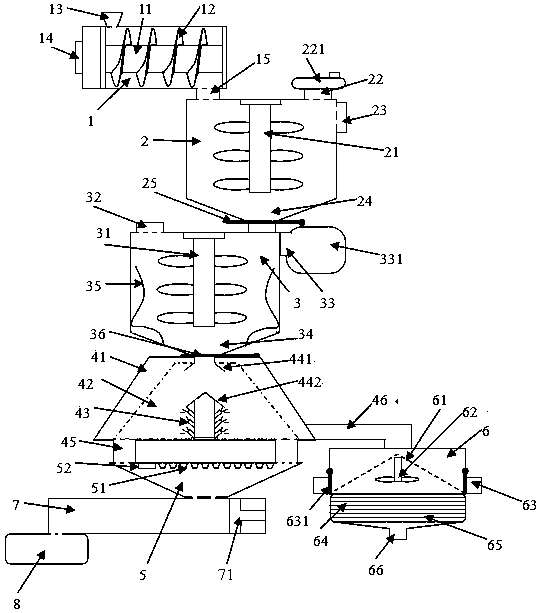

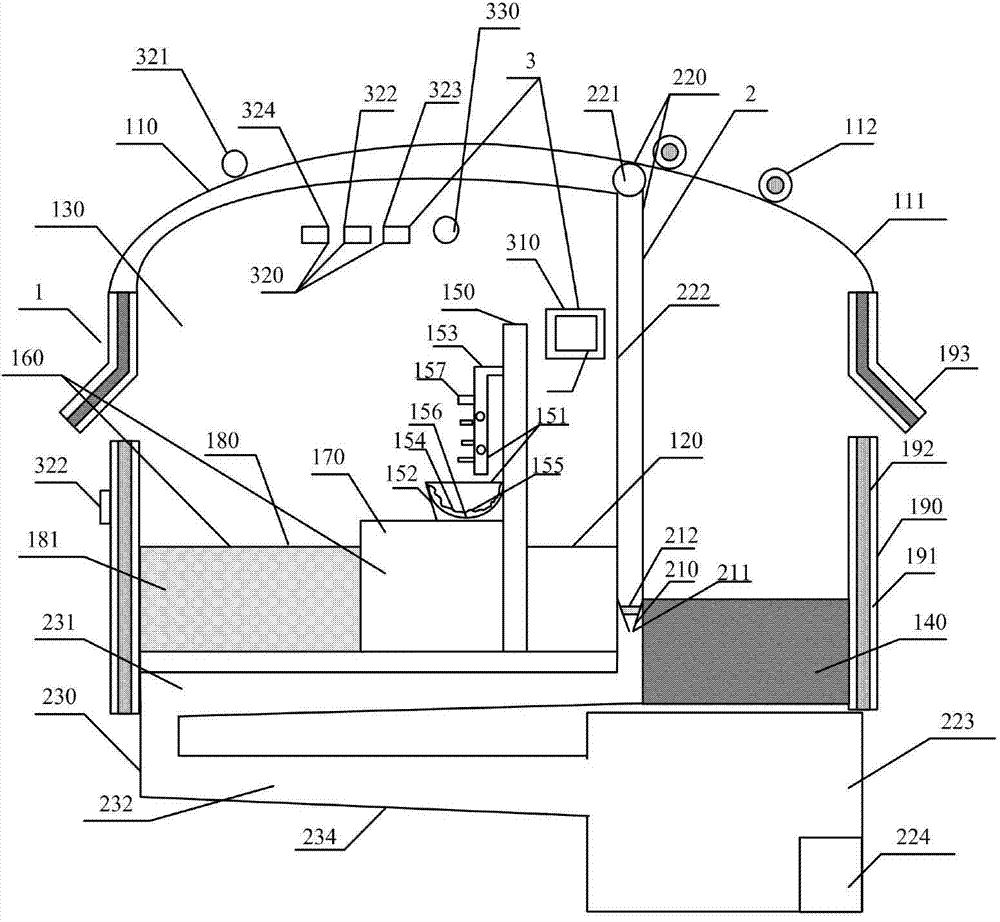

Green livestock cultivation system and method

ActiveCN104719172ASkin Health Problem ControlReduce fermentationAnimal watering devicesClimate change adaptationWater storageWater leakage

The invention discloses a green livestock cultivation system. The green livestock cultivation system comprises a cultivation shed, a temperature adjusting unit and a control unit, wherein biological litter in the cultivation shed contains traditional Chinese medicine composition capable of relieving itching and sterilizing; the temperature adjusting unit comprises a V-shaped water tank, a water discharge component and a water return chamber, the water return chamber is formed below a cultivation chamber and includes a first water return chamber and a second water return chamber, the second water return chamber is located below the first water return chamber and communicated with the same, the first water return chamber receives water from a plurality of water leakage holes and forms a flowing water cooling face below the cultivation chamber, and the second water return chamber is communicated to a water storage chamber. The green livestock cultivation system is healthy, environmental friendly, zero in emission, good in stability and high in practicality. The invention further provides a cultivation method which is ecological and environmental friendly in cultivation mode, easy to implement and good in environment factor controllability.

Owner:绵阳瑞丰中升农业科技有限公司

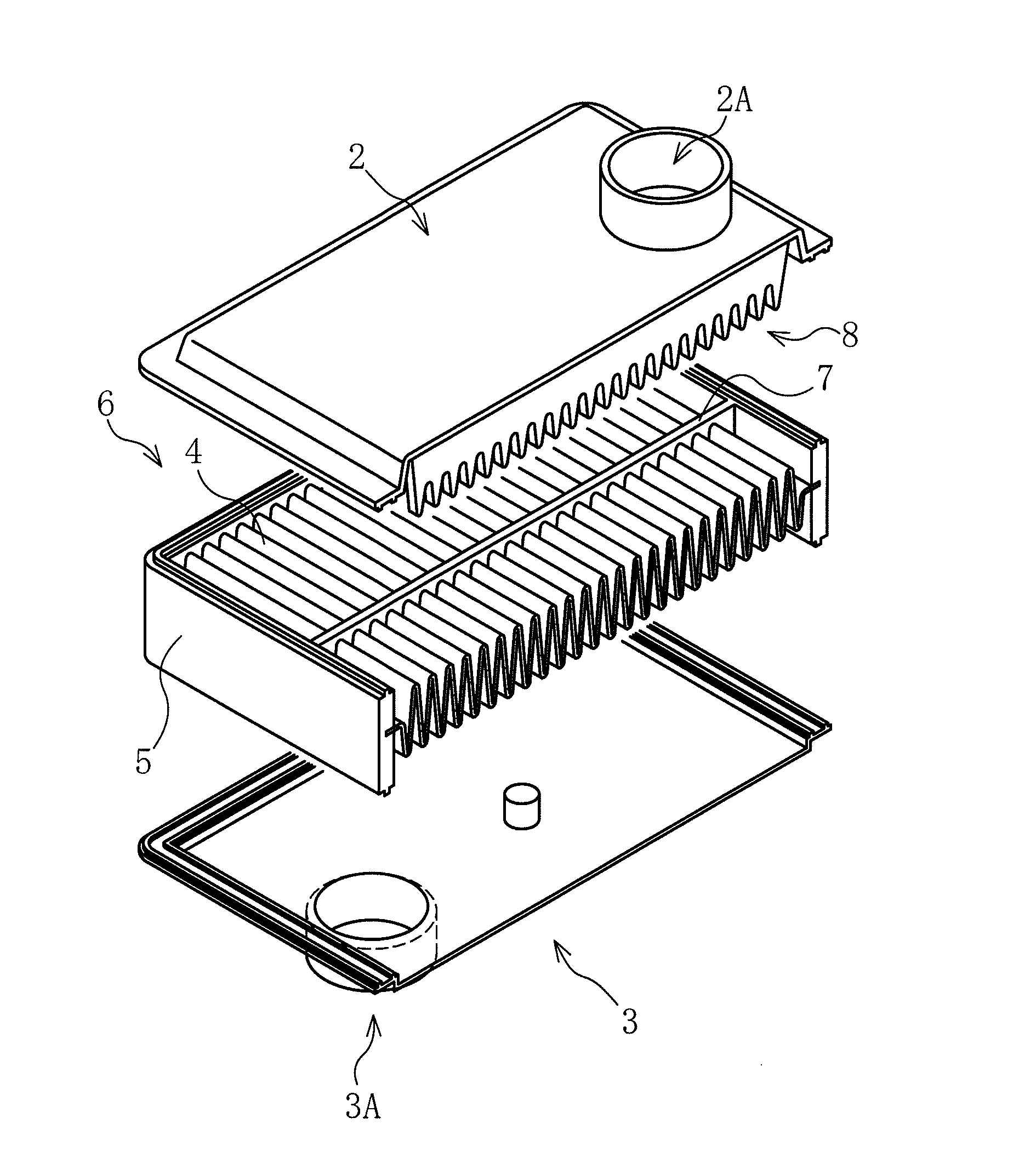

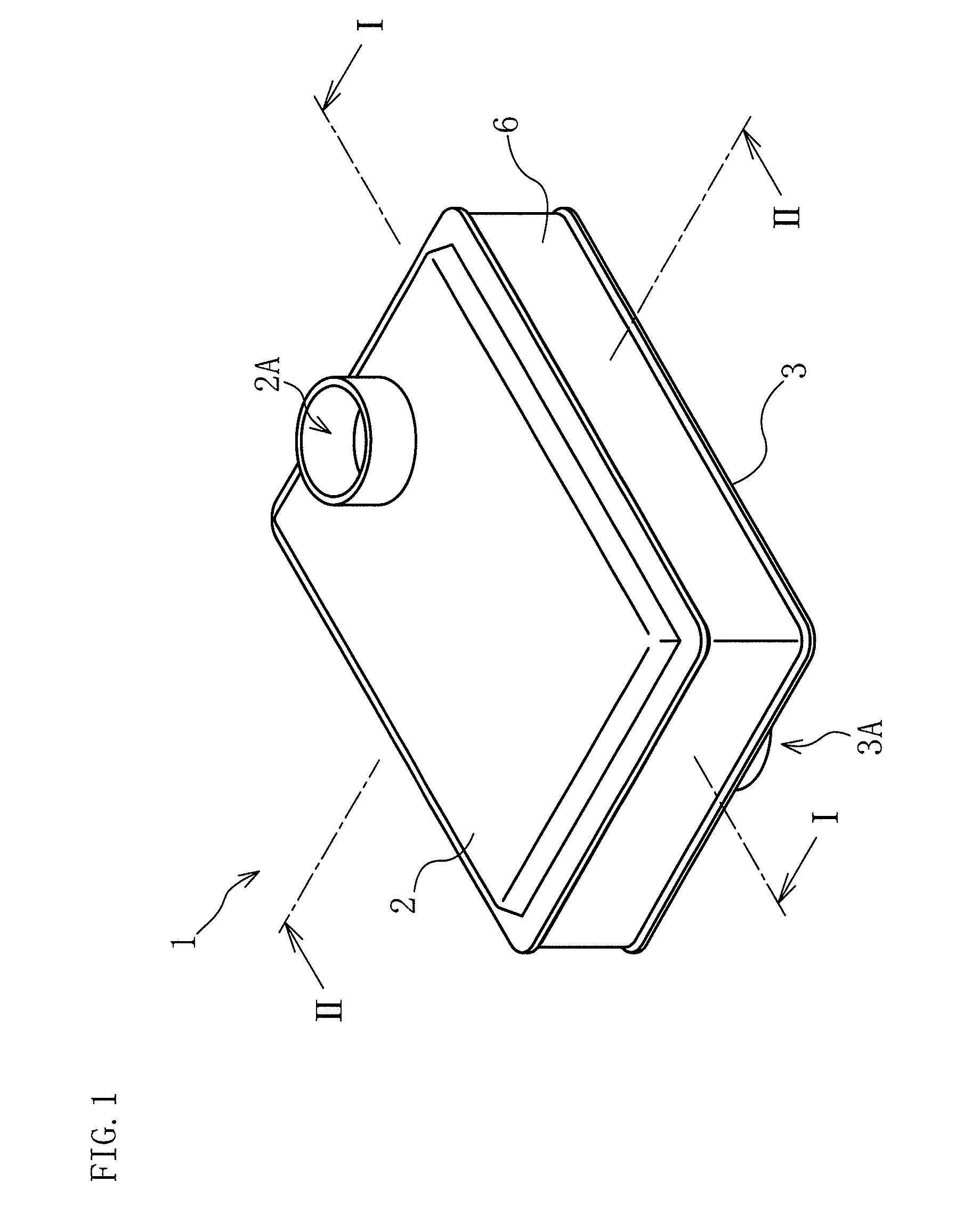

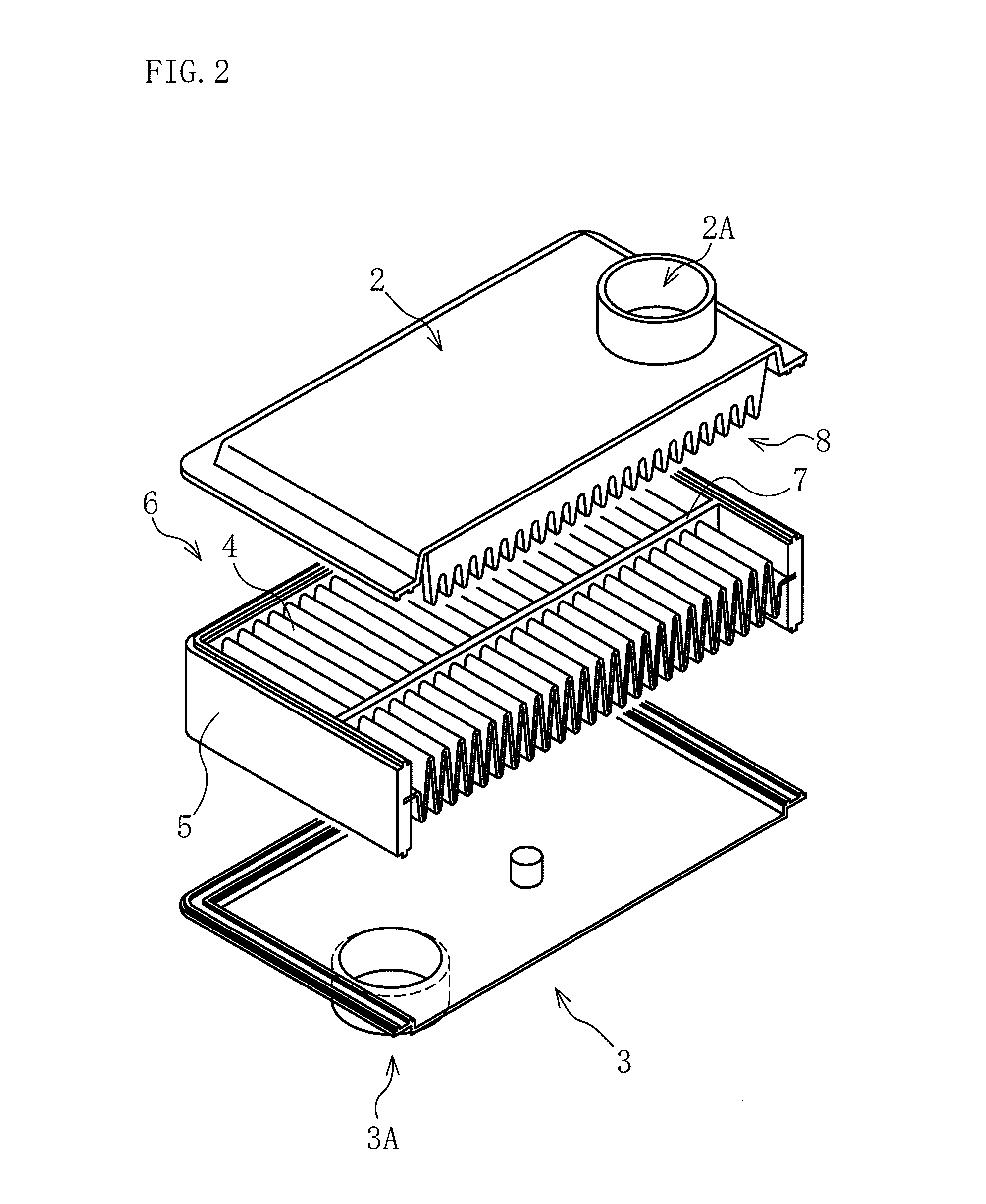

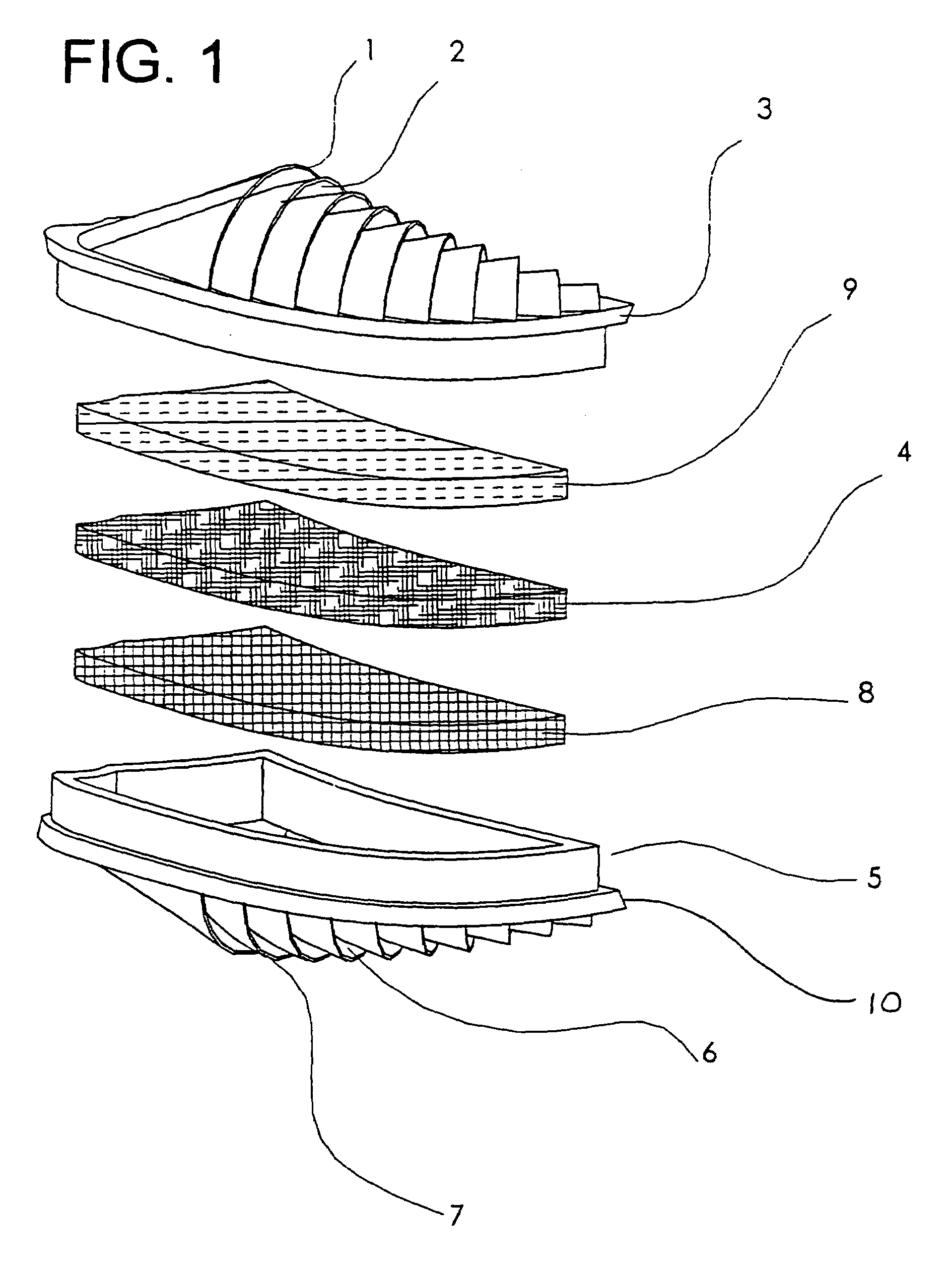

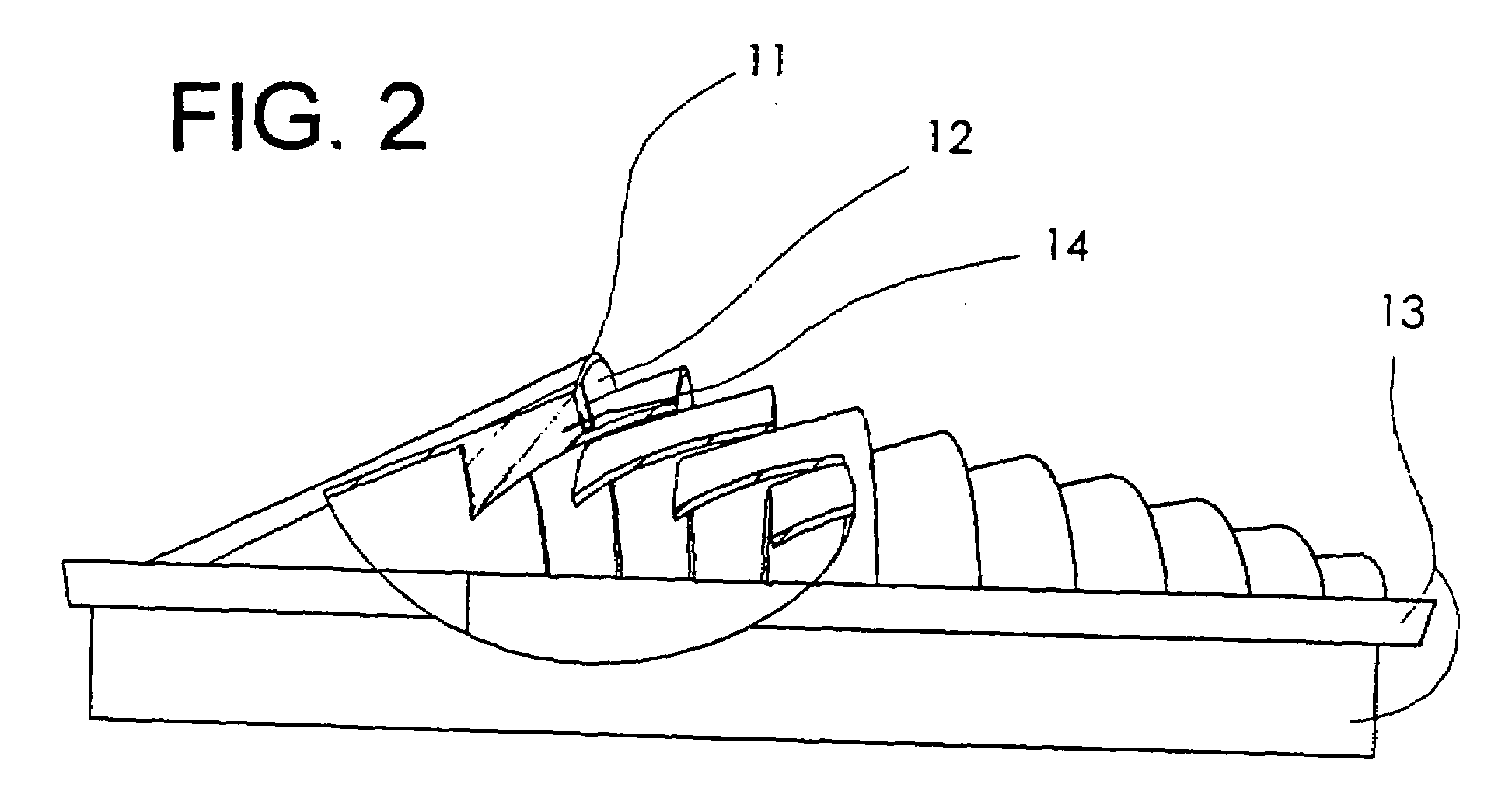

Fluid filter

InactiveUS20130008845A1Suppressing deformationAvoid deformationDispersed particle filtrationMembrane filtersEngineeringFilter material

A fluid filter including: an upper case member having a flow outlet; a lower case member having a flow inlet; a filter element having a folded filter material and a holding frame which holds the circumferential part of the filter material and is sandwiched between the upper case member and the lower case member; and a reinforcing member provided to extend in a direction crossing the ridge line direction of the folds of the filter material, the reinforcing member is provided in such a manner that, when the height of the folds is defined as h1, the lower end thereof is positioned above a position of 0.6 h1 from the upper end of the folds.

Owner:TOYOTA BOSHOKU KK

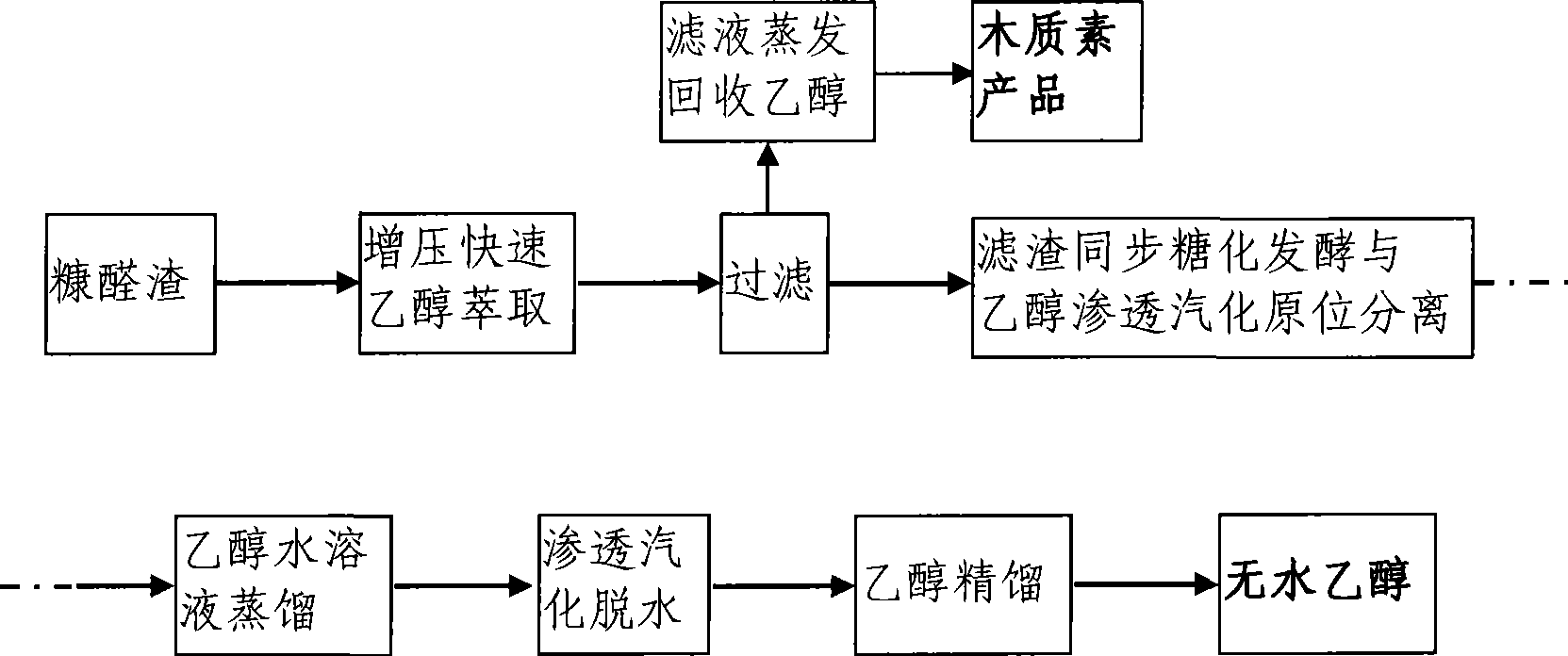

Method for preparing absolute ethyl alcohol from furfural residue

InactiveCN101413017ALarge amount of resourcesLow priceMicroorganism based processesFermentationFiberAlcohol

The invention provides a method for preparing absolute ethyl alcohol by furfural residues. A furfural residue cellulose raw material is adopted, lignin is separated, and then the absolute ethyl alcohol is obtained through synchronous diastatic fermentation and pervaporation coupling separation of alcohol, then distillation, pervaporation dehydration and rectification. The method has the advantages that the method organically combines the prior mature rectification technology with a modern advanced separation technology to improve the production efficiency when high fiber raw materials are used to prepare the absolute ethyl alcohol.

Owner:BEIJING FORESTRY UNIVERSITY

Processing method of Congou black tea

InactiveCN104430993AStrong tendernessRich in endoplasmPre-extraction tea treatmentOrange FlavorBlack tea

The invention discloses a processing method of Congou black tea. Common fresh tea leaves are taken as raw materials and the processing method comprises the following steps of cold air withering, hot air withering, spreading, rolling, fermenting and drying. According to the invention, the original technology of Congou black tea is inherited, improved and innovated, so that the problems of low efficiency and high quality fluctuation of Congou black tea in the production process are solved effectively; the prepared Congou black tea is thin and fine, shows peak seedlings, is smooth in color, has bright red and yellow soup color, is mellow in taste, has heavy sweet orange flavor, is bright red in leaf bottom, and lays a good foundation for occupying the tea leaf market for the Congou black tea.

Owner:YIBIN CHUANHONG TEA IND GRP

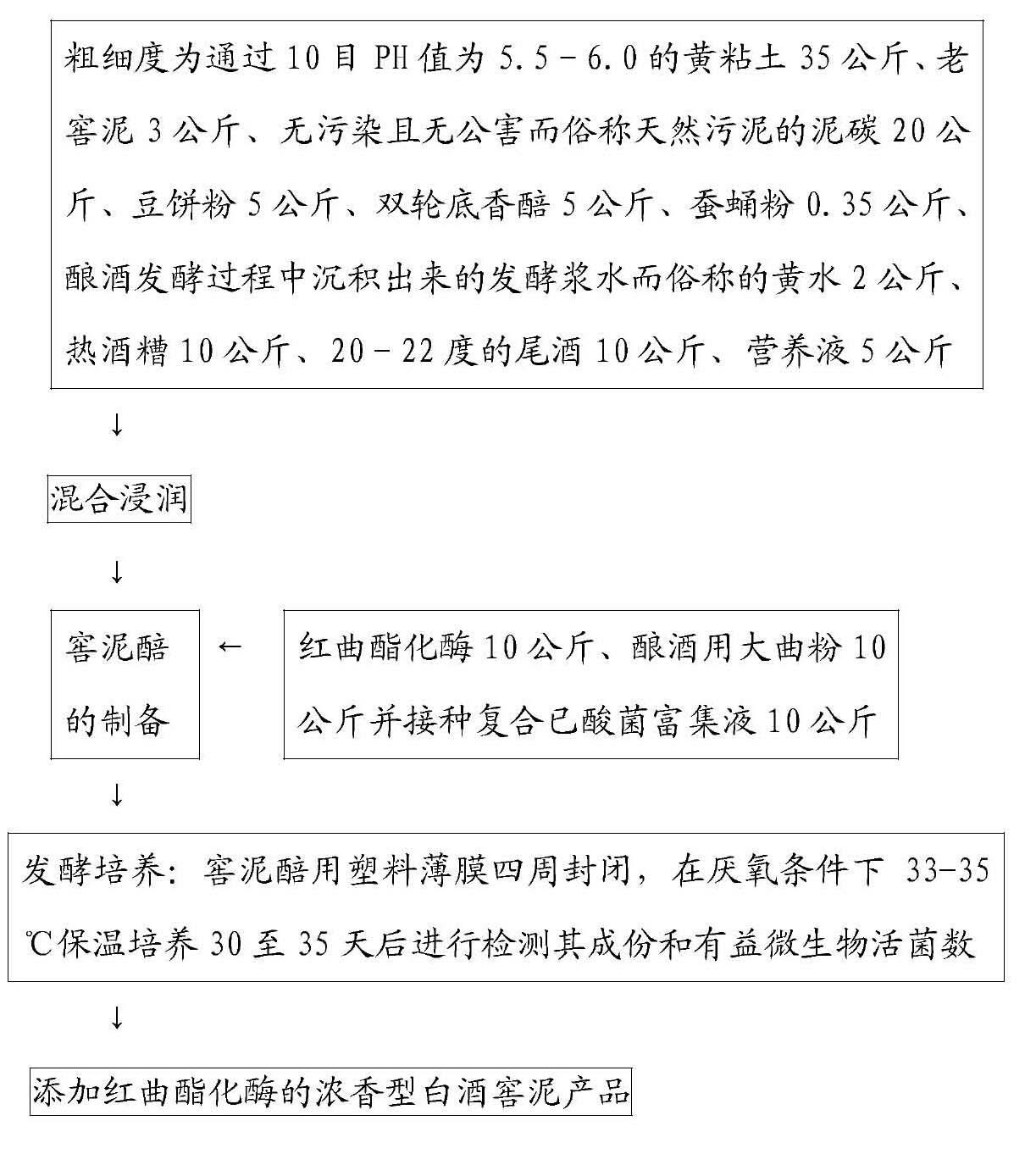

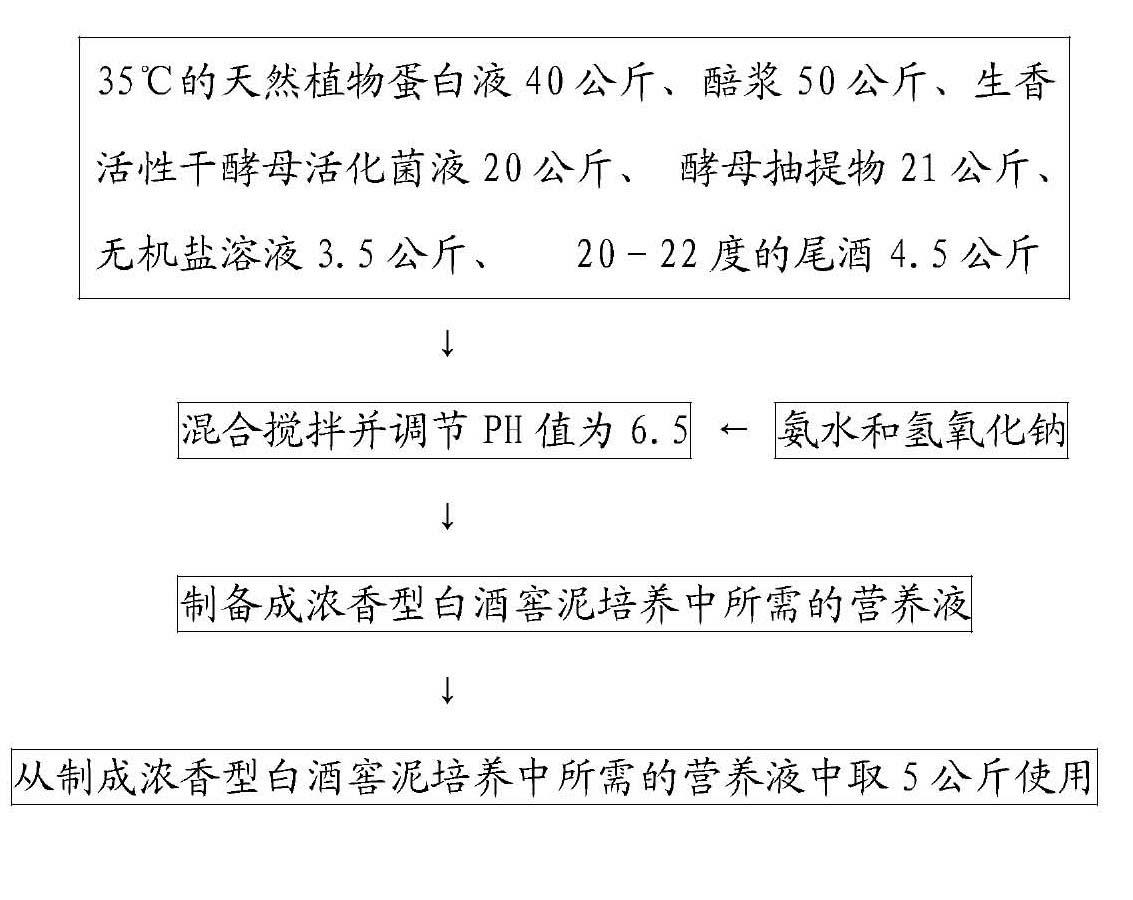

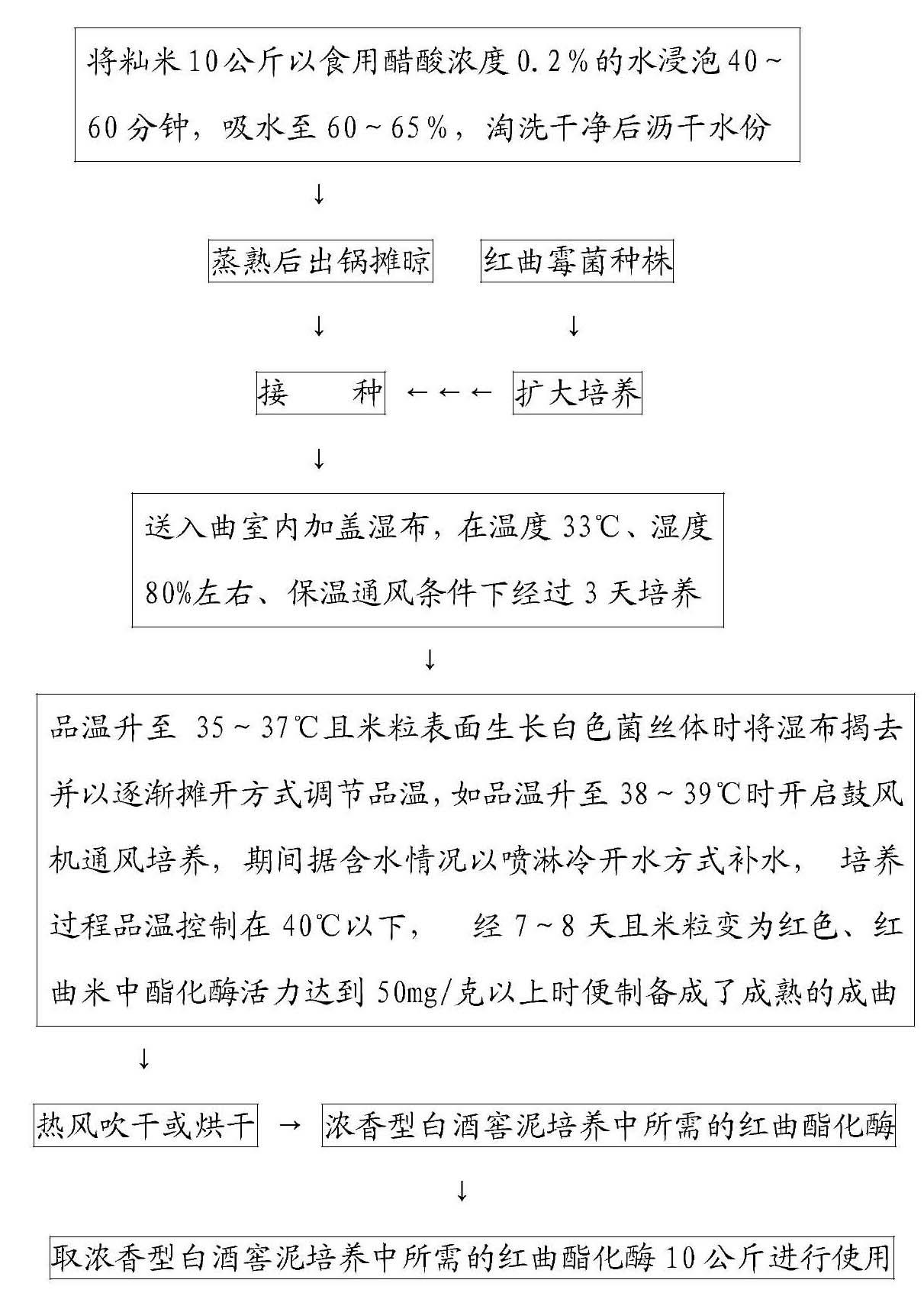

Preparation method of strong aromatic Chinese spirits pit mud by adding red yeast esterified enzyme

InactiveCN102154081AQuality improvementImprove the quality rateAlcoholic beverage preparationYeastTrace element

The invention provides a preparation method of strong aromatic Chinese spirits pit mud by adding red yeast esterified enzyme, and relates to the technical field of spirits making. The preparation method comprises the following steps of: adding 10kg of red yeast esterified enzyme and 10kg of yeast powder into mixed infiltrating body of 35kg of yellow clay, 3kg of old pit mud, 20kg of mud carbon, 5kg of bean cake powder, 5kg of double-wheel bottom flavour grains, 0.35kg of silkworm chrysalis powder, 2kg of yellow water, 10kg of hot vinasse, 10kg of 20 to 22-degree cocktail and 5kg of nutrient solution which respectively can pass a screen mesh of 10 and have the pH value of 5.5-6.0; vaccinating 10kg of compound hexanoic acid bacteria-enriched liquid, stirring and mixing to prepare pit mud grains; sealing the periphery of the pit mud grains by a plastic film; and cultivating for 30-35 days under the anaerobic condition at the temperature of 33-35 DEG C, and detecting the components and the beneficial microbe bacterial counts of the pit mud to obtain the strong aromatic Chinese spirits pit mud by adding the red yeast esterified enzyme. The preparation method is used for cultivating the pit mud in a strong aromatic Chinese spirits preparation technology. The preparation highlights a nitrogen source, trace element and the red yeast esterified enzyme which influences aroma-producing substances and flavor-producing substances of the Chinese spirits.

Owner:湖北黄山头酒业有限公司

Production method of germinated milled rice

InactiveCN101617793AReduce pollutionReduce usageFood preparationMicroorganismGamma-Aminobutyric acid

The invention provides a production method of germinated milled rice, comprising the following steps: adopting milled germ-retaining rice that is produced by a special process as germinating materials, sterilizing the milled germ-retaining rice in water solution with the ozone concentration of 1.0-1.5mg / kg, coating by 1-2 percent of chitosan solution, soaking in clear water or 0.005-0.015 percent of gibberellin for 20-30 hours, culturing in the situation of 20-30 DEG C, and drying at 50-60 DEG C when the length of germs of germinated rice is 0.5-1.0 mm to obtain the germinated milled rice. In the production method, the germination ratio is more than 95 percent, Gamma-aminobutyric acid is more than 60mg every 100g of germinated rice, and the water content is 12-15 percent. The invention has simple process, reduces the microbial contamination in the germinating process and solves the difficult problems of brown stains, cracking, and the like in the drying process; and the germinated milled rice obtained by the method is better than germinated brown rice and milled germ-retaining rice on the taste, and has good colors, rich nutriments and strong heath care function.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Emission reduction drying type cultivation method for producing non-antibiotics pork

InactiveCN101213951AAvoid pollutionAvoid influenceAnimal feeding stuffAnimal housingDiseaseAnimal science

The invention relates to an emission reduction dry-type culture method for producing nonreactive pork. The method uses pig feeds, which contain feedstuff additive premix, and active water agent to feed the pigs. An organic adhesive layer is laid inside a pig shed. The active water agent contains natural plant extract and bacillus subtilis, and is drunk by the pigs through a leak protection and filtering water device arranged inside the pig shed. The feedstuff additive premix contains NSP enzyme, micro-ecological agent, plant extract and acidifier. The method can prevent the pigs from having intestinal bacteria and viral diseases and respiratory diseases, and reduce the discharge of fecaluria and living water, harmful gas produced by pig fecaluria and stench, and through which prevents the breeding of flies. At the same time of producing nonreactive port, the method can reduce the pollution caused by excreta.

Owner:BEIJING ZHONGSAI TIANDI TECH CORP

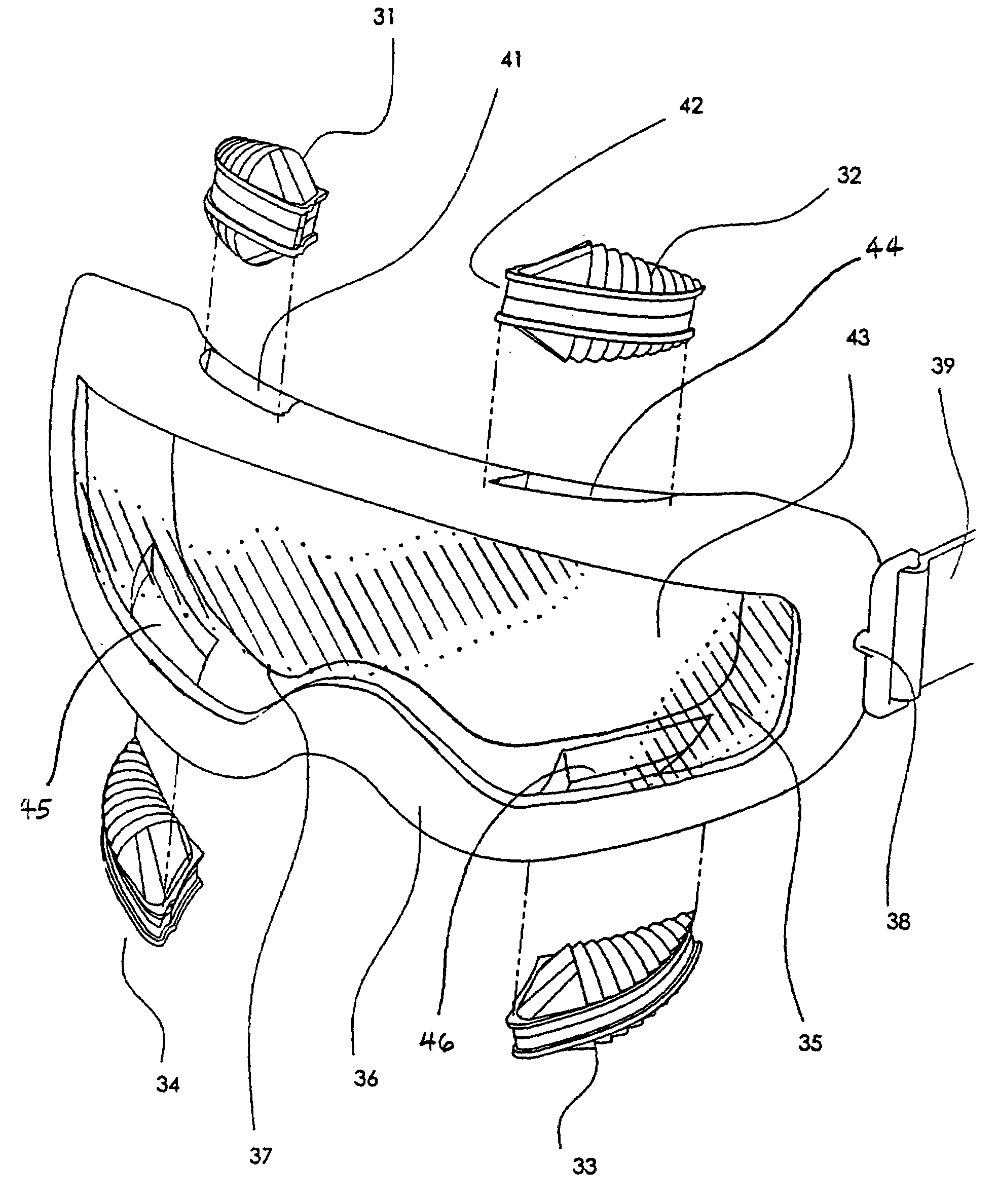

Electrostatic filtered eyewear

ActiveUS6994433B2Improved airflow characteristicsHigh degreeGogglesNon-optical adjunctsParticulatesEyewear

An eyewear has a gasket between the user and lenses that electrostatically filter the air flow of particulate while still permitting a gentle flow of air to maintain comfort to the wearer of the eyewear, and prevent fogging on the lenses. The electret filter material forms a perimeter around the eyes and lenses to remove, small to large particulates, from microns to millimeters. The filters can be formed with a choice of face contact gasket, baffles, coarse filters, and electret filter density. Baffles or coarse filters over the electret filters are used to protect the electret filter from damage from larger particles and transfer heat to the airflow.

Owner:ARENA INDS

Method for preparing flavored health beverage by fermenting vegetables and fruits

InactiveCN103932343AHigh nutritional valueHigh health valueYeast food ingredientsFood ingredient functionsYeastInorganic salts

The invention provides a method for preparing a flavored health beverage by fermenting vegetables and fruits. The method comprises the following steps: mixing the vegetables with the fruits in proportion, homogenizing, adding a proper amount of sugar, protein meal, inorganic salt and water, adjusting the pH value to be 7.6, putting into a fermentation tank, sterilizing by steam, cooling, and fermenting by the following five steps: (1) introducing aseptic air according to a ventilation ratio of 0.4-0.6, inoculating with a yeast seed solution, and fermenting at the temperature of 23-30 DEG C and the stirring rotation speed of 150-220r / min for 20-30 hours; (2) heating to 50-60 DEG C and keeping the temperature for 15-25 minutes; (3) increasing the ventilation ratio to 0.6-1.2, inoculating with a bacillus subtilis seed solution, fermenting at the stirring rotation speed of 160-260r / min and the temperature of 26-30 DEG C for 30-40 hours, heating to 34-37 DEG C, and fermenting for 8-16 hours; (4) stopping air introduction, switching off all valves connected with the fermentation tank, and fermenting at the stirring rotation speed of 200-250r / min and the temperature of 46-50 DEG C for 5-10 hours; and (5) inoculating with a lactobacillus seed solution, and fermenting at the temperature of 40-44 DEG C and the stirring rotation speed of 150-200r / min for 8-10 hours, thus obtaining the viable type flavored health beverage containing the bacillus subtilis and the lactobacillus after fermenting.

Owner:西倍健生物科技(深圳)有限公司

Sweet osmanthus seedling culture medium and manufacturing method thereof

InactiveCN103288542APromote growthSuitable for acid-loving propertiesCultivating equipmentsFertilizer mixturesHuskSeedling

The invention belongs to the technical field of agricultural technologies, and particularly relates to a sweet osmanthus seedling culture medium and a manufacturing method thereof. The sweet osmanthus seedling culture medium is prepared by mixing rice husk, loess, perlite and the like according to a certain ratio. The sweet osmanthus seedling culture medium has a good water-retaining property and high air permeability and fertilizer efficiency; the pH value of the culture medium is very suitable for the growth of sweet osmanthus seedlings; the sweet osmanthus seedling culture medium obviously promotes the growth of sweet osmanthus, and is low in cost; the sweet osmanthus seedling culture medium effectively utilizes the rich waste agricultural rice husk, thus being in accordance with the requirements of environmental protection and energy conservation, and having a wide application prospect in the garden seedling culture industry.

Owner:SHENZHEN WENKE GARDENING IND

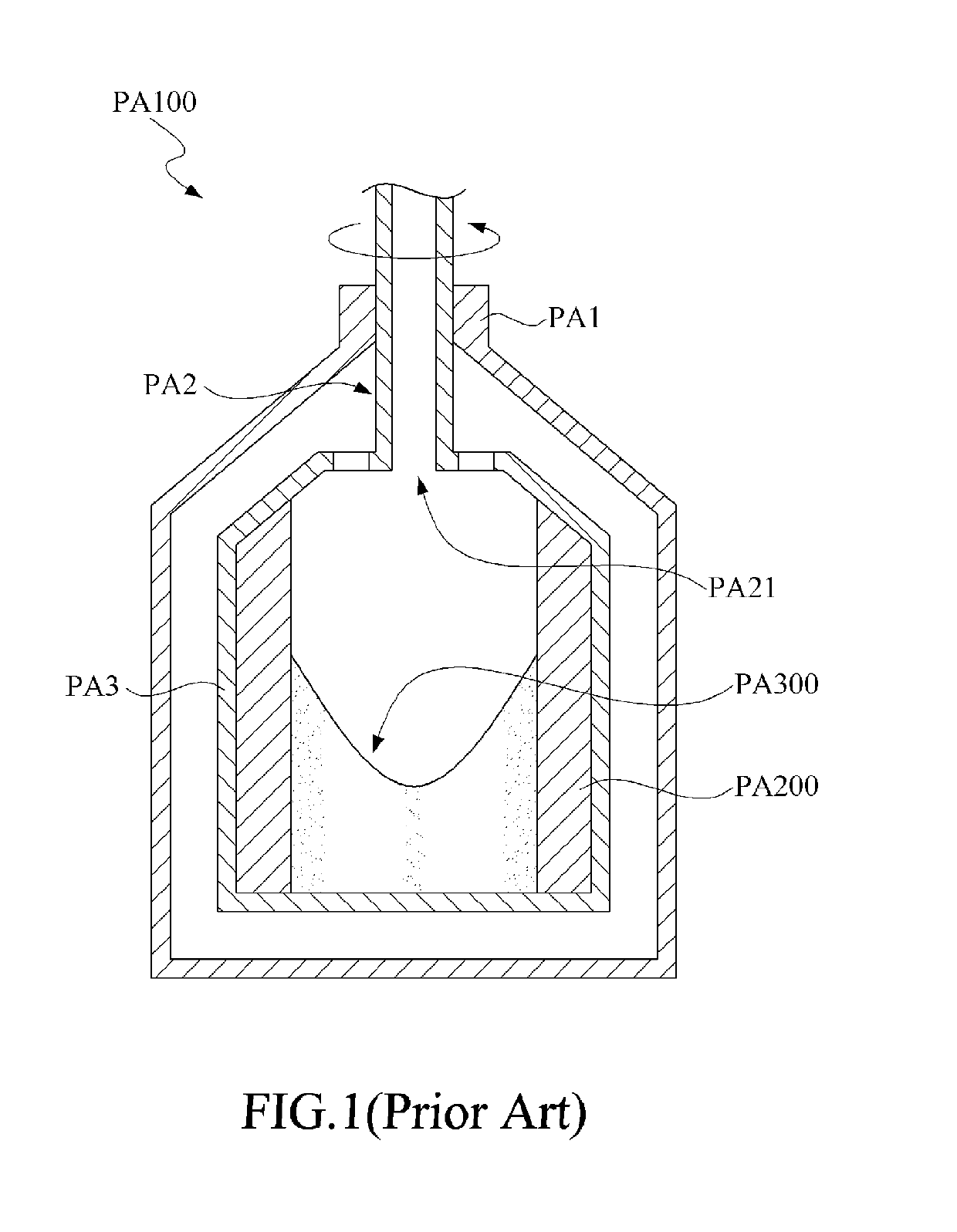

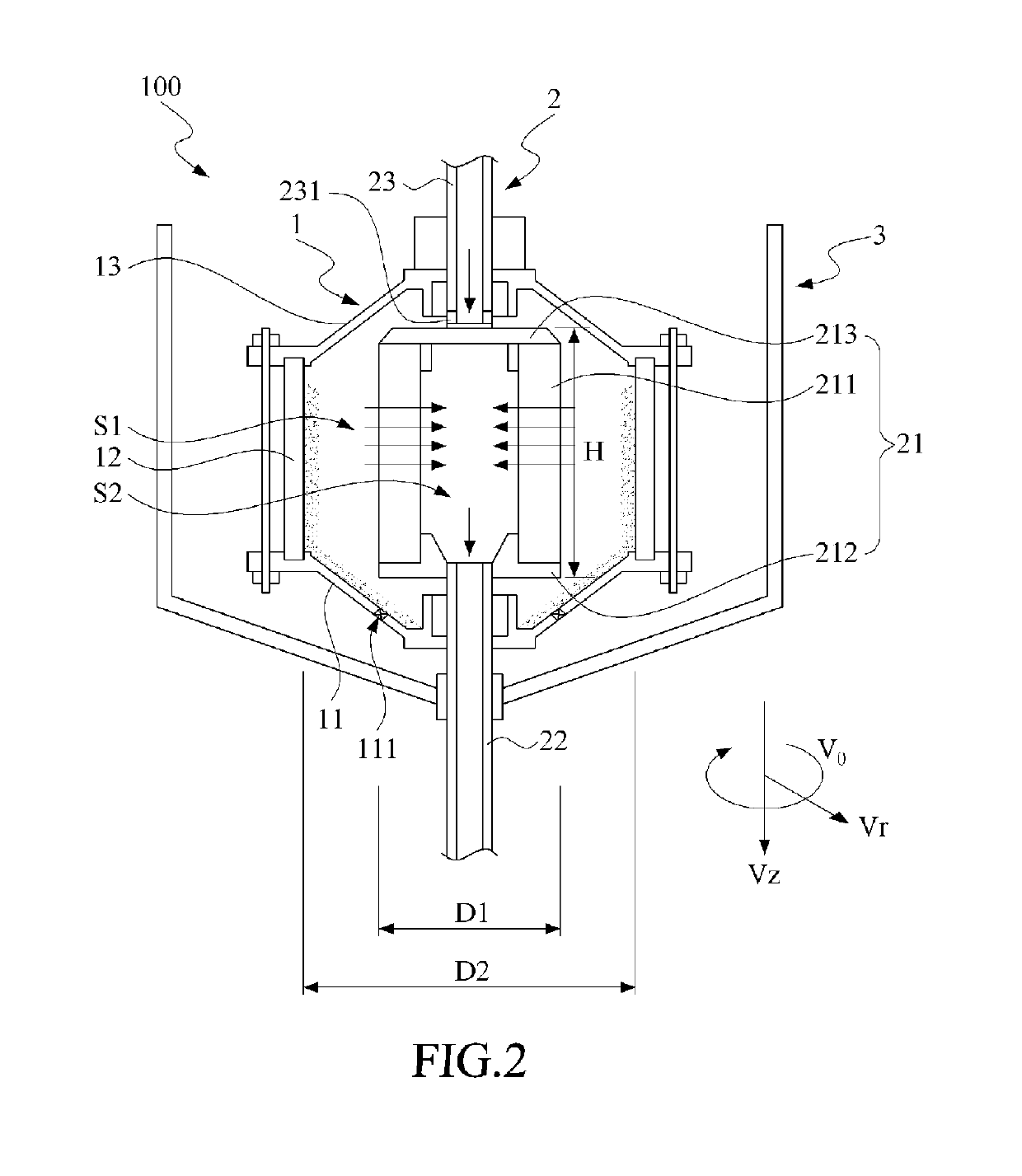

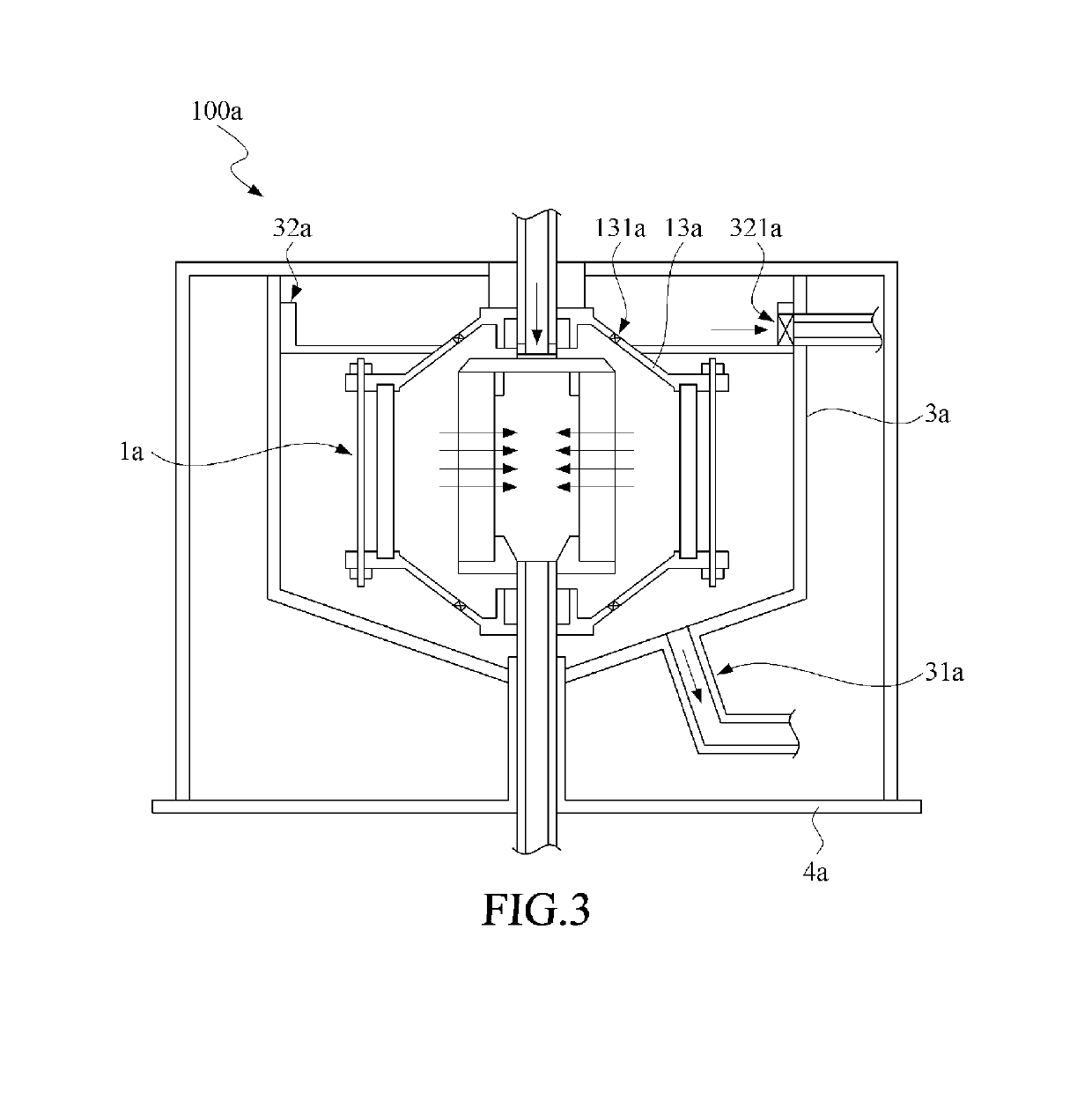

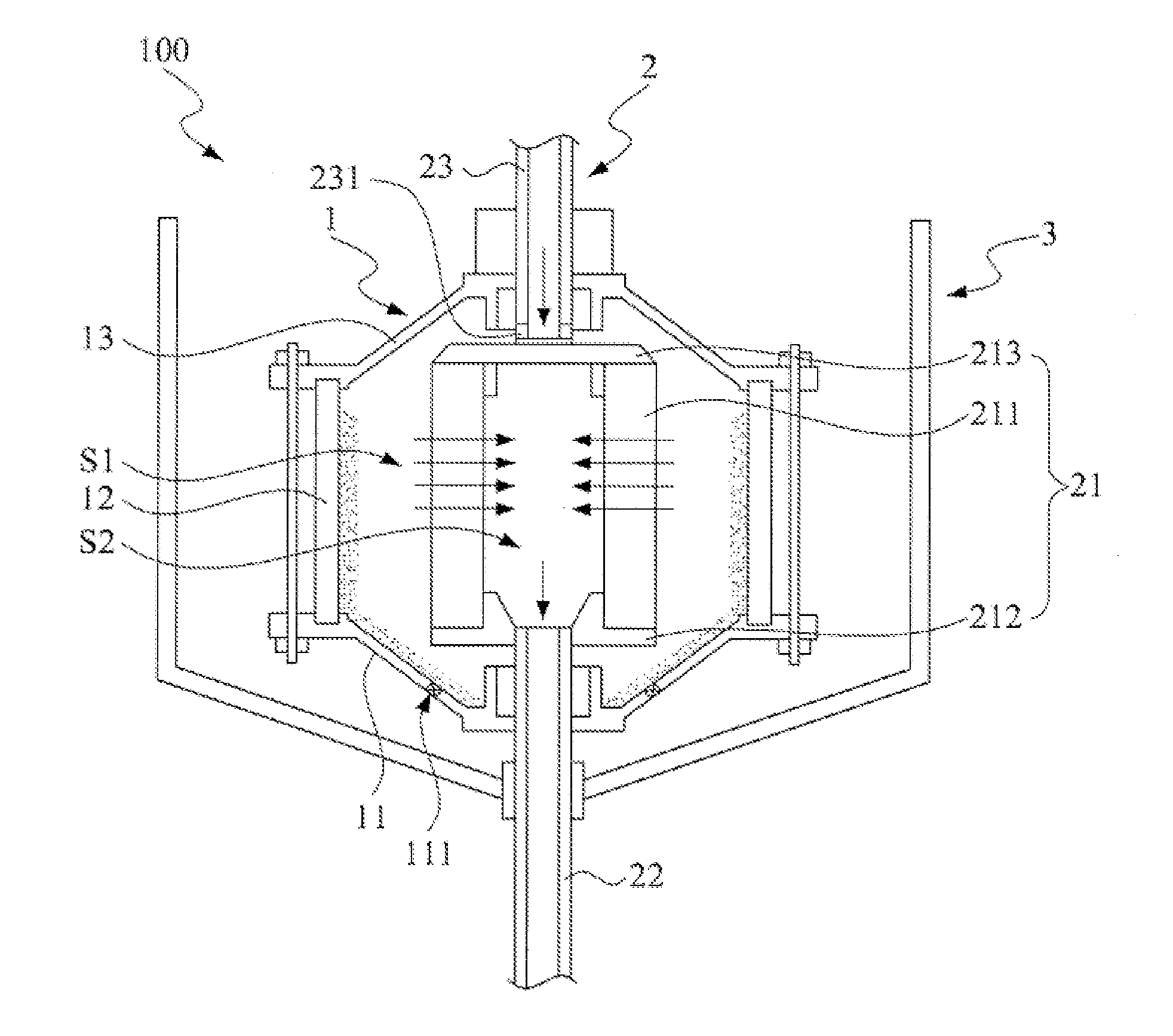

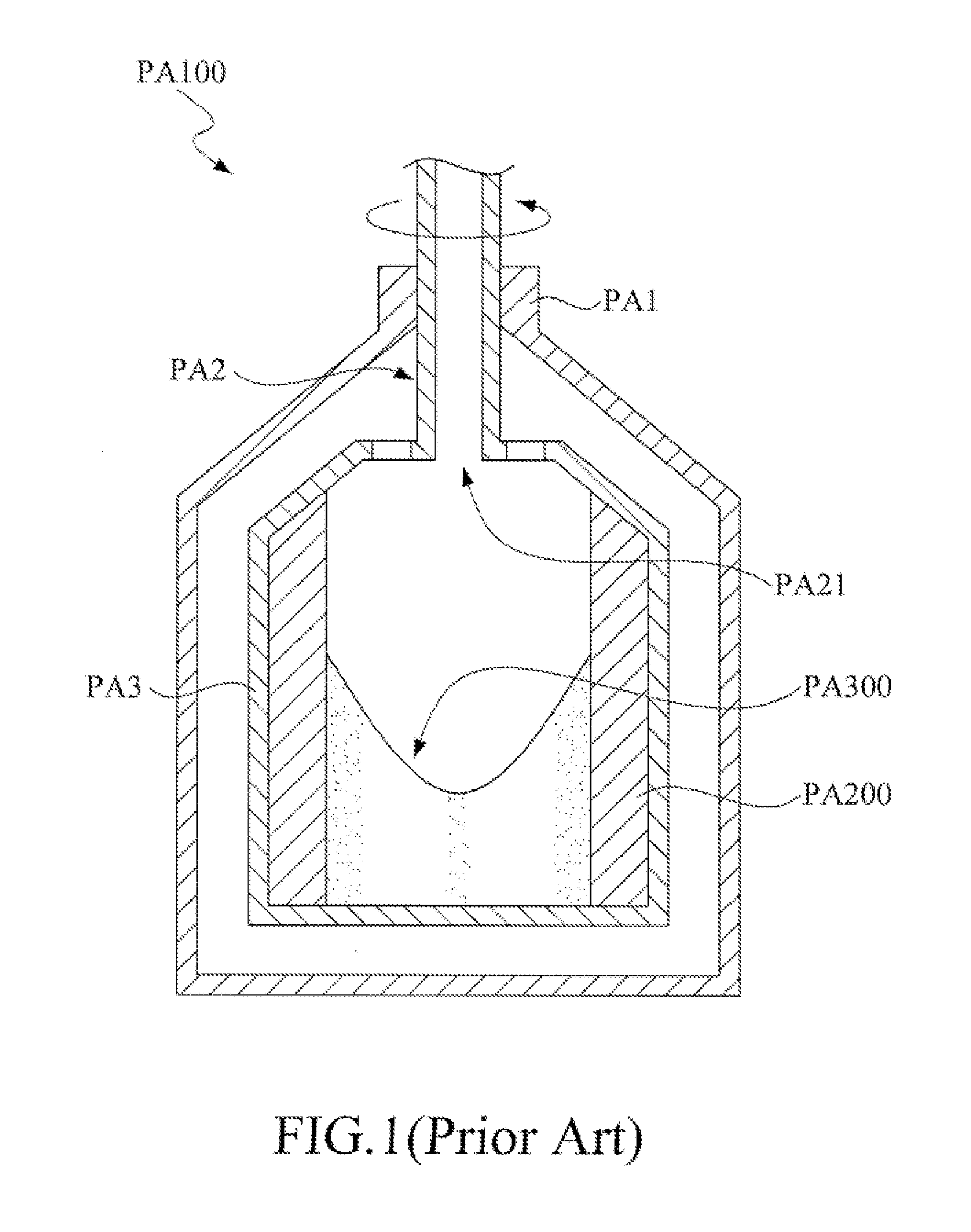

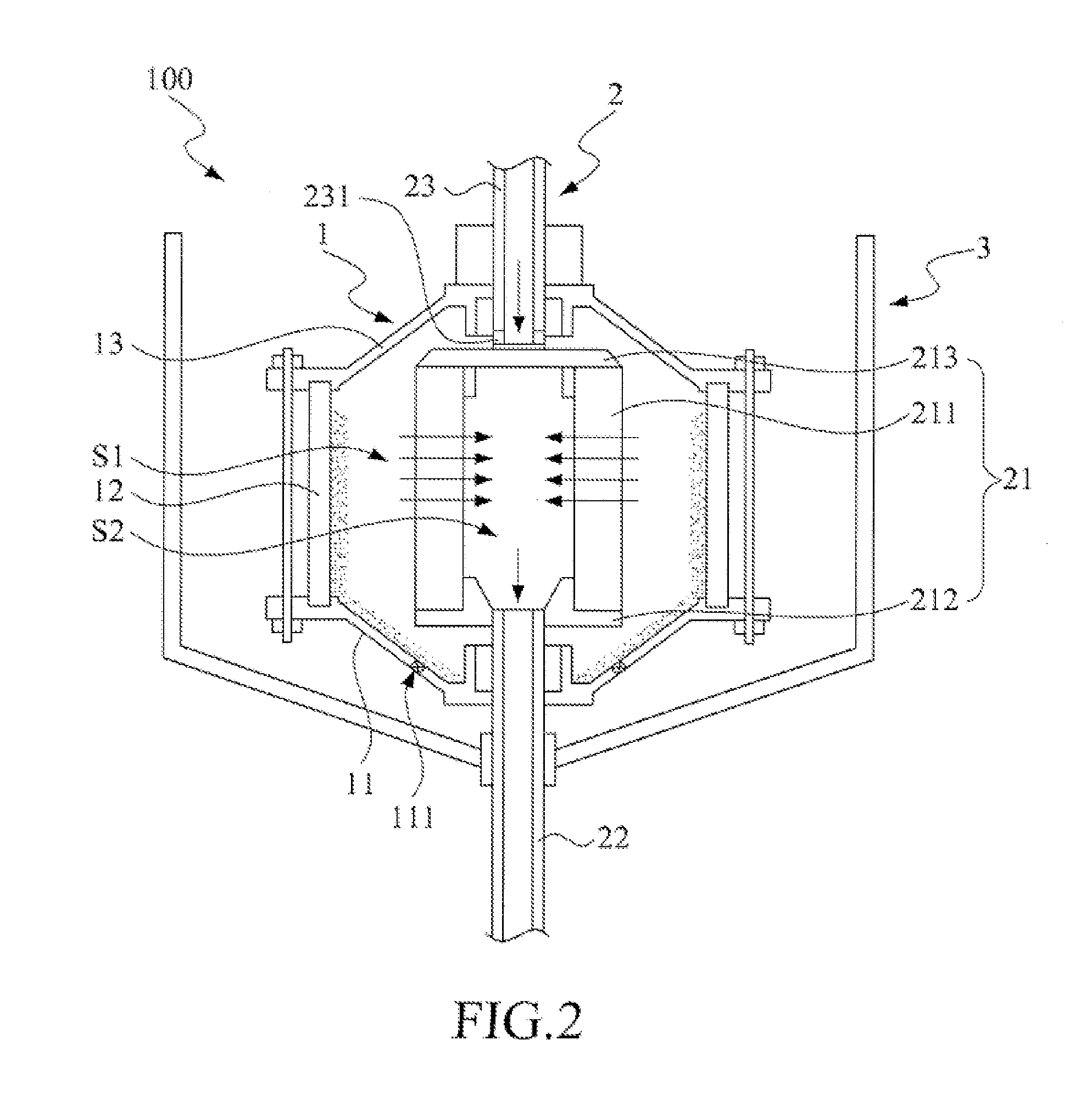

Centrifugal filtering device and method for operating the same

ActiveUS20190247864A1Reducing filtration rateMore cleaningRotary centrifugesNon-miscible liquid separationEngineeringCentrifugal force

A centrifugal filtering device includes a centrifugal drum and a rotary filter. The centrifugal drum has a receiving space for accommodating the source fluid. The rotary filter rotatably mounted in the receiving space includes a filter body and a filtrate discharge pipe. The filter body includes a filter cartridge defining a filtrate-collecting space. The filtrate discharge pipe connecting the filter body is communicative in space with the filtrate-collecting space. By rotating at least one of the centrifugal drum and the rotary filter, the source fluid is driven to generate a vortex by a centrifugal force. The centrifugal force drives the source fluid to form a heavy-phase fluid hitting the centrifugal drum and a light-phase fluid approaching the filter cartridge. The light-phase fluid passes the filter cartridge and then reaches the filtrate-collecting space as a filtrate, and the filtrate is exhausted via the filtrate discharge pipe of the centrifugal filtering device.

Owner:WU JUNG MING

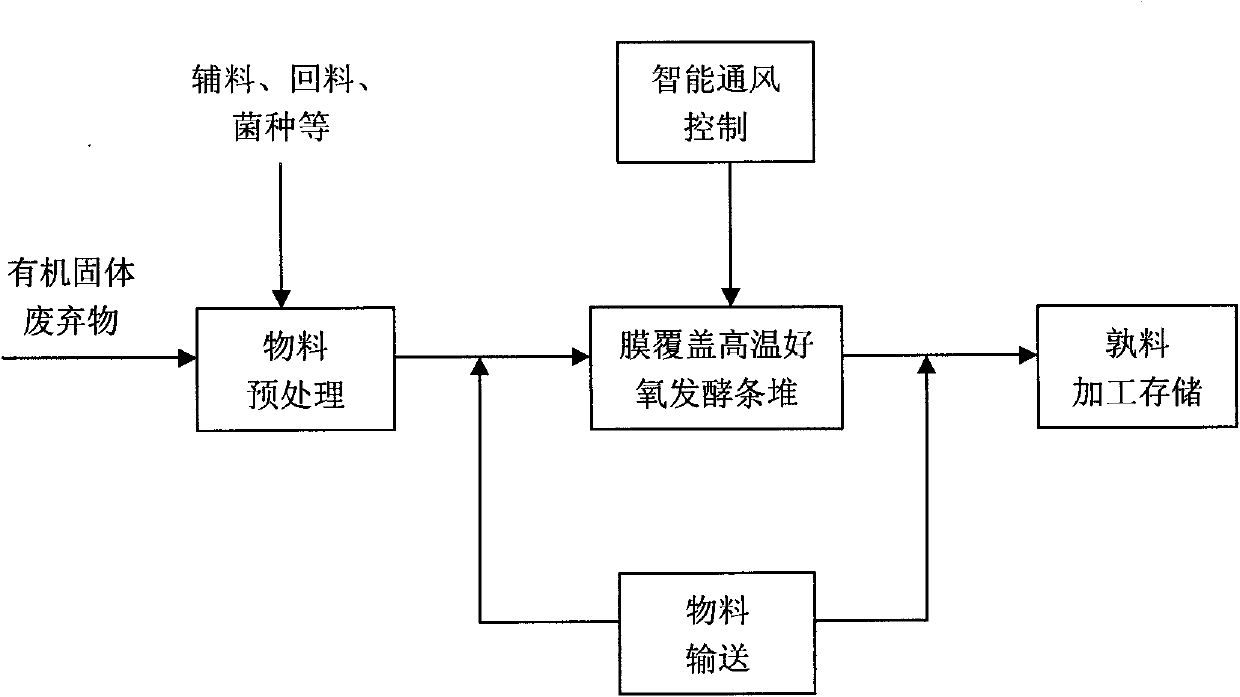

Organic solid waste film covering high-temperature aerobic fermentation method

InactiveCN101792339AThermal insulationReduce the impactBio-organic fraction processingClimate change adaptationControl systemAgricultural engineering

The invention relates to the technical field of organic solid waste processing, in particular to an organic solid waste film covering high-temperature aerobic fermentation method. The fermentation method is characterized in that the organic solid waste is pretreated; the pretreated material is piled in strip pile; the material strip pile is provided with a sensor and covered with a waterproof breathable film; a blower and an air-pipe under the material are used for supplying oxygen to the material; an intelligent ventilating control system is used for optimizing the fermentation process; after the material is fully decomposed, the waterproof breathable film on the material strip pile is removed, and then the material strip pile is transported into a clinker storing or processing area. Compared with the prior art, the fermentation method has short building period, few disposable investment, flexible construction, low operating cost, small odor influence, rain-proof, wind prevention and heat preservation effect and can protect the material from being affected by outside weathers.

Owner:SHANGHAI YUANJUN ENVIRONMENTAL PROTECTION TECH CO LTD

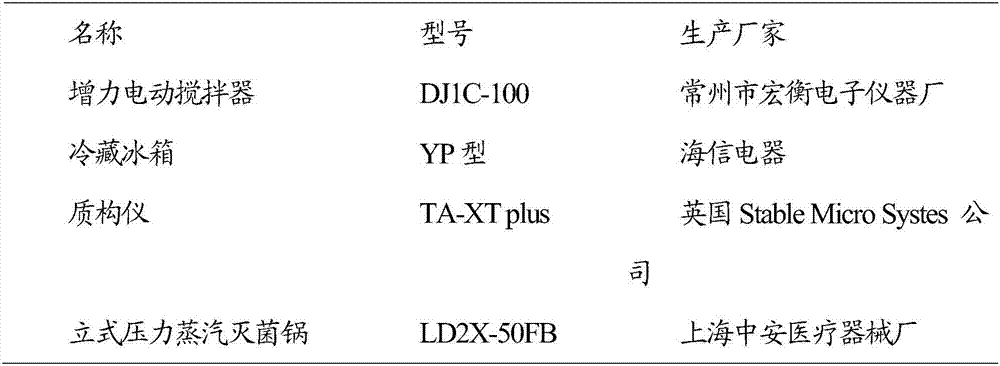

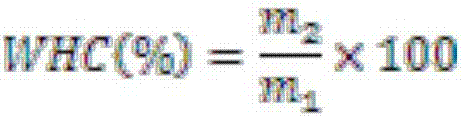

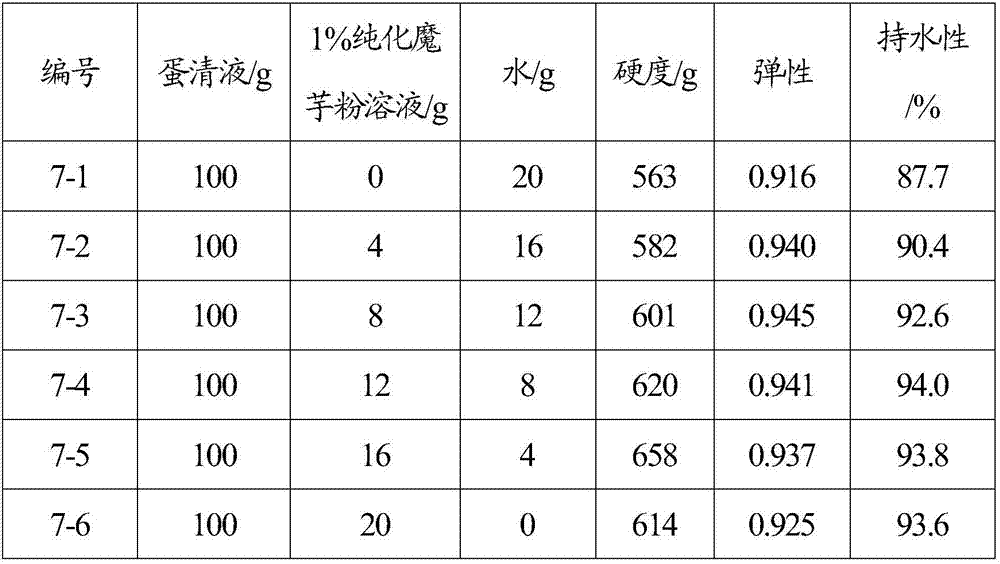

Dried konjak egg curd and making method thereof

InactiveCN107041519AHigh hardnessImprove toughnessFood preservationFood ingredient as flavour affecting agentHardnessFermentation

The invention discloses a dried konjak egg curd and a making method thereof. The making method comprises the following steps: (1) providing egg white; 2, uniformly mixing 100 parts by weight of the egg white with 1-40 parts by weight of a konjak powder solution, 1-10 parts by weight of a first seasoning mixture and 1-12 parts by weight of a second seasoning mixture to obtain a mixed solution; 3, steaming the mixed solution, solidifying the steamed mixed solution, cooling the solidified mixed solution, and shaping the cooled mixed solution to obtain semi-finished dried konjak egg curd; and 4, marinating the shaped semi-finished dried konjak egg curd, and drying the marinated semi-finished dried konjak egg curd to obtain the dried konjak egg curd. The konjak powder is added to raw materials, so the healthcare functions of the dried egg curd are increased, protein fermentation is reduced, the hardness, the toughness and the water retention property of the dried egg curd are improved, and the yield is increased.

Owner:四川众润食品有限公司

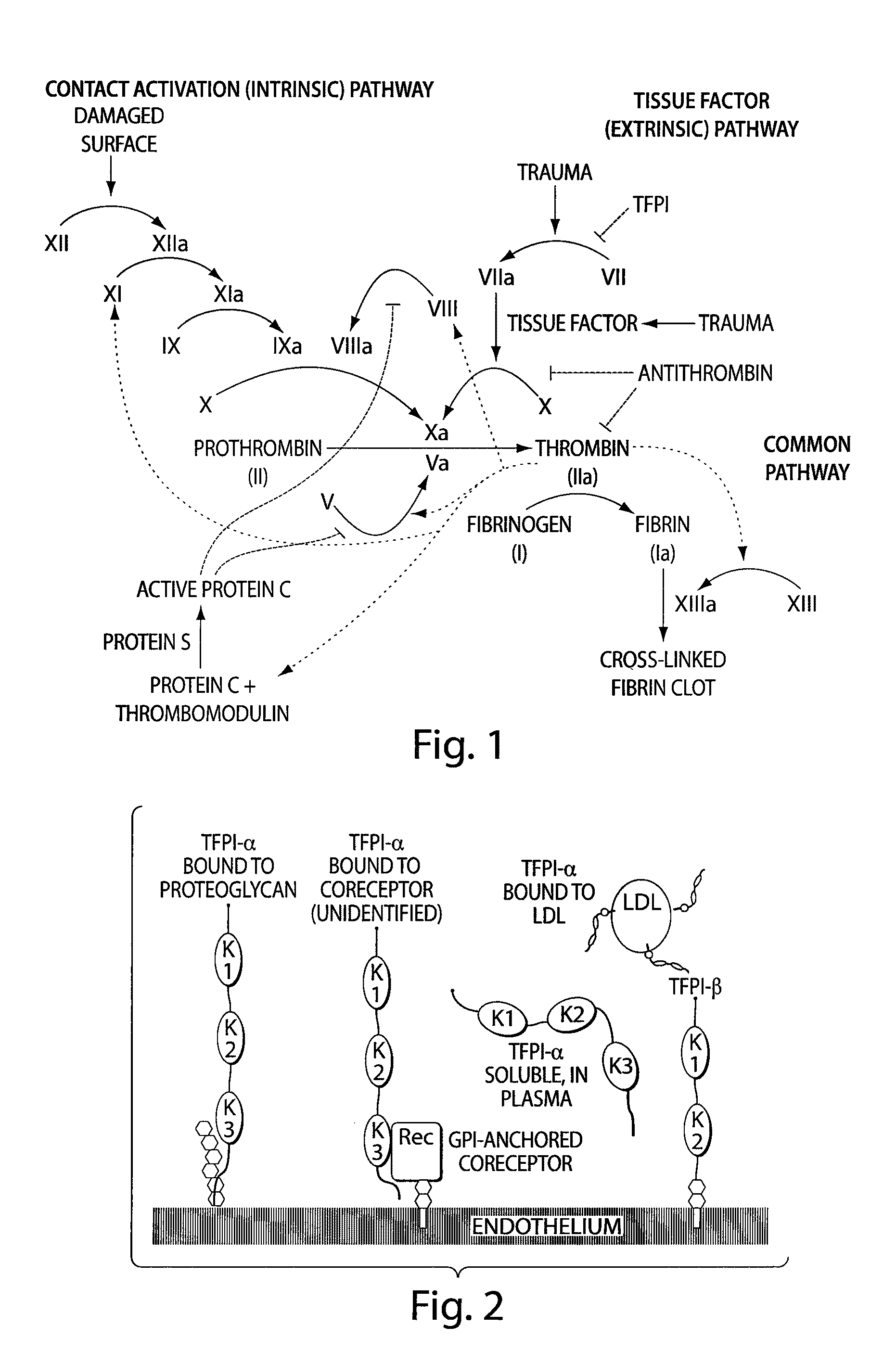

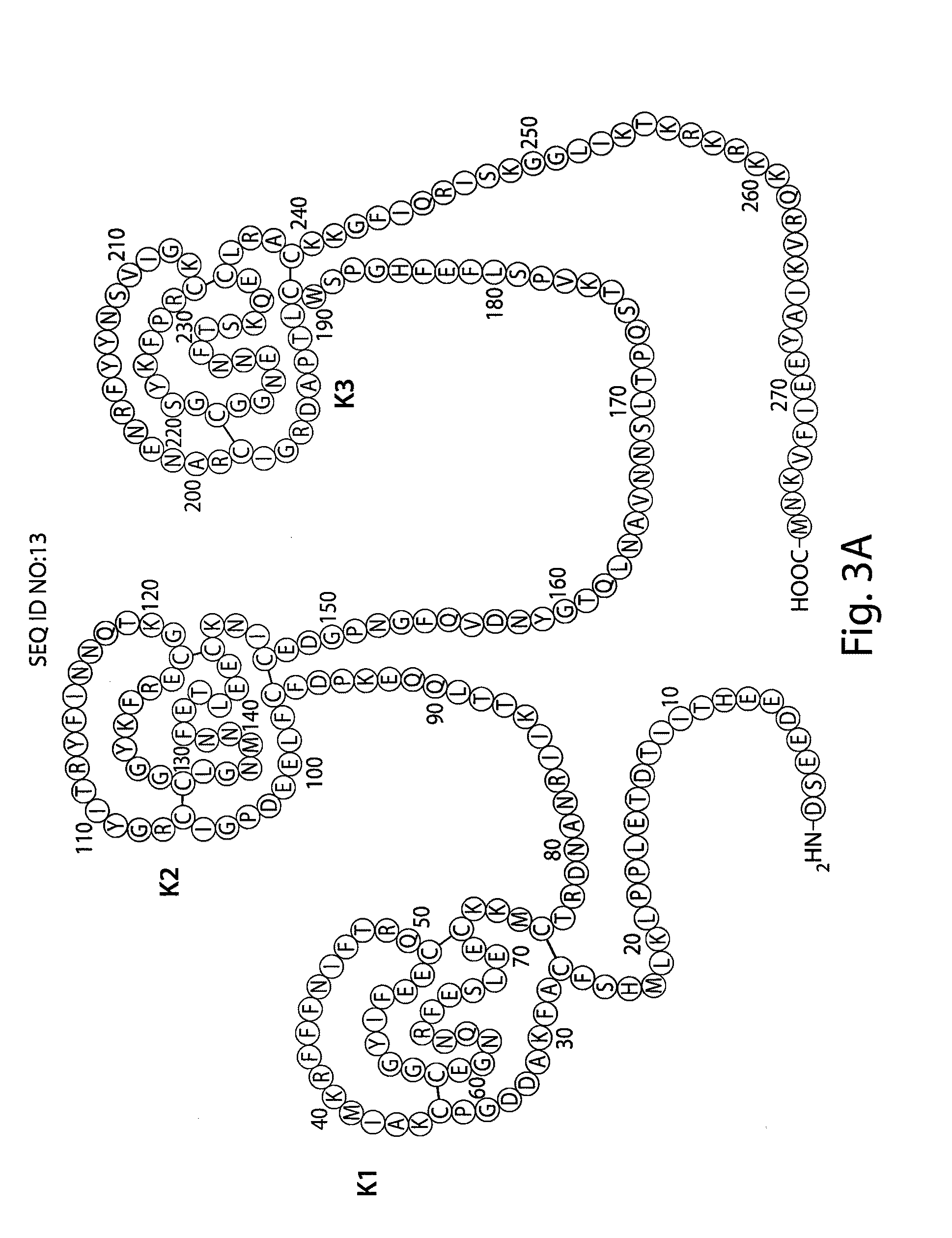

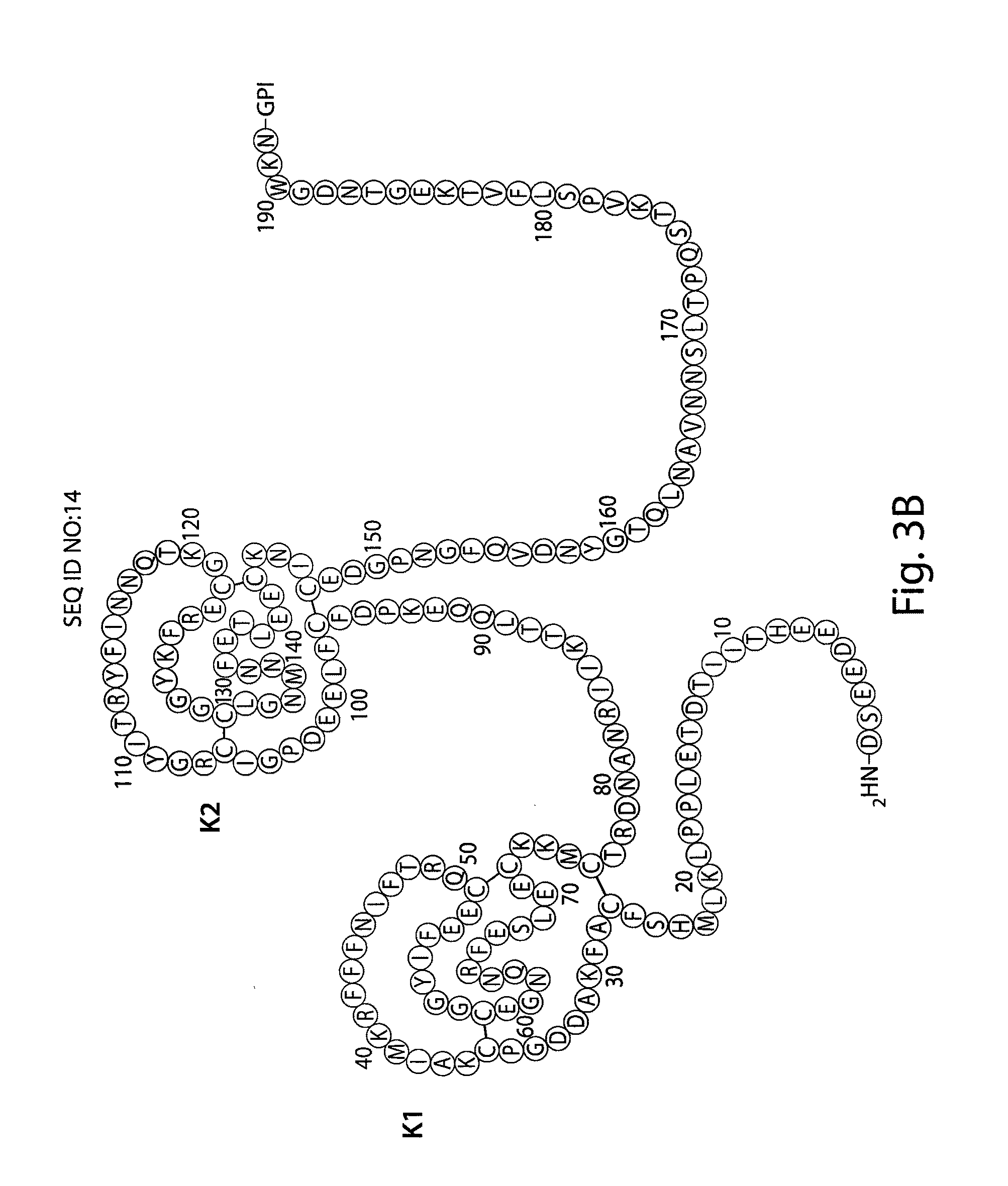

Aptamers to tissue factor pathway inhibitor and their use as bleeding disorder therapeutics

ActiveUS20110281938A1Reduce complicationsEliminate side effectsOrganic active ingredientsSugar derivativesDiseaseSide effect

Owner:BAXALTA GMBH

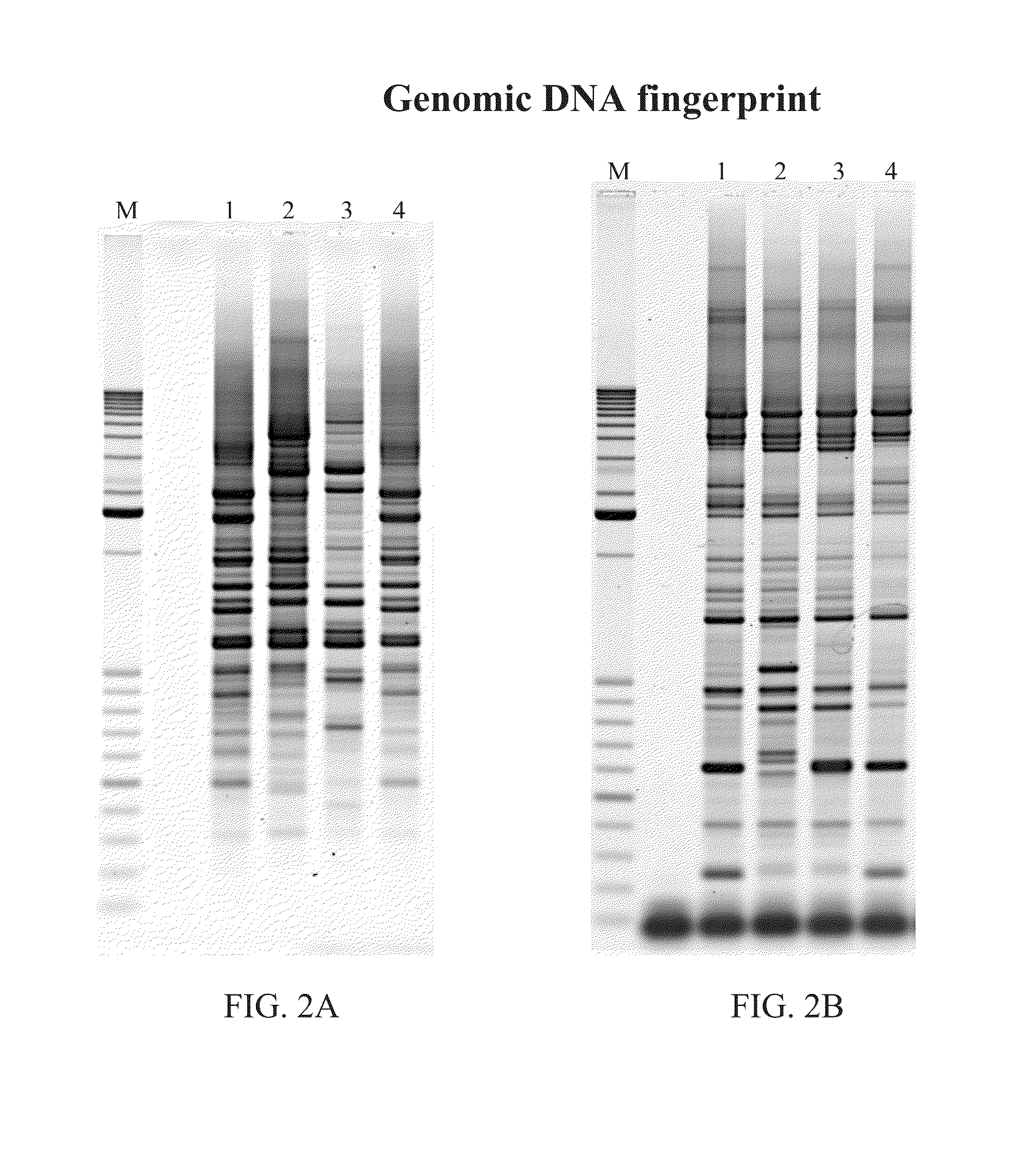

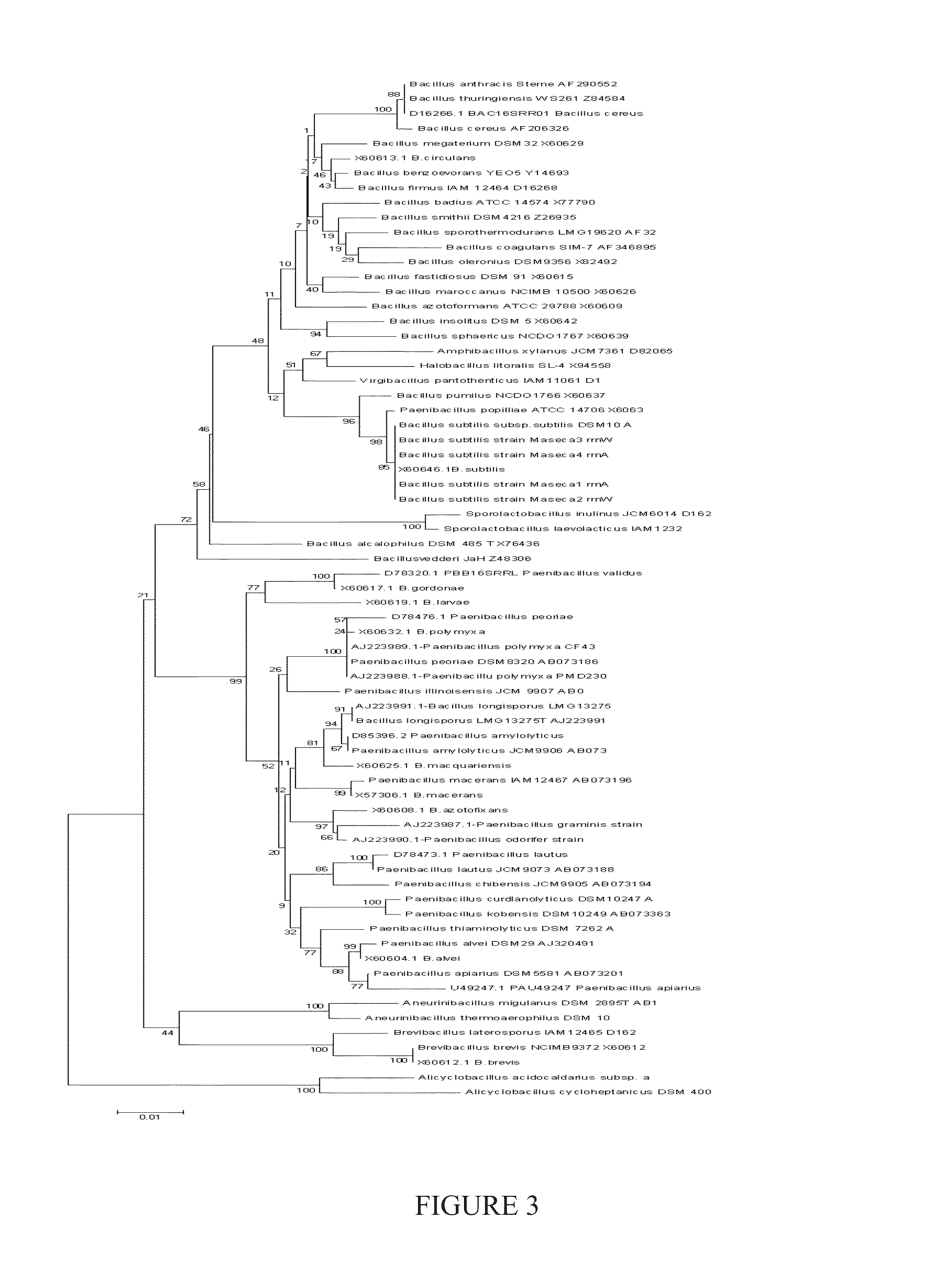

Bacillus subtilis isolate from corn and extracts that inhibit the growth of undesirable microorganisms in food products

ActiveUS20160007614A1Preventing and inhibiting growthGrowth inhibitionAntibacterial agentsBiocideBiotechnologyBacteroides

Biologically pure cultures of Bacillus subtilis Maseca-1 strain were isolated from the pericarp of nixtamalized corn. The Bacillus Maseca-1 strain was characterized and found to produce peptides and / or other compounds that have antimicrobial activity. An extract prepared from the Bacillus Maseca-1 strain is active against microorganisms such as bacteria and mold and may be used as an agent to inhibit the growth of undesirable microorganisms and thereby prevent spoilage and extend the shelf life in foods.

Owner:GRUMA S A B DE CV

Centrifugal filtering device and method for operating the same

InactiveUS20170001203A1Reducing filtration rateMore cleaningRotary centrifugesMoving filtering element filtersEngineeringCentrifugal force

A centrifugal filtering device includes a centrifugal drum and a rotary filter. The centrifugal drum has a receiving space for accommodating the source fluid. The rotary filter rotatably mounted in the receiving space includes a filter body and a filtrate discharge pipe. The filter body includes a filter cartridge defining a filtrate-collecting space. The filtrate discharge pipe connecting the filter body is communicative in space with the filtrate-collecting space. By rotating at least one of the centrifugal drum and the rotary filter, the source fluid is driven to generate a vortex by a centrifugal force. The centrifugal force drives the source fluid to form a heavy-phase fluid hitting the centrifugal drum and a light-phase fluid approaching the filter cartridge. The light-phase fluid passes the filter cartridge and then reaches the filtrate-collecting space as a filtrate, and the filtrate is exhausted via the filtrate discharge pipe of the centrifugal filtering device.

Owner:SEVEN JUICE CO LTD

Method for preparing corn straw coarse feed by microbial beneficial living bacteria

InactiveCN104012787AGrowth inhibitionFor long-term storageFood processingAnimal feeding stuffBiotechnologyLactobacillus acidophilus

The invention relates to a method for preparing corn straw coarse feed by microbial beneficial living bacteria. The method comprises the steps of (1) preparing microbial strains: respectively feeding two strains of bacillus subtilis, one strain of lactobacillus acidophilus, one strain of lactobacillus bulgaricus and one strain of rhodopseudomonas palustris onto corresponding culture mediums, culturing, carrying out expanding propagation, and mixing 20g of bacillus subtilis, 20g of lactobacillus acidophilus, 20g of lactobacillus bulgaricus and 20g of rhodopseudomonas palustris for later use; preparing 100g of cellulase; (2) preparing corn straw: flattening the corn straw, and drawing into hair shape with a wire drawing machine for later use; (3) preparing the corn straw coarse feed: putting 1000g of prepared corn straw into a fermentation container, and evenly spraying 5g of cellulase onto the corn straw; diluting microorganism with well water, then spraying onto the corn straw, and fermenting in an airtight way for 7-10 days; taking out the product, drying and packaging to obtain the corn straw coarse feed. The method is simple in technology and short in fermentation period, and is capable of saving a great deal of grain; the prepared biological straw feed is good in palatability, high in lactic acid content and more in beneficial bacteria.

Owner:山西海洲生物科技有限公司

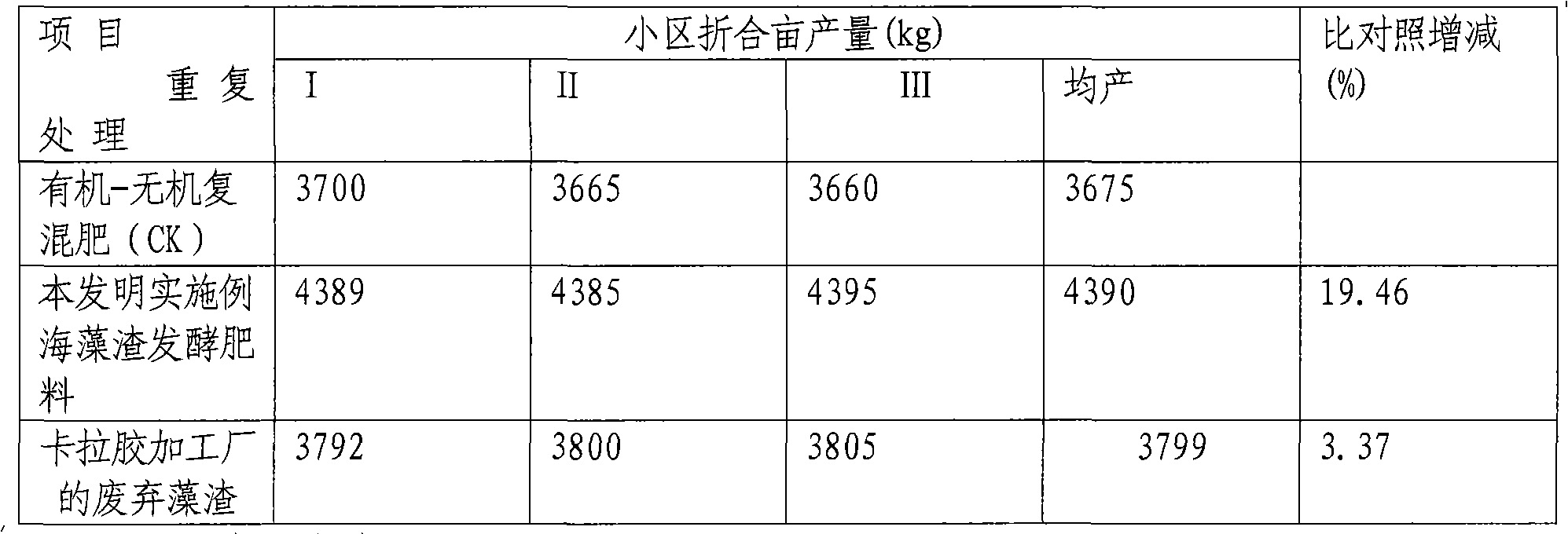

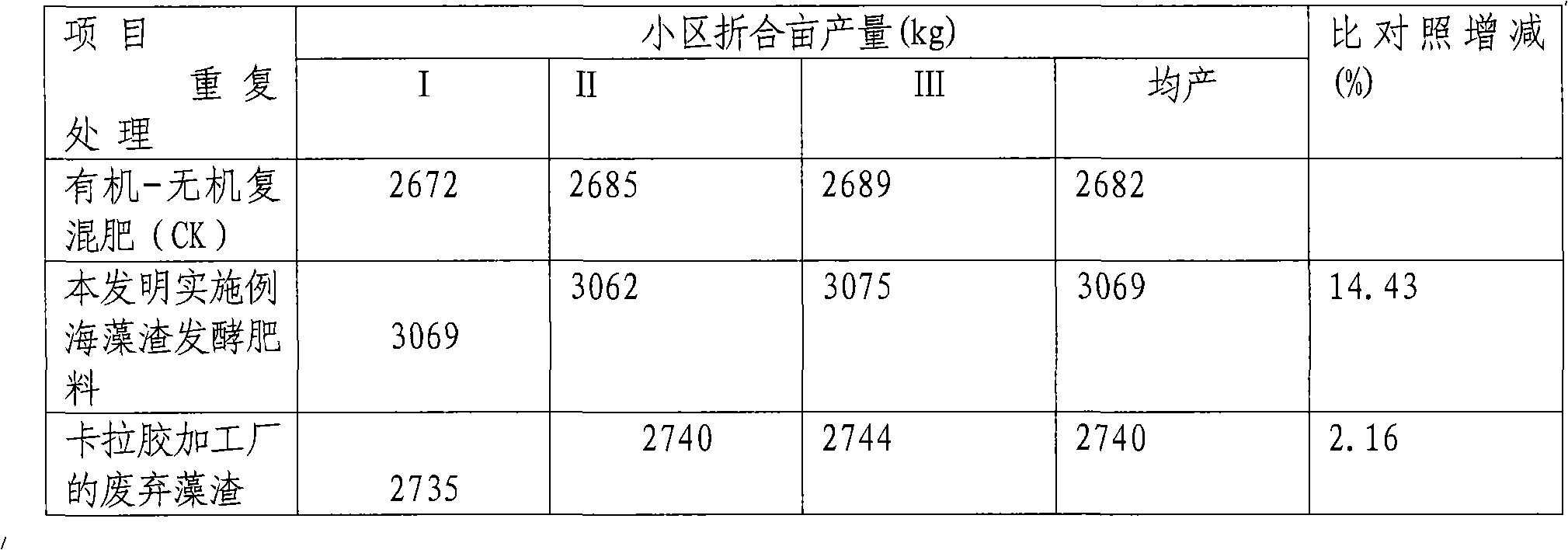

Carrageenan algae residue organic fertilizer and preparation method thereof

InactiveCN102372506ALower the pH valueReduce lossesBio-organic fraction processingClimate change adaptationCarrageenanPhosphate

The invention relates to the field of biological fertilizers and in particular discloses a carrageenan algae residue organic fertilizer and a preparation method thereof. The carrageenan algae residue organic fertilizer consists of the following components in percentage by weight: 0.05 to 0.5 percent of monoammonium phosphate, 0 to 30 percent of auxiliary materials, 0.025 to 0.5 percent of microbial fermentation agent and the balance of carrageenan algae residue. The preparation method comprises the following steps of: adding the monoammonium phosphate into the carrageenan algae residue according to the proportion, regulating the pH value of materials to be 7.0 to 8.0, adding bran and the microbial fermentation agent into the materials, fully mixing and stirring, fermenting a compost, turning the pile in time and supplementing the moisture when the fermentation temperature is 65 to 68 DEG C, turning the pile once on 3rd, 5th and 7th days after inoculation respectively, and maintaining the fermentation temperature of the compost to 45 to 65 DEG C, wherein the aerobic fermentation time is 12 to 20 days; and after the composting is finished, ensuring that the water content of the fermented materials is 20 to 25 percent at the temperature of between 50 and 70 DEG C to obtain the carrageenan algae residue organic fertilizer. By the method, the waste is turned into wealth, the high-efficiency and low-cost organic fertilizer is obtained, the environmental pollution is also treated, and the ecological balance is better kept.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

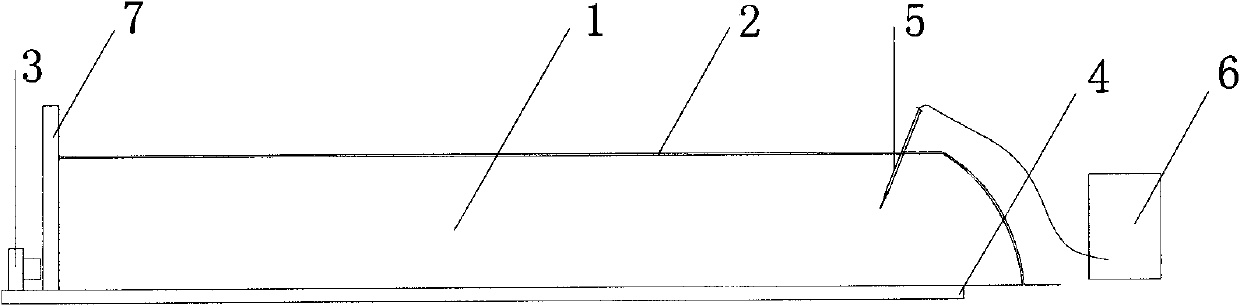

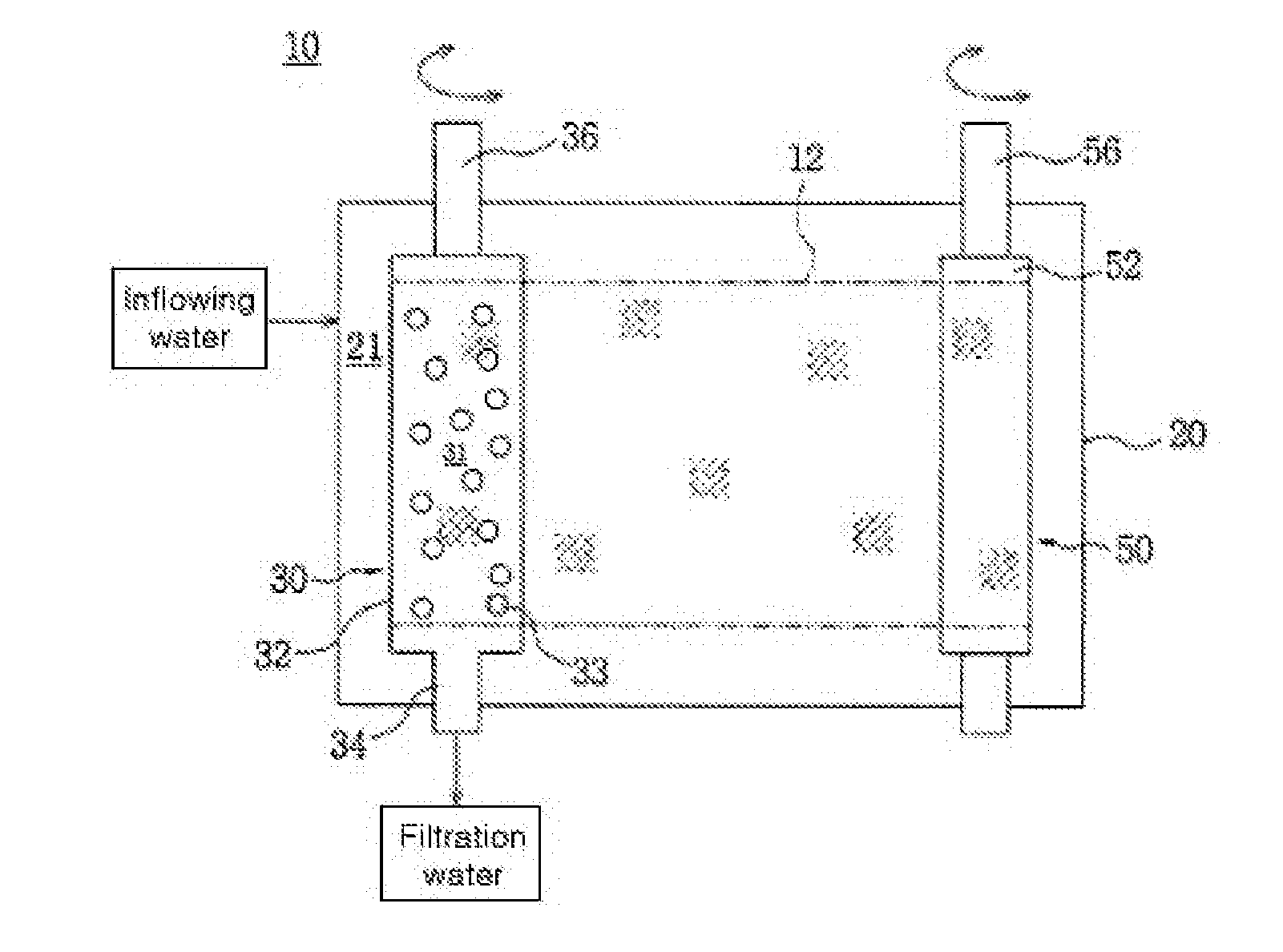

Variable fitration device

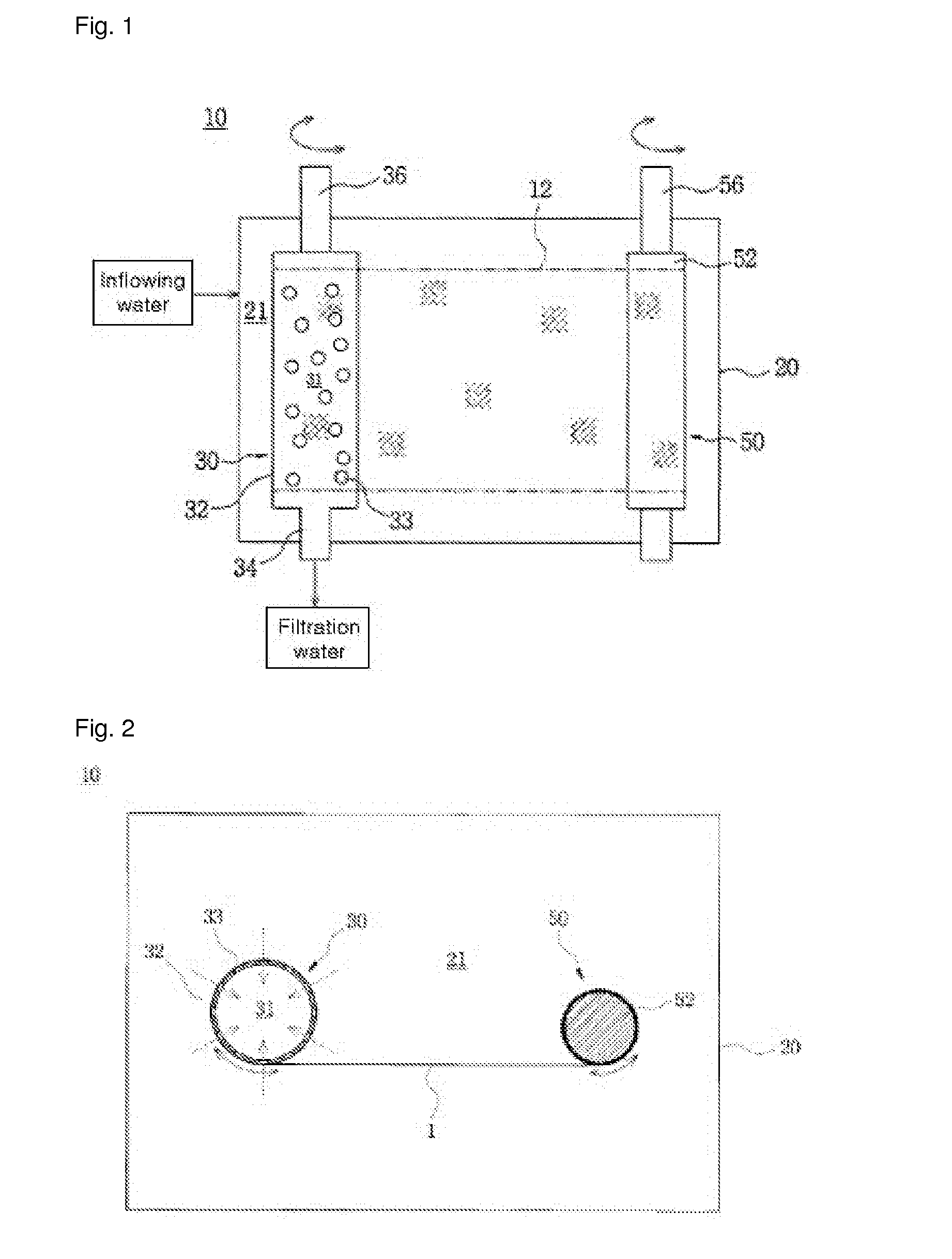

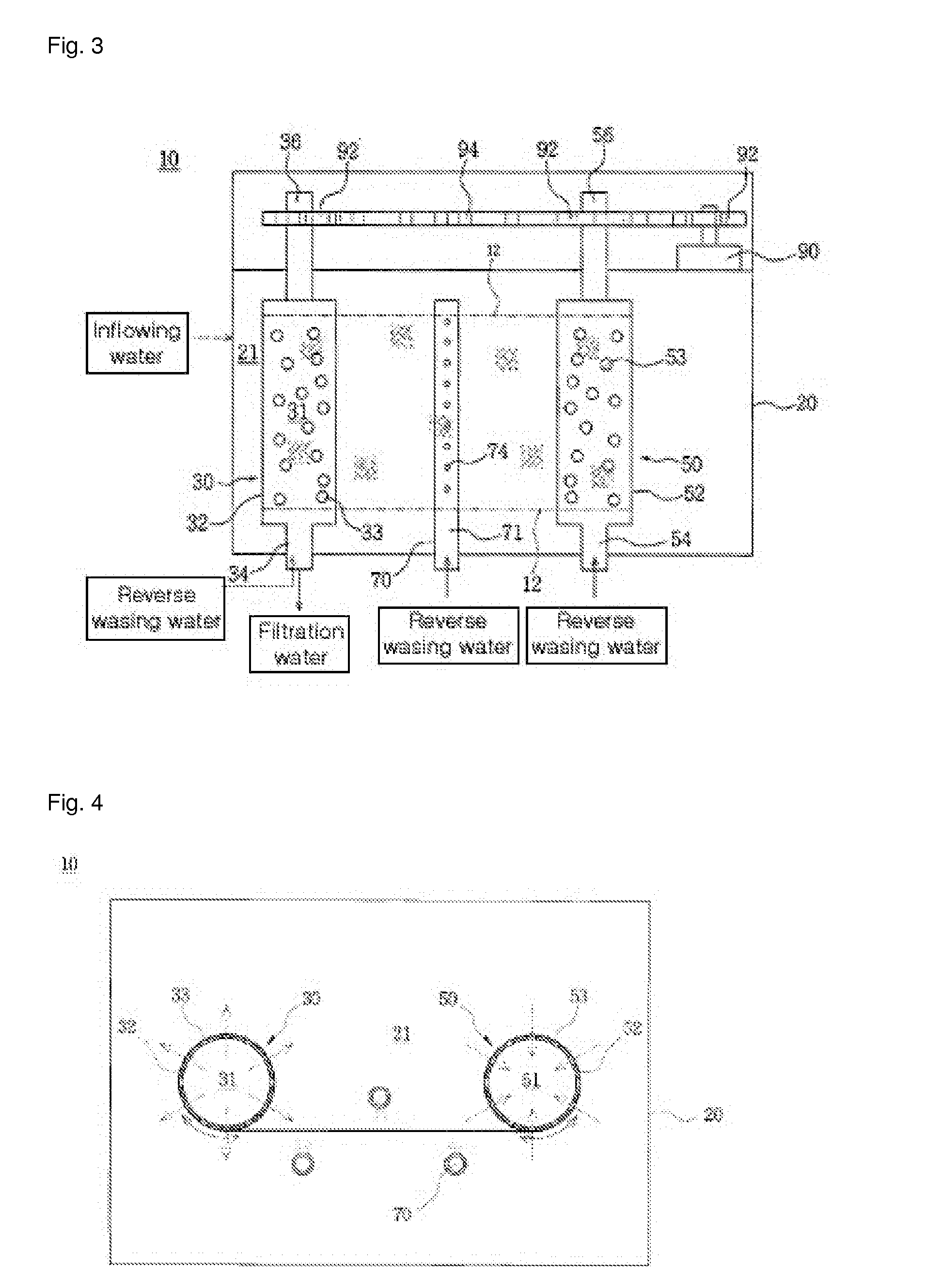

ActiveUS20120152819A1Reduce fermentationEasy to controlMembrane filtersStationary filtering element filtersSewageWater quality

Provided is a filtration device used in order to improve the water quality of the final effluent in an advanced treatment facility for sewage and wastewater. The variable filtration device (10) of this type comprises a filtration tank (20), a filtration unit (30), a winding unit (50) and a filter cloth (12) arranged in such a way that the filtration conditions can be controlled by adjusting the number of turns of winding and the extent of pulling of the filter cloth in the chamber where the filtered water is formed, thereby allowing relatively easy porosity control as compared with the prior art, so enabling ready adjustment to the target water quality and water quantity even when the quality of the inflowing water varies.

Owner:CHO HYUN CHEUL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com