Kitchen garbage disposal method

A technology of kitchen waste and treatment method, which is applied in the treatment, application, organic fertilizer and other directions of biological organic parts, can solve the problem that the treatment method cannot meet the amount of waste, and achieve the effect of improving efficiency and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

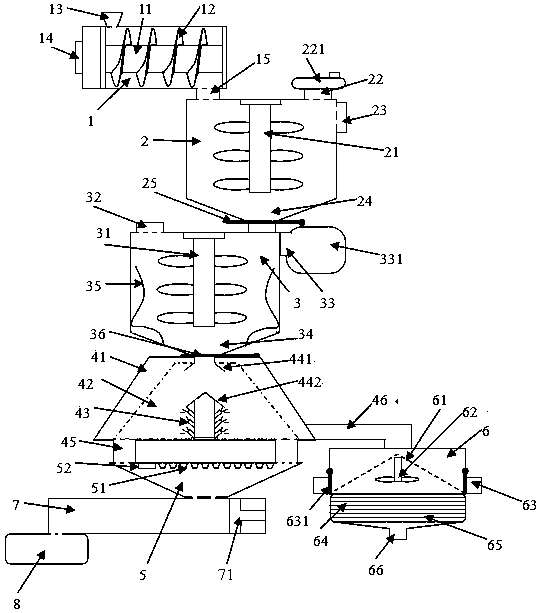

[0041] A kitchen waste treatment method adopts a kitchen waste treatment device. The kitchen waste treatment device includes a crushing room, a disinfection room, a fermentation room, a separation room, a drying room, a sewage treatment chamber, a compression room, and an organic fertilizer storage box .

[0042] The crushing chamber includes a crushing chamber shell, a crushing shaft, a crushing blade, a kitchen waste inlet, a motor, and a crushing chamber outlet. The crushing chamber shell is in the shape of a transverse cylinder, and a crushing shaft is arranged transversely inside, and is arranged on the top of one end of the crushing chamber shell There is a kitchen waste inlet, a crushing chamber outlet is arranged at the bottom of the other end, a crushing blade is spirally arranged on the crushing shaft, and a motor for controlling the rotation of the crushing shaft is arranged outside the shell of the crushing chamber at one end of the crushing shaft.

[0043] The disinfec...

Embodiment 2

[0063] A kitchen waste treatment method adopts a kitchen waste treatment device. The kitchen waste treatment device includes a crushing room, a disinfection room, a fermentation room, a separation room, a drying room, a sewage treatment chamber, a compression room, and an organic fertilizer storage box .

[0064] The crushing chamber includes a crushing chamber shell, a crushing shaft, a crushing blade, a kitchen waste inlet, a motor, and a crushing chamber outlet. The crushing chamber shell is in the shape of a transverse cylinder, and a crushing shaft is arranged transversely inside, and is arranged on the top of one end of the crushing chamber shell There is a kitchen waste inlet, a crushing chamber outlet is arranged at the bottom of the other end, a crushing blade is spirally arranged on the crushing shaft, and a motor for controlling the rotation of the crushing shaft is arranged outside the shell of the crushing chamber at one end of the crushing shaft.

[0065] The disinfec...

Embodiment 3

[0086] A kitchen waste treatment method adopts a kitchen waste treatment device. The kitchen waste treatment device includes a crushing room, a disinfection room, a fermentation room, a separation room, a drying room, a sewage treatment chamber, a compression room, and an organic fertilizer storage box .

[0087] The crushing chamber includes a crushing chamber shell, a crushing shaft, a crushing blade, a kitchen waste inlet, a motor, and a crushing chamber outlet. The crushing chamber shell is in the shape of a transverse cylinder, and a crushing shaft is arranged transversely inside, and is arranged on the top of one end of the crushing chamber shell There is a kitchen waste inlet, a crushing chamber outlet is arranged at the bottom of the other end, a crushing blade is spirally arranged on the crushing shaft, and a motor for controlling the rotation of the crushing shaft is arranged outside the shell of the crushing chamber at one end of the crushing shaft.

[0088] The disinfec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com