Patents

Literature

156results about How to "Raise the fermentation temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Kitchen garbage disposal method

ActiveCN107824601AImprove processing efficiencyFull recoveryBio-organic fraction processingSolid waste disposalLitterReclaimed water

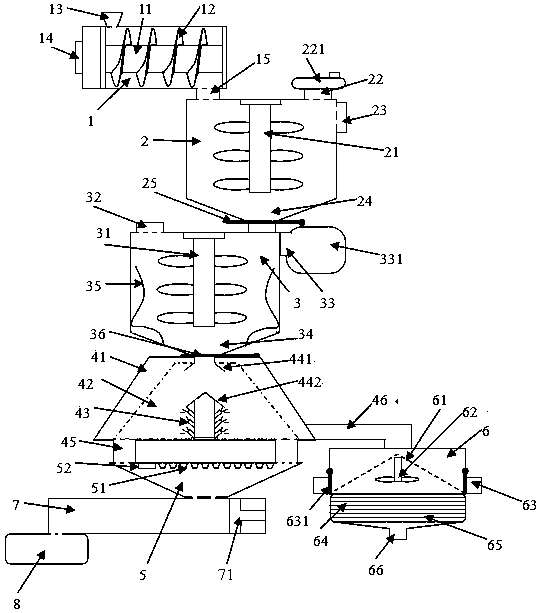

The invention relates to a kitchen garbage disposal method. The kitchen garbage disposal method adopts a kitchen garbage disposal device which comprises a crushing chamber, a disinfection chamber, a fermentation chamber, a separation chamber, a drying chamber, a sewage treatment cavity, a compression chamber and an organic fertilizer storage box. Through such steps as crushing, disinfection, fermentation, solid-liquid separation, sewage treatment, drying, compression and storage, solids of kitchen garbage form an organic fertilizer, liquid is processed to obtain reclaimed water, produced gas forms marsh gas, and therefore, full recycling and reusing of kitchen garbage are truly realized.

Owner:广东人峰实业有限公司

Equipment and method using fermentation dross to produce high activity high nutrition forage

ActiveCN105054261AIncrease contentReduce energy consumptionFeeding-stuffFood processingFiberAir filter

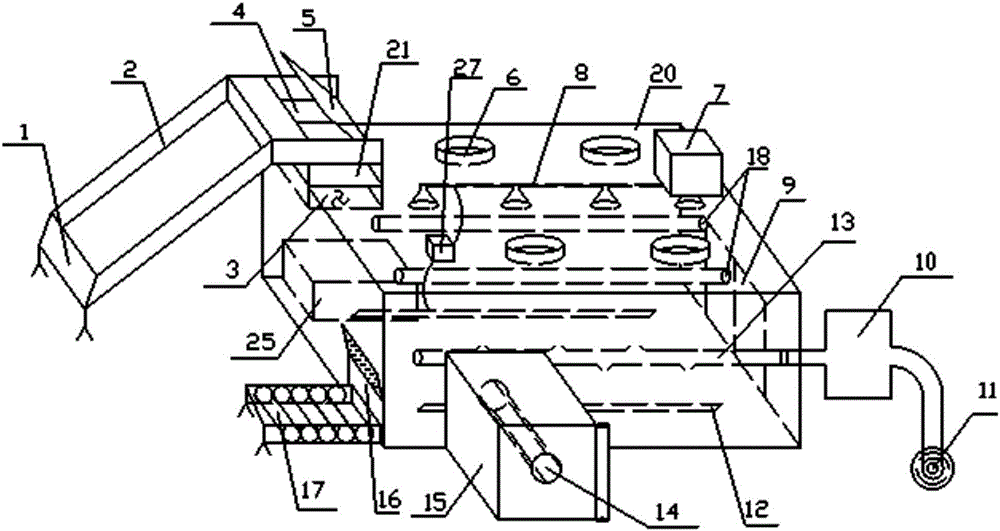

The invention discloses equipment using fermentation dross to produce high activity high nutrition forage; the equipment comprises a box body; an inner side of the top of the box body is provided with an air window, an atomizer mechanism, and ultraviolet lamp tubes; an outer side of the top of the box body is provided with a water container and a mixing chamber; the upper portion of the mixing chamber is provided with a cooling zone; the lower portion of the mixing chamber is provided with a blender and a connected fermentation bed mechanism arranged in sequence from top to bottom, wherein the fermentation bed mechanism is arranged in the box body; the bottom of the box body is provided with a ventilation input pipe and electric heaters; the ventilation input pipe is connected in sequence with an air filter and a blower / air cooler; a side face of the box body is provided with a discharge window, another side face of the box body is provided with an access door and an ozone generator, and a temperature humidity control module is arranged in the box body. The invention also discloses a method using fermentation dross to produce high activity high nutrition forage; the method can realize full fermentation, is high in fiber degraded rate, large in protein raising rate, high in active substance content, and less in energy loss; inner environment conditions of the equipment are easy to control.

Owner:肖兵南

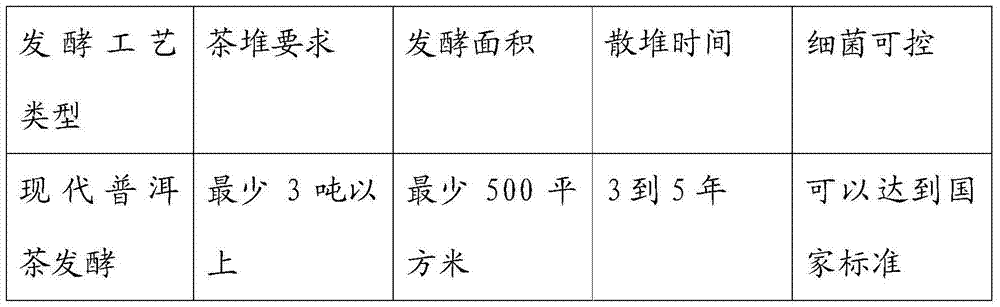

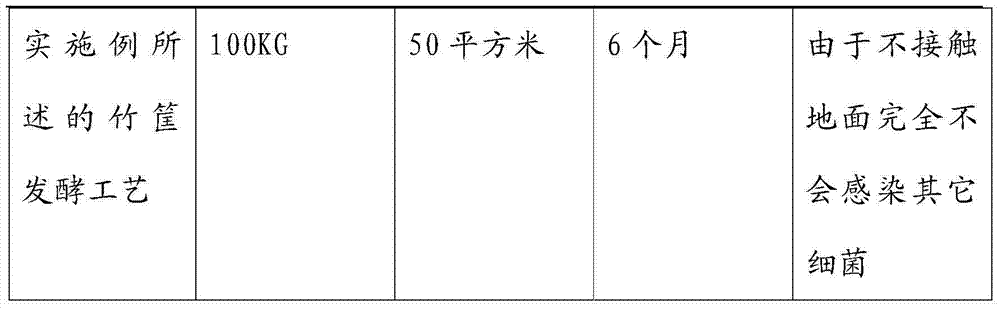

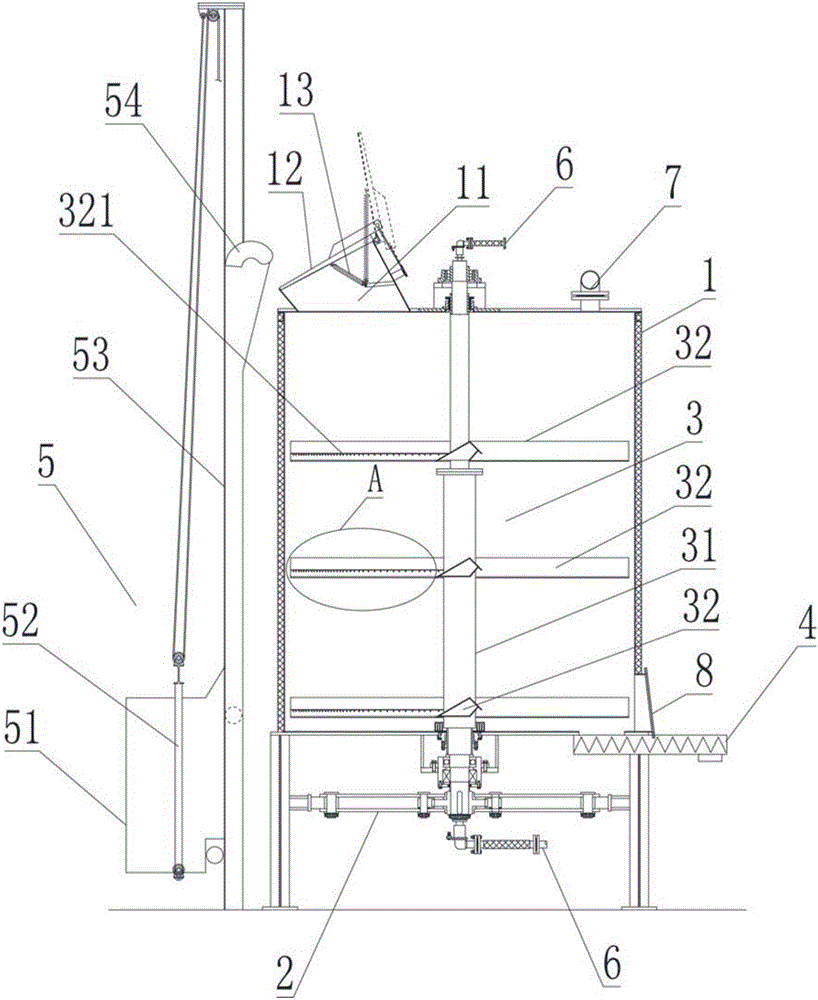

Method for preparing puer tea by adopting bamboo basket fermentation

InactiveCN103583713AAvoid absorptionRaise the fermentation temperaturePre-extraction tea treatmentClimate change adaptationFermentationTea leaf

The invention discloses a method for preparing puer tea by adopting bamboo basket fermentation. The method comprises the following steps: (1) preparing materials, namely selecting Yunnan large-leaf sun-dried raw tea as a tea leaf raw material; (2) carrying out pile fermentation, namely (2-1) arranging a round bamboo basket above the ground; filling the bamboo basket with 100kg-3000kg of the tea leaves, and sprinkling water to the tea leaves to wet the tea leaves thoroughly to form a tea pile, wherein the weight ratio of the tea leaves to the water is 7 to 3; wrapping the four sides and the top surface of the bamboo basket with a jute bag, inserting a temperature meter into the tea pile, and fermenting; (2-2) turning the pile and supplementing water, namely fermenting for three weeks, opening the jute bag for the first time, uniformly turning the tea pile, and supplementing the water for the first time; after water supplementation is finished, wrapping the four sides and the top surface of the bamboo basket with the jute bag; (2-3) controlling the fermenting time to be 40-70 days in the whole fermenting process; controlling the temperature not to exceed 65 DEG C from the first day. The method can be used for achieving the purpose of fermenting the small pile (such as 100kg) of Yunnan camellia arborescens.

Owner:卢志明

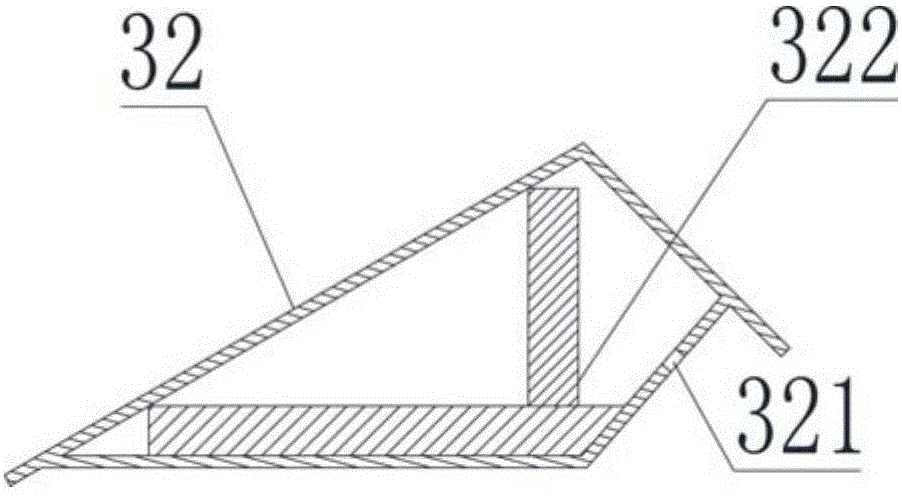

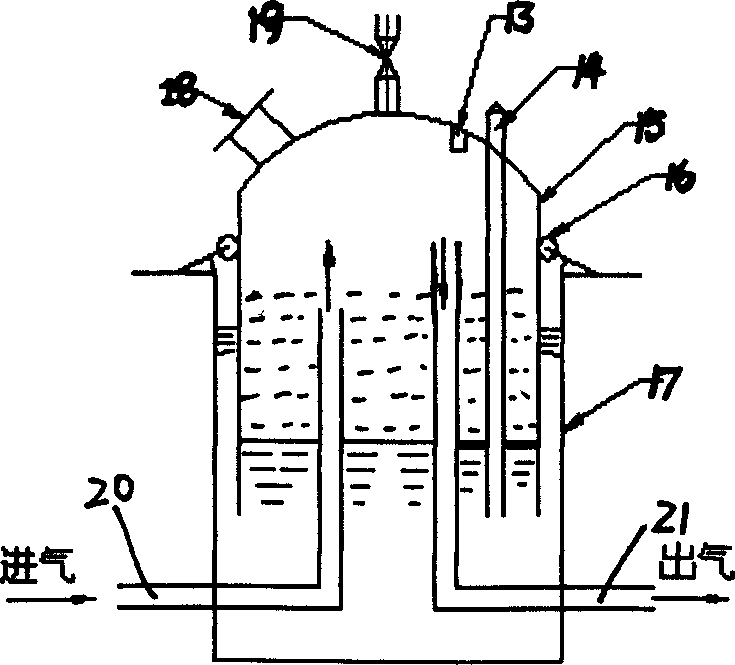

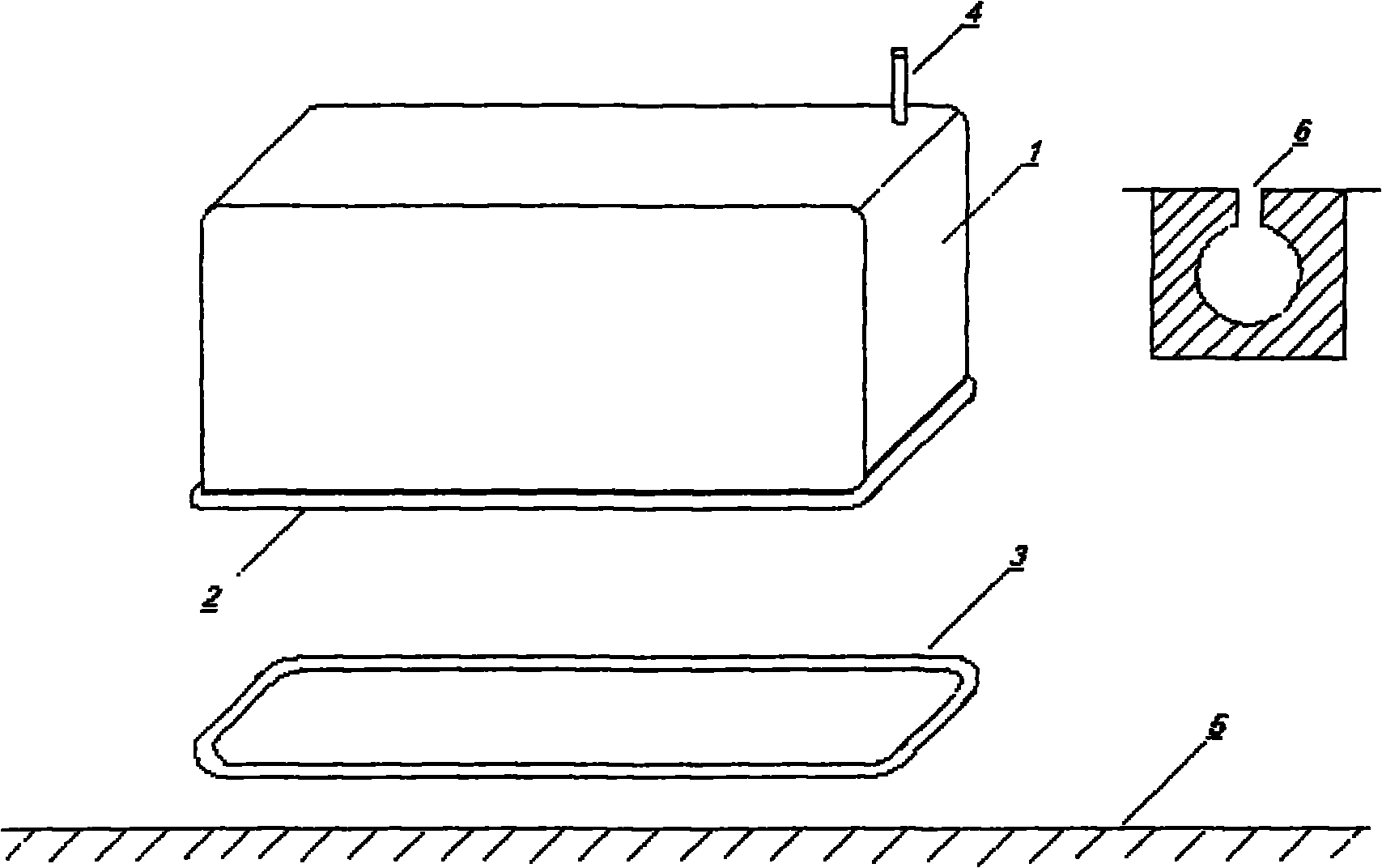

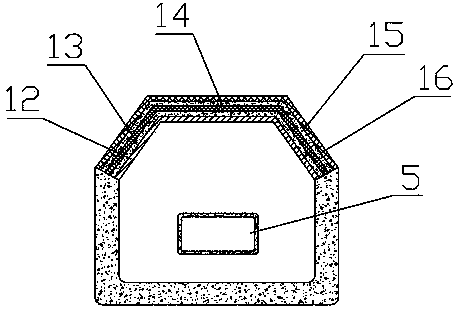

Closed silo composting reactor

InactiveCN105060962APrevent compactionRaise the fermentation temperatureBio-organic fraction processingOrganic fertiliser preparationEffective volumeFermentation

The invention relates to the technical field of organic solid waste treatment, in particular to a closed silo composting reactor. The closed silo composting reactor comprises a composting silo, a stirring device, a hydraulic drive device and a discharge screw conveyor, wherein a feed port and an exhaust port are formed in the top of the composting silo; a discharge port is formed in the bottom of the composting silo; the discharge screw conveyor corresponds to the discharge port; the stirring device is arranged in the composting silo; the hydraulic drive device drives the stirring device to rotate and stir. The composting silo adopts vertical closed design, has high effective volume and can increase fermentation temperature, so that the fermentation period is greatly shortened; the stirring device performs continuous dynamic stirring, thereby having stirring, mixing and loosening effects and avoiding material compaction; with the adoption of rotating aeration, effectiveness and uniformity of aeration are improved.

Owner:北京沃土天地生物科技股份有限公司

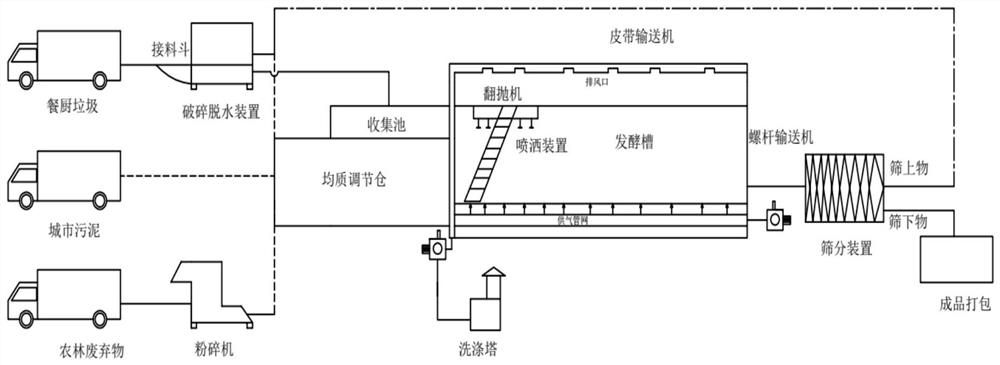

Kitchen waste, municipal sludge and forestry and agricultural residue fermentation tank ultrahigh-temperature aerobic fermentation composting method

PendingCN112479757AQuick breakdownEfficient killingBio-organic fraction processingMicroorganism based treatmentMicroorganismDecomposition

The invention relates to the technical field of organic solid waste treatment and renewable energy treatment, in particular to a kitchen waste, municipal sludge and forestry and agricultural residue fermentation tank ultrahigh-temperature aerobic fermentation composting method which comprises the following steps: (1) pretreating; (2) fermenting in a fermentation tank at ultra-high temperature: 1)adjusting physicochemical indexes; 2) building a pile; 3), aerating; 4), turning and throwing; 5), inoculating extreme thermophilic microorganisms; and (3) screening the decomposed material, transporting the undersize material as a finished product, and refluxing and utilizing the oversize material. According to the method, the kitchen waste, the municipal sludge and the forestry and agriculturalresidues are used as raw materials for mixed fermentation, decomposed substances are organic fertilizers and can be reused for soil, and waste is turned into wealth. According to the method, the fermentation temperature exceeds 80 DEG C, the highest fermentation temperature can reach 110 DEG C, the fermentation temperature is high, the fermentation period is short, organic matter decomposition isfast, germs, viruses and worm eggs in the garbage are effectively killed, and garbage reduction, harmlessness and resourceful treatment are fast achieved.

Owner:HUBEI JUNJI WATER TREATMENT

Controllable box type complete equipment for anaerobic fermentation and methane liquid treatment

ActiveCN1631823AEnsure normal gas productionRaise the fermentation temperatureWaste based fuelEnergy based wastewater treatmentPig farmsMarsh

Disclosed is a controllable piquid of swamp processing equipment, the fermentation of marsh gas system mainly comprises of solar energy heating barn, more than two fermentation of marsh gas pool connected together in-line and its entrance for material and exit for material, feed inlet and discharge outlet auxiliary heating system and other parts. The fermentation of marsh gas pool includes material exhausting chamber, pool and steal cover of it; the solar energy heating barnincludes the frame and plastic film covering on it; the auxiliary heating system comprise of heating furnace and heating recycling pipe which has recycling water pump and value on it, its one end is linking to the material exhausting chamber of fermentation of marsh gas pool and another one to the heating water jacket in the heating furnace, the heating-recycling piquid of swamp recycling auxiliary heating system through the their covers. The invention is an auxiliary heating marsh gasengineering suitable for scalized pig farm, mainly aiming at solving problems existing in conventional marsh gas pool, such as fermentation in low temperature, insufficient time for production, small ratio of volume and productivity and so on. The conventional marsh gas pool cannot assure the stable temperature and productivity for marsh gas, while the engineering makes use of solar energy heating and auxiliary heating equipment, which has solved the problems above completely, and its advantages includes: (1) reasonable in structure and practical in technology; (2) has remarkable economic benefit, high productivity and short term for compensating investment, about 1.23 years; (3) is suitable for payoff pariod and waste water procession in scalized pig farm, with high processing efficiency, has supplied a new processing approach for pig farm .

Owner:HENAN AGRICULTURAL UNIVERSITY

Cordycep enzyme bath combination and fermentation production and application thereof

ActiveCN104856923ALoose textureDoes not hinder breathingCosmetic preparationsToilet preparationsPhysical well beingEnzyme system

The invention provides a cordycep enzyme bath combination and fermentation production and an application thereof. Bacillus subtilis is added into cordycep enzyme fermentation materials according to the weight percentage of 0.1 to 0.5% to form the cordycep enzyme bath combination, wherein 0.2 to 0.8 part of probiotics are added after 50 to 70 parts of plant materials, 20 to 30 parts of cordycep enzyme, 50 to 80 parts of hot water at 60 to 100 DEG C and 20 to 40 parts of brown sugar are mixed to form the cordycep enzyme fermentation materials through fermentation. The cordycep enzyme bath combination is applied according to a warm bath method. According to the cordycep enzyme bath combination and the fermentation production and the application thereof, the one hundred percent of natural fermentation heat is achieved, the water content is low, and accordingly the skin swelling is not caused and the heat conductivity is low in comparison with water; the heart burden is small and the skin breathing is not blocked; body parts are stimulated through biont and accordingly the body health is facilitated; the mixed fermentation is performed through the enzyme and enzyme bath materials, meanwhile the rich probiotics and enzyme system are contained in the enzyme, and accordingly the fermentation temperature of an enzyme bath is effectively improved, the cycle is short, the economic and environment-friendly effect is achieved, and the human body absorption and the improvement on health level are facilitated.

Owner:西藏月王藏药科技有限公司

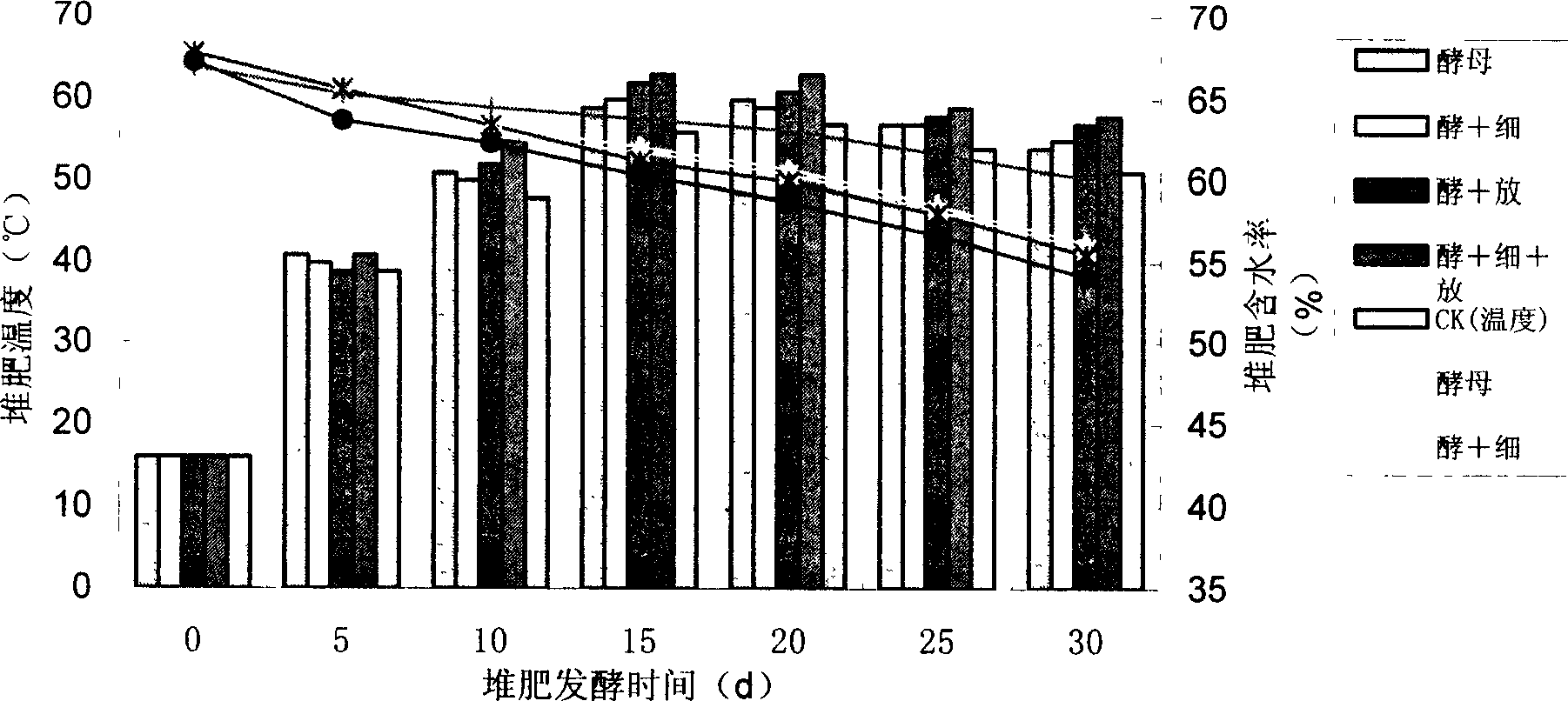

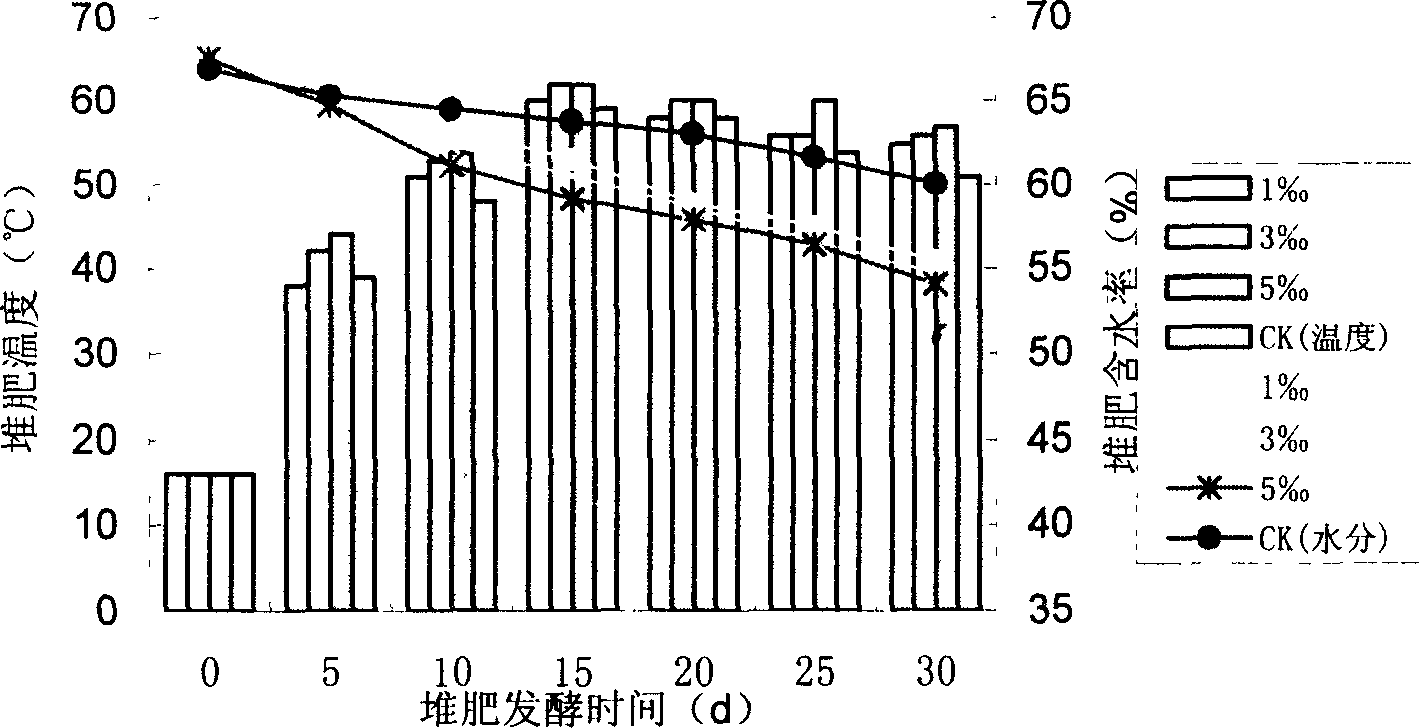

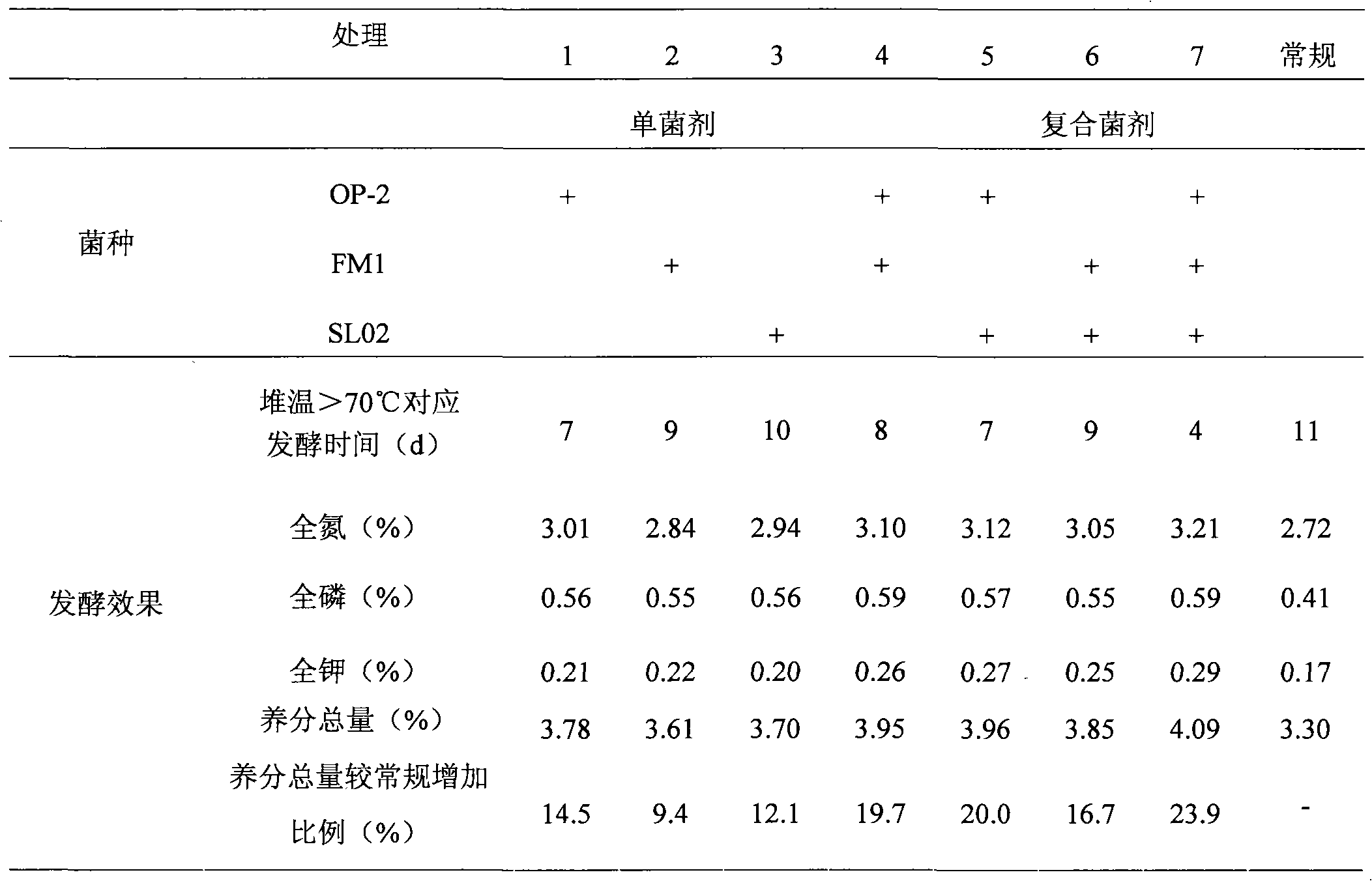

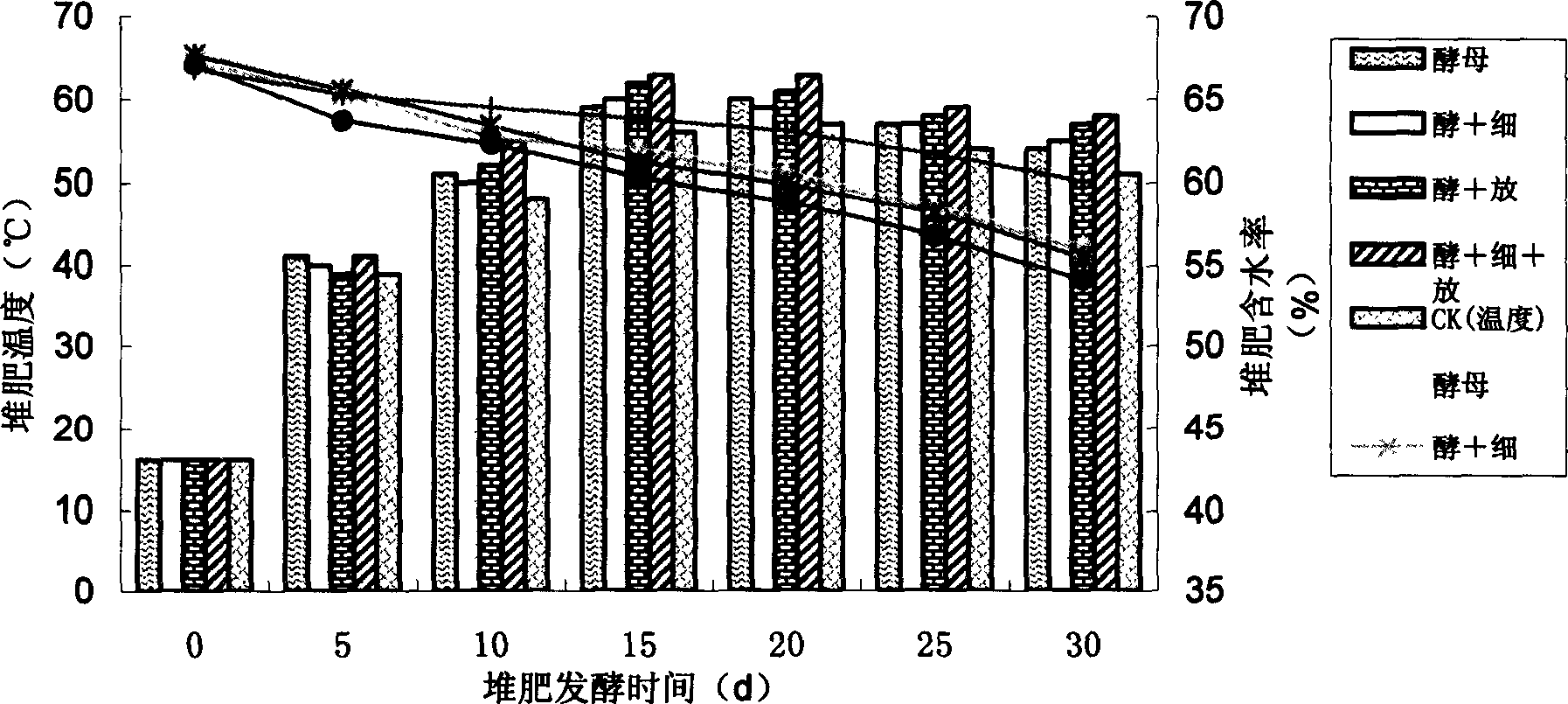

Zymogen agent for treating agricultural wastes and preparation method

A formentation bacterial agent for processing agricultural waste is composite or single bacterial agent prepared by cultivating and fermenting three bacterial agents of retaining cupsule film spoyeast ZJY2, griseolutein W, and cerecin ME1-2. The application process includes controlling water content rate of waste to be 55-56%, adding and mixing the agent, stirring the mixer for ventilation at setting time for 20-30 days and achieving the aim of making the waste nonhazardous and resources.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

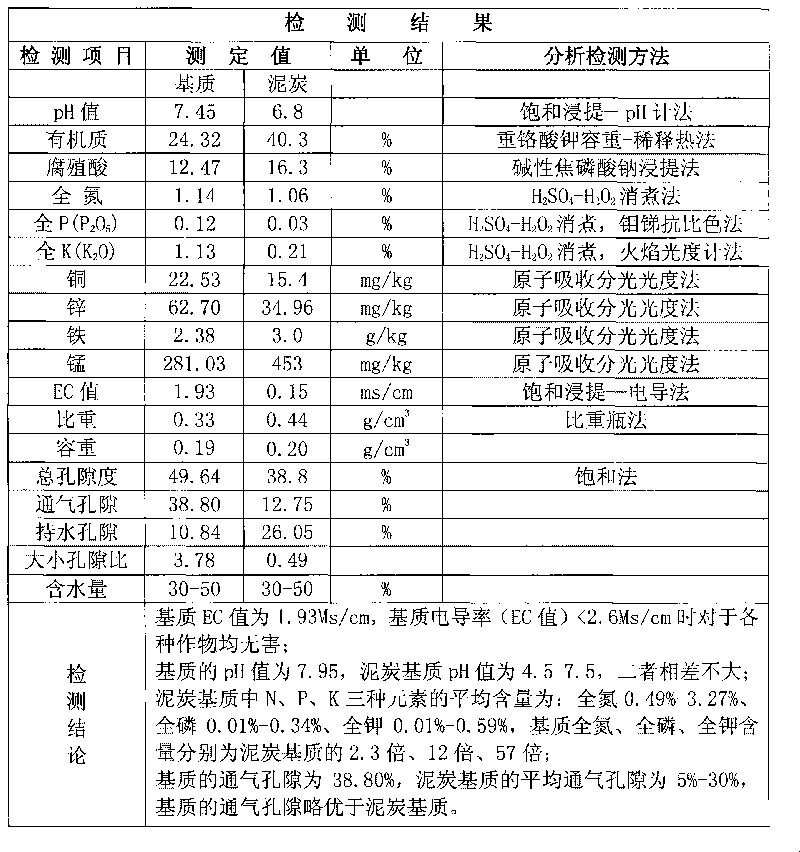

Seedling medium and preparation method thereof

ActiveCN101759449AHigh cost of preparationRaise the fermentation temperatureBio-organic fraction processingOrganic fertiliser preparationChemistryRoot system

The invention relates to a seedling medium and a preparation method thereof, wherein the medium comprises the following components of raw materials: one or more of crop by-products, organic wastes, by-products generated in grass pulping process when preparing materials, and ammonia water. The method comprises the following steps: mixing one or more of the crop by-products, the organic wastes, theby-products of the grass pulping process when preparing the materials, and the ammonia water, and then fermenting to gain the medium, wherein nitrogenous condensate water generated when concentratingblack liquid generated in a neutral ammonium sulfite process is optimally selected as the ammonia water, and optimally, the condensate water with 0.05-0.55% of nitrogen content and at the temperatureof 25-70 DEG C is the best; and by-products generated in preparation department in the neutral ammonium sulfite process are optimally selected as the crop by-products. The method re-uses the waste and waste liquid which are generated in the neutral ammonium sulfite process to turn waste into wealth. The permeability and nutrient content of the medium are respectively superior to that of peat perlite, when the medium is used in the growth test of nursery stock of forest, the nursery stock has obvious grow, and the quantity of the root system can be increased by over 30 percent.

Owner:SHANDONG TRALIN PAPER

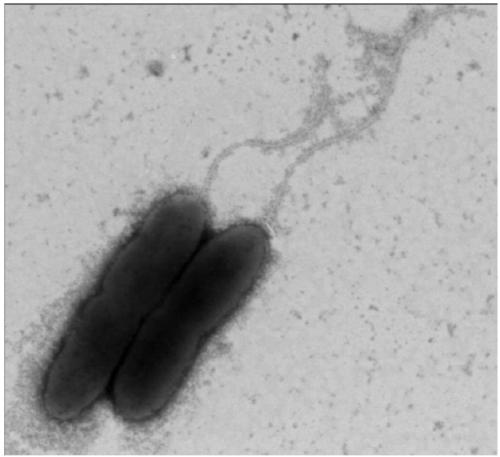

Shewanella putrefaciens and application thereof in organic waste treatment

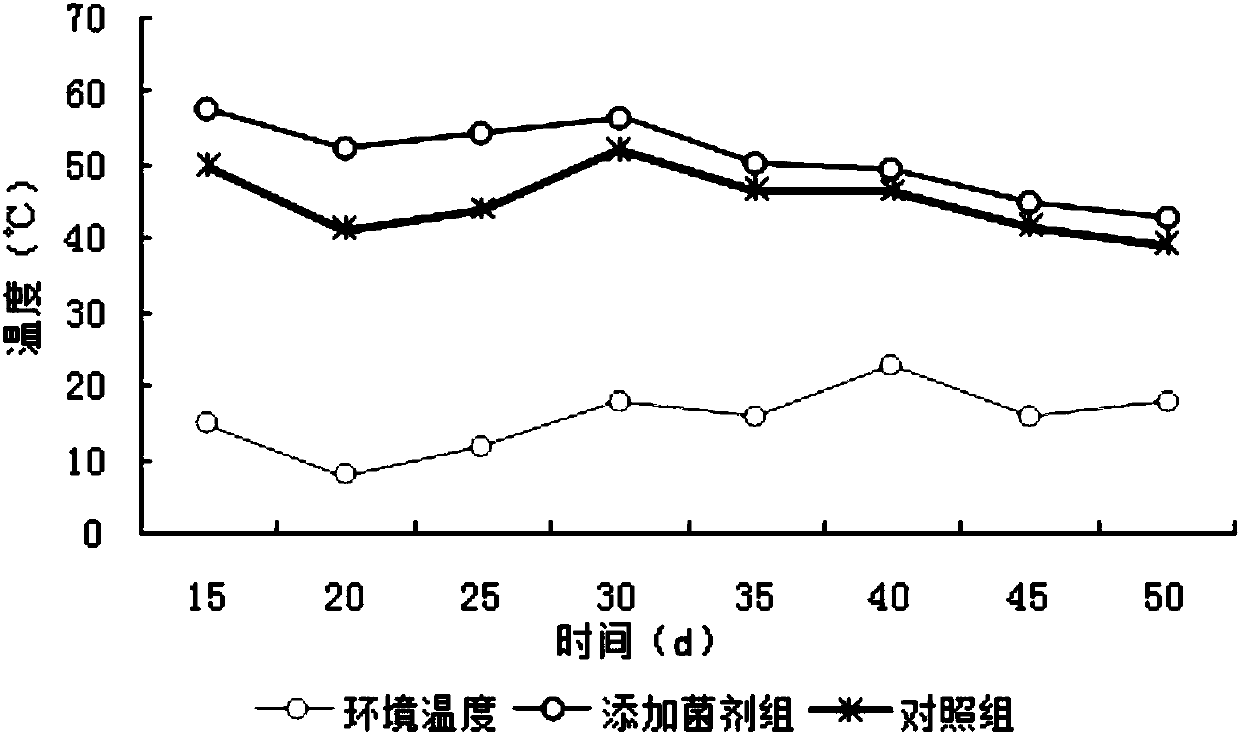

InactiveCN102925383AWell mixedRaise the fermentation temperatureBio-organic fraction processingBacteriaAgricultural sciencePoultry manure

The invention discloses a shewanella putrefaciens CR7 strain of which the preservation number is CGMCC NO.6192. The strain is separated out from cattle manure compost which is kept in a low-temperature environment for a long time; and a microbial inoculum prepared from the strain can be applied to livestock and poultry manure compost such as cattle manure and the like in winter, and has the effects of quickly starting compost fermentation, increasing compost fermentation temperature, shortening compost fermentation period and reducing nitrogen element loss. The microbial inoculum prepared from the strain is used for producing an organic fertilizer in winter, and can omit the heating procedure in the early stage of the composting of the organic fertilizer, shorten the production period of the organic fertilizer, increase the yield and lower the production cost.

Owner:NANJING NORMAL UNIVERSITY

Bio-fertilizer produced by fermenting steel slag, vinegar residue and weathered coal through microbes and preparation method thereof

InactiveCN101786916ARich in metabolitesGood deodorizing effectBio-organic fraction processingOrganic fertiliser preparationMicroorganismOrganic acid

The invention relates to a bio-fertilizer produced by fermenting steel slag, vinegar residue and weathered coal through microbes and a preparation method thereof. The bio-fertilizer comprises the following components in percentage by weight: 15 to 20 percent of steel slag, 5 to 73 percent of vinegar residue, 10 to 15 percent of weathered coal and 0.05 to 0.1 percent of microbes. The preparation method comprises the following steps: selecting the microbes; activating the microbes; performing first-stage and second-stage rocker expansion; mixing; fermenting; turning a pile; obtaining finished products; drying at low temperature; detecting; and metering and packaging. The steel slag, the vinegar residue and the weathered coal are subjected to high temperature fermentation by utilizing the microbes; metallic oxides in the steel slag and organic acid in the vinegar residual undergo neutralization reaction to generate an organic complex under the action of the weathered coal and the synergy of the microbes so as to improve the effectiveness of the fertilizer; and the method can be promoted and applied to innocent treatment for various industrial and agricultural wastes such as flyash in a power plant, vinasse in a winery, decoction dreg in a pharmaceutical factory, urban garbage and the like, can change the wastes into treasure, and protects the environment simultaneously.

Owner:山西晨雨科技开发有限公司

Vinegar residue fermented complex micro organism fungicide and preparation method thereof

InactiveCN101805697ARaise the fermentation temperatureSpeed up the fermentation processBio-organic fraction processingFungiPotassiumMixed materials

The invention discloses a preparation method of vinegar residue fermented complex micro organism fungicide. The fungicide is formed by single strain fungicides of bacillusacidocaldarius., rhizopus stolonifer and trichoderma viride by weight ratio of 1:1:1, wherein firstly stock seeds of the single strain fungicides are respectively multiplied by a primary test tube and are respectively subject to secondary liquid culture to obtain bacteria; then 50-60% of rice bran and 50-40% of wheat bran are mixed by weight percent and stirring to be uniform is carried out to obtain mixed material, the cultured bacteria are respectively inoculated according to the volume weight ratio of bacterium and mixed material, thus obtaining single strain fungicide. The complex micro organism fungicide provided by the method can increase fermentation temperature of vinegar residue compost and speed up fermentation, and fermentation finished product thereof has high content of full dose nutrients (nitrogen, phosphorous and potassium) and good nutrition.

Owner:JIANGSU UNIV

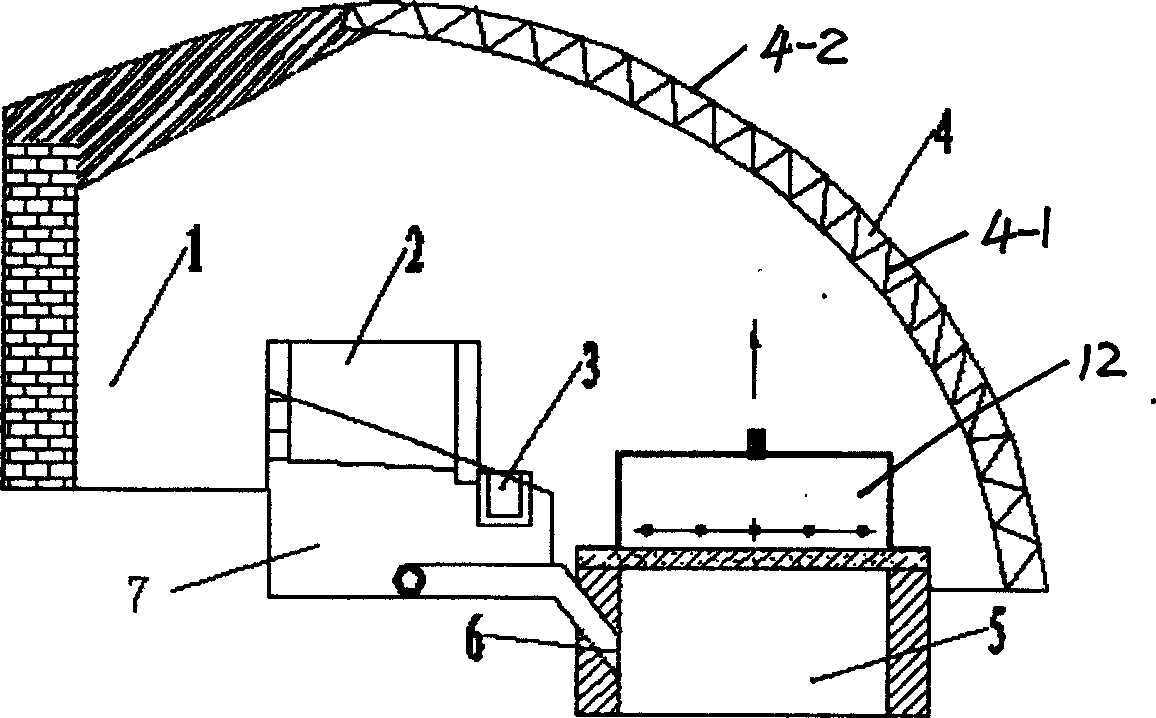

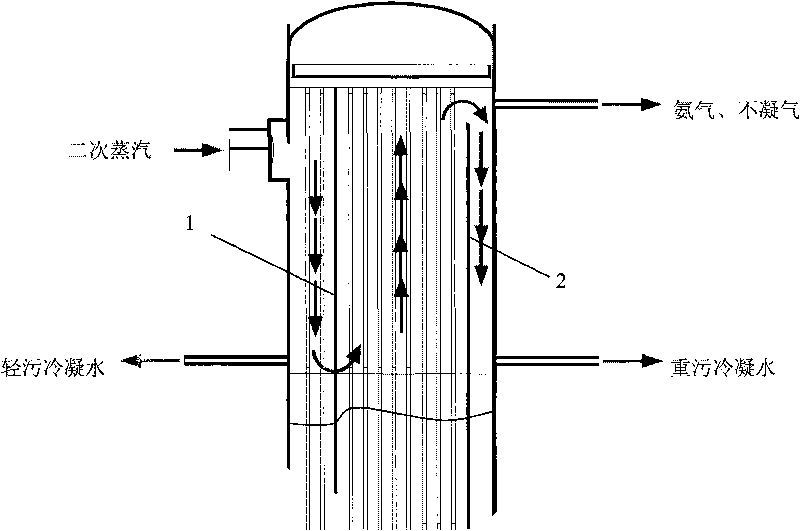

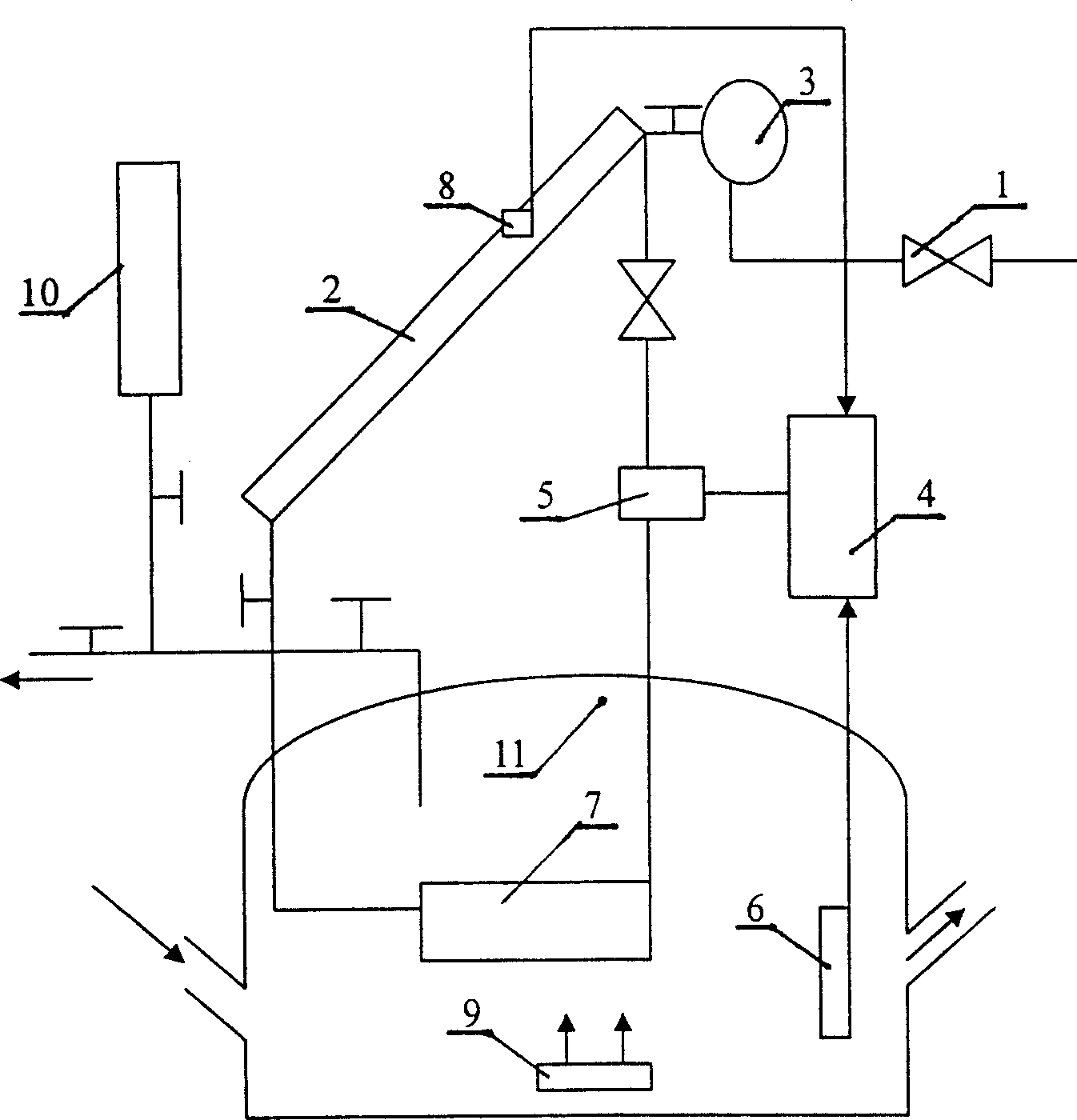

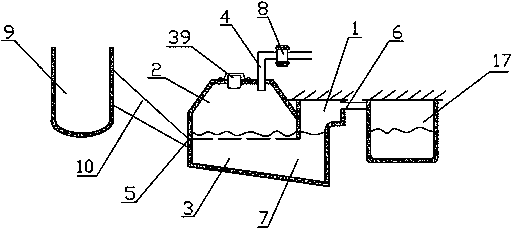

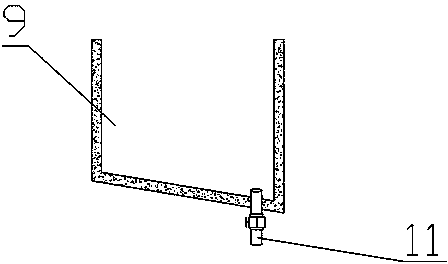

Solarheat-collecting applicator in marsh-gas fermentation pool

InactiveCN1896218ARaise the fermentation temperatureIncrease gas productionGas production bioreactorsWaste based fuelEngineeringCirculating pump

A solar heat-collecting applicator in marsh gas fermentation pool consists of solar heat collector (2), gas-storage tank (10), temperature adjuster (4) and marsh gas pool (11). The solar heat collector (2) is installed outside of marsh gas pool (11), discharging pipe on bottom of solar heat collector (2) is connected to entrance end of internal heat exchanger (7) of marsh gas pool (11) by valve, outlet pipe of heat exchanger (7) is connected to inlet pipe on top of solar heat collector (2) by circulating pump (5) and valve. It has higher fermentation temperature and more marsh gas output.

Owner:袁铭鉴

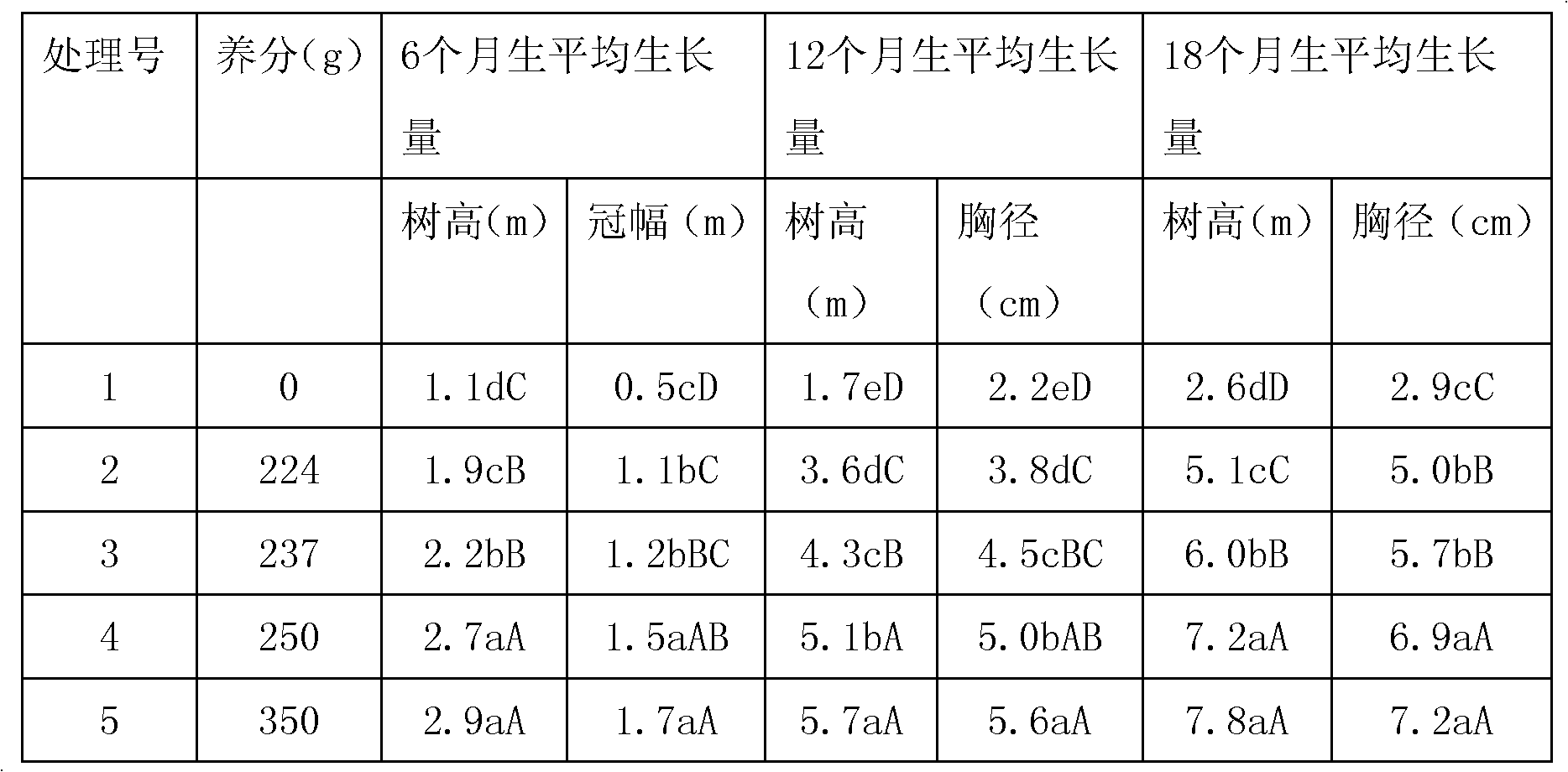

Sludge organic fertilizer for forestry and afforestation and preparation method thereof

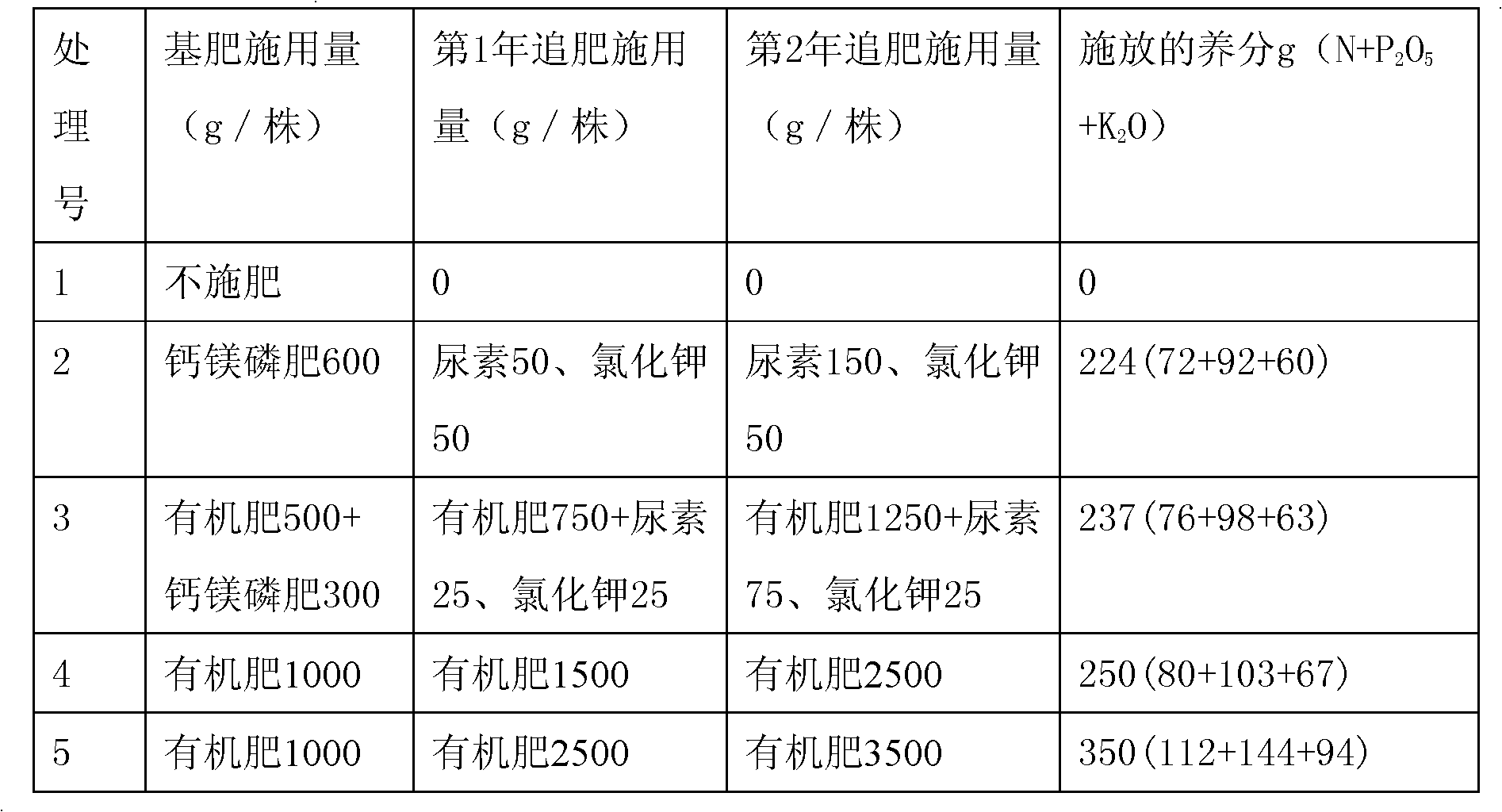

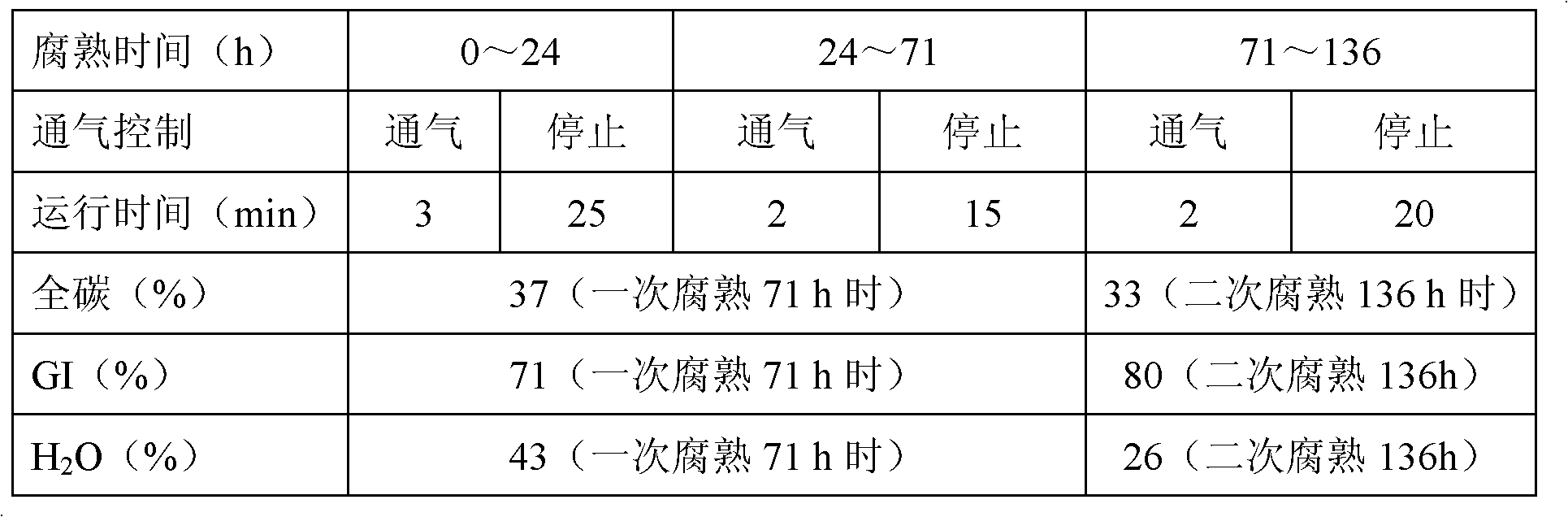

InactiveCN102303984AShorten the maturity timeEasy to handleBio-organic fraction processingClimate change adaptationForest industrySoil science

The invention claims a sludge organic fertilizer for forestry and afforestation and a preparation method thereof. The organic fertilizer comprises 30-35% of total carbon, 1-2% of N, 2-3% of P2O5, 1-3% of K2O and 25-30% of water. The organic fertilizer is prepared by fermentation of sludge. The specific preparation method comprises the following steps of: A, regulating a water content of the sludge to 55-65%, a C / N value to 27-33, and a content of the total carbon to 35-45%; B, fermenting and composting for the first time for 65-75 hours at a temperature in a range of 50-52 DEG C and a pH value of 7-11; and C, fermenting and composting for the second time for 55-75 h at a temperature in a range of 53-55 DEG C and the pH value of 7-9. According to the invention, the organic fertilizer is prepared by two-step aerobic composting to shorten an aging time of a traditional windrow sludge composting method from 30-40 days to 110-160 hours. Compared with the traditional method, the method provided by the invention is characterized by lower fermentation temperature (but not lower than 50 DEG C), low production energy consumption caused by high water content of the organic fertilizer and low production cost. The method is used for fertilization production on the aspect of afforestation. The sewage sludge fertilizer is used for increasing organic matter of soil, is good for growth of forest vegetation, and embodies a theory of forest ecological balance and circulation economy.

Owner:SUBTROPICAL CROPS INST OF FUJIAN PROVINCE +1

Agricultural waste fermenting bacterial prepn and its prepn process

InactiveCN1772880AIncrease profitSpeed up evaporationBacteriaMicroorganism based processesTectorial membraneYeast

The present invention discloses fermented bacteria preparation for agricultural waste treatment and its preparation process. The present invention separates and breeds three kinds of bacteria with fast growth and high heat resistance, including two strains of tectorial membrane yeast ZJY2 and Strreptomyces griseus W1 and one known strain Bacillus cereus ME1-2. These three kinds of spawn are cultured and fermentation produced separately and further produced into compound bacteria preparation in certain ratio or single bacteria preparation. When the bacteria preparation is used in treating agricultural waste, the waste is added with regulator to control the water content in 55-65 wt% and the bacteria preparation in 0.1-0.5 wt% is added through stirring, and the mixture is aerobic high temperature fermented for 20-30 days to reduce amount, reduce harm and become useful resource.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Organic fertilizer production technology

InactiveCN110204400ASolve the problem of incinerationIncrease temperatureBio-organic fraction processingExcrement fertilisersThermal insulationSoil fertility

The invention discloses organic fertilizer production technology. The organic fertilizer production technology comprises following steps: straw is crushed into pieces with a length lower than 5cm, andis introduced into a straw storage warehouse for further processing; livestock and poultry waste is collected in a storage warehouse for further processing; a fermentation biological bacterium agentis activated for further process; the straw and the livestock and poultry waste are mixed and stirred to be uniform for 2min at a ratio of 1:2, 30kg of the fermentation biological bacterium agent is added for uniform mixing, and water content is adjusted to 45 to 55% so as to obtain a material for fermentation; the material for fermentation is introduced into a fermentation tank, a steam generatoris turned on for heating; thermal insulation treatment is carried out for 180min; a fermentation product is conveyed to a secondary fermentation zone; open air composting natural fermentation is adopted for secondary fermentation for 3 days; after secondary fermentation, an obtained organic fertilizer is introduced into a wet type crushing machine for crushing into powder with a particle size of1mm or lower; drying is carried out until water content is lower than 30% so as to obtain an organic fertilizer. The organic fertilizer production technology is capable of shortening fermentation time, protecting soil, improving soil fertility, and avoiding environment pollution caused by straw burning completely.

Owner:黑龙江双发环保科技有限公司

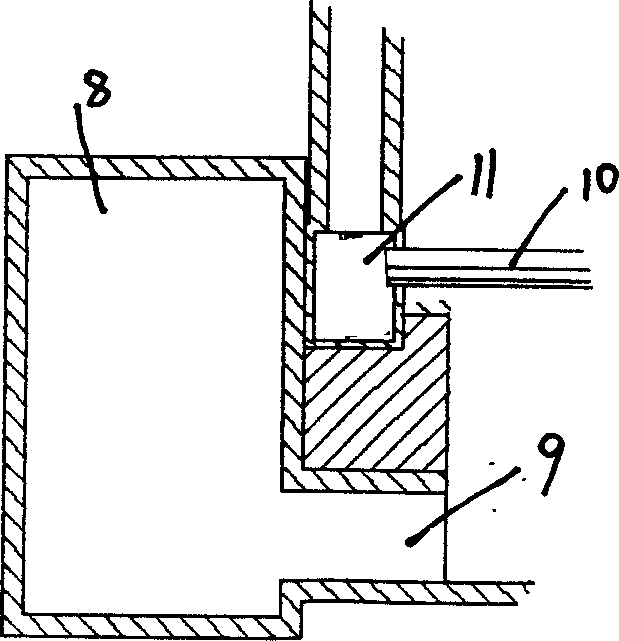

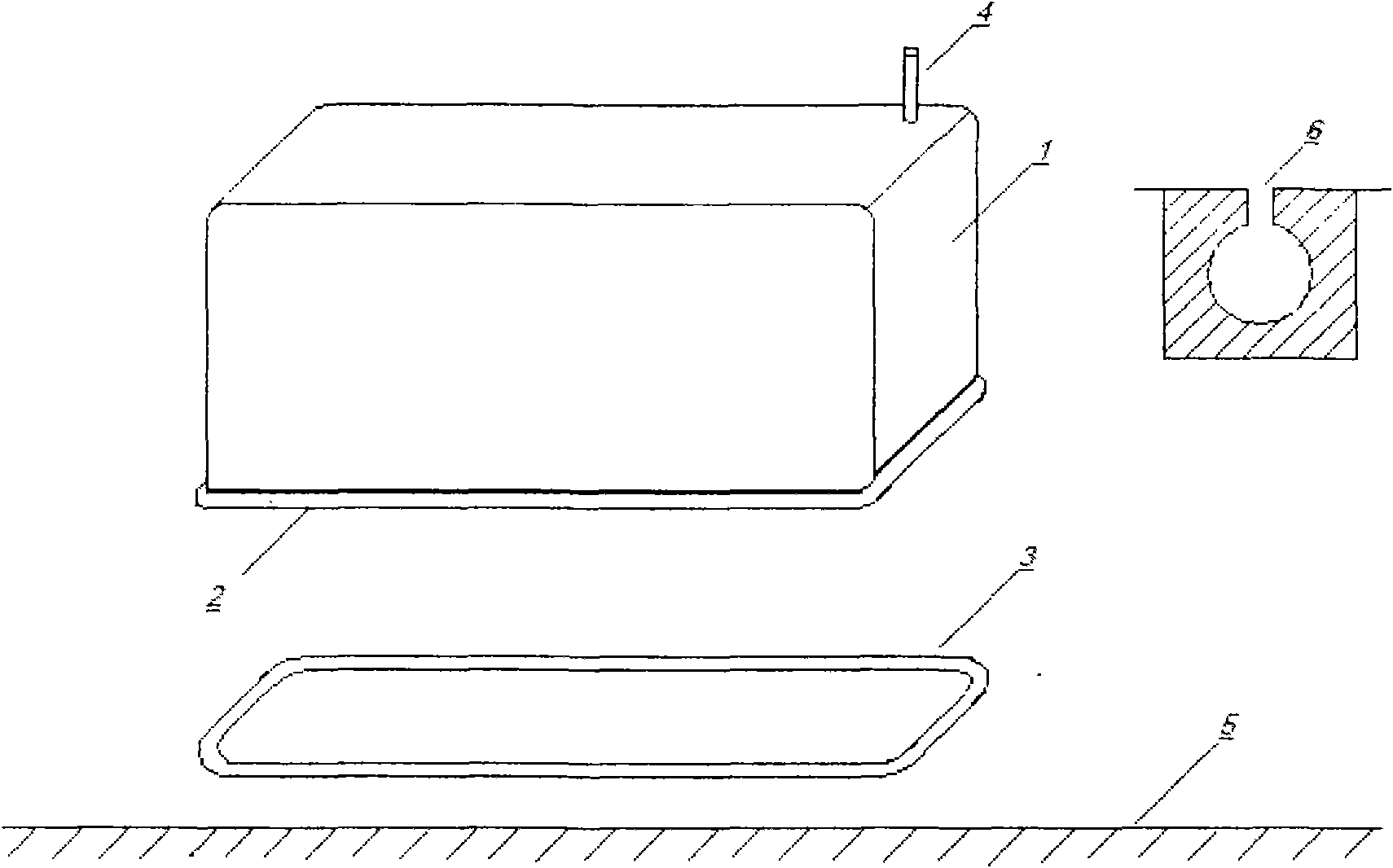

Rheid fermenting cellar and method for producing methane by utilizing rheid fermenting cellar

InactiveCN101928664AImprove securityAvoid explosionGas production bioreactorsWaste based fuelMechanical engineeringRheid

The invention discloses a rheid fermenting cellar and a method for producing methane by utilizing the rheid fermenting cellar. The rheid fermenting cellar comprises a seal housing (1) and cement floor (5), the seal housing (1) is made from flexible sealing membrane material and the lower edge of the seal housing (1) is a ring-shaped air inflation sealing ring (2).The cement floor (5) is embedded with a ring-shaped groove (3), the cross section of the groove is in the shape of an inverted ohm shape with the small opening and the large cavity. The air inflation sealing ring (2) is integrated with the ring-shaped groove (3) and tightly integrates the seal housing (1) and the cement floor (5) after being aerated, thus forming a sealed rheid fermenting cellar. The top of the rheid fermenting cellar is provided with a methane outlet pipe (4).In the invention, the solid state fermentation technology is adopted, the pretreated ferment raw material is charged in a split mode in plastic boxes( barrels) suitable for transportation, and piled up and stacked in advance in the rheid fermenting cellar. The method of the invention has large production of methane, simple device structure, easy construction, small investment and low cost.

Owner:刘慧敏

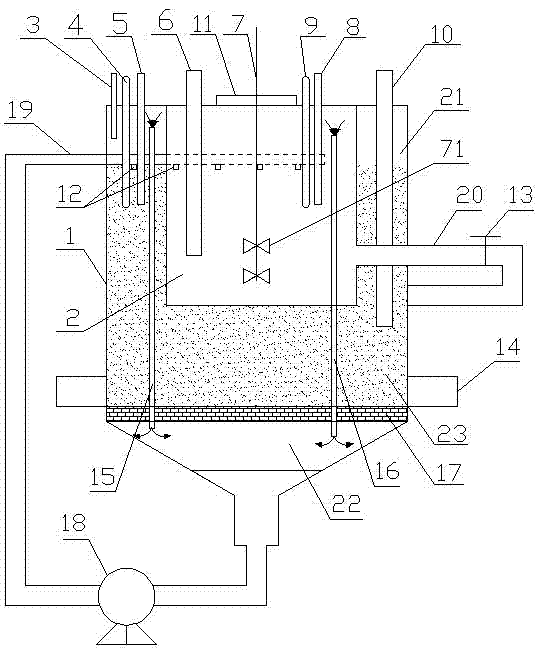

Dry-wet-coupled marsh gas fermentation device

InactiveCN102827761APlay a role in heat preservationRaise the fermentation temperatureGas production bioreactorsWaste based fuelSlagProduction rate

The invention discloses a dry-wet-coupled marsh gas fermentation device which comprises a dry fermentation tank and a wet fermentation tank, which the wet fermentation tank is positioned in the dry fermentation tank; the dry fermentation tank is provided with a dry fermentation tank gas valve, a dry tank feed port and a slag discharge port; the bottom of the dry fermentation tank is provided with a liquid return pipe leading to the upper part of the dry fermentation tank; the liquid return pipe is provided with a percolate back-ejection pump; the liquid return pipe is provided with a sprayer; the bottom of the dry fermentation tank is provided with a hard see-through lining board; the hard see-through lining board divides the dry fermentation into an upper gas chamber and a lower gas chamber which are respectively arranged at the upper part and the lower part; a dry tank circulating pipe and a wet tank circulating pipe which are penetrated through the hard see-through lining board are arranged in the dry fermentation tank; the upper end of the dry tank circulating pipe is positioned in the upper gas chamber, and the lower end is positioned in the lower gas chamber; the upper end of the wet tank circulating pipe is positioned in the wet fermentation tank, and the lower end is positioned in the lower gas chamber; and the wet fermentation tank is provided with a wet tank feed port and a mixer shaft device. According to the invention, the fermentation temperature of the whole fermentation process is stable, the gas production rate per unit mass of raw material can be increased, the volume gas production rate of a reactor can be increased, and the fermentation period of the reactor can be shortened.

Owner:HENAN AGRICULTURAL UNIVERSITY

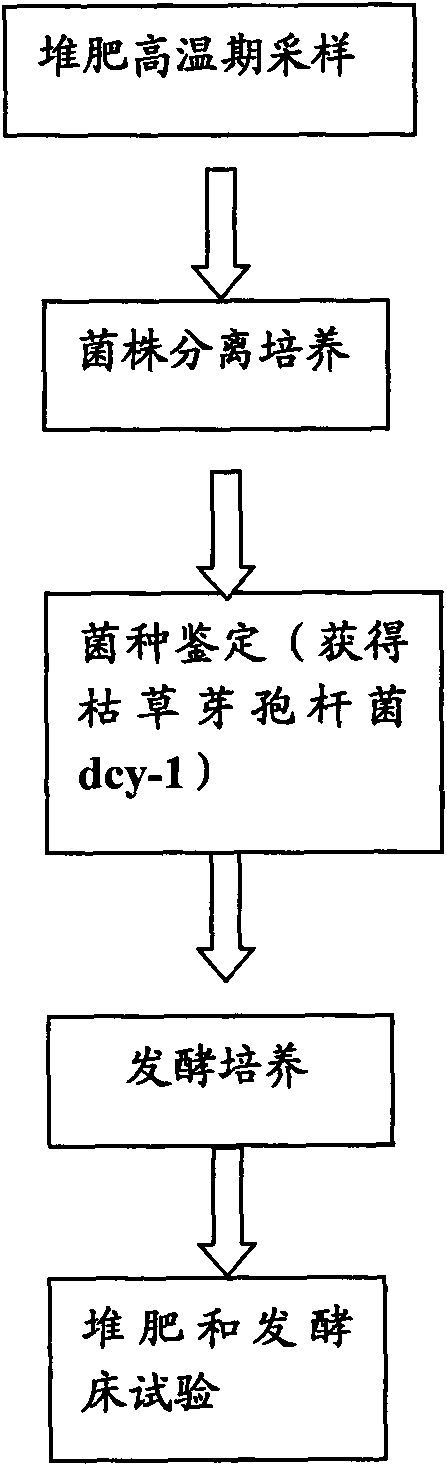

Bacillus subtilis dcy-1 and application thereof in biofermentation

InactiveCN101525583ASpeed up fermentationLow costBio-organic fraction processingBacteriaMicroorganismFiltration

The invention belongs to the technical field of livestock-raising, in particular relates to the filtration of the separated bacterial strain of bacillus subtilis and an application of the bacillus subtilis in the pig manure composting production and biofermentation bed. The invention also belongs to the technical fields of agricultural microbiological application and the composting production. A bacillus subtilis dcy-1 suitable for the pig manure composting production and the biofermentation bed is obtained through separation, filtration and authentication, and the bacterial strain is persevered in China Center for Type Culture Collection (CCTCC) with the preservation serial number: CCTCC NO: M 208122. The bacterial strain is made into microbial inoculums and successfully applied to the pig manure composting production and scale raising cabiofermentation bed. The invention is suitable for the livestock feces treatment of scale raising piggeries.

Owner:HUAZHONG AGRI UNIV

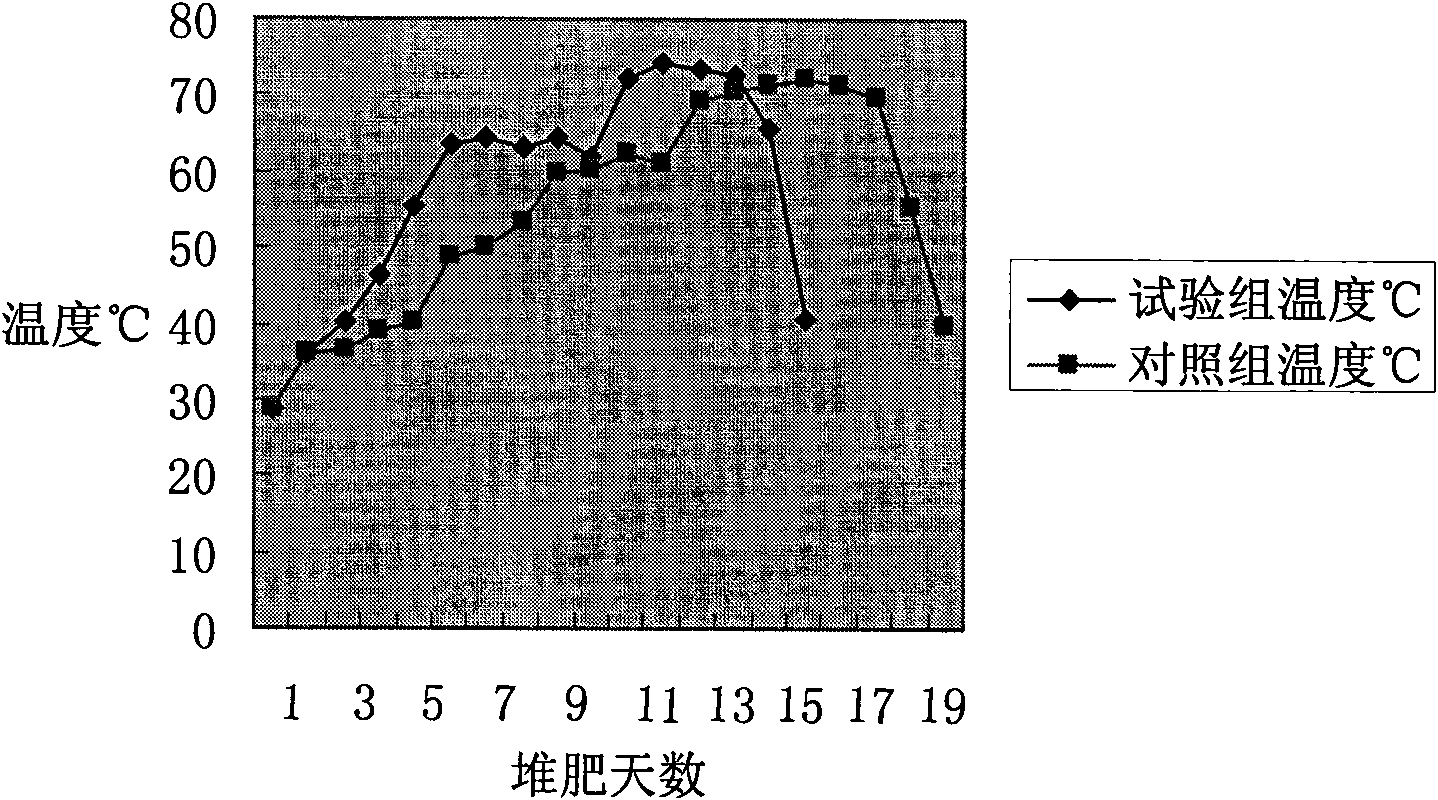

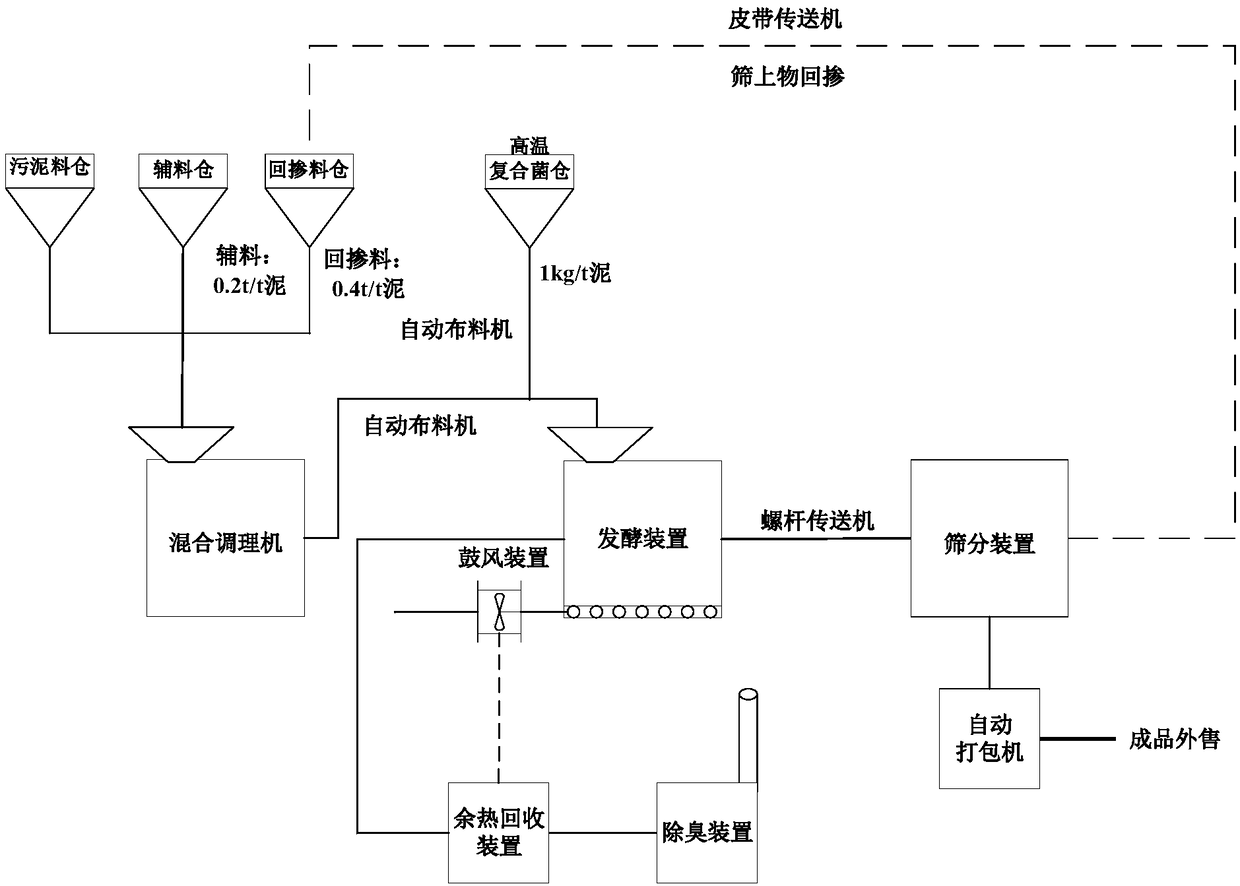

High-temperature aerobic fermentation method for sludge

InactiveCN108341729AHigh degree of automationRaise the fermentation temperatureBio-organic fraction processingGrowth substratesAutomatic controlMoisture

The invention discloses a high-temperature aerobic fermentation method for sludge. The method includes the steps of blending sludge, auxiliary materials and remixed materials, and adjusting the C / N ratio and moisture content of the sludge to (25-35):1 and 50-60% respectively; blending a mixture formed after treatment in step A with a high-temperature aerobic composite microbial inoculant for fermentation; screening a fermented material after fermentation in step B is finished and then completing the whole process. According to the method, the auxiliary materials and the remixed materials are utilized to adjust the C / N ratio and moisture content of the sludge, automatic control over process parameters such as a material preparation proportion, pile overturning frequency, fermentation temperature and oxygen content is achieved, and a waste heat recovery device is utilized to achieve waste heat recovery and reutilization. The process has the advantages that the automation degree is high,the fermentation temperature is high, the fermentation cycle is short, the energy consumption and the running cost are low, slight odor is produced, and the moisture content of the fermented materialis low. By means of the process, fast harmlessness, stabilization and recycling of urban sludge can be achieved, a circular economy principle is satisfied, and the method has a broad application prospect.

Owner:上海尚泥环境科技有限公司

Harmless treatment method of chlortetracycline hydrochloride bacterial residue

PendingCN109665877AGood effectLow costBio-organic fraction processingBioloigcal waste fertilisersHumic acidBacillus amyloliquefaciens

The invention provides a harmless treatment method of aureomycin hydrochloride bacterial residue. The harmless treatment method includes the process of treating aureomycin hydrochloride bacterial residue with a compound bacterium agent for fermentation treatment, wherein the compound bacterium agent is prepared by compounding the bacterium agent of aspergillus niger, bacillus subtilis, bacillus licheniformis and bacillus amyloliquefaciens, the mass content of each bacterium agent in the composite bacterium agent is 10-30%. The harmless treatment method of aureomycin hydrochloride bacterial residue has the advantages of short treatment time, high efficiency and excellent degradation effect, and can significantly increase the content of humus and humic acid in the bacterial residue, so thatthe fermented bacterial residue can be used as the main raw material of biological fertilizer and is widely applied in agricultural production.

Owner:山东淳和万生环境技术有限公司

Fermentation type edible mushroom vegetarian ham and preparation method thereof

ActiveCN107581589AImprove physiological activityHigh nutritional valueFood scienceBiotechnologyHealthy diet

The invention belongs to the technical field of processing of edible mushrooms, and particularly relates to a fermentation type edible mushroom vegetarian ham and a preparation method thereof. The fermentation type edible mushroom vegetarian ham is prepared through the following steps of performing vacuum infiltration inoculating on the edible mushroom raw materials with probiotic bacteria speciescultured with a specially-made culture medium, performing solid-state fermentation, and mixing the fermented edible mushrooms with white fungus powder and other ingredients. The edible mushrooms areused as main raw materials, and probiotics are artificially added for fermentation, so that products have high nutrient value and flavor characteristics. Meat is not added, so that the mouth feel of fermentation type edible mushroom vegetarian ham has special fermentation flavor of the edible mushrooms and chewing sense of meat fibers. The fermentation type edible mushroom vegetarian ham is a healthy novel fermented vegetarian ham sausage, and conforms to convenient, nutritive and healthy diet requirements of modern consumers.

Owner:HENAN ACAD OF AGRI SCI

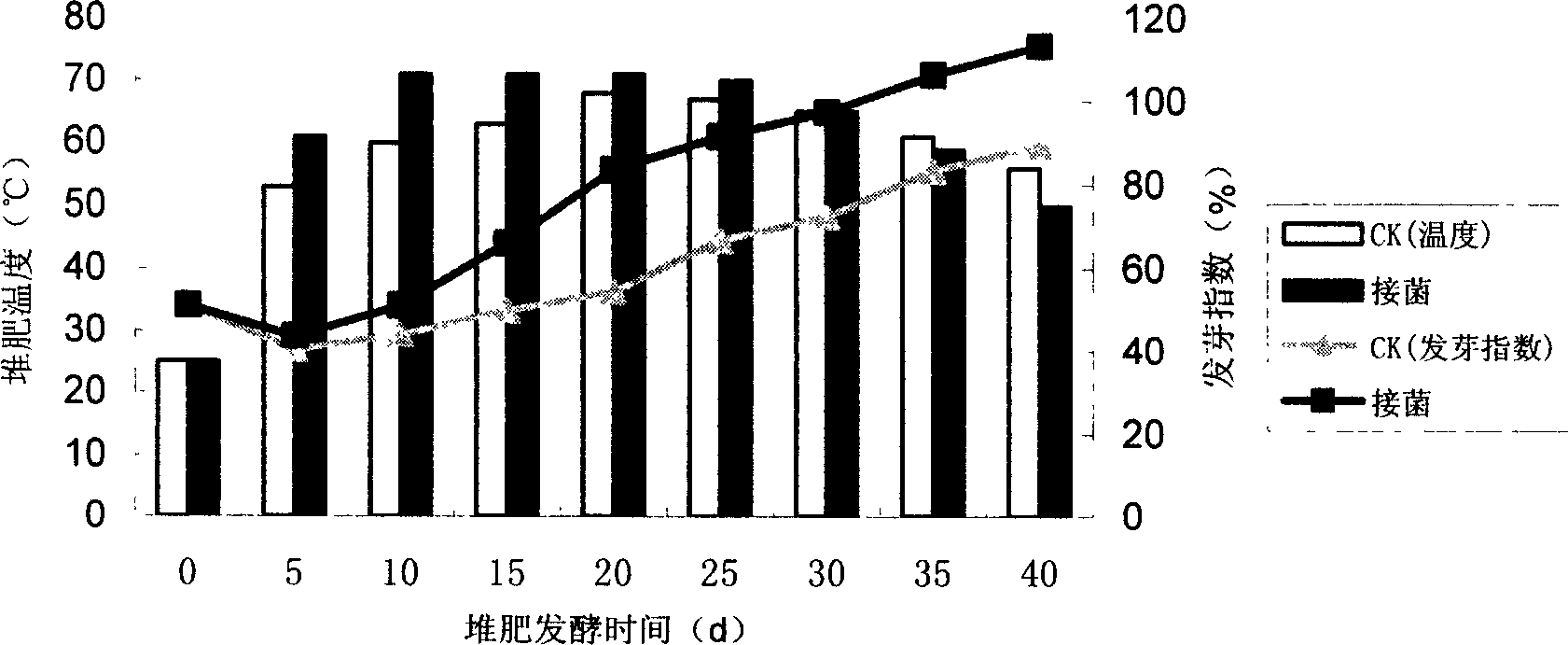

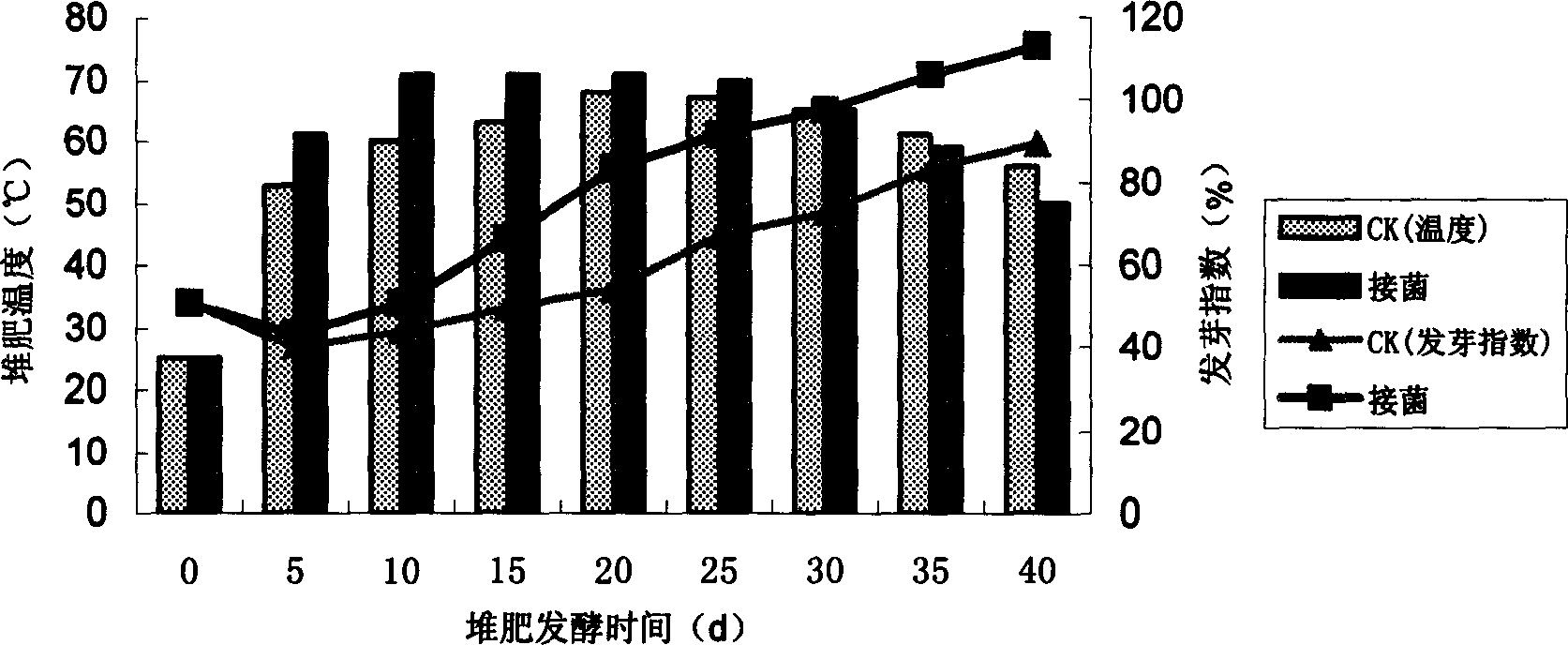

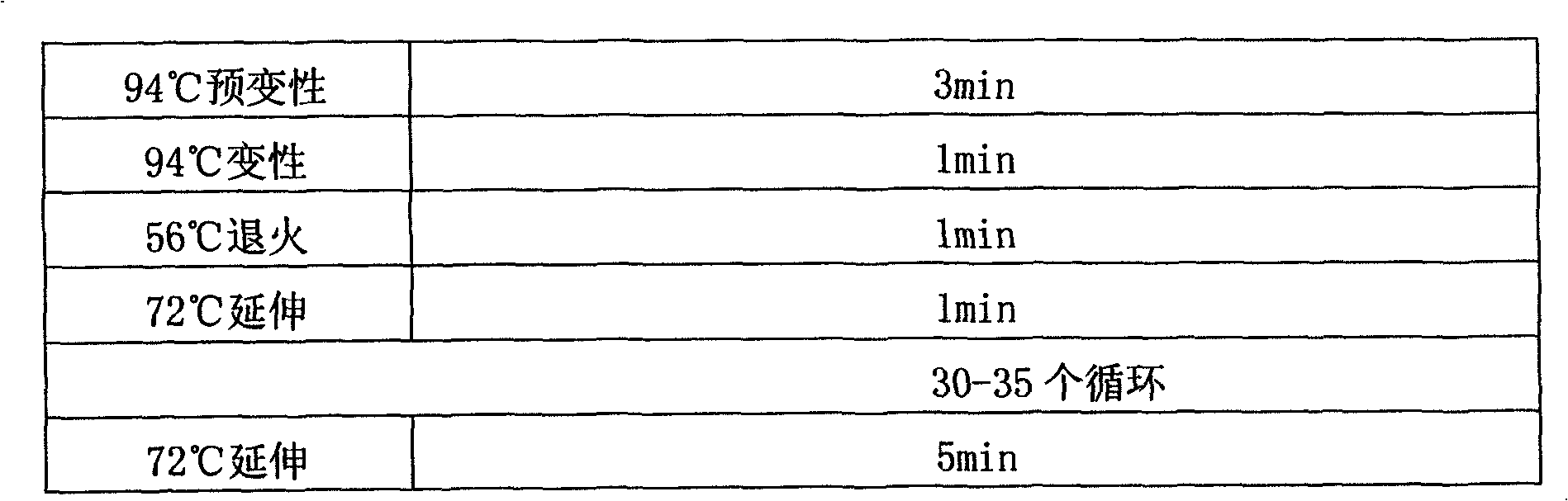

Microbial agent for promoting aerobic composting of dead pigs and application of microbial agent

ActiveCN107653200ARaise the fermentation temperatureEfficient killingBio-organic fraction processingBacteriaBacillus licheniformisMicrobial agent

The invention discloses a microbial agent for promoting aerobic composting of dead pigs and an application of the microbial agent. The microbial agent includes bacillus licheniformis ZR-1, bacillus subtilis dcy-1, bacillus methylotrophicus F7 and bacillus amyloliquefaciens YZ-0001. The microbial agent beneficial to degradation of organic matter is inoculated in the beginning of composting, maximumtemperature of a composting body is increased, high-temperature phase of the composting body is prolonged, pathogenic microbes are inactivated, composting of dead bodies is fastened, degradation of plant toxicity is promoted, and seed germination index is increased; the microbial agent is low in cost, simple in composition, convenient in preparation and easy to promote and apply; the microbial agent of aerobic composting of the dead pigs can generate stable humus and can be used as organic fertilizer applied to crop planting, suppress phytopathogens and reduce use of the fertilizer, and gooddevelopment prospect is achieved.

Owner:HUAZHONG AGRI UNIV

Method for returning crop stalks to field by microbial fermentation

InactiveCN106348798AReduce pollutionPromote sustainable developmentBio-organic fraction processingExcrement fertilisersAgricultural sciencePenicillium oxalicum

The invention discloses a method for returning crop stalks to the field by microbial fermentation. The method for returning crop stalks to the field comprises the following steps: crop stalks treatment, applying of farm manure, fermenting treatment and cropland application. According to the method for returning crop stalks to the field by microbial fermentation, penicillium oxalicum NJGZ-2 bacteria as microorganisms and a biogas digester are combined to ferment and degrade the crop stalks which are returned to the field directly, environmental pollution caused by crop stalk waste can be reduced, furthermore, the fermenting time can be shortened, fermenting temperature can be increased effectively, the purpose of thoroughly killing some pathogens such as insect ova and vectors is achieved, degraded soil can further be repaired, development of green agriculture is facilitated, and sustainable development of the agriculture is promoted.

Owner:宿州市埇桥区杨园种植专业合作社

Methane tank with novel structure

InactiveCN104073431AGuaranteed stabilitySatisfy the requirements of gas stabilityBiological substance pretreatmentsGas production bioreactorsEngineeringFermentation

The invention discloses a methane tank with a novel structure, which comprises a main tank and a water pressure chamber, wherein the main tank comprises a methane storage room and a fermentation tank, a methane guide pipe is arranged at the top of the methane storage chamber, an excrement inlet is formed in one side of the main tank, and the other side of the main tank is communicated with the water pressure room; an overflow opening is formed in the water pressure chamber, and the excrement inlet is formed in the sidewall of the fermentation tank; an excrement outlet is formed between the fermentation tank and the water pressure chamber, and the excrement outlet is located in the other sidewall of the fermentation tank; the upper edge of the excrement inlet and the top end of the excrement outlet are on the same horizontal line; the bottom of the fermentation tank downwards inclines to the water pressure chamber from the sidewall, where the excrement inlet is located in, and extends to the sidewall where the overflow opening of the water pressure chamber is located in; an excrement dreg drainage channel with a concave semi-spherical cross section is arranged at the bottom of the fermentation tank; the whole methane storage chamber takes the shape of a trapezoid wider in upper part and narrow in lower part, the upper edge of the excrement inlet is arranged at the bottom end of the sidewall of the methane storage chamber, the methane guide pipe is located at the top of the trapezoid and provided with a safety valve. The invention aims to provide the methane tank with the novel structure, which is constant in pressure, convenient for discharging dreg, low in probability of incrustation and high in methane output.

Owner:何跃超

Production method of pest control organic fertilizer

The invention discloses a production method of a pest control organic fertilizer and belongs to the technical field of organic fertilizer production. The production method comprises the following process steps in sequence: (1) extracting nicotine sulfate; (2) performing pre-fermentation, namely mixing cow dung with tobacco waste residues obtained after extracting nicotine sulfate in a weight ratio of 1:3, adding a fermentation strain and a fermentation loosening agent, introducing oxygen and stirring to ferment for 3 days; (3) performing main fermentation, namely adding the fermentation loosening agent into a main fermentation bin, and introducing oxygen to ferment for 18 days; (4) performing secondary fermentation, namely adding the fermentation loosening agent into a decomposition fermentation bin, and introducing oxygen to ferment for 5 days to prepare a decomposed organic fertilizer; (5) compounding, namely adding 0.05% of nicotine sulfate; and (6) crushing and screening. The production method disclosed by the invention can be used for performing full fermentation on the extracted waste residues in tobacco solid wastes, improving the fertilizer effect of the organic fertilizer, and ensuring that the organic fertilizer simultaneously has the beneficial effects of functions of preventing diseases and insects and the like.

Owner:云南顺丰洱海环保科技股份有限公司

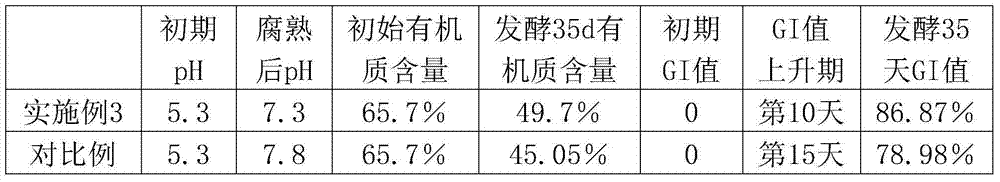

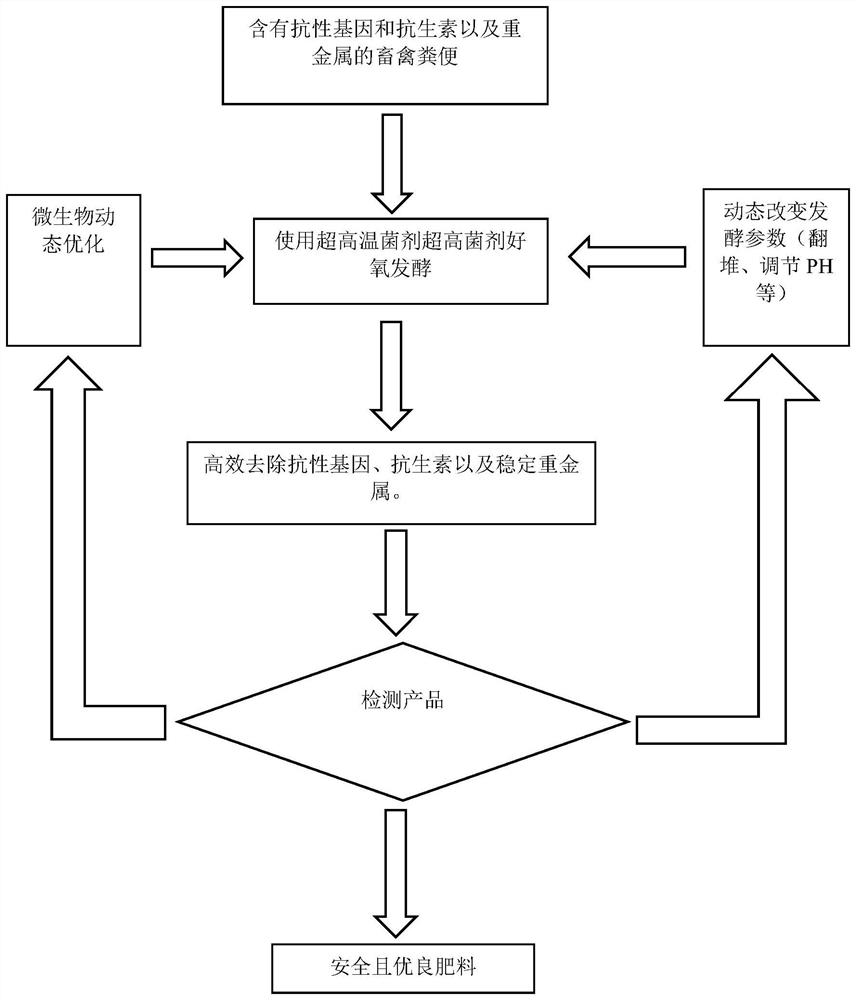

Method for efficiently removing antibiotics and resistance genes and stabilizing heavy metals in livestock and poultry manure based on ultrahigh-temperature aerobic fermentation technology

PendingCN113416097AEasy to handleAvoid harmBio-organic fraction processingExcrement fertilisersBiotechnologyMicroorganism

The invention relates to a method for efficiently removing antibiotics and resistance genes and stabilizing heavy metals in livestock and poultry manure based on an ultrahigh-temperature aerobic fermentation technology. The method comprises the following steps: carrying out fermentation pretreatment, fermentation detection, fermentation control, product inspection and product use on the livestock and poultry manure by adopting an ultrahigh-temperature fermentation inoculant. Through the growth metabolism effect of ultra-high-temperature microorganisms and the heat generated by fermentation, resistance genes and antibiotics in the livestock and poultry manure are efficiently treated, meanwhile, heavy metals in the livestock and poultry manure are stabilized, and an excellent organic fertilizer is generated through the fermentation. The heavy metals are prevented from entering a human body through an enrichment effect to harm human health, and the harm of the resistance genes, the antibiotics and the heavy metals to human is eliminated from the source. The fermentation product of the livestock and poultry manure is used as a good organic fertilizer, and the purposes of reduction, harmlessness, stabilization and recycling of the livestock and poultry manure are achieved. Meanwhile, the ultrahigh-temperature aerobic fermentation technology is expected to become an industrial standard for treating livestock and poultry compost.

Owner:NORTHEASTERN UNIV LIAONING

Preparation method of turtle feed

InactiveCN104824367APromote rapid reproductionPromote reproductionAnimal feeding stuffMicroorganismYeast

The invention provides a preparation method of turtle feed. The method includes: using kernels as raw materials, crushing, adjusting water content to 40-50%, processing for 10-25 minutes under 100-150MPa, adding fermentation agent into raw materials according to the weight ratio of the raw materials to the fermentation agent being 50-100:1, well mixing, fermenting under 40-45 DEG C for 1-2 hours, and drying to allow the water content to be lower than 10% to obtain the turtle feed, wherein the fermentation agent is mixed bacteria containing photosynthetic bacteria, bacillus, lactobacillus and yeast according to the weight ratio of 0.5-1:1-1.5:1-2:1.5-2. The method is low in time consumption, and feed deterioration caused by easy contaminating microorganism contamination.

Owner:郭心仪

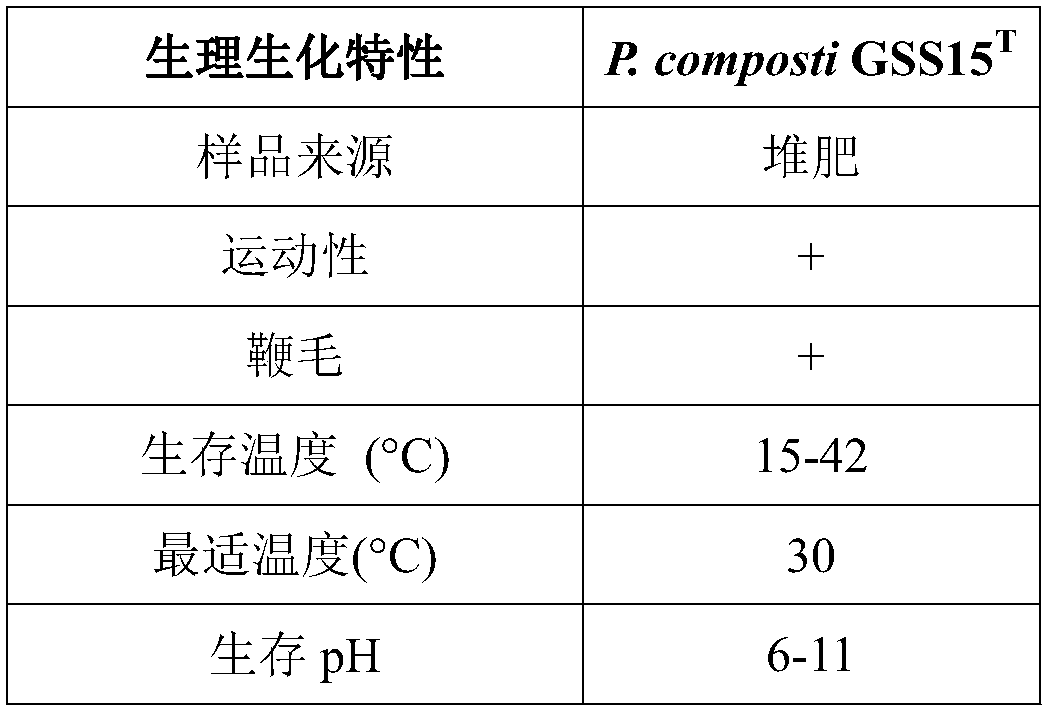

Application of pseudoxanthomonas composti and microbial preparation thereof in biological composting

ActiveCN109294951ARaise the fermentation temperatureImprove fermentation quality and efficiencyBio-organic fraction processingBacteriaGermplasmPseudoxanthomonas

The invention discloses an application of pseudoxanthomonas composti and a microbial preparation thereof in biological composting. The pseudoxanthomonas composti GSS15T is classified as pseudoxanthomonas composti GSS15T, is preserved in Guangdong Microbial Culture Collection Center, and has the preservation number of GDMCC No.60454. According to the microbial germplasm resource GSS15T and the microbial preparation thereof, the microbial preparation prepared by the pseudoxanthomonas composti GSS15T can improve the fermentation temperature of organic waste high-temperature aerobic composting, shortens the composting fermentation period, and improves the quality and efficiency of composting fermentation.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

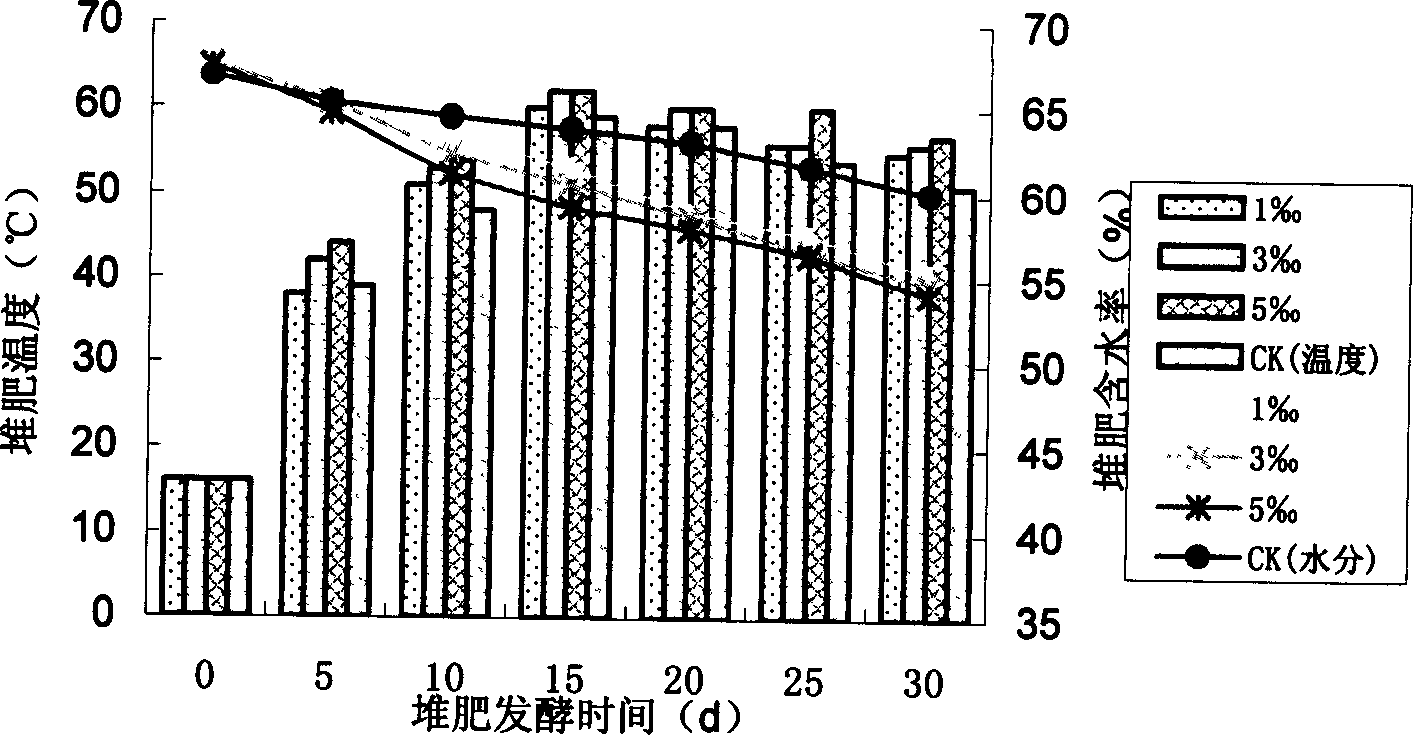

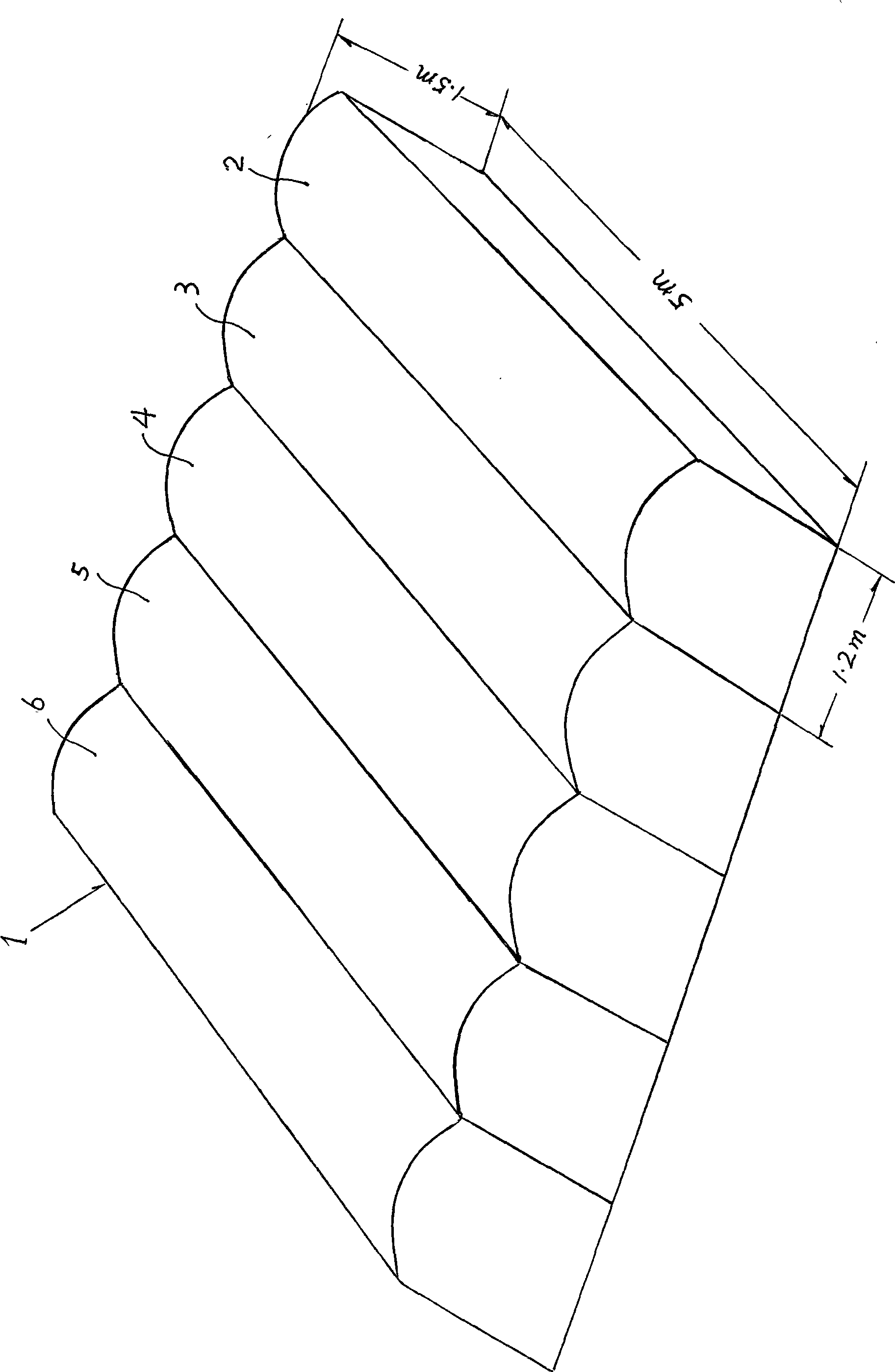

Cultivation material heap fermentation method capable of reducing Agaricus blazei diseases and pests

InactiveCN101486602ARaise the fermentation temperatureSoft textureBio-organic fraction processingOrganic fertiliser preparationDiseaseBiotechnology

The invention discloses a composting and fermentation method of composts that can reduce agaricus blazei murrill diseases and pests, which is characterized in that: the first fermentation of the compost heap, i.e., the pre-fermentation, is to employ a multi-heap composite integrated composting method to pile the compost in a plurality of rows and carry out fermentation treatment according to the composting and fermentation theory; the method for the composting pre-fermentation comprises the following steps: pre-composting, compost building, i.e., the first pile-turning, the second pile-turning, the third pile-turning and the fourth pile-turning; and then arranging the compost into a chamber and placed on the bed to carry out the second fermentation. The method can overcome the defect that the marginal material is excessively exposed when the compost is piled dispersedly and fodders are dried easily which result in too low humidity and temperature and failing to generate enough bioenergy to help the normal fermentation of microorganisms, and can promote mass propagation of such fungus as actinomycete which is beneficial for agaricus blazei murrill, thus piling excellent compost to facilitate the growth of the hypha and the encarpium of the agaricus blazei murrill, solving the problems of production reduction and even no harvest caused by sundry fungus as walnut-fleshy fungus in large areas during the culturing process, improving the yield by 30 to 50 percent, and improving the yield and saving time and labor.

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com