High-temperature aerobic fermentation method for sludge

An aerobic fermentation and high temperature technology, applied in sewage/sludge fertilizers, botany equipment and methods, planting substrates, etc., can solve the problems of high moisture content of fermentation products, high operating costs, large initial investment, etc., and reach the fermentation temperature High, early investment savings, low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

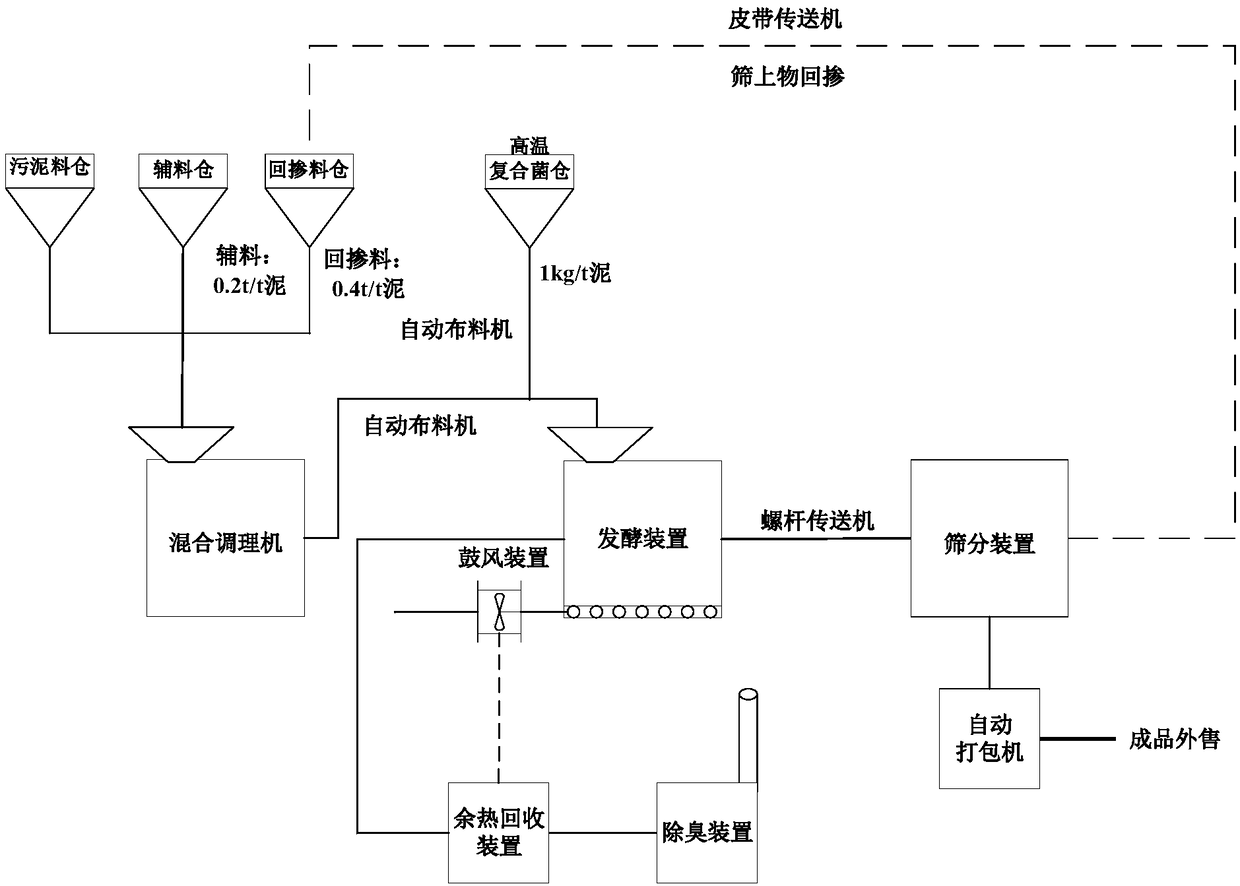

[0052] The amount of dewatered sludge produced by the sewage treatment station of a certain pharmaceutical factory in Shanghai is 1t / d, and the water content is 82%. The process of the present invention has been used for high-temperature aerobic fermentation, such as figure 1 As shown, it specifically includes the following steps:

[0053] (1) mixed conditioning

[0054] Sludge, auxiliary materials (sawdust), and remixing materials (clinker) are discharged from the warehouse by a screw conveyor with a metering function, and the mass ratio is controlled at 1:0.4:1, using a mixing conditioner (screw conveying mixing mixer) Mix well to adjust the C / N ratio and water content of the mixture to 35:1 and 60% respectively. The moisture content of sludge, sawdust and back-admixture is 82%, 15% and 20% respectively.

[0055] (2) High temperature aerobic fermentation

[0056] The mixture and high-temperature aerobic fermentation compound bacteria enter the aerobic fermentation tank th...

Embodiment 2

[0065] The output of dewatered sludge in a sewage treatment station of a paper mill in Hainan is 400t / d, and the water content is 80%. The process of the present invention is used to carry out high-temperature aerobic fermentation, such as figure 1 As shown, it specifically includes the following steps:

[0066] (1) mixed conditioning

[0067] Sludge, auxiliary materials (straw), and remixing materials (clinker) are discharged from the warehouse by a screw conveyor with a metering function, and the mass ratio is controlled at 1:0.4:1. Mix well to adjust the C / N ratio and water content of the mixture to 25:1 and 50% respectively. The moisture content of sludge, straw and back-admixture is 82%, 15% and 20% respectively.

[0068] (2) High temperature aerobic fermentation

[0069] The mixture and high-temperature aerobic fermentation composite bacteria enter the aerobic fermentation tank through the automatic distribution machine. The aerobic fermentation tank includes tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com