Methane tank with novel structure

A new type of structure and biogas digester technology, applied in the field of biogas digesters, can solve problems such as complex structure, poor heat preservation, and increased cost, and achieve the effects of improving fermentation efficiency, avoiding safety hazards, and improving repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

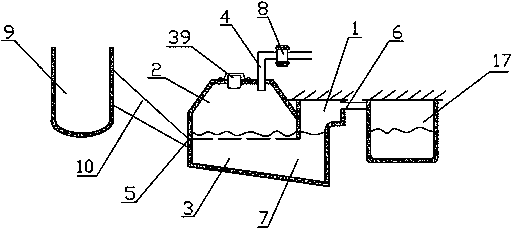

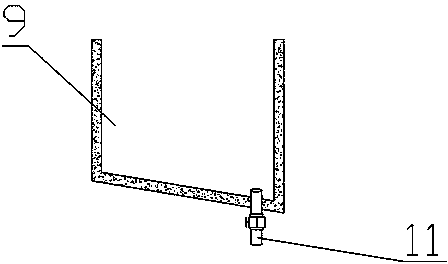

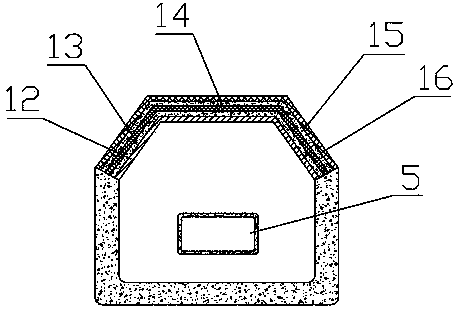

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0026] Such as figure 1 , Figure 4 As shown, a biogas digester with a new structure includes a main pool and a hydraulic room 1. The main pool is composed of a gas storage room 2 and a fermentation tank 3. The top of the gas storage room 2 is provided with an air guide pipe 4. One side of the main pool is There is a manure inlet 5, and the other side communicates with the water pressure room 1; the water pressure room 1 is provided with an overflow port 6, and the manure inlet 5 is located on the side wall of the fermentation tank 3; between the fermentation tank 3 and the water pressure room 1 The excrement outlet 7 is arranged in the room, the height of the excrement outlet 7 is 1 meter, and the width of the water pressure room 1 is 1.2 meters. The excrement outlet 7 is located on the other side wall of the fermentation tank 3; Located...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com