Dry-wet-coupled marsh gas fermentation device

A biogas fermentation, dry-wet coupling technology, applied in solid-phase fermentation bioreactors, gas production bioreactors, biochemical instruments, etc., can solve the problems of clogged reactors and high investment costs, and achieve improved gas production rate and fermentation temperature Stabilize and reduce the effect of the fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

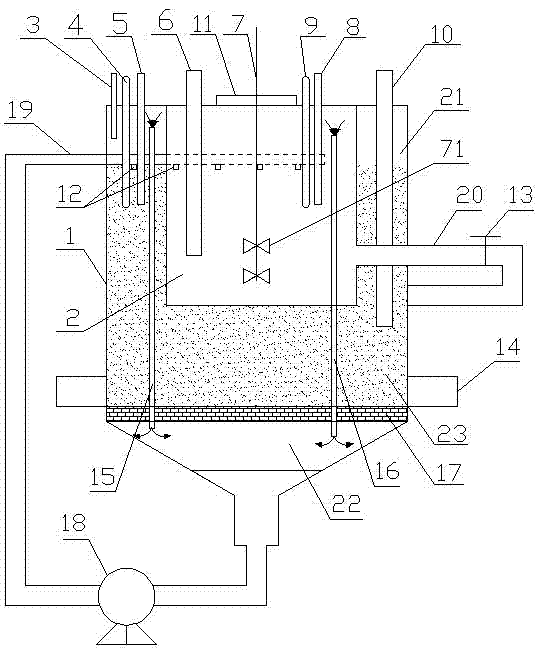

[0017] Such as figure 1 A dry-wet coupling biogas fermentation device is shown, which includes a closed dry fermentation tank 1 and a wet fermentation tank 2, the wet fermentation tank 2 is located in the dry fermentation tank 1, and the dry fermentation tank 1 and the wet fermentation tank 2 are coaxially arranged .

[0018] Dry fermentation tank 1 is provided with dry fermentation tank gas valve 3, dry tank feed port 10 and slag discharge port 14, dry fermentation tank gas valve 3 and dry tank feed port 10 are located on the top of dry fermentation tank 1, dry The fermentation tank air valve 3 is used to collect the biogas produced by the dry fermentation tank 1 and the wet fermentation tank 2; there are four slag outlets 14, which are evenly distributed on the lower peripheral wall of the dry fermentation tank 1, and are used to discharge the dry fermentation tank 1 of biogas residues. The bottom of the dry fermentation tank 1 is provided with a liquid return pipe 19 lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com