Patents

Literature

464results about How to "Increase gas production rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

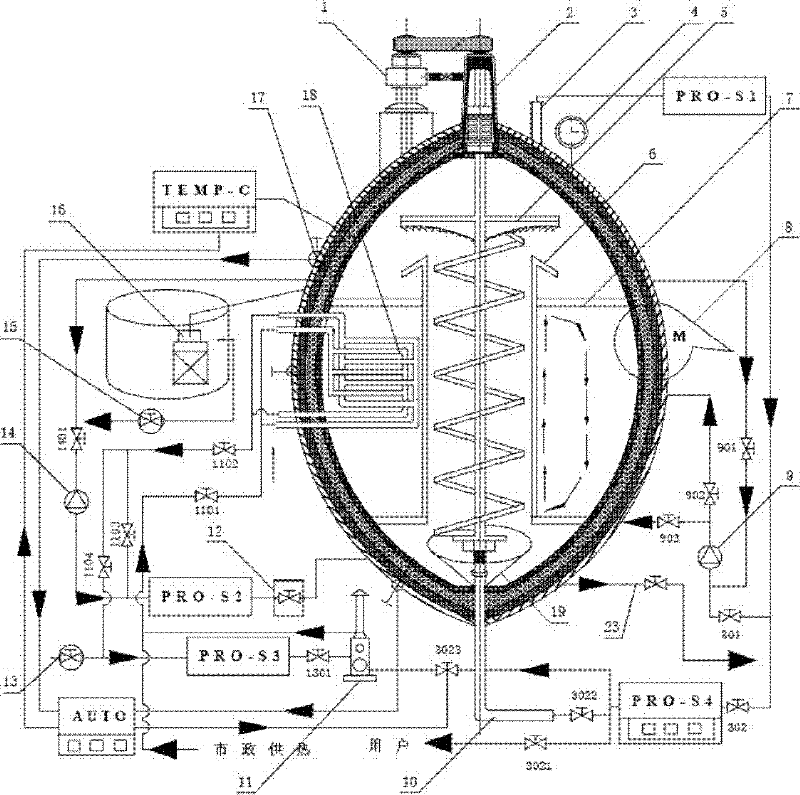

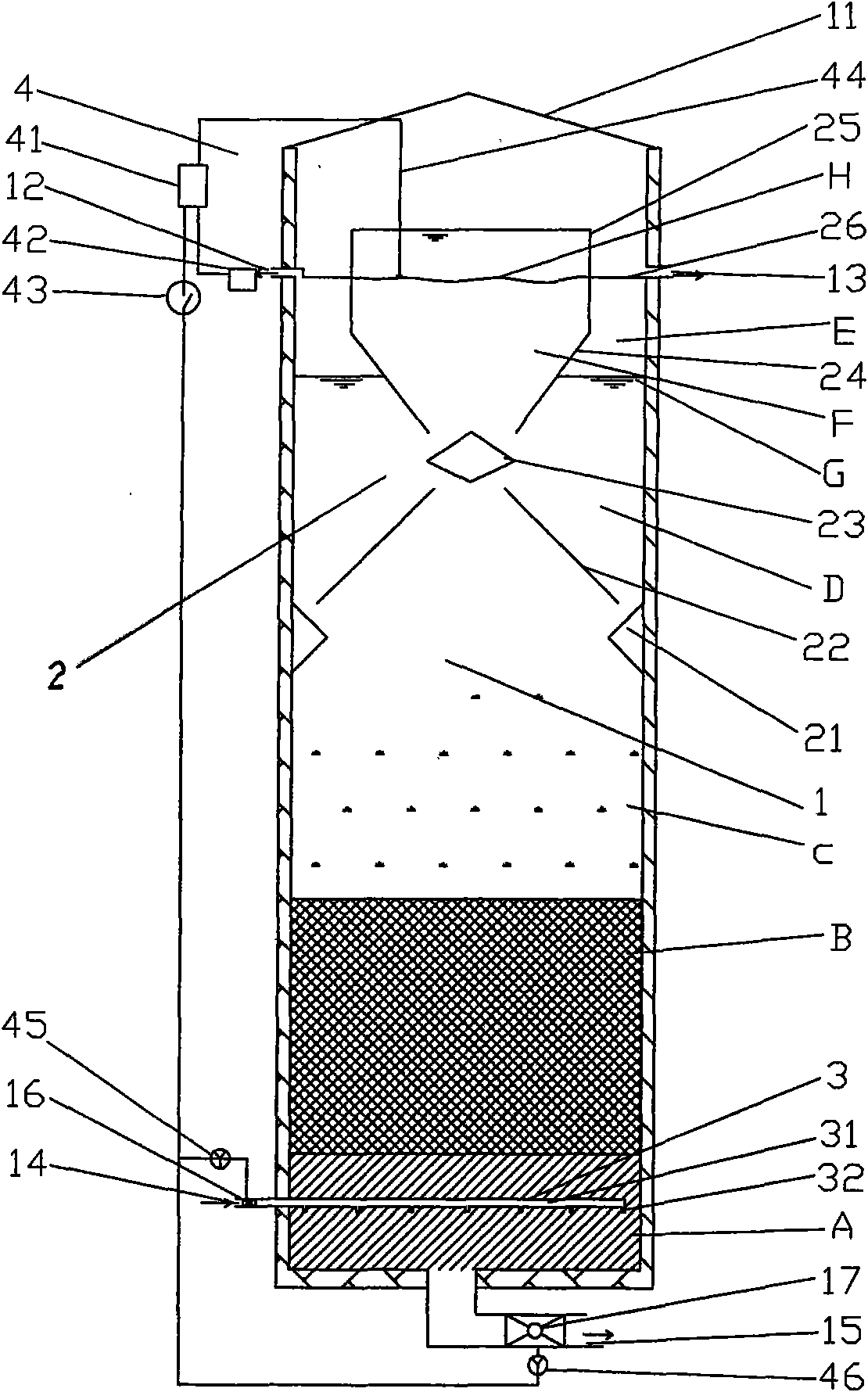

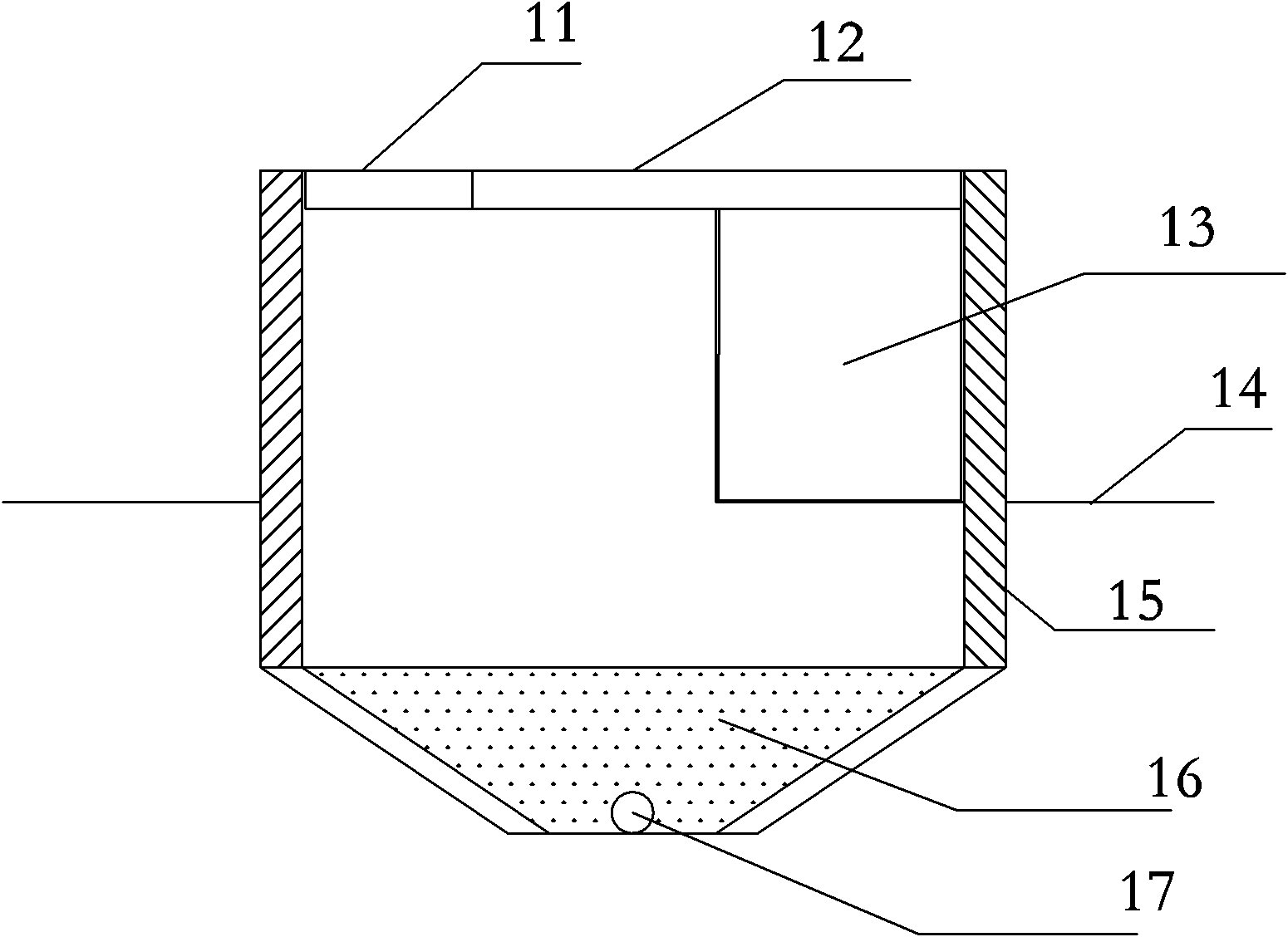

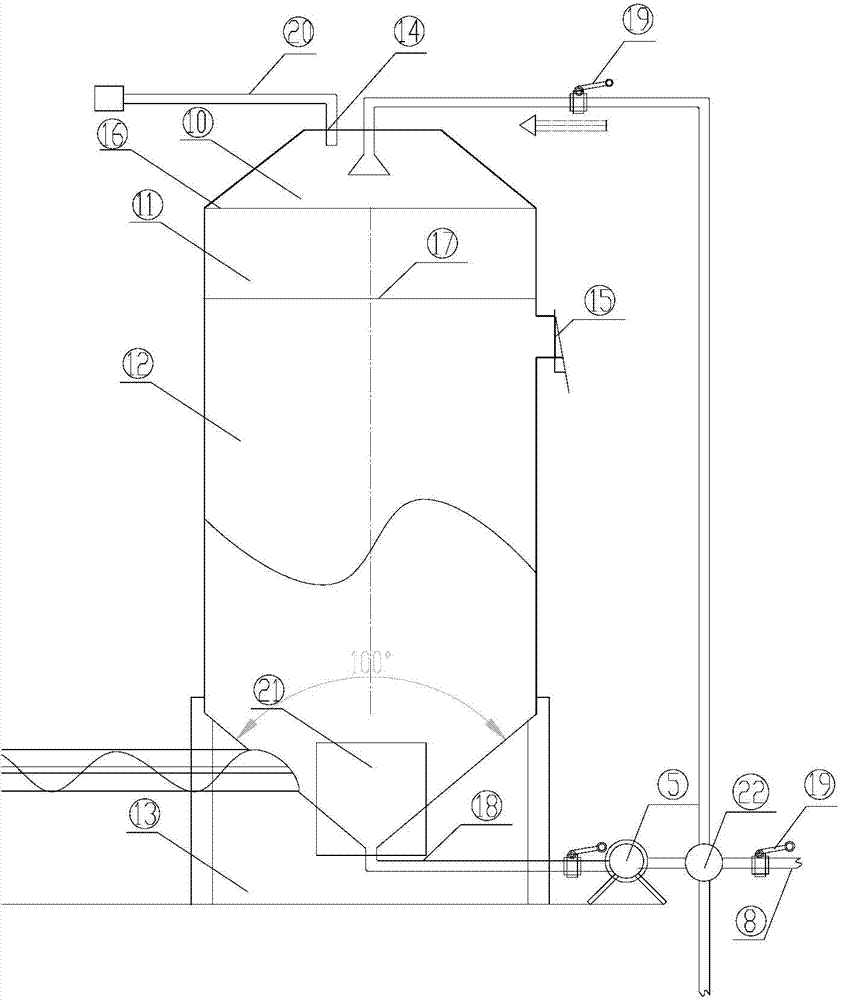

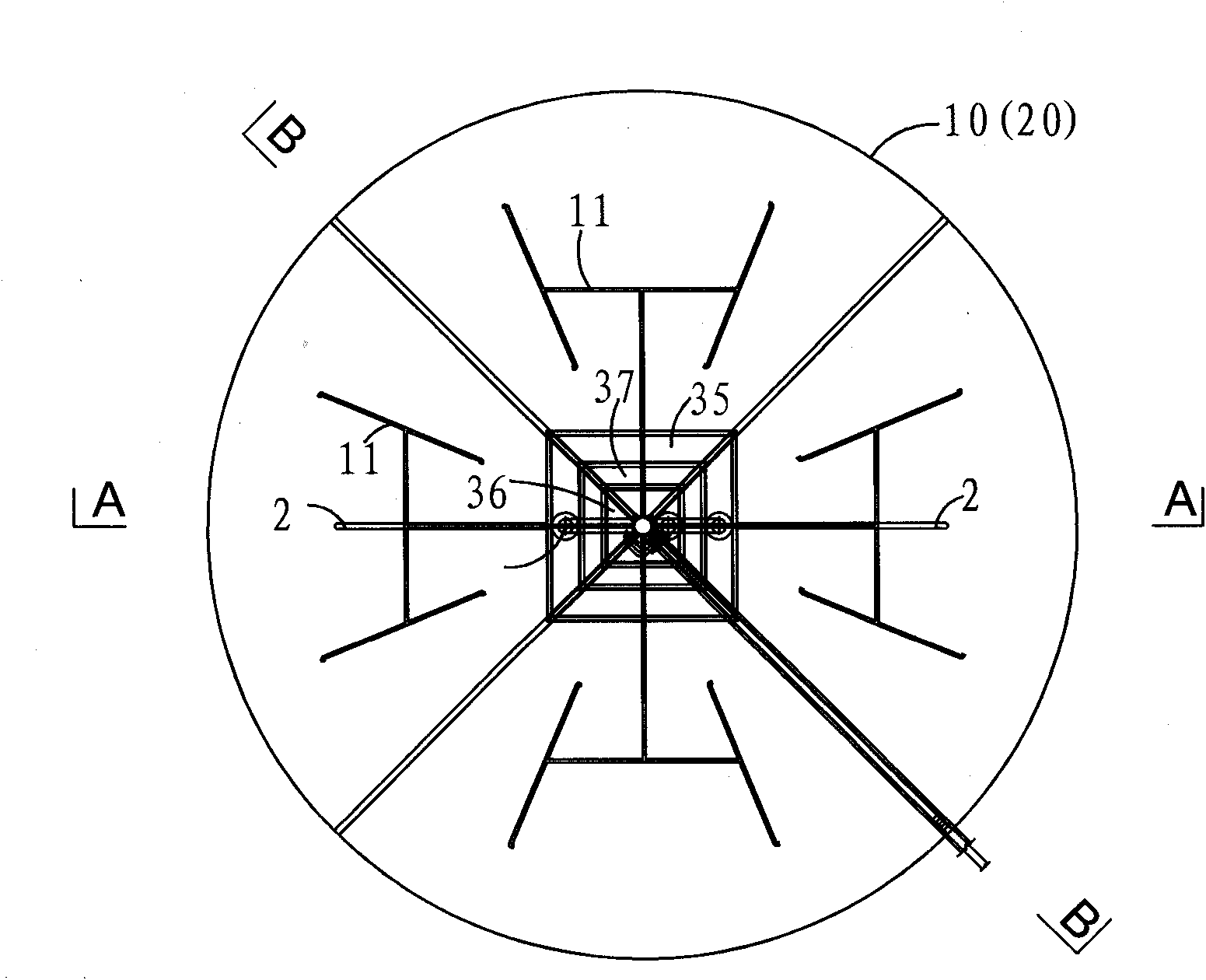

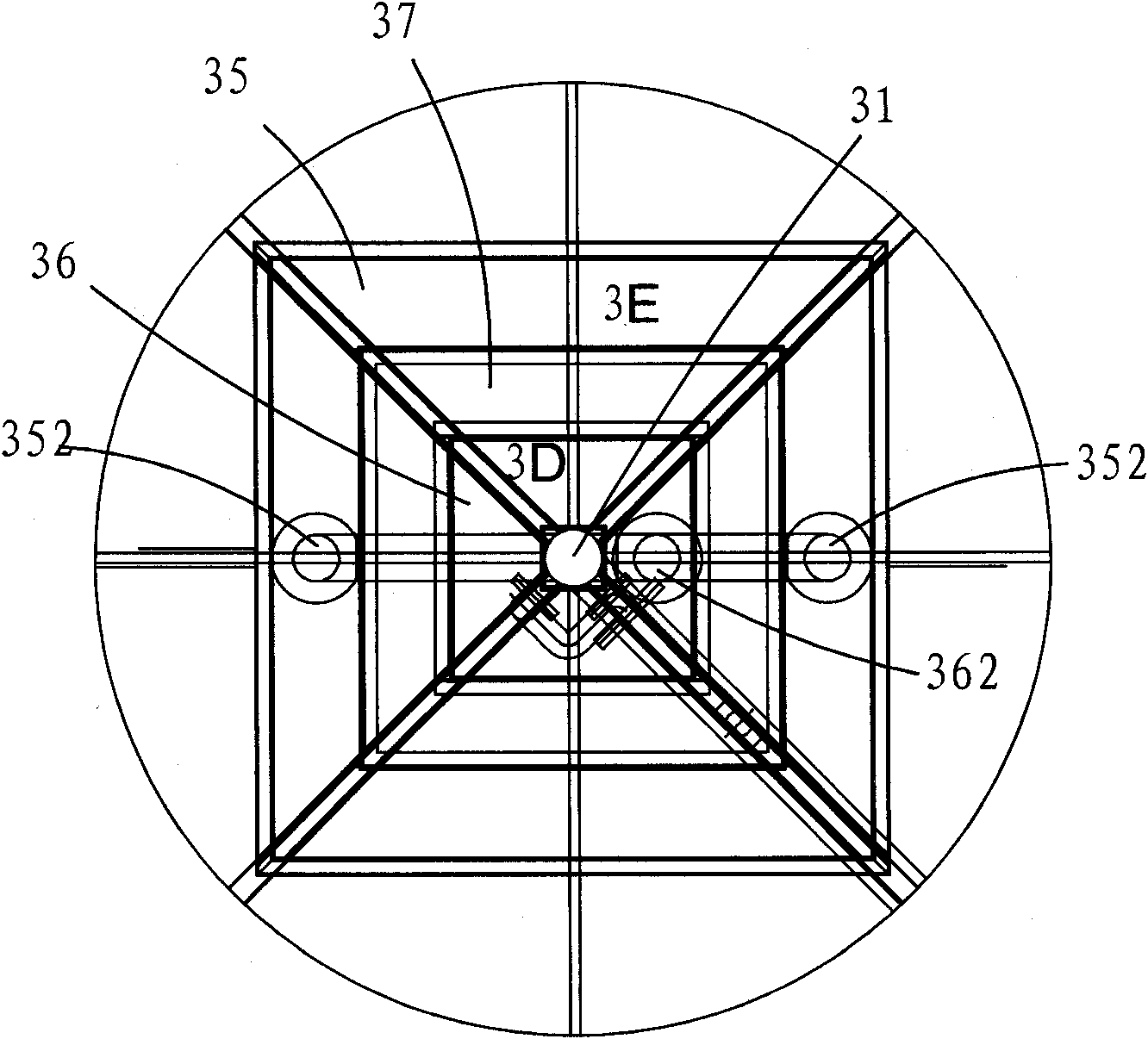

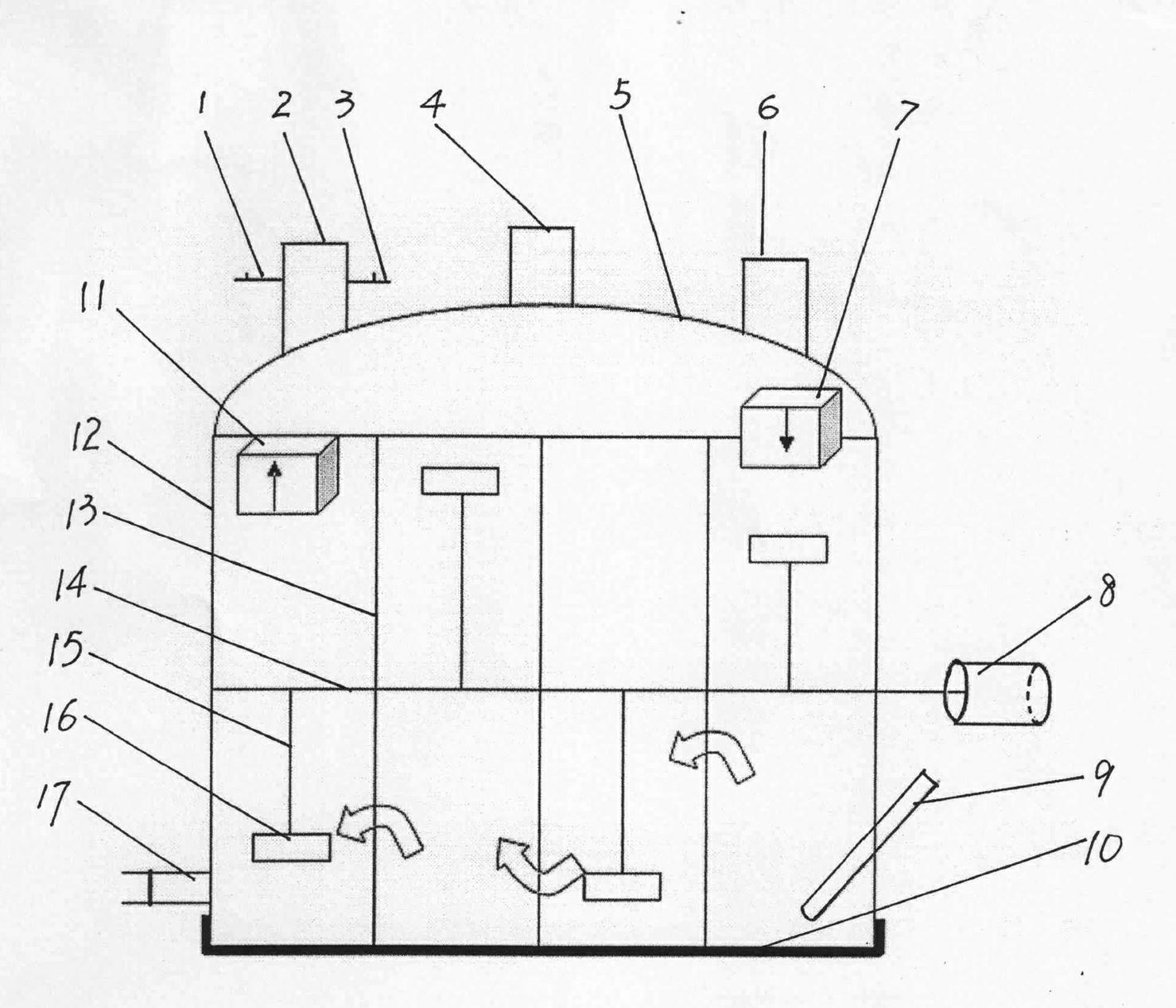

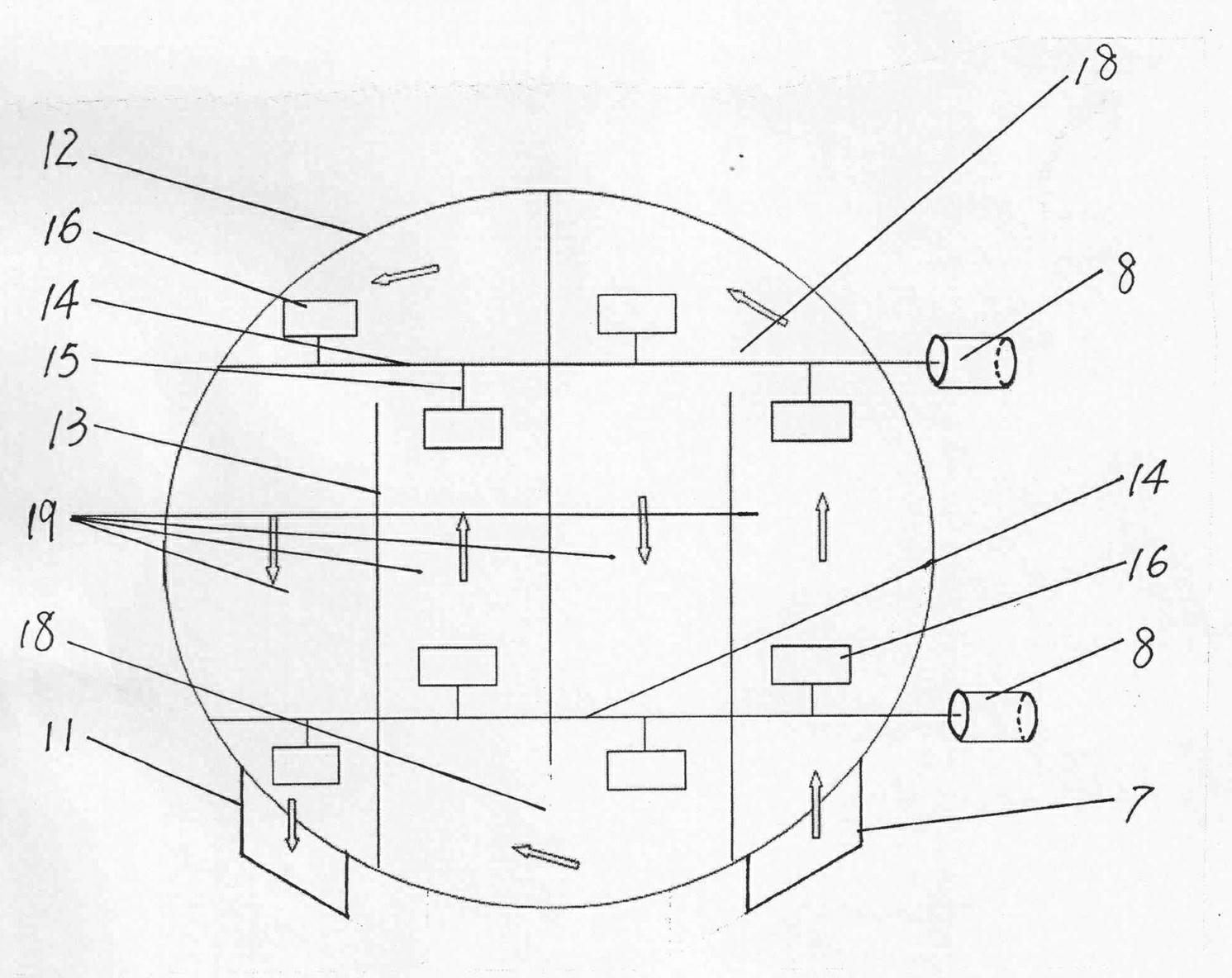

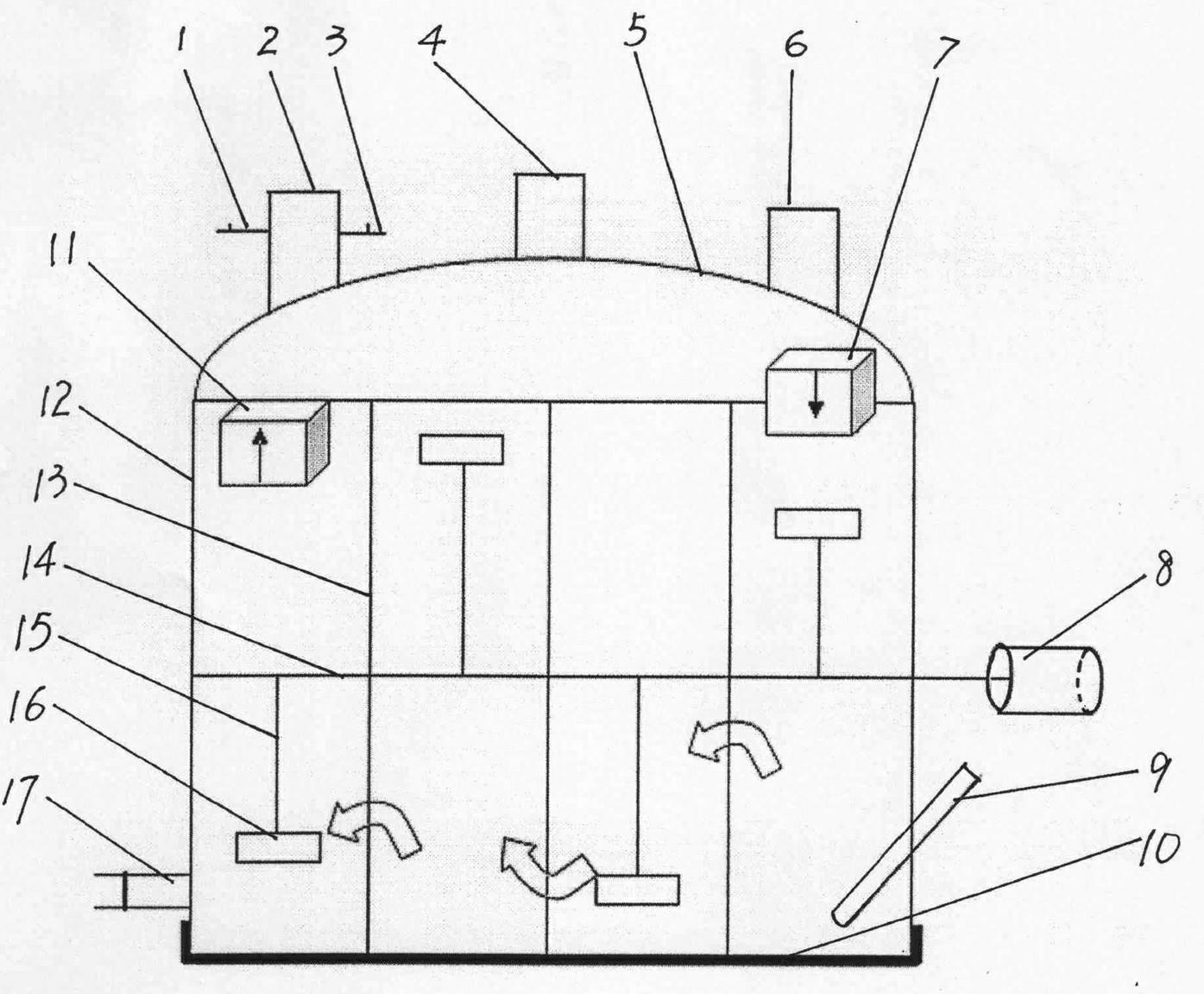

Multi-cycle stirring egg-shaped anaerobic fermentation system

ActiveCN102517199ASimple structureReasonable designBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringSlurry

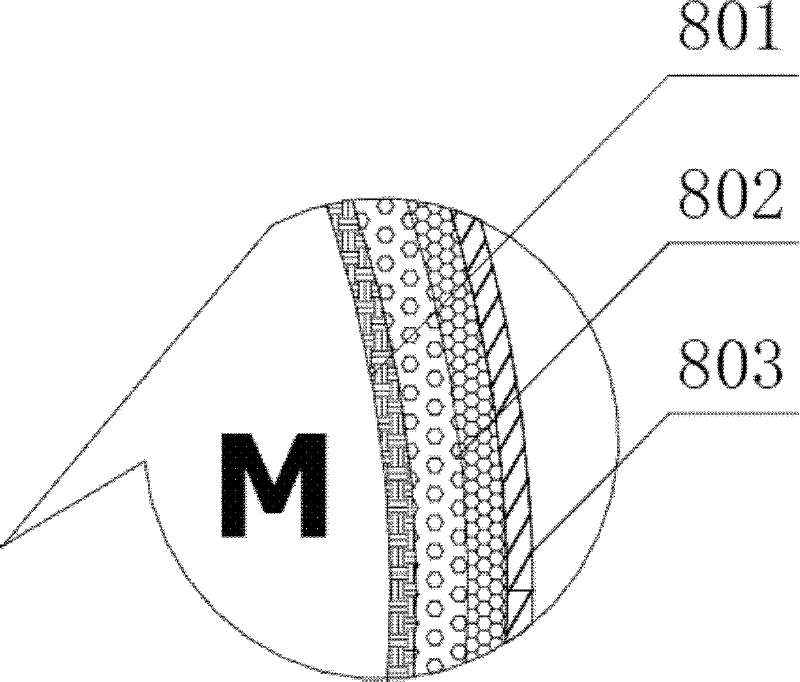

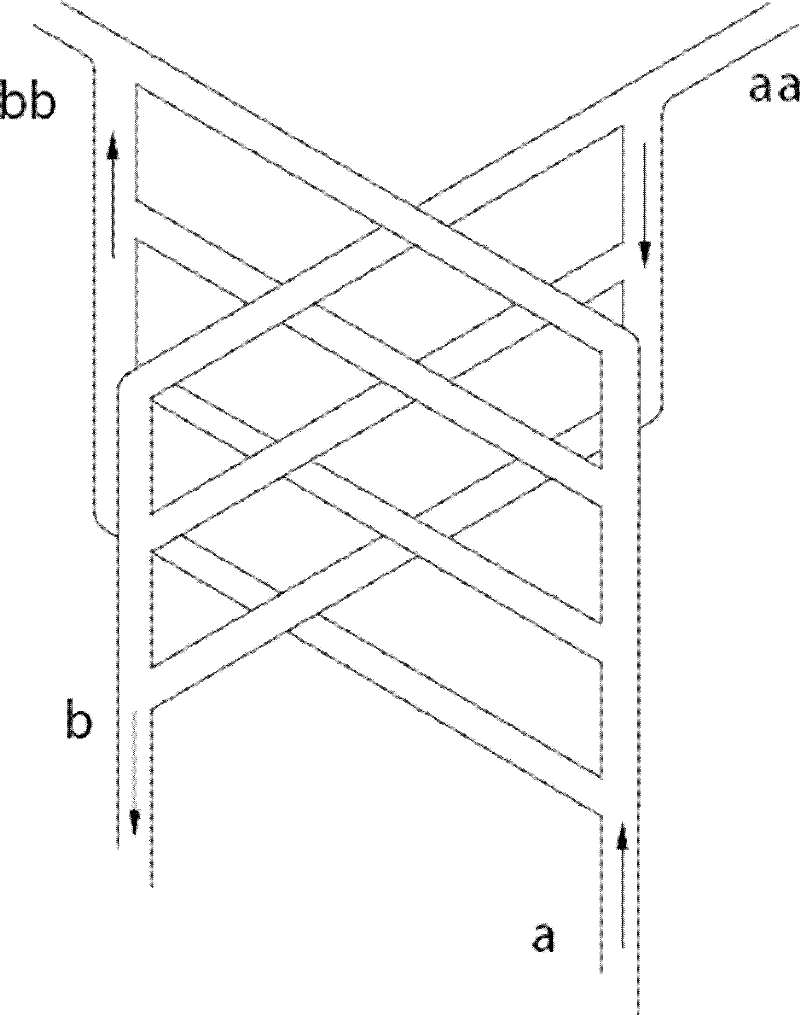

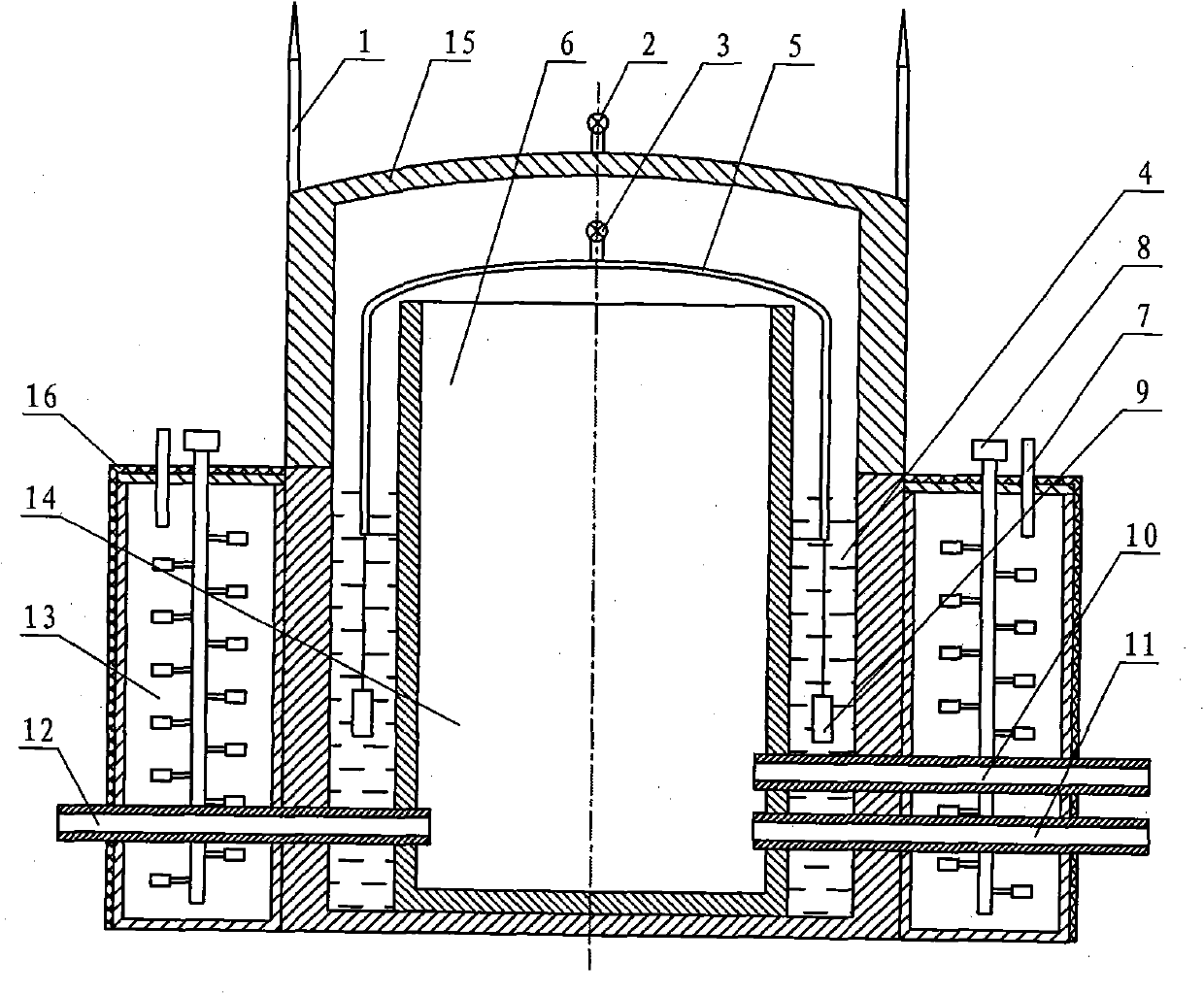

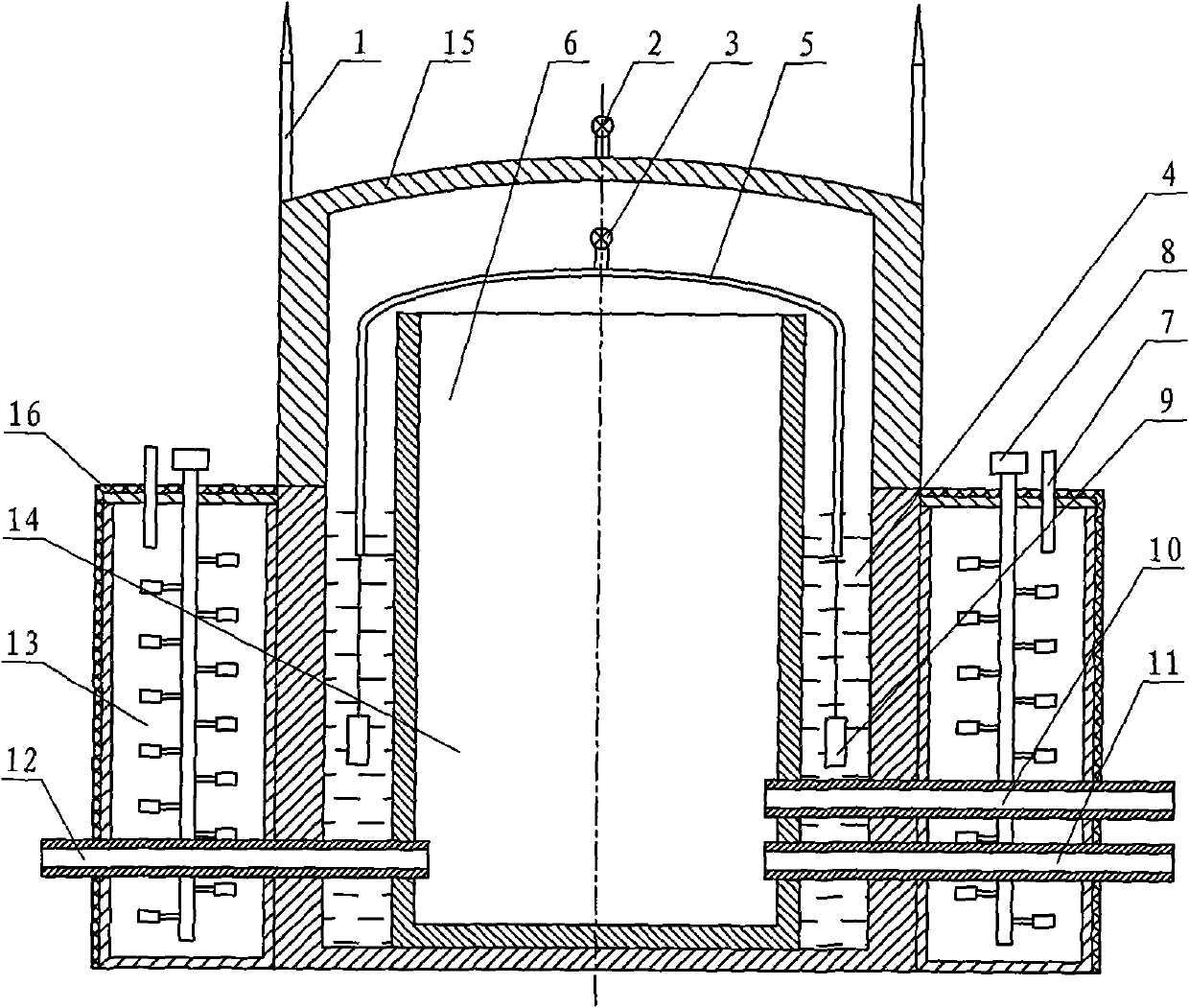

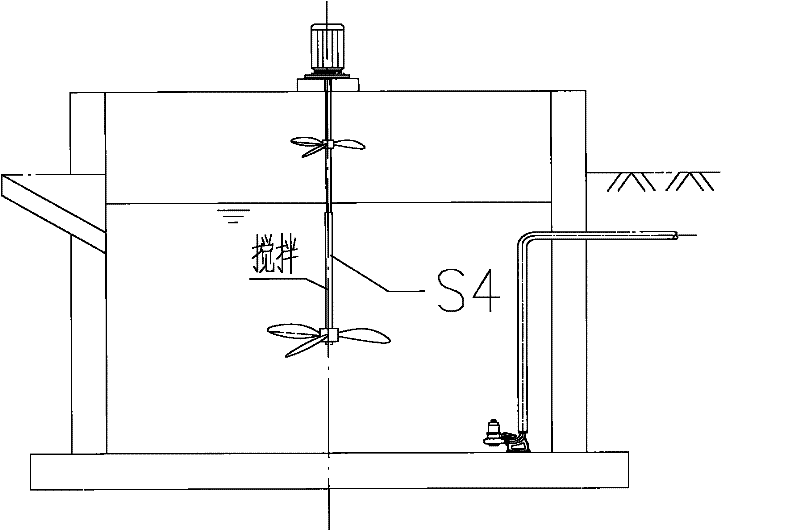

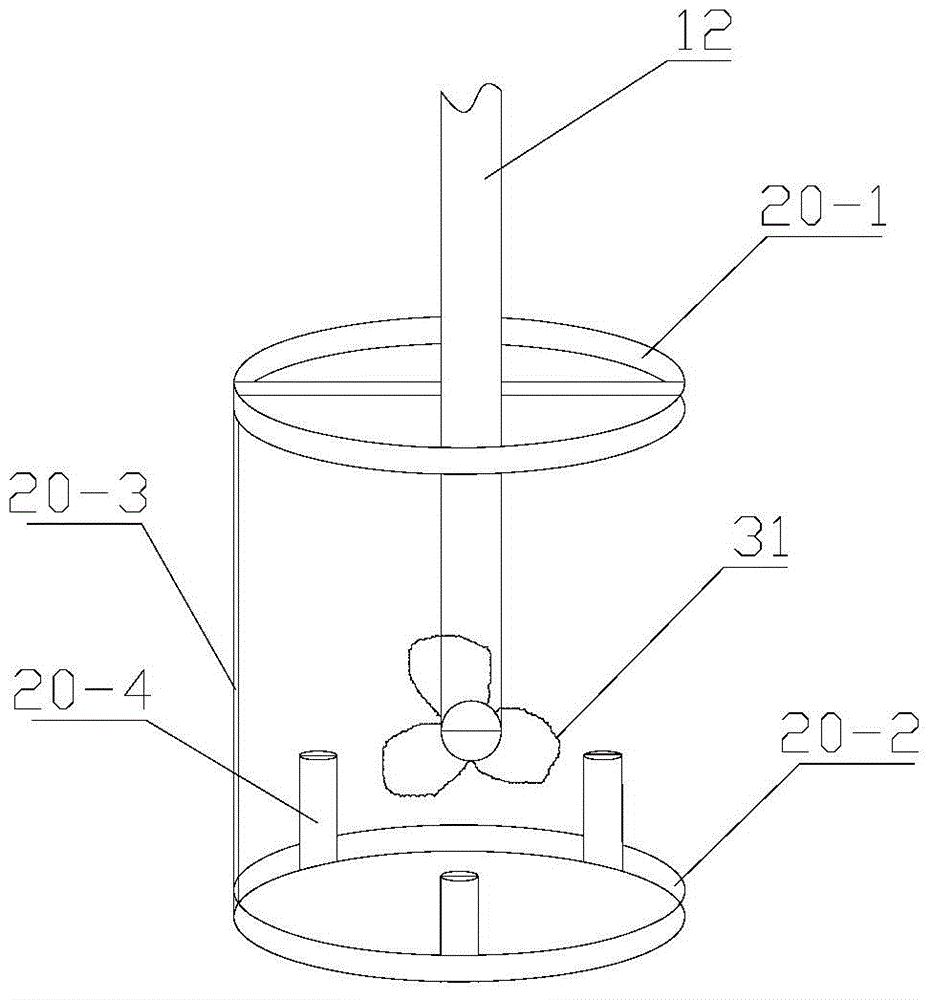

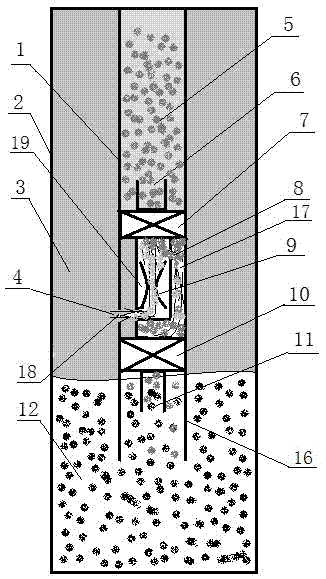

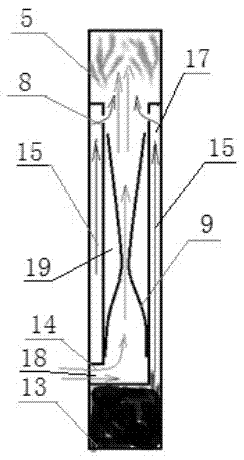

The invention discloses a multi-cycle stirring egg-shaped anaerobic fermentation system. The system comprises a fermentation tank body and a driving device arranged on the fermentation tank body, wherein the fermentation tank body is egg-shaped, the center of the inner cavity of the fermentation tank body is provided with an inner barrel type spiral stirrer, the outside of the inner barrel type spiral stirrer is provided with a stirrer inner barrel, a temperature heating device is arranged between the wall of the fermentation tank body and the stirrer inner barrel, the bottom of the inside ofthe tank is provided with an umbrella-shaped gas flow distribution device; the upper part of the fermentation tank body is provided with a vent pipe and a pressure control device, the bottom of the fermentation tank body is provided with an umbrella-shaped gas flow distribution device gas inlet pipe and a mud-discharging and sand-discharging outlet; and the side wall of the fermentation tank bodyis communicated with a biogas circulation system, a biogas slurry circulation system, a gas-liquid circulation system, a heating system, a temperature control system and a biogas residue and biogas slurry storage pool respectively. The multi-cycle stirring egg-shaped anaerobic fermentation system adopts multi-cycle stirring to increase the stirring efficiency of the system; and the anaerobic fermentation environment is improved, the fluid is mixed evenly, the temperature difference slightly fluctuates, the energy consumption of the system is low, the fermentation rate is high and the system is suitable for popularization and application.

Owner:INNER MONGOLIA HUAMENG KECHUANG ENVIRONMENTAL PROTECTION TECH ENG CO LTD

Marsh gas fermentation process with composite microbial prepn pre-treated stalk

InactiveCN1888073AReduce financial burdenInitial gas production time shortenedGas production bioreactorsMicroorganism based processesSodium bicarbonateFeces

The marsh gas fermentation process with composite microbial preparation treated stalk includes the following steps: crushing stalk material, wetting with water for 18 hr, adding composite microbial preparation and ammonium bicarbonate as the nitrogen source, replenishing water and mixing, stacking and covering with plastic foil, fermenting for 3-6 days and maintaining at temperature over 50 deg.c for 3 days, transferring to marsh gas tank, adding ammonium bicarbonate methane producing inoculum and sealing for 2-7 days to produce marsh gas. The present invention has fast marsh gas producing speed and raised marsh gas producing quantity.

Owner:北京合百意生态能源科技开发有限公司 +1

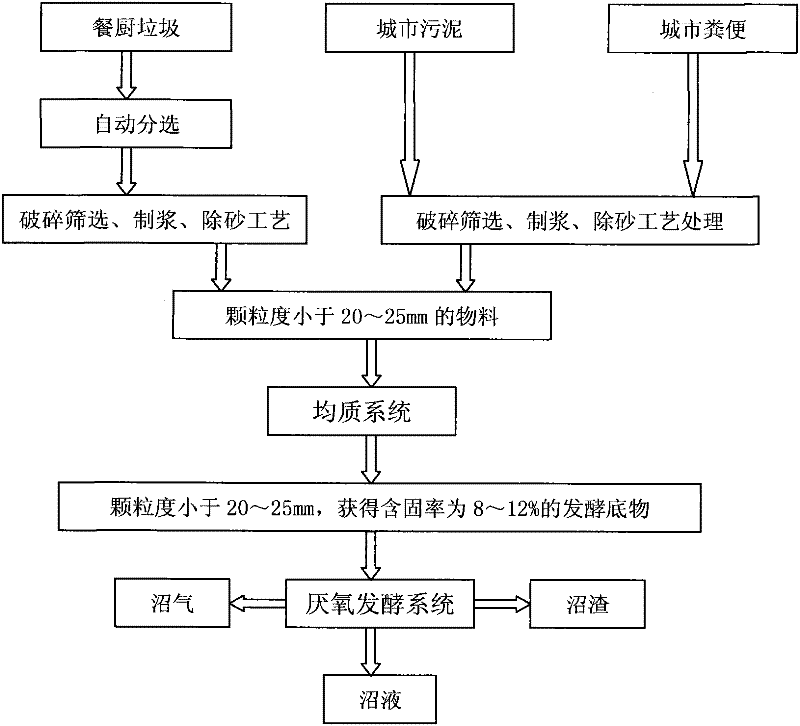

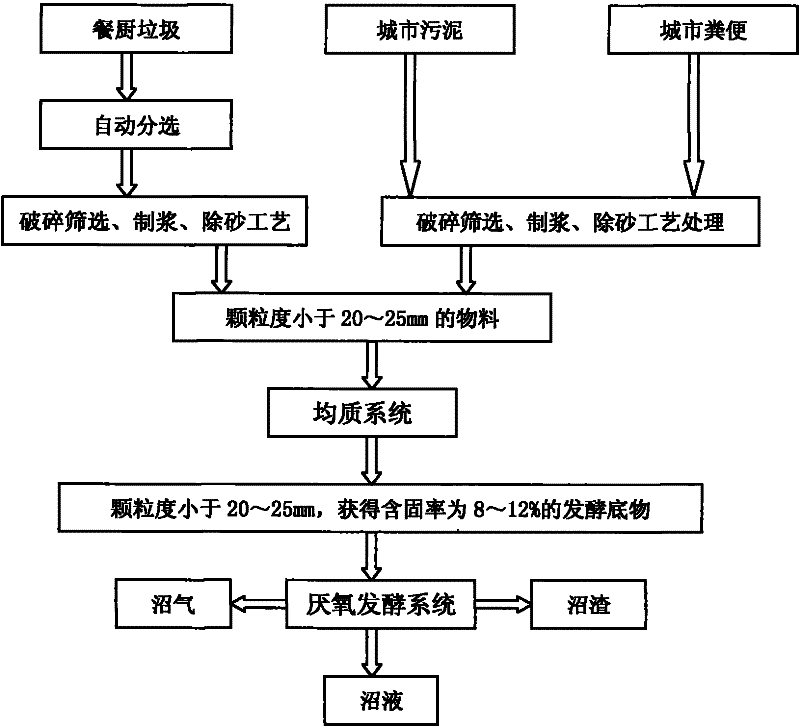

A method for preparing biogas from kitchen waste, urban sludge and urban excrement

InactiveCN102286541AFully fermentedOvercoming the deficiency of high energy consumption in high temperature fermentationWaste based fuelFermentationParticulatesFeces

A method for preparing biogas by joint anaerobic fermentation of food waste, urban sludge and urban excrement, comprising the following steps: (1) pretreatment system: food waste, urban sludge and urban excrement undergo a pretreatment process to obtain granules (2) homogeneous system: the materials processed in step (1) enter the homogenizing tank one after another, mix evenly and degrade part of the suspended matter, so that the particle size of the solid material is less than 20-25mm, and obtain Fermentation substrate with a solid content rate of 8 to 12%; (3) anaerobic fermentation system: the fermentation substrate treated in step (2) is transported to an anaerobic fermentation tank by a pump and adopts a continuous fermentation process and a mesophilic anaerobic fermentation The anaerobic fermentation method combined with jet stirring produces biogas, biogas residue and biogas slurry. The combined anaerobic fermentation preparation method of the present invention has the effects of complete material fermentation and high gas production rate.

Owner:ZHONGCHENG HONGTIAN BEIJING ENVIRONMENT TECH DEV

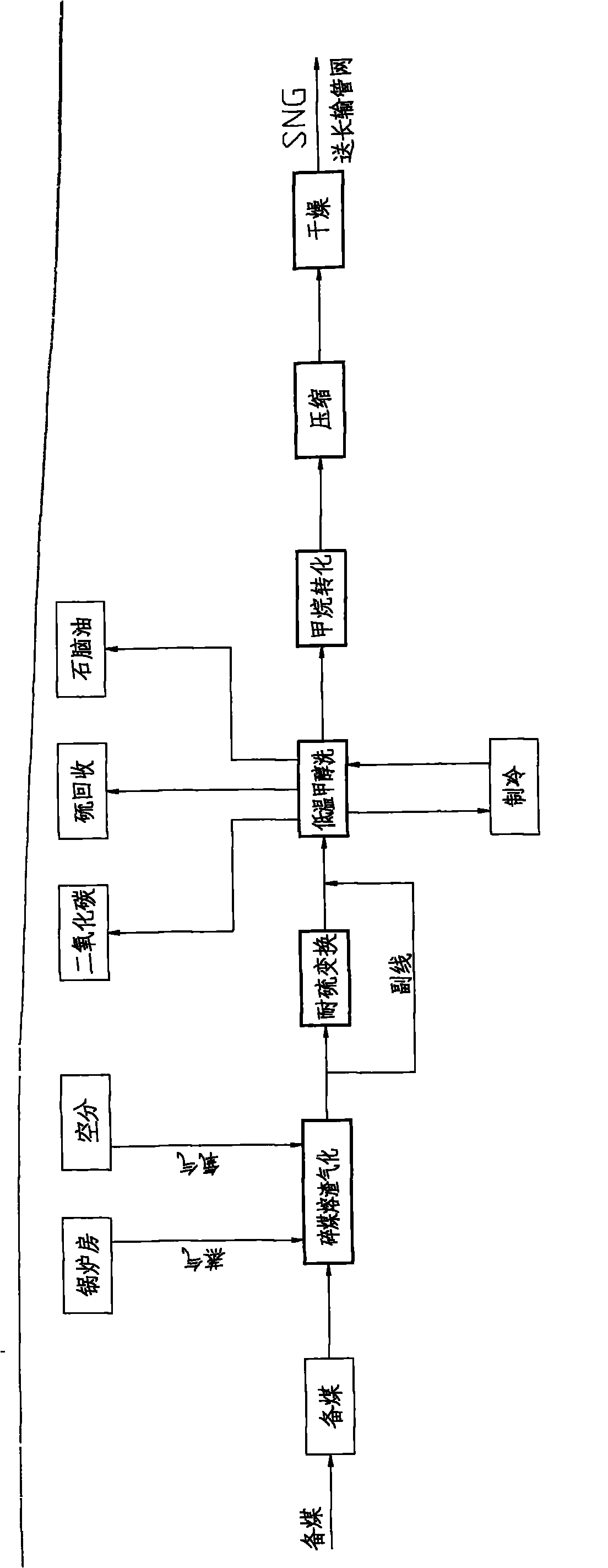

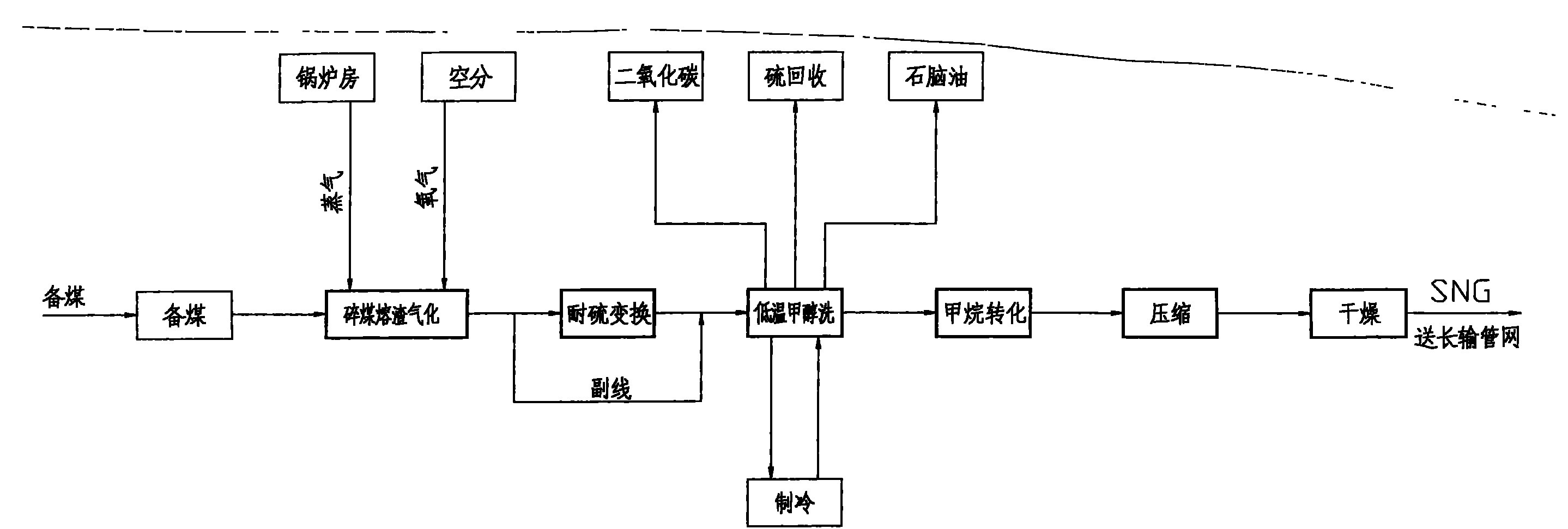

Technique for producing coal natural gas by utilizing crushed coal slag through gasification

ActiveCN101768488AMature and reliable technologyStable operation and maintenanceGaseous fuelsCombustible gas catalytic treatmentNaphthaSulfur

A technique for producing coal natural gas by utilizing crushed coal slag through gasification includes that part of crude coal gas containing CH4 produced by crushed coal slag through gasification receives sulfur tolerant shift, the other part of crude coal gas is conveyed in a sub-line and converges with the gas after sulfur tolerant shift to be cooled, the cooled gas is purified to remove CO2,H2S, naphtha and H2O and other impurities to obtain synthesis gas meeting the methane synthesis H / C ratio, the synthesis gas performs methane synthesis under the effect of methane conversion catalyst, and the methane-synthesis natural gas (SNG) is transmitted in long-distance pipeline network after compression and drying. The invention has the advantages of high gasification rate, high gasification intensity, low consumption and low water content of coal gas.

Owner:SEDIN ENG

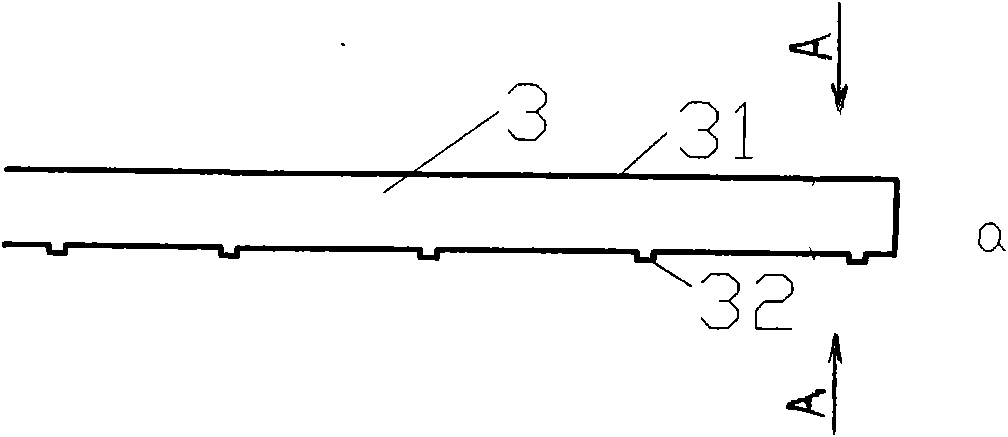

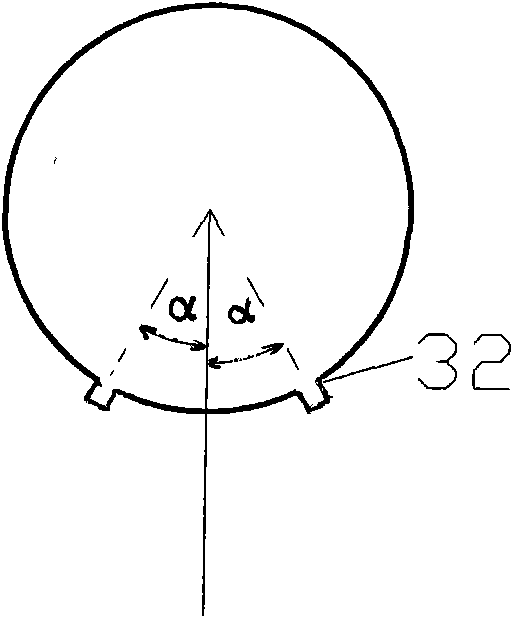

Device and method applicable to anaerobic treatment of solid and liquid mixed sewage of breeding field

InactiveCN101643273AImprove passabilityReduce churnWater treatment parameter controlGas production bioreactorsSlagMethanation

The invention relates to a device and a method applicable to anaerobic treatment of solid and liquid mixed sewage of a breeding field, the treatment device comprises a main body of a reactor, a three-phase separator, a water distributor and a liquid level control system, wherein, the main body of the reactor is cylindrical; the structural setting of the water distributor can adapt to fecal residues and sewage containing higher suspended solids; the three-phase separator adopts the design of a dual-layer structure and is not provided with a biological filter part for improving the passing capacity of sewage and dirt and avoiding blockage phenomenon; the liquid level control system regulates a sludge interface by controlling pressure of a gas chamber, water inlet and slag discharge; the mainbody of the reactor is provided with an acidified sludge layer, a methanation sludge layer and a floating sludge layer from the bottom and is equipped with sludge internal circulation, thereby reducing sludge loss amount and greatly improving treatment capacity; and the treatment device can operate stably under high loads of 15-22kgCOD / m<3>.d at normal temperature. The device is the novel devicewhich is applicable to intensive resource utilization of the fecal residues and the sewage of the breeding field and characterized by low investment, stable operation, simple operation, low treatmentcost and the like.

Owner:TIANJIN INST OF AGRI RESOURCES & ENVIRONMENTAL

Safety belt pre-tightening instrument gas production medicine and preparation method thereof

The gas forming agent for safety belt pre-fastener consists of nitrocellulose 60-90 wt%, combustion improver 1-10 wt%, oxidant 1-20 wt% and adhesive 1-10 wt%. The combustion improver is one or several selected from boron powder and inflammable metal powder; the oxidant is one or several selected from nitrate, chlorate and perchlorate; and the adhesive is one or several selected from phenolic resin, shellac varnish, bone glue, cellulose-base polymer and its salt. The gas forming agent for safety belt pre-fastener has no combustion residue, high gas producing rate and excellent safety belt fastening performance.

Owner:BYD CO LTD

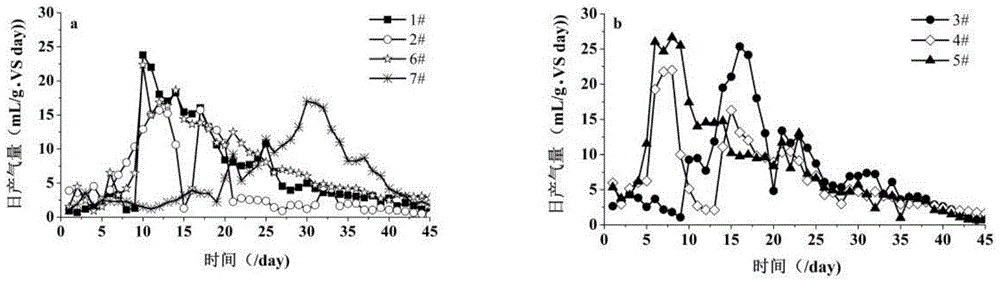

Process for producing biogas by two-stage anaerobic fermentation of crop stalk or livestock excrement

InactiveCN101857882AShort reaction timeIncrease gas production rateMicroorganism based processesWaste based fuelBiotechnologyRetention period

The invention relates to a process for producing biogas by the two-stage anaerobic fermentation of crop stalks or livestock excrement, which is characterized by comprising the following steps: a raw material preparation step, in which 1 to 2 mass parts of crop stalks with a particle diameter of 2 to 10 millimeters, 2 to 3 mass parts (on a dry basis) of livestock excrement and 2 to 3 parts of water are prepared; an acidification step, in which the temperature is 20 to 30 DEG C, the pH value is 4.5 to 6 and the retention period is 48 to 60 hours; a step of adding water into the discharged material of the acidification step to adjust a solid content to 15 to 20 percent; an anaerobic fermentation step, in which the temperature is 40 to 50 DEG C, the pH value is 6.8 to 7.2 and the retention period is 6 to 8 days; and a step of material discharge and sorting treatment. The process has the advantages of improving the utilization rate of the crop stalks in an anaerobic fermentation process, reducing the reaction time for the anaerobic fermentation, improving gas production rate, fully utilizing livestock excrement, promoting the recycling of rural organic waste, controlling overall source pollution in rural areas and improving the sanitation and environment of the rural areas.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

Technique for preparing biogas by high-temperature anaerobic zymosis method using animal manure as raw material

InactiveCN101358209AQuality assuranceImprove filtration efficiencyBio-organic fraction processingClimate change adaptationSludgeAnimal feces

The present invention relates to a technique which utilizes animal and poultry feces as material to prepare biogas underground by anaerobic fermentation, which belongs to the technical field of environment-friendly energy. The technique utilizes the cheap animal and poultry feces as material, in which liquid dung or active sludge perennially accumulated in a farm is added when fermentation is started; high temperature can ensure good growth, thus increasing fermentation efficiency; by a high temperature of 58 DEG C plus or minus 1 DEG C and 8 to 30 grades of anaerobic fermentation, the degradation period of feces and sludge can be shortened; harmful bacteria can be thoroughly sterilized in order to ensure harmlessness; moreover, the post-fermentation biogas residue and biogas slurry can be used as high-quality organic manure; and the produced residual heat can be used for fermentation heat supply or factory heat preservation and heating.

Owner:张永军

Method for increasing coal bed gas yield through indigenous bacteria

InactiveCN106285581AIncrease gas outputImprove porosity and permeabilityBacteriaPreparing sample for investigationFermentationCoal

The invention provides a method for increasing the coal bed gas yield through indigenous bacteria. The method comprises the steps of (1) a methanogens community is enriched and cultured, specifically, a coal sample and a water sample are collected from a target zone, enrichment culture and fermentation of the methanogens community are conducted, and fermentation liquor is obtained; (2) ultrasonic coupling supercritical CO2 treatment is conducted, specifically, a laboratory operation and maintenance management system is used, the optimal condition for ultrasonic coupling supercritical CO2 treatment on the coal seam sample is analyzed in a laboratory, and a target coal seam is treated under the optimal condition; and (3) coal degradation through microorganism is conducted, specifically, the fermentation liquor obtained in the step (1) is injected into the target coal seam, changes of injection wellhead gas components and the methane concentration are detected continuously, and methane is gathered in drainage, pressure lowering and recovering modes. The treatment time is effectively shortened through the ultrasonic coupling supercritical CO2 treatment, the coal bed gas generation speed is increased, and meanwhile the working efficiency is effectively improved through the laboratory operation and maintenance management system.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

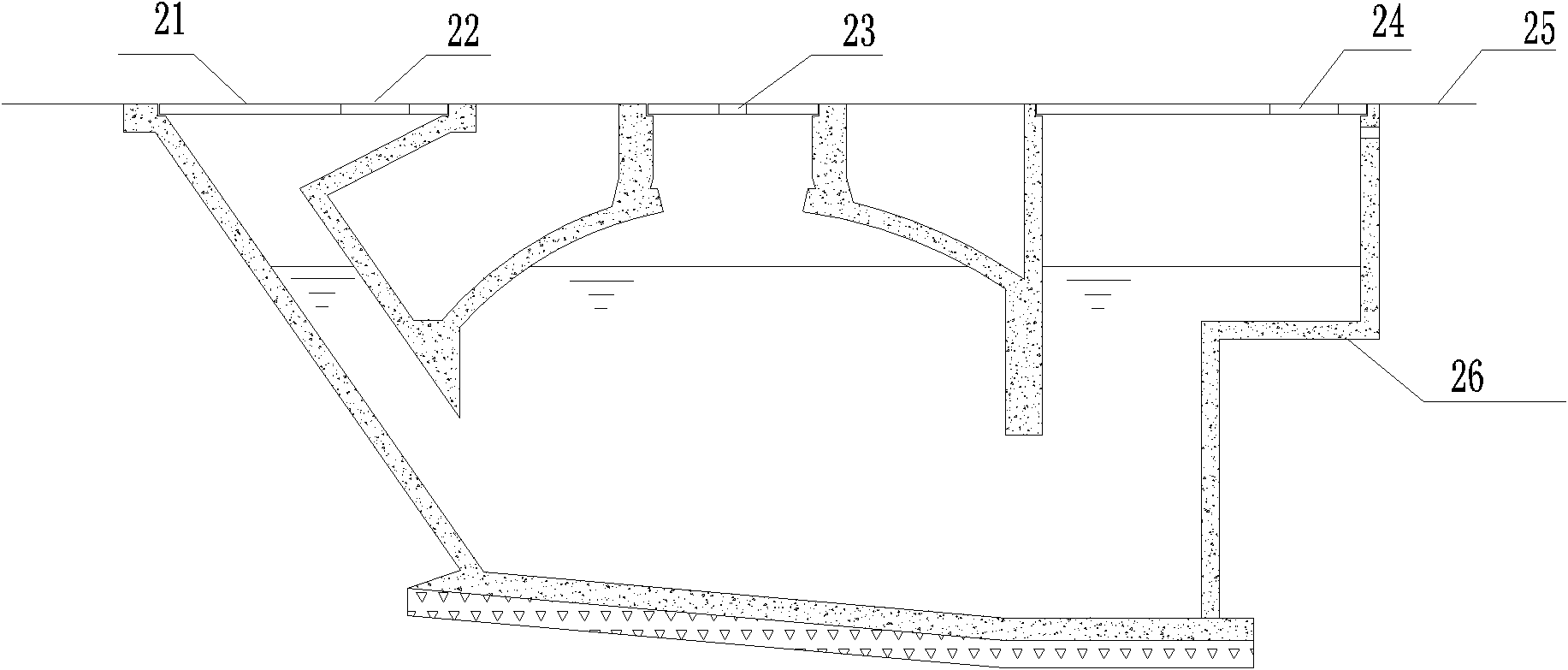

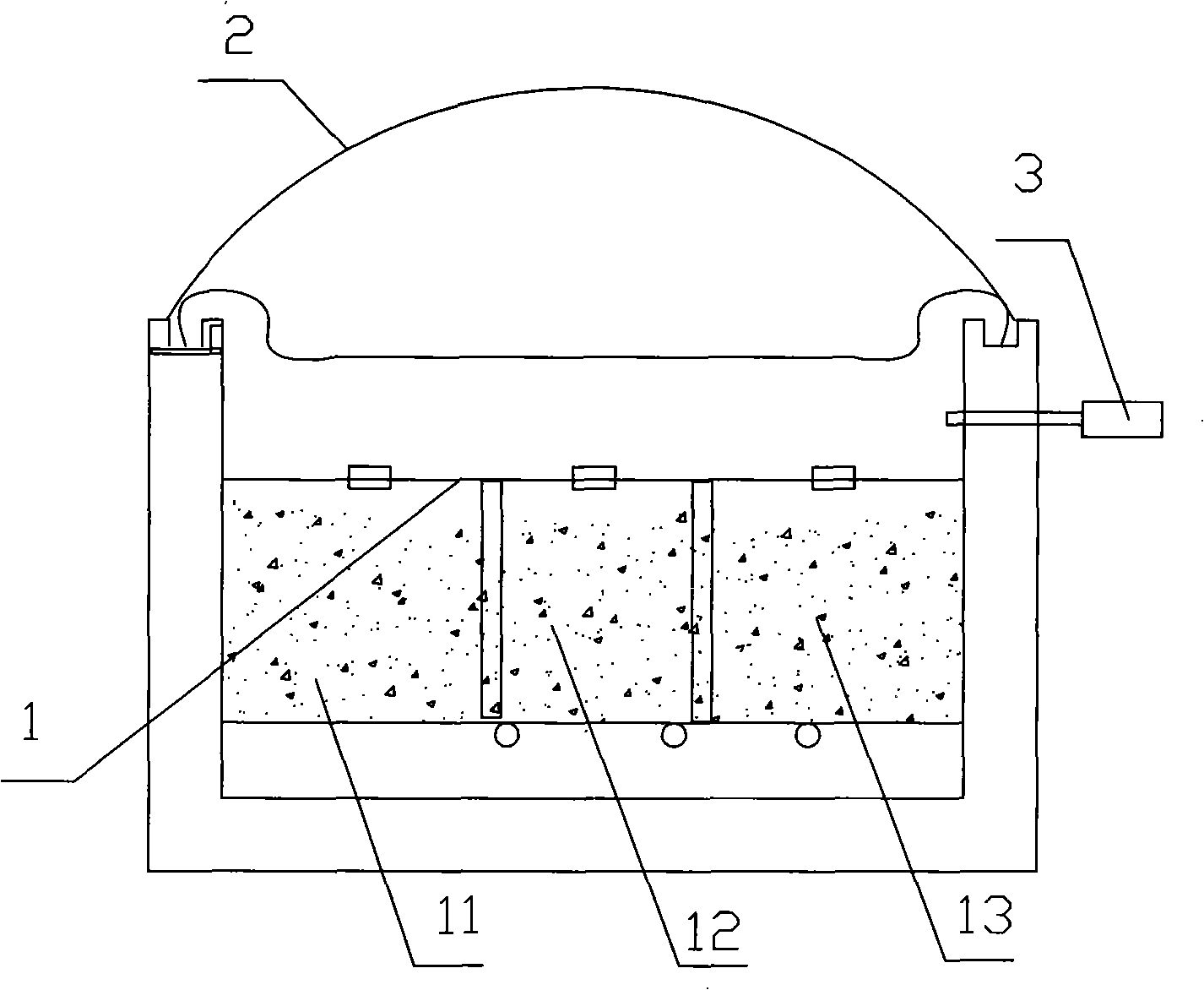

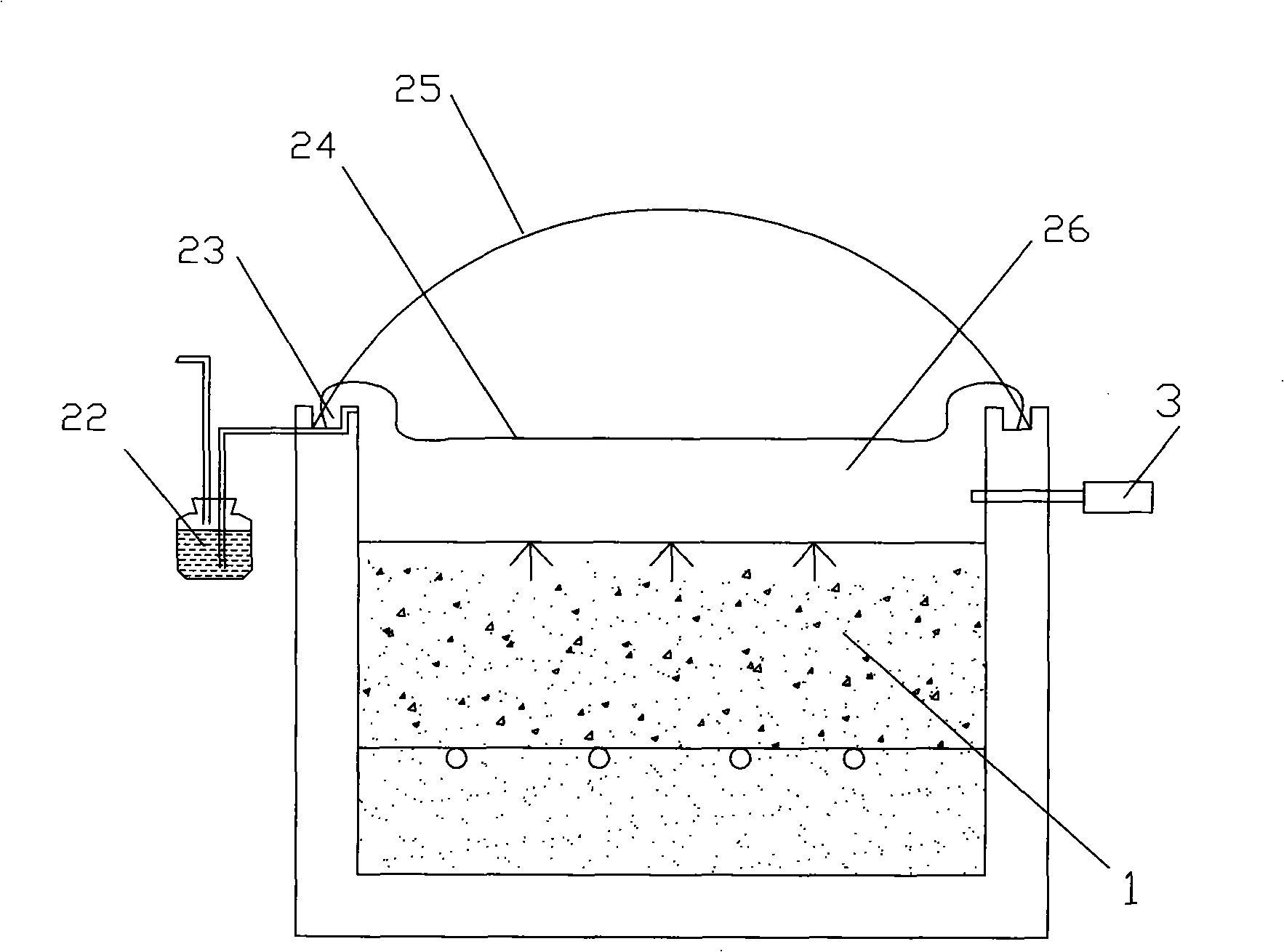

Large-sized open mouthed combined methane tank

InactiveCN101353623ALimited activity spaceFree from wear and tearBioreactor/fermenter combinationsBiological substance pretreatmentsCirculating pumpCharge and discharge

The invention discloses a large-scale open compound methane tank, including a fermenting tank (1), a gas collection and storage device (2), and an air feeder (3) connected with the fermenting tank, wherein, the fermenting tank includes a plurality of independent fermenting tanks which can be communicated or disconnected mutually. The methane tank also includes the gas collection and storage device, the air feeder, a solar warming device, a charging / discharging device and an anti-encrustation device of the methane tank. When in use, as the structure of the invention is provided with a plurality of independent fermenting tanks, the air can be fed continuously in the raw material renewal process; the charging / discharging device accelerates the material charging and discharging; the gas collection and storage device of the methane tank has low construction cost, a software cover can be opened or retracted according to gas production, a gas collection and storage chamber can be changed according to the methane quantity, the pressure in the gas collection and storage chamber can not be too high, and the solar warming device increases the temperature in the methane tank so as to lead the straw material to produce the methane under the suitable temperature in winter; and a circulating pump is used for spraying the methane fluid onto the straw material through a nozzle so as to avoid encrustation.

Owner:南阳市绿野循环农业研究所 +1

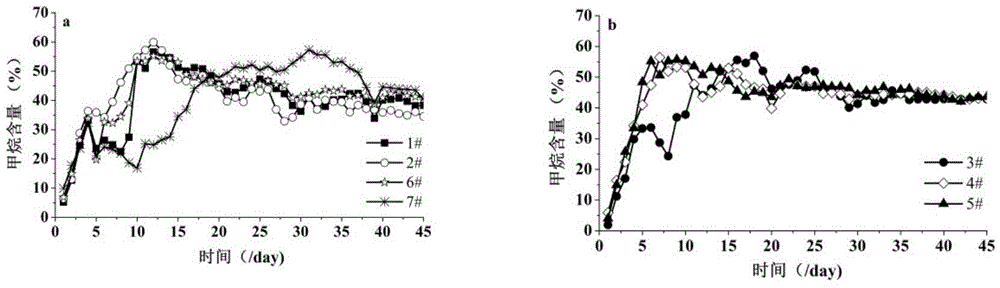

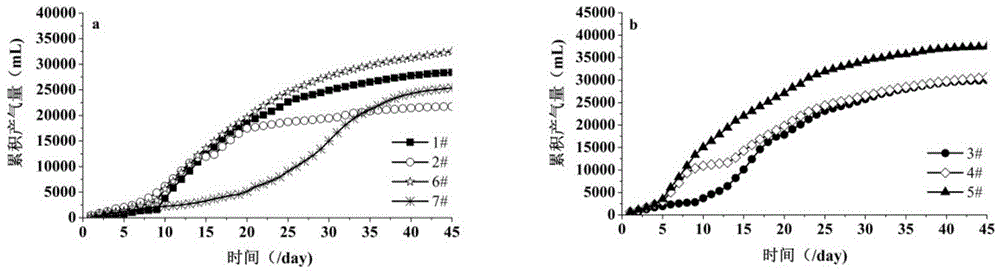

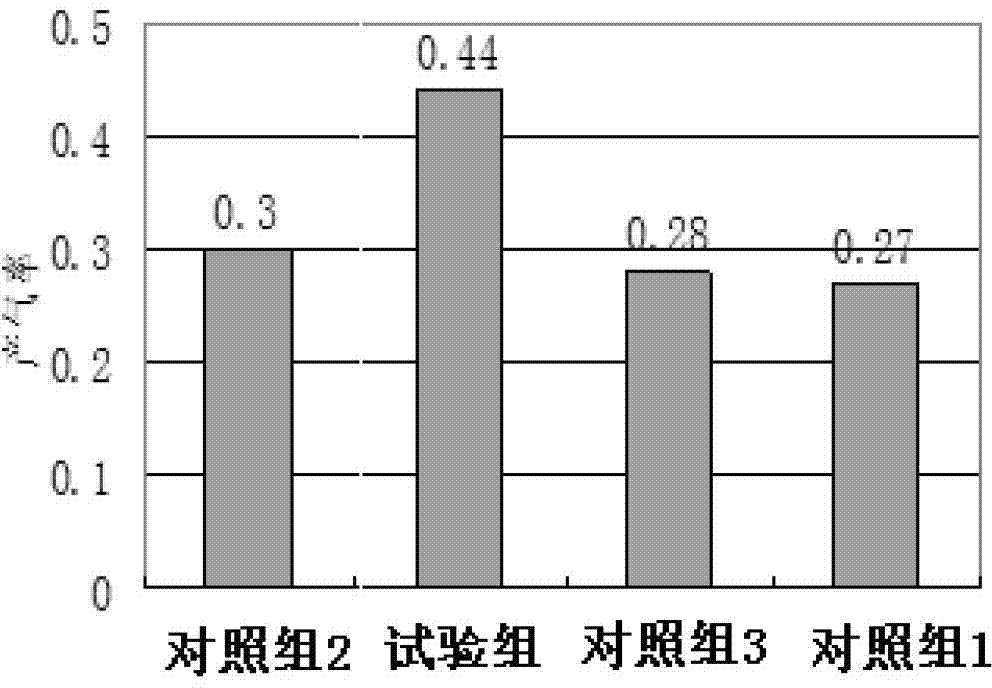

Method for efficiently producing marsh gas by performing moderate-temperature anaerobic dry fermentation on agricultural waste

InactiveCN104357487AResolution timeImprove buffering effectBio-organic fraction processingClimate change adaptationFecesPoultry manure

The invention relates to a method for efficiently producing marsh gas by performing moderate-temperature anaerobic dry fermentation on agricultural waste, which comprises the following steps: uniformly mixing livestock / poultry manure, crop straw and vegetable waste to obtain a mixture, adding an inoculum into the mixture, and carrying out moderate-temperature anaerobic dry fermentation to obtain the marsh gas, wherein the dry matter mass ratio of the sum of the livestock / poultry manure and vegetable waste to the crop straw is (0.3-0.4):1, and the dry matter mass ratio of the livestock / poultry manure to the vegetable waste is (0.1-0.3):(0.1-0.2). The method solves the problems of long fermentation time, low gas production rate, high acidification tendency and the like in the independent anaerobic fermentation of the material, greatly enhances the buffer property of the system, reduces the inhibiting effect due to overhigh concentration of the ammonia nitrogen or other inhibitors, widens the selection range of the fermentation raw materials, increases the treatment power on the organic solid waste, reduces the discharge of the agricultural waste, saves the resources and protects the environment.

Owner:CHINA AGRI UNIV

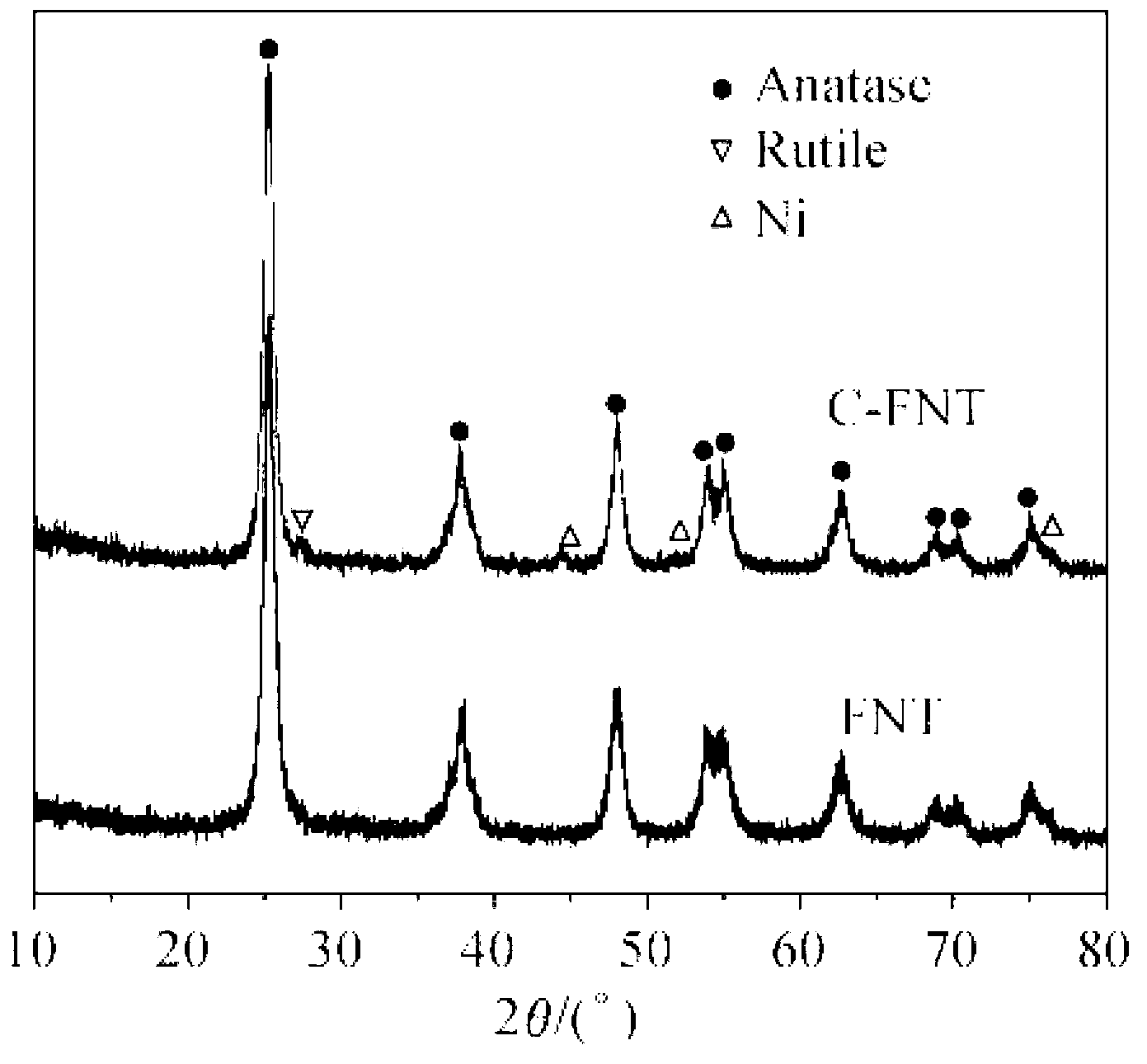

Cold-region methane accelerator and preparation method thereof

InactiveCN102732566AImprove the nutritional environmentGrow fastWaste based fuelFermentationProduction rateSorbent

The invention discloses a cold-region methane accelerator and a preparation method of the cold-region methane accelerator and relates to a methane accelerator and a preparation method of the methane accelerator. The invention aims at solving the technical problems that the existing methane accelerators can not improve gas production rate at low temperature and are difficult to obtain. The cold-region methane accelerator provided by the invention comprises ferrum, cobalt, nickel, organic matters, an adsorbent and a filler. The preparation method comprises the following steps that: (1) ferrous sulfate, cobalt chloride, nickel chloride, the organic matters, the adsorbent and the filler are weighed; (2) distilled water is added to the weighed ferrous sulfate, cobalt chloride and nickel chloride to prepare saturated solution; the adsorbent is added; a crusher is used for crushing after drying to obtain powder; and (3) the organic matters and the filler are added to the powder and the mixture is evenly mixed to obtain the cold-region methane accelerator. The methane accelerator and the preparation method are applicable to the methane field.

Owner:黑龙江省农业科学院农村能源研究所

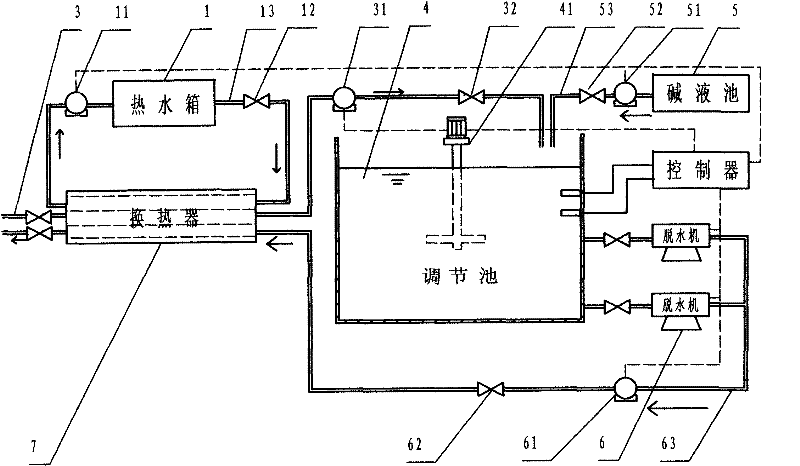

Device and method for cell wall breaking in municipal sludge dewatering process

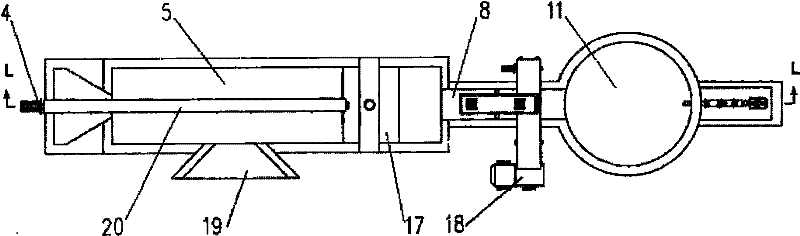

ActiveCN102173556ASimple methodEasy to operateSludge treatment by de-watering/drying/thickeningLiquid tankPulp and paper industry

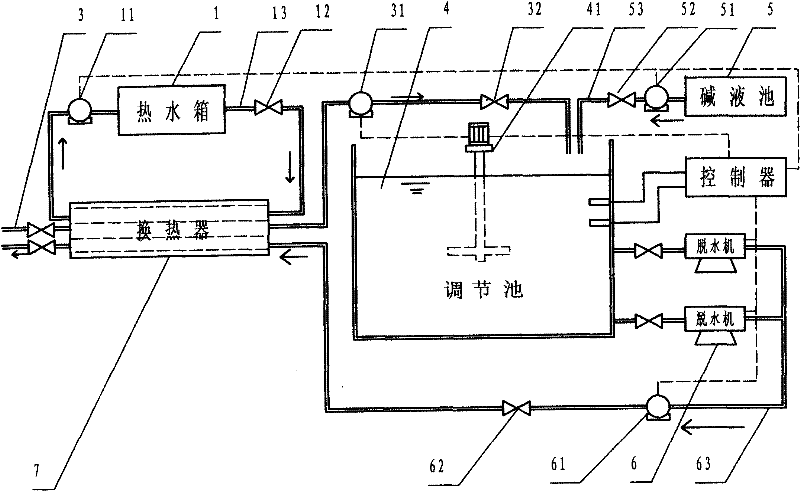

The invention discloses device and method for cell wall breaking in a municipal sludge dewatering process. The device comprises an adjusting pond, a stirrer, a hot water tank, a hot water pump, a hot water pipe which is communicated with the adjusting pond through a heat exchanger, a sludge pump, a valve, a sludge inlet pipe which is communicated with the adjusting pond through the heat exchanger, an alkaline liquid tank, an alkaline liquid pump, an alkaline liquid pipe which is communicated with the adjusting pond, and a dewatering machine which is connected with the adjusting pond, wherein the filtrate from the dewatering machine is discharged through the heat exchanger, and the adjusting pond is provided with an alkaline liquid concentration sensor, a temperature sensor and a controller and is in connected connection with the sludge pump, a water pump, the alkaline liquid pump, the motor of the stirrer, the dewatering machine and the valve. The cell wall breaking method comprises the following steps of: (1) performing a pretest; (2) preparing an alkaline liquid; (3) loading sludge to the adjusting pond in which the sludge is preheated; (4) adding alkali to adjust the pH of the sludge and allowing mixed reactions to take place; (5) starting the dewatering machine and a filtrate return device; (6) detecting the sludge mixed reaction results at a preset time, to ensure optimum wall-breaking dewatering effect of the sludge; and (7) repeating from the step (3) to the step (6). The device and method provided by the invention are applied to the wall-breaking treatment prior to the dewatering treatment of the sludge, has a perfect structure, is easy to operate, and improves effects.

Owner:BEIJING DRAINAGE GRP CO LTD

Double-chamber anaerobic methane secondary fermentation device

InactiveCN102021110ALow costCompact structureGas production bioreactorsWaste based fuelProduction rateSlag

The invention relates to a double-chamber anaerobic methane secondary fermentation device. The double-chamber anaerobic methane secondary fermentation device consists of a primary fermentation chamber and a secondary fermentation chamber, wherein the primary fermentation chamber is provided with a feed port; a stirrer is arranged in the primary fermentation chamber; the secondary fermentation chamber is arranged in the primary fermentation chamber; a water layer is arranged between the primary fermentation chamber and the secondary fermentation chamber; the secondary fermentation chamber is covered by a gas storage cover; a counter weight block is arranged at the bottom of the gas storage cover and is placed into the water layer, so that a constant pressure gas storage chamber is formed on the upper part of the gas storage cover; and a slag outlet pipe, a gas storage pipe and a liquid outlet pipe are arranged in the secondary fermentation chamber. The double-chamber anaerobic methane secondary fermentation device has the advantages that: 1. the device has a compact structure and small occupied area, can reduce construction cost by 30 percent, and is convenient to operate, manage and maintain; 2, the device is safe and reliable in use and has low operating cost; 3, the digestibility of raw materials can reach 85 percent and gas yield is increased by 30 percent; and 4, the temperature of the whole fermentation device can be increased, the fermentation is performed completely, and the temperature can be maintained, so that normal gas production rate in winter can be guaranteed.

Owner:TIANJIN DESHENGYUAN ENVIRONMENT ENG

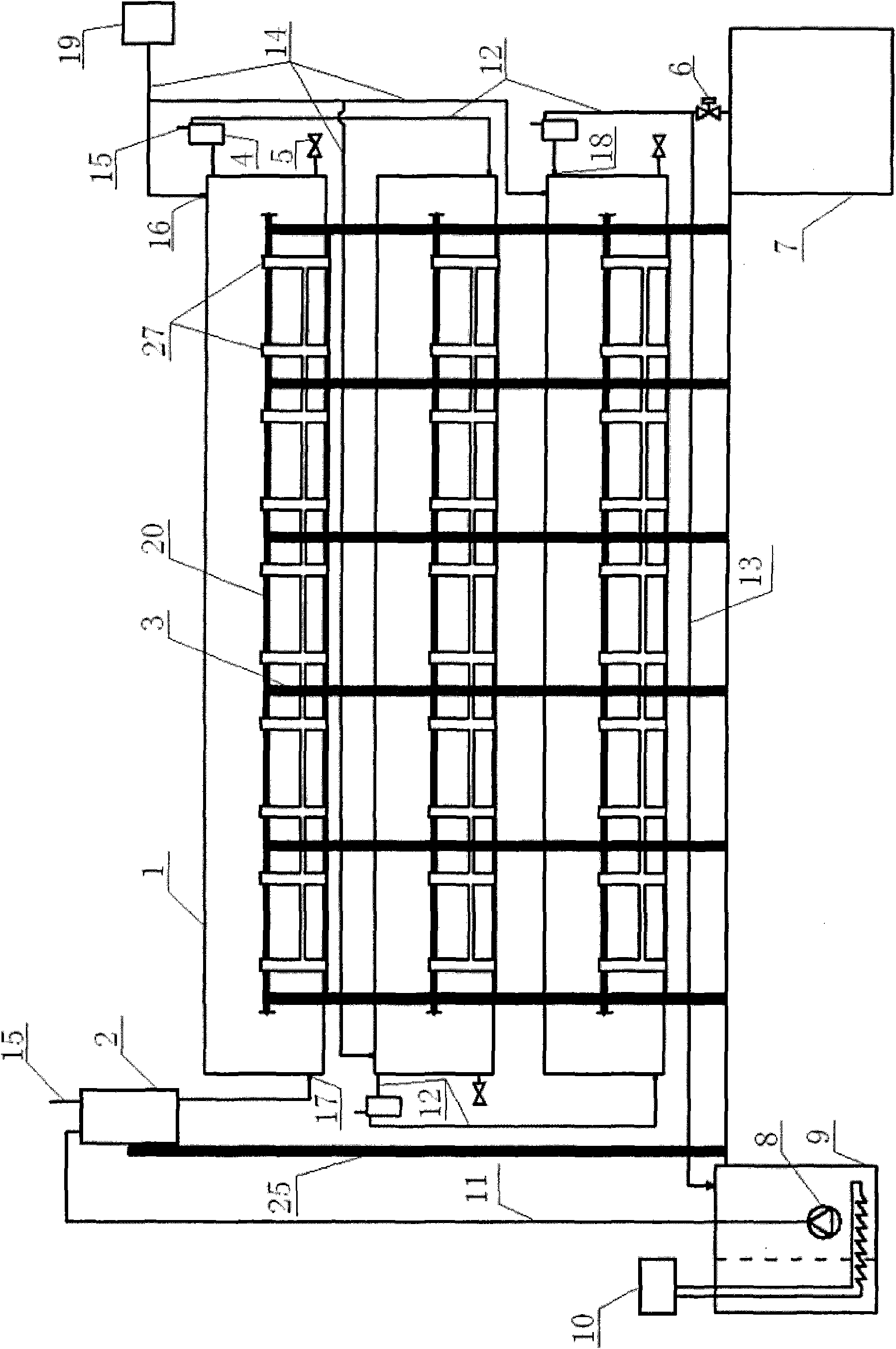

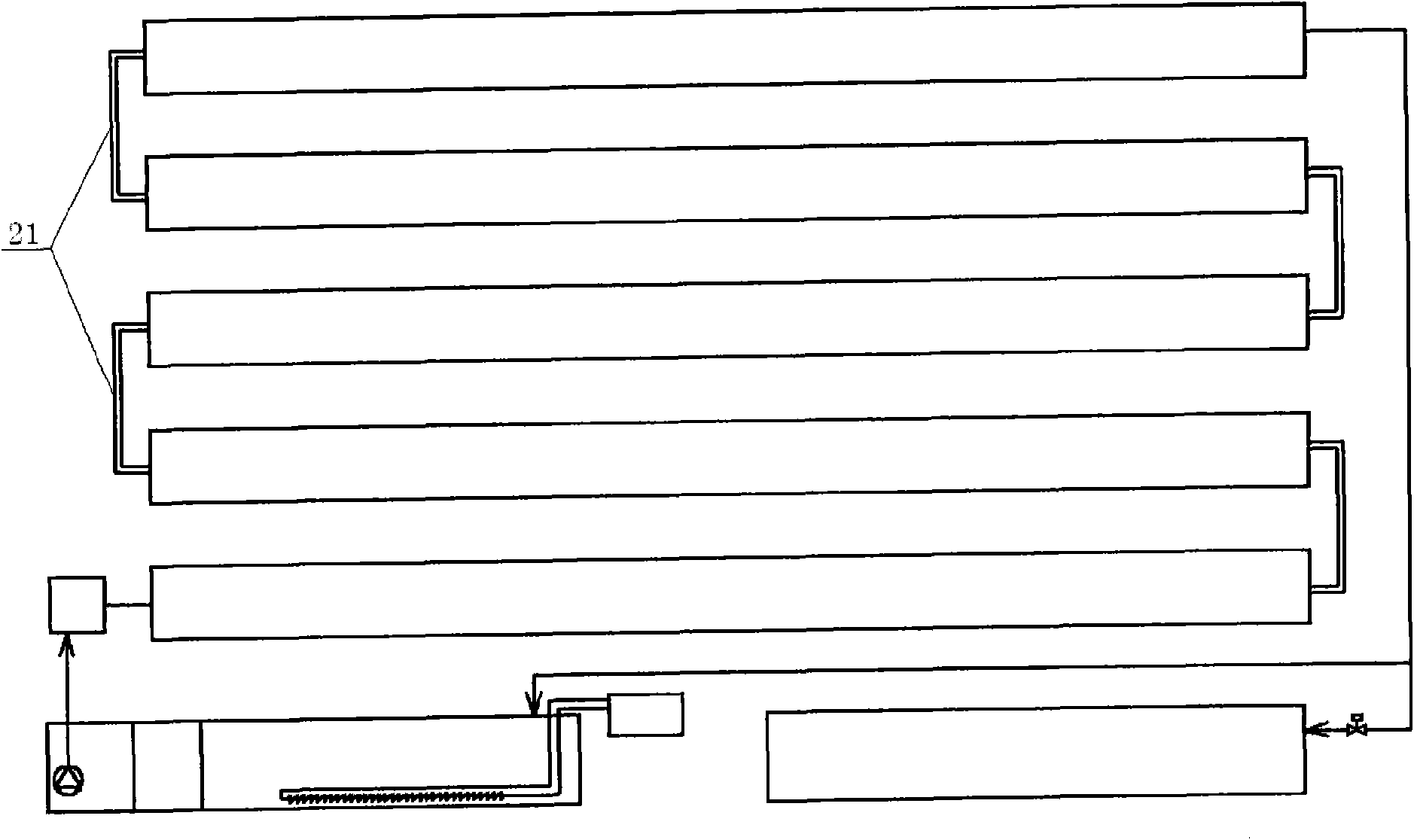

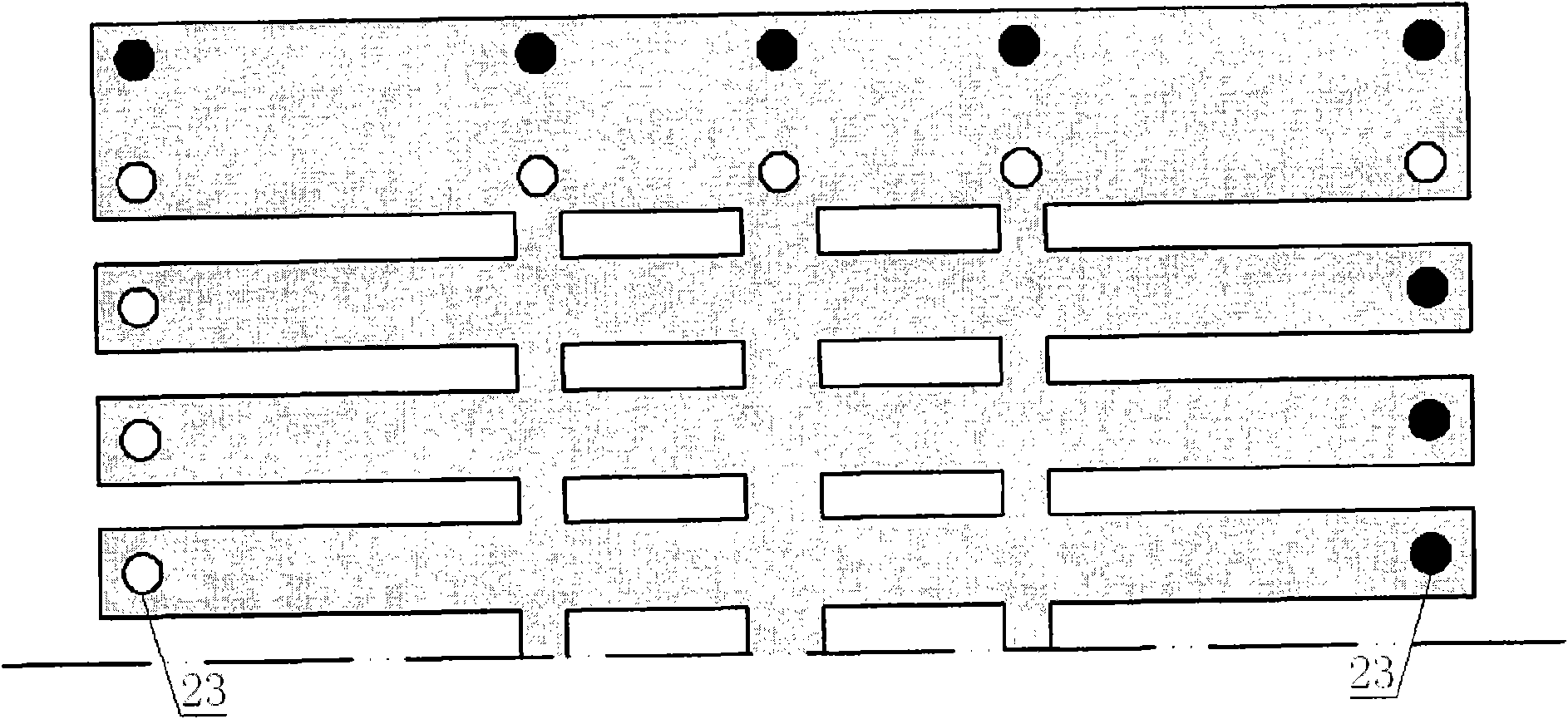

Biogas reaction device

InactiveCN101613658AAchieving Scale ProcessingReduce energy consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsNew energySewage

The invention relates to a biogas reaction device, which mainly comprises reaction bed monomers (1), an equalizer (2), an upright post (3), a current limiter (4), a charging pump (8), a support (20), a connector (21), a support bed (27) and a heating pool (9). The reaction bed has three layers, the reaction bed monomers (1) on each layer are combined through series connection, and the charging pump (8) is used for charging material and circulating material liquid. The core equipment of the reaction bed monomers (1) is made of a soft material, so the product is foldable, convenient to transport and suitable for factory production. The invention relates to the field of new energy and environmental protection and provides a bionic biogas reaction device which can be widely used for processing organic materials such as organic sewage, household garbage, human and animal excreta and crop straws.

Owner:吴兆流

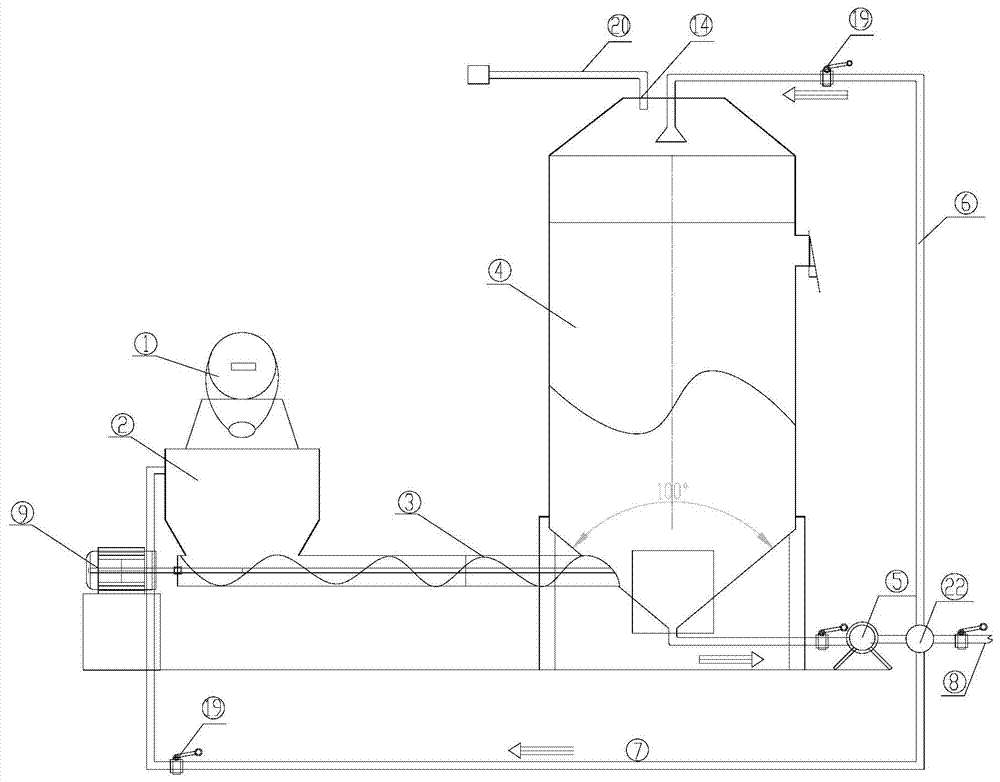

High-solid anaerobic reaction device and method for organic garbage

ActiveCN103614288AImprove processing efficiencyGuaranteed uptimeBiological substance pretreatmentsGas production bioreactorsPipe fittingSmall footprint

The invention relates to a high-solid anaerobic reaction device and method for organic garbage. The device comprises a pulverizer, a pretreatment pond and an anaerobic fermentation tank, wherein the pulverizer is arranged above the pretreatment pond; a spiral conveying device is arranged below the material outlet of the pretreatment pond and connected with the anaerobic fermentation tank; a liquid-collecting pipe is connected to the bottom of the anaerobic fermentation tank and connected to a four-way pipe fitting; the other three ports of the four-way pipe fitting are connected with a water draining pipe, a pretreatment pond backflow pipe and a biogas slurry spraying return pipe respectively; the anaerobic fermentation tank is internally sequentially provided with a spraying perforated plate and a sieve plate from top to bottom. According to the anaerobic reaction device for the organic garbage with the high solid content, the material pulverization, pretreatment and fermentation are integrated, the material uniformity is guaranteed, an anaerobic fermentation process is facilitated, the solid concentration and uniformity of a material are regulated through fermentation liquor backflow, and the stable fermentation of organic garbage is realized; the anaerobic reaction device has the characteristics of wide adaptability, high treatment efficiency, compact layout, stable operation, small land occupation area and the like.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

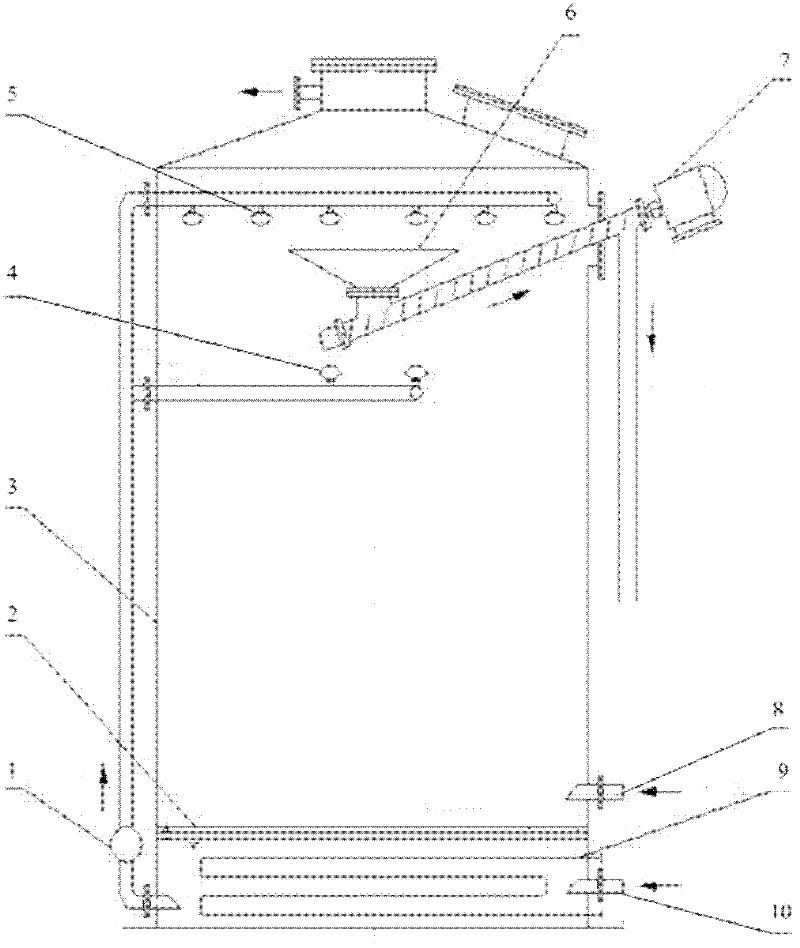

Novel vertical flexible covering film anaerobic fermentation device

InactiveCN101775351ASolve churnFixed way is flexibleGas production bioreactorsWaste based fuelSludgeFermentation

The invention provides a novel vertical flexible covering film anaerobic fermentation device, comprising an anaerobic fermentation reactor and a flexible covering film fixed to the anaerobic fermentation reactor, wherein the anaerobic fermentation reactor is provided with, from bottom to top, a methane stirring device, a multipoint self-rotating water distributing device and a four-phase separator. The device is a novel vertical flexible covering film anaerobic fermentation device having the characteristics of: being low constant pressure and anaerobic, high-efficiency production of methane, long sludge age, low energy consumption and convenient operation and maintenance.

Owner:张华 +1

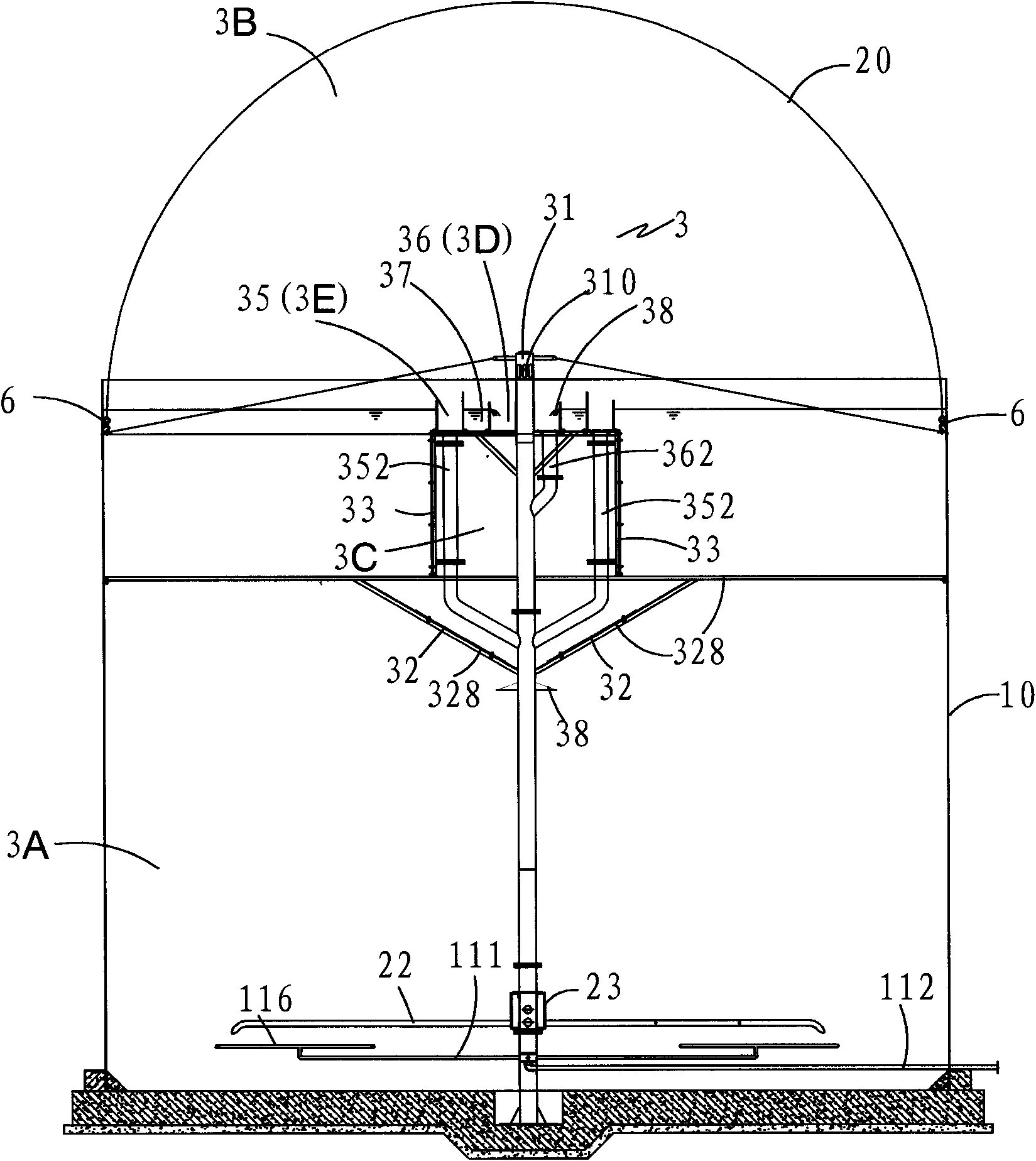

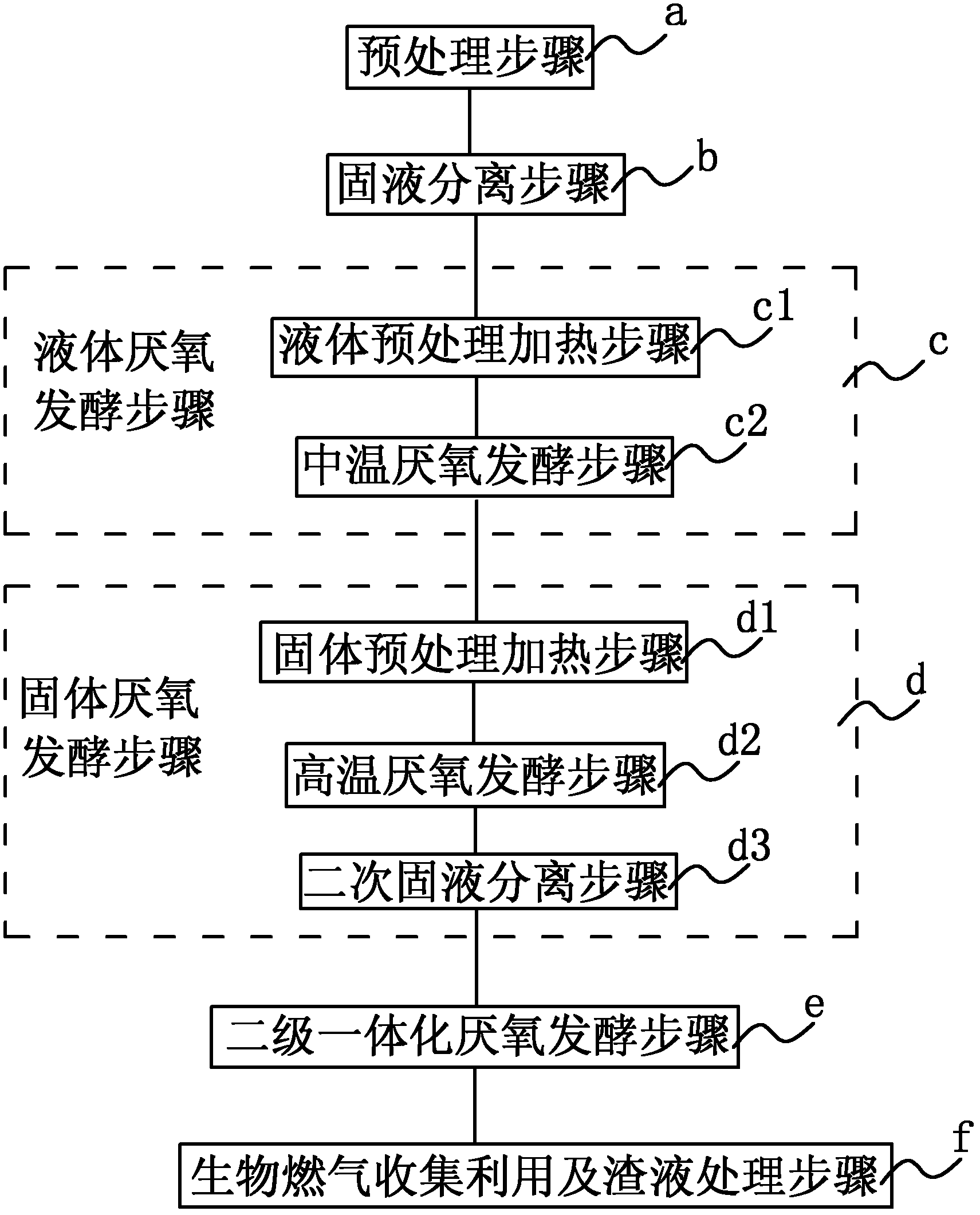

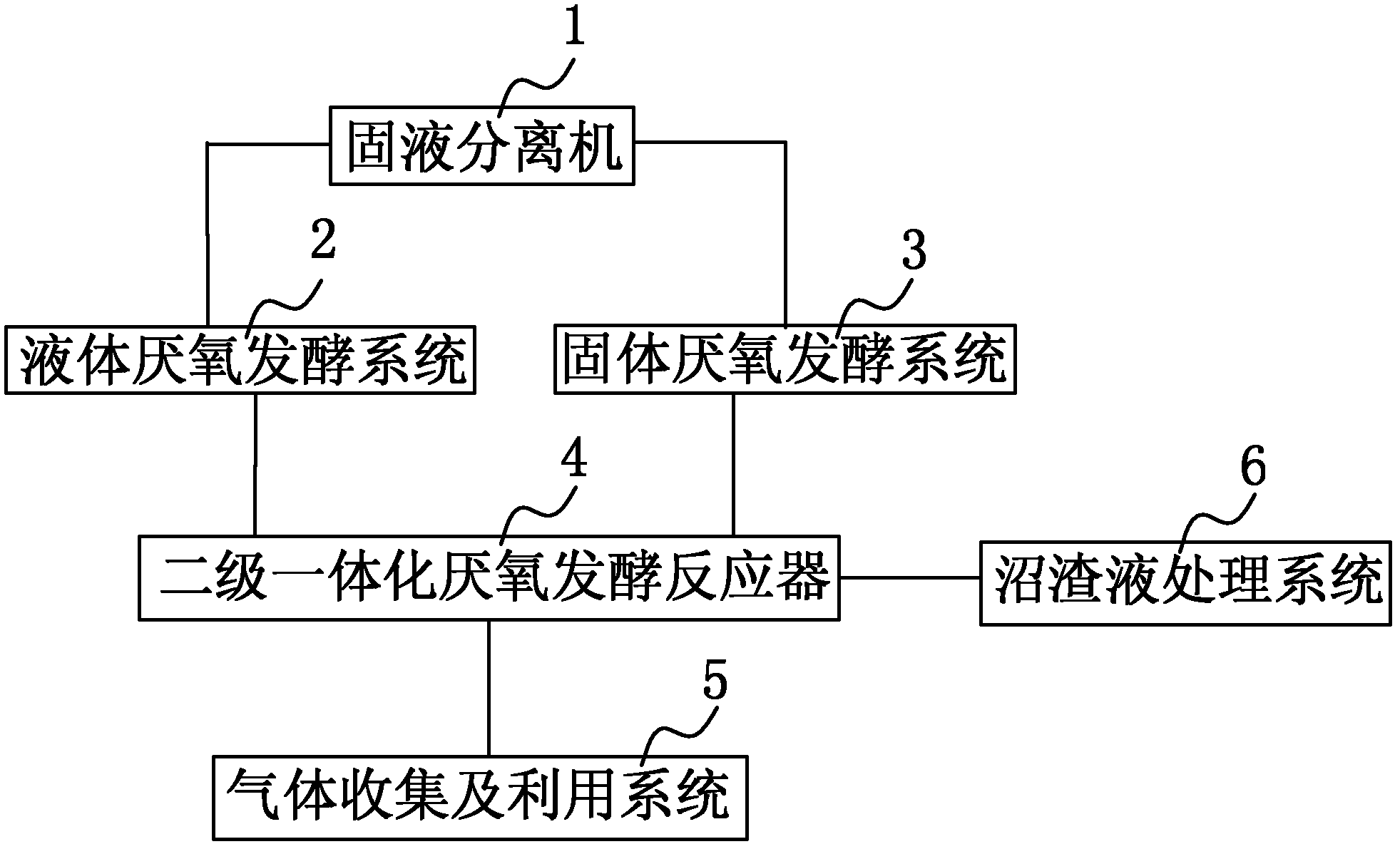

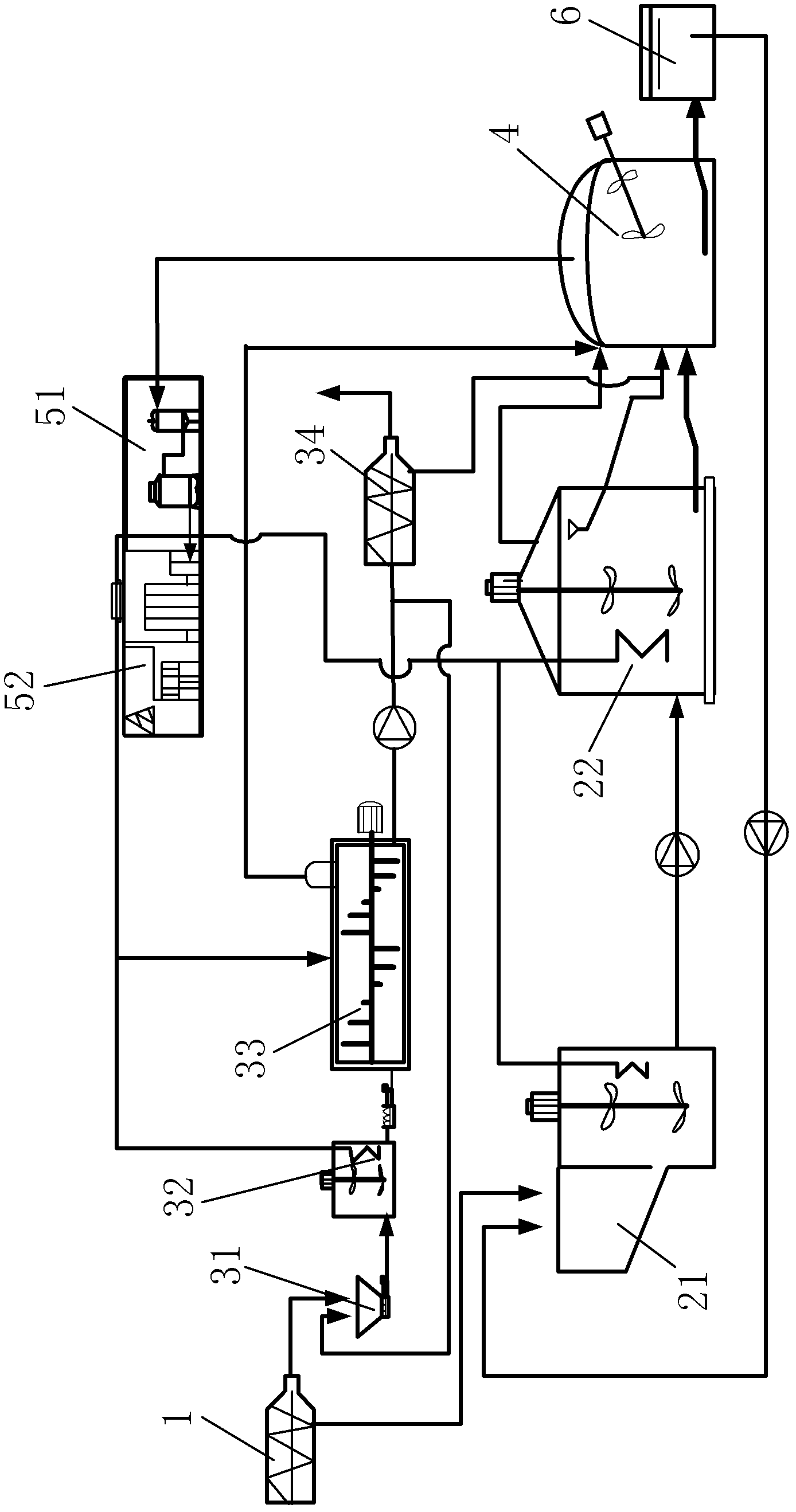

Method and device for producing biogas by solid organic waste

ActiveCN102321673ASimple preprocessingProcess operation management is simpleBiological substance pretreatmentsSolid waste disposalBiogasChemistry

A method and a device for producing biogas by solid organic wastes. The method comprises the following steps of: a pretreatment step; a solid-liquid separation step; a liquid anaerobic fermentation step; a solid anaerobic fermentation step; a secondary integrated anaerobic fermentation step, and a biogas collection utilization and residue liquid treatment step. The device comprises a solid-liquid separator, a liquid anaerobic fermentation system, a solid anaerobic fermentation system, a secondary integrated anaerobic fermentation reactor, a gas collection and utilization system, and a biogas residue liquid treatment system; the solid-liquid separator is connected with the liquid anaerobic fermentation system and the solid anaerobic fermentation system respectively; the liquid anaerobic fermentation system and the solid anaerobic fermentation system are connected with the secondary integrated anaerobic fermentation reactor respectively; the secondary integrated anaerobic fermentation reactor is connected with the gas collection and utilization system and the biogas residue liquid treatment system respectively. The invention realizes the harmless treatment and energy utilization of organic wastes.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

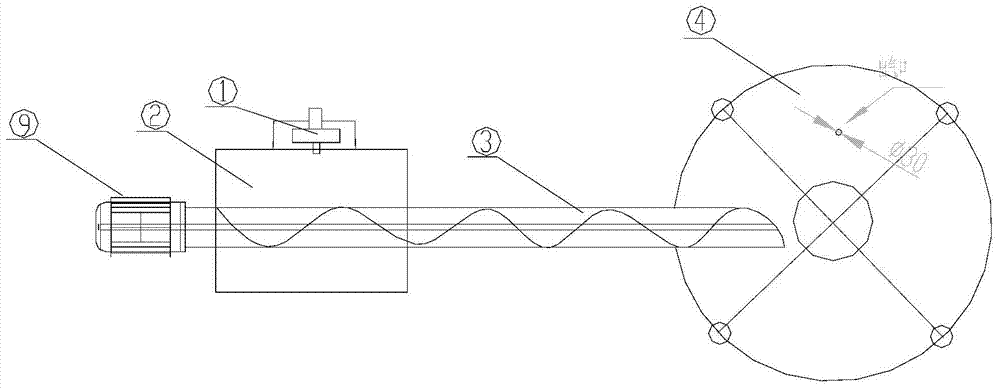

Horizontal stirring methane fermentation device with vertical cylindrical tank

ActiveCN102321528ALow thermal conductivityLow costBioreactor/fermenter combinationsBiological substance pretreatmentsProduction rateBiochemical engineering

The invention relates to a horizontal stirring methane fermentation device with a vertical cylindrical tank. The device is a cylindrical vertical fermentation tank, wherein clapboards are longitudinally arranged in a tank body and parallel to one another; the middle part of the tank body is provided with at least one group of horizontal stirrers; a feeding hole is formed outside the tank body corresponding to the first clapboard; a discharge hole is formed outside the tank body corresponding to the last clapboard, is lower than the feeding hole and is connected with a liquid delivery pipeline; an overhaul well is arranged outside the semispherical top of the tank body; and a gas guide pipe and a gas exhaust pipe are arranged on the side wall of a shaft of the overhaul well. The device effectively solves the problems of miniaturization, low concentration, high construction cost, high operating cost, incomplete reaction, abnormal gas production in winter and the like of the conventionalmethane tank, effectively solves the problems of direct current and non-uniform mixing, is high in gas production rate, cannot be incrusted, is low in operating cost and construction cost, and is particularly suitable for the large-scale industrial, intensive and commercial production of methane.

Owner:朱林

Dry straw fermentation device

InactiveCN102517201AAvoid heatingReduce dosageGas production bioreactorsSolid phase fermentation bioreactorsWater useResource utilization

The invention provides a dry straw fermentation device. In the dry straw fermentation device, straw is discharged in a way of combining upward push flow with a mechanical structure, straw is fed from a straw feeding hole at the bottom of a fermentation tank body, the straw fed at an earlier stage is pushed upwards to form upward push flow, finally enters a gravity precipitator, and is discharged through a spiral conveyer, so that material change is completed; in a material changing way, the straw is prevented from forming hardening and a tower-bridge phenomenon easily, and fermentation is performed in combination with spraying, so that active sewage can be contacted fully with straw, and the gas producing rate is increased; by adopting a dry fermentation technology and circular utilization of active sewage, the water using amount is greatly reduced, sewage is drained hardly, and the resource utilization ratio is high; and moreover, a heat exchange pipe is arranged at the bottom of the fermentation tank body, so that the temperature of active sewage and the internal temperature of the fermentation tank can be kept, the fermentation temperature is kept at about 35 DEG C, and a best fermentation effect is achieved.

Owner:BIOGAS SCI RES INST MIN OF AGRI

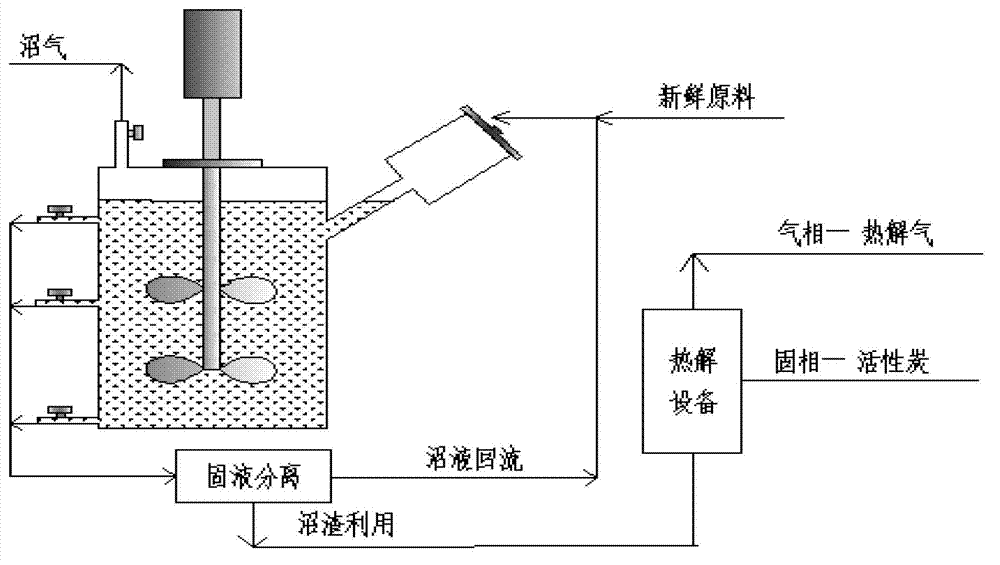

Method for processing industrial wastes of edible vinegar through anaerobic digestion coupling pyrolysis technology

InactiveCN103088073AIncrease gas production rateAdd lessWaste based fuelFermentationSingle stageGeneration rate

The invention discloses a method for processing industrial wastes of edible vinegar through an anaerobic digestion coupling pyrolysis technology, and belongs to the field of the high-efficiency recycle of organic solid wastes. The method comprises the following steps: mixing vinegar residues with water and an inoculum, adding the obtained mixture to a CSTR anaerobic digestion reactor, and carrying out an anaerobic digestion biogas generation reaction; and carrying out solid-liquid separation of an anaerobic digestion reaction discharge material, mixing the obtained separated biogas slurry with new vinegar residues to a constant volume, allowing the obtained new mixture to the CSTR reactor, continuously carrying out the anaerobic digestion biogas generation reaction, drying the obtained biogas residues, allowing the dried biogas residues to enter a single-stage tubular pyrolysis furnace, and carrying out a pyrolysis reaction. Compared with the prior art, the method disclosed in the invention has the advantages of enhancement of the stability and the load change buffer capability of an anaerobic digestion system, improvement of the biogas generation rate and the recycle rate of the vinegar residues, and simultaneous reaction of the liquid phase product proportion of the pyrolysis process.

Owner:BEIJING UNIV OF CHEM TECH

Liquid fuel and preparation method thereof

InactiveCN101886001AEasy to prepareHigh yieldLiquid carbonaceous fuelsHazardous substanceLiquid fuel

The invention relates to a liquid fuel and a preparation method thereof. The liquid fuel is prepared by completely stirring the complex of alkylamine and alkyl borane, which serves as a main raw material, and hydrogenated light distillate and aluminum ethyl, which serve as auxiliary materials, under the normal temperature and the normal pressure. The liquid fuel has the characteristics of high heat sink, more pyrolysis products, high eneyne hydrocarbon product selectivity, low coking rate, particular suitability for heat transfer under the supercritical condition of 500 to 1,100 DEG C, simple preparation method and the like. The combustion product of the preparation method does not contain any toxic and harmful substance and meets the environmental requirement.

Owner:BEIJING POWER MACHINERY INST

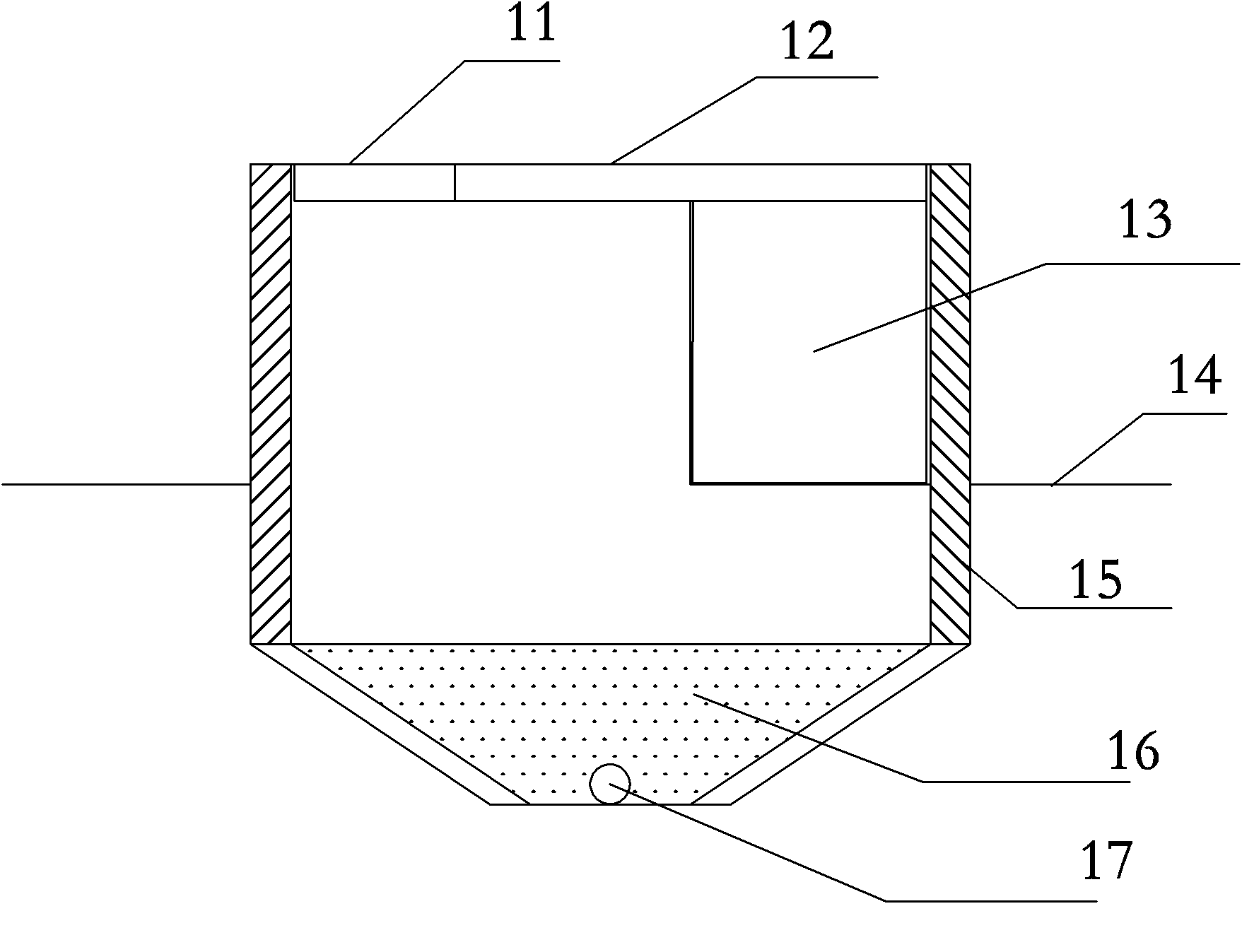

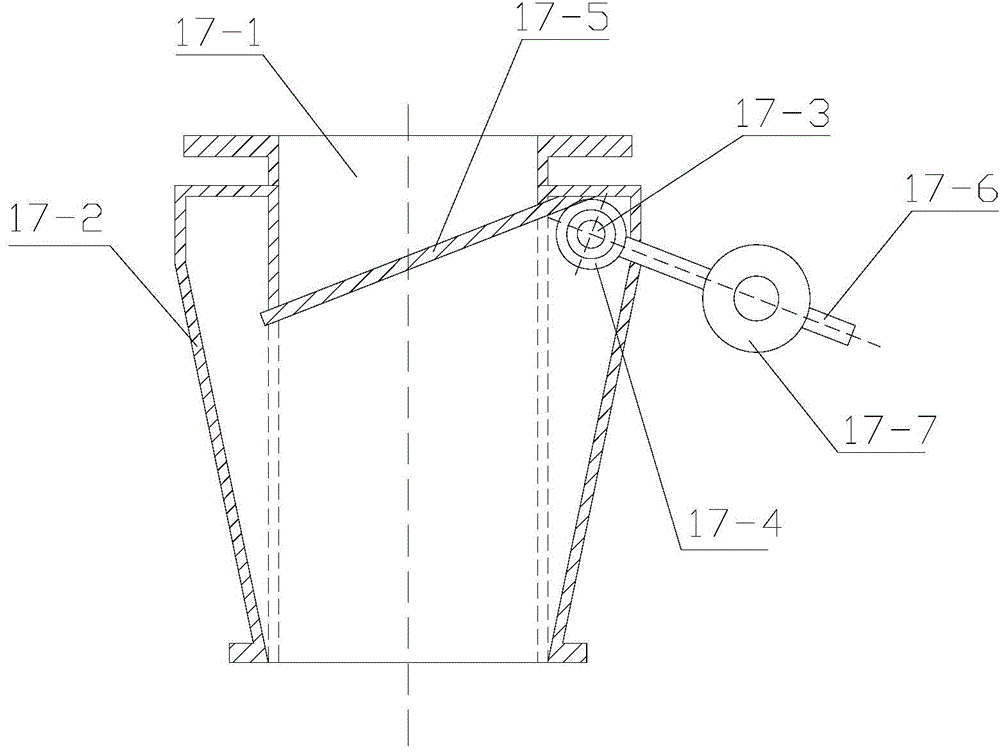

Pretreatment system and method for raw anaerobic fermentation material

ActiveCN102225833AOvercoming high impurity contentOvercoming separationWaste based fuelBiological sludge treatmentPretreatment methodFrost

The invention discloses a pretreatment system and method for raw anaerobic fermentation materials. The pretreatment system comprises a pretreatment pool filled with raw anaerobic fermentation materials, wherein dilution, stirring and settlement layering of the raw anaerobic fermentation materials are carried out in the pretreatment pool so as to enable the materials to be divided into a top layerof scum silica frost, a middle layer of nutriments and a bottom layer of sand settling; a grating ditch communicating with the pretreatment pool, wherein the scum silica frost in the top layer and the nutriments in the middle layer of the pretreatment pool pass through the grating ditch and scum silica frost is filtered; and a sand-water separator with one end extending into the bottom of the pretreatment pool and the other end extending out of the pretreatment pool, wherein the sand-water separator sucks in the sand settling in the bottom layer and separates sand from water. According to theinvention, the problems in existing anaerobic fermentation technology for the production of biogas that raw materials are difficult to purify and subsequent processing has great load are overcome; utilization rate of the raw materials is enhanced; and running cost is reduced.

Owner:北京联合创业环保工程股份有限公司

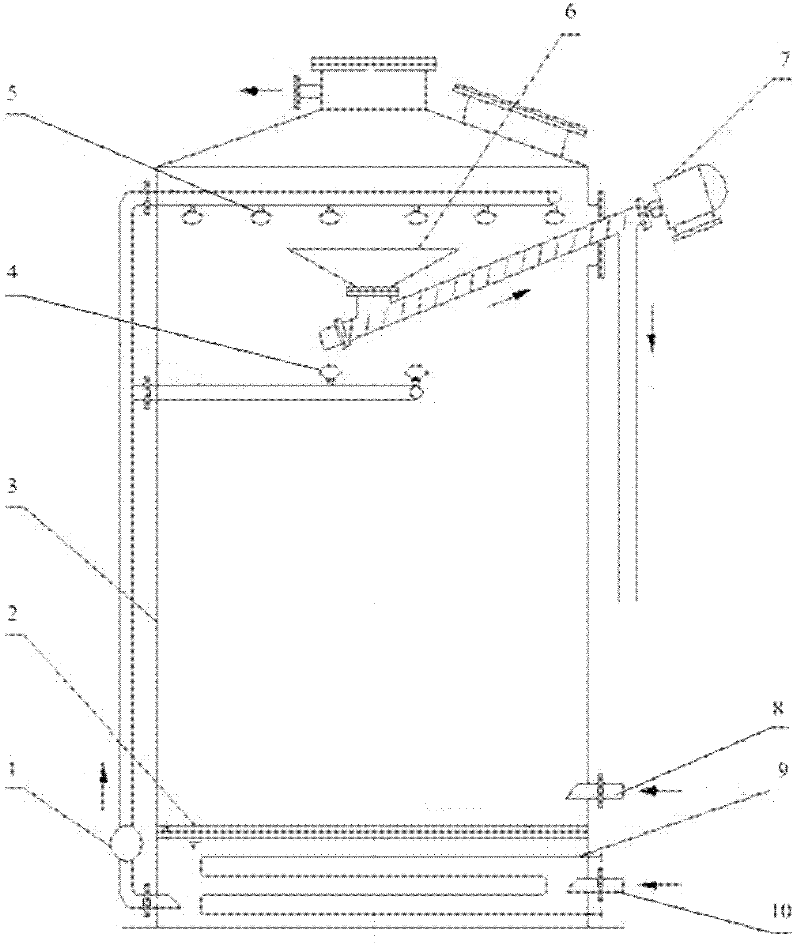

Constant-temperature biogas tank with sewage source heat pump

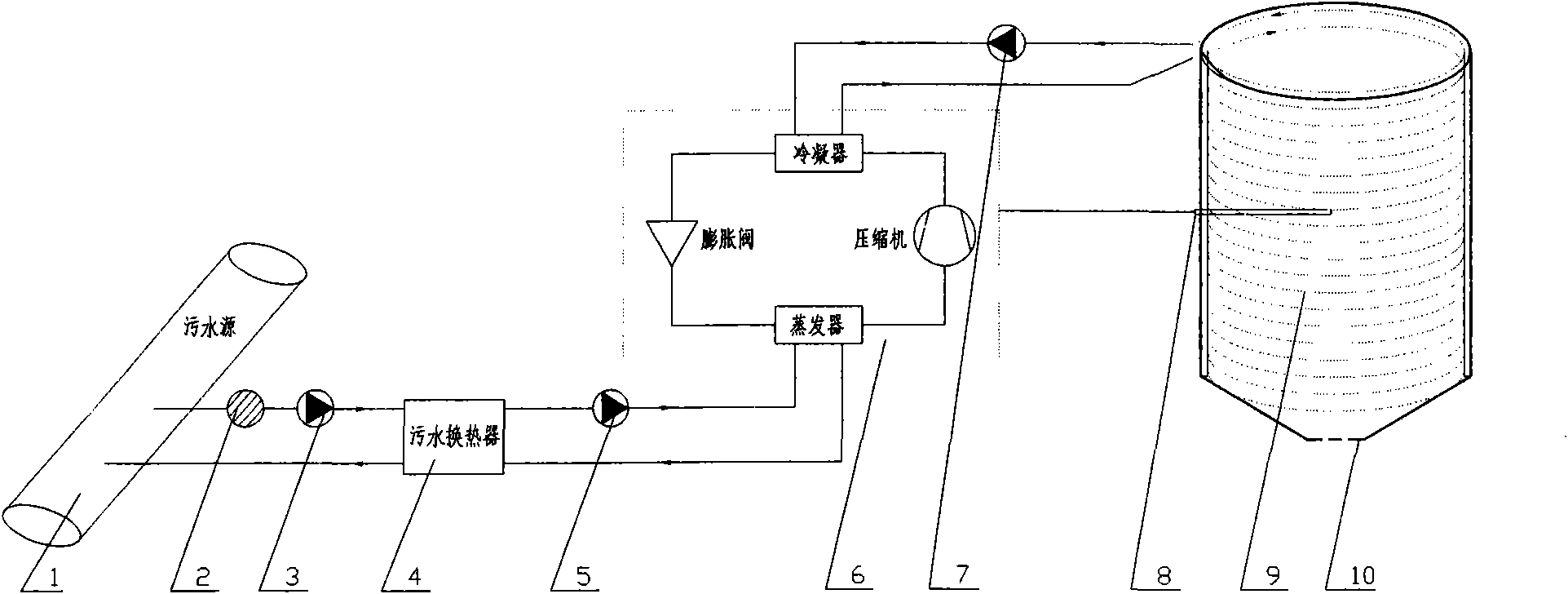

InactiveCN101603001AIncrease gas production rateReduce energy consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasEvaporator

The invention discloses a constant-temperature biogas tank with a sewage source heat pump, which belongs to the field of energy conservation and environmental protection. The constant-temperature biogas tank with the sewage source heat pump comprises a sewage source 1, a fully-automatic filter 2, a sewage circulating pump 3, a sewage heat exchanger 4, circulating water pumps 5, a sewage source heat pump unit 6 (an evaporator, a compressor, a condenser, and an expansion valve), a circulating water pump 7, a temperature sensor 8, a heating coil 9 and a biogas tank 10. The sewage source heat pump unit is connected with water return pipelines of sewage and water supply and return pipelines of hot water, and can realize the programmable control of a PLC; the sewage source is connected with the water supply and return pipelines of the sewage to form closed circulation; the circulating water pumps are arranged on the water return pipes of the sewage and the hot water respectively, and the automatic starting / stopping of the circulating water pumps is controlled by the sewage source heat pump unit; the heating coil is fixed on the inner wall of the biogas tank, and forms a loop with the sewage source heat pump unit through a heating pipe; and the temperature sensor is arranged in the dry fermentation biogas tank, monitors the temperature in the tank at any time, is in interlocking control with the heat pump unit, and controls the starting / stopping of the sewage source heat pump unit. The heating coil is fixed on the inner wall of the biogas tank. The invention can ensure that the biogas tank can operate all year around and is not affected by environmental factors and geographic factors, and can improve the biogas yield of the biogas tank.

Owner:UNIV OF SCI & TECH BEIJING +1

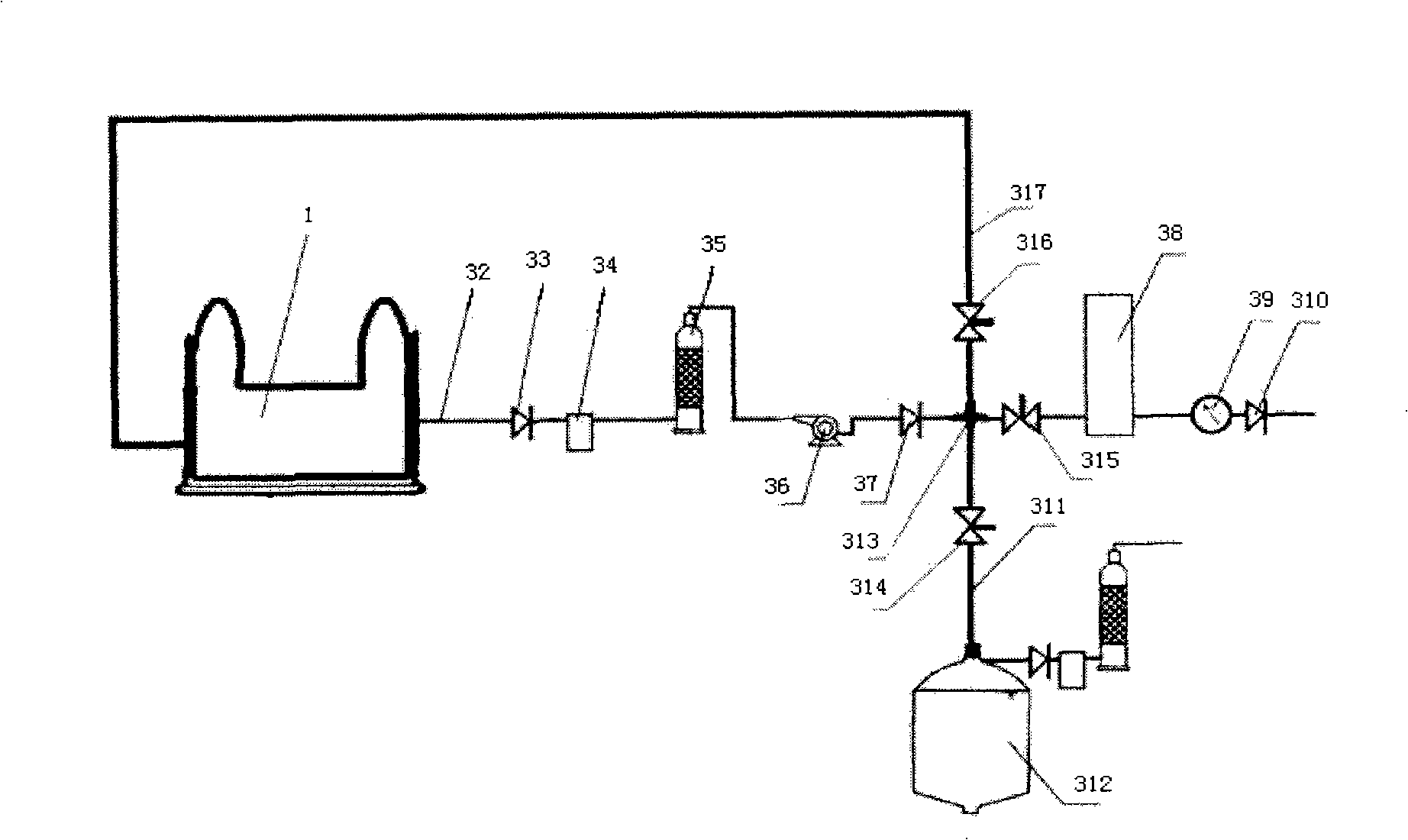

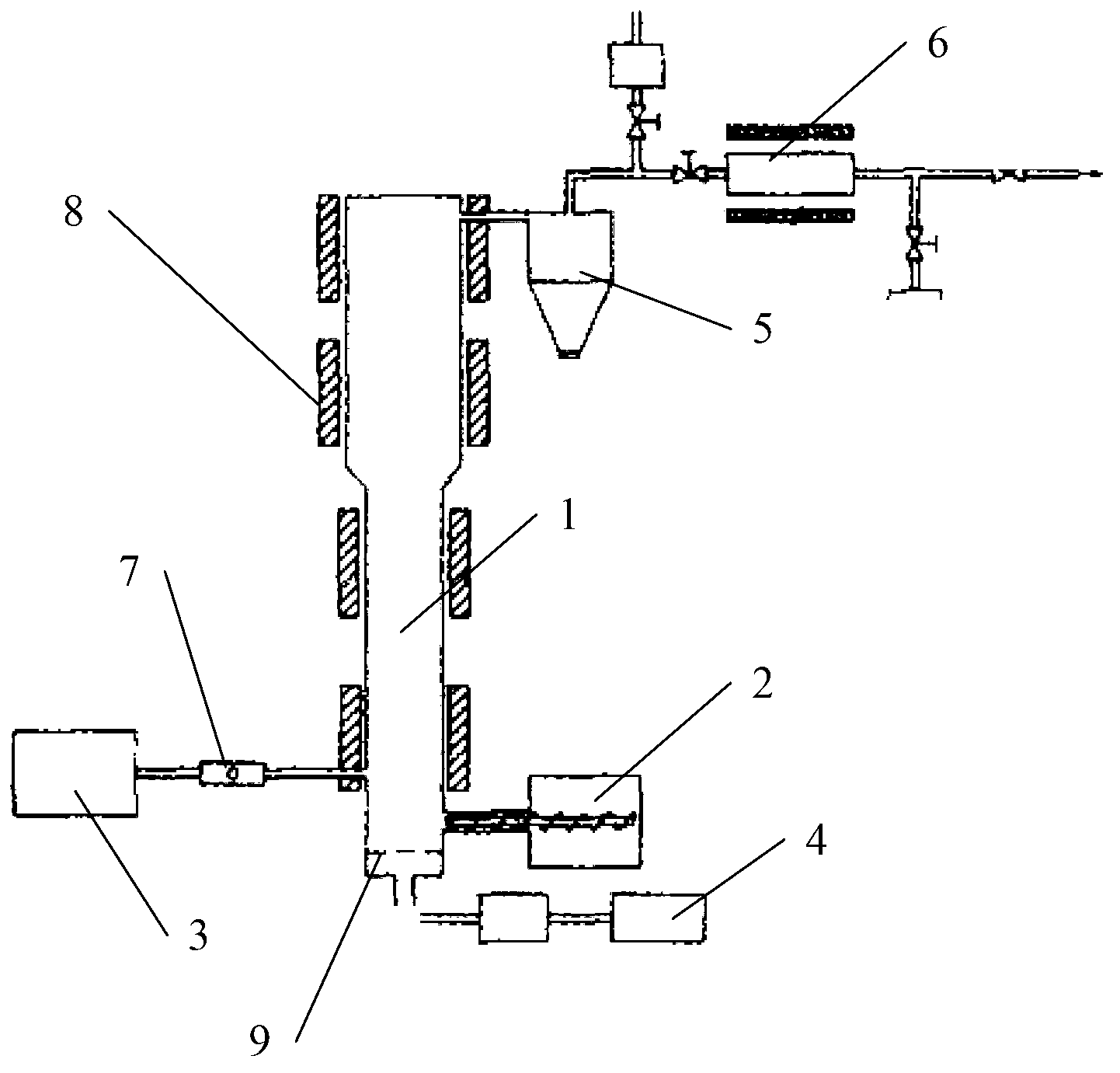

Laboratory continuous biogas anaerobic fermentation device

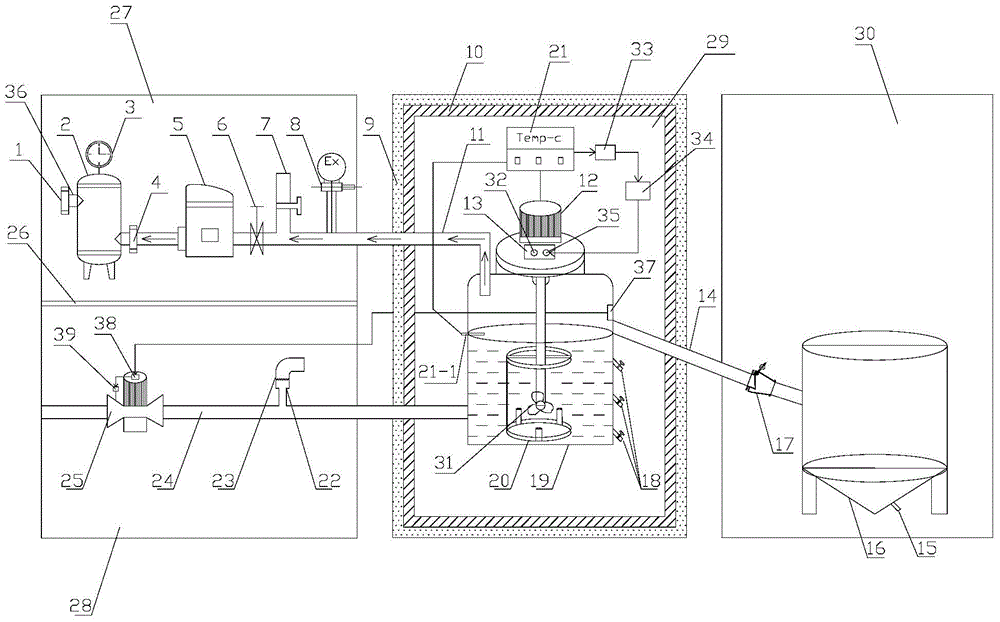

ActiveCN104357322AHeating evenlyGuaranteed uniformityBioreactor/fermenter combinationsBiological substance pretreatmentsGas compressorInlet valve

The invention discloses a laboratory continuous biogas anaerobic fermentation device. The laboratory continuous biogas anaerobic fermentation device comprises a gas collection and storage chamber, a feeding chamber, a fermentation chamber and a biogas residue and biogas slurry chamber, wherein a fermentation tank, a fermentation temperature controller and a vertical mixer are arranged in the fermentation chamber; a mixing blade and an electric heating element are mounted on the mixing rod of the vertical mixer; a plurality of outlets are formed in the sidewall of the body of the fermentation tank; a feeding pipe is arranged in the feeding chamber and a circulating pump and an exhaust pipe are connected to the feeding pipe; a gasholder is arranged in the gas collection and storage chamber, the middle lower part of the gas holder is communicated with the upper part of the fermentation tank by use of a gas collecting pipe, and a gas flowmeter, a pipeline valve, a gas compressor, a gas inlet valve and a gas distribution pipe are connected to the gas collecting pipe; a biogas residue and biogas slurry storage tank is arranged in the biogas residue and biogas slurry chamber, the middle upper part of the biogas residue and biogas slurry storage tank is communicated with the middle upper part of the fermentation tank by use of a waste discharge pipe and a flap valve, and a waste liquid outlet is formed in the bottom of the biogas residue and biogas slurry storage tank. The laboratory continuous biogas anaerobic fermentation device has the advantages that fermentation raw materials can be added to the fermentation tank any time and continuous biogas anaerobic fermentation can be realized based on the laboratory platform.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

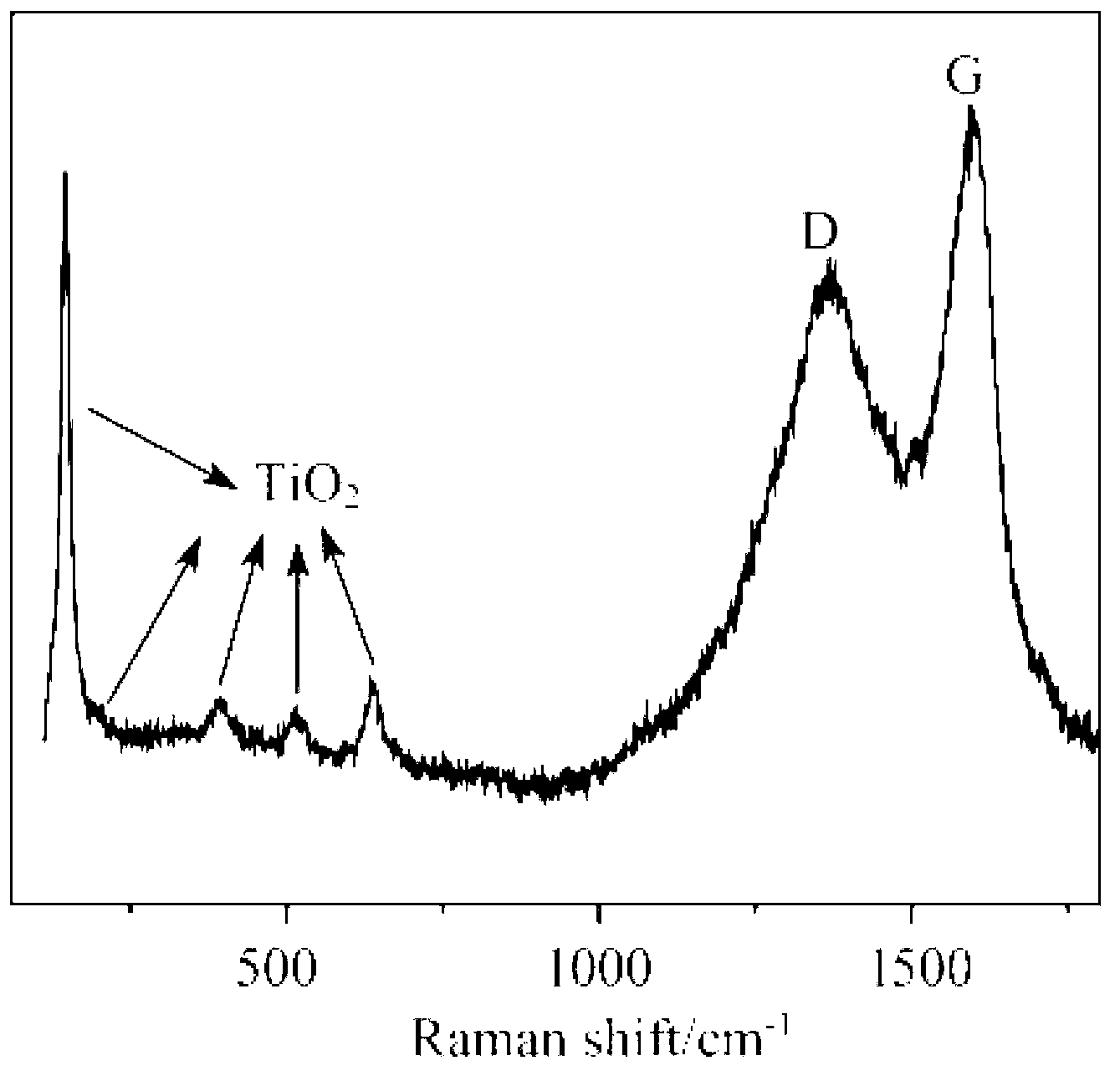

Method for preparing fuel gas by burning biomass

InactiveCN103242922AReduce tar contentIncrease gas production rateGaseous fuelsGas purification by non-gaseous materials condensationTarBiomass

The invention provides a method for preparing fuel gas by burning biomass. The method comprises the following steps of: firstly, smashing, namely smashing a biomass reaction material; secondly, gasifying, namely gasifying the smashed biomass reaction material to generate synthesis gas; thirdly, primarily purifying, namely removing particulate matter, acidic gas and tar in the synthesis gas obtained by the step two; fourthly, deeply purifying, namely removing sulphide in the synthesis gas obtained by primary purification; fifthly, carrying out methanation, namely carrying out methanation on the synthesis gas purified by the step four to obtain fuel gas; and sixthly, improving quality of gas, namely removing saturated steam, CO2 and unreacted H2 and N2 in the fuel gas subjected to methanation. By adopting the method, two different catalysts are used, so that content of tar produced by burning the biomass is reduced, and gas production rate is increased.

Owner:青岛新奥胶城燃气有限公司

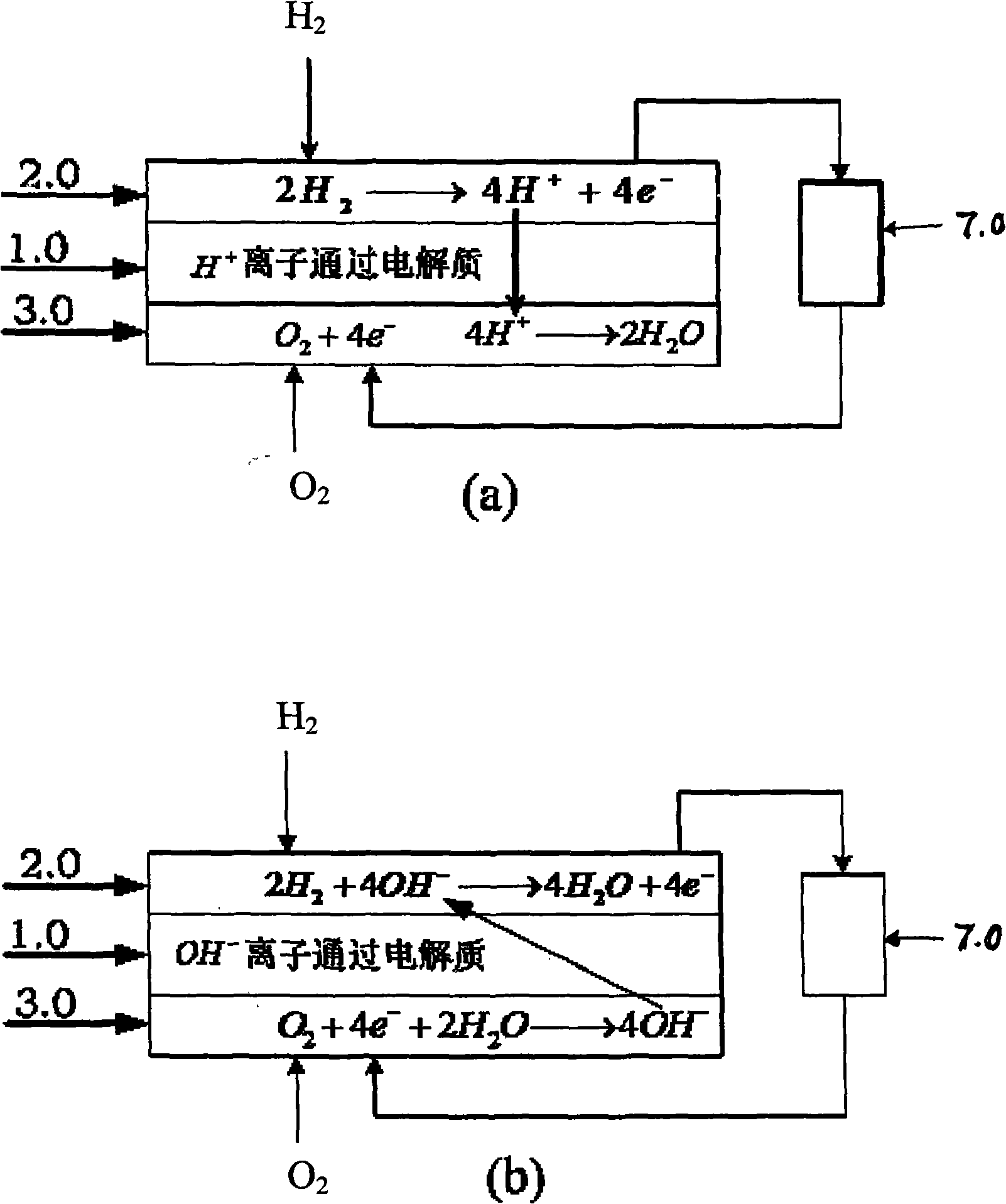

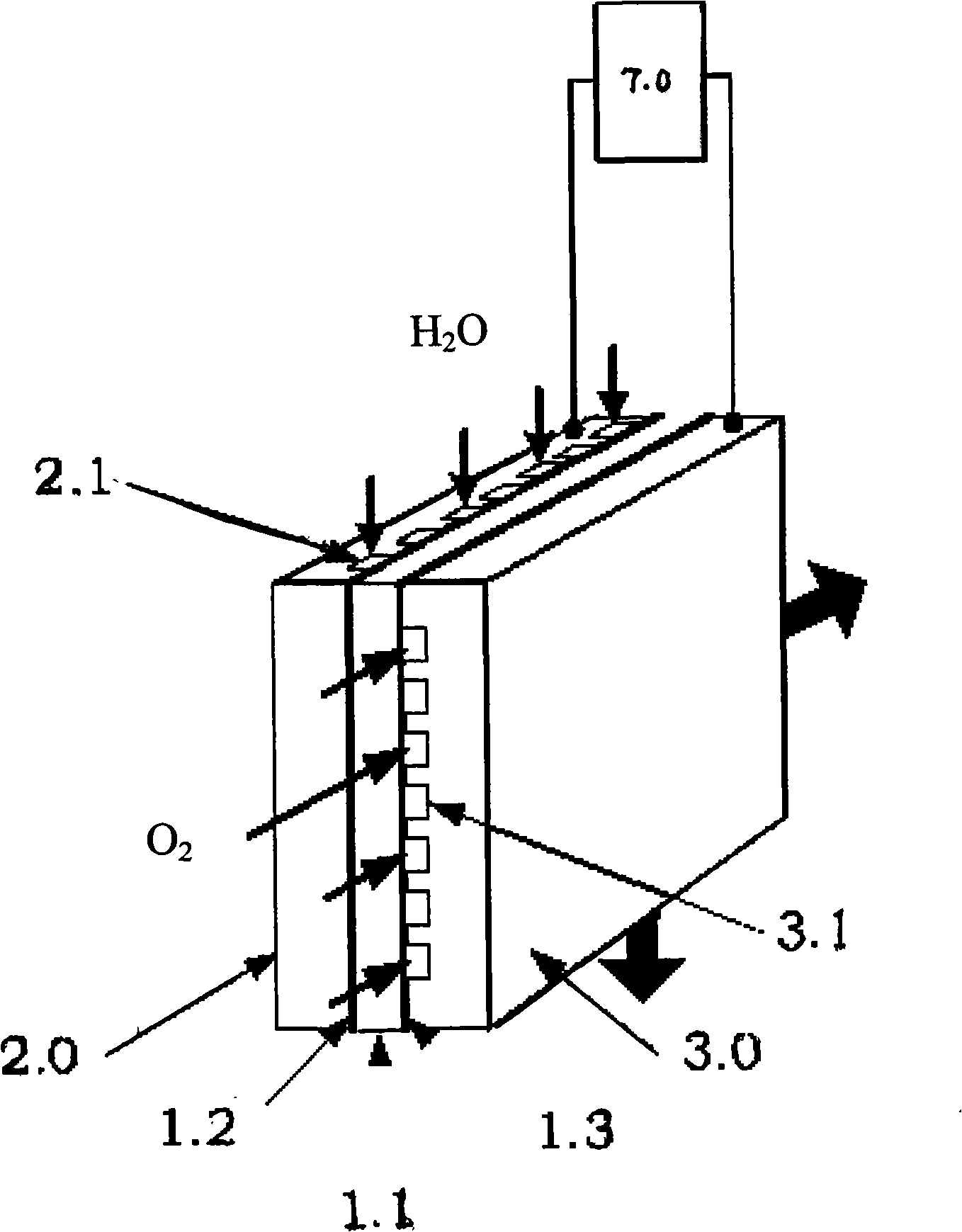

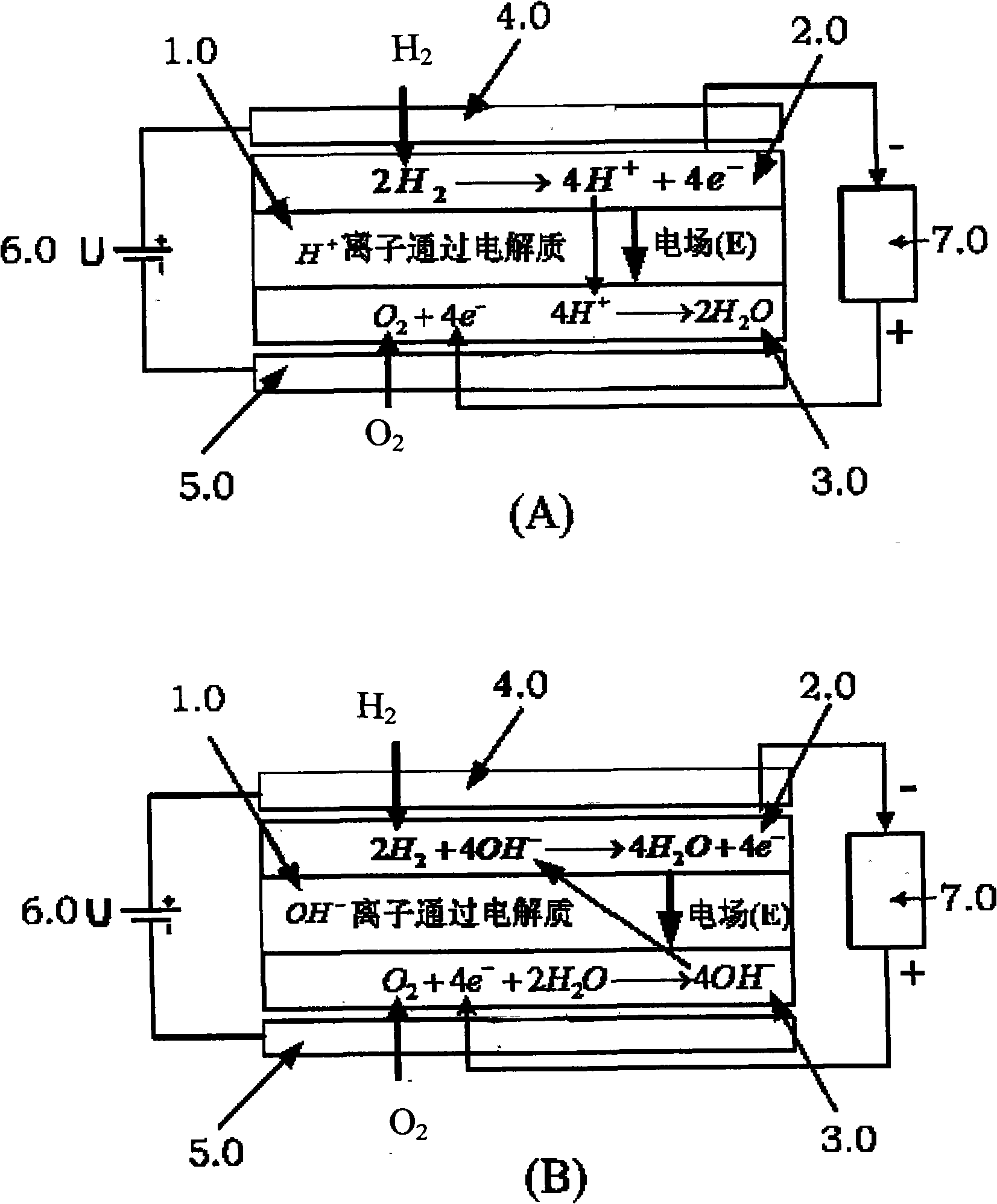

Fuel battery unit with electric field-membrane electrode combined structure and a reversible regenerable oxyhydrogen electrolysis unit thereof

ActiveCN101540409AReduce activation lossImprove performanceCellsBatteries circuit arrangementsElectric fieldOhm

The invention relates to a fuel battery unit with an electric field-membrane electrode combined structure and a reversible regenerable oxyhydrogen electrolysis unit thereof. The fuel battery unit has the structure that electrolyte is arranged between an anode and a cathode. The fuel battery unit is characterized in that an electric field anode insulated with the anode is arranged outside the anode; an electric field cathode insulated with the cathode is arranged outside the cathode; and the electric field anode and the electric field cathode are connected with a DC power supply. The fuel battery unit with the electric field-membrane electrode combined structure can effectively reduce the activation loss, the penetration of the fuel, the internal short-circuit current and the ohm loss, improves the performance of the fuel battery unit and overcomes the defect that prior fuel battery units cannot reduce the activation loss. The application of the fuel battery unit with the electric field-membrane electrode combined structure in the reversible regenerable oxyhydrogen electrolysis unit can also reduce the activation loss and improve the electrolysis efficiency.

Owner:郭建国 +1

Low-pressure gas well two-fluid supersonic atomization drainage gas recovery system and process thereof

InactiveCN105443088ASolve the problem of drainage and gas extractionSolve effusionFluid removalVapor liquidVapor–liquid separator

The invention belongs to the technical field of drainage gas recovery process, and specifically provides a low-pressure gas well two-fluid supersonic atomization drainage gas recovery system and a process thereof, wherein a wellbore is taken as a good gas-liquid separator, and gas in a casing pipe is introduced to a Laval nozzle to form supersonic gas flow; by utilizing the characteristic that the air pressure of the casing pipe is higher than that of an oil pipe, accumulated liquid in a well is introduced to a supersonic area of the Laval nozzle through the oil pipe, so as to form a two-fluid supersonic atomization technology. Moreover, through a control method of digitized gas recovery, the ratio of pressure at an inlet to pressure at an outlet, entering an atomizer reaches an atomization condition, through a constant pressure valve switching technology and a diameter extra-long pipe restriction decompression technology, the maximum flow of accumulated liquid entering the atomizer is controlled, the vapor liquid ratio of atomization liquid drainage is reached, and the critical technical problem that the atomizer is liable to block is solved. The system and the process thereof, provided by the invention can effectively utilize energy in the well to perform atomization liquid drainage, solve the problem of accumulated liquid in the well, improve the gas recovery speed and reduce gas recovery cost.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

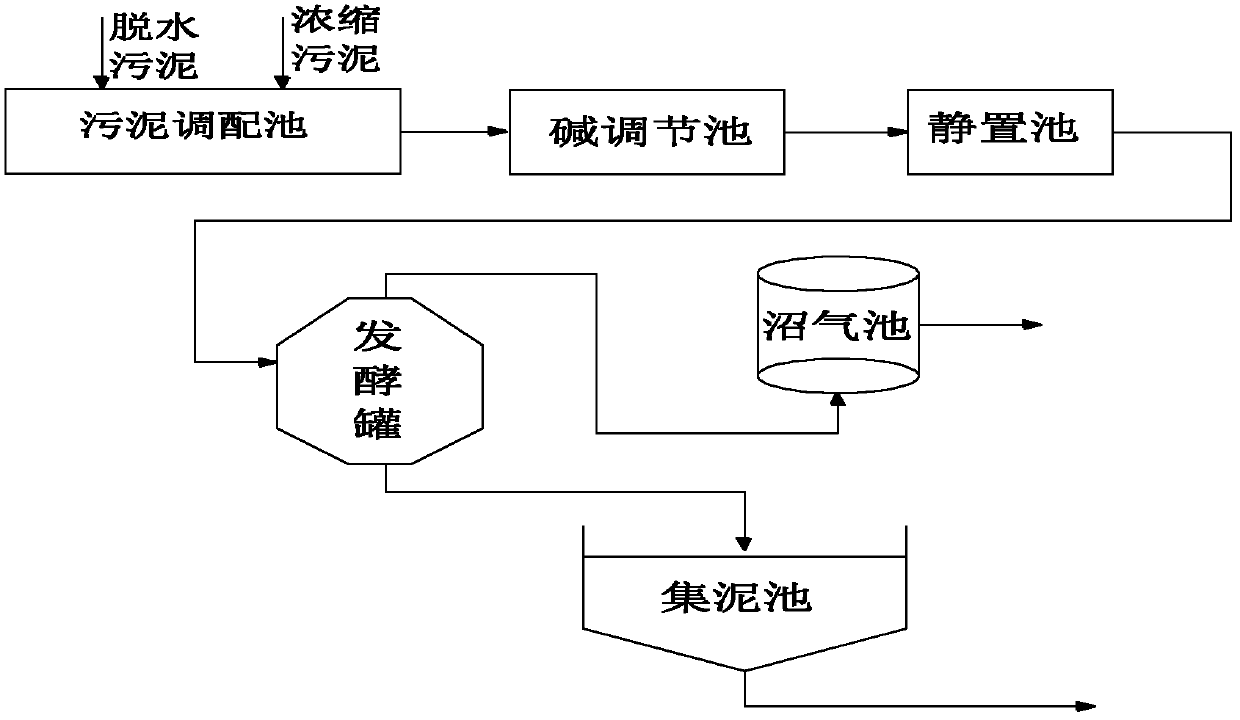

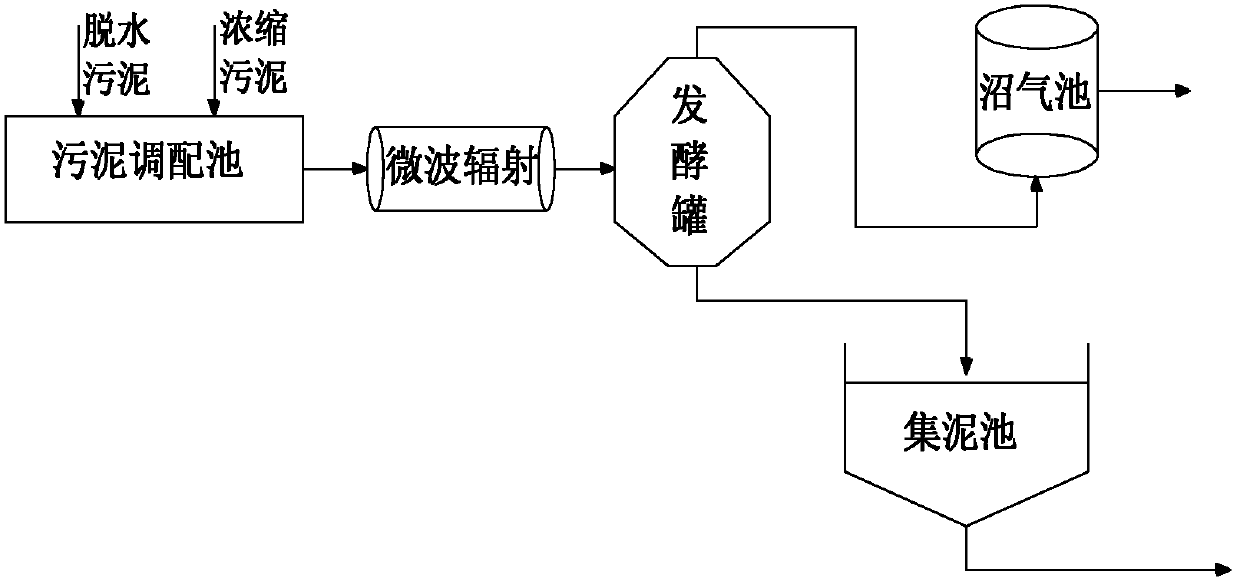

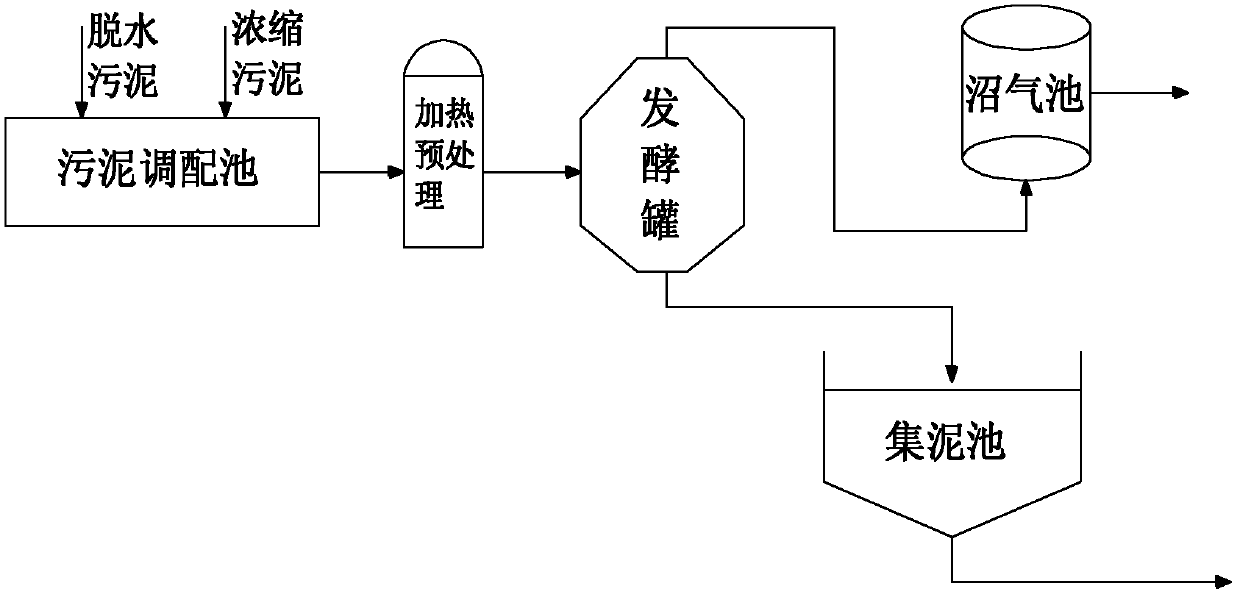

Method for improving methane yield through anaerobic fermentation of low organic matter sludge by pretreatment

InactiveCN102603141AImprove the efficiency of anaerobic fermentation gas productionPromote resource utilizationWaste based fuelBiological sludge treatmentStart timeMethane yield

The invention belongs to the technical field of solid waste reclamation, and discloses a method for improving methane yield through anaerobic fermentation of low organic matter sludge by pretreatment. The method comprises the following steps of: preparing concentrated sludge and dewatered sludge into mixed sludge for pretreatment; carrying out anaerobic fermentation on the mixed sludge as a feedstock and discharging sludge the volume of which is the same as that of the mixed sludge; and collecting methane. By using the method, the efficiency of producing methane by anaerobic fermentation of the low organic matter sludge is improved, methane production quantity is stable, the energy consumption is low, the application is convenient, and further, and the sludge reclamation is further promoted; the anaerobic starting time of the low organic matter sludge is shortened, the total quantity of methane produced by anaerobic digestion of the low organic matter sludge is increased, and the reclamation utilization of the low organic matter sludge is promoted.

Owner:TONGJI UNIV

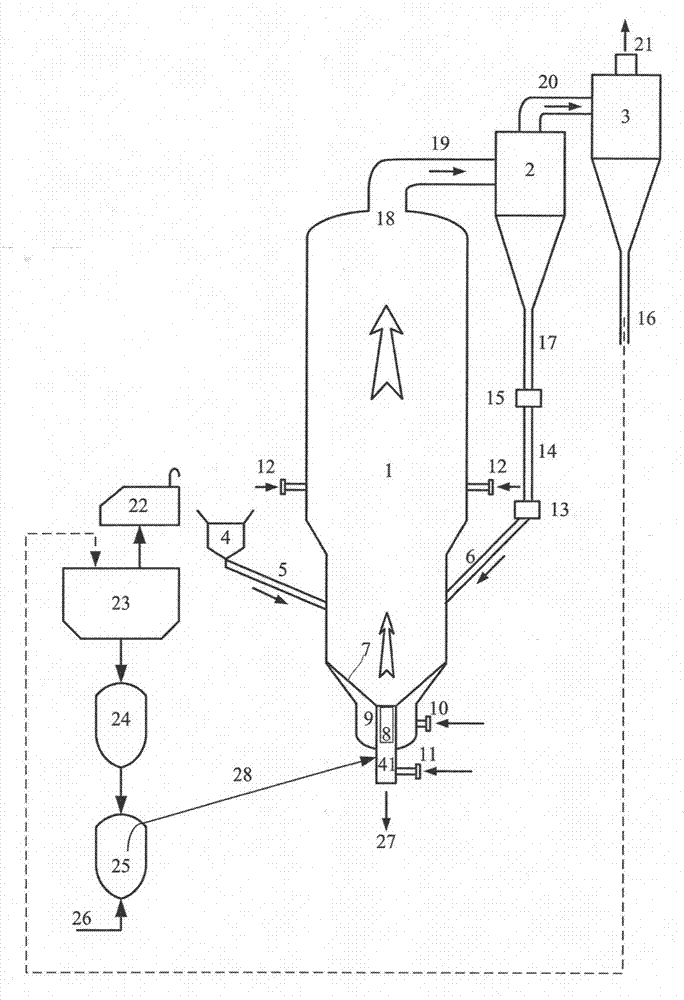

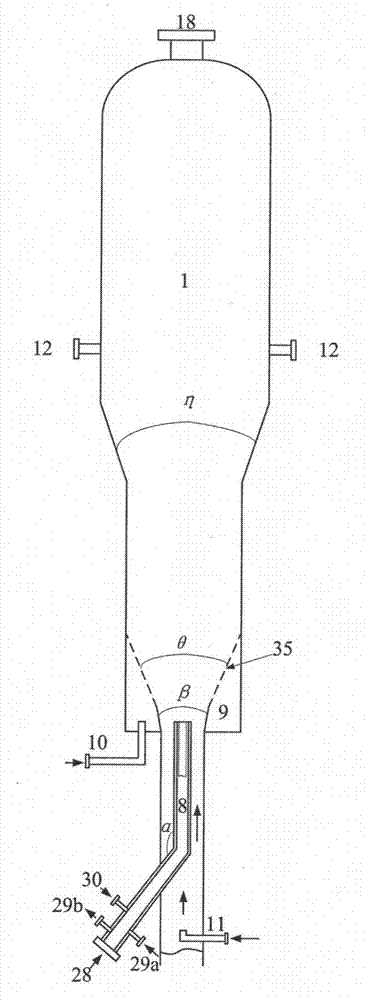

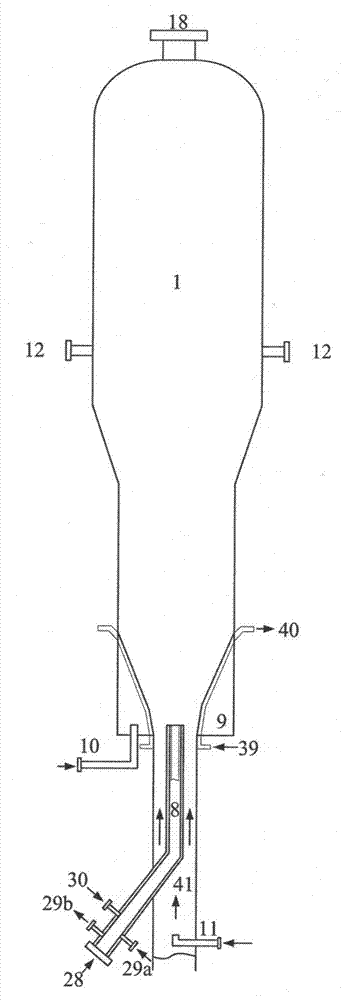

Compound circulating fluidized bed gasification reaction device

ActiveCN104498103AImprove adaptabilityIncrease temperatureGasifier feeding meansGasification processes detailsCycloneFluidized bed

The invention provides a compound circulating fluidized bed gasification reaction device. The compound circulating fluidized bed gasification reaction device comprises a reactor body, a multistage cyclone separator, a particle fuel feeding system, a powder fuel feeding system, a central jet flow gasification burner nozzle and a material returning system, wherein the outlet of the reactor is connected with a primary cyclone separator; the primary cyclone separator is connected with a secondary cyclone separator; crude particles separated by the primary cyclone separator are returned to a gasification furnace body by virtue of the material returning system; fine particles separated by the secondary cyclone separator enter the central jet flow gasification burner nozzle by virtue of the powder fuel feeding system and are finally sprayed to the gasification furnace body. A circulating fluidized bed reactor is used as a gas reaction body; the slag is continuously discharged by gasifying at a medium-high temperature; by virtue of application of high-temperature jet flow two-stage grading gasification, the carbon conversion rate and the cold gas efficiency are increased; a simplified slag discharging device is combined with the design of an air distributing plate; the operation stability and the running stability are improved; the compound circulating fluidized bed gasification reaction device is suitable for gasifying and converting various carbon-containing solid fuels and has large-scale popularization and application prospects.

Owner:SHANGHAI BOILER WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com