Method and device for producing biogas by solid organic waste

A technology of organic waste and biogas, which is applied in the fields of solid waste removal, biochemical equipment and methods, waste fuel, etc., can solve problems such as heat transfer difficulties, secondary pollution, dry fermentation feeding and discharging, difficulties, etc., and achieve process Simple operation and management, good environmental and economic benefits, and small biogas slurry production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

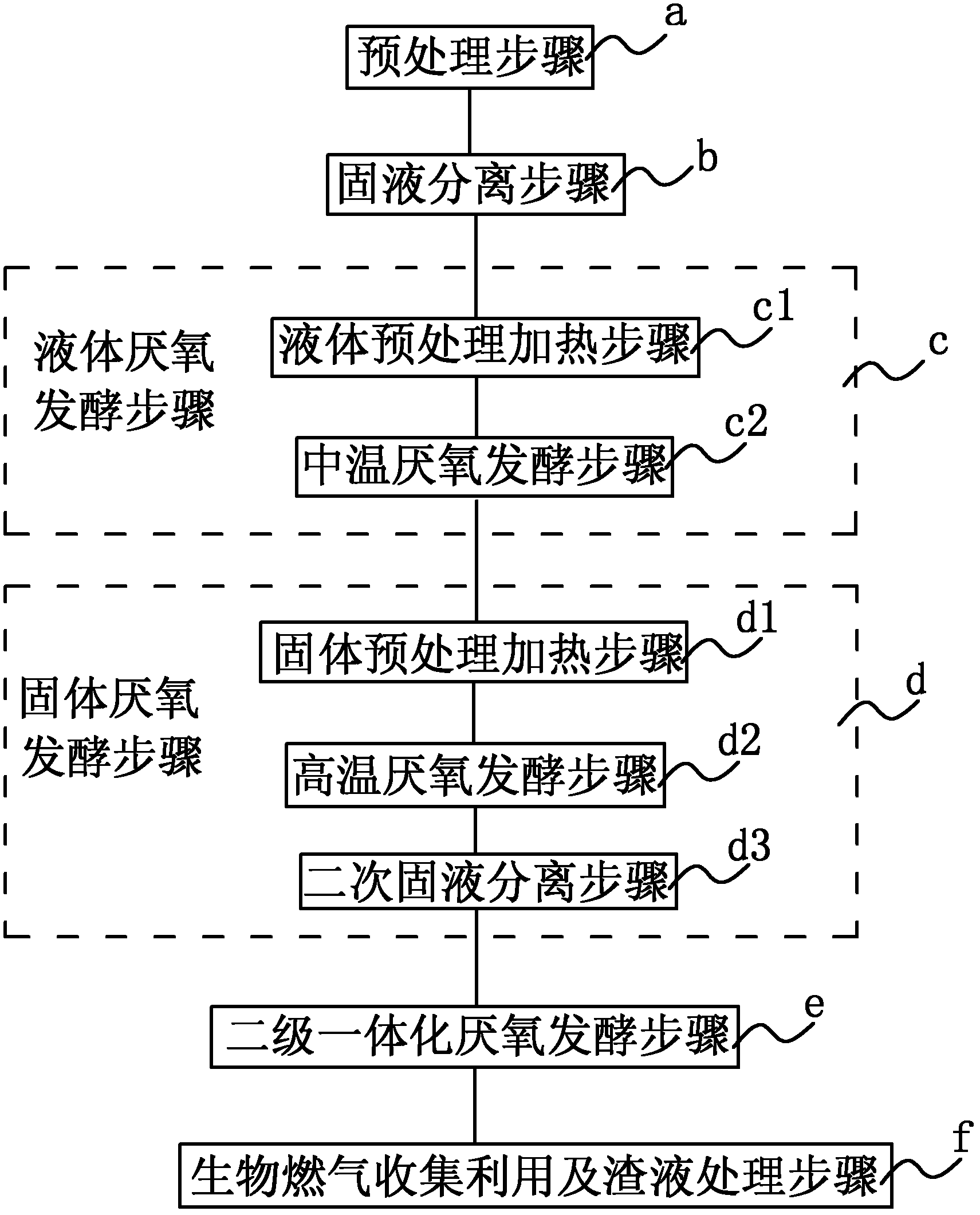

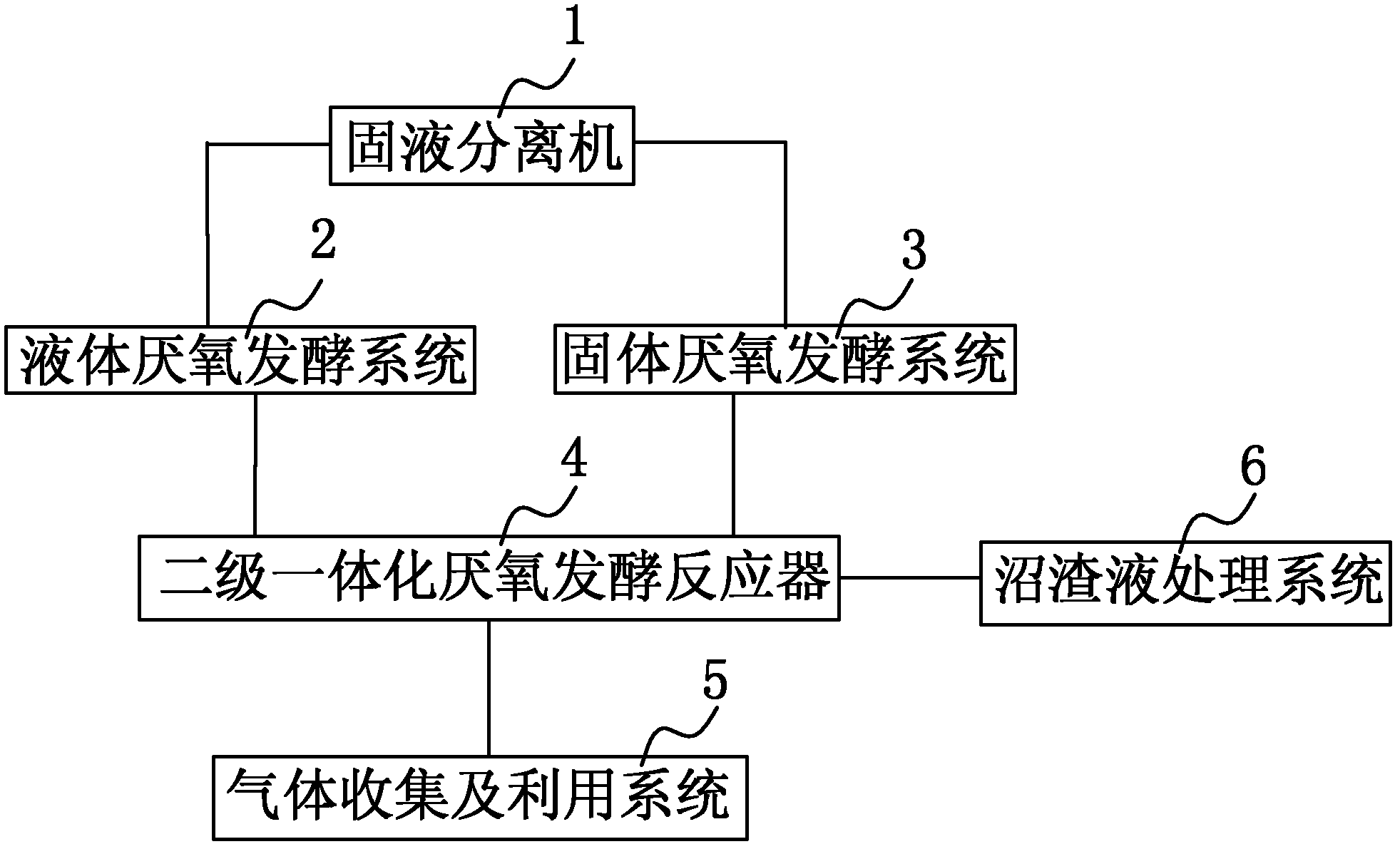

Method used

Image

Examples

Embodiment 1

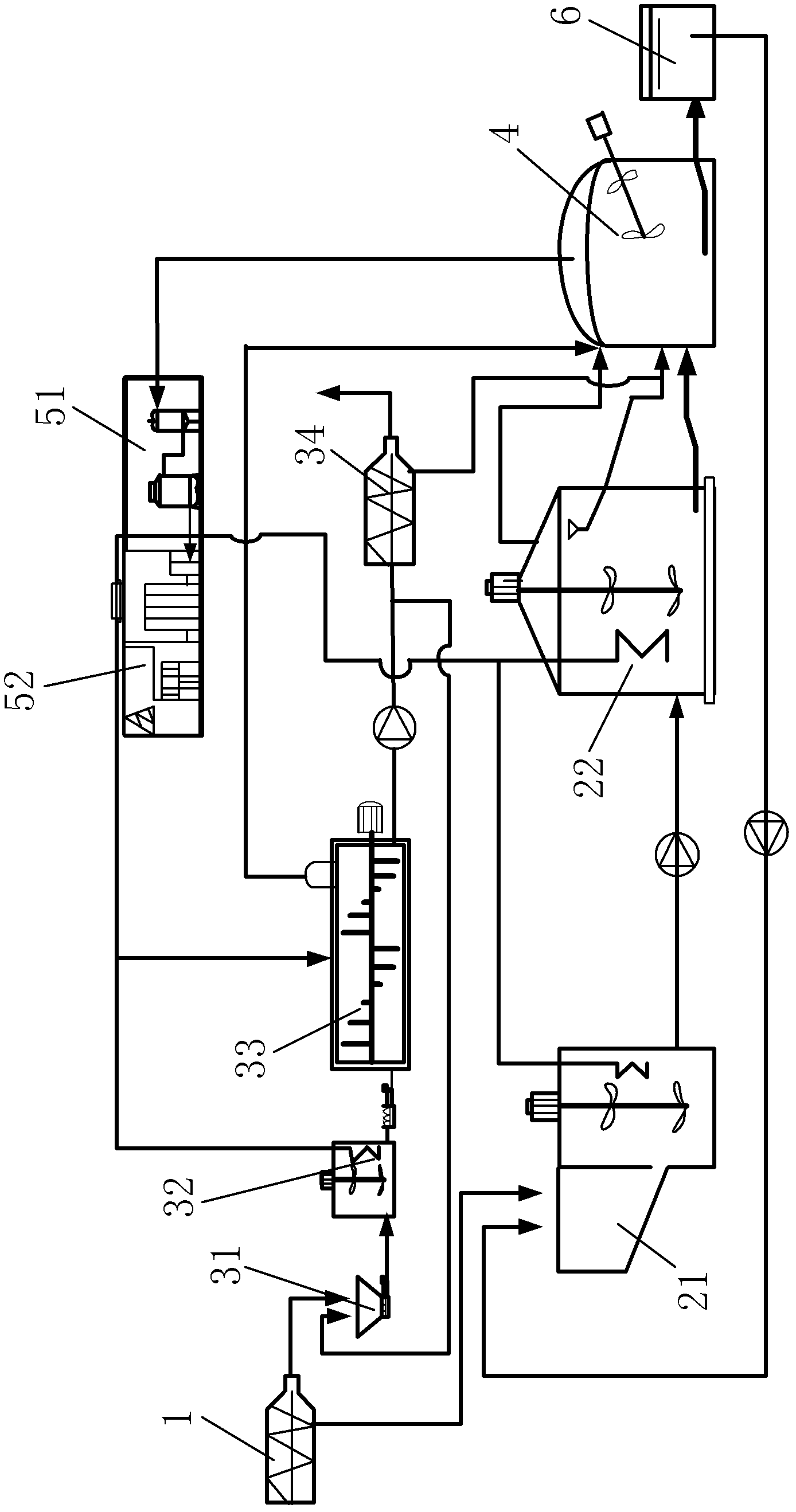

[0067] The raw material is cow manure from a dairy farm in city A, and the anaerobic fermentation inoculum comes from anaerobic activated sludge from a biogas plant.

[0068] In the mesophilic anaerobic fermentation reactor 22, the mesophilic anaerobic activated sludge from the biogas plant is used for inoculation and acclimatization.

[0069] In the solid high-temperature fermentation reactor 33, high-temperature anaerobic activated sludge from a biogas plant is used for inoculation and acclimatization.

[0070] After the inoculation and acclimatization is completed, carry out the fermentation process of cattle manure in the following steps:

[0071] (1) The feces of the cattle farm are collected by a forklift and sent to the solid-liquid separator 1 through a conveying device for solid-liquid separation;

[0072] (2) Pump the liquid separated by the solid-liquid separator 1 to the liquid pretreatment heating pool 21 for heating, control the temperature of the liquid pretrea...

Embodiment 2

[0082] The raw materials are sorted organic kitchen waste from city B, and the anaerobic fermentation inoculum comes from anaerobic activated sludge from municipal sewage treatment plants.

[0083] In the mesophilic anaerobic fermentation reactor 22, adopt the mesophilic anaerobic activated sludge of the municipal sewage treatment plant to inoculate and domesticate;

[0084] In the solid high-temperature fermentation reactor 33, the anaerobic activated sludge of the above-mentioned municipal sewage treatment plant is used for inoculation and acclimatization, and the temperature increase mode of increasing 1 ° C per day is gradually raised to a high temperature (58 ° C). Inoculum.

[0085] After the domestication and inoculation is completed, the sorted urban kitchen organic waste is anaerobically fermented to produce biogas according to the following steps:

[0086] (1) Use the solid-liquid separator 1 to separate the collected, sorted, and broken kitchen waste into solid and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com