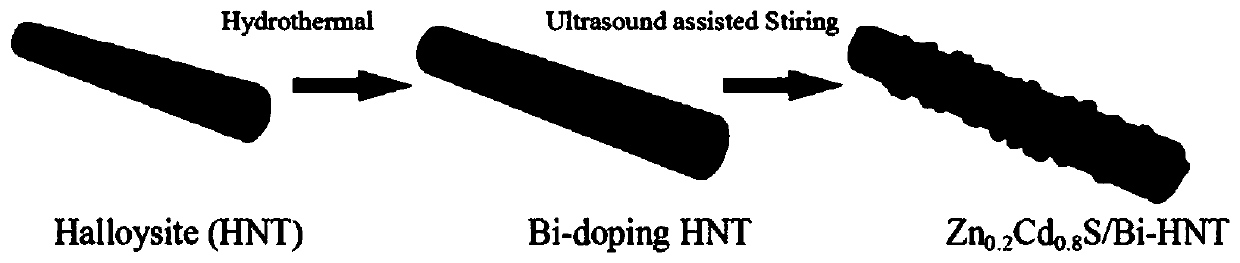

Zinc cadmium sulfur-bismuth doped indianite composite photocatalyst and preparation method thereof

A composite light and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as agglomeration of zinc, cadmium, and sulfur nanocrystals, and achieve rich resources, simple pretreatment methods, and excellent The effect of catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

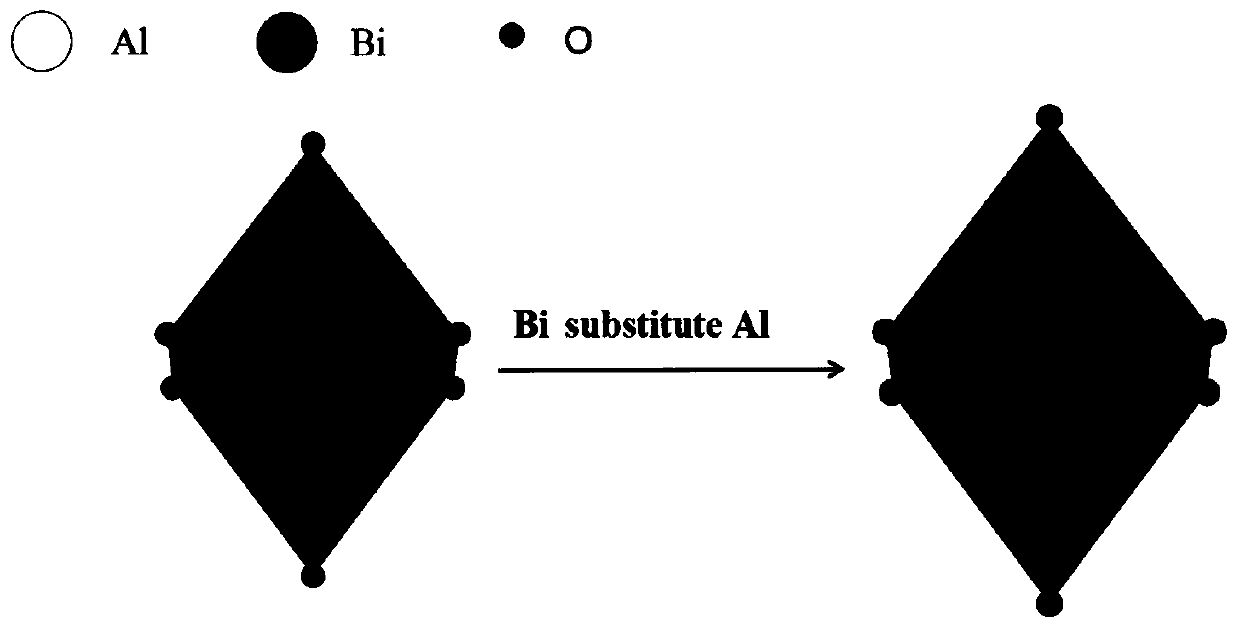

[0029] In the first step, 1.5mmol halloysite (258g / mol) was mixed with saturated aluminum chloride solution, ultrasonically dispersed for 10min, and then stirred on a magnetic stirrer for 0.5h;

[0030] In the second step, weigh 0.3 mmol of bismuth nitrate pentahydrate (1:5 molar ratio to halloysite) and disperse it in 5 mL of ethylene glycol solution for 10 min;

[0031] In the third step, the solution obtained in the second step is added dropwise to the suspension obtained in the first step and transferred to a 100mL polytetrafluoroethylene reactor, and taken out after solvent heating in an oven at 180°C for 24 hours;

[0032] In the fourth step, the sample obtained in the third step was washed by centrifugation, and dried in an oven at 60° C. for 12 hours to prepare a modified bismuth-doped halloysite nanomaterial.

[0033] figure 2 It is the optical picture of the unmodified halloysite nanotube (A) prepared in Example 1 and the halloysite (B) after bismuth doping. It ca...

Embodiment 2

[0035] The first step is to disperse 100mg of bismuth-doped halloysite in 50mL of deionized water, and ultrasonically disperse for more than 30min;

[0036] In the second step, quantitatively add 0.8 mmol cadmium acetate dihydrate and 0.2 mmol zinc acetate dihydrate (molar ratio 8:2) to the solution obtained in the first step, and ultrasonically stir for more than 1 hour;

[0037] In the third step, 1 mmol thioacetamide was added to the solution obtained in the second step, and ultrasonically mechanically stirred for 2 h;

[0038]In the fourth step, the samples obtained in the third step were washed by centrifugation, and dried in an oven at 60° C. for 12 hours to obtain a zinc cadmium sulfur-bismuth doped halloysite composite material (named ZCS / Bi-HNT-1).

Embodiment 3

[0040] In the first step, 20 mg of zinc cadmium sulfur-bismuth doped halloysite was dispersed in 50 mL of 10 mg / L rhodamine B solution, and stirred in a dark room for 1 h;

[0041] In the second step, the suspension obtained in the first step is placed under a 300W xenon lamp (λ>420nm) for light, with 3 mL of liquid at intervals of 10 minutes;

[0042] In the third step, the liquid sample obtained in the second step is centrifuged at 9000r / min for 1min to remove the catalyst;

[0043] In the fourth step, the centrifuged liquid obtained in the third step is detected in an ultraviolet-visible spectrophotometer to evaluate the photocatalytic performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com