Patents

Literature

231 results about "Cadmium acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cadmium acetate is the chemical compound with the formula Cd(CH₃CO₂)₂. This colourless solid is classified coordination polymer, featuring acetate ligands interconnecting cadmium centers. The compound exists in anhydrous form and as a dihydrate.

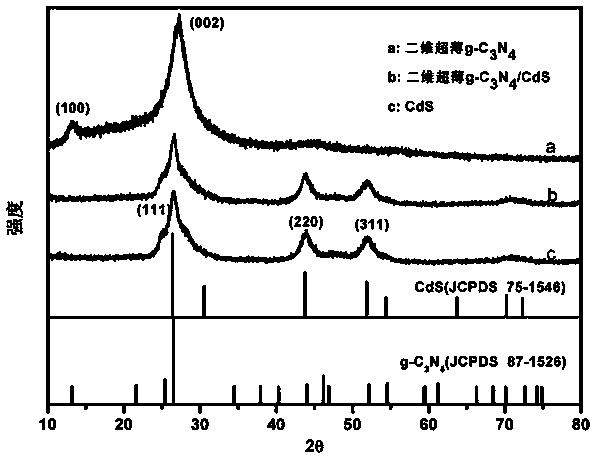

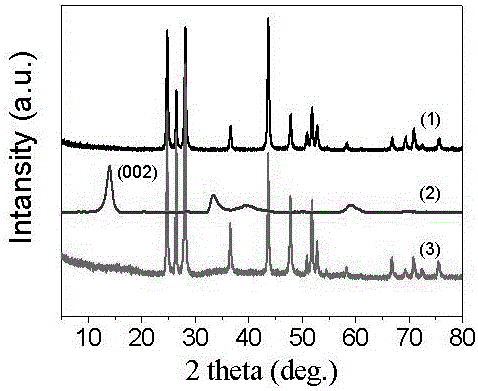

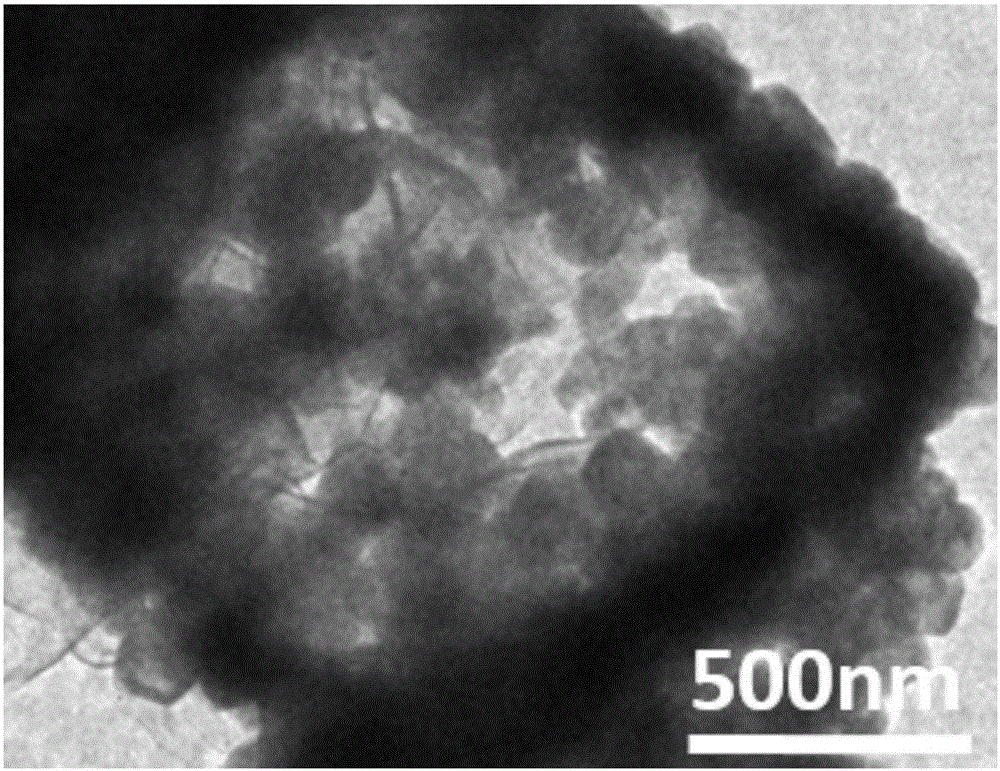

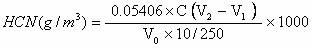

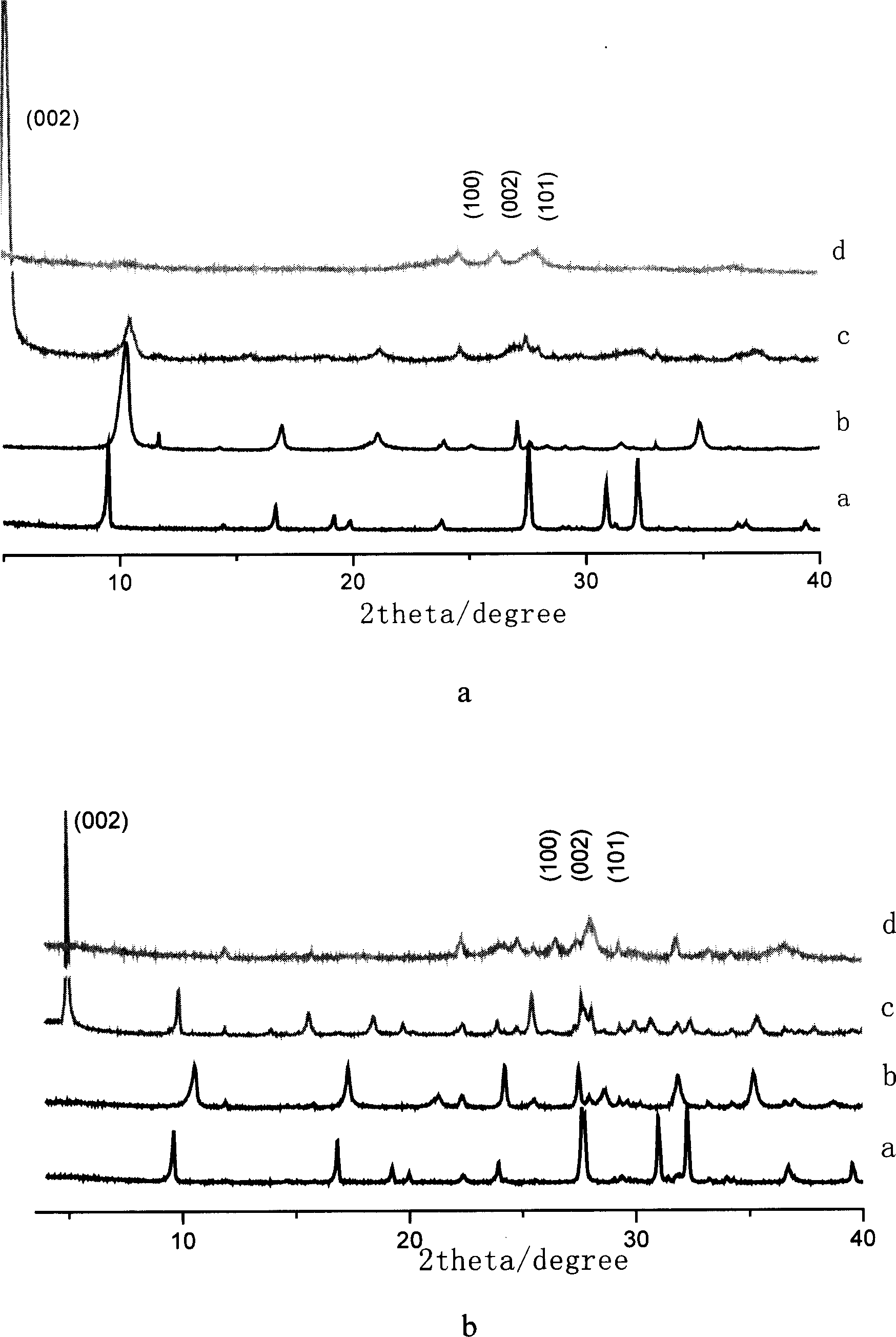

g-C3N4 nanosheet/CdS composite visible-light-driven photocatalyst

InactiveCN103785434AImprove separation efficiencyImprove photocatalytic efficiencyPhysical/chemical process catalystsWater/sewage treatment by irradiationPtru catalystThio-

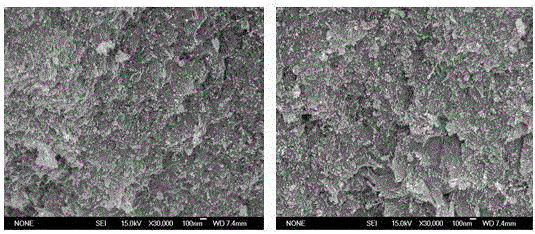

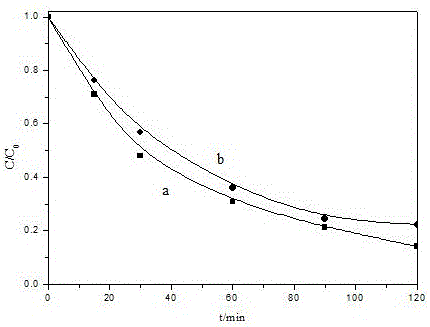

The invention discloses a g-C3N4 nanosheet / CdS composite visible-light-driven photocatalyst and a preparing method and application thereof and belongs to the technical field of material preparation and photocatalysis. The catalyst is directly obtained with the solvothermal method by taking two-dimensional ultra-thin g-C3N4 nanosheets as the matrix, cadmium acetate dihydrate and thioacetamide as raw materials, and ethyl alcohol as the solvent. Compared with general block g-C3N4 / CdS, the two-dimensional ultra-thin g-C3N4 nanosheet / CdS composite photocatalyst prepared with the method has the advantages that the two substances are in tighter contact, the specific surface area is larger, photon-generated electron-hole can be better separated, and photocatalytic efficiency is higher. Under the shining of sunlight, the composite photocatalyst enables catalytic degradation of organic pollutants such as methyl orange in water to be achieved well. The preparing method is easy, raw materials are easy to obtain, visible light catalysis efficiency is high, and the application prospect is wide in the photocatalysis field.

Owner:FUZHOU UNIV

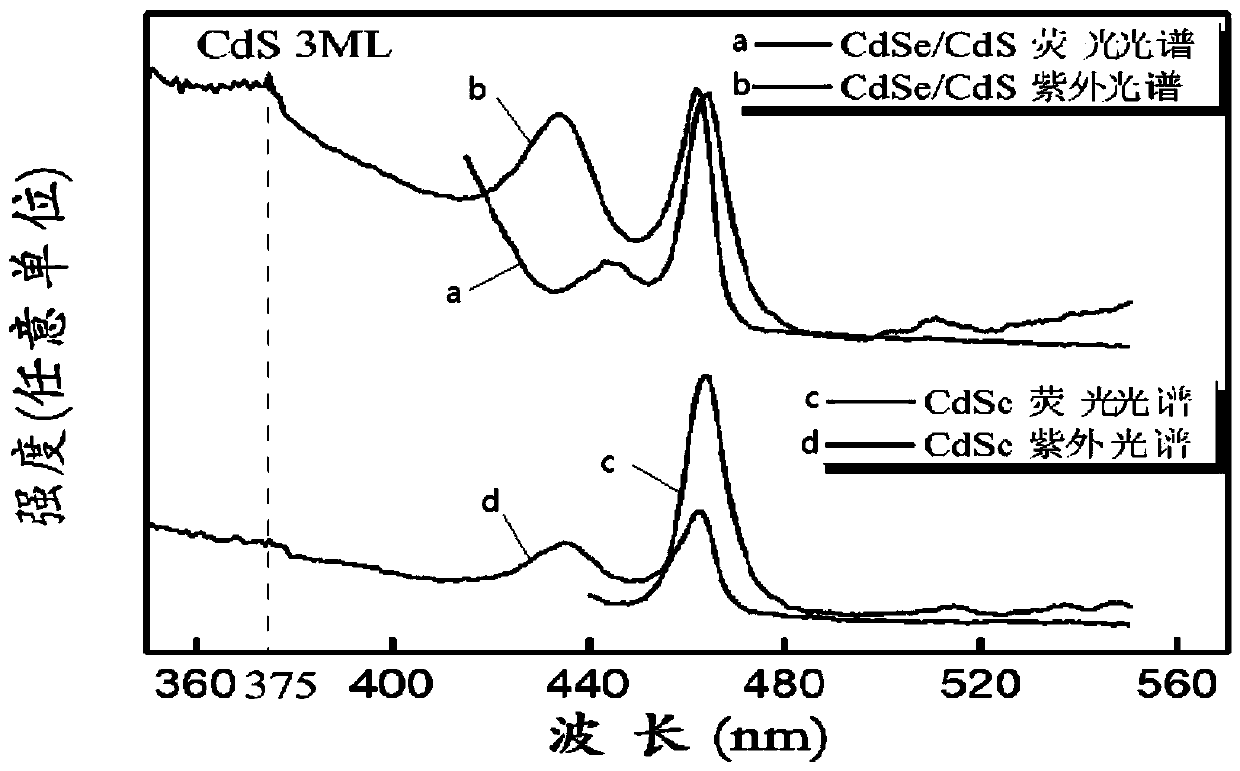

Prepn of CdSe/CdS or CdSe/ZnS core-shell quantum dot

InactiveCN1403379ARaw materials are safe and easy to obtainLow priceFrom normal temperature solutionsCadmium sulfidesQuantum yieldQuantum dot

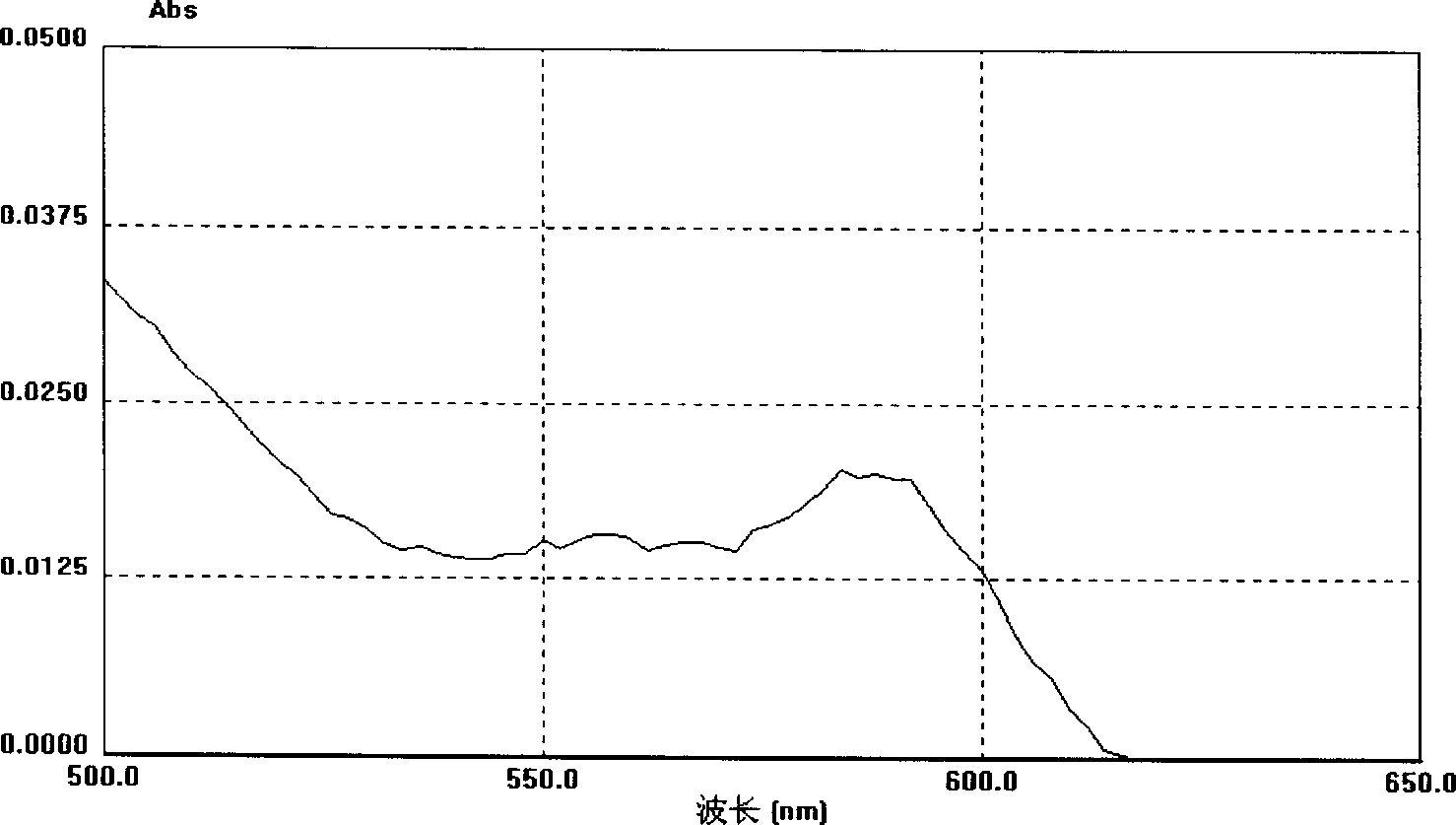

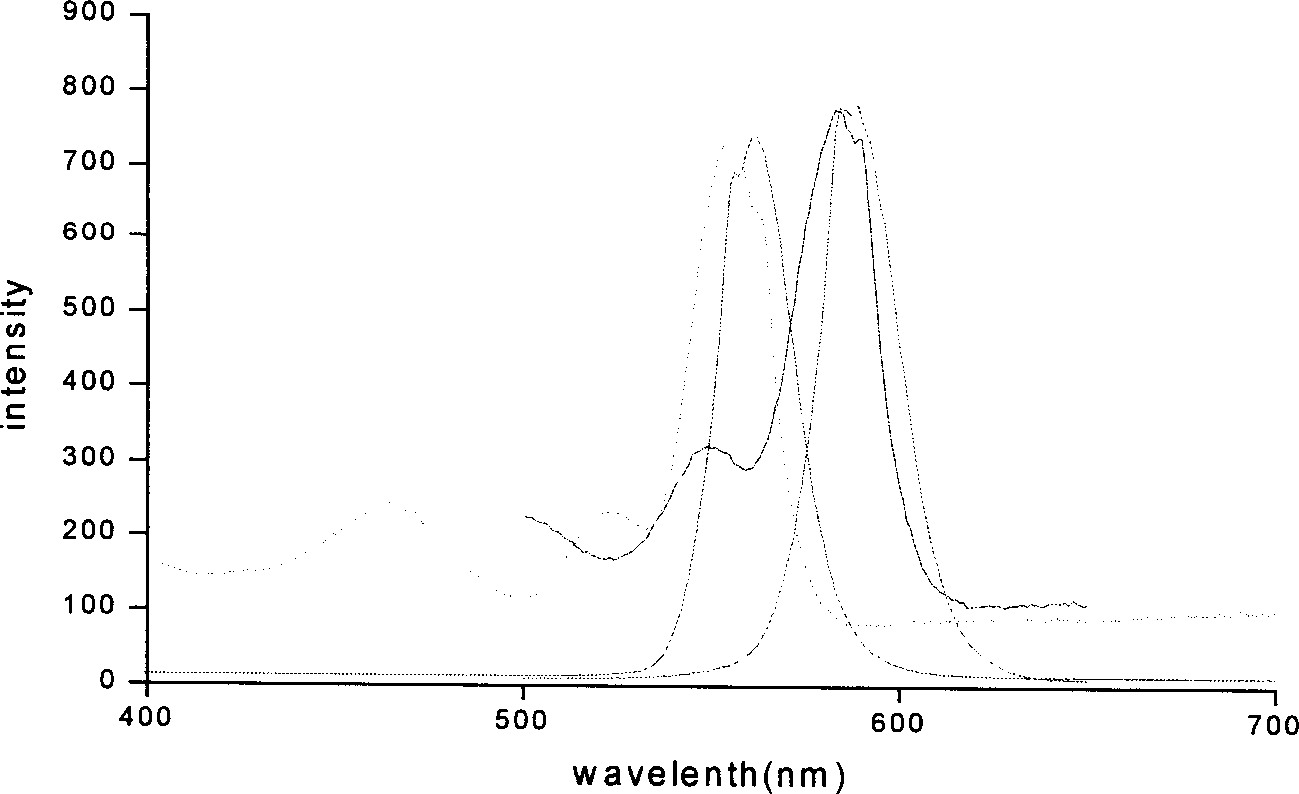

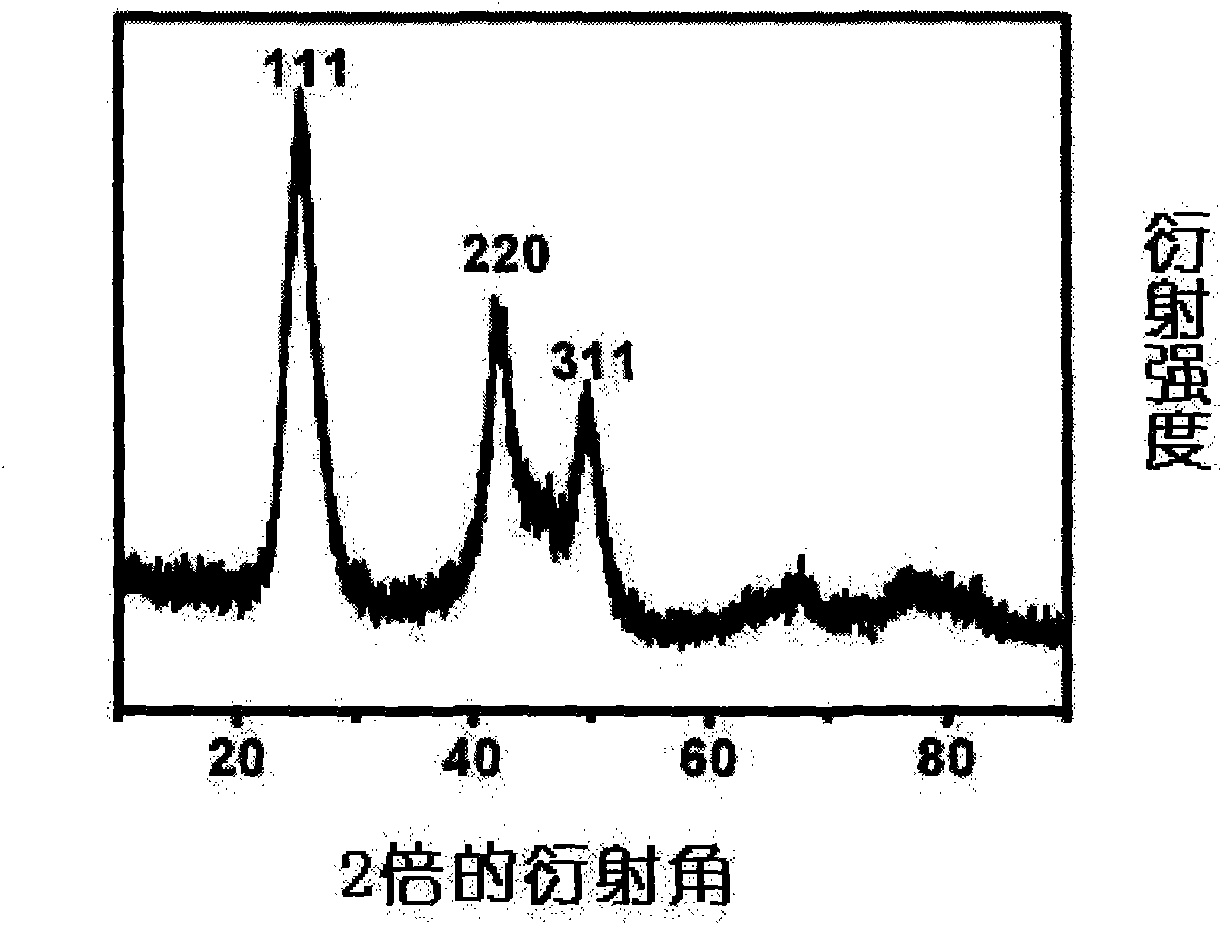

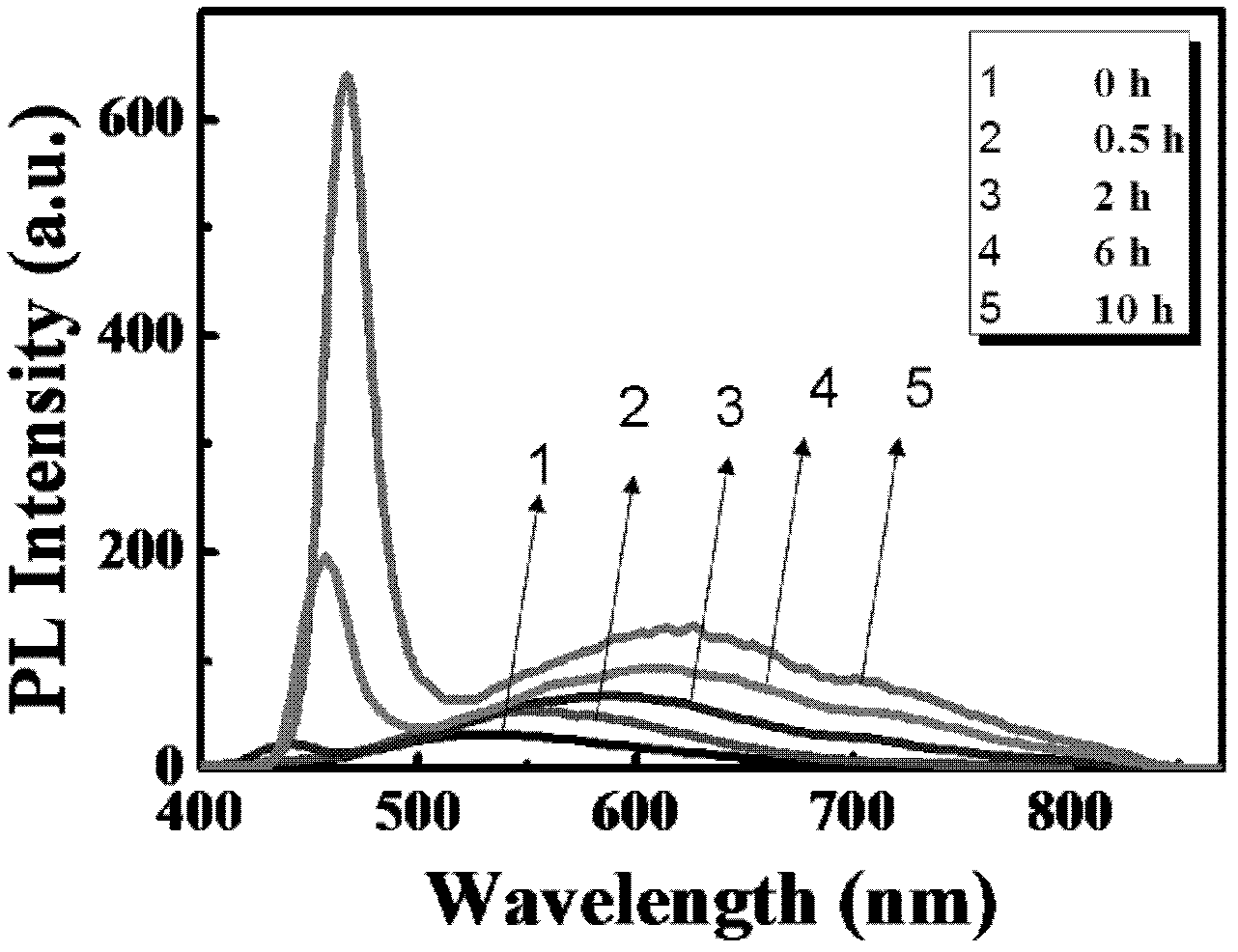

The present invention discloses the preparation process of CdSe / CdS, CdSe / ZnS and other II-VI type core-shell quantum dot. The CdSe / CdS and CdSe / ZnS core-shell quantum dot are prepared with cadmium acetate, zinc acetate or other inorganic compound, instead of Cd(CH3)2, Zn(CH3)2 or other inflammable, detonable and expensive organic metal compound, as material. The prdouct has excellent single dispersivity, improved fluorescent property, high quantum yield, high stability, and may be used widely as the fluorescent mark for biological detection and analysis.

Owner:WUHAN UNIV

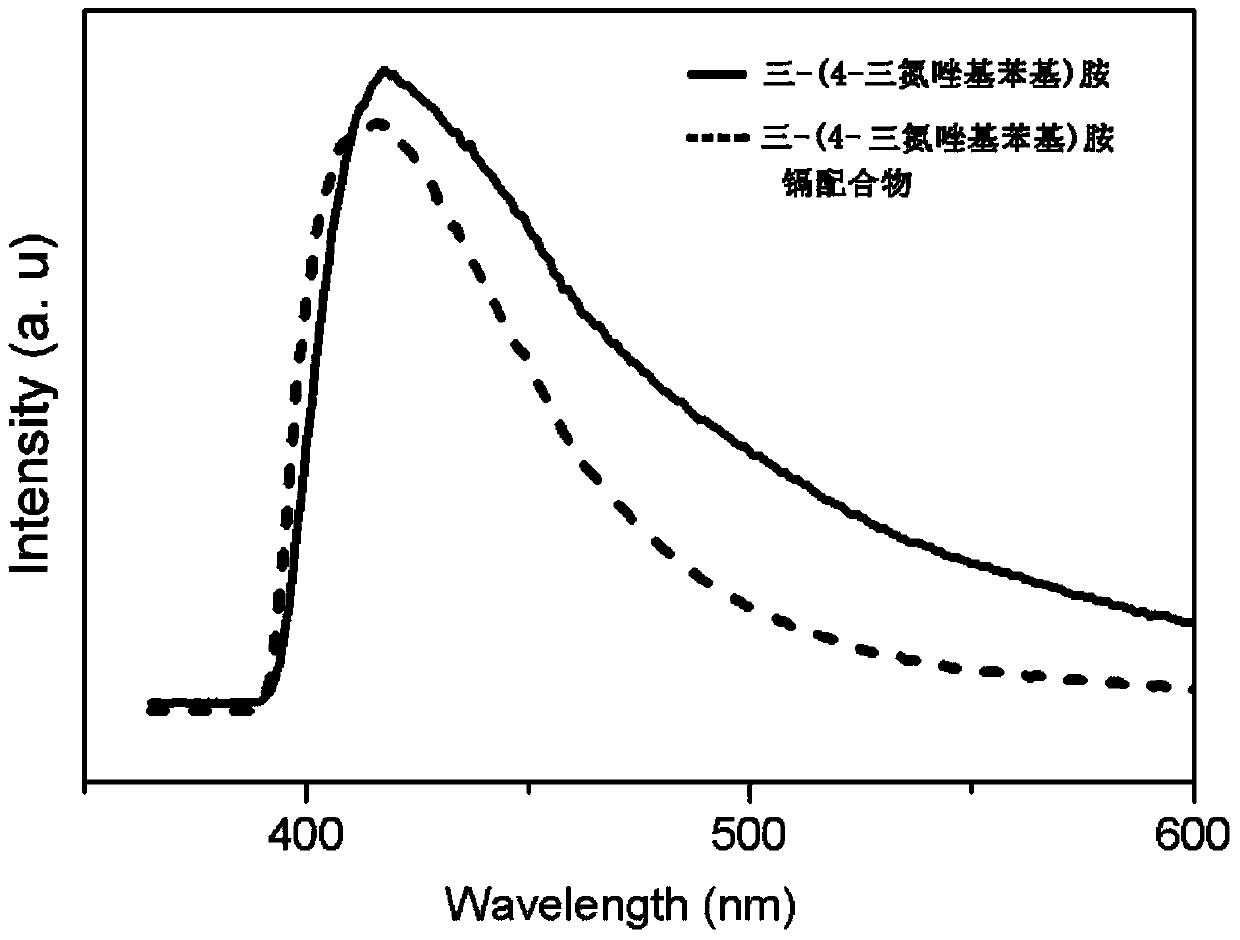

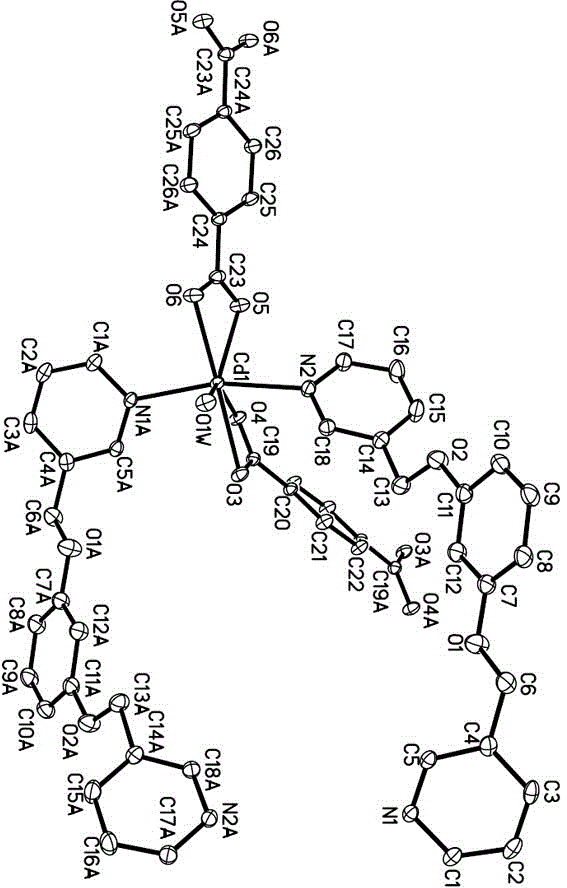

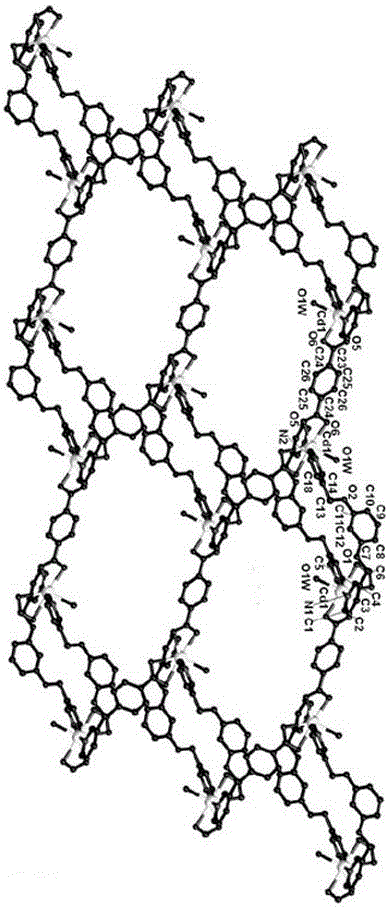

Synthesis methods of tri-(4-triazolyl phenyl) amine and tri-(4-triazolyl phenyl)amine cadmium complex

InactiveCN104193691AThe detection method is simpleHigh selectivityFluorescence/phosphorescenceGroup 2/12 organic compounds without C-metal linkagesSynthesis methodsCopper oxide

The invention discloses synthesis methods of a tri-(4-triazolyl phenyl) amine and a tri-(4-triazolyl phenyl) amine cadmium complex, and relates to the field of luminescent materials. The synthesis method of the tri-(4-triazolyl phenyl) amine takes copper oxide as a catalyst and dimethylsulfoxide as a solvent, tri-(4-iodobenzene) amine and triazole react at the temperature of 120-170 DEG C, then the mixture is diluted by the solvent, filtered, decolored, separated and purified sequentially to obtain the tri-(4-triazolyl phenyl) amine; the synthesis method of the cadmium complex is carried out by mixing 5-aminoisophthalic acid, 3-(4-triazolyl phenyl) amine and cadmium acetate into a mixed solution of water and alcohol, then the mixture is uniformly stirred under the acid or neutral condition to obtain a reaction liquid, and the reaction liquid is put into a reaction kettle to crystalize and react to obtain the tri-(4-triazolyl phenyl) amine cadmium complex. The synthesis methods obtain the tri-(4-triazolyl phenyl) amine and the tri-(4-triazolyl phenyl) amine cadmium complex, whose crystal purities are more than 95% and whose yields are more than 85%, through the simple synthesis route.

Owner:NANJING AGRICULTURAL UNIVERSITY

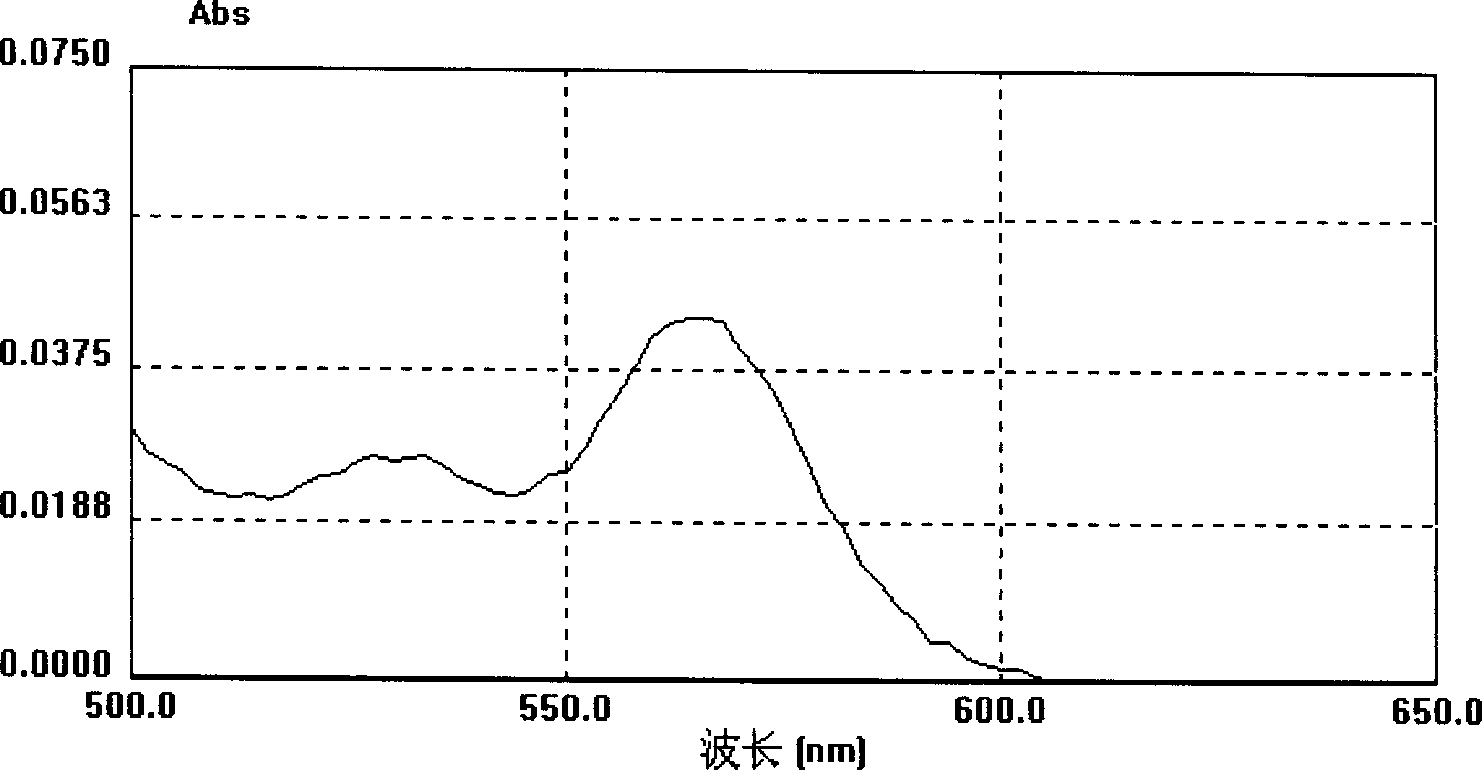

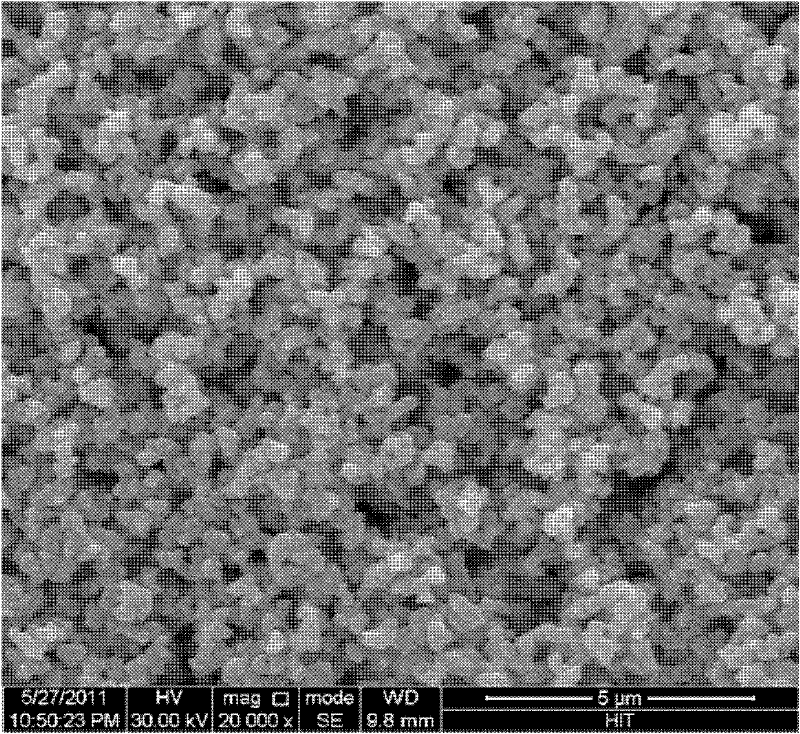

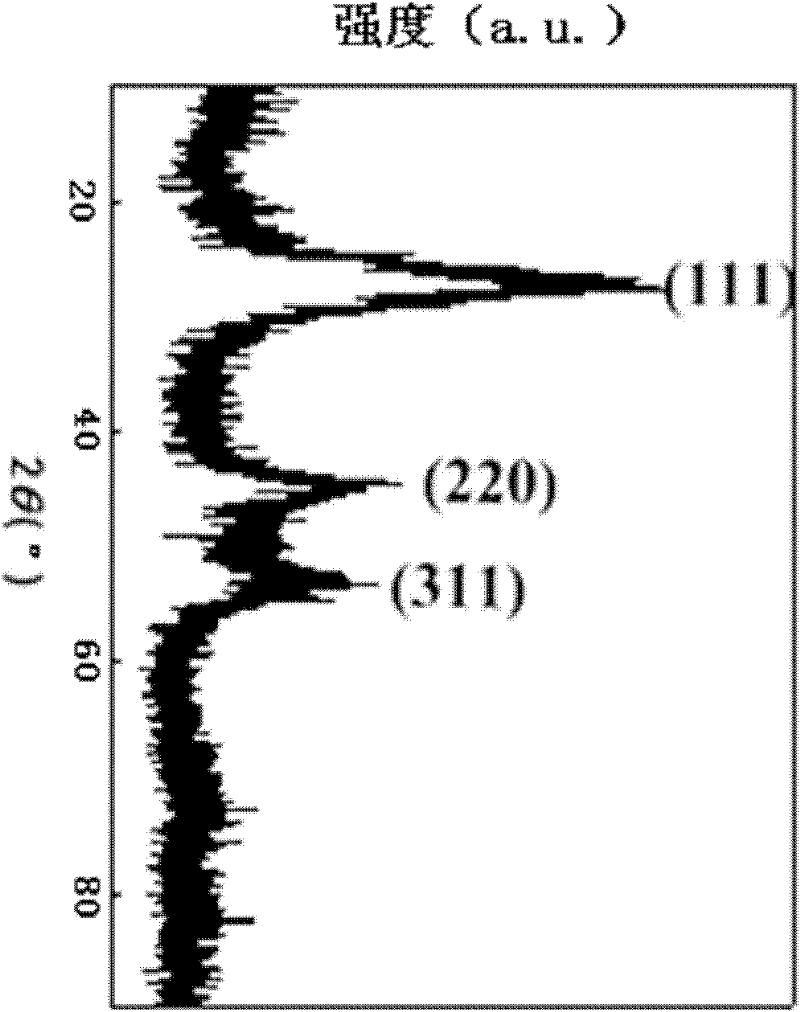

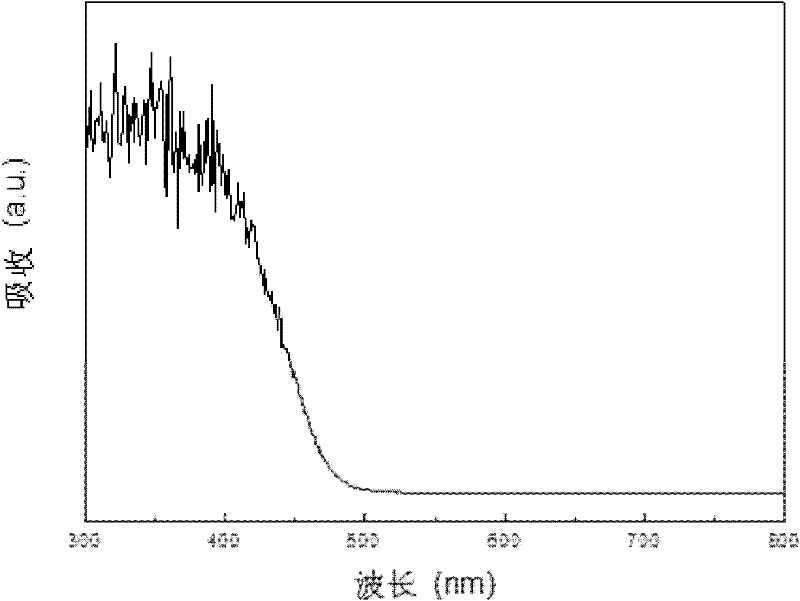

A kind of synthesis method and application of nano zinc cadmium sulfide with visible light catalytic activity

InactiveCN102285682AGood hydrogen production performance by photolysis of waterStrong absorption capacityPhysical/chemical process catalystsCadmium sulfidesGeneration rateSynthesis methods

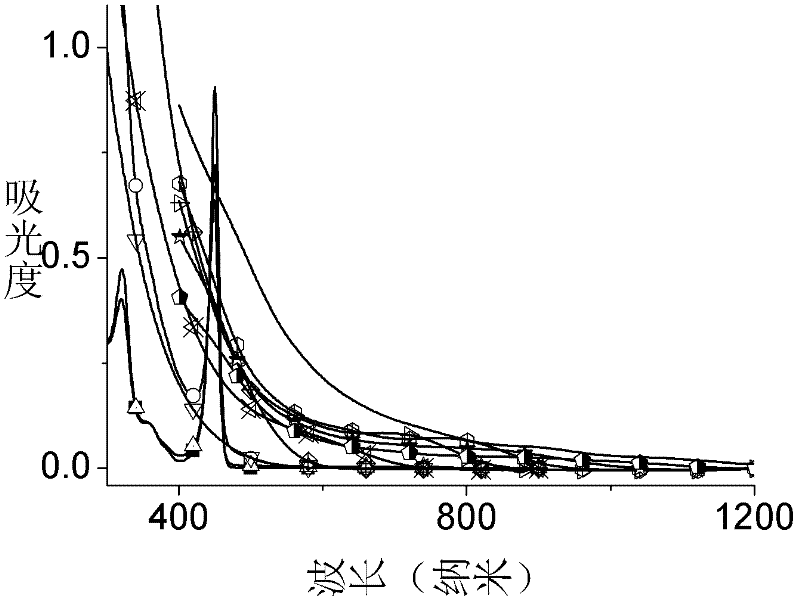

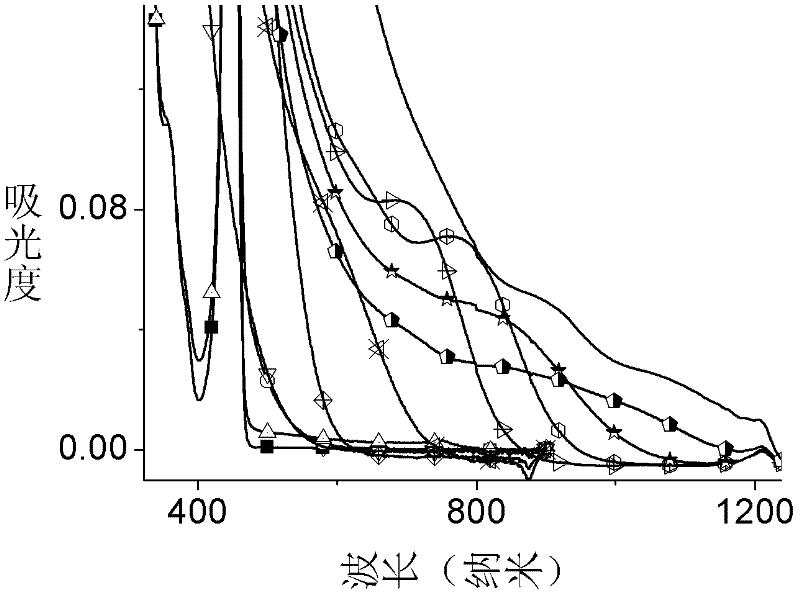

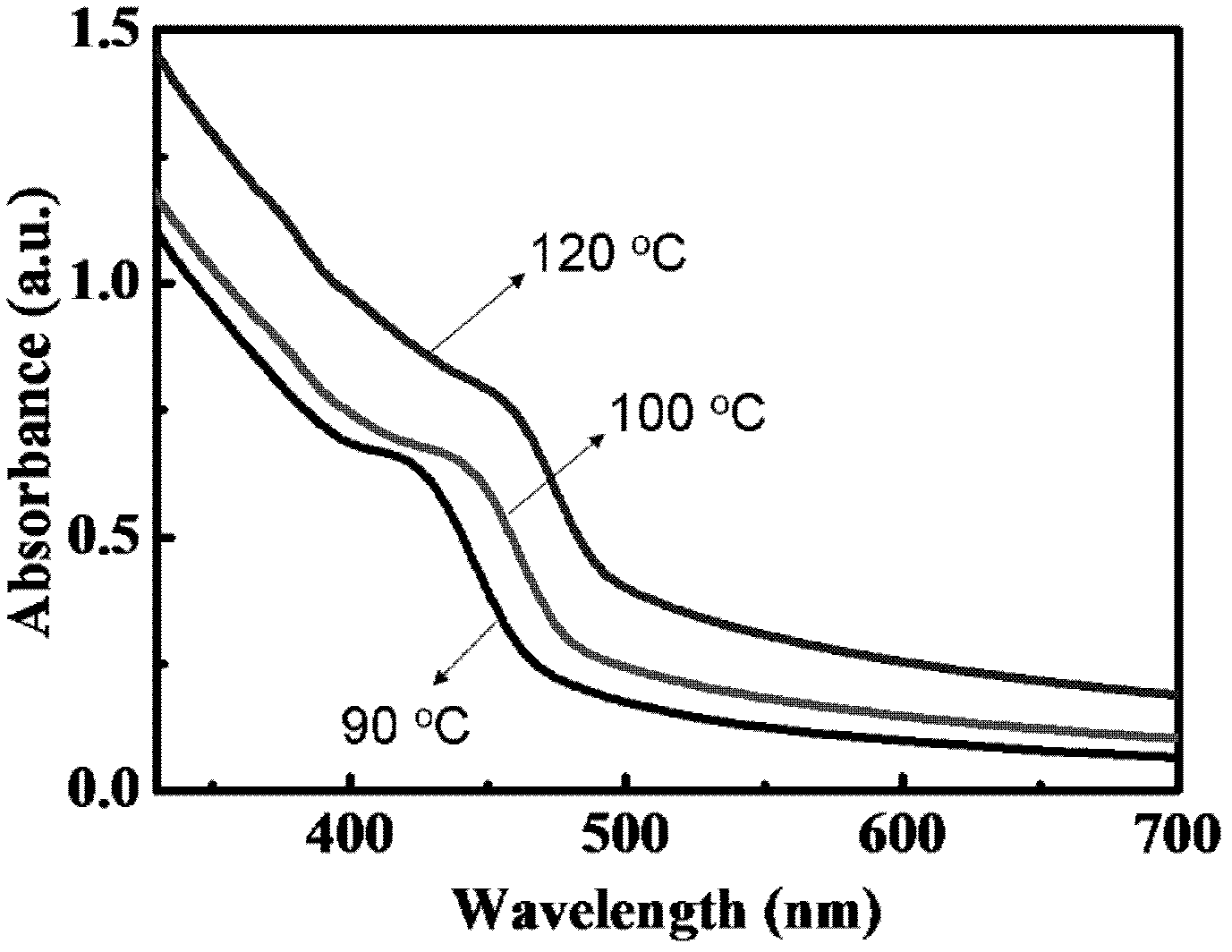

The invention discloses a synthesis method and use of nano cadmium zinc sulfide with visible light catalytic activity and relates to a synthesis method and use of a sulfide having visible light catalytic activity. When the synthesis method is used, the long reaction time and high reaction temperature problems of the conventional method for preparing cadmium zinc sulfide are solved. The synthesis method comprises: dissolving zinc acetate, cadmium acetate, thioacetamide and dodecyl benzene sulphonic acid in alcohol solvent to obtain mixed solution; and placing the mixed solution in microwaves for reaction. The nano cadmium zinc sulfide synthesized by the method can be used as a photocatalytic material for use in the hydrogen production by decomposition in visible light. The synthesis methoddisclosed by the invention adopts a simple process and readily available raw material, and can synthesize the nano cadmium zinc sulfide quickly with small energy consumption and high yield. The nano cadmium zinc sulfide has uniform particles and high purity and has high strong absorbability at wavelength of about 490 nanometers; and the nano cadmium zinc sulfide demonstrates good visible light response property, and the hydrogen generation rate reaches 300 to 450 millimoles / h<-1>.g<-1>, which is very high.

Owner:HARBIN INST OF TECH

Preparation method of magnetic fluorescent composite nanospheres

InactiveCN103372407AEasy to manufactureSimple processMaterial nanotechnologyInorganic non-active ingredientsSolubilitySodium acetate

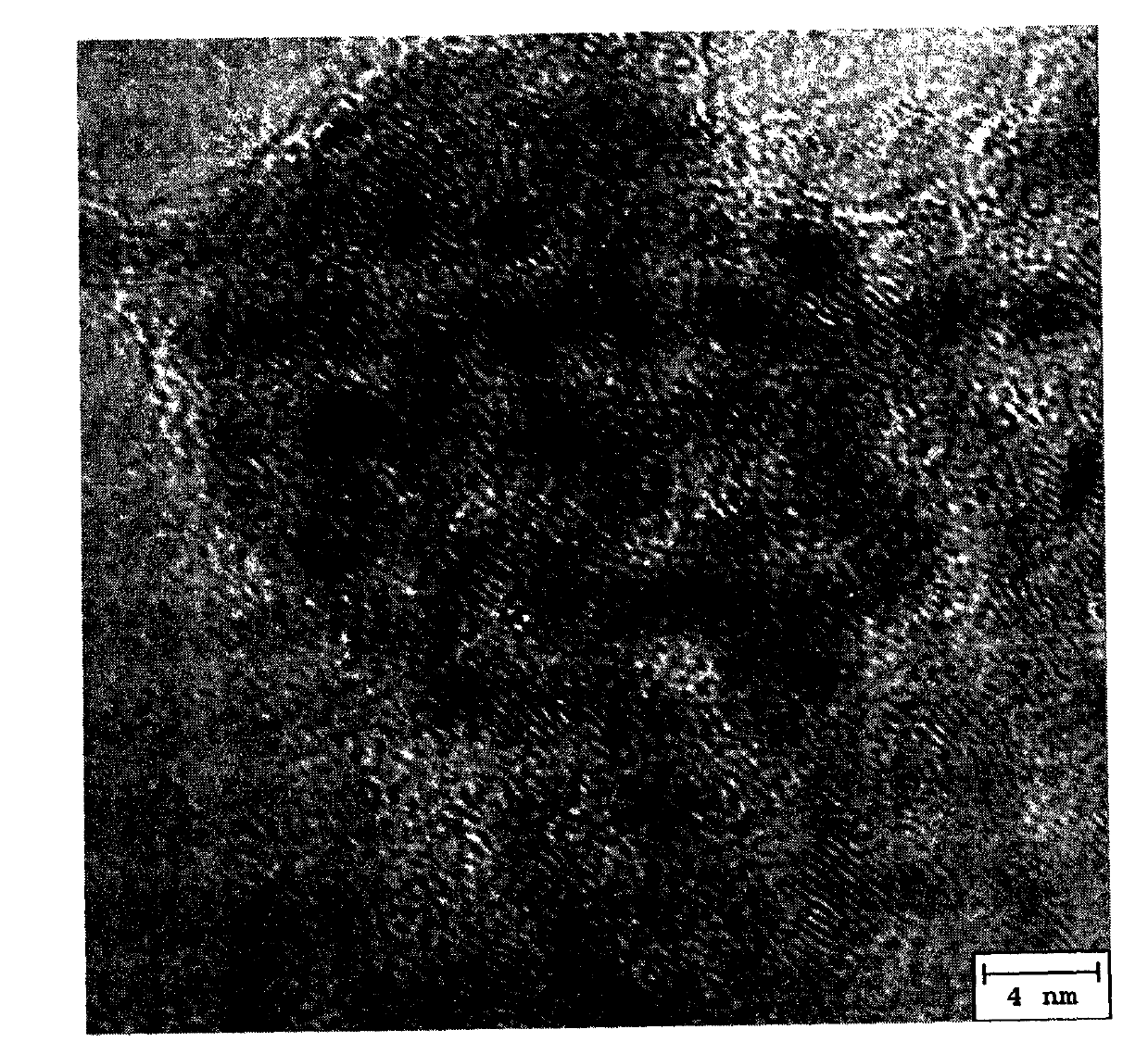

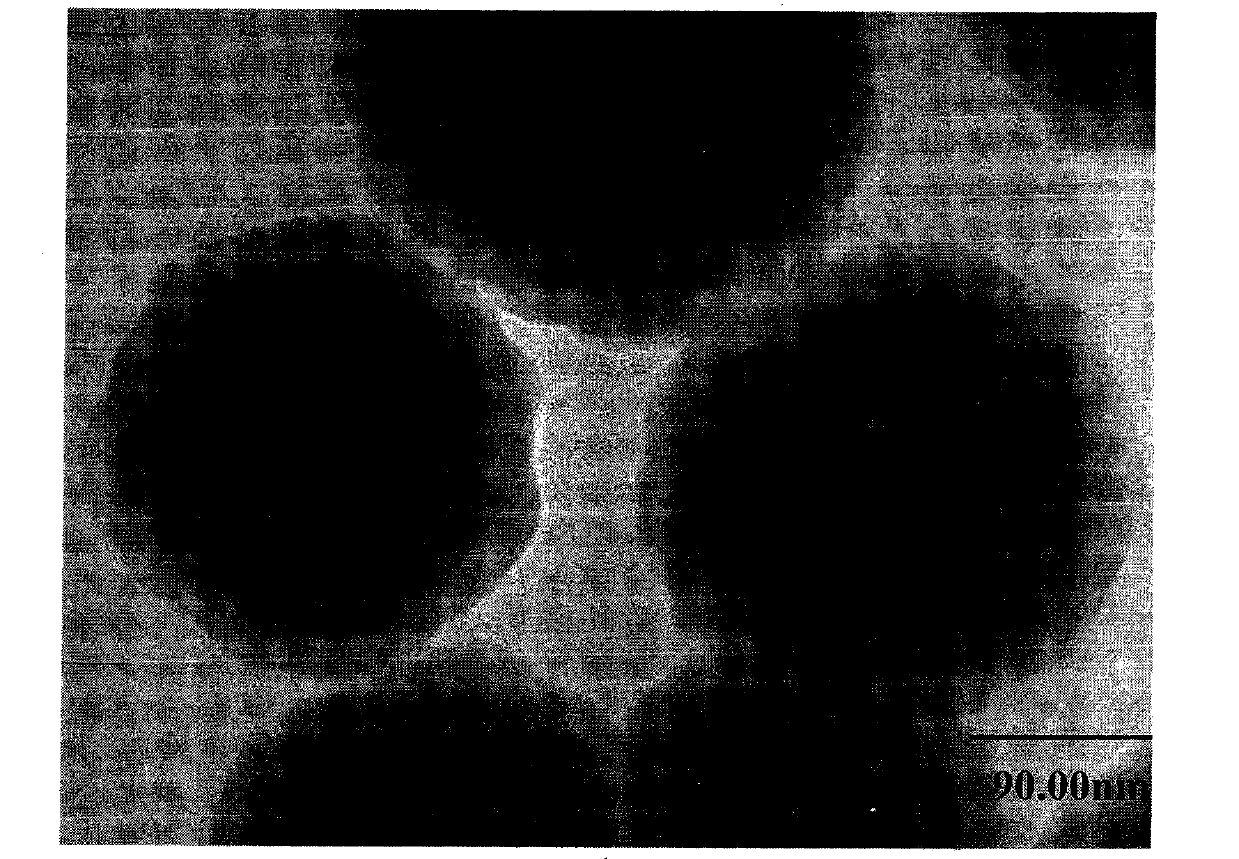

The invention provides a preparation method of magnetic fluorescent composite nanospheres. The preparation method comprises the steps of (1) preparing CdSe quantum dots by taking Na2SO3, selenium powder, cadmium acetate, N-acetylcysteine and deionized water as raw materials; (2) with FeCl3.6H2O sodium acetate anhydrous and ethylene glycol as raw materials, reacting in an autoclave to obtain Fe3O4 nanoparticles; (3) preparing a Fe3O4@SiO2 product by taking the Fe3O4 nanoparticles, tetraethoxysilane, absolute ethyl alcohol, deionized water and ammonium hydroxide as raw materials; and (4) conducting amino modification on the surface of the Fe3O4@SiO2 by utilizing a silane coupling agent KH-550, then loading CdSe onto the surface of the SiO2 through reaction, so as to obtain the final product magnetic fluorescent composite nanospheres. The preparation method has the characteristics that the prepared CdSe quantum dots have excellent water solubility and excellent fluorescent property and are about 3-4nm in diameter; the Fe3O4 nanoparticles are even in particle size and have good dispersity; the Fe3O4@SiO2 nanoparticles have an obvious core-shell structure, shell layers are evenly coated and are consistent in thickness; the magnetic fluorescent composite nanospheres has strong magnetism and excellent fluorescence property and can be used for site-specific drug transportation in a biological body and the fluorescence imaging of the biological body.

Owner:BEIJING UNIV OF CHEM TECH

Modified butanediol ester poly succinic acid and synthetic method

InactiveCN1796435AImproved crystallization behaviorSlow crystallization ratePolymer scienceSynthesis methods

This invention relates to a cyclic compound, especially poly (butylenes succinate) modified by copolymerization with maleopimaric anhydride and its synthesis method. Succinic acid, 1,4-butanediol are mixed at a mole ratio of 1:1~4, and 4~20g maleopimaric imine dicarboxylic ester oligomers are added per 163g succinic acid / 1,4-butanediol mixture. The system is stirred at a temperature of 160~200 deg.C in the presence of inert gas, and cadmium acetate, zincum acetate, stibium oxide, butyl titanate or their optional combinations are added as catalysts at a mass fraction of 0.1~3% for a polymerization at a temperature of 230~280 deg.C and a pressure of 5~10Pa to produce modified poly(butylenes succinate) with a following structure. Such an environmentally friendly polymer performs a good elongation rate at break, impact-resistance strength and bending strength.

Owner:INST OF CHEM CHINESE ACAD OF SCI

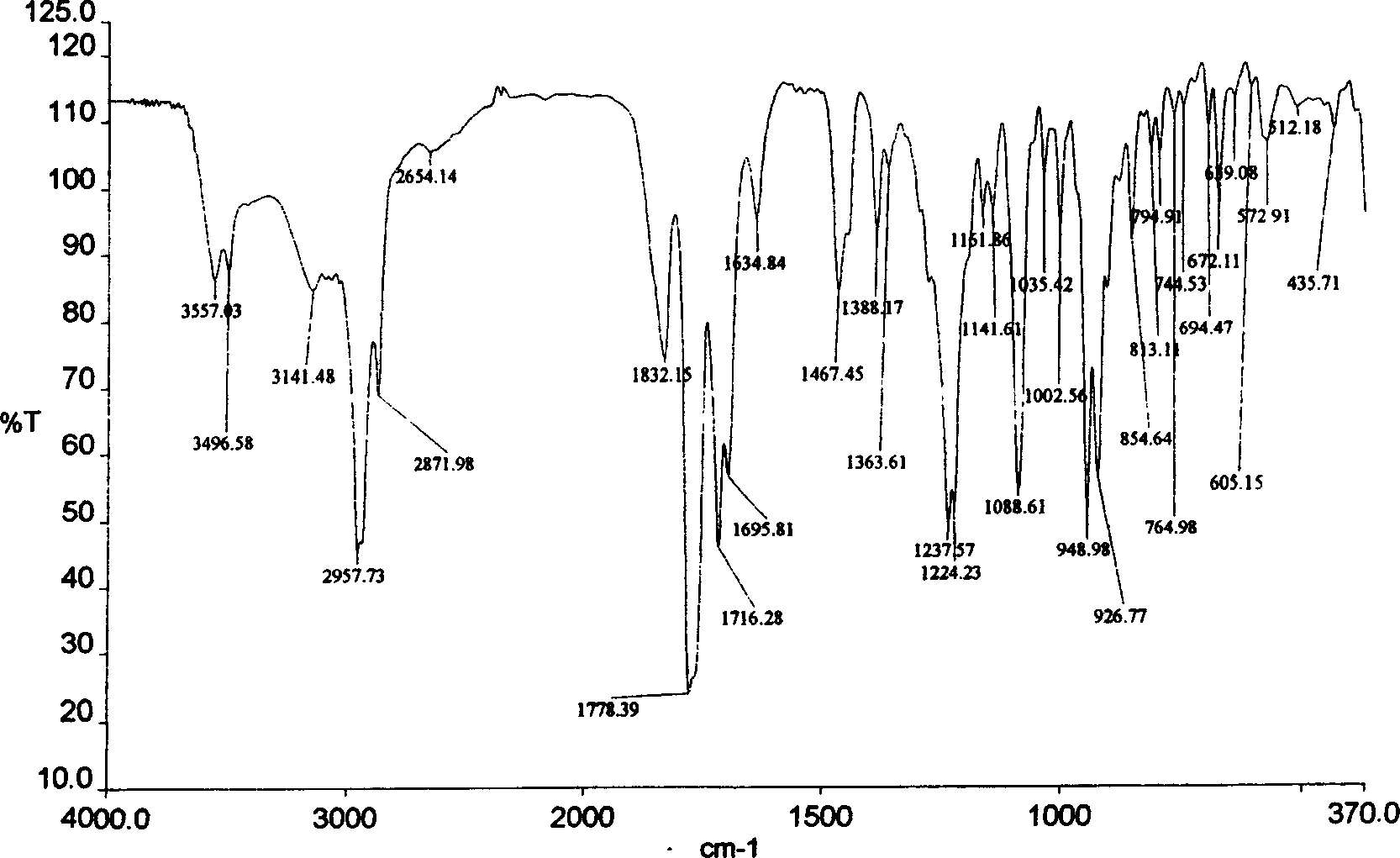

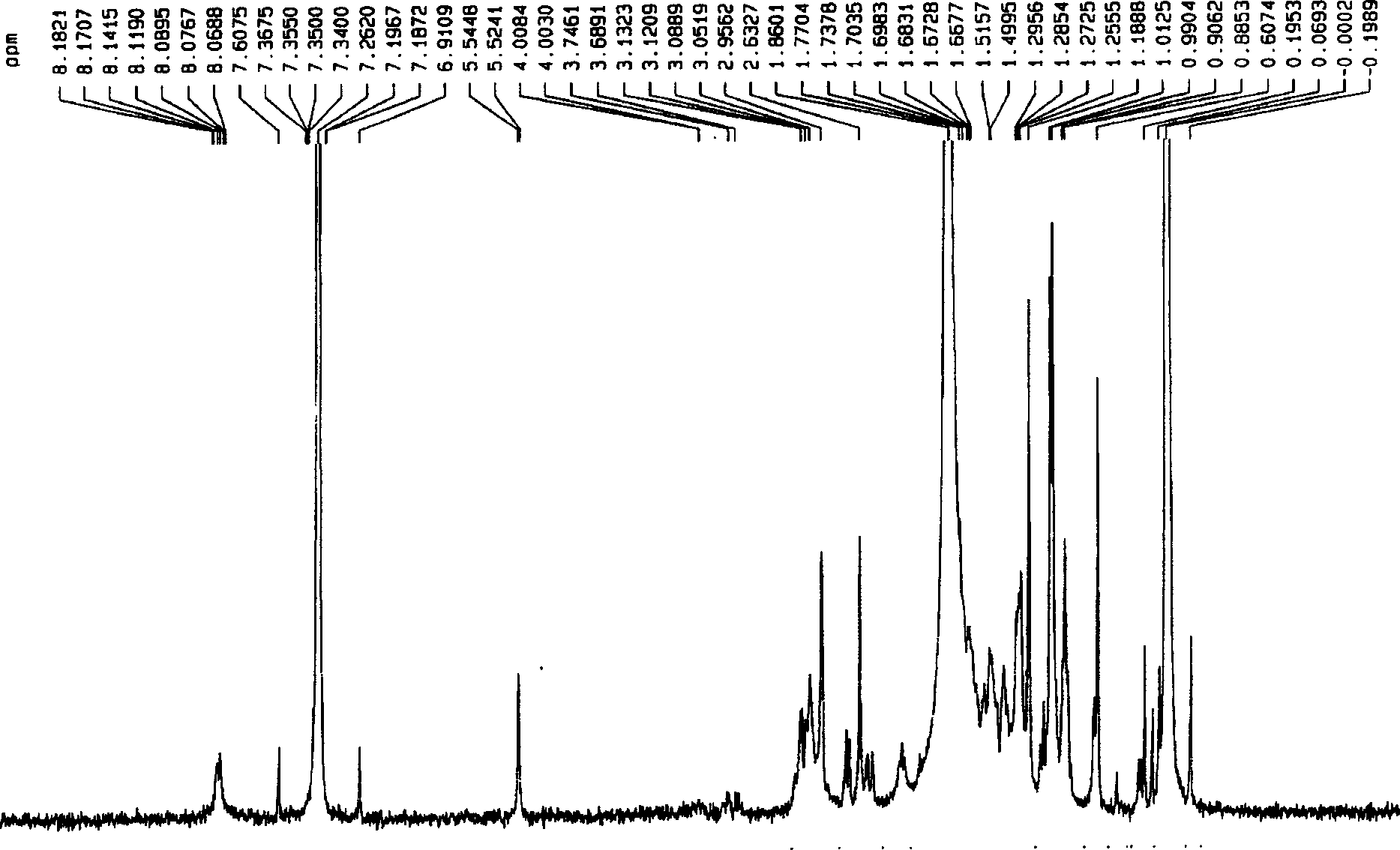

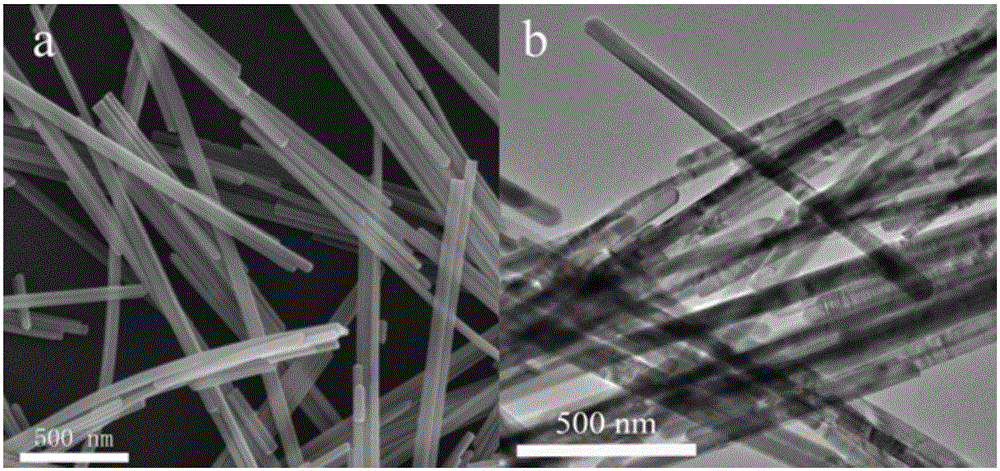

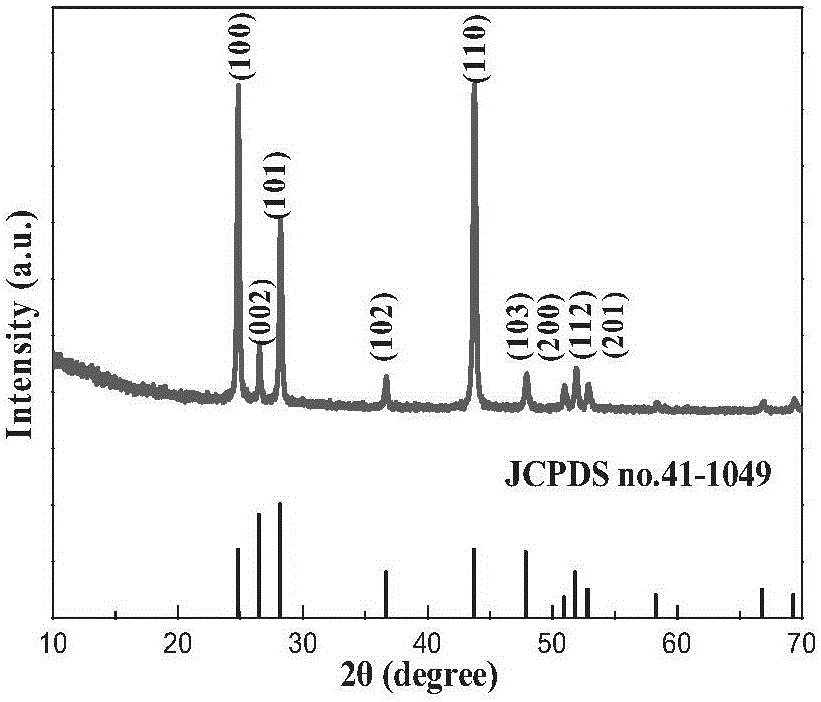

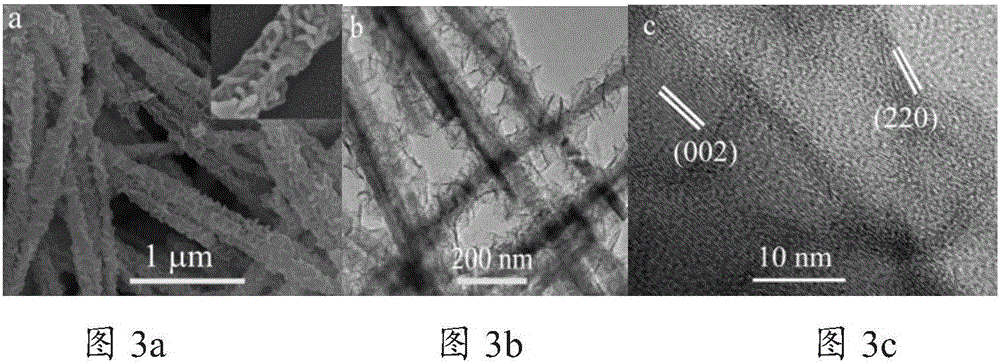

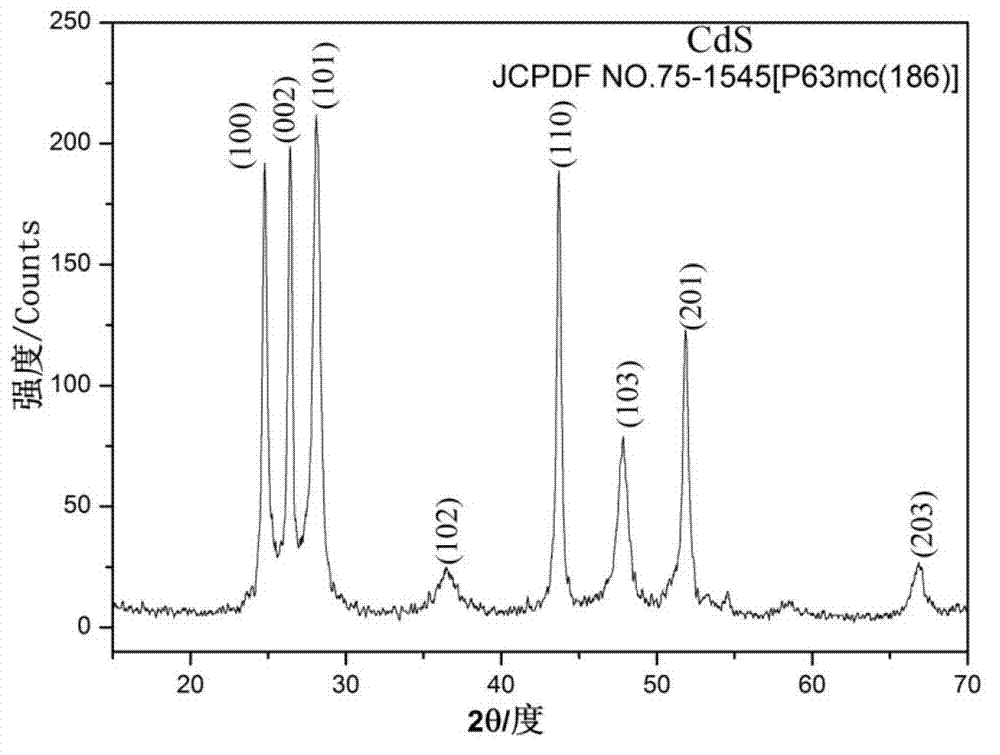

Preparation method of high efficiency CdS-CdIn2S4 superstructure photocatalyst

InactiveCN106076364ARich sourcesEasy to operateElectrolysis componentsPhysical/chemical process catalystsDecompositionCadmium acetate

The invention discloses a preparation method of a high efficiency CdS-CdIn2S4 superstructure photocatalyst. The preparation method comprises that 1, cadmium acetate and sodium diethyldithiocarbamate as raw materials undergo a solvothermal reaction in an ethylenediamine-dodecanethiol mixed solvent at a temperature of 180 DEG C for 24h to produce a CdS nano-wire, and 2, the prepared CdS nano-wire, InCl3. 4H2O and L-cysteine undergo a reaction in ethanediol as a solvent at a temperature of 200 DEG C under the condition of backflow for some time to produce a finished product. The preparation method is green and environmentally friendly and realizes large scale production. The CdS nano-wire / CdIn2S4 nano-sheet composite superstructure can be used in the field of energy conversion such as water decomposition hydrogen production based on photocatalysis and photoelectrocatalysis.

Owner:WENZHOU UNIVERSITY

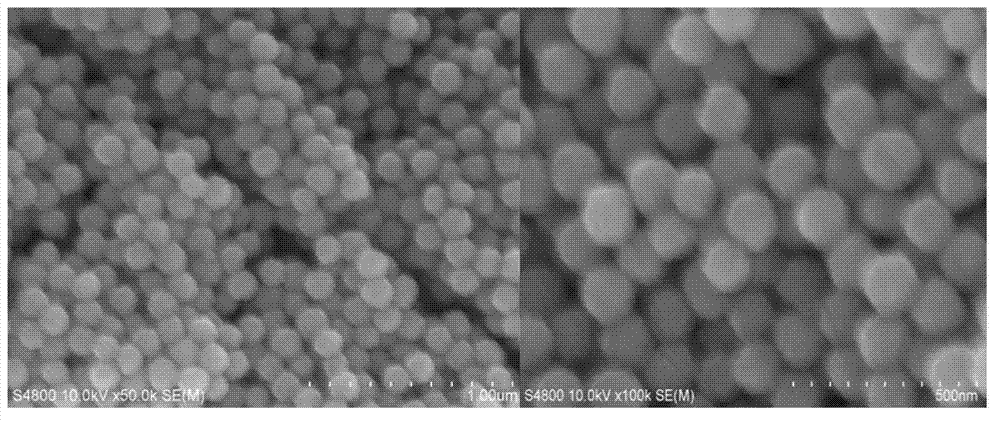

Method for preparing monodisperse cadmium sulfide nanospheres

InactiveCN102951675AGood repeatabilityShort preparation cycleMaterial nanotechnologyCadmium sulfidesMicrowave methodTemperature control mode

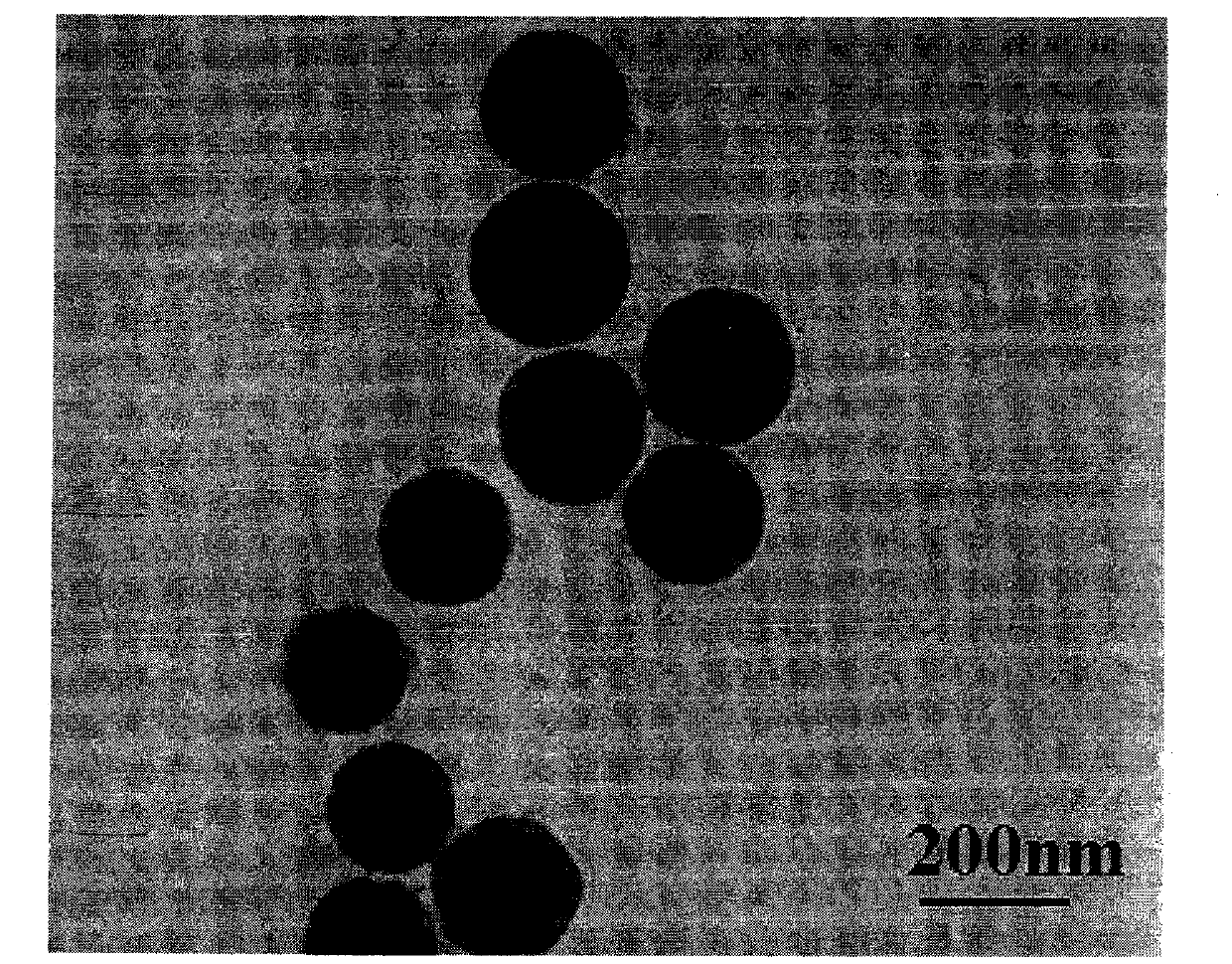

The invention provides a method for preparing monodisperse cadmium sulfide nanospheres, comprising steps of adding cadmium acetate dihydrate and sulfourea into deionized water respectively to obtain a solution A and a solution B, and adding the solution B into the solution A to obtain a solution C; uniformly mixing a PVP (Polyvinyl Pyrrolidone) solution D and the solution C to obtain a solution E; transferring the solution E into a hydrothermal reactor with Teflon as a lining, sealing the hydrothermal reactor, then putting the hydrothermal reactor into a temperature-pressure dual-control microwave hydrothermal reaction instrument for implementation of a preparation reaction in a temperature control mode, and naturally cooling after reaction completion; opening the hydrothermal reactor under the room temperature, washing with ethanol, then washing with the deionized water, performing centrifugal collection by taking absolute ethyl alcohol as a solvent, and drying at the temperature of 60 DEG C to obtain products CdS nanospheres. With the adoption of the method for preparing the monodisperse cadmium sulfide nanospheres, the high-temperature high-pressure environment of a hydrothermal method and the fast heating characteristic of a microwave method are combined; and with the adoption of a preparation technology of a microwave hydrothermal method, the monodisperse cadmium sulfide nanospheres with a regular spherical shape are prepared; and in addition, the method is short in preparation period, low in required temperature, small in pollution, low in energy consumption, simple to operate and high in repeatability, thereby being applicable for mass production.

Owner:SHAANXI UNIV OF SCI & TECH

Method of assembling quantum dot in mesoporous silica dioxide

InactiveCN101012372ASolve insolubleEasy to operateLuminescent compositionsDielectricMesoporous silica

The invention discloses an assembling method of quantum point in the dielectric silica, which comprises the following steps: adopting SBA-15 as mould; making amino propyl trimethoxy silane to decorate dielectric silica; adding cadmium acetate; adsorbing Cd2+ in the channel to form SBA-15-Cd2+; reacting with TOPO, Se or Te; controlling reacting time to the grain size of cadmium selenide of quantum point of or cadmium telluride in the channel.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

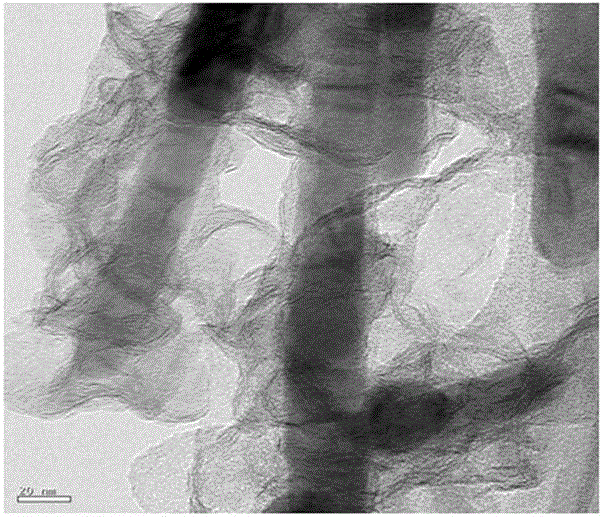

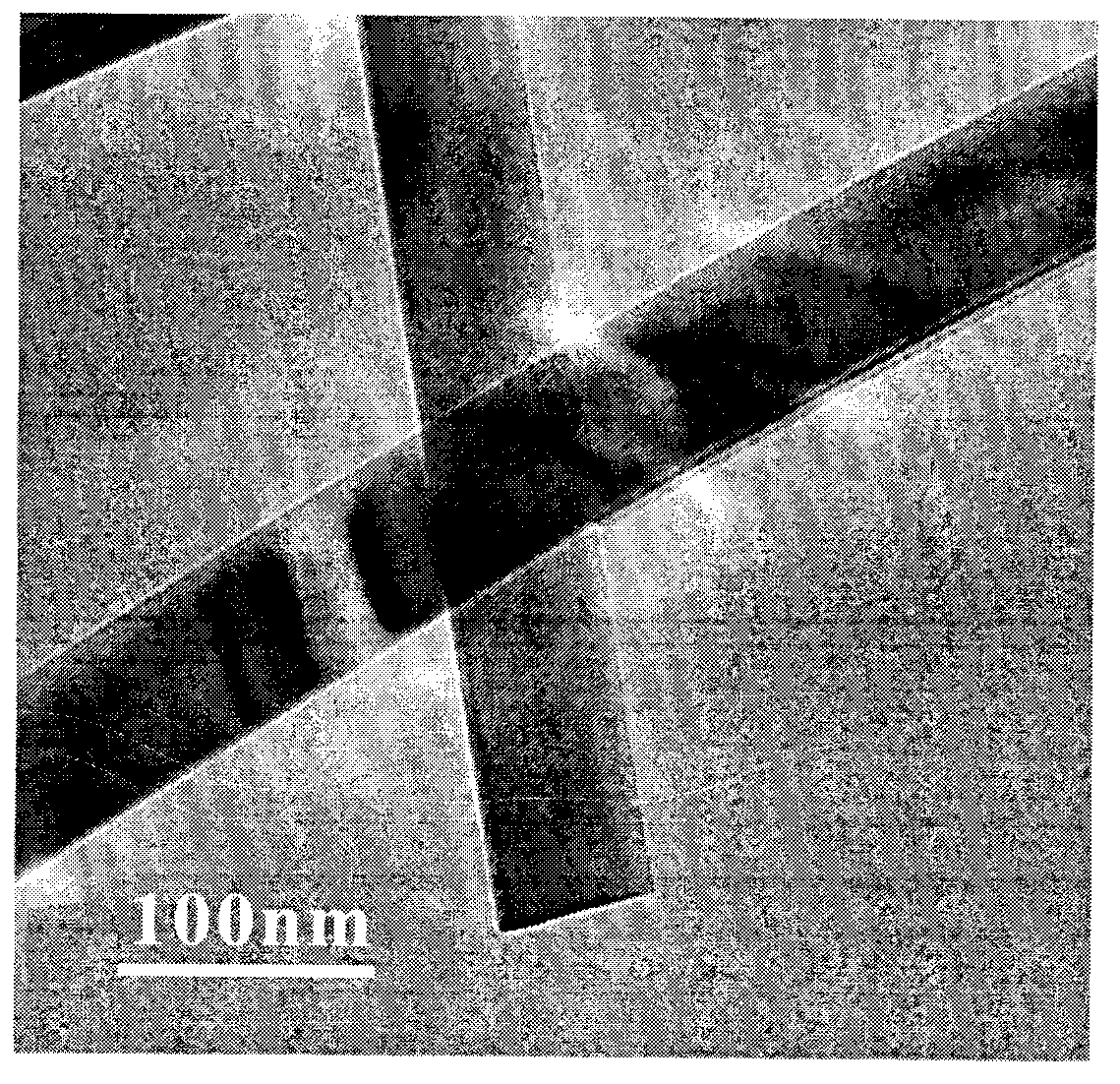

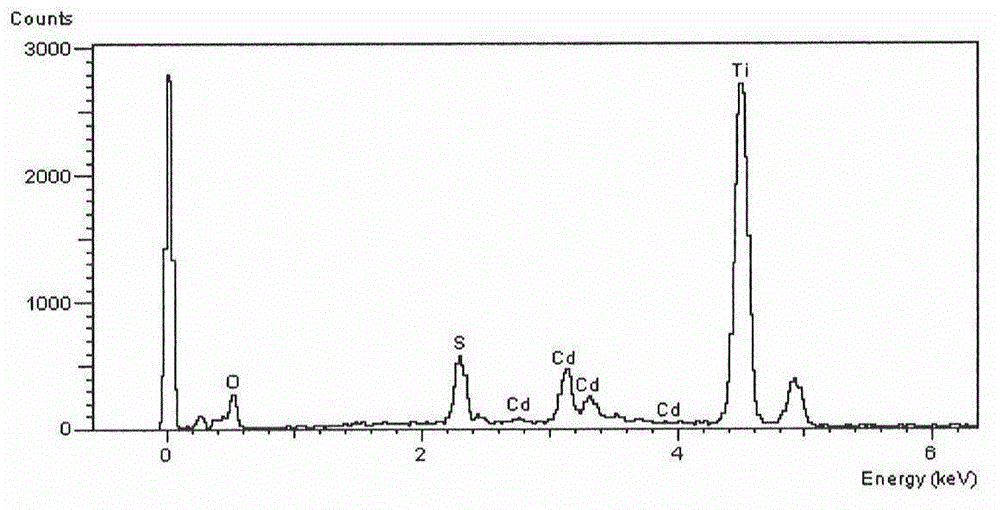

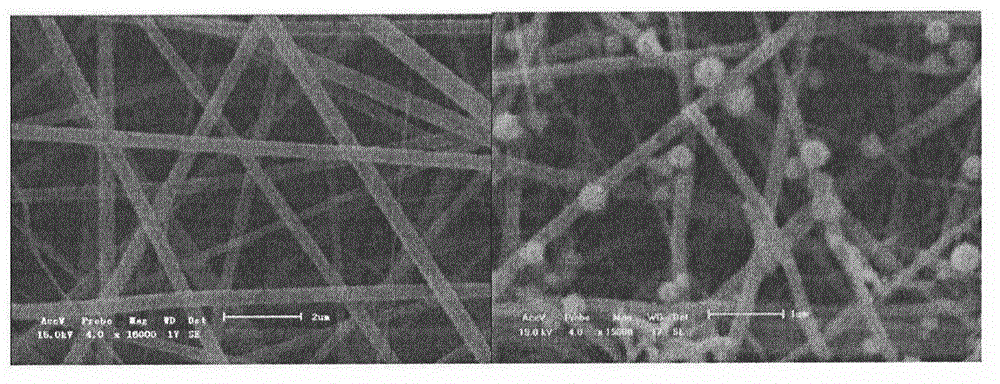

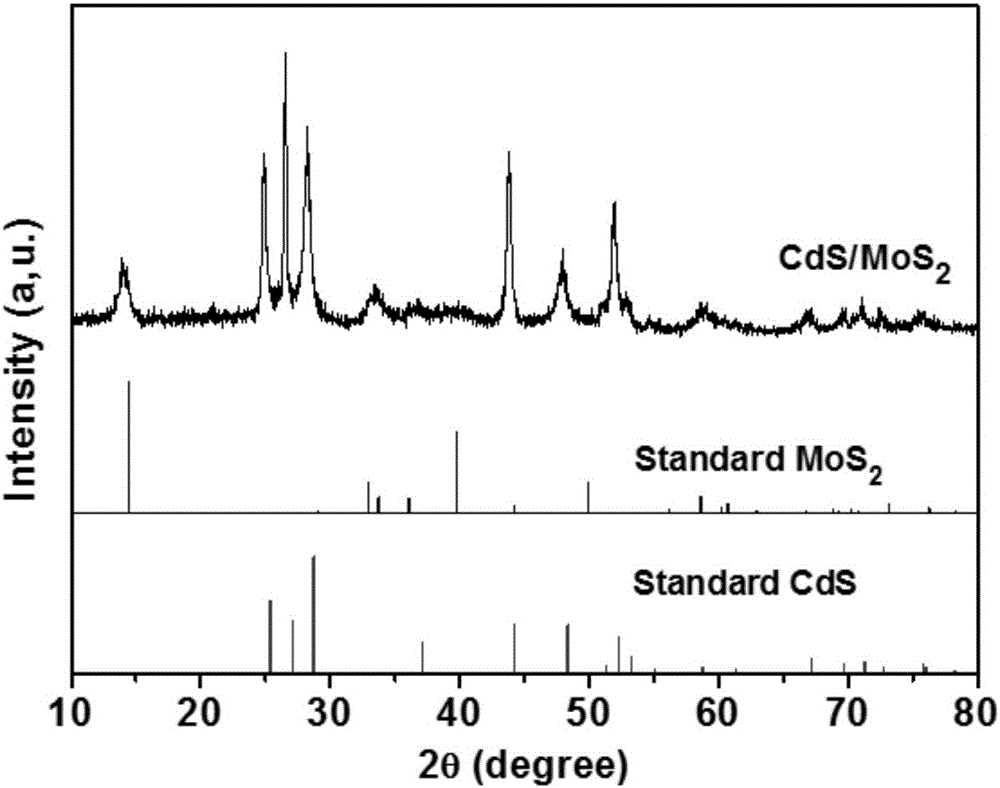

Preparation method for 1D/2D vertical Cds/MoS2 catalyst used for hydrogen production

ActiveCN106362774AIncrease the areaImprove adsorption capacityPhysical/chemical process catalystsHydrogen productionEthylenediamineCadmium acetate

The invention discloses a preparation method for a 1D / 2D vertical Cds / MoS2 catalyst used for hydrogen production. The preparation method comprises the following steps: uniformly mixing cadmium acetate, sulfur powder ethylenediamine under stirring so as to obtain a yellow mixture A; placing the yellow mixture in a hydro-thermal reaction vessel and carrying out heating at 180 to 220 DEG C for 3 to 5 h so as to obtain a sample B; cooling the sample B and successively carrying out centrifugation, washing and drying so as to obtain a CdS nanowire; dissolving a molybdenum source and a sulfur source in a glucose solution and carrying out uniform mixing so as to obtain a mixture C; adding the CdS nanowire into the mixture C obtained in the previous step, carrying out uniform mixing under stirring, and carrying out heating in a hydro-thermal reaction vessel at 180 to 220 DEG C for 10 to 26 h so as to obtain a sample E; and naturally cooling the sample E to room temperature and successively carrying out centrifugation, washing and drying so as to obtain a Cds / MoS2 composite nanomaterial. MoS2 nanoflakes vertically growing on the CdS nanowire allows more active sites to be exposed and a faster electron transport rate to be obtained, thereby facilitating photocatalytic hydrogen production.

Owner:HENAN INST OF ENG

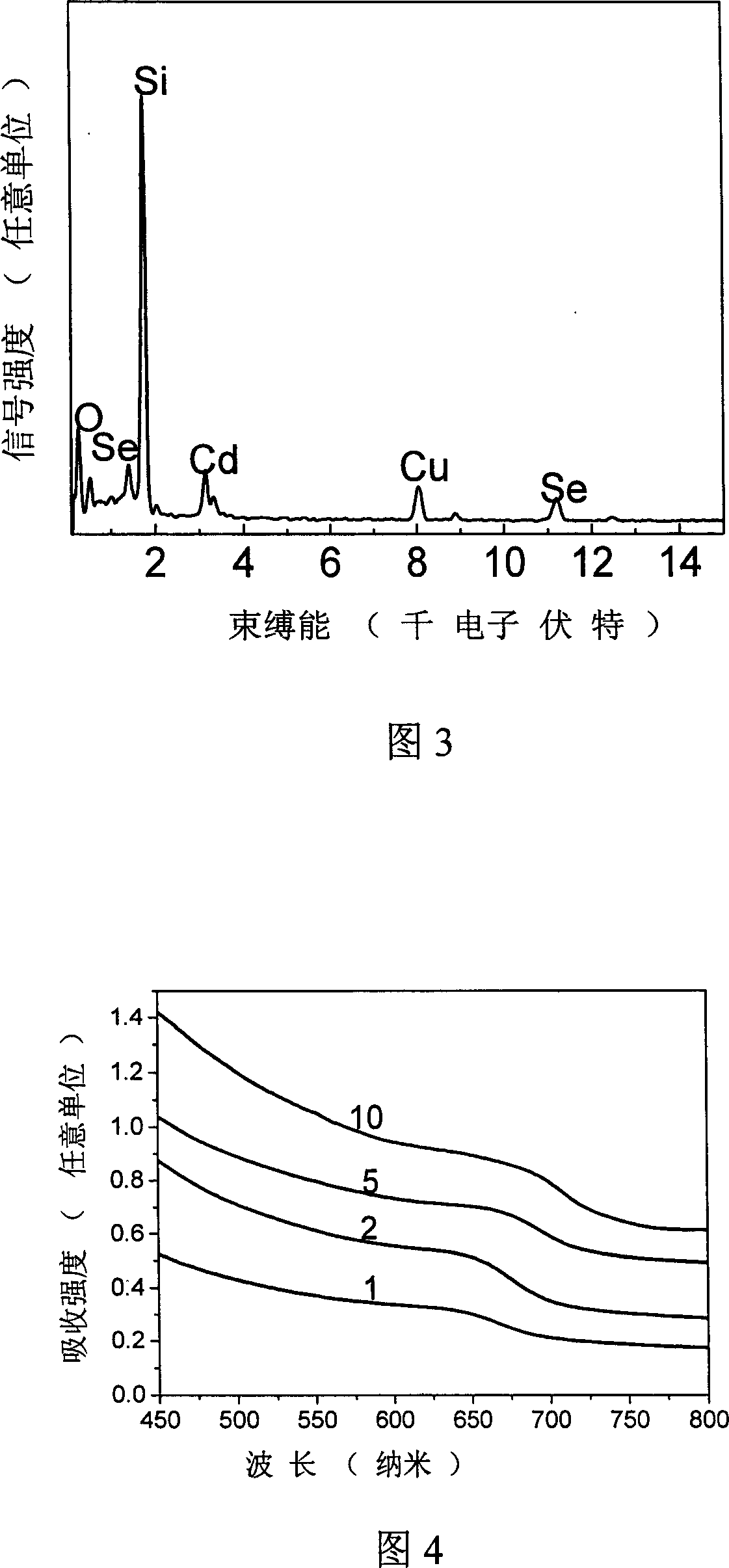

Preparation method of Cu2CdSnSe4 nano crystals

The invention discloses a preparation method of low-cost and high-quality Cu2CdSnSe4 nano crystals. The method comprises the following steps of: adding oleamide, acetylacetone acid copper, cadmium acetate, tin acetate and selenium powder which are reactant precursors into a reaction flask; then raising the temperature for reacting; and finally obtaining the high-quality Cu2CdSnSe4 nano crystals. The invention has the advantages that the preparation method of the nano crystals is simple; the used precursor materials have low cost; and the prepared nano crystal granules have better dispersity and crystallinity, and the like. The nano crystals prepared by using the method can be used as materials of thermoelectric devices.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Method for synthesizing powder of cadmium selenide quanta dots capable of emitting blue light

InactiveCN101585517AGood water solubilitySimple processNanostructure manufactureLuminescent compositionsSolubilityFluorescence

The invention relates to a method for synthesizing powder of cadmium selenide quanta dots capable of emitting blue light, belonging to the technical field of processing nanometer inorganic compound material of semiconductor. With cadmium acetate dehydrate and sodium selenite as raw material, disodium ethylenediamintetraacetate as chelating agent, and in the aqueous solution with weak alkaline, cadmium selenide quanta dots are synthesized by being radiated by electron beams. The powder of cadmium selenide quanta dots is obtained after separating the synthesized product. The cadmium selenide powder prepared by the invention has extremely good water solubility, good monodispersity, and even size with an average particle size of three nanometers. The cadmium selenide powder emits blue light, has good fluorescence characteristics and is used for manufacturing biological fluorescence probe.

Owner:SHANGHAI UNIV

CdTeS/ZnS cladding quantum dot and preparation thereof

InactiveCN101328408AControl emission wavelengthHigh fluorescence intensityLuminescent compositionsQuantum yieldQuantum dot

The invention discloses a CdSeS / ZnS jacketing quantum spot and a preparation method thereof. The method comprises the following steps that: inorganic substances such as cadmium oxide or cadmium acetate are taken as a raw material, the CdSeS quantum spot is prepared at a certain temperature, and ZnS is jacketed. The method avoids the complicated preparation process of the prior nuclear / housing quantum spot and overcomes the shortcomings that the organic cadmium such as Cd(CH3) 2 is flammable and combustible and the price is high. The method has simple and convenient operation, good repetitiveness, safety and easy implementation, and low cost. The prepared CdSeS / ZnS jacketing quantum spot not only has the characteristics of high fluorescence intensity, narrow half-peak width, high quantum productivity and good stability but also reduces the toxicity and further widens the application range of the quantum spot.

Owner:天津游瑞量子点技术发展有限公司

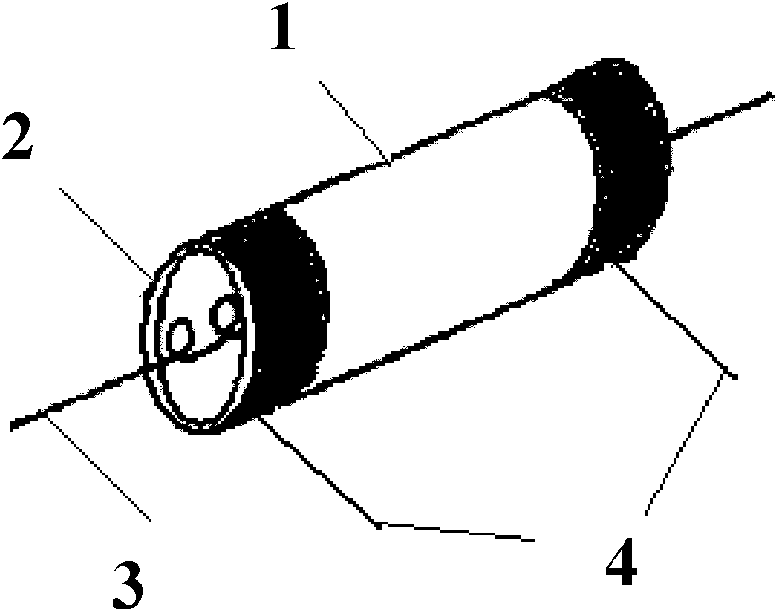

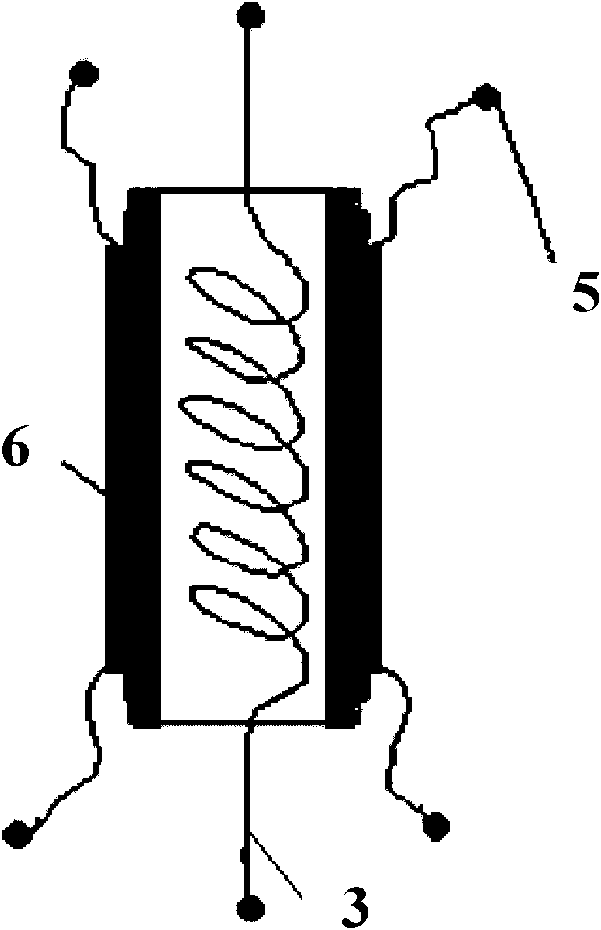

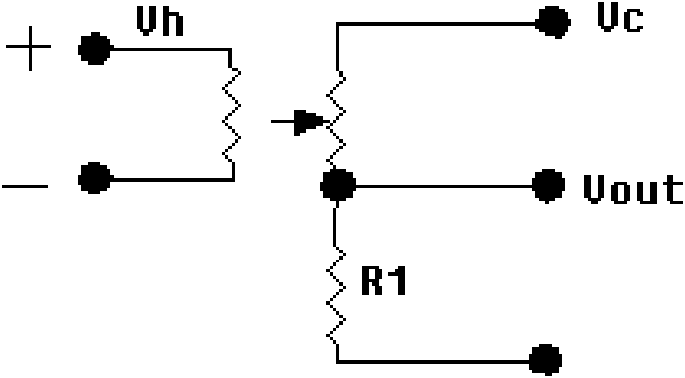

Cadmium sulfide coating carbon nano tube gas-sensitive material and manufacture method of gas-sensitive element

The invention discloses a cadmium sulfide coating carbon nano tube gas-sensitive material and a manufacture method of a gas-sensitive element. The manufacture method comprises the following steps: a carbon nano tube is processed by ultrasonic dispersion in the room temperature, and then a certain amount of thiacetamide and cadmium acetate is sequentially added; after that, the mixture is processed by the ultrasound for half an hour and placed in the water bath of 60 DEG C to 90 DEG C to be blended for 0.5 to 6 hours, thus obtaining the cadmium sulfide coating multi-walled carbon nano-tube nano powder material; after being dried in vacuum, the power material is prepared into sizing agent which is coated on a ceramic tube carrier, undergoes heat treatment of 400 to 500 DEG C, is welded and encapsulated and undergoes the electrical ageing, thus obtaining the side-heating type gas-sensitive element which has high sensitivity and good selectivity of ethanol gas. The gas-sensitive element has the simple structure, low request on manufacturing techniques and use conditions, convenient and reliable use, and low manufacturing cost.

Owner:CENT SOUTH UNIV

A kind of preparation method of low-cost cadmium phosphide quantum dot material

InactiveCN102268253AThe synthesis method is simpleContinuous operationLuminescent compositionsSynthesis methodsReaction temperature

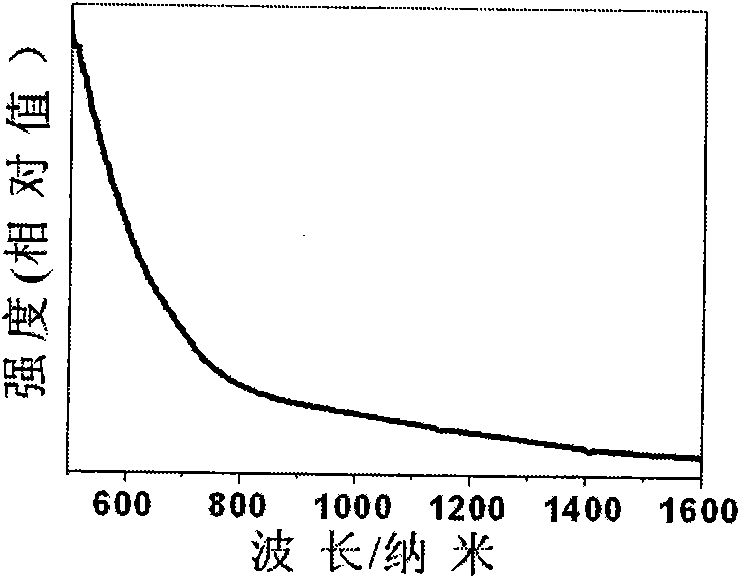

The invention discloses a preparation method of a low-cost cadmium phosphide quantum dot material. The preparation method comprises the following steps: based on a cheap cadmium compound such as cadmium oxide, cadmium acetate or cadmium cetylacetonate and the like as a raw material, dissolving the cadmium compound and long-chain fatty acid in octadecylene at a high temperature so as to prepare a long-chain fatty acid salt of cadmium; or dissolving cadmium cetylacetonate in organic amine, and then carrying out a gas-liquid reaction based on hydrogen phosphide as a phosphorus source so as to prepare the high-quality cadmium phosphide quantum dot luminescent material. According to the invention, a cheap and continuously operable synthesis method is provided for the cadmium phosphide quantum dot material, and a solid foundation is provided for industrialized production of the cadmium phosphide quantum dot material; and through controlling factors such as reaction temperature, time and the like, the luminescence of the cadmium phosphide quantum dot material can be achieved in a wide region ranging from visible light (460nm) to infrared light (1500nm).

Owner:HEFEI UNIV OF TECH

Preparation method of cadmium vanadate nanorods

InactiveCN103130276AImprove electrochemical performanceSmall diameterMaterial nanotechnologyVanadium compoundsCadmium acetateSolvent

The invention discloses a preparation method of cadmium vanadate nanorods, belonging to the technical field of nano material preparation. The preparation method comprises the following steps: by using cadmium acetate and sodium vanadate in a mol ratio of 1:1 as raw materials, polyvinylpyrrolidone (PVP) as a surfactant and water as a solvent, evenly mixing the cadmium acetate, sodium vanadate, PVP and water, sealing in a reaction vessel, and keeping at the temperature of 100-200 DEG C for 2-24 hours, wherein the amount of the cadmium acetate and sodium vanadate is not greater than 10 wt% of the water, and the amount of the PVP is not greater than 10 wt% of the water. The invention has the advantages of low preparation temperature, simple preparation process, no after-treatment procedure, low cost, and high purity and degree of crystallinity of the obtained cadmium vanadate nanorods, and thus, can easily implement industrialized production.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

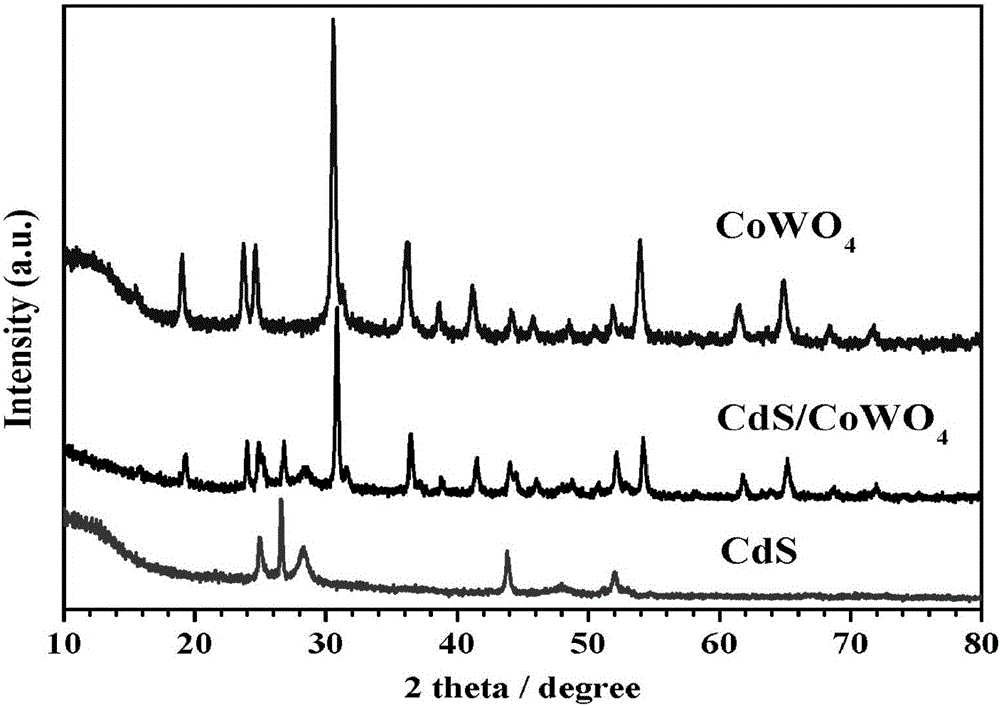

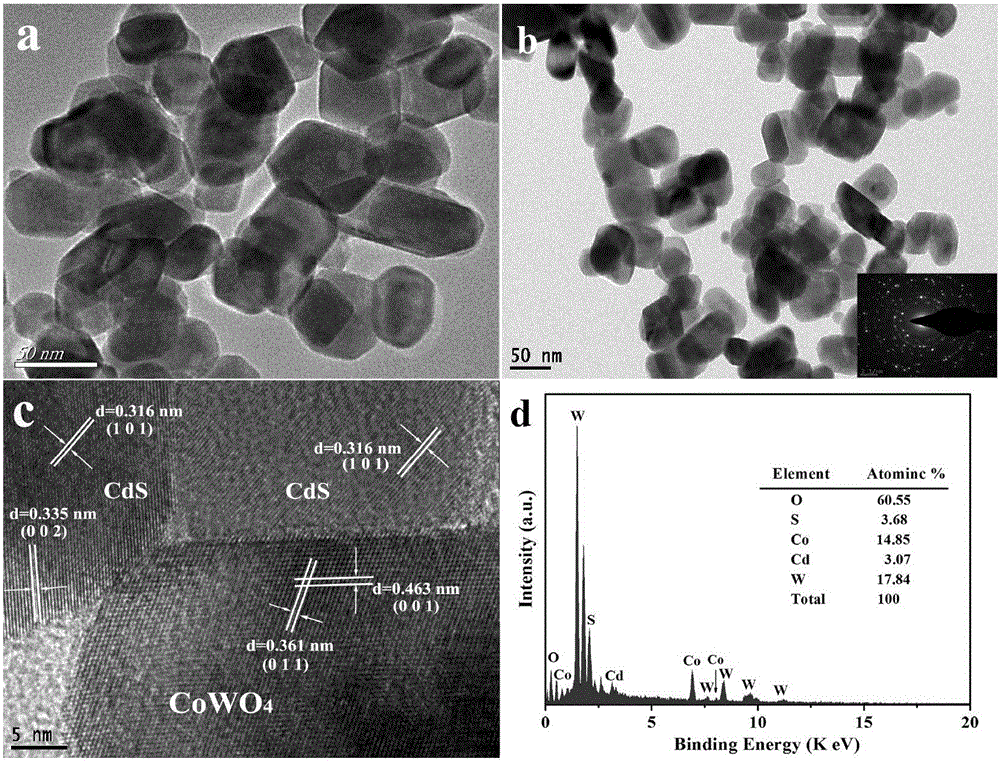

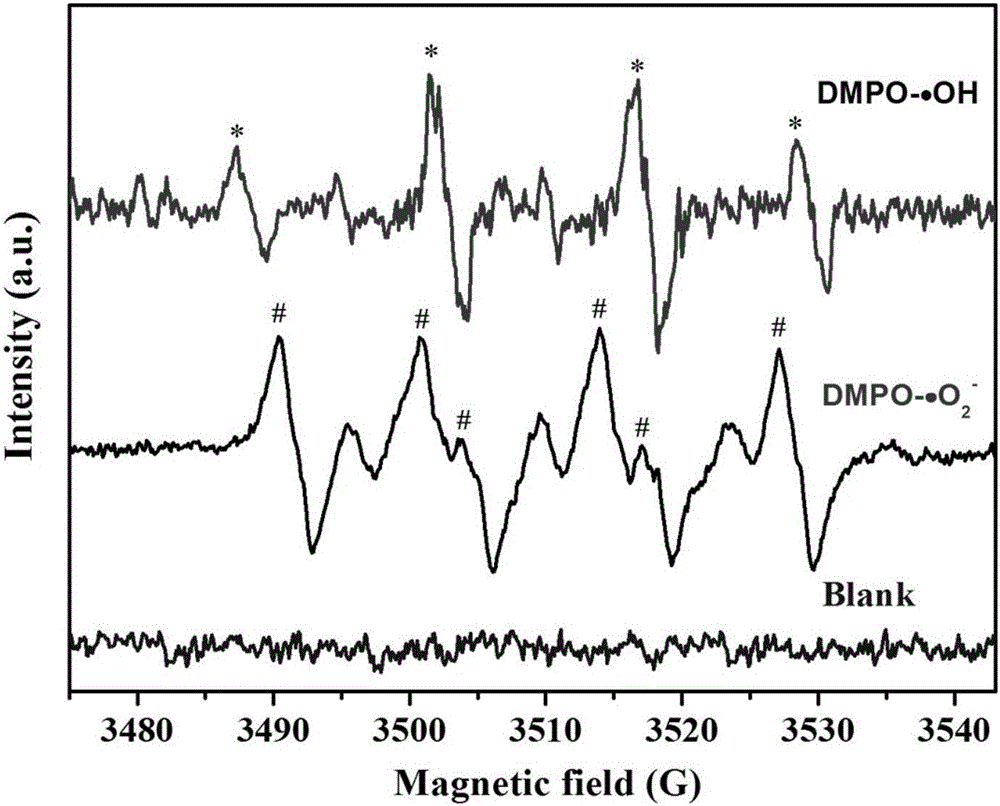

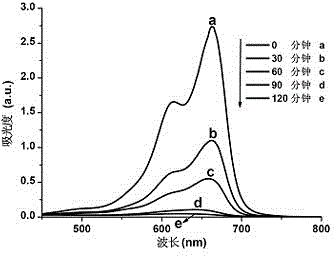

Method for preparing CdS/CoWO4 heterojunction composite photocatalyst

ActiveCN106076367AAssess photocatalytic activityMaterial nanotechnologyPhysical/chemical process catalystsHeterojunctionThiourea

The invention relates to transition metal tungstate, and concretely relates to a method for preparing a CdS / CoWO4 heterojunction composite photocatalyst by taking sodium hydroxide, sodium tungstate and cobalt nitrate as raw materials. The method comprises the following steps: taking a proper amount of sodium tungstate, adding the sodium tungstate in a cobaltous chloride-containing solution, adding a certain amount of sodium hydroxide while stirring, adjusting the pH value of the solution to 8, performing a hydrothermal reaction at the temperature of 180 DEG C for 12 hours, alternatively cleaning ethanol used for precipitation and deionized water for three times; performing ultrasonic disperse on CoWO4 in deionized water, adding equal amount of thiourea and cadmium acetate, continuously stirring the materials and uniformly mixing the materials, performing the hydrothermal reaction at the temperature of 180 DEG C for 24 hours, after the reaction is complete, filtering a precipitate, washing the precipitate, and drying the precipitate to obtain the CdS / CoWO4 heterojunction composite photocatalyst. The composite photocatalyst has good photocatalytic activity proved by methylene blue (MB) degradation experiment under visible light.

Owner:JIANGSU UNIV

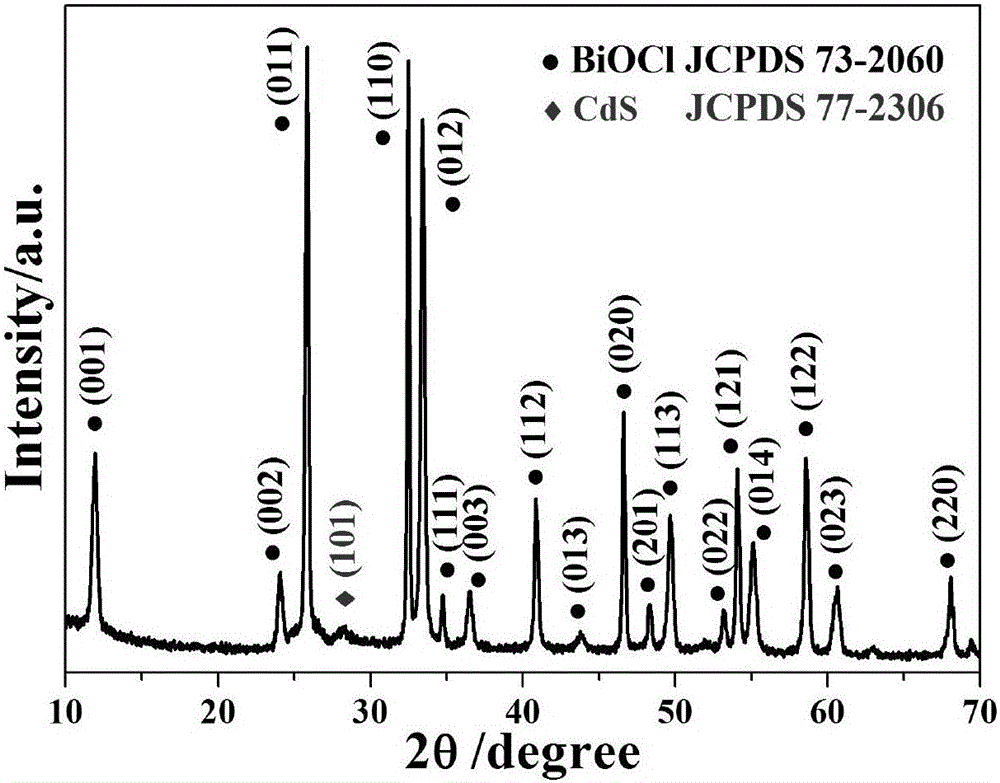

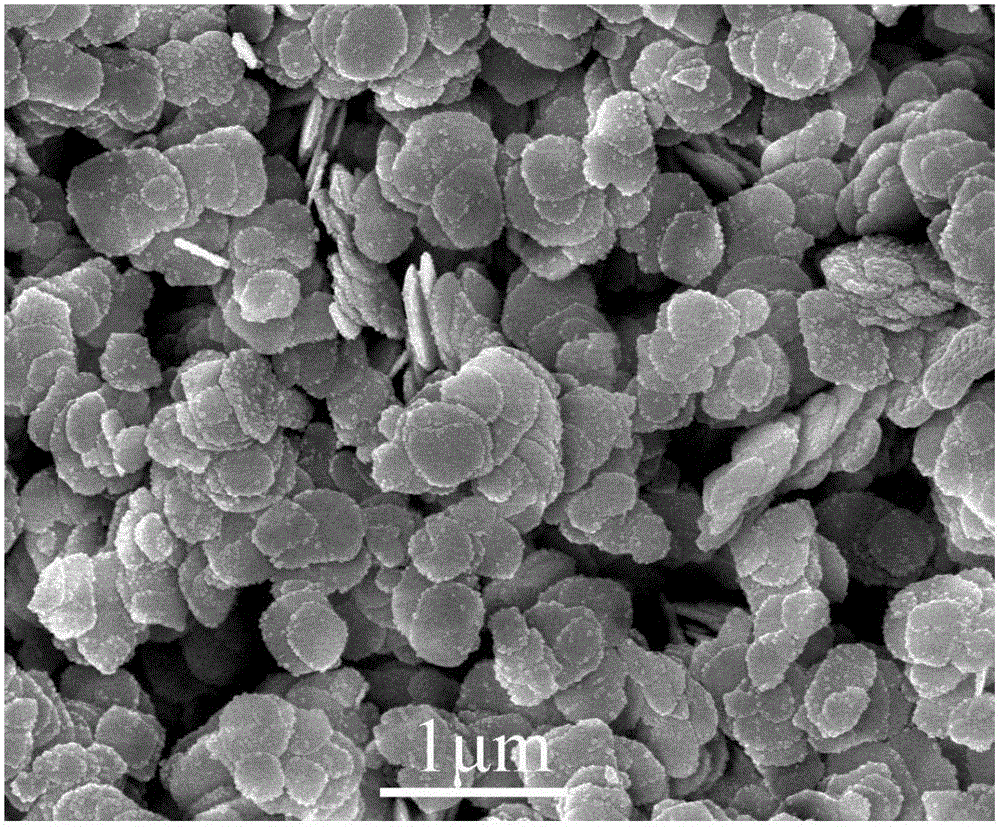

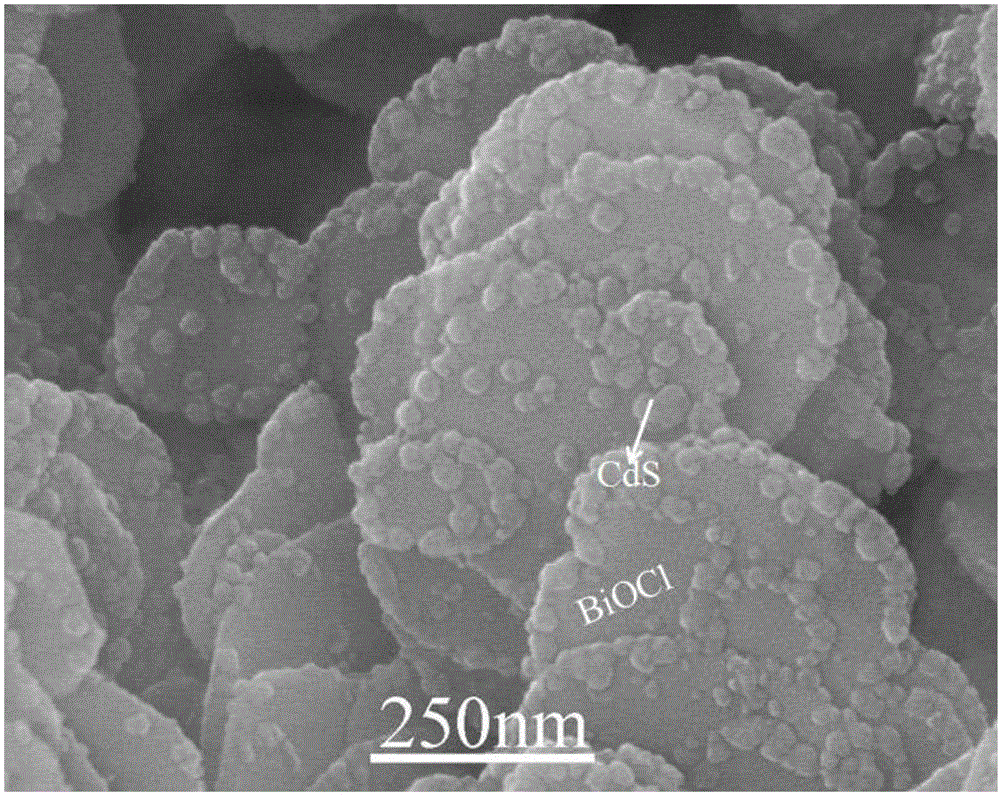

Flaky CdS/BiOCl composite nanometer material and preparation method thereof

InactiveCN106000431ARaw materials are easy to getLow costPhysical/chemical process catalystsMicrowave ovenThiourea

The invention discloses a flaky CdS / BiOCl composite nanometer material and a preparation method thereof. The preparation method comprises the following steps: mixing an ethanol solution containing an appropriate amount of bismuth nitrate with a sodium chloride water solution, magnetically stirring for 10 to 20 minutes, and conducting microwave reaction to obtain BiOCl nanometer powder; weighing 0.2 g of BiOCl to be added into 30 mL of a water solution containing a certain amount of cadmium acetate, and conducting ultrasound dispersion for 15 to 20 minutes to obtain a dispersion liquid A; weighing an appropriate amount of thiourea to be added into 30 mL of deionized water, and dissolving to obtain a solution B; adding the solution B into the dispersion liquid A, magnetically stirring for 10 to 20 minutes, placing a reaction mixture in a household microwave oven, setting a low fire level, and heating for 20 minutes; after the reaction is finished, naturally cooling, and conducting suction filtration and drying, so as to obtain the flaky CdS / BiOCl composite nanometer material. The flaky CdS / BiOCl composite nanometer material is high in yield and novel in structure, the size is 200-600 nm, the nanometer flaky substrate is BiOCl, and the granular CdS nanocrystals are compactly loaded on the surface of BiOCl flakes. The flaky CdS / BiOCl composite nanometer material and the preparation method thereof have the advantages that the operation is simple, the repeatability is good, the environment can be protected, and the energy can be saved.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

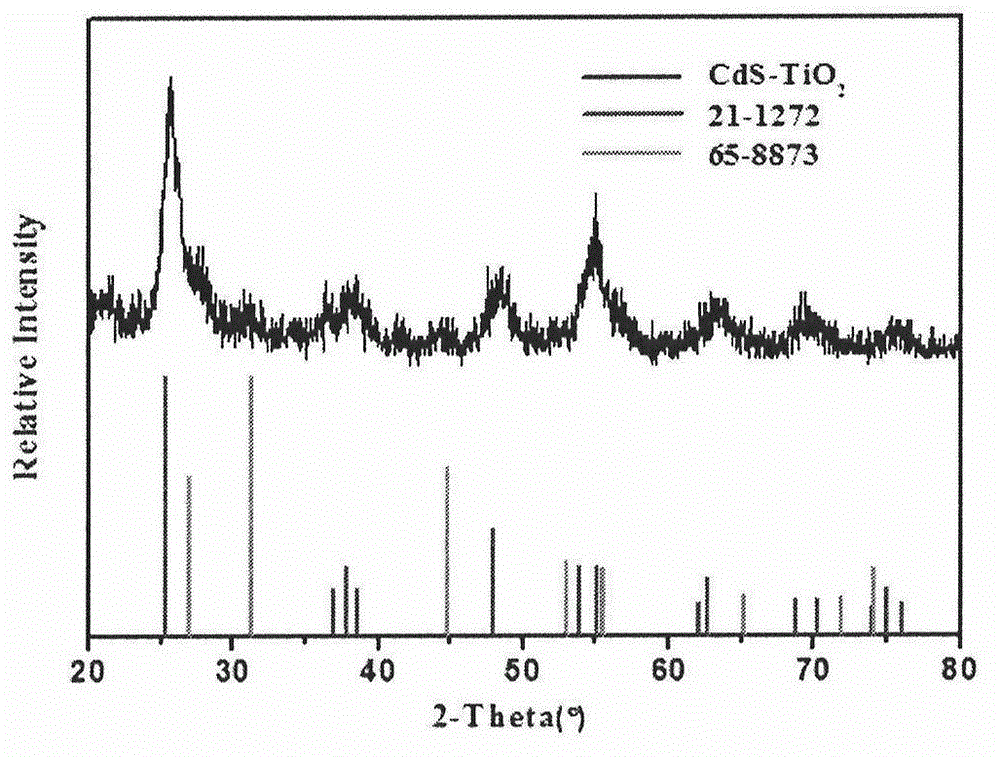

Catalyst for catalytic degradation of pollutants by ultraviolet light and preparation method of catalyst

InactiveCN104667903AImprove the efficiency of degrading organic pollutantsImprove efficiencyWater/sewage treatment by irradiationEnergy based wastewater treatmentFiberVulcanization

The invention discloses a preparation method of a catalyst for catalytic degradation of pollutants by ultraviolet light. The preparation method comprises the step of preparation of cadmium acetate, titanate and a PVP (polyvinyl pyrrolidone) precursor, and is characterized in that a cadmium sulfide and titanium dioxide catalyst is prepared with the process of first electrostatic spinning and later hydrothermal vulcanization. Cadmium salt is uniformly mixed into fiber with an electrostatic spinning method, and cadmium oxide is vulcanized with a hydrothermal method, so that cadmium sulfide is uniformly dispersed into the fiber; the reaction condition is mild, operation is simple and convenient, and the catalyst efficiency is high. Therefore, the preparation method has certain application value in the aspect of catalytic degradation of the pollutants by the ultraviolet light.

Owner:赵莎莎

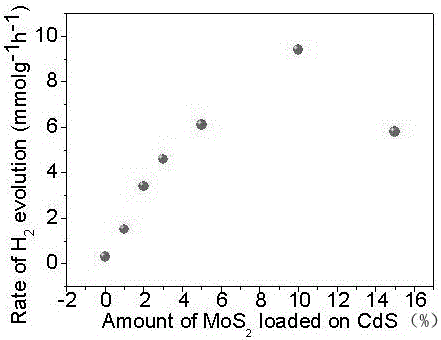

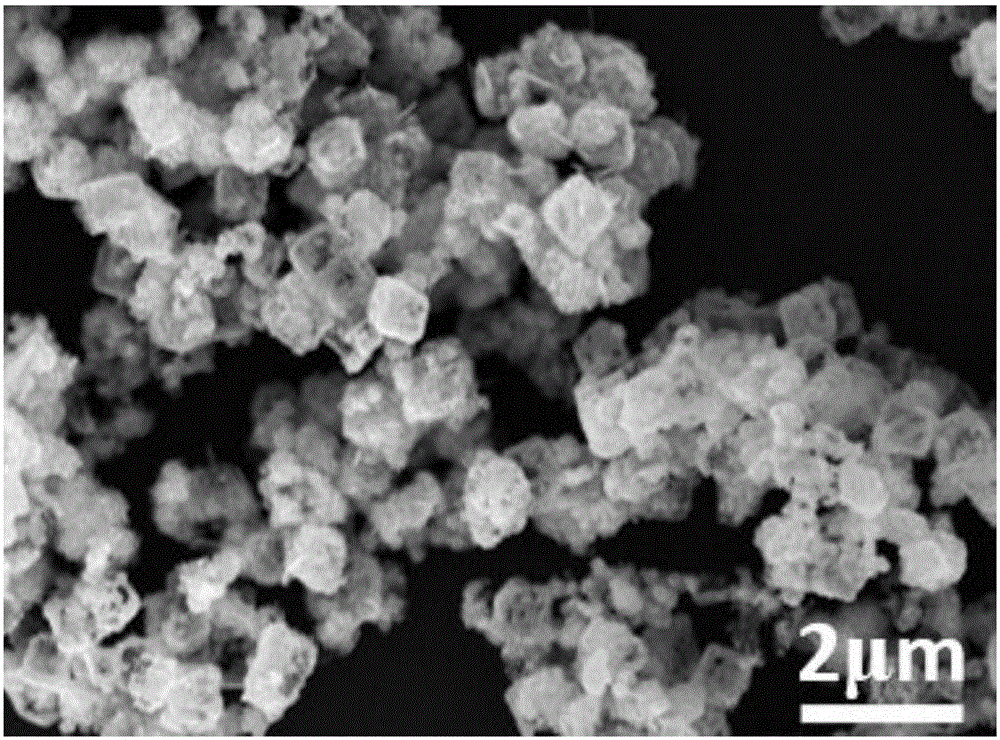

Method for preparing CdS/MoS2 composite hollow-block photocatalyst

InactiveCN106378160AFully crystallizedGood dispersionCatalyst activation/preparationSodium bicarbonateSodium molybdate

The invention relates to the technical field of composite nanomaterials and in particular discloses a method for preparing a CdS / MoS2 composite hollow-block photocatalyst by taking cadmium acetate, sodium bicarbonate, PVP, sodium molybdate and thiourea as raw materials, particularly a method for preparing a component photocatalyst with the advantages of simple preparation process and excellent visible-light catalytic activity of the product. The method comprises the following steps: weighing cadmium acetate and PVP, and dissolving in deionized water according to a mass ratio of 1:10; adding sodium bicarbonate into the mixture, so that the mass ratio of the cadmium acetate to sodium bicarbonate is 1:2; stirring and reacting at room temperature for 2 hours, washing and centrifuging the product after the reaction is completed, thereby obtaining cadmium carbonate; dissolving the cadmium carbonate, sodium molybdate and thiourea in the deionized water according to a mass ratio of (1):(0.15-1.4):(4), mixing and stirring, carrying out a hydrothermal reaction under the condition of 220 DEG C for 24 hours, washing and centrifuging the product after the reaction is completed, and drying, thereby obtaining the CdS / MoS2 composite photocatalyst.

Owner:JIANGSU UNIV

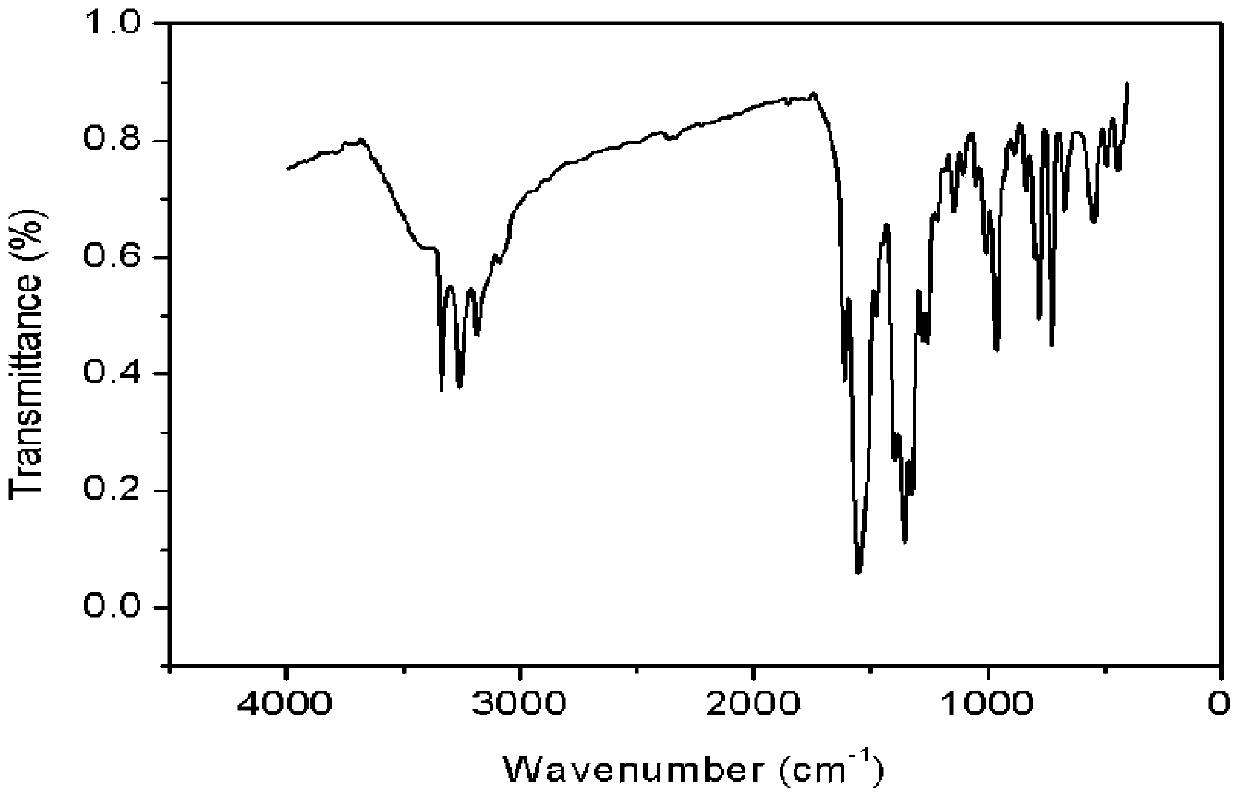

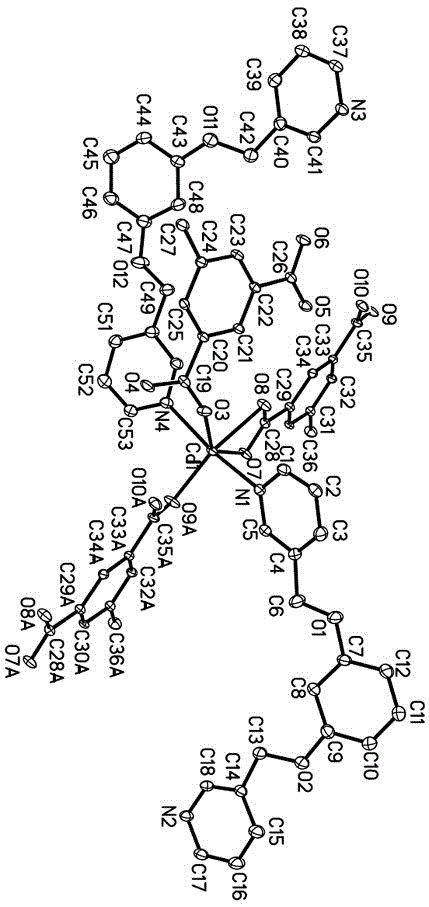

Cadmium metal complex with dye catalytic light degradation property and preparation method of cadmium metal complex

InactiveCN104693224ASimple processHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsCadmium organic compoundsCadmium acetateCadmium Metal

The invention discloses a cadmium coordination polymer adopting 1,3-bi(pyridine-3-methoxyl) benzene and 5-methyl isophthalic acid as ligands, and belongs to the chemical field. The chemical formula of the compound is as follows: [Cd2(5-Me-1,3-BDC)2(bpmb)2]n, wherein 5-Me-1,3-H2BDC is 5-methyl isophthalic acid; bpmb is 1, 3-bi(pyridine-3-methoxyl) benzene. The cadmium metal complex is prepared by adopting cadmium acetate dehydrate, 5-methyl isophthalic acid and 1,3-bi(pyridine-3-methoxyl) benzene. The preparation method of the complex is simple in process and relatively high in yield. The cadmium metal complex is stable in light catalytic degradation dye performance at a normal temperature and can be used for further developing a novel dye degradation material, so that novel vitality can be brought to the field of the material science.

Owner:ANYANG NORMAL UNIV

Preparation method of blue-light sphalerite CdSe/CdS nuclear crown structure nano sheet

ActiveCN110127631AEasy to bendAvoid problemsMaterial nanotechnologyCadmium sulfidesFiberSynthesis methods

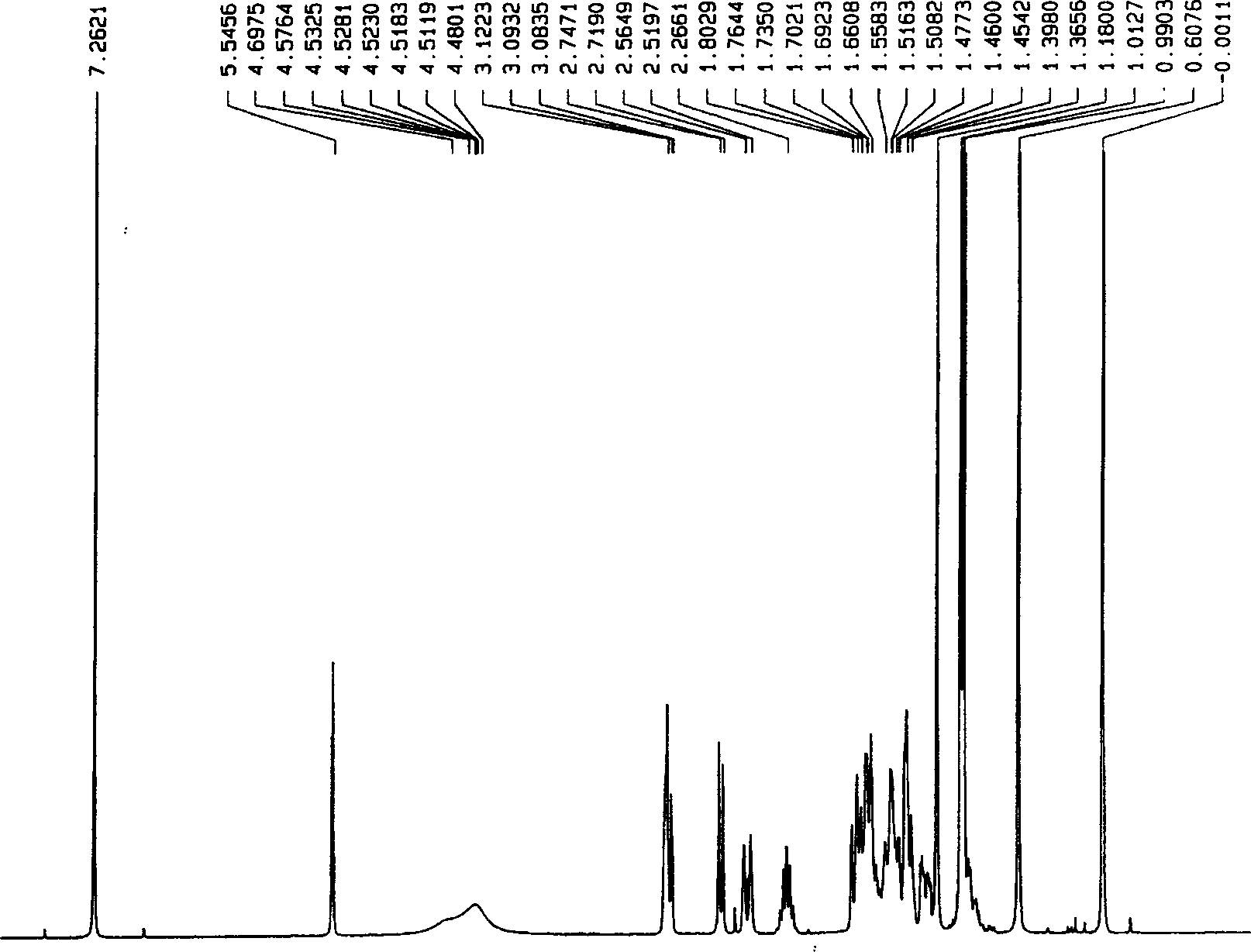

The invention discloses a preparation method of a blue-light sphalerite CdSe / CdS nuclear crown structure nano sheet. The method comprises the following steps: dissolving cadmium acetate dihydrate andchemically pure selenium powder in solvent octadecene, and reacting for 1 hour under the protection of an inert gas at 140-160 DEG C to prepare a blue-fiber sphalerite CdSe nanosheet solution; preparing a crown-packing precursor CdS solution step by step by using the cadmium acetate dihydrate, the ODE and sulfur powder; heating the blue-fiber sphalerite CdSe nanosheet solution to 150 DEG C-170 DEGC, pouring the crown-packing precursor CdS solution, stirring for reaction, and purifying to obtain the blue-light sphalerite CdSe / CdS nuclear crown structure nano sheet. The blue-light sphalerite CdSe / CdS nuclear crown structure nano sheet has the advantages of low preparation temperature, small core size, flat nano sheet, difficult edge bending and good dispersibility, narrower half-peak widthof the emission peak of the nano sheet after crown packing, better single luminous color and higher stability. The synthesis method is simple and can be produced on a large scale.

Owner:HUBEI UNIV

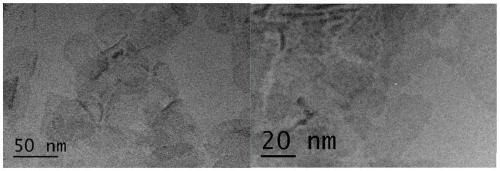

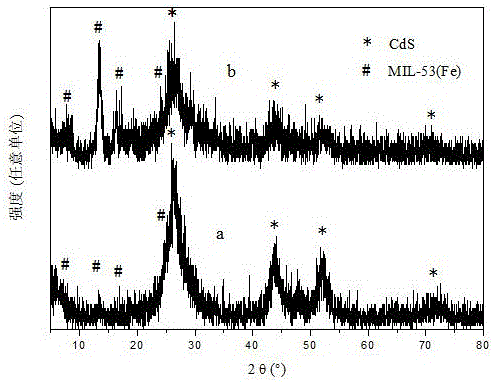

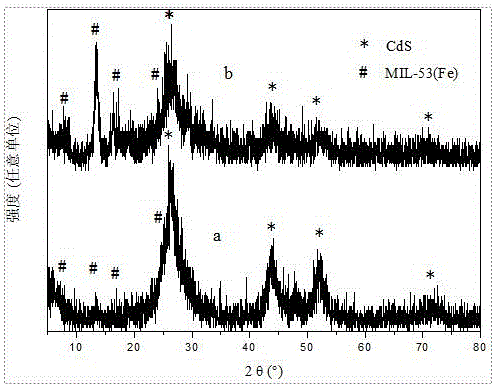

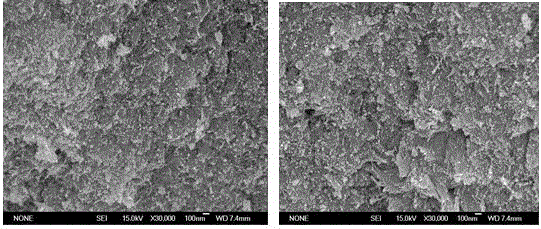

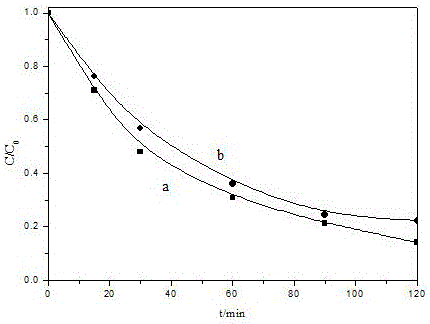

Preparation method for CdS/MIL-53 (Fe) visible light catalyst

InactiveCN106582719APromote generationRefine the grain sizePhysical/chemical process catalystsWater/sewage treatment by irradiationN dimethylformamideCadmium acetate

The invention relates to a preparation method for a novel CdS / MIL-53 (Fe) visible light catalyst. The preparation method comprises the steps that an MIL-53 (Fe) material is prepared from ferric trichloride, terephthalic acid and N,N-dimethylformamide at the molar ratio of 1:1:65 by adopting the solvothermal method at first; then cadmium acetate, thioacetamide, polyvinylpyrrolidone, ethylene glycol and MIL-53 (Fe) are weighed according to the mass ratio of cadmium sulfide to the MIL-53 (Fe) being (1-1.5):1, and the MIL-53 (Fe) is dispersed in the ethylene glycol; the cadmium acetate is added; and the thioacetamide and the polyvinylpyrrolidone are added, reaction is conducted for 12 hours at the temperature of 180 DEG C, centrifugation, secondary distilled water washing and absolute ethyl alcohol washing are conducted for 5-6 times, drying is conducted for 10 hours at the temperature of 60 DEG C, and the CdS / MIL-53 (Fe) visible light catalyst is finally obtained. The catalytic activity of the CdS / MIL-53 (Fe) visible light catalyst is excellent, and the degradation rate of the visible light catalyst on rhodamine B is 71%-90%.

Owner:SHANGHAI UNIV

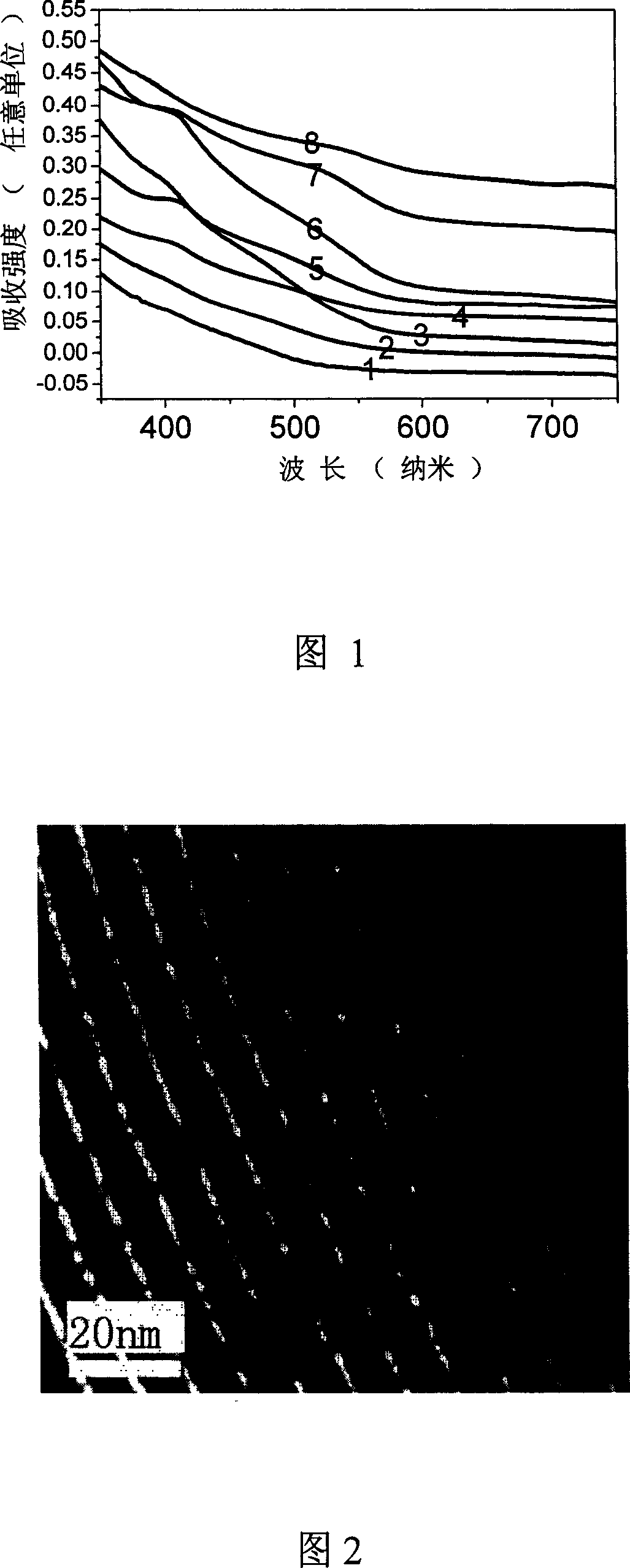

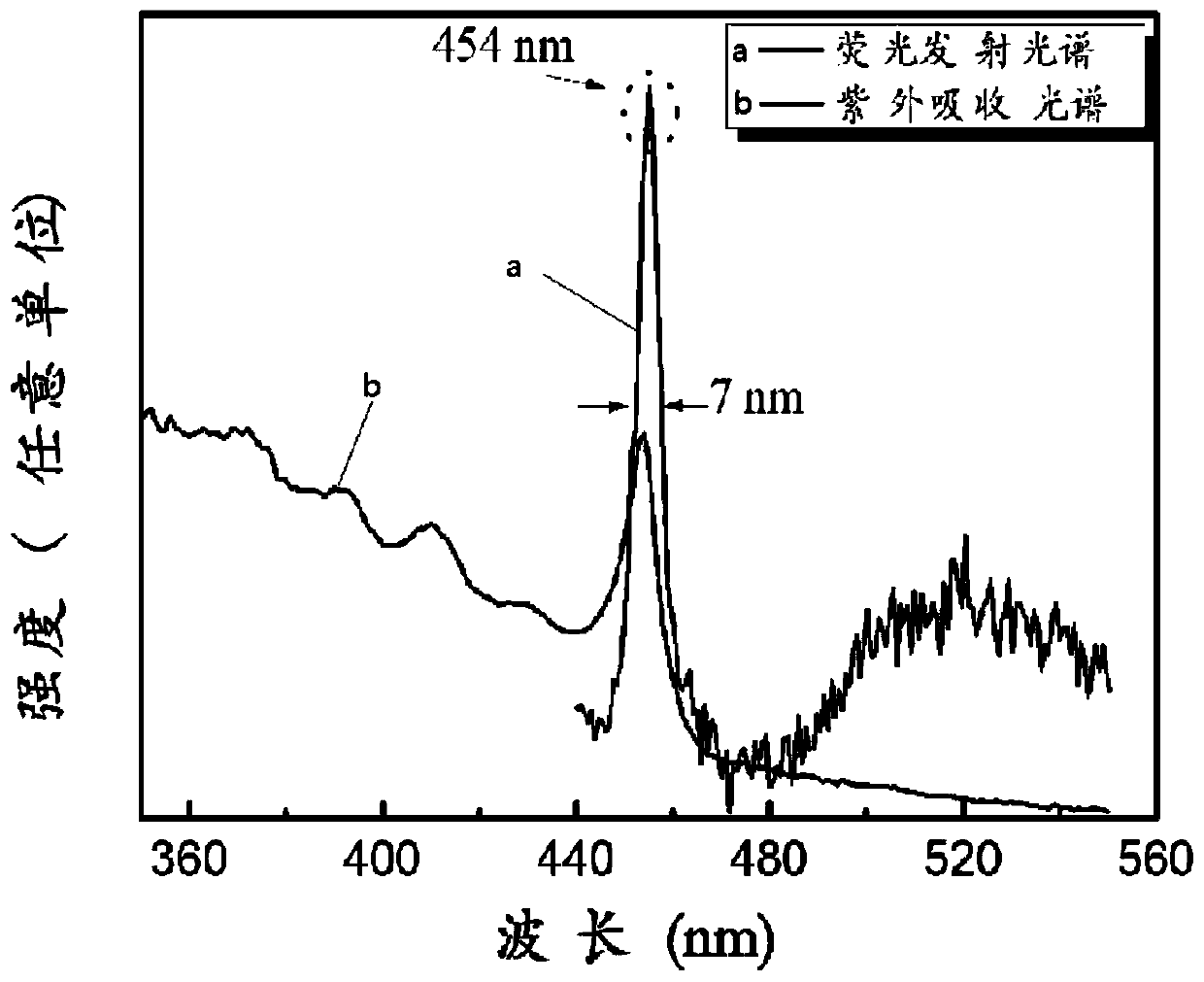

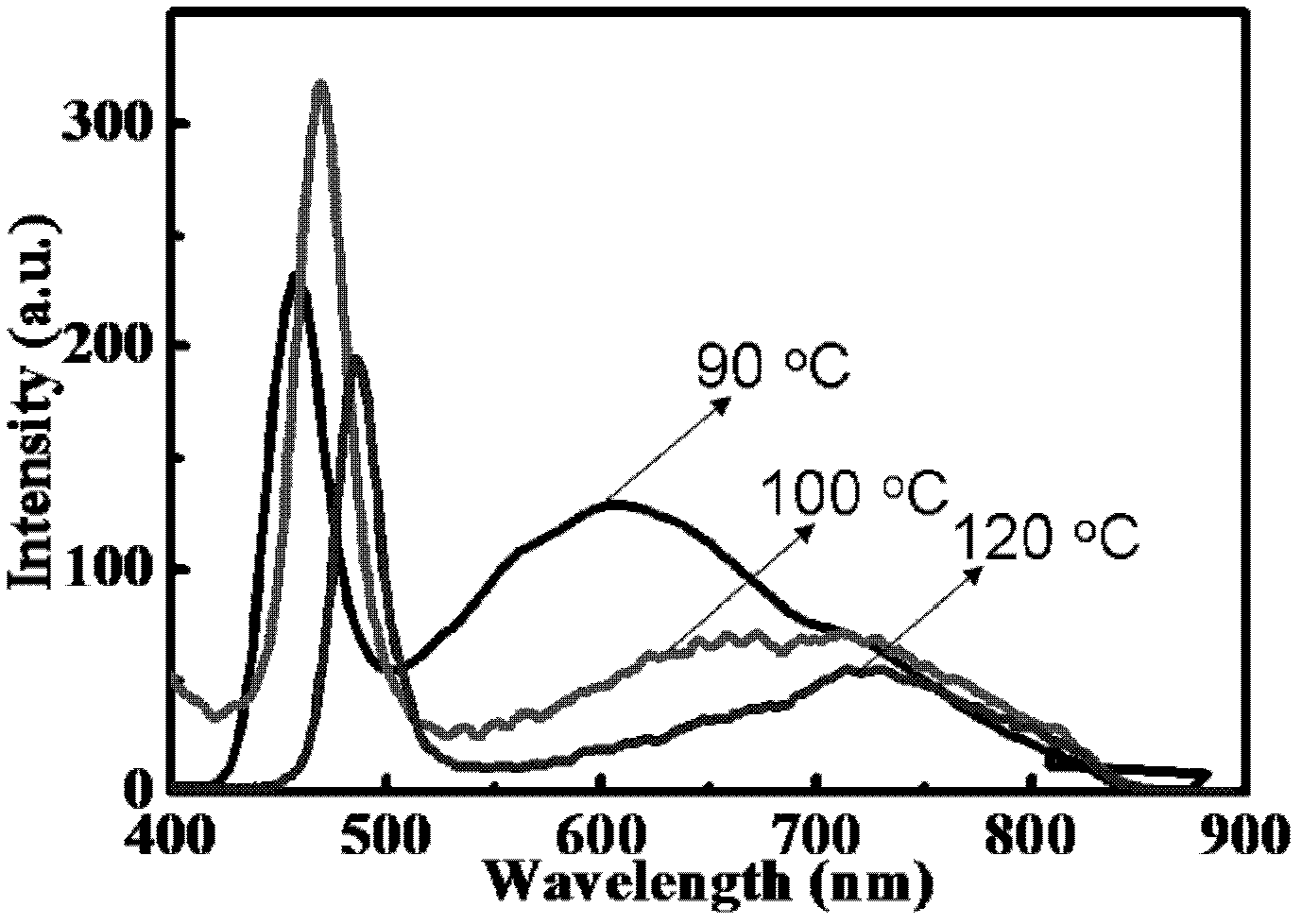

Luminescence-adjustable ligand-free cadmium sulfide semiconductor quantum dot and preparation method thereof

InactiveCN102634336ARaw materials are easy to getLow costCadmium sulfidesLuminescent compositionsThioureaCadmium acetate

The invention discloses a method for preparing a luminescence-adjustable ligand-free cadmium sulfide quantum dot. The quantum dot does not need any organic molecules as ligands, has good stability, can be effectively hybridized with organic materials and prevents the phenomenon of phase separation in the hybridization process, and the luminescence wave length can be precisely adjusted along with a synthesis condition. According to the preparation method of the luminescence-adjustable ligand-free cadmium sulfide semiconductor quantum dot, cadmium acetate, cadmium propionate or cadmium stearate is selected as a cadmium source, and thiourea or sodium sulfide is selected as a sulfur source, and the luminescence-adjustable ligand-free cadmium sulfide semiconductor quantum dot can be prepared without any organic molecules as a cladding agent.

Owner:NANJING UNIV OF TECH

Method for preparing CdS/MIL-53(Fe) visible-light-induced photocatalyst

ActiveCN106513050APromote generationRefine the grain sizeWater/sewage treatment by irradiationWater treatment compoundsCadmium acetateCadmium sulfide

The invention relates to a method for preparing a novel CdS / MIL-53(Fe) visible-light-induced photocatalyst. The method comprises the following steps: firstly, preparing an MIL-53 (Fe) material from ferric trichloride, terephthalic acid and N,N-dimethyl formamide in a molar ratio of 1:1:65 by adopting a solvothermal method; respectively weighing cadmium acetate, thioacetamide, polyvinylpyrrolidone, ethylene glycol and MIL-53(Fe) with corresponding mass according to the mass ratio of cadmium sulfide to MIL053(Fe) being (1-1.5):1, dispersing MIL-53(Fe) in ethylene glycol, and sufficiently stirring; adding cadmium acetate, and sufficiently stirring until cadmium acetate is completely dissolved; and adding thioacetamide and polyvinylpyrrolidone, and sufficiently stirring until thioacetamide and polyvinylpyrrolidone are completely dissolved, transferring into a reactor to react for 12 hours at 180 DEG C, centrifuging, washing for 5-6 times with redistilled water and absolute ethyl alcohol, and drying for 10 hours at 60 DEG C to finally obtain the CdS / MIL-53(Fe) visible-light-induced photocatalyst. In the CdS / MIL-53(Fe) visible-light-induced photocatalyst, spherical CdS has an average grain size of 10nm and is uniformly distributed on the surface of the MIL-53(Fe) material. The visible-light-induced photocatalyst has excellent catalytic activity, and has a degradation rate for rhodamine B being 71-90 percent.

Owner:SHANGHAI UNIV

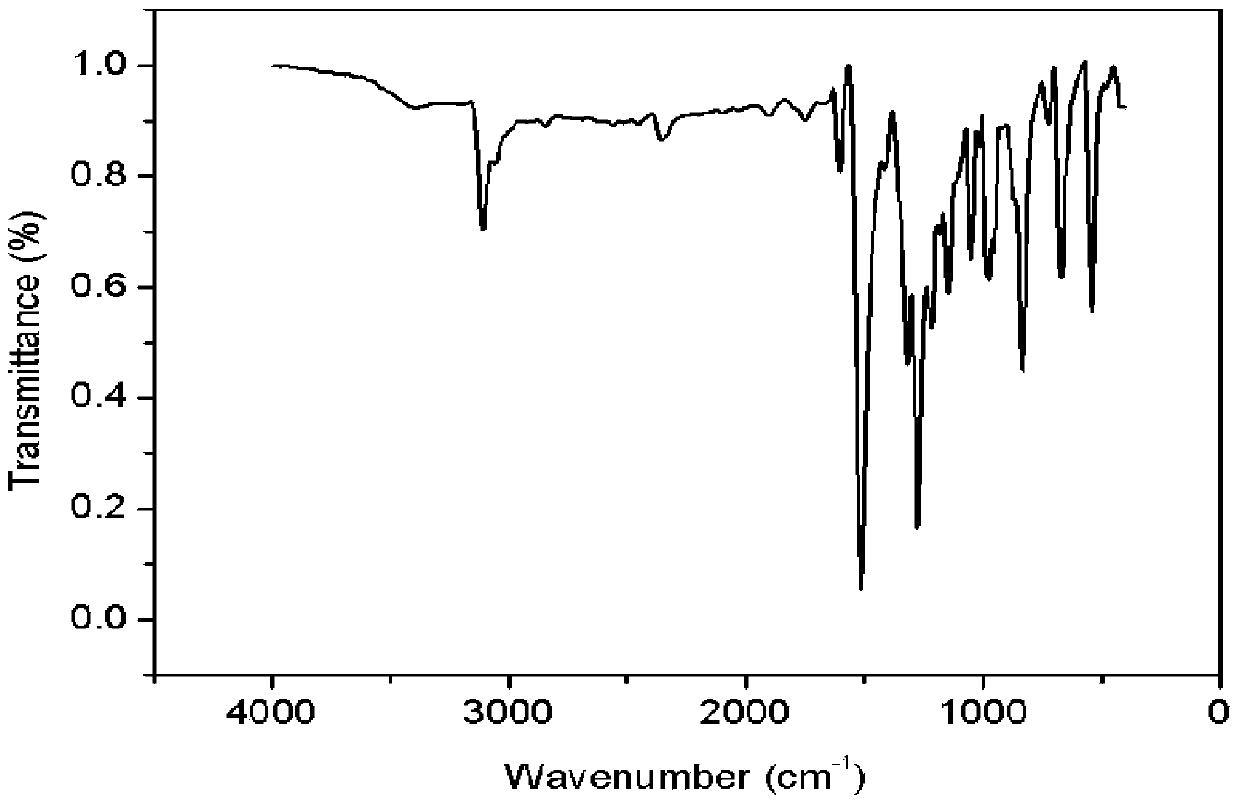

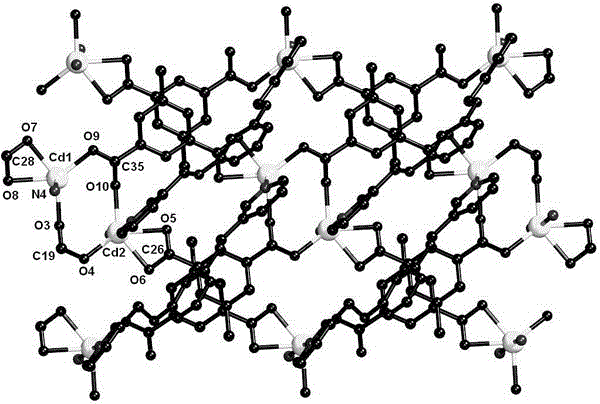

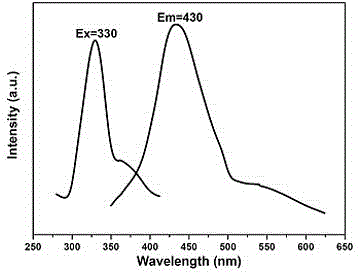

Cadmium coordination polymer as well as preparation method and applications thereof

InactiveCN104693223ASimple processHigh yieldLuminescent compositionsCadmium organic compoundsCadmium acetatePhthalic acid

The invention discloses a cadmium coordination polymer by taking 1,3-bis(pyridine-3-methoxy)benzen and 1,4-phthalic acid as ligands, and a preparation method and fluorescent performance of the coordination polymer, belonging to the field of chemistry. The chemical formula of the coordination polymer is [Cd(1,4-BDC)(bpmb)(H2O)]<n>, wherein 1,4-H2BDC is equal to 1,4-phthalic acid; bpmb is equal to 1,3-bis(pyridine-3-methoxy)benzen. The coordinate polymer is prepared from cadmium acetate dihydrate, 1,4-phthalic acid, 1,3-bis(pyridine-3-methoxy)benzen. The complex can be specifically applied onto a fluorescent material. The coordination polymer is stable at room temperature, the preparation method is simple in technology, and the coordination polymer has stable fluorescent performance at room temperature.

Owner:ANYANG NORMAL UNIV

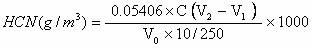

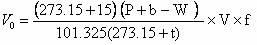

Method for testing content of hydrogen cyanide in gas

InactiveCN102636616ARapid determinationAccurate measurementChemical analysis using titrationPotassium hydroxideSulfide

The invention provides a method for testing content of hydrogen cyanide in gas. The method comprises the following steps of: absorbing the hydrogen cyanide in the gas by adopting a potassium hydroxide solution, transferring the absorption solution to a volumetric flask with a certain volume, taking a certain amount of absorption solution, adding a cadmium acetate solution to make sulfide in the absorption solution to form indissolvable cadmium sulfide to sediment, filtering and sintering the absorption solution to eliminate the sediments, taking Dabr as an indicator of the solution, taking a standard silver nitrate solution to titrate, making cyanide ions react with silver nitrateto form soluble cyanide complex ion (Ag(CN)2), making excessive silver ions react with the Dabar indicator so as to make the color of the solution change from yellow to orange to the end, and calculating the content of the hydrogen cyanide according to the volume of the consumed standard silver nitrate solution. The method provided by the invention solves the problems that various kinds of reagents used in the prior art are poisonous and harmful, and moreover the reagents have the disadvantages of complex analysis step, long elapsed time and the like, have potential safety hazards existing in the testing process, and enhance the sewage treatment load of the back section. The method can rapidly and accurately test the content of the hydrogen cyanide in coke oven coal.

Owner:云南昆钢煤焦化有限公司

Tantalum titanate cadmium sulphide platinum-carried laminated composite catalyst and its preparation method

ActiveCN1803278AEnhance photocatalytic hydrogen production activityImprove stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsIon exchangeCadmium acetate

The invention discloses a layered stromal HTiTaO5 / CdS Pt-carrying new-typed composite catalyst and making method, which comprises the following steps: mixing K2CO3, Ta2O5 and TiO2 at chemical gauge rate; sintering to obtain the KTiTaO5 product; proceeding KTiTaO5 to obtain catalyst layered stromal HTiTaO5 through nitric ion exchange; exchanging the stromal HTiTaO5 with saturated cadmium acetate ion through pile-supported propanamine; vulcanizing the exchanged stromal HTiTaO5 in the pipe-typed furnace hydrogen sulfide atmosphere at high temperature to produce HTiTaO5 / CdS; carrying Pt through photoreduction. The invention reaches the highest hydrogen-producing rate at 144umol / h and 6.3 percent quantum efficiency at 420 nm and 1.67 percent optical conversion efficiency for all-band of visible light, which improves the product activity.

Owner:陕西中核交大超洁能源技术有限公司

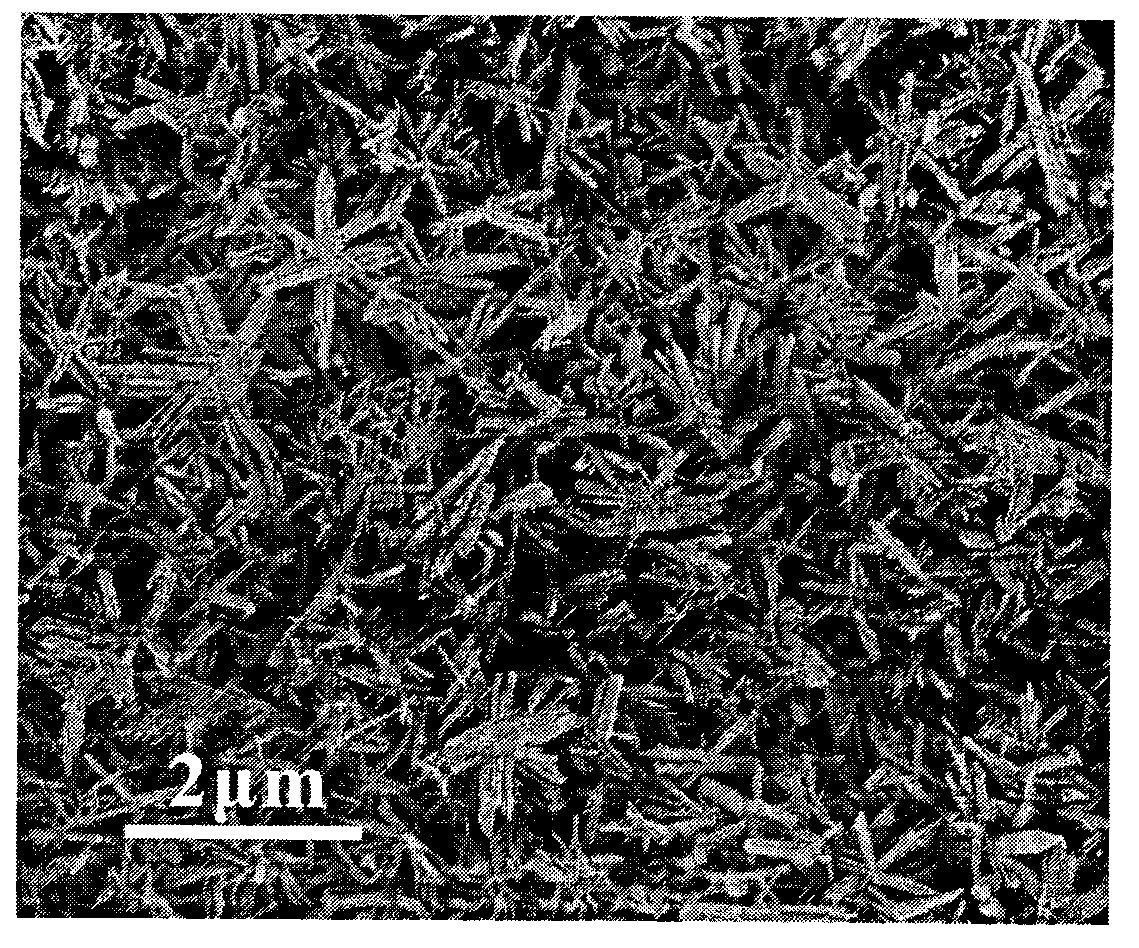

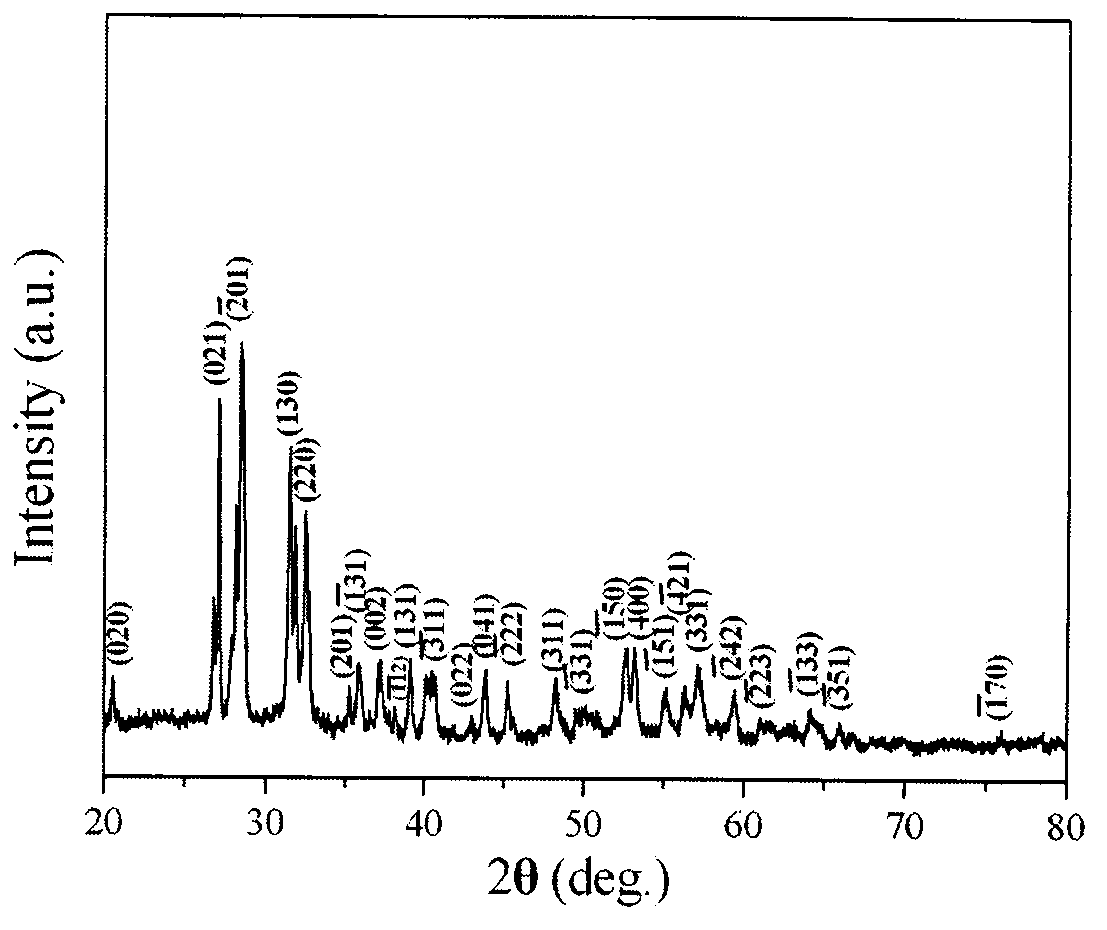

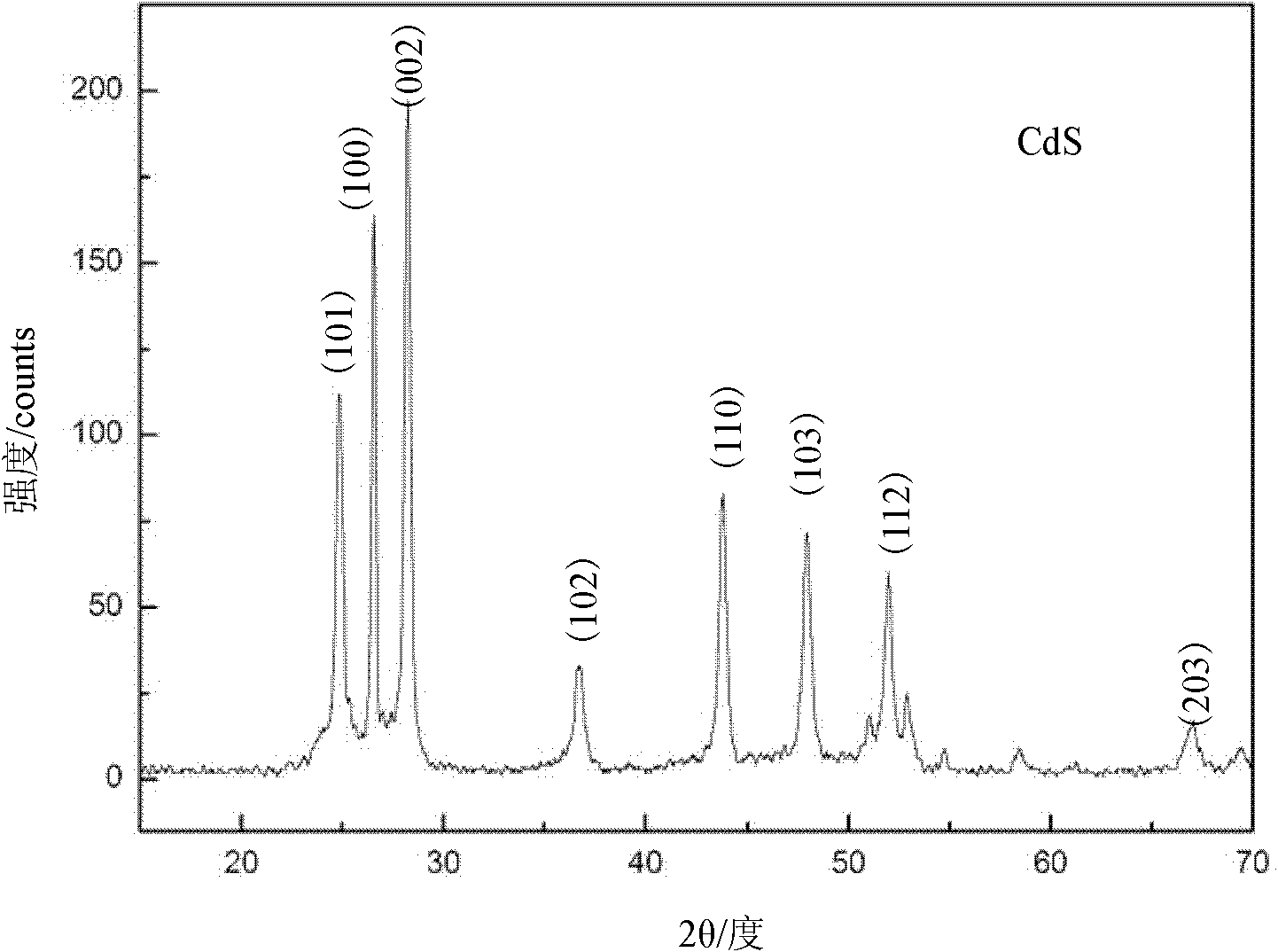

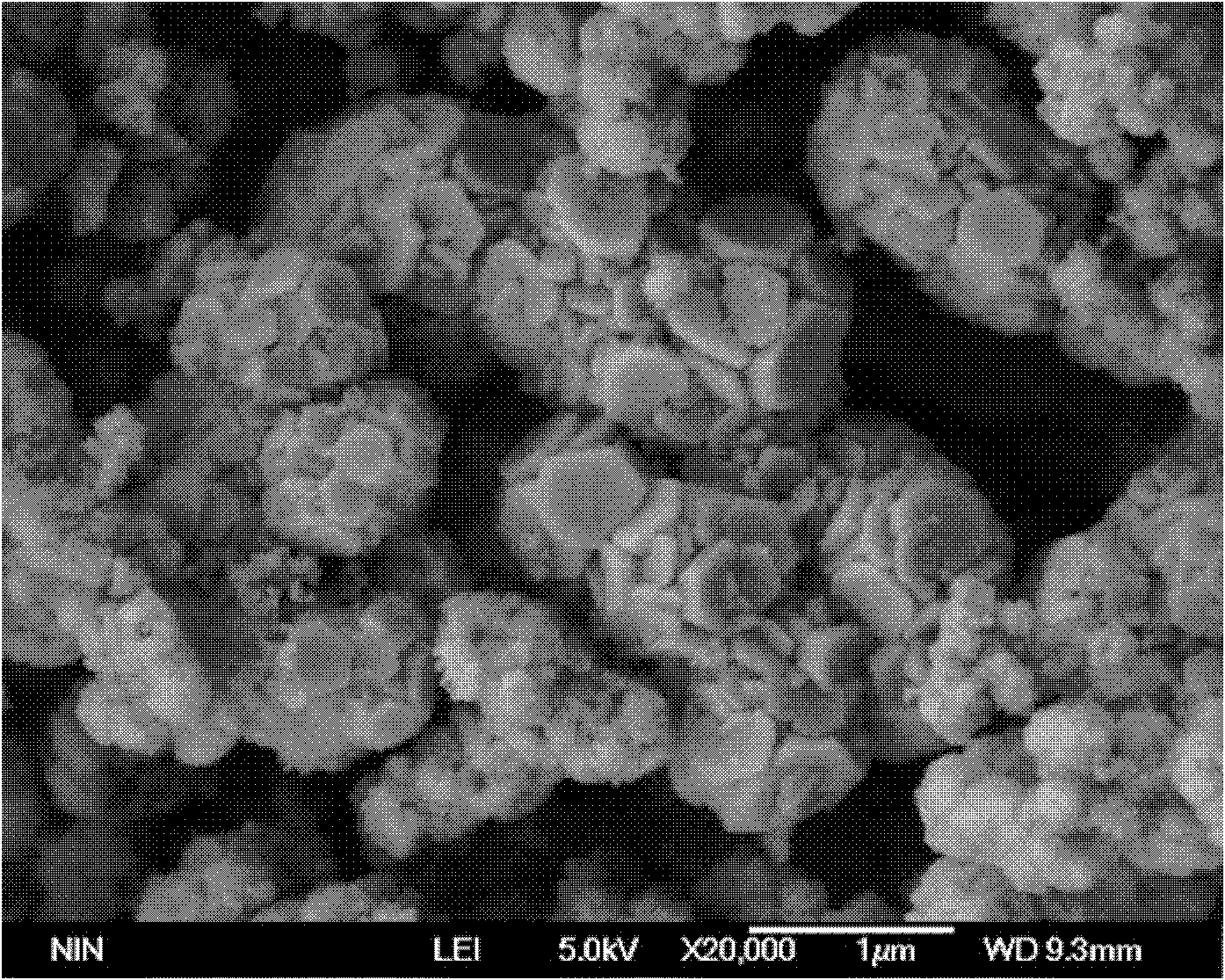

Method for preparing hierarchical hexagonal flake cadmium sulfide crystals by microwave hydration heat

The invention discloses a method for preparing hierarchical hexagonal flake cadmium sulfide crystals by microwave hydration heat, which comprises the following steps of: mixing cadmium acetate dihydrate and ethylenediamine monohydrate to obtain A; adding deionized water into the A to obtain B; adding thiourea into the B solution to obtain C; adjusting the pH value of the C to between 2.0 and 7.0 to obtain D; pouring the D into a microwave hydrothermal reaction kettle, sealing the hydrothermal reaction kettle, then putting the hydrothermal reaction kettle into a microwave hydrothermal reaction instrument, and naturally cooling a reaction product to room temperature after the hydrothermal reaction is finished; and opening the microwave hydrothermal reaction kettle, centrifuging the reaction product and collecting a sample, washing the sample by using deionized water and acetone respectively, and then drying the sample to obtain the hexagonal flake cadmium sulfide crystals. The method prepares a cluster cadmium sulfide structure with a diameter of about 1 micron by combining a microwave method and a hydration heat method and adopting a simple microwave hydrothermal preparation process, and the cluster structure is assembled by the hexagonal flake cadmium sulfide crystals with the side length of about 100 nanometers and the thickness of about 20 to 50 nanometers.

Owner:SHAANXI UNIV OF SCI & TECH

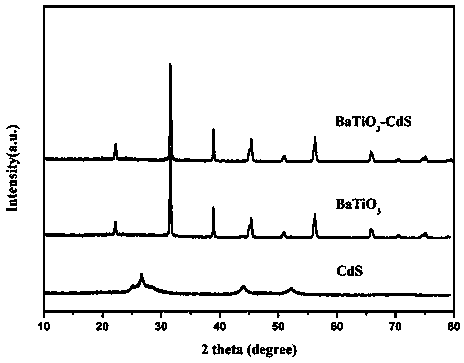

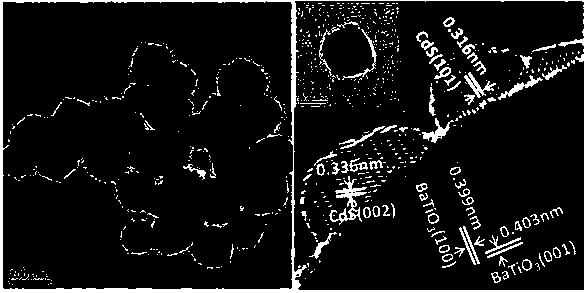

BaTiO3-CdS nanometer composite photocatalyst and preparation method thereof

ActiveCN107670672AImprove photocatalytic activityEasy to separatePhysical/chemical process catalystsHydrogen productionThioureaBarium titanate

The invention relates to a BaTiO3-CdS nanometer composite photocatalyst and a preparation method thereof and belongs to the technical fields of material preparation and photocatalysis. The method comprises the steps: firstly, synthesizing barium titanate by taking tetrabutyl titanate, potassium hydroxide, barium hydroxide, cadmium acetate and thiourea as raw materials and using a sol-gel method; and then, synthesizing a BaTiO3-CdS nanometer composite structure step by step by using a coprecipitation method. The composite catalyst prepared by using the method can be used for effectively improving the separation of photon-generated carriers, reducing the recombination ratio of the carriers and catalyzing water splitting hydrogen production, has good photocatalytic activity and shows a more excellent photocatalytic performance than a single material. The photocatalytic activity is 88.5 times as much as that of pure CdS, and therefore, the BaTiO3-CdS nanometer composite photocatalyst has awide application prospect in the field of photocatalysis.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com