g-C3N4 nanosheet/CdS composite visible-light-driven photocatalyst

A technology of g-c3n4 and nanosheets, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of low separation efficiency of photogenerated carriers, achieve good catalytic degradation effect, visible light High catalytic efficiency and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Block g-C 3 N 4 Catalyst preparation

[0025] Weigh 10 grams of melamine into a corundum ark, place it in the middle of a tube furnace, heat it up to 550°C at a heating rate of 2°C / min, and keep it at 550°C for 4 hours. The whole process is carried out under a nitrogen atmosphere, and wait for natural cooling Then it was taken out and ground with a mortar to obtain a yellow powder sample.

Embodiment 2

[0026] Example 2 Two-dimensional ultra-thin g-C 3 N 4 Preparation of nanosheets

[0027] Weigh 0.4 grams of the sample in Example 1 and put it into a jar, add 80 milliliters of isopropanol, and tighten the bottle cap. Place the jar containing the sample in the ultrasonic machine for 10 hours to form a suspension, then centrifuge the suspension at 3000 rpm for 10 minutes to remove the sediment, and then centrifuge the upper suspension at 12000 rpm Minutes of high-speed centrifugation down to obtain light yellow solid samples.

Embodiment 3

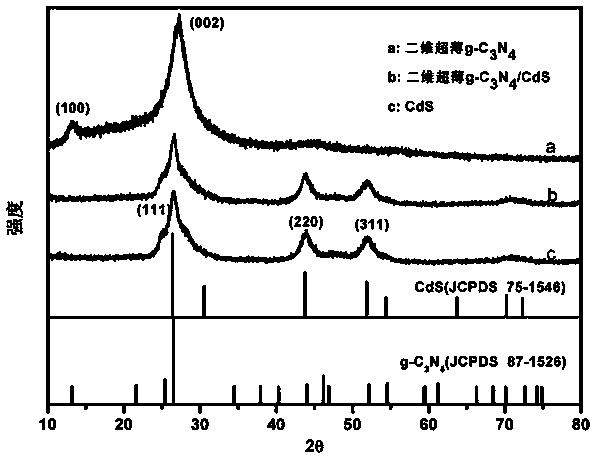

[0029] The catalyst synthesized by the method of embodiment 1 and 2, after X-ray diffractometer scanning, see figure 1 , for g-C 3 N 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com