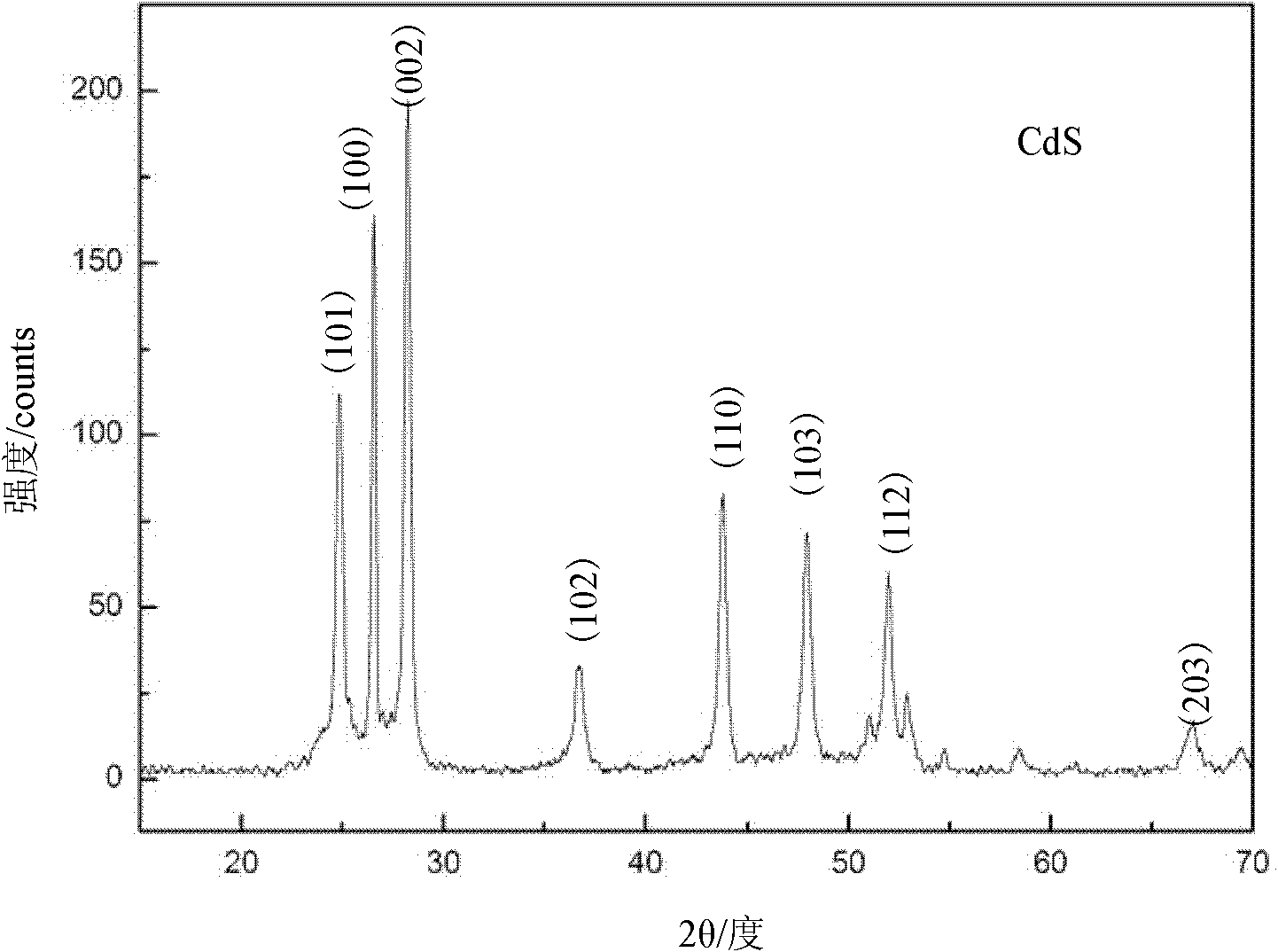

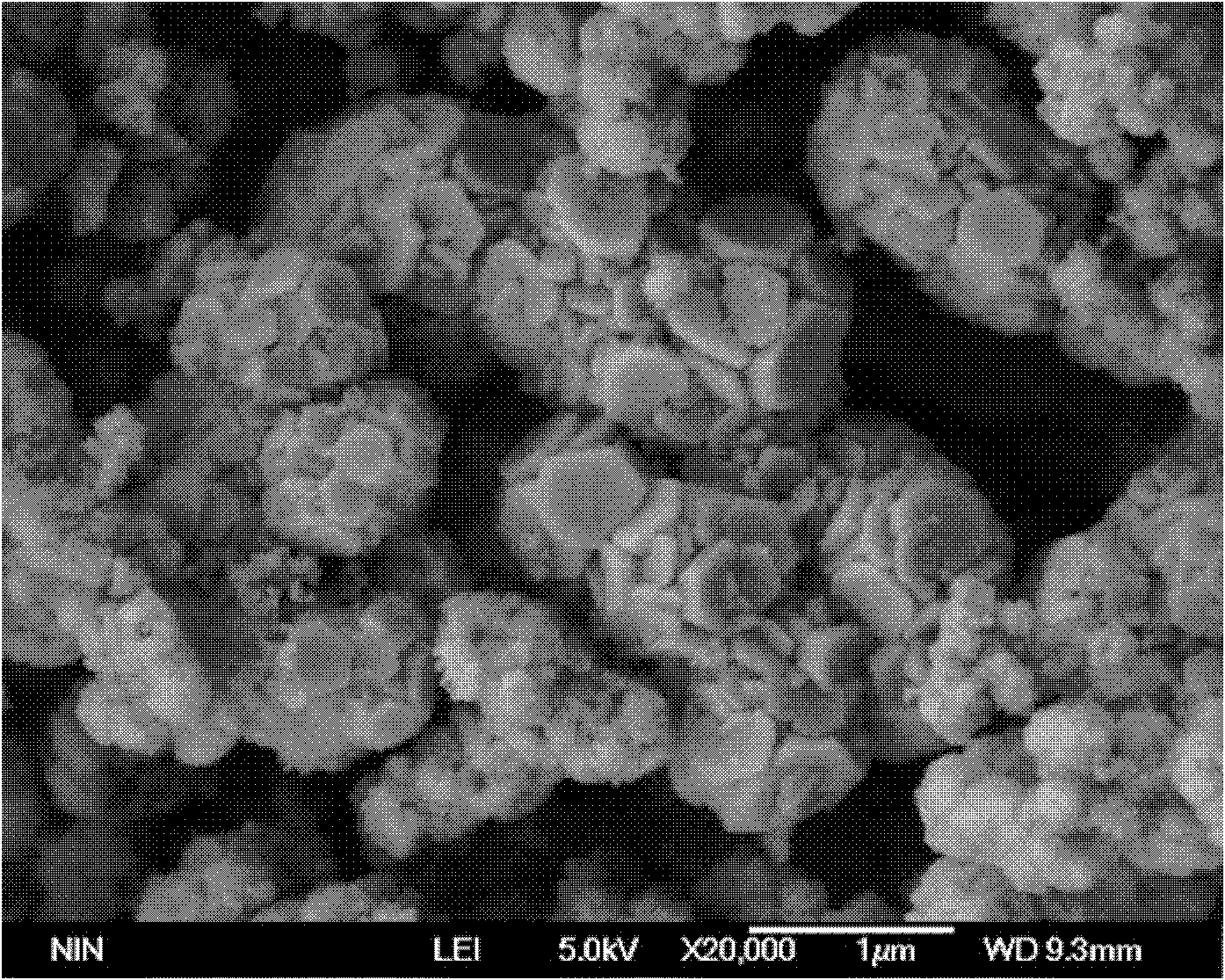

Method for preparing hierarchical hexagonal flake cadmium sulfide crystals by microwave hydration heat

A microwave hydrothermal, hexagonal flake technology, applied in cadmium sulfide and other directions, can solve the problems of toxic raw materials, complex and harsh operating conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: 1) get the analytically pure cadmium acetate dihydrate (Cd(CH3COO) of 0.80g 2 2H 2 O) Place in a beaker, add 6mL of ethylenediamine monohydrate (C2H8N2·H) dropwise to the beaker 2 O) the resulting mixed substance is denoted as A; 2) adding deionized water to A, and constantly stirring, is configured into a transparent solution of 100mL, and the gained solution is denoted as B; 3) adding 3.00g of analytically pure thiourea to the B solution (molecular formula: NH2CSNH2), and keep stirring, the obtained solution is recorded as C; 4) adjust the pH value of solution C to 2.5, and the obtained solution is recorded as D; 5) pour solution D into the microwave hydrothermal reaction kettle, and control the filling The temperature is 65%; after sealing the hydrothermal reactor, put it into the microwave hydrothermal reactor; the hydrothermal temperature is controlled at 110 ° C, react for 3 minutes, and naturally cool to room temperature after the reaction; 6) Afte...

Embodiment 2

[0012] Embodiment 2: 1) get the analytically pure cadmium acetate dihydrate (Cd(CH COO) of 2.50g 2 2H 2 O) Place in a beaker, add 7mL of ethylenediamine monohydrate (C2H8N2·H) dropwise to the beaker 2 O) the resulting mixed substance is denoted as A; 2) adding deionized water to A, and constantly stirring, is configured into a transparent solution of 100mL, and the gained solution is denoted as B; 3) adding 4.00g analytically pure thiourea to the B solution (molecular formula: NH2CSNH2), and keep stirring, the obtained solution is recorded as C; 4) adjust the pH value of solution C to 4.0, and the obtained solution is recorded as D; 5) pour solution D into the microwave hydrothermal reaction kettle, and control the filling The temperature is 70%; after sealing the hydrothermal reactor, put it into the microwave hydrothermal reactor; the hydrothermal temperature is controlled at 100 °C, react for 10 minutes, and naturally cool to room temperature after the reaction; 6) After t...

Embodiment 3

[0013] Embodiment 3: 1) get the analytically pure cadmium acetate dihydrate (Cd(CH3COO) of 4.00g 2 2H 2 O) Place in a beaker, add 9 mL of ethylenediamine monohydrate (C2H8N2·H) dropwise to the beaker 2 0) the resulting mixed substance is denoted as A; 2) adding deionized water to A, and constantly stirring, is configured into a transparent solution of 100mL, and the gained solution is denoted as B; 3) adding 8.00g of analytically pure thiourea to the B solution (molecular formula: NH2CSNH2), and keep stirring, the obtained solution is recorded as C; 4) adjust the pH value of solution C to 6.0, and the obtained solution is recorded as D; 5) pour solution D into the microwave hydrothermal reaction kettle, and control the filling The temperature is 75%; after sealing the hydrothermal reactor, put it into the microwave hydrothermal reactor; the hydrothermal temperature is controlled at 150°C, react for 1min, and naturally cool to room temperature after the reaction; 6) After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com